Page 1

INSTRUCTIONS FOR USE

Automated Blood Coagulation Analyzer

CA-500 series

CHAPTER 1: Introduction

CHAPTER 2: Safety Information

CHAPTER 3: Design and Function

CHAPTER 4: Installation Environment

CHAPTER 5: Operation

CHAPTER 6: Display and Processing of

Analysis Results

CHAPTER 7: Output

CHAPTER 8: Quality Control

CHAPTER 9: Setting Standard Curve

CHAPTER 10: Instrument Setup

CHAPTER 11: Maintenance and Supplies

Replacement

CHAPTER 12: Troubleshooting

CHAPTER 13: Functional Description

CHAPTER 14: Technical Information

CHAPTER 15: Index

CHAPTER 16: Appendix (A)

SYSMEX CORPORATION

KOBE, JAPAN

Copyright © 2001-2004 by SYSMEX CORPORATION

All rights reserved. No part of this Instruction for Use may be

reproduced in any form or by any means whatsoever without

prior written permission of SYSMEX CORPORATION.

Code No. 461-2655-0

PRINTED IN JAPAN

Date of Last Revision: April 2004

Software version 00-17 and onwards

Page 2

Table of Contents

1. Introduction .........................................................1-1

1.1 Introduction ........................... ............................................. .....1-1

1.2 Explanation of Signs ...............................................................1-3

1.3 Names .................................................................................... 1-4

1.4 Serial Number..........................................................................1-4

1.5 Revision History ......................................................................1-4

2. Safety Information ...............................................2-1

2.1 Specified Conditions of Use ................................................... 2-1

2.2 General Information ................................................................2-1

2.3 Installation Location ................................................................2-3

2.4 Avoidance of Infections .......................................................... 2-3

2.5 Handling of Reagents ............................................................. 2-4

2.6 Maintenance of the Instrument ............................................... 2-5

2.7 Disposal of Materials .............................................................. 2-5

2.8 Markings on the Instrument .................................................... 2-6

2.9 Personnel ............................................................................... 2-8

2.10 Storage Condition (Transportation)......................................... 2-8

3. Design and Function ........................................... 3-1

3.1 Overview ......................... ................ ................ ................ ........ 3-1

3.2 Operation Flow ....................................................................... 3-8

4. Installation Environment ....................................4-1

4.1 Installation and Relocation ..................................................... 4-1

4.2 Installation Location ................................................................4-1

4.3 Basic Instrument Settings .......................................................4-3

Revised November 2003 - 2.0_en

Sysmex CA-500 series I

Page 3

5. Operation ..............................................................5-1

5.1 Display Screens and Operation Keys .....................................5-1

5.2 Menu Tree ............................. ... ... ... ... .....................................5-3

5.3 Types of Alarm ................................... .... ... ... ... .... ....................5-5

5.4 Inspection before Turning ON the Power ...............................5-5

5.5 Turn ON the Power .................................................................5-7

5.6 Prepare Reagents ...................................................................5-8

5.7 Set Reaction Tubes ..............................................................5-13

5.8 Confirm Standard Curve .......................................................5-14

5.9 Execute Quality Control ........................................................5-15

5.10 Prepare Samples ..................................................................5-15

5.11 Set Sample Nos. ...................................................................5-19

5.12 Manual Inquiry ...................................................................... 5-22

5.13 Automatic Inquiry ................................................... ...............5-22

5.14 Start Analysis ......................... ... ... ... ... .... ... ... ... ......................5-24

5.15 Automatic Sensitivity Adjustment of the Detector

(for CA-530, CA-540, CA-550 and CA-560 only) ..................5-26

5.16 Display Analysis Result ........................................................5-27

5.17 Interrupt Analysis ..................................................................5-28

5.18 Add Samples ........................................................................5-29

5.19 Analyze STAT Sample .......................................................... 5-30

5.20 Emergency Stop ................................................................... 5-31

5.21 Shutdown ........................................................ ...................... 5-33

6. Display and Processing of Analysis Results ....6-1

6.1 List Display/Graphic Display ...................................................6-1

6.2 Search .................................................................................... 6-6

6.3 Sort in Sequence of Sample ID Nos. and Analyses ........... ... . 6-9

6.4 Select Display ......................................................................... 6-9

6.5 Edit ID No. ............................................................................6-11

6.6 Deletion ................................................................................. 6-12

7. Output ...................................................................7-1

7.1 Automatic Printout of Analysis Data .......................................7-1

7.2 Output of Analysis Data ..........................................................7-1

7.3 Example of Printout ................................................................7-3

8. Quality Control .....................................................8-1

8.1 Quality Control Methods .........................................................8-1

8.2 QC File Setting .......................................................................8-1

8.3 Execute Quality Control ..........................................................8-5

8.4 Display QC Charts .................................................................. 8-5

8.5 Delete QC File ........................................................................8-7

8.6 Delete QC Data ......................................................................8-8

8.7 Print QC data .......................................................................... 8-9

II Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 4

9. Setting Standard Curve ...................................... 9-1

9.1 Display Standard Curve ..................... ... .... ... ... ... ... .... ... ... ... .... . 9-1

9.2 Standard Curve Analysis ................ ...... .... ... ... ... ... .... ... ... ... .... . 9-3

9.3 INR Manual Dilution Analysis ................................................ . 9-6

9.4 Manual Entry ..........................................................................9-8

9.5 Set Reagent Information ........................... ................ .............. 9-9

9.6 Set Calculation Parameters .................................................. 9-10

9.7 Print Standard Curve ............................................................ 9-13

10. Instrument Setup ...............................................10-1

10.1 General Information ..............................................................10-1

10.2 Setup of Automatic Transfer/Printout ................................... 10-2

10.3 Judgment on Analysis Result ............................................... 10-4

10.4 Replication Range .......... ... ... ... .... ... ... ... .... ... ... ... ... .... ...... ... ... 10-6

10.5 Report Limit ....... ... ... .... ... ... ................................................... 10-7

10.6 Setup of Test Name ..............................................................10-8

10.7 Reagent Name ..................................................................... 10-9

10.8 Test Protocol ............................................... ... ... ... .... ...... ... . 10-10

10.9 Replication ............................................................ ..............10-19

10.10 Setup of Test Group ........................................................... 10-20

10.11 Reagent Holder ..................................................................10-21

10.12 Setup of Reagent Volume Monitoring ................ ................. 10-23

10.13 Setting of Conversion Formula ........................................... 10-23

10.14 Devices to be Connected ...................................................10-24

10.15 Setup of System ................................................................. 10-26

10.16 Password Settings .............................................................. 10-28

10.17 Printout of Settings ............................... .... ... ... ... ... .... ... ... ... . 10-29

10.18 Addition of New Analysis Parameters ................................10-30

10.19 Reagent Name/Holder List ................................................. 10-31

Revised January 2003 - 2.0_en

Sysmex CA-500 series III

Page 5

11. Maintenance and Supplies Replacement ........11-1

11.1 Maintenance Schedule ...................... .... ... ... ....... ... ... ... ... .... .. 11-1

11.2 Clean Sample Probe .............................................................11-2

11.3 Discard Used Reaction Tubes .............................................. 11-3

11.4 Dispose of Waste ......................................................... ... ......11-4

11.5 Remove Dew from Reagent Rack

(for CA-530, CA-540, CA-550 and CA-560 only) ..................11-5

11.6 LED Calibration .....................................................................11-6

11.7 Replace Rinse Filter .............................................................11-9

11.8 Supply Printer Paper ............................................................. 11-9

11.9 Replace Fuse ......................................................................11-11

11.10 Check and Drain Trap Chamber ..... .................................... 11-11

11.11 Prime Rinse Solution to Hydraulic Line ..............................11-12

11.12 Clean Instrument ................................................................11-13

11.13 Replenish Reagent ...................................... ... .... ... ...... ... .... 11-14

11.14 Replenish Reaction Tubes .................................................. 11-16

11.15 Replenish Rinse Solution .................................................... 11-18

11.16 Supply Parts List .................................................................11-19

12. Troubleshooting ................................................12-1

12.1 Introduction ..................................................... ...................... 12-1

12.2 Error Corrective Procedure ...................................................12-2

12.3 Analysis Data Error ............................................................. 12-13

12.4 Cycle Counter .....................................................................12-14

12.5 Sysmex Menu .....................................................................12-15

12.6 Special Operation ...............................................................12-16

13. Functional Description ......................................13-1

13.1 Detection Principle of Coagulation Method (PT, APTT,

Fbg, TT, PCcl, BXT, LA1*, LA2*, Factor Deficiency) ............13-1

13.2 Detection Principle of Chromogenic Method (AT3, APL*, Plg*,

PC, Hep: CA-530, CA-540, CA-550 and CA-560 only) .........13-4

13.3 Detection Principle of Immunology Method

(D-Dimer, P-FDP*: CA-550 and CA-560 only) ......................13-5

13.4 Analysis Mechanism .............................................................13-7

13.5 Analysis Flow ........................................................................ 13-7

13.6 Reference Procedures ........................................................13-16

14. Technical Information .......................................14-1

14.1 Instrument Specifications ...................................................... 14-1

14.2 Installation ....................................................... .... ... ... ... ... ......14-8

14.3 Serial Interface for Host Computer ..................................... 14-17

14.4 Text Format ........................................................................14-24

14.5 ID Barcode ............................. ... ... ... ... .... ... ..........................14-34

15. Index ...................................................................15-1

16. Appendix (A) ......................................................16-1

16.1 Maintenance CheckList ........................................................ 16-1

16.2 Reagents .............................................................................. 16-3

Revised January 2003 - 2.0_en

IV Sysmex CA-500 series

Page 6

1. Introduction ..............................................................1-1

1.1 Introduction .................................................................................1-1

1.2 Explanation of Signs ...................................................................1-3

1.3 Names ................................ .................................... ..................... 1-4

1.4 Serial Number..............................................................................1-4

1.5 Revision History ..........................................................................1-4

Revised January 2003 - 2.0_en

Sysmex CA-500 series

Page 7

1. Introduction

1.1 Introduction

Introduction

The Sysmex® Automated Blood Coagulation Analyzer CA-500 series is

a compact fully-automated instrument capable of 5-parameter random

analysis for In Vitro Diagnostic use.

This instrument incorporates latest technologies as represented by microcomputers, thus enabling analysis of multiple parameters with increased

flexibility. Of PT, APTT, Fbg, Thrombin Time (Coagulation Method),

and Antithrombin III (Chromogenic Method: Can be analyzed only with

CA-530, CA-540, CA-550 and CA-560), D-Dimer (Immunology

Method: Can be analyzed only with CA-550 and CA-560), etc., this

instrument is able to analyze 5 parameters simultaneously. In addition, it

has a number of functions including preferential processing of STAT

samples and a built-in quality control function. Moreover, it allows

analyzed data to be displayed and printed out together with reaction

curves, thus making it possible to obtain highly reliable analysis results.

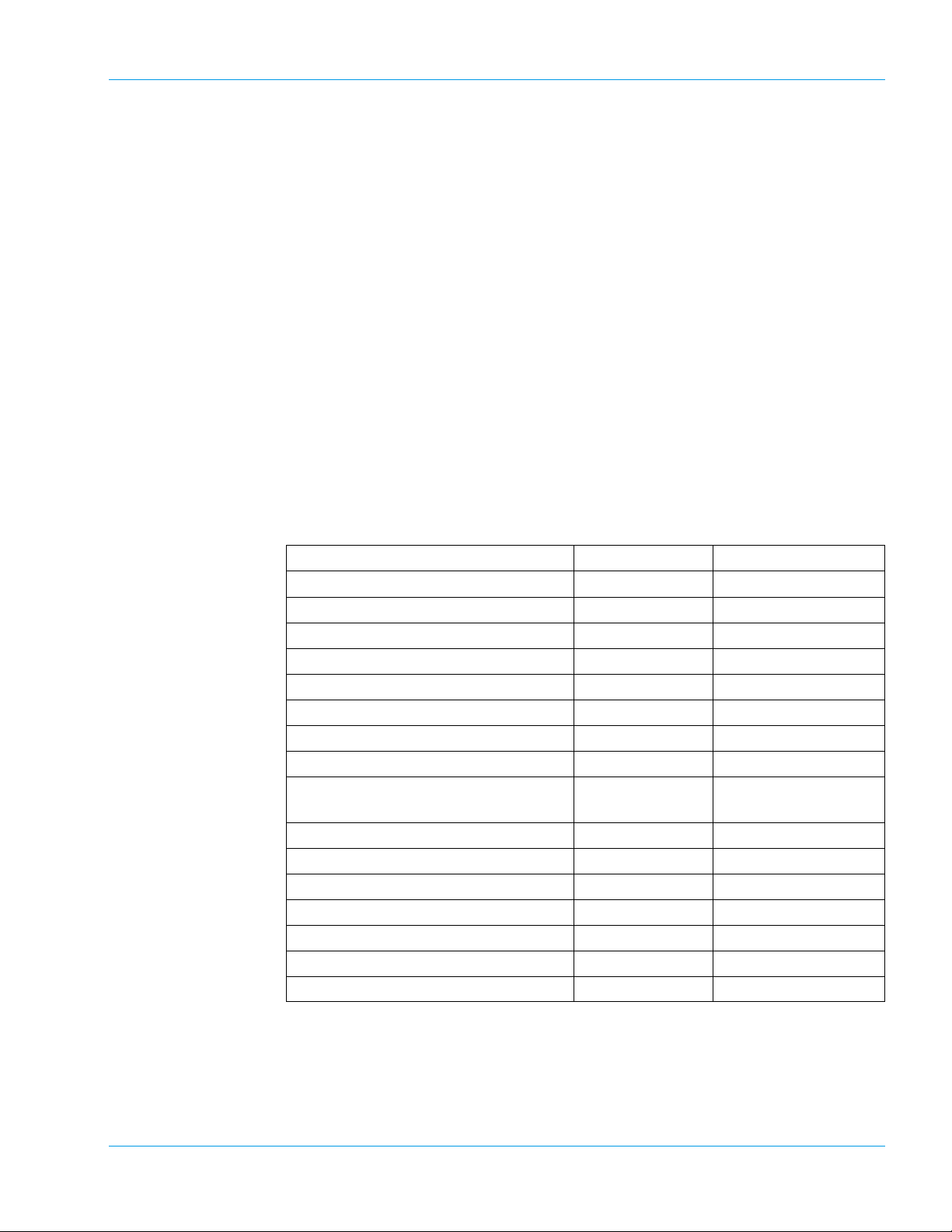

Analysis Parameters and Detection Principles

Parameter Test name Applied

Prothrombin Time PT Coagulation Method

Activated Partial Thromboplastin Time APTT Coagulation Method

Fibrinogen Fbg Coagulation Method

Thrombin Time TT Coagulation Method

Protein C coagulometric PCcl Coagulation Method

Batroxobin BXT Coagulation Method

LA1 Screening* LA1 Coagulation Method

LA2 Confirmation* LA2 Coagulation Method

Factor Assay** II, V, VII, VIII, IX,

Antithrombin III AT3 Chromogenic Method

α2-Antiplasmin* APL Chromogenic Method

Plasminogen* Plg Chromogenic Method

Protein C chromogenic BCPC Chromogenic Method

Heparin Hep Chromogenic Method

D-Dimer Plus*, Advanced D-Dimer*** DDPl, AdDD Immunoassay Method

P-FDP**** PFDP Immunoassay Method

Coagulation Method

X, XI, XII

(*) Not available in the USA.

(**) Data evaluated for factors VII and VIII only.

(***) Only available for use in the USA.

(****) Only available for use in Asia.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 1-1

Page 8

Introduction

Manufacturer

SYSMEX CORPORATION

1-5-1 Wakinohama-Kaigandori

Chuo-ku, Kobe 651-0073

Japan

European Representative

SYSMEX EUROPE GmbH

Bornbarch 1

D – 22848 Norderstedt

Tel.: +49 40 5 27 26-0

Fax: Tel.: +49 40 5 27 26-100

Ordering of Supplies and Replacement Parts

If you need to order supplies or replacement parts, please contact your

local Sysmex representative.

Service and Maintenance

Training Courses

CE-Mark

Please contact the Service Department of your local Sysmex representative.

For further information please contact the Sysmex representative in your

country.

The IVD system described in this manual is marked with a CE mark

which confirms the observance of the essential requirements of the following European directives:

-98/79/EC in-Vitro Diagnostics Directive.

CA-500 series instruments with serial numbers shown below or smaller

numbers only conform to the 89/336/EEC electromagnetic compatibility.

CA-510 A1342

CA-520 A1017

CA-530 A1902

CA-540 A3883

CA-550 A1051

CA-560 A1110

1-2 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 9

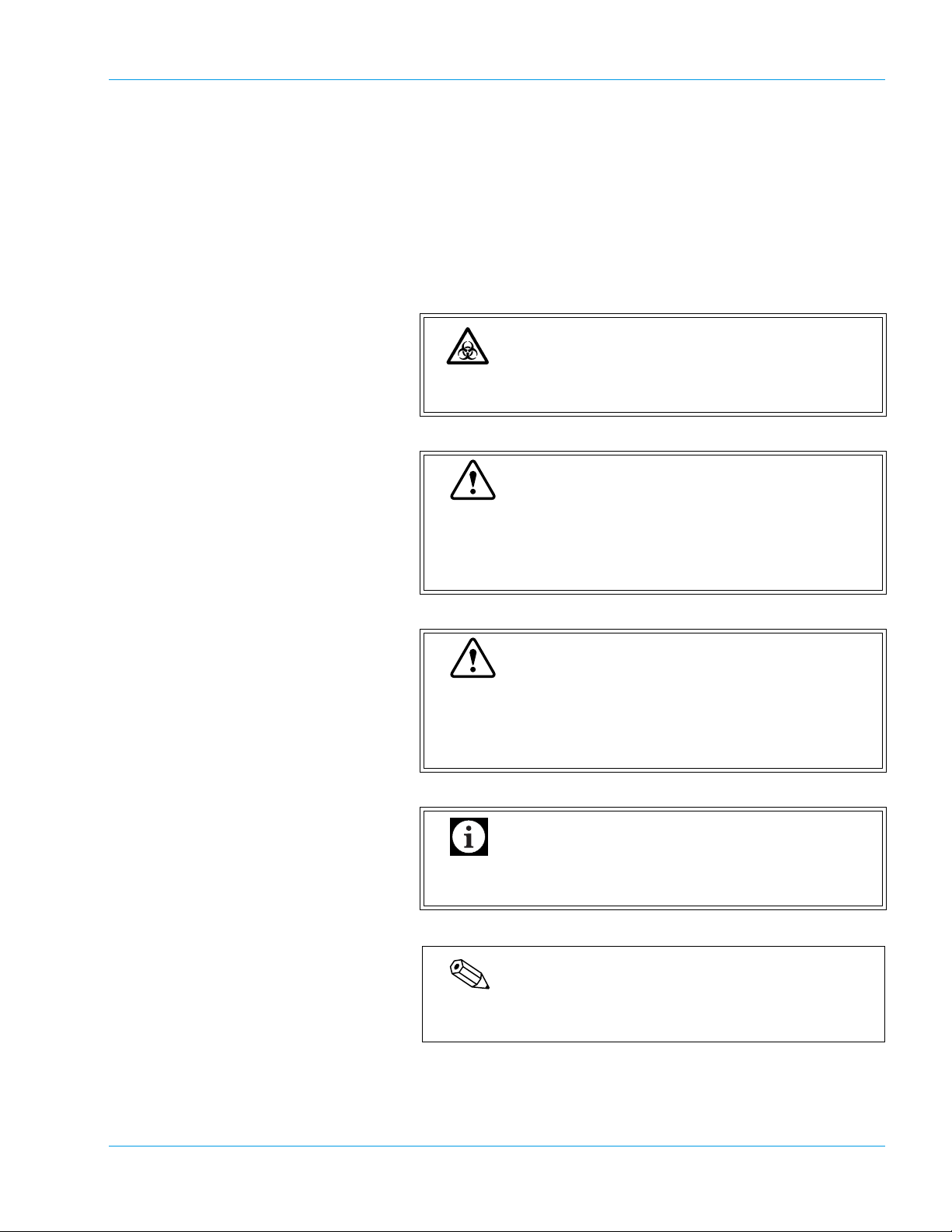

1.2 Explanation of Signs

Introduction

This manual carries a variety of illustrations to make sure that the product can be used safely and correctly, thus preventing users and others

from suffering injuries and damage to property.

The illustrations and meaning are described in the following.

Do understand what they mean before proceeding to the text of the

MANUAL.

Risk of Infection

Indicates the presence of a biohazardous material or

condition.

Warning

If this sign is ignored and the instrument is operated

incorrectly, there is a potentially hazardous situation

which could result in death or serious injury of operator,

or grave property damage.

Revised November 2003 - 2.0_en

Caution

If this sign is ignored and the instrument is operated

incorrectly, there is a potentially hazardous situation

which may result in injury of operator, adverse effect on

results, or may cause property damage.

Important

Indicates what we would like you to know to maintain

instrument performance and prevent its damage.

Note

Indicates information which will come handy in operating the

instrument.

Sysmex CA-500 series 1-3

Page 10

Introduction

1.3 Names

• Sysmex is a registered trademark of SYSMEX CORPORATION in

the USA, in Germany and other countries.

• CA CLEAN I and CA CLEAN II are trademarks of SYSMEX COR-

PORATION in the USA, in Germany and other countries.

• Actin, Ci-Trol, Data-Fi and Innovin are registered trademarks of

Dade Behring Inc in the USA, in Germany and other countries.

• Dade is a registered trademark of Dade Behring Inc.

• Pathromtin and Thromborel are registered trademarks of Dade

Behring Marburg GmbH in Germany and other countries and are

trademarks of Dade Behring Marburg GmbH in the USA.

• VACUTAINER is a registered trademark of Becton, Dickinson and

Company.

• VACUETTE is a registered trademark of Greiner Bio-One GmbH.

1.4 Serial Number

1.5 Revision History

• Other trademarks referenced are property of their respective owners.

CA-500 series instruments with serial numbers below or smaller

CA-510 A1300

CA-520 A1018

CA-530 A1805

CA-540 A3405

will not have the capability to manage more than 7 Assays/Standard

curves and they are limited to use 7 × 6 QC files.

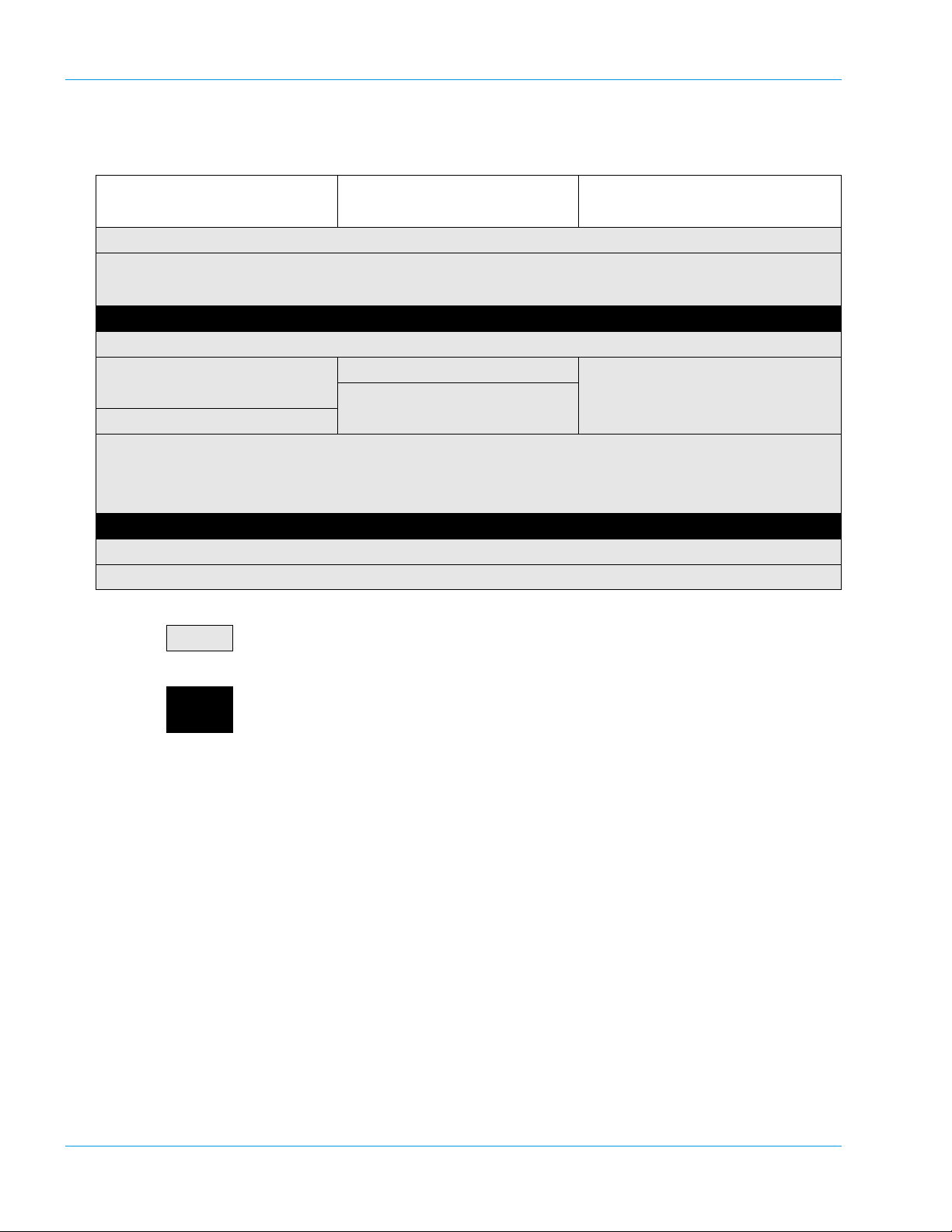

Version Date Changes

Manual Software

1.0 00-13 October 2001 Launch Version

2.0 00-15 January 2003 Second Edition

2.0 00-15 May 2003 Minor Correction

2.0 00-15 September 2003 Minor Correction

2.0 00-15 November 2003 To conform with IVD

Directive

2.0 00-17 April 2004 Minor Correction

1-4 Sysmex CA-500 series

Revised April 2004 - 2.0_en

Page 11

2. Safety Information ...................................................2-1

2.1 Specified Conditions of Use ........................................................2-1

2.2 General Information ....................................................................2-1

2.3 Installation Location ..................... ... ... .... .....................................2-3

2.4 Avoidance of Infections ...............................................................2-3

2.5 Handling of Reagents ............................. ... ... ... ... .... .....................2-4

2.6 Maintenance of the Instrument ....................................................2-5

2.7 Disposal of Materials ...................................................................2-5

2.8 Markings on the Instrument .........................................................2-6

2.9 Personnel .................................. .................................................. 2-8

2.10 Storage Condition (Transportation) .. ... .... ... ... ... ... .... ... ... ....... ... ... ..2-8

Revised November 2003 - 2.0_en

Sysmex CA-500 series

Page 12

2. Safety Information

Before operating this instrument, carefully read this manual, and strictly

follow the instructions given in them.

2.1 Specified Conditions of Use

The instrument shall only be used for in vitro analysis of human blood or

artificial control blood. It may not be used for any other purpose.

Only reagents and cleaning solutions mentioned in this manual are permitted for use.

By observing the specified conditions of use, the frequency of cleaning

and maintenance work can be reduced.

2.2 General Information

Safety Information

Warning

• Keep long hair, fingers and clothing away from rotating parts of the instrument.

• During analysis, do not open the light shield cover

and put in hands or fingers.

This could cause injury. When the light shield cover

is opened during analysis, the alarm sounds and the

operation stops.

• In the event that the instrument emits an abnormal

odor or any smoke, turn off its power supply immediately and pull out the power plug from the wall

socket.

If the instrument is used continuously in that state,

there is a hazard that fire, electrical shock, or injury

may result. Contact your local service representative

for inspection.

• Take care not to spill blood or reagent, or drop wire

staples or paper clips into the instrument.

These might cause short circuit or smoke emission. If

such problem should occur, turn off the power supply

immediately and pull out the power plug from the wall

socket. Then contact your local service representative for inspection.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 2-1

Page 13

Safety Information

Warning

• Do not touch the electric circuits inside the instrument. Especially with wet hands there is a risk of

electric shock.

• Never put the power plug in any socket other than

that specified. When installing the instrument, be

sure to ground it. Otherwise, fire or electrical shock

will result.

• Take care not to damage the power cord, put a

heavy thing on it, or pull it forcibly. Otherwise, the

wire may become shorted or break, causing fire or

electrical shock.

• When connecting the instrument to a peripheral (host

computer, etc.), be sure to switch off the power supply beforehand. Otherwise, fire or electrical shock

may result.

• Use the check-digit as much as possible. If the

check-digit cannot be used, the potential of the incorrect reading of the barcode label may be increased.

Caution

• Read this manual carefully to operate the instrument

by the proper method. Keep it securely in a specified

location for future reference.

• This instrument must only be operated as instructed

in this manual.

2-2 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 14

2.3 Installation Location

Safety Information

Caution

• Install in a place which is not subject to water splash.

• Install in a place which is not subject to adverse

effects of high temperature, high humidity, dust,

direct sunlight, etc.

• Do not give the instrument a strong vibration or

impact.

• Install at a place which is well ventilated.

• Do not install near devices that cause signal noise,

such as radios and centrifugal machines.

• Do not install near chemicals storage or in a place

where gas is generated.

2.4 Avoidance of Infections

Risk of Infection

• In principle, all parts and surfaces of the instrument

must be regarded as infective.

• Never touch waste, or parts having been in contact

with waste, with bare hands.

• Should you inadvertently come in contact with potentially infective materials or surfaces, immediately

rinse skin thoroughly with plenty of water, then follow

the antiseptic regulations of your laboratory.

• Be careful when handling samples. Always wear

latex or non latex examination gloves; otherwise contamination could result. If a sample happens to enter

your eye or a cut, wash it off with plenty of water, and

immediately visit a physician.

• Control plasma may also be infective. Wear latex or

non latex examination gloves during QC process. If

plasma happens to enter your eye or a cut, wash it

off with plenty of water, and immediately visit a physician.

• Use care when handling waste liquid. If it adheres to

the skin or clothing, wash it off using an antiseptic

solution.

Revised November 2003 - 2.0_en

Sysmex CA-500 series 2-3

Page 15

Safety Information

2.5 Handling of Reagents

Warning

• Avoid direct contact with reagents. Reagents can

cause irritation of the eyes, skin and mucous membranes.

• If a reagent happens to adhere to the hand or the

skin of another area, wash it off immediately using

plenty of water.

• If a reagent happens to enter your eye, wash it off

immediately using plenty of water, and take medical

treatment at once.

• If you should swallow it inadvertently, call for a physician immediately, drink a large volume of water, and

then induce vomiting.

• CA CLEAN I is a strong alkaline cleaning material. It

should not come in contact with skin or clothing. If it

happens nevertheless, rinse skin or clothing with

plenty of water to avoid injury or damage.

Caution

• Read the instructions described on the reagent containers.

• After unpacking, be sure not to allow dust, dirt, or

bacteria into the reagents.

• Do not use reagents that have passed the expiration

period.

• Handle a reagent gently to prevent formation of bubbles. Shake carefully if necessary.

Do not use directly after transportation.

• Take care not to spill a reagent. If it has spilled, wipe

it off immediately using a wet cloth or something.

• Prepare a sufficient volume of reagent which takes

into consideration the minimum sample volume

required. When the volume of the reagent is insufficient, sample may not be analyzed accurately.

• The CA CLEAN I rinse solution contains sodium

hypochlorite. If the material makes contact with the

instrument's surfaces, it will affect the surface finish.

There is a danger of corrosion. Immediately wipe up

CA CLEAN I with a damp cloth.

• A reagent is a chemical substance employed for

external diagnosis and cannot be used for any medical treatment.

Revised January 2003 - 2.0_en

2-4 Sysmex CA-500 series

Page 16

2.6 Maintenance of the Instrument

Always wear latex or non latex examination gloves when

performing maintenance work or inspection. Also use the

specified tools and parts. After work is over, wash the

hands in an antiseptic solution. There is a possibility that

those areas of the hand which came in contact with

blood could suffer infection.

When carrying out inspection and maintenance of the

instrument, use only the specified tools and parts. Never

use substitute parts or modify parts. Such actions are

dangerous and prohibited by the Pharmaceutical Affairs

Law.

Safety Information

Risk of Infection

Warning

2.7 Disposal of Materials

Risk of Infection

When discarding waste liquid, instrument consumables

and instrument, take proper steps to dispose of them as

medical, infective and industrial wastes.

If they are contaminated with blood, there is a possibility

of bacterial infection occurring.

Revised November 2003 - 2.0_en

Sysmex CA-500 series 2-5

Page 17

Safety Information

2.8 Markings on the Instrument

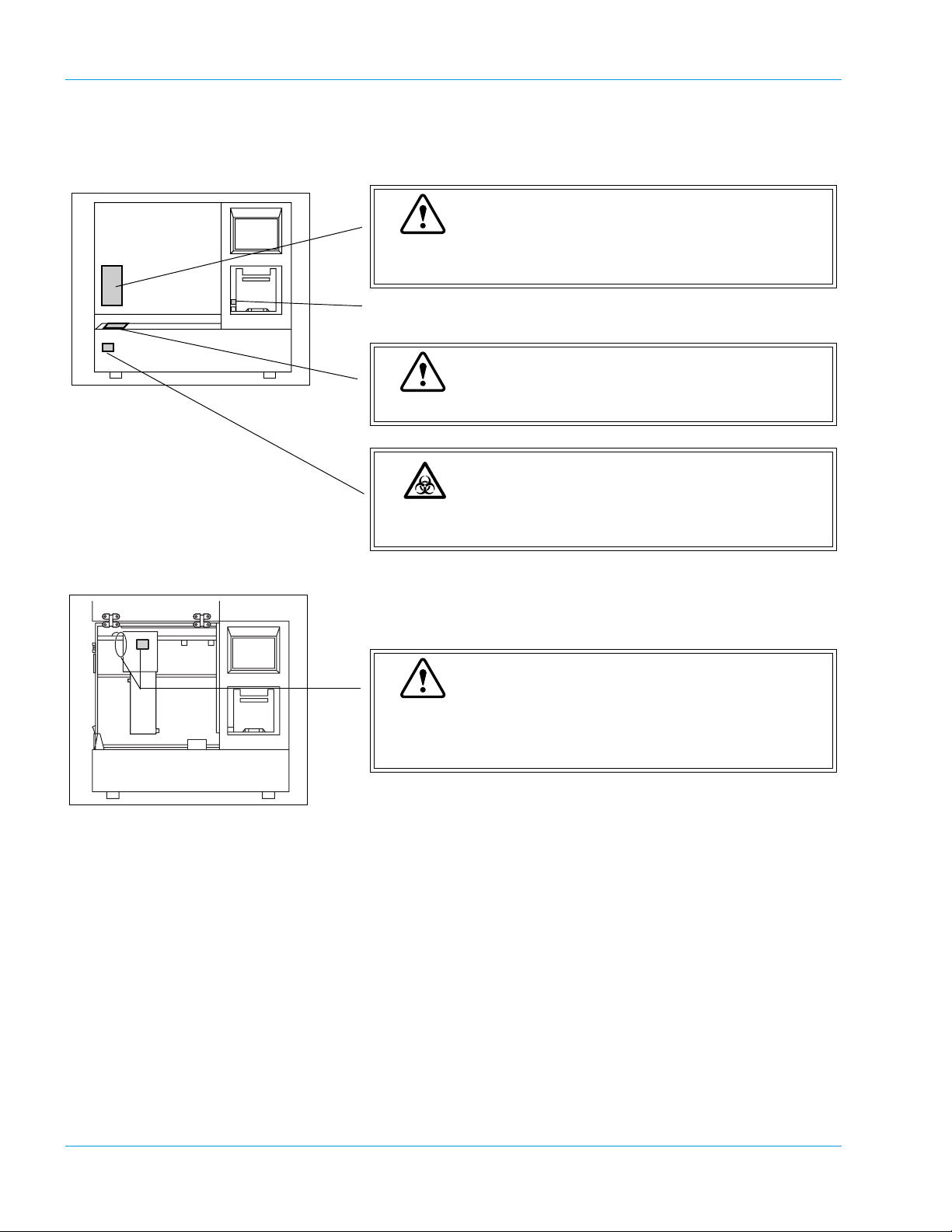

Warning

DO NOT place your fingers and hands inside while analyzing. Pipette can move in any direction.

Fast Stop (Mechanical Stop)

Warning

DO NOT press on the sampler unit to prevent damage.

Risk of Infection

In principle, all parts and surfaces of the instrument must

be regarded as infective.

Warning

When the arm is to be moved while the pipette is in the

down position, pull up the pipette to the same height as

catcher, and move the arm.

Revised November 2003 - 2.0_en

2-6 Sysmex CA-500 series

Page 18

Safety Information

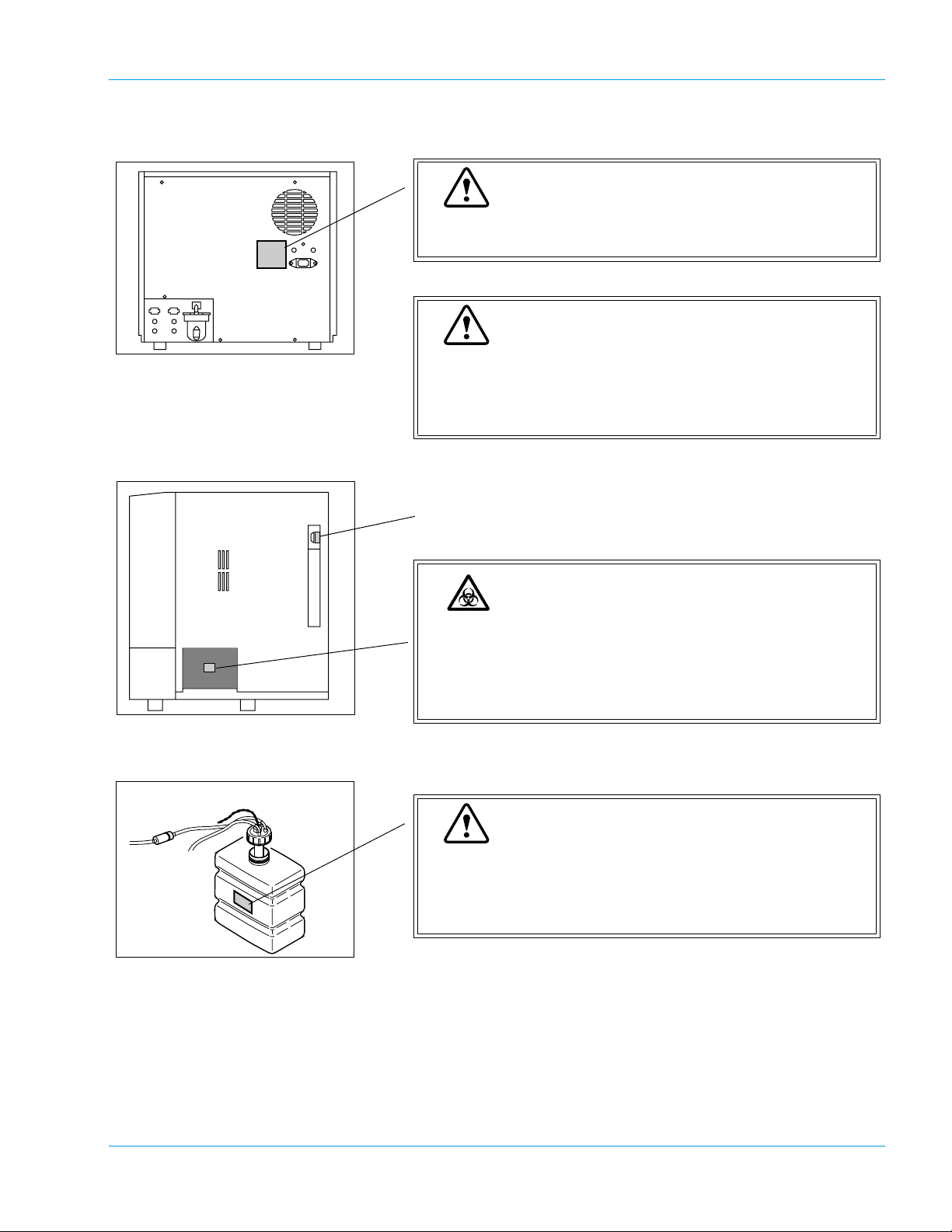

Warning

To avoid risk of electrical shock, disconnect the power

cord before replacing the fuse.

Warning

Proper use of the appropriate power cord assures adequate grounding for the system. Failure to properly

ground the instrument bypasses important safety features and may result in an electrical hazard.

RS-232C Serial Port (HC Connector)

Risk of Infection

To avoid contact with biohazardous materials, gloves

must be worn when handling the tube trash and used

reaction tubes.

Wash your hands with an antimicrobial solution after

completing the procedure.

Warning

To avoid dusts or contaminants entering the rinse bottle,

ensure the float switch does not touch any surfaces

when replenishing distilled water. Dusts or contaminants

will cause malfunction of the solenoid value.

Revised April 2004 - 2.0_en

Sysmex CA-500 series 2-7

Page 19

Safety Information

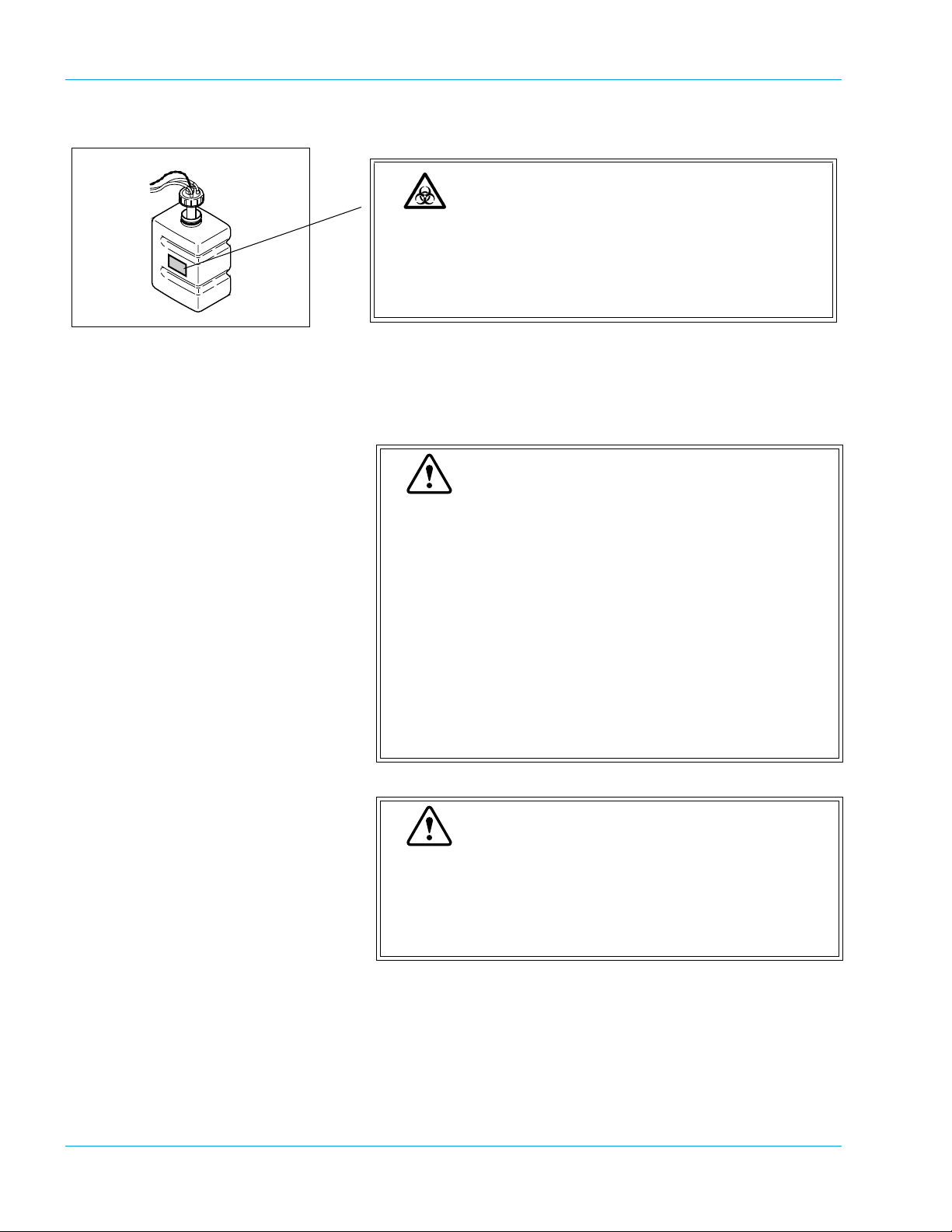

2.9 Personnel

Risk of Infection

The waste container and contents should be considered

potentially biohazardous. Do not handle the waste container without proper protective equipment. Wear gloves

when handling. Wash your hands with an antiseptic solution after completing the procedure.

Caution

• Those who have no or only limited experience in

using the instrument are recommended to have guidance or assistance from those with sufficient experience.

• If the instrument has developed a problem by any

chance, a person in charge of it should take steps

within the range specified in Instructions For Use. As

to problems other than those mentioned, contact

your local service representative for repair.

• Instrument unpacking, installation, and confirmation

of initial operation must be done by your local service

representative.

Warning

This instrument is clinical laboratory equipment for

screening.

When making clinical judgment based on analysis

results, the doctor must also consider clinical conditions

and other inspection results for an overall judgment.

2.10 Storage Condition (Transportation)

• Ambient Temperature: -10ºC to +60ºC

• Relative humidity: 95% or less

(Non condensing / Keep dry)

2-8 Sysmex CA-500 series

Revised November 2003 - 2.0_en

Page 20

3. Design and Function ...............................................3-1

3.1 Overview ..................................................................................... 3-1

3.2 Operation Flow ....................................................... .....................3-8

Revised January 2003 - 2.0_en

Sysmex CA-500 series

Page 21

3. Design and Function

3.1 Overview

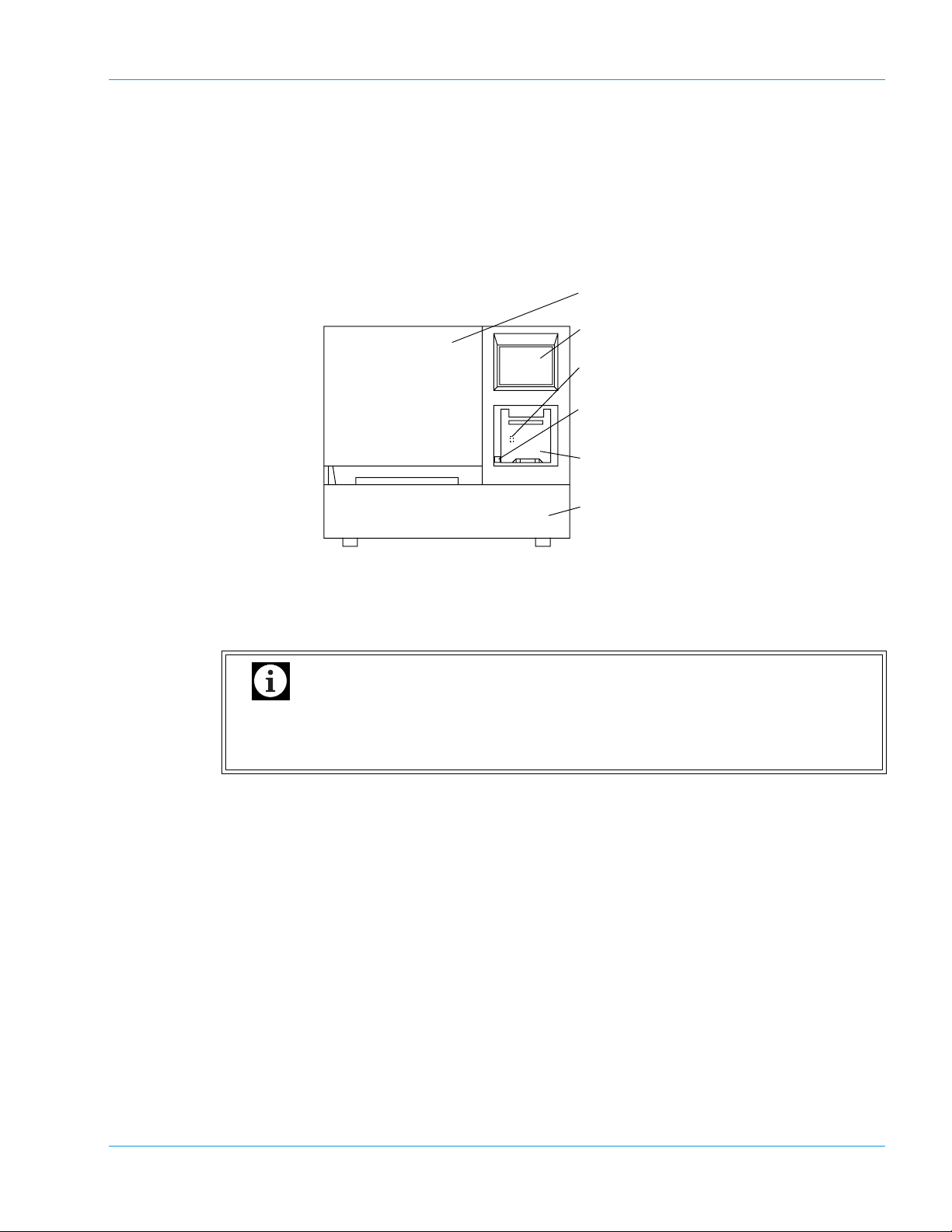

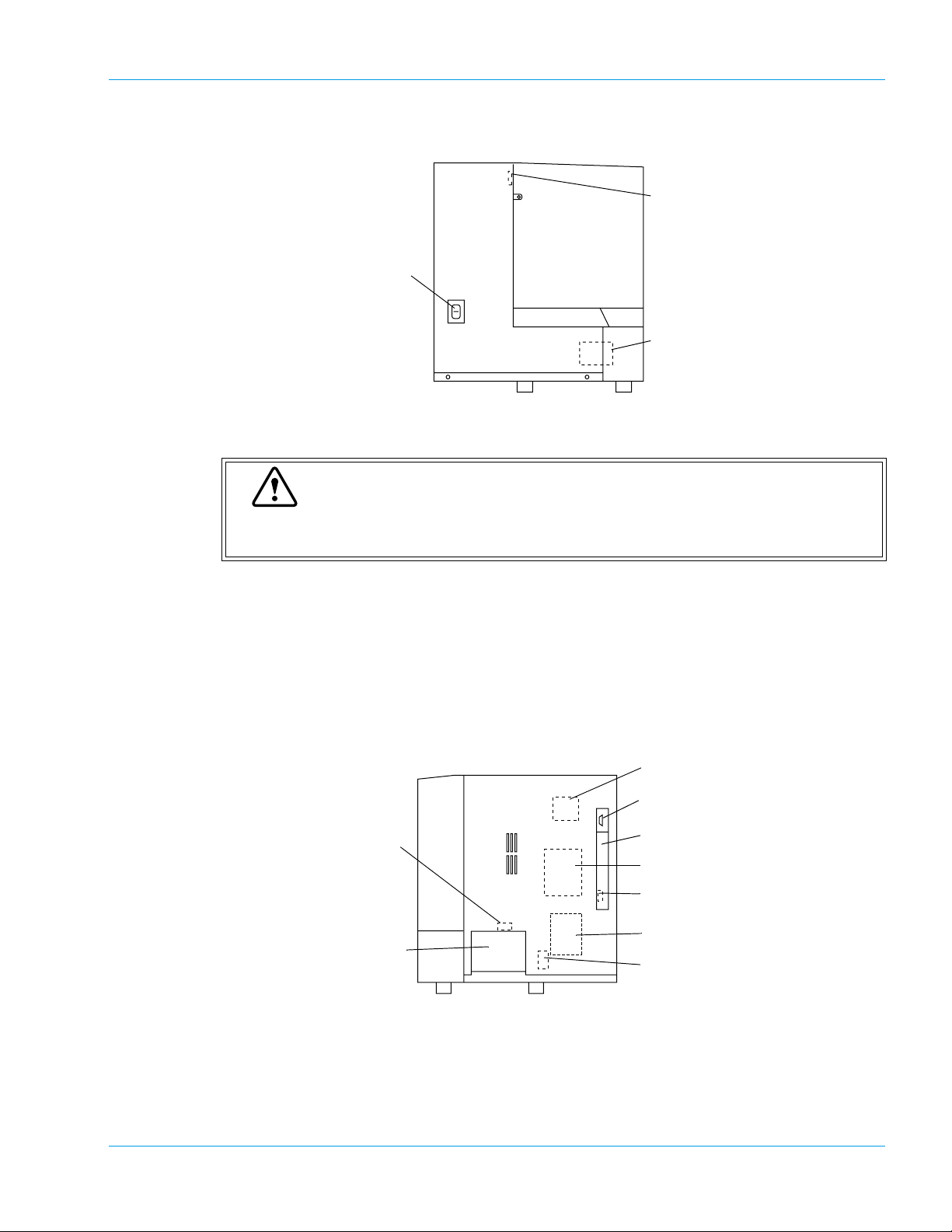

Front

Design and Function

1. Light Shield Cover

2. LCD (Liquid Crystal Display)

3. LCD Contrast Adjustment Knob

4. Mechanical Stop Switch

5. Built-in Printer

6. Sampler

1. Light Shield Cover

Prevents photoelectric detection from being affected by scattered light from external sources.

Ensure this cover is shut before proceeding to analyze any samples. Analysis cannot be started

if this cover remains open.

Important

Do not open the Light Shield Cover while analysing. Opening the cover will suspend analysis and beep the alarm. Also, opening the cover and inserting your hand

may cause injury.

2. Liquid Crystal Display (LCD)

Displays analysis results, reaction curves, sample numbers, test conditions, etc.

The LCD functions as a touch-sensitive control panel. The operator can execute various opera-

tions and enter settings by lightly touching keys displayed on the LCD.

3. LCD Contrast Adjustment Knob

Controls LCD contrast. This knob is located inside the printer cover.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 3-1

Page 22

Design and Function

4. Mechanical Stop Switch

Used to immediately stop the mechanical unit in the instrument in the event of an emergency.

Note that the power of the instrument is not turned off even when this switch is turned on. If

emergency stop of the instrument is required due to power failure of the laboratory, immediately turn off the power of the instrument.

If there is a sample that has been already dispensed, this sample has to be reanalyzed from the start.

5. Built-in Printer

Setting conditions, error messages and analysis results are printed out on the thermal paper of

the graphic printer. The LCD contrast adjustment knob is located inside the built-in printer.

6. Sampler

The sampler has a load capacity of one sampler rack with 10 sample tubes. The sampler racks

are specific for Sysmex instruments. One rack can be set on the sampler at a time.

Pull out the Sampler toward you to load a rack. Once the rack is loaded, the sampler will oper-

ate without the need for intervention by the operator.

Important

Note

• The sampler unit is locked while sampling and dispensing. Once the status has become

ready to set samples, the sampler lock is released. You can pull out the sampler to set

samples on available positions on the rack in use, or to place a next rack to allow continuous analyses.

• The sampler unit can also be pulled out by the STAT sample analysis procedure to

allow an analysis of a STAT sample.

3-2 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 23

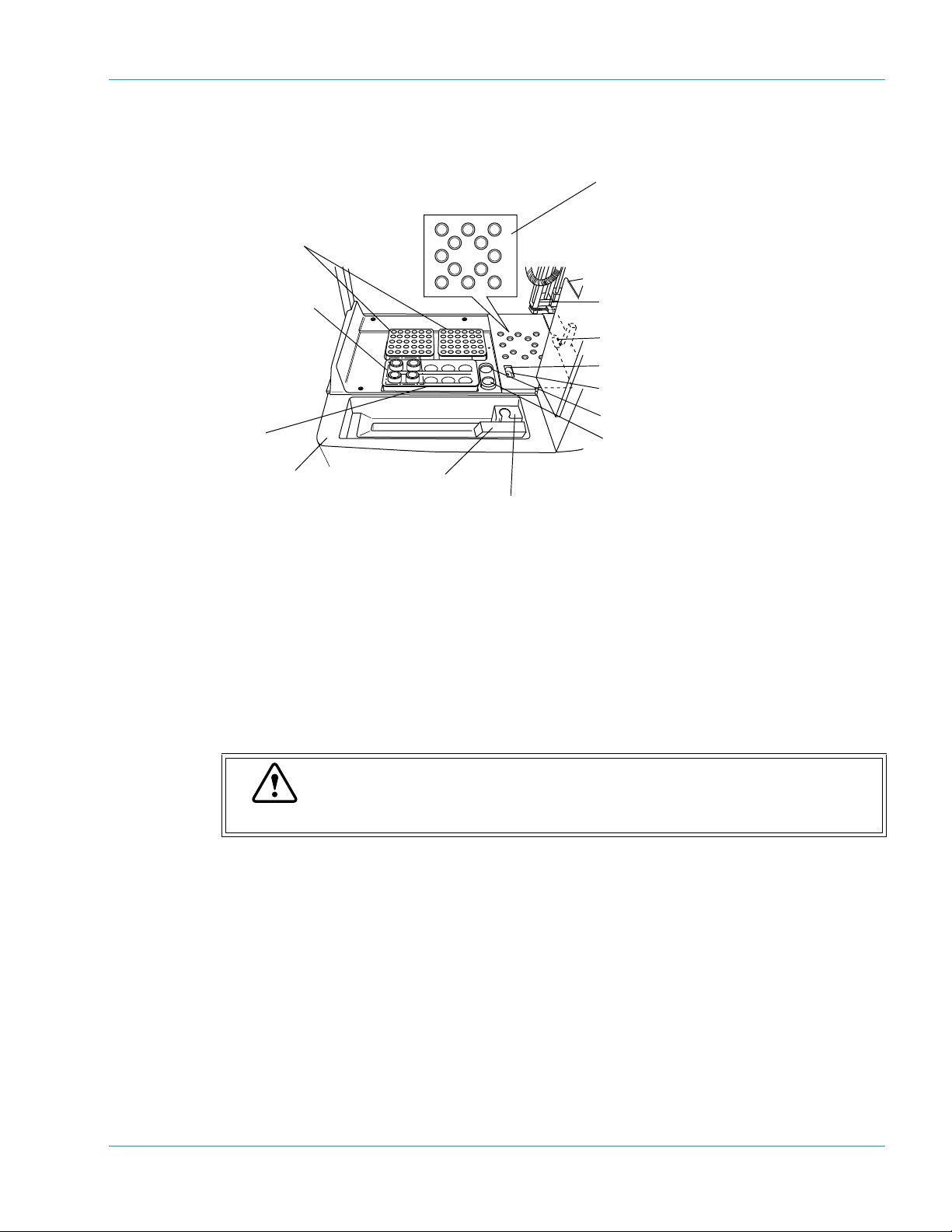

Front Interior (When Opening Light Shield Cover)

888

10

10 10

8

10

97

88

1. Reaction Tube Rack

2. Reagent Cooler Holder

3. Reagent Rack

Design and Function

7. Detection Well (For Immunology

Method)

8. Sample Incubation Wells

9. Detection Well (For Chromogenic

Method)

10. Detection Well (For Coagulation

Method)

11. Probe

12. Reaction Tube Trash

13. Probe Rinse Cup (Outside)

14. Probe Rinse Cup (Inside)

15. CA CLEAN I Holder (default)

16. Buffer Holder (default)

4. Sampler

5. ID Barcode Reader

6. STAT Sample Rack

1. Reaction Tube Rack

Two reaction tube racks can be set. One rack holds up to 30 reaction tubes (SU-40). Tube posi-

tion numbers are assigned from the right rear position of the right rack (No. 1) and count

upwards moving toward the front.

2. Reagent Cooler Holders (For CA-530, CA-540, CA-550 and CA-560 only)

Can hold up to 4 vials with cooler function.

3. Reagent Rack

Reagent vials, whose outer diameter is 22 mm and he ight is 40 mm , can be set directly. Use

sample cups or optional holders to place any vial with other outer diameters.

Caution

If any vial higher than 40 mm is used, the Probe will be damaged permanently.

4. Sampler

Can hold one sample rack.

5. ID Barcode Reader (Optional on CA-510, CA-530 and CA-550)

ID Barcode Reader moves in front of the rack and reads the barcoded label automatically.

6. STAT Sample Rack

Place a STAT sample collection tube or sample cup here. If a sample collection tube is placed,

use optional holders to make the tube diameter fit the rack.

7. Detection well (For Immunology Method: CA-550 and CA-560 only)

Detection well for the immunologic sample. The number of wells is one. The detector is always

kept at 37.0ºC ± 1.0ºC.

Revised September 2003 - 2.0_en

Sysmex CA-500 series 3-3

Page 24

Design and Function

8. Sample Incubation Wells

Six incubation wells are provided, and these wells are kept at 37.0ºC ± 1.0ºC.

9. Detection Well (For Chromogenic Method: CA-530, CA-540, CA-550 and CA-560 only)

Detection well for the chromogenic sample. The number of wells is one. The detector is always

kept at 37.0ºC ± 1.0ºC.

10. Detection Wells (For Coagulation Method)

Four scattered light detection wells are provided, and these wells are kept at 37.0ºC ± 1.0ºC.

11. Probe

This pipette is used to aspirate samples and reagents. It is kept at 37.0ºC ± 1.0ºC.

12. Reaction Tube Trash

Used reaction tubes are disposed into this trash.

13. Probe Rinse Cup (Outside)

The outside of the probe is rinsed with the rinse fluid kept in this rinse cup.

14. Probe Rinse Cup (Inside)

The inside of the probe is rinsed in this rinse cup.

15. CA CLEAN I Holder

CA CLEAN I detergent is set in the vial, whose outer diameter is 22 mm or less, and height is

50 mm or less.

Caution

Use the provided vials to hold the CA CLEAN I detergent. If any vial higher than

50 mm is used, the Probe will be damaged permanently.

16. Buffer Holder

Buffer diluent used for sample dilution is set in the vial, whose outer diameter is 22 mm or less,

and height is 50 mm or less.

Caution

Use the provided vials for the container to keep the Buffer. If any vial higher than

50 mm is used, the Probe will be damaged permanently.

3-4 Sysmex CA-500 series

Revised April 2004 - 2.0_en

Page 25

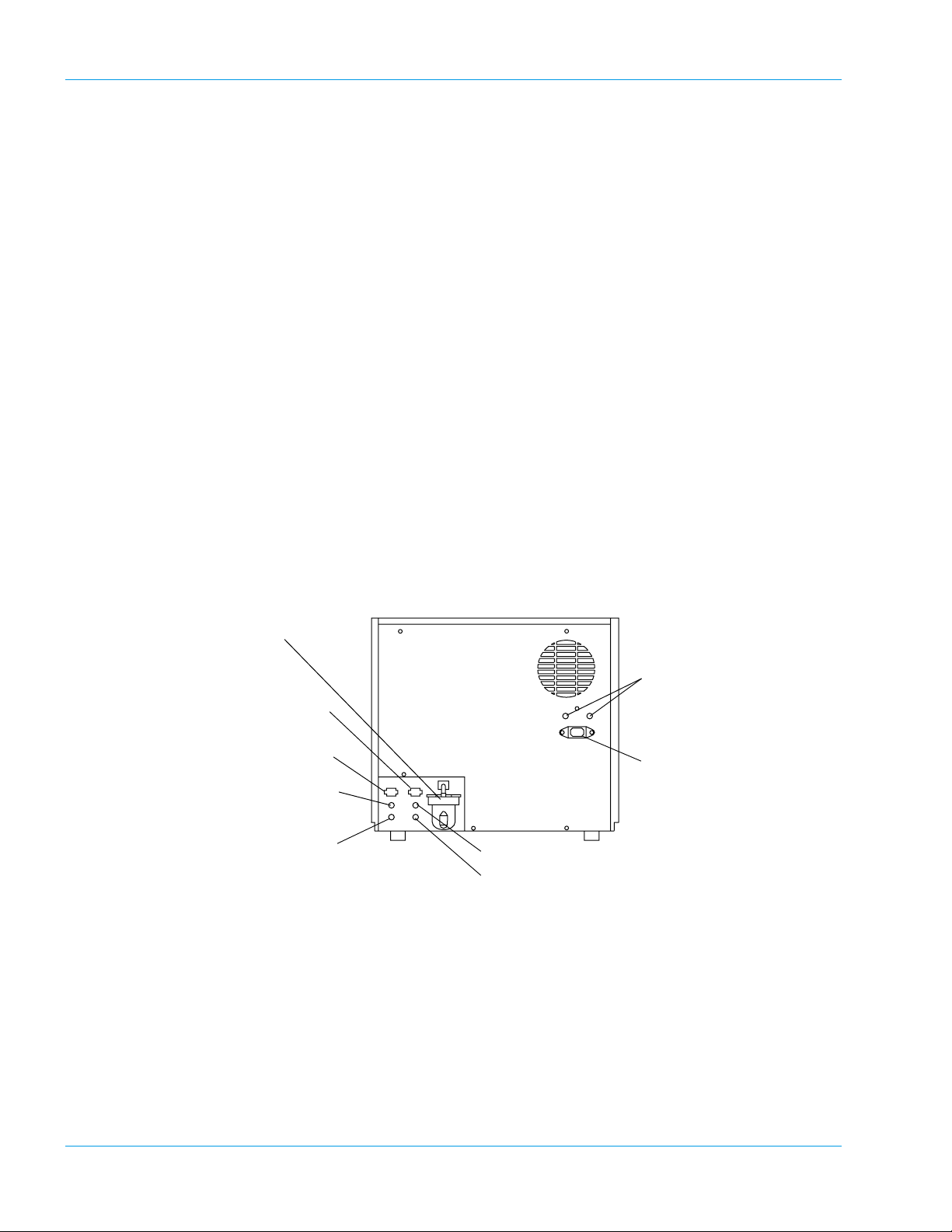

Left Side

Design and Function

2. Cover Sensor Switch

1. Power Switch

3. Cooler Unit

1. Power Switch

Turns the power ON or OFF.

Caution

Please allow at least 5 seconds between turning the instrument OFF and back ON,

or the fuse may be blown.

Right Side

2. Cover Sensor Switch

This monitors if the Light Shield Cover is closed.

3. Cooler Unit

This keeps the reagent cool.

8. Solenoid Valve

for Sample Aspiration

9. Reaction Tube Trash

Drawer

1. X-Y Drive Motor

This motor drives the Probe unit in the X-axis and Y-axis directions.

1. X-Y Drive Motor

2. Host Computer Serial Port

3. Memory Card Cover

4. Pressure Pump

5. DIP Switch

6. Vacuum Pump

7. Solenoid Valve

for Probe Rinse

2. Host Computer Serial Port

For connecting to an external host computer.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 3-5

Page 26

Design and Function

3. Memory Card Cover

This card has PROM chips to load the CA-500 program in to RAM memory. (In tended for your

local service representative use only)

4. Pressure Pump

Supplies the pressure. The instrument cannot function properly at lower pressures.

5. DIP Switch

Changes the system settings.

(Intended for your local service representative use only)

6. Vacuum Pump

Supplies vacuum. The instrument cannot function properly if the vacuum level is lower.

7. Solenoid Valve for Probe Rinse

This valve controls the supply of the rinse solution to the rinse cup unit.

8. Solenoid Valve for Sample Aspiration

This valve controls the aspiration of sample plasma with high accuracy.

9. Reaction Tube Trash Drawer

Rear

Used for storing used reaction tubes.

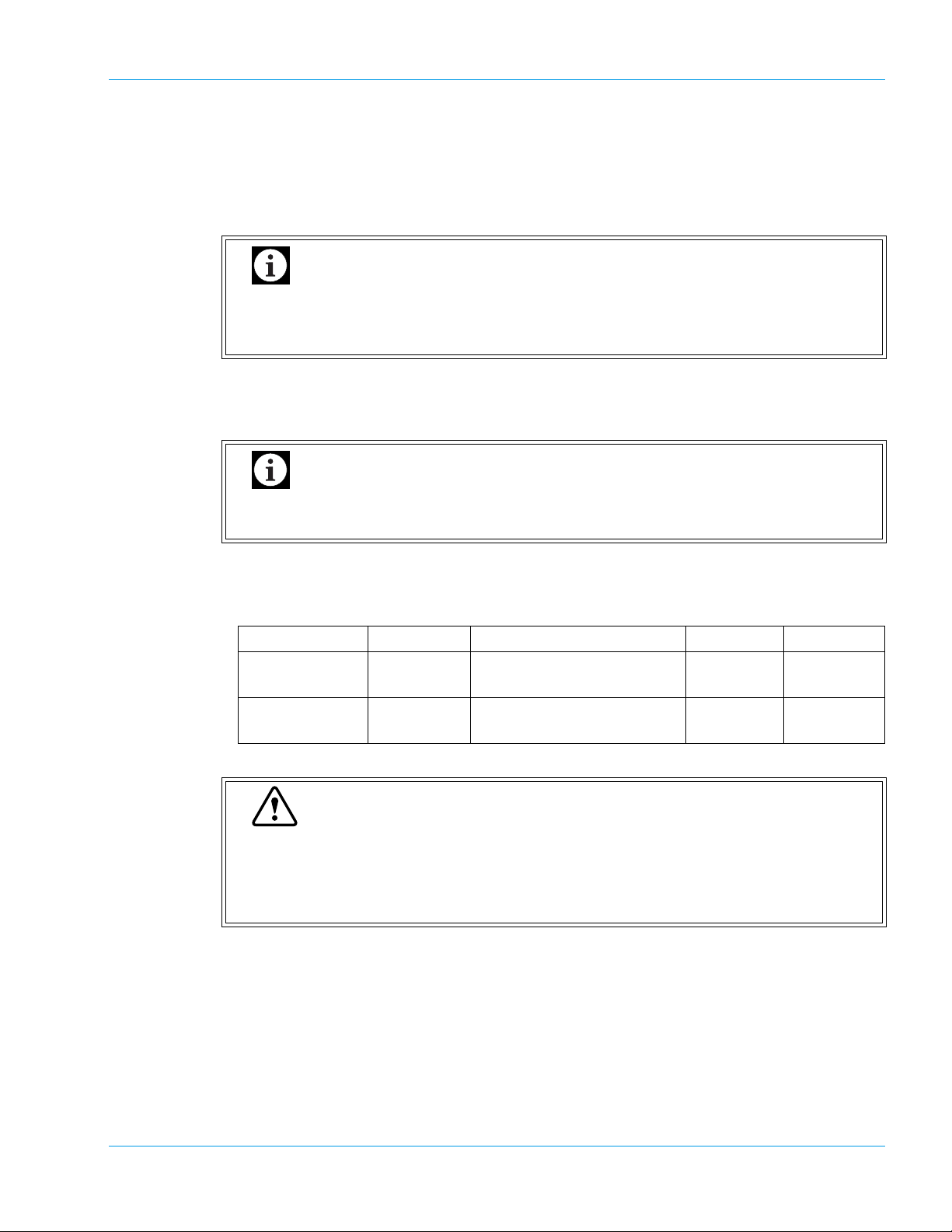

1. Trap Chamber

6. Fuse Holder

2. Float Switch Connector

for Waste Bottle

3. Float Switch Connector

for Rinse Bottle

4. Pressure Supply Nipple

for Rinse Bottle

5. Rinse Aspiration Nipple

8. Vacuum Nipple for Waste Bottle

9. Waste Outlet Nipple

7. Power Connector

1. Trap Chamber

Prevents the waste fluid from flowing back to affect the vacuum pump, in the event of an

abnormality with the instrument.

2. Float Sensor Connector for Waste Bottle (“WASTE”)

For connecting the float sensor switch, located on the waste container, for detecting the waste

fluid level.

3-6 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 27

Design and Function

3. Float Sensor Connector for Rinse Bottle (“RINSE”)

For connecting the float sensor switch, located on the rinse container, for detecting rinse water

level.

4. Pressure Supply Nipple for Rinse Bottle (Colored Black)

To be connected via a tube with the Rinse Bottle.

Important

When the Rinse Bottle is to be opened, disconnect this tubing first to release the

pressure accumulated inside the Rinse Bottle. Failing to do this will splash the pressurized rinse fluid.

5. Rinse Aspiration Nipple (Colored Blue)

For aspirating the rinse water from the Rinse Bottle. To be connected via a tube to the Rinse

Bottle.

Important

When the Rinse Bottle is to be opened, disc onnecting this tubing first will splash the

pressurized rinse fluid. Disconnect the black tubing first.

6. Fuse Holder

Two time-lag type fuses are installed in this Fuse Holder. Replace with the correct type of fuse

(supplied). The rating will be different depending on the instrument specification as below.

Specification Part No. Description Fuse Type Location

117 VAC 266-5106-0 Fuse 250V 6.3A ST4-6.3A-N1

Time Lag Rear Panel

(N.Amer)

220-240 VAC 266-5293-0 Fuse 250V 3.15A No. 19195

(Europe)

Time Lag Rear Panel

Warning

• To avoid risk of electrical shock, disconnect the power cord before replacing the

fuses.

• For continued protection against risk of fire, replace only with a fuse of the specified type and current ratings.

7. Power Connector

For connecting the main power supply (via the supplied power cable).

8. Vacuum Nipple for Waste Bottle (Colored Green)

To be connected via a tube with the Trap Chamber.

9. Waste Outlet Nipple (Colored Red)

For draining waste fluids. Must be connected via a tube to the Waste Bottle.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 3-7

Page 28

Design and Function

3.2 Operation Flow

Manual Order Registration On-Line Order Registration

(Manual Inquiry)

Inspection Before Turning On Power

Turn On Power

• Self Check

Ready

Prepare Reagents

Register Analysis

(Manual Registration)

Prepare Samples

Operation After Completion of Analysis

: Indicates actions performed by the operator.

Prepare Samples

Register Analysis

Press [HC] key

Press [Start] key

• Execution of Analysis

• Completion of Analysis

Ready

Turn Off Power

On-Line Order Registration

(Auto Inquiry)

Prepare Samples

: The message "Ready" will appear on the LCD screen, indicating that analysis, setting, dat a

processing and other operations can be executed.

Revised January 2003 - 2.0_en

3-8 Sysmex CA-500 series

Page 29

4. Installation Environment .........................................4-1

4.1 Installation and Relocation ........................ ... ... ... .... ... ... ... .... ... ... ..4-1

4.2 Installation Location ..................... ... ... .... ... ... ... ... .... ... ... ... .... ........4-1

4.3 Basic Instrument Settings ...................... ... ... ... ... .... ... ... ... .... ... .....4-3

Revised January 2003 - 2.0_en

Sysmex CA-500 series

Page 30

4. Installation Environment

4.1 Installation and Relocation

Installation of the instrument must be conducted by your local service

representative. If it is necessary to relocate the instrument, contact your

local service representative.

It is to be noted that if problems should develop as a result of relocation

conducted by a customer, it will void the warranty even if the instrument

is in the warranty period.

4.2 Installation Location

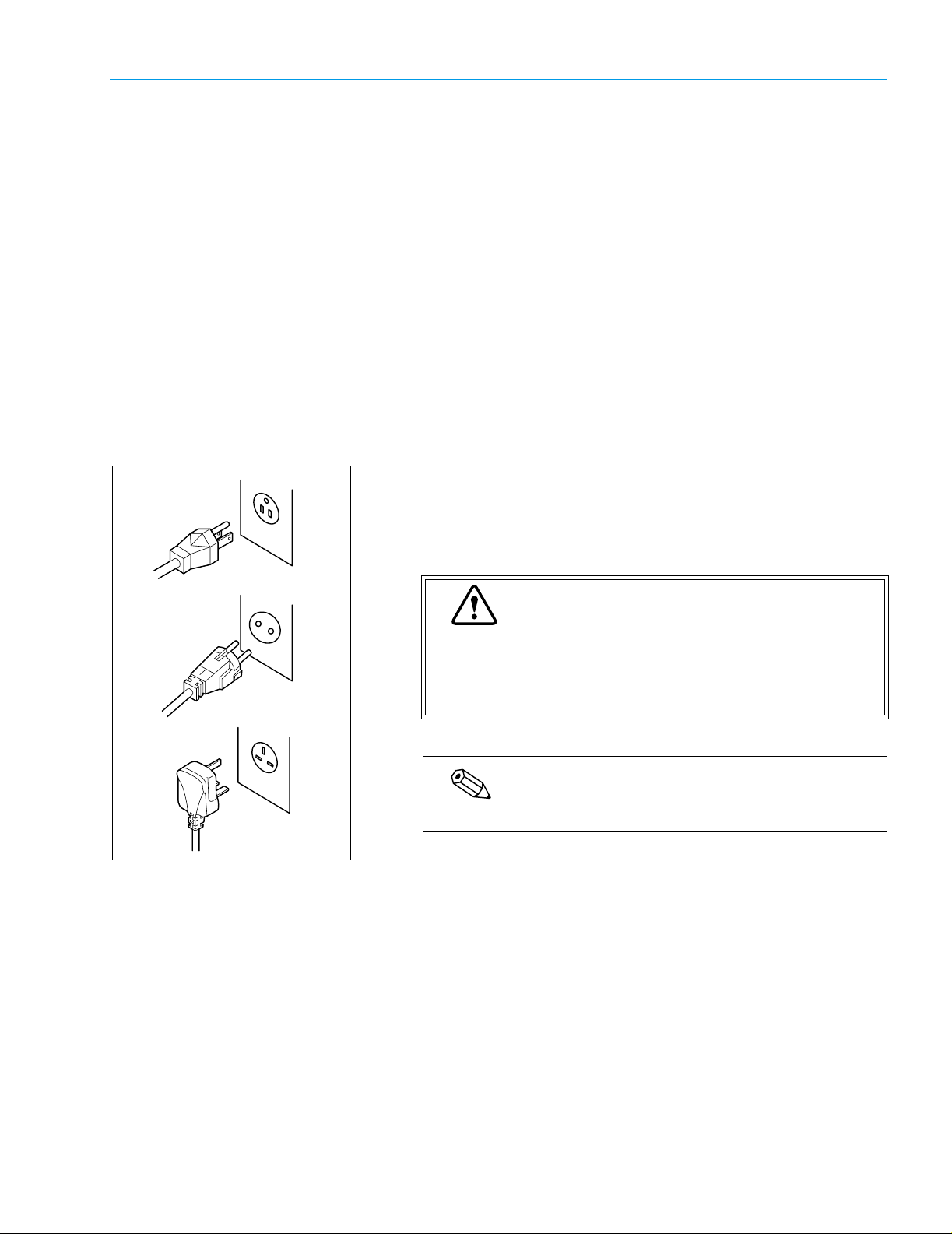

Grounding

The power cord of each instrument uses the 3P plug. When the power

supply socket is 3P (with ground) type, simply plug it to the socket. The

type of cord and plug supplied depends on the source voltage for the system.

Installation Environment

Installation Space

Warning

Proper use of the appropriate power cord assures adequate grounding for the system. Failure to properly

ground the instrument bypasses important safety features and may result in an electric hazard.

Note

The number of power supply sockets required is one.

To ensure optional instrument performance properly, install it at an

appropriate location.

• Select a place where the power supply is located close.

• Be sure to use the supplied bottles to collect rinse solution and waste.

• Keep a space for maintenance and service. Giving consideration to

heat radiation by the instrument, provide at least 50 cm distance from

the wall to sides, rear, and top panels.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 4-1

Page 31

Installation Environment

The dimensions of the instrument are shown below. The power cord is

1.8 m long.

Width (mm) Depth (mm) Height (mm) Weight (kg)

Main unit 540 470 487 Approx. 45

487

540

470

Caution

Be sure to place the rinse bottle and waste bottle on the

base on which the instrument is set. Do not place them

on the instrument. They may cause the instrument to

break down or to fail to produce correct results.

4-2 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 32

Installation Environment

• Use the instrument at an ambient temperature of 15 - 35ºC.

• Use it at a relative humidity range of 30 - 85%.

• When the ambient temperature and humidity are not appropriate,

• Avoid using the instrument in a place where the temperature can

• Avoid using the instrument in a place where it may be frozen.

• Avoid using the instrument where it can be exposed to direct sun-

• Select a well-ventilated place.

• Avoid using it at a place close to a wireless telegraph, communica-

4.3 Basic Instrument Settings

Installation Environment

control by air conditioning.

become extremely high or low.

light.

tion equipment, etc. which may emit high-frequency waves or interfere with radio waves.

Contrast Adjustment for LCD Screen

Remove the printer cover, and adjust LCD screen contrast (shade) using

the contrast adjust dial on the left side of the printer.

Dark

Light

Turning up the dial makes the screen darker and turning down makes it

lighter.

Setup of System (Date/Time)

Set date and time.

The instrument has a built-in clock, so there is no need to set the date and

time every day. Should the power be turned off, the built-in clock is powered by an internal battery.

1. Press [Special Menu] key on the Root Menu screen.

2. Press [Settings] key on the Root Menu screen.

The contents of the Root Menu will change over.

The Setting Menu screen will appear.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 4-3

Page 33

Installation Environment

Ready

Sysmex

Settings

General Set Up

Date/Time

Date 12/01/2001

Time 16:35:38

Replace Rack? YES!

Auto Val/Out

Data Check

Analysis Settings

I/O Setting

General Set Up

Ready

Sysmex

Replace Rack? YES!

Date/Time

Date Format

Password Setting

Ready

Sysmex

Replace Rack? YES!

HC IP

Print Settings

HC IP

HC IP

7

4

1

0

C

Main

Menu

Return

Date

89

5

6

3

2

/

Enter

Quit

3. Press [General Set Up] key on the Setting Menu screen.

The General Set Up Menu screen will appear.

4. Press [Date/Time] key on the General Set Up Menu screen.

The Date/Time Setting screen will display current date and time.

5. Using [↑] and [↓] keys, move the cursor to select Date or Time.

6. Using the numeric keys, set Date and Time, and press [Enter] key.

The parameter in the cursor position is set and the cursor will move

to the next parameter.

Important

• When entry is made in the wrong format, the setting

is not executed.

• If the number of day or month is a single digit, enter it

with a 0 preceding it.

• Enter the time in a 24-hour clock system.

7. When setting is completed, press [Quit] key.

The Renew Confirmation screen will appear.

Sysmex

Replace Rack? YES!

HC IPReady

8. Press [FIX] key, [Continue] key, or [Cancel] key.

[FIX] key: Changes to the renewed setting and returns to the

General Set Up Menu screen.

RENEW SETTING ?

[Continue] key: Returns to the Date/Time Setting screen and allows

continued operation.

[Cancel] key: Cancels the renewed setting and returns to the Gen-

ContinueCancel FIX

4-4 Sysmex CA-500 series

eral Set Up Menu screen.

Revised January 2003 - 2.0_en

Page 34

5. Operation ..................................................................5-1

5.1 Display Screens and Operation Keys .........................................5-1

5.2 Menu Tree ...................................................................................5-3

5.3 Types of Alarm ............................................................................5-5

5.4 Inspection before Turning ON the Power ....................................5-5

5.5 Turn ON the Power .....................................................................5-7

5.6 Prepare Reagents .......................................................................5-8

5.7 Set Reaction Tubes ...................................................................5-13

5.8 Confirm Standard Curve ...........................................................5-14

5.9 Execute Quality Control ............................................................5-15

5.10 Prepare Samples ......................................................................5-15

5.11 Set Sample Nos. .......................................................................5-19

5.12 Manual Inquiry ................................. ... .... ... ... ... ... .... ... ... ... .... ... ...5-22

5.13 Automatic Inquiry ......................................................................5-22

5.14 Start Analysis ............................................................................5-24

5.15 Automatic Sensitivity Adjustment of the Detector

(for CA-530, CA-540, CA-550 and CA-560 only) ......................5-26

5.16 Display Analysis Result .............................................................5-27

5.17 Interrupt Analysis ......................................................................5-28

5.18 Add Samples ... ... ... ... .... ... ... ... .... ... ... ..........................................5-29

5.19 Analyze STAT Sample ..............................................................5-30

5.20 Emergency Stop ................................. .... ... ... ... ... .... ... ... ... .... ... ...5-31

5.21 Shutdown .................................................................................. 5-33

Revised January 2003 - 2.0_en

Sysmex CA-500 series

Page 35

5. Operation

5.1 Display Screens and Operation Keys

The instrument displays all information including the instrument status,

analysis results, etc. on the LCD screen. The LCD screen is divided into

system status area, data processing area, and menu processing area. Press

a key pad, and the function indicated on the key will work.

Operation

System Status Area

(1) (2)

Ready

Sysmex

Stored

Data

Replace Rack? YES!

QC

Main Menu

1 PT 2 APTT 3 Fbg

Rack ID No.

01-01

01-02

01-03

01-04

01-05

(3)

4 TT 5 AT3

12345

Repeat

Standaed

Curve

(4)

HC IP

Group 1

ID No.

Entry

Test

Group

(5)

(6)

Start

Prev

Next

HC

Special

Menu

System Status

Data Processing

Menu Processing

The System Status Area displays [Sysmex] key, error message, analysis

status, and the status of externally connected instruments.

1. [Sysmex] key

Press this key to display Sysmex menu showing Error List, Temperature, and Paper Feed. When the instrument develops an error, causing

the alarm to sound, [ALARM RESET] key appears. Press [Error

List] key to display Error History. Press [Temperature] key to display temperatures of various units. Press [P. FEED] key to feed

printer paper.

For Sysmex Menu, refer to “12. Troubleshooting”.

2. Analysis Status

This indicates analysis status with the current instrument. “Ready”,

“Analyzing”, “Waiting” will appear.

3. Rack Replacement

This indicates whether the sample rack can be replaced or not.

4. HC (Host Computer)

The host computer is set to “Connected”. “HC” appears when sample

data for automatic output becomes available.

5. IP (Internal Printer)

“IP” appears when sample data for automatic output to the internal

printer becomes available.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-1

Page 36

Operation

Data Processing Area

Menu Processing Area

6. [Start]/[INTERR] key

Press this key to start/stop the sampler analysis.

For STAT sample analysis, [Start STAT] key appears.

The data processing area displays analysis progress status, work list,

stored data list, reaction curve, quality control data, standard curve data,

instrument setup status, etc.

When the power supply is turned on, the work list screen (Root Menu

screen) appears.

The menu processing area always displays the menu for function selection.

In selecting a menu, touch a key that shows a menu you want to see.

After power supply turn-on, when system check is completed, the Root

Menu appears. The Root Menu is the basic menu for selecting functions

of this instrument.

5-2 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 37

5.2 Menu Tree

Root Menu 5.5 ↑ 5.11

↓ 5.11

Repeat 5.11

ID No. Entry 5.11

HC 5.12

Stored Data 6.1 ← Top 6.2

QC 8.5 Settings 8.3

Operation

→ Bottom 6.2

↑ Search 6.2

↓ ID No./seq 6.3

Mark Select Display 6.4

Graph Delete 6.6

Prev Edit ID No. 6.5

Next Output 7.2

More Marked All Clear 6.6

Change Scale 8.5 (*1)

← 8.5 (*1)

→ 8.5 (*1)

Delete 8.7 (*1)

Print 8.8

Select File 8.5

Select Test 8.5

Standard Curve 9.1 Next 9.1 (*2)

Test Group 5.11 Set Reagents 5.6

Special Menu

Sysmex 12.5 Error List

Temperature

P.FEED

Main Menu

Start 5.14

INTERR 5.17

Prev 5.16

Next 5.16

Standard Analysis 9.2 (*2)

Manual Entry 9.4 (*2)

Select Param. 9.6

Select Test 9.1

Graph 9.1 (*2)

Print 9.7 (*2)

Lot No. Entry 9.5

Settings 10.1

Rinse Probe 11.2

Special Operate 12.6

: If set, password has to be entered.

*1: This item is displayed only when QC data is st ored.

*2: This item is displayed only when calculat ion

parameter is set.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-3

Page 38

Operation

Root Menu Special Menu Settings Auto Val/Out 10.2

Data Check Mark Limits 10.3

Analysis Settings Set Test Name 10.6

I/O Settings 10.14 Host Comp ute r

General Set Up Date/Time 10.15

Print Settings 10.17 Auto Val/Out

Replic. Limits 10.4

Report Limits 10.5

Set Reagent Name 10 .7

Test Protocol 10.8

Set Replication 10.9

Test Group 10.10

Reagents Holder 10.11

Alarm Settings 10.12

Conversion 10.13

Barcode Scanner

Date Format 10.15

Password Setting 10.16

Data Check

Analysis Settings

I/O setting

General Set Up

All Set Data

Special Operate Rinse Prepa r e 11.11

System Tests 12.6 LCD

Cycle Counter 12.4

LED Calibration 11.6

: If set, password has to be entered.

Touch Screen

Host Computer

Printer

Barcode Scanner

Sensor Status

5-4 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 39

5.3 Types of Alarm

Operation

The instrument alarm emits 4 different sounds:

• Key entry sound (pip)

Sounds about 0.1 sec. when a touch panel key is pressed.

• Rack replacement sound (pip, pip, pip)

Sounds when sampling and dispensing of all set samples are completed and the system becomes ready to add orders or replace racks.

• Analysis completion sound (pip, pip, peep)

Sounds when analysis of all registered samples is completed.

• Instrument error sound (beep)

Sounds when some error has occurred in the instrument.

This sound continues until [ALARM RESET] key is pressed.

While the alarm is sounding, the [ALARM RESET] key is dis-

played in place of [Sysmex] key.

This sound is emitted also when the sample rack has been lifted after

the system ran out of sample tubes or reagents or when they were

being replenished.

This alarm sound stops when the [Conf.] key is pressed or when the

sample rack is set correctly.

5.4 Inspection before Turning ON the Power

Inspect Rinse Bottle

When the rinse solution level is found low, replenish the rinse bottle with

distilled water. As to the procedure for replenishing rinse solution, refer

to “11.15 Replenish Rinse Solution”.

Caution

When analysis is made with the rinse bottle laid down,

there is a possibility that correct analysis result may not

be obtained. Make sure the rinse bottle is standing

upright.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-5

Page 40

Operation

Inspect Waste bottle

When waste liquid has collected in the waste bottle, discard the contents.

Regarding how to dispose of waste liquid, refer to “11.4 Dispose of

Waste”.

Risk of Infection

When disposing of waste liquid, always wear latex or

non latex examination gloves. After work is over, wash

the hands in anti-septic solution.

If hands are contaminated with blood, which could result

in infection by pathogenic organisms, give careful consideration to the hazards of medical or infective waste

materials.

Important

When analysis is made with the waste bottle laid down,

waste may flow back into the vacuum pump, causing the

pump to fail.

Make sure the waste bottle is standing upright.

Check Power Cord

Check Connection Cord

Check Tube Trash Drawer

Check Printer Paper

Check Light Shield Cover

Check to see the power cord is securely plugged in the socket.

When the instrument is connected with the host computer, check to see

the connection cord is securely connected.

When used reaction tubes remain in the tube trash drawer, discard them.

As to discarding, refer to “11.3 Disc ard Used Reaction Tubes”.

Check to see the internal printer has enough paper to handle the number

of samples expected that day.

Open the cover and check to see there are no obstacles for analysis.

5-6 Sysmex CA-500 series

Revised November 2003 - 2.0_en

Page 41

5.5 Turn ON the Power

Turn ON the Power

Automated Blood Coagulation Analyzer

CA-500

Check in Progress

Operation

1. Turn on the power switch on the left side of the instrument.

The system automatically performs a roughly 10-second self check,

and the Root Menu screen will appear.

Ready

Sysmex

Stored

Data

Replace Rack? YES!

QC

Main Menu

1 PT 2 APTT 3 Fbg

Rack ID No.

01-01

01-02

01-03

01-04

01-05

4 TT 5 AT3

12345

Repeat

Standaed

Curve

HC IP

Group 1

ID No.

Entry

Test

Group

Special

Confirm Automatic Output

Ready

Sysmex

Stored

Data

Replace Rack? YES!

QC

Main Menu

1 PT 2 APTT 3 Fbg

Rack ID No.

01-01

01-02

01-03

01-04

01-05

4 TT 5 AT3

12345

Repeat

Standaed

Curve

HC IP

Group 1

ID No.

Entry

Test

Group

Special

Start

Prev

Next

HC

Menu

Start

Prev

Next

HC

Menu

2. When the detector and cooler reach an analysis-permitting temperature, the Root Menu screen displays “Ready”.

Note

• The detector and cooler reach an analysis-permitting tem-

perature in about 5 - 30 minutes after power turn-on.

• When the system is waiting for an analysis-permitting

temperature, the message “Not Ready” is displayed and

“Start” key is not displayed.

When automatic output to the internal printer or host computer becomes

necessary, make this confirmation.

1. Confirm that the System Status area displays “HC” and “IP”.

2. Confirm the settings for automatic transfer/printout.

Refer to “10.2 Setup of Automatic Transfer/Printout”.

Note

[HC] key is displayed only when the system is set for manual

inquiry to the host computer. For detail, refer to “5.12 Manual

Inquiry”.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-7

Page 42

Operation

5.6 Prepare Reagents

Prepare Reagents

Prepare coagulation reagents needed for analysis, Owren’s Veronal

Buffer, and rinse solution. Refer to the package insert of each reagent for

more information.

Parame-

ter

PT PT Reagent 100 µL

APTT APTT Reagent 50 µL

Calcium Chloride Solution (0.025 mol/L) 50 µL

Fbg Thrombin Reagent 50 µL

Owren’s Veronal Buffer 90 µL

TT Thrombin Clotting Time Reagent 100 µL

PCcl Protein C Deficient Plasma 45 µL

Protein C Activator 50 µL

PC APTT Reagent 50 µL

Calcium Chloride Solution 50 µL

BXT Batroxobin Reagent 100 µL

LA1* LA1 Screening Reagent 100 µL

LA2* LA2 Confirmation Reagent 100 µL

AT3 Berichrom° Antithrombin III (A)

Thrombin Reagent 125 µL

Substrate 33 µL

Owren’s Veronal Buffer 83 µL

BCPC Berichrom° Protein C

Protein C Activator 125 µL

Substrate 30 µL

APL* Berichrom° α2-Antiplasmin

Antiplasmin Reagent 125 µL

Substrate 25 µL

Owren’s Veronal Buffer 112 µL

Plg* Berichrom° Plasminogen

Streptokinase Reagent 125 µL

Substrate 25 µL

Owren’s Veronal Buffer 112 µL

Reagent Consumption per

Test

5-8 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 43

Operation

Parame-

ter

Hep Berichrom° Heparin

AT3 Reagent 20 µL

FXa Reagent 125 µL

Heparin Substrate 40 µL

DDPl* D-Dimer PLUS

Accelerator 25 µL

Latex Reagent 150 µL

AdDD** Advanced D-Dimer

Accelerator 25 µL

Latex Reagent 150 µL

PFDP*** Latex Test BL-2 P-FDP

Reagent 66 µL

Latex 94 µL

P-FDP Diluents 112 µL

Rinse

Solution

Distilled Water (Rinse Bottle) Max. 24 mL per

CA CLEAN I 10 µL more than

Reagent Consumption per

Test

test

the required reagent volume.

(*) Not available for use in the USA.

(**) Only available for use in the USA.

(***) Only available for use in Asia.

The amount of Owren’s Veronal Buffer per test includes the amount

used in dilution for each analysis parameter.

When analyzing the parameters that require two reagents, a rinse operation is performed three times in total after dispensing samples and reagents.

Thus the amount used per test is approximately 24 mL. However, the

number of rinse operations can be changed. (Refer to “10.8 Test Protocol”.)

CA CLEAN I is used after the reagent is dispensed. The amount used for

one rinse is the amount of the reagent + 10 µL.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-9

Page 44

Operation

Caution

• Prepare each reagent taking into consideration the

analysis parameters and the number of the samples

to be analyzed. Prepare extra volumes as shown

below, in addition to the required volumes for analysis:

Each coagulation reagent: Approx. 0.6 mL

Distilled water: Approx. 500 mL

Owren’s Veronal Buffer: Approx. 0.9 mL

CA CLEAN I: Approx. 0.9 mL

• The amount of reagent used in the initial operation

(rinse operation) after analysis starts is as follows:

Distilled water: Approx. 20 mL

CA CLEAN I: Approx. 125 µL

Owren’s Veronal Buffer: Approx. 200 µL (*)

(*)only when parameters are analyzed for the Chro-

mogenic Method or Immunology Method

The amount of extra reagents required vary according to the containe r

used.

Sample cup conical (4 mL): Approx. 0.2 mL

®

Behring 4 mL vial: Approx. 1.0 mL

Dade

®

Dade

Behring 5 mL vial (GW5): Approx. 0.8 mL

TTO, NT 3 mL vial: Approx. 0.4 mL

Push Vial PV-10 (22 mm OD × 40 mm high): Approx. 0.9 mL

SLD Vial: Approx. 0.4 mL

The extra volumes shown are the maximum which may be required.

There may be variation due to differences in fluid viscosity and slight

vial to vial variation.

Caution

Prepare a sufficient volume of reagent which takes into

consideration the minimum sample volume required.

When the volume of the reagent is insufficient, sample

may not be analyzed accurately.

5-10 Sysmex CA-500 series

Revised April 2004 - 2.0_en

Page 45

Operation

Dade Behring

Thromboplastin•C Plus

[ ]

[ ]

[ ]

Holder No. 11

1. Prepare Reagents.

Prepare reagents as per the document supplied with each reagent.

Caution

Strictly follow the instructions as given in the package

[ ]

insert supplied with each reagent. Otherwise, you will fail

to obtain correct analysis result.

2. Set the reagents on the rack.

Reagent bottles (each measuring 22 mm OD and 40 mm height), or

optional reagent holders and sample cups can be set in the reagent

rack. (Refer to “10.19 Reagent Name/Holder List”.)

Caution

• Always set the reagents at the specified positions to

obtain correct results.

• Confirm that reagents contain no bubbles. Otherwise, correct analysis results cannot be obtained.

• Be sure to set CA CLEAN I in Holder No. 11 (inner

right side).

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-11

Page 46

Operation

Register Reagent Volume

7

CaCl2

0.0mL

0.0mL

8

HC IP

9

10 12

11

CleanI

OVB

Ready

Sysmex

PT

5.0mL

4.8mL

2

Fbg

AT3Thro

Replace Rack? YES!

3

APTT

0.0mL

0.0mL

4

AT3Subs

0.0mL

0.0mL

Enter Reagent Volume

51

0.0mL

0.0mL

6

0.0mL

0.0mL

0.0mL

0.0mL

0.0mL

0.0mL

Main

Menu

1. Press [Special Menu] key on the Root Menu screen.

The contents of the Root Menu will change over.

2. Press [Set Reagents] key in the Root Menu.

The Reagent Volume screen will display reagent level for each reagent holder.

3. Press the key of the reagent holder to be registered.

The Reagent Volume Entry Screen will display the numeric keys to

enter reagent volume.

Ready

Sysmex

Sysmex

1

PT

5. 0 m L

5. 0 m L

Replace Rack? YES!

Ready

Replace Rack? YES!

RENEW SETTING ?

Enter Reagent Volume

Enter Reagent Volume

IP HC

7

4

1

0

C

HC IP

89

5

6

3

2

Enter

.

Quit

4. Enter the reagent volume set on the reagent holder and press

[ENTER] key.

The value entered at the cursor position will be displayed. The second line will automatically display the available reagent volume to

be used for the analyses.

By pressing [↑] and [↓] keys, movement can be effected to the preceding or following reagent holder No.

Note

• If the Reagent Volume Monitoring is set to “Valid”, each

time the reagent is dispensed, the volume for the test will

be subtracted from the entered value.

• Refer to “10.12 Setup of Reagent Volume Monitoring” for

the setting procedures.

• Refer to “10.11 Reagent Holder” for confirmation of vial

type.

5. Press [Quit] key on the numeric keys.

The Reagent Volume Screen will reappear.

Confirm the entered value.

6. Press [Main Menu] key on the Reagent Volume screen.

The Renew Check screen is displayed. Press [Cancel] key, [FIX]

key, or [Continue] key to return to the Root Menu screen.

Important

The reagent amount which was input is erased when the

FIX ContinueCancel

5-12 Sysmex CA-500 series

power is turned OFF.

Revised January 2003 - 2.0_en

Page 47

5.7 Set Reaction Tubes

Operation

Reaction tube

30

Reaction tube rack

1

Set the reaction tubes for analysis on the reaction tube rack.

Set the reaction tube rack on the specified location on the analysis table.

Caution

• When setting reaction tubes on the reaction tube

rack, be careful not to drop sweat or the saliva into

the reaction tube. This will alter the analysis result.

• Reaction tubes are for single use only or incorrect

results may occur.

Important

• Set the reaction tube rack securely to prevent the

tubes from unseating and rising; otherwise, the probe

might be damaged.

• The reaction tubes are set successively from the first

position (top on extreme right-hand column). Therefore, make sure no position is left empty.

• Make ready some extra reaction tubes in addition to

the quantity needed for analysis.

• Be sure to use the supplied reaction tubes (SU-40).

The reaction tubes (SUA-400A) for CA-6000, etc. or

those manufactured by other companies cannot be

used.

Note

A maximum of 30 reaction tubes can be mounted on a reaction

tube rack. Since two reaction tube racks can be used, the maximum number of reaction tubes that can be set is 60.

Revised January 2003 - 2.0_en

Sysmex CA-500 series 5-13

Page 48

Operation

5.8 Confirm Standard Curve

Ready

Sysmex

%

50.0

25.0

12.5

6.3

3.1

sec

11.4

17.4

27.9

52.6

11.4

1.73

Replace Rack? YES!

Cal Date 12/01/2001

PT Apc.63

Ref.

0.0

0.0

Standard

Analysis

Standard Curve PT

PT%

100.0

Normal

ISI

HC IP

Lot No.EXP.

Manual

Entry

12/31/2001

12/31/2001

Select

Param.

Confirm before performing analysis that the standard curve is correctly

set.

Caution

Unless the standard curve is properly set, percent activity, concentration, and other calculation parameters cannot be reported.

1. Press [Standard Curve] key on the Root Menu screen.

The Standard Curve screen will be displayed.

2. Press [Select Test] key on the Standard Curve screen.

The Select Test screen will appear.

Select

Sysmex

Standard Curve

PT

VIII

Sysmex

Standard Curve PT

PT%

%

100.0

50.0

25.0

12.5

Normal

ISI

Select

Graph

Test

Ready

Replace Rack? YES!

APTT Fbg TT

AT3 BCPC Hep

Ready

Replace Rack? YES!

sec

PT Apc.63

11.4

17.4

27.9

52.6

0.0

6.3

0.0

3.1

11.4

1.73

Graph

Test

Print

Cal Date 12/01/2001

Ref.

Standard

Analysis

Print

Lot No.

Entry

HC IP

II

DDPl

HC IP

Lot No.EXP.

Manual

Entry

Lot No.

Entry

12/31/2001

12/31/2001

Main

Menu

Cancel

Select

Param.

Main

Menu

3. Press the analysis parameter key to be confirmed.

The standard curve data of the parameter selected will appear on the

standard curve screen.

4. Press [Graph] key.

Check the standard curve.

5. Press [Main Menu] key.

The standard curve setting program is now completed.

Repeat the above Step-(2 - 3) to confirm the standard curve of each analysis parameter. For detail, refer to “9.2 Standard Curve Analysis”.

5-14 Sysmex CA-500 series

Revised January 2003 - 2.0_en

Page 49

5.9 Execute Quality Control

5.10 Prepare Samples

Operation

To maintain the reliability of analyzed data, quality control has to be performed.

With the instrument, when QC File No. (QC01 - QC06) is registered for

ID No., and QC sample (control plasma, pooled plasma, etc.) is analyzed, then analysis data is kept in the QC File. It is by processing this

analysis data with the QC Program that instrument stability that varies

from-time- to-time is monitored.

For detail of the QC Program, refer to “8. Quality Control”.

Set sample tubes or dispensed sample cups on the sampler rack.

Caution

If samples are left at room temperature for a long time,

they may deteriorate. Set samples to the sampler just

before analysis starts.

A

75mm18mm

1. Prepare plasma.

1) Add 1 part of 3.8%, 3.2% or 3.13%* sodium citrate solution as

anticoagulant to 9 parts of venous blood, and mix the contents

thoroughly.

2) Centrifuge the mixture at 3000 rpm for 15 minutes to separate

plasma components from blood components.

*Not for use in the USA.

3) Affix Barcode Label (Option).

To ensure correct reading of a barcode, a barcode label has to be

affixed at the proper position.

4) Set, in the supplied sample rack, the centrifuged blood tube itself

or the plasma which has been removed and put into another test

tube.

Insert the test tube securely to the bottom of the rack.

When an optional sample barcode scanner is used, set barcode

labels so as to face the scanner.

Warning