Page 1

844E

SPRAYER CONTROL

USER MANUAL

Installation, Programming and Operating

Page 2

844-E Sprayer Control

Table of Contents

CHAPTER 1 INTRODUCTION 1

CHAPTER 2 MOUNTING SPRAYER COMPONENTS 2

Pressure Regulator in Bypass Mode ............................................................................................................................................................... 2

Pressure Regulator in Throttling Mode ......................................................................................................................................................... 3

Flow Meter .............................................................................................................................................................................................................. 4

Boom Control Valves ........................................................................................................................................................................................... 4

Pressure Transducer ............................................................................................................................................................................................. 4

INSTALLING THE SPEED SENSOR ASSEMBLY 5

Components ..................................................................................................................................................................................5

Speed Step 1 - Location ...................................................................................................................................................................................... 5

Proximity Sensor (optional) ............................................................................................................................................................5

Speed Step 2 - Installing The Wheel Magnets ............................................................................................................................................ 6

Speed Step 3 - Installing the Magnetic Sensor .......................................................................................................................................... 6

Speed Step 4 - Conrming Speed Sensor Installation ............................................................................................................................ 7

Magnetic Wheel Sensor .................................................................................................................................................................7

Radar .............................................................................................................................................................................................7

MOUNTING THE TEEJET 844 CONSOLE 7

Console Step 1 - Location .................................................................................................................................................................................. 7

Console Step 2 - Mounting ............................................................................................................................................................................... 7

Console Step 3 - Power Connection .............................................................................................................................................................. 8

Console Step 4 - Connecting Component Cables .................................................................................................................................... 9

Connect Step 1 - Wiring Layout ..................................................................................................................................................................... 10

Connect Step 2 - Making The Connection .................................................................................................................................................11

CHAPTER 3 PROGRAMMING 13

Important Preliminary Information..............................................................................................................................................................13

Steps to Successful Programming ................................................................................................................................................................13

SYSTEM SETUP MODE 14

Program Units ......................................................................................................................................................................................................14

Setting Your Program Mode (U.S., Turf, NH3, Imperial, S.I.) .......................................................................................................14

Reset Defaults ...................................................................................................................................................................................................... 14

Reset To Default Settings ............................................................................................................................................................14

Sensor Type ...........................................................................................................................................................................................................14

Flow Meter or Pressure Based ....................................................................................................................................................14

Flow Meter Calibration .....................................................................................................................................................................................14

Flow Meter Pulses .......................................................................................................................................................................14

Pressure Transducer ........................................................................................................................................................................................... 15

Maximum rating (P Hi) .................................................................................................................................................................15

Low Pressure Calibration (P rEF) ................................................................................................................................................15

Nozzle Spacing ....................................................................................................................................................................................................15

Tips Per Boom Section ......................................................................................................................................................................................15

Number of Spray Tips Per Boom Section ....................................................................................................................................15

ii

www.teejet.com

Page 3

844-E Sprayer Control

User Program Tip.................................................................................................................................................................................................16

User Programmable Tip ...............................................................................................................................................................16

Pressure Regulation ...........................................................................................................................................................................................16

Pressure Regulation Mode ..........................................................................................................................................................16

Regulation Adjustment Speed.......................................................................................................................................................................17

Control Valve Type .............................................................................................................................................................................................. 17

Boom Control Valve Type: 2-Way/3-Way .....................................................................................................................................17

Calibrate Speed ...................................................................................................................................................................................................18

Speed Sensor Calibration ............................................................................................................................................................18

Proximity/Magnetic Pulses ...........................................................................................................................................................18

Automatic Calibration ...........................................................................................................................................................18

Manual Calculation: .............................................................................................................................................................18

Radar Speed Pulses ............................................................................................................................................................................................ 18

Automatic Calibration: ..................................................................................................................................................................18

Manual Calculation: .............................................................................................................................................................18

Distance Counter ................................................................................................................................................................................................19

Simulated Ground Speed ................................................................................................................................................................................19

Program Specic Gravity ..................................................................................................................................................................................19

Liquid Specic Gravity (Density) ................................................................................................................................................................... 19

Communications ................................................................................................................................................................................................20

Minimum Pressure .............................................................................................................................................................................................20

Minimum Regulating Pressure Setting ........................................................................................................................................20

APPLICATION SETUP MODE 20

Target Application Rate .................................................................................................................................................................................... 20

Nozzle Selection .................................................................................................................................................................................................. 21

Required Speed to Achieve the Application Rate ................................................................................................................21

Calculation Troubleshooting ..........................................................................................................................................................................22

Adjust Speed: ..............................................................................................................................................................................22

Adjust Pressure: ..........................................................................................................................................................................22

Liquid Density: .............................................................................................................................................................................22

CHAPTER 4 OPERATING INSTRUCTIONS 23

Sprayer Checkout ...............................................................................................................................................................................................23

The Spraying Operation ...................................................................................................................................................................................23

CHAPTER 5 FEATURES 24

Boost Mode ........................................................................................................................................................................................................... 24

Area/Volume Feature ........................................................................................................................................................................................24

Flow Rate Feature ............................................................................................................................................................................................... 24

Application Alarm...............................................................................................................................................................................................24

No Flow Alarm .....................................................................................................................................................................................................24

Printing ...................................................................................................................................................................................................................25

CHAPTER 6 TROUBLESHOOTING GUIDE 26

98-70006-ENUS R4

iii

Page 4

844-E Sprayer Control

CHAPTER 7 FLOW METER CALIBRATION 29

Method 1 – Known Volume ............................................................................................................................................................................29

Step 1 – Known Value .................................................................................................................................................................29

Step 2 – Programming Calibration Number .................................................................................................................................29

Step 3 – Resetting Volume Counter ............................................................................................................................................29

Step 4 – Spraying Known Volume ...............................................................................................................................................29

Step 5 – Entering in New Flow meter Calibration Number ..........................................................................................................29

Step 6 – Double-checking the New Value ...................................................................................................................................29

Method 2 – Known Tip Size Method ............................................................................................................................................................29

Step 1 – Check Tip Size ..............................................................................................................................................................29

Step 2 – Count Tips .....................................................................................................................................................................29

Step 3 – Calculated Flow .............................................................................................................................................................29

Step 4 – Measure ........................................................................................................................................................................30

Step 5 – Adjustments ...................................................................................................................................................................30

Copyrights

© 2013 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied,

photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

iv

www.teejet.com

Page 5

844-E Sprayer Control

CHAPTER 1 INTRODUCTION

Congratulations! And thank you for choosing TeeJet Technologies’ advanced 844-E sprayer control system. With its proper installation and

maintenance, you can enjoy many seasons of accurate and uniform spray application with ngertip convenience and ease of operation.

Installation and Programming of your control system will be covered in easy to follow, step-by-step instructions.

WE RECOMMEND THAT YOU READ THESE INSTRUCTIONS COMPLETELY

before attempting installation and programming of your 844 sprayer control. The unit’s performance will depend on its proper installation

and programming, along with planned preventative maintenance of your entire sprayer.

Easily Accessible

Programming Mode

is very user-friendly. The

process is made simple

with a series of easy-

to-follow, symbol-driven

programming steps.

Auto/Manual Control

gives the operator a manual

application option for fail-

safe reliability.

Master Shuto

controls all boom sections

with one switch.

Aluminum Console Housing

with sealed computer switch panel

resists electronic interference and

damage through rough handling for

years of reliable service.

A Large, Backlit Display

continuously displays all vital spraying

functions. With a quick glance, the display

reveals the application rate (automatically

switches between target and actual),

pressure, speed, and area covered.

Individual Boom Controls

give independent control of up to ve boom sections,

allowing better management of varying eld features

like waterways and terraces.

Color-Coded Tip Selection Bar

allows for easy user programming by

matching the color of TeeJet VisiFlo®

spray tips.

• Full-featured sprayer control with industry-leading ease of use

• Large back-lit display shows all spraying information at a glance

• Color-coded tip selection for easy programming

• Communication Port for PC and GPS interfacing

• Flow or pressure based regulation options provide reliability and exibility

• Five boom section switches plus master shutoff

• Built in application planning tool

• Durable, weather-resistant aluminum housing

• Single cable connection for quick hookup

98-70006-ENUS R4

1

Page 6

844-E Sprayer Control

CHAPTER 2 MOUNTING SPRAYER COMPONENTS

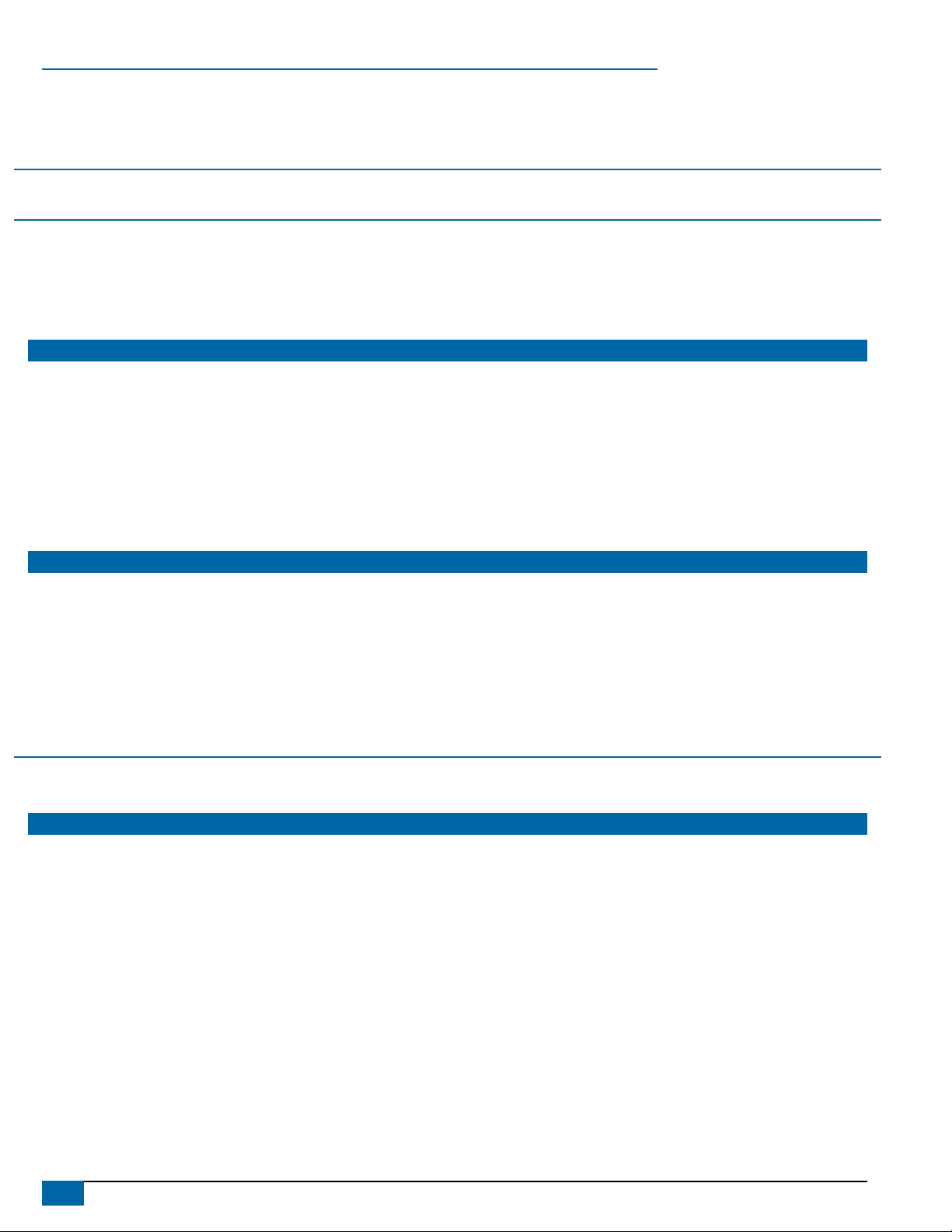

Pressure Regulator in Bypass Mode

All pressure regulating valves for the 844 will be wired for use in a bypass system. While plumbed in a by-pass mode, with the Auto/Manual

key in the “MAN” mode, the valve should close when the Plus key is

pressed and open when the Minus key is pressed.

The pressure regulating valve can also be mounted in a throttling

situation as an alternative location. Refer to pages 3 and 4, and Figures

3 and 4.

NOTE: The diagrams in Figures 1 and 2 are shown as general

guidelines to follow when plumbing the 844 components. The

type of pump used and location of other components can

vary from sprayer to sprayer. It is important to ensure that if a

pressure transducer is used, it is located as close to the spray

tips as possible. Normally, this is at the boom control valves.

However, if one particular boom section is always used, the

pressure transducer can be mounted on that particular boom

section. If a flow meter is used, make sure that all of the flow

going through the flow meter is directed to the spray tips. Make

sure that proper distance is allowed on the inlet and outlet side

of the flow meter (refer to Figures 2 and 3).

Figure 1: Bypass Plumbing Diagram - Pressure Based System

2

www.teejet.com

Page 7

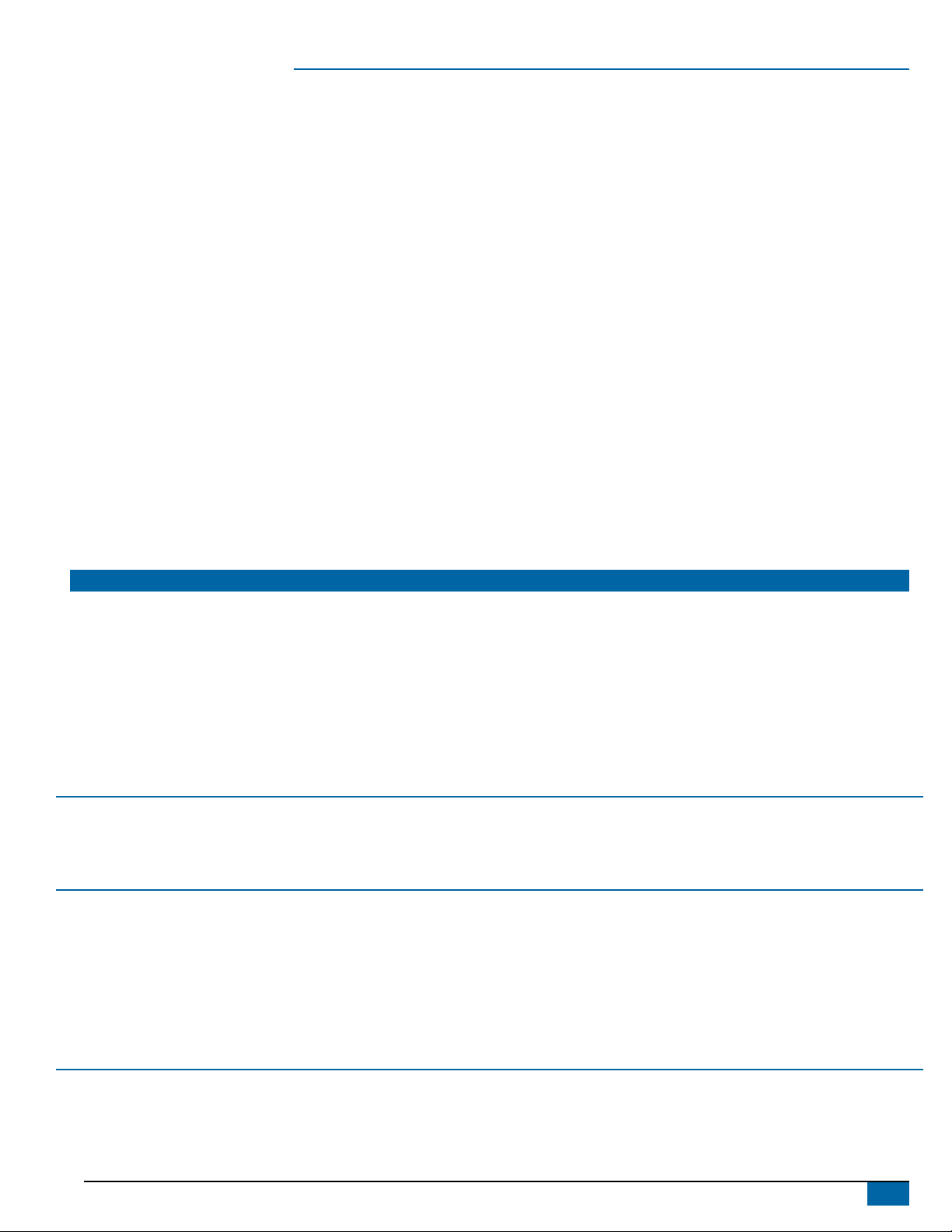

Figure 2: Bypass Plumbing Diagram - Flow Based System

844-E Sprayer Control

Pressure Regulator in Throttling Mode

The pressure regulating valve, as shown in the gures below, can be located in the supply line before the boom control valves. If you choose this

location, the 844 will need to be properly programmed to reverse the polarity of the valve. This step can be found in the System Setup instructions

on page 14. When in throttling mode, the valve should open when the Plus key is pressed, and close when the Minus key is pressed. Be

sure to check this before plumbing the valve into the system.

Figure 3: Throttling Plumbing Diagram - Flow Based System

98-70006-ENUS R4

3

Page 8

844-E Sprayer Control

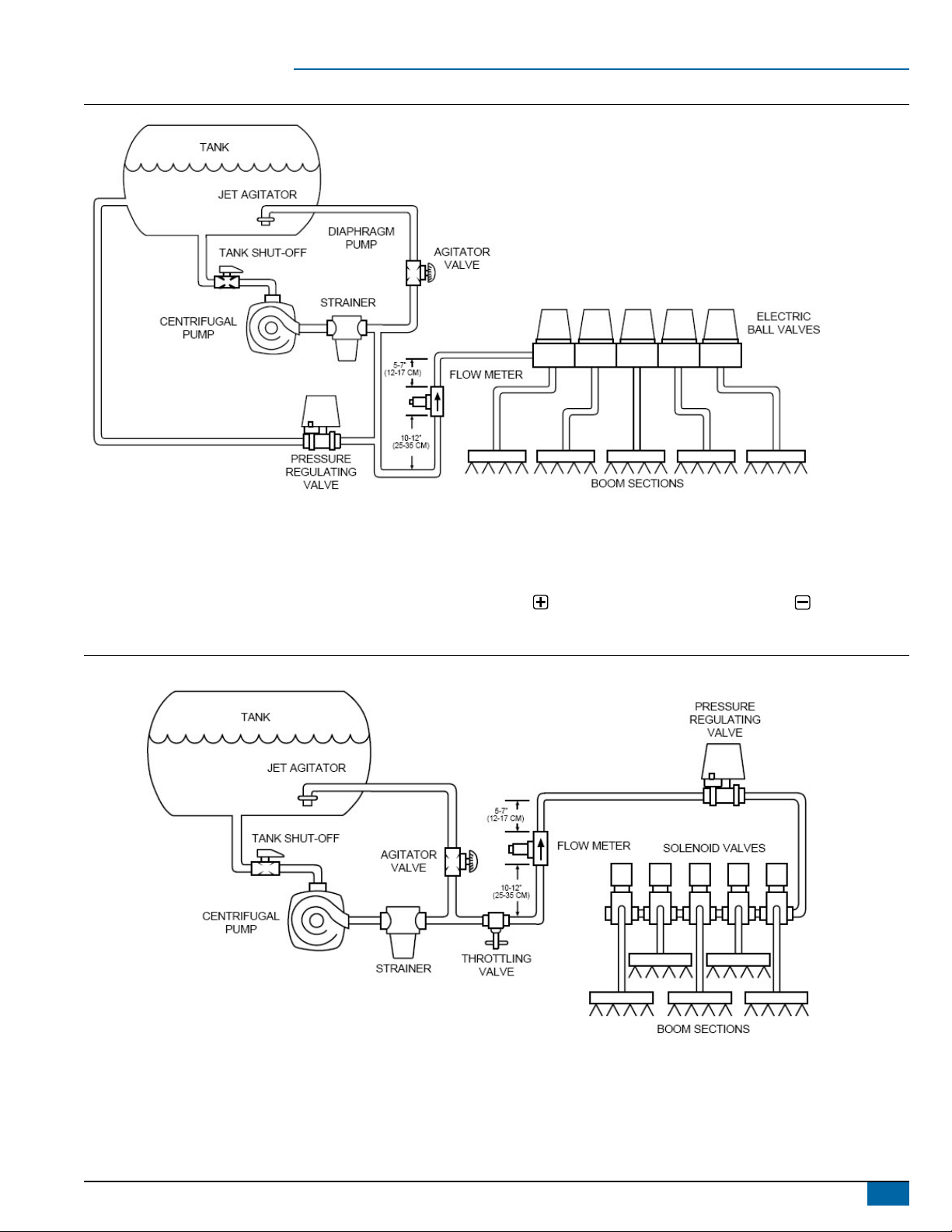

Figure 4: Throttling Plumbing Diagram - Pressure Based System

Flow Meter

To ensure accurate readings, the ow meter (if used) must be mounted

10″ to 12″ (25-35 cm) from other pipe ttings, preferably in a vertical

position with the ow going up. It should also be mounted with the

direction of ow arrow pointing toward the boom control valves. Refer to

Figures 2 and 3.

Be sure the ow meter is plumbed so that all liquid passing through it

is routed to the booms and not back to the tank. When using three-way

boom control valves, refer to page 13 of this manual for programming

guidelines.

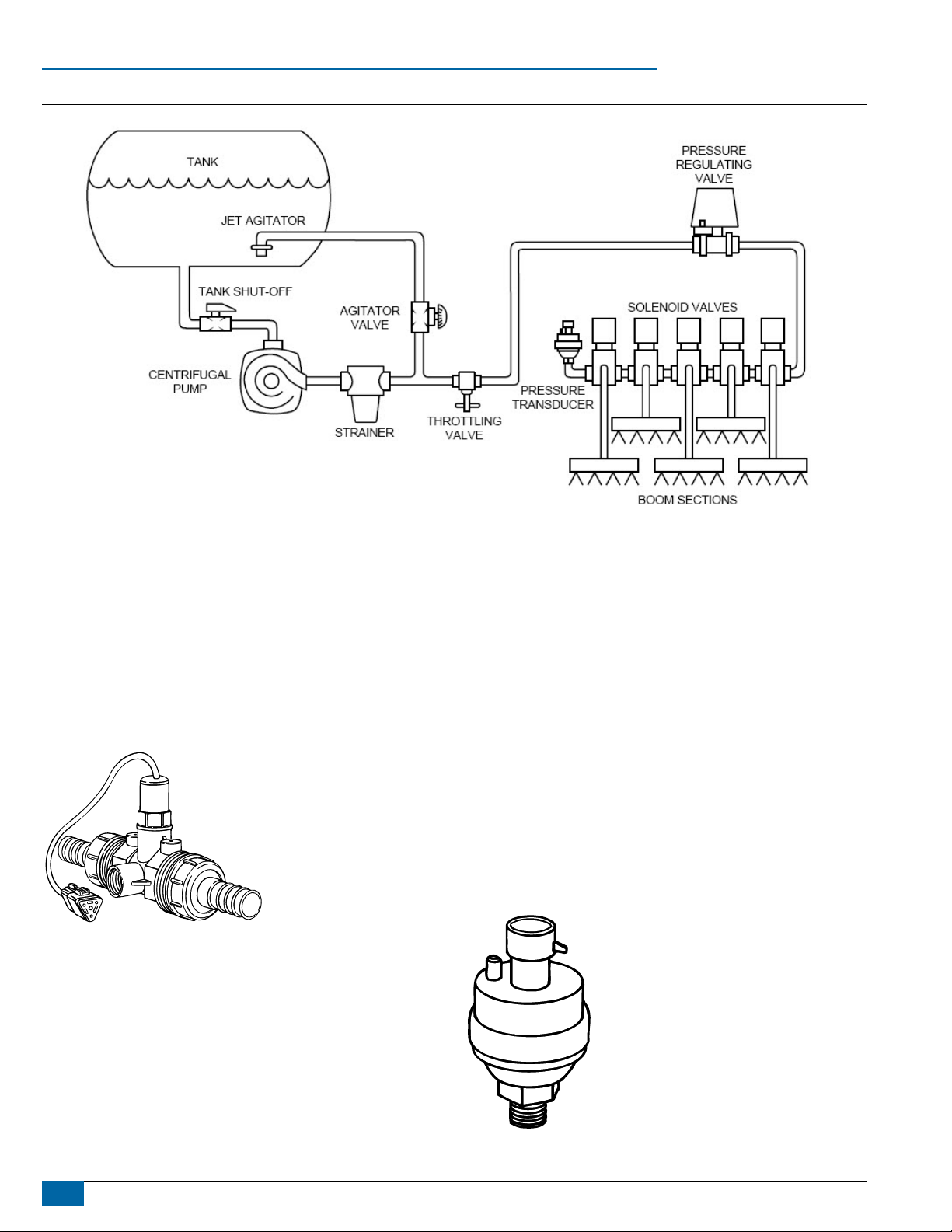

Boom Control Valves

The Boom Control Valves are connected in tandem and centered in

front of the boom sections. See the Control Valve Instruction Manual for

mounting instructions. If using three-way valves, refer to the instruction

manual of the valves you are using for valve calibration instructions.

Pressure Transducer

The pressure transducer (if used) should be installed as close to

the spray tips as possible. Normally this is at the boom control valve

assembly. Refer to Figures 1 through 3. Mount the unit vertically on a

short stand pipe to help protect the sensor.

NOTE: Pressure drop, to some degree, is found in most plumbing

systems. Pressure drop is created when there is any kind of

restriction in the spray line that reduces flow rate and is quite

often produced between the boom control valve assembly and

the spray tips. If one of the boom sections on the sprayer is

always used, the pressure transducer can be installed on that

particular boom section, minimizing any potential pressure drops

between the sensor and spray tips. If the pressure drop in your

system is greater than 5 psi (0.3 bar), you should consider this

as an alternative location for the pressure transducer.

Check all components to make sure they are mounted securely to avoid

excessive vibration.

4

www.teejet.com

Page 9

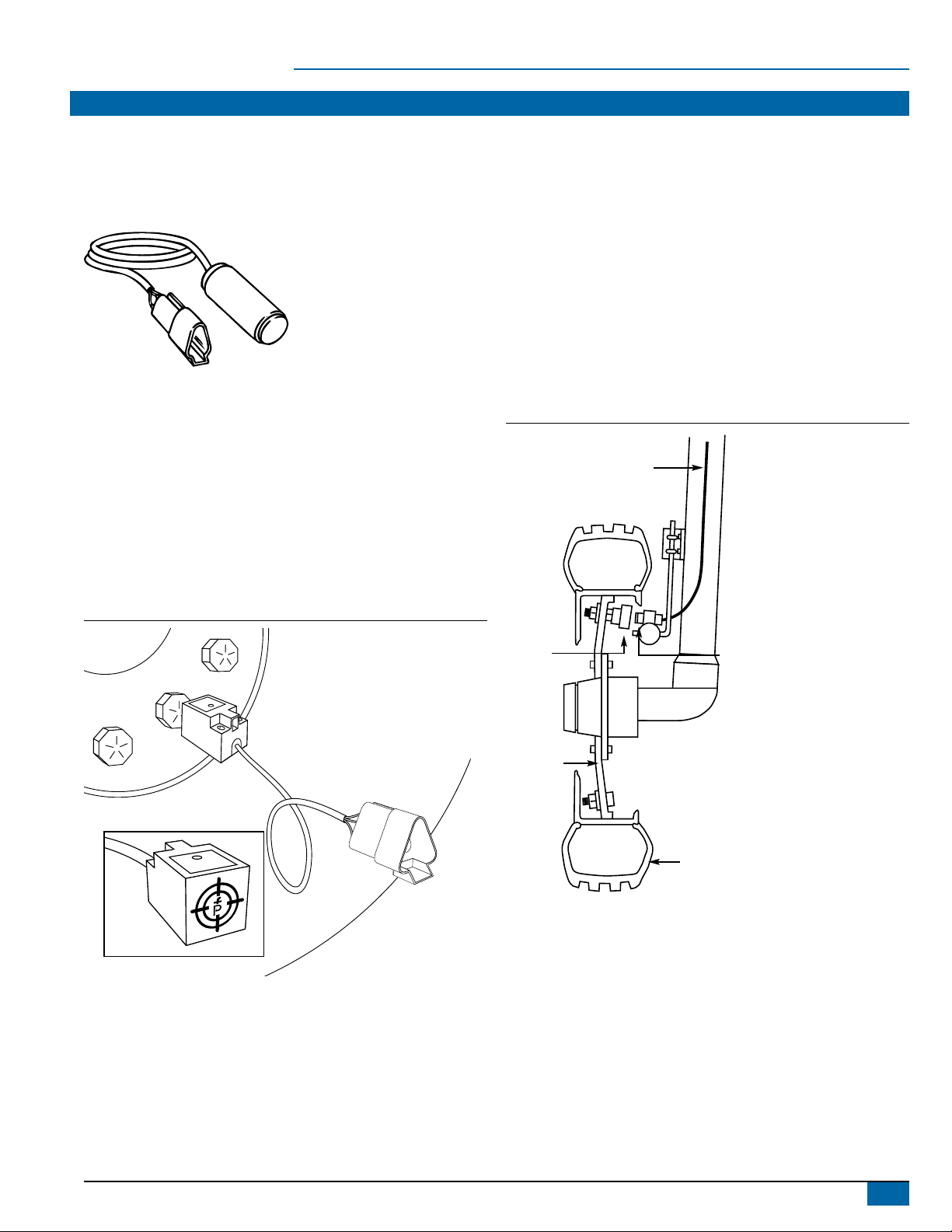

INSTALLING THE SPEED SENSOR ASSEMBLY

TIRE LUGS

Components

Two (2) magnets, Sensor with attached connector cable, and mounting

hardware. If you are installing a radar ground speed sensor, follow the

instructions supplied with that unit.

Speed Step 1 - Location

The speed sensor assembly should be installed on a non-driven wheel

to avoid potential errors that are likely to occur from a slipping drive

wheel. Refer to Figure 5.

Proximity Sensor (optional)

An optional proximity sensor is available to use in cases where space

is limited or for drive shaft mounting.

The proximity sensor will work by sensing any metal object. The

proximity sensor must be mounted so that the sensor face is within 1/8″

to 3/8″ (3-10 mm) of the metal object being read.

844-E Sprayer Control

Figure 6: Wheel Mounting of Magnetic Speed Sensor

CABLE

Figure 5: Wheel Mounting of Speed Sensor

NOTE:

TARGET FACES

Note: Target faces tire lugs

MAGNET

SENSOR

RIM

TIRE

98-70006-ENUS R4

5

Page 10

844-E Sprayer Control

MAGNET

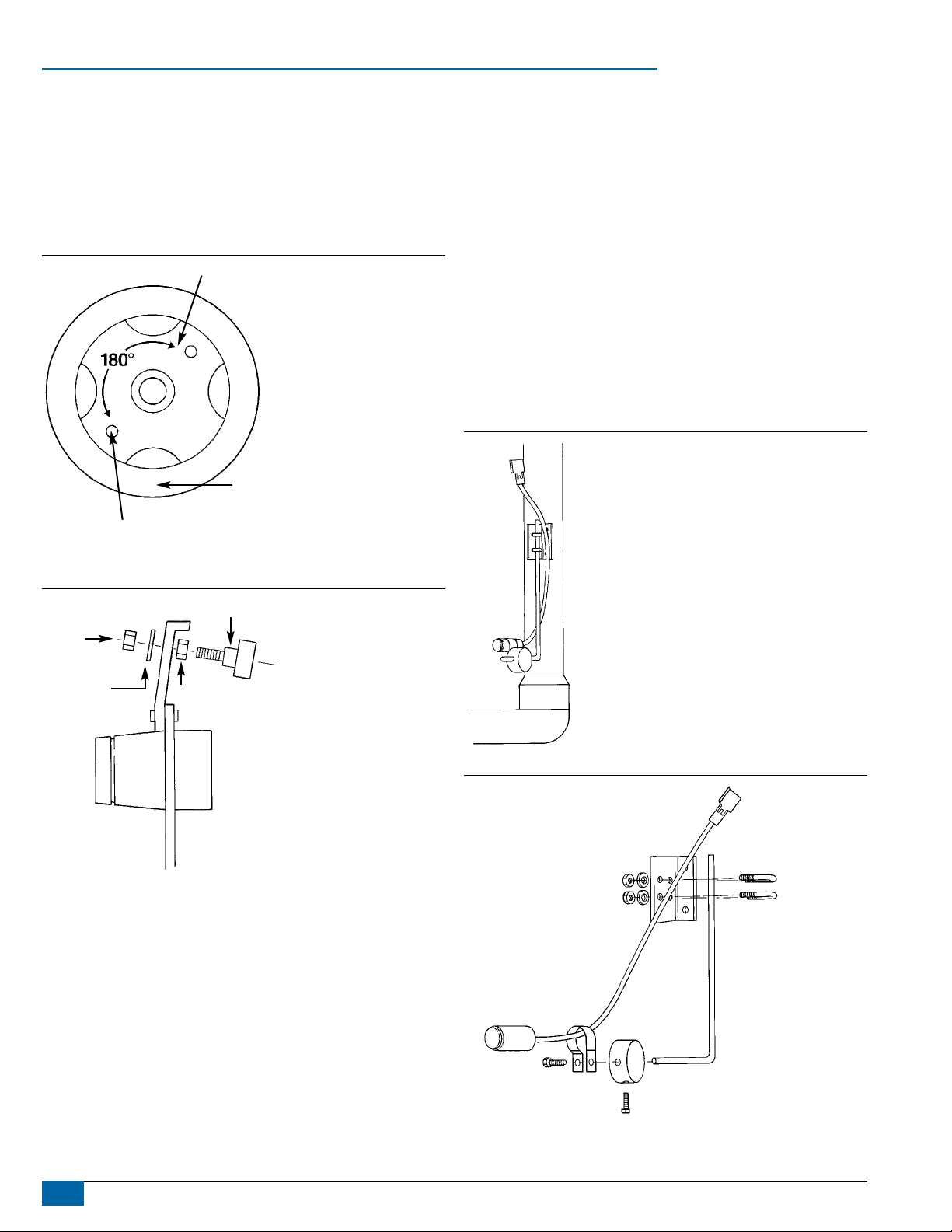

Speed Step 2 - Installing The Wheel Magnets

Check for pre-drilled holes in the wheel rim. If pre-drilled holes are not

available, layout a pattern as shown in Figure 7 and drill two 3/8″ (10

mm) holes near the outer edge of the rim if possible, and 180° from

each other.

Place the magnets into each of the two holes on the inside rim and

securely fasten them using the nuts and washers provided.

Figure 7: Magnet Locations

WHEEL

TIRE

3/8˝ (10 mm)

HOLE FOR

Speed Step 3 - Installing the Magnetic Sensor

The at, pressed L bracket of the wheel speed sensor kit should be

secured to a vertical member near the non-driven wheel. The round,

right angle steel bracket is then secured to the at bracket with the

two U-bolts and necessary hardware provided. The round, right angle

bracket is then used to secure the magnetic sensor mounting clamp.

The magnetic sensor should be inserted into the mounting clamp and

positioned within 1/8″ to 3/8″ (3-10 mm) of the wheel magnet. Tighten

the sensor clamp using the clamp screw per Figure 10.

Your installation will likely vary from the example. It may be necessary

to customize the installation to accommodate your specic machine.

Keep in mind that the two magnets must be spaced an equal distance

around the wheel. The magnetic sensor must be mounted in-line with

the magnets and positioned within 1/8″ to 3/8″ (3-10 mm) from each

magnet as they pass the Sensor assembly.

Figure 9: Sensor Mounting

Figure 8: Magnet Assembly

NUT

WASHER

NUT

MAGNET

Figure 10: Sensor Assembly

FLAT

L BRACKET

BRACKET

SENSOR

6

www.teejet.com

CLAMP

SCREW

Page 11

844-E Sprayer Control

Speed Step 4 - Conrming Speed Sensor

Installation

Magnetic Wheel Sensor

After your wheel or proximity sensor is installed and once the 844

console is installed and powered up, you can test the speed sensor

installation. Connect the wheel speed or proximity sensor to the sensor

cable, and in turn connect the sensor cable to the 844 console. When

the connection is made, rotate the wheel on which the magnets are

installed. If using a proximity sensor, you will be sensing metal objects

and not magnets. Each time a magnet (metal object for proximity

sensor) passes the sensor a red LED (orange LED for proximity

sensor) on the back of the sensor will light. The LCD display on the

console will also indicate a speed as the sensor receives and sends

electronic pulses.

Radar

If you are using a radar speed sensor it should be connected to the

speed sensor connector on the sensor end cable. An adapter cable

will be necessary when using most radars and are available through

your TeeJet Technologies dealer. The 844 will automatically sense if

the speed sensor is a wheel speed, proximity type or radar type sensor

during calibration. The 844 is automatically adapted to most brands

of radar speed sensors provided that the appropriate adapter cable

is used. If using a radar sensor, the 844 will display rAd during the

calibration procedure.

MOUNTING THE TEEJET 844 CONSOLE

Console Step 1 - Location

Determine the best location for the control console in the cab or

operator’s compartment. Allow sufcient clearance, approximately 4-5″

(10-12 cm) to accommodate for the cable that will be connected to the

right side of the console.

Console Step 2 - Mounting

Mount the console to a rm support within the cab area, and secure

using the slots provided on the top, back, or bottom of the Console.

Although two simple brackets are supplied with the unit, some

additional bracketing may be necessary. The slots in the 844 will accept

1/4″ (6 mm) bolts.

Figure 11: Brackets Provide Angle Adjustment

98-70006-ENUS R4

7

Page 12

844-E Sprayer Control

Console Step 3 - Power Connection

Locate the power cable that has a black connector on one end and two battery terminal rings on the other. Extend the battery terminal ring end of

this cable from the cab to the battery.

NOTE: Some tractors use two 6 Volt batteries as a power source. Make sure there are a total of 12 Volts delivered to the controller by connecting

to the (+) terminal on one battery and the (-) terminal on the other battery. Reliable operation of the 844 Sprayer Control depends on a

clean power supply. Ensure this by connecting the power cables directly to the battery and not to another power source.

Connect the battery terminal rings to the battery posts, making sure that the positive (red) and negative (black) wires correspond with the polarity

of the battery terminals.

NOTE: The power cable is designed to provide the simple addition of a remote master boom switch in a convenient location (i.e. on the throttle,

gear shift, or floor switch). To install a remote boom switch, simply install a switch to the brown wire in the power cable. The switch should

be rated to handle the total current used by all boom section valves combined. If installed, the remote master switch will operate in series

with the boom switches on the console.

Connect the battery cable to the power cable lead that extends from the main cable.

Test the installation by pressing the Program key once to turn the 844 console on. If the display shows information, you have wired the power

correctly.

NOTE: The TeeJet 844 Sprayer Control has an automatic power down feature. With the master boom switch in the “off” position, the 844 will

automatically shut down after 10 minutes of no inputs. This prevents possible battery drainage. To turn the console “off” with the Master

Switch located in the “off” position, press and hold the Minus key while pressing the Program key once, and then releasing both

keys. The console will shut down providing no other keys are pressed.

Figure 12: Power Connection

8

www.teejet.com

Page 13

844-E Sprayer Control

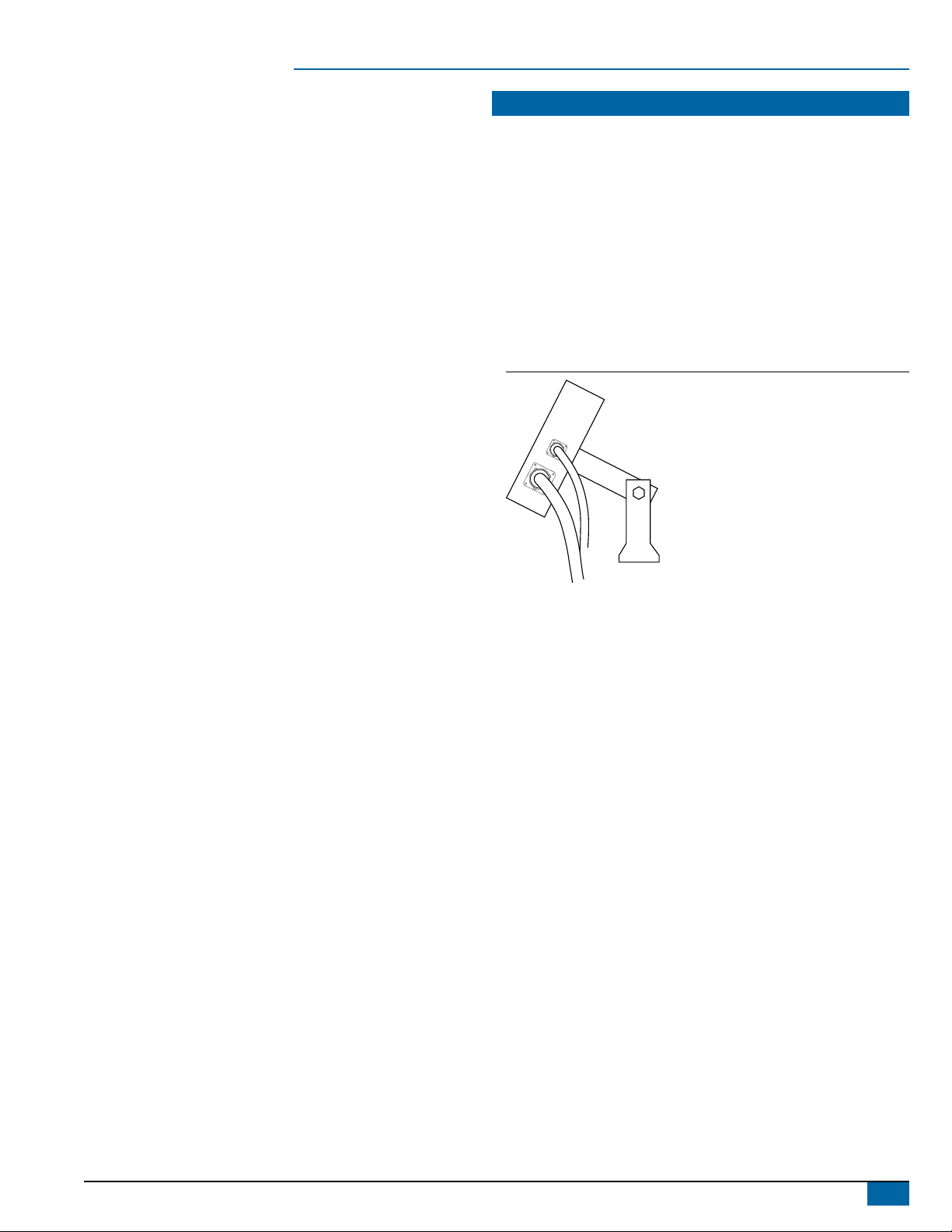

Console Step 4 - Connecting Component Cables

Now that you have the console installed you can begin connecting it to the other components of the 844 system. The standard kit contains a main

cable that attaches to the boom control valves, the pressure regulating valve, ow meter and/or pressure sensor, a magnetic wheel speed sensor,

and a proximity speed sensor or radar speed sensor. Lay out each of the valve and sensor leads before installing the sprayer components to be

sure the cables are long enough in length from the sensor connections to the 844 console connection. If your installation requires longer cables,

several extension cables are available. If an exit hole has to be cut in the cab, be sure the edges are deburred and protected to prevent damage to

the cables.

Figure 13: Wiring Diagram

COMMUNICATION

CABLE CONNECTION

POWER

TANK

TANK SHUT-OFF

CENTRIFUGAL

PUMP

JET AGITATOR

AGITATOR

VALVE

STRAINER

MAIN CABLE

CONNECTION

5-7˝

(12-17 CM)

FLOW METER

(IF USED)

10-12˝

(25-35 CM)

PRESSURE

TRANSDUCER

(IF USED)

844 SPRAYER CONTROL

PRESSURE

REGULATING

VALVE

SOLENOID VALVES

SPEED SENSOR

BOOM SECTIONS

98-70006-ENUS R4

9

Page 14

844-E Sprayer Control

Connect Step 1 - Wiring Layout

Determine the best cable routing to the sprayer control components on the sprayer. This may be along the ow line, main frame of the sprayer, or

wherever the cables can be conveniently secured. Avoid any situation where the cables may lay in puddles, or come in contact with extreme heat

sources.

WARNING: System Components should be mounted at least 3 ft / 1 m from areas of excessive vibration (i.e. engines) to avoid high frequency

interference.

Figure 14: Wiring Layout

10

www.teejet.com

Page 15

844-E Sprayer Control

Connect Step 2 - Making The Connection

Now, extend the cable leads to the Flow meter or Pressure Sensor, and Wheel Sensor or Radar Sensor to the furthest component. Select the

appropriate lead and connect to this component. Run the cable to the other component, taking care to safely secure the cable along the route.

Refer to the diagram on page 10.

Repeat this procedure with the cable leads to the Pressure Regulating Valve and the Boom Control Valves. Refer to the chart below when

attaching the boom section wires. T-tap connectors must be attached to the +12vDc and ground wires to connect them to the boom control valves

(when using ball valves), which should be evenly distributed across the two.

If both the ow meter and pressure transducer are not used simultaneously, there will be one extra connection on the cable. Simply tie this part of

the cable back as it will not be used.

When all connections have been made, connect the large plug into the side of the Control Console.

Figure 15: Console Connector

Console Connector Pin No. Wire Color Signal Name

B White Section 1

C Brown Section 2

D Green Section 3

E Yellow Section 4

F Gray Section 5

R White Flow Signal

S White Pressure Signal

T White Speed Signal

V Brown Power Out

a White Regulation Valve (+)

b Brown Regulation Valve (-)

c Blue +12 VDC

d Blue Pink Ground Free End (Valves)

e Red Black +12 VDC Free End

Figure 16: Power Connector

Power Connector Pin No. Wire Color Signal Name

1 Brown +12 VDC (Computer)

2 Blue +12 VDC (Valves)

3 Yellow/Green Ground

Figure 17: Speed Sensor Connector

Speed Sensor Connector Pin No. Wire Color Signal Name

A Brown Power Out

B White Speed Signal

C Green Ground

98-70006-ENUS R4

11

Page 16

844-E Sprayer Control

Figure 18: Pressure Sensor Connector

Pressure Sensor Connector Pin No. Wire Color Signal Name

A White Power Out

B Black Pressure Signal

C N/C

Figure 19: Flow Sensor Connector

Flow Sensor Connector Pin No. Wire Color Signal Name

A Brown Power Out

B White Flow Signal

C Green Sensor Ground

Figure 20: Regulator Connector

Regulator Connector Pin No. Wire Color Signal Name

1 White Regulation Valve (+)

2 Brown Regulation Valve (-)

NOTE: The 844 is designed to handle a maximum of 4 amps per boom section.

You are now ready to begin the programming of the TeeJet 844 Sprayer Control.

NOTE: Valves requiring DPDT switches are not compatible with the TeeJet 844 Sprayer Control.

12

www.teejet.com

Page 17

CHAPTER 3 PROGRAMMING

844-E Sprayer Control

Important Preliminary Information

Before you begin, we recommend that you review the following

Programming Guidelines that control the programming process:

• For your convenience, the programming of the 844 has been

divided into two programming categories; System Setup Mode and

Application Setup Mode.

• Pressing the Program key once will ash “ ” in the upper

left hand corner of the display window. The word “USEr” will be

displayed in the lower right corner indicating you are about to

enter the Application Setup Mode. Pressing the Program key

a second time will put the Control Console into the Application

Setup Mode. If you inadvertently press the Program key

once, wait for three (3) seconds and the Control Console will

return to its normal operating mode.

• Pressing and holding the Plus key and Minus key while

simultaneously pressing the Program key once will ash “ ”

in the upper left hand corner of the display window. The word

“PrO” will be displayed at the right of the display window

indicating you are about to enter the System Setup Mode.

Pressing the Program key a second time will put the Control

Console into the System Setup Mode. A delay of three (3) seconds

will return the Control Console to its normal operating mode.

The System Setup programming steps will likely only need to be

programmed once to customize the controller to your sprayer.

• For either setup mode, if you press and hold the Program

key for three (3) seconds, your inputs will be saved and

the computer will exit the respective setup mode. This action

will not be necessary until the last programming step has

been completed.

• To increase the value of a programmable digit, press the

Plus key . To decrease the value, press the Minus .

These keys are located directly to the right of the display. For

some programming steps, pressing and holding Plus key

or Minus key will change the programmable value rapidly.

Pressing the Plus key or Minus key once will change

the value by one increment. Pressing the Plus key and

Minus key simultaneously in some programming steps will

set the value to “0”.

• For either setup mode, pressing the Program key will advance

you to the next programming step.

Steps to Successful Programming

To begin the programming process:

• Read above for programming tips.

• Be sure the “master” boom switch is “OFF.”

• Turn console “ON” by pressing the Program key . When

the Control Console is turned on, the software version will be

displayed at the top of the display and the serial number will be

displayed in the lower half of the display. This information will be

needed when calling for service support.

• To turn the console “off”, press and hold the key while

pressing the Program key once, and then releasing both keys.

The console display will shut down providing no other keys are

depressed.

98-70006-ENUS R4

13

Page 18

844-E Sprayer Control

SYSTEM SETUP MODE

The System Setup Mode contains the programming steps that

customize the controller to the sprayer or sprayer components. These

include calibration steps and parameters that, once programmed, will

likely never change.

To enter the System Setup Mode, press and hold the Plus key

and Minus key simultaneously. While holding the Plus key

and Minus key in, press the Program key twice (within three

(3) seconds), and release to enter the System Setup Mode. The rst

programming step should be visible.

Program Units

Setting Your Program Mode (U.S., Turf, NH3, Imperial, S.I.)

Default = US

The 844 console will display a large “US” in the center of the display.

The default value “US” indicates that all default values will be shown

in U.S. measurements, unless changed to Turf (trF), Anhydrous

(nh3), Imperial Gallons (INP), or Metric (Si) units. Turf units displays

information in Gallons per 1000 ft2, NH3 displays units in Pounds of

Nitrogen per Acre; Imperial displays units in Imperial Gallons per Acre;

and SI displays all units in Metric (l/min, l/ha, km/h, cm).

If you will be using U.S. measurements, no change is necessary. Press

the Program key to advance to the next programming step.

If you will be using one of the other units listed, press the

Plus key or Minus key to select the units you will be

using. Press the Program key to accept the value and

advance to the next program step.

Reset Defaults

Reset To Default Settings

If the units in the rst programming step have been changed, the

console will ask if you would like to reset all of the program values to

the default settings for the units selected. If you wish to reset to the

defaults, use the Plus key or Minus key to select “YES” and

press the Program key to activate the resetting process.

If you do not want to reset to the default values, select “no” using the

Plus key or Minus key and the Program key to advance to

the next step.

NOTE: If you inadvertently changed the Program Units, select “no”

in this step. Advance to the Program Units step again using

the key and change back to your desired units. Select “no”

again at the Reset Defaults step and exit the program mode by

pressing and holding the key for three (3) seconds.

Sensor Type

Flow Meter or Pressure Based

Default = FLO

The 844 system can be used with either a ow meter, pressure

transducer or both. This step tells the computer which sensor you will

be using on your sprayer to control the ow regulation.

The default value is set for a “FLO” based system using a ow meter. If

this is what you have installed on your sprayer, then press the Program

key to advance to the next step.

If, you have installed a pressure transducer instead, use the

Plus key or Minus key to select “PrS” for a pressure

based system. Then, press the Program key to advance to

the next step.

If both sensors have been installed on the sprayer, this step will

determine which sensor will be used by the 844 to determine pressure/

ow regulation. If “FLO” is selected, the ow meter will be used to

control the ow and the pressure transducer will be used only to display

the actual pressure. If “PrS” is selected, the pressure transducer will

be used to control the ow and display the actual pressure. The ow

meter signals will be ignored.

Flow Meter Calibration

Flow Meter Pulses

Default = 650

During the Flow meter Calibration Step, the turbine symbol

ashing at the top of the console display.

First, locate the factory ow meter pulse rate tag on the ow meter. If

this varies from the default value of the console, use the Plus key

or Minus key to modify the value. Pressing the Plus key and

Minus key simultaneously will clear the value to zero. In some

cases, larger ow meters with small calibration numbers will include

decimals for greater accuracy. To add a decimal to the 844 calibration

number, press the Auto/Manual key.

If you are not using a ow meter, but are using a pressure transducer

instead and have selected “PrS” in the previous step, this step will not

appear.

NOTE: This flow meter number represents the number of pulses per

liter of liquid. The 844 console makes all of the necessary

conversions if using units other than metric. The same

calibration number will be used for all units.

will be

14

www.teejet.com

Page 19

844-E Sprayer Control

Pressure Transducer

Maximum rating (P Hi)

Default = 150 (PSI in US, trF and INP Modes)

Default = 10.0 (bar in Si Mode)

This step is used to set the maximum rating of the pressure

transducer in your system. This number can be found stamped on the

pressure transducer itself. If your transducer has a maximum rating of

145 psi (10 bar in SI mode) and that number is shown in the display,

then advance to the next step by pressing the Program key . If,

however, the maximum rating is 363 psi (25 bar in SI mode), use

the Plus key and Minus key to change the value. Press the

Program key to advance to the next step.

NOTE: If you are not using a pressure transducer but are using a flow

meter instead, skip this step by pressing , leaving the default

value programmed.

Low Pressure Calibration (P rEF)

Default = 4.0

This step is used to calibrate the “0” pressure setting of the pressure

transducer installed in your system. The pressure transducer used with

the 844 is a current type transducer and uses a 4-20 mA reading. 4.0

mA represents 0 pressure.

This step uses an auto-calibration feature to calibrate the transducer.

Make sure that the sprayer pump is off and there is absolutely no

pressure in the system. Press and release the Plus key and Minus

key simultaneously to activate the auto calibration feature. You

will see the message “NES” in the lower left of the display and the

lower right of the display count the numbers “0” through “9”. When the

display nishes counting, a number close to 4.0 should be displayed.

The low pressure value of the transducer is now calibrated.

Press the Program key to advance to the next step.

NOTE: If you have selected a “FLO” based system, skip this step

by pressing the Program key and leave this value at the

default of 4.0.

Nozzle Spacing

Default = 20 (inches in US, trF, and INP Modes)

Default = 50 (centimeters in Si Mode)

Default = 30 (inches in nh3 Mode)

While in the Nozzle Spacing step, the nozzle spacing symbol

be ashing at the top of the console display. Nozzle spacing should be

recorded in inches (cm in SI mode).

If the default value is correct, press the Program key to accept

the value. If the nozzle spacing is different than that shown as a

default, then add or reduce this number by using the Plus key

or Minus key keys to record the new value. Pressing the Plus

key and Minus key simultaneously will clear the value to

zero.

When the correct value has been entered, press the

Program key to accept the value and advance to the next step.

When broadcast or broad acre spraying, enter the nozzle spacing in

the display.

If banding, enter the band width as your spacing. If directed spraying,

enter the row spacing divided by the number of nozzles per row as your

spacing.

2

NOTE: All Application rate readings (US GPA, G/1000 ft

Imp. GPA, and l/ha) and area readings are expressed in treated

acres (hectares).

, #N/acre,

will

Tips Per Boom Section

Number of Spray Tips Per Boom Section

Default = 6 (tips per section in US, trF, INP and Si modes)

Default = 12 (tips per section 1, 0 for the others in nh3 mode)

While in the Tips Per Boom Section step, the #tips symbol

ashing at the top of the console display. The console will also display

“SEC 1” at the left and a number (6) at the right of the display. The

“SEC 1” refers to boom section #1 on your console. The number at

the right is to be adjusted to match the number of tips you have on

boom switch 1.

The default value of “6” will appear for all booms sections. The next

ve programming steps are Number of Spray Tips Per Boom Section

steps. These steps correspond with the ve boom switches on the

lower portion of the console. The section you are programming can be

identied by looking at the SEC # at the left of the display.

You must program the correct number of spray tips for each boom

section on your sprayer. Use the Plus key

produce the correct value. Pressing the Plus key and Minus key

simultaneously will clear the value to zero.

Advance to the next step by pressing the Program key . This must

be done for all Number of Spray Tips Per Boom Section steps.

Any individual boom switches not being used must be programmed to a

“0” value. When you have programmed and validated the last Number

of Spray Tips Per Boom Section step, advance to the next program

step by pressing the Program key .

or Minus key to

will be

98-70006-ENUS R4

15

Page 20

844-E Sprayer Control

User Program Tip

User Programmable Tip

Default = 0.00

While in the User Programmable Tip step, the tip indicator arrow

will be ashing above the

In some cases you may nd that nozzles other than those pre-

programmed for the 844 Sprayer Control will need to be used. If

one of the eleven pre-programmed tips do not meet your needs, this

programming step allows the user to manually program a tip.

Use the Plus key or Minus key to adjust ow rate in US

Gallons Per Minute (Liters Per Minute) {Imperial Gallons Per Minute}

at 40 psi (2 bar). Pressing the Plus key and Minus key

simultaneously will clear the value to zero. To accept the value, press

the Program key to advance to the next programming step.

The ow rate information for the tip is only used to calculate the

pressure reading for ow based controls. With non-linear tips, the

calculation would be incorrect. Therefore we recommend a “0.00”

setting for non-linear tips so that the pressure will read “0” at all times,

instead of an inaccurate pressure. Non linear tips should not be used

with pressure based controls. Pressure based controls use the tip ow

rate information to adjust the pressure to achieve the right application

rate based on the size of the tips. With non linear tips, there is no way

for the controller to accurately calculate what the pressure should be at

various speeds.

WARNING: If the user is using tips other than the TeeJet®‚ VisiFlo®

brand, the corresponding colors may not match. In this

case, the user should determine the flow rate of the tip

being used at 40 psi (2 bar), and enter this flow rate as the

programmable tip.

NOTE: The flow rate will be automatically displayed at 40 psi (2 bar).

This pressure must be used for determining your tip’s flow rate.

Actual operation pressure is not important.

When the correct nozzle ow rate has been entered, advance to the

next programming step by pressing the Program key .

P tab at the bottom of the display.

Pressure Regulation

Pressure Regulation Mode

Default = byp (By-pass for US, trF, INP, and Si Modes)

Default = thr (Throttling for nh3 Mode)

While in the Pressure Regulating Mode step, the regulator symbol

will be ashing at the top of the console display.

This step tells the 844 where the regulating valve has been plumbed.

Once set correctly, this value should not change unless the regulating

valve is physically moved to a new point in the plumbing. For more

information on plumbing refer to pages 2 and 3 of this manual.

The default value “bYP” indicates that the pressure regulating valve

is plumbed in the bypass line. In most situations, especially total ows

below 4 US GPM (15 l/min) {3.3 Imperial GPM}, this is the preferred

installation position. If the default is correct, press the Program key

to accept the value and advance to the next step.

NOTE: When programmed in the bypass mode, with the controller in

“MAN” mode, the pressure regulating valve should close when

the Plus key is pressed, and open when the Minus key

is pressed.

The pressure regulating valve can be located in the supply line

between the ow meter and the boom control valves. If you will be

locating the pressure regulating valve in this position, use the Plus key

or Minus key to change the value to tHr (Throttling Mode).

By doing this, you have reversed the polarity that the console uses to

control the regulating valve.

NOTE: When programmed in the throttling mode with the controller

in “MAN” mode, the valve should open when the Plus key

is pressed and close when the Minus key is pressed.

Press the Program key to advance to the next step.

16

www.teejet.com

Page 21

844-E Sprayer Control

Regulation Adjustment Speed

Default = 9.5 (byp Mode)

While in this step, the regulator symbol

of the console display. This step allows you to regulate the speed of the

pressure regulating valve to accommodate different application needs.

Operating conditions may necessitate a higher or lower response

speed for the regulating valve. To change the response time number,

simply use the Plus key and Minus key to increase or decrease

the number. Any number between 0.0 and 9.9 can be selected. The

rst digit sets the speed for the coarse adjustment in relation to a large

percentage outside of the target application rate. The second digit sets

the speed for the ne tune adjustment in relation to a small percentage

close to the target application rate.

will be ashing at the top

9.5

Coarse adjustment Fine adjustment

If your system is plumbed in a bypass mode, the valve speed number

of 9.5 works very well in most applications.

If your system is plumbed in a throttling mode, start with a valve speed

number of 3 and adjust the number according to your application

requirements. Low ow situations will require a slower response time.

Adjusting agitation volumes to accommodate the regulating valve to

work in a more fully open position allows for a faster response time,

with little to no searching.

To accept this value and advance to the next step, press the Program

key .

Control Valve Type

Boom Control Valve Type: 2-Way/3-Way

Default = 2 Way

While in this step, the regulator symbol

of the display. The programmable information (2 Way or 3 Way) will be

displayed at the left in the console display.

This programming step is used to distinguish the type of on-off boom

control valves you have on your system. There are two types of valves

that can be used, 2-way control valves or 3-way control valves.

A 2-way control valve is simply an on/off valve. Flow is either directed

to the boom section(s) or it is blocked or diverted away from the booms.

A 3-way control valve is know as a by-pass valve. Flow continuously

passes through this valve. When the valve is activated (on), ow is

directed to the boom section(s). When the valve is not activated (off),

ow is directed through a bypass port, back to the supply tank.

If you are using the 3-way type of boom control valves in your system,

change the value using the Plus key or Minus key .

Press the Program key to accept the value and advance to the next

programming step.

If the default value is correct, press the Program key to accept the

value and advance to the next programming step.

NOTE: If using 3-way, bypass boom control valves, refer to the

instruction manual of the valve you are using for proper

calibration instructions.

will be ashing at the top

NOTE: This speed value can be adjusted to optimize system

performance. If you notice that the valve seems to “search” for

the programmed application rate by cycling the pressure up

and down continuously, reduce the number until the “searching”

is minimized or eliminated. Conversely, a higher number will

increase the valve response speed and speed up the rate of

adjustment.

98-70006-ENUS R4

17

Page 22

844-E Sprayer Control

Calibrate Speed

Speed Sensor Calibration

Default = 250

NOTE: During Speed Calibration, the 844 will automatically sense whether a Wheel Speed or Radar Speed Sensor is being used.

While in the Speed Calibration Programming Step, the calibrate speed symbol

value (250) will be displayed in the lower right corner of the display.

will be ashing at the top of the display. The programmable

Proximity/Magnetic Pulses

The speed sensor needs to be calibrated in order to provide the proper speed and area readings. The value for this step is the number of pulses

generated by the speed sensor in 300 ft / 100 m. This value can be determined by automatic calibration while driving exactly 300 ft /100 m, or by

entering the number manually.

Automatic Calibration

To automatically calibrate the speed sensor, mark off a distance of exactly 300 ft / 100 m. While still in the speed calibration program step, position

your sprayer at the beginning of your 300 ft / 100 m course and press the Plus key and Minus key simultaneously to clear the contents of

the display and to activate the auto calibration mode. When the auto calibration mode has been activated, CAL will be displayed at the lower right

of the display. Next, press the Plus key once to begin the calibration process. Now drive the course and the 844 will count the pulses as the

sprayer moves. The speed at which you drive over the course is not important. Stop the sprayer at exactly

300 ft (100 m in SI mode) and press the Program key to validate the number in the display.

The speed sensor is now properly calibrated.

NOTE: Once the auto calibration mode has been activated, no other functions of the 844 are possible until the console receives speed impulses

for calibration. To deactivate the auto calibration mode, press the key twice.

During the automatic calibration step, the 844 automatically senses if a radar ground speed sensor is installed. If you prefer to enter the speed

value manually, refer to the following instructions.

Manual Calculation:

To manually calculate the proper value for Wheel Speed Sensor pulses, you need to know the circumference of the wheel to which the sensor is

mounted. It can be measured by marking the tire and measuring the distance covered as that mark makes one full revolution.

Then use the following formula:

The result can be entered as an alternative to using the automatic calibration method. Use the Plus key or Minus key to adjust the value.

Press the Program key to validate the value and advance to the next programming step.

Radar Speed Pulses

Automatic Calibration:

The automatic calibration of a Radar speed sensor is similar to the automatic calibration of a wheel speed sensor. Refer to the directions above.

When the console has determined that a Radar Speed Sensor is being used, rAd will be displayed in the lower left of the console display.

Manual Calculation:

To manually enter the radar calibration value, rst press the Auto/Manual key to put the control console into radar mode. When the Control

Console is in the manual radar calibration mode, rAd will be displayed in the lower left of the console display. Now use the Plus key or Minus

key to adjust the value. When the correct value has been entered, press the Program key to validate this value.

18

www.teejet.com

Page 23

844-E Sprayer Control

Distance Counter

Default = 0

This step is a feature, not a calibration step. No specic value needs to

be entered here for the controller to operate correctly.

This feature will measure distance in feet (meters). This can be used to

measure elds, fence lines or to conrm Automatic Speed Calibration.

To activate the counter the Master Boom Switch must be on. To avoid

actually spraying during this task, toggle the individual boom sections

off. Anytime that the Master Boom is on during this step the console will

measure distance. If the Master switch is toggled off, the console will

stop counting distance.

To clear an existing distance, press the Plus key and Minus key

simultaneously.

NOTE: To confirm Automatic Speed Calibration, first complete the

calibration procedure. Advance to Distance Counter step.

Drive across the same 300 ft / 100 m course turning the

Master Switch ON at the start point and OFF at the finish

point. Distance measured should be 300 ft / 100 m +/- 6 ft

/ 2 m.

Simulated Ground Speed

Default = 6.0

While in the Simulated Ground Speed step, the calibrate speed symbol

will be ashing at the top of the display. The default value of 6.0

will be displayed in the middle of the display.

The simulated ground speed allows you to check out the functions and

operations of the console and of the sprayer, spraying water, without

actually moving the sprayer. This can and should be done prior to any

spraying activity.

NOTE: If you are using a Radar Speed Sensor, disconnect the Radar

connection from the main console. Because of the sensitivity of

this unit, any movement can disable simulated speed.

To set the simulated speed, use the Plus key and Minus key

to adjust the value. When the value is set, press the Program key

to advance to the next step. The simulated speed will be activated after

you exit the system setup mode.

NOTE: Once the sprayer begins moving and the 844 receives actual

speed pulses, the simulated speed feature is deactivated.

Program Specic Gravity

Liquid Specic Gravity (Density)

Default = 1.00

While in the Liquid Specic Gravity (Density) Programming Step, the

density symbol D, will be ashing at the top of the console display.

The default value of “1.00” corresponds with the specic gravity of

water and is correct for most pesticide applications. Occasionally some

spray solutions, such as fertilizer, have different densities. If you are

using such a material, a new value should replace the default value.

The chart to the left can help you determine the specic gravity of other

solutions.

To change the default value to your new value, use the Plus key

or Minus key to change the value in the display. Pressing the Plus

key and Minus key simultaneously will clear the value to zero.

To accept the value and advance to the next programming step, press

the Program key . If the solution that you are using can not be

found on the chart to the right.

Weight of Solution Per Gallon Specic Gravity

7.0 lb 0.84

8.0 lb 0.96

8.34 lb - water 1.00

10.0 lb 1.20

10.65 lb - 28%N 1.28

10.85 lb - 30%N 1.30

11.0 lb 1.32

12.0 lb 1.44

14.0 lb 1.68

NOTE: Water weighs 8.34 lb/gal or 1 Kg/L

The Specic Gravity can be calculated as follows:

NOTE: To activate this specific gravity number, while in the Application

Setup Mode, press the Auto/Manual key so the “D” is displayed

at the top of the screen. When the “D” is displayed, all

calculations performed will use the specific gravity programmed

in this step. To remove the “D” press the Auto/Manual key.

When the “D” is not displayed all calculations performed will

use the specific gravity of water (1.00) regardless of whether

another density is programmed into this step or not.

98-70006-ENUS R4

19

Page 24

844-E Sprayer Control

Communications

Default = no COn (no communications)

This step lets you select what type of communication you will be

using. The choices available are the default of “no COn” (no

communications), “prt” (Printing Capability), “gps” (Global

Positioning Communication Capability), or “lOg” (Downloading to a

PC on the go capability).

Use the Plus key or Minus key to select the type of

communication you will be using. After selecting the communication

you will be using, press the Program key to advance to the next

step.

NOTE: If a communications feature is selected, you must exit the

setup mode, power down the console ( + ) then restart

the console ( ). This activates the selected communication

feature.

WARNING: The 844 must be powered on before connecting to a

communication device (i.e. printer, computer, GPS). The

844 will not completely power on if it is first connected to a

communication device.

Minimum Pressure

Minimum Regulating Pressure Setting

Default = 10 PSI (0.7 bar)

This programming step allows you to set the minimum pressure that

the sprayer control will regulate to. Sometimes when the sprayer speed

slows down, the control system will regulate the pressure so low that it

falls below the manufacturer’s recommended pressure for the spray tip

or reduces system ow to the point where the ow meter will stall.

To avoid these situations, the TeeJet 844 can be programmed to not

regulate below the pressure set in this step. If this step is set for the

default of 10 psi (0.7 bar), the pressure will not go below 10 psi (0.7

bar) while spraying in automatic mode.

NOTE: Not all 844 models contain this programming step. If this step is

not displayed, the 844 has an automatic low pressure setting of

10 psi (i.e. the system will not regulate below 10 psi (0.7 bar).

When you have completed the Minimum Regulating Pressure Setting

Step, you have completed the System Setup Mode of the TeeJet 844

Sprayer Control.

NOW, PRESS AND HOLD THE PROGRAM KEY FOR THREE (3)

SECONDS, AND THE ENTIRE PROGRAM SYSTEM WILL BE

STORED IN THE COMPUTER’S MEMORY.

APPLICATION SETUP MODE

The Application Setup Mode contains the programming steps that

are most frequently changed (target application rate, and nozzles

used). Spraying Systems Co. has added this separate setup mode

to speed the programming process when minor changes are made

in the spraying operation (i.e. changing elds, switching nozzles,

changing crops, etc.). The operator can avoid toggling through all of the

programming steps unnecessarily.

To enter the Application Setup Mode, press the Program key twice.

Pressing the key once inadvertently will cause the display to ash “ ”

in the upper left and “USEr” at the lower right of the display for

three (3) seconds before the 844 will return to normal operating mode.

The “ ” / “USEr” indicates that the console is about to enter the

Application Setup Mode. Pressing the Program key a second time

within three (3) seconds puts the Control Console into the Application

Setup Mode.

Target Application Rate

US Default = 20.0 US GPA

TrF Default = 2.00 Gal/1000 ft

InP Default = 20.0 Imperial GPA

Nh3 Default = 200 Pounds of Nitrogen/Acre

Si Default = 200 l/ha

While in the Target Application Rate step, the application rate,

pressure, speed, and ow rate in US GPM (l/min) {Imperial GPM}, will

be displayed. The application rate units (GPA, G/1000 ft2 or l/ha) will

be ashing indicating that the corresponding value can be adjusted or

programmed.

Your target application rate should be entered in this step. Use the Plus

key or Minus key to adjust the value. Pressing the Plus key

and Minus key simultaneously will clear the value to zero. When

the desired application rate has been entered, press the Program key

to accept the value and advance to the next step.

NOTE: If you are using NH3 units, only the Target Application Rate will

appear in this step.

2

NOTE: For your protection, the 844 console will not automatically

power down while in the System Setup Mode. You must exit

properly, as described above, to enable the console auto power

down feature.

NOTE: Cutting the power to the controller while in the System Setup

Mode will not save any changes into the computer’s memory.

20

www.teejet.com

Page 25

844-E Sprayer Control

Nozzle Selection

Default = Red or 0.4 US GPM (1.29 l/min) {0.33 Imperial GPM}

While in the nozzle selection step, the display will remain the same as in the Target Application Rate step except the indicator arrow

ashing at the bottom of the display just above a color coded strip.

NOTE: The tabbed color strip along the bottom of the display represents color coding for TeeJet® VisiFlo® spray tips. If you are using tips made

by another manufacturer, you should use the programmable tip capacity as explained in the System Setup section on page 14.

Select the representative color to match the spray tips being used to apply the desired application rate. Use the Plus key or Minus key

to toggle the indicator arrow

through the tabbed color strip at the bottom of the display panel. The corresponding ow rate for each color will

be displayed in US Gallons Per Minute (Liters Per Minute) {Imperial Gallons Per Minute} at 40 psi (2 bar) at the lower right of the display. If the

programmable tip is to be used, toggle the indicator arrow

symbol to the “P” tab. Flow rate will always be displayed in US Gallons Per Minute

(Liters Per Minute) {Imperial Gallons Per Minute} at 40 psi (2 bar) regardless of any changes to other display parameters.

The table at the bottom indicates ow rates in US Gallons Per Minute (Liters per Minute) {Imperial Gallons Per Minute} at 40 psi (2 bar) for the

TeeJet® VisiFlo® color coded spray tips represented in the 844 Spray Control.

WARNING: Color coding of spray tips is not uniform from manufacturer to manufacturer. Flow rates for all nozzles should be checked prior to use.

Tips that are worn should be replaced to ensure an accurate application rate.

Required Speed to Achieve the Application Rate

Based on the tip programmed and nozzle spacing (programmed in the System Setup Mode), the 844 console will calculate the required

speed to achieve the application rate that was entered in the last programming step. The speed will be displayed in the lower left corner of the

display window. Keep in mind that this speed is based on a spraying pressure of 40 psi (2 bar). More calculations can be performed in the next

programming step.

When the correct ow rate for the spray tips being used has been entered, press the Program key to accept the value and advance to the next

step.

will be

TeeJet® VisiFlo®

Tip Color

Orange 0.10 0.32 0.08

Green 0.15 0.48 0.12

Yellow 0.20 0.64 0.17

Blue 0.30 0.97 0.25

Red 0.40 1.29 0.33

Brown 0.50 1.61 0.42

Gray 0.60 1.93 0.50

White 0.80 2.58 0.67

Light Blue 1.00 3.22 0.83

Light Green 1.50 4.83 1.25

Black 2.00 6.45 1.67

Flow Rate in

US GPM at 40 PSI

Flow Rate in

l/min at 2 bar

Flow Rate in Imperial

GPM at 40 PSI

98-70006-ENUS R4

21

Page 26

844-E Sprayer Control

Calculation Troubleshooting

This Programming Step is a diagnostic tool only

This programming step has no effect on the operation of the TeeJet

844 Sprayer Control. It allows the user to adjust the indicated pressure

to see what effects it would have on the operating speed; or the user

can adjust the speed to see what pressure would need to be used to

maintain the target application rate. This step should help determine if

the correct nozzle size was chosen for the application.

While in the calculation step, either the pressure “PSI” (bar) or speed

“MPH” (km/h) units will be ashing.

Adjust Speed:

While in the Calculation Step, the user is able to view the nozzle

ow rate, pressure, speed and application rate simultaneously.

When rst entering this step, the speed “MPH” (km/h) units will be

ashing, indicating that this digit can be changed. By pressing the

Plus key or Minus key , the programmer can change the

indicated speed to a desirable speed or typical operating speed.

The 844 will immediately calculate what the pressure would need to

be to maintain the target application rate at this speed. If the pressure

is too high, you will need larger spray tips or will have to slow down. If

the pressure is too low, you will need smaller spray tips or will have to

speed up.

Adjust Pressure:

If you wish to adjust the pressure, press the Program key

once so that the pressure “PSI” (Bar) units begin to ash. Use the

Plus key or Minus key to adjust the indicated pressure to

a desired or recommended pressure. The 844 will immediately

determine what the operating speed would need to be to achieve

the target application rate at this pressure. If the speed indicated

is too high, a smaller nozzle is needed. If the speed indicated is

too low, a larger nozzle is needed.

Liquid Density:

All calculations performed in the normal Calculation Step are based

on spraying water. To convert these calculations to the Liquid Density

programmed in the Liquid Specic Gravity (Density) Step in the System

Setup Mode (page 14), press the Auto/Manual key. When calculations

are using the programmed Specic Gravity (Density), the D symbol

will be displayed at the top of the display window. To go back to the

calculations based on spraying water, press the Auto/Manual key.

NOTE: If you are going to be spraying with a different density of liquid

other than water and you have programmed that specific

gravity (density) into the Specific Gravity (Density) Step in the

System Setup Mode, you must select the density symbol D at

the top of the display in order for all of the calculations to be

performed in the regular spraying mode. If when in the regular

spraying mode, you do not see the density symbol D at the

top of the display, this means that you have not selected a

different specific gravity of liquid and that all calculations will

be performed with water (1.00).To spray with a different density

liquid, the specific gravity must first be programmed into the

System Setup Mode in the Specific Gravity (density) step on

page 19. Once a number has been programmed into that step,

you must select the density symbol D in the Application Setup

Mode by pressing the Auto/Manual key.

NOTE: The tip flow rate, in the lower right corner of the display, will

always display the flow rate in US Gallons Per Minute (Liters

Per Minute) {Imperial Gallons Per Minute} at 40 psi (2 bar),

regardless of changes to the indicated pressure.

After performing the calculations, you can advance to the beginning

of the Application Setup sequence to make any changes by pressing

the Program key once. If no changes are necessary, you have

completed the Application Setup Mode of the TeeJet 844 Sprayer

Control.

NOW, PRESS AND HOLD THE PROGRAM KEY FOR THREE (3)

SECONDS, AND THE ENTIRE APPLICATION SETUP MODE WILL BE

STORED IN THE COMPUTER’S MEMORY.

NOTE: For your protection, the 844 console will not automatically

power down while in the Application Setup Mode. You must exit

properly as described above to enable the console auto power

down feature.

NOTE: Cutting the power to the controller while in the Application

Setup Mode will not save any changes made into the

computer’s memory.

22

www.teejet.com

Page 27

CHAPTER 4 OPERATING INSTRUCTIONS

844-E Sprayer Control

Sprayer Checkout

Before spraying, check all connections related to the Sprayer Control

assembly. Particular attention should be given to the speed sensor to

be sure the sensor and magnets are in line, and properly secured.

WARNING: Whenever you are working around a sprayer or farm

chemicals, be sure to wear protective clothing and eye

wear.

Partially ll the sprayer tank with water to ush the system and to make

a visual check of the spray tips to be sure all tips are delivering a good

spray pattern.

Follow these steps, in sequence, being sure the Master Boom Switch is

in its “off” position:

1. Be sure the tank shut-off valve is open.

2. Start the engine, engage pump, and set the rpm to that which will

be used when spraying.

3. Switch the computer on by pressing the Program key on the

display panel.