Page 1

ET6000, ET6010, ET6500

ExacTime GPS Time Code

And Frequency Generator

Covering Configurations:

ET6000, ET6010, ET6500-TCXO

ET6000, ET6010, ET6500-OCXO

ET6000, ET6010, ET6500-RB1

Revision C

User’s Guide

8500-0105

June, 2005

Page 2

ET6000, ET6010, and ET6500

EXACTIME GPS TIME CODE AND FREQUENCY GENERATOR

TABLE OF CONTENTS

SECTION PAGE

CHAPTER ONE

GENERAL INFORMATION

1.0 INTRODUCTION ................................................................................................................1-1

1.1 USER'S GUIDE SUMMARY ..............................................................................................1-1

1.2 NAVSTAR/GPS DESCRIPTION ........................................................................................1-2

1.3 PRODUCT DESCRIPTION.................................................................................................1-3

1.4 SPECIFICATIONS...............................................................................................................1-4

1.4.1 GPS SUBSYSTEM................................................................................................ 1-4

1.4.2 TIMING OUTPUTS..............................................................................................1-4

1.4.3 ACCURACY .........................................................................................................1-7

1.4.4 TIMING INPUTS..................................................................................................1-7

1.4.5 J12 RS-232 I/O INTERFACE ............................................................................... 1-8

1.4.6 INTERNAL TIME BASE......................................................................................1-8

1.4.7 PRIMARY POWER ............................................................................................1-11

1.4.8 DIMENSIONS..................................................................................................... 1-13

1.4.9 WEIGHT..............................................................................................................1-13

1.4.10 ENVIRONMENT.............................................................................................. 1-13

1.5 ADDITIONAL SPECIFICATIONS................................................................................... 1-14

1.5.1 ANTENNA/PREAMP.........................................................................................1-14

1.5.2 GPS RPU AND ANTENNA................................................................................1-14

1.6 FUNCTIONAL CHARACTERISTICS.............................................................................. 1-14

1.6.1 ACQUISITION....................................................................................................1-14

1.6.2 SIGNAL INTERRUPTION.................................................................................1-15

1.6.3 POSITION AND VELOCITY SOLUTION........................................................1-15

1.6.4 DYNAMIC CAPABILITY.................................................................................. 1-16

1.6.5 RF JAMMING RESISTANCE AND BURN-OUT PROTECTION................... 1-16

1.6.6 SYSTEM STATUS AND DIAGNOSTICS ........................................................1-16

1.6.7 GPS SOLUTION MODES .................................................................................. 1-16

1.6.8 ELEVATION ANGLE MASK............................................................................1-17

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) i

Page 3

TABLE OF CONTENTS

CHAPTER TWO

INSTALLATION

2.0 INTRODUCTION ................................................................................................................2-1

2.1 UNPACKING AND INSPECTION.....................................................................................2-1

2.2 RACK MOUNTING PROCEDURE.................................................................................... 2-1

2.2.1 TMRA....................................................................................................................2-1

2.2.2 ELEVATED AMBIENT OPERATING TEMPERATURE..................................2-1

2.2.3 REDUCED AIR FLOW.........................................................................................2-2

2.2.4 MECHANICAL LOADING.................................................................................. 2-2

2.2.5 CIRCUIT OVERLOADING ................................................................................. 2-2

2.2.6 RELIABLE EARTHING.......................................................................................2-2

2.3 ANTENNA/PREAMP INSTALLATION............................................................................2-2

2.4 ANTENNA/PREAMP INTERFACE CONNECTIONS......................................................2-2

2.5 PRIMARY POWER CONNECTION ..................................................................................2-3

2.6 GPS TIMING UNIT INTERFACE CONNECTIONS.........................................................2-6

2.6.1 RS-232 I/O INTERFACE J12 ............................................................................... 2-6

2.6.2 PRINTER OUTPUT PORT J11 ............................................................................2-7

2.6.3 TIMING OUTPUTS..............................................................................................2-7

2.6.4 1PPS INPUT..........................................................................................................2-8

2.6.5 OSCILLATOR CONFIGURATION..................................................................... 2-8

CHAPTER THREE

OPERATION

3.0 INTRODUCTION ................................................................................................................3-1

3.1 OPERATIONAL STEPS......................................................................................................3-1

3.1.1 INITIALIZATION (UNKNOWN POSITION)..................................................... 3-1

3.1.2 INITIALIZATION (KNOWN POSITION)...........................................................3-3

3.2 OPERATIONAL CHARACTERISTICS............................................................................. 3-4

3.3 LIQUID CRYSTAL DISPLAY............................................................................................ 3-4

3.3.1 MAIN MENU SCREEN........................................................................................3-4

3.3.2 POSITION MENU SCREEN ................................................................................ 3-9

3.3.3 SET-UP MENU SCREEN................................................................................... 3-10

3.3.4 RS232 I/O CONFIGURATION MENU SCREEN .............................................3-15

3.3.5 MULTIPLE TIME CODE OUTPUTS MENU SCREEN...................................3-16

3.3.6 PRESET COINCIDENCE MENU SCREEN...................................................... 3-16

3.3.7 EXTERNAL FREQUENCY MEASUREMENT MENU SCREEN...................3-17

3.3.8 SINGLE EVENT LOG MENU SCREEN........................................................... 3-18

3.3.9 50/60HZ MEASUREMENT SCREEN ...............................................................3-19

3.3.10 AUTO DAYLIGHT SAVINGS MENU SCREEN ........................................... 3-20

3.3.11 MUX OUTPUT MENU SCREEN ....................................................................3-21

ii

ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 4

TABLE OF CONTENTS

3.3.12 PRINTER PORT CONFIGURATION MENU SCREEN.................................3-23

3.3.13 IEEE-488 I/O INTERFACE MENU SCREEN.................................................3-26

3.4 CONFIGURATION OF REAR PANEL BNC CONNECTORS J4-J9..............................3-26

CHAPTER FOUR

I/O PORT DATA INPUT/OUTPUT

4.0 INTRODUCTION ................................................................................................................4-1

4.1 SYMMETRICOM FIRMWARE VERSION........................................................................4-3

4.2 UTC SYNC........................................................................................................................... 4-4

4.3 GPS SYNC............................................................................................................................4-4

4.4 PRINT FREQUENCY OFFSET........................................................................................... 4-4

4.5 PRINT TIME, STATUS, ERROR CODE, AND SATELLITE VEHICLE NUMBERS..... 4-4

4.6 PRINT POSITION................................................................................................................4-6

4.7 CLEAR EVENT DATA ...................................................................................................... 4-7

4.8 PRINT EVENT DATA.........................................................................................................4-7

4.9 REQUEST ONE EVENT LOG DATA................................................................................ 4-8

4.10 ENABLE SINGLE EVENT LOG ...................................................................................... 4-9

4.11 DISABLE SINGLE EVENT LOG..................................................................................... 4-9

4.12 SELECT MODE.................................................................................................................4-9

4.13 ENABLE TIME INTERVAL...........................................................................................4-10

4.14 DISABLE TIME INTERVAL.......................................................................................... 4-10

4.15 REQUEST TIME INTERVAL.........................................................................................4-10

4.16 REQUEST ELEVATION MASK ANGLE...................................................................... 4-11

4.17 ENTER ELEVATION MASK ANGLE........................................................................... 4-11

4.18 ENABLE DISCIPLINING ...............................................................................................4-11

4.19 DISABLE DISCIPLINING.............................................................................................. 4-11

4.20 ENTER POSITION .......................................................................................................... 4-12

4.21 ENTER DAC VALUE...................................................................................................... 4-12

4.22 REQUEST DAC VALUE................................................................................................. 4-13

4.23 NUMBER OF POSITION AVERAGES.......................................................................... 4-13

4.24 ENTER LOCAL OFFSET................................................................................................ 4-13

4.25 ENTER CABLE DELAY.................................................................................................4-14

4.26 REQUEST CABLE DELAY............................................................................................ 4-14

4.27 RESYNCHRONIZE MINOR TIME................................................................................4-14

4.28 SELECT DEFAULT VALUES........................................................................................ 4-15

4.29 EXTERNAL FREQUENCY MEASUREMENT – SELECT INPUT FREQUENCY.....4-15

4.30 EXTERNAL FREQUENCY MEASUREMENT – ENABLE/DISABLE ........................4-16

4.31 EXTERNAL FREQUENCY MEASUREMENT – REQUEST DATA............................4-16

4.32 REQUEST SATELLITE SIGNAL SNR..........................................................................4-16

4.33 REQUEST UNIT OPERATING PARAMETERS........................................................... 4-17

4.34 ENABLE 50/60HZ MEASUREMENT............................................................................ 4-18

Symmetricom Inc ET6xxx ExacTime GPS TCode & FG (Rev C)

iii

Page 5

TABLE OF CONTENTS

4.35 50/60HZ SELECTION .....................................................................................................4-18

4.36 ENTER 50/60HZ OFFSET DATA................................................................................... 4-18

4.37 REQUEST 50/60HZ MEASUREMENT DATA............................................................... 4-19

4.38 PRINTER – SET-UP CONFIGURATION.......................................................................4-19

4.39 PRINTER – REQUEST CONFIGURATION..................................................................4-20

4.40 PRINTER PORT MODE SELECTION........................................................................... 4-20

4.41 PRINTER – SELECT OUTPUT RATE...........................................................................4-21

4.42 PRINTER – REQUEST OUTPUT RATE........................................................................4-21

4.43 ENABLE/DISABLE & DATA SELECT......................................................................... 4-21

4.44 ENTER PRESET COINCIDENCE TIME .......................................................................4-23

4.45 REQUEST MUX OUTPUT ............................................................................................. 4-24

4.46 SET MUX OUTPUT ........................................................................................................4-25

4.47 SET MAJOR TIME – TOD (TIME OF DAY)................................................................. 4-25

4.48 SET YEAR........................................................................................................................4-25

4.49 AUTOMATIC DAYLIGHT SAVINGS TIME................................................................ 4-26

4.49.1 DISABLE AUTO DAYLIGHT SAVINGS TIME FUNCTION....................... 4-26

4.49.2 ENABLE AUTO DAYLIGHT SAVINGS TIME FUNCTION........................4-26

4.49.3 SET AUTO DAYLIGHT SAVINGS TIME DEFAULT INTERVAL ............. 4-26

4.49.4 REQUEST AUTO DAYLIGHT SAVINGS TIME INTERVAL......................4-27

4.49.5 SET AUTO DAYLIGHT SAVINGS TIME INTERVAL................................. 4-27

4.50 REQUEST UNIT SERIAL NUMBER............................................................................. 4-28

CHAPTER FIVE

MAINTENANCE/TROUBLESHOOTING

5.0 MAINTENANCE................................................................................................................. 5-1

5.1 ADJUSTMENTS..................................................................................................................5-1

5.1.1 INTERNAL OSCILLATOR CALIBRATION...................................................... 5-1

5.1.2 LCD ADJUSTMENT ............................................................................................5-3

5.1.3 AC CODE ADJUSTMENTS................................................................................. 5-3

5.1.4 10MHZ SINE WAVE............................................................................................5-3

5.1.5 10MHZ SQUARE WAVE..................................................................................... 5-3

5.2 TROUBLESHOOTING........................................................................................................ 5-4

5.2.1 GENERAL............................................................................................................. 5-4

5.2.2 POWER LED WILL NOT ILLUMINATE WHEN ON/OFF SWITCH IS

ACTIVATED........................................................................................................ 5-4

5.2.3 TRACKING LED DOES NOT ILLUMINATE.................................................... 5-4

5.2.4 LOCKED LED DOES NOT ILLUMINATE ........................................................ 5-5

5.2.5 UNIT DOES NOT TRACK SATELLITES, ERROR MESSAGE/CODE –

ANTENNA UNDERCURRENT ..........................................................................5-5

5.2.6 COLD RESET ....................................................................................................... 5-5

5.3 THEORY OF OPERATION................................................................................................. 5-6

5.3.1 GPS SYSTEM OPERATION................................................................................5-6

iv

ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 6

TABLE OF CONTENTS

5.3.2 MODES OF OPERATION....................................................................................5-6

5.3.3 EXACTIME INTERNAL CONFIGURATION....................................................5-8

5.3.4 MICROCOMPUTER PROGRAM THEORY OF OPERATION.........................5-9

APPENDIX A

ASCII CHARACTER CODE TABLE

PART ONE................................................................................................................................. A-1

PART TWO................................................................................................................................ A-2

PART THREE ............................................................................................................................ A-3

PART FOUR............................................................................................................................... A-4

APPENDIX B

GLOSSARY OF TERMS

A...................................................................................................................................................B-1

B...................................................................................................................................................B-2

C...................................................................................................................................................B-2

D...................................................................................................................................................B-3

E...................................................................................................................................................B-3

F ...................................................................................................................................................B-4

G...................................................................................................................................................B-4

H...................................................................................................................................................B-5

I....................................................................................................................................................B-5

J....................................................................................................................................................B-6

K...................................................................................................................................................B-6

L...................................................................................................................................................B-6

M..................................................................................................................................................B-7

N...................................................................................................................................................B-7

O...................................................................................................................................................B-8

P ...................................................................................................................................................B-8

Q...................................................................................................................................................B-9

R...................................................................................................................................................B-9

S ...................................................................................................................................................B-9

T.................................................................................................................................................B-10

U.................................................................................................................................................B-10

V.................................................................................................................................................B-10

W................................................................................................................................................B-11

X.................................................................................................................................................B-11

Y.................................................................................................................................................B-11

Z.................................................................................................................................................B-11

Symmetricom Inc ET6xxx ExacTime GPS TCode & FG (Rev C)

v

Page 7

TABLE OF CONTENTS

APPENDIX C

OPTION DESCRIPTIONS

GPS Opt 01/01A Three Channel Encoder .....................................................................C-1

GPS Opt 06A 1 MHz Sine Wave Shaper................................................................C-16

GPS Opt 07A 5 MHz Sine Wave Shaper................................................................C-17

GPS Opt 08CE 10-37VDC Dual Power Input ..........................................................C-18

GPS Opt 08G 38-73VDC Power Supply................................................................C-21

GPS Opt 08GP 38-73VDC Power Supply................................................................C-23

GPS Opt 10B Low Phase Noise Oscillator.............................................................C-28

GPS Opt 13A Parallel BCD Output (Days – Milliseconds) ...................................C-31

GPS Opt 14 IEEE-488 I/O Interface....................................................................C-36

GPS Opt 15A/15P Rubidium Time Base 10MHz Oscillator (LPRO) ...........................C-42

GPS Opt 15C Rubidium Time Base 10MHz Oscillator (X72)...............................C-45

GPS Opt 21A 10MHz Sine Wave Shaper...............................................................C-47

GPS Opt 23A/23B Lightning Arrestor (w/25 or 50 ft. Antenna Cable ..........................C-48

GPS Opt 27A,B,C,D Signal Distribution...........................................................................C-53

GPS Opt 33A 1.544/2.048MHz Square Wave Output............................................C-56

GPS Opt 33B/33C T1/E1 Framed Ones – Balanced Output ..........................................C-57

GPS Opt 33D/33E T1/E1 Framed Ones – Balanced Output w/Frame Marker etc. .......C-65

GPS Opt 40/40P GPS Option Motherboard (w/6 BNC outputs) ................................C-73

GPS Opt 40A/40AP GPS Option Motherboard (w/1 BNC output)..................................C-75

GPS Opt 40B/40BP GPS Option Motherboard (w/3 BNC outputs) ................................C-77

GPS Opt 48 Pulse Rate Module...........................................................................C-79

APPENDIX D

ANTENNA REPLACEMENT KIT

D.0 Antenna Replacement Kit................................................................. D-1

vi

ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 8

CHAPTER ONE

GENERAL INFORMATION

1.0 INTRODUCTION

This User’s Guide describes the installation and operation of the ExacTime ET6xxx Global

Positioning System (GPS) Time Code and Frequency Generator (TC&FG). Excluding options and

size, the only difference between the different configurations is the oscillator.

The following are the available configurations and their respective oscillators:

ET6000-TCXO 10MHz Voltage Controlled Temperature Compensated Crystal Oscillator.

ET6010-TCXO

ET6500-TCXO

ET6000-OCXO 10MHz Voltage Controlled Ovenized Crystal Oscillator.

ET6010-OCXO

ET6500-OCXO

ET6000-RB1 10MHz Rubidium Oscillator with an aging rate of 5E-11 per month.

ET6010-RB1

ET6500-RB1

1.1 USER'S GUIDE SUMMARY

This User’s Guide is divided into the following chapters:

A. CHAPTER ONE - GENERAL INFORMATION

This chapter includes a general description of the GPS Timing Unit and provides

technical specifications.

B. CHAPTER TWO - INSTALLATION

Describes initial inspection, preparation for use, interconnections to antenna/preamp,

power connections, and signal interconnections.

C. CHAPTER THREE - OPERATION

Describes the local operation of the unit.

D. CHAPTER FOUR - I/O PORT DATA INPUT/OUTPUT

Provides information on the protocol and data available through the RS-232C I/O

port.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-1

Page 9

CHAPTER ONE

E. CHAPTER FIVE - MAINTENANCE/TROUBLESHOOTING

Provides a guide to the maintenance and troubleshooting of this instrument. A

description of the available adjustments is also provided.

F. APPENDIX A - ASCII CHARACTER CODES

Provides the cross reference of the ASCII character set to decimal, octal, and

hexadecimal numbers.

G. APPENDIX B - ACRONYMS AND ABBREVIATIONS

Provides a list of acronyms and abbreviations used in this User’s Guide.

H. APPENDIX C -OPTION DESCRIPTIONS

The Option Descriptions that are available with this instrument are located in this

Appendix.

I. APPENDIX D –ANTENNA REPLACEMENT KIT

Provides superseded model information.

1.2 NAVSTAR/GPS DESCRIPTION

The Navstar/GPS satellite-based timing and navigation system consists of a constellation of high

altitude satellites orbiting the earth every twelve sidereal hours, a group of ground-based

control/monitoring stations and the user equipment which may be located on land, sea and/or air.

The GPS System was completed in the early 1990’s and provides three dimensional positioning,

velocity, and time, on a continuous world-wide basis. The constellation is comprised of twenty-one

satellites and three spares. The satellites are located in six different orbital planes inclined

approximately sixty degrees to the equator at altitudes of 10,400 miles above the earth.

The GPS Timing Unit determines time and frequency by measuring the time of arrival of the

precise timing mark and measuring the Doppler effect from one satellite. A previously entered or

determined position allows computation of the receivers time offset. An accurate timing mark

(1pps) can be set, and an input 1pps pulse can be measured with respect to UTC. The satellite

positions are known within a few meters and the satellite clocks are calibrated within a few

nanoseconds so position can be computed within an absolute accuracy of better than 120 meters

(with current selective availability).

The GPS signal transmitted from a satellite consists of two carrier frequencies. L1 at a frequency of

1575.42 MHz and L2 at a frequency of 1227.6 MHz. The L1 signal is modulated with both a

precision (P) code and a coarse acquisition (C/A) code. The precision (P) code is available to

authorized users only. The GPS Timing Unit operates on the C/A code.

Each satellite transmits a unique C/A code that reflects the satellite identity for acquisition and

tracking. The C/A PRN code is a gold code of 1023 bits repeating at a one-millisecond rate.

1-2 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 10

GENERAL INFORMATION

The L1 and L2 frequency is also modulated with a fifty-bit-per-second data stream providing

satellite ephemerides, system time, satellite clock behavior, and status information on all satellites.

The data message is contained in a data frame that is 1,500 bits long.

Ground based control/monitoring stations track the satellites and provide an upload several times

each day to provide a prediction of each satellites ephemeris and clock behavior for the next day’s

operation.

1.3 PRODUCT DESCRIPTION

The GPS Timing Unit operates on the civilian L-band (1575.42MHz) utilizing C/A (Coarse

Acquisition) code transmissions to monitor time and frequency data from the Navstar satellite

constellation. Time and frequency is determined from satellite transmissions and calculations

referenced to USNO (United States Naval Observatory) through the GPS Master Clock system.

This link provides traceability to USNO and all international time scales through the use of

publications from NIST (National Institute of Standards Technology), USNO, and BIPM (Bureau of

International Des Poids et Measurements) in Servres, France.

The unit automatically acquires and tracks satellites based on health status and elevation angle. In

the Stationary mode, time and frequency monitoring requires only one satellite, once accurate

position data has been acquired or entered, although the receiver will use as many satellites as

available. In “AUTO” mode, and the “Dynamic” mode, a minimum of four satellites are required

for the GPS Timing unit to do three dimensional (latitude, longitude, and altitude) position fixes.

The basic GPS Timing Unit configuration includes the GPS Main Module, an antenna/preamp and

a coaxial cable for interconnection. A corrected 1pps output signal and a 10MHz Sine Wave are

provided. An RS-232 I/O Port is also provided in the basic configuration which can be used to

control the unit as well to get data from the unit. The basic unit has an LCD Display and a

keyboard. It generates IRIG B Serial Time Code, and has the capability of measuring the time

interval difference between the GPS 1pps and an externally input 1pps (or it can measure an

external frequency input – Models ET6000 and ET6010 only). It contains an RS-232 printer port.

Optional features listed in Appendix C are available to meet specific requirements. Refer to the

GPS Option/Connector Configuration sheet located in this manual for the options supplied with this

instrument. The Option Descriptions are located in Appendix C.

Note: The GPS antenna and cable described in this manual have been replaced as described in

“Appendix D: Antenna Replacement Kit” on page D-1.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-3

Page 11

CHAPTER ONE

1.4 SPECIFICATIONS

The electrical, physical, and environmental specifications for the ExacTime are listed below.

1.4.1 GPS SUBSYSTEM

A. TIME ACCURACY

After power-up, when LOCKED and using 200 Position Averages, will be better

than ± 125 nanoseconds relative to UTC with SA on within:

4 hours using a Rubidium oscillator.

2 hours using an Oven oscillator.

1 hour using a TCXO oscillator.

B. FREQUENCY ACCURACY

90% of the time, better than: 1E-9 for TCXO

1.5E-10 for Oven (OCXO)

1E-11 for Rubidium

C. POSITION ACCURACY

100m 2dRMS with SA

Less than 25m SEP without SA.

D. MAXIMUM VELOCITY

515 meters/second. (1000 knotts/hour).

E. TRACKING CHANNELS

Eight parallel.

F. RECEIVER FREQUENCY

L1 1.575 GHz, C/A Code.

G. ACQUISITION TIME

Time to first fix is less than 5 minutes with timing accuracy better than two μS and

frequency accuracy better than 1E-8. Full system accuracy with oven (OCXO)

oscillator is provided within 2 hours after LOCKED.

1.4.2 TIMING OUTPUTS

Rear panel BNCs J4 through J9 can output a 10MHz sine wave, IRIG B (AC), various pulse rates,

or alarm outputs. The following is the standard output configuration for the rear panel BNC

connectors. To change the outputs from the factory set standard configuration, see the paragraph

titled “Timing Outputs” in Chapter Two and the paragraph titled “Optional Pulse Rate Outputs” in

this section of the User’s Guide. Each output is via a 50Ω driver.

1-4 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 12

GENERAL INFORMATION

A. J4 - TRACKING

This CMOS output level is “low” when the unit is actively acquiring data from

satellites. In the Stationary Mode, the unit has to track at least one satellite for the

Tracking level to go “low”. In the Dynamic Mode, the unit has to track at least four

satellites, for the Tracking level to go “low”, and all available satellites are used for

the time solution. The Tracking level is “high” when the unit is not acquiring data

from any satellite or the satellites are not used for the time solution (as in the

Flywheel Mode).

B. J5 - LOCKED

When this CMOS output level is “low” (LOCKED), the 1pps output is coherent to

the internal 10MHz Oscillator. The DAC voltage controls the 10MHz oscillator

from which the 1PPS is derived. When this CMOS output level is “high” (i.e., not

locked), the 1pps is constantly being corrected (jammed) to on time using the 1PPS

from the GPS Receiver Module. In this mode, the 1PPS output can jump.

C. J6 - 1PPS

This output is a thirty to fifty μsec wide pulse at CMOS levels. The rise and fall

times are ≤ 6 nanoseconds. It is positive (rising) edge on time, within ±125

nanoseconds relative to either UTC or GPS with six or more satellite averaging with

95% confidence.

D. J7 - 10MHz SINE WAVE

This output has a nominal amplitude of one volt RMS into a 50Ω load.

Note: The output amplitude of the 10MHz sine wave is dependent on the internal

time base. This amplitude specification is for the Voltage Controlled

Temperature Compensated Crystal oscillator.

J7 – COINCIDENCE OUTPUT (ET6500 ONLY)

The Preset Coincidence Pulse occurs 200 Nanoseconds late. Its pulse width is

approximately two (2) microseconds wide, positive edge on-time. It is capable of

driving 10 LSTTL loads.

To enable this output, on the GPS Main Assembly 100015, jumper J17 pins 7-8

(only). See Figure 2-3 in Chapter Two.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-5

Page 13

CHAPTER ONE

E. J8 - IRIG B (AC)

This output is Amplitude Modulated IRIG B122 Serial Time Code. This output is

available only after the unit has tracked satellites and set time.

Carrier 1KHz

Modulation Ratio 3:1

Amplitude Three volts peak-to-peak on the Mark Pulse

Note: When enabled, the unit will output a modified IRIG B per IEEE Std. 1344

that has data in the Control Function bit area. Refer to Table One at the end

of this chapter for the Control Function Bit Assignments.

F. J9 - IRIG B (DC)

This output is Pulse Width Modulated IRIG B002 Serial Time Code at CMOS levels.

This output is available only after the unit has tracked satellites and set time

G. J11 – PRINTER OUTPUT PORT

This DB9 connector can output data to an RS232 compatible serial printer or

terminal.

It can be configured to operate in the Standard RS232 output or the One Second

RS232 ASCII Burst Mode output. For the operation and configurations, refer to

Chapters Three and Four.

H. OPTIONAL PULSE RATE OUTPUTS

The following is a list of optional pulse rate outputs available for selection on BNC

connectors J4-J9. They are positive (rising) edge on-time. The majority of these

rates have a 80/20 duty cycle with the exception of the 10MHz and the 5MHz which

are square waves, and the 1PPM which is 40/20.

10MHz 5MHz 1MHz

100KHz 10KHz/2PPH* 1KHz

100Hz 10Hz/1PPH* 1Hz

.1Hz 1PPM

Models ET6000 and ET6010 output 10KHz and 10Hz. Model ET6500 outputs

2PPH and 1PPH. For further clarification and/or configuration of the above outputs,

See Chapters Two and Three.

1-6 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 14

GENERAL INFORMATION

1.4.3 ACCURACY

The accuracy of the pulse rates listed in Section 1.4.2H is the same as that in Section 1.4.1A.

1.4.4 TIMING INPUTS

A. J10 - 1PPS INPUT (TIME INTERVAL MEASUREMENT) or

EXTERNAL FREQUENCY MEASUREMENT or

SINGLE EVENT LOG

TIME INTERVAL MEASUREMENT

Used to measure the time interval between the internally generated GPS 1PPS and an

external 1PPS input. The resolution of this measurement is 1 nanosecond with

accuracy better than 10 nanoseconds. At power-up, this feature is DISABLED. If

enabled, the measurement is displayed on the Second Menu Screen. Refer to

Chapter Three. Also see paragraphs entitled, “Enable Time Interval,” “Disable Time

Interval,” and “Request Time Interval,” in Chapter Four of this User’s Guide.

EXTERNAL FREQUENCY MEASUREMENT (MODELS ET6000 AND

ET6010 ONLY)

Frequency Range

1Hz to 10MHz (discrete, whole numbers - not fractional parts).

Input Wave Form From 1Hz to 10MHz

Rectangular or square wave (minimum pulse width fifty nanoseconds).

Amplitude Range:

Logic “0” +0.2V ±0.2VDC

Logic “1” +2.4V to +15VDC

Input Wave Form From 100KHz to 10MHz

Sinusoidal Amplitude Range: 1 - 5 volts peak-to-peak

SINGLE EVENT LOG

This option provides the capability of logging the time occurrences of up to 256

events from one input. A pulse on the event input will cause the time to be

logged/stored on either the rising (positive going) or falling (negative-going) edge of

the input pulse. The edge designated as on time is programmable via the front panel

keyboard or remotely via the RS-232 I/O. Each event will have a defining number

from zero to 255 and the channel identifier.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-7

Page 15

CHAPTER ONE

The event memory can be read and/or cleared via the RS-232 I/O. Refer to Chapter

Four of this User's Guide. If the inputs exceed 256 events (occurrences), the new

data will be lost. If two events occur less than ten milliseconds apart, it is possible

that one of the events may be lost. This will be reported as a missed event in the

status code when the data is output. This event log option can also be enabled or

disabled. Refer to Chapter Four of this User’s Guide.

The event time resolution is from hundreds of nanoseconds through hundreds-ofdays.

1.4.5 J12 RS-232 I/O INTERFACE

Full remote control of all operating functions in a complete ASCII protocol. Baud rate, parity, word

length, and stop bits are selectable. See paragraph titled, “Fourth Menu Screen – RS232 I/O

Configuration” in Chapter Three of this User’s Guide. A description of the remote control

functions is contained in Chapter Four.

1.4.6 INTERNAL TIME BASE

This unit can have one of three internal time bases depending on customer requirements. Unless

otherwise specified, the following are the specifications for the oscillators used as the internal time

base - not the specifications of the unit’s 10MHz sine wave output.

A. VOLTAGE CONTROLLED TEMPERATURE COMPENSATED CRYSTAL

OSCILLATOR (Configuration –TCXO) with the following specifications:

OUTPUT FREQUENCY/WAVEFORM

10MHz Sine Wave.

OUTPUT AMPLITUDE OF CRYSTAL OSCILLATOR

1.0 volt peak-to-peak minimum clipped sine wave into 20KΩ load. Harmonics 20dBc maximum.

AGING RATE

1E-7 per day or ±1.0PPM maximum per year.

1-8 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 16

GENERAL INFORMATION

PHASE NOISE

The following specifications are for the 10MHz sine wave output available on rear

panel BNC connectors J4-J9:

1Hz -72 dBc/Hz

10Hz -93 dBc/Hz

100 Hz -115 dBc/Hz

1KHz -126 dBc/Hz

10KHz -136 dBc/Hz

100 KHz -136 dBc/Hz

TEMPERATURE RANGE AND STABILITY

±1.0PPM from -30o to +75oC.

ADJUSTMENT RANGE

±3.0PPM minimum by internal manual trimmer.

VOLTAGE CONTROL

±3.0PPM minimum from +0.5 to +4.5 VDC.

B. LOW NOISE OVEN OSCILLATOR (Configuration –OCXO) with the

following specifications:

OUTPUT FREQUENCY/WAVEFORM

10MHz Sine Wave.

OUTPUT AMPLITUDE OF CRYSTAL OSCILLATOR

1.0 volt RMS into 50 ohms.

AGING RATE

±5 x 10

-10

per day, ±5 x 10-8 per year.

TEMPERATURE STABILITY

-8

±1 x 10

over a temperature range of –20ºC to +75ºC.

OPERATING TEMPERATURE

–20ºC to +75ºC.

ALTITUDE

Sea level to +50,000 feet.

ELECTRICAL TUNING

±1PPM (minimum) / ±2PPM (maximum).

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-9

Page 17

CHAPTER ONE

1Hz -100 dBc/Hz

10Hz -120 dBc/Hz

100Hz -140 dBc/Hz

1KHz -144 dBc/Hz

10KHz -144 dBc/Hz

100KHz -144 dBc/Hz

C. RUBIDIUM OSCILLATOR (either X72 or LPRO) with the following

CONTROL VOLTAGE

0 to +6 volts.

MECHANICAL FREQUENCY ADJUST

±1PPM (minimum) / ±3PPM (maximum).

The following specifications apply to the selected 10MHz sine wave output at a +13

dbm level:

HARMONICS

-45 dBc

SPURIOUS NOISE

>-70 dBc

PHASE NOISE

specifications:

OUTPUT FREQUENCY/WAVEFORM

10MHz Sine Wave.

OUTPUT AMPLITUDE OF OSCILLATOR

0.55VRMS ±0.05VRMS into 50 ohms.

AGING RATE

≤5 x 10

-11

per month, 5 x 10

-10

per year.

OPERATING TEMPERATURE

–20ºC to +70ºC measured at the base plate.

STORAGE TEMPERATURE

-55ºC to +85ºC

1-10 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 18

GENERAL INFORMATION

ALTITUDE

-200 feet to +40,000 feet (operating).

FREQUENCY CONTROL - INTERNAL TRIM RANGE

±1.5 x 10

-9

FREQUENCY CONTROL - EXTERNAL (ELECTRICAL) TRIM RANGE

±1.5 x 10

-9

(0V to +5V).

The following specifications apply to the selected 10MHz sine wave output at a +13

dbm level:

HARMONICS

-42 dBc

SPURIOUS NOISE

>-80 dBc

PHASE NOISE

1Hz -82 dBc/Hz

10Hz -91 dBc/Hz

100Hz -131 dBc/Hz

1KHz -144 dBc/Hz

10KHz -146 dBc/Hz

100KHz -147 dBc/Hz

1.4.7 PRIMARY POWER

Models ET6000 and ET6010 utilize a Power Entry Module and the Standard Power Supply.

Input Voltage AC = 85 to 264 VAC (47-440 Hz) @ less than thirty watts.

DC = +120 to 373 VDC

Input Frequency Range 47 to 440 Hz

Note: When using 120 VAC, install 1 Amp Line Fuses. When using 220 VAC, install ½ Amp

Line Fuses. Fuses are found in the Shipping Kit.

Model ET6500 utilizes a Power Entry and Alarm Relay Module (Assembly 55191) and the

Standard Power Supply.

This module takes a nominal input of 115 VAC or 125 VDC through a rear panel terminal strip and

provides +5 and ±12 VDC to power the GPS Time Code and Frequency Generator. It provides

timing and fault status relay closures.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-11

Page 19

CHAPTER ONE

It also has the capability of measuring the frequency, phase angle, and elapsed time offset of an

externally applied 50 or 60Hz AC sine wave.

Input Voltage AC = 85 to 264 VAC (47-440 Hz) @ less than thirty watts.

DC = +120 to 373 VDC

Input Frequency Range 47 to 440 Hz

Fault Relay Closure on fault.

Timing Relay Closure when not locked.

Relay Contact Ratings 10 watts, 0.5 amps, 200 volts.

50/60Hz Measurement Input 85-250 VAC.

Note: When using 120 VAC, install 1 Amp Line Fuses. When using 220 VAC, install ½ Amp

Line Fuses. Fuses are found in the Shipping Kit.

All input/outputs from the 55191 are from a rear panel terminal strip TB1.

All input/outputs have metal oxide varistors for transient voltage suppression.

The pin assignments for TB1 are shown below (as viewed from the rear of the unit):

TB1-1 TB1-12

Pin Assignments

TB1-1 AC HI Input

TB1-2 AC LO Input

TB1-3 Chassis Ground

TB1-4 Fault Relay - Common Contact

TB1-5 Fault Relay - Normally Closed Contact

TB1-6 Timing Relay - Common Contact

TB1-7 Timing Relay - Normally Closed Contact

TB1-8 50/60Hz Measurement Input - HI

TB1-9 50/60Hz Measurement Input - LO

TB1-10 Not Used

TB1-11 Not Used

TB1-12 Not Used

1-12 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 20

GENERAL INFORMATION

This Power Entry and Alarm Relay Module has two relay closures to indicate timing/fault of the

unit. The fault relay output on the rear panel terminal strip TB1-4 and 5 will provide contact

closure upon the following conditions:

A processor error, from the GPS Receiver Module

Loss of +5VDC.

If the DAC value goes below 300 or above 65,000.

The timing relay (output on the rear panel terminal strip TB1-6 and 7) provides a contact closure

until the unit has achieved oscillator lock. For example, until the front panel LOCKED LED

illuminates.

1.4.8 DIMENSIONS

Chassis:

Height 1.75 Inches. Model ET6010 is 3.50 Inches.

Width 17 Inches.

Depth 12 Inches Maximum.

1.4.9 WEIGHT

ExacTime Unit Approximately ten pounds.

Antenna/Preamp Less than 1.5 pounds.

1.4.10 ENVIRONMENT

A. OPERATING TEMPERATURE

ExacTime Unit: 0oC to +50oC.

o

Antenna/Preamp: -40

C to +85oC.

B. STORAGE TEMPERATURE

ExacTime Unit: -20

Antenna/Preamp: -55

o

C to +70oC.

o

C to +100oC.

C. HUMIDITY

ExacTime Unit 95% (non-condensing) up to 40oC.

Antenna/Preamp Unlimited.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-13

Page 21

CHAPTER ONE

1.5 ADDITIONAL SPECIFICATIONS

The following is additional information regarding the GPS RPU (Receiver Processing Unit) located

within the GPS Time Code and Frequency Generator, and the antenna/preamp.

1.5.1 ANTENNA/PREAMP

The antenna/preamp satisfies performance requirements at altitudes of up to +59,000 feet.

1.5.2 GPS RPU AND ANTENNA

The GPS RPU (Receiver Processor Unit) and antenna/preamp set has burn-out protection which

prevents damage from an RF signal at power densities of up to one watt at the antenna. The RF

signal must be 100MHz out of band. The C/A band of 1575.42MHz has a bandwidth of 20.48MHz.

1.6 FUNCTIONAL CHARACTERISTICS

The following is a description of the functional characteristics of the GPS RPU.

1.6.1 ACQUISITION

The GPS RPU position fix, acquisition and tracking processes feature the ability to determine its

own position (that of the antenna/preamp), not the TC&FG Module, utilizing a position averaging

technique and assuming the unit has been set to the “AUTO,” or “DYNAMIC” mode. See “Third

Menu Screen” in Chapter Three of this User’s Guide for selection and an explanation of each

MODE SELECTION using the front panel LCD and Keyboard. Mode selection may also be made

via the RS-232 Interface. See the paragraph titled “Select Mode” in Chapter Four for mode

selection using the RS-232 I/O.

The GPS RPU has an eight parallel channel design capable of tracking eight satellites

simultaneously. The module receives the L1 GPS signal (1575.42 MHz) from the antenna and

operates off the coarse/acquisition (C/A) code tracking. The code tracking is carrier aided.

Time recovery capability is inherent in the architecture.

The GPS RPU is designed specifically for precise timing applications.

Upon powering up the system, the unit begins a systematic search for satellites which are expected

to be above the horizon. In this start-up mode of operation it uses the last position data stored in the

battery backed RAM as a starting point. If it is in the A (Auto) mode, it will begin doing a running

average of position fixes. After 200 averages, the unit will have acquired its position and will

switch automatically to the S (Stationary) mode. The number of position averages is user selectable

via the RS-232 I/O. See paragraph titled “Number of Averages” in Chapter Four.

1-14 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 22

GENERAL INFORMATION

If in the D (Dynamic) mode, the unit will use the last position data stored in battery backed RAM as

a starting point to begin its systematic search for satellites. It will continue to do three dimensional

position fixes (latitude, longitude, and altitude) upon acquiring four or more satellites until the

mode is changed. If in the “STATIONARY” mode and a known position has been entered, the unit

will use the position information stored in battery backed RAM as a starting point to begin its

systematic search for satellites.

1.6.2 SIGNAL INTERRUPTION

During GPS ExacTime operation, should the signal from the satellites be interrupted, the antenna

disconnected or blocked, the reacquisition time is dependent upon events during the interruption.

For the first minute of the interruption, the GPS RPU continues to search for the last satellite signals

to which it was locked. If the signal is regained during this minute, reacquisition will be almost

immediate if the users velocity has not changed by more than fifty meters per second.

If the velocity has changed, the Doppler frequency has shifted. The GPS RPU must finish its search

of previous satellite signals and will then expand the search to reacquire. The search time will

depend on the amount of velocity change, but it is usually within fifteen seconds.

If the signal is regained within one minute, the expanding frequency search will already have begun

cycling. In this case, reacquisition may require a few minutes depending upon where the RPU is in

the frequency search when the signal is regained.

If the signal is regained within one hour, the same search must take place, then the new ephemeris

data must be collected. In this case, reacquisition will occur within a few minutes.

The user should realize that obstructions, shading of the antenna, and satellite transmission

interruptions can degrade the signal reception and length of acquisition times.

1.6.3 POSITION AND VELOCITY SOLUTION

The position and velocity, along with the time tag of the measurement, are digitally output from the

RPU to the GPS ExacTime Processor. The position data is three dimensional and available in a

latitude, longitude, and altitude (WGS-84) coordinate frame. The GPS solutions are computed at

typically less than one second intervals.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-15

Page 23

CHAPTER ONE

1.6.4 DYNAMIC CAPABILITY

The following specifications are operational dynamic limits for GPS Timing Unit operation.

A. VELOCITY

The velocity of the user is limited to 515 m/sec for proper GPS Receiver operation.

B. ACCELERATION

User acceleration cannot exceed four 4g (39.2 m/sec2).

C. JERK

The rate of change of acceleration is not to exceed 5 m/sec3.

1.6.5 RF JAMMING RESISTANCE AND BURN-OUT PROTECTION

The GPS RPU provides resistance to all forms of jamming whose effect results in jamming to signal

power ratios of twenty-four dB or less as measured at the antenna/preamplifier interface when the

input signal is at -163 dBm. The GPS RPU/antenna set provides burn-out protection to prevent

damage at RF power densities up to one watt (CW) at the antenna, provided the signal is 100MHz

out of the GPS frequency band.

1.6.6 SYSTEM STATUS AND DIAGNOSTICS

All digital circuitry is tested to the greatest extent possible at power-up. This includes testing the

memory systems, and processor, as well as monitoring the performance of the channel processors.

Should a failure occur in any of these areas, it will be available as status on the RS-232 I/O and will

be displayed on the LCD Display as an error.

1.6.7 GPS POSITION SOLUTION MODES

The user may select either the Auto Mode or the Dynamic Mode for position solutions. (In the

Stationary Mode, the position is already predetermined.) See SELECT MODE in Chapter Three for

front panel LCD and keyboard selection. See Chapter Four for MODE SELECTION using the RS232 I/O.

The AUTO mode is actually a combination of the DYNAMIC and the STATIONARY modes.

When powered up in the AUTO mode, the unit will acquire some number of positions in the

DYNAMIC mode calculating an average latitude, longitude, and altitude when there are at least

four satellites in view. The factory set default number of averages is 200. These position averages

are loaded into battery backed memory for future use.

1-16 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 24

GENERAL INFORMATION

The number of positions used to calculate the averages is user selectable via the RS-232 I/O

interface. Once the average position has been determined, the unit will switch to the

STATIONARY mode. The AUTO mode provides an averaged solution of the time information

from as many satellites as the receiver is tracking.

In the DYNAMIC mode, the system will select the best available satellites based on PDOP

(Position Dilution Of Precision) and provide a continuous navigational solution in three dimensions

(latitude, longitude, and altitude). The DYNAMIC mode does not automatically switch to the

STATIONARY mode.

1.6.8 ELEVATION MASK ANGLE

This mask is used to specify the elevation angle below which the use of satellites is prohibited.

Signal integrity from satellites very low on the horizon can be degraded. Obstructions will block

the signal. For land-based applications where there are local obstructions (foliage, buildings, etc.)

system performance will be smoother with an elevation mask of fifteen to twenty degrees. For

marine or aircraft applications, it is usually possible to use the satellites very close to the horizon,

although the pitch/roll should be considered. The system default is that set by the user. Refer to

Chapter Four, paragraph titled “ENTER ELEVATION MASK ANGLE” for instruction on selecting

elevation mask.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 1-17

Page 25

CHAPTER ONE

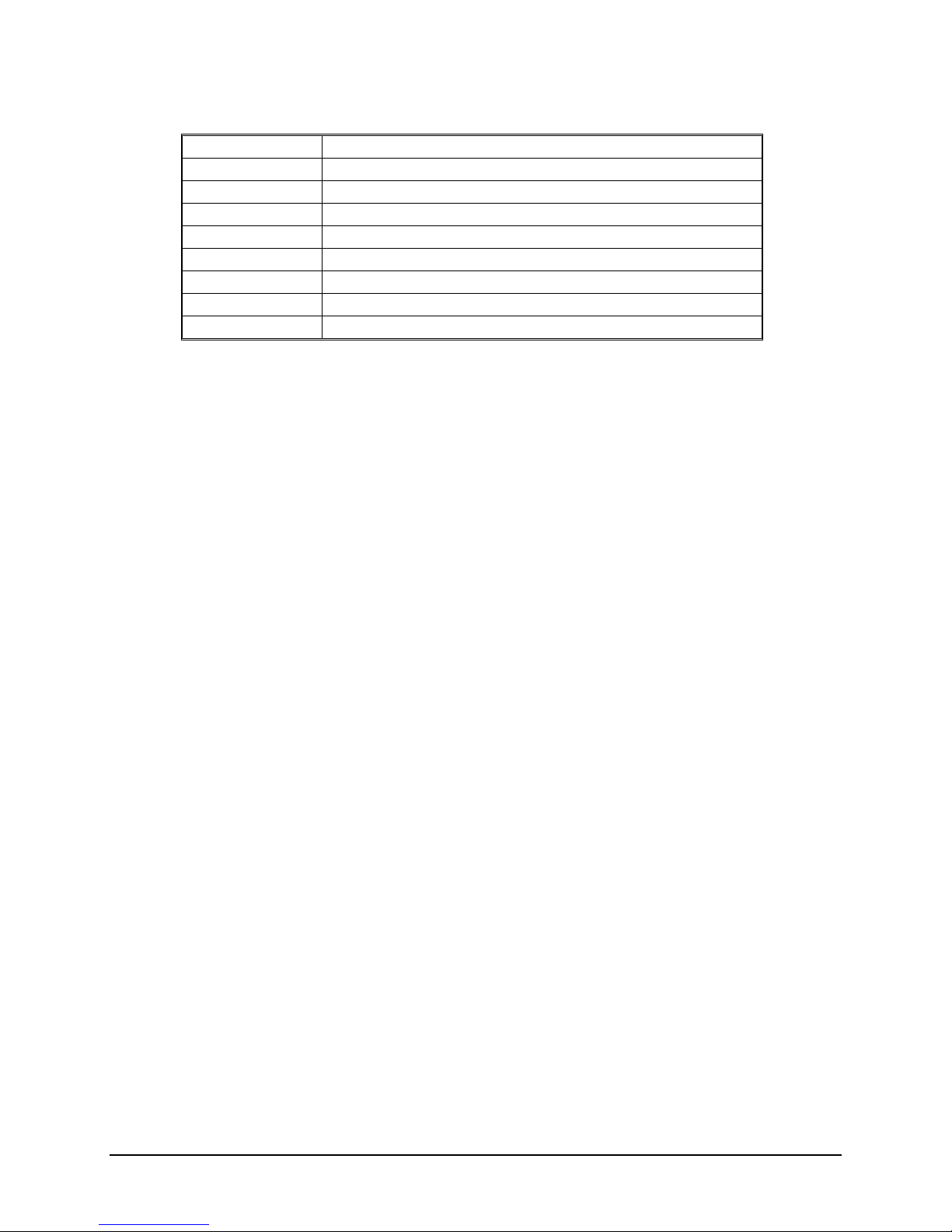

Table One

Control Function Bit Assignments

IRIG B

Positive ID

Control

Bit #

Designation Explanation

P50 1 Year, BCD 1 Last two digits of year in BCD.

P51 2 Year, BCD 2 IBID.

P52 3 Year, BCD 4 IBID.

P53 4 Year, BCD 8 IBID.

P54 5 Not Used Unassigned.

P55 6 Year, BCD 10 Last two digits of year in BCD.

P56 7 Year, BCD 20 IBID.

P57 8 Year, BCD 40 IBID.

P58 9 Year, BCD 80 IBID.

P59 N/A P6 Position identifier number six.

P60 10 Leap Second Pending

(LSP)

Becomes 1 up to 59 s BEFORE leap second

insert.

P61 11 Leap Second (LS) 0 = add leap second, 1 = delete leap second.

P62 12 Not Used

P63 13 Not Used

P64 14 Time Offset Sign Time offset sign 0 = +, 1 = P65 15 Time Offset - Binary 1 Offset from coded IRIG B time to UTC time.

P66 16 Time Offset - Binary 2 IRIG coded time plus time offset (including

P67 17 Time Offset - Binary 4 sign) equals UTC time at all times (offset will

change during daylight savings).

P68 18 Time Offset - Binary 8

P69 N/A P7 Position identifier number.

P70 19 Time Offset - 0.5 Hour 0 = none, 1 = additional 0.5 h time offset

P71 20 Time Quality 4 bit code representing approx. clock time error

P72 21 Time Quality 0000 = clock locked, maximum accuracy.

P73 22 Time Quality 1111 = clock failed, data unreliable.

P74 23 Time Quality

P75 24 PARITY Parity on all preceding data bits.

P76 25 Not Used Unassigned.

P77 26 Not Used Unassigned.

P78 27 Not Used Unassigned.

P79 N/A P8 Position identifier number eight.

1-18 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 26

CHAPTER TWO

INSTALLATION

2.0 INTRODUCTION

This section describes the unpacking, inspection, and installation of the GPS Timing Unit.

2.1 UNPACKING AND INSPECTION

The GPS Timing Unit is packaged in one shipping container. Inspect the unit for visible damage

(scratches, dents, etc.). If the instrument is damaged, immediately notify both Symmetricom Inc

and the responsible carrier. Keep the shipping container and packing material for the carrier’s

inspection.

Note: When communicating with either Symmetricom Inc or the responsible carrier regarding

shipping damage, refer to the serial number. This number is located on the rear panel of

the GPS Timing Unit.

2.2 RACK MOUNTING PROCEDURE

The GPS Timing Unit is designed for standard nineteen inch rack mounting.

Optional chassis slides are recommended if the unit is to be installed in an equipment rack. If

slides are not used, a supporting bar or tray should be provided for the rear of the instrument.

The chassis slides attach to the sides of the GPS Timing Unit. To mount it using the optional

slide mounting kit, use the eight #6 self tapping screws provided in the kit.

*** CAUTION ***

General Cautions/Hazards to be considered when installing the GPS Timing Unit into an

equipment rack:

2.2.1 TMRA – The maximum recommended ambient temperature (Tmra) that this equipment

is specified to operate in is 50°C.

2.2.2 ELEVATED OPERATING AMBIENT TEMPERATURE – If installed in a closed or

multi-unit rack assembly, the operating ambient temperature of the rack environment

may be greater than room ambient. Therefor, consideration should be given to installing

the equipment in an environment compatible with the maximum rated ambient

temperature (Tmra).

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 2-1

Page 27

CHAPTER TWO

2.2.3 REDUCED AIR FLOW - The equipment has no cooling fans and depends on

convection for cooling. Installation in a rack may cause an excessive heat rise if sufficient air

flow is not available. Installation should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

2.2.4 MECHANICAL LOADING – Mounting of the equipment in the rack should be such

that a hazardous condition is not achieved due to uneven mechanical loading.

2.2.5 CIRCUIT OVERLOADING – Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of circuits might have on

over current protection and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this concern.

2.2.6 RELIABLE EARTHING – Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply connections other than direct

connections to the branch circuit (e.g., use power strips).

2.3 ANTENNA/PREAMP INSTALLATION

The antenna/preamp is enclosed in a weatherproof housing suitable for permanent installation in

an exposed location. The unit should be located with an unobstructed view of the horizon for

optimum tracking conditions. The signal will not penetrate foliage. Multi-path signals may be

generated from vertical surfaces, which are above the plane of the base of the antenna/preamp.

The antenna/preamp, which is designed for fixed ground or marine applications, requires no

special ground plane, but a large metal surface below the antenna/preamp may reduce multi-path

effects. The unit may be mounted on any level surface or on a vertical pipe having ¾ - 14 NPT

threads. See Figures 2-1, and 2-4, “Antenna/Preamp Installation,” for mounting.

*** CAUTION ***

A high powered radar beamed directly at the antenna/preamp may damage it and a signal

within a few MHz of the carrier frequency may jam the GPS RPU.

2.4 ANTENNA/PREAMP INTERFACE CONNECTIONS

A fifty foot long RG-58A/U coaxial cable is provided to connect the antenna/preamp to the GPS

Timing Unit. For cable lengths greater than seventy-five feet, an optional low loss coaxial cable

(such as Belden 9913) must be used.

Note: The GPS antenna and cable described in this manual have been replaced as described in

“Appendix D: Antenna Replacement Kit” on page D-1.

2-2 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 28

INSTALLATION

The antenna/preamp power is provided by the GPS Timing Unit via the coaxial cable. No

additional cabling is required to power the antenna/preamp.

Cables attached to the antenna/preamp should be strain relieved and secured to some permanent

fixture.

Cables attached to the antenna/preamp which are exposed to the elements should be wrapped

with a weather-proof tape after being connected.

Cables from the antenna/preamp should be secured as required with cable clamps and should not

put a strain on the antenna/preamp connector as it may damage the unit.

2.5 PRIMARY POWER CONNECTION

The GPS Timing Unit is operated from external AC power. The AC power specifications are

listed in the specification section in Chapter One of this User’s Guide.

Models ET6000 and ET6010 utilize a power cord that plugs into a Power Entry Module.

Note: Check the AC line fuses located in the power entry module on the rear panel and assure

the correct fuse is installed for the AC Line voltage being used to power the unit. The

AC line fuses should be 1 Amp for an AC input of 120 volts or ½ amp for an AC input of

220 volts.

Model ET6500 utilizes a terminal strip Power Entry and Alarm Relay Module (Assembly

55191).

Note: Check the AC line fuses located in the power entry module inside the unit and assure the

correct fuse is installed for the AC Line voltage being used to power the unit. The AC

line fuses should be 1 Amp for an AC input of 120 volts or ½ amp for an AC input of 220

volts.

The terminal strip pin designations are shown below:

REAR VIEW OF ET6500 SHOWING 55191

POWER ENTRY AND ALARM RELAY MODULE

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 2-3

19

TB1

Page 29

CHAPTER TWO

PIN ASSIGNMENTS

TB1 Pin 1 AC High Input

TB1 Pin 2 AC Low Input

TB1 Pin 3 Chassis Ground

TB1 Pin 4 Fault Relay – Common Contact

TB1 Pin 5 Fault Relay – Normally Closed Contact

TB1 Pin 6 Timing Relay – Common Contact

TB1 Pin 7 Timing Relay – Normally Closed Contact

TB1 Pin 8 50/60Hz Measurement Input - High

TB1 Pin 9 50/60Hz Measurement Input - Low

This assembly has two relay closures to indicate timing/fault of the unit. The fault relay output

on the rear panel terminal strip TB1-4 and 5 will provide contact closure upon the following

conditions:

A processor error, Channel One error, or Channel Two error from the GPS receiver.

Loss of +5VDC.

If the DAC value goes below 300 or above 65,000.

The timing relay output on the rear panel terminal strip TB1-6 and 7 provides a contact closure

until the unit has achieved unit stabilization. For example, until the front panel LOCKED LED

illuminates.

If this unit is provided with a power supply other than the standard, its specifications will be

found in the Option Description envelope located on the inside cover of this User’s Guide.

2-4 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 30

INSTALLATION

Figure 2-1

Antenna/Preamp Installation

5000-0001 Bullet Antenna

(Mfg P/N 25045-10*)

* Dash number is the software revision. This

is subject to change without notice.

1704-9389 Type F to Type N

Connector Adapter

1. Material* PVC or CPVC Schedule 80, Gray Color.

Note: The GPS antenna and cable described in this manual have been replaced as described in

“Appendix D: Antenna Replacement Kit” on page D-1.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 2-5

Page 31

CHAPTER TWO

2.6 GPS TIMING UNIT INTERFACE CONNECTIONS

The GPS Timing Unit interface connections consist of cabling to the antenna/preamp assembly

from J2 on the unit’s rear panel, the RS-232 I/O port J12 (if used), and the time and frequency

inputs and outputs and/or other optional inputs or outputs.

2.6.1 RS-232 I/O INTERFACE J12

This port provides the basic read/write mode of operation.

Before connecting a peripheral device to this port, read the manual accompanying the product

and be aware of the necessary precautions. Determine the BAUD rate, parity word length, stop

bits, and interconnections with the equipment.

This I/O port is configured as a DCE, and is intended to be used by intelligent peripherals such

as a computer. The RS-232 I/O port uses a standard DB-9 I/O connector with the pin

configuration shown in Figure 2-2.

The RS-232 protocol is described in Chapter Four in the paragraph titled “Information.”

Figure 2-2

RS-232 I/O Cable Pin Assignments

GPS ExacTime Computer

1

2

3

4

5

6

7

8

9

1

2 RX

3 TX

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9

The RS-232 I/O interface uses a standard PC compatible one-to-one cable using nine Pin D type

connectors. Handshaking is not used. Pin 6 (DSR) and pin 8 (CTS) on J12 are internally set

high.

2-6 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 32

INSTALLATION

2.6.2 PRINTER OUTPUT PORT J11

This connector can output data to an RS232 compatible serial printer or terminal. It can be

configured to output data in the Standard configuration or the One Second ASCII Burst Mode

Output. Refer to Chapter Three (Tenth Menu Screen) for more specific details on configuration

and operation.

Connector configuration:

1

2

3

4

5

6

7

8

9

NOT USED

INPUT LINE TO ET6XXX - NOT USED

TX (Data Out)

NOT USED

GROUND

NOT USED

NO CONNECTION

OUTPUT LINE FROM ET6XXX - NOT USED

NOT USED

2.6.3 TIMING OUTPUTS

Various timing output signals can be provided on the rear panel BNC connectors J4 through J9.

The selection of these outputs is made using jumper pins/blocks on the GPS Main Assembly

100015, as shown in Figure 2-3, and the front panel keyboard, or via the RS-232 I/O.

To check or reconfigure these outputs via the front panel keyboard, see the paragraph titled

“Configuration of Rear Panel BNC Connectors J4-J9” in Chapter Three of this User’s Guide.

To check or reconfigure these outputs via the RS-232 I/O, see the paragraphs titled “Request

MUX Outputs,” and “Set MUX Output” in Chapter Four of this User’s Guide.

The standard configuration is as follows:

J4 Tracking (TTL)* Jumper J14 7 and 8, and J24 1 and 2.

J5 Locked (TTL)** Jumper J15 7 and 8, and J25 1 and 2.

J6 1pps Jumper J16 1 and 2.

J7 10MHz Sine Wave Jumper J17 5 and 6.

J8 IRIG B (AC) Jumper J18 3 and4, and J28 1 and 2.

J9 IRIG B (DC) Jumper J19 1 and 2, and J29 1 and 2.

J10 1pps Input (Time Interval Measurement).

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 2-7

Page 33

CHAPTER TWO

* Tracking output is low when unit is tracking, high when unit is not tracking.

** Locked output is low when unit is locked, high when unit is not locked.

For additional pulse rate selections available on BNC connectors J4-J9, see Chapter One of this

User’s Guide.

Configurations other than the standard above will be found in the GPS Option/Connector

Configuration Sheet located in this User’s Guide.

2.6.4 1PPS INPUT

A 1pps pulse can be input on a rear panel BNC connector labeled J10. This input can be utilized

when making time interval measurements between the internal corrected GPS 1pps and an

external 1pps input pulse. This is a multipurpose input that may also be optionally utilized to

record an event or accept a frequency for external measurement purposes.

2.6.5 OSCILLATOR CONFIGURATION

The jumper blocks at J27 enable the processor (and the program) to determine which oscillator is

installed on the board. This provides for the selection of the specific gain and correction voltage

(i.e. the discipline voltage) for each oscillator. The jumpers are factory set for the oscillator in

your specific configuration, and shouldn’t need to be changed unless the oscillator type is

changed.

J27 OSCILLATOR CONFIGURATION

OCXO LPROTCXO

12

3

4

12

3

4

For the TCXO, no jumpers are installed.

For the OCXO, jumper pins 1-2.

For the Rubidium LPRO, jumper pins 3-4.

For the Rubidium X-72, jumper pins 1-2, and 3-4.

12

3

4

RB

12

3

4

2-8 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 34

INSTALLATION

Figure 2-3

GPS Main Assembly 100015

6

4

J14

2

1

3

5

7 8

2

J4

J24

4

Relay-

3

Rear

Below

See Inset

Buffered Out -

2

4

Relay-

1

3

Buffered Out -

J6 J5

J7

2

4

J28 J25

1

3

J15

J16J17

J18J19

MUX Ch: 1 -

AC Code Out -

4

2

1

3

MUX Ch: 2 -

AC Code Out -

4

2

1

3

MUX Ch: 3 -

AC Code Out -

4

2

1

3

MUX Ch: 4 -

AC Code Out -

4

2

1

3

Tracking -

10 MHz Sine -

6

5

7 8

Locked-

10 MHz Sine -

6

5

7 8

Unused -

10 MHz Sine -

6

5

7 8

Unused -

10 MHz Sine -

6

5

7 8

2

J24

1

Buffered Out -

Inset

Outputs."

J24 & J25 above are jumpered for "Buffered

The diagram below illustrates the jumper positions

2

J25

1

Buffered Out -

for "Relay Outputs."

Main GPS Board

Assembly 100015

4

Relay-

3

4

Relay-

3

Buffered Out -

2 1

J9 J8

J29

1

Buffered Out -

J10

Time Interval Input

Ext. Freq. Measurement Input

Event 1 Input

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 2-9

Event 3 In -

3 4

-

Event 2 In

MUX Ch: 2 -

AC Code Out -

4

2

1

3

MUX Ch: 1 -

AC Code Out -

Unused -

10 MHz Sine -

6

5

7 8

Unused -

10 MHz Sine -

1. Mux Channel 1 can be output on both J4 and J9.

2. Mux Channel 2 can be output on both J5 and J8.

3. Shaded areas are the standard (default) configuration.

Notes:

Example: Inserting jumper blocks into J14-5&6, and J24-1&2 will output a 10 MHz sine wave on rear panel BNC connector J4.

Page 35

CHAPTER TWO

Figure 2-4

Antenna/Preamp Installation

5000-0001

Bullet Antenna

(Mfg P/N 25045-10)

1704-9389 Type F

to Type N Connector

Adapter

Antenna Mast 711700:

Secure to an existing vent pipe using hose

clamps or secure to a flat surface using

pipe straps and screws.

Antenna Cable with

Type N Connector

Note: The GPS antenna and cable described in this manual have been replaced as described in

“Appendix D: Antenna Replacement Kit” on page D-1.

2-10 ET6xxx ExacTime GPS TC & FG (Rev C) Symmetricom Inc

Page 36

CHAPTER THREE

OPERATION

3.0 INTRODUCTION

This chapter describes the operation of the basic GPS ExacTime. Operating instructions for the

optional features are contained Appendix C of this User’s Guide.

Note: The GPS antenna and cable described in this manual have been replaced as described in

“Appendix D: Antenna Replacement Kit” on page D-1.

3.1 OPERATIONAL STEPS

The following are the initial installation steps necessary for the operation of your unit:

• Connect the appropriate input/output cables and components including as a minimum the

power cable, the antenna, and antenna cable.

• Apply power to the unit. Initially the front panel TRACKING and LOCKED LED’s will

flash and the POWER LED will illuminate. This signifies that the microprocessor and

associated circuitry have been initialized correctly and are operating.

• At this point, the Operational Mode needs to be selected. See the section entitled “SET-UP

MENU SCREEN – SET MODE” (this chapter). The criteria for selecting the various modes

can be summarized as follows:

AUTO – Use if your position (i.e. the position of the antenna) is unknown, and

stationary. This is the default mode. See section titled “Initialization (Unknown

Position).”

DYNAMIC - This mode would be selected if the unit is mounted in a moving vehicle.

By definition, your position is unknown. See section titled “Initialization (Unknown

Position).”

STATIONARY - Use if your position is known, stationary, and accurately surveyed.

See the section titled “Initialization (Known Position).”

FLYWHEEL – To use your unit as a time code generator only. Position is not

determined and the internal oscillator is not disciplined.

3.1.1 INITIALIZATION (UNKNOWN POSITION)

• Set the SET MODE to “AUTO” if it is not already in the “AUTO” mode. The unit will then

start to track satellites (refer to the Main Menu Screen – this chapter). When satellites are

acquired and ready for time solution, the TRACKING LED will illuminate signifying that

the unit is tracking satellites.

Symmetricom Inc ET6xxx ExacTime GPS TC & FG (Rev C) 3-1

Page 37

CHAPTER THREE

• The message “GPS Time Not Acquired” will be displayed until the unit receives the Leap

Second information. At that point, the unit will set time and the message “ZZZZ Stabilizing

XX” will be displayed.

ZZZZ = The internal 10MHz oscillator installed in the unit. Either TCXO, OCXO,

LPRO, or X72. (LPRO and X72 are both versions of a Rubidium oscillator.)

XX = A number (10 to 1) indicating the progression through a series of oscillator

stabilization steps.

• After the oscillator stabilization step is finished, the unit will begin doing position averaging

in order to derive the position. The number of averages is set to the default number of 200

but is user selectable via the RS-232 I/O Interface. See paragraph titled “Number of Position

Averages” in Chapter Four of this User’s Guide. A position fix takes approximately seven

seconds, so the position averaging itself could take about 20 minutes.

• Once the unit has accomplished its position averaging, the unit will switch to the

STATIONARY mode. At this time, the 1pps will be coherent with the internal disciplined

10MHz oscillator.

• Unit stabilizing will begin. The unit starts to discipline the internal oscillator. Once the

unit’s discipline process has stabilized, the LOCKED LED will illuminate indicating that the

unit is completely functional.

For a TCXO oscillator, this process will take about 30 minutes.

For a OCXO oscillator, this process will take about 90 minutes.

For a Rubidium oscillator, this process will take about 3.5 hours.

• If the LOCKED front panel LED does not illuminate within the specified time above, check

the DAC value displayed on the POSITION MENU SCREEN, and/or the status displayed on

the MAIN MENU SCREEN, or via the RS-232 I/O interface (see Chapter Four, paragraphs

titled “Request DAC Value,” and “Print Time, Status, Error Code, and Satellite Vehicle

Numbers” respectively). If DAC value number has approached either one of its extremes

(00000 or 65535), the internal oscillator needs to be nulled/calibrated. Refer to the “Internal

Oscillator Calibration” procedure in Chapter Five of this User’s Guide.

• If the unit stops tracking satellites at any point after initial power-up, the TRACKING LED

will be turned off. At that time, an internal elapsed time counter will be started and the short

term oscillator stability will be stored in memory. Based upon the type of internal 10MHz