Page 1

TANDBERG

Series SOOOX

SERVICE

;

ir--I

ll

"--:

";'

t

TANDAERG

MANUAL

I

ryr;

A

*q

r

oc

reCOAO LEEL

ruc

"t

-

;

TANDBERGS

RADIOFABRIKK

A/S

Page 2

-

-

A

^a

Page 3

.G.

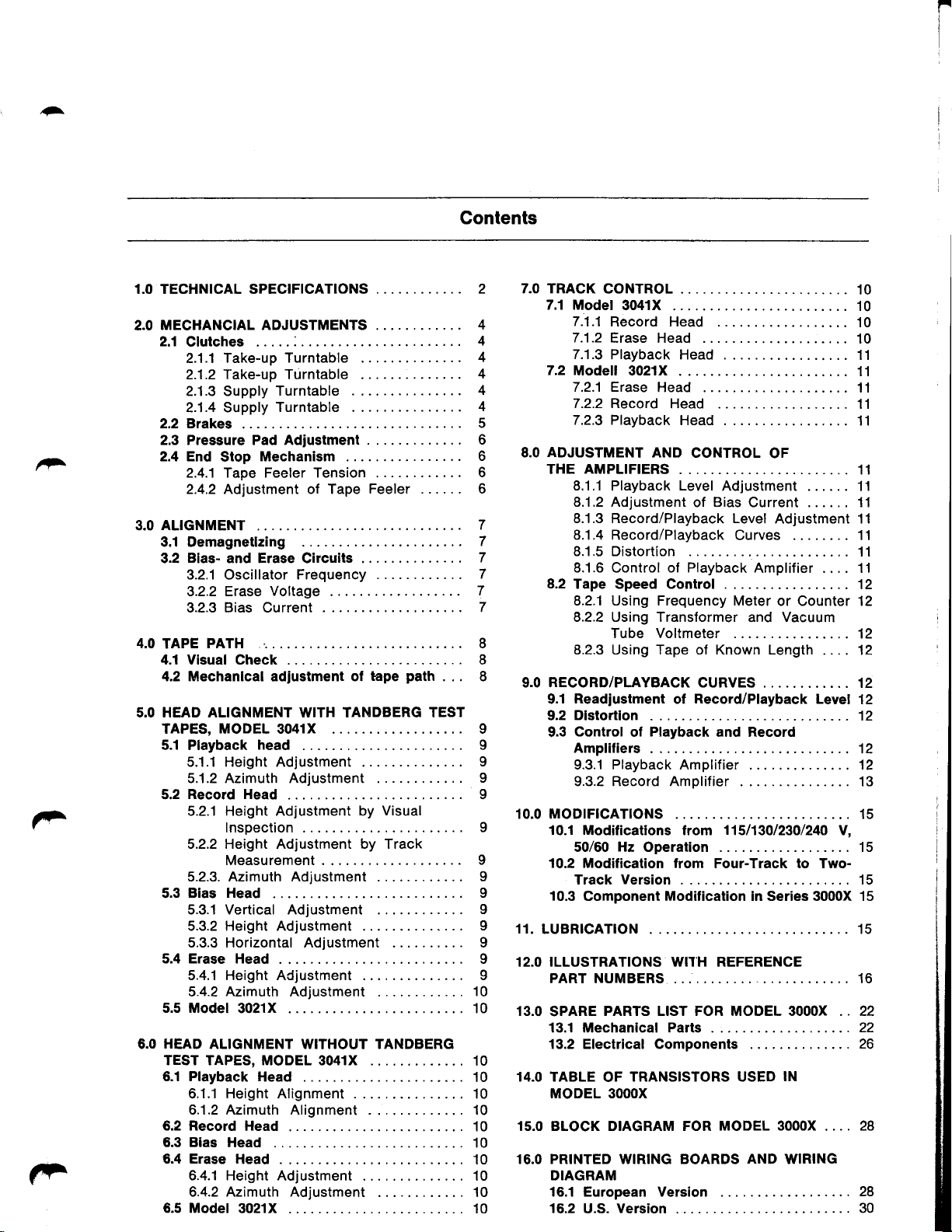

Contents

1.0 TECHNICAL SPECIFICATIONS

MECHANCIAL ADJUSTMENTS

2.0

2.1

Clutches .....:.

2.1.1 Take-up

Take-up Turntable

2.1 .2

2.1.3 Supply

2.1.4 Supply

2.2 Brakes

2.3 Pressure Pad Adiustment . .

F

2.4 End

ALIGNMENT

3.0

3.1 Demagnetlzing

3.2

4.0

TAPE

4.1 Visual Check

4.2 Mechanlcal adjustment ol

5.0 HEAD ALIGNMENT WITH TANDBERG TEST

TAPES, MODEL 3041X

5.1 Playback

5.2

5.3

5.4 Erase Head

5.5 Model

HEAD

6.0

TEST TAPES, MODEL 3041X

6.1 Playback

6.2 Record

6.3 Bias

6.4 Erase

6.5 Model

Stop

2.4.1 Tape Feeler Tension

2.4.2 Adjustment of Tape

Blas-

and Erase Circuits

3.2.1

Oscillator

3.2.2 Erase

3.2.3 Bias Current

PATH

5.1.1 Height Adjustment

5.1.2 Azimuth Adjustment

Record Head

5.2.1 Height Adlustment by

Inspection

5.2.2 Height Adjustment by Track

Measurement . ....

5.2.3. Azimuth Adjustment ...

Bias Head

5.3.1 Vertical Adjustment ....

5.3.2 Height Adjustment

5.3.3 Horizontal Adjustment

5.4.1 Height Adjustment

5.4.2 Azimuth Adjustment

3021X .

ALIGNMENT WITHOUT TANDBERG

Height Alignment

6.1.1

6.1.2 Azimuth Alignment .

Head

Head .

6.4.1 Height

6.4.2 Azimuth Adjustment

3021X

Turntable

Turntable

Turntable

Mechanism .

.

Frequency

Voltage

head

.

.

Head .

Head

.

Adjustment

.

Feeler

. . .

tape

Visual

...

path

. . .

10

10

10

10

10

10

10

10

10

10

10

10

7.0 TRACK

7.1 Model

4

4

4

4

4

4

5

6

6

6

6

7

7

7

7

7

7

8

8

8

I

I

9

9

9

7.2

ADJUSTMENT

8.0

THE

8.2

RECORD/PLAYBACK

9.0

9.1

9.2Dlstortlon.... .........12

9.3

10.0 MoDrFtcATroNS ... 15

9

9

I

9

9

9

9

I

I

10.1

10.2 Modification lrom

10.3

11.

LUBRTCATTON . ...... 15

12.0 ILLUSTRATIONS WITH REFERENCE

PART NUMBERS .. ..... 16

13.0

SPARE

13.1 Mechanical Parts . .. ...

13.2 Electrica! Components . . .... .

14.0 TABLE

MODEL 3OOOX

15.0 BLOCK DIAGRAM FOR

16.0 PRINTED WIRING BOARDS AND WIRING

DIAGRAM

16.1 European Version

16.2

CONTROL

3041X

7.1.1

Record Head

7.1.2

Erase Head .

7.1.3

Playback Head

Modell 3021X

7.2.1 Erase

7.2.2 Record

7.2.3 Playback

AMPLIFIERS

8.1.1 Playback Level

8.1.2 Adjustment

8.1.3 Record/Playback Level

8.1.4 Record/Playback

8.1.5 Distortion

8.1.6

Control

Tape Speed Control

8.2.1 Using Frequency Meter

8.2.2 Using Transformer

Tube Voltmeter ..

8.2.3 Using Tape of Known Length

Readjustment

Control

Ampliliers

9.3.1 Playback Amplifier ....

9.3.2 Record Amplifier .........

Modilications from

50/60 Hz Operation . .. . 15

TrackVersion... ......15

Component Modification in Series 3000X 15

PARTS LIST FOR MODEL 3OOOX .. 22

OF

.

.

Head .

Head

Head

AND

CONTROL

Adjustment ......

Bias

of

of Playback

CURVES

Record/Playback

ol

Playback

of

TRANSISTORS USED

and Record

Four-Track to Two-

MODEL SOOOX . ... 28

OF

Current ...... 11

Curves ... ..... 11

Amplifier .... 1'l

and

11511301230/240

Adiustment 11

........ 11

or Counter 12

Vacuum

...... . 12

.... ...

IN

10

10

'10

10

11

11

11

11

11

... 11

11

.... 12

.... 12

..... 12

Level

12

12

12

...

13

V,

22

26

28

U.S.

Version

30

Page 4

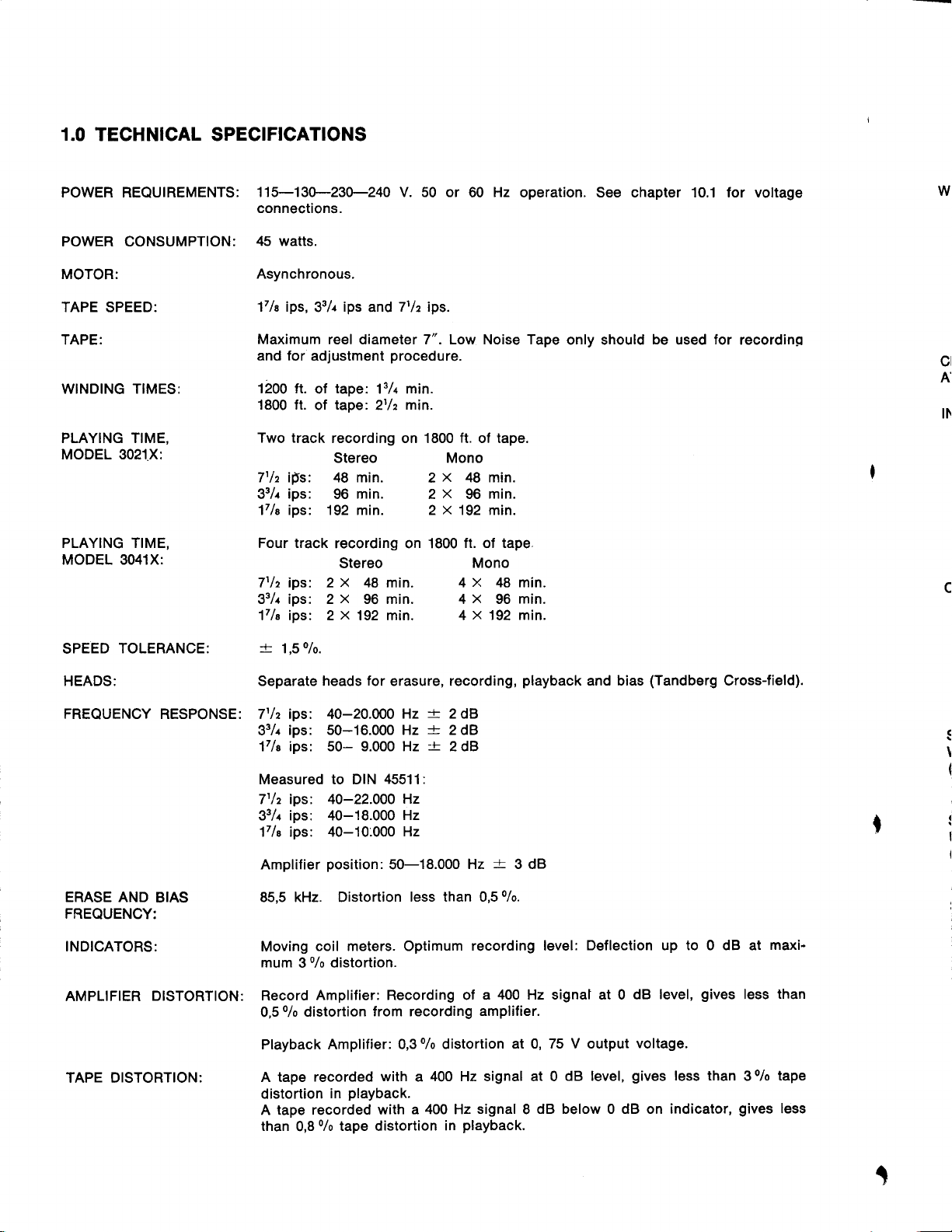

1.0 TECHNICAL SPECIFICATIONS

POWER REQUIREMENTS:

POWER CONSUMPTION:

MOTOR:

TAPE

SPEED:

TAPE:

WINDING

PLAYING TIME,

MODEL 3021X:

PLAYING TIME, Four track

MODEL 3041X:

TIMES:

115-130-230-240 V. 50 or

connections.

45 watts.

Asynchronous.

17le ips,

Maximum reel diameter 7". Low Noise Tape

and

1200 ft.

1800 ft.

Two track

7t/z ips: 48 min.

33/,r

17la ips: 192 min. 2 X 192 min.

71/z ips: 2 x 48 min. 4 x 48 min.

33/r ips: 2 x 96 min. 4 x 96

17le ips: 2 x 192 min. 4

33/r

for

adjustment

of

of

ips:

Hz

60

ips

tape;

tape:

recording on 1800 ft. of tape.

Stereo Mono

96

recording on 1800

Stereo

and

131 min.

2t/z

min.

7tlz ips.

procedure.

min.

x

2

2 x 96

48 min.

ft. of tape.

x

operation. See chapter 10.1 for voltage

min.

Mono

min.

192 min.

only should

be

used

for

recordinq

Wl

cl

A

SPEED

HEADS: Separate heads

FREQUENCY RESPONSE: 7t/z ips: 40-20.000

ERASE AND

FREQUENCY:

INDICATORS: Moving

AMPLIFIER

TAPE DISTORTION:

TOLERANCE:

BIAS

DISTORTION:

-+

1,50/0.

for

ips: 50-16.000 Hz

33/r

17e ips: 50- 9.000 Hz

Measured to DIN

7t/z ips: 4O-22.0O0

33/r ips: 40-18.000

17la ips: 40-10.000

Amplifier

85,5 kHz. Distortion

mum

Record

0,5

Playback Amplifier: 0,3

A tape

distortion

A tape

than

position:

coil meters. Optimum

o/o

3

distortion.

Amplifier: Recording of

0/o

distortion

recorded

in

recorded with

0/o

0,8

45511:

50-18.000

from recording

with a 40O Hz signal at 0

playback.

tape distortion

erasure, recording,

-+

Hz

Hz

Hz

2dB

-+-

2dB

-+

2dB

Hz

-+

Hz

less than 0,5 %.

recording level:

a 400 Hz signat at 0 dB

amplifier.

0/o

distortion

a 400 Hz

signal 8 dB below 0 dB on indicator,

playback.

in

3 dB

at 0, 75 V output

playback

dB level,

and bias

Deflection up to 0 dB at

(Tandberg

level,

voltage.

gives

less than

Cross-field).

gives

less

30/o

gives

C

!

(

fi

(

maxi-

than

tape

less

i

Page 5

-

a

WOW:

CROSSTALK

ATTENUATION:

INPUTS:

OUTPUTS:

W.

R. M. S.:

7t/z

ips

33/r ips

17le

ips

DtN

45511 :

71/z

ips - better

33/r ips

17le

ips

At

1OOO

Mono

Each

1.

Microphone

200-700

DIN

2.

Line input

400 Hz: 100

3. Line input

400 Hz:

channel:

Emitter

SocKetS,

Minimum

signal

jack

for connection

Stereo

version

and

RIGHT.

better

-

-

-

-

Hz:

60

)

channel has the following

socket.

follower

OUTPUT

load

at 0

jack

stereo

than

better

than

better

than

than

better

lhan

better

than

dB

input for

ohm. Sensitivity

US-version,

for

high

mV.

for low impedance

mV.

5

Pin 4, right

outputs,

LEFT

impedance:

dB level,

is connected

jack

o/o

0,07

0,140/o

0,280/o

o/o

0,1

O,2o/o

0,40lo

Stereo

dynamic low impedance

Telephone

impedance

Maximum

Maxirnum

channel.

RADIO DIN

and RIGHT.

100 ohm.

gives

approx.

of

headphones.

in

is

connected

SO OA

)

inputs:

at 400

parallel

Hz: 0,1 mV.

jack.

source. lmpedance: 1

input level: 20

socket

Output

RADIO

with

lmpedance:

with

source.

input level: 1 V.

US-version:

0,75 V in

parallel

microphone.

Maximum

Phono

V.

DIN

Phono sockets

pins

level:

playback.

phono

sockets,

57

socket RADIO:

3 and

A

tape recorded

socket

sockets

lmpedance:

input level:

Mohm.

LINE lNpUTS.

kohm. Sensitivity

LOW

5. US-version:

HEADPHONES,

pins

and

3

OUTPUT LEFT

25 mV.

Sensitivity at

Pin 1, left

lN.

with 400 Hz

5.

On

at

phono

stereo

US-

SfGNAL TAPE/NOISE

WEIGHTED

(GERAUSCHSPANNUNG):

SIGNAL TAPE/NOISE

UNWEIGHTED

(FREMDSPANNUNG):

SIGNAL/TAPE

SfGNAL/TAPE

NOISE:

NOISE:

Wetonreo

(lEC

A-CURVE)

DfMENSIONS:

WEIGHT:

R. M.

S.:

Peak

value measured

tape

distortion:

4-track

54

dB

Peak value

distortion:

4-track

51 dB

Measured linear

4-track

57 dB

Measured at

4-track

62 dB 64 dB

Note:

At

noise)

Length: 151/2"

(9,1

20 lbs

2-track

56 dB

measured

2-track

51 dB

2-track

s7 dB

tape speed

z-track

0/o

3

distortion

are reduced by 2

(39,4

kg).

according

according to

R.M.S.

cm),

to DIN 45511

DIN 45511

at tape speed

7t/z ips and 5

all signal to noise

dB.

heigth:

6t/2"

7'lz ips

0/o

(16,5

at tape speed

at tape speed 7t/z ips

o/o

and 5

distortion:

ratio measurements (Signal/tape

and depth:

cm)

71/z ips

distortion:

123la"

(31,6

and

5olo

and 5o/o

cm).

Page 6

2.0 MECHANICAL

ADJUSTMENTS

2.1

Glutches

Control

Note:

2.1.1

Normal

Set the

position

in

of

All

controls and

ried out

horizontal

All

tig. 2.2

control.

trol of supply

Take-up

Forward Winding

operating lever to

v.rith the motor running. The

table tig. 2.3,

0.5 - 0,9mm

(0.02t'

-

0.035'r

Winding

controls

Torque

measurements must

with the tape recorder

position

which

Take-up

Turntable

pos.

)

and

accomplished

are

presents

turntable

turntable, reverse the

Torque

1.

Ensure that the

be car-

placed

with empty reels only.

shown

as

two optimal modes

is shown. By con-

figure.

Normal

Forward

torque is

drive

read

clearance

between

turntable

0,5--O,9 mm

screw

A as shown

in

2.1.2

Take-up Turntable

in

Fast

of

Forward Winding

The

torque is read in

torque deviates

check and,

263737B.

Ensure that

on bushing

2.1.3

Supply Turntable

Tape

Tension

The

torque

2.1.4

Supply Turntable

Fast

Reverse

The torque is read in table fig.

torque deviates

check

and, if

2618054.

polyurethane

the

and friction

(0.02"-0.035").

in

from the

if necessary,

there is

2640834

read

is

Winding

lrom

necessary,

See fig. 2.5.

friction

disc 991009

lf

fig.

2.1.

Torque

table fig.

specifications

alter the

a clearance

and lever

in table

Torque

the specifications

alter the

necessary,

2.3,

pressure

between the

991013.

2.3,

fig.

2.3,

pressure

pads

lays

pos.

in

See

pos

pos.

in

under

between

adjust

3. lf the

the table,

of

spring

studs

fig.

2.

3. lf

the

table,

of

spring

the

2.4.

the

*

1

Pot

2

Pot

3

,l

I

a

I

i

(

i

991017

9910r3

261841 2673?38

Fig. 2.1 .

mm

30

2640834'

radius

991009

The difference between

Fast

Reverse

(measured

1309

at 80 mm radius). lf necessary, alter the

spring 261805A

Winding

at 30 mm

(fig.

80 mm

Fast Winding

Torque

radius),

2.5),

or spring

radius

should be less than

509

or

2673738

Torque and

(measured

pressure

(fig.

ot

2.1).

t

t

Fig 2.2.

Page 7

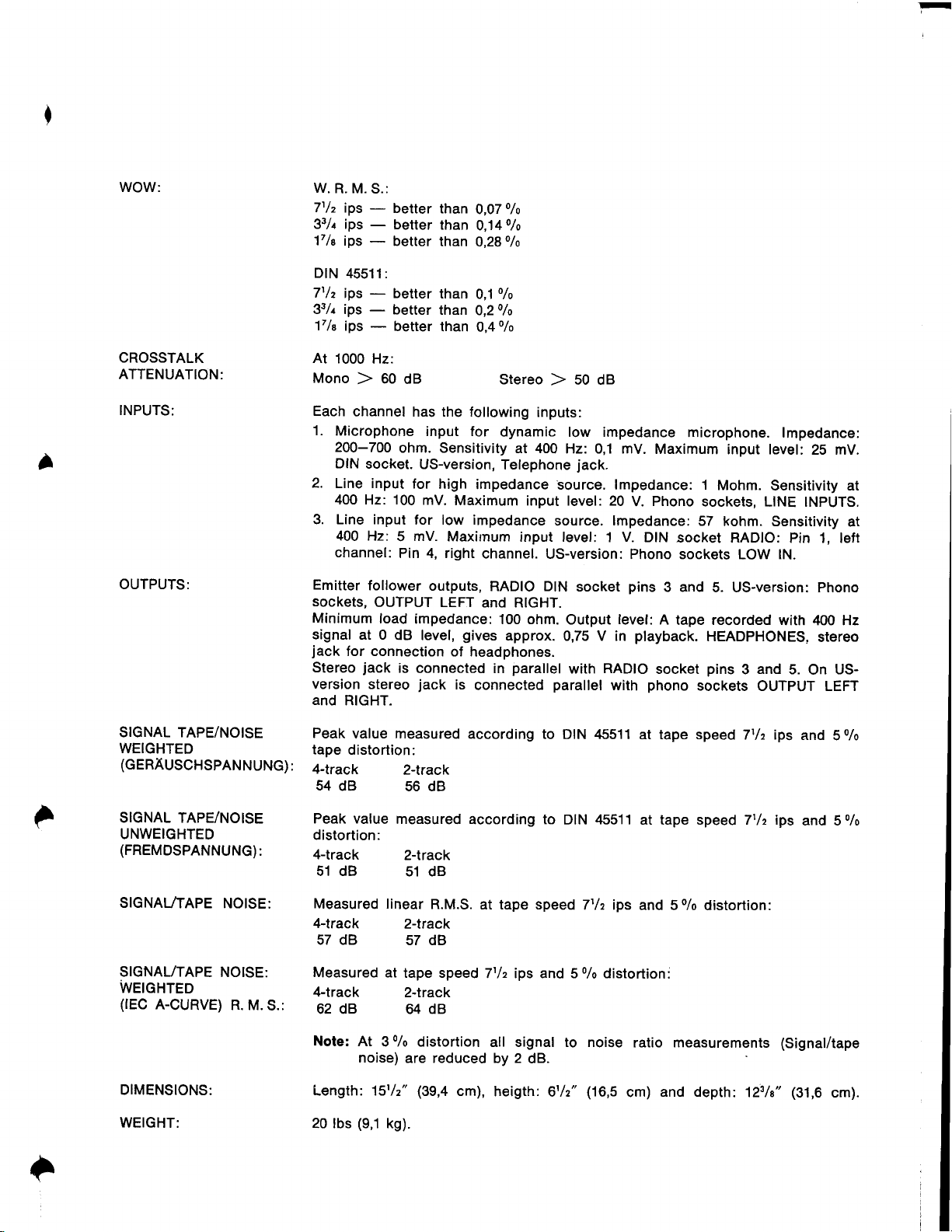

Table for Winding Torques

Torque

tit

winding

Pos

tape rensron

2

Pos

Fast winding

3

t

*

After a longer

increase of the torque

as normal.

Ensure

in the

table

position,

cal

turntable.

periode

that the

by

and with

of continuous operation,

by 2G-30

torque is within the

running

the tape recorder in vertia tull 7" reel on take-up

0/o

is

considered

specifications

Fig. 2.3.

an

C

mm

30

radius

at

Torque

at

80 mm

radius

159-

309-

o- 8g

909-250g

264930

Fig. 2.6.

991 01

?

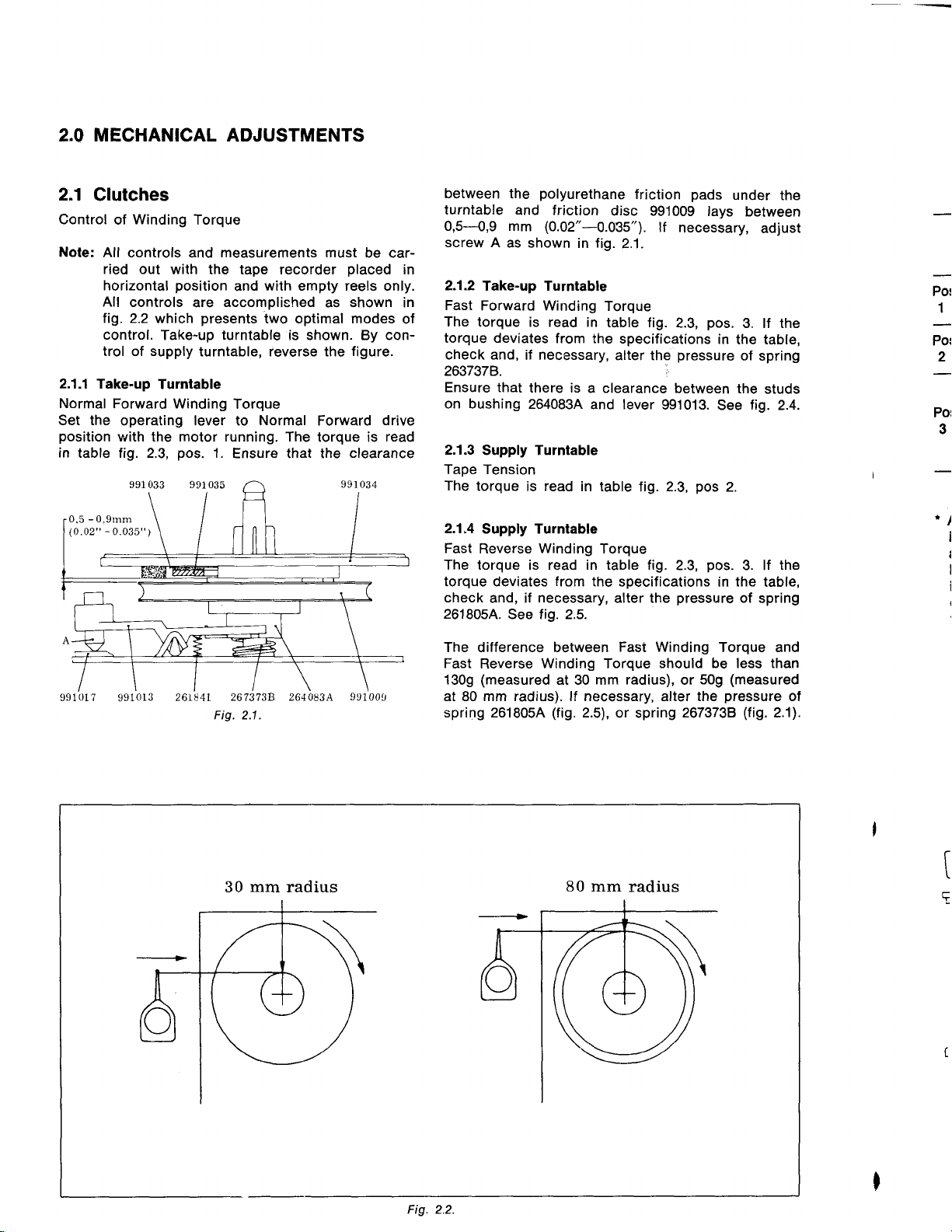

2.2 Brakes

See fig. 2.6

Set the operating lever to Normal

position.

brake

I

min 0,lmm

(0.004,')

Fig.

2.4.

lf necessary,

Set the operating lever to Fast

Fast

that the

of the hinged

lays between

adjust screw

The adjustment

tables.

Check

pad

and the turntable is

Reverse Winding

clearance between screw

A

251489

that the

adjust screw D.

delrin

0,5-1 mm

C.

procedure

clearance between

position

parts

on

(0.02"-4.O4"

operating arm 991017

is

Forward

approx 1 mm

Forward Winding

respectively.

C and the bottom

).

for both turn-

equal

(0.04").

Ensure

lf

necessary,

drive

the

or

@

261 805A

Fig.

2.5.

Fig.

2.7.

Page 8

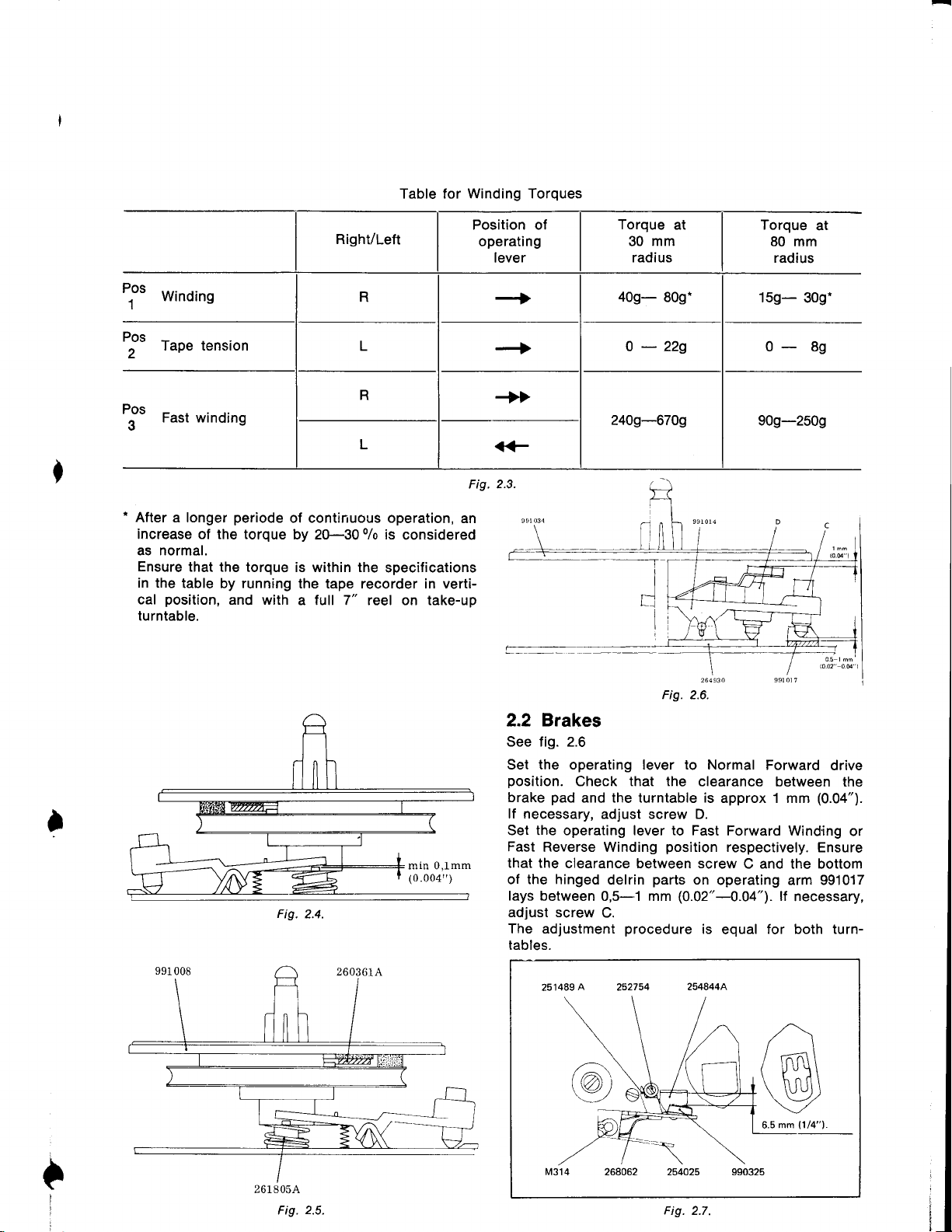

Pressure Pad

2.3

the

Set

clearance

tape rest 254844A

shown

by bending

See

operating lever

between

in fig.

2.7.

the arm

fig. 2.8.

Adjustment

to Neutral

pressure

the

should be approx. 6,5 mm

lf

necessary, adlust the clearance

254025 with

2.8.

Fig.

position.

pad

990325 and the

pair

a

(tlr")

of

pliers.

The

as

2.4

End

2.4.1

Tape

The

feeler tension

tween

modes.

by

lig.

8 and 10

Adjustment of

tightening or

2.12.

Stop

Feeler

Mechanism

Tenslon

against the tape should lay

g (0.28-0.35

the

tension is

slackening the spring 243990.

Fig.2.10.

in drive winding

oz)

be-

accomplished

See

I

l1

a

(

t

a

I

a

the operating

Set

position.

rest should

of the

end

lf

necessary, adjust the

spring

268062

zzl

pressure

The

be 80

pressure

with a

252754

g

/:\

(@,

tM3l4

lever

(2,8

pad

pair

Fig. 2.9.

Normal

to

at the

-+

ozl

arm

pressure

pliers.

of

80s

12.82

l,

a-\\

',-/

Forward drive

pad

against the tape

0/0,

10

measured on the

254025.

by bending

See

!

ozl

See fig.

fig. 2.10.

2.9.

the

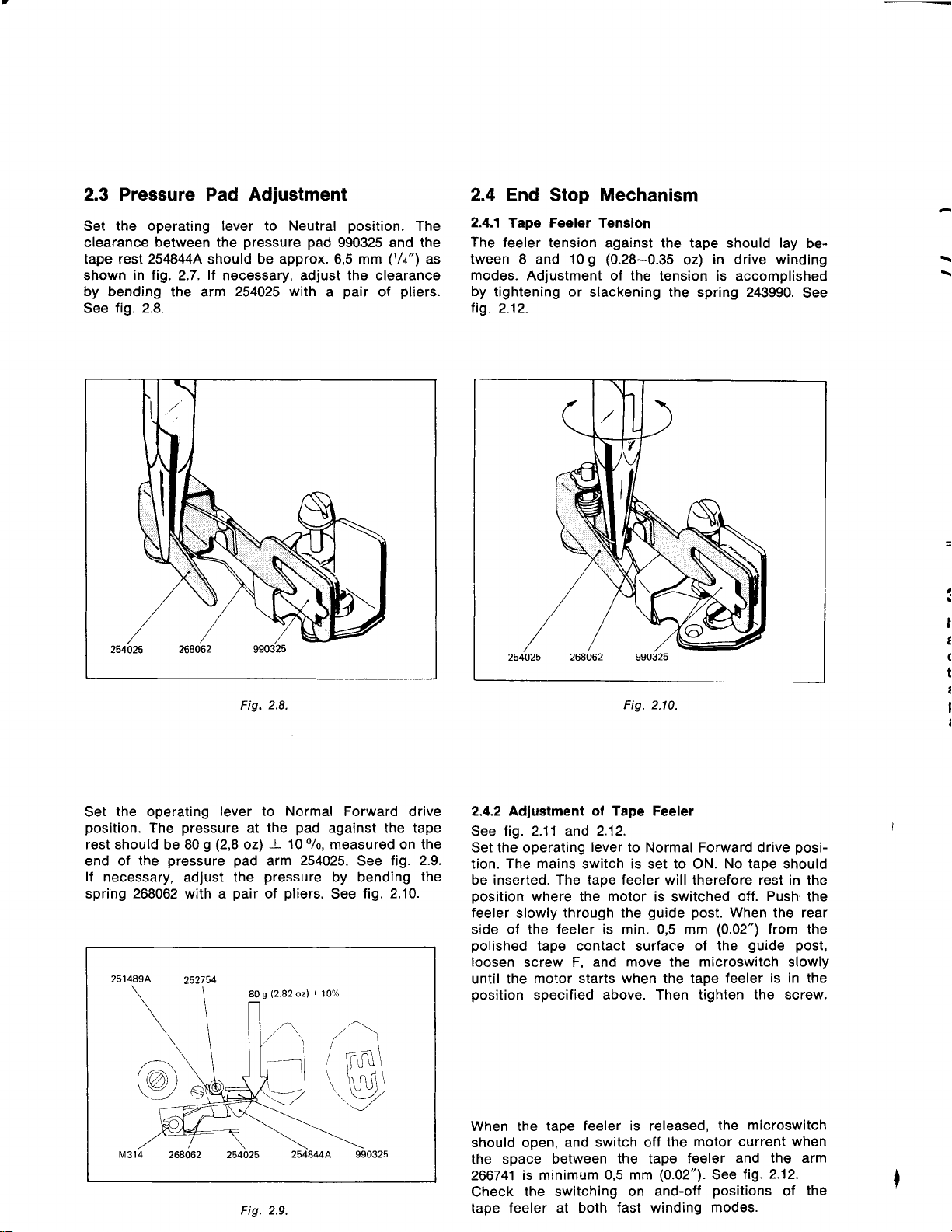

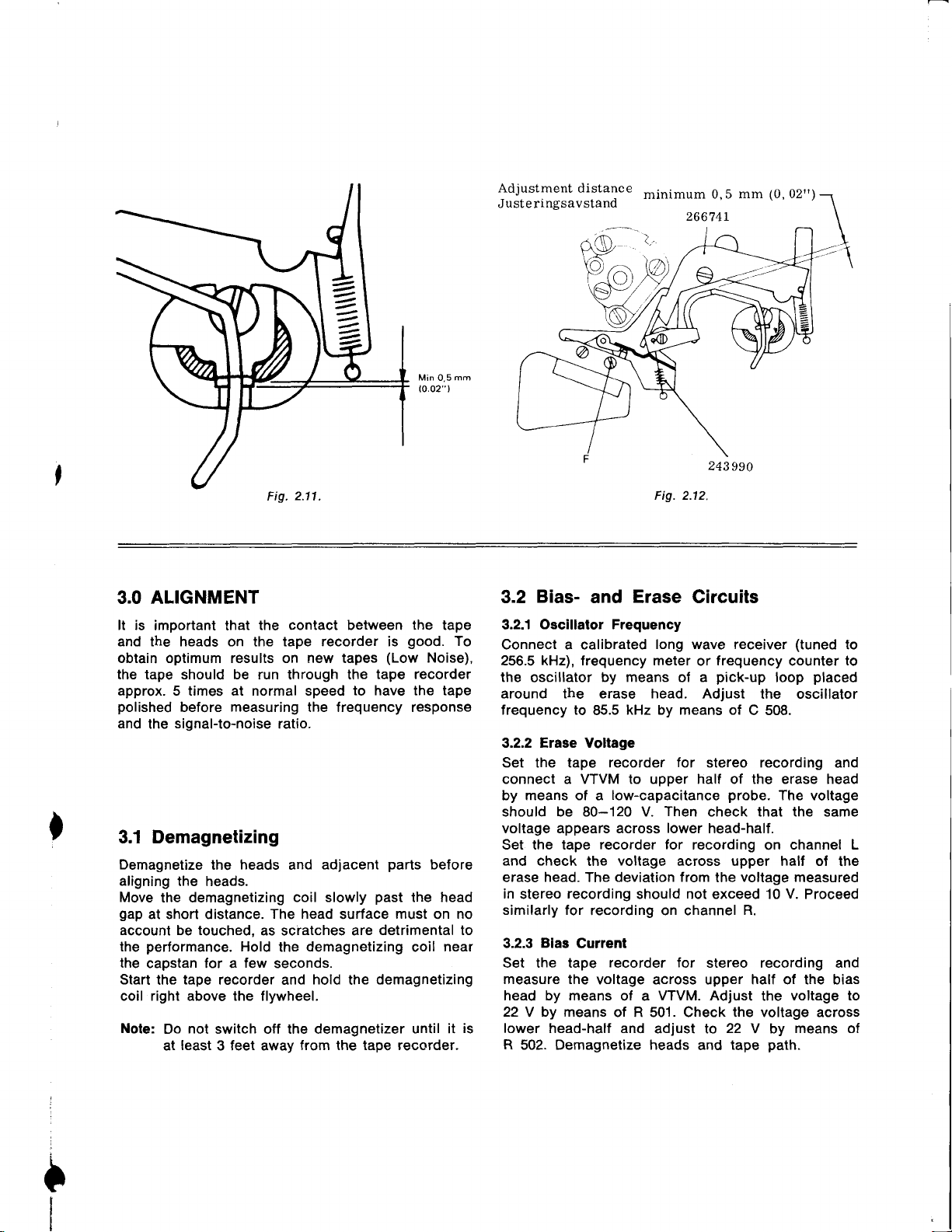

2.4.2 Adjustmenl of Tape Feeler

fig. 2.11 and 2.12.

See

Set the operating

tion. The

be inserted.

position

feeler

side of the

polished

loosen

until the

position

When the

should open,

the space

266741

Check

tape feeler at

mains

where

slowly

tape contact surface

screw

motor starts when the tape

specified above. Then tighten

is minimum

the switching on

lever to

switch is set to ON. No tape should

The tape feeler will

the

through the

feeler is

F, and move the microswitch slowly

tape feeler is released,

and switch off

between

both

Normal Forward drive

motor

0,5 mm

is switched

guide

min. 0,5

the

tape

(O.O2").

and-off

fast

winding

the

posi-

therefore

post.

mm

of the

motor current when

feeler

modes.

rest in

off. Push

When the rear

(0.02")

the microswitch

See

positions

from

guide post,

feeler is

and the arm

in

the

screw.

fig. 2.12.

of

the

the

the

the

the

Page 9

Min

0,5

(o.02"

Adjustment

Juste ringsavstand

mm

l

distance

minimum

266741

mm

0,5

243990

(0,02rr)

v

2.11.

Fig.

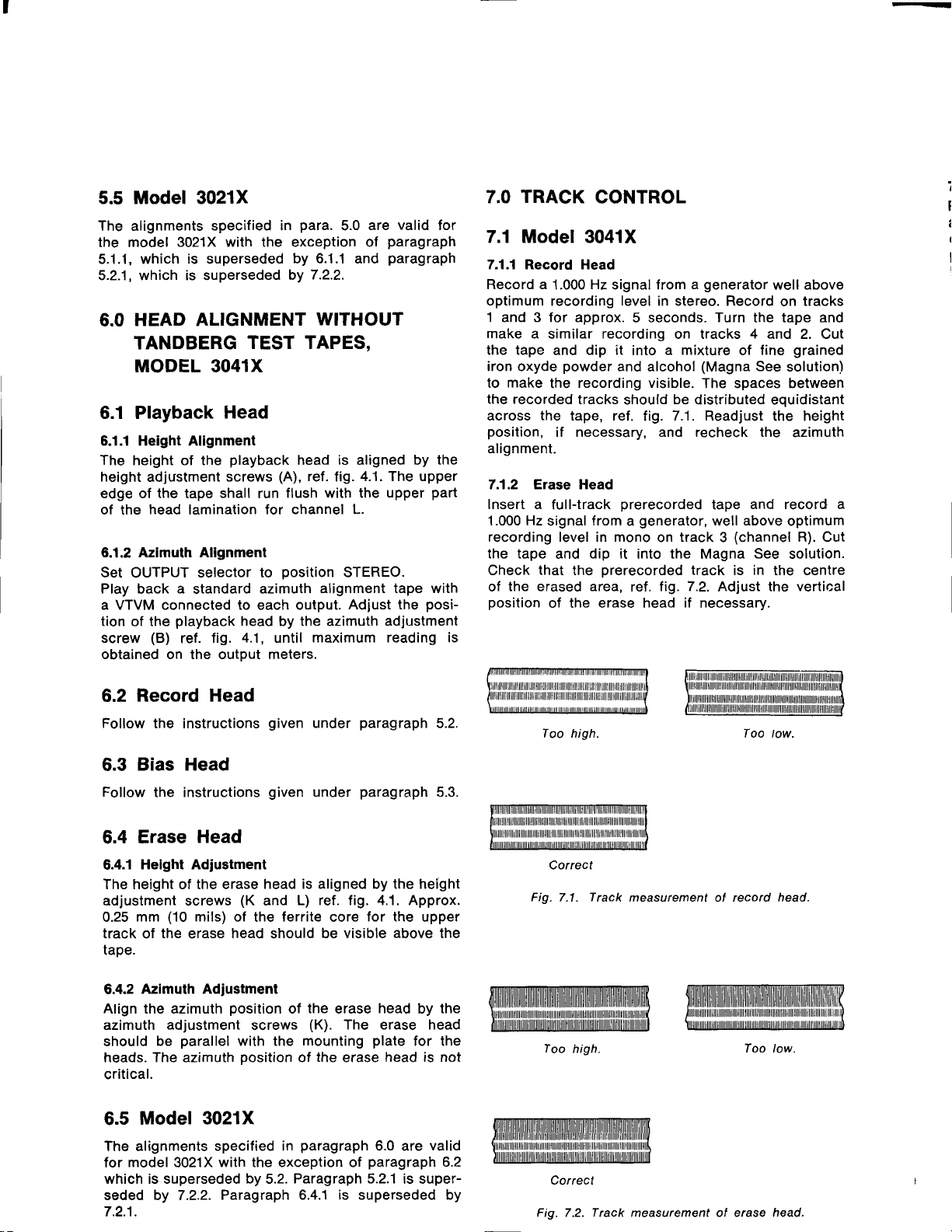

3.0 ALIGNMENT

It is

important that

and the heads on the tape recorder is

obtain optimum results on new tapes

the tape should be run

approx. 5 times at normal speed

polished

and

3.1

Demagnetize

aligning

Move

gap

account be touched,

the

the

Start

coil right above the flywheel.

Note:

before

signal-to-noise

the

Demagnetizang

the

the heads.

the demagnetizing

at short distance.

performance.

capstan for a

tape

the

not

Do

least

at

the contact between the tape

(Low

tape recorder

through

measuring

ratio.

heads

Hold

recorder and

switch off the demagnetizer

3 feet away

and

coil slowly

The head

as scratches are

the

few

seconds.

from the tape recorder.

the

to have the tape

the frequency response

adjacent

surface

demagnetizing

hold

parts

past

detrimental to

demagnetizing

the

good.

Noise),

before

the head

must

on

coil

until it

To

no

near

is

Fig. 2.12.

Bias-

3.2

Oscillalor Frequency

3.2.1

Connect a calibrated

256.5 kHz), frequency meter

the

oscillator

around the erase head.

frequency to

3.2.2 Erase Voltage

Set

the

connect a VTVM to upper half of the erase head

by means of

should be 80-120 V.

voltage appears across

Set the tape

and check

erase

in

stereo

similarly for

Bias

3.2.3

Set the tape

measure the

head by means

22 Y by means

lower

R

502. Demagnetize heads

and Erase Circuits

long wave receiver

by means

kHz by means of

85.5

tape recorder

low-capacitance

a

Then

recorder for

voltage

the

head.

recording

head-half and

deviation from

The

should not exceed 10

recording on channel

Current

recorder for

voltage across upper half of the bias

VTVM. Adjust

of a

of R 501 . Check the voltage across

adjust to

(tuned

frequency

or

pick-up

of a

Adjust the oscillator

for

stereo recording

probe.

check ihat the same

lower

head-half.

recording

across upper half of

voltage

the

stereo recording and

22

tape

and

loop

C 508.

The voltage

on

R.

the

Y by

path.

counter

channel L

measured

V.

voltage to

means of

placed

and

the

Proceed

to

to

Page 10

TAPE PATH

4.0

4.1 Visual Check

the recorder with a tape,

Load

operating

position.

the

head

record

parallel

Operate

tape

rubber without

pressure

the

the tape touches the flanges of the

when the recorder is in normal

as the drive mechanism is engaged. The

however,

lever

slowly

Check that the

height adjustment

guide

plate,

base

head.

to the

runs within

Also check that

record

the

start/stop

wheel.

posts

by no means bulge at the flanges.

to the normal

bias head

screws

presses

nor

head.

knob, and

the rims of

flickering on

Check that

is correct.

lt

(C)

the

the

the

neither

height

can be tolerated that

forward

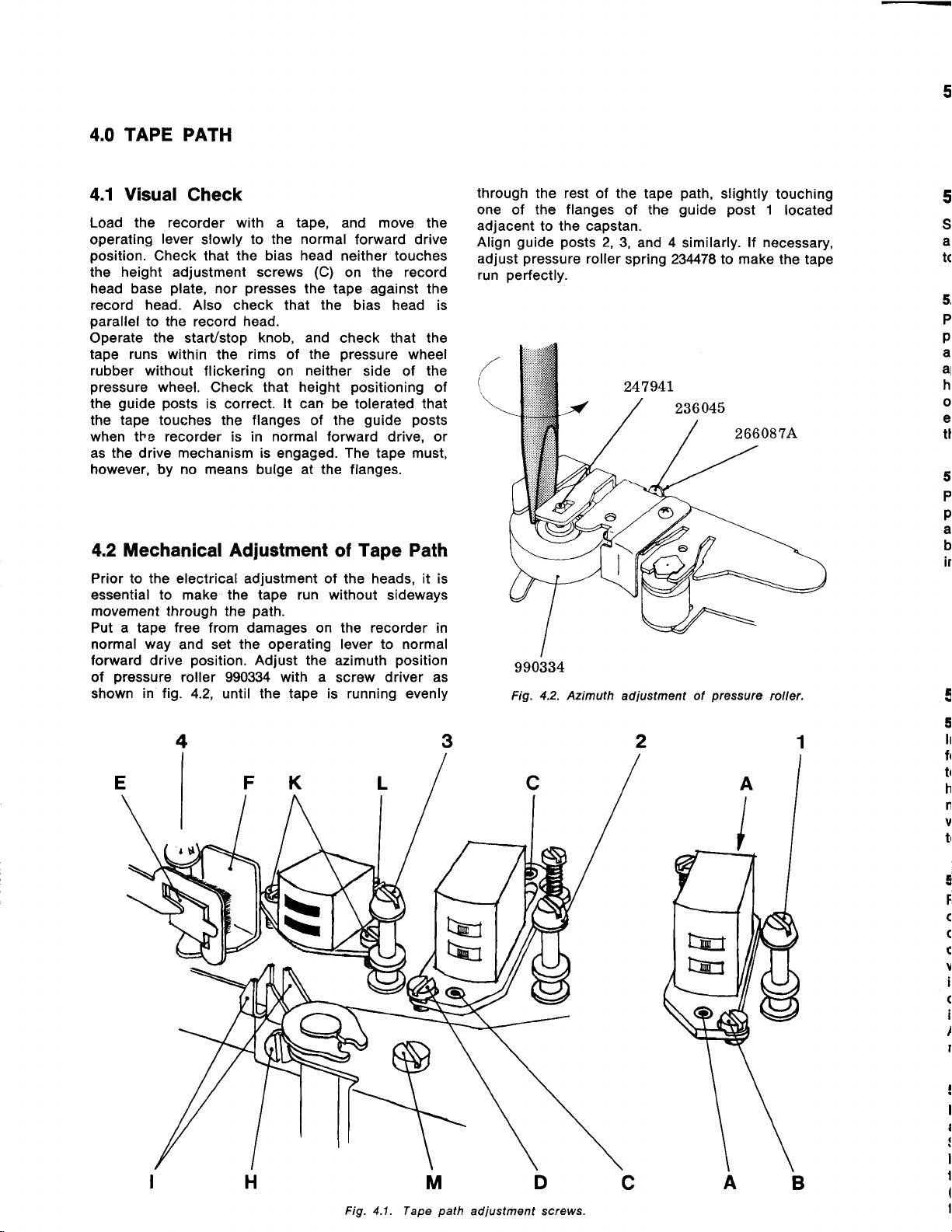

4.2 Mechanical Adjustment

Prior to the electrical adjustment of

essential to make the tape run without

movement

Put a tape

normal way

forward drive

pressure

of

shown in tig. 4.2, until the tape is running evenly

through the

free

and set

position.

roller

path.

from damages on the recorder in

the operating lever to normal

Adjust

990334

the azimuth

with a

move

and

forward drive

neither touches

on the record

tape against the

bias head is

check that the

pressure

side of the

positioning

guide posts

tape

Tape Path

of

heads, it is

the

screw

the

wheel

of

drive, or

must,

sideways

position

driver as

through

one of the

adjacent

Align

adjust

run

the rest of the

to the capstan.

guide posts

pressure

perfectly.

(

990334

Fig. 4.2. Azimuth

flanges

2,

roller

path,

tape

guide post

the

of

3,

and 4 similarly.

spring

adiustment

234478 to make

ol

slightly

lf necessary,

pressure

touching

1

located

the tape

roller.

5

$,

a

tc

5.

P

pl

al

al

hr

o

el

tt

5,

P

p

a

b

ir

E

5

4

Ir

ft

tt

h

n

v

tt

I

F

C

(

c

v

I

(

I

I

I

Fig. 4.1 . Tape

MD

path

adiustment screws.

Page 11

HEAD ALIGNMENT WITH

5.0

TANDBERG

MODEL

TEST

3041X

TAPES,

rg

)d

v,

)e

Playback

5.1

the recorder

Set

a VTVM to each

position

to

Helght

5.1.1

Tandberg

Play

prerecorded

and with area

approx. 30 dB. Adjust the height of the

head by means

output

endeavouring to maintain the headfront

the tape.

5.1.2

Play

prerecorded

al 7t/t ips.

back head by

indication

5.2

5.2.1

forward

to run

head,

necessary,

while endeavouring to maintain

to the tape.

is

obtained from track

Azlmuth

Tandberg

on the VTVM is obtained.

Record

Height

Insert a new

drive. Check

parallel

with

Head

stereo

for

of the outputs. Output selector

one

STEREO.

Adiuslment

test tape No. 1. This

tape with 1.000 Hz recorded at

corresponding to track 3

the

of

Adjustment

test tape No. 2. This

tape with 10.000 or 15.000

Adjust the azimuth

means of the screw

playback

screws

3

position

and

is

(A)

until minimum

(channel

is

Hz

(B),

until maximum

Head

Adiustment by Visual

tape, and start the recorder

visually

with the upper

play

a

adjust the

of approx.

height

Inspectlon

that the tape

track of the record

mm

0.1

with

screws

the headfront

a full track

reduced

a full track

of the

connect

71/z

playback

R), while

parallel

recorded

play-

in normal

appears

(4

mils). lf

(C)

fig.

parallel

ips,

by

to

4.1

5.3 Bias Head

5.3.1. Vertlcal

Move

the operating lever slowly to

forward

fronts

necessary, bend

required.

5.3.2 Height

Set the tape

unscrew

Connect a VTVM

halves.

adjustment screw

on the voltpeter.

the

is

the

position

clearance

plate

bias head slightly.

5.3.3 Horlzontal Adjustment

Connect a

fig.

Then

screwdriver towards the

voltage

maximum.

,

of

groove

sufficient clearance between the

mounting

for the

head-halves,

recording. Insert a

4.1, and

pull

side until

maximum. When

tighten

horizontal

output voltage.

the

horizontal

Adjustment

position

drive

bias-

and record heads are

Adjustment

recorder

locking

the

the

Move

in lront

plate

the bias head is not critical, and if the

of

between

record

VTVM

and set the

pull

the

bias head carefully

(bias)

the screw

in recording head increases to a

Continue

the

bias is reduced by 10-150/o below

position

lf

procedure

normal

the

and check that the head

the arm of the bias

stereo

in

screw

across each one of the record

bias head

(M)

for the

Check that

of the

for

the

the bias head and

head is insufficient, raise the

across

the bias head to the right.

the

of the head.

a noticeable change has

each

screwdriver

pulling

position

(H)

while

has

record mode,

(H)

fig.

4.1, about

up

or down by

highest

the

tape runs

bias head

record head. The height

one of the

tape recorder for stereo

in

left

hand side. lnduced

the

head towards

has

maintaining correct

Then

to be repeated.

parallel.

head

means

possible

that there

and

head and

bias

mounting

the

groove

means of the

by

been

recheck

r/z

reading

freely

occured,

as

and

turn.

head

of

in

record

l,

ref.

left

found,

the

ll

Height

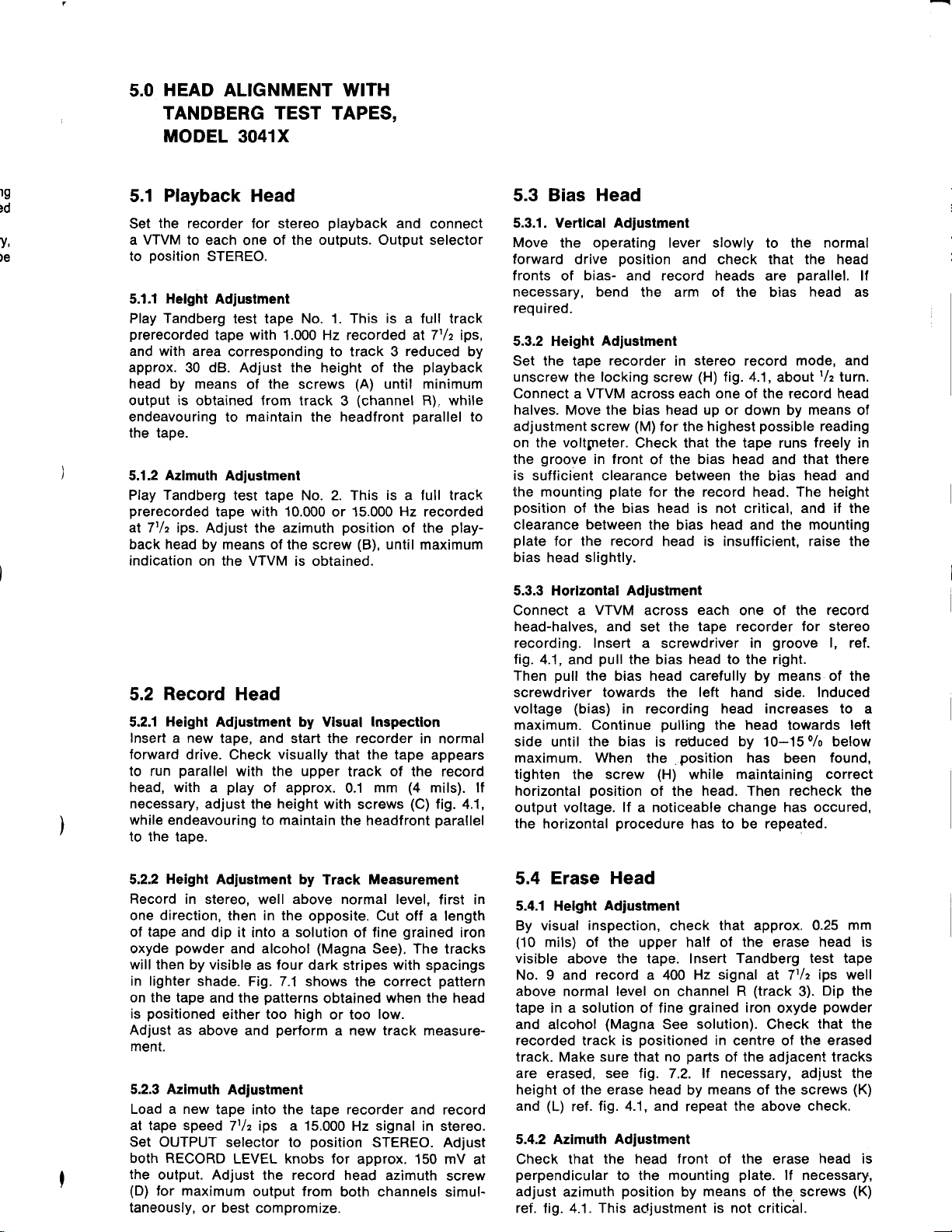

5.2.2

Record

direction,

one

of tape

oxyde

will then

in

lighter shade. Fig.7.1

on

the

positioned

is

Adjust as above

ment.

5.2.3 Azimuth

Load a new

at tape speed

Set OUTPUT

RECORD

both

the

output.

(D)

for

taneously,

Adjustment

in stereo,

then in the

and

dip it

powder

by visible

tape

maximum

or best compromize.

into

and alcohol

and the

either

and

Adjustment

tape into the tape recorder

7tl2 ips a 15.000

selector to

LEVEL knobs for

Adjust

by Track Measurement

above normal level,

well

opposite. Cut off a length

a solution

four

as

shows the correct

patterns

too high

perform

the record head

output from

of

(Magna

dark stripes

obtained

or too

new track measure-

a

Hz

position

approx. 150 mV

both channels simul-

first in

grained

fine

See). The tracks

with

when the

low.

and record

signal

STEREO. Adjust

azimuth

iron

spacings

pattern

head

in stereo.

at

screw

Erase Head

5.4

5.4.1 Helght

By visual

(10

mils) of the upper half of

visible

No. 9 and record a 400 Hz

above normal

tape in a solution of fine

and alcohol

recorded

track.

are

erased,

height

(L)

and

5.4.2 Azlmuth

Check that

perpendicular

adjust

ref.

fig. 4.1.

Adjustment

inspection,

above the tape. Insert

level

(Magna

is

track

sure that no

Make

see fig. 7.2. lt necessary,

of the erase

fig.4.1, and

ref.

Adjustment

the head

to the

azimuth

position

This

check

on channel

grained

solution).

See

positioned

parts

head

by

repeat

front

mounting

by

adjustment

that

approx.

the

erase

Tandberg test tape

signal

in

means

ol the

means

is not

at 7tlz

(track

R

iron

oxyde

Check

centre of the

the

of

adjacent

of the screws

the

above

erase

plate.

lf

of the. screws

critical.

0.25 mm

head is

ips well

Dip the

3).

powder

that the

erased

tracks

check.

head

the

(K)

is

(K)

adjust

necessary,

Page 12

<

5.5 Model 3021X

The

alignments

the model

5.1.1, which is superseded

5.2.1 , which is superseded

HEAD ALIGNMENT

6.0

TANDBERG

specified in

3021X with the exception of

TEST TAPES,

para.

by 6.1.1 and

7.2.2.

by

WITHOUT

MODEL 3041X

6.1 Playback

6.1.1 Helght Alignment

The

height of the

height

adjustment

edge of the tape shall run

of the

6.1.2 Azimuth Alignment

Set OUTPUT selector to

Play

a VTVM connected to each output.

tion

screw

obtained on the output meters.

head

back a standard

playback

the

of

(B)

Head

playback

screws

lamination

fig.

ref.

(A), ref.

flush with the

for channel

position

azimuth

head

by

4.1,

until

head is aligned by

fig.

alignment tape with

the

azimuth

maximum reading is

valid

are

5.0

paragraph

paragraph

4.1. The upper

upper

L.

STEREO.

Adjust the

adjustment

for

the

part

posi-

7.0 TRACK

7.1 Model

7.1.1 Record Head

Record a

optimum

1 and 3 for

make a

the tape

iron oxyde

to

the recorded

across the tape, ref.

position,

alignment.

7.'1.2 Erase Head

lnsert a

1.000 Hz

recording level in mono

the tape

Check

of

position

similar

make

signal

that

the erased area,

of the erase head

CONTROL

3041X

Hz

1.000

recording

and

powder

the

if necessary, and recheck the

full-track

and

signal from

level

approx. 5 seconds. Turn the tape and

recording

dip it

into

and

recording visible.

tracks

the

should

prerecorded

from

dip it

generator,

a

into

prerecorded

ref.

generator

a

in stereo. Record

on tracks 4 and 2. Cut

a mixture

alcohol

be

7.1.

fig.

track

on

the

1i9.7.2.

if

(Magna

The spaces between

distributed equidistant

Readjust the height

tape

well above

Magna

track

necessary.

fine

of

See

and record a

(channel

3

See

is in the centre

Adjust the

above

well

tracks

on

grained

solution)

azimuth

optimum

R). Cut

solution.

vertical

Record Head

6.2

Follow

6.3

Follow

6.4

6.4.1

The height of the erase

adjustment screws

0.25

track of

tape.

6.4.2

Align the azimuth

azimuth

should

heads.

critical.

6.5

The alignments

for

which is superseded

seded by 7.2.2.

7.2.1.

the instructions

Bias Head

the instructions

Erase

Helght Adjustment

mm

Azimuth Adjustment

Head

(10

mils) of

the

erase

adjustment

parallel

be

The

azimuth

head

position

with the

Model 3021X

specified in

model

with the exception of

3021X

Paragraph 6.4.1 is superseded by

(K

the

screws

position

by

given

under

given

under

head is aligned by the height

L) ref. fig. 4.1. Approx.

and

lerrite

should

the

of

(K).

mounting

of

paragraph

Paragraph 5.2.1

5.2.

paragraph

paragraph

for the

core

be visible

erase

The erase head

the

erase

above

head

plate

head is not

6.0 are

paragraph

5.2.

5.3.

upper

the

by the

for the

valid

6.2

is super-

Too high. Too

Correct

Fig.

Fig. 7.2. Track

7.1 .

Too

high.

Cotrect

Track

measurement

measurement

record head.

of

ol erase head.

Too

low.

low.

Page 13

te

(s

td

Tt

rd

t)

rn

It

It

h

2

n

t

t.

I

I

7.1.3

Playback

Record a 1.000 Hz signal on

a 500 Hz signal on

optimum recording

position

back track 2

Raise the

heard. Lower the

is heard. Recheck

Head

STEREO.

(channel

playback

playback

track

track

levels. Set OUTPUT selector

Turn the tape around

head

the azimuth

(channel

3

R).

No signal should

if the

head if the 500 Hz signal

R) well

1.000 Hz signal is

position.

L) and

above

and

be heard.

(channel

1

to

play

7.2 Model 3021X

7.2.1 Erase Head

The height of the erase

adjustment screws

a 1.000 Hz

recording level

the tape in the Magna See solution and check

the tracks are distributed symmetrically across

Readjust

tape.

necessary.

7.2.2 Record Head

The height

height

signal in

on a full-track

Magna See solution and

distributed symmetrically across the tape. Readlust

the erase and the record heads. if necessarv.

7.2.3 Playback Head

The

height of the

height adjustment screws

parallel

channel L. Readjust the azimuth

signal

a full-track

on

the erase and

of the

adjustment screws

stereo

with

record head is aligned

well

prerecorded

playback

the upper

8.0 ADJUSTMENT

THE

OF

8.1.1 Playback Level Adjustment

Connect a VTVM

OUTPUT

recorder lor 7t/z

No. 4 and adjust R451

reading

on both vacuum tube voltmeters.

AMPLIFIERS

to each one of the outputs, and set

selector to

ips

head is aligned by the

(K

and L) ref. fig. 4.1. Record

in stereo well above optimum

above

playback

prerecorded

the record heads, if

(C).

Record a 1.000 Hz

optimum recording level

tape. Dip the tape in

check

edge

AND

position

(L)

that the tracks are

head is aligned by the

(A).

The

the lamination for

of

position

CONTROL

STEREO. Set the

Tandberg

of

and R351

tape. Dip

tape shall

if necessary.

(R)

that

the

the

by

run

test tape

for

0.7

mum deflection

maximum on right channel

Note: The 2-lrack

individually

The values ot C5O2, C503, C515 and C516 are

labelled on the bias- and erase

tively. The capacitances are

Upper number

8.1.3 Record/Playback

Connect

a new tape and record a

rator at

tion SOURCE. Adjust the

indication of 0,7

for a 0 dB reading on

R333 for

OUTPUT selector to

R451

8.1.4

Ref.

curves.

8.1.5 Dlstortion

Connect signal

and distortion

both channels. OUTPUT

Set the tape

Record Level

cators. Check

distortion exceeds 30/o

indicator, ref.

8.1.6 Control of

Connect

selector to

Play back

prerecorded

250-10.000-5.000-1.000-100-50-250

at

N. A. B.

0-

quencies

in level between the two channels

than 3 dB.

V

a VTVM to each one of the outputs.

7t/z

(L)

Record/Playback Curves

paragraph

a VTVM to each one of

71/z ips tape speed.

standard.

+ 4 dB, 5 kHz - 1

on left channel VTVM, and R502 to

model is also equipped with

tuned bias- and erase

refers to upper track.

Level

400 Hz

A-test.

ips in

volt

the same

and R351

9.0

generator,

meter to outputs.

recorder for stereo

controls

distortion to be

paragraph

Playback

position

Tandberg

tape with the following

The output tolerances

have tolerances

OUTPUT

both

at

left record level indicator and

reading on right indicator. Set

position

(R)

to 0,7

for

control

400 Hz 0.5

selector to

to 0 dB deflection

readjust recording level and

8.1.3.

STEREO.

test

The

-

VTVM.

heads.

heads

respec-

given

Adjustment

from a

signal

selector to

input levels for a VTVM

outputs.

STEREO and adjust

V indication

of record/playback

Record in B-test

Amplifier

the outputs. OUTPUT

No. 3. This is a

tape conforms

+

3dB.

t

2 dB. The difference

Adjust

V, to High Input

position

recording. Adjust

less

than 3

frequencies:

Hz recorded

are: 10 kHz:

The

should be less

pF.

in

Insert

gene-

posi-

R433

VTVM.

on

STEREO.

on indi-

0/0.

full

track

with the

fre-

other

on

lf

8.1.2 Adjustment

Insert

a new reel

Connect a VTVM

generator

generator

selector to STEREO. Set the tape recorder for

stereo recording. Adjust the Record Level

to 75 mV

to HIGH Input terminals and set the

for 1.000 Hz

deflection on VTVM. Adiust

Bias

of

good

of

to Output

Current

quality

terminals, and signal

0.5 volt.

and

tape

(Low

R501

Set

Control

to maxi-

Noise).

output

Tape Speed Control

8.2

Using Frequency

8.2.1

Set OUTPUT selector

Connect a frequency

play

and

at

speed is indicated in

7tlz ips

back Tandberg

tape speed.

Meter

or Counter

position

to

meter

test tape No. 11

Difference from

0/0.

Tolerance:

L.

counter to

or

correct

-r-

1,50/0.

Output

(1.000

tape

L

Hz)

Page 14

Uslng

8.2.2

Connect

Translormer

a transformer

Hz and a WVM to

fig.

in

8.1,

dotted

version.

Tandberg test tape

back

Hz)

50

tape

ips

OUTPUT selector to

Set

19

No.

or

speed.

and Vacuum

115/0.S V

Output

and the

line indicates

No.

10 a

(mains

a

frequency 60

or

phono

Deviation from correct tape speed

across the VTVM.

Clock

the time

for

complete

10

meter needle.

Read the speed deviation in

to this

particular

time from the nomogram in

per

cent corresponding

Brake left hand turntable slightly

speed is too high

indicates too

At 33/r ips,

low

play

Tandberg test

or

tape

low.

too

speed.

Increased deviation

tape

mains frequency). Proceed as for

speed accuracy.

Speed tolerance: + 1,50/0.

v.T.v.M

Tube Voltmeter

230/0.5

mains

socket on

position

(mains

50i60

V,

as shown

US-

Play

L.

frequency

Hz) al 71/z

give

will

excursions

a beat

of the

fig. 8.2.

to decide if tape

No. 10 b

(50

71/z ips to tind

check

Perform

position.

current by means

for

channel R.

lf

the voltage is

frequency

voltage

and

the

16.000

met,

tween

-+

2 dB from reference level.

Perform

between

lor

400

Hz

The

any

the

that

output voltage is

fine adjustment

lf the voltage

of

to 1.000

means

by

Hz

of

R respectively.

reference level.

Hz. When the

check that

50

the

40

17/a

ips

the output level at frequencies

16.000 Hz

and

same

and

20.000

between

Hz.

output

levels

of the

frequency differ

within

)-

2

dB.

of record head azimuth

is too high,

R501

for

channel L and R502

low,

too

and

R501

Then

alter the input signal

adjust for maximum

and

go

back to 400

and recheck the

tolerance at 16.000

increase

R502 for

output

bias

output

channels L

Hz, establish

level

at

has

Hz

been

be-

do not deviate more than

check for 7tlz ips at freguencies

Hz,

and then finally check

50 and

two

more

by

channels should not at

than 3 dB.

Hz. Ref. level

9.000

9.3

Cc

thr

a

Sh

Se

ler

do

on

on

ac

9(

|.uuo

,oo

,,

Fig. 8.1

3.0 2,5

+d1l!l-,t,,,

8.2.3 Using

Insert a tape

play

it back. Time taken for the whole length should

2p

r,5

r,0

|

'

15

20 25 30 r0

Fig. 8.2.

of Known Length

Tape

of known length

oulSu

'

0,5

| I lSpeeddevioiion{'/.)

tl

0,1

I-I-IJ

50 60 66

450"

0,3

(1

Time

for

excursions.

144

be:

71lz

ips: 60 seconds

331 ips:

17la

Tolerance for

RECORD/PLAYBACK

9.0

Connect a WVM

R. ln

order to

voltage, a

kHz must be inserted between

85.5

voltmeters.

the

the

Set

in

ips

Tape a

optimum

120

seconds

ips: 240 seconds

all tape

to each one of the outputs L and

avoid interlerence from the

stop or

band

recorder

tape

400

(0

(STEREO)

signal

Hz

dB).

at a

Use the output VTVM readings as

B-test

speeds: + 1,50/0.

CURVES

pass

a low

stereo recording al 33/t

for

and record on Low Noise

recording

filter

the

level

outputs

30 dB

reference levels.

Then record a

16.000

Hz signal at the

same level and

in

sonds

l0

complete

cm) and

oscillator

tuned to

and

below

9.1 Readjustment

Record/Playback

of

level

For

readjustments

paragraph

8.1.3.

Record/Playback

of

level ref.

9.2 Distortion

paragraph

Ref.

for adjustment

8.1.5

and control

distortion.

9.3 Control of Playback and Record

Amplifiers

lf the

specified tolerances for

are

exceeded, check the

amplifiers.

9.3.1 Playback Amplifier

lnsert

a 22 ohm resistor in series with

junction

and

Connect a signal

resistor

see

Connect

output

correct

the

and a 100

fig.

9.'1.

also

selector to

signal

generator

below 0.75

(59).

52

generator

pF

VTVM

response,

to 400

V,

i.e. 75 mV.

capacitor and

to each

position

Hz and adiust the

response according to

tig.

frequency

playback

response

and record

playback

in series with a 1

playback

the outputs and set

of

STEREO.

To ensure

apply oscilloscope.

level

Check the frequency

9.2.

20 dB

of

head

kohm

head,

Tune

Page 15

t-

Record

9.3.2

Connect

the

record

a signal

Amplilier

a VTVM

head

to a

and

generator

100

ohm resistor in series

ground

to

as shown in fig.

HIGH Input

Shortcircuit trimming capacitor

Set

level30

down

on

on VTVM deflection.

according to tig.

tape recorder for stereo

the

dB below 0 dB indicator

by

means of

signal

generator,

Record

and use 400 Hz as reference

Check the frequency response

Remove

9.4.

Level

Controls, 20 dB down

shortcircuit of C508.

Signol

generqtor

Fig.

9.1

with

9.3 and

for each channel.

C508 in oscillator.

recording. Set the

deflection i.e. 10 dB

(o105)

(s9)

s2

R332

Fig.

(R132)

VTVM

9.3.

Components connected

ott

tope speeds

-

Q

- Ttlz ips

a

33/1

ips

-

O

t7l8

ips

-

ot:

Fig.

9.2. Playback

ctJrves.

Page 16

10

dB

26

2t,

22

20

t8

to

11

12

10

10

r

I

Th,

acr

111

w1

m(

ilr

50

60

WI

|'

o

1

L

I

0

500

1000

2000

s000

10000

Components

-

Q

-

O

-

O

dB

6

t,

2

0

6

L

2

0

6

tope speeds

olt

ips

33ii

l7l8 ips

connected

R426

c413.

c 4t6, c417,

c4r5,

qt

Fig.

9.4.

Record

curves.

c414,

R

R430

R429

'2

t,

0

20Hz

50

Fig.9.5

lO0 2m

lrequency

Total

5OO

response

IOOO

tolerances

2000

according

5000

to

DIN

t0000

45511'

20000

Page 17

a--

10.0 MoDtFrcATtoNs

10.1

Modification

from 1 15/130/230/240V.

50/60 Hz Operation

The

transformer and

according

115/130/230/240 V

When modifying from 50 to 60 Hz or

motor

Motor

50 Hz operation,

Hz operation,

60

When ordering motor

to

pulley

pulley:

o---{

50Hz

240V

figures below

has to

part

part

motor must be rewired

when

operation.

be changed.

number: 243940C

number: 248351

pulley,

specify

changing from

vice

B

part

versa,

number.

the

10.2 Modification

to Two-Track

The following components have to be changed when

modifying from lour-track to two-track.

Value of

heads.

Part

Record

Record

Playback

Erase Head

Erase Head

Bias

R432

R332

c515

c516

c502

c503

*

--

total

capacitance is

Head

Head

Head

Head

Valid

on models below serial

Valid

models above

on

from Four-Track

Version

labelled' on

c04-11R"

F53-11 R*.

c03-10P

D84-18EG51-18E..

D90-038

5,6kohm

5,6kohm

250pF

250pF

3300pF

3300pF

serial

two-track

Two-track

F82-07R

F82-07R

F83-1 1 P

D87-20E

D87-20E

D92-048

2,7kohm

2,7kohm

capacitance

lAdd

(until

labelled

(capacitance

is

obtained

J

No.

2733300

No.

2733300

----l

go

L----

1l5V 50Hz

Hz

l30V 50

Fig. 10.1 . Motor

and translormer

11.0 LUBRICATION

The

Motor:

The

motor should be

every 3000

The

upper and the

with a

hours

Teresso

lubricated after approximately

of use.

lower

bearing should

43

oil

or 47

connections.

from Esso.

be

lubricated

10.3

Componenl

in

Series

Transistor

O

to

BC107B.

2.2 kohm to 1 kohm.

introduced from

R116 and R216 are changed from 1 kohm to

O

220

6800

duced from serial number 2744100.

The

Sell

The turntables,

wheel are mounted in self lubricating bearings

should usually

should be necessary

any reason, use Teresso

Note:

Utmost

Use

bearing. Excessive

the triction drive.

Q503

ohm. C109 and C209 are

pF

lo O,O22

Lubricating Bearings:

care must be taken while lubricating.

only

Modification

3000X

is changed from

Resistor R505 is

Both

number 2741500.

serial

pF.

Both modifications

flywheel and

the

not be

one

lubricated.

lubricate the

to

43

oil

fractional

might

oil

drop of oil for each

type BC147B

changed from

modifications

changed from

are intro-

the speed transfer-

lf, however, it

bearings

47

or

from Esso.

seriously affect

are

and

for

Page 18

-

ILLUSTRATIONS

12.0

REFERENCE

264248 261655

264435

261303

264786

274535

2633

WITH

PART NUMBERS

991038

260?00

261 655

I

I

t

991

039

263688

262322

269255

272854

260641

268

277523

262984

264665

VEBT.

-r'

MOIjNT.

262M4 TEAK

264564 ROSEWOOD

269??2 WALNUT

262984

264665 VERT.

12.1

Fig.

MOLJNT.

Page 19

.

991 033

261841

991008.

21 9816

26 0361A

991

01 0

264083A

261805A'

26 1 841

991 034

21

9816

991035

991

009

20a013------.-*<5

Fig. 12.2.

-r-

?-N

16l

Supply

turntable.

2r8767

204013---_____________

/-

t'6t

,,@),

\=Z

Fig.

12.3. Take

=,

-T'

up turntable.

--

215053

Page 20

EI

204013

214895

990334

214895

204013

266791

266 08

7A

247941

235420

236045

210622

214270

$-,,nn,u

$-z4s'\so

25

2L

25rl

99

25

26

2(

25

21

207977

Fig. 12.4.

229565

2622s8

Pressure roller

263939 202r5r

arm, assembly.

207977

267768 202309

24.13124

260577

24

261

991406

0948

COMPLETE

265 06 0A

263 932A

Fig. 12.5.

Upper mounting

plate

seen lrom

underneath

Page 21

254844

D84-188

D90_03U

"/

C0.1_l1R

990233

262481

240267A

264762

260290

243

013

242503

990334

26506

268422

273407

266797

0A

EU

VERS.229565

LTS.

VERS.

249630

IANOB€iC

IA'€

rcm!

vorrs

FiEO

TAilDSEftes

Fig.

R€COiOER

3a.r

;3r:

r;

.ii\

irtl.O

:6ri\2?

991 028

12.6.

r

.

ai

RAOlOraEpt{{

:u3trir

I

261460

path

Tape

and

aaIooaaa

{:aoa

L'i.-:

L

(]

a

ar5

:c't,tl

|

2?3939

ptessure

rruoc

I

230183

roller

zt,cqsg

I

269801A

arm

zegqtz

rEF

RIGHT

LINE

zacjz:o

I

'{PUTS

{O

21i7416

I

q

,l

274762

269

?86

Fig.

12.7. Rear

European

version

Page 22

-

9911

O

T^N08eRe

TAPT

R€COqO€R

tooEl

volls

FiEO

.

i9i9.i

oaaaaaaa

Jar;r

I

{

tr'

ia

SC

268221 2619704

Fig.

991402 264996

oaao

OO

12.8.

Rear view. U.S.

f

o

o

I

L_}R

}IORMAL

R+R

991046 260620A 2657354

o

o

269902

version.

990:

991i

991i

2701

2651

260r

20L

212036

269902

Fig. 12.9.

252715 252496

Bottom view.

241009 236159A 2490688

264578

262739

263888

211339

?395

260289

254779

2e

Zl

Page 23

991 041

2483518 (60

243940C

(50

99033019910431242331

Hz)

Hz)

262969

262854

990204

2649?3

991008

991 014

99101

270821

265096

260045

20L95

R 108

R

208 211418

Fig

12.10.

264054

Top

26630e

view with

covers

removed

267476

249630

I 034

9903 12

I 014

991 013

240276A

266741

264270

263709

273134

263932

265 060A

268422

2605L2

263601A

991 014

262L93.

991 01

224795

25952

26 1 051

R 108

Fig

991 4

12.1

2605L2

1920

991 014

013

r 015

023

9529

1031

1030

101?

00

1

99t402

Top

264996

view with

upper

990312

mounting

plate

266238

removed

249630

Page 24

-

Part

13.0 SPARE

numbers of

The

identical with

figures

on

available

as spare

PARTS

the mechanical

part

the

without existing

parts

13.1 Mechanical

ffin

'rl-l

for

201957

2A2008

202151

202309

203250

204013

207977

208724

209306

210622

2'11339

211418

212036

21 2066

214270

214895

215053

216734

218767

219234

21 981 6

224795

229565

230183

2306298

234478

234960

235420

236045

236159A

240276A.

240406F'

2408794

241009

242331

242503

243013

243150

243940C

243990

Shaft

Mains cable.

Microswitch RX1

for eccentric

Shaft

Mains cable,

Washer, 7,5

Delrin roller for

segment

Clamp

Spring

Adjustment screw

3X18mm

Pulley for revolution

Shaft

pad

Holder for operating

Nut for mounting of cabinet

Screw

pressure

Washer, 7,5

Pulley for turntable

Spring

Nut for turntable shaft

Shaft

Flange for turntable

Support

DIN-connector

Shield

Roller

Spring for

Washer, speed

Shaft

Adj.

Clamp

Screw

Spring

adjustment

Bracket

Motor 110/220 V

Spring for cam disc

Tape feeler

Tape

Spring for tape feeler, end stop

for mains cable

for lever operating

arm

for adj.

for

for

for

for

plate

for end stop

guide,

Delrin

arm

pulley,

Motor

nrechanism

LIST FOR SERIES 3OOOX

parts

on figures are Ordering

in the

alone.

in store. Part shown

parts

list are not

numbers

Parts

pressure pad

115 V. 7FT

230 V 2?-O

x

4,2 X 0,5 mm

indexing eccent.

for transfer wheel arm

plate,

roller

x

4,2

for cam disc

pressure

for

PW board

for microphone

playback

speed

bias head adjustment

selector knob.

start/stop

for spring,

for supporting

for record-playback head

for transfer wire

for

end stop

right

for

bias

50 Hz

arm

for

for bias head,

x

roller arm assy.

selector arm

stop

end

segment

cm w/olrrq

counter

press

lever ball

spring

mm turbax

0,3

housing L&R

head

lever

pressure

motor.

lever

arm

mechanism

head adj.

rol

When

the appropriate

rence in this manual, be specified.

For ordering of electrical components,

position

Note: lf modifications

lFig.Ref.

12.10

12.8

12.5

12.5

12.7

12.2, 12.3, 12.4

12.4. 12.5

12.4

12.9

12.10

12.9

12.4

12.4

12.3

12.2

12.6

12.2, 12.3

12.11

12.5, 12.6

12.6

12.7,

12.8

12.4

12.1

12.4

4.2, 12.4

12.9

12.6, 12j0

12.9

12.10

12.6

12.6

12.4

12.10

2.12. 12.5

of Parts

ordering a

number

from a certain serial

must be

mechanical

part

number being used

must

be used.

according

specified.

ltot""

part,

it is essential that

however, the

to list are

number, this

as a refe-

introduced

number

2443

246,2

2473

2479

zffi

2481

2&

249(

24fi

%11

2511

2521

252.

252l

2521,

zil|.

2il,

2il

257.

259

259

259

260

260

260

260

26C

260

26(

26(

26(

26(

26(

26(

26(

26'

26

26

26

26

26

2C

2e

2(

2l

21

2l

2r

2l

2

2

2

z

a

I

a

a

Page 25

Part

No.

Description

244342A

246231

247395

247941

248027

248157

248351

2490688

249630

251 1

30

2514894

252115

252172

252496

252754

254025

254779

254844A

257517

259529

259758

259773

260045

260289

260290

26A325

260361A

2605'12

260577

m0620A

260641

260700

260735

260929

260965

261051

2610948

261216

261303

261460

261525

261

655

261805A

26'1841

261885

261920

261970A

261992

262021

262064

2621938

Clamp

Clip

Shaft for

Insulator

Bushing

B

Motor

Box for

Connector

head

Lever

Tape

Equalization

Lower

Clamp,

Tape

Pressure

Power

Support

Drive

Lamp

Phono

Bracket

Instrument,

leuel

Side

Tape

Contact

Tape

Spring,

Bearing

Front

Knob

Knob

Tape

Rear

Spring for

Socket

Index

Adj.

levers

Screw,

plate

Button

Stud

Screw,

rear

Coil

Coil

levers

Screw

Arm,

Bottom

Thrust

Arm,

Teak

Mylar

Lever for

for

9 mm (3/e")

pulley,

set

for

support,

bearing

link,

guide,

transformer

for

belt

for

connector

for

indicator

plate,

support,

spring

tightening

brake

for

panel

for

for

guide,

cover

for

guide

screw

3

for

for

lifting

japanned,

cover

spring

spring

for

brake

cover

disc

bias

cabinet

slide

end stop

end

pressure

for

for

motor

for microphone

pressure

pad

pressure

for

counter

fastening

record

right

flutter

operating

cueing

not

plate

cueing

lamp,

for

for

X

10

recording

plate

for

for

feeler

right,

for

head

plate

switch

stop

swiich

for

vrires

roller

end

stop

adj.

of tape

60 Hz

pad

left

switch

for

flywheel

equal.

adjustable

switch

arm

counter

and

meter

for

input

and

right

disc left

lever

left

filter

lever

control

adjustable

control

indicator

operating

clutch-

mm

for

left

arm

X

3

left

friction

clutch-

arm,

end

acetal

flywheel

swiich

guide

arm

pad

& tape

24 V

board

input

playback

and right

arm

arm

lever

and

front

channel

10

mm

disc

and

stop

bearing

wires

and

1

board

br

cover

brake

'12.5

12.5

12.9

4.2,

12.4

12.5

12.1A

12.9

12.6,

12.10,

12.6

2.7,

2.9,

12.9

12.9

2.7,

2.9,

2.7,

2.8,

12.9

2.7,

2.9,

12.9

12.11

12.7,

12.8

12.10

12.9

12.6

2.5,

12.2

12.11

12.4

12.9

12.1

12.1

12.6

't2.1

12.11

12.5

12.1

12.6

12.1

2.5, 12.2

2.1,

12.2,

12.11

12.8

12.6

12.1

12.11

12.6

12.6

2.9,

12.6

12.3

12.11

2.10,

12.6

262258

262322

262402

262416

262481

262509

Flutter

Knob

for

Contact

holder

Shaft

for

Tape

braking

Shield

for

filter

roller

speed

spring

start/stop

indicator

selector

for

arm,

counter

knob

start/stop

12.4

12.1

lamp

12.6

Page 26

Part

No.

Description

Fig.

Rel.

E

t1'

262545

262732

262739

262854

262969

262984

263077

2631

05A

263278

263393

263443

263493A

263522A

263601A

263688

263709

263874

263888

263932A

264003

264054

264075

264083A

264162

264226

264248

264270

264420

264435

264564

264578

264593

264665

264786

264830

264865

264866

264909

264930

2e/,973

264996

265060A

265096

2651464

265735A

266072

266087A

266238

266309

266439

266540

266741

266791

266827

2673738

267416

267768

268062

268120

268221

268422

Holder

spring

Grommet

Lower

Speed

Bracket

Screw

Spring

Upper

Bracket

Button

select.

Bracket

Button

Upper

Arm,

Screw

cover

Button

Bushing

Power

Guide for

Side

Spring

Spring for

Bushing

Rubber

Guide

Button,

Revolution

Sleeve for

Felt

Rosewood

Bracket

Bushing

Screw for vertical

Upper

Rubber

Terminal

board

Spring for tape

Post

Bracket

Reinforcing

Function

Guide arm,

Tape

Rubber

Transistor

Loose

Spring for

Output switch

Sleeve

Lever for instantaneous

mechanism

Rear

Arm for

Fork for instantaneous

mechanism

Guide

Coil

Spring

Eccentric

Spring for

Bracket

Rear

Spring for end

for

speed

selector

for

mains

spring

selector

lor

speed

5/e"

lor

for tape

plate,

side

power

for

for start/stop

switch

for flywheel

for

recording

spring

brake left,

3 X 8

plate

plate,

ring for

lor

guide,

cover

panel,

plate

spring for

panel,

mm c.sunk

power

for

for

operating

switch

power

left

for bias

clutch,

for

friction

tape

brake

for slide

volume

counter

slide

volume

cabinet

for

operating lever

for

operating

plate,

side

foot

for vertical

plug

pressure

for

turntable brake

plate

switch

end

left

snap

lock for

cooling

plate

pressure

for end stop

European version

end stop mechanism

for

for inst.

segment

pressure

for instantaneous

US

cable

for

operating

arm

selector

cabinet

tightening

right

switch

bearing

right

for operating

acetal

switch

without

switch

head

take

disc

arm

arm damping

knob

mount.

left

pin,

7

brake

roller arm

for rear corners

stop

fin

for

roller

lever

push

right friction

start/stop arm.

pad

version

stop

and function

lever

button

button

arm

up tu

lever index

mount.

main ampl.

arm

reel

rear connect.

start-stop

buttons

arm

arm

lever

disc

channel

lever

for

rear

spr

star:t/sto

disc

arm

start/

12.9

12.10

12.10

12.1

12.2

12.1

12.1

'12.11

12.1

12.10

12.9

12.5,

12.10

12.10

12.3

2.1,

12.2,

't2.6

12.1

12.10

12.1

12.1

12.9

12.1

12.1

12.6

2.6

12.10

12.9,

12.11

't2.5,

12.6,

12.10

12.9

'12.'l

4.2, 12.4

12.6,

12j1

12.10

12.7

2.12, 12.10

12.4,

12.6

12.6

',12.3

2.1,

12.6, 12.10

12.5

2.8,

2.7,

12.8

12.6.

2.9, 2.10,

12.10

12.3

12.10

12.6

Vafid

below ser.no.

Valid

below

Valid

below ser.no.

2741076

ser.no. 2741076

2741076

2f,f!i7

26897

269G

2@11

26925

26944

2@n

2@78

2S80

26990

nw

27M2

27?fF/

27245

27513

273/fi

27355

27390

27416

27418

n45fr

2n52

s902(

99021

9002!

99GT

99(xl1

9903'

gSGX

99@(

99@

9910(

9910(

901q

99101

9910'

9910'

9910'

9910'

s910

9910

9910

9910

9910

9910

9010

9910

9910

9910

991C

991C

991(

991(

991(

991(

991(

991(

9911

9911

991,

991,

991,

991

991

Page 27

Part No.

268472

268975

269097

?59112

269255

269449

269772

269786

269801A

269902

27A469

270821

272050

272854

273134

273/;07

273559

273939

274162

274183

274535

277523

990204

990213

990233

990305

990812

990325

990330

990334

990346

991006

991007

991008

991009

991010

991013

991014

991015

991017

991018

99't021

991022

991023

991024

991025

991026

991027

991028

991030

991031

991033

991034

991035

991038

991039

99't041

991042

991046

991400

991401

991402

991404

991406

Description

Arm

for instantaneous

Front

cover

plate

Strap for transfer wire

Rubber

Screw for cover bracket

Bracket

Walnut

Bracket

Shaft

Sound

Shaft

Rear

Stop

Right

Power

Spring for fork,

Window

Return

DIN-connector

Spring

Left

Front

Parallel

Holder

Transfer

Arm

Flywheel

Pressure

Lifting

Pressure roller

Bracket

Front

Rear tape

Supply turntable

Right

Left

R &

R

Releasing

Arm

Cueing

Left

Right

Flywheel

Thrust

Housing

Vertical

Upper

Record

foot

PW-board

cabinet

for fastening rear cover

inst. start/stop lever

for

on Sound

for cover

bracket

bracket

bracket for cover interlock

switch

switch

interlock