Tadano GR-750XL Service Manual

GR-750XL

75 Ton Capacity (68 Metric Tons)

HYDRAULIC ROUGH TERRAIN CRANE

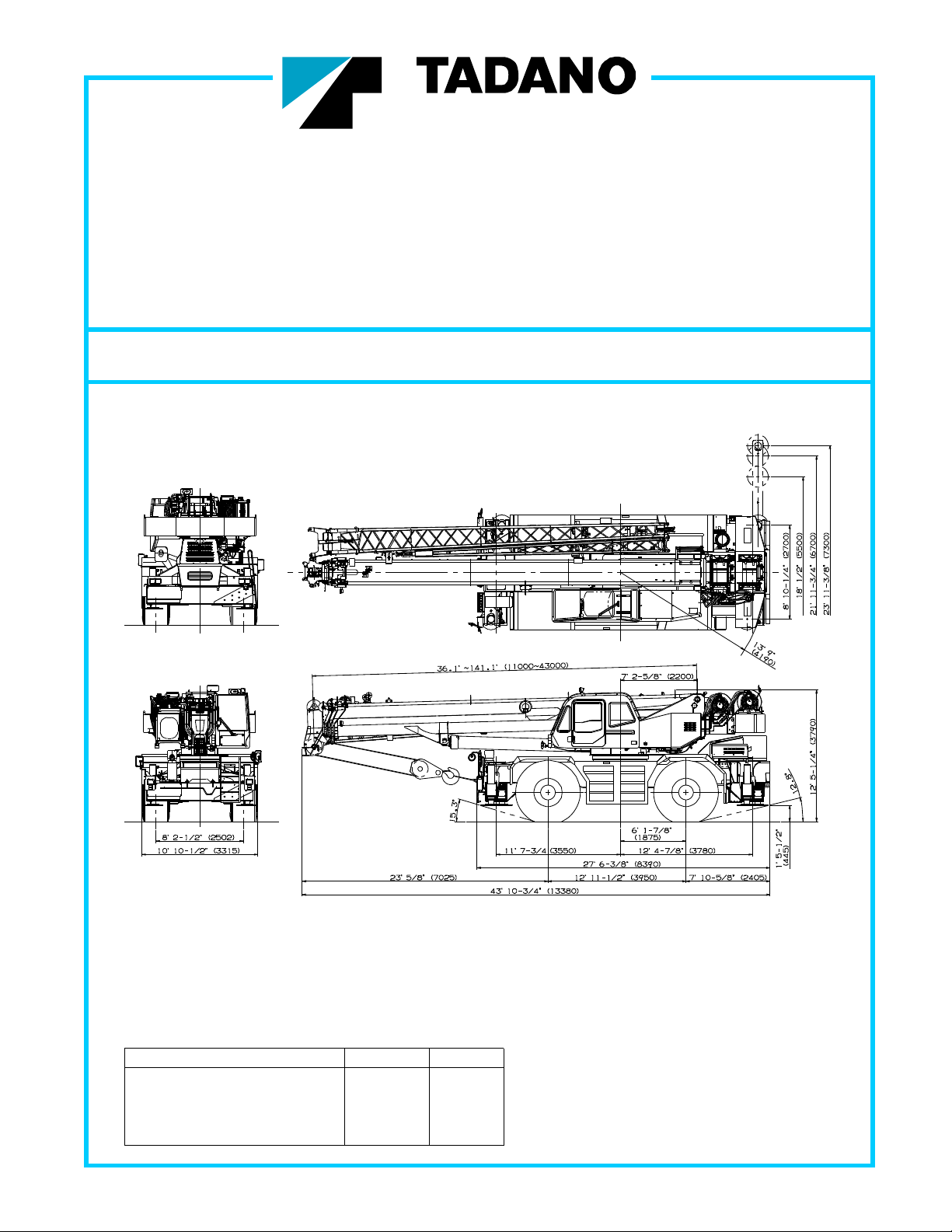

DIMENSIONS

GENERAL DIMENSIONS

(29.5 - 25 Tires)

Feet Meters

Turning radius

4 wheel steer 22' 4" 6.8

2 wheel steer 39' 1" 11.9

Tail swing of counterweight 13' 9" 4.19

Note : Dimen sion is with boom angle at -1.6 degr ee.

Specifications are subject to change without notice.

Specification effective with serial number 548831 and up.

CRANE SPECIFICATIONS

BOOM WIRE ROPE - Warrington seal wire, extra improved plow steel,

Five section full power synchronized telescoping boom, preformed, independent wire rope core, right regular lay.

36.1'~141.1' (11.0m~43.0m), of round box construction 3/4" (19 mm) 6x31 class

with six sheaves, 17-5/16" (0.44m) root diameter, at boom head. Breaking strength (Main and Aux): 54,700 lbs (24,800 kg)

The synchronization system consists of two telescope cylinders,

an extension cable and retraction cable. Hydraulic cylinder fitted HOOK BLOCKS

with holding valve. Two easily removable wire rope guards, 75 ton (68 metric ton) - 7 sheaves with swivel hook block and safety latch.

rope dead end provided on both sides of boom head. Boom telescope 6.2 ton (5.6 metric ton) - Weighted hook ball with swivel and safety latch.

sections are supported by wear pads both vertically and horizontally.

Extension speed 105' in 128 seconds.

HYDRAULIC SYSTEM

BOOM ELEVATION - By a double acting hydraulic cylinder with

holding valve. Elevation -1.6 o~80.3 o, combination controls for hand

or foot operation. Boom angle indicator. Tandem gear pump for steering, slewing and optional equipment.

Automatic speed reduction and soft stop function. Powered by carrier engine. Pump disconnect for crane is

Boom raising speed 20 o to 60 o in 46 sec. engaged/disengaged by rotary switch from operator's cab.

JIB - Two stage bi-fold lattice type with 3.5 o, 25 o or 45 o offset (tilt type). CONTROL VALVES - Multiple valves actuated by pilot pressure

Single sheave, 15-5/8" (0.396m) root diameter, at the head of both with integral pressure relief valves.

jib sections. Stored alongside base boom section. Jib length is

33.2' (10.1m) or 58.1' (17.7m). Assistant cylinders for mounting RESERVOIR - 202 gallon (763 lit.) capacity. External sight level

and stowing, controlled at right side of superstructure. gauge.

Self stowing jib mounting pins.

AUXILIARY LIFTING SHEAVE (SINGLE TOP) protection, located inside of hydraulic reservoir. Accessible for

Single sheave, 15-5/8" (0.396m) root diameter. Mounted to main easy replacement.

boom head for single line work (storable).

ANTI-TWO BLOCK - Pendant type over-winding cut out device

with audio-visual (FAILURE lamp/BUZZER) warning system.

SLEWING

Hydraulic axial piston motor through planetary slewing speed Both crane and drive operations can be performed from one cab

reducer. Continuous 360 o full circle slewing on ball bearing turn mounted on rotating superstructure.

table at 2.4min

slewing brake. A 360 o positive slewing lock for pick and carry and travel Left side, 1 man type, steel construction with sliding door access

modes, manually engaged in cab. Twin slewing system: Free slewing and safety glass windows opening at side. Door window is

or lock slewing controlled by selector switch on front console. powered control. Windshield glass window and roof glass window

HOIST control lever stands for slewing, boom elevating, boom telescoping,

MAIN HOIST - Variable speed type with grooved drum driven by neutral positions and tilt for easy access to cab. 3 way adjustable

hydraulic axial piston motor through speed reducer. Power load operator's seat with high back, headrest and armrest. Engine

lowering and raising. Equipped with automatic brake (neutral brake) throttle knob. Foot operated controls: boom elevating,

and counterbalance valve. Controlled independently of auxiliary hoist. boom telescoping, service brake and engine throttle.

Equipped with cable follower and drum rotation indicator. Hot water cab heater and air conditioning.

-1

{rpm}. Equipped with manually locked/released

PUMPS - Two variable piston pumps for crane functions.

FILTRATION - BETA10=10 return filter, full flow with bypass

OIL COOLER - Air cooled fan type.

CAB AND CONTROLS

are shatter-resistant. Tilt-telescoping steering wheel. Adjustable

auxiliary hoist and main hoist. Control lever stands can change

DRUM - Grooved 14-1/4" (0.362m) root diameter x 23-5/8" (0.6m) Dash-mounted engine start/stop, monitor lamps, cigarette lighter,

wide. Wire rope: 771' of 3/4" diameter rope (235m of 19mm). drive selector switch, parking brake switch, steering mode

Drum capacity: 997' (304m) 7 layers. select switch, power window switch, pump engaged/disengaged

Maximum single line pull (available): 16,500 lbs (7,480kg). switch, slewing brake switch, telescoping/auxiliary hoist select

Maximum line speed: 479FPM (146m/min) at the 6th layer. switch, outrigger controls, free slewing / lock slewing selector switch,

eco mode switch and ashtray.

AUXILIARY HOIST - Variable speed type with grooved drum driven

by hydraulic axial piston motor through speed reducer. Power load

lowering and raising. Equipped with automatic brake (neutral brake) Instruments - Torque converter oil temperature, engine water

and counterbalance valve. Controlled independently of main hoist. temperature, air pressure, fuel, speedometer, tachometer,

Equipped with cable follower and drum rotation indicator. hour meter and odometer / tripmeter. Hydraulic oil pressure is

monitored and displayed on the AML-C display panel.

DRUM - Grooved 14-1/4" (0.362m) root diameter x 23-5/8" (0.6m)

wide. Wire rope: 436' of 3/4" diameter rope (133m of 19mm).

Drum capacity: 997' (304m) 7 layers.

Maximum single line pull (available): 16,500 lbs (7,480kg).

Maximum line speed: 420FPM (128m/min) at the 4th layer.

2

Tadano electronic LOAD MOMENT INDICATOR system TADANO AML-C monitors outrigger extended length and

(AML-C) including: automatically programs the corresponding "RATED LIFTING

Control lever lockout function CAPACITIES" table

Boom position indicator

Outrigger state indicator Operator's right hand console includes transmission gear

Boom angle / boom length / jib offset angle / jib length / load selector, and slewing lock lever and sight level bubble.

radius / rated lifting capacities / actual loads read out Upper console includes working light switch, roof washer

Ratio of actual load moment to rated load moment and wiper switch, emergency outrigger set up key switch,

indication jib equipped/removed select switch, eco mode switch

Automatic Speed Reduction and Slow Stop function and air conditioning control switch.

on boom elevation and slewing

Working condition register switch NOTE: Each crane motion speed is based on unloaded

Load radius / boom angle / tip height / slewing range conditions.

preset function

External warning lamp

Tare function

Fuel consumption monitor

Main hoist / auxiliary hoist select

Drum rotation indicator (audible and visible type) main and

auxiliary hoist

CARRIER SPECIFICATIONS

TYPE - Rear engine, left hand steering, driving axle 2-way SUSPENSION - Front: Rigid mounted to frame.

selected type by manual switch, 4x2 front drive, 4x4 front and Rear: Pivot mounted with hydraulic lockout device.

rear drive.

FRAME - High tensile steel, all welded mono-box construction. BRAKE SYSTEMS - Service: Air over hydraulic disc brakes on

all 4 wheels. Parking/Emergency: Spring applied-air released

TRANSMISSION - Electronically controlled full automatic brake acting on input shaft of front axle. Auxiliary: Electro-

transmission. Torque converter driving full powershift with pneumatic operated exhaust brake.

driving axle selector. 6 forward and 2 reverse speeds, constant

mesh. TIRES - 29.5-25 22PR(OR) or 29.5-25 28PR(OR)

3 speeds - high range - 2 wheel drive; 4 wheel drive

3 speeds - low range - 4 wheel drive OUTRIGGERS - Four hydraulic, beam and jack outriggers.

Vertical jack cylinders equipped with integral holding valve. Each

TRAVEL SPEED - 22 mph (36 km/h) outrigger beam and jack is controlled independently from cab.

Beams extend to 23' 11-3/8" (7.3 m) center-line and retract to

GRADEABILITY (tan) - 147% (at stall), **57% within 10' 10-1/2" (3.315 m) overall width with floats. Outrigger

** Machine should be operated within the limit of engine design. jack floats are attached thus eliminating the need of manually

** (30°: Cummins QSB6.7) attaching and detaching them. Controls and sight bubble located

in superstructure cab. Four outrigger extension lengths are

AXLE - Front: Full floating type, steering and driving axle with provided with corresponding "RATED LIFTING CAPACITIES" for

planetary reduction. Rear: Full floating type, steering and driving crane duty in confined areas.

axle with planetary reduction and non-spin rear differential. Min. Extension 8' 10-1/4" (2.7m) center to center

Mid. Extension 18' 1/2" (5.5m) center to center

STEERING- Hydraulic power steering controlled by steering Mid. Extension 21' 11-3/4" (6.7m) center to center

wheel. Four steering modes available: 2 wheel front, 2 wheel Max. Extension 23' 11-3/8" (7.3m) center to center

rear, 4 wheel coordinated and 4 wheel crab . Float size(Diameter) 1' 11- 5/8" (0.6m)

ENGINE

Model Cummins QSB6.7 [Tier 4] Radiator Fin and tube core, thermostat controlled

Type Direct injection diesel Fan, in.(mm) Suction type, 9-blade, 28 (711) dia.

No. of cylinders 6 Starting 24 volt

Combustion 4 cycle, turbo charged and after cooled Charging 24 volt system, negative ground

BoreXStroke, in.(mm) 4.212 x 4.882 (107 x 124) Battery 2-120 amp. Hour

Displacement, cu. in (liters) 409 (6.700) Compressor, air, CFM(l /min) 17.0 CFM (481) at 2,400rpm

Air inlet heater 24 volt preheat Horsepower (kW) Gross 270 (201) at 2,000rpm

Air cleaner Dry type, replaceable element Torque, Max. ft-lb (Nm) 730 (990) at 1,500rpm

Oil filter Full flow with replaceable element Capacity, gal.(liters)

Fuel filter Full flow with replaceable element Cooling water 7.4 (28)

Fuel tank, gal.(liters) 79.2 (300), right side of carrier Lubrication 4.0 (15)

Cooling Liquid pressurized, recirculating by-pass Fuel 79.2 (300)

DEF 10.0 (38)

3

e

h

1

STANDARD EQUIPMENT

- Five section full power partially synchronized boom - Independently controlled outriggers

36.1'~141.1' (11.0 m~43.0 m) - Four outrigger extension positions

- 33.2' or 58.1' (10.1 m or 17.7 m) bi-fold lattice jib (tilt type) - Self-storing outrigger pads

with 3.5 o, 25 o or 45 o pinned offsets and self storing pins. - Cummins QSB6.7 turbo charged

- Auxiliary lifting sheave (single top) storable after cooled engine (270HP) with exhaust brake

- Variable speed main hoist with grooved drum, cable follower - Electronic controlled automatic transmission driven

and 771' of 3/4" cable. by torque converter

- Variable speed auxiliary hoist with grooved drum, cable follower - 4 X 4 X 4 drive/steer

and 436' of 3/4" cable. - Non-spin rear differential

- Drum rotation indicator (audible, visible and thumper type) main and auxiliary hoist - 29.5-25 22PR(OR) tires or 29.5-25 28PR(OR) tires

- Anti-Two block device (overwind cutout) - Disc brakes

- Boom angle indicator - Fenders

- Tadano electronic load moment indicator system (AML-C) - Air dryer

- Outrigger extension length detector - Water separator with filter(high filtration)

- Electronic crane monitoring system - Engine over-run alarm

- Tadano twin slewing system and 360 o positive slewing lock - Back-up alarm

- Self centering finger control levers with pilot control - Low oil pressure/high water temp. warning device (visual)

- Control pedals for boom elevating and boom telescoping - Rear steer centering light

- 3 way adjustable cloth seat with armrests, high back - Air cleaner dust indicator

and seat belt - Full instrumentation package

- Tilt-telescoping steering wheel - Complete highway light package

- Tinted safety glass and sun visor - Tool storage compartment

- Front windshield wiper and washer - Tire inflation kit

- Roof window wiper and washer - 24 volt electric system

- Power window (cab door ) - 6.2 ton (5.6 metric ton) hook ball with swivel

- Rear view mirrors (right and left side) - 75 ton (68 metric ton) - 7 sheaves with swivel hook block

- Mirror for main and auxiliary hoists and safety latch for 3/4"(19mm) wire rope

- Cigarette lighter and ashtray - Towing hooks-Front and rear

-

Cab floor mat - Lifting eyes

- Pump disconnect in operator's cab - Hook block tie down (front bumper)

- Hydraulic oil cooler - Weighted hook storage compartment

- Hot water cab heater and air conditioner - Halogen head lamp

- Positive control - Telematics (machine data logging and monitoring system)

- Quick reeving type bi-fold jib with HELLO-NET via internet

- Work lights - Fuel consumption monitor

Automatic rear axle oscillation lockout system

- Eco mode system

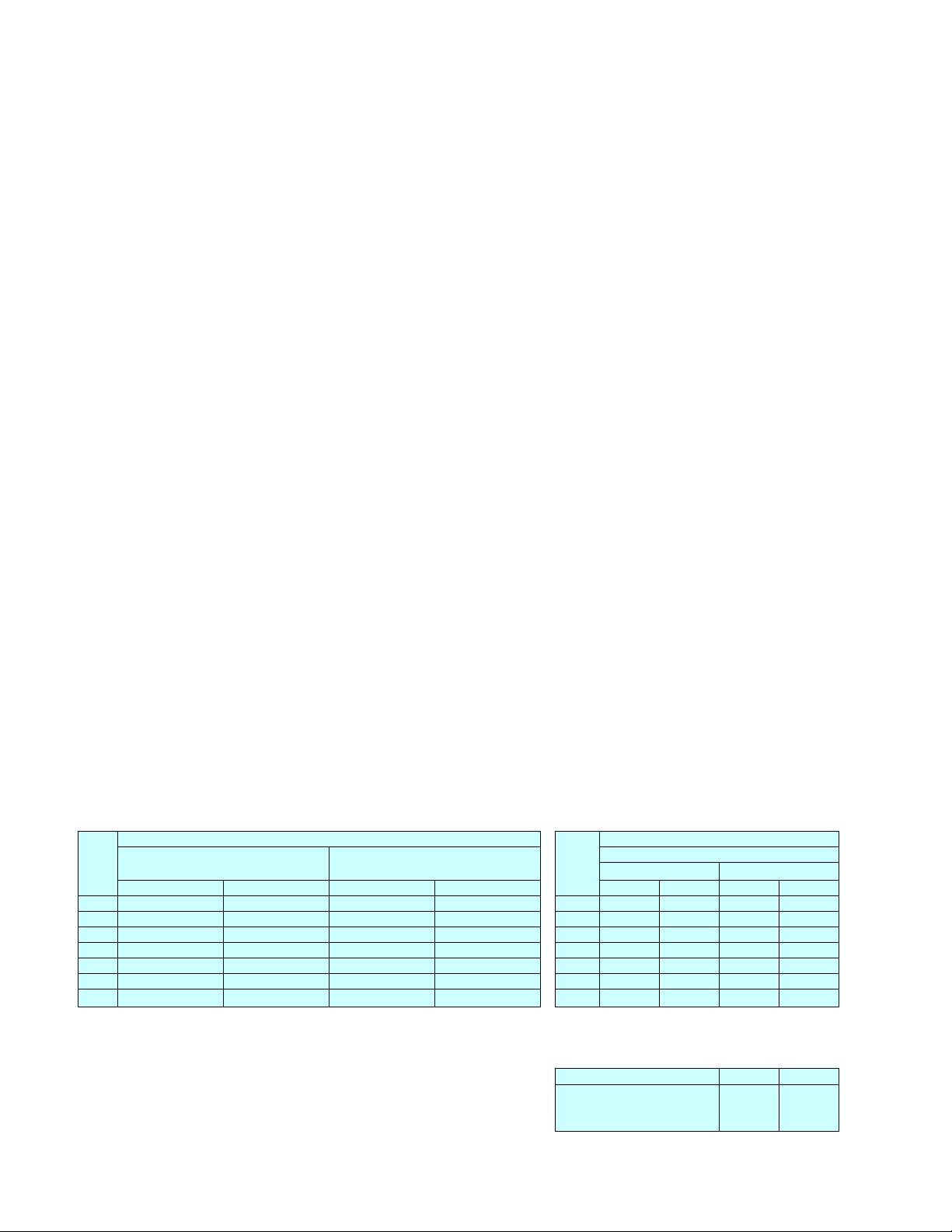

HOISTING PERFORMANCE

LINE SPEEDS AND PULLS

Main or auxiliary hoist - 14-1/4" (0.362m) drum

Layer

Line speeds

1

Line pulls

Availabl

2

F.P.M. m/min Lbs. kgf Feet Meters Feet Meters

1st 331 101 16,500 7,480 112.2 34.2 112.2 34.2

2nd 361 110 15,200 6,900 122.3 37.3 234.5 71.5

3rd 390 119 13,800 6,260 132.2 40.3 366.8 111.8

4th 420 128 12,700 5,760 142.3 43.4 509.1 155.2

5th 450 137 11,900 5,400 152.2 46.4 661.4 201.6

6th 479 146 11,000 4,990 162.4 49.5 823.8 251.1

3

7t

509 155 10,300 4,670 172.5 52.6 996.4 303.7

* Maximum permissible line pull may be affected by wire rope strength.

Maximum lifting capacity per line (Main & Aux.): 12,300 lbs (5,600 kg)

Line speeds based only on hook block, not loaded. DRUM DIMENSIONS

2

Developed by machinery with each layer of wire rope, but not based Inch mm

on rope strength or other limitation in machinery or equipment. 14-1/4" 362

3

Seventh layer of wire rope are not recommended 23-5/8" 600

for hoisting operations. 25-7/8" 657

4

DRUM WIRE ROPE CAPACITIES

Main and auxiliary drum grooved lagging

Wire

rope

layer

3/4" (19mm) wire rope

Rope per layer Total wire rope

1

2

3

4

5

6

7

Root diameter

Length

Flange diameter

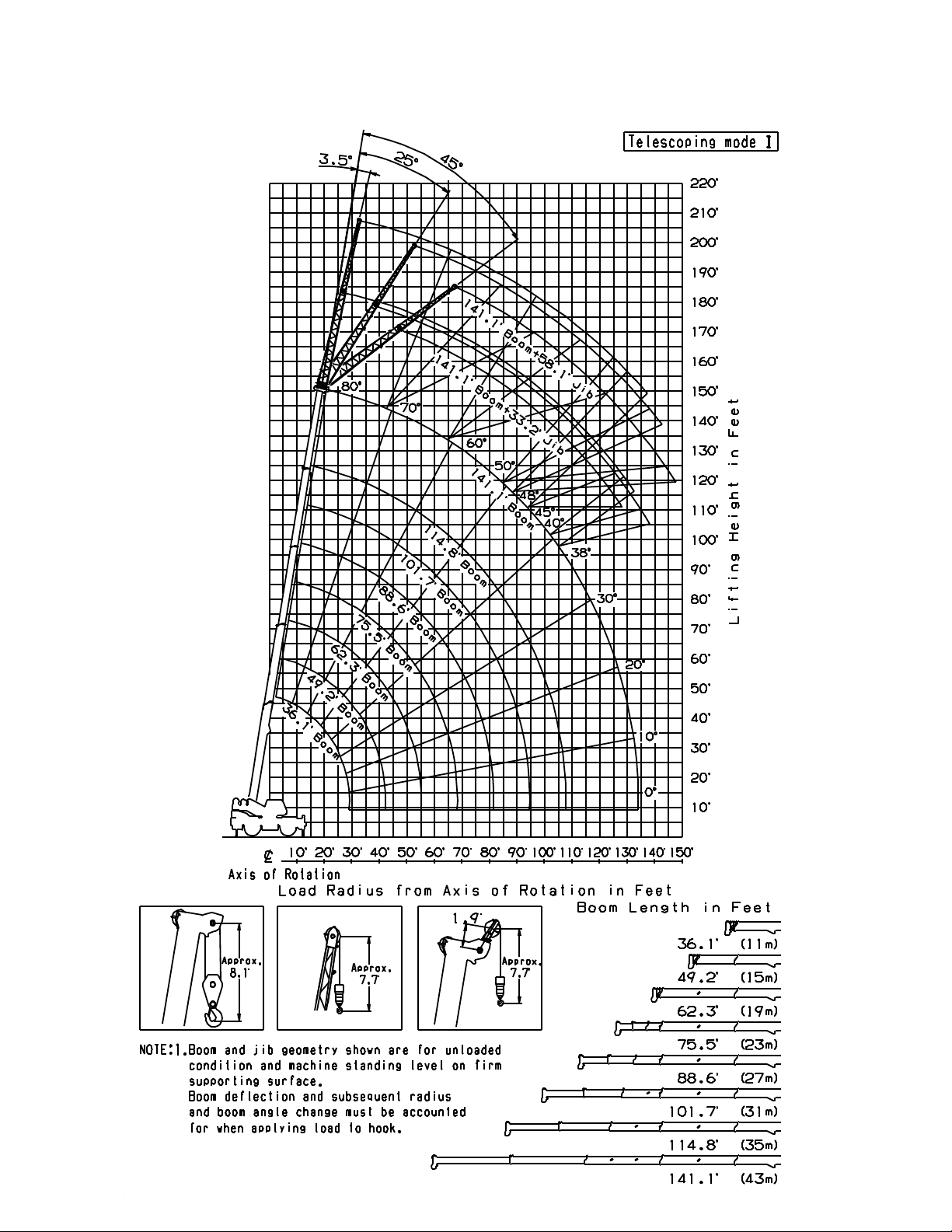

GR-750XL WORKING RANGE CHART

5

Loading...

Loading...