SERVICE MANUAL

Automated Blood Coagulation Analyzer

CA-500

Section 1 Specifications

Section 2 Hydraulics and Mechanics

Section 3 Electronics

Section 4 Adjustment

Section 5 Service Program

Section 6 Error Messages and Troubleshooting

Section 7 Schematics

Appendix A Parts List

Appendix B Installation

Appendix C Disassembly

SYSMEX CORPORATION

KOBE, JAPAN

SYSMEX CORPORATION, TECHNO CENTER

4-4-4 Takatsukadai, Nishi-ku, Kobe 651-2271, Japan

TELEPHONE: 81-78-991-1911

FAX: 81-78-992-3274

URL=http://www.sysmex.co.jp

SYSMEX AMERICA, Inc.

1 Nelson C. White Parkway, Mundelein IL 60060, U.S.A.

TELEPHONE: 1-847-996-4500

FAX: 1-847-996-4505

URL=http://www.sysmex.com/

SYSMEX UK LIMITED

Sunrise Parkway, Linford Wood (East), Milton Keynes, Buckinghamshire, MK14 6QF, U.K.

TELEPHONE: 44-1908-669555

FAX: 44-1908-669409

SYSMEX EUROPE GmbH

Bornbarch 1 22848, Norderstedt, Germany

TELEPHONE: 49-40-527260

FAX: 49-40-52726100

SYSMEX SINGAPORE PTE LTD.

2 Woodlands Sector 1, #01-06, Woodlands Spectrum Singapore 738068

TELEPHONE: 65-221-3629

FAX: 65-221-3687

Copyright © 1999 through 2001 by SYSMEX CORPORATION

First Edition November 1999

Second Edition December 2001

All right reserved. No part of this book may be reproduced in any form or by

any electronic or mechanical means, including information storage and

retrieval systems, without written permission from the publisher.

Printed in Japan

Part Code Number

Printed Manual: 601-8244-3

CD-ROM Manual: 601-8268-2

SECTION 1 SPECIFICATIONS

To Cover

1.1 Outline ..................................................................................................................................................1-1

1.2 Name and Model ..................................................................................................................................1-1

1.3 Configuration and Dimensions .............................................................................................................1-1

1.3.1 Configuration and Expandability of the System.......................................................................1-1

1.3.2 Power Source..........................................................................................................................1-2

1.3.3 Dimensions and Weight ..........................................................................................................1-2

1.3.4 Each Unit Function and Operation ..........................................................................................1-2

1.3.5 Principles of Measurement......................................................................................................1-3

1.4 Performance, Intended Use and Effectiveness ....................................................................................1-3

1.4.1 Intended Use...........................................................................................................................1-3

1.4.2 Performance............................................................................................................................1-3

1.4.3 Functions.................................................................................................................................1-9

1.5 Acoustic Noise Level ..........................................................................................................................1-13

1.6 Environmental Conditions...................................................................................................................1-14

1.6.1 Operating Environment .........................................................................................................1-14

1.6.2 Reagents to be used .............................................................................................................1-14

1.7 How to Operate ..................................................................................................................................1-15

CA-500 Series S/M Revised December 2001 8

SECTION 1 SPECIFICATIONS

1.1 OUTLINE

The Sysmex CA-500 Automated Blood Coagulation Analyzer obtains clotting times by detecting changes in

scattered light intensity reflected from a diluted sample with buffer reagent which are illuminated by red light of

LED.

Incubated plasma taken from the centrifuged sample blood is rapidly mixed with warmed reagent and

coagulation is performed and analyzed. Its result can be automatically displayed and printed. In accordance

with the way of coagulation the chromogenics substrate method and the method of immunoassay are optionally

available on this unit .

1.2 NAME AND MODEL

Name: AUTOMATED BLOOD COAGULATION ANALYZER

Model: CA-510, CA-520, CA-530, CA-540, CA-550, CA-560

1.3 CONFIGURATION AND DIMENSIONS

1.3.1 Configuration and Expandability of the System

(1) Configuration

1) Main Unit (including Sampler Unit, Pneumatic Unit and Built-in Printer)

2) Chromogenic Unit and Bar Code Reader can be connected according to the following combinations

as the factory option.

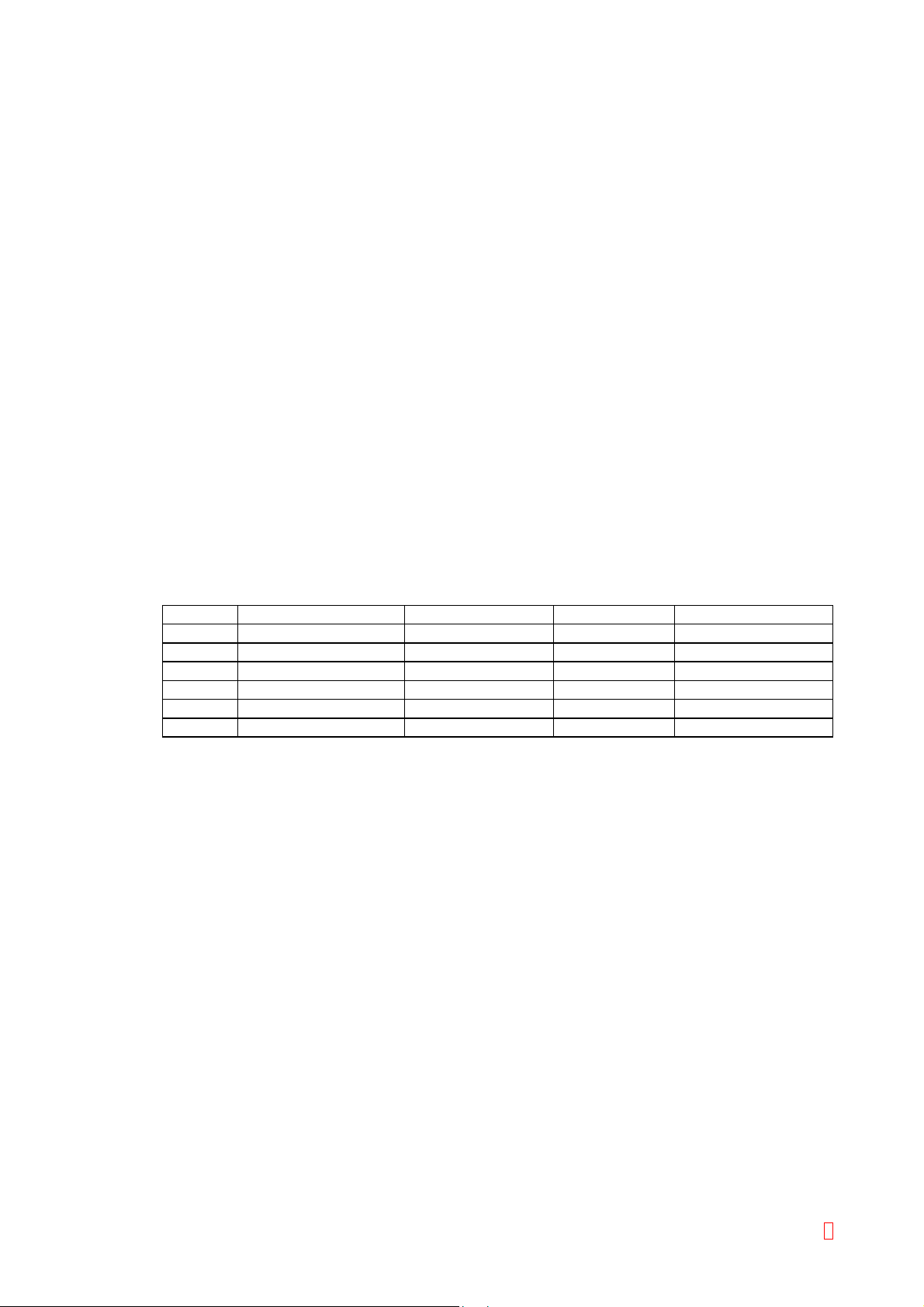

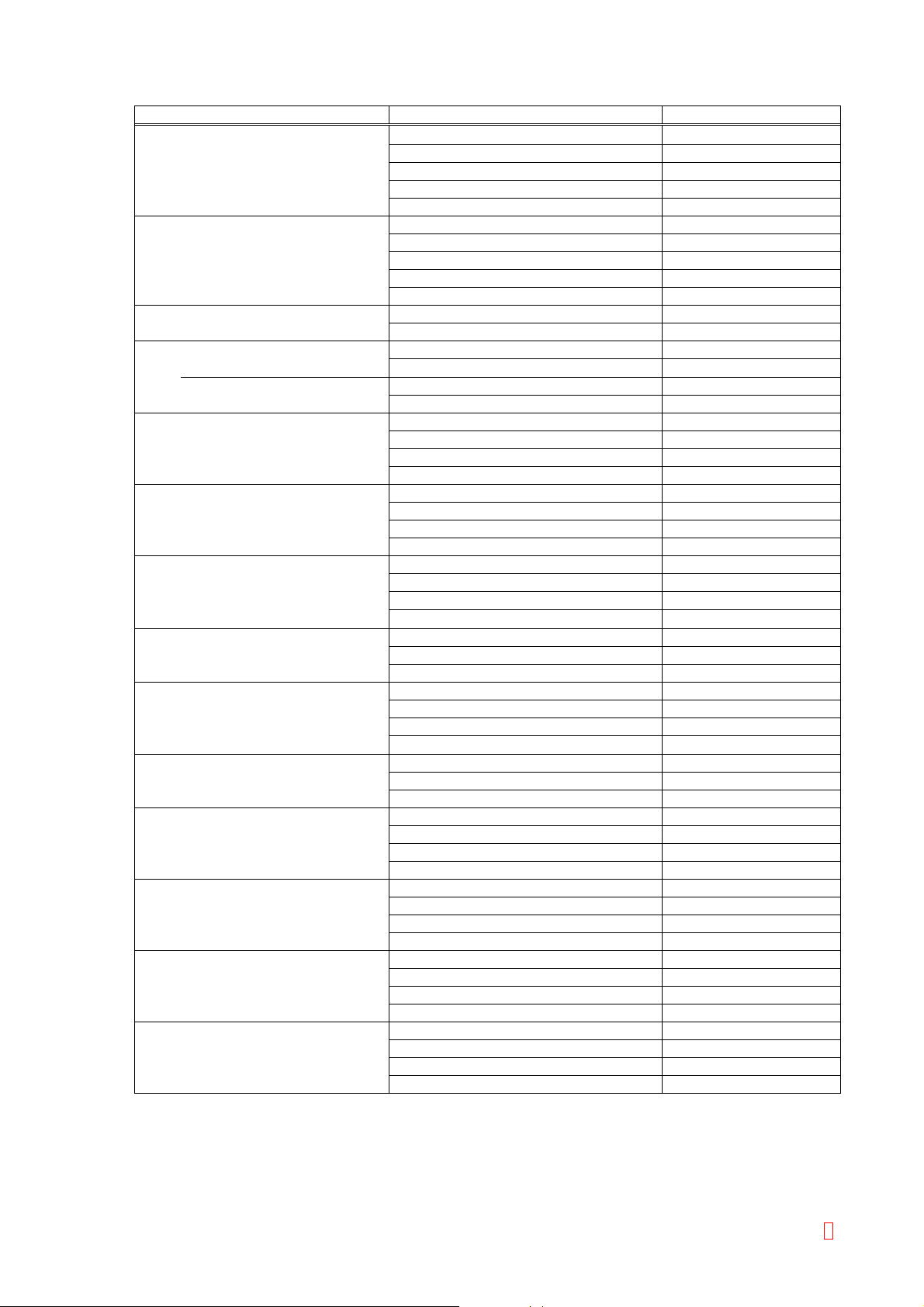

Reagent Cooler Unit Chromogenic Unit Immunoassay Bar Code Reader

CA-510 – – – Option

CA-520 – – – O

CA-530 O O – Option

CA-540 O O – O

CA-550 O O O* Option

CA-560 O O O* O

* 575 nm is used for Immunoassy.

(2) Factory Option

1) ID Bar Code Reader (optional supply is available for CA-510 and CA-530)

Sample ID numbers can be automatically read by Built-in Type Bar Code Reader (built in the

sampler unit), which can scan the samples in one rack and the STAT sample. (CA-520, CA-540)

2) Chromogenic Unit

The chromogenic analysis is available on Chromogenic Unit built in Main Unit. (CA-530, CA-540)

3) Immunoassay Unit

The immunoassay is available on Immunoassay Unit built in Main Unit. (CA-550, CA-560)

4) Reagent Cooler Unit

Cooling reagent (for four parameters) is available on Reagent Cooler Unit built in Main Unit.

(CA-530, CA-540)

(3) Interface with Other Instruments

1) RS-232C

2) PC-DPS(C), CA-DPS, SIS, or Host Computer can be connected.

CA-500 Series S/M 1-1 Revised December 2001 8

1.3.2 Power Source

(1) Rated voltage

AC 100 V/117 V ± 10%

AC 230 V ± 15%

(2) Type of Current

Direct Current

(3) Frequency

50 or 60 Hz

(4) Maximum power consumption

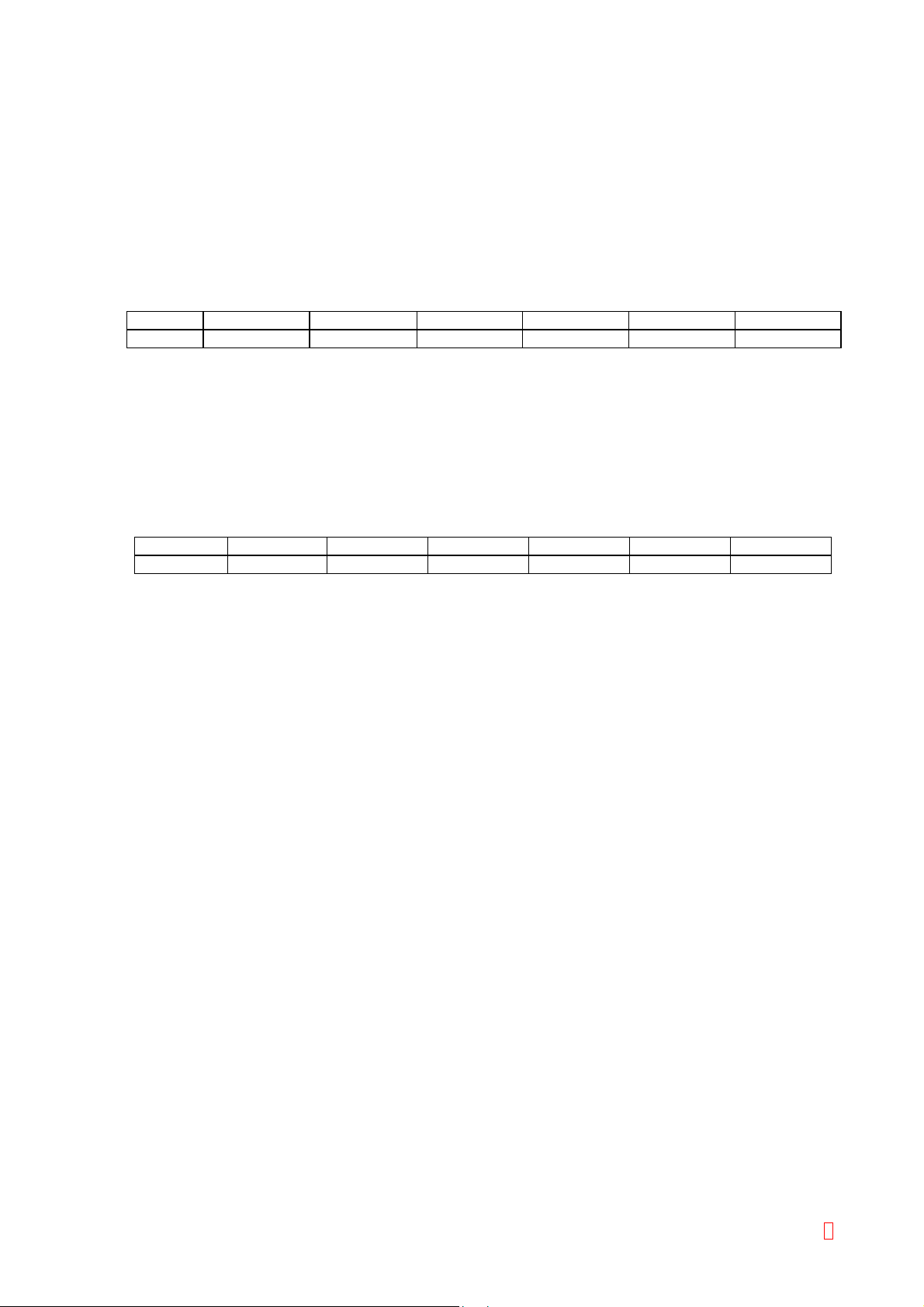

Unit CA-510 CA-520 CA-530 CA-540 CA-550 CA-560

Main Unit 310 VA or less 320 VA or less 380 VA or less 400 VA or less 380 VA or less 400 VA or less

(5) Class and Type of Electrical Protection

Class-I electrical apparatus, Type-B electrical apparatus

1.3.3 Dimensions and Weight

(1) Dimensions (excluding projections)

540 mm (width) X 487 mm (height) X 470 mm (depth) ± 3% respectively

(2) Weight

Unit CA-510 CA-520 CA-530 CA-540 CA-550 CA-560

Main Unit 43 kg 44 kg 44 kg 45 kg 44 kg 45 kg

1.3.4 Each Unit Function and Operation

(1) Main Unit Power Switch

Turns the power ON/OFF

(2) Display Unit

Displays the analysis registrations, analysis results, stored information and operation contents on the

LCD.

(3) Control Unit

Using LCD and Touch Panel, controls the operation in dialog.

(4) XYZ Drive Mechanism

Dispenses sample and reagent. Transfers the reaction tubes.

(5) Mechanical Stop Switch

Stops the operation temporary.

(6) Detector Block

Determines the coagulation time by measuring changes in the intensity of light scattered by increasing

turbidity.

(7) Chromogenic Unit

Detects the changes in the light absorbance by the transmitted light.

(8) Immunoassay Unit

Detects the changes in the light absorbance by the transmitted light.

(9) Temperature Control Unit

Controls temperatures for Detector Block, Reagent Heater Section and Cooling Section.

(10) System Control Unit

Controls Main Unit system.

(11) Drive Circuit Unit

Controls each motor ‘s driving.

(12) Pneumatic Unit

(13) Sampler Unit

Enables the continuous automatic operations by the sampler. One sampler rack can contain 10 sample

tubes.

CA-500 Series S/M 1-2 Revised December 2001 8

1.3.5 Principles of Measurement

1.3.5.1 Biological Activation Method

(1) Coagulation Reaction Detection Method (Scattered Light Measuring Method):

Red light (660 nm) is irradiated onto the mixture of plasma and reagent and the change of the scattered

light is detected, corresponding to the turbidity change when the fibrinogen is converted to fibrin.

(2) Coagulation End-Point Detection Method (Percent Detection Method):

Let the scattered light intensity at the time when the coagulation reagent is added to be 0% and that when

the coagulation reaction is completed to 100. The coagulation time is obtained from the time to reach the

presumed percent of the coagulation curve.

1.3.5.2 Chromogenic Substrate Method

(1) Calorimetric Method

Rate Method

1.4 PERFORMANCE, INTENDED USE AND EFFECTIVENESS

1.4.1 Intended Use

This unit measures the coagulation of the plasma or serum component of anti-coagulant (sodium citrate) added

human blood.

1.4.2 Performance

(1) Measurement Parameters and Display Parameters (Default Unit is shown in [ ]).

1) Prothrombin Time (PT) [second]

Calculated Parameters:

(a) Prothrombin Activation Percent [%]

(b) Prothrombin Ratio [ – ]

(c) International Normalized Ratio (INR) [ INR ]

(d) Derived Fbg (for export specification only) [mg/dL]

2) Activated Partial Thromboplastin Time (APTT) [second]

Calculated Parameters:

(a) APTT Ratio [ – ]

(b) Activation Percent (for European and UK specifications only) [% ]

3) Fibrinogen (Fbg) [second]

Calculated Parameters:

(a) Fibrinogen Concentration [mg/dL]

4) Thrombo Test (Plasma Method) [second]

Calculated Parameters:

(a) Activation Percent [%]

(b) INR (for European and UK specification only) [ – ]

CA-500 Series S/M 1-3 Revised December 2001 8

5) Normotest (NT) [second]

Calculated Parameters:

(a) Activation Percent [%]

(b) INR (for European and UK specification only) [ – ]

6) Thrombin Time (for export specifications only) [second]

7) Factor (II, V, VII, VIII, IX, X, XI, XII) [second]

Calculated Parameters:

(a) Activation Percent [%]

8) Protein C Coagulum (PCc) [second]

Calculated Parameters:

(a) Activation Percent [%]

(9) Batroxithonbin (BXT) [second]

(10) LA1, LA2 [second]

[Options]

(11) Anti-thrombin III (AT-III) [%]

(12) α2 Anti-plasmin (APL) [%]

(13) Anti-plasminogen (Plg) [%]

(14) Protein C (PC) [%]

(15) Heparin (Hep) [%]

International Unit [IU/mL]

(16) FDP (SFDP) [µg/mL]

(17) Plasma FDP (PFDP) [µg/mL]

(18) D-Dimer (DPI/DD) [g/mL] [µg/mL]

(2) Measurement Ranges

1) Fbg

Measuring is possible from 25 mg/dL to 1000 mg/dL of the fibrinogen concentration.

(In case of 450 mg/dL or above, measurement is performed with automatic re-dilution in high Fbg

concentration mode, and in case of 50 mg/dL or less, in low Fbg concentration mode. In CA-550 and

CA-560, measurement for 900 mg/dL or above is performed in high Fbg concentration mode, and for

100 mg/dL or less, in low Fbg concentration mode. )

2) D-Dimer (CA-550 and CA-560 only)

With applicable reagents, measuring is possible from 50 to 9999 µ/gL. However, the concentration of

2000 µ/gL or above is measureed in 8-hold dilution mode (+D-Dimer).

3) Serum FDP(CA-550 and CA-560 only)

With applicable reagents, measuring is possible from 2.5 to 320 µg/mL . However, the concentration

of 40 µg/mL or above is measureed in 8-hold dilution mode (+PFC).

4) Plasma FDP (CA-550 and CA-560 only)

With applicable reagents, measuring is possible from 2.5 to 480 µg/mL. However, in the concentration

of 60 µg/mL or above, measurement is performed in 8-hold dilution mode (+PFC).

CA-500 Series S/M 1-4 Revised December 2001 8

(3) Measurement Time

1) Maximum Measurement Time in Standard Mode

PT 100 seconds (120 seconds in CA-550 and CA-560)

Fbg 100 seconds

Others 190 seconds

ATIII 30 seconds

2) Maximum Measurement Time in Automatic Extended Mode

All Parameters 600 seconds

(4) Accuracy

When control plasma N is measured consecutively 10 times, measurement error of the average time

(second) should lie within the following ranges. (The ambient temperature must be 25 ± 10°C.)

PT ± 8% or less

APTT ± 8% or less

(5) Reproducibility

Coefficient of variation, when control plasma N is measured consecutively 10 times, should lie within the

following ranges with 95 % confidence if specified reagents are used. The ranges should be observed

when measuring was performed on 10 to 30 µg/mL of diluent sample with SFDP and PFDP, and on 500

to 1000 µg/mL of diluent sample with D-Dimer.

PT, APTT [second] CV within 2%

TTO, NT [second] CV within 4%

Fbg [second] CV within 4%

Factor (II, V, VII, VIII, IX, X, XI, XII)

[second] CV within 5%

TT [second] CV within 10%

BXT [second] CV within 4%

LA1/LA2 [second] CV within 4%

PCc [second] CV within 5%

AT-III [%] CV within 5%

APL [%] CV within 5%

Plg [%] CV within 5%

BCPC [%] CV within 5%

Hep [IU/mL] CV within 5%

SFDP [µg/mL] CV within 10%

PFDP [µg/mL] CV within 10%

D-Dimmer [µg/L] [µg/mL] CV within 10%

CA-500 Series S/M 1-5 Revised December 2001 8

(6) Stability

1) Temperature Stability

Variation of measurement (Activation % for AT III) at 15°C (C

) or 35°C (C35) from that at 25°C (C25) lies

15

within the following ranges, when this formula is used.

C15 (or C35) - C25

x 100

C25

PT, APTT (second) ± 8% or less

Fbg, TTO, HpT (second) ± 10% or less

AT III (%) ± 10% or less

D-Dimmer (µg/L) ± 10% or less

2) Stability within-a-day

Variation of measurement (Activation % for AT III) at the time of 2, 4 and 8 hours from that at 30 minutes

after the power is turned on (initial value) lies within the following ranges. The ambient temperature at the

time of measurement should be within the specified range. Temperature variation must be within 5°C.

( Measurement after 2, 4 or 8 hours ) - ( Measurement at 30 minutes )

x 100

( Measurement at 30 minutes )

PT, APTT (second) ± 8% or less

Fbg, TTO, HpT (second) ± 10% or less

AT III (%) ± 10% or less

D-Dimmer (µg/L) ± 10% or less

3) Long-term Stability (daily variation)

Variations in measurement values (Activation % for AT III) during the continuous 10 days lie within the

following ranges. The ambient temperature at the time of measurement should be within the specified

range. Temperature variation must be within 5°C.

( Measurement after second day ) - ( Mean Measurement )

x 100

( Mean Measurement )

PT, APTT (second) ± 8% or less

Fbg, TTO, HpT (second) ± 10% or less

AT III (%) ± 10% or less

D-Dimmer (µg/L) ± 10% or less

4) Stability against Power Source Variation

Variation of measurement (Activation % for AT III) lies within the following ranges when the rated voltage

changes at ±10%.

( Measurement at +10% or -10% ) - ( Measurement at rated voltage )

x 100

( Measurement at rated voltage )

PT, APTT (second) ± 8% or less

Fbg, TTO, HpT (second) ± 10% or less

AT III (%) ± 10% or less

D-Dimmer (µg/L) ± 10% or less

CA-500 Series S/M 1-6 Revised December 2001

8

(7) Analysis Mode and Sample Throughput

1) Analysis Mode

5 parameters are selected out of 7 parameters (14 parameters in CA-550 and CA-560) to perform

random analysis.

2) Sample Throughput

Maximum Throughput: approx. 54 tests/hour (when PT single parameter is measured)

Mean Throughput (PT, APTT, Fbg): approx. 40 tests/hour (when three parameters are measured at

the same time)

Mean throughput in this case means the mean throughput at the point of which an hour has passed from

a Start-key entry.

(8) Time Resolution

1) Coagulation

Time resolution is as follows depending on the elapsed time from the start of measurement.

0.1 second 2 through 120 seconds

0.2 second 120 through 240 seconds

1.0 second 240 through 600 seconds

2) Chromogenics Substrate Method and Immunoassay Method

The unit can continue performing sampling every second up to 600 seconds at maximum.

(9) Compensation functions

1) Setting of Coagulation Detection End Point

The coagulation detection point can be set every 1% within the range of 2 to 80%, enabling the data

calibration.

2) External compensation Function

The measured data is corrected with the linear equation.

(10) Required Volume of Plasma and Reagent

The required sample amount for each parameter and the required volume of reagent for the

measurement of one sample are shown below. (Unit in µL)

Parameter Sample/Reagent Quantity

Citrated Plasma 50 (1) PT

Pt 100

(2) APTT

Citrated Plasma 50

Aptt 50

CaC12 50

(3) Fbg

Citrated Plasma 5

Owren’s Veronal buffer 95

Fbg 50

(4) TTO

Citrated Plasma 20

Owren’s Veronal buffer 30

CA-Series Comlex Factor TTO 125

(5) HpT

Citrated Plasma 10

Owren’s Veronal buffer 40

CA-Series Complex Factor HPT 125

Citrated Plasma 100 (6) TT

Owren’s Veronal buffer 50

(7) II, V, YII, X

Citrated Plasma 5

Owren’s Veronal buffer 45

Factor Deficient Plasma 50

PT 100

(Continues to the next page.)

CA-500 Series S/M 1-7 Revised December 2001 8

(Continued from the previous page.)

Parameter Sample/Reagent Quantity

(8) VII, IX, XI, XII

Citrated Plasma 5 or 10

Owren’s Veronal buffer 45 or40

Factor Deficient Plasma 50

APTT 50

Calcium Chroride 50

(9) PC.c

Citrated Plasma 5

Protein C Deficient Plasma 35

Protein C Activator 40

APTT 40

Calcium Chloride 40

Citrated Plasma 50 (10) BXT

Batroxobin 100

(11)

Citrated Plasma 100 La1

LA1 100

La2

Citrated Plasma 100

LA2 100

(12) AT3

Citrated Plasma 10

Owren’s Veronal buffer 83

Thrombin Reagent 125

Substrate Reagent 33

(13) APL

Citrated Plasma 16

Owren’s Veronal buffer 83

Plasmin 125

Plasmin Substrate 33

(14) Plg

Citrated Plasma 16

Owren’s Veronal buffer 112

Streptkinase Reagent 125

Plasmin Substrate 25

(15) BCPC

Citrated Plasma 20

Protein C Activator 125

Substrate Reagent 30

(16) Hep

Citrated Plasma 20

ATIII Reagent 20

Factor Xa Reagent 125

Heparin Substrate 40

(17) DDPI

AdDD

Citrated Plasma 50

Accelerator 25

Latex 150

(18) DD

D-D Dimer Standard 16

Elpia Ace D-D Dimer Stabilizer 116

Elpia Ace D-D Dimer Latex 33

Elpia Ace D-D Dimer Diluent 112

(19) SFDP

Standard Set For Elpia FDP 10

Elpia FDP Stabilizer 122

Elpia FDP Latex 22

Owren’s Veronal buffer 97

(20) PFDP (in 800 nm analysis)

P-Fdp Standard 16

Latex Test BL-2 P-FDP Diluent 66

Latex Test BL-2 P-FDP Latex 94

P-FDP Diluent 80

(21) PFDP (in 575 nm analysis)

P-FDP Standard 16

Latex Test BL-2 P-FDP Diluent 66

Latex Test BL-2 P-FDP Latex 94

P-FDP Diluent 112

Additionally, approximately 6 mL of distilled water and approximately 212 µL (at the maximum) of rinsing

solution (CA CLEAN I) are required for rinsing per test.

CA-500 Series S/M 1-8 Revised December 2001 8

1.4.3 Functions

(1) Sample Tube Transportation Function

Sample tube is transported from the sample tube rack to the sample incubation unit by the Slide Catcher

Method.

(2) Reaction Tube Feeding Function

1) Reaction Tube Feeding Method: Fed manually to Reaction Tube Rack

2) Number of Reaction Tube: 2 racks containing 30 tubes each (maximum 60 reaction tubes)

3) Kinds of Reaction Tube: Tube SU-40 for CA-1000

4) Detecting Reaction Tube: Detected by Reaction Tube Detective Sensor

(3) Sample Plasma and Reagent Dispensing Function

One dispensing pipette with the heating function moves up and down, traverses, and dispenses the

sample and the reagent.

1) Temperature Control Accuracy: 37.0 ± 1.0°C (with ambient temperature of 15 ~ 30°C)

2) Waiting Time for Setting Temp.: within 30 minutes

3) Volumetric Method: Sample and reagent are aspirated, dispensed and rinsed by the

syringe.

4) Volumetric Syringe: 1

5) Pipette: 1

(4) Liquid Surface Detection Function

The pipette has the liquid surface detection function, so that it senses the meniscus automatically and

then stops at a certain depth of the sample or the reagent.

(5) Sampler Function

1) Sample Storing Method: Sysmex Rack

2) Maximum Sample Storage: 1 rack (10 samples)

3) Usable Collection Tubes:

The following types with inside diameter of 8 mm or more.

(i) 15 (OD) X 75 ~ 100 mm length

(ii) 12 (OD) X 75 ~ 100 mm length

(iii) 10 (OD) X 65 mm length (The optional spacer is required.)

(iv) Sample cup of 2 mL or 4 mL

4) Sample Cooling Function: None

5) Sample ID Reading Function: Sample ID No. can be read by the Bar Code Reader.

(6) STAT Sample Measurement Function

1) The specified sample in the STAT Sample Rack can be analyzed, interrupting the usual analysis.

Within 10 minutes from the interruption by the STAT sample analysis, the analysis result can be

output (when the single parameter is analyzed).

2) Number of STAT sample

One sample only.

(7) Measurement Interrupt/Restart Function (CA-550 and CA-560 only)

The analyzer has the function to allow setting additional samples to the rack in process after starting a

measurement and measuring them. The registration of the additional samples can be made on the left

side from the left-end tube position for the samples already set in rack and registered for measurement.

CA-500 Series S/M 1-9 Revised December 2001 8

(8) Reagent Storage Function

1) Reagent Storage Method: Stored in the reagent rack

2) Reagent holder capacity: Maximum 10 kinds of reagent bottles can be set in the reagent

rack. Buffer and rinsing solution can also be set.

3) Usable container: Dade Bering’s old DADE for 5 mL, a sample cup, can be set, and

also GW5, a new type of reagent bottles only for

CA-550/CA-560, can be set.

(The outer diameter of the reagent bottle should be less than

22.5 mm, and also, if the inner diameter is too small, use the

4) Reagent Cooling Function: Four reagents can be cooled. (CA-530, CA-540)

5) Temperature Control Accuracy: within 15 ± 2°C (Room temperature: 15°C - 30°C)

6) W aiting time for setting temp.: within 30 minutes

bottle adapter.)

7) Reagent Mixing Function: None

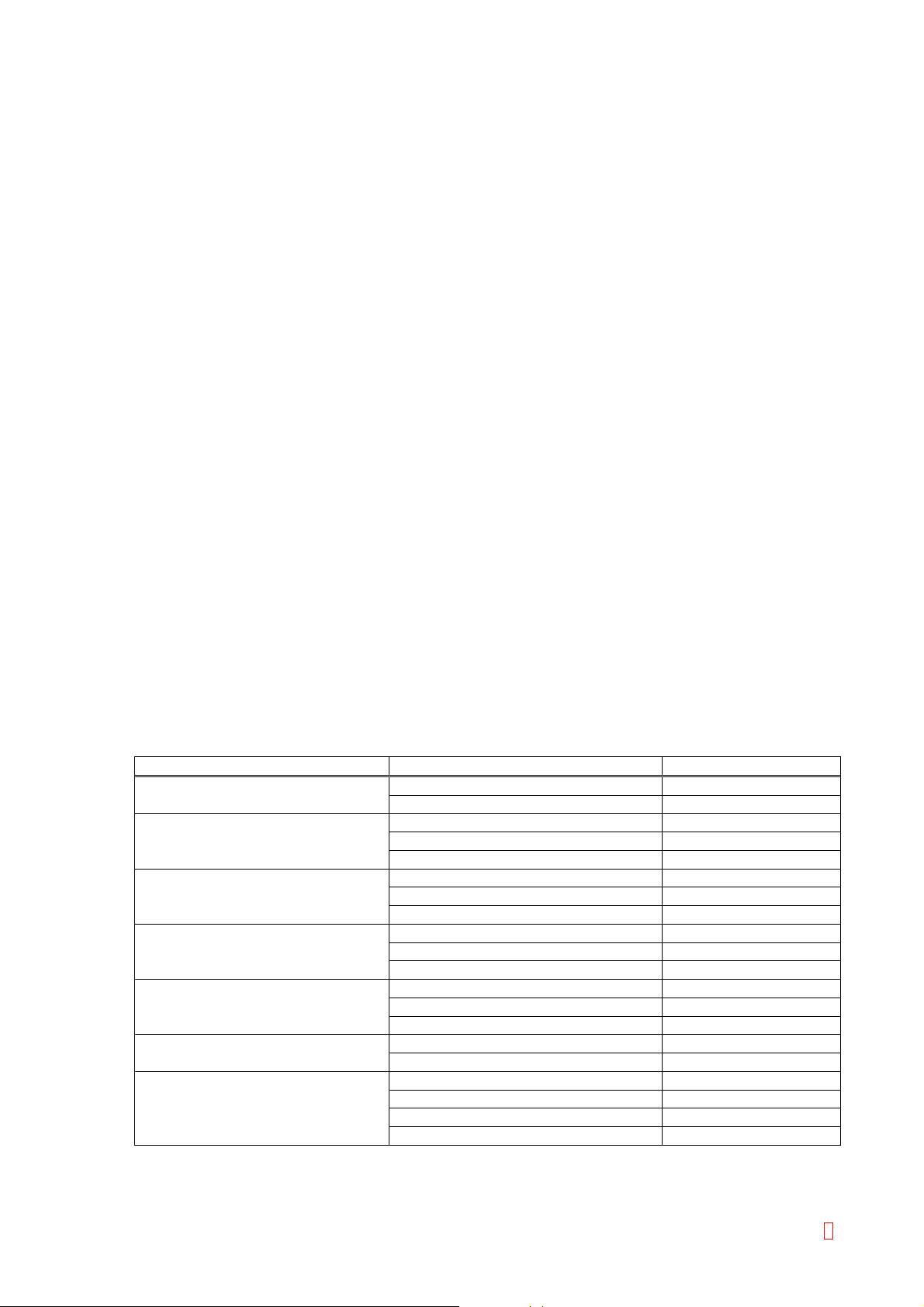

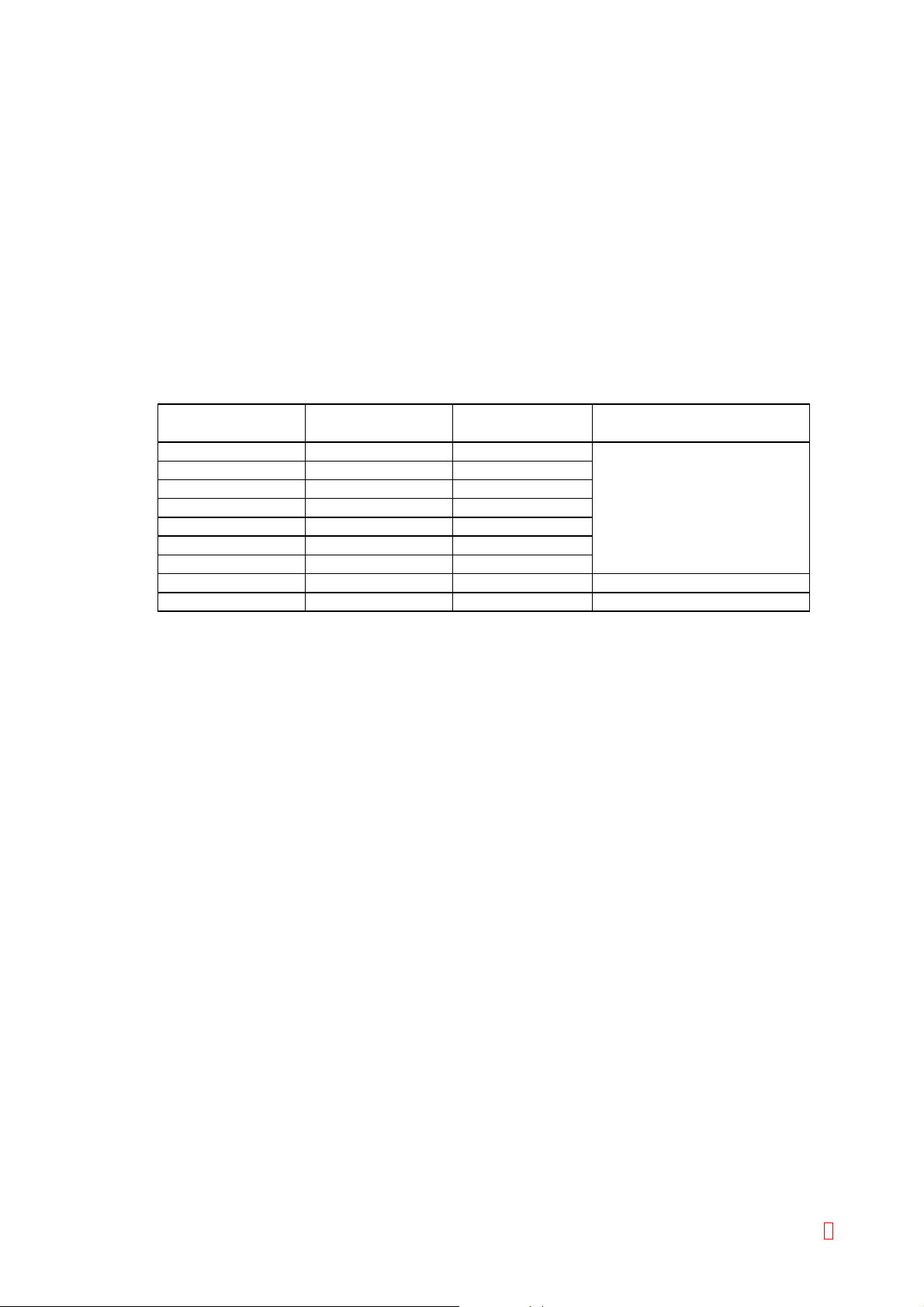

Type of reagent Number of

accommodation

Cooling function Container which can be

accommodated

PT 1 Yes

APTT 2 No

Fbg 1 Yes DADE 5 mL Reagent Bottle

TTO 1 No (with outer diameter of

NT 1 No 22.3 mm)

TT 1 Yes

AT-III 2 Yes (only one)

Buffer 1 No

CA CLEAN I 1 No

(9) Detection Function

1) Principle of Measurement

[Coagulation Method]: Scattered Light Measuring Method (wave length 660 nm)

[Chromogenic Method]: Calorimetric method (wave length 405 nm)

[Immunoassay]: Colorimetric method (wave length 575 nm)

2) Number of Detectors

[Coagulation Method]: 4 detection wells (High and Low sensitivity automatic switching)

[Chromogenic Method]: 1 detection well

[Immunoassay]: 1 detection well

3) No. of Incubation wells: 6 wells

4) Temperature Control Accuracy: within 37.0 ± 0.5°C (ambient temperature: 15°C-30°C)

within 37.0 ± 1.0°C for Incubation Well

5) W aiting time for setting temp.: within 30 minutes

(10) Pipette Rinsing Function

1) External Container: Rinse Bottle and W aste Bottle

2) Rinse Cup: Probe Rinse Cup (Outside) and Probe Rinse Cup (Inside)

3) Rinsing Function: Pipette is rinsed by controlling the syringe and the solenoid valve, with

applying the pressure on the Rinse Bottle.

4) Waste Draining: The waste is aspirated by controlling the solenoid valve, with applying

vacuum on the waste bottle.

CA-500 Series S/M 1-10 Revised December 2001 8

(11) XYZ Driving Function

Pipette and sample catcher mechanism on the head unit (Z axis) is driven by the XY-axis mechanism to

dispense sample and reagent and transfer and discard the reaction tubes.

1) XY-axis Mechanism: Linear Slider driven by stepper motor

2) Z-axis Mechanism: Pipette and sample tube catcher are driven by one motor.

(12) Mixing Function

After dispensing the reagent, the reaction tube is vibrated and mixed by the miniature motor.

(13) Sample Data Storage Function

1) Contents of Data

(i) Measurement data

(ii) Setting values

(iii) Quality control data

(iv) Date (year, month, day, hour, minute)

2) Memory Capacity

(i) Data of 300 samples (maximum 1500 tests = 300 samples X 5 parameters). The analysis

print data is not stored once the power is OFF. As for the reaction curve, the latest 600 tests

are stored.

(ii) Quality control data: 12 kinds X 7 parameters X 180 plots (CA-510 to CA-540)

6 kinds X 14 parameters X 180 plots. To the Quality Control file, the

parameters of dilution magnification such as -Fbg, +Fbg, +DD, +DDPl, +SFD, and +PFD are

also included. (CA-550 and CA-560 only)

(14) Display and Input Function

1) Display Type

Graphic panel display + touch panel using a 3.2 X 4 inch liquid crystal display (white and black back

light)

2) Displayed Data

(i) Date

(ii) Measurement condition, Analysis status, Results

(iii) Stored sample: Stored sample list: Date, Time, Sample ID number, Parameter name,

Measured data, Reaction curves (CA-550 and CA-560 allow zooming in to view), Rack

number. (CA-550 and CA-560 only).

(iv) Quality control (QC data, QC chart)

(Only CA-550 and CA-560 can carry markings on screen display about the data beyond the

upper and lower limits of quality control. In addition, the CA-550 and CA-560 analyzers stores

the data of slight coagulation errors.)

(v) Standard curve (SC data, SC chart)

(vi) Operation messages

(vii) Error messages

(viii) Maintenance information and various setting values

(ix) Temperatures at incubation well, heater pipette, reagent cooler unit

3) Input Method

Change, select, and set functions on each screen by LCD touch panel method.

CA-500 Series S/M 1-11 Revised December 2001 8

(15) Printing Function

1) Printing Method

Graphic print by a built-in thermal printer

2) Printed Data

(i) Stored sample data (the same as the measured data)

(ii) Quality control (QC data, QC chart)

(iii) Measured data (Date, Time, Sample ID number, Parameter name, Measured data, Reaction

curve, Analysis print data, Rack number (CA-550 and CA-560 only))

(iv) Standard curve (SC data, SC chart)

(v) Confirmation messages, Error messages

(vi) Maintenance information and various setting values (CA-550 and CA-560 can print at each

parameter.)

(16) Quality Control Function

1) L-J control or X control is possible using control material.

2) Applicable parameters: PT, APTT, Fbg, TTO, NT, TT, AT III

14 parameters (CA-550 and CA-560 only)

-Fbg, +Fbg, +DD, +DDPl, +SFD, and +PFD are also treated as

parameters and QC analysis can be performed on each parameter.

(CA-550 and CA-560 only)

3) Number of stored files: 12 files for each parameter

67 files (CA-550 and CA-560 only)

4) Number of data points: 180 for each parameter

(17) Select Function

1) Measurement Mode

(i) Random access measurement mode

5 parameters are selected out of 7 parameters (14 parameters in CA-550 and CA-560) and the

five parameters are measured at random.

(ii) Programmable measurement mode

All parameters are measured with changing the measurement order.

(iii) Replication mode

The same sample is measured twice (or more) and the mean value is determined to be the

measurement result. However, the throughput is less than half number of that of ordinary

measurement.

2) Settings

(i) Sample ID number

(ii) Date/Time

(iii) Setting function for APTT heating time

2, 3, 4 or 5 (minutes) of heating time can be set. (Standard setting is 3 minutes and the

throughput changes if other time is set.)

3) Output

Automatic transfer or Manual transfer can be set.

Raw data output is available in Service mode. (CA-550 and CA-560 only)

4) Stored data processing

Displaying and printing the stored data is possible.

5) Service Function

For the Customer: Displaying of standard curve data and setting of abnormal values

(range)

For the Servicing Personnel: Service mode, System tests, Memory Initialization, and

adjustment/setting (of X-Y axis position)

CA-500 Series S/M 1-12 Revised December 2001 8

(18) Standard Curve Setting Function

Standard curve of seven parameters (14 parameters in CA-550 and CA-560) can be set at six points or

less within the measurable range. Setting Standard Curve is performed by the Auto dilution or Manual

Entry. (Manual dilution analysis is available only in CA-550 and CA-560.) Two kinds of standard curves

can be set to one parameter (only in CA-550 and CA-560). Settings should be given to each parameter

individually.

(19) Analytical Algorithm corresponding to V-Lin-Integral (CA-550 and CA-560 only)

As a new analysis method, analytical algorithm equivalent to V-Lin-Integral is provided.

(20) APTT Initial Reaction Check Algorithm (CA-550 and CA-560 only)

An algorithm to check APTT’s initial reactions is newly provided.

(21) Detector Block Self-Checking Function (CA-550 and CA-560 only)

Besides the already-provided functions to adjust the detector block, a function is newly provided that the

analyzer self-monitors the state of the detector block and carry out auto calibration.

(22) Error Alert Function

1) Unit Error monitoring function

(i) Temperature of heater section

(ii) Shortage of reagent

(iii) Presence or absence of sample rack

(iv) Shortage of rinse solution

(v) Overflow from the waste bottle

(vi) Operation of mechanical parts

(vii) Operation of printer

(viii) Shortage of printer paper

(ix) Serial output

(x) Other self-diagnosis by service mode

2) Sample Abnormality monitoring function

(i) Upper and lower limit judgment (PT, APTT, Fbg, TTO, NT, TT, AT-III)

Display when the measured data exceeds the preset range.

(23) External Input/Output Function

The I/O terminal in accordance with RS-232C is provided as bit serial voltage I/O.

(24) Protection Function

1) Over-heat protection thermal fuse (Pipette Unit and Detector Block)

2) Mechanical stop switch

3) Light Shield cover open/close switch

4) Sampler position sensor

(25) Display Languages

Capable of displaying six languages such as Japanese, English, French, Italian, German, and Spanish.

Screen displays and messages should be consistent with those of existing models.

1.5 ACOUSTIC NOISE LEVEL

Noise level should be within the following values. (The measuring position is 1 meter from the front of the

product.

(1) Stand-by status: 58 dB or less

(2) Measuring operation status: 60 dB or less

Temporary noises (less than 65 dB continued within 5 seconds) are produced on occasions, such as home

positioning of X-Y table or syringe drive mechanism are not included.

CA-500 Series S/M 1-13 Revised December 2001 8

1.6 ENVIRONMENTAL CONDITIONS

1.6.1 Operating Environment

(1) Ambient temperature: 15 ~ 35°C

(2) Relative humidity: 30 ~ 85% (non-condensing)

(3) Atmospheric pressure: 70 ~ 106 kPa

(4) Place to be installed: avoid direct sunlight, dust, vibration and acid vapors

1.6.2 Reagents to be used

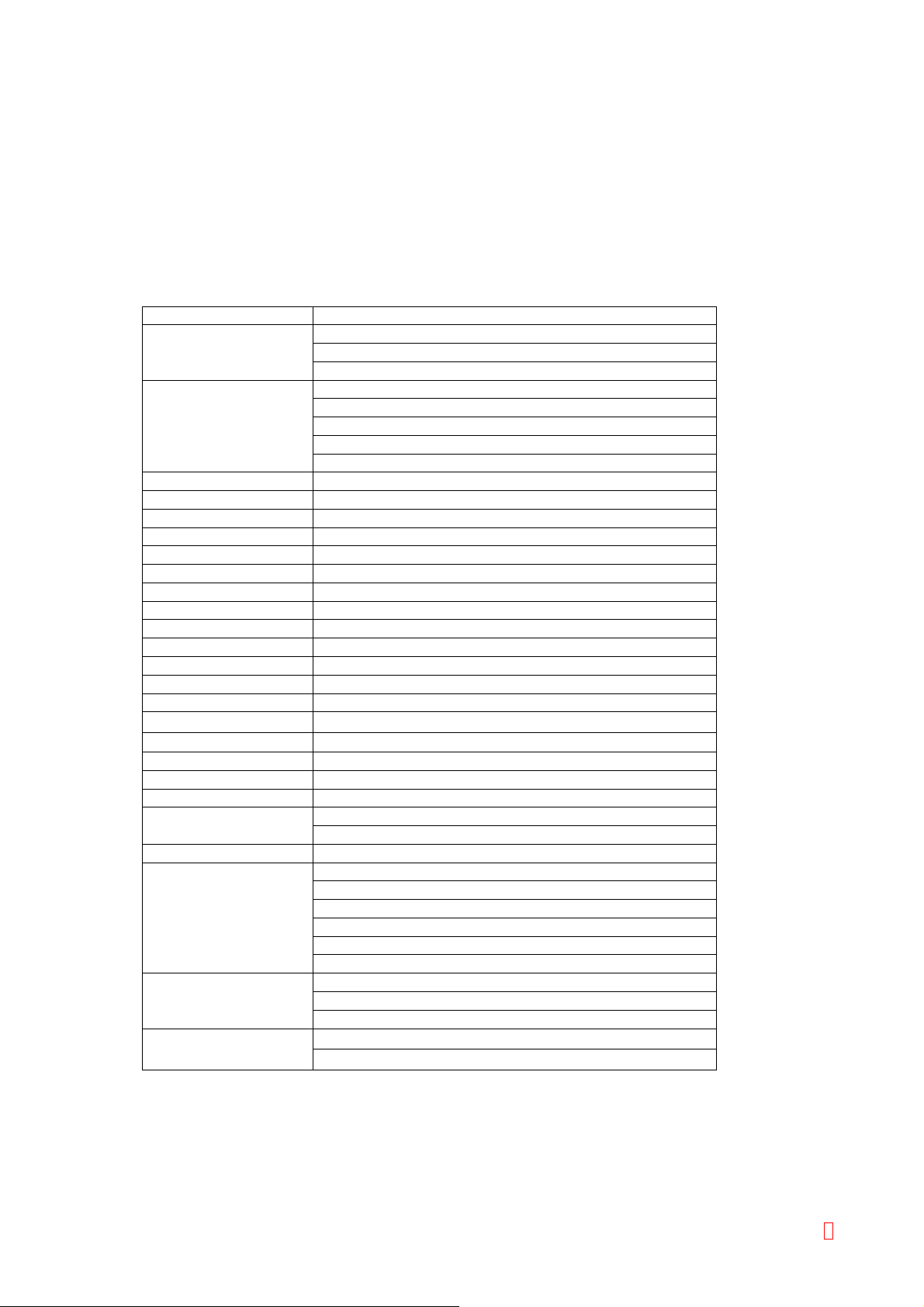

Parameter Reagent

PT

APTT

Fbg Dade Thrombin Reagent

TT Thrombin Clotting Time Reagent

II Clotting Factor-II Deficient Plasma

V Clotting Factor-V Deficient Plasma

YII Clotting Factor-VII Deficient Plasma

X Clotting Factor-X Deficient Plasma

VIII Clotting Factor-VIII Deficient Plasma

IX Clotting Factor-IX Deficient Plasma

XI Clotting Factor-XI Deficient Plasma

XII Clotting Factor-XII Deficient Plasma

LA1/LA2 LA1 Screening Reagent/LA2 Confirmation Reagent

PC.c Protein C reagent

BXT Batroxobin reagent

AT3

APL

Plg Berichrom Plasminogen

BCPC Berichrom Protein C

Hep Berichrom Heparin

DDPI/AdDD D-Dimer PLUS/Advanced D-Dimer

Thromborel S

Dade Innovin

Dade Thromboplastin C plus

Pathromtin SL

Dade Actia Activated Cephanloplastin Reagent

Dade Actia FS Activated FTT Reagent

Dade Actia FSL Activated FTT Reagent

Calcium Chroloride Solution (0.025 mol/l)

Berichrom Antithrombin Ⅲ (A)

Berichrom α2-Antiplasmin

Latex Test BL-2 P-FDP PFDP

P-FDP Diluents

Control Plasma N(Human)

Control Plasma P(Human)

DadeCi-Trol Coagulation Control,Level 1

DadeCi-Trol Coagulation Control,Level 2

DadeCi-Trol Coagulation Control,Level 3

Standard Human Plasma

P-FDP Standard

D-Dimer PLUS Standard Plasma

PT Calibration Plasma Kit

CA CLEAN Ⅰ

CA CLEAN Ⅱ

CA-500 Series S/M 1-14 Revised December 2001 8

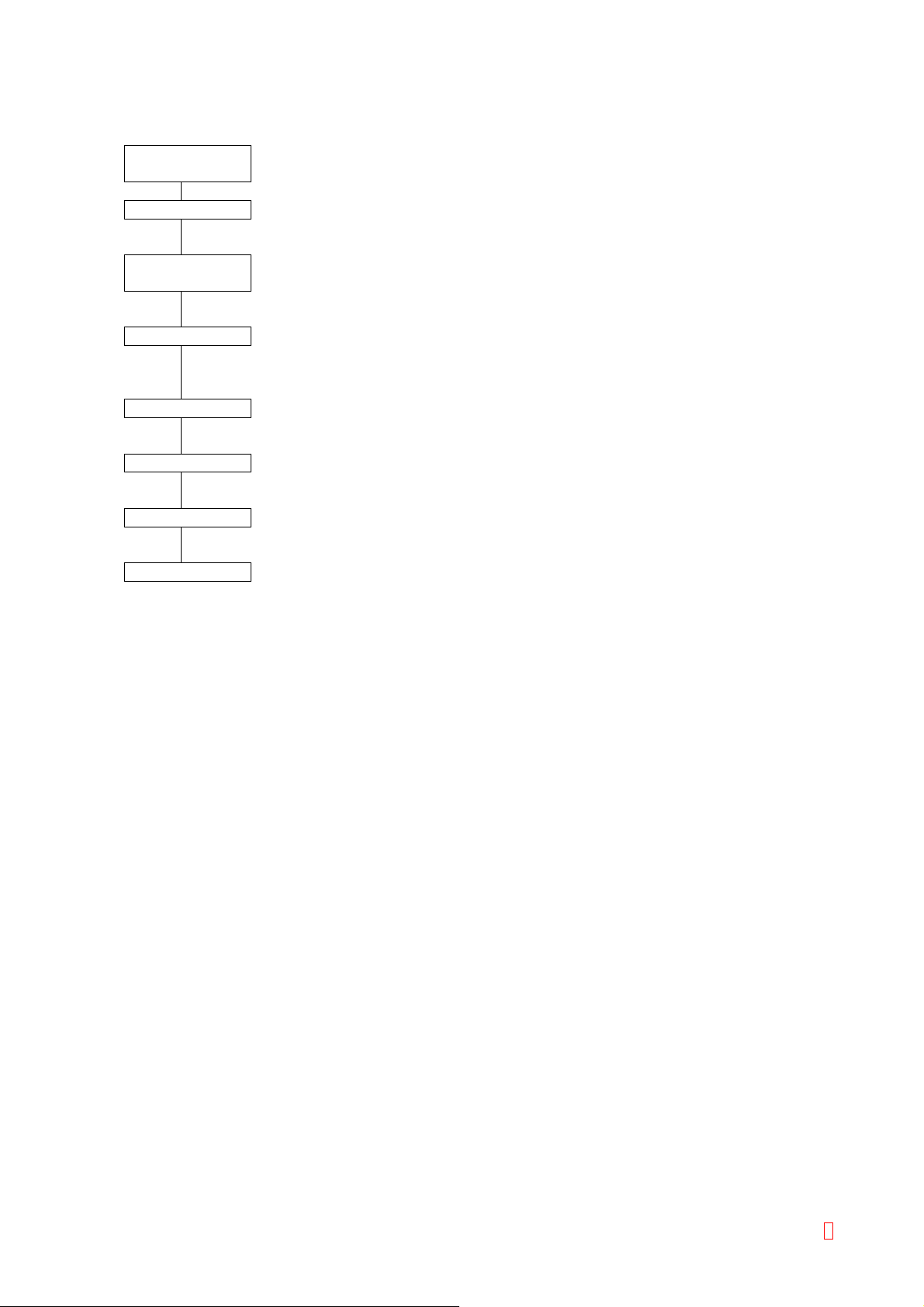

1.7 HOW TO OPERATE

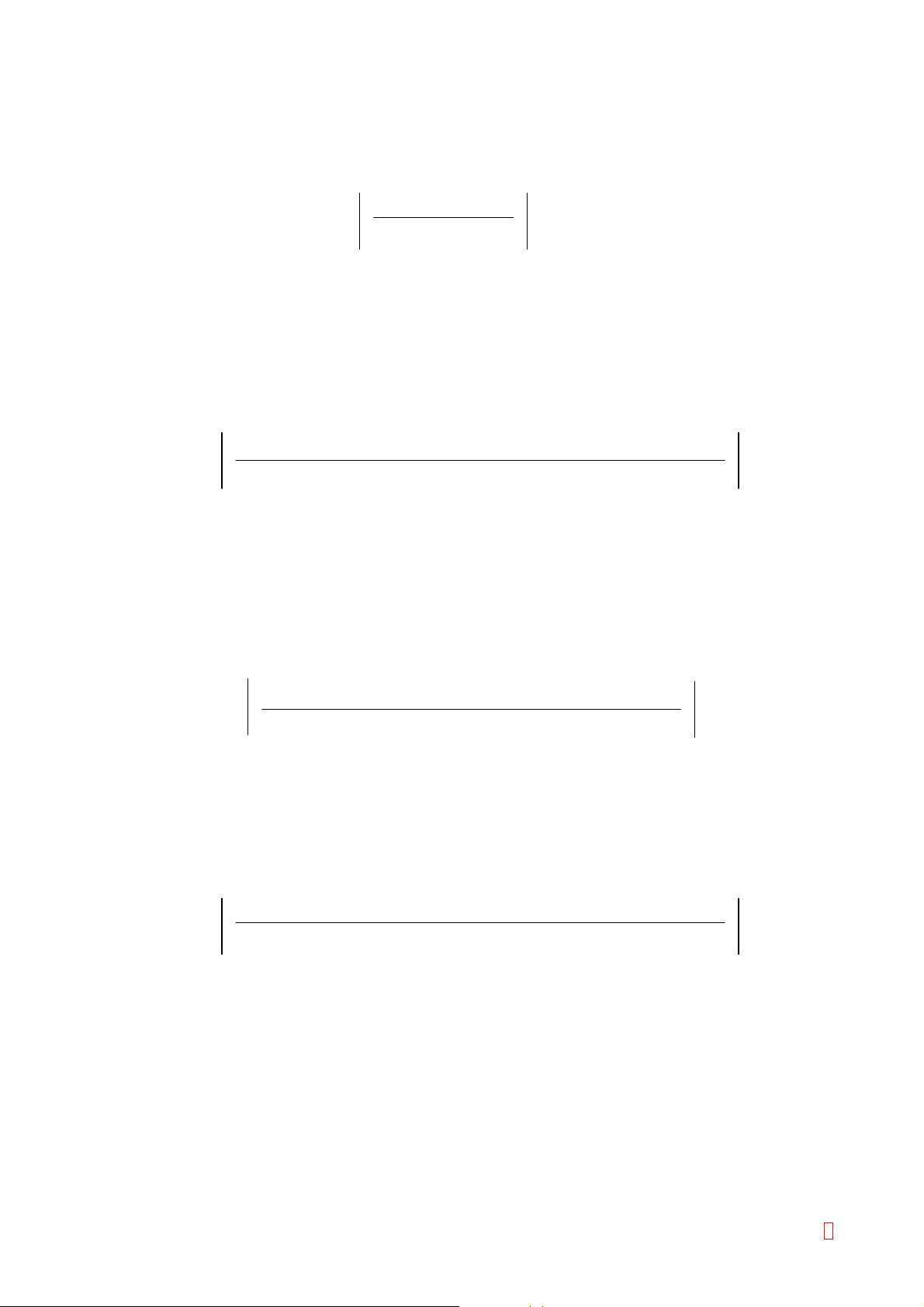

Start Analysis

Result Output

End Analysis

Check

Instrument

Power ON

Analysis

Preparation

Shutdown

Power OFF • Rinse the pipette and turn the instrument power OFF.

• Check the rinse solution (distilled water) to make sure that the analyzer is ready

for operation.

• Turn the instrument power ON 30 minutes before the analysis.

• Dissolve reagents 30 minutes before the analysis.

Set the reagents to the reagent holder.

Execute the quality control to check the instrument condition.

• Set the sample to the sampler.

Enter sample orders to be analyzed.

Press the [Start] key to start analysis.

• The analysis results will be displayed on LCD and printed out on printer paper.

• Remove the reagents and the sample.

• Execute the daily maintenance for the next analysis.

CA-500 Series S/M 1-15 Revised December 2001 8

SECTION 2 HYDRAULIC/MECHANICAL SYSTEMS

To Cover

2.1 TUBING DIAGRAM..............................................................................................................................2-1

2.2 HYDRAULIC SYSTEM OPERATION ..................................................................................................2-2

2.2.1 Structure ................................................................................................................................2-2

2.2.2 Operation...............................................................................................................................2-2

2.3 PRESSURE CIRCUIT..........................................................................................................................2-4

2.3.1 Structure ................................................................................................................................2-4

2.3.2 Operation...............................................................................................................................2-4

2.4 DETECTOR BLOCK ............................................................................................................................2-5

2.4.1 Outline ...................................................................................................................................2-5

2.4.2 Specifications/Functions........................................................................................................2-5

2.4.3 Assembly Diagram ................................................................................................................2-5

2.5 REAGENT COOLING UNIT ................................................................................................................2-6

2.5.1 Outline ...................................................................................................................................2-6

2.5.2 Specifications/Functions........................................................................................................2-6

2.5.3 Assembly Diagram ................................................................................................................2-6

2.6 VOLUMETRIC UNIT ............................................................................................................................2-7

2.6.1 Outline ...................................................................................................................................2-7

2.6.2 Specifications/Functions........................................................................................................2-7

2.6.3 Assembly Diagram ................................................................................................................2-7

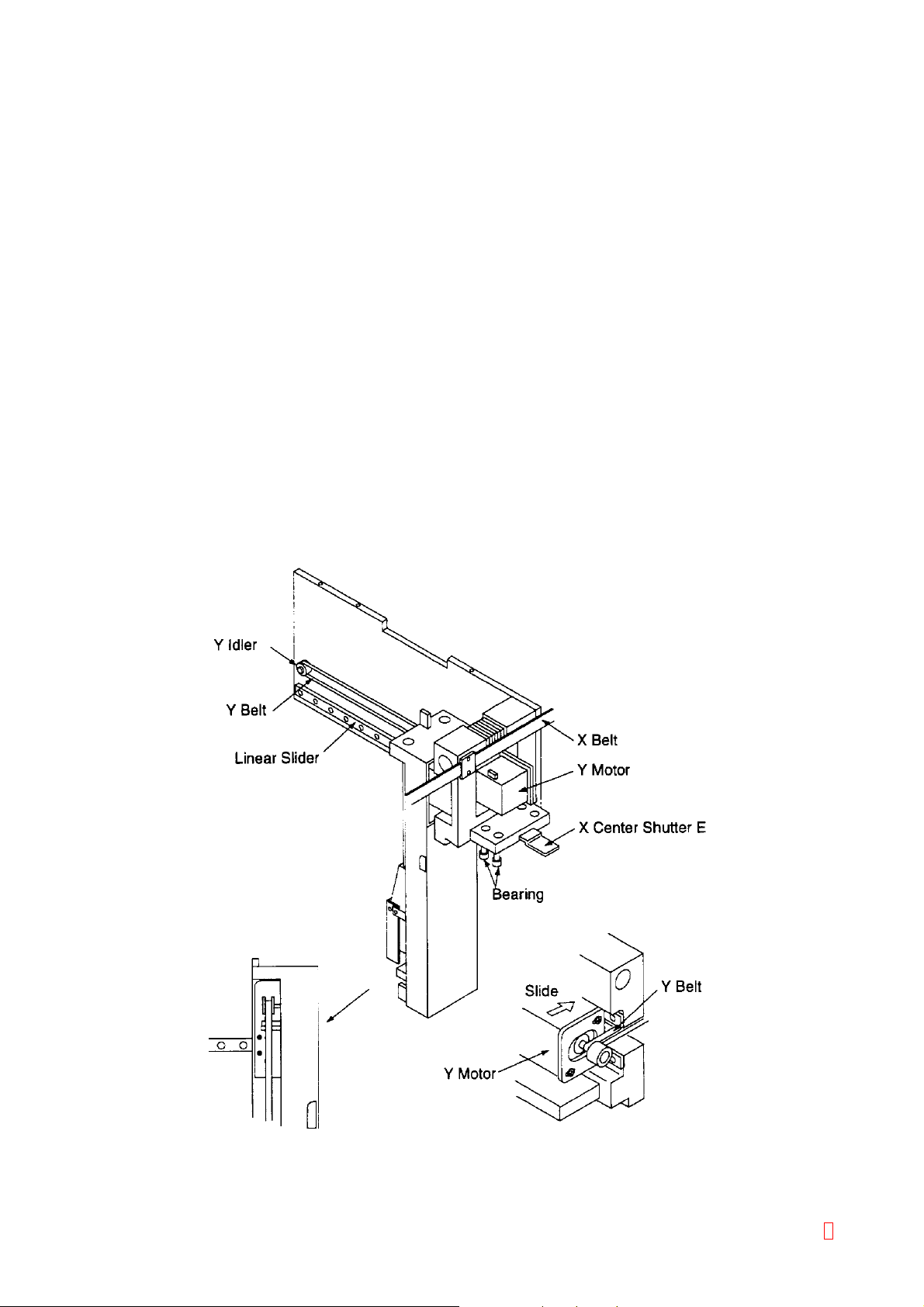

2.7 X-Y DRIVE UNIT (X-AXIS MOTOR ASSEMBLY/DRIVE-AXIS ARM ASSEMBLY)............................. 2-8

2.7.1 Outline ...................................................................................................................................2-8

2.7.2 Specifications/Functions........................................................................................................2-8

2.7.3 Assembly Diagram ................................................................................................................2-8

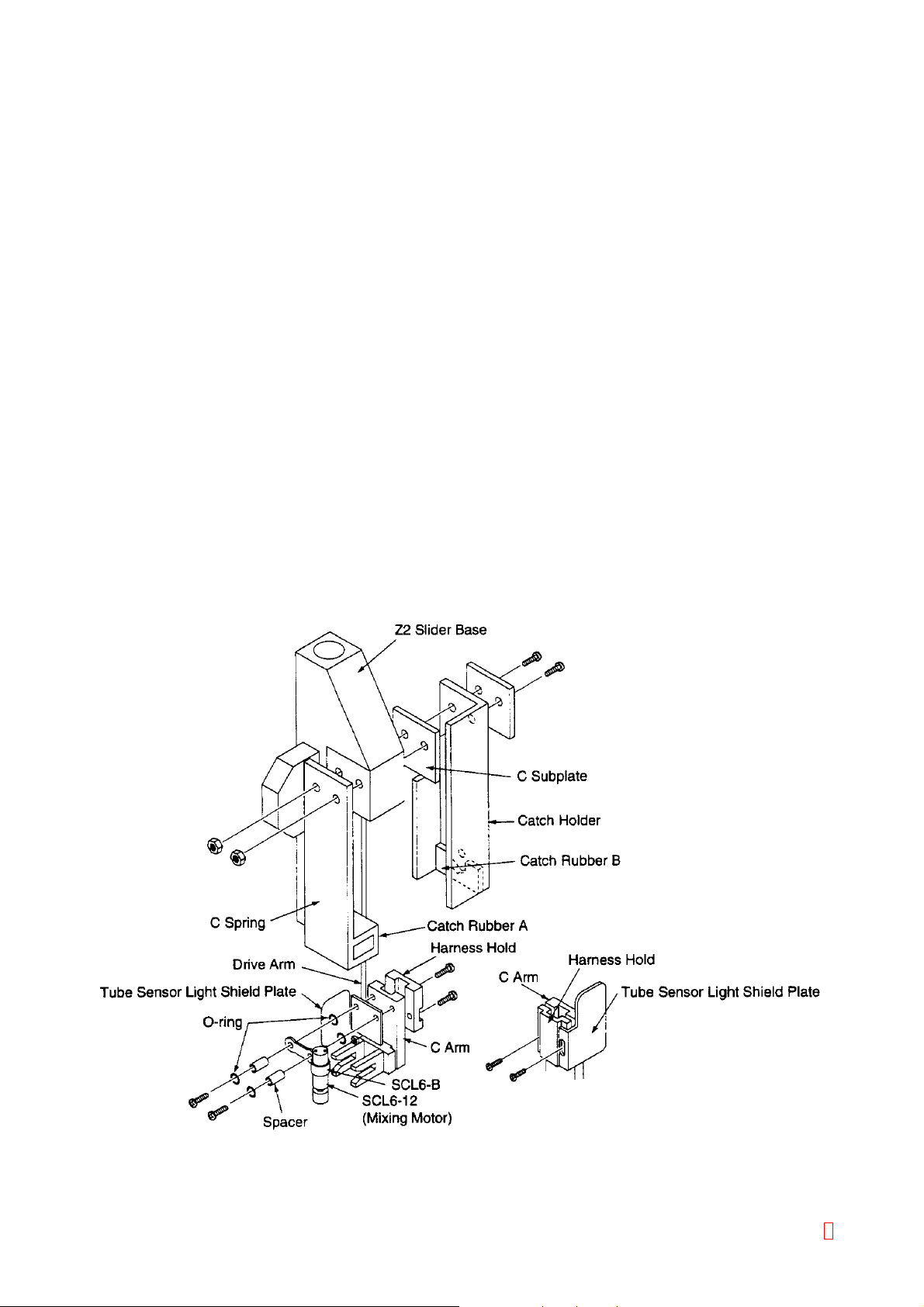

2.8 Z-AXIS DRIVE UNIT (Z-AXIS BASE ASSEMBLY) ..............................................................................2-9

2.8.1 Outline ...................................................................................................................................2-9

2.8.2 Specifications/Functions........................................................................................................2-9

2.8.3 Assembly Diagram ................................................................................................................2-9

2.9 BAR CODE READER UNIT (ID COMPLETED PARTS) ...................................................................2-10

2.9.1 Outline .................................................................................................................................2-10

2.9.2 Specifications/Functions......................................................................................................2-10

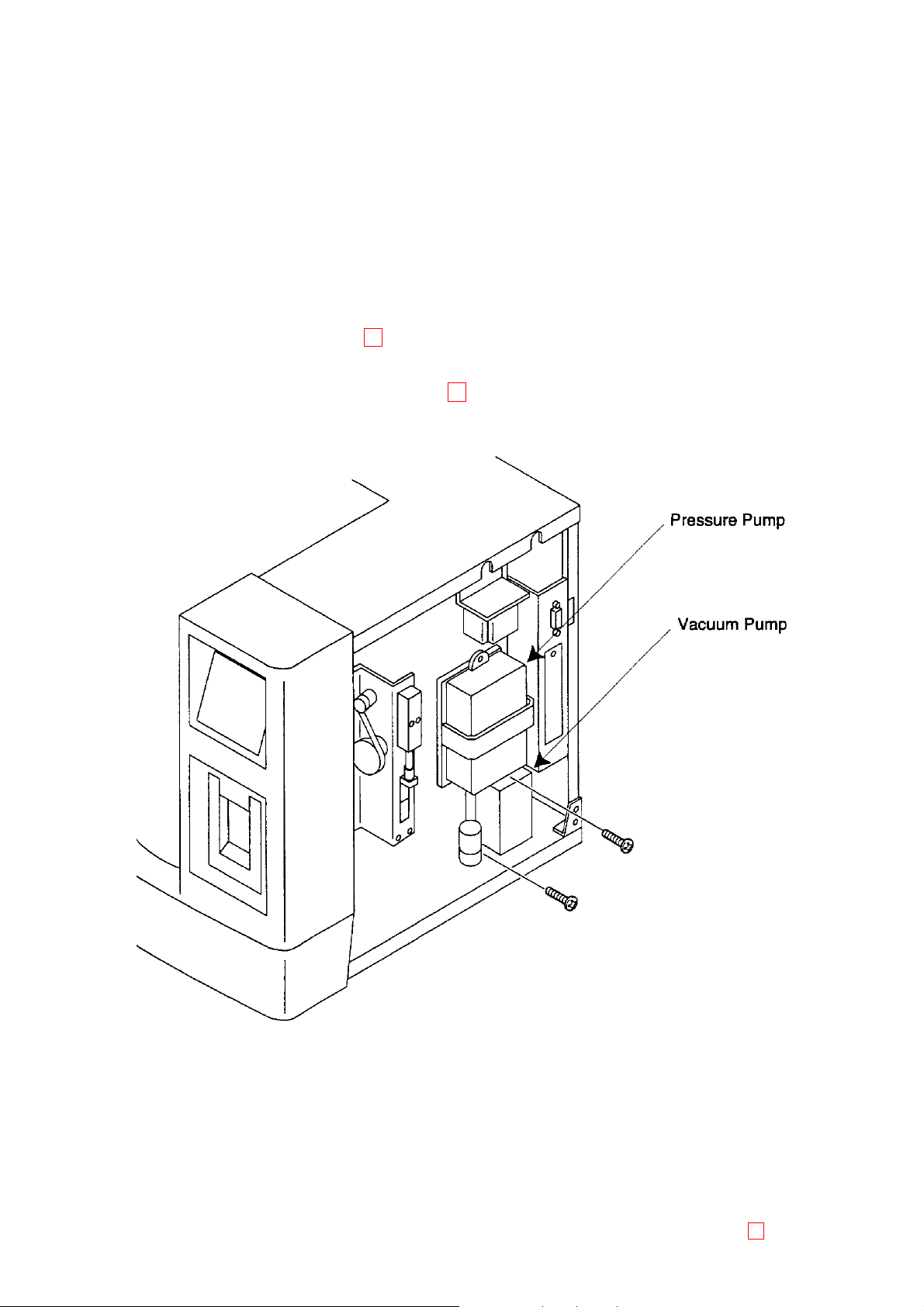

2.10 PUMP UNIT (PRESSURE PUMP/VACUUM PUMP COMPLETED PARTS) ....................................2-11

2.10.1 Outline .................................................................................................................................2-11

2.10.2 Specifications/Functions......................................................................................................2-11

2.10.3 Assembly Diagram ..............................................................................................................2-11

CA-500 Series S/M Revised December 2001 8

SECTION 2 HYDRAULIC/MECHANICAL SYSTEMS

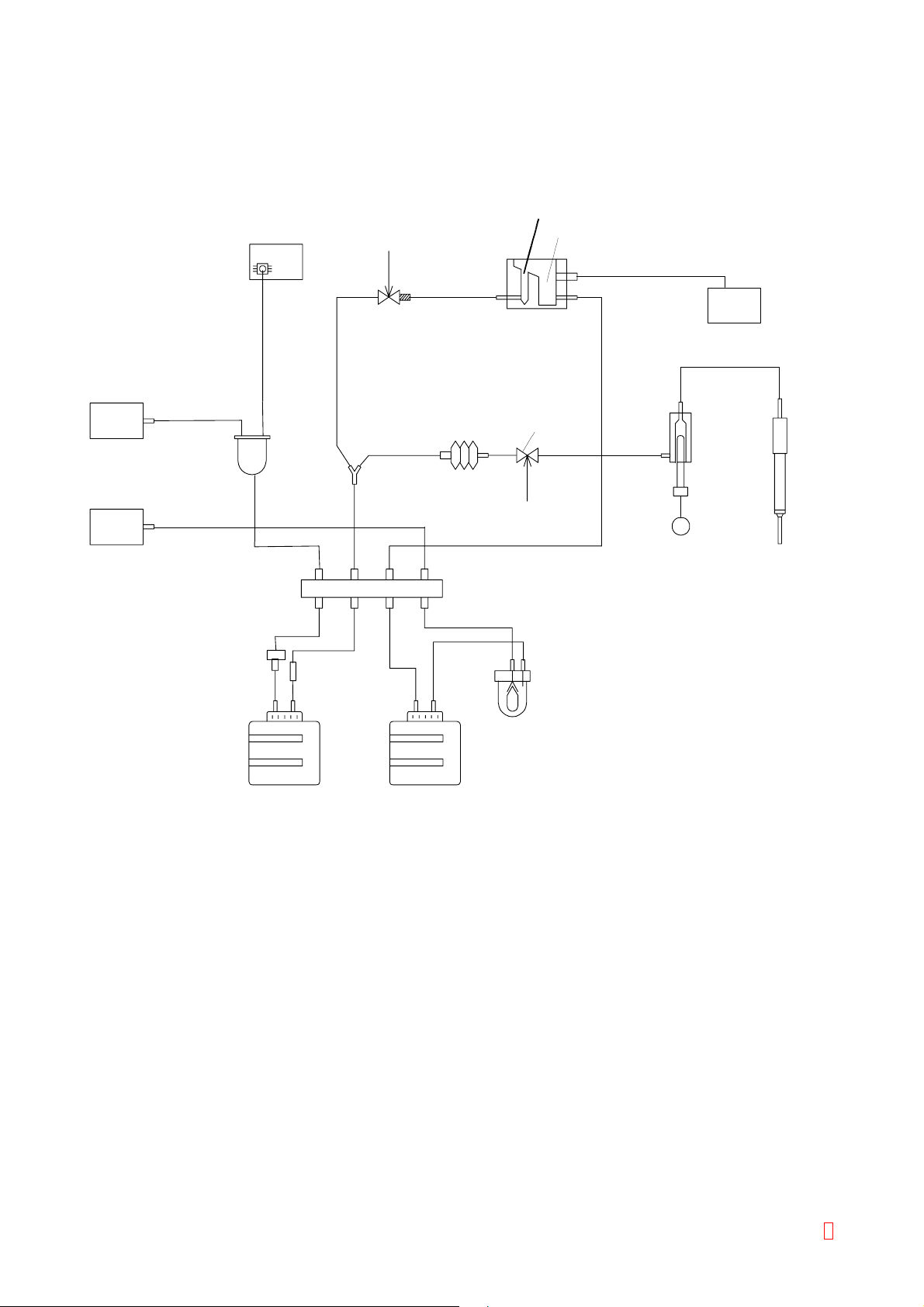

2.1 TUBING DIAGRAM

Probe Rinse Cup (Outside)

MAIN (PCNo.6362)

Probe Rinse Cup (Inside)

Pressure

Pump

Vacuum

Pump

Si2

(240)

Chamber No. 4

(160)

TA

Check Valve

TA

(520)

Si2

(240)

Si2

(240)

Si1

(620)

black redblue

Rubber Tube No. 7

SV No.14

TA

(100)

TA (250)

TA

(80)

BBSB

green

Si2

(240)

Filter

Si2

(240)

(500) (500)

TF2 (450)

Rinse Cup

Si3

(12)

Hydraulic Connector

No. 23

Rear Panel

Si2

(200)

Si2Si2

LFAA

1201518H

Si2

(530)

TF1

(200)

Si4

(95)

M

TF1

Piston

Trash Box

(1600)

PipetteVolumetric

Trap Chamber

No. 7Assy

Rinse Bottle Waste Bottle

Si2

(500)

Si1: Tube Silicone 2 x 5

Si2: Tube Silicone 4 x 8

Si3: Tube Silicone 1/32 x 3/32 inches

Si4: Tube Silicone 6 x 10

TF1: Tube Teflon 1.2 x 2.0

TF2: Tube Teflon 1.5 x 2.5

TA: Tube Toalone 3 x 6

B: Connecting Tube No. 50

C: Connecting Tube No. 3

S: Nipple No. 123

CA-500 Series S/M 2-1 Revised December 2001

8

2.2 HYDRAULIC SYSTEM OPERATION

2.2.1 Structure

The hydraulic system consists of the volumetric syringe for volumetric dispensing of samples or reagent, the

filling line using the pressure pump and solenoid valve, and the drain line using the vacuum pump.

2.2.2 Operation

(1) Outline of Hydraulic System Operation

This system's filling and draining are operated by pressure created by the pressure pump and vacuum

pump in the system. Therefore the pressure is applied to the rinse bottle and the vacuum is applied to the

waste bottle.

(a) Filling line

A constant pressure is applied to the rinse bottle. The valve connected to the line opens to feed rinse

solution.

(b) Drain Line

The drain line is released to the atmosphere at the rinse cup. The vacuum pump operates only when

the vacuum to aspirate the waste into the waste bottle. The vacuum is not monitored. Instead,

instrument checks if the liquid level becomes abnormal when the sample probe is moved to the

Probe Rinse Cup (inside) (if liquid is not drained properly, the drain error occurs).

(2) Analysis Starting Operation

(a) Rinsing at Analysis Start

The sample probe moves to the Probe Rinse Cup (outside) to detect the syringe home position. The

probe moves into the Probe Rinse Cup (inside) to remove remaining liquid on the probe tip. The

probe moves to rinse solution position to aspirate CACLEAN I. Aspirated rinse solution is kept in the

probe for a certain time to rinse the probe inside. (This can be changed in Service Program.)

The sample probe moves to the Probe Rinse Cup (inside), and the rinsing solution flows by opening

SV on Rinse Cup. At this time, the syringe piston moves to drain the rinse solution.

The probe moves into the Probe Rinse Cup (outside), and both the Probe Rinse Cup valve and the

valve on probe open to rinse the probe.

(b) Reagent Aspirating and Dispensing

When aspirating sample or reagent, the probe moves to a sample to aspirate, lowers into the test

tube, detects the liquid surface, then the volumetric syringe descends and aspirates the sample. At

this time, the solenoid valve does not operate (keep closed).

When draining, the probe moves to the reaction tube in the Reaction Tube Rack to dispense, the

volumetric syringe ascends and dispenses the sample. After that, the probe moves to home position,

and moves to the Probe Rinse Cup (inside).

CA-500 Series S/M 2-2 Revised December 2001 8

(c) Probe Rinsing after Sample Aspiration

The probe moves to the Probe Rinse Cup (inside). The Probe Rinse Cup (inside) valve opens to

empty rinse solution from the probe.

Then the probe moves to the Probe Rinse Cup (outside) to remove a drop from the probe tip.

(d) Reagent Aspiration and Dispensing

The probe, which stops for cleaning after sample aspiration, moves to the reagent rack to aspirate,

descends into the reagent vial, detects the liquid surface, and then the volumetric syringe descends

to aspirate the reagent.

At this time, the solenoid valves does not function (closed).

When dispensing, the probe moves to the heated reaction tube, catches that reaction tube, then

moves to the dispensing position, and dispenses the heated reagent into the reaction tube.

After dispensing, the mixing motor mixes the sample and reagent in the tube, and sets it in the

detecting well.

(e) Rinsing after Reagent Dispensing and Mixing

After reagent dispensing and mixing, the probe moves to the Probe Rinse Cup (inside). The Probe

Rinse Cup (inside) valve opens to flow rinse solution out of the probe.

Next, the probe moves to the Probe Rinse Cup (outside), the probe tip touches the liquid, and then a

drop adhering on its tip is removed. The probe then moves to rinse solution and aspirates CACLEAN

I. After aspiration, it moves to the Probe Rinse Cup (inside), and the probe valve opens to feed out

rinse solution. At this time, the syringe piston moves to dispense the rinse solution.

The probe moves to the Probe Rinse Cup (outside), and both the Probe Rinse Cup valve and the

valve on probe open to rinse the probe.

(f) Probe Rinsing

The Rinse Probe key causes the probe to move to Probe Rinse Cup (outside) and detect the syringe

home position. Then the probe moves into the Probe Rinse Cup (inside), and any liquid remaining on

the probe tip is removed. After that, the probe moves to rinse solution and aspirates CACLEAN I.

After aspiration, the probe aspirates rinse solution 2 minutes to clean the its inside.

Now the probe moves to the Probe Rinse Cup (inside) and causes the probe valve to open and feed

out rinse solution. At this time, the syringe piston moves to dispense the rinse solution.

Next, the probe moves to the Probe Rinse Cup (outside), and both the Probe Rinse Cup (outside)

valve and the valve on probe open to rinse the probe.

After rinsing, the probe returns to the home position.

CA-500 Series S/M 2-3 Revised December 2001 8

2.3 PRESSURE CIRCUIT

2.3.1 Structure

The pressure circuit of this system consists of two circuits: the pressure circuit designed for filling solution by the

pressure pump and the vacuum circuit designed for liquid draining by the vacuum pump.

The pressure system comprises the pressure pump, circuit for its control, pump driving circuit, a bottle for filling,

and a valve for filling line circuit.

The vacuum circuit system comprises the vacuum pump, pump driving circuit, and drain line circuit with a waste

bottle.

For the hydraulic circuit that uses pressure to flow rinse solution.

2.3.2 Operation

(1) Outline of Pump Operation

The filling and draining by this system are performed by the pressure and vacuum. Therefore the

pressure is applied to the rinse bottles connected to the outside of the system.

(a) Pressure System

The pressure system generates pressure by the pressure pump, and utilizes the pressure sensor to

monitor and control the generated pressure to maintain a predetermined amount of rinse solution.

The rinse solution in the rinse bottle is kept under a certain pressure by the pressure controlling, and

it is supplied by opening the valve connected to the system.

(b) Vacuum System

The vacuum circuit is released to the atmosphere at the rinse cup. The vacuum pump operates only

at the time of draining to aspirate the waste into its bottle. The vacuum circuit is not monitored.

Instead, checking is made on whether or not the liquid level becomes abnormal when the sample

probe moves into the Probe Rinse Cup (inside) (if waste is not drained properly, the drain error

occurs).

(2) Specifications/Functions

(a) Pressure Pump

Pump type:

Drive power supply: AC 100 V, 50/60 Hz

Pressure generation: Over 300 g/cm

(b) Vacuum Pump

Pump type:

Drive power supply: AC 100 V, 50/60 Hz

Vacuum generation: Over -100 g/cm

2

2

CA-500 Series S/M 2-4 Revised December 2001 8

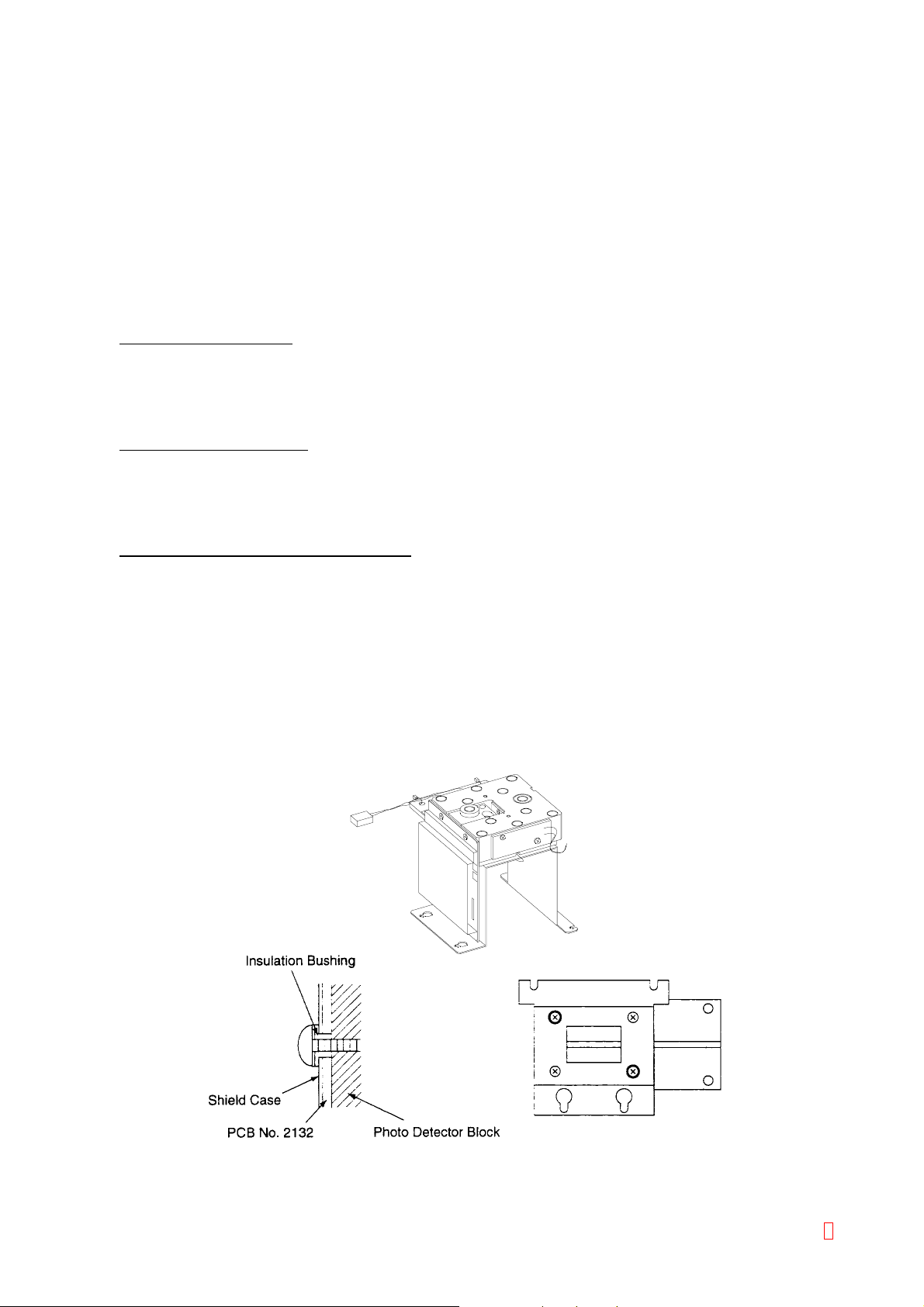

2.4 DETECTOR BLOCK

2.4.1 Outline

The CA-500 detector block is provided with 4 scattered light detecting ports, 1 transmitted light detecting port,

and 6 incubation wells.

The detector block is kept at 37°C by the heater and the semiconductor temperature sensor.

2.4.2 Specifications/Functions

(1) Analysis System

Scattered Light Detection Detector Unit: 4 ports Light Source: LED H-2000L (peak wavelength 660 nm) Photo Diode: S1133 silicon diode Filter: R-60 (band-pass: over 600 nm)

Transmitted Light Detection Detector Unit: 1 port Light Source: LED NLPB-500 Photo Diode: S1133 silicon diode Filter: 405 nm band-pass filter

Transmitted Light Detection (Immunoassy) Detector Unit: 1 port Light Source: LED TLGE159P Photo Diode: S1133 silicon diode Filter: 575 nm band-pass filter

(2) Other

Incubation well: 6 wells

Heater: 28 W film heater

Overheat protection: 76°C thermal fuse

2.4.3 Assembly Diagram

CA-500 Series S/M 2-5 Revised December 2001

8

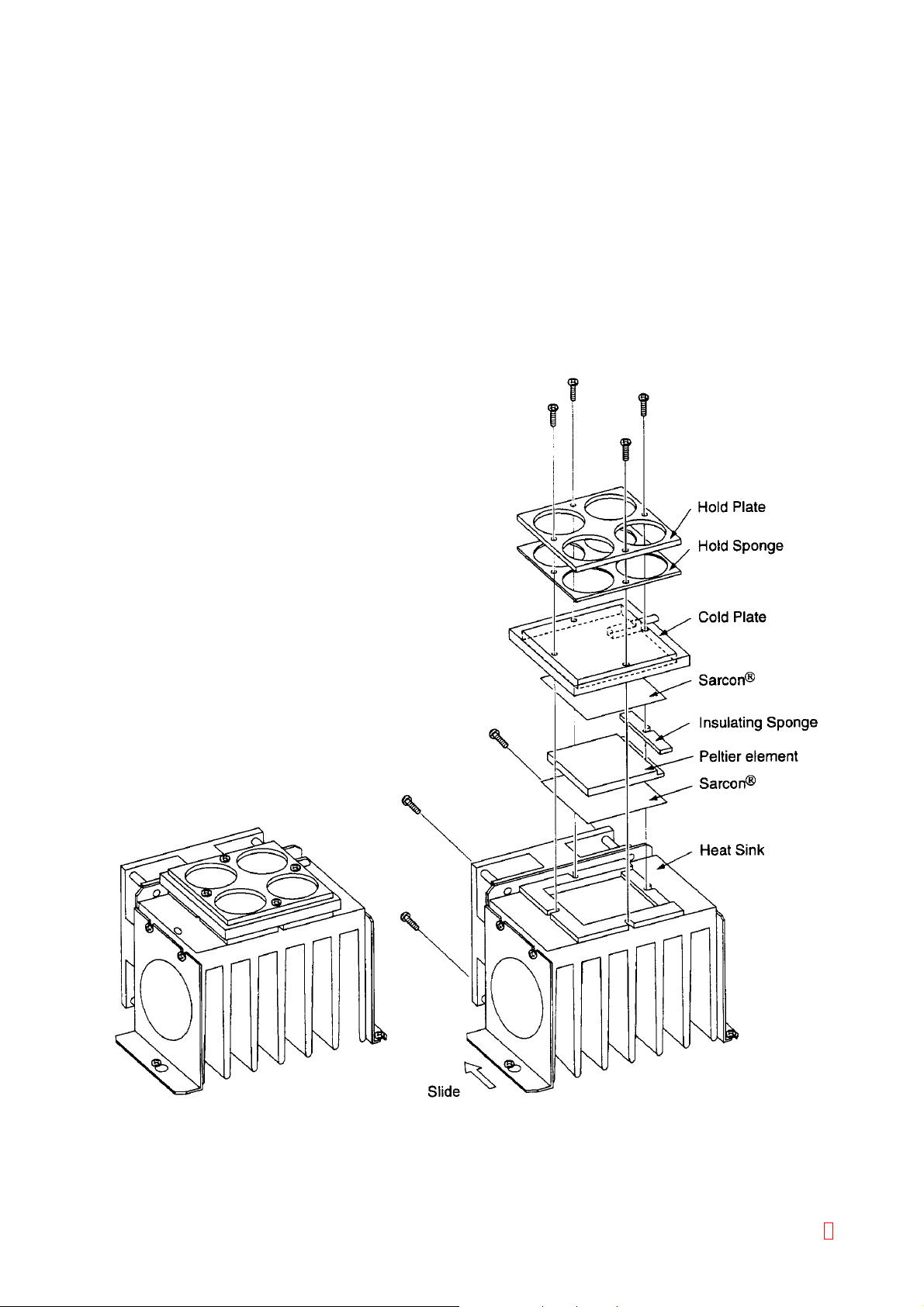

2.5 REAGENT COOLING UNIT

2.5.1 Outline

To cold-store reagents, electronic cooling element (Peltier element) cools the 4-hole reagent set.

2.5.2 Specifications/Functions

Cooling source: Peltier element (1 piece, DC 12 V applied)

Cooling: 1 unit of DC fan and fin-type radiator

Temperature detection: Semiconductor temperature sensor - 1 unit

2.5.3 Assembly Diagram

CA-500 Series S/M 2-6 Revised December 2001

8

2.6 VOLUMETRIC UNIT

2.6.1 Outline

The volumetric unit is used to measure a predetermined volume of sample, reagent, buffer, and rinse.

2.6.2 Specifications/Functions

(1) Drive System

Drive source: Unipolar-type stepping motor (1-2 phase excitation, constant current drive)

Power transmission: Timing belt type

Resolving power: Approx. 0.02 mm/step

Drive speed: Approx. 1300 pps (at high speed in trapezoidal control)

Sensor: For drive unit home position (transmission type) - 1 unit

(2) Syringe System

Piston diameter: 3 mm

Vertical stroke: Approx. 21 mm

Syringe volume: Approx. 151 µL/21 mm

Life: 300,000 cycles

2.6.3 Assembly Diagram

CA-500 Series S/M 2-7 Revised December 2001

8

2.7 X-Y DRIVE UNIT (X-AXIS MOTOR ASSEMBLY/DRIVE-AXIS ARM ASSEMBLY)

2.7.1 Outline

This unit moves the sample probe, which aspirates and dispense plasma and reagent, to the Sample Rack,

Reagent Rack, and Reaction Tube Rack; and drives, in X-Y direction, the catcher which moves reaction tubes

from the reaction tube rack to the heater section, detector block, and further to dispense/discard hole.

2.7.2 Specifications/Functions

(1) X-Direction System

Drive Source: Unipolar type stepping motor (1-2 phase excitation, constant current drive)

Drive transmission: Timing belt type

Resolving power: Approx. 0.08 mm/step

Drive speed: Approx. 4500 pps (at high speed in trapezoidal control)

Sensor: For drive unit home position (transmission type) - 1 unit

(2) Y-Direction System

Drive Source: Unipolar type stepping motor (1-2 phase excitation, constant current drive)

Drive transmission: Timing belt type

Resolving power: Approx. 0.08 mm/step

Drive speed: Approx. 4000 pps (at high speed in trapezoidal control)

Sensor: For drive unit home position (transmission type) - 1 unit

2.7.3 Assembly Diagram

CA-500 Series S/M 2-8 Revised December 2001

8

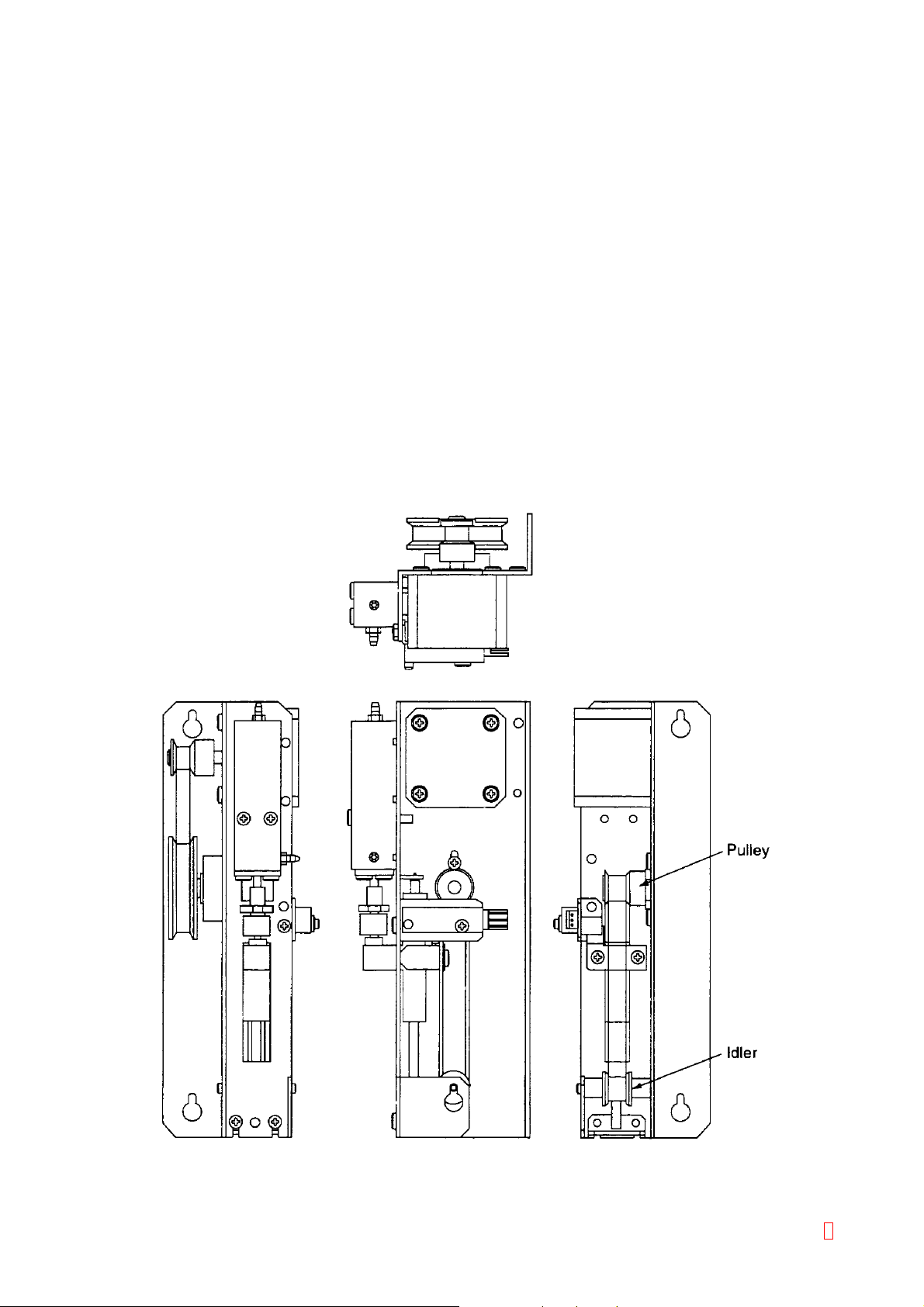

2.8 Z-AXIS DRIVE UNIT (Z-AXIS BASE ASSEMBLY)

2.8.1 Outline

To use the sample probe for aspiration or draining and to move reaction tubes, this unit grips the catcher and

drives it in Z direction. The Z-axis base assembly incorporates a mechanism for mixing plasma and reagent in

reaction tubes.

2.8.2 Specifications/Functions

(1) Z-Direction System

Drive Source: Unipolar type stepping motor (1-2 phase excitation, constant current drive)

Drive transmission: Timing belt type

Resolving power: Approx. 0.08 mm/step

Drive speed: Approx. 3100 pps (at high speed in trapezoidal control)

Sensor: For drive unit home position (transmission type) - 1 unit

(2) Stirring Function

Power source: DC motor (Driving voltage: 1.05 V)

(3) Reaction tube Presence Detection

Sensor: Detects presence of reaction tubes (modulation-reflection type) - 1 unit

(4) Sample Probe

Shape⋅Material: ID 0.50 mm/OD 0.85 mm, SUS316

Heater:

Sensor: Glass chip thermistor

Overheat protection: Thermal fuse 76°C

2.8.3 Assembly Diagram

CA-500 Series S/M 2-9 Revised December 2001

8

2.9 BAR CODE READER UNIT (ID COMPLETED PARTS)

2.9.1 Outline

This unit drives the bar code reader, which reads ID labels affixed on the sampler set on the sample table.

2.9.2 Specifications/Functions

(1) Drive System

Drive Source: Unipolar-type stepping motor (2-phase excitation, constant current drive)

Drive Transmission: Timing belt type

Resolving Power: Approx. mm/step

Drive Speed: Approx. pps (at high speed in constant control)

Sensor: For drive unit home position (transmission type) - 1 unit

(2) ID Specifications

Light Source/Receptor Element: LED/CCD image sensor

Read Width: 80 mm

Scan Cycles: 500 scans/500 decodes per second

Interface: Conforms to RS-232C

Power Source: DC 5 V, 300 mA

Corresponding Code: CODE39, NW-7, Industrial 2 of 5, CODE 128, etc.

CA-500 Series S/M 2-10 Revised December 2001 8

2.10 PUMP UNIT (PRESSURE PUMP/VACUUM PUMP COMPLETED PARTS)

2.10.1 Outline

The pump unit comprises the pressure pump that applies positive pressure into the bottle to feed rinse solution

from the rinse bottle into the system and the vacuum pump that applies vacuum into the bottle to feed out

waste from the system into waste bottle.

2.10.2 Specifications/Functions

(1) Pressure Pump

Structure:

Pressure: 250 mmHg as adjusted 19

(2) Vacuum Pump

Structure:

Vacuum: Approx. 180 mmHg as not adjusted 19

2.10.3 Assembly Diagram

CA-500 Series S/M 2-11 Revised February 2004

19 TB200408

Loading...

Loading...