DATA SHEET

DOC NO. 06-xxx 01

S1500 / S1501 Reader

User programmable Read/Write station

Copyright

The copyright/ownership of this document is and will remain ours. The document must not be used without our authorization or brought to the knowledge of a third party. TagMaster AB.

Disclaimer

The information in this document is subject to change without notice. While the information contained herein is assumed to be accurate, TagMaster AB assumes no responsibility for any errors

or omissions.

TagMaster AB S1500 / S1501 Reader Data Sheet Issue 01

R

M

R

E

D

M

Functional description

S1500 readers are a 2.45 GHz circular polarised

read/write station for TagMaster RFID tags.

Reading distance is typically up to 6 metres. The

reader has 99 RF channels to eliminate

interference of other nearby readers. Transmitted

power and reception sensitivity is also adjustable

with SW commands for optimising any

installation.

S1500 has a movement detection function for

detecting people and vehicles, or even smaller

objects, even if not using a tag. It can determine

their moving speed in approaching or retreating

directions.

S1500 is user programmable and has a large

memory for application programs and built in

database functions for fast, customised and

efficient stand-alone operation. User software is

downloaded and saved in EEPROM through a

serial communication line. If user programming is

not required, there is a ready-to-use standard

application SW in the reader.

A local database in EEPROM can be loaded with

over 15,000 tag entries for extremely fast readvalidate-activate response times.

The ConfiTalk protocol is used for serial

communication in a polled RS485 network or

point-to-point in RS232 connections. There are

ConfiTalk communication drivers available for

95/98/ME and NT/2000/XP with interface for

C/C++, Delphi and Visual Basic.

S1500 has two serial ports, a DTMF port for

keypads, LED interfaces, relay, parallel I/O

(emulating magcard data as an option).

A control panel with a 7-segment LED display,

two push buttons, a three colour LED, a buzzer

and a reset button is available for local

configuration and start up of test programs as

installation aids. The unit can also be configured

using a hand held computer or terminal

connected locally.

S1500 is sealed from water spray and dust. Noncorrosive materials are used in external parts.

Connections are made through rubber bushings,

or via cable glands in a steel back plane.

Jackable screw connectors connect the wires.

Built in DC/DC converters tolerate noisy voltages,

provide low power consumption (3W) and can be

set to 24 as well as 12 V

DC

6 m reading range

ange/channel setting by SW

Tag programming

ovement detection at up to 5 m

3-colour LED and buzzer

DC supply

User programmable

C, Delphi and VB drivers

Flash EEPROM database

TMF and LED interface

aintenance functions

Radiated 2.45 GHz signal

Microwave/Antenna block

Processor block

I/O block

RS 232a

RS 232b

RS 485

DTMF/LED

Relay

Opto I/O

S232 and 2/4 wire RS485

3 parallel in, 2 parallel out

optoisolated. Relay and

tamper switches

MI tolerant DC/DC conv.

24V or 12V powering

TagMaster AB S1500 / S1501 Reader Data Sheet Issue 01

General

S1500 comprises a plastic cover and a metal

chassis for two PC boards, where the upper

position carries a standard board and the

lower is for an option board. A rubber gasket

seals the unit.

The standard board includes a Processor and

I/O block with analogue and digital circuits,

and is integrated with a Microwave and

Antenna block.

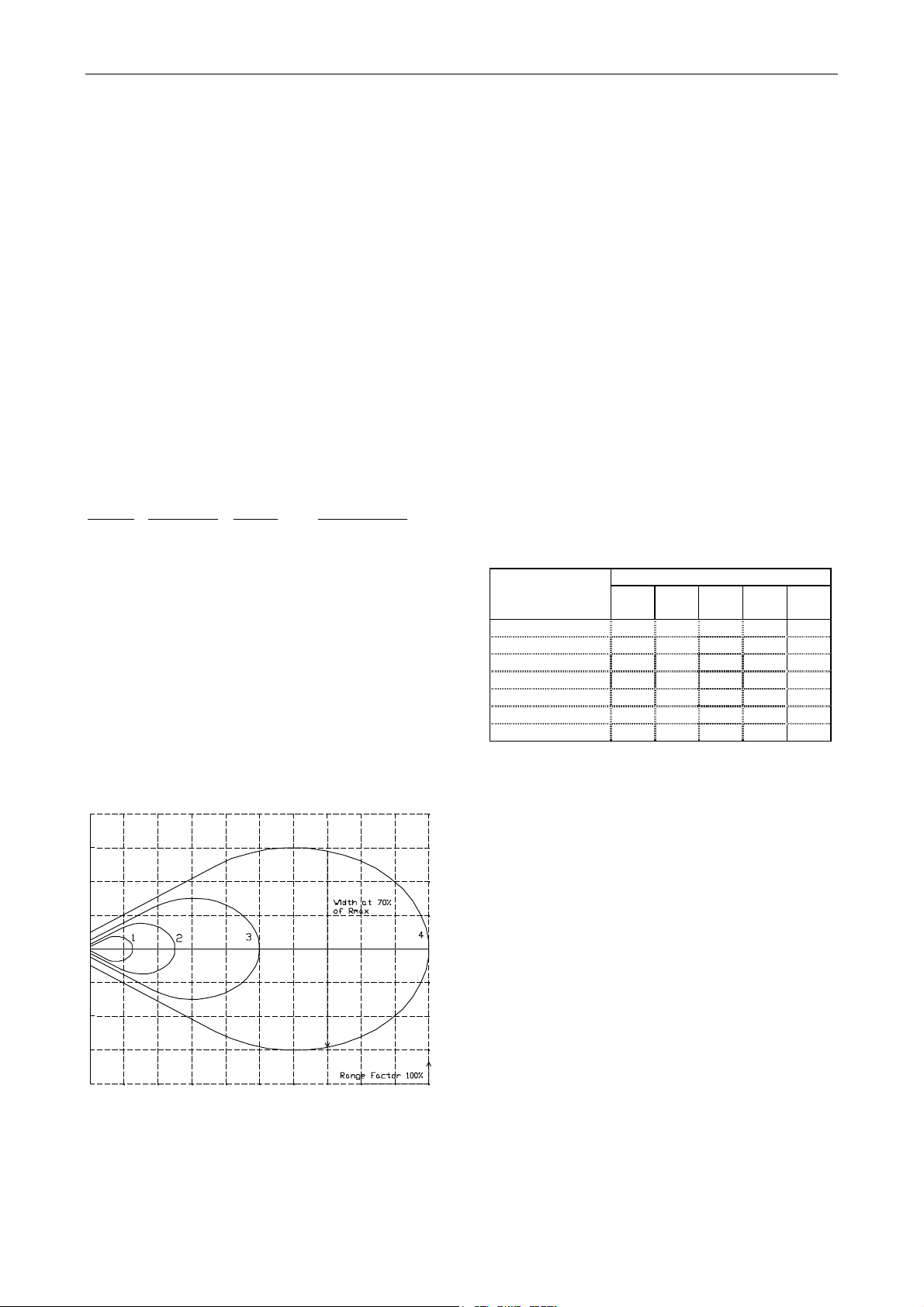

The antenna system is circular polarised and

radiates through the front cover, with a lobe

that is directed perpendicularly to the front

surface of S1500. The lobe shape can be

described as an ellipsoid with a circular cross

section, as shown in the figure below.

CONFIDENT

The reading and writing distances depend on

the tag type and on the power and sensitivity

SW settings. Typically, S1500 can read

TagMaster tags at up to 6 m distance. See

Reading/Writing range for details.

8,7

236,6

When dismounting the cover, it separates

from the cable inlets to conveniently operate

the unit also without cover. Screw connectors

are jackable and in logical groups, i.e. it is not

needed to disconnect each wire to replace the

electronics.

J1 DTMF, LED, external tamper line

J2 RS232 for terminal

J3 RS232 and RS 485 for host

J4 Parallel out and relay

J5 Parallel in

J6 DC supply

To hide the cables, S1500 can be connected

via cable glands in the back plane. Dual

tamper switches monitor that the cover is

closed. When removed, a software as well as

hardware alarm is generated.

For service and setup purposes there is a

control panel with a 7-segment LED display, 2

control buttons, a reset button, a LED and a

buzzer. There are also jumpers for RS232/485

and 12/24V selection.

A corrosion resistant mounting bracket that

gives additional sealing for rough

environments is separately available. It fits the

mounting holes of S1500, and has a flexible

joint for easy adjustment to different mounting

angles.

120,0

23,7

Diameter of holes: 4,2 mm

J1 J2 J3 J4 J5 J6

TagMaster AB S1500 / S1501 Reader Data Sheet Issue 01

Example: Your reading range has been calculated

Reading/writing range

The maximum reading or writing range is defined

as the maximum distance along the radiation axis

where the tag can be communicated when the tag

and reader face each other and when there is free

space in between.

The free space reading range for S1500 is up to

more than 6 m (20 Ft).

In a typical installation the reading range is up to

4m (13 Ft)

Writing range is up to 0.25 m (0.8 Ft)

The reading range depends on the tag reflectivity,

the data speed (high/low), power output and

sensitivity settings.

If using low power and/or low sensitivity the

reading range is reduced according to the

following table.

Range

Sensitivity Power Range factor

4 HIGH HIGH 100%

3 HIGH LOW 50%

2 LOW HIGH 25%

1 LOW LOW 12%

Writing must be done at high power. The writing

range is normally not affected by speed and

sensitivity settings.

Lobe width

The lobe diagram shows, in a proportional scale,

the approximate lobe shapes of the S1500 and

S1501 readers.

to 4.0 meters, meaning each square in the

diagram is 4.0/10=0.4 meters. The lobe width at

70% range is then 5.5 squares * 0.4 = 2.2 meters.

The diagram concerns a free space installation,

and does not take into account possible

influences from signal reflections or attenuating

structures.

For reliability reasons, it is recommended that

tags are passing at 70 % or less of specified

reading and writing range.

Reading/writing time

The time for reading and writing tags are specified

in the tag data sheets. Please refer to the data

sheet of the specific tag concerned.

Passage speed

The table shows the maximum allowed passage

speed in km/h for combinations of tag reading

time and lobe widths.

Lobe width [m]

Reading time

[ms]

20 180 270 360 450 540

50 72 108 144 180 216

70 51 77 103 129 154

100 36 54 72 90 108

130 28 42 56 69 83

150 24 36 48 60 72

200 18 27 36 45 54

1 1.5 2.0 2.5 3.0

Tag orientation

Thanks to the circular polarisation, the reading

and writing ranges are independent from the

rotational orientation around the radiation axis.

The reading time for the tag, can be found in the

tag datasheets. If the ID tag is tilted in relation to

the reader, a range reduction may occur. Since

this effect depends mainly on the specific

installation, it is recommended that a test is made.

S1500 can be set to a "read beep" mode to

conveniently check out the reading range.

Movement detection

Curves 4, 3, 2 and 1 show areas for safe reading

for the four different combinations of power and

sensitivity.

Copyright

The copyright/ownership of this document is and will remain ours. The document must not be used without our authorization or brought to the knowledge of a third party. TagMaster

AB.

Disclaimer

The information in this document is subject to change without notice. While the information contained herein is assumed to be accurate, TagMaster AB assumes no responsibility for

any errors or omissions.

S1500 detects a moving person or car at up to 5

meters (16Ft) distance, even when moving slowly.

The reader senses if the object is approaching or

moving away from the reader, and at what radial

TagMaster AB S1500 / S1501 Reader Data Sheet 2006-06-07

speed. The detection threshold can be set to

different sensitivity levels.

Software

The readers are delivered with the pre-installed

software Pyramid for standard applications.

However, you can easily develop your own

application software to be executed inside the

reader. This will give you the full power of

controlling the reader operation for flexible

solutions and fast response times.

User application development

For user application development there are

complete software development kits (SDK)

including compilers, loaders, tools, drivers and

libraries supporting the complete development

phase for reader applications as well as PC

applications.

User

applicati ons

C/C++

Delphi

Visual

Basic

Reader applications are developed in a PC

environment with the cross compiler ConfiComp

and can be executed in the PC for testing and

debugging. The complete software is finally

downloaded, using ConfiLoad, to the reader for

permanent storage in EEPROM. PC applications

are developed with any PC software development

tool. For application programmers a ConfiTalk

Commander is available for training and low level

communications management.

ConfiLib

ConfiLib is a function library with hundreds of

functions for reader management and ConfiTalk

protocol handling. ConfiLib exist in versions both

for readers and PC environments including DOS,

Windows 3.1, 95/98/ME and NT/2000/XP.

The reader version of ConfiLib is a function library

package in C language. For PC environments, the

ConfiLib API comes as dynamic link libraries

(DLL) with C/C++ interface. There are also

separate interface modules for Visual Basic and

Delphi available. Typical functions include

read/write/format tags, read/write/search

database, HW/SW configuration, read/write I/O,

ConfiTalk send/receive, timers, buffers, mail

management, etc.

PC Communicator

User or standar d

ConfiLib

DLL

ConfiTalk

RS232

RS485

applicati on

ConfiLib

ConfiTalk

ConfiTalk is the standard serial communications

protocol used by the readers. The protocol

transfers data to and from a reader and handles

flow control, retransmissions, checksums and

data transparency. It can be used both for pointto-point and multidrop networks, using a polling

procedure.

ConfiTalk can also be replaced by a user defined

protocol.

Pyramid application

Pyramid application operates stand-alone reading

tags, validating according to a downloaded

database white list, activating relays for valid tags

and producing logs for a PC to collect on- or offline. Pyramid can also sense movements of

people and vehicles using the movement

detection.

Events

Following events may trig actions:

• A tag is read

• A tag is read and found in the database

(validated)

• A movement is detected

Actions

For each event following actions may be

specified:

• The event is logged

• The relay is pulled

• The buzzer is turned on

• The LED is set to different colours

Alarms

Following alarms can be generated:

• Tamper switch alarm

• Reset alarm

Database

The database in S1500 stores more than 15.000

tag identities.

Movement detection

When enabled, this feature can sense movements

5 meters away or at reduced ranges.

Timer

Relay activation time and tag timeout can be set.

Logging

All events and alarms are logged to be retrieved

by a PC on- or off-line. Log size is 250-1000

events.

Terminal

For serial port configuration and local operating at

installation time, an optional terminal can be

connected to the terminal interface Check SW.

Pyramid may also be set to Off mode without any

stand-alone operation. Instead, all ConfiLib

commands are available on the serial port

interface for a PC controller.

TagMaster AB S1500 / S1501 Reader Data Sheet 2006-06-07

Control panel setup

Under the cover of the S1500 there is a control

panel available for local configuration and

operation without the need of a terminal or PC.

The left black button is used for parameter

selection and the right black button is used for

value selection.

Example to change the ConfiTalk address: Push

the left button repeatedly until ‘Ad’ is displayed.

Push the right button to display the current

address. Repeat pushing the right button until the

wanted address is displayed. Press the left button

to save the configuration. When there are

unsaved changes, the LED is red.

The configuration is stored in non-volatile

memory, and is retained after a power failure.

To reset the reader to default configuration and

erase the database, keep the two black buttons

pushed while pressing the red reset button. .

Release the buttons when the LED blinks yellow.

Push the red button again.

To invoke the terminal interface Check SW in

S1500, keep one of the two black buttons pushed

while pressing the red button.

Hardware

Processor block

The processor block includes a 16 bit

microprocessor, 384 kByte Flash EEPROM, 100

byte EEPROM, 128 kByte SRAM and a bus

interface for an external option board. Option

boards are inserted in the lower position slot.

Flash EEPROM is used for program code and

databases while the small EEPROM may be used

for configuration data. This information is retained

even after DC power interruption for any period of

time. Programs and configuration can therefore

be downloaded at production time and remains

unchanged even after transportation.

The SRAM memory is used for program data, tag

reading logs, reader mail messages, etc.

The processor block includes a real time clock

(RTC) and a watchdog for automatic restart in

case of software failure.

A rechargeable backup battery for SRAM and

RTC is automatically charged as soon as the unit

is under voltage, and retains its voltage during two

weeks after loss of power provided that the

battery jumper is in the on position.

Jumper settings

There are jumpers for selecting if the second

serial port should be RS232 or RS485 and if the

RAM backup battery shall be connected. See

figure below.

Battery on

Host RS232 (Tx)

Host RS232 (Rx)

Under the rightmost antenna, additional jumpers

are available for setting the unit to 12 or 24 volt

operation. Markings on the PC board indicate how

to set these jumpers. The factory setting is 24 V.

Battery off

Host RS485 (Tx)

Host RS485 (Rx)

TagMaster AB S1500 / S1501 Reader Data Sheet 2006-06-07

Hardware interface

The I/O block comprise the following interface.

DTMF

2-wire interface to receive a dual tone signal and

to power a DTMF device.

Parameter

Line volt. @ 10 mA 4.1 4.5 V

Tone level -26 0 dBm

RS 232 - host and terminal

Default: 9600 bps, 8 bits, no parity, 1 stop bit,

ConfiTalk address 1

Parameter

Baud rate 1.2 19.2 kbits/s

Data bits 7 8 bits

Stop bits 1 2 bits

Parity no - odd - even

RS 485 - host

Full (4 wire) or half duplex (2 wire). Default: 9600

bps, 8 bits, no parity, 1 stop bit, ConfiTalk address

1

Parameter

Baud rate 1.2 38.4 kbits/s

Data bits 7 8 bits

Stop bits 1 2 bits

Parity no - odd - even

Optocoupler inputs

Parameter

High voltage 2,4 30 V

Low voltage 0.0 0.2 V

Open collector outputs

Parameter Min

Allowed voltage 1 30 V

Sink current Out 1 0 500 mA

Sink current Out 2 0 100 mA

Relay

Parameter Min

Switch current 2 A

Switch voltage DC 220 V

Switch voltage AC 125 V

Switch power 50 W

Power

The S1500 is set for 24 VDC when delivered from

factory. By changing the top jumper settings, the

unit can also be supplied with 12 VDC.

Min Max Unit

Min Max Unit

Min Max Unit

Min Max Unit

Max Unit

Max Unit

Connection diagram

The electrical interface is shown in the diagram

below. J1, J2 etc. represent different logical (as

well as physical) connectors, which can all be

individually disconnected.

J1: 1

J2: 1

J3: 1

J5: 1

2

3

2

3

4

5

6

7

8

9

10

2

3

4

5

6

7

8

2

3

4

5

6

2

3

4

5

6

7

LED

LED 2

GndLED

SDTMF

RtnDTMF

Tamp a

Tamp b

Tx232a

Rx232a

Gnd 232a

Tx232b

Rx232b

Gnd 232b

CGnd

Tx-/Rx-485

Tx+/Rx+485

Gnd485t

Rx485-

Rx485+

Gnd485r

Outspl1J4: 1

Out 1c

Out

Out 2c

Out 2e

R1c

R1b

R1m

In 1a

In 1c

In 2a

In 2c

In 3a

In 3c

470 470

100

Cover on

100

100

2,2 k

2,2 k

2,2 k

DTMF

receiver

Standard IC

Standard IC

Standard IC

Standard IC

J6: 1

Spl 1

Rtnspl 1

2

Spl 2

3

Rtnspl 2

4

DC/DC converter

or linear regulator

TagMaster AB S1500 / S1501 Reader Data Sheet 2006-06-07

Installation aspects

Microwaves penetrate most non-metallic materials,

such as gypsum, wood, plastics, glass, dirt and

snow. The unit should however if possible be

installed and used so that free space is available

between the ID tag and the reader.

If large reflecting surfaces are present in the

reading zone, the antenna diagram may be

distorted. In such a case, it is recommended to

shorten the distance to the ID tag to achieve a

stronger signal. The system works safely at all

distances down to zero.

If the reader is installed with a low grazing angle to

a reflecting surface such as a road or floor, the

multipath effect can increase the reading distance.

Since the multipath effect may reduce the lobe

width, a test is recommended to check the reader

in such installations, e.g. with the ”Read Beep” test

function available at the control panel.

In the control panel, push the left black button until

”OP” is displayed. Press the right button until ”rb”

is displayed. Press the left button again. In the

read beep operation mode, a short beep is

sounded from the buzzer every time a tag is read,

thus helping to verify the actual reading zone at

installation time.

Restore the reader to normal operation mode by

pressing the right button until ”On” is displayed and

then press the left button.

If several readers are to be operated close to

each other, it is recommended to use different RF

channels to avoid interference. There are 100

channels available.

If tags are passing at a close distance from the

reader it might be a recommendation to reduce

the reading range to avoid unwanted readings of

a remote tag. The range is reduced by setting of

the power and sensitivity parameters.

If the reader is to be used in wet conditions, the

cable inlets should be oriented downwards. It is

recommended to protect the reader from direct

water spray or rain.

Screened cables shall be used with the screens

clamped according to the figure below.

Note. The DTMF input may be disturbed if the

DTMF cable is exposed to signals in the 1 - 3

MHz region and the prescribed test level (ETS

301 489) for conducted interference is exceeded.

Warning: To comply with the FCC RF

exposure limits, it is recommended that the reader

is installed so that a separation distance of at

least 20 cm (8 inches) from all persons is

provided.

Saccess

To enable a quick start to TAGMASTER, the

SACCESS Windows application is available for

demonstration purposes.

The main functionality is:

• Tag reading

• Tag writing

• Stand alone capability with tag validation and

relay activation

• Database update

• Event and action configuration

• Logging events on screen and file

• Reader serial port and address configuration

S1501 stripped down version

The Reader S1501 is a stripped down version of

the S1500. It is based on the same hardware with

the following differences.

• Application SW: Solid which is used for host

controlled applications.

• 128 Kbyte Flash EEPROM for SW (No

EEPROM database).

• No 7-segment display.

• No buzzer.

• No HW support for 4 wire RS485.

• 12V supply only. Standard voltage regulator

instead of DC/DC converter.

• No real time clock. ConfiLib emulates a real

time clock in software with less accuracy.

TagMaster AB S1500 / S1501 Reader Data Sheet 2006-06-07

yy

Electrical data

Data regards the temperature range -20 to 60 °C.

Parameter

DC Supply voltage 20 - 28 V

(selectable by jumper) 10 - 14 V

Consumption 12 V 500 mA

Consumption 24 V 150 mA

Radiation frequency 2435 – 2465 MHz

Output power 10 mW e.i.r.p

Polarisation circular

Tx modulation ASK

Number of RF channels 99

Radiation reduction -12 dB

Sensitivity reduction -24 dB

Reading data speed, high 16 kbit/s

Reading data speed, low 4 kbit/s

Writing data speed 4 kbit/s

Movement det., min speed 0,3 m/s

Movement det., max speed 9,2 m/s

Movement det. max range 5 m

Value Unit

Mechanical data

Product information according to the figure below

is marked on the cover of S1500. A marking

sticker is also placed inside the unit to avoid

mixing up covers and chassis.

Example of marking label:

54 mm

(2,13 In)

176 mm

(6,93 In)

TagMaster AB

OMMUNICATOR

C

S1500/00 Rev 05

mm nnnnn

FCC ID:

DC 24V M AX 1A

M39LRXX

Communication range

data

Reading range typical inst.: 0 to 4 m (13 Ft)

Reading range up to: 6 m (20 Ft)

Writing range : 0 to 0,25 m (0.8

Ft)

Environmental data

Cold -20ºC (-4ºFh)

IEC68-2-1 Ad

Heat +60ºC(+140ºFh)

IEC68-2-2 Bd

Sealing IP 54

IEC 529

Shock 50 G, 6 ms,

IEC68-2-27 Ea 10x 3 dir

Bump 25 G 6 ms,

IEC68-2-29 Eb 1000x 3 dir

Sine vibration 5G/0,55mm,

IEC68-2-6 Fc 500Hz, 10m,

4 worst freq

Random Vibration

IEC 60068-2-64

263mm (10,35In)

Weight 1,8 kg

Dimensions (WxLxH): 176 x 263 x 54 mm

Front colour Light grey

Front material Polycarbonate

Back material Stainless steel

Sealing method Rubber gasket

Immunity Acc. to CE

leg.

ETSI EN 301 489-3

v1.2.1(0208)

Emission Acc. to CE

leg.

ETSI EN 300 440-1

v1.3.1(0109)

Solar radiation 1120 W/sqm

IEC68-2-5 Sa C 56 days

Safety Electrical and Radio

EN 60950 and EN 60215

Loading...

Loading...