Page 1

844-AB

SPRAYER CONTROL

USER GUIDE MANUAL

For use with software version 4.02.

Page 2

Copyrights

© 2013 TeeJet Technologies. All rights reserved. No part of this document or the computer programmes described in it may be reproduced,

copied, photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without

prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or

organisations.

Limitation of liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY

LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH

DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

Page 3

844-AB

Table of Contents

CHAPTER 1 - INTRODUCTION 3

Power on the console .......................................................................................................................................................................................... 3

Power o the console ......................................................................................................................................................................................... 3

CHAPTER 2 - APPLICATION MODE 4

Airblast mode ......................................................................................................................................................................................................... 4

Vineyard mode ...................................................................................................................................................................................................... 4

CHAPTER 3 - OEM SETUP 4

Application type ................................................................................................................................................................................................... 4

Number of sections .............................................................................................................................................................................................. 4

Minimum voltage ................................................................................................................................................................................................. 5

Deadband ................................................................................................................................................................................................................ 5

Rotation speed ...................................................................................................................................................................................................... 5

Display stable ......................................................................................................................................................................................................... 5

Total area ................................................................................................................................................................................................................. 5

Maximum speed ................................................................................................................................................................................................... 5

Memory option ..................................................................................................................................................................................................... 6

Tank content ........................................................................................................................................................................................................... 6

CHAPTER 4 - SYSTEM SETUP 6

Units of measurement ........................................................................................................................................................................................ 6

Reset to default ..............................................................................................................................................................................7

Sensor selection .................................................................................................................................................................................................... 7

Flow meter impulses ........................................................................................................................................................................................... 7

Manual entry ..................................................................................................................................................................................7

Automatic calibration .....................................................................................................................................................................7

Pressure transducer low pressure calibration (P Ref ) .............................................................................................................................. 8

Manual entry ..................................................................................................................................................................................8

Automatic calibration .....................................................................................................................................................................8

Pressure transducer maximum rating (PHI) ............................................................................................................................................... 8

Speed sensor calibration.................................................................................................................................................................................... 9

Proximity/magnetic impulses .........................................................................................................................................................9

Automatic calibration..............................................................................................................................................................9

Manual calculation .................................................................................................................................................................9

Radar speed impulses ...................................................................................................................................................................9

Automatic calibration............................................................................................................................................................10

Manual calculation ...............................................................................................................................................................10

Simulated ground speed .................................................................................................................................................................................10

Reference ow rate per section .....................................................................................................................................................................11

1. Select section ..........................................................................................................................................................................11

2. Reference pressure .................................................................................................................................................................11

3. Reference ow ......................................................................................................................................................................... 11

Next section ................................................................................................................................................................................. 11

Regulating valve response time ....................................................................................................................................................................12

Pressure regulating mode ...............................................................................................................................................................................12

Minimum pressure setting ..............................................................................................................................................................................12

Density (Liquid specic gravity) .................................................................................................................................................................... 13

Communications ................................................................................................................................................................................................13

98-70007-EN R4

1

Page 4

844-AB

Faces per section setting (HC mode only) .................................................................................................................................................13

CHAPTER 5 - SWATH WIDTH PRESETS 14

Selecting swath preset .....................................................................................................................................................................................14

CHAPTER 6 - APPLICATION SETUP 15

Preset ow rate selection .................................................................................................................................................................................15

Nozzles per face .................................................................................................................................................................................................15

Target application rate ...................................................................................................................................................................................... 15

Calculation diagnostic .....................................................................................................................................................................................15

Adjust pressure ............................................................................................................................................................................16

Adjust speed ................................................................................................................................................................................16

Liquid density ......................................................................................................................................................................................................16

CHAPTER 7 - OPERATIONS 17

Spraying .................................................................................................................................................................................................................17

CHAPTER 8 - FEATURES 18

Boost mode...........................................................................................................................................................................................................18

Area/volume display..........................................................................................................................................................................................18

Application alarm ............................................................................................................................................................................................... 18

No ow alarm ....................................................................................................................................................................................................... 19

Automatic power down ...................................................................................................................................................................................19

Printing ...................................................................................................................................................................................................................19

2

www.teejet.com

Page 5

844-AB

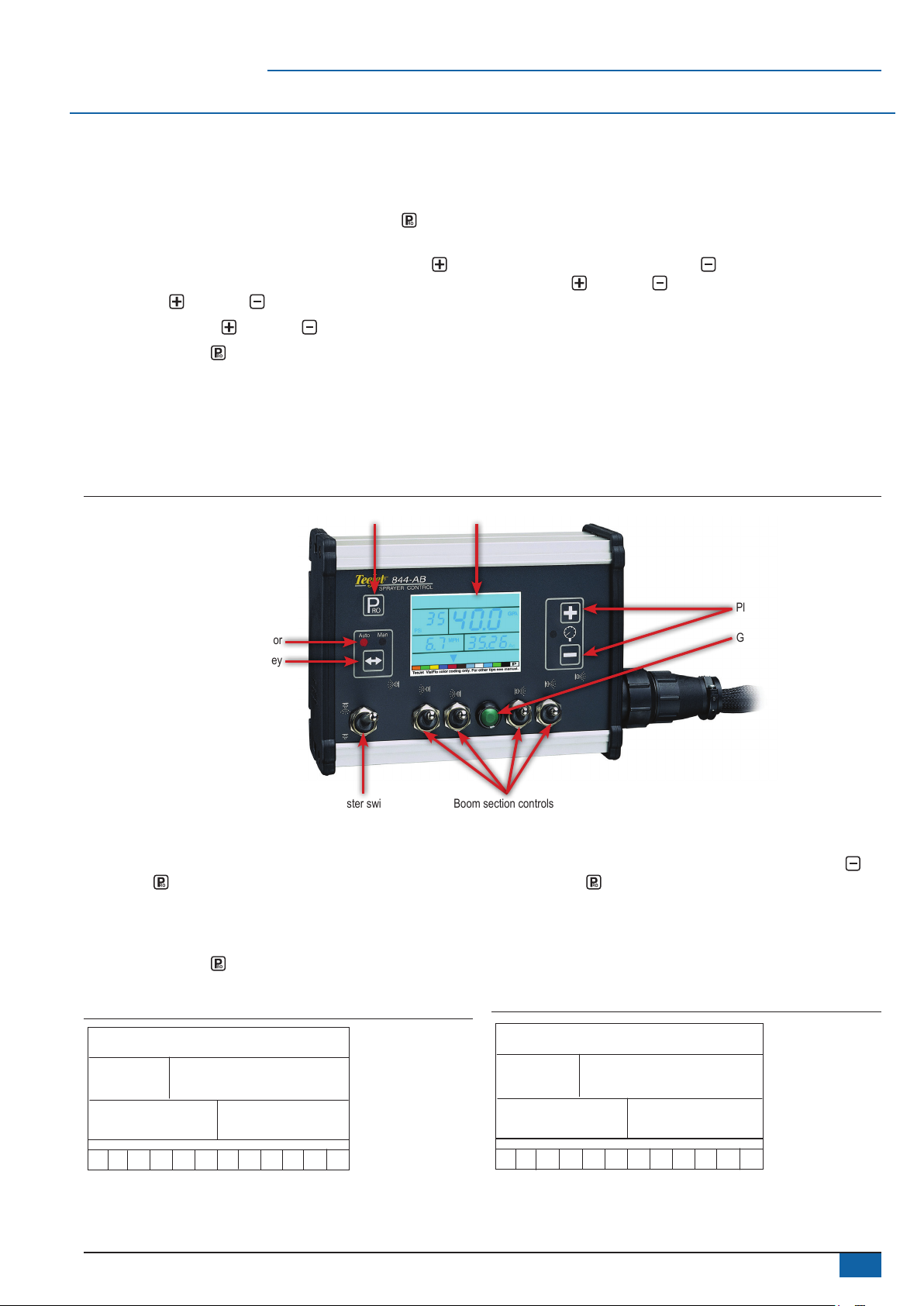

CHAPTER 1 - INTRODUCTION

This user guide provides information for software version 4.02.

Make sure that all hardware components are properly installed and tested. Before starting the programming process, conrm that the console

and all sensors are working properly.

IMPORTANT! Before beginning, review the following programme guidelines that control the programming process.

To exit any Setup mode, press and hold the Programme key for 3 seconds. The inputs are stored and the computer will exit Programme

mode.

To increase the value of a programmable digit, press the Plus key. To decrease the value, press the Minus key. These keys are located

directly to the right of the display. For some programme steps, press and hold the Plus and Minus keys to quickly change the values.

Press the Plus and Minus keys once to increment/decrement the values by one unit.

Press and hold the Plus and Minus keys simultaneously to reset the value to “0” or begin automatic calibration.

Press the Programme key to advance the system to the next programme step. After the nal programme step is complete, the console will

nish the programming loop and return to the initial programming step.

System setup mode contains the options that customize the controller to the sprayer or sprayer components. These include calibration steps

and parameters that seldom change once programmed.

Application setup mode contains settings that are frequently changed (nozzle spacing, number of nozzles per boom section, density, nozzles

used and target application rate).

Figure 1: 844-AB console

On/programme button Display

Auto/manual mode indicator

Auto/man key

Boom section controlsMaster switch

Power on the console

The 844-AB console can be powered on by pressing the

Programme key one time. The console will initially display the

software version at the top of the screen and the serial number of the

console at the bottom of the screen. After approximately 5 seconds,

the console will enter into swath width view.

Press the Programme key to advance to normal Operations

mode.

Figure 2: Power on the console

Plus and minus keys

GREEN button

Power o the console

To power off the 844-AB console, press and release the Minus

and Programme keys simultaneously. The console will save new

information (area and volume counters) to memory before it powers

down. “Off” will be displayed on the console, followed by a 5-second

countdown, indicating the console is about to power down. The

console also has an automatic power down feature. This is described

in further detail in the Features section of this User guide.

Figure 3: Power off the console

ABL

g22

1 2 3 4 5 6 7 8 9 10 11 12

4.03

5555

OFF

5

1 2 3 4 5 6 7 8 9 10 11 12

98-70007-EN R4

3

Page 6

844-AB

CHAPTER 2 - APPLICATION MODE

The 844-AB gives the possibility of working in two different ways

to t the application. Therefore, the console should be set up and

consequent programming and working features will be dependant of

the chosen mode.

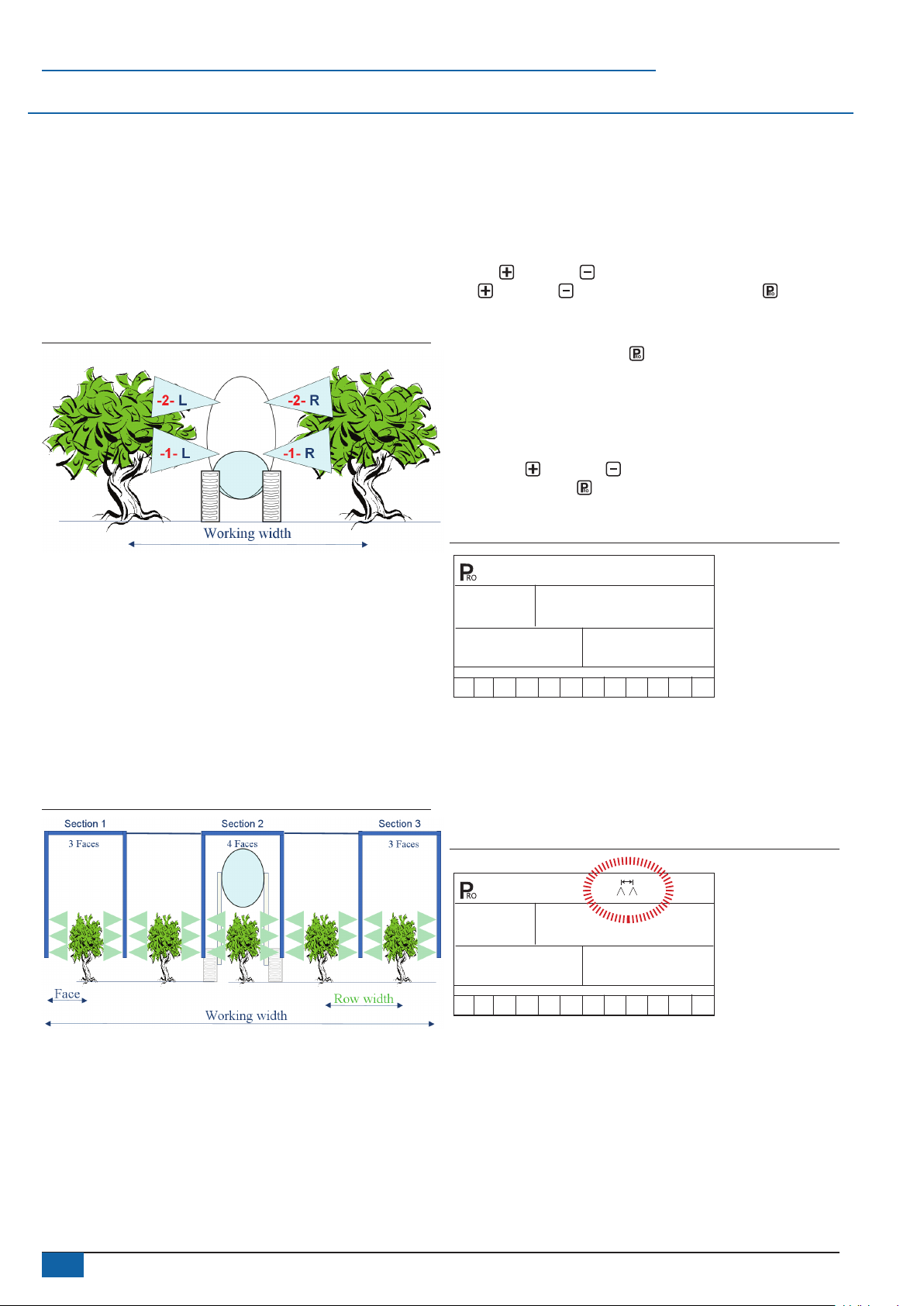

Airblast mode

This mode is designed to work with Airblast sprayers, mostly

spraying on two sides (left and right) with the possibility to switch

on or off sections in the height. The working width is dened by

the distance between two rows of trees. This mode is called AB

(airblast).

Figure 4: Airblast (AB) principle

CHAPTER 3 - OEM SETUP

OEM setup mode contains the options that customize the controller

to the sprayer or sprayer components. These include calibration

steps and parameters that will never change once programmed.

ADVISORY! OEM setup parameters (except HC/AB mode) should

not be changed unless advised by TeeJet Technologies or an

authorized dealer.

To enter System setup mode, power off the console. Press and hold

the Plus and Minus keys simultaneously. While holding the

Plus and Minus keys, also press the Programme key four

times (within 3 seconds) and then release all keys to enter OEM

setup mode.

Press and hold the Programme key for three seconds to exit OEM

setup mode. Changes will be saved to the console’s memory.

Application type

As explained above, the 844-AB is capable of working in either

Airblast (AB) or Vineyard (HC) mode.

Use the Plus and Minus keys to switch from AB to HC mode.

Press the Programme key to accept the value and advance to the

next programme step.

Figure 6: Application type

Vineyard mode

This mode is designed to work with vineyard sprayers that are

spraying horizontally. Several rows are covered and sections can be

switched on or off to adapt the working width. Each section covers

a number of faces. The working width is dened by the number of

faces and the row width.

One or more nozzles can be spraying each face. If all nozzles

spraying on a face are not equal, they should be considered as a

unique nozzle and the total ow has to be set up in the conguration

menu. But all faces have to be sprayed equally. This mode is called

HC (vineyard).

Figure 5: Vineyard (HC) principle

typ

1 2 3 4 5 6 7 8 9 10 11 12

AB

Number of sections

This will determine the maximum number of sections available on the

sprayer.

◄In AB mode, only even values are allowed (2,4,6).

◄In HC mode, all values between 1 and 7 are allowed.

Figure 7: Number of sections

nr

4

se[

1 2 3 4 5 6 7 8 9 10 11 12

4

www.teejet.com

Page 7

844-AB

Minimum voltage

This will determine the minimum voltage that can be applied to the

regulation valve. If too low, the valve won’t ne tune the dose rate. If

too high, the valve could have some unstable regulation.

Figure 8: Minimum voltage

3.5

Min

1 2 3 4 5 6 7 8 9 10 11 12

Deadband

This will determine the regulation dead band. This setting will avoid

continuous regulation when the dose rate is very close to the target

doise rate. If too low, the valve could have some unstable regulation.

If too high, the real dose rate could be far away from the target.

Figure 9: Deadband

STp

bnd

1 2 3 4 5 6 7 8 9 10 11 12

Rotation speed

This will determine the time needed by the regulation valve to travel

at maximum speed from fully close to fully open. This value must be

set according to the specications of the valve.

UOlt

1.5

Display stable

This will determine allowed tolerance percentage on the displayed

dose rate. If the difference between the real and the target dose

rates is smaller than it, the target will be displayed.

Figure 11: Display stable

5

dsp

1 2 3 4 5 6 7 8 9 10 11 12

Total area

This counter is a hidden counter that can be reset only by the

manufacturer. It shows the total area covered since last reset.

Figure 12: Total area

stbl

tot

Ha

21341

1 2 3 4 5 6 7 8 9 10 11 12

Maximum speed

This counter is a hidden counter that can be reset only by the

manufacturer. It shows the maximum speed reached by the sprayer.

Figure 13: Maximum speed

Figure 10: Rotation speed

rot

spd

1 2 3 4 5 6 7 8 9 10 11 12

6

seC

25.2

1 2 3 4 5 6 7 8 9 10 11 12

Km/h

XI6H

98-70007-EN R4

5

Page 8

844-AB

Memory option

This feature enables the user counters.

Select NO to disable this feature or YES to enable it.

Figure 14: Memory option

No

mem

1 2 3 4 5 6 7 8 9 10 11 12

CHAPTER 4 - SYSTEM SETUP

System setup mode contains the options that customize the

controller to the sprayer or sprayer components. These include

calibration steps and parameters that will rarely change once

programmed.

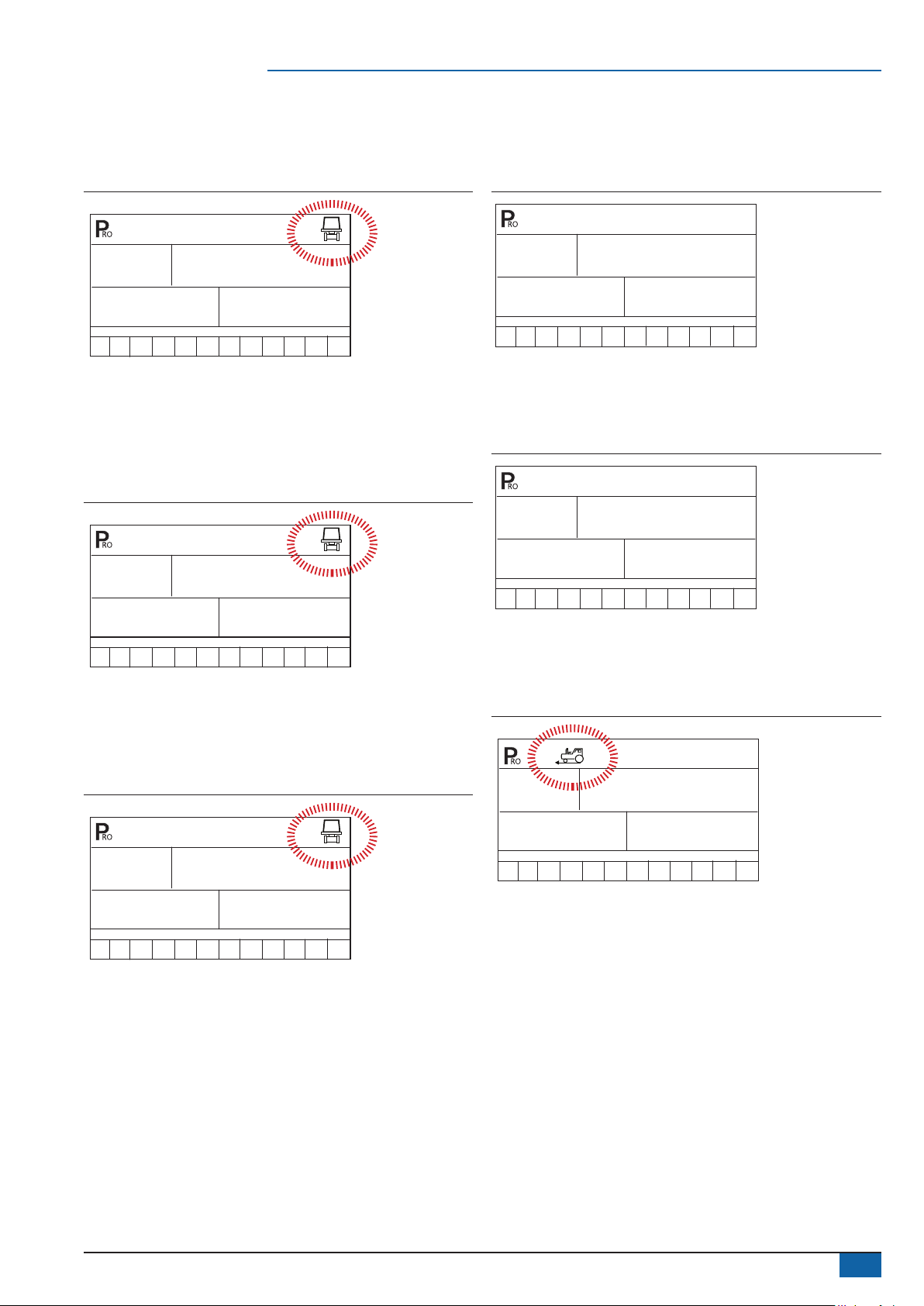

Table 1: System setup mode sequence

Units of measurement

Sensor selection

Flow meter impulses

Pressure transducer low pressure calibration (P Ref)

Pressure transducer maximum rating (P HI)

Speed sensor calibration*

Simulated ground speed

Reference ow rate per

section

Regulating valve response time

Pressure regulating mode

Minimum pressure setting

Density (Liquid specic gravity)

Communications

Faces per section setting, Section 1 (HC Mode only)**

Faces per section setting, Section 2 (HC Mode only)**

Faces per section setting, Section 3 (HC Mode only)**

Faces per section setting, Section 4 (HC Mode only)**

Faces per section setting, Section 5 (HC Mode only)**

Faces per section setting, Section 6 (HC Mode only)**

Faces per section setting, Section 7 (HC Mode only)**

* During speed calibration, the 844-AB will automatically sense whether a Wheel

speed or Radar speed sensor is being used.

** The number of sections available is determined within the OEM setup options.

Proximity/magnetic impulses

Radar speed impulses

Select section

Reference pressure

Reference ow

Repeat for section 2 to 12

Tank content

This feature enables a tank content counter. This counter should be

set after lling the tank and will count down according to the sprayed

volume. A zero value will disable this feature.

Figure 15: Tank content

T==1

0

1 2 3 4 5 6 7 8 9 10 11 12

To enter System setup mode, press and hold the Plus and Minus

keys simultaneously. While holding the Plus and Minus keys,

also press the Programme key twice (within 3 seconds) and then

release all keys to enter System setup mode.

Press and hold the Programme key for three seconds to exit

System setup mode. Changes will be saved to the console’s

memory.

NOTE: The 844-AB console will not automatically power down

during System setup mode. The system must be exited by

holding the Programme key for three seconds. A loss of

power to the controller during System setup mode will erase

all changes not previously saved to system memory.

Units of measurement

The 844-AB is capable of working in either US or SI (Standard

international metric). Use the Plus and Minus keys to switch

units. Press the Programme key to accept the value and advance

to the next programme step.

Figure 16: Units of measurement selection

US

1 2 3 4 5 6 7 8 9 10 11 12

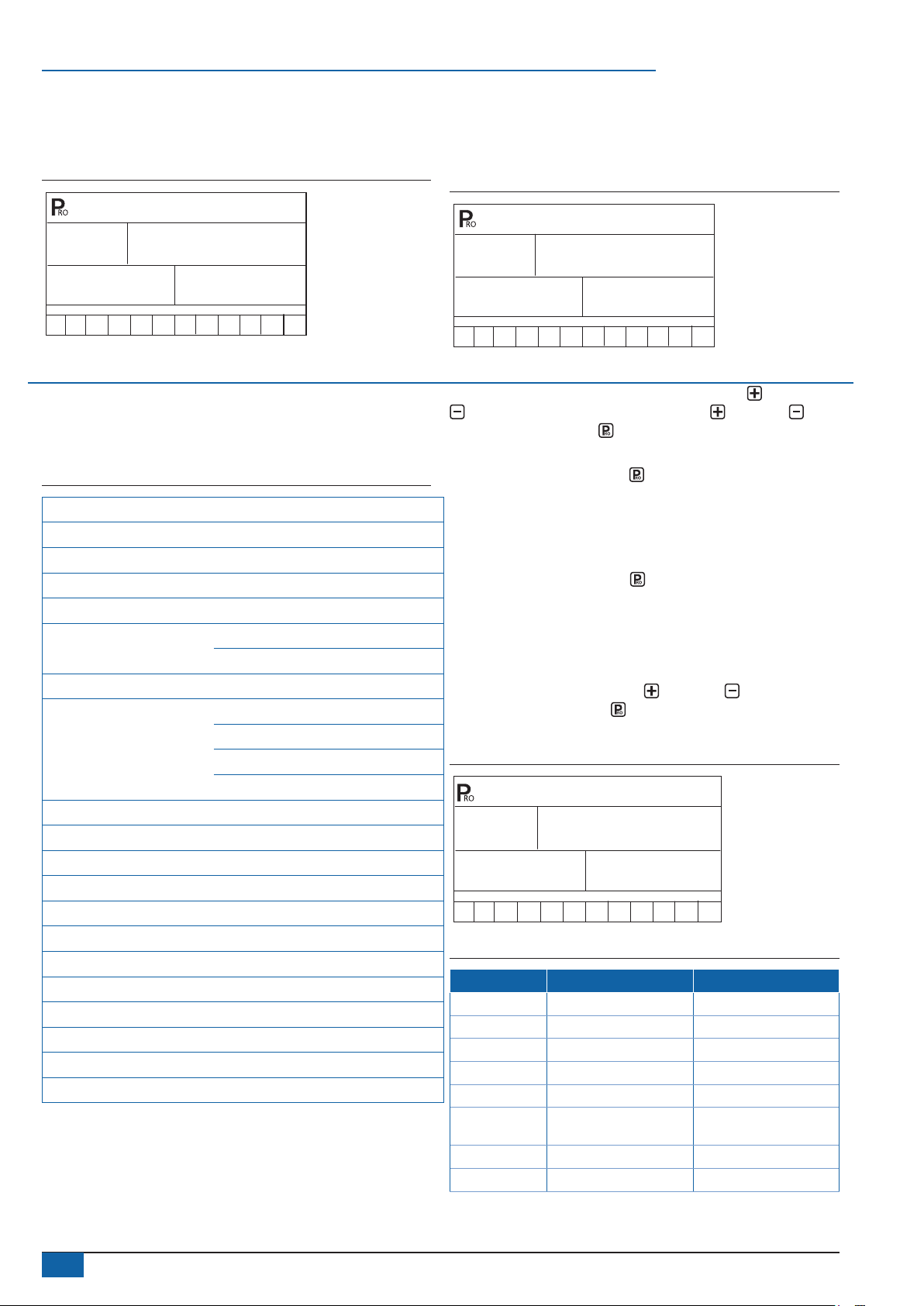

Table 2: Units of measurement

US SI

Speed MPH (miles per hour) Km/h (kilometres per hour)

Flow GPM (gallons per minute) L/min (litres per minute)

Area Acres Ha (hectares)

Pressure PSI (pounds per square inch) Bar

Volume Gal (gallon) L (litre)

Speed impulses

Tree spacing Inch cm (centimetre)

Dose rate GPA (gallons per acre) L/Ha (litres per hectare)

impulses/300ft

(impulses per 300 feet)

impulses/100m

(impluses per 100 metres)

6

www.teejet.com

Page 9

844-AB

Reset to default

If units of measurement changes were made, the console will display

a message asking if programme parameters should be reset to

default before advancing to the next screen. Use the Plus or

Minus keys to select either “Yes” or “No” on the screen. Press the

Programme key to accept the value and advance to the next

programme step.

NOTE: If changes were not made to Units of measurement, this

step will be skipped and the screen will advance to Sensor

selection.

Figure 17: Reset to default

rES

YES

dEF

1 2 3 4 5 6 7 8 9 10 11 12

Sensor selection

The 844-AB can accommodate a ow meter, pressure transducer or

both. Sensor selection instructs the console which sensor is being

used on the sprayer. The default value is “FLO” (ow-based system)

using a ow meter. To maintain this setting, press the Programme

key to advance to Flow meter impulses. To change the setting to

“PRS” (pressure based system), use the Plus or Minus keys

to select “PRS”. Press the Programme key to advance to Flow

meter impulses.

NOTE: Pressure-based regulation is used only with linear nozzles.

For non-linear nozzles, ALWAYS select flow-based

regulation. Most nozzles are linear and may be used with

pressure-based regulation. ConeJet nozzles are non-linear.

If both sensors have been installed on the sprayer, this step will

determine which sensor will be used.

◄If “FLO” is selected, the ow meter will be used to control ow

and the pressure transducer will be used only to display actual

pressure.

◄If “PRS” is selected, the pressure transducer will be used

to control ow and display the actual pressure. Flow meter

signals will be ignored.

The regulation mode determines the following programme steps.

◄If “FLO” is selected, the next Setup mode screen displayed

will be the calibration step for the ow sensor (refer to Flow

meter impulses).

◄If “PRS” is selected, the next Setup mode screen displayed

will be the calibration step for the pressure transducer (ow

sensor calibration will be skipped).

Figure 18: Sensor selection

Flow meter impulses

During the Flow meter impulses step, the symbol (ow meter

turbine) will ash at the top of the console. The ow meter calibration

number can be entered manually from the factory-calibrated ow

meter pulse rate tag or an Auto calibration procedure can be

activated to determine ow meter impulses based on a known

volume of uid.

Figure 19: Flow meter impulses

650

1 2 3 4 5 6 7 8 9 10 11 12

Manual entry

Locate the factory-calibrated ow meter pulse rate tag on the ow

meter. If this varies from the default value (it usually does) of the

console, use the Plus or Minus keys to modify the value.

In some cases, larger ow meters with small calibration numbers

will include decimals for greater accuracy. To add a decimal to the

calibration number, press the Auto/man key.

Automatic calibration

To complete an automatic calibration of the ow meter, press the

Plus and Minus keys simultaneously. This will clear the

existing value and initiate the calibration procedure. “CAL” will be

displayed in the screen. This indicates that the controller is ready to

begin the calibration process.

Figure 20: Calibration procedure

CAL

0

1 2 3 4 5 6 7 8 9 10 11 12

Engage the sprayer pump. Turn the boom sections “On” and begin

spraying a known volume of uid (e.g. 400 litres). As the known

amount is sprayed, the console will count the impulses. After the

known volume has been sprayed, turn the Master switch “Off” to stop

counting impulses.

Figure 21: Calibration procedure

FLO

1 2 3 4 5 6 7 8 9 10 11 12

CAL

23

1 2 3 4 5 6 7 8 9 10 11 12

2777

98-70007-EN R4

7

Page 10

844-AB

Press the Programme key. The console will ask for the volume

that was sprayed. Use the Plus or Minus keys to adjust the

value to match the volume sprayed in litres.

Figure 22: Calibration procedure

uOL

1 2 3 4 5 6 7 8 9 10 11 12

Press the Programme key to return to the Setup mode. The

new ow meter calibration number will be displayed. To accept the

value displayed, press the Programme key again. To repeat the

calibration procedure, repeat the previous steps.

Figure 23: Calibration procedure

378

Automatic calibration

Make sure the sprayer pump is turned “Off” and there is no pressure

in the system. Press and release the Plus and Minus keys

simultaneously to activate the auto-calibration feature. The message

“MES” will be displayed. A count of “0” to “9” will appear on the lower

right portion of the screen.

Figure 25: Pressure transducer low pressure calibration

160

MES

1 2 3 4 5 6 7 8 9 10 11 12

Once the display nishes counting, a number close to 4.0 (+/- 0.2)

should be displayed. The low pressure value of the transducer is

calibrated. Press the Programme key to advance to the next step.

Figure 26: Pressure transducer low pressure calibration

3.9

9

615

1 2 3 4 5 6 7 8 9 10 11 12

Pressure transducer low pressure

calibration (P Ref)

The Pressure transducer low pressure calibration step is used to

calibrate the “0” pressure setting of the pressure transducer. The

pressure transducer used with the 844-AB uses a 4-20 mA reading

(4.0 mA represents 0 pressure).

Figure 24: Pressure transducer low pressure calibration

P

4.0

REF

1 2 3 4 5 6 7 8 9 10 11 12

Manual entry

Use the Plus or Minus keys to modify the value.

P

3.9

REF

1 2 3 4 5 6 7 8 9 10 11 12

NOTE: If a pressure transducer is not installed on the system, skip

this step by pressing the Programme key. Leave the

default value at “4.0”.

Pressure transducer maximum rating

(PHI)

The Pressure transducer maximum rating establishes the maximum

rating of the pressure transducer. This number can be found stamped

on the pressure transducer. If the transducer has a maximum rating

of 10 bar and the number is shown on the display, advance to the

next step by pressing the Programme key.

If the maximum rating is 25 bar, use the Plus or Minus keys to

change the value. Press the Programme key to advance to the

next step.

Figure 27: Pressure transducer maximum rating

8

www.teejet.com

P

Bar

3.5

Hi

1 2 3 4 5 6 7 8 9 10 11 12

NOTE: If a pressure transducer is not installed on the system, skip

this step by pressing the Programme key. Leave the

default value at “10 Bar”.

Page 11

844-AB

Speed sensor calibration

The speed sensor must be calibrated in order to provide the proper

speed and area readings. The value is determined by the number

of impulses generated by the speed sensor in 100 metres, or by

manually entering the number.

NOTE: During speed calibration, the 844-AB will automatically sense

whether a Wheel speed or Radar speed sensor is being

used.

Proximity/magnetic impulses

Figure 28: Proximity/magnet impulses

250

1 2 3 4 5 6 7 8 9 10 11 12

Automatic calibration

To automatically calibrate the speed sensor, mark a distance

of exactly 100 metres. Press the Plus and Minus keys

simultaneously to clear the contents of the display and activate

auto calibration mode. “CAL” will be displayed on the lower right

of the screen.

Figure 30: Speed sensor automatic calibration

CAL

157

1 2 3 4 5 6 7 8 9 10 11 12

NOTE: Once the automatic speed calibration process has been

activated, no other functions will operate until the console

receives speed impulses for calibration. To deactivate

automatic calibration mode, press the Plus key twice.

During the automatic calibration process, the 844-AB will

automatically sense whether a proximity/magnetic or radar ground

speed sensor is installed. If a manual entry is preferred, refer to

Manual calculation.

Manual calculation

To manually calculate the proper value for Wheel speed sensor

impulses, the circumference of the wheel to which the sensor is

mounted must be known. It can be measured by marking the tire

and measuring the distance covered as the mark makes one full

revolution. Once the number is known, use the following formula:

Figure 29: Speed sensor automatic calibration

CAL

1 2 3 4 5 6 7 8 9 10 11 12

Drive toward the initial point of the of designated 100 metres.

At the starting location, press the Plus key once to begin the

calibration process. Continue driving the course. The 844-AB

will count the impulses as the sprayer moves. The speed at

which the vehicle travels is not important. As the ending point is

reached, press the Plus key again. The console will display

the speed calibration number.

NOTES: The auto speed calibration process should take place in a

field-like environment with the sprayer tank at least half full.

It is recommended to repeat the automatic speed calibration

process at least twice and use an average of the speed

calibration numbers.

The result can be entered instead of using the automatic calibration

method. Use the Plus or Minus keys to adjust the value. Press

the Programme key to save the value and advance to the next

programme step.

Radar speed impulses

Figure 31: Radar speed sensor

rAd

1 2 3 4 5 6 7 8 9 10 11 12

250

98-70007-EN R4

9

Page 12

844-AB

Automatic calibration

To automatically calibrate the radar speed sensor, mark a distance

of exactly 100 metres. Press the Plus and Minus keys

simultaneously to clear the contents of the display and to activate

auto calibration mode. Once auto calibration mode is activated,

“RAD” will be displayed on the lower left of the screen.

Figure 32: Radar speed sensor automatic calibration

CAL

rAd

1 2 3 4 5 6 7 8 9 10 11 12

Drive toward the initial point of the designated 100 metres. At the

starting location, press the Plus key once to begin the calibration

process. Continue driving the course. The 844-AB will count the

impulses as the sprayer moves. The speed at which the vehicle

travels is not important. As the ending point is reached, press

the Plus key again. The console will display the radar speed

calibration number.

NOTES: The radar speed calibration process should take place in a

field-like environment with the sprayer tank at least half full.

It is recommended to repeat the radar speed calibration

process at least twice and use an average of the speed

calibration numbers.

Manual calculation

It is not possible to manually calculate the calibration value of a

radar. However, the value can be entered manually if it is known

from a prior calibration. To manually enter the radar calibration

value, press the Auto/man key to enter Radar mode. Once radar

calibration mode is activated, “RAD” will be displayed on the lower

left of the screen. Use the Plus or Minus keys to adjust the

value. Press the Programme key to save the value and advance

to the next programme step.

118

Simulated ground speed

Simulated ground speed allows the console and sprayer to be tested

(and actually spray water) without physically moving the sprayer.

This can and should be tested prior to any spraying activity.

The 844-AB has a low and high simulated ground speed. This allows

the operator to switch between the two to simulate a speed change

and ensure the console is regulating properly during the sprayer

checkout.

Figure 33: Simulated ground speed

SIM

9.7

1 2 3 4 5 6 7 8 9 10 11 12

SIM

9.0

1 2 3 4 5 6 7 8 9 10 11 12

To enter simulated speeds, determine whether the low or high

simulated speed is displayed on the console. Change from low to

high by pressing the Auto/man key.

Use the Plus or Minus keys to adjust the values. Press the

Auto/man key to switch to the other setting (either low or high)

and adjust the value with the Plus or Minus keys. Once both

values are entered, press the Programme key to advance to the

next step.

The console will display the simulated speed upon exiting System

Setup mode. The simulated speed will remain on the Operation

mode display until the console receives actual speed impulses. While

in Operation mode, with the Master switch in the “On” position, press

the Programme

press the Programme and Plus keys for high simulated speed.

SPD

Km/H

LO

SPD

Km/H

HIgH

and Minus keys for low simulated speed;

10

www.teejet.com

NOTES: The simulated speed feature will be deactivated once

the sprayer begins moving and the 844-AB receives actual

speed impulses. If a radar speed sensor is being used,

disconnect the radar connection from the main console. Any

movement can disable the simulated speed test due to the

sensitivity of the speed sensor.

The LOW SIMULATED SPEED will be used during the first

3 seconds after Master is set in the ON position whatever the

real forward speed. This will help starting a new row in the

best conditions.

Page 13

844-AB

Reference ow rate per section

AB mode – The ow rate for each section of the sprayer must be

input into the 844-AB console so that the necessary adjustments

can be made when boom sections are shut off. The console is

programmed to treat the left and right boom sections as symmetrical;

therefore the console treats the ow rate for the lower left section

(L1) identically to the ow rate of the lower right section (R1). The

ow rate entered for section 1 will serve as reference ow for L1 and/

or R1.

Figure 34: AB flow rate illustration

HC mode – The ow rate for a single nozzle must be input into the

844-AB console so that the necessary adjustments can be made

when boom sections are shut off. If several different nozzles are

mounted to spray on a face, they should be considered as ONE

nozzle and the total ow should be programmed.

Figure 35: HC flow rate illustration

2. Reference pressure

Before entering the reference ow, determine the pressure at which

the ow will be referenced. Use the Plus or Minus keys to

adjust the value of the pressure Bar to be used as ow reference.

The pressure selected to reference ow is not critical (any pressure

can be used). Select a pressure that is close to normal operating

pressure or select a pressure from the ow rate chart for the nozzles

being used.

Figure 37: Reference pressure

3.0

1 2 3 4 5 6 7 8 9 10 11 12

Press the Auto/man key to advance to the reference ow for

current preset section.

Bar

REF

3. Reference ow

Calculate (add) the ow rates at the referenced pressure from all

nozzles on the current preset section (left or right should be the

same). Enter the total ow rate in litres/min. for the current preset

section. Use the Plus or Minus keys to adjust the value.

1. Select section

Up to twelve preset ow congurations can be entered into the

844-AB. The presets are represented by the numbers “1-12” at the

bottom of the display. The arrow symbol indicates which preset is

being programmed.

Select which preset ow conguration to programme. Use the Plus

or Minus keys to toggle through the twelve presets.

Figure 36: Preset selection

SEL

ConF

1 2 3 4 5 6 7 8 9 10 11 12

Press the Auto/man key to setup the reference pressure and

reference ow of the selected preset.

Press the Programme key to advance to the next programme

step in System setup mode. It is not necessary to programme all

twelve presets unless they are to be used. Programme the number of

presets required. Press the Programme key again to continue in

System setup mode.

Figure 38: Reference flow (Section one entry)

3.0

Bar

-1-

1 2 3 4 5 6 7 8 9 10 11 12

Press the Auto/man key to return to the select section option.

1.36

LPm

Next section

Repeat steps 1-3 for all sections as needed.

Figure 39: Reference flow (Section two entry)

3.0

Bar

-1-

1 2 3 4 5 6 7 8 9 10 11 12

Once programming is complete for all presets, press the

Programme key to advance to the next programming step.

0.85

LPM

98-70007-EN R4

11

Page 14

844-AB

Regulating valve response time

Operating conditions may require a higher or lower response speed

for the regulating valve. To change the response time number, use

the Plus or Minus keys to increase or decrease the number.

Any number between 0.0 and 9.9 may be selected (0=Slow; 9=Fast).

The default value is 9.5. The rst digit establishes the speed for

coarse adjustments (when relatively far from the target rate). The

second digit establishes the speed for the ne adjustment (when

relatively close to the target rate). If the regulating valve is plumbed

in a bypass line, the valve speed number of 9.5 works well for most

applications.

Figure 40: Regulating valve actuating factor

(fine)

(coarse)

RE6

9.5

ACT

1 2 3 4 5 6 7 8 9 10 11 12

If the regulating valve is plumbed in the throttling position (supply

line), start with a valve speed of 3.0 and adjust the number according

to application requirements. Adjusting agitation volumes can often

assist the regulating valve operation. Press the Programme key to

accept the entry and advance to the next step.

NOTE: The speed value can be adjusted to optimize system

performance. If the valve tends to “search” for the

programmed application rate by cycling the pressure up and

down continuously, reduce the number until the “searching”

is minimal or eliminated. A higher number will increase the

valve response speed and increase the rate of adjustment.

Pressure regulating mode

Pressure regulating mode directs the 844-AB to the location of the

regulating valve plumbing. Once established, this value should not

change unless the regulating valve is physically moved to a new

plumbing location. For additional information about plumbing, refer to

the Plumbing and installation manual supplied with this kit.

The default value of bypass “BYP” indicates that the pressure

regulating valve is plumbed in a bypass line. If no changes are

necessary, press the Programme key to accept the value and

advance to the next step.

NOTE: Once the bypass mode is selected and the console is set to

“manual” mode, the pressure regulating valve should close

when the Plus key is pressed and open when the

Minus key is pressed.

If the pressure regulating valve has been plumbed into in a supply

line to the booms, it is considered a “throttling position”. Use the

Plus or Minus keys to change the displayed value to “THR”

(throttling mode). By doing this, the polarity that the console uses to

control the regulating valve will be reversed.

Figure 42: Pressure regulating mode (Throttling mode)

ThR

1 2 3 4 5 6 7 8 9 10 11 12

NOTE: Once the throttling mode is selected and the console is set

to “manual” mode, the pressure regulating valve should open

when the Plus key is pressed and close when the

Minus key is pressed.

Press the Programme key to accept the entry and advance to the

next step.

Minimum pressure setting

The Minimum pressure setting establishes the minimum pressure

the sprayer will regulate. When the vehicle slows down, the control

system will sometimes regulate the pressure so low that it falls below

the manufacturer’s recommended pressure for the spray nozzle. It

may also reduce system ow to the point where the ow meter will

stall.

To avoid these situations, the 844-AB can be programmed to avoid

regulating below the pressure established with this setting. If the

default setting of 0.7 bar is used, the pressure will not fall below 0.7

bar while spraying in automatic mode.

Use the Plus or Minus keys to adjust the value. Press the

Programme key to advance to the next programme step.

Figure 43: Minimum pressure setting

Figure 41: Pressure regulating mode (Bypass mode)

BYP

1 2 3 4 5 6 7 8 9 10 11 12

12

www.teejet.com

0.7

Bar

MiN

1 2 3 4 5 6 7 8 9 10 11 12

PRS

Page 15

844-AB

Density (Liquid specic gravity)

The default value of “1.00” corresponds with the specic gravity of

water and is correct for most pesticide applications. Some spray

solutions, such as fertiliser, have different densities. If such a

material is being used, a new value should replace the default.

Figure 44: Density display

1.28

1 2 3 4 5 6 7 8 9 10 11 12

Use the Plus or Minus keys to change the value. Press the

Plus and Minus keys simultaneously to clear the value to

“0”. Press the Programme key to accept the value and advance

to the next step.

The following chart will help determine the density of other solutions.

Table 3: Density settings

Weight of solution per

7.0 lb 0.84 Kg 0.84

8.0 lb 0.96 Kg 0.96

8.34 lb (water) 1.00 Kg 1.00

10.0 lb 1.20 Kg 1.20

10.65 lb (28% N) 1.28 Kg 1.28

10.85 lb (30% N) 1.30 Kg 1.30

11.0 lb 1.32 Kg 1.32

12.0 lb 1.44 Kg 1.44

14.0 lb 1.68 Kg 1.68

If the solution is not identied on the chart (above), the Specic

gravity can be calculated as follows:

• Water weighs 1 Kg/L.

• To activate the specic gravity number while in the Application

setup mode, press the Auto/man key so “D” is displayed on

the top of the screen. All calculations will use the specic gravity

entered during this step. To remove the “D” press the

Auto/man key again. Once the “D” is not displayed, all

calculations will use the specic gravity of water (1.00)

regardless of whether another density was programmed or not.

Refer to Application setup mode for additional information.

Specic GravityGallon Litre

Communications

If the 844-AB has been upgraded and is communications compatible,

a variety of communications options can be entered. Choices

available include the default of no communications “no com”,

contractor printing ”cnt prt” , user printing “usr prt”, global positioning

system communications capability “gps”, downloading to a pc ‘onthe-go’ capability “log” or PC link “pc” (not used).

Figure 45: Communications settings

COM

1 2 3 4 5 6 7 8 9 10 11 12

If the 844-AB has not been upgraded with the communication

package, no change is required. If a change is necessary, press the

Plus or Minus keys to select the type of communication used.

Press the Programme key to accept the value and advance to the

beginning of System Setup mode.

Faces per section setting (HC mode only)

As HC mode calculates working width based on the number of faces

sprayed by each section. Additional steps are required to setup these

values.

Figure 46: Section 1 Faces settings

se[

1

1 2 3 4 5 6 7 8 9 10 11 12

Use the Plus or Minus keys to adjust the value. This step will

repeat for each section. Press the Programme key to advance

to the next section. The number of sections available is determined

within the OEM setup options.

Figure 47: Section 7 faces settings

se[

1

fA[e

1

7

1 2 3 4 5 6 7 8 9 10 11 12

After cycling through all sections, press the Programme key to

advance and return to the rst programme step.

fA[e

98-70007-EN R4

13

Page 16

844-AB

CHAPTER 5 - SWATH WIDTH PRESETS

The 844-AB can be programmed with up to 6 swath widths. This

allows the operator to easily change from one swath to another

during application. (This is essential when spraying orchards that

have varying swath widths.)

To enter Swath width presets mode, press and hold the GREEN

button for 3 seconds. The swath width setting screen for preset

number 1 will be displayed. The swath width is displayed on the

lower right of the console (measured in metres for SI [metric] units).

Figure 48: Entering swath width presets

Selecting swath preset

Once the swath widths are programmed, select the swath width to

be used by pressing the GREEN button during Operations mode.

The console will display which swath preset is being used. If the

preset displayed is correct, press the Programme key to return to

Operations mode.

Figure 50: Swath width selection

11.0

11.0

1 2 3 4 5 6 7 8 9 10 11 12

Use the Plus and Minus keys to adjust the value for the rst

swath preset. Press the GREEN button or the Programme key

to advance to the next swath preset. Use the Plus and Minus

keys to adjust the swath value. Continue this process through the six

possible presets. If all six presets are not required, enter values only

for the necessary number of presets. All others should be set to “0”.

Values set to “0” will not be available for selection. Once the presets

have been entered, press the GREEN button or the Programme

key to return to the Operations mode.

Figure 49: Entering swath width

13.0

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

Should a different swath preset be desired, press the GREEN button

again to advance to the next swath selection. Continue to press the

GREEN button until the appropriate swath preset is displayed. Press

the Programme key to select the preset and return to Operations

mode.

NOTE: When toggling through swath width selections, only those

with presets programmed will be displayed (if presents

5 and 6 are set to “0”, they will not be displayed).

14

www.teejet.com

Page 17

CHAPTER 6 - APPLICATION SETUP

Application Setup mode contains the most frequently changed setup

parameters (target application rate and nozzles used). TeeJet has

added this separate setup mode to speed the programming process

when minor changes are made during operation (e.g., changing

orchards, switching nozzles, changing crops, etc.).

To enter Application Setup mode, while in Operations mode press the

Programme key twice (within 3 seconds). One press of the

Programme key will display “PRO USER,” indicating the console

is about to enter Application Setup mode. If the Programme key is

pressed inadvertently, the console will display “PRO USER” for three

seconds before returning to Operations mode. Pressing the

Programme key a second time within 3 seconds will enter

Application Setup mode.

Figure 51: Entering application setup

844-AB

Nozzles per face

NOTE: If AB mode has been selected, this step will be skipped and

the screen will advance to Target application rate step.

The nozzle symbol will ash during the Nozzle per Face step. Press

the Plus or Minus keys to adjust the value. Pressing the

Plus or Minus keys simultaneously will clear the value to “0”.

Press the Programme key to advance to the next step.

Figure 53: Nozzles per face

6.8

6.9

Bar

90.0

Km/H

L/Ha

4

PRO

USER

1 2 3 4 5 6 7 8 9 10 11 12

Table 4: Application setup mode sequence

Preset ow rate selection

Nozzles per face

Target application rate

Calculation diagnostic

Liquid density

Preset ow rate selection

The symbol will ash at the bottom of the screen. The numbers

1-12, also located at the bottom of the screen, represent the 12

preset dose rates. Use the Plus and Minus keys to toggle

through the presets and select the appropriate one for application.

Press the Programme key to advance to the next step.

Figure 52: Preset flow rate selection

4.1

Bar

90.0

Adjust pressure

Adjust speed

L/Ha

1 2 3 4 5 6 7 8 9 10 11 12

Target application rate

The application rate units (e.g., L/Ha) will ash during the Target

application rate step. Press the Plus or Minus keys to adjust

the value of the target application rate. Pressing the Plus and

Minus keys simultaneously will clear the value to “0”. Press the

Programme key to advance to the next step.

Figure 54: Target application rate

6.8

Bar

6.9 4

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

90.0

L/Ha

Calculation diagnostic

NOTE: This step is used for diagnostic purposes only. It has no

affect on the operation of the 844-AB.

This diagnostic tool will allow the operator to adjust the indicated

pressure to see what affect, if any, it would have on operating speed.

The operator can also adjust the speed to see what pressure is

required to maintain the target application rate. This process will

help determine if the correct nozzle conguration was chosen for

the application. While in the calculation step, either the pressure or

speed units will ash.

8.7 4

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

98-70007-EN R4

15

Page 18

844-AB

Adjust pressure

If an approximate operating pressure is known, use the Plus or

Minus keys to adjust the value. The 844-AB will determine what

operating speed is required to achieve the target application rate

at the entered pressure. If the speed is too high, a set of smaller

nozzles is necessary. If the speed is too low, a set of larger nozzles

is necessary.

Figure 55: Adjust pressure

2.8

Bar

6.8

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

70.0

L/Ha

Adjust speed

If an adjustment to the speed setting is required, press the

Programme key once. The speed units will ash. Use the Plus

or Minus keys to adjust the speed to the desired value. The 844AB will calculate the required pressure to maintain target application

rate at the entered speed. If the pressure is too high, a set of larger

nozzles is necessary or the speed must decrease. If the pressure

is too low, a set of smaller nozzles is necessary or the speed must

increase.

Figure 56: Adjust speed

NOTE: If a liquid with a density other than water will be sprayed,

and that density was programmed into the Specific gravity

(Density) step during System setup mode, the “D” symbol

must be selected during Application setup mode to activate

the alternate density.

Press the Auto/man key during Application setup mode to

activate the alternate density. A “D” will be displayed at the

top of the console to indicate the alternate density is active.

This must be displayed so that all calculations will use the

alternate density during operations. If the “D” is not at the top

of the display, calculations will be based on water (1.00).

Figure 58: Liquid density

5.7

Bar

10.0

1 2 3 4 5 6 7 8 9 10 11 12

After performing the calculations, advance to the beginning of

Application Setup mode to make changes by pressing the

Programme key. If no changes are necessary then Application

setup mode is complete. Press and hold the Programme key for

three seconds. Changes to Application setup mode will be stored in

the console’s memory.

Km/H

70.0

L/Ha

5.2

Bar

10.0

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

70.0

L/Ha

Liquid density

To activate the Liquid density setting, press the Auto/man key.

The D symbol will be displayed at the top of the screen. The Liquid

Density that is programmed into the console will also be displayed.

To change density, press the Plus

Programme key to accept the changes and return to the current

application setup step. The calculations will use the Specic gravity

(Density).

To revert back to the calculation based on spraying water, press the

Auto/man key.

Figure 57: Liquid density

or Minus keys. Press the

NOTE: The 844-AB console will not automatically power down

during Application setup mode. The system must be exited

by holding the Programme key for three seconds. A loss

of power to the controller during Application setup mode will

erase all changes not saved to system memory.

1.28

1 2 3 4 5 6 7 8 9 10 11 12

16

www.teejet.com

Page 19

CHAPTER 7 - OPERATIONS

Before operating, check connections related to the Sprayer control

assembly. The sensors should be checked to ensure the console

receives uninterrupted signals.

IMPORTANT! When work occurs around a sprayer/farm chemicals,

wear protective clothing and eye wear. Partially fill the

sprayer tank with water to flush the system. Perform an

inspection of the spray nozzles to ensure they are spraying

the correct pattern.

The Master Boom Switch should be in the “Off” position. Perform the

following steps prior to application:

1. Ensure the tank shut-off valve is “Open”.

2. Start the engine, engage the pump and set the RPM to the level

to be used during application.

3. Power on the 844-AB by pressing the Programme key.

4. Ensure the preset reference ow number matches the nozzles

being used.

5. Ensure the console recognizes simulated speed. If the simulated

speed has been disabled due to movement of the sprayer,

press the Programme and Plus keys to activate the high

simulated speed. Press the Programme and Minus keys to

activate the low simulated speed.

Figure 59: Simulated speed (Low)

SIM

9.7

1 2 3 4 5 6 7 8 9 10 11 12

6. Power “ON” the toggle switches for each spray boom section.

7. Press the Auto/man key so the red LED light indicates “MAN”

mode.

8. Toggle the Master boom switch to “ON”.

9. Adjust the pressure with the Plus and Minus keys. The

pressure should increase with the Plus key and decrease with

the Minus key. During adjustment, the sprayer will be active

so spray nozzle performance can be visually monitored.

10. Press the Auto/man key so the red LED light indicates “Auto”

mode. The 844-AB should adjust to the appropriate target

application rate for the simulated speed.

11. Press the Programme and Plus keys simultaneously

during spraying to switch the console to “high” simulated speed.

The 844-AB should adjust to the appropriate target application

rate for the simulated speed.

12. Press the Programme and Minus keys simultaneously

during spraying to switch the console to “low” simulated speed.

The 844-AB should adjust to the appropriate target application

rate for the simulated speed.

Toggle the Master boom switch to “OFF” to stop spraying.

SPD

Km/H

LO

844-AB

NOTE: It is recommended that the entire sprayer be calibrated in

preparation for operation and to diagnose wear to spray

nozzles. Worn nozzles can contribute to costly chemical

waste and inaccurate spraying regardless of sprayer control

use. Calibration is important to obtain the benefits associated

with computerized sprayer control.

Spraying

Fill the sprayer tank and mix the chemical(s). The application rate

should already be programmed, as well as the spray nozzle size.

1. Power on the 844-AB by pressing the Programme key.

2. Toggle the appropriate individual boom switches to the “ON”

position.

3. Press the Auto/man key so the red LED light indicates “Auto”

mode.

4. With the Master boom switch in the “OFF” position, the target

application rate and the target symbol will be displayed on the

console.

5. With the Master boom switch in the “ON” position, the actual

application rate will be displayed and the target symbol will no

longer appear. The console will display the actual application

rate, vehicle speed, application area covered/total volume

applied and pressure (if a pressure transducer has been

installed).

6. Turn the Master boom switch to the “On” position as the area to

apply is entered. Spraying will begin.

7. Maintain vehicle speed for spraying. Moderate changes in

vehicle speed will not affect the application rate (changes are

compensated by automatic pressure increases or decreases).

To stop spraying, turn the Master boom switch to the “OFF” position.

Alarm warnings may occur momentarily while the pressure regulating

valve searches for a new setting (i.e. after the close of a boom

section or other changes in normal operation). However, if the alarm

continues for a longer time, the valve may have reached its limit and

the system will be unable to regulate ow correctly.

98-70007-EN R4

17

Page 20

844-AB

CHAPTER 8 - FEATURES

Boost mode

Increased or decreased chemical application may be required during

certain areas of application. The Plus and Minus keys allow for

easy adjustment. Boost mode can be activated while spraying during

“Auto” mode by pressing either the Plus or Minus keys once.

With each subsequent press of the Plus key, the application rate

will increase by 10%. With each subsequent press of the Minus

key, the application rate will decrease by 10%.

If the Plus or Minus key is pressed inadvertently during

operation, a delay of three seconds will deactivate Boost mode.

Succeeding presses will change the target rate in 10% increments to

a maximum of +/- 90% of the target rate.

Example: To increase the application rate by 10%, press the

Plus key once to activate Boost mode. Press the

Plus key again to initiate a 10% increase. To decrease

the application rate by 10%, press the Minus key once to

activate Boost mode. Press the Minus key again to initiate

a 10% decrease.

Application rate changes are monitored on the display as they occur.

The console will display “UP 10”, “UP 20”, “DN 20”, “DN 30”, etc. for

approximately three seconds before returning to actual application

rates.

Figure 60: Boost mode

Area/volume display

The 844-AB records application area and measures the total volume

applied while the Master boom switch is in the “ON” position. The

area counter measures treated hectares and is dependent on

the value programmed for swath width. The volume measured is

dependent on ow meter impulses and is available on ow-based

models only.

The console will alternately display the treated area sprayed and

the total volume applied (litres) since the last time the area counter/

volume measure was cleared.

To clear the area counter/volume measure, press and hold the

Plus and Minus keys simultaneously for three seconds. The

area/volume measure can only be cleared during Operations mode

with the Master boom switch in the “Off” position.

Figure 61: Area/volume display

3.1

Bar

5.6

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

60.0

1.507

L/Ha

Ha

UP

Bar

32

1 2 3 4 5 6 7 8 9 10 11 12

To return the application rate to the original target rate, use the

Plus or Minus keys individually to increase/decrease the

rate in 10% increments, or press the Plus and Minus keys

simultaneously to return to the programmed target application rate.

NOTE: During boost mode, the target symbol will flash at the top

of the console to indicate the sprayer is not operating at the

target application rate.

Km/H

70

0.166

L/Ha

Ha

NOTES: The area counter/volume measure works only when the

Master boom switch is in the “On” position.

If a pressure-based controller is being used, the volume

feature will be disabled. The total area will be displayed at

all times.

Application alarm

If the 844-AB detects a continuous discrepancy of 10% or more

between the Target application rate and the Actual application rate,

the application rate units (L/Ha) will ash in the display window. This

will alert the operator to a problem with the plumbing, operation or

programming.

Figure 62: Application alarm

3.1

Bar

4.8

1 2 3 4 5 6 7 8 9 10 11 12

Km/H

Err

.545

L/Ha

Ha

18

www.teejet.com

Page 21

No ow alarm

If the 844-AB stops receiving impulses from the ow meter, the

turbine symbol will ash at the top of the display. This indicates that

there is a problem with the ow meter or elsewhere in the system.

This alarm will occur only when the Master boom switch and at least

one boom toggle switch are set to the “ON” position.

Figure 63: No flow alarm

844-AB

0.00

1 2 3 4 5 6 7 8 9 10 11 12

5.8

Bar

Km/H

0.00

2.223

L/Ha

Ha

Automatic power down

The 844-AB console is designed to power off after 10 minutes of

inactivity. This feature prevents the console from draining the battery

on the sprayer if the operator inadvertently leaves the console

powered on for an extended period. This feature is only enabled

when the Master boom switch is turned “Off” and the console is not

receiving inputs from any of the sensors (the sprayer is inactive).

To manually power down the console, refer to Power off the console.

NOTE: The Automatic power down feature will be disabled any time

the console enters into any programme mode. Programme

modes must be exited first before powering down to ensure

all information is saved to the console’s memory.

Printing

The printing feature is only available on 844-AB consoles that have

been upgraded with the communications package. The 844-AB

communications package is available through authorized TeeJet

Technologies suppliers.

The printout generated by the 844-AB contains information collected

from 844-AB memory. To ready the 844-AB for printing, refer to

Communications in System Setup mode and select either “user prt”

or “cn prt” depending on which report is desired. Exit the mode by

pressing and holding the Programme key for three seconds.

Connect a standard serial port printer to the 844-AB console and

make sure that the printer LED’s are lit, indicating that the printer

has power. Ensure that the console is in Operations mode and the

Master boom switch is set to “Off”. Press and hold the Minus key

for three seconds to begin printing. To reset the values to zero, press

and hold the Plus and Minus keys simultaneously for three

seconds.

NOTE: Printing is available only to those 844-AB consoles that have

been upgraded with the COMMUNICATIONS PACKAGE.

To determine 844-AB console printing capabilities, examine

the left end plate of the console. A communications-ready

console will have an RS-232 pin connector attached to the

left end plate. If the end plate has no connector, the console

has not been upgraded and cannot print.

98-70007-EN R4

19

Page 22

Page 23

Page 24

844AB

SPRAYER CONTROL

USER GUIDE MANUAL

TeeJet Aabybro

Mølhavevej 2

DK 9440 Aabybro

Danmark

www.teejet.com

98-70007-EN R4 English/International

© TeeJet Technologies 2013

Loading...

Loading...