Sysmex XP-Series Maintenance procedure

XP Series PM Standard Procedure

Customer Support Headquarters

Sysmex Corporation

Version 2 March 4, 2013

(Version 2)

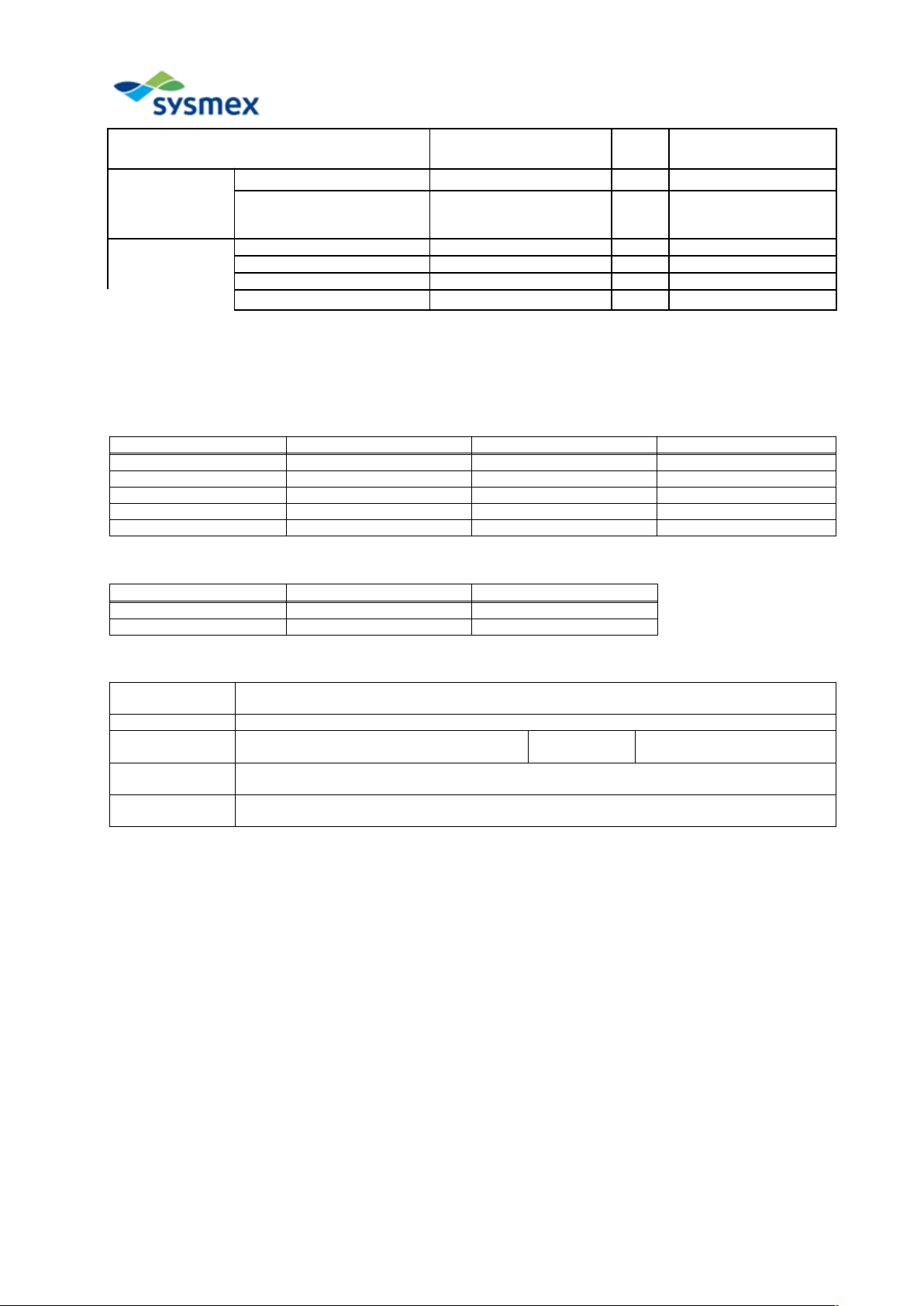

XP Series Preventive Maintenance Checklist

Check Items Schedule Check Remarks

Check setting

values

Print setting values □

HOST Output Setting OFF □

Check data

before

maintenance

Check background data □

Check data using control

material or samples

□

Check adjustment

values before

maintenance

□

*

SRV

Disassemble and clean SRV □

Clean the tray □

Replace whole blood tube

manually

□

Rinse Cup

Clean Rinse Cup □

Replace Tube Pharmed for

Waste Line

Once a year □

Waste Chamber

Disassemble and rinse

Waste Chamber

□

Replace Waste Chamber

Drain Line silicon tubes.

Once a year □

Replace Waste Chamber

Every 5 years (or as

needed)

□

Bellows Unit

Disassemble and rinse

Bellows Unit, Clean needle

□

Rinse orifice tube □

Pneumatic Unit

Rinse Trap Chamber □

Replace Pneumatic Unit

protection filter

Every 2 years □

Replace Compressor

Positive pressure is no

more than 0.22 MPa or

negative pressure is no

more than -0.04MPa.

□

Transducer

Clean WBC transducer

aperture

□

Clean RBC transducer

aperture

□

Clean inside of Transducer

Assy

□

Pressure

adjustment

0.05MPa pressure

adjustment

□

*

-0.0333MPa pressure

adjustment

□

*

HYDRAULIC

UNIT

Transducer cleaning

sequence

□

Waste Chamber Rinse

Sequence

□

Other

adjustments

Adjust HGB background

count level

□

*

Adjust WBC clog level □ *

Adjust RBC clog level □ *

Main Unit, Interior

Clean inside of Main Unit □

Lubricate mechanism □

Checking data

Check background count

level

□

Check data using control

material or samples

□

(Version 2)

Check Items Schedule Check Remarks

Main Unit,

Exterior

Clean Main Unit covers □

Clean peripheral device

(printer etc.)

Cleaning

□

Check after

maintenance

Restore host output settings □

Check program version □ *

Cycle counts □ *

Final performance check □

* “Schedule” is only a guideline and differs according to status of use.

* If “Schedule” is blank, it means that the items need to be checked for every periodic maintenance.

* The replaced parts which are not in the check list and the parts that a service engineer recommends to replace in

future are mentioned in “Remarks”.

【Details of Adjustment Items】

Adjustment Items Specified Range Value Before Adjustment Value After Adjustment

0.05MPa pressure 0.05 +/- 0.01 (MPa)

-0.0333MPa pressure -0.0333 +/- 0.0013 (MPa)

HGB background convert 2000+/-200

WBC clog level 100.0+/-1.0

RBC clog level 100.0+/-1.0

【Details of Check Items】

Adjustment Items Specified Range Confirmed Value

Program Version Cycle counts -

* Refer to Job List or QC Chart for control, or sample analysis values.

Maintenance

Report No.

Facility Name

Instrument

Name

XP-100/XP-300 Serial No.

Maintenance

Date

Name of Service

Engineer

Loading...

Loading...