Page 1

SERVICE

MANUAL

Model SB25

Blended Ice Machine

Original Service Instructions

081218-S

8/12/14 (Original Publication)

(Updated 3/26/15)

Page 2

Page 3

Table of Contents

Section 1: Introduction 1...............................................

Safety 2.............................................................

SB25 Specifications 4.................................................

General Installation Instructions 6.......................................

Environmental Notices 8...............................................

Section 2: Controls and Systems 9......................................

Control Overview 10....................................................

Keypad 11............................................................

PC Connection 12......................................................

General Repairs 17....................................................

Blender Drive Board 30.................................................

Blender Pitcher Rinse Station 31.........................................

Blender Pitcher Rinse Station Repairs 32.................................

Section 3: Troubleshooting 37...........................................

General Troubleshooting 38.............................................

Rinse Station Troubleshooting 41........................................

Blender Troubleshooting 42.............................................

Section 4: Parts 45......................................................

Warranty Explanation 46................................................

Model SB25 Operator Parts 49..........................................

Model SB25 Internal Service Parts 51....................................

Model SB25 Drain Assembly 53.........................................

Model SB25 Front Panel 55.............................................

Model SB25 Manifold 082222-12 56......................................

Model SB25 Pump-Cane A. - X82356 57..................................

Rinse Station 58.......................................................

Table of Contents Model SB25

Page 4

Table of Contents - Page 2

Rinse Station Manifold 082222-05 59.....................................

Parts List 60...........................................................

Wiring Diagram 68.....................................................

CAUTION: Information in this manual is intended to be used by Taylor Authorized

Service Technicians only.

Note: Continuing research results in steady improvements; therefore,information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of instructions.

E 2014 Carrier Commercial Refrigeration, Inc. (Original Publication)

(Updated March, 2015)

081218-S

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this

work may be a violationof Copyright Law ofthe United States of America and other countries, could result

in the awarding of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result

in further civil and criminal penalties. All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Model SB25 Table of Contents

Page 5

Section 1: Introduction

S Safety

S Specifications

S General Installation Instructions

S Environmental Notices

Model SB25

1

Introduction

Page 6

Safety

______________________________

We at Taylor are committed to manufacturing safe

operating and serviceable equipment. The many

built-in safety features that are part of all Taylor®

equipment are aimed at protecting operators and

trained service technicians alike.

This manual is intended exclusively for

Taylor authorized service personnel.

DO NOT attempt to run the equipment

unless you have been properly trained to do so.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! Do not operate this unit

unless it is properly grounded and all service panels

and access doors are restrained with screws. Failure

to do so can result in severe personal injury from

electrical shock!

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected, not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current,

installed by authorized personnel to the local

codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

Failure to follow these instructions may result in

electrocution or damage to the unit.

S DO NOT attempt any repairs unless the

main power supply to the unit has been

disconnected.

S DO NOT operate the unit with larger fuses

than specified on the data label.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

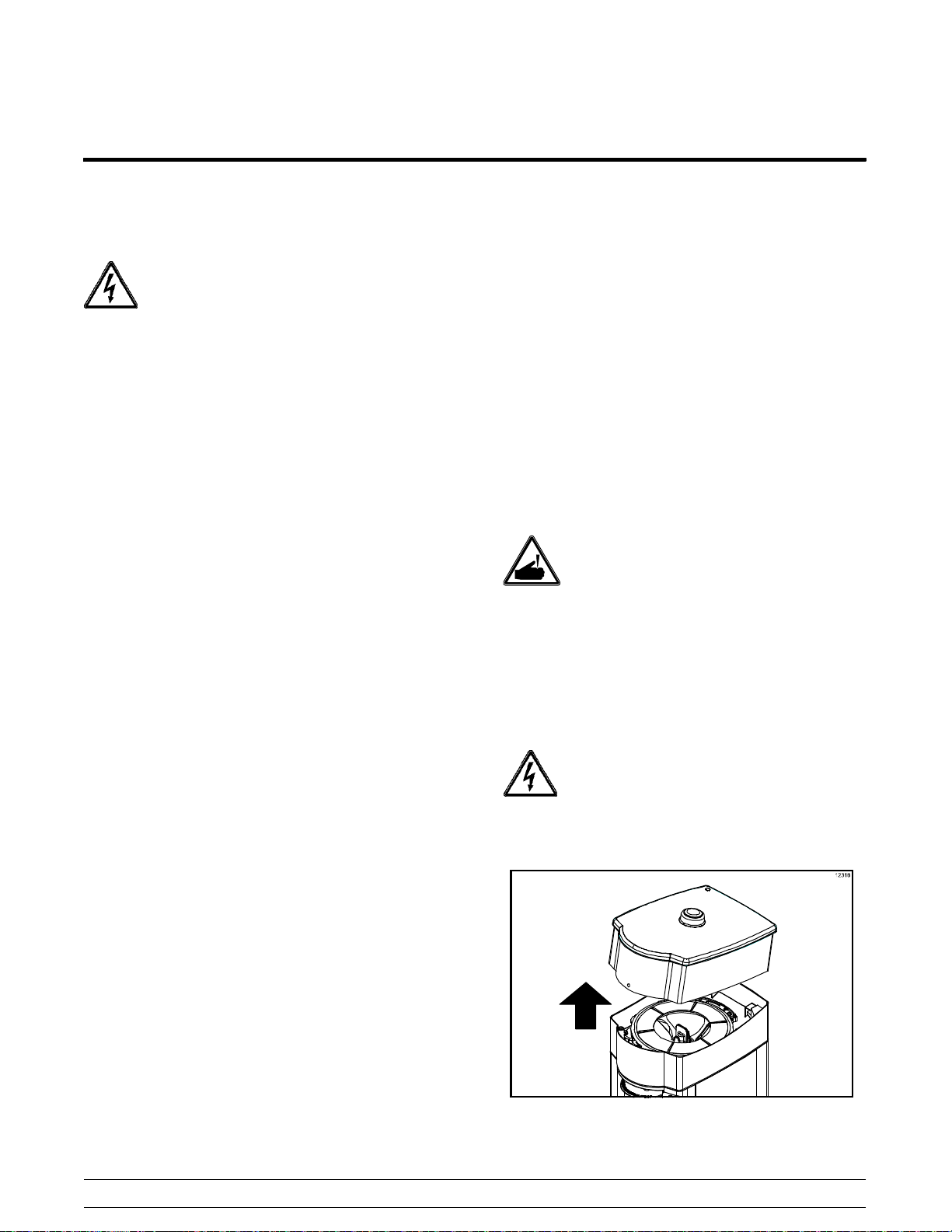

DO NOT partially remove the ice hopper

cover. Complete removal of the hopper cover is

required when accessing the ice bin. Failure to

follow this instruction may result in personal injury.

DO NOT remove any internal operating

parts unless all control switches are in the OFF

position. Failure to follow these instructions may

result in severe personal injury from hazardous

moving parts.

Introduction

2

Model SB25

Page 7

THIS UNIT HAS MANY SHARP EDGES

THAT CAN CAUSE SEVERE INJURIES.

This unit must be installed on a level

surface to avoid the hazard of tipping. Extreme care

should be taken in moving this equipment for any

reason.

Two or more people are required to safely move this

unit. Failure to comply may result in personal injury

or equipment damage.

This appliance is only intended to be

installed in a location where its use and maintenance

is restricted to trained personnel.

This unit must NOT be installed in an area

where a water jet or hose can be used. NEVER use

a water jet or hose to rinse or clean this unit. Using a

water jet or hose on or around this equipment may

result in the electrocution of the user or damage to

the equipment.

Cleaning and sanitizing schedules are

governed by your state or local regulatory agencies

and must be followed accordingly. Please refer to

the cleaning section of the Operator Manual for the

proper procedure to clean this unit.

WARNING!

Some consumers are highly allergic to

strawberries. In some severe cases, allergic

reactions to strawberries can cause death.

When blending natural strawberry

products, make sure excess product is

removed from the pitcher to eliminate

product carryover.

Model SB25

3

Introduction

Page 8

SB25 Specifications

The Model SB25 is a combination unit consisting of

the Model SB24 commercial ice shaver/blender unit

and a rinse station.

The Model SB24 shaver/blender unit has the option

of metered water and liquid sugar cane dispensing.

The rinse station is a timer controlled, automatic

system that rinses the interior of the blender

pitchers.

Ice Hopper

The standard frosted ice hopper holds approximately

28 lbs (13 kg) of ice. An optional clear ice hopper is

available which holds approximately 15 lbs (7 kg) of

ice.

Blender Pitcher

The maximum fill capacity of the blender pitcher is

48 fl oz (1.4 liters).

Electrical

Two dedicated electrical connection are required for

the SB24 and X81173-12. See the electrical chart

for proper electrical requirements. Manufactured to

be cord connected. Cord length is 9 ft. (274 mm)

external to unit.

Blender Station

Electrical Total Amps

115/60/1 10.0A 5-15P

Supplied with

NEMA Cord

Water

A 3/8” (9.5 mm) water line with minimum 55 PSI

(380 kPa) is required.

INSTALL POTABLE WATER CONNECTION

WITH ADEQUATE BACK-FLOW

PROTECTION TO COMPLY WITH

APPLICABLE NATIONAL, STATE AND

LOCAL CODES. WATER TEMPERATURE IS

NOT TO EXCEED 125°F (51°C).

Drain

A drain is required. The drain must be able to

accommodate a 1-1/8” (29 mm) diameter drain tube.

A minimum of 1” (25 mm) air gap is required

between the end of the drain tube and the drain to

ensure proper flow.

IMPORTANT: The unit must be installed on a level

surface for proper drainage.

Accessories include 10 ft. (3050 mm) of 7/8” (222

mm) ID drain hose.

Air Cooled

No additional clearance is required on either side of

the unit for air inlet or discharge.

2” (50 mm) of clearance is required behind the unit

to allow for proper routing of the drainage hardware.

12” (304 mm) of air clearance is required above the

unit to allow for proper loading of ice into the ice

hopper.

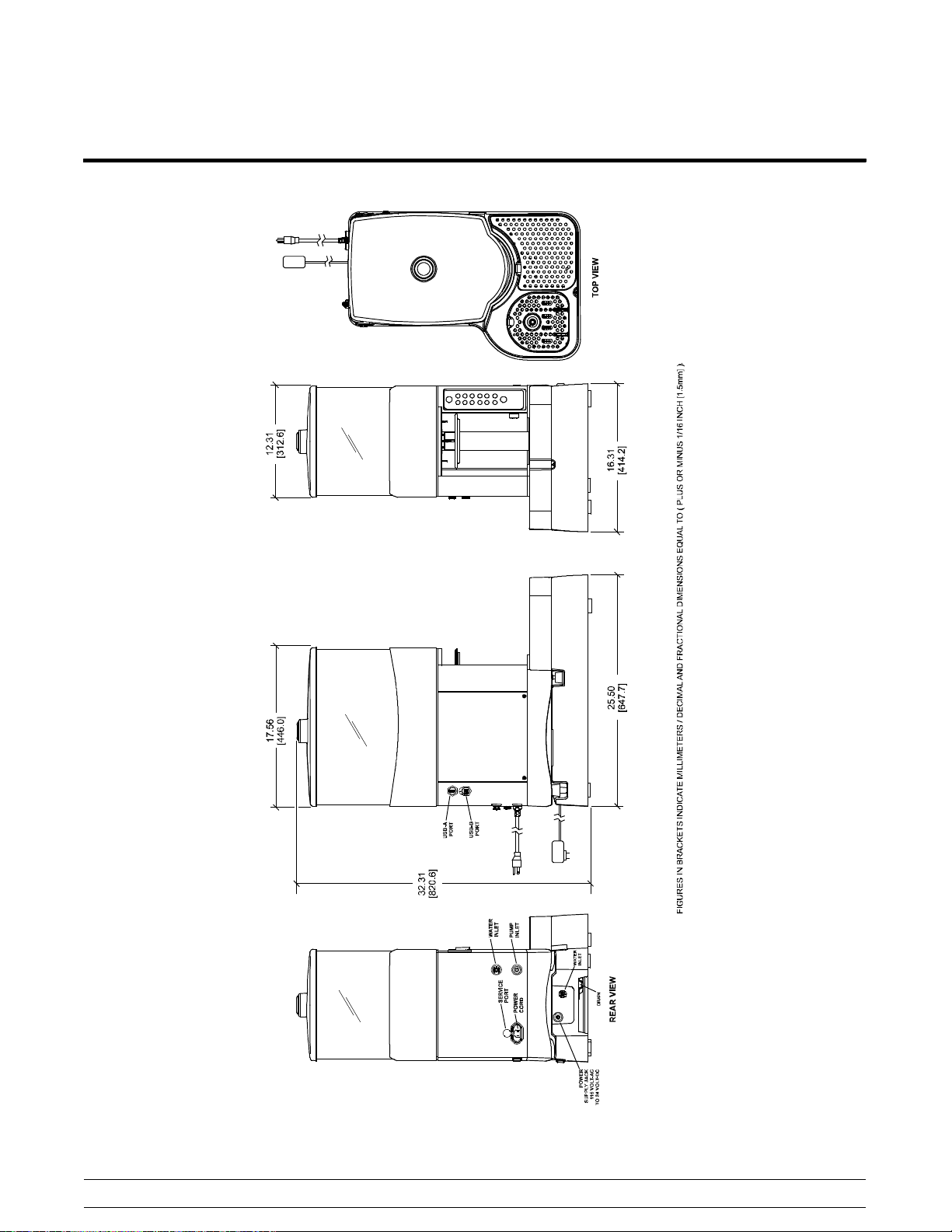

Dimensions

Width: 12-1/4” (311 mm)

Depth: 18” (457 mm)

Height:23-1/2” (597 mm)

Rinse Station

Electrical Total Amps Power Supply

24 VAC 0.63A 115V

This unit may be manufactured with other electrical

characteristics. Refer to the local Taylor Distributor

for availability. (For exact electrical information,

always refer to the data label of the unit.)

Introduction

Approximate Weights

Net: 35 lb (15.9 kgs)

Crated: Carton #1 35 lbs. (15.9 kgs)

Carton #2 11 lbs. (5 kgs)

Water Pressure

55 PSI (380 kPa) minimum incoming

100 PSI (690 kPa) maximum incoming

4

Model SB25

Page 9

SB25 Specifications (Continued)

Model SB25

5

Introduction

Page 10

General Installation Instructions

CAUTION: Only trained, authorized service

technicians should install the Blended Ice Machine.

Failure to comply will void the factory warranty.

The following are general installation instructions.

For complete installation instructions, please see the

Installation Checklist.

ALL WIRING AND PLUMBING MUST

CONFORM TO NATIONAL AND LOCAL CODES.

INSTALL POTABLE WATER CONNECTION

WITH ADEQUATE BACK-FLOW

PROTECTION TO COMPLY WITH

APPLICABLE NATIONAL, STATE AND

LOCAL CODES.

This unit must be installed on a level

surface to avoid the hazard of tipping. Extreme care

should be taken in moving this equipment for any

reason.

Two or more people are required to safely move this

unit. Failure to comply may result in personal injury

or equipment damage.

Uncrate the unit. Inspect the unit for damage. Report

any damage to the Taylor Factory immediately.

This unit is made using USA sizes of hardware. All

metric conversions are approximate.

Air Clearance:

Site Preparation

Review the area where the unit will be installed

before uncrating the unit. Make sure that all possible

hazards to the installer, user, and the unit have been

addressed.

For Indoor Use Only: This unit is designed to

operate indoors, under normal ambient

temperatures of 70° - 75°F (21° - 24°C). The unit

has successfully performed in high ambient

temperatures of 104°(40°C) at reduced capacities.

This unit must NOT beinstalledinanarea

where a water jet or hose can be used. NEVER use

a water jet or hose to rinse or clean this unit. Using a

water jet or hose on or around this equipment may

result in the electrocution of the user or damage to

the equipment.

No additional clearance is required on either side of

the unit for air inlet or discharge.

2” (50 mm) of clearance is required behind the unit

to allow for proper routing of the drainage hardware.

12” (304 mm) of air clearance is required above the

unit to allow for proper loading of ice into the ice

hopper.

Unit Preparation: Freezing Conditions

Storage

In order to prevent the freezing of water lines in the

unit, the drinking and rinse water lines shall be

drained prior to storage of the unit in a location

below freezing. If freezing of water in these lines

does occur, thaw the lines in normal ambient

conditions and check the water lines for signs of

damage before and after supplying water to the unit.

Introduction

6

Model SB25

Page 11

Installer Safety

Electrical Connections

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor® equipment.

S Only authorized Taylor service personnel

should perform installation, maintenance,

and repairs on Taylor equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper personal protective

equipment (PPE) is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

The main power supply(s) to the units must

be disconnected prior to performing any installation,

maintenance, or repairs. Failure to follow this

instruction may result in personal injury or death

from electrical shock or hazardous moving parts as

well as poor performance or damage to the unit.

In the United States, this equipment is

intended to be installed in accordance with the

National Electrical Code (NEC), ANSI/NFPA

70-1987. The purpose of the NEC code is the

practical safeguarding of persons and property from

hazards arising from the use of electricity. This code

contains provisions considered necessary for safety.

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Each unit requires one power supply. Check the

data label on the unit for fuse, circuit ampacity and

other electrical specifications. Refer to the wiring

diagram provided inside the control box for proper

power connections.

Refer to the Electrical Specifications on page 4 for

proper field wire connection.

It is recommended that the unit be plugged into an

electrical surge protector for added protection

against power surges, which could damage an

electrical/electronics component. An electrical surge

event may cause the unit to shut down. Such an

event would require service by a qualified service

technician if the unit was not adequately protected.

A good surge protector, as would normally be used

on a home computer, should be adequate and is

available at most computer retail outlets or electrical

supply stores.

This unit has many sharp edges that can

cause severe injuries.

Water Connection

New hose sets supplied with the appliance are to be

used and old hose sets should not be re-used.

Model SB25

FOLLOW YOUR LOCAL ELECTRICAL CODES!

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

7

Introduction

Page 12

S DO NOT operate the unit with larger fuses

than specified on the data label.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected, not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current,

installed by authorized personnel to the local

codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

Failure to follow these instructions may result in

electrocution or damage to the unit.

Environmental Notices

______________________________

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

NOISE LEVEL: Airborne noise emission does not

exceed 89 dB(A) when measured at a distance of

1.0 meter from the surface of the unit and at a

height of 1.6 meters from the floor.

Introduction

8

Model SB25

Page 13

Section 2: Controls and Systems

S Control Overview

S Keypad

S PC Connection

S General Repairs

S Blender Drive Board

S Blender Pitcher Rinse Station

Model SB25

9

Controls and Systems

Page 14

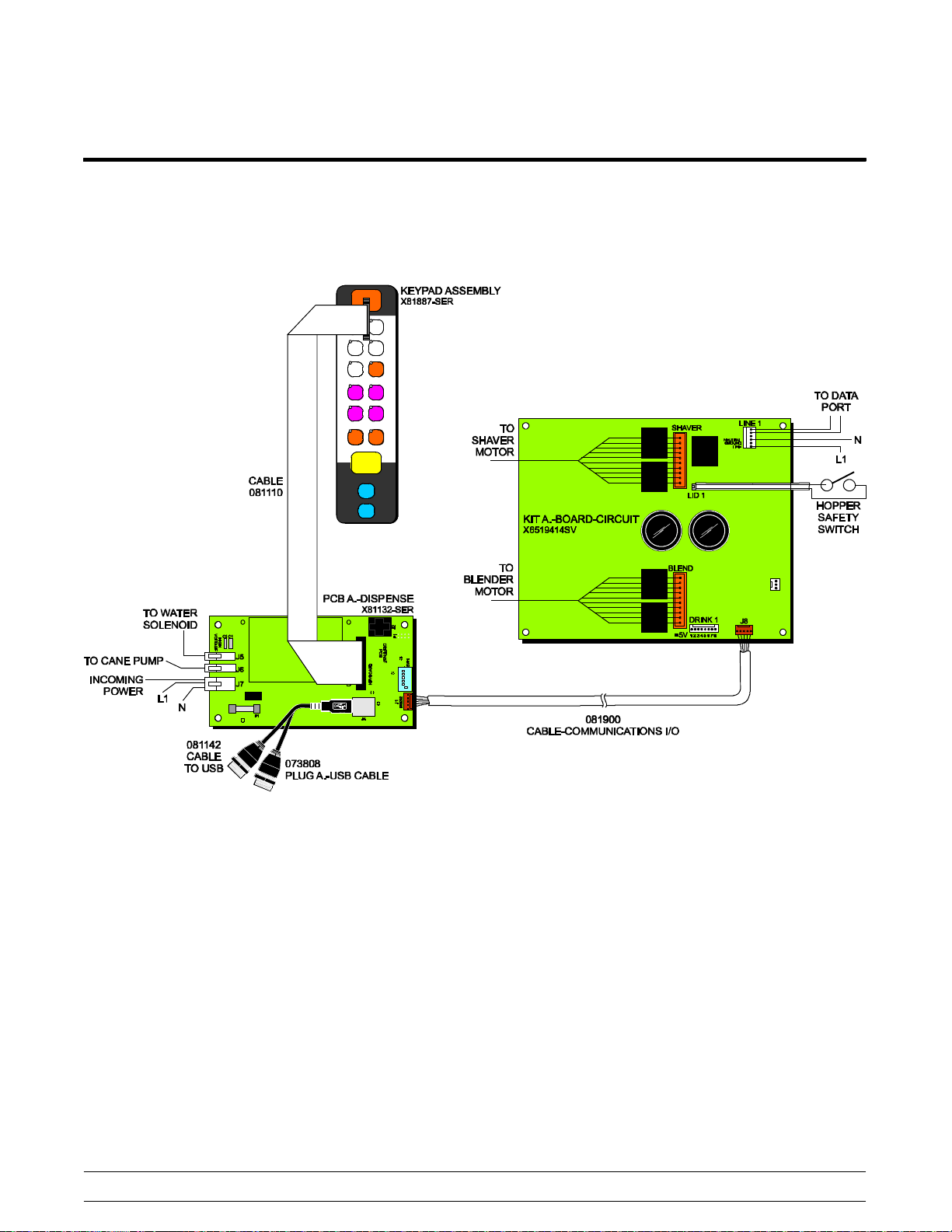

Control Overview

Controls and Systems

Figure 1

10

Model SB25

Page 15

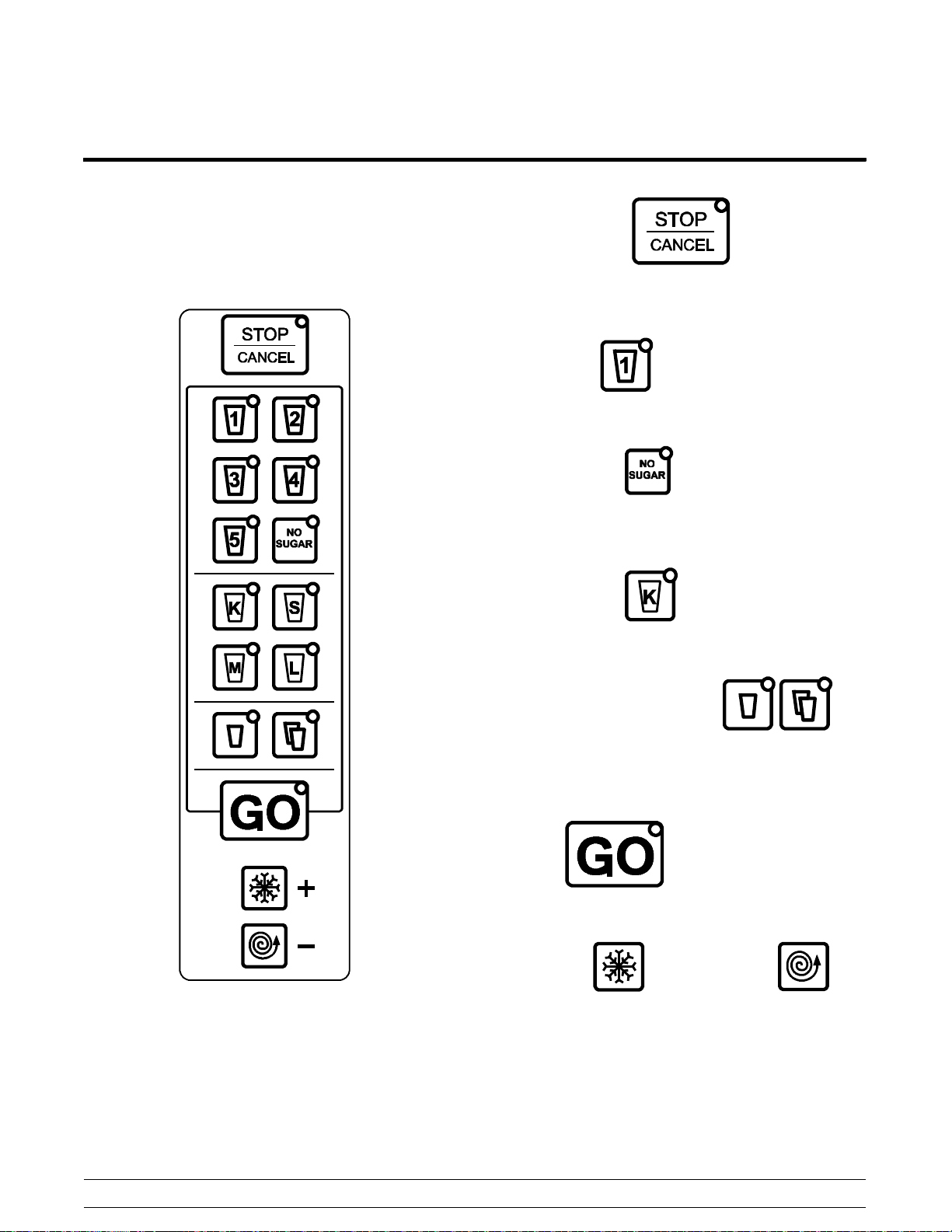

Keypad

The keypad allows the operator to control the

functions of the unit. It is located in the front face of

the blender. (See Figure 2.)

Stop/Cancel Key

Pressing this key will shut down the unit and cancel

the drink cycle.

Recipe Keys

Selects pre-programmed flavor/recipes.

NO SUGAR Key

Removes cane sugar from the drink recipe currently

being dispensed.

Figure 2

Drink Size Keys

Selects the drink size.

Single/Double Quantity Keys

Allows the operator to make a single or double

serving of K, S, and M drink sizes. It will not make a

double L drink.

GO Key

The GO key starts the selected drink cycle.

Shaver Key

These keys are used to manually shave ice and

blend product.

and Blender Key

Model SB25

11

Controls and Systems

Page 16

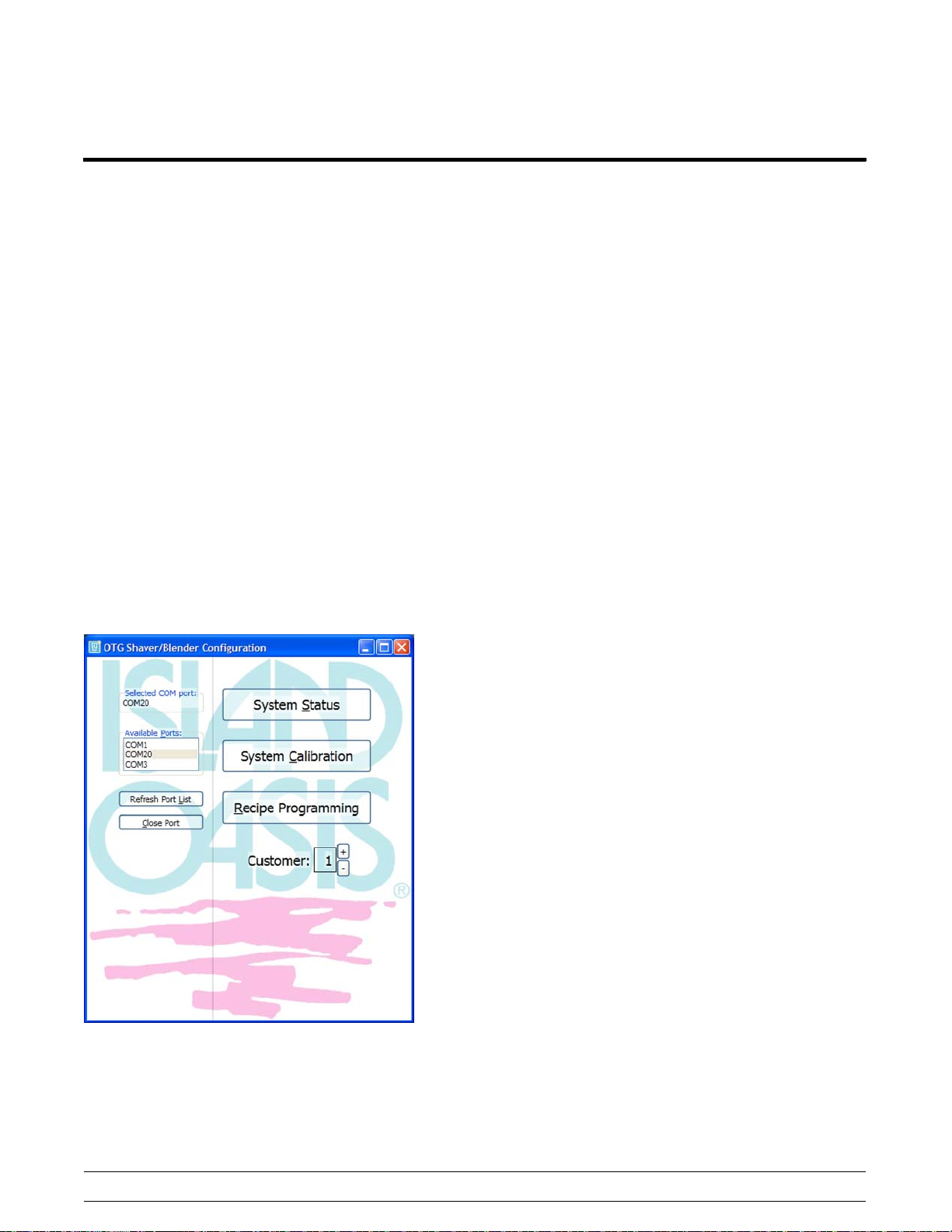

PC Connection

The SB25 can be connected to a PC in order to

manage recipes and system calibration, using the

supplied software. A PC running Windows XP or

greater with a USB port is required.

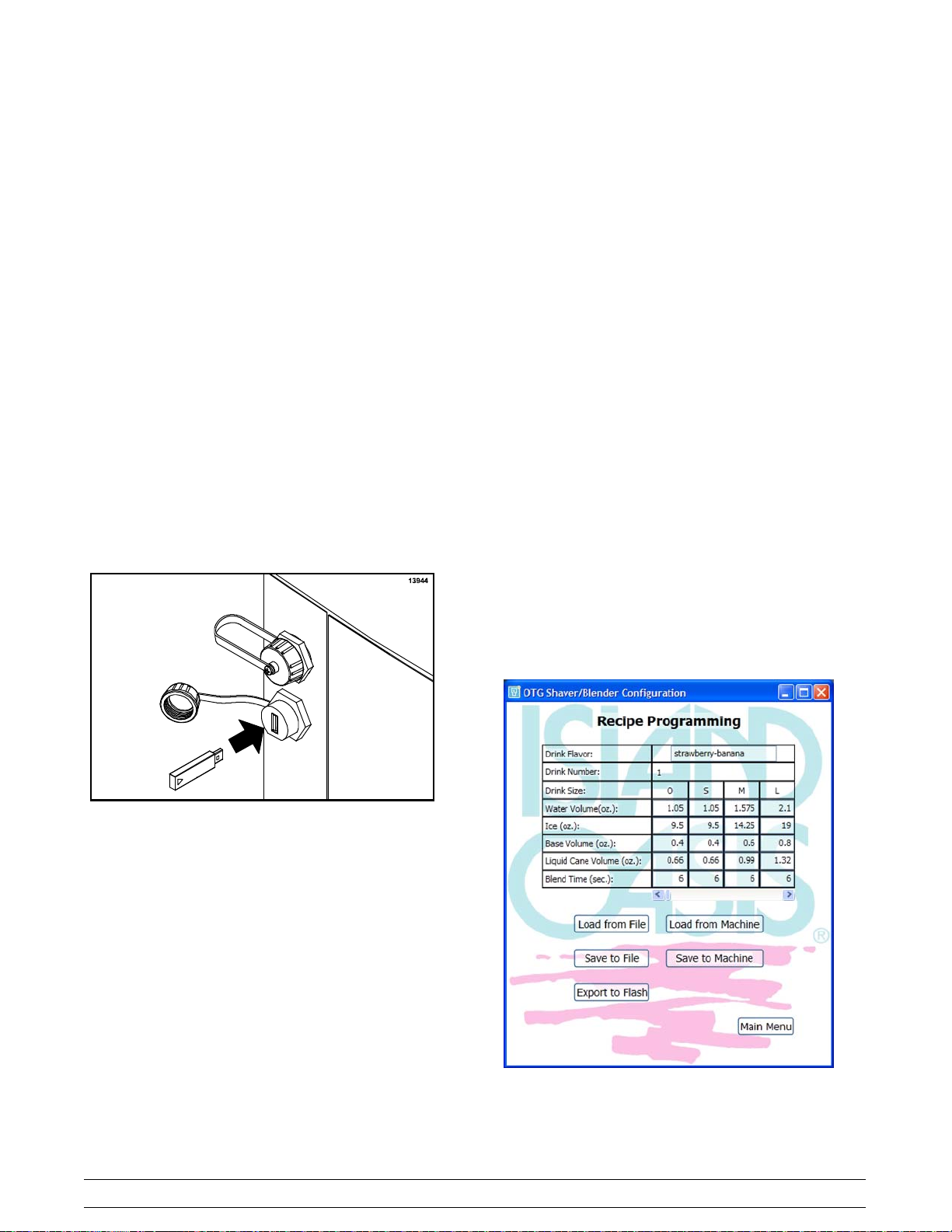

1. Remove the cover from the upper USB port on

the left side of the system by unscrewing the

cap counter-clockwise.

2. Connect the USB cable from the PC to the

USB-B connector on the unit.

3. Switch the main power ON.

4. The first time you connect to the unit and start

the PC software, you may be prompted to

install the proper drivers on your PC. Follow the

on screen instructions to install the proper

drivers. Note: This requires an Internet

connection.

5. Open the programming software:

“OTGConfig Rels Rev A.exe”

6. Refresh the Port List and select the proper

COM Port from the list of Available Ports. This

is usually the highest numbered port in the list.

(See Figure 3.)

7. To reset the connection select “Close Port” and

reselect.

Customer Numbers

Two customer numbers can be stored in the

shaver/blender controller PCA memory, containing

separate recipe and calibration settings. These are

selected by a DIP switch setting inside the system,

located on the top edge of the dispense PCA

assembly. Position 5 is used to select the customer

number. (Position 6 is used to enable or disable the

cane pump option on the SB25, if it is functioning.)

S Customer 1 - Switch Position 5 OFF

S Customer 2 - Switch Position 5 ON

When you power up the system, the customer

selected number is displayed briefly (one second)

before showing the default menu settings.

S If recipe key 1 is on briefly at power up, the

DIP switch is set to customer 1.

S If recipe key 2 is on briefly at power up, the

DIP switch is set to customer 2.

Figure 3

Customer configurations are generated in the

supplied PC software. The main page of the

supplied software will indicate the current DIP switch

setting. Any combination of customer configurations

can be loaded into the system. If you select a

configuration that hasn't been downloaded, the

default values in the software will be used.

Controls and Systems

12

Model SB25

Page 17

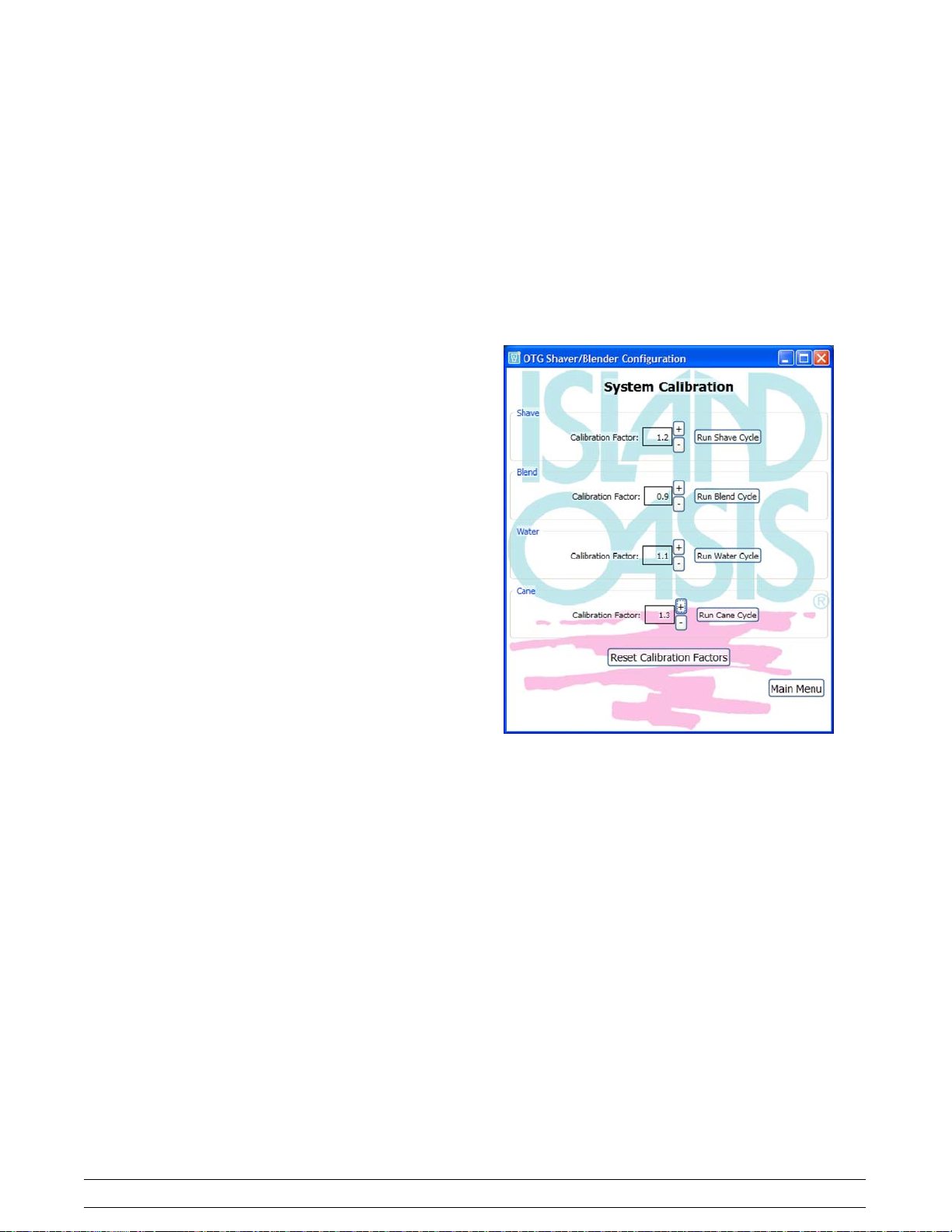

Calibration

______________________________

The SB25 unit can be calibrated using the supplied

PC software or by using the manual calibration

method through the main keypad.

Target Calibration Settings

S Shaved Ice: 10 oz. (by weight)

S Water Dispense: 4 oz (by volume)

S Cane Dispense: 4 oz (by volume)

PC Calibration

Step 1

Refer to PC Connection on page 12.

Step 2

Select “System Calibration” from the supplied

software. (See Figure 4.)

Step 3

The current system Calibration Factor values for

Shave, Blend, Water and Cane dispense times are

displayed.

Step 6

Select “Reset Calibration Factors” to return all

values to 1.0.

Step 7

Select “Main Menu”, select recipe settings, and

select save to unit.

Step 4

Use the +/- buttons next to each Calibration Factor

to increase or decrease calibration settings to

achieve desired results. Note that this changes the

Calibration Factor on the shaver/blender system

immediately.

Step 5

Select the Run Cycle button next to each Calibration

Factor to run that particular function with the

Calibration Factor applied.

Figure 4

Model SB25

13

Controls and Systems

Page 18

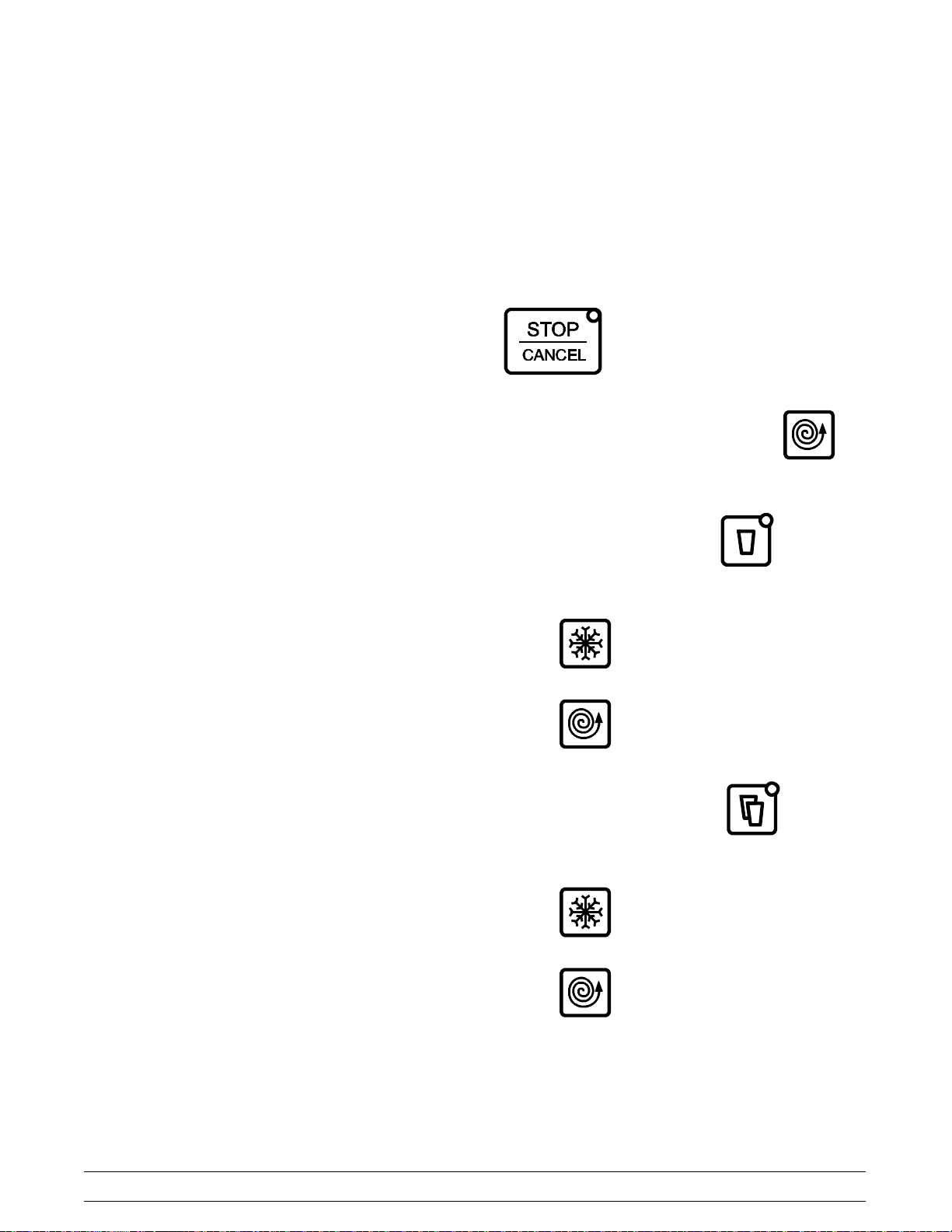

Keypad Calibration

Test Mode

______________________________

Step 1

Enter the keypad calibration mode by holding the

Stop button until all recipe key LED's blink.

S Press recipe 1 key to change the Shave

calibration value.

S Press recipe 3 key to change the Water

calibration value.

S Press recipe 4 key to change the Cane

calibration value (Model SB25, only).

When the value to be changed has been selected, it

will blink at a slow rate, along with the recipe1 & 2

serving size LED's.

Note: The serving size LED's blink to indicate that

the calibration value can now be changed.

Step 2

Use the +/- buttons to increase or decrease the

calibration settings to achieve the desired results.

The Test Mode within the Calibration Mode allows

all motors, valves, and pumps to be run manually.

This can be useful in diagnosing motor or dispensing

issues.

Step 1

Enter the calibration mode by holding the

button for 3 seconds.

Step 2

Press and hold the manual blend button

3 seconds.

Step 3

Press the single serving button

blender motor testing:

for shaver or

for

S Press and hold the manual shave button

Step 3

Press the STOP/CANCEL button to cancel any

unsaved changes and exit the calibration mode.

Step 4

Press the NO SUGAR button to save the current

calibration value and run a test cycle of the item

being calibrated:

S Shave – dispense 10 oz of ice with the

current calibration value applied.

S Blend – run blender for “2 seconds” with the

current calibration value applied.

S Water - dispense 4 oz of water with the

current calibration value applied.

S Cane - dispense 4 oz of cane with the

current calibration value applied.

S Press “GO” to save the changes.

to run the shaver motor.

S Press and hold the manual blend button

to run the blender motor.

Step 4

Press the double serving button

dispense testing:

for water

S Press and hold the manual shave button

to run the cane pump.

S Press and hold the manual blend button

to activate the water valve.

Step 5

Press the STOP/CANCEL button to exit the Test

Mode.

Controls and Systems

14

Model SB25

Page 19

Programming & Recipe Storage

______________________________

The customer recipe information is held in the

microprocessor memory. Recipes distributed on

USB memory sticks can be uploaded to the system

automatically. Note: When new recipes are

uploaded, any recipes currently on the system

will be overwritten.

Programming Using USB Stick

Note: Do not plug in a thumb drive and the PC

USB cable at the same time.

Step 1

Switch the main power OFF.

Step 2

Remove the cover from the lower USB port on the

left side of the system by unscrewing the cap

counter-clockwise. (See Figure 5.)

Step 8

Place the main power switch in the ON position.

PC Recipe Management

The supplied software can be used to transfer drink

recipe information back and forth from a PC to the

shaver/blender. It can also be used to create USB

flash drives in order to distribute recipes to customer

sites.

Recipe Programming

Step 1

Refer to PC Connection on page 12.

Step 2

Select “Recipe Programming” from the supplied

software. (See Figure 6.)

Figure 5

Step 3

Insert the USB stick.

Step 4

Switch the main power ON.

Step 5

The SB25 will automatically download and save the

recipeinformation to the unit.

Step 6

Place the main power switch in the OFF position.

Step 7

Remove the USB stick and reinstall the USB port

cover.

Model SB25

15

Figure 6

Controls and Systems

Page 20

Step 3

To load an existing recipe file, select “Load from

File” and browse to the folder. Select the file name

and select “Open.” This will overwrite the recipe set

shown in the table.

Step 4

To load recipes from the shaver/blender, select

“Load from Machine.” This will overwrite the recipe

set shown in the table.

Step 5

The recipe table is used to display and edit a set of

drink recipes.

a. Use the left/right arrow keys to select drink

numbers.

b. Enter the Drink Flavor - This is descriptive text to

identify the drink, e.g. “Strawberry Banana.”

c. Drink size – Corresponds to the drink sizes on

the system (Note that “O” on the PC stands for

“K” on the keypad).

d. Water Volume (oz.) – Amount of water dispensed

for each drink size.

e. Ice (oz.) – Amount of ice dispensed for each

drink size.

f. Base Volume (oz.) – Amount of flavor base that

needs to be manually added before shaving/

blending. This parameter is for reference and is

not used by the unit.

g. Liquid Cane Volume (oz.) – Amount of liquid

cane dispensed for each drink size.

h. Blend Time (sec.) – Duration of blend cycle for

each drink size.

Step 6

To store the recipe set to the PC, select “Save to

File,” browse to a folder, enter the file name, and

select “Save.”

Select “Save to Machine” to store the recipes on the

unit. This will overwrite the recipe set stored on the

system.

Step 7

TostorearecipesettoaUSBflashdrive,plugthe

drive into the PC’s USB port and select “Export to

Flash.” Select the USB device from the browser and

select “Save” (file will be named CUST1.txt,

CUST2.txt depending on the DIP switch customer

number system setting).

Step 8

Select “Main Menu” when done.

Controls and Systems

16

Model SB25

Page 21

General Repairs

IMPORTANT!

DO NOT attempt any interior repairs

until the following steps are completed. Failure

to follow these instructions may result in personal

injury or death from electrical shock or from

hazardous moving parts, as well as poor

performance or damage to the unit.

1. Disconnect the main power supply to the unit.

2. Disconnect the power cord at the plug.

3. Remove the ice hopper.

(Note: Remove the ice before removing the ice

hopper.)

4. Remove the side panels.

5. Remove the drive board cover.

6. Remove the water and cane lines.

Ice Hopper

______________________________

The ice hopper is the container for the ice cubes that

are consumed in the shaving process. The hopper

and lid have an integral magnetic mechanism that

triggers a safety switch which allows system

operation only when the hopper and lid are installed

correctly.

Disassembly

Step 1

Remove the hopper cover.

Step 2

Using a scoop, carefully remove the ice from the

hopper.

WARNING: The shaver blade is very

sharp. Cautionmustbeusedwhenworkinginor

near the shaver assembly. Failure to follow this

instruction may result in personal injury from blade

contact.

Step 3

Install the hopper cover and run the manual blend

cycle until all remaining ice is dispensed.

Step 4

Wait 30 seconds after disconnecting power

before removing the drive board cover.

Electrostatic Discharge Protection

Electrostatic Discharge (ESD) is the rapid discharge

of static electricity from one conductor to another of

a different potential.

An electrostatic discharge can damage integrated

circuits found in computer and communications

equipment. Follow instructions where noted.

Model SB25

Turn off the power switch and unplug the

power cord.

Step 5

Remove the hopper and hopper cover.

Figure 7

17

Controls and Systems

Page 22

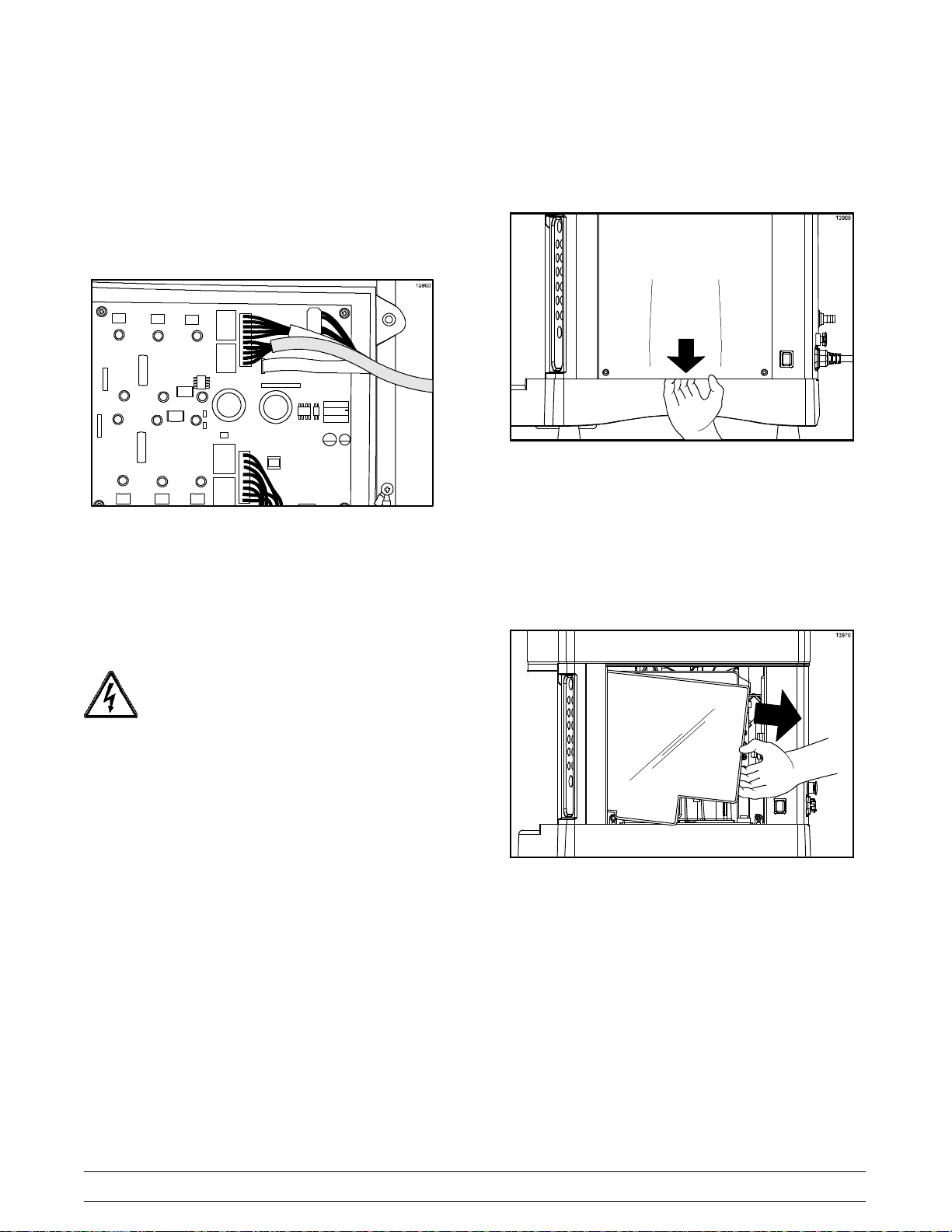

Drive Board

______________________________

The Drive Board functions as the control center of

the Shaver/Blender. The removal of the Drive Board

is sometimes necessary to access other areas of the

system.

Step 5

Insert your fingers under the bottom edge of panel

and pull downward.

Figure 9

Figure 8

Note: See page 43 for the Drive Board

Troubleshooting Guide.

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the right side panel screws.

Step 3

Remove the right side panel.

Step 4

Insert a flat screwdriver in the screw hole and bow

the cover slightly.

Step 6

Remove the screw (black box to post).

Step 7

Remove the black box cover.

Figure 10

Controls and Systems

18

Model SB25

Page 23

Step 8

Place an anti-static wrist strap around your wrist.

Attach the clip on the other end of the strap to the

ground post.

Main Drain Assembly

______________________________

The Main Drain Assembly consists of the main drain

housing, shaver assembly, shaver motor, and lid

sensor. Removal of the Main Drain Assembly is

sometimes necessary to access other areas of the

system.

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Figure 11

Step 9

Remove the connectors.

Figure 12

Step 10

Lift the black box and pivot it around the left front

post.

Step 11

Remove the black box.

Step 2

Remove ice hopper and lid. (See page 17.)

Step 3

Remove the Drive Board. (See page 18.)

Step 4

Remove the four nuts securing the top frame.

Note: Per torque specifications, nuts are tightened

to 75 inch/pounds.

Figure 13

Model SB25

19

Controls and Systems

Page 24

Step 5

Loosen the main drain assembly. Remove the fluid

fittings from the water valve and cane pump by

pushing the gray collar toward the fitting and pulling

on the tube. Remove the main drain assembly.

Figure 14

Dispense PCB

______________________________

The Dispense PCB is the main communications link

between the Keypad, Water Dispense Unit, Cane

Dispense Unit and the Drive Board. It stores all

recipes and enables USB communications through a

PC or USB stick.

Check the fuse. Visually, the fuse filament should be

continuous and not burnt. Check the continuity with

the multimeter. The fuse should not read “OL” when

measuring ohms.

Note: Dip switch #6 must be in the ON position for

units equipped with a cane pump.

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the left side panel.

Step 3

Remove the box cover.

Step 4

Place an anti-static wrist strap around your wrist.

Attach the clip on the other end of the strap to the

ground post.

Step 5

Remove the connectors.

Step 6

Remove the PCB mounting screws and remove the

board.

Keypad

______________________________

The keypad serves as the main control center for all

functions of the unit.

Troubleshooting

If keypad functions do not work properly, check the

connections to the keypad and the Dispense PCB

and for any condensation build-up on wire

connections. Before replacing the keypad, plug in a

new keypad and test the functions.

Figure 15

Controls and Systems

Replacement

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the ice hopper and lid. (See page 17.)

Step 3

Remove the Drive Board. (See page 18.)

Step 4

Remove the main drain assembly. (See page 19.)

20

Model SB25

Page 25

Step 5

Remove the four screws securing the keypad to the

front panel.

Rotary Wing

______________________________

The rotary wing agitates the ice and forces it against

the shaver blade.

Troubleshooting

If the unit does not shave ice, but the motor is

running check for the following:

S Blade damage

S Possible broken or cored-out rotary wing

Disassembly

Step 1

Remove the ice hopper and lid. (See page 17.)

Step 2

Figure 16

Step 6

Disconnect the ribbon cable from the keypad. The

ribbon cable header is equipped with a locking

mechanism. To disconnect the ribbon cable, move

the two locking tabs away from the header, toward

the outside of the board.

Turn off the power switch and unplug the

power cord.

WARNING: The shaver blade is very

sharp. Cautionmustbeusedwhenworkinginor

near the shaver assembly. Failure to follow this

instruction may result in personal injury from blade

contact.

Step 3

Remove the ice shaver cone cover by pressing the

rear tab inward and rotating the cover clockwise.

Model SB25

Figure 17

21

Figure 18

Controls and Systems

Page 26

Step 4

Remove the ice scrambler by squeezing the tabs

inward and rotating clockwise while holding the wing

securely. (Note: Secure the o-ring for re-assembly.)

Figure 19

Step 5

Remove the rotary wing by lifting it straight up off the

motor shaft.

Shaver Motor

______________________________

Description

Disassembly

Step 1

Remove the ice hopper and lid. (See page 17.)

Step 2

Turn off the power switch and unplug the

power cord.

Step 3

Remove both side panels.

Step 4

Remove the drive board. (See page 18.)

Step 5

Remove the shaver motor ground wire from the

grounding post.

Step 6

Remove the rotary wing. (See page 21).

Step 7

Remove the main drain assembly and place it on a

flat surface. (See page 19.)

The shaver motor is the power supply for the ice

shaving function.

Troubleshooting

If the shaver motor is not running, check the

following:

1. Power supply

2. Cycle unit OFF, then ON

3. Safety switch (hopper/cover)

4. Ice jam in hopper

5. Possible broken/cored out wing

6. Shaver motor for damage

7. Keypad error

8. Main power board

Note: See page 42 for Shaver Motor

Troubleshooting Guide.

Step 8

Remove the 4 bolts securing the shaver motor.

Note: Per torque specifications, the bolts tightened

to 76 inch/pounds.

Figure 20

Controls and Systems

22

Model SB25

Page 27

Blender Motor

______________________________

Description

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove ice hopper and lid. (See page 17.)

The blender motor is the power supply for the

blender function.

Troubleshooting

If unit does not blend, check the following:

1. Power supply

2. ON-OFF/Reset button

3. Safety switch (hopper/cover)

4. Combination of drink sizes

5. Portion of product used for drink size

6. Blender pitcher for damage

Step 3

Remove the Drive Board. (See page 18.)

Figure 21

Step 4

Position the unit on its side as shown in Figure 22.

7. Blender motor

8. Main power board

Note: See page 42 for Blender Motor

Troubleshooting Guide.

Model SB25

23

Figure 22

Controls and Systems

Page 28

Step 5

Remove the blender motor screws and remove the

motor. (Note: Per torque specifications, the screws

are tightened to 16 inch/pounds.)

To Remove: Holding the splash guard at a slight

angle, lift up and pull out and away from the ice

chute to disengage the hooks from the ice chute.

Figure 25

Figure 23

Step 6

Remove the wire harness by pulling it through the

access hole. Bending the wire harness against the

connector is necessary in order to pull the harness

out. Do not cut the wires.

Ice Chute & Splash Guard

______________________________

Splash Guard

To Install: Hold the splash guard at a slight angle

and lift the splash guard up and forward, locking the

hooks of the splash guard onto the posts on the ice

chute.

Ice Chute

To Remove: Squeeze the tabs on the ice chute and

gently pull down on the chute to disengage.

Figure 26

To Install: Lifttheicechuteupintoplaceinthe

main drain. Be sure both tabs are locked securely

into place by gently pulling down on the ice chute.

Figure 24

Controls and Systems

24

Figure 27

Model SB25

Page 29

Shaver Cartridge

______________________________

The shaver blade has a single edge design that

cannot be re-sharpened.

Troubleshooting

If the shaved ice becomes inconsistent in the

texture, check the blade for damage and dullness.

Replace the blade if necessary.

If there is not enough ice being shaved, check the

blade for dullness. The timing can also be adjusted

for the required ice flow.

Replacement

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the ice hopper and lid. (See page 17.)

Step 4

Remove ice scrambler by squeezing the tabs inward

and rotating clockwise while holding the wing

securely. (Note: Secure the o-ring for re-assembly.)

Figure 29

Step 5

Slide the shaver cartridge out of the cone.

WARNING: The shaver blade is very

sharp. Cautionmustbeusedwhenworkinginor

near the shaver assembly. Failure to follow this

instruction may result in personal injury from blade

contact.

Step 3

Remove the ice shaver cone cover by pressing the

rear tab inward and rotating the cover clockwise.

Figure 28

Figure 30

Step 6

Reassemble the system and check the ice volume

for proper calibration.

Model SB25

25

Controls and Systems

Page 30

On-Off/Reset Switch

______________________________

The On-Off/Reset switch provides power to the unit

and is also used to reset the Drive Board in the

event of a shaver or blender motor lock.

Troubleshooting

If there is no power to the unit check the following:

1. Check outlet

2. Check power cord at outlet

3. Toggle switch

4. Drive board and dispense board fuses

5. Check connection at the switch to the harness.

Step 4

Remount the switch into the panel.

Figure 32

Drain System

______________________________

Figure 31

Replacement

Step 1

Disconnect the power cord from the outlet.

Step 2

Press the toggle switch snap-in feature to remove

the panel (keep wires connected).

Step 3

Using a pair of needle nose pliers, remove the wire

connectors, one at a time, and reconnect to the new

switch.

The shaver/blender drain system consists of a

series of hoses. There is one interior hose and one

exterior hose that connect to an exterior drip pan.

These must be kept clean to maintain water flow.

The exterior hose must be running downhill, with no

kinks.

Note: This is not required when the shaver unit is

being used with the rinse station. When using the

rinse station, the drain pan should be removed.

Troubleshooting

If the drain lines are not kept clean, a build-up of

algae will occur. This will block the water flow and

cause back-up and possible leaks. The use of a

cleaner will prevent this problem. To clean clogged

drain lines, use a small wire bottle brush available

from your Taylor Distributor. To check for leaks,

pour water into the top and bottom drain holes.

Note: To remove the drain hose from its

connection, if necessary, cut the hose with a razor

blade. This will allow for easy removal.

Controls and Systems

26

Model SB25

Page 31

Blender Pitcher

______________________________

Water Dispense

______________________________

The blender pitcher was designed with no

replaceable wear items and will only sit on the

blender base in one position. (Note: Never wash the

blender pitcher in the dishwasher.)

Safety Switch

______________________________

The purpose of the safety switch is to interrupt

power to the unit when the cover is removed. If the

safety switch is not performing this function, check

that the white safety switch rod located in the rear

left hand corner of the ice hopper is in place.

Check to see if the magnet located in the rear left

hand corner of the hopper cover which engages the

safety switch rod is in place. Replace the ice hopper

or the ice hopper cover if either component is

missing.

Correct Cover Placement

The water dispense supplies water to the blender

pitcher during drink dispensing.

Troubleshooting

If water is not dispensed or an incorrect amount is

dispensed, check the following:

Step 1

Make sure the water line is connected to the rear of

the system and is free from kinks.

Step 2

Make sure that adequate water pressure is being

supplied to the system.

Step 3

Make sure the water filtration is working properly.

Figure 33

Incorrect Cover Placement

Figure 34

Step 4

Check the system for leaks.

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the ice hopper and lid. (See page 17.)

Step 3

Remove the main drain assembly. (See page 19).

Step 4

Remove the Dispense PCB cover.

Model SB25

27

Controls and Systems

Page 32

Step 5

Disconnect and remove the water valve connector

from the Dispense PCB.

Step 6

Remove the water inlet tube from the manifold

assembly.

Step 7

Remove the manifold mounting screws located in

the Dispense PCB mounting box.

Figure 35

Step 8

Removethe manifold.

Cane Dispense

______________________________

The Cane Dispense supplies liquid cane to the

blender pitcher during drink dispensing.

Troubleshooting

If cane is not dispensed or an incorrect amount is

dispensed, check the following:

Step 1

Make sure the cane source is present and has an

adequate supply.

Step 2

Make sure the cane line is connected to the rear of

the system and is free from kinks.

Step 3

Check the system for leaks.

Disassembly

Step 1

Turn off the power switch and unplug the

power cord.

Step 2

Remove the ice hopper and lid. (See page 17.)

Step 3

Remove the Drive Board. (See page 18.)

Step 4

Remove the main drain assembly. (See page 19).

Step 5

Remove the Dispense PCB cover.

Step 6

Remove the cane pump connector from the

Dispense PCB.

Figure 36

Controls and Systems

28

Figure 37

Model SB25

Page 33

Step 7

Remove the cane pump ground lug from the

grounding post.

Step 8

Remove the four (4) screws from the rear of the unit.

Remove the pump assembly.

Figure 38

Step 9

Remove the elbow connection from the pump inlet

by sliding the retaining tab down and pulling out the

elbow.

Figure 39

Step 10

Remove the inner jam nut holding the cane inlet

connector and slide the pump inlet tube and elbow

out through the rear of the unit.

Model SB25

29

Controls and Systems

Page 34

Blender Drive Board

Figure 40

Note: See page 43 for blender drive board LED indicator troubleshooting.

ITEM DESCRIPTION

1 KIT A.-MOTOR SHAVER

*2 DRAIN-MAIN W/SAFETY SWITCH

**3 POWER SUPPLY 115 VAC

4 FUSE-BOARD-DRIVER I.O.

5 LED-HEARTBEAT

6 LED-TROUBLESHOOTING

**7 COMMUNICATION CABLE TO DISPENSE BOARD

8 KIT A.-MOTOR BLENDER

* LID-IN-PLACESENSOR IS IN ICE HOPPER SUPPORT

** PART OF 066891 HARNESS

Controls and Systems

30

Model SB25

Page 35

Blender Pitcher Rinse Station

The blender pitcher rinse station is activated when a

pitcher is properly placed in position, which lowers

the actuator. When the actuator is lowered, the

magnet inside the actuator closes a reed switch

beneath the bowl. After a short delay, rinse water

begins to flow from the spray rinse nozzle.

If the water pressure to the unit is correct, the water

will flow for approximately six seconds and dispense

approximately 25 ounces of water.

Note: The rinse duration setting is adjustable and

can be set to 5, 7, 9, or 12 seconds. (See page 32.)

To repeat this cycle, the pitcher must be removed,

allowing the actuator to rise to its natural “up”

position. This action opens the reed switch. Once

the reed switch is open, the rinse cycle resets. This

allows the cycle to repeat when another pitcher is

placed on the rinse station.

Model SB25

Figure 41

31

Controls and Systems

Page 36

Blender Pitcher Rinse Station Repairs

Rinse Duration Settings

______________________________

The rinse duration is adjustable to 5, 7, 9, or 12

seconds. Adjust the rinse time by using the rotary

dip switch on the control PCB located under the

bottom cover of the unit. Note the dip switchsettings

listed in the table below.

Figure 42

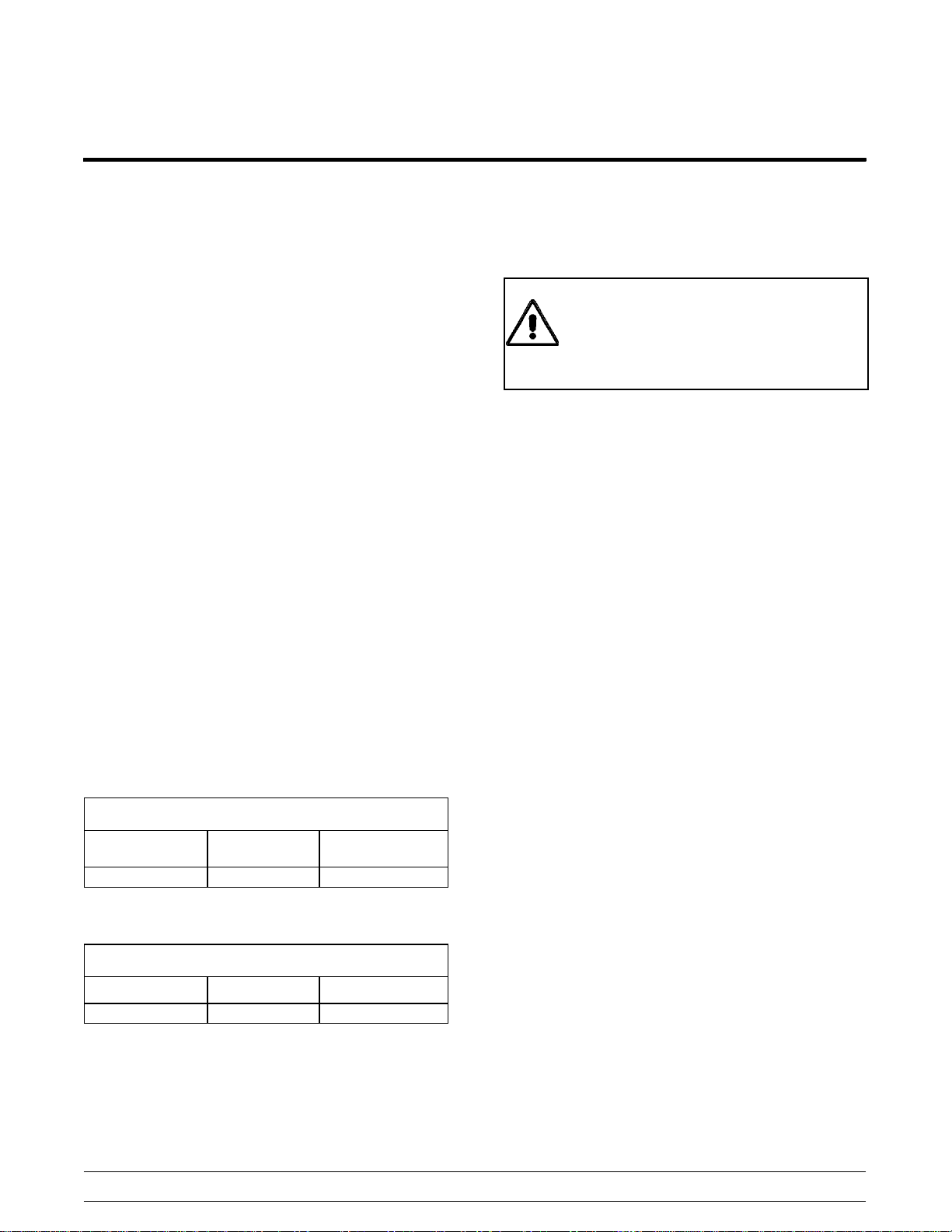

Water Usage (gallons)

Based on Inlet Pressure & Rinse Time Settings

Dip

Switch

Setting

0

1

2

3

Rinse

Times

5 seconds 0.29 gal 0.33 gal 0.41 gal

7 seconds 0.41 gal 0.47 gal 0.57 gal

9 seconds 0.52 gal 0.60 gal 0.74 gal

12 seconds 0.69 gal 0.80 gal 0.98 gal

Incoming Water Pressure

30 psi 40 psi 60 psi

parts as well as poor performance or damage to the

unit.

1.

2. Disconnect the water supply at the quick

connect fitting.

3. Remove the front pan assembly.

4. Remove the bottom cover by removing the

screws.

5. Install a jumper on P1 to put the drive board

into the Test Mode. This will allow the triggers

to be tested individually.

Turn off the main power to the unit.

Figure 43

Rinse Station Triggers

______________________________

The Rinse Station detects the placement of the

blender pitcher on the rinse station pitcher platform.

If the pitcher triggers are not working properly, an

adjustment to the reed switches may be necessary.

The main power supply(s) to the unit

must be disconnected prior to performing any

installation, maintenance, or repairs. Failure to

follow this instruction may result in personal injury or

death from electrical shock or hazardous moving

Controls and Systems

Figure 44

6. Replace the front pan.

7. Place the main power switch in the ON position.

8. Test the triggers separately.

32

Model SB25

Page 37

9. Adjust the reed switches until the triggers are

functioning properly. Functioning triggers will

cause an audible click of the solenoid.

Figure 45

10. Swap the triggers and ensure that the triggers

will function in either position.

Figure 46

11.

12. Remove the jumper.

13. Reassemble the unit.

Turn off the main power.

Filter Screen

______________________________

The filter is designed to keep debris away from the

solenoid that triggers the flow of water through the

Rinse Station spray nozzle.

To clean or replace the filter screen, perform the

following steps.

1.

2. Disconnect the power adaptor from the main

power jack.

3. Disconnect the water supply at the quick

connect fitting.

4. Remove the front pan assembly.

5. Remove the filter cover by turning the cover to

the left 1/4 turn.

Turn off the main power to the unit.

Figure 47

6. Remove the hex cap on the filter.

Figure 48

7. Remove and clean or replace the screen.

8. Reassemble the unit.

Model SB25

33

Controls and Systems

Page 38

Main Power Wiring Harness

______________________________

The main power wiring harness provides power to

the main control PCB.

To replace the main wiring harness, perform the

following steps.

5. Disconnect the wiring harness from the PC

board.

1.

2. Disconnect the power adaptor from the main

power jack.

3. Remove the bottom cover.

4. Remove the power cover by removing the

screw.

Turn off the main power to the unit.

Figure 50

6. Remove the main power jack from the Rinse

Station base.

Figure 51

7. Remove the main power switch and pull the

wiring harness out through the main power

switch hole.

Figure 49

Controls and Systems

8. Reverse the process to replace the wiring

harness.

34

Model SB25

Page 39

Rinse PCB

______________________________

Rinse Manifold Replacement

______________________________

The rinse PCB functions as the control center of the

Rinse Station.

To replace the rinse PCB, perform the following

steps.

1.

2. Disconnect the power adaptor from the main

power jack.

3. Disconnect the water supply at the quick

connect fitting.

4. Remove the bottom cover.

5. Disconnect all four (4) connections from the

rinse PC board.

Turn off the main power to the unit.

To replace the rinse manifold, perform the following

steps.

1.

2. Disconnect the power adaptor from the main

power jack.

3. Disconnect the water supply at the quick

connect fitting.

4. Remove the bottom cover.

5. Disconnect the tubing from each end of the

water valve manifold.

Turn off the main power to the unit.

Figure 52

6. Remove the four (4) screws holding the PC

board onto the base.

7. Install the new PC board.

8. Reassemble the unit.

Figure 53

6. Remove the three (3) screws which secure the

water valve manifold to the rinse station

bracket.

7. Remove the three (3) screws which secure the

bracket to the base.

8. Install the new water valve manifold.

9. Reconnect the tubing.

10. Reinstall the bottom cover.

Model SB25

35

Controls and Systems

Page 40

Notes:

Controls and Systems

36

Model SB25

Page 41

Section 3: Troubleshooting

S General Troubleshooting

S Rinse Station Troubleshooting

S Blender Troubleshooting

Model SB25

37

Troubleshooting

Page 42

General Troubleshooting

PROBLEM POSSIBLE CAUSE REMEDY

Blender pitcher is damaged. Abuse or excessive wear. Replace blender pitcher.

Shaved ice has inconsistent texture. The shaver blade is worn. Replace the shaver blade.

Unit runs, but does not shave ice. The ice hopper is empty. Refill the hopper.

The shaver blade is damaged. Replace the shaver blade.

Unit runs, but does not blend ice. Wrong volume or product was

added.

Wrong volume of ice. Check the ice volume. Adjust

Wrong volume of water. Check the water volume. Adjust

Wrong volume of cane sugar. Check the cane sugar volume.

Unit has no power and no lights. The power switch is OFF Place the power switch in the ON

The power cord is not plugged in. Check the connection at the

Safety switch is open. Ensure that the hopper cover is

Drive board and/or dispense

board issue and/or fuse blown.

Water is not dispensing. Water line at the back of the unit

is not connected.

Water line is kinked. Straighten water line.

Low water pressure in the store. Check filter and store plumbing.

Remeasure and pour product.

calibration as needed.

calibration as needed.

Adjust calibration as needed.

position.

outlet and ensure the outlet is

functioning.

properly seated on the hopper.

Check motors, replace board /

fuse.

Connect the water line.

Water is leaking from the unit. Poor fitting/hose connection. Check all visible fittings and

ensure all hoses are fitted into

the fittings properly.

Cracked hose. Replace cracked hose.

Broken fitting. Replace fitting.

Troubleshooting

38

Model SB25

Page 43

PROBLEM POSSIBLE CAUSE REMEDY

Cane sugar is leaking from the unit. Poor fitting/hose connection. Check all visible fittings and

ensure all hoses are fitted into

the fittings properly.

Cracked hose. Replace hose.

Broken fitting. Replace fitting.

Pump issue. Check pump and replace if

necessary.

Cane sugar is not dispensing or is

dispensing an incorrect amount.

STOP/CANCEL button and recipe

buttons are flashing.

Recipe key #1 - fast blink (hopper/lid

sensor fault).

Recipe key #2 - fast blink (shaver is

jammed).

The cane sugar bottle is missing

or has an inadequate supply.

Poor fitting/hose connection. Check the connection at the rear

Cracked hose. Repair/replace hose.

Broken fitting. Replace the fitting.

The pump is not working. Evaluate the pump. Replace if

Cable is disconnected or has a

poor connection.

Hopper cover is not seated

properly.

Hopper is not seated properly. Adjust hopper to sit properly in

Safety switch issue. Check ribbon cable connection

Large piece of ice has jammed

the shaver.

Replace the cane sugar supply.

of the unit.

necessary.

Properly connect the cable.

Adjust hopper cover. Replace

cover if broken.

main unit. Replace hopper if

broken.

on main board/replace safety

switch board if necessary .

Remove ice, fill with new ice

cubes, and reset the unit.

Recipe key #2 - slow blink (shaver is

over temperature).

Model SB25

Foreign object is causing the

jam.

Motor failure. Reset the unit. Use the Motor

The shaver motor is over

temperature.

Motor failure. Use the Motor Troubleshooting

39

Remove the object and reset the

unit.

Troubleshooting Guide to

evaluate the motor and replace if

necessary.

Reset the unit. Use the Motor

Troubleshooting Guide to

evaluate the motor and replace if

necessary.

Guide to evaluate the motor and

replace if necessary.

Troubleshooting

Page 44

PROBLEM POSSIBLE CAUSE REMEDY

Recipe key #2 - continuous

illumination (thermistor open fault).

Recipe key #3 - fast blink (blender

over temperature or jam).

Recipe key #3 - slow blink (blender

over temperature)

Recipe key #3 - continuous

illumination (thermistor open fault).

Recipe key #4 - fast blink (over

temperature fault).

Recipe key #4 - slow blink (low bus

voltage).

Motor failure. Use the Motor Troubleshooting

Guide to evaluate the motor and

replace if necessary.

Blender motor is jammed. Reset the unit and press the

BLEND key. Repeated jams

indicate a failed blender motor.

Use the Motor Troubleshooting

Guide to evaluate the motor and

replace if necessary.

The blender motor is over

temperature.

Motor failure. Use the Motor Troubleshooting

Motor drive board is over

temperature.

Low voltage supplied to unit. Use the Drive Board

Reset the unit. Use the Motor

Troubleshooting Guide to

evaluate the motor and replace if

necessary.

Guide to evaluate the motor and

replace if necessary.

Reset the unit. Use the Drive

Board Troubleshooting guide to

evaluate the board and replace if

necessary.

Troubleshooting guide to

evaluate the board and replace if

necessary.

Recipe key #1, 2, 3, or 4 - fast blink

(communication fault).

No communication between the

keypad and the dispense board.

Check the ribbon cable

connections. Replace keypad,

ribbon cable, or the dispense

PCB if necessary.

Troubleshooting

40

Model SB25

Page 45

Rinse Station Troubleshooting

PROBLEM POSSIBLE CAUSE REMEDY

Unit will not rinse. The power switch is in the OFF

position.

The power plug is not inserted

into the power jack.

The DC converter is not plugged

into the wall outlet.

The DC converter is not

providing 24 volts.

The reed switch(es) is not in

position or is defective.

One or both actuators are

missing or missing a magnet.

The rinse PCB is defective. Evaluate PCB and replace if

Blender pitcher is not being rinsed

completely.

The water line at the back of the

unit is not connected.

The water line is kinked. Straighten the water line.

Cold water is being used for

rinsing.

The rinse cycle is not long

enough.

Place the power switch in the ON

position.

Check/correct the connection at

the rear of the unit.

Check/correct the connection at

the outlet.

Check the output of the

converter.

Check position of reed switch. It

should be fully inserted into the

threads. Replace if necessary.

Replace, if necessary.

necessary.

Connect the water line.

Use warm water to aid in the

rinsing process.

Adjust the cycle time on the Rinse

PCB.

Blender pitcher is not being rinsed

completely.

Water is leaking from the unit. Poor fitting/hose connection. Check all visible fittings and

Unit is not draining. The drain line is kinked. Straighten the drain line.

Low water pressure in the store. Inform the store.

ensure all hoses are fitted into

the fittings properly.

The hose is cracked. Replace the hose if necessary.

Broken fitting. Replace the fitting if necessary.

The water manifold is defective. Repair with service parts; replace

if necessary.

There is no air gap between the

drain line and the drain.

The drain line is clogged. Unclog the drain line.

Provide air gap.

Model SB25

41

Troubleshooting

Page 46

Blender Troubleshooting

Ice Shaver Motor Troubleshooting

1. Pin Continuity

a. Pins 8, 9, and 10 should have continuity.

b. Pins 8, 9, and 10 should NOT have

continuity to pins 1 -7.

c. No pins should have continuity to ground.

If any of the continuity tests above fail, replace

the motor.

2. Motor Shaft

a. Facing the motor shaft, turn the shaft

counter-clockwise. Use caution as the

shaver blade is extremely sharp. The shaft

should turn smoothly, not drag or make a

noise while turning. (Note: This motor

requires some force to turn and will cog or

step into position.) If the motor does not

turn freely, replace the motor.

3. Power Leads Resistance

a. Remove the orange connector from the

drive board and insert the header into the

connector.

Blender Motor Troubleshooting

1. Pin Continuity

a. Pins 1, 2, and 3 should have continuity.

b. Pins 1, 2, and 3 should NOT have

continuity to pins 4 - 10.

c. No pins should have continuity to ground.

If any of the continuity tests above fail, replace

the motor.

2. Motor Shaft

a. Facing the motor shaft, turn the shaft

(using a metal object) counter-clockwise.

The shaft should turn smoothly, not drag

or make a noise while turning. (Note: This

motor turns freely with minimal force and

does not cog.)

3. Power Leads Resistance

a. Remove the orange connector from the

drive board and insert the header into the

connector.

b. Check the resistance between the motor

power leads (red, white, and black). This

reading should be ~ 11.3 Ω.The

acceptable range is 9.8 Ω to 12.3 Ω.Ifthe

resistance is outside the acceptable range,

replace the motor.

c. Check resistance between the two gray

wires (thermistor). The reading should be

~ 11.3 KΩ at 70 F. The typical range at 70

Fis8.8KΩ to 13.65 KΩ. If the multimeter

reads “OL”, the thermistor is broken. If the

multimeter displays less than 5 Ω or “0”,

the thermistor is shorted. If the thermistor

is broken or shorted, replace the motor.

d. Check continuity between the ground

(green/yellow) wire and each lead, one at

a time. The multimeter should display “OL”

for each measurement. If not, there is a

dead short in the motor and the motor

should be replaced.

b. Check resistance between the motor

power leads (red, white, and black). This

reading should be ~ 1.3 Ω. The acceptable

range is 0.8 Ω to 1.5 Ω. If the resistance is

outside the acceptable range, replace the

motor.

c. Check resistance between the two gray

wires (thermistor). The reading should be

~ 11.3 KΩ at 70 F. The typical range at 70

Fis8.8KΩ to 13.65 KΩ. If the multimeter

reads “OL”, the thermistor is broken. If the

multimeter displays less than 5 Ω or “0”,

the thermistor is shorted. If the thermistor

is broken or shorted, replace the motor.

d. Check continuity between the ground

(green/yellow) wire and each lead, one at

a time. The multimeter should display “OL”

for each measurement. If not, there is a

dead short in the motor and the motor

should be replaced.

Troubleshooting

42

Model SB25

Page 47

Drive Board Troubleshooting

1. Check the supply circuit providing power to the

machine for proper voltage (~120 VAC).

2. Turn the machine off, unplug, and wait 10

seconds for the charged capacitors to lose

charge. Expose the drive board and check

these items in the following order:

a. Make sure all connectors are seated firmly

onto their pins. Loose or unseated

connectors will cause fault readings.

b. Check the fuse. Visually, the fuse filament

should be continuous and not burnt. Check

continuity with the multimeter. The fuse

should not read “OL” when measuring

ohms.

c. Plug in and turn on the machine. Locate

the green LED (D36) on the drive board,

which is approximately 1.5” above the

lower right corner of the drive board. The

green LED should be illuminated

continuously. If the LED is not illuminated,

the board is defective. Replace the drive

board.

d. Locate the red LED (D21) on the drive

board, which is approximately 0.5” above

the lower right corner of the drive board.

4. If the LED is flashing 2 times, pauses

and repeats, the drive board detects a

locked blender motor. Check for

obstructions in the blender pitcher.

Troubleshoot the blender motor.

5. If the LED is flashing 3 times, pauses

and repeats, the drive board detects a

locked ice shaver motor. Check for

obstructions in the ice hopper.

Troubleshoot the ice shaver motor.

6. If the LED is flashing 4 times, pauses

and repeats, the drive board detects

over temperature of the blender motor.

This may occur due to high frequency

use of the machine. If the blender

motor connector is not seated, this

error may occur. Troubleshoot the

blender motor.

7. If the LED is flashing 5 times, pauses

and repeats, the drive board detects

over temperature of the ice shaver

motor. This may occur due to high

frequency use of the machine. If the

ice shaver motor connector is not

seated, this error may occur.

Troubleshoot the ice shaver motor.

1. If the LED is flashing 1 second on then

1 second off, the drive board operation

is normal.

2. If the LED is flashing 2 pulses per

second, the drive detects low voltage

on the power bus. If the supply circuit

voltage is correct, replace the drive

board.

3. If the LED is flashing once every two

seconds, the ice hopper lid switch is in

the open state. Check that the ice

hopper lid is on and the sensor pulls up

magnetically. Check that the LID1

connector is firmly attached to the

board. Simulate a closed state on the

drive board by jumping LID1 pins

together with a two pin jumper or a

patch cord. If the error goes away

while jumped, check the lid sensor

mechanism. If jumping LID1 does not

change the state of the error, replace

the drive board.

8. If the LED is flashing 6 times, pauses

and repeats, the drive board detects

over temperature of the motor. This

may occur due to high frequency use

of machine. The drive board heat sink

is a black section of metal below the

left side of the electronics. If the metal

is cool while the control indicates over

temperature, replace the drive board. If

the metal is hot, troubleshoot both

motors.

9. If the LED is flashing 8 times, the

blender circuit detects an over current

fault. Field test the motor. If the motor

is okay and the fault persists, replace

the drive.

10. If the LED is flashing 9 times, the

shaver circuit detects an over current

fault. Field test the motor. If the motor

is okay and the fault persists, replace

the drive.

Model SB25

43

Troubleshooting

Page 48

11. If the LED is flashing 10 times, the

blender motor winding has a short to

motor case. Field test the motor.

**(Controller will not be damaged by

bad motor.) **This reports on

Touchscreen as BLENDER MOTOR

LOCK. Check software version. This

applies to v2.98 USA; 1.30 and later

for International.

12. If the LED is flashing 11 times, the

shaver motor winding has a short to

motor case. Field test the motor.

**(Controller will not be damaged by

bad motor.) **This reports on

Touchscreen as SHAVER MOTOR

LOCK. Check the software version.

This applies to v2.98 USA; 1.30 and

later for International.

Troubleshooting

44

Model SB25

Page 49

Section 4: Parts

S Warranty Explanation

S Exploded Views

S Parts List

S Wiring Diagram

Model SB25

45

Parts

Page 50

Warranty Explanation

TAYLOR COMPANY LIMITED WARRANTY ON TAYLOR GENUINE PARTS

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this limited

warranty on new Taylor genuine replacement components and parts available from Taylor to the market generally

(the “Parts”) to the original purchaser only.

LIMITED WARRANTY

Taylor warrants the Parts against failure due to defect in materials or workmanship under normal use and service

as follows. All warranty periods begin on the date of original installation of the Part in the Taylor unit. If a Part fails

due to defect during the applicable warranty period, Taylor, through an authorized Taylor distributor or service

agency, will provide a new or re-manufactured Part, at Taylor’s option, to replace the failed defective Part at no

charge for the Part. Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited

warranty for a Part failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions

listed below and on the reverse (if any) of this document.

Part's Warranty Class Code or Part

Class 103 Parts¹ Three (3) months

Class 212 Parts² Twelve (12) months

Class 512 Parts Twelve (12) months

Class 000 Parts No warranty

Taylor Part #072454 (Motor-24VDC *C832/C842*) Four (4) years

LIMITED WARRANTY CONDITIONS

1. If the date of original installation of the Part cannot be otherwise verified, proof of purchase may be required

at time of service.

2. This limited warranty is valid only if the Part is installed and all required service work in connection with the

Part is performed by an authorized Taylor distributor or service agency.

3. The limited warranty applies only to Parts remaining in use by their original owner at their original installation

location in the unit of original installation.

4. Installation, use, care, and maintenance must be normal and in accordance with all instructions contained in

the Taylor Operator’s Manual.

5. Defective Parts must be returned to the authorized Taylor distributor or service agency for credit.

6. This warranty is not intended to shorten the length of any warranty coverage provided pursuant to a separate

Taylor Limited Warranty on freezer or grill equipment.

Limited Warranty Period

7. The use of any refrigerant other than that specified for the unit in which the Part is installed will void this

limited warranty.

1, 2

Except that Taylor Part #032129SER2 (Compressor-Air-230V SERV) and Taylor Part #075506SER1

(Compressor-Air-115V 60HZ) shall have a limited warranty period of twelve (12) months when used in Taylor

freezer equipment and a limited warranty period of two (2) years when used in Taylor grill equipment.

Parts

46

Model SB25

Page 51

LIMITED WARRANTY EXCEPTIONS

This limited warranty does not

1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of

defective Parts, replacement Parts, or new Parts.

2. Normal maintenance, cleaning and lubrication as outlined in the Taylor Operator’s Manual, including cleaning

of condensers or carbon and grease buildup.

3. Required service, whether cleaning or general repairs, to return the cooking surface assemblies, including

the upper platen and lower plate, to an operational condition to achieve proper cooking or allow proper

assembly of release sheets and clips as a result of grease build-up on the cooking surfaces, including but

not limited to the platen and plate, sides of the shroud or top of the shroud.

4. Replacement of cooking surfaces, including the upper platen and lower plate, due to pitting or corrosion (or

in the case of the upper platen, due to loss of plating) as a result of damage due to the impact of spatulas or

other small wares used during the cooking process or as a result of the use of cleaners, cleaning materials

or cleaning processes not approved for use by Taylor.

5. Replacement of wear items designated as Class “000” Parts in the Taylor Operator’s Manual, as well as any

release sheets and clips for the Product’s upper platen assembly.

6. External hoses, electrical power supplies, and machine grounding.

7. Parts not supplied or designated by Taylor, or damages resulting from their use.

8. Return trips or waiting time required because a service technician is prevented from beginning warranty

service work promptly upon arrival.

cover:

9. Failure, damage or repairs due to faulty installation, misapplication, abuse, no or improper servicing,

unauthorized alteration or improper operation or use as indicated in the Taylor Operator’s Manual, including

but not limited to the failure to use proper assembly and cleaning techniques, tools, or approved cleaning

supplies.

10. Failure, damage or repairs due to theft, vandalism, wind, rain, flood, high water, water, lightning, earthquake

or any other natural disaster, fire, corrosive environments, insect or rodent infestation, or other casualty,

accident or condition beyond the reasonable control of Taylor; operation above or below the gas, electrical or