Page 1

SECTION 4 ADJUSTMENT

To Cover

4.1 Pressure Adjustment .............................................................................................................................. 1

4.1.1 Adjustment of Pressure Detector Circuit....................................................................................1

4.1.2 Adjustment of Pressure Indication.............................................................................................3

4.2 Detector Block Sensitivity Adjustment .................................................................................................... 4

4.2.1 Required Tools for Adjustment .................................................................................................. 4

4.2.2 Overview of Adjustment Screen (Description)........................................................................... 4

4.2.3 Adjustment of Detector Well for analyzing the scattered light ...................................................6

4.2.4 Adjustment of Detector Well for analyzing the transmitted light

(Chromogenic and Immunoassy)...............................................................................................8

4.2.5 Exit Adjustment .......................................................................................................................... 9

4.2.6 Target Value List for Adjustment ...............................................................................................9

4.3 Mechanical System Adjustment............................................................................................................10

4.3.1 Required Tools for Adjustment ................................................................................................ 10

4.3.2 How to Enter the Mechanical System Position Adjustment Mode ........................................... 10

4.3.3 The Mechanical System Position Adjustment Screen ............................................................. 11

4.3.4 Position Adjustment Procedure of Pipette (“[1]blood 1”, “[2]blood 10”, and “[3]blood_stat”) ...13

4.3.5 Position Adjustment Procedure of Pipette (“[4]reag 1”) (“[5]reag 9”) (“[6]reag 10”) ................. 16

4.3.6 Position Adjustment Procedure of Pipette (“[7]reag_rinse”) (“[8] buffer”) ................................17

4.3.7 Position Adjustment Procedure of Pipette (“[10]wash_o) ........................................................ 19

4.3.8 Position Adjustment Procedure of Pipette (“[11]p_tube 1)....................................................... 21

4.3.9 Position Adjustment Procedure of Catcher (“[17]c_tube 1) .....................................................22

4.3.10 Position Adjustment Procedure of Catcher (“[23]warm 1) .......................................................24

4.3.11 Position Adjustment Procedure of Catcher (“[27]shake) ......................................................... 26

4.3.12 Position Adjustment Procedure of Catcher (“[28]dust) ............................................................27

4.3.13 Position Adjustment Procedure of Catcher (“[29]immunoassy)............................................... 28

4.3.14 Output Setting Values .............................................................................................................. 29

4.4 Temperature Adjustment ...................................................................................................................... 30

4.4.1 Temperature Control Summary...............................................................................................30

4.4.2 Temperature Verification at Each Unit 4 ................................................................................ 30

4.4.3 Temperature Adjustment Procedures 4 ................................................................................. 31

4.5 Electrical Adjustment ............................................................................................................................ 32

4.5.1 PCB No. 6362: MAIN (CPU, I/O, Motor Control, Temperature Control, A/D)..........................32

PCB No. 6373: MAIN-2 (CPU, I/O, Motor Control, Temperature Control, A/D)....................... 32

4.5.2 PCB No. 4086: PS (Power Source, Motor Driver) ................................................................... 34

CA-500 Series S/M Revised December 2001

8

Page 2

SECTION 4 ADJUSTMENT

4.1 PRESSURE ADJUSTMENT

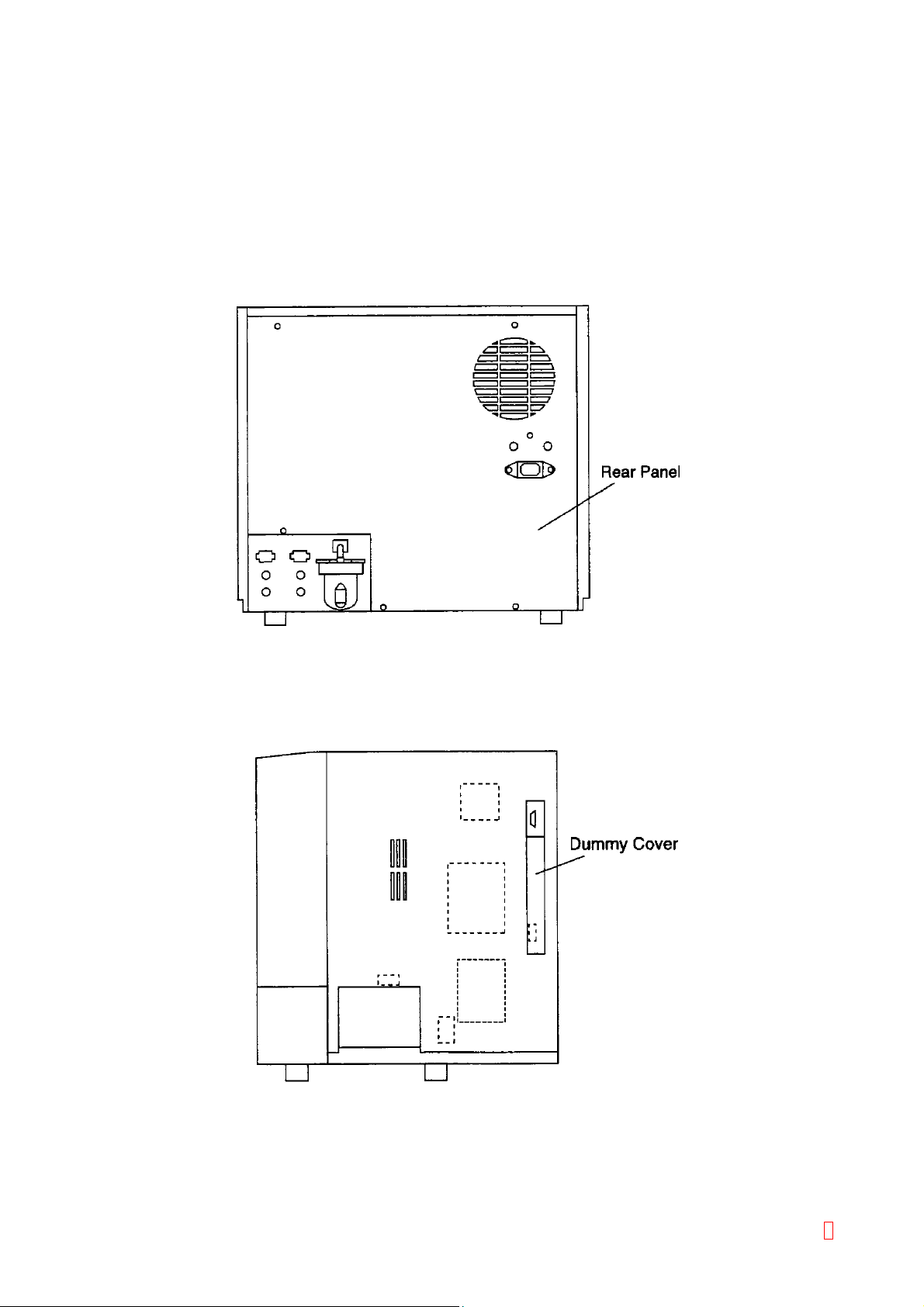

4.1.1 Adjustment of Pressure Detector Circuit

(1) Verify that the ambient temperature where the unit is located is within the range of 15°C - 35°C. (The

optimum recommended temperature range is 20°C - 30°C.)

(2) Prepare the Pressure Gauge (which can measure the pressure of 0.3 kg/cm

on the rear panel.

2

) in the pressure line (black)

Figure 4-1-1: Rear View

(3) Adjustment procedure:

1) Turn the power OFF. Remove the rear panel and the dummy cover under the HOST connector.

Figure 4-1-2: Dummy Cover (Left Side View)

CA-500 Series S/M 4-1 Revised December 2001

8

Page 3

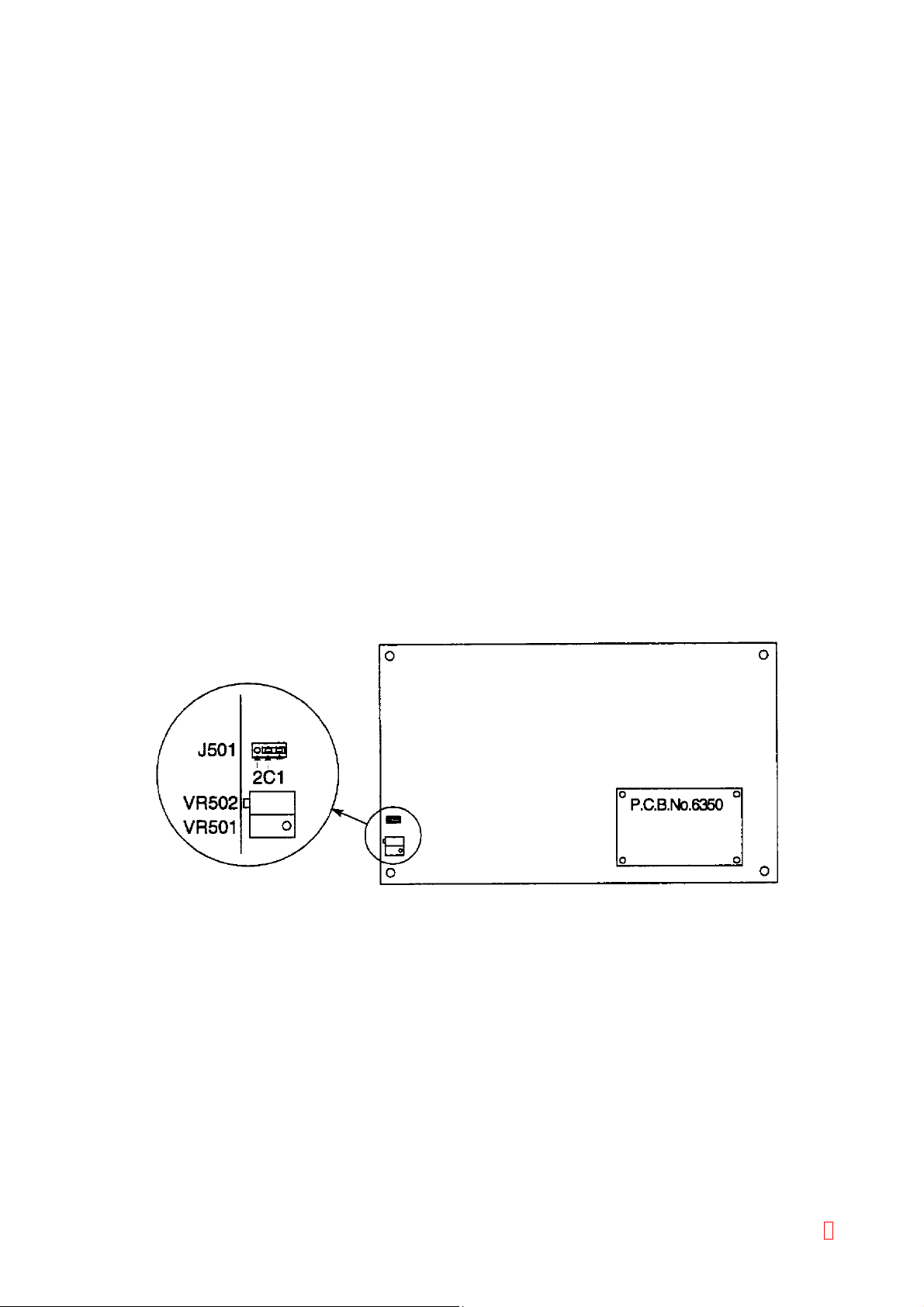

2) Connect Jumper Pin J501 of PCB No. 6362 or PCB No. 6373 to C-2.

3) Loosen and remove the rinse bottle cap carefully because the cap will be lifted up by the pressure inside

the rinse bottle.

4) Disconnect the black marked silicone tube connected to the rear panel at the rinse bottle.

5) Connect the pressure gauge to the silicone tube.

6) Turn the power ON.

7) Adjust the VR502 (OFFSET) so that the pressure becomes 225 ± 3 g/cm

increased when VR is turned to CW direction. Disconnect the pressure gauge from the tube once when

adjusting the pressure decreasing.)

8) Remove Jumper Pin J501. (Do not lose the jumper pin because it is placed on the PC board.)

9) Adjust the VR501 (GAIN) so that the pressure becomes 275 ± 3 g/cm

when VR is turned to CW direction. Disconnect the pressure gauge from the tube once when adjusting

the pressure decreasing.)

10) Verify Steps 1) to 5) again. As the VR502 (OFFSET) and the VR501 (GAIN) are related each other, adjust

them repeatedly until the set values are obtained by repeating Steps 1) to 5).

11) Reconnect Jumper Pin J501 to C-1.

12) Disconnect the tube to decrease pressure, and reconnect it.

13) Verify that pressure is 250 ± 3 g/cm

* If pressure is not 250 ± 3 g/cm

2

.

2

, check and adjust again by repeating Steps 1) to 5).

2

. (The pressure will be

2

. (The pressure will be increased

Figure 4-1-3: PCB No. 6362 Jumper, VR Location

CA-500 Series S/M 4-2 Revised December 2001

8

Page 4

4.1.2 Adjustment of Pressure Indication

(1) Verify that the ambient temperature where the unit is located is within the range of 15°C ~ 35°C. (The

optimum recommended temperature range is 20°C ~ 30°C.)

(2) Connect the Pressure Gauge (with resolution of more than 28 g/cm

300 g/cm

2

) to the pressure line (black) on the rear panel.

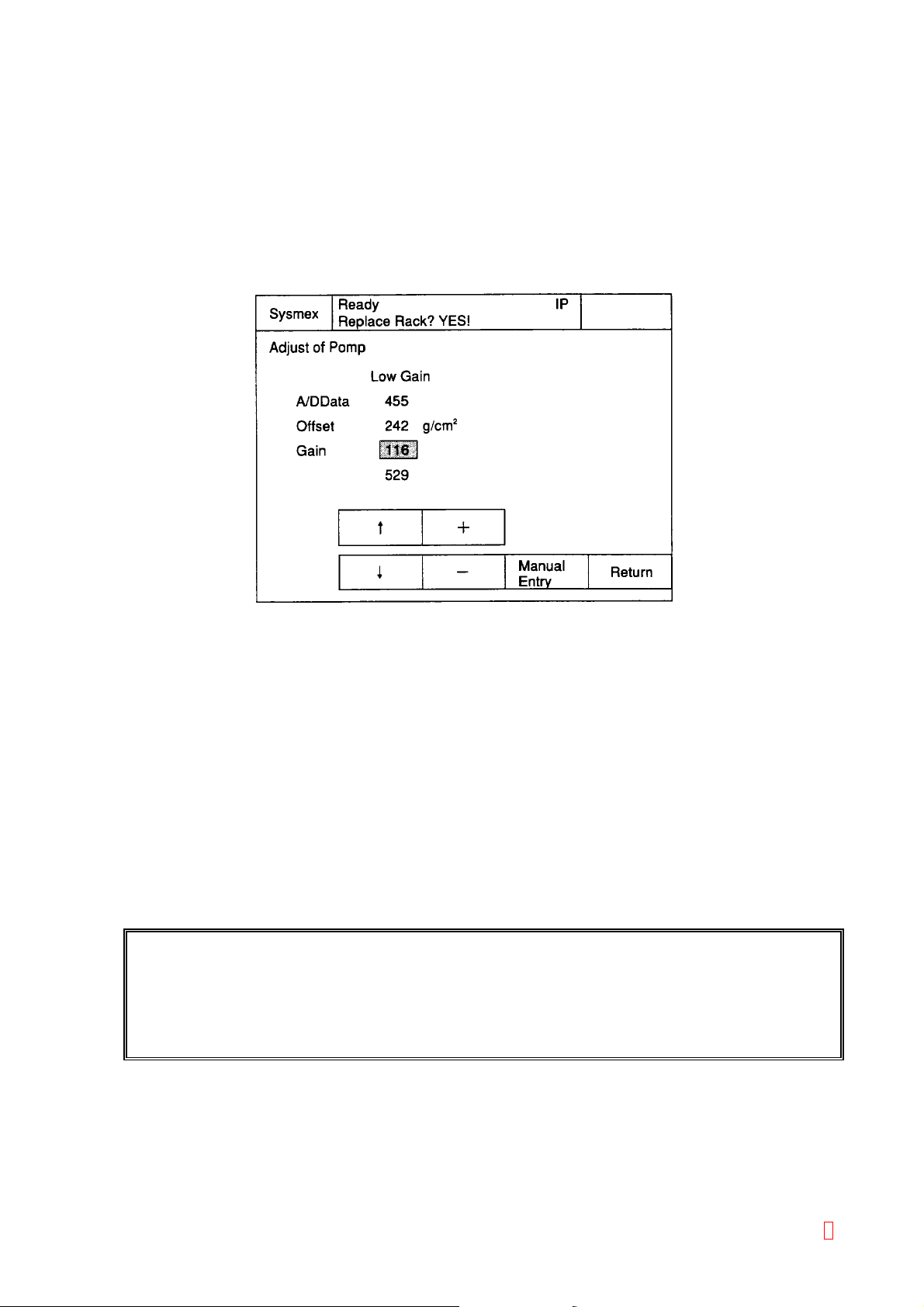

(3) Adjustment procedure:

1) Start Service Mode.

2) Select [Special Operate] Æ [Service] Æ [Adjust] Æ [Adjust. of Pump].

2

, which can measure the pressure of

Figure 4-1-4: Adjust Pump Screen

3) Disconnect the tube at the pressure side (the black marking line on the rear panel) to release the

pressure sensor (so that the pressure sensor shows the atmospheric pressure).

4) Offset the cursor by using [↑] and [↓] keys.

5) Adjust the offset value by using [+] and [-] keys so that the pressure gauge shows 1 g/cm

the offset value is lowered, A/D value also becomes lower.) (Actually, there is a fluctuation of 0 ~ 4

for the value, therefore, adjust it so that it shows the value, which approaches 0 most.)

6) Re-connect the pressure gauge to the pressure line on the rear panel.

7) Move the cursor to the gain by using “↑” and “↓” keys.

8) Adjust the gain value by using [+] and [-] keys so that the pressure gauge value (adjusted 250 g/cm

by the procedure described in 4.1.1 Adjustment of Pressure Detector Circuit) agrees with the

displayed pressure value on CA-500. The difference between the pressure gauge value and

CA-500 displayed value should be adjusted within 3 g/cm

2

.

9) Verify Steps 3) to 8) again, and if the value is within the specified range. Press the [Return] key.

10) Confirmation screen will be displayed by pressing “Return” key.

REFERENCE: Pressure is adjusted at the factory in principle, therefore, it is not necessary to adjust

in the field. Setting values are stored in EEPROM on the PCB No. 6362 or PCB No.

6373.

In case of erasing the EEPROM, these printed values are attached on the memory

card socket.

Select the appropriate key.

FIX: The new setting value is fixed.

Cancel: The new setting value is deleted and Adjust of Pump program will be quitted.

Continue: The adjustment can be continued.

2

. (When

2

CA-500 Series S/M 4-3 Revised December 2001

8

Page 5

4.2 DETECTOR BLOCK SENSITIVITY ADJUSTMENT

4.2.1 Required Tools for Adjustment

(1) CA-Series Standard Scattering Stick Set

(2) Reaction Tube

(3) Micro Pipette

(4) Ebonite Stick for adjusting offset value

4.2.2 Overview of Adjustment Screen (Description)

(Adjustment procedure starts from 4.2.3 Adjustment of Detector Well for Analyzing the Scattered Light)

(1) Verify that the ambient temperature where the unit is located is within the range of 15°C - 35°C.

(The optimum recommended temperature range is 20°C - 30°C.)

(2) Start Service Mode.

(3) Select [Special Operate] Æ [Service] Æ [Adjust] Æ [Detector Gain].

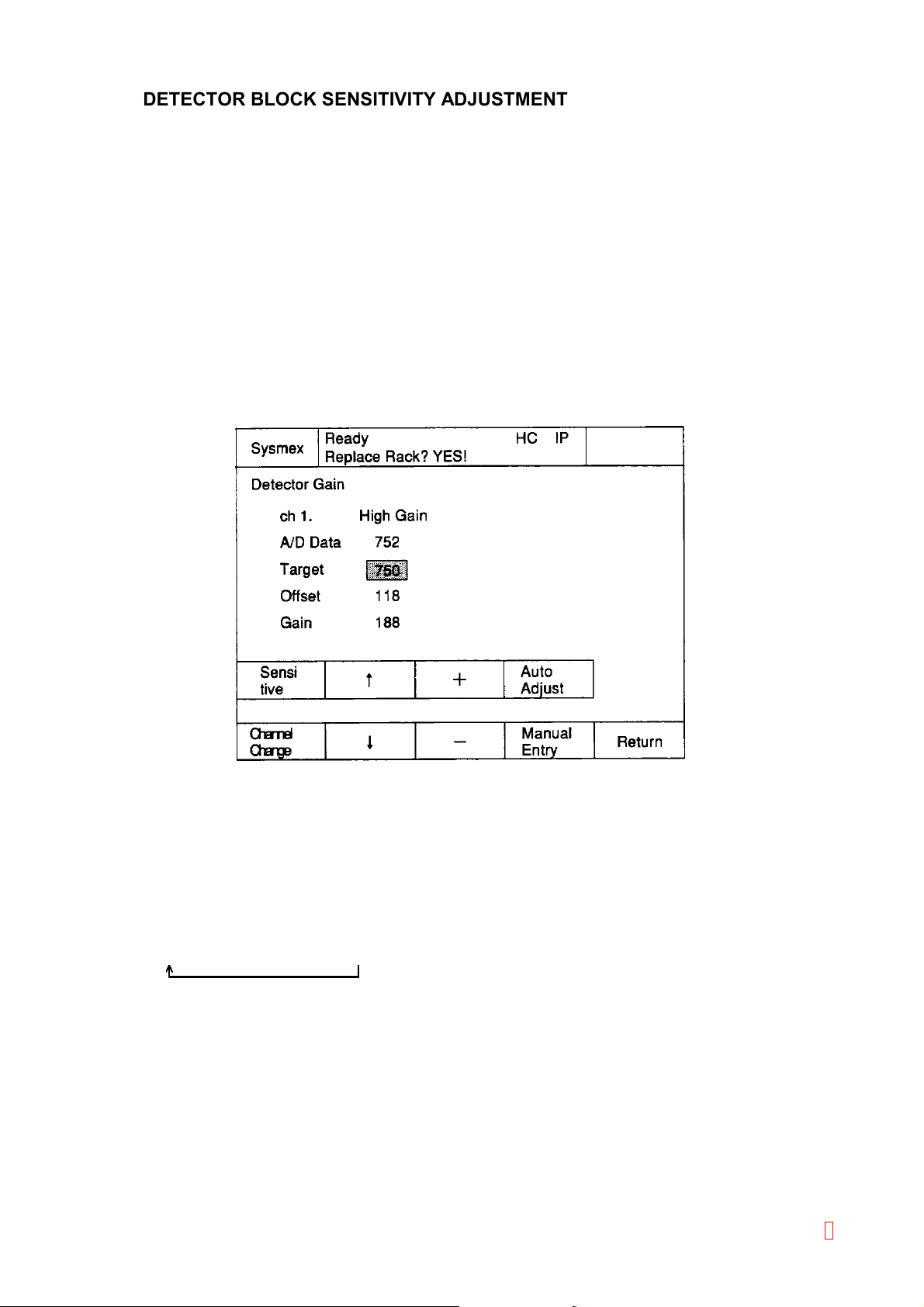

(4) The Detector Gain screen will be displayed.

Figure 4-2-1: Detector Gain Screen

1) To change or adjust a value (Target, Offset, Gain), select the value by using [↑] and [↓] keys.

The selected value is displayed in the reverse video, and inputting by pressing [+] and [–] keys or

inputting numerals in the [Manual Entry] screen is available.

2) Select a channel among CH1 (Detector Well 1) Æ CH2 (Detector Well 2) Æ CH3 (Detector Well 3) Æ

CH4 (Detector Well 4) Æ CH5 (Detector Well 5) Æ CH6 (Detector Well 6) in the order by pressing

[Channel Change] key.

3) Press [Sensitive] key to alternate the sensitivity of the selected channel in the order of

High Gain Æ Low Gain Æ PT Gain.

4) Start the automatic adjustment for the offset/gain value by pressing [Auto Adjust] key.

CA-500 Series S/M 4-4 Revised December 2001

8

Page 6

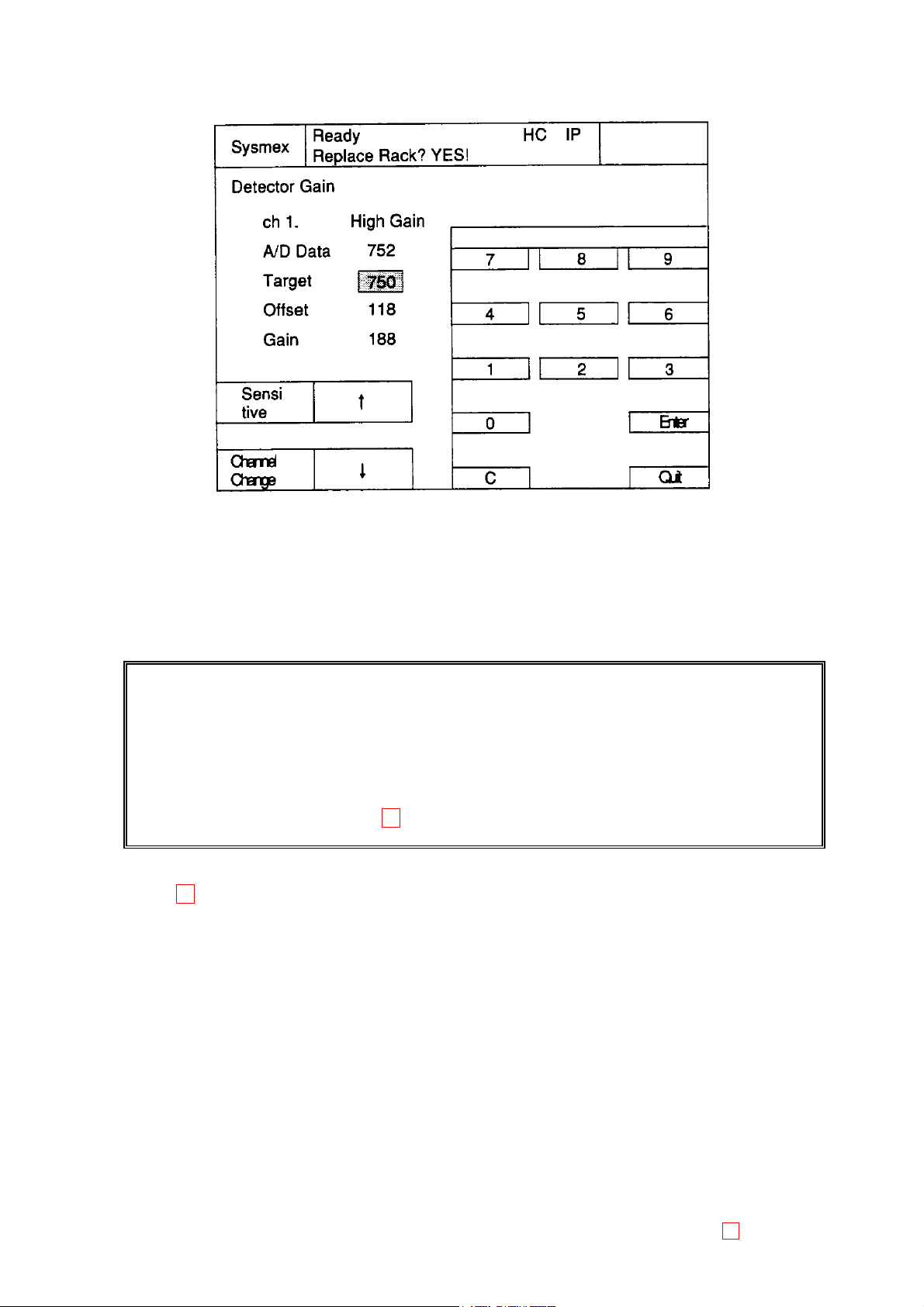

(5) Press [Manual Entry] key to display the screen that the manual entry by numeric keys is available.

Figure 4-2-2: Manual Entry Screen

1) Pressing the numeric keys [0] to [9] can set the desirable value directly.

2) Pressing [C] key can clear the set value.

3) Press [Enter] key to settle the set value. The set value cannot be settled if [Quit] key is pressed

without pressing [Enter] key.

4) Press [Quit] to return the previous screen.

CAUTION: 1) This adjustment should be done more than 30 minutes after the power-ON the

instrument.

2) Use the scattering stick after being heated for more than 10 minutes in the detector

well or the incubation well.

3) Close the light shield cover to avoid the influence by the external light during

adjustment.

4) When Detector Adjustment Error occurs, the channel No. with the error is added to

the error message. 13

Note: 13 1) Transmitted Light calibration will be performed automatically before the first

measurement after switching on the instrument or after 24 hour continuous operation. It

will be performed when a chromogenic or immunologic parameter is selectable in the

actual group setting.

2) Instruments with new main board (PCB NO.6373) are able to switch off LEDs during

standby operation automatically in order to prolong the life time of the LEDs.

CA-500 Series S/M 4-5 Revised May 2003

13 ECR 303C012

Page 7

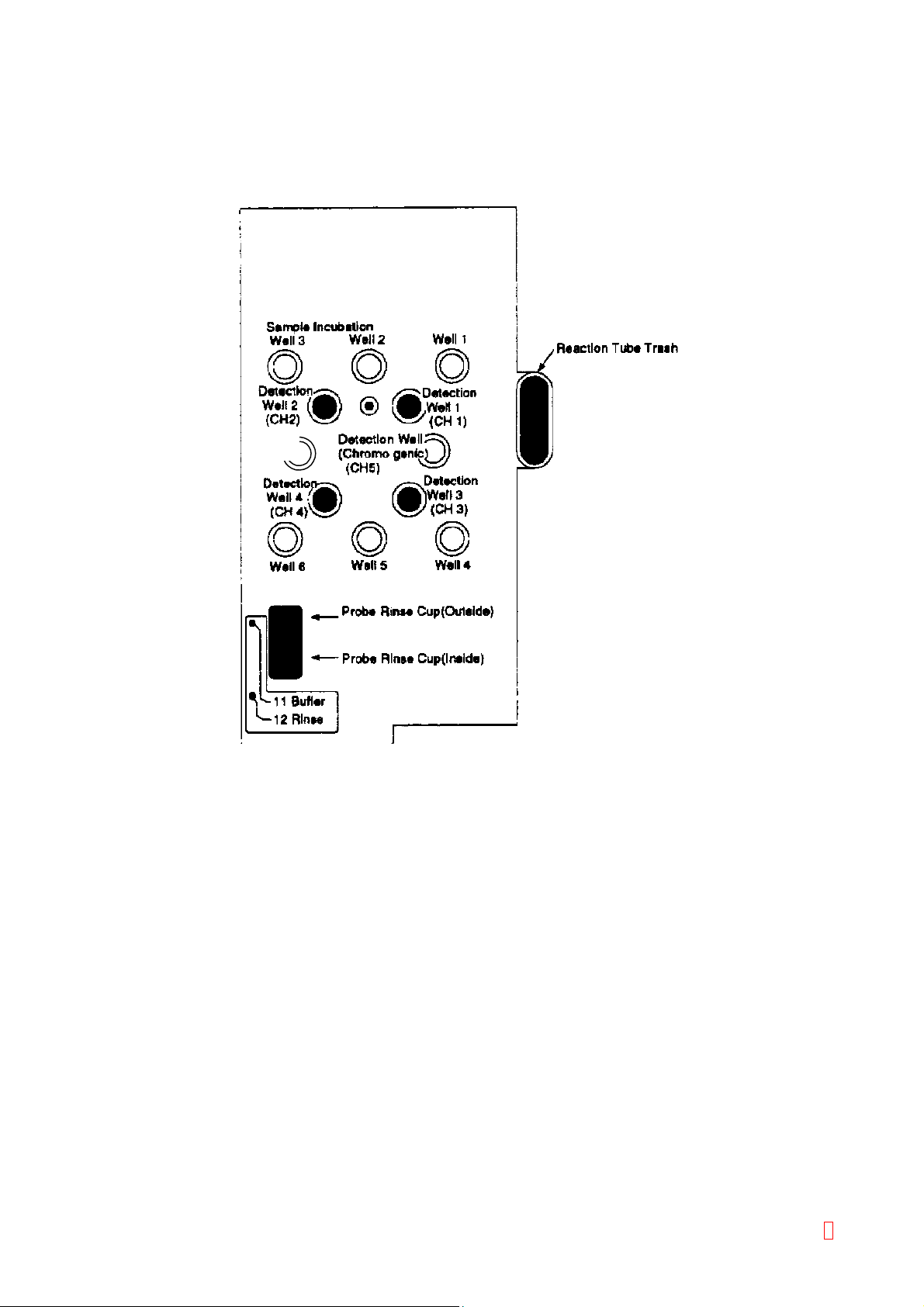

4.2.3 Adjustment of Detector Well for analyzing the scattered light

(1) Offset adjustment

1) Insert the ebonite stick for adjusting the offset value in the detector well to be adjusted.

Detection Well

(Immunoassy)

(CH6)

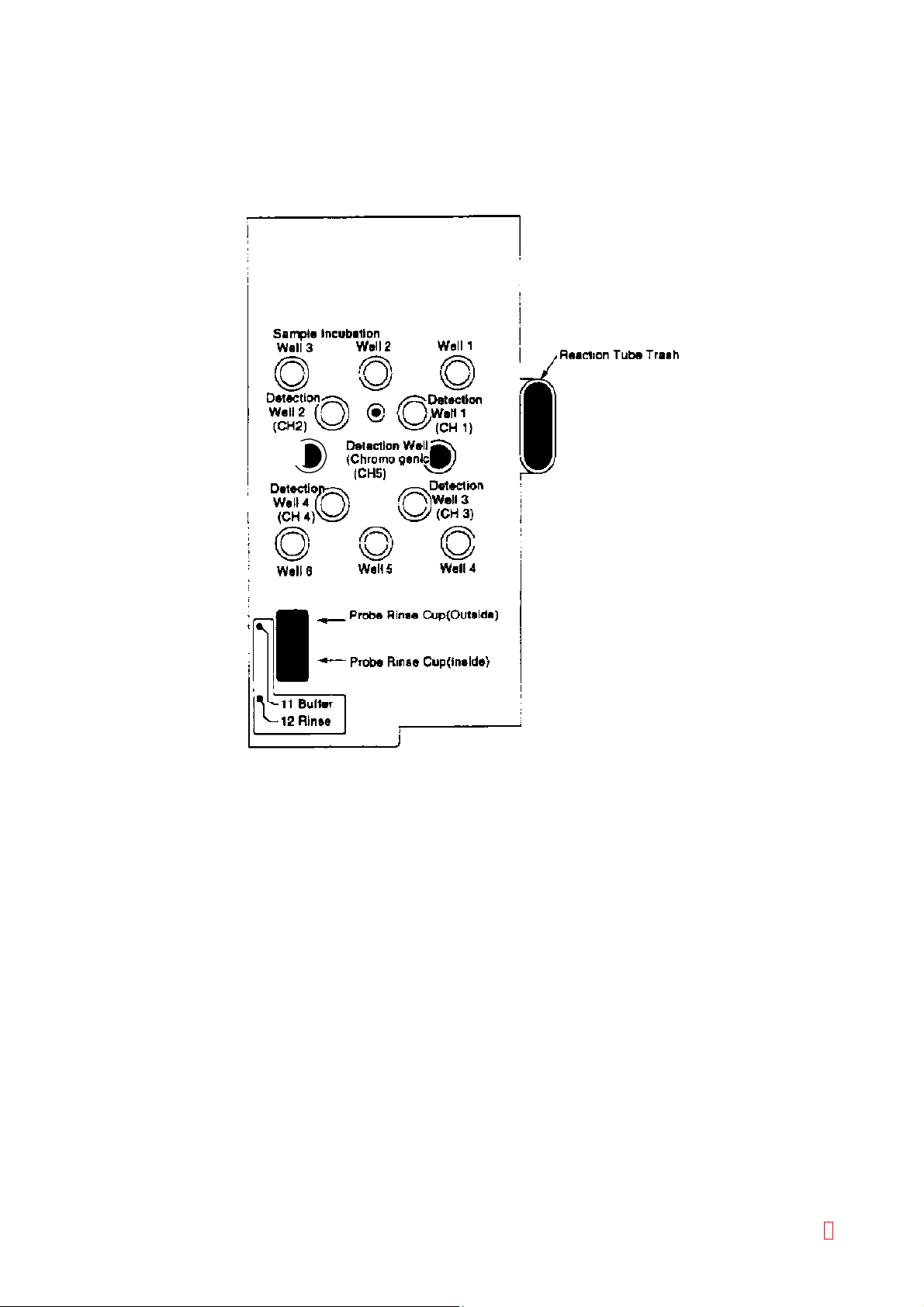

Figure 4-2-3: Detector Well Positions

2) Close the light shield cover.

3) Select channel 1 by using [Channel Change] key, select Low Gain by using [Sensitive] key, and select

[Offset] position by pressing [↑] or [↓] key.

4) Press [Auto Adjust] key to start the automatic offset adjustment, and when the adjustment is

completed, the alarm sounds.

5) Change Gain to PT Gain and enter Offset value manually in executing Step 3). (Press [+] and [–] keys

or [Manual Entry] key to adjust manually.)

6) Execute Steps 1) to 5) for channels 2 to 4.

(2) High Sensitivity Adjustment (Gain Adjustment)

1) Insert the heated high sensitivity scattering stick (labeled usually as “750”) into the detector well to be

adjusted (CH1 to 4).

2) Close the light shield cover.

3) Select channel 1 by using [Channel Change] key, select High Gain by using [Sensitive] key, and select

[Gain] position by pressing [↑] or [↓] key.

4) Press [Auto Adjust] key to start the automatic gain adjustment, and when the adjustment is

completed, the alarm sounds.

5) Execute Steps 1) to 5) for channels 2 to 4.

CA-500 Series S/M 4-6 Revised December 2001

8

Page 8

(3) Low Sensitivity Adjustment (Gain Adjustment)

1) Insert the heated low sensitivity scattering stick (labeled usually as “430”) into the detector well to be

adjusted (CH1 to 4).

2) Close the light shield cover.

3) Select channel 1 by using [Channel Change] key, select Low Gain by using [Sensitive] key, and select

[Gain] position by pressing [↑] or [↓] key.

4) Press [Auto Adjust] key to start the automatic gain adjustment, and when the adjustment is

completed, the alarm sounds.

5) Change the sensitivity to PT Gain, and verity that both Offset and Gain values for PT Sensitivity are

automatically set when changing Offset and Gain values for Low Sensitivity.

To set PT sensitivity individually, execute the same procedure as (1) Offset Adjustment and (3) Low

Sensitivity Adjustment or enter values manually using numeric keys.

6) Execute Steps 1) to 5) for channels 2 to 4.

NOTE: The gain adjustment and the offset adjustment have an influence on each other,

therefore, reconfirm that the set value after each adjustment is within the specified

range of values. Refer to 5.9.2 Detector Block Adjustment Value for default value.

CA-500 Series S/M 4-7 Revised December 2001 8

Page 9

4.2.4 Adjustment of Detector Well for analyzing the transmitted light

(Chromogenic and Immunoassy)

(1) Offset adjustment

1) Insert the ebonite stick for adjusting the offset value in the channel 5 of the detector well.

Detection Well

(Imm unoassy)

(CH6)

Figure 4-2-4: Detector Well Positions (Chrom, Immunoassy)

2) Close the light shield cover.

3) Select [CH5] by using [Channel Change] key and select [Offset] position by pressing [↑] or [↓] key.

(Low Gain is fixed and cannot be changed.)

4) Press [Auto Adjust] key to start the automatic offset adjustment, and when the adjustment is

completed, the alarm sounds.

5) Execute Steps 1) to 4) for channel 6.

(2) Gain adjustment (Dynamic Range adjustment)

1) Dispense 200 µL of distilled water or buffer (OV-30) into a reaction tube in advance, set it into the

transmitted light detector well (channel 5), and heat it up for approximately 10 minutes.

2) Close the light shield cover.

3) Select [CH5] by using [Channel Change] key and select [Gain] position by pressing [↑] or [↓] key.

(Low Gain is fixed and cannot be changed.)

4) Press [Auto Adjust] key to start the gain adjustment, and when the adjustment is completed, the alarm

sounds.

5) Open the light shield cover, rotate the reaction tube set in the channel 5 detector well and verify that

the indicated A/D value does not exceed 4,000. At this time, avoid the external light as much as

possible. If the A/D value exceeds 4,000, set the reaction tube at the position where the indicated A/D

value is the biggest and press [Auto Adjust] key again to start the adjustment.

6) Execute Steps 1) to 5) for channel 6.

CA-500 Series S/M 4-8 Revised December 2001

8

Page 10

4.2.5 Exit Adjustment

(1) When the adjustment is completed, press [Return] key.

(2) FIX, Cancel the set value, and continue the adjustment:

1) When the adjusted value is settled and the adjustment is completed, press [FIX].

Store the new setting value in the memory and output the value on the built-in printer, and then return

to the sub-menu.

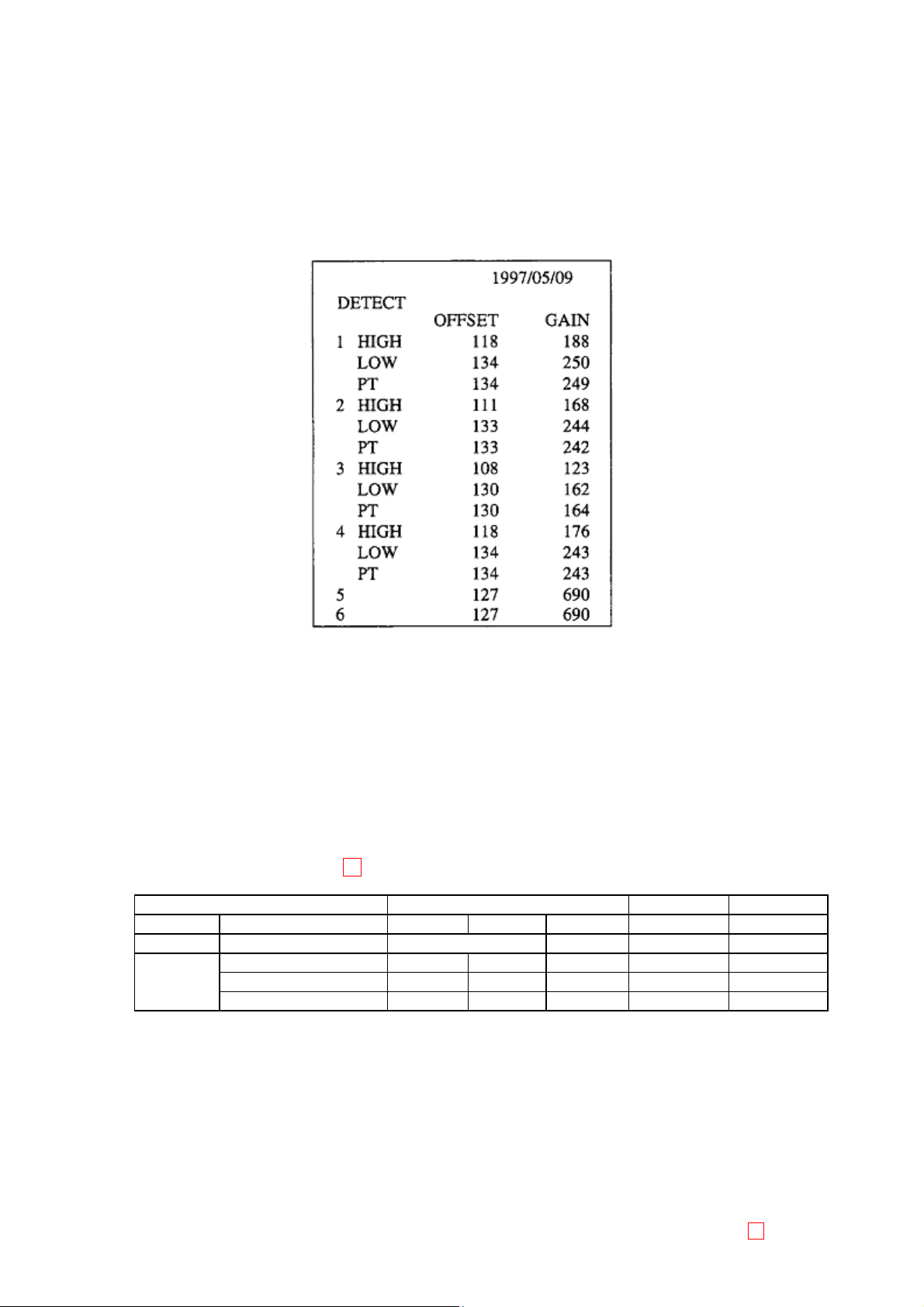

Figure 4-2-5: Output Example

2) When the adjusted value is discarded and the adjustment is completed, press [Cancel] key. In this

case, the setting value data is not changed and returned to the sub-menu.

3) When the adjustment is continued, press [Continue] key.

In this case, the screen returns to the previous set screen, so you can continue the adjustment.

4.2.6 Target Value List for Adjustment

Detector Well Specified Values 19

(A/D Display Value for Offset and Gain)

Detector Well CH1 ~ 4 CH5 CH6

Tools HIGH LOW PT LOW LOW

OFFSET Ebonite Stick < 30 1 - 20 1 - 20

480* Scattering Stick – 480 ± 15 480 ± 15 – –

GAIN 910* Scattering Stick 910 ± 20 – – – –

Distilled Water – – – 3800 - 4000 3800 - 4000

*Varies lot by lot.

CA-500 Series S/M 4-9-1 Revised February 2004

19 TB200408

Page 11

4.2.7 LED Auto Calibration 13

(1) Press [Special Operate]-[Calibration] keys. The LED Calibration screen will appear.

Sysmex

Ready

Replace Rack? YES!

LED Calibration

Target Value

Vial Type

Please set Calibrator

on Reagent Holder 1

900

Cup

and set Clean1 on

Reagent Holder 11.

Press [set] key.

Set

(2) Enter a target value.

Enter an indicated value (100 - 999) which is given in the calibrators table of assigned values for

calibration using the numeric keys, and press [Enter] key.

(3) Select a container of the calibrator for calibration.

Move the cursor to “Vial Type” using [↑] and [↓] keys, and press [Next] key to select the container.

(4) Set the calibrator for calibration to the reagent holder 1 and set CA CLEAN I to the reagent holder 11.

(5) Press [Set]-[OK] keys to start LED calibration.

When the operation is completed, the LED Calibration Update Confirmation screen will appear.

Sysmex

Ready

Replace Rack? YES!

LED Calibration Update Confirmation

IP

7

4

1

0

C

89

5

2

6

3

Enter

Quit

IP

(1)

45

*OK

CH2

130

OK

CH1

Too weak to use:

Weak, but still available:

CH3

ERR1

22

CH3

CH1

CH4

130

OK

(2)

(3)

Please refer to Operator's Manual

Set

Cancel

Displayed contents

(1) Channel No.

(2) LED status

(3) OK: Available

*OK: Available. However, replacement is required within a few months.

ERRxx: Not available

(6) When updating a new adjustment value, press [FIX] key.

When the status of all channels is OK

The new adjustment value is saved, and returns to the LED Calibration screen.

When there is a channel with a calibration error

The confirmation screen will appear.

Press [Cancel] key to return to the LED Calibration Update Confirmation screen.

Press [OK] key to save the new adjustment value, and return to Calibration screen.

(7) Take out the calibrator for the calibration, and set the former reagent.

CA-500 Series S/M 4-9-2 Revised May 2003

13 ECR 303C012

Page 12

4.3 Mechanical System Adjustment

4.3.1 Required Tools for Adjustment

(1) Sample Cup (small)

(2) Reaction Tube

(3) Collection Tube (15 mm diameter)

(4) Dade 1 mL Reagent Bottle

(5) Push Vial Bottle

(6) Water (distilled water)

(7) Dispensing Pipette (50 and 60 µL)

(8) CA-5H

4.3.2 How to Enter the Mechanical System Position Adjustment Mode

(1) Start the service mode by pressing “ID No. Entry”, “C”, “9”, “-”, “0”, “Enter”, and “Quit”.

(2) The screen changes from “Main Menu” to “Mecha Position” by pressing keys of [Special Operate] Æ

[Service] Æ [Adjust] Æ [Mecha Position].

Select the unit to be adjusted on this screen and perform the position adjustment.

Z-axis Position Adjustment Tool PM (031-0171-4) 13

CA-500 Series S/M 4-10 Revised May 2003

13 ECR 303C012

Page 13

4.3.3 The Mechanical System Position Adjustment Screen

Figure 4-3-1: Mecha Position Screen

(1) Indicating the title of displayed screen.

(2) Display setting values, which indicate number of pulses of moved probe.

The probe moves to these setting values by pressing “XY TEST” and “Z ADJUST” keys.

(3) Display pulses of the probe position.

Moves to these setting values by pressing “XY TEST” and “Z ADJUST” keys.

(4) Display status of the sensor at the home position on each XYZ drive axis:

Black Circle Æ Detected (Activated), White Circle Æ Not Detected (Not Activated)

(5) Display pipette lower limit.

Usually, it is automatically set 25 pulses added to Z position adjustment value.

(6) Display selected setting position.

(Normal: Fine Adjustment Mode/Reverse: Basic Position Adjustment Mode.)

(7) Display status of each sensor on the probe:

Black Circle Æ Detected (Activated), White Circle Æ Not Detected (Not Activated)

REFERENCE: The reaction tube, held by the catcher, is detected by the reflection sensor at the

detection position. When Z is at the home position, the black circle will be displayed

because usually the sensor is in front of the catcher.

(8) [Reset Liq. Sen]Key: Reset the detecting status of the liquid surface sensor.

(9) [Pipette Bottom], [Tube Free], [Tube Catch] Keys: Change depending to the setting position.

• Pipette Adjustment: [Pipette Bottom]

• Catcher Adjustment: [Tube Free] Å Æ [Tube Catch]

(10) [Z ADJUST] Key: Move the pipette or the catcher according to the setting pulses.

(11) [Z ORG] Key: Return the pipette or the catcher to Z home position.

(12) [XY TEST] Key: Move XY drive according to the setting pulses.

When the probe is not at the home position, it will move to the setting value after returning to the home

position.

CA-500 Series S/M 4-11 Revised December 2001

8

Page 14

(13) [XY ORG] Key: Return XY drive to the home position.

When this key is pressed, Y axis then X axis returns to the home position after Z axis returns to the home

position.

(14) [Pos. -], [Pos. +] Key: Switch setting position from [1] to [29].

(15) Either [Pipette] or [Catcher] Key: Move the pipette or the catcher. Moves 1 pulse by 1 press.

• Pipette Adjustment: [Pipette UP], [Pipette DOWN]

• Catcher Adjustment: [Catcher UP], [Catcher DOW N]

(16) [Arrow] Keys: Move 1 pulse by 1 press. (0,085 mm/pulse)

• [Å]: Move X axis to the left (away from the home position)

• [Æ]: Move X axis to the right (toward the home position)

• [↑]: Moves Y axis toward the home position.

• [↓]: Moves Y axis away from the home position.

(17) [Enter Pulses] Key: Press to enter pulses manually using the numeric keys.

(18) Display number of pulses stored in EEPROM to be updated by fixing the set value.

(19) [Z TEST] key: Press to move to the Z position currently set. This is not for changing the set value, but for

check only.

(20) [MODE CHANGE] key: Press to change modes.

Fine Adjustment (Individual position) Mode: Set each position for 29 points.

Basic Position Adjustment Mode: Set the basic position for each block.

By this setting, the accompanying position within the block can be set automatically.

Dete ction Well

Immunoassy

[CH6]

Figure 4-3-2: Table Positions

CA-500 Series S/M 4-12 Revised December 2001

8

Page 15

4.3.4 Position Adjustment Procedure of Pipette (“[1]blood 1”, “[2]blood 10”, and “[3]blood_stat”)

(1) XYZ Adjustment

CAUTION: 1) When setting the sample rack, be sure that the plate is inserted to the groove of the rack

correctly. It may cause the pipette to be bent.

Figure 4-3-3: Setting Sample Rack

2) When setting the 15-diameter tube into the sample rack, set the tube straight into the

sample rack.

1) Pour 50 µL of distilled water into the 4 mL sample cup or 50 µL of distilled water into the 15 mm

diameter test tube and set it into the sample rack No.1. (Set a cup or a tube for the customer’s use.)

Figure 4-3-4: Sample Cup and Test Tube with Distilled Water

CAUTION: If the customer uses test tube, do not set the sample cup. The sample probe

descends insufficiently when the z axis is adjusted by a sample cup.

2) Verify that the “[1] blood 1” is shown on the left center of the screen. If not, change to “[1] blood 1” by

using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

CA-500 Series S/M 4-13 Revised December 2001

8

Page 16

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

Figure 4-3-5: Pipette Tip Position

5) Press [Z TEST] key to descent the pipette. The pipette detects the 50 µL of distilled water and stops.

CAUTION: Probe descend until probe detect liquid surface or pipette bottom pulse value. When the

probe stops before detecting liquid surface, perform Section 4.3.4, (3) Pipette Lower

Limit Adjustment.

6) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

7) Press [Z ADJUST] key again to ascend and descend the pipette. Verify that the pipette is placed at

the center of the sample cup. (Z pulses will be stored as the setting value in the memory when

“Mecha Position” adjustment is completed.)

8) Press [XY ORG] key to return the pipette (head) to the home position.

9) Move sample cup to the sample rack No. 10.

10) Press [Pos. +] key to select the setting position “[2]blood 10”.

11) Execute Steps 3) to 8).

12) Move the sample cup to the blood_stat position.

13) Press [Pos. +] key to select the setting position “[3]blood_stat”.

14) Execute Steps 3) to 8).

CA-500 Series S/M 4-14 Revised December 2001

8

Page 17

15) The confirmation screen will be displayed by pressing [Quit] key.

Figure 4-3-6: Confirmation Screen

16) When pressing [FIX] key, new position adjustment data will be printout and return to adjustment

selection screen.

(3) Pipette Lower Limit Adjustment

When [FIX] key is pressed to complete adjustment, 25 pulses are added to Z pulse setting value and the value

is automatically set as the pipette lower limit.

Large value should be set as the pipette lower limit when executing Z adjustment so that the probe can seek a

liquid surface at the lowest point. Be sure to set water inside the tube when setting large value manually as Z

pulse. If not, it may cause the pipette to crash at the bottom of the tube or the motor to be mis-adjusted by the

pulse beyond the limit.

1) Press [Pipette Bottom] key to display Manual Entry Screen. The pipette lower limit will be reverse

displayed and manual change is available.

Figure 4-3-7: Pipette Lower Limit Adjustment Screen

2) Use numeric keys to input the value.

When “Z Adjustment” is disable by the insufficient pulse, input “1275” for temporary.

The pipette lower limit value “1250” is set by pressing [1], [2], [5], [0], [Enter], [Quit] and returns to the

Mecha. Position Adjustment screen. Be sure to press [Enter] key to set the value.

3) When pressing [FIX] key, 25 pulses are added to Z pulse setting value and the value is automatically set

as the pipette lower limit.

CA-500 Series S/M 4-15 Revised December 2001

8

Page 18

4.3.5 Position Adjustment Procedure of Pipette (“[4]reag 1”) (“[5]reag 9”) (“[6]reag 10”)

Continuous Z position adjustment is possible on software version 00-14 or later. Refer to 4.3.6-2 11

(1) XYZ Adjustment

1) Set the sample cup holder to the reagent rack No. 1. Place 60 µL of distilled water into the 4 mL

sample cup.

Figure 4-3-8: Sample Cup with 60 µL Distilled Water

2) Verify that the “[4]reag 1” is shown on the left center of the screen. If not, change to “[4]reag 1” by

using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

Figure 4-3-9: Pipette Tip Position

5) Press [Z TEST] key to descent the pipette. The pipette detects the 60 µL of distilled water and stops.

6) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

7) Press [Z ADJUST] key to ascend and descend the pipette. Verify the pipette is placed at the center

of the sample cup.

8) Press [XY ORG] key to return the pipette (head) to the home position.

9) Adjust “[5]reag 9” and “[6]reag 10” in the same way.

CAUTION: 1) Descent the pipette lower limit to the lowest for Z axis adjustment value. Adjust

after executing Section 4.3.4: Position Adjustment Procedure of Pipette, (3)

Pipette Lower Limit Adjustment when it stops before detecting liquid surface.

Set “650” pulse for the pipette lower limit of the reagent rack.

CA-500 Series S/M 4-16 Revised December 2001

8

Page 19

4.3.6 Position Adjustment Procedure of Pipette (“[7]reag_rinse”) (“[8] buffer”)

Continuous Z position adjustment is possible on software version 00-14 or later. Refer to 4.3.6-2 11

(1) XY Adjustment

1) Set the sample cup holder to the CA CLEAN I Holder. Place 60 µL of distilled water into the 4 mL

sample cup.

Figure 4-3-10: Sample Cup with 60 µL Distilled Water

2) Verify that the “[7]reag_rinse” is shown on the left center of the screen. . If not, change to

“[7]reag_rinse” by using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

Figure 4-3-11: Pipette Tip Position

5) Press [Z TEST] key to descent the pipette. The pipette detects the 60 µL of distilled water and stops.

6) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

7) Press [Z TEST] key again to ascend and descend the pipette. Verify that the pipette is placed at the

center of the sample cup.

8) Press [XY ORG] key to return the pipette (head) to the home position.

9) Adjust “[8]buffer” in the same way

CA-500 Series S/M 4-17 Revised December 2001

8

Page 20

(2) Z Adjustment

1) Set the sample cup holder to the CA CLEAN I Holder. Place 60 µL of distilled water into the 4 mL

sample cup.

Figure 4-3-12: Sample Cup with 60 µL Distilled Water

2) Move the pipette to the adjustment position by using [XY TEST] key.

3) Press [Z ADJUST] key to descent the pipette.

4) The pipette detects the 60 µL of distilled water and stops. Z pulses will be stored as the setting

value in the memory when “Mecha Position” adjustment is completed.

CAUTION: Descent the pipette lower limit to the lowest for Z axis adjustment value. Adjust after

executing Section 4.3.4: Position Adjustment Procedure of Pipette, (3) Pipette Lower

Limit Adjustment when it stops before detecting liquid surface.

Set “650” pulse for the pipette lower limit of the reagent rack.

5) Adjust “[8]buffer” in the same way.

CA-500 Series S/M 4-18-1 Revised December 2001

8

Page 21

4.3.7 Continuous Z Position Adjustment Procedure of Pipette (Ver.00-14 or later) 9

(1) XY Adjustment (“[4]reag 1”) (“[5]reag 9”) (“[6]reag 10”) (“[7]reag_rinse”) (“[8] buffer”)

1) Set the sample cup to the reagent rack No.1.

Figure 4-3-13: Sample Cup

2) Verify that the “[4]reag 1” is shown on the left center of the screen. If not, change to “[4]reag 1” by

using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the sample cup.

5) Adjust “[5] reag 9”, “[6] reag 10”, “[7] reag_rinse” and “[8] buffer” in the same way.

(2) Z Continuous Adjustment 13

Select “Reag1” by pressing [Pos+], [Pos-].

1)

2) Press [Enter Pulses] and increase Z pulse by 50 steps using the numeric key.

3) Save parameters by pressing [Return]-[Fix].

4) Enter “Mecha Position” screen again.

5) Set Z-axis Position Adjustment Tools (031-0171-4) for Reag1 through Reag10, Rinse and Buffer

(12 places).

6) Select “Reag 1” by pressing [Pos +], [Pos -] and press [Z adjust].

7) Check the check-boxes of [Z adjuster], [Continuous].

Sysmex

Reagent Z continuous adjustment

Adjuster Z Adjuster

Ready

Replace Rack ? OK

IP

V

4mLvial+60uL

Adjust Mode Continuous

Single

Set

V

Return

Figure 4-3-14: Reagent Z continuous adjustment

8) Press [Set] to carry out Auto Z-axis Position Adjustment.

9) Press [Return]Æ[Fix] to save parameters.

When there is no available Z-axis Position Adjustment Tools, carry out the adjustment as below.

1) Dispense 60uL of distilled water into the 4mL sample cups and set the sample cups for Reag1

through Reag10, Rinse, Buffer (12 places).

2) Press [Z adjust] and check the check-boxes of [4mL vial + 60µL], [Continuous].

3) Press [Set] to carry out Auto Z-axis Position Adjustment.

4) Press [Return]Æ[Fix] to save parameters.

When ‘Single’ is selected, Z position adjustment at each of R1 to R10 can be performed individually.

CA-500 Series S/M 4-18-2 Revised May 2003

13 303C012

Page 22

4.3.7 Position Adjustment Procedure of Pipette (“[10]wash_o)

(1) XY Adjustment

1) Select [Special Operate] Æ [Rinse & Prepare] from the Main Menu and supply rinse reagent into the

probe rinse cup (outside).

2) Verify that the “[10]wash_o” is shown on the left center of the screen. . If not, change to “[10]wash_o”

by using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the rinse cup.

5) Press [Z TEST] key to descent the pipette. The pipette detects the distilled water and stops.

6) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the probe rinse cup

(outside).

7) Press [Z TEST] key again to ascend and descend the pipette. Verify that the pipette is placed at the

center of the sample cup.

Figure 4-3-13: Probe Rinse Cup (Outside)

8) Press [XY ORG] key to return the pipette (head) to the home position.

CA-500 Series S/M 4-19 Revised December 2001

8

Page 23

(2) Z Adjustment

1) Select [Special Operate] Æ [Rinse & Prepare] from the Main Menu and supply rinse reagent into the

probe rinse cup (outside).

2) Move the pipette to the adjustment position by using [XY TEST] key.

3) Press [Z ADJUST] key to descent the pipette.

4) The pipette detects the liquid surface of the probe rinse cup and stops. The following screen will

appear by pressing [Enter Pulses] key. Press [X/Y/Z] key twice to move cursor to “Z”. Enter 25 added

pulses to present Z pulses and press [Enter] and then [Quit] key. The value will be stored in the

memory when “Mecha Position” adjustment is completed.

Figure 4-3-14: Enter Pulses Screen

“[9]wash_i” Adjustment

CAUTION:

[9]wash-i setting value

X value Same as Probe Rinse Cup (Outside)Value

Y value Probe Rinse Cup (Outside)Value + 200

Z value Same as Probe Rinse Cup (Outside)Value

“[9]wash_i” Adjustment:

In Basic Position Adjustment mode, the value of the probe rinse cup (inside) is

calculated automatically from the setting value of the probe rinse cup (outside). It

will be stored in the memory when “Mecha Position” adjustment is completed.

In Fine Adjustment mode, set the value of the probe rinse cup (inside) by

selecting [Enter Pulses] key.

Probe Rinse Cup (Inside) Value

CA-500 Series S/M 4-20 Revised December 2001

8

Page 24

4.3.8 Position Adjustment Procedure of Pipette (“[11]p_tube 1)

Adjustment Parameter: Pipette Position XYZ

Summary: Use the sample tube with 50 µL of distilled water inside for the position adjustment of

the reaction tube rack.

Adjust 3 positions for each two separated reaction tube rack.

Standard:

XY direction: The center of each sample tube set into the adjustment position of the reaction tube

rack.

Z direction: The lowest point of the pipette descended to the sample tube, with 50 µL of the

distilled water inside, of each adjustment position of the reaction tube rack.

(1) XY Adjustment

1) Place 50 µL of distilled water into the reaction tube and set it into the tube No. 1 of the reaction tube

rack.

Figure 4-3-15: Reaction Tube with 50 µL Distilled W ater

2) Verify that the “[11]p_tube 1” is shown on the left center of the screen. If not, change to “[11]p_tube

1” by using [Pos. -] and [Pos. +] keys.

3) Move the pipette to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the reaction tube.

Figure 4-3-16: Pipette Tip inside Reaction Tube

CAUTION: 1) Do not execute Z operation when XY adjustment is insufficient.

2) Be sure that the pipette tip is at the center of the reaction tube.

If not, it may cause the pipette to touch the reaction tube when descended.

CA-500 Series S/M 4-21 Revised December 2001

8

Page 25

5) Press [Z TEST] key to descent the pipette. The pipette detects the 50 µL of distilled water and stops.

6) Use [↑], [↓], [←], and [Æ] keys to adjust the pipette tip to become the center of the reaction tube.

7) Press [Z ADJUST] key again to ascend and descend the pipette. Verify that the pipette is placed at

the center of the sample cup. The pipette detects the 50 µL of distilled water inside the reaction tube

and stops. Z pulses will be stored as the setting value in the memory when “Mecha Position”

adjustment is completed.

8) Press [XY ORG] key to return the pipette (head) to the home position.

9) Setting Position: [11]p_tube 1, [12]p_tube 5, [13]p_tube 26,

[14]p_tube 31, [15]p_tube 35, [16]p_tube 56

Adjust above 6 positions in the same way.

Æ

NOTE: Refer to 5.10.1 Position Adjustment for the default values. Jump to Section 5.10.1

4.3.9 Position Adjustment Procedure of Catcher (“[17]c_tube 1)

Adjustment Parameter: Catcher Position XYZ pulses of Reaction Tube Rack

Summary: Adjust the catcher position of the reaction tube rack by setting the reaction tube to the

catcher.

Adjust 3 positions for each two separated reaction tube rack.

Standard Position:

X direction: 5 pulses to the left of the line where the left surface of the reaction tube, when

descended, agrees the interior surface of the reaction tube rack.

Y direction: The center of the catcher agrees the center of the reaction tube when the reaction

tube is descended.

Z direction: 5 pulses above the line where the bottom of the reaction tube agrees to the bottom of

the reaction tube rack.

The lower edge of the reaction tube brim should be aligned with the upper surface of

the lower catcher part.

(1) XYZ Adjustment

1) Place the reaction tube to the catcher.

2) Verify that the “[17]c_tube 1” is shown on the left center of the screen. . If not, change to “[17]c_tube

1” by using [Pos. -] and [Pos. +] keys.

3) Move the catcher to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [→] keys to adjust the reaction tube placed to the catcher to become the center

of the reaction tube rack hole.

5) Press [Z TEST] key to descent the catcher.

6) Press [Tube Free] and [Tube Catch] keys to release and catch the reaction tube.

(a) Y direction: Use [↑] and [↓] keys to adjust the center of the reaction tube agrees the center of

the catcher.

Figure 4-3-17: Y Direction Adjustment

CA-500 Series S/M 4-22 Revised December 2001

8

Page 26

(b) X direction: Use [←], and [Æ] keys to adjust the horizontal position of catcher. The catcher

once ascends and then descends by pressing [Z ADJUST] key. Adjust the

reaction tube position in X direction to touch the left part of the inner wall of the

reaction tube rack by repeating this operation.

Figure 4-3-18: X Direction Adjustment

(c) Z direction: Use [Catcher DOWN] key to confirm the position where the reaction tube hit the

bottom of the reaction tube rack. (Touch around the reaction tube rack hole to

confirm the vibration of the hit, or touch the reaction tube to verify that there is no

more play.) Press [Catcher UP] key for 5 times.

Press [Z Adjust] key for 2 or 3 times to confirm that the reaction tube does not hit

the bottom of the reaction tube rack.

The Z position can be also adjusted by using [Tube Catch] key and [Tube Free]

key and aligning the lower edge of the reaction tube brim with the upper surface of

the lower catcher part.

Figure 4-3-19: Z Direction Adjustment

7) Press [Tube Free] and [Tube Catch] keys to verify that the reaction tube to be caught and released

smoothly.

8) When the adjustment is completed, catch the reaction tube and return the catcher to the Z home

position by using [Z ORG] key. Move X axis 5 pulses towards to the left by pressing [Å] key (for 5

times). This is the X adjustment value.

9) When completed, press [XY ORG] key to return the catcher to the home position.

10) Setting Position: [18]c_tube 5, [19]c_tube 26, [20]c_tube 31,

[21]c_tube 35, [22]c_tube 56

Adjust above 5 positions in the same way.

CA-500 Series S/M 4-23 Revised December 2001

8

Page 27

4.3.10 Position Adjustment Procedure of Catcher (“[23]warm 1)

Adjustment Parameter: Catcher Position XYZ pulses of Detector Block

Summary: Adjust the catcher XY and Z positions of the detector block by setting the reaction

tube to the catcher.

Standard Position:

X direction: 5 pulses to the left of the line where the left surface of the reaction tube, when

descended, agrees the interior surface of the sample incubation well.

Y direction: The center of the catcher agrees the center of the reaction tube when the reaction

tube is descended.

Z direction: 5 pulses above the line where the bottom of the reaction tube agrees to the bottom of

the incubation well.

The lower edge of the reaction tube brim should be aligned with the upper surface of

the lower catcher part.

(1) XYZ Adjustment

1) Place the reaction tube to the catcher.

2) Verify that the “[23]warm 1” is shown on the left center of the screen. . If not, change to “[23]warm 1”

by using [Pos. -] and [Pos. +] keys.

3) Move the catcher to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust the reaction tube placed to the catcher to become the center

of the sample incubation well.

5) Press [Z TEST] key to descent the catcher.

6) Press [Tube Free] and [Tube Catch] keys to release and catch the reaction tube.

(a) Y direction: Use [↑] and [↓] keys to adjust the center of the reaction tube agrees the center of

the catcher.

Figure 4-3-20: Y Direction Adjustment

CA-500 Series S/M 4-24 Revised December 2001

8

Page 28

(b) X direction: Use [←], and [Æ] keys to adjust the horizontal position of catcher. The catcher

once ascends and then descends by pressing [Z ADJUST] key. Adjust the

reaction tube position in X direction to touch the left part of the inner wall of the

incubation well by repeating this operation.

Figure 4-3-21: X Direction Adjustment

(c) Z direction: Use [Catcher DOWN] key to confirm the position where the reaction tube hit the

bottom of the incubation well. (Touch around the incubation well to confirm the

vibration of the hit, or touch the reaction tube to verify that there is no more play.)

Press [Catcher UP] key for 5 times.

Press [Z Adjust] key for 2 or 3 times to confirm that the reaction tube does not hit

the bottom of the incubation well.

The Z position can be also adjusted by using [Tube Catch] key and [Tube Free]

key and aligning the lower edge of the reaction tube brim with the upper surface of

the lower catcher part.

Figure 4-3-22: Z Direction Adjustment

7) Press [Tube Free] and [Tube Catch] keys to verify that the reaction tube to be caught and released

smoothly.

8) When the adjustment is completed, catch the reaction tube and return the catcher to the Z home

position by using [Z ORG] key. Move X axis 5 pulses towards to the left by pressing [Å] key (for 5

times). This is the X adjustment value.

9) When completed, press [XY ORG] key to return the catcher to the home position.

10) Setting Position: [24]warm 3, [25]warm 4, [26]comp,

Adjust above 3 positions in the same way.

CA-500 Series S/M 4-25 Revised December 2001

8

Page 29

4.3.11 Position Adjustment Procedure of Catcher (“[27]shake)

Adjustment Parameter: XYZ pulses of Reagent Dispensing Position

Summary: Use the JIG tube for adjustment to adjust reagent dispensing position.

The JIG tube is the reaction tube that the 3 mm width x 15 mm length copper tape is

attached inside. (The copper tape should be attached straight from the top of the

flange.)

Figure 4-3-23: JIG Tube

(1) XY Adjustment

1) Place the JIG tube to the catcher.

2) Change the setting position to “[27]shake” by using [Pos. -] and [Pos. +] keys.

3) Input Z pulse “-40” by selecting “Enter Pulses”.

4) Press [XY TEST] key to move XY of the pipette to the dispensing position. Press [Pipette 70 Step] key

to ascend the catcher for 70 pulses.

5) Use [Å], and [Æ] keys to move the pipette position to touch the interior surface of the reaction tube.

When the pipette tip touches to the copper tape inside the tube, the liquid sensor display on the

screen changes from the white circle to the black circle. This X pulse is the setting value.

6) Press [Pipette Return] key to descend the catcher for 70 pulses. (Z pulse will be back to “-40”).

Figure 4-3-24: Catcher Adjustment

7) Press [XY ORG] key to return the pipette to the home position.

CAUTION: DO NOT press [Z ORG], [Z TEST] or [Z ADJUST] key. That will cause pipette crash.

CA-500 Series S/M 4-26 Revised December 2001

8

Page 30

4.3.12 Position Adjustment Procedure of Catcher (“[28]dust)

Adjustment Parameter: Catcher Position XYZ pulses of Reaction Tube Trash

Summary: Adjust the catcher XY and Z positions of the reaction tube trash by setting the reaction

tube to the catcher.

Standard Position:

Y direction: A center of the waste position mark on the panel agrees a center of the reaction tube.

Z direction: Z pulse position is at 13 pulses (approx. 1 mm) above the panel.

X direction: When Z pulse is as above, the reaction tube caught by the catcher is at the panel side

of the reaction tube trash. (Almost touches the trash.)

(1) XY Adjustment

1) Place the reaction tube to the catcher.

2) Verify that the “[28]dust” is shown on the left center of the screen. If not, change to “[28]dust” by using

[Pos. -] and [Pos. +] keys.

3) Move the catcher to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [Æ] keys to adjust Y direction to a center of the waste position mark and the

reaction tube. Adjust X direction at the panel side of the reaction tube trash.

Figure 4-3-25: XY Direction Adjustment

5) Press [Z ADJUST] key to descent the catcher.

6) Use [↑], [↓], [←], [Æ], [Catcher UP], and [Catcher DOWN] keys to adjust the catcher position so that Z

pulse to become 13 pulses (approx. 1 mm) above the reaction tube trash panel. Adjust Y direction to

the center of the waste position mark and the reaction tube. Adjust the reaction tube position in X

direction to touch the panel side of the reaction tube trash.

Figure 4-3-26: Z Direction Adjustment

7) Press [Z TEST] key to return to the home position and descent the catcher. Verify that the reaction

tube to enter smoothly into the reaction tube trash.

8) Press [Z TEST] key to descent the catcher.

9) Use [Tube Free] and [Tube Catch] keys to verify that the reaction tube to enter smoothly into the

reaction tube trash.

10) When the adjustment is completed, press [XY ORG] key to return pipette (head) to the home position.

CA-500 Series S/M 4-27 Revised December 2001

8

Page 31

4.3.13 Position Adjustment Procedure of Catcher (“[29]immunoassy)

Adjustment Parameter: Catcher Position XYZ pulses of Detector Block

Summary: Adjust the catcher XY and Z positions of the detector block by setting the reaction

tube to the catcher.

Standard Position:

X direction: 5 pulses to the left of the line where the left surface of the reaction tube, when

descended, agrees the interior surface of the immunoassay well.

Y direction: The center of the catcher agrees the center of the reaction tube when the reaction

tube is descended.

Z direction: 2 pulses above the line where the bottom of the reaction tube agrees to the bottom of

the immunoassay well.

The upper edge of the reaction tube brim should be aligned with the lower surface of

the upper catcher part.

(1) XYZ Adjustment, X Correction

1) Place the reaction tube to the catcher.

2) Verify that the “[29]immunoassy” is shown on the left center of the screen. . If not, change to

“[29]immunoassy” by using [Pos. -] and [Pos. +] keys.

3) Move the catcher to the setting position by using [XY TEST] key.

4) Use [↑], [↓], [←], and [→] keys to adjust the reaction tube placed to the catcher to become the center

of the immunoassy well.

5) Press [Z TEST] key to descent the catcher.

6) Press [Tube Free] and [Tube Catch] keys to release and catch the reaction tube.

(a) Y direction: Use [↑] and [↓] keys to adjust the center of the reaction tube agrees the center of

the catcher.

Figure 4-3-26: Y Direction Adjustment

(b) X direction: Use [←], and [Æ] keys to adjust the horizontal position of catcher. The catcher

once ascends and then descends by pressing [Z ADJUST] key. Adjust the

reaction tube position in X direction to touch the left part of the inner wall of the

immunoassay well by repeating this operation.

Figure 4-3-27: X Direction Adjustment

CA-500 Series S/M 4-28 Revised December 2001

8

Page 32

(c) Z direction: Use [Catcher DOWN] key to confirm the position where the reaction tube hit the

bottom of the immunoassay well. (Touch around the immunoassay well to confirm

the vibration of the hit, or touch the reaction tube to verify that there is no more

play.) Press [Catcher UP] key for 2 times.

The Z position can be also adjusted by using [Tube Catch] key and [Tube Free]

key and aligning the upper edge of the reaction tube brim with the lower surface of

the upper catcher part.

Figure 4-3-19: Z Direction Adjustment

7) Press [Tube Free] and [Tube Catch] keys to verify that the reaction tube to be caught and released

smoothly.

8) When the adjustment is completed, catch the reaction tube and return the catcher to the Z home

position by using [Z ORG] key. Move X axis 5 pulses towards to the left by pressing [Å] key (for 5

times). This is the X adjustment value.

9) When completed, press [XY ORG] key to return the catcher to the home position.

4.3.14 Output Setting Values

(1) Press [Return] or [Quit] key on the right bottom of the screen to display the confirmation screen as follows:

Figure 4-3-27: Confirmation Screen

(2) Press [FIX] key to update the setting value and then output.

CA-500 Series S/M 4-29 Revised December 2001

8

Page 33

4.4 TEMPERATURE ADJUSTMENT

4.4.1 Temperature Control Summary

The temperature control CPU gets each unit’s temperature by A/D converted signal as a temperature from the

sensor.

Due to the voltage comes out from the temperature sensor is various, the Main CPU sends the Offset value to

the temperature control CPU for each sensor to get the temperature within the range.

4.4.2 Temperature Verification at Each Unit 4

The unit temperatures displayed on the Temp. Control screen are the temperatures at each thermister.

For the temperature adjustment, the actual temperature at each unit must be checked as follows.

4.4.2.1 Cooling section (Reagent Cooler)

After 30 minutes since turning power ON of CA-500, perform the following procedures.

1) Pour 4 mL of distilled water into DADE 1 mL bottle, and put it into position No.4 of reagent rack.

2) Measure temperature of the water, and confirm that temperature is within 15.0 +/-2°C.

4.4.2.2 Detector Block

After 30 minutes since turning power ON of CA-500, perform the following procedures.

1) Pour 150 µL of distilled water into two reaction tubes, and put it into detection well CH5 and

incubation well #6.

2) Measure temperature of the water, and confirm that temperature is within the following range.

Detection Well CH5: 37.0 +/- 0.5°C

Incubation Well #6: 37.0 +/- 1.0°C

(Measure the temperature after temperature of the water becomes stable.)

4.4.2.3 Reagent Nozzle 19

Perform the temperature adjustment for reagent nozzle after the temperature adjustments of the detector

block and reagent block are passed successfully.

1) Enter the service mode and select [Special Operate] Æ [Service] Æ [Adjust] Æ [Temp. Control].

2) Press "Nozzle" area and input the D/A value attached on the heated probe to "S:xxx" area.

3) To verify the Temperature refer to Section 5.5.4 Reagent Temp. for the procedures

Jump to Section 5.5.4

4.4.2.4 Room Temperature

1) Enter the service mode and select [Special Operate] Æ [Service] Æ [Adjust] Æ [Temp. Control].

2) Verify that the room temperature by thermometer is within the displayed temperature +/- 3°C.

3) Press [Return] key to finish the confirmation.

CA-500 Series S/M 4-30 Revised February 2004

19 TB200408

Page 34

4.4.3 Temperature Adjustment Procedures 4

To adjust the temperature at each temperature-controlled unit, follow the steps below.

(1) Measure the actual temperature of the unit by referring to Section 4.4.2.

(2) Enter the service mode.

(3) Select [Special Operate] Æ [Service] Æ [Adjust] Æ [Temp. Control].

Figure 4-4-1: Temp. Control Screen

(4) Touch the desired sensor area to adjust the temperature.

“M:XXX” is Main value and “S:XXX” is Sub value. The cursor must be at “S:XXX” position.

IMPORTANT: Do not change the “M:XXX” value. This is the preset value during shipping

inspection for the temperature control circuit on the PCB No. 6362. It is not

necessary to adjust it in the market field.

Since the value is stored in EEPROM on PCB No. 6362, there may be the case

where it is erased. Then input the M:XXX value by referring to the label attached on

the memory card socket.

(5) Change the provided Sub value “S:XXX”, so that the displayed temperature should be the same as the

measured temperature. Use the numeric keys, which appears by pressing [Manual Entry] key or [+] [-]

keys.

When pressing [+]/[-] key, the displayed temperature will increase/decrease. When numeric keys are

used, the displayed temperature will change after pressing [Enter].

REFERENCE: The Sub value is fixed by the shipping test and attached to the PM parts for the

maintenance purpose. Its adjustment after shipment is not basically required.

(6) The unit temperature is automatically changed, by changing the Sub value, to be controlled at the target

temperature of each unit.

(7) Press [Enter] key and then [Quit] key to complete number input.

(8) Press [Clear] key returns the cursor positioned value before it is changed, which is stored in EEPROM.

(9) It will be stored in the memory by pressing [FIX] key when exiting the Temp. Control screen.

CA-500 Series S/M 4-31 Revised December 2001

8

Page 35

4.5 ELECTRICAL ADJUSTMENT

4.5.1 PCB No. 6362: MAIN (CPU, I/O, Motor Control, Temperature Control, A/D)

PCB No. 6373: MAIN-2 (CPU, I/O, Motor Control, Temperature Control, A/D)

4.5.1.1 Setting and Adjustments

(1) Switch Setting

1. SW202

Bit Setting Function

1

2

3

4

5

6

7

8

9

2. J501

Used for the Gain adjustment for the pressure sensor of the pressure pump.

Used usually with inserting the jumper pin between 1 and C.

(2) Pressure Adjustment

VR502 is to adjust OFFSET. VR501 is to adjust GAIN, however, it is adjusted and fixed at shipment.

Refer to Section 4.1 for the procedures.

(3) Mixing Motor Driving Power Adjustment

VR101 is provided for the adjustment of mixing motor driving power, however, it is adjusted and fixed

at shipment. The below is for reference only.

1) Connect the voltmeter between TP101 and the frame (GND).

2) Adjust VR101 so that the voltage when rotating the mixing motor becomes 1.05 ± 0.02 V.

3) Fix VR101 with paint lock.

Table 4-5-1: Dip Switch Setting on PCB No. 6362

Language Setting

Bit 1 Bit 2 Bit 3

OFF OFF OFF Japanese

ON OFF OFF English

OFF ON OFF Germany

ON ON OFF French

OFF OFF ON Italian

ON OFF ON Spanish

OFF ON ON English (for U. K.)

ON ON ON Not used

Chromogenic Unit

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Chromogenic Unit is used.

Chromogenic Unit is not used.

Cooler Unit Assembly

Cooler Unit is not used.

Cooler Unit is used.

B. B. RAM Clear Setting

B. B. RAM Clear at power ON

Normal Setting

Not used

--------------------

Normal Setting

EEPROM Clear Setting

EEPROM Clear

Normal Setting

Not used

--------------------

Normal Setting

CA-500 Series S/M 4-32 Revised December 2001 8

Page 36

4.5.1.2 LED and Test Point

(1) LED

Unit Letters

LED Color Status

on PCB

Reagent Cooler Unit COL. D403 Green Lit while power of the thermo-module is ON

Probe Unit NOZ. D402 Green Lit while the heater is ON

Detector Block DET. D401 Green Lit while the heater is ON

(2) Test Point

TP101 Mixing Motor Voltage Adjustment

TP201 Verify CPU Clock

TP202 GND

TP401 Verify A/D Converter Reference Voltage for Temperature Control

TP402 Analog GND

TP501 Verify A/D Converter Reference Voltage for Detector Signal

TP502 Analog GND

TP503 Verify Pressure Sensor Analog Output

4.5.1.3 Assembly Drawing

TP201

TP202

VR501

VR101

D403

D401

D402

VR502

TP502

NOZ.

TP101

DET.

COL.

TP503

TP501

CN101

TP402TP401

Figure 4-5-1: PCB No. 6362 Assembly Drawing

MAIN DP0173C

CN104

CA-500 Series S/M 4-33 Revised December 2001

8

Page 37

4.5.2 PCB No. 4086: PS (Power Source, Motor Driver)

4.5.2.1 CA-500 Power Supply System Check

Check the voltages for each switching regulator and PS Board (PCB No. 4086), following the procedure

below.

(1) Make sure that the Main Unit Power of CA-500 is turned OFF.

(2) Disconnect the following connectors to be free from any load:

CN101, CN104 on MAIN BOARD (PCB No. 6362)

CN2 on PRCN1 (PCB No. 6350)

(3) Turn the CA-500 Main Unit power OFF.

(4) Make sure that the voltage on each switching regulator and PS Board (PCB No. 4086) shows the

output voltage in Table below. (There is no adjusting point.)

(5) Turn the power switch of the CA-500 Main Unit OFF and connect CN101, CN104 on Main Board

(PCB No. 6362) with CN2 on PCN1 (PCB No. 6350).

PS BOARD (PCB No. 4086) Connector

(The other side is connected to TP1 (GND))

CN14 pin 9 +24 V ± 1 V

CN8 pin 5 +12 V ± 0.5 V

CN12 pin 3 +5 V ± 0.2 V

CN9 pin 3 +5 V ± 0.2 V

CN12 pin 1 +15 V ± 0.6 V

CN12 pin 2 –15 V ± 0.6 V

4.5.2.2 LED and Test Point

(1) LED

Sensor Letters

on PCB

Liquid Surface Sensor LIQUID D7 Red Lit when the liquid surface is detected

Probe Crash CRASH D8 Green Lit when the probe crashes

These LEDs turn OFF by the RESET signal (P-RES).

(2) Test Point

TP1 GND

TP2 Analog Signal of Liquid Surface Detection for checking

TP3 Comparator Output Signal of Liquid Surface Detection for checking

LED Color Status

Output Voltage

CA-500 Series S/M 4-34 Revised December 2001 8

Loading...

Loading...