Suzuki SV1000 2003-2005 Service Manual 6 Chassis

40

CHASSIS 6-1

CHASSIS

CONTENTS

EXTERIOR PARTS

CONSTRUCTION

REMOVAL

REMOUNTING

FRONT WHEEL

CONSTRUCTION

REMOVAL

INSPECTION AND DISASSEMBLY

REASSEMBLY AND REMOUNTING

FRONT FORK

CONSTRUCTION

REMOVAL AND DISASSEMBLY

INSPECTION

REASSEMBLY AND REMOUNTING

SUSPENSION SETTING

STEERING DAMPER

CONSTRUCTION

REMOVAL

INSPECTION

REMOUNTING

HANDLEBAR

CONSTRUCTION

REMOVAL AND DISASSEMBLY

REASSEMBL Y AND REMOUNTING

STEERING

REAR WHEEL

REAR SHOCK ABSORBER

REAR SWINGARM

~

CONSTRUCTION

REMOVAL AND DISASSEMBLY

INSPECTION AND DISASSEMBLY

REASSEMBLYAND REMOUNTING

STEERING TENSION ADJUSTMENT

CONSTRUCTION

REMOVAL

INSPECTION AND DISASSEMBLY

REASSEMBL Y AND REMOUNTING

CONSTRUCTION

REMOVAL

INSPECTION

REAR SHOCK ABSORBER DISPOSAL

REMOUNTING

SUSPENSION SETTING

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

. . . . . . . ..... . . . . . . . . . .

~

~

~

~

. . .

. .

~

6-55

~

~

. . . . . . . .

. . . . . . . . . . . . . ..... . . . . . . . ....... . . . . . . . . . . .

~

~

~

~

~

~

~

~

~

. . . .

~

..... . . . . . . . . . . .

.

~

. . . . . . . .

. . . .

. . . . . . . . . .

~

~

~

. . . . . . .

. . .

. . . . .

. ...

. . . .

. . . . . . . . .

. . . . . . . . .

. . . . . ..... . . . . . . . ....... . . . . . . . . . . . . . . .

. . .

. . . . . . . . .

. . .

. . . . . . . . . . ..... . . . . . . . . . . .

. . .

.6-19

.

.6-43

.6-53

6- 3

6- 3

6- 5

6-10

6-11

6-11

6-12

6-13

6-15

6-19

6-20

6-23

6-24

6-29

6-30

6-30

6-30

6-30

6-31

6-32

6-32

6-32

6-33

6-36

6-36

6-37

6-38

6-39

6-41

6-42

6-42

6-44

6-46

6-50

6-50

6-51

6-51

6-52

6-54

6

6

.2 CHASSIS

CHASSIS

CONTENTS

CONSTRUCTION

REMOVAL

INSPECTION AND DISASSEMBLY

REASSEMBLY

REMOUNTING

FINAL INSPECTION AND ADJUSTMENT

FRONT BRAKE

CONSTRUCTION

BRAKE PAD REPLACEMENT

BRAKE FLUID REPLACEMENT

CALIPER REMOVAL AND DISASSEMBLY

CALIPER INSPECTION

CALIPER REASSEMBLY AND REMOUNTING

BRAKE DISC INSPECTION

MASTER CYLINDER REMOVAL AND DISASSEMBLY

MASTER CYLINDER INSPECTION

MASTER CYLINDER REASSEMBL Y AND REMOUNTING

REAR BRAKE

CONSTRUCTION

BRAKE PAD REPLACEMENT

BRAKE FLUID REPLACEMENT

CALIPER REMOVAL AND DISASSEMBLY

CALIPER INSPECTION

BRAKE DISC INSPECTION

CALIPER REASSEMBLY AND REMOUNTING

MASTER CYLINDER REMOVAL AND DISASSEMBLY

MASTER CYLINDER INSPECTION

MASTER CYLINDER REASSEMBLY AND REMOUNTING

CLUTCH RELEASE CYLINDER AND MASTER CYLINDER

CONSTRUCTION

CLUTCH FLUID REPLACEMENT

CLUTCH RELEASE CYLINDER REMOVAL AND DISASSEMBLY

CLUTCH RELEASE CYLINDER INSPECTION

CLUTCH RELEASE CYLINDER REASSEMBLY AND REMOUNTING

CLUTCH MASTER CYLINDER REMOVAL AND DISASSEMBLY

CLUTCH MASTER CYLINDER INSPECTION

CLUTCH MASTER CYLINDER REASSEMBLY AND REMOUNTING

TIRE AND WHEEL

TIRE REMOVAL

INSPECTION

VALVE INSTALLATION

TIRE INSTALLATION

BALANCER WEIGHT INSTALLATION

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

6-55

6-56

6-57

6-61

6-63

6-64

6-65

6-65

6-66

6-67

6-68

6-69

6-70

6-71

~

~

~

~

~

6-72

6-73

6-74

6-76

6-76

6-77

6-78

6-79

6-80

6-81

6-82

6-83

6-84

6-85

6-87

6-87

6-88

. . . .

6-88

6-89

6-89

6-91

6-92

~

6-93

6-95

6-95

6-95

6-96

6-96

6-97

Id

40

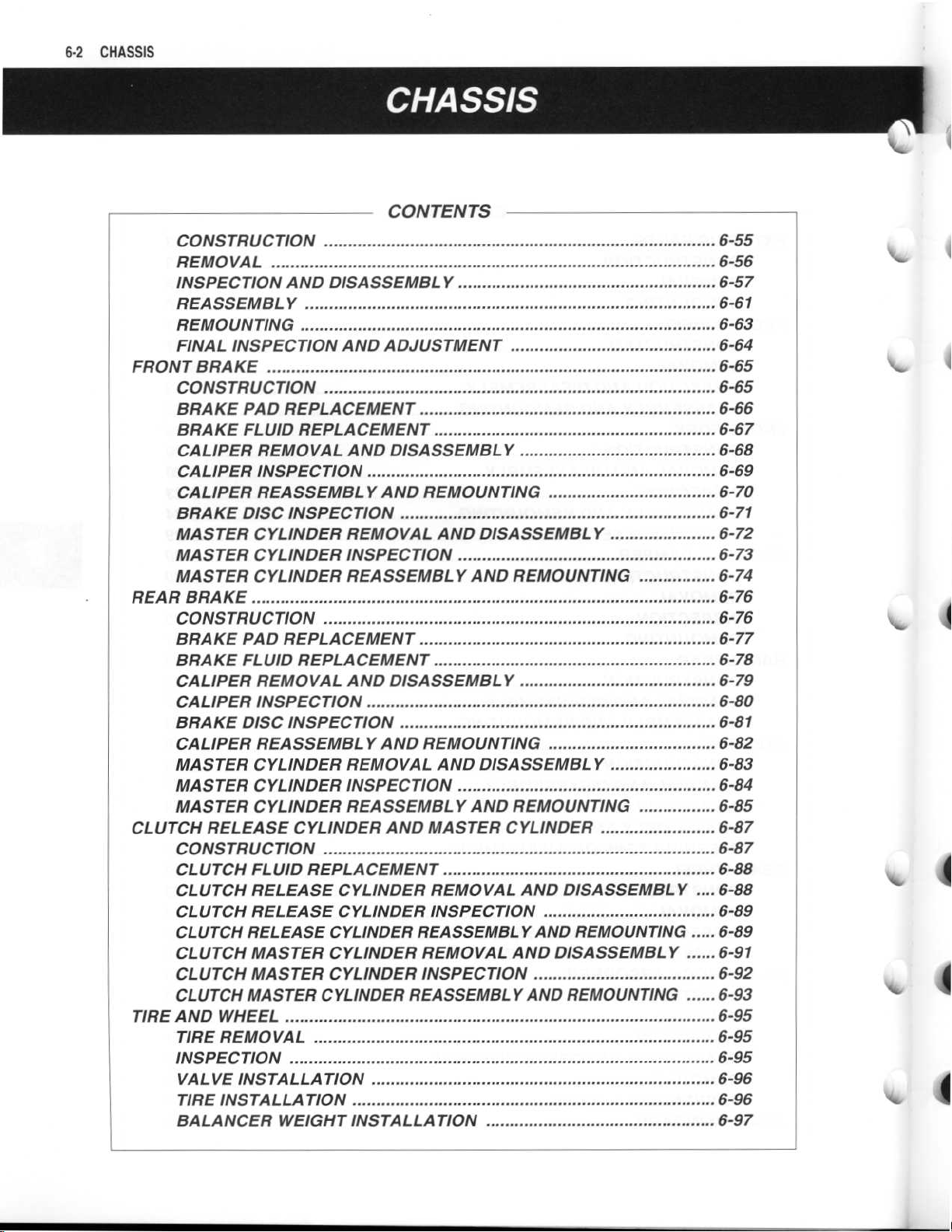

EXTERIOR PARTS

CONSTRUCTION

CHASSIS

6-

3

~

~

~

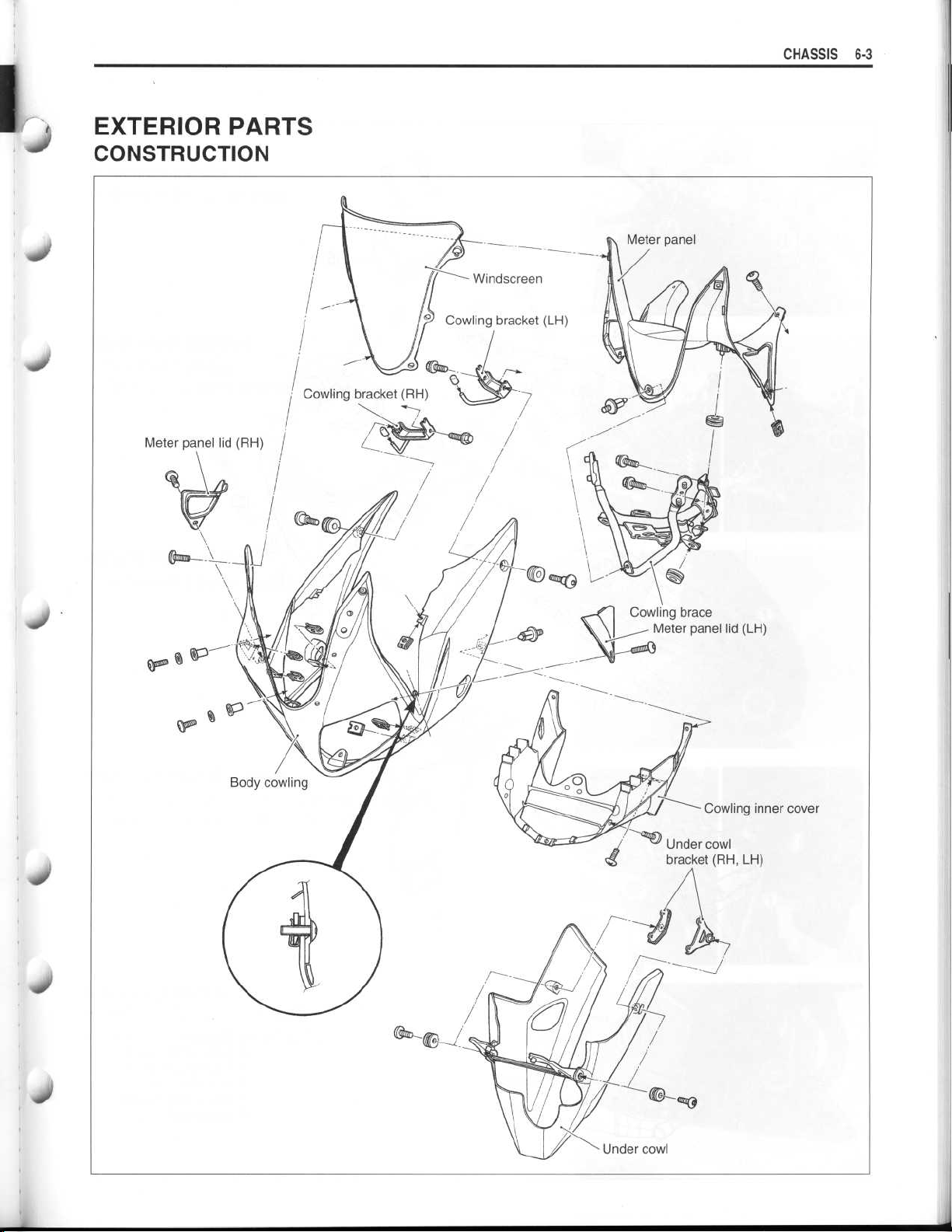

CHASSIS

6-4

00

Seat

eat tail

02 Rear fender No

03 Rear fender No

Seat tail cover

•

•

Pillion rider handle

Mud guard

•

. 1

. 2

~

~

~

~

~

~

~

~

~

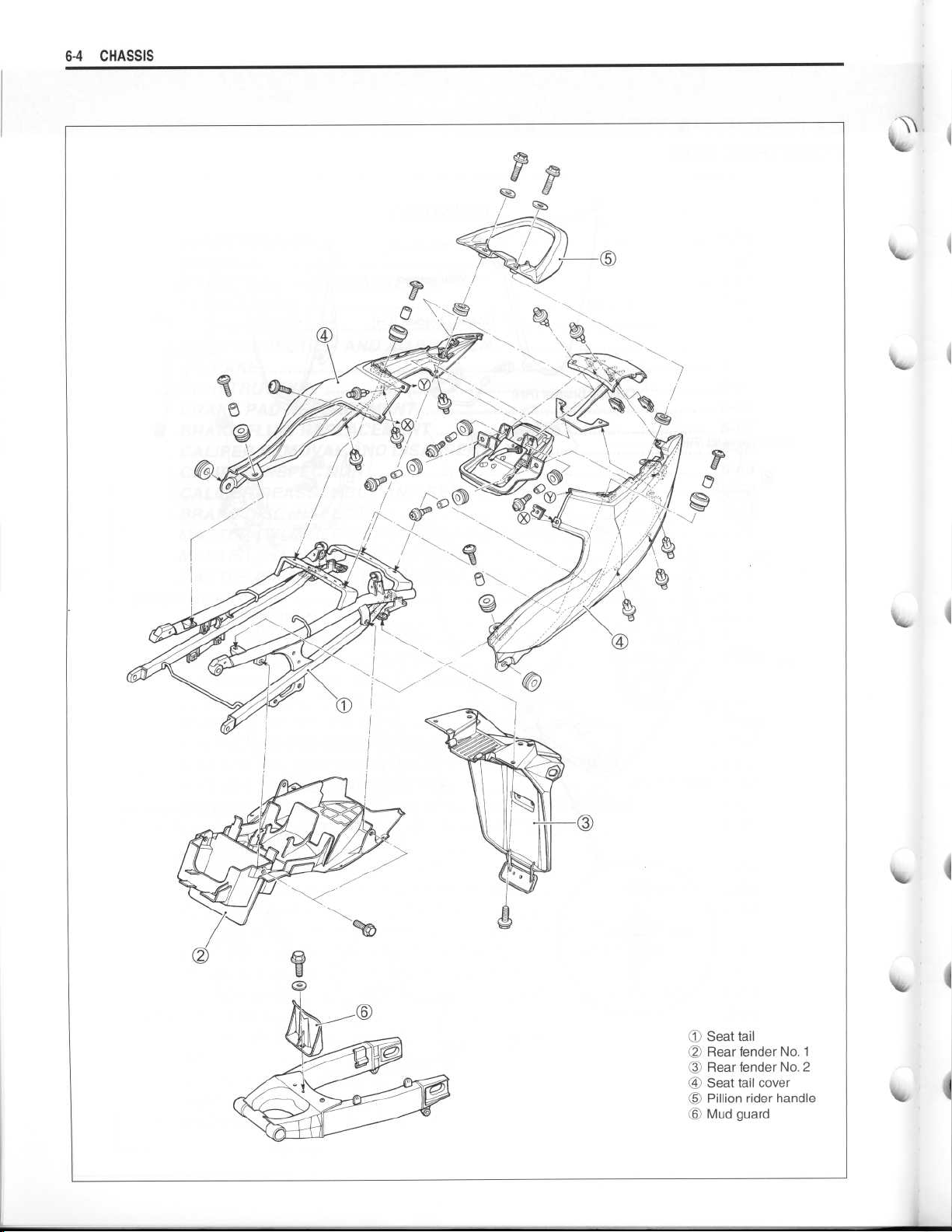

REMOVAL

WINDSCREEN

•

Remove the screws

•

Remove the windscreen

REAR VIEW MIRROR

•

Remove the caps

•

Remove the bolts and rear view mirrors

.

.

.

.

CHASSIS 6-

5

40

S

METER PANEL LID

•

Remove the meter panel lids ®

INNER COWLING COVER

•

Remove the screws and fasteners

•

Remove the inner cowling cover

UNDER COWLING

•

Remove the screws

•

Remove the under cowling

. (L & R)

. (L & R)

T

.

. (L & R)

D

.

Y^~

:

Hooked part

40

~

~

~

~

~

~

~

~

~

~

~

6-6 CHASSIS

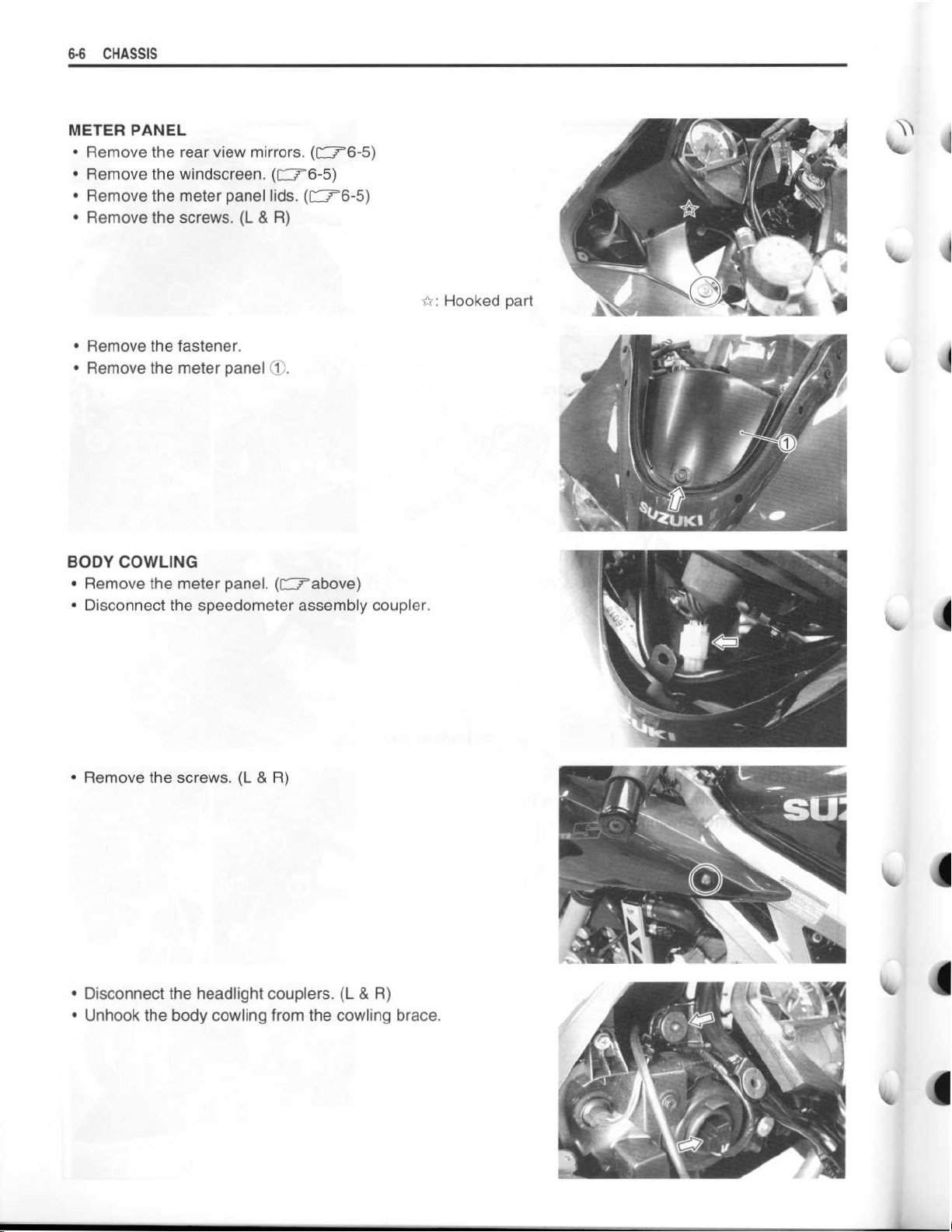

METER PANEL

•

Remove the rear view mirrors

•

Remove the windscreen

•

Remove the meter panel lids

•

Remove the screws

•

Remove the fastener

•

Remove the meter panel

. (L & R)

.

. (=6-5)

. (11'6-5)

.(Cr6-5)

O

.

Hooked part

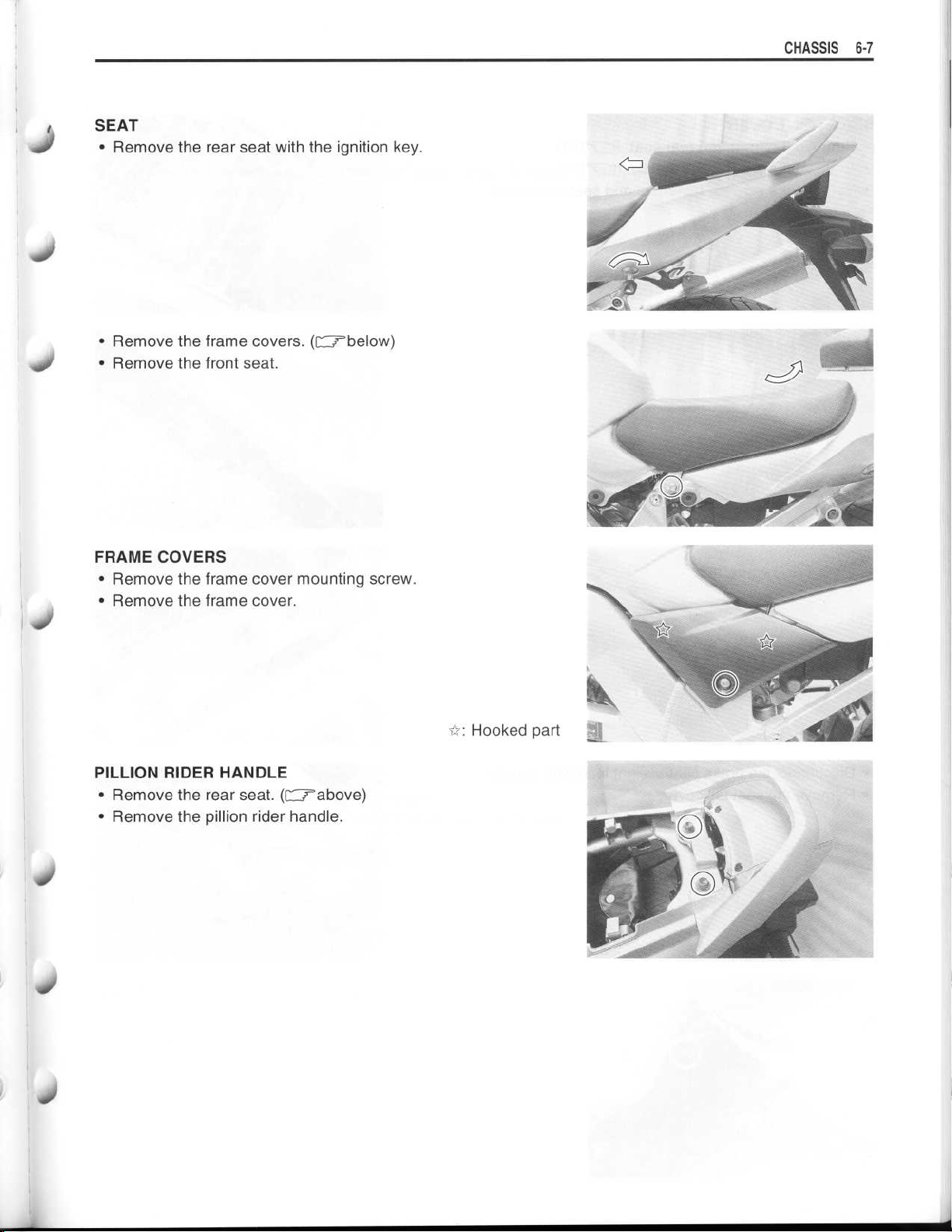

BODY COWLING

•

Remove the meter panel

•

Disconnect the speedometer assembly coupler

•

Remove the screws

•

Disconnect the headlight couplers

•

Unhook the body cowling from the cowling brace

. ((above)

. (L & R)

. (L & R)

.

.

~

~

~

~

~

~

~

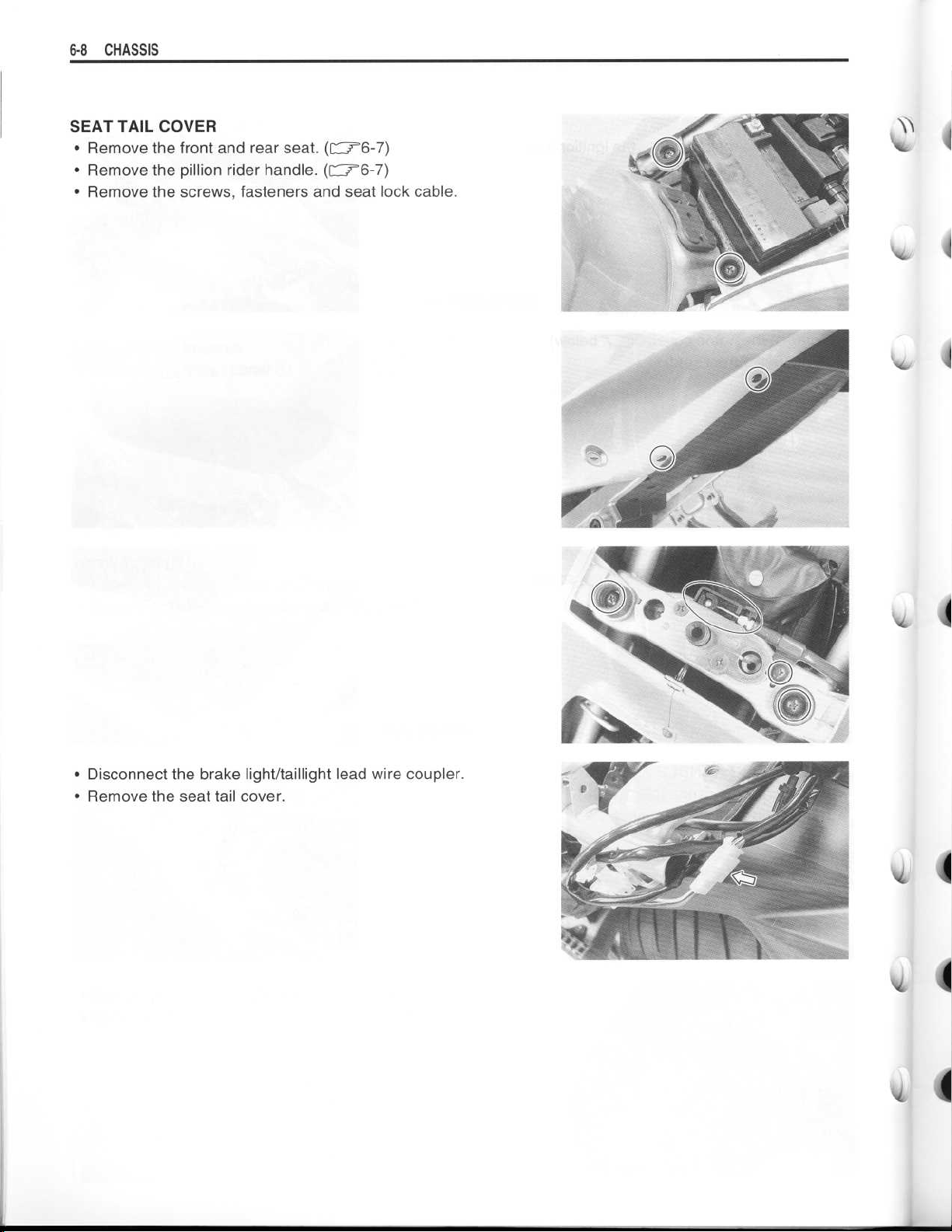

SEAT

•

Remove the rear seat with the ignition key

•

Remove the frame covers

•

Remove the front seat

.

(r

r

below)

.

.

CHASSIS

6 -7

FRAME COVERS

•

Remove the frame cover mounting screw

•

Remove the frame cover

PILLION RIDER HANDLE

•

Remove the rear seat.(f 7

•

Remove the pillion rider handle

.

above)

.

.

~

: Hooked part

~

~

~

~

~

6.8CHASSIS

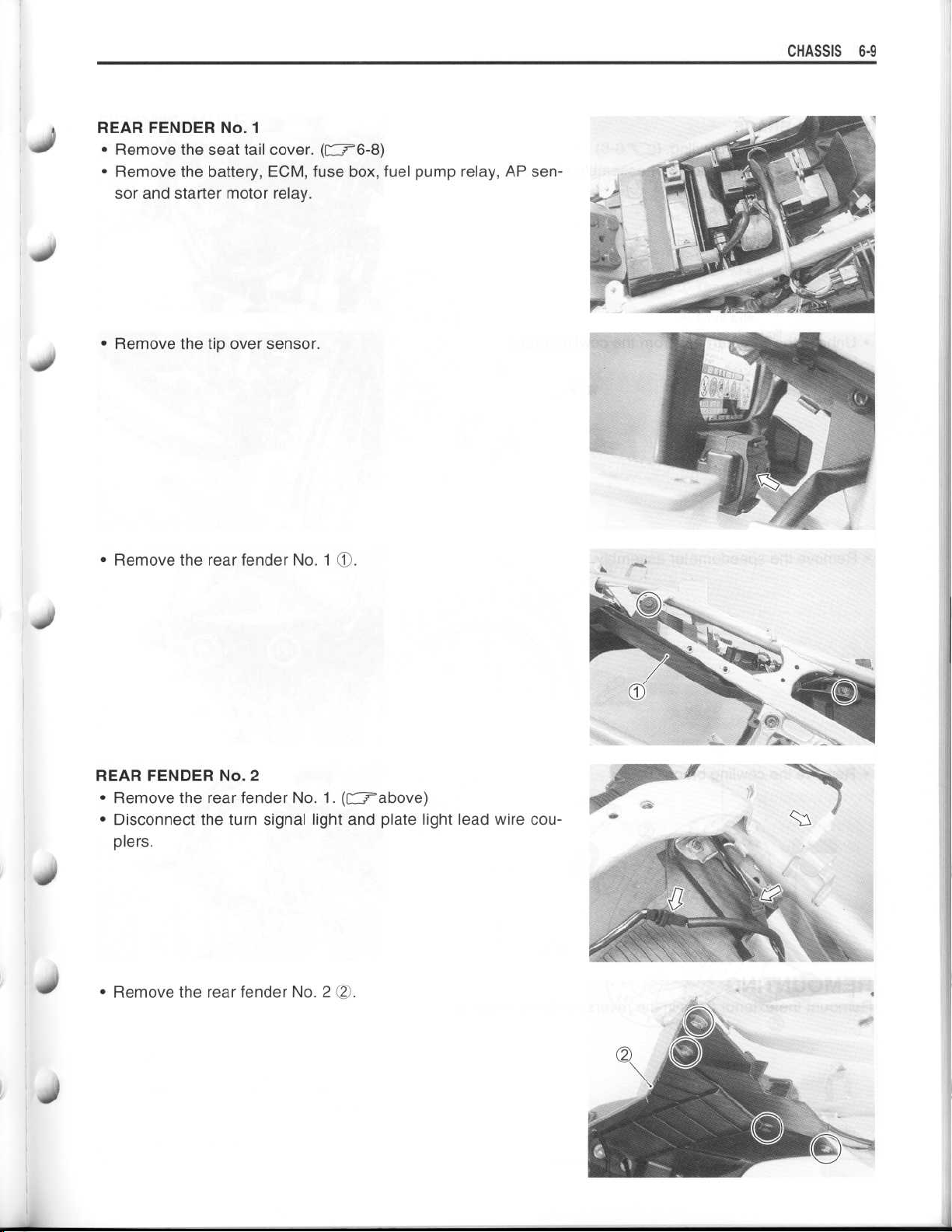

SEAT TAIL COVER

•

Remove the front and rear seat

•

Remove the pillion rider handle

•

Remove the screws, fasteners and seat lock cable

. (C1F6-7)

.

(r

--

r6-7)

.

•

Disconnect the brake light/taillight lead wire coupler

•

Remove the seat tail cover

.

.

C

~

~

~

~

~

~

~

CHASSIS 6-9

REAR FENDER No

•

Remove the seat tail cover

•

Remove the battery, ECM, fuse box, fuel pump relay, AP sensor and starter motor relay

•

Remove the tip over sensor

•

Remove the rear fender No

. 1

.

(E'6-8)

.

.

. 1 90

.

REAR FENDER No

•

Remove the rear fender No

•

Disconnect the turn signal light and plate light lead wire couplers

.

•

Remove the rear fender No

. 2

. 1

. (

r

-

. 2 02

.

Tabove)

~

~

~

~

~

6-10 CHASSIS

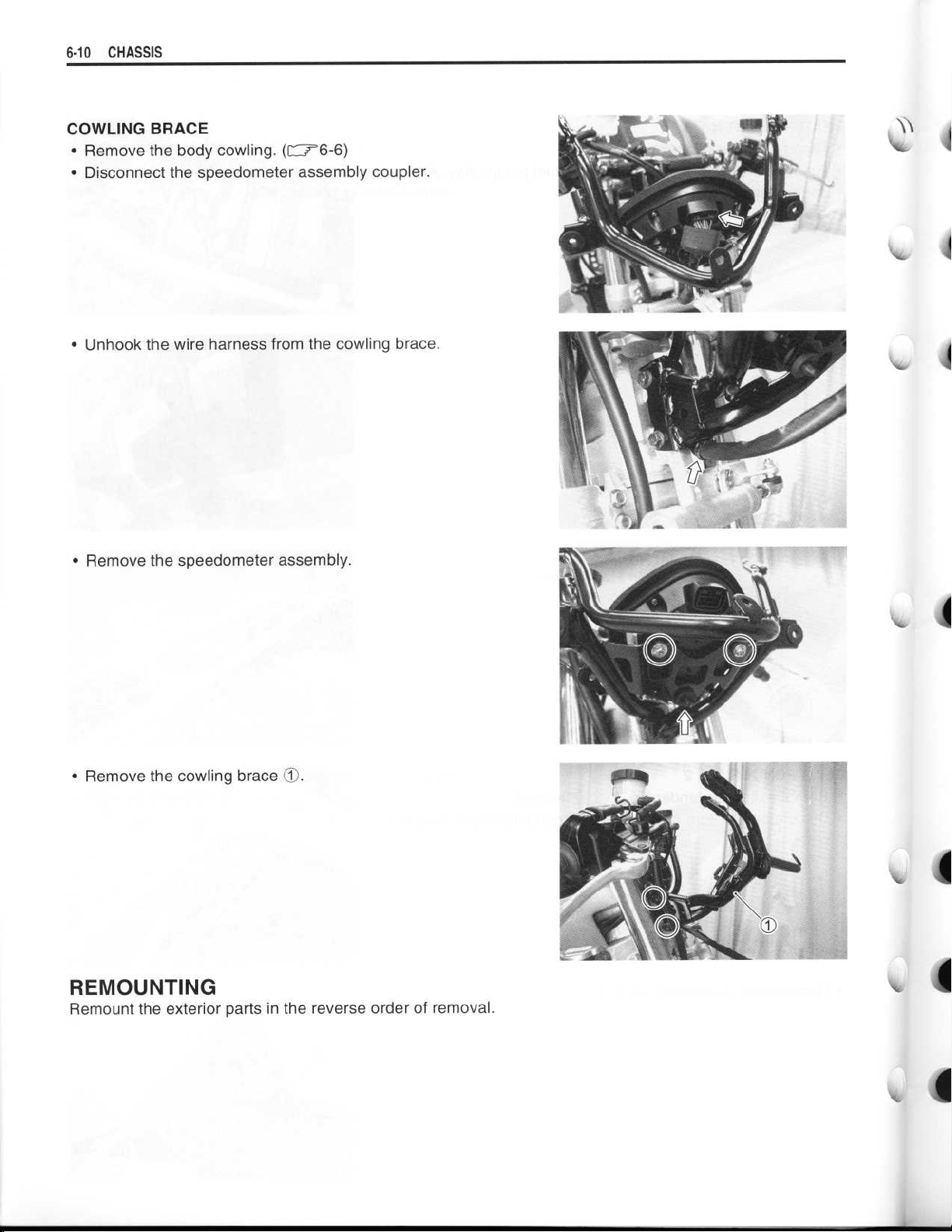

COWLING BRACE

•

Remove the body cowling.(["r'6-6)

•

Disconnect the speedometer assembly coupler

.

•

Unhook the wire harness from the cowling brace

•

Remove the speedometer assembly

•

Remove the cowling brace 10

.

.

.

REMOUNTING

Remount the exterior parts in the reverse order of removal

.

~

~

~

~

~

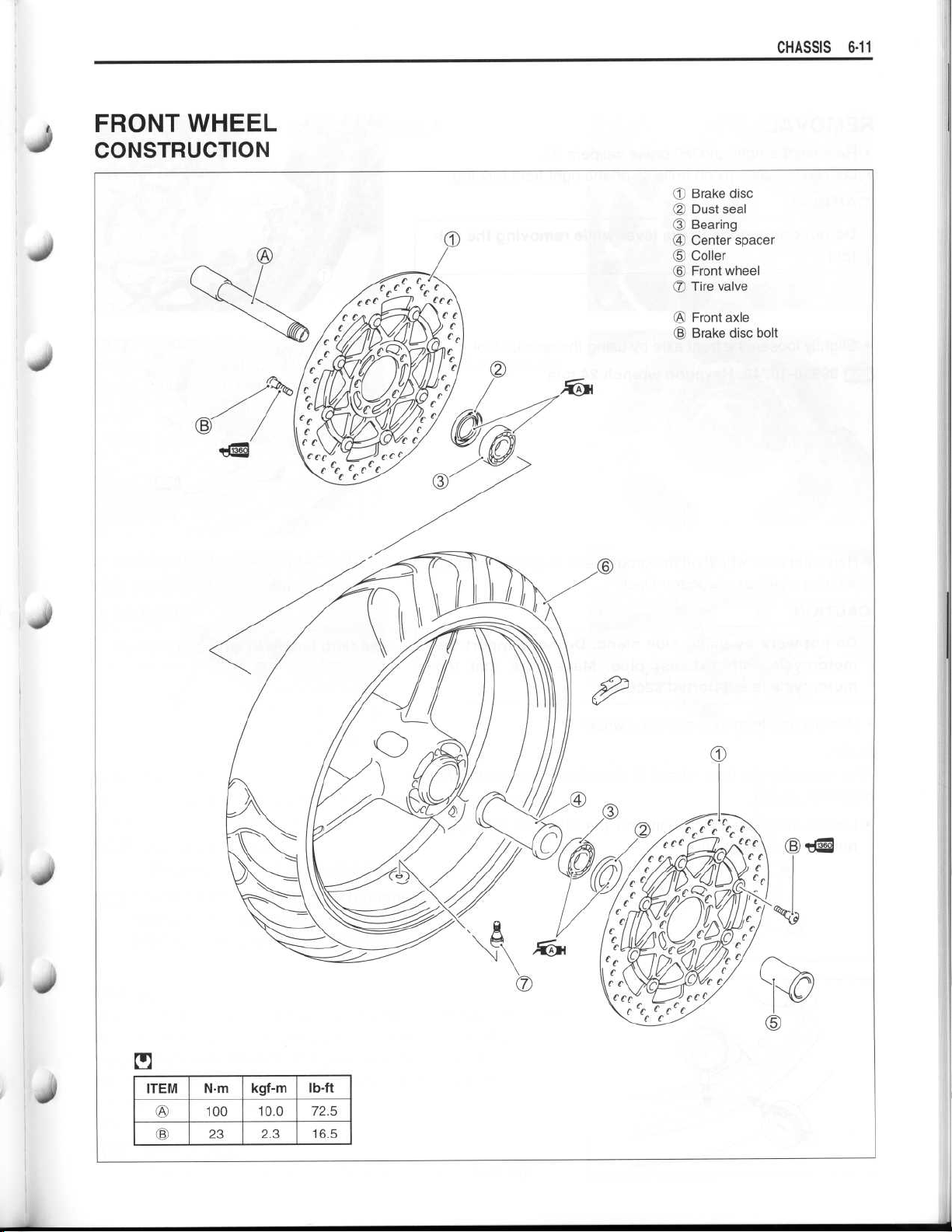

FRONT WHEEL

CONSTRUCTION

1~ Brake disc

~2 Dust seal

03 Bearing

Center spacer

•

Coller

•

•

Front wheel

(7 Tire valve

•

Front axle

•

Brake disc bolt

CHASSIS

6

-11

0

ITEM

OO

N

100

23

•m

kgf-m

10

.0

2

.3

lb-ft

72

.5

16

.5

6.1

CHASSIS

2

~

~

~

~

~

~

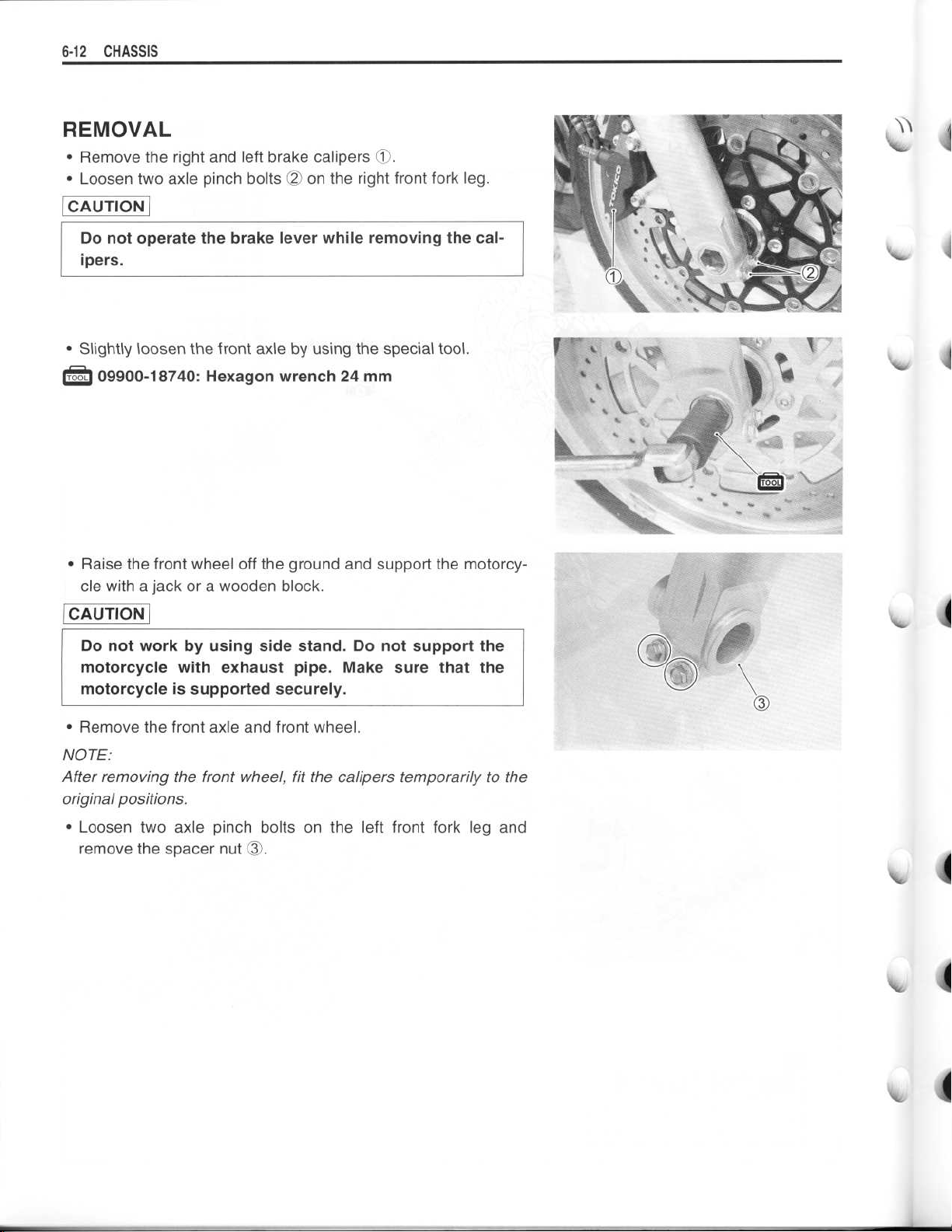

REMOVAL

•

Remove the right and left brake calipers i Ei

•

Loosen two axle pinch bolts OO on the right front fork leg

.

.

CAUTION

Do not operate the brake lever while removing the calipers

.

•

Slightly loosen the front axle by using the special tool

09900-18740

•

Raise the front wheel off the ground and support the motorcycle with a jack or a wooden block

: Hexagon wrench 24 mm

.

.

SW46

.~J

CAUTION

Do not work by using side stand

motorcycle with exhaust pipe

motorcycle is supported securely

•

Remove the front axle and front wheel

NOTE

:

. Do not support the

. Make sure that the

.

.

After removing the front wheel, fit the calipers temporarily to the

original positions

•

Loosen two axle pinch bolts on the left front fork leg and

remove the spacer nut (3

.

.

~

~

~

~

~

.,0

INSPECTION AND DISASSEMBLY

TIRE (=6-95)

BRAKE DISC

•

Remove the brake discs

DUST SEAL

Inspect the dust seal lip for wear or damage

found, replace the dust seal with a new one

(f

7

6-71)

.

. If any damages are

.

CHASSIS 6-13

.r

,

•

Remove the dust seal by using the oil seal remover

. .

09913-50121

CAUTION

Do not reuse the removed dust seal

FRONT AXLE

Using a dial gauge, check the front axle for runout and replace it

if the runout exceeds the limit

Axle shaft runout

•

Service Limit

09900-20607

09900-20701

09900-21304

WHEEL

Make sure that the wheel runout checked as shown does not

exceed the service limit

worn or loosened wheel bearings and can be reduced by replacing the bearings

runout, replace the wheel

(Wheel inspection

: Oil seal remover

.

.

: 0

.25 mm (0

: Dial gauge (1/100 mm)

: Magnetic stand

: V-block set (100 mm)

. An excessive runout is usually due to

. If bearing replacement fails to reduce the

.

:

r -

76-95)

.010 in)

.

•

Wheel runout

Service Limit (Axial and Radial)

: 2

.0 mm (0

.08 in)

~

6- 14CHASSIS

WHEEL BEARING

Inspect the play of the wheel bearings by finger while they are in

the wheel

mal noise and smooth rotation

. Rotate the inner race by finger to inspect for abnor-

.

Replace the bearing in the following procedure if there is anything unusual

.

•

Remove the wheel bearing by using the special tool

09921-20240

: Bearing remover set

.

CAUTION

Do not reuse the removed bearing

.

4

EM

~

~

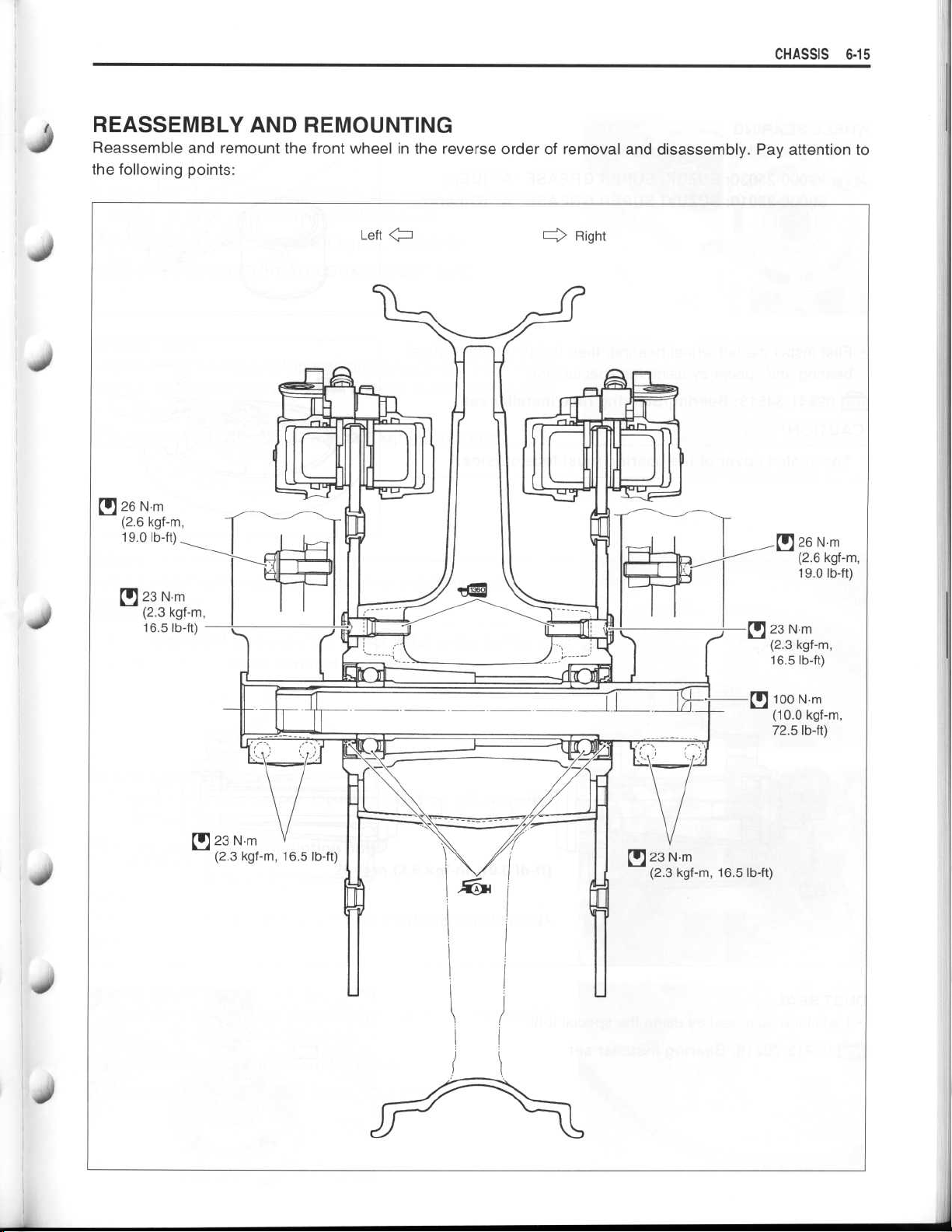

CHASSIS 6-15

REASSEMBLY AND REMOUNTING

Reassemble and remount the front wheel in the reverse order of removal and disassembly

the following points

:

:

Left

E

Right

Oft

n

. Pay attention to

26 N

•m

(2

.6 kgf-m,

19

.0 Ib-ft)

23 N

•m

(2

.3 kgf-m,

16

.5 Ib-ft)

11

Ii

-

t

I-

I

7f"I

23 N

•m

(2

.3 kgf-m, 16

.5 Ib-ft)

I

flit~1)~j

III

u

i

∎

)J]R!

∎

1

I I

1

=

.

r

23 N

•m

(2

.3 kgf-m, 16

23

(2

.3 kgf-m,

16

100

(10

72

.5 Ib-ft)

26 N

•m

(2

.6 kgf-m,

.0 Ib-ft)

19

N

•m

.5 Ib-ft)

N

•m

.0 kgf-m,

.5 Ib-ft)

~

~

~

6-16

CHASSIS

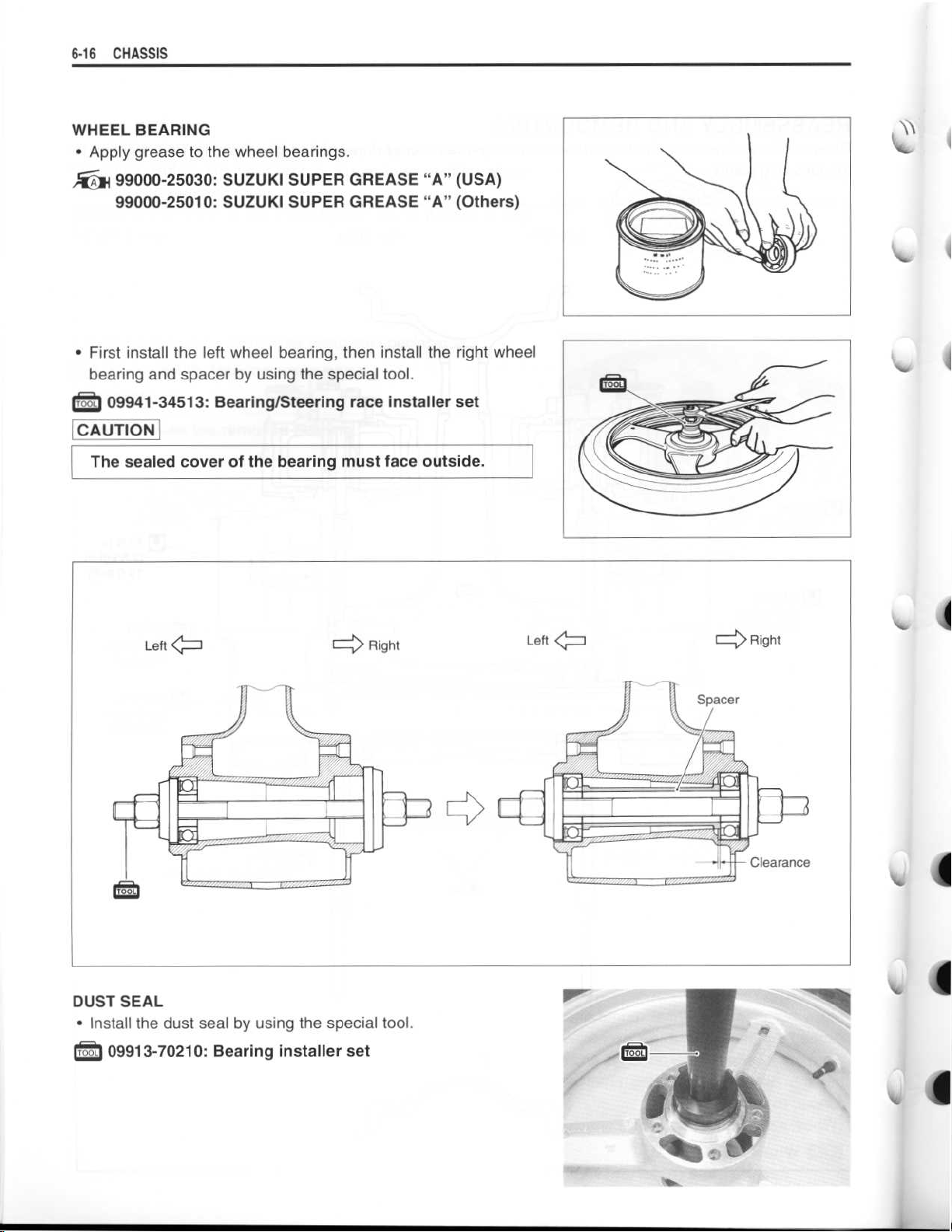

WHEEL BEARING

•

Apply grease to the wheel bearings

.

99000-25030

99000-25010

•

First install the left wheel bearing, then install the right wheel

bearing and spacer by using the special tool

. .

09941-34513

CAUTION

The sealed cover of the bearing must face outside

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

.

: Bearing/Steering race installer set

.

DUST SEAL

•

Install the dust seal by using the special tool

. .

09913-70210

: Bearing installer set

.

I

I

I

~

~

~

~

~

~

~

CHASSIS 6-17

BRAKE DISC

Make sure that the brake disc is clean and free of any greasy

matter

.

•

Apply THREAD LOCK SUPER to the brake disc mounting

bolts and tighten them to the specified torque

.

Ij

40

Brake disk bolt

0

99000-32130

SPACER NUT

After touching the flange of spacer nut being contact with the left

front fork leg, tighten two axle pinch bolts on the left front fork leg

to the specified torque

Front axle pinch bolt

•

WHEEL

Install the front wheel and tighten the front axle temporarily

A

WARNING

The directional arrow on the wheel must point to the

wheel rotation, when remounting the wheel

: 23 N

.m (2

.3 kgf-m, 16

: THREAD LOCK SUPER "1360"

.

: 23 N

.m (2 .3 kgf-m, 16

.5

ID-TI)

.5 lb-ft)

.

.

BRAKE CALIPER

•

Tighten the brake caliper mounting bolts to the specified

torque

.

•

Front brake caliper mounting bolt

NOTE

:

Push the pistons all the way into the caliper and remount the calipers

.

FRONT AXLE

•

Tighten the front axle to the specified torque with the special

tool

.

:

.

09900-18740

Front axle

•

: Hexagon wrench 24 mm

: 100 N

.m (10

.0 kgf-m, 72

26 N

:

.m (2

.6 kgf-m, 19

.5 lb-ft)

.0 lb-ft)

~

6- 18CHASSIS

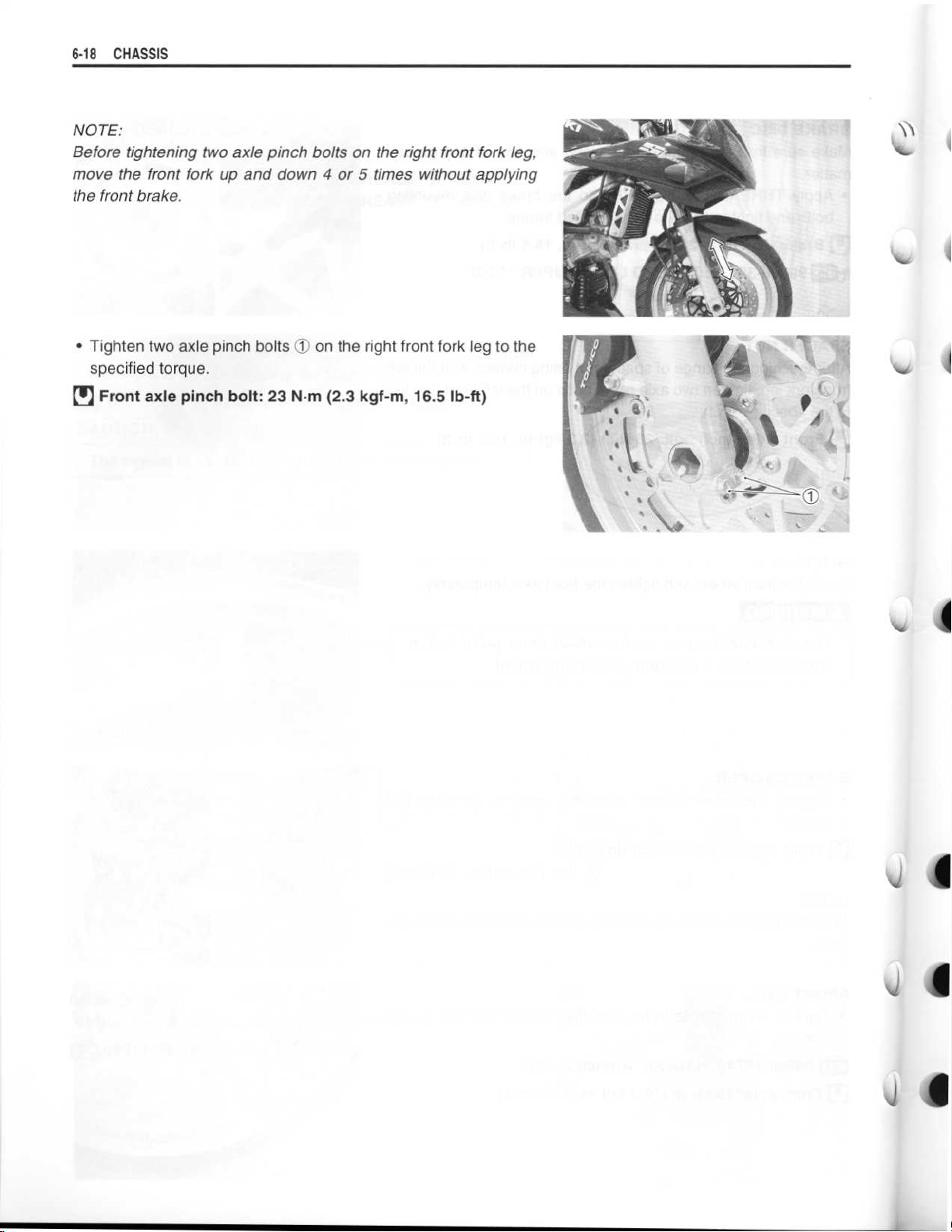

NOTE

:

Before tightening two axle pinch bolts on the right front fork leg,

move the front fork up and down 4 or 5 times without applying

the front brake

•

Tighten two axle pinch bolts 1O on the right front fork leg to the

specified torque

.

.

4

Front axle pinch bolt

0

: 23 N-rn (2

.3 kgf-m, 16

.5 lb-ft)

IN

~

-4

Id

-40

CHASSIS

6-19

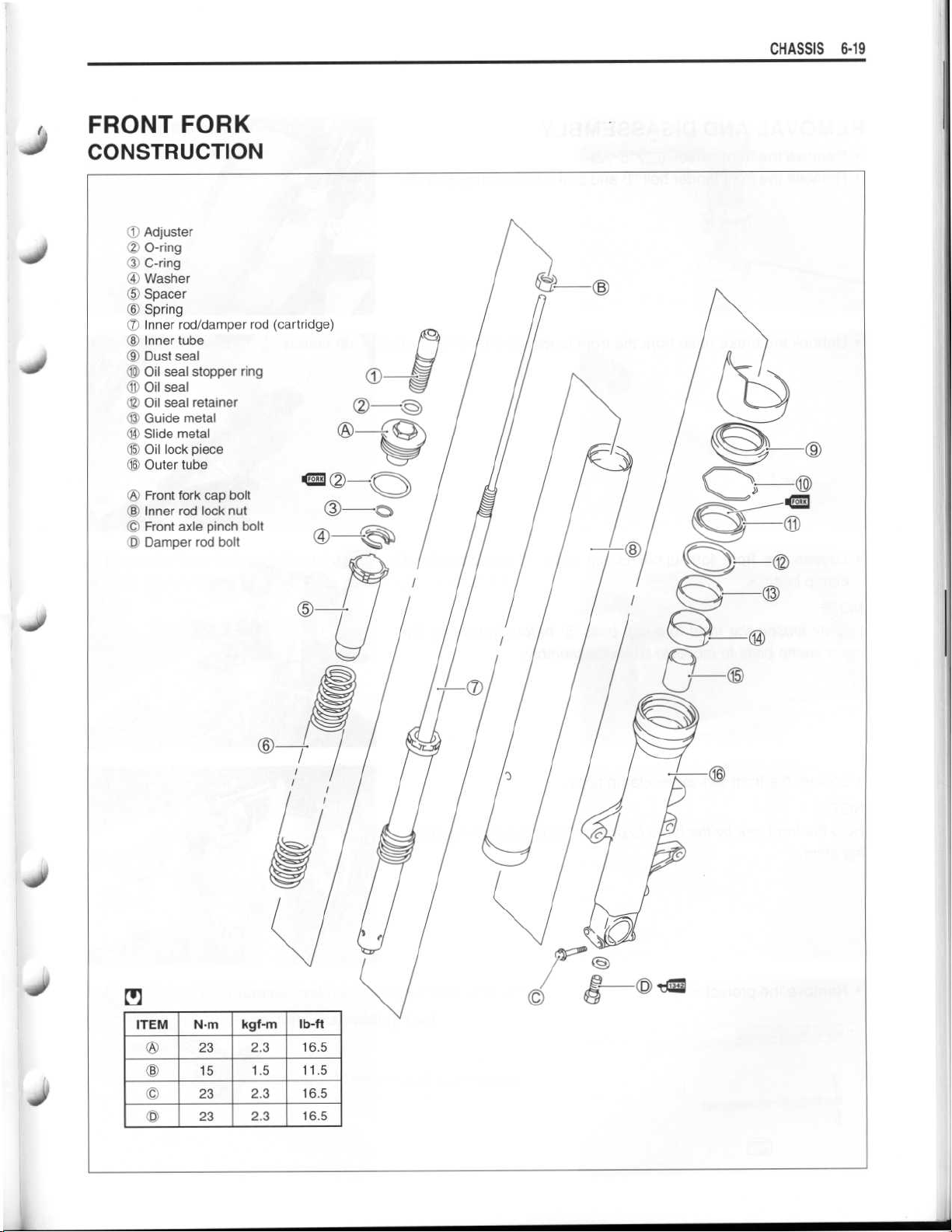

FRONT FORK

0

CONSTRUCTION

90 Adjuster

02 O-ring

O3 C-ring

® Washer

05 Spacer

© Spring

7~ Inner rod/damper rod (cartridge)

•

Inner tube

~9 Dust seal

1o Oil seal stopper ring

11 Oil seal

© Oil seal retainer

13 Guide metal

14 Slide metal

© Oil lock piece

16 Outer tube

•

Front fork cap bolt

•

Inner rod lock nut

Front axle pinch bolt

•

© Damper rod bolt

J)

si

QQ

o

law

40

0

ITEM

OO

©

J

©

0

N

.m

23

15

23

23

kgf-m

2

2

2

Ib-ft

.3

16

.5

1

.5

11

.5

.3

16

.5

.3

165

~

~

~

~

~

~

~

6

.20 CHASSIS

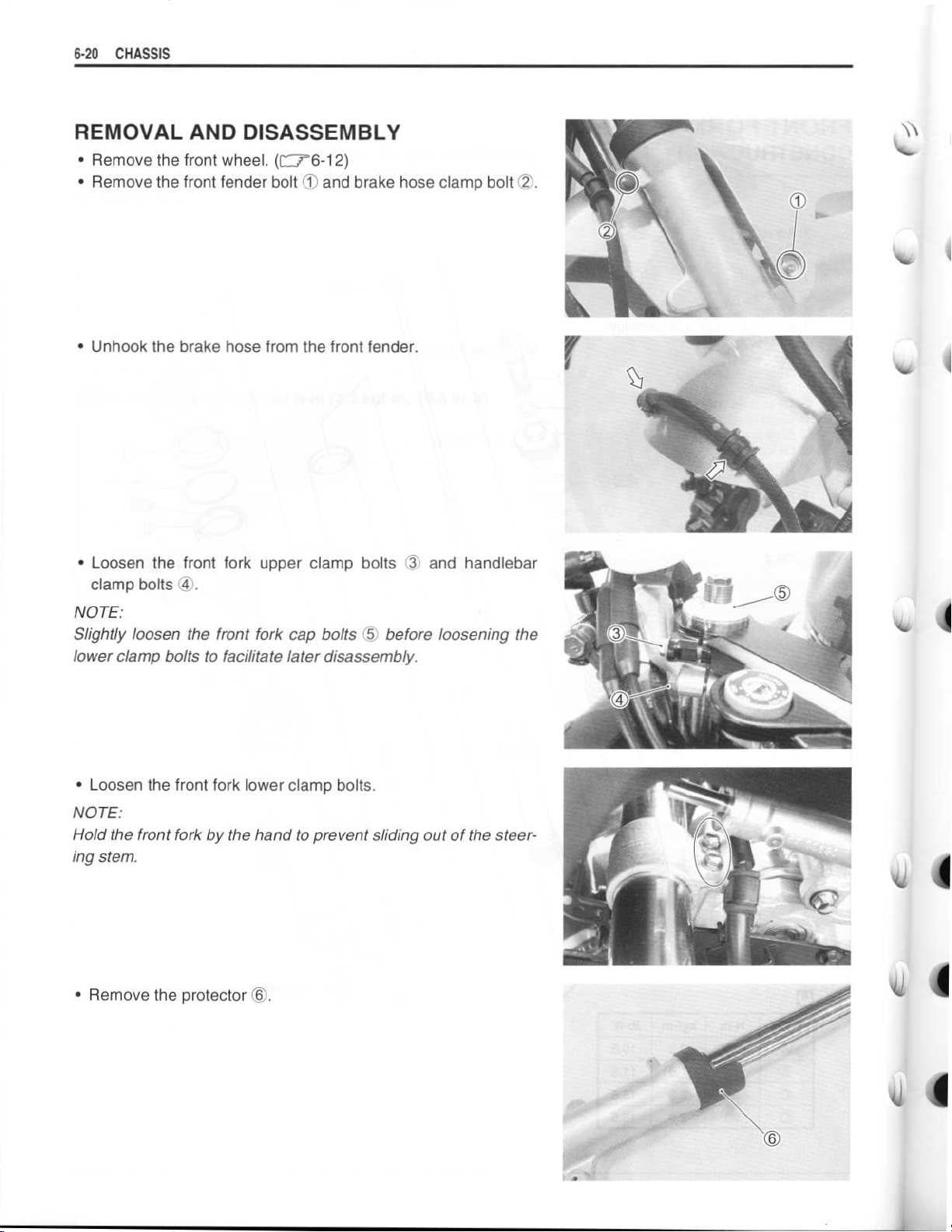

REMOVAL AND DISASSEMBLY

•

Remove the front wheel

•

Remove the front fender bolt r10 and brake hose clamp bolt

•

Unhook the brake hose from the front fender

.

(F-

76-12)

.

~tl

OO

.

w~.

.

•

Loosen the front fork upper clamp bolts (3

clamp bolts ®

NOTE

:

.

Slightly loosen the front fork cap bolts

lower clamp bolts to facilitate later disassembly

•

Loosen the front fork lower clamp bolts

NOTE

:

.

and handlebar

before loosening the

.

Hold the front fork by the hand to prevent sliding out of the steering stem

•

.

Remove the protector ©

.

~

~

~

~

~

CHASSIS6.21

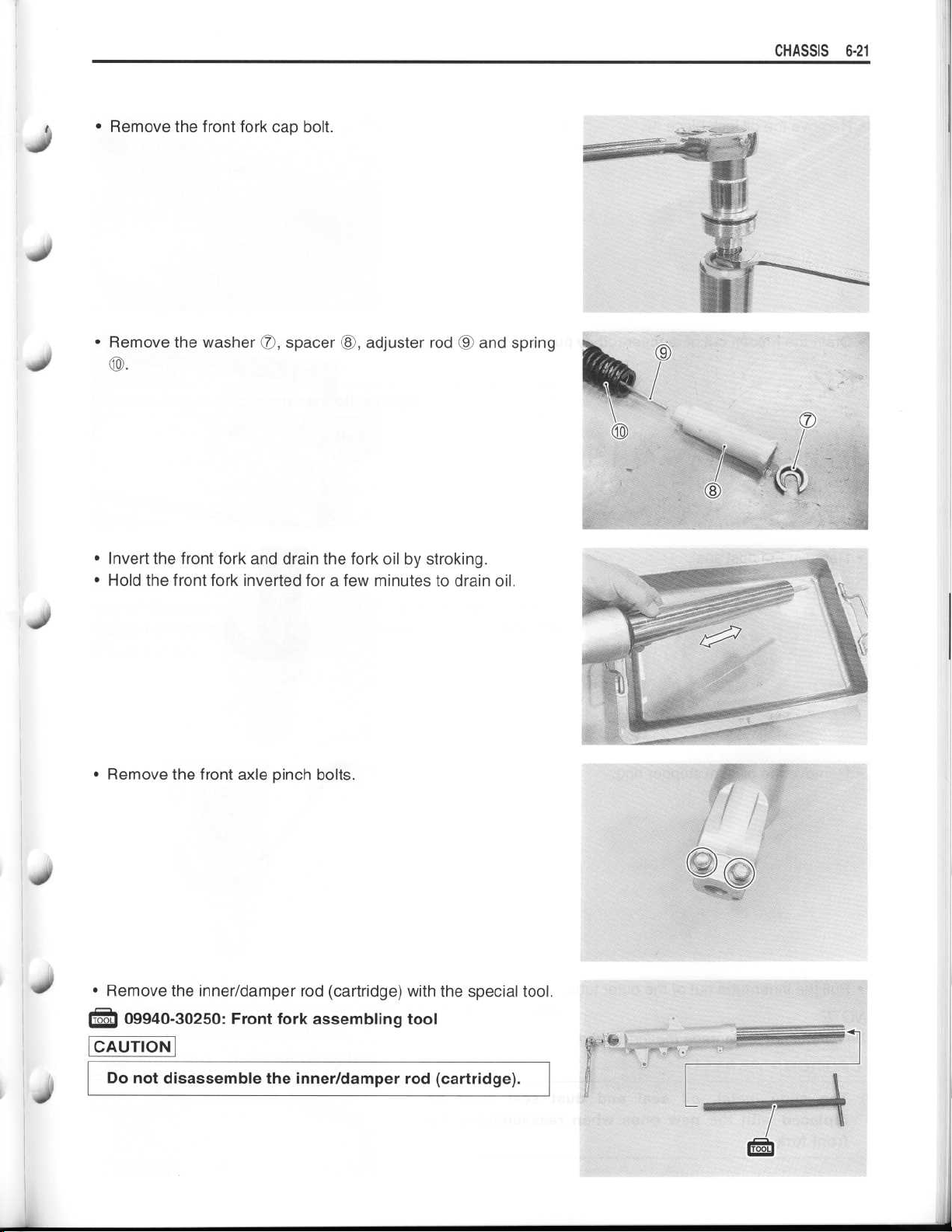

• Remove the front fork cap bolt

•

Remove the washer (7

(S

.

•

Invert the front fork and drain the fork oil by stroking

•

Hold the front fork inverted for a few minutes to drain oil

,

.

spacer ®, adjuster rodOand spring

.

.

•

Remove the front axle pinch bolts

•

Remove the inner/damper rod (cartridge) with the special tool

.

.

09940-30250

CAUTION

Do not disassemble the inner/damper rod (cartridge)

: Front fork assembling tool

.

.

.

~

~

~

~

~

6

.22 CHASSIS

•

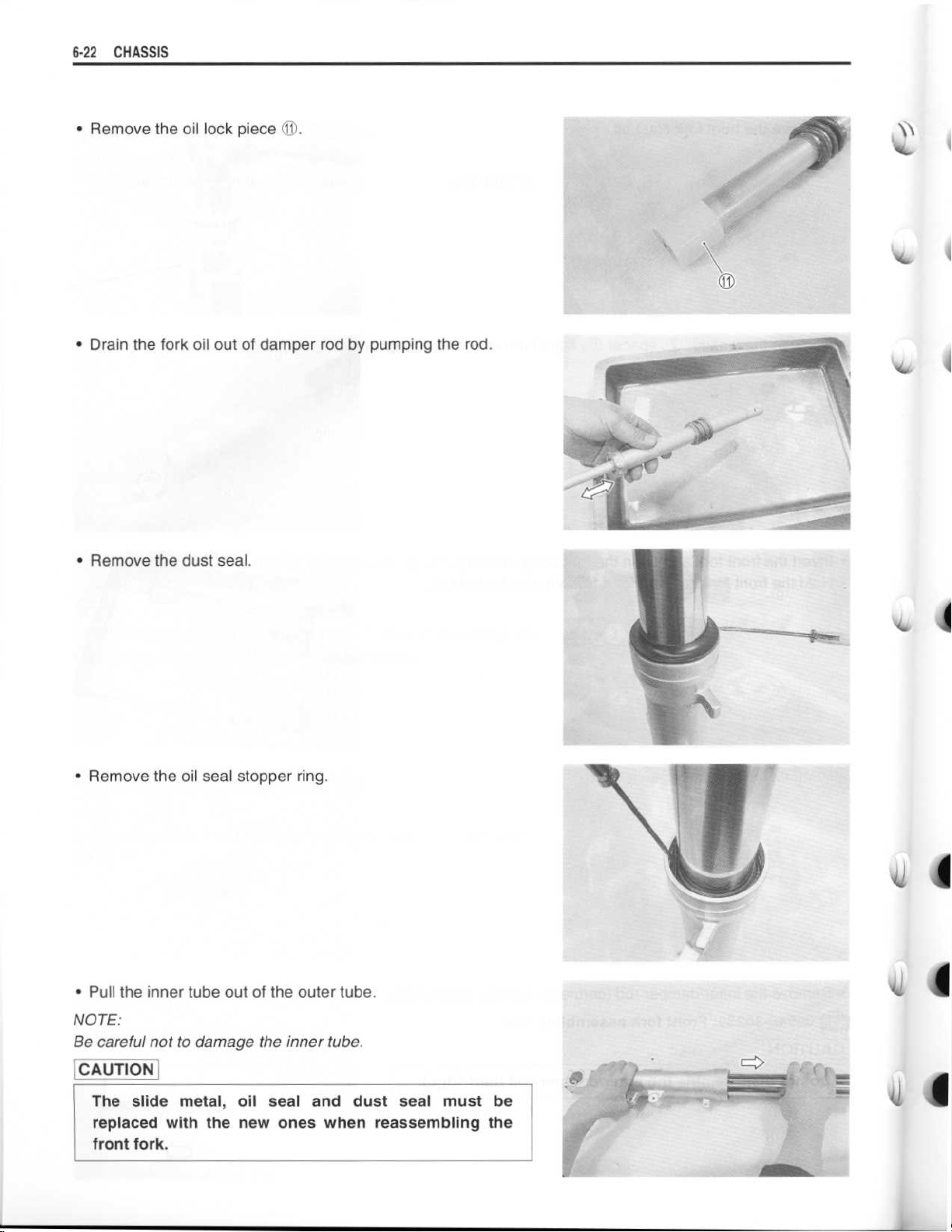

Remove the oil lock piece

•

Drain the fork oil out of damper rod by pumping the rod

j

ij

.

.

•

Remove the dust seal

•

Remove the oil seal stopper ring

•

Pull the inner tube out of the outer tube

.

.

.

44

NOTE

:

Be careful not to damage the inner tube

CAUTION

The slide metal, oil seal and

replaced with the new ones when reassembling the

front fork

.

.

dust seal must be

~

~

CHASSIS6-23

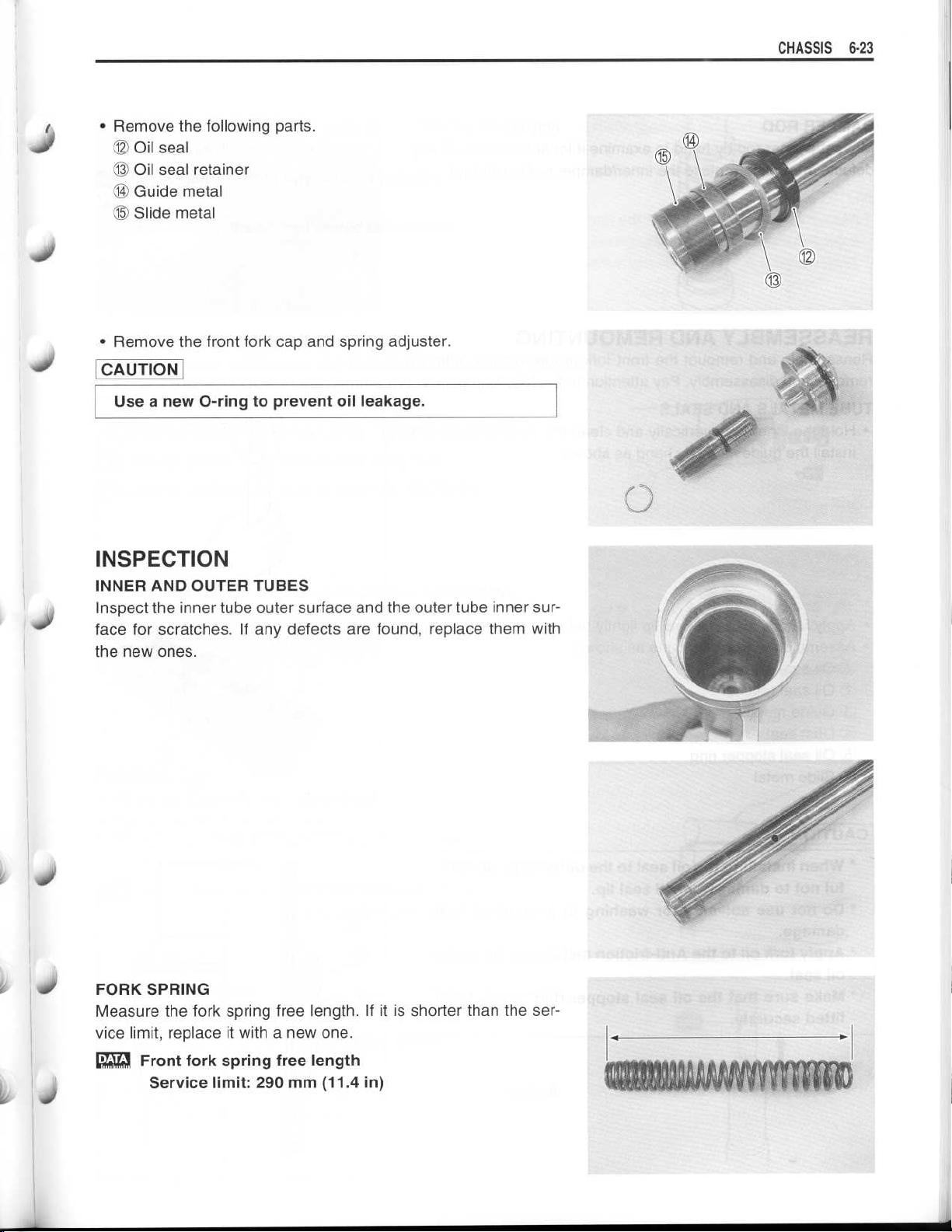

• Remove the following parts

.

Oil seal

13 Oil seal retainer

14 Guide metal

15 Slide metal

•

Remove the front fork cap and spring adjuster

.

CAUTION

Use a new 0-ring to prevent oil leakage

.

INSPECTION

INNER AND OUTER TUBES

Inspect the inner tube outer surface and the outer tube inner surface for scratches . If any defects are found, replace them with

the new ones

.

13

11

FORK SPRING

Measure the fork spring free length

vice limit, replace it with a new one

(

Front fork spring free length

Service limit

: 290 mm (11

. If it is shorter than the ser-

.

.4 in)

~

~

~

~

~

~

~

~

~

~

~

-24 CHASSIS

6

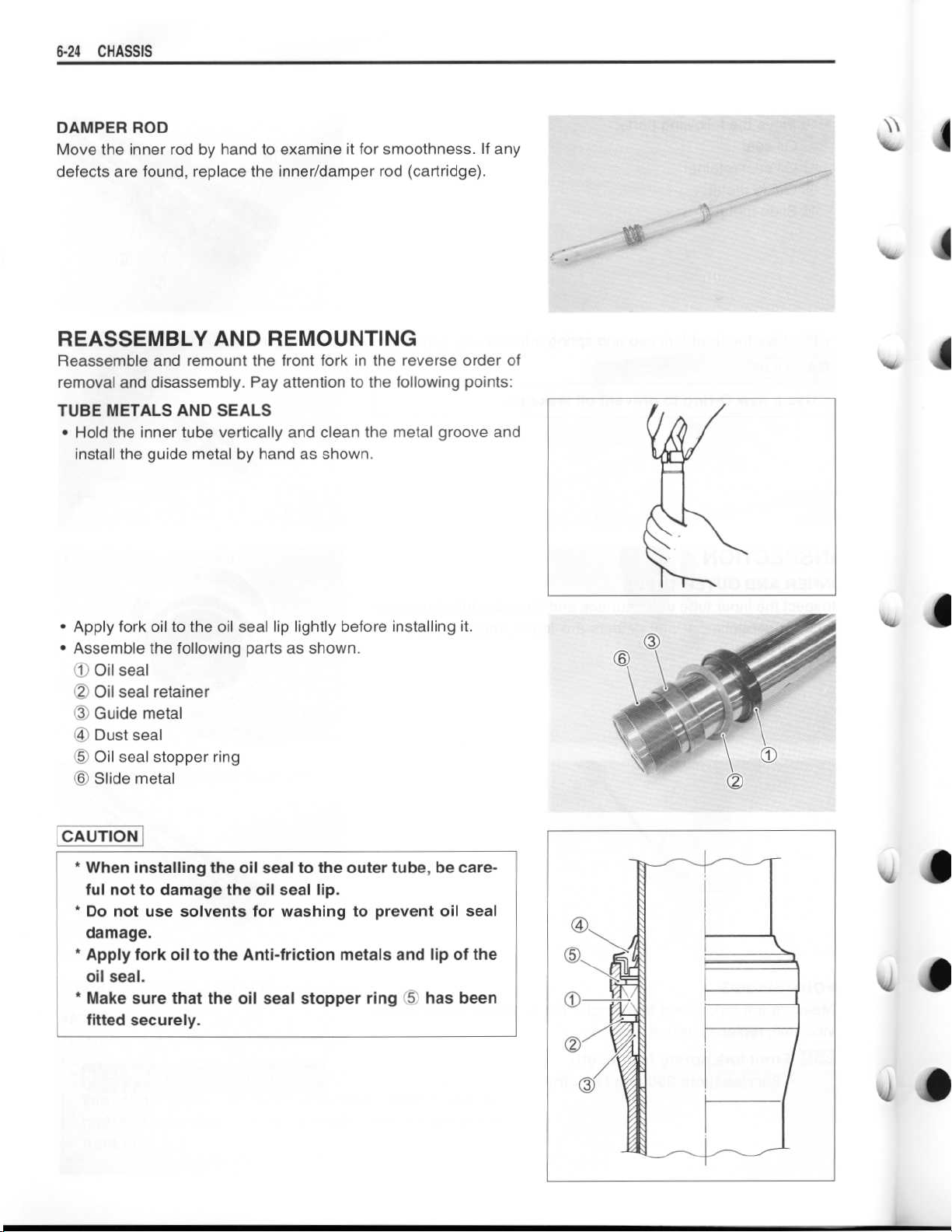

DAMPER ROD

Move the inner rod by hand to examine it for smoothness

defects are found, replace the inner/damper rod (cartridge)

REASSEMBLY AND REMOUNTING

Reassemble and remount the front fork in the reverse order of

removal and disassembly

TUBE METALS AND SEALS

Hold the inner tube vertically and clean the metal groove and

•

install the guide metal by hand as shown

. Pay attention to the following points

.

. If any

.

:

\\

1W

•

Apply fork oil to the oil seal lip lightly before installing it

•

Assemble the following parts as shown

•

Oil seal

02 Oil seal retainer

Guide metal

•

•

Dust seal

Oil seal stopper ring

O5

Slide metal

•

CAUTION

* When installing the oil seal to the outer tube, be care-

ful not to damage the oil seal lip

•

Do not use solvents for washing to prevent oil seal

damage

•

Apply fork oil to the Anti-friction metals and lip of the

oil seal

•

Make sure that the oil seal stopper ring

fitted securely

.

.

.

.

.

05

.

has been

02

~

~

~

~

~

~

~

CHASSIS 6-25

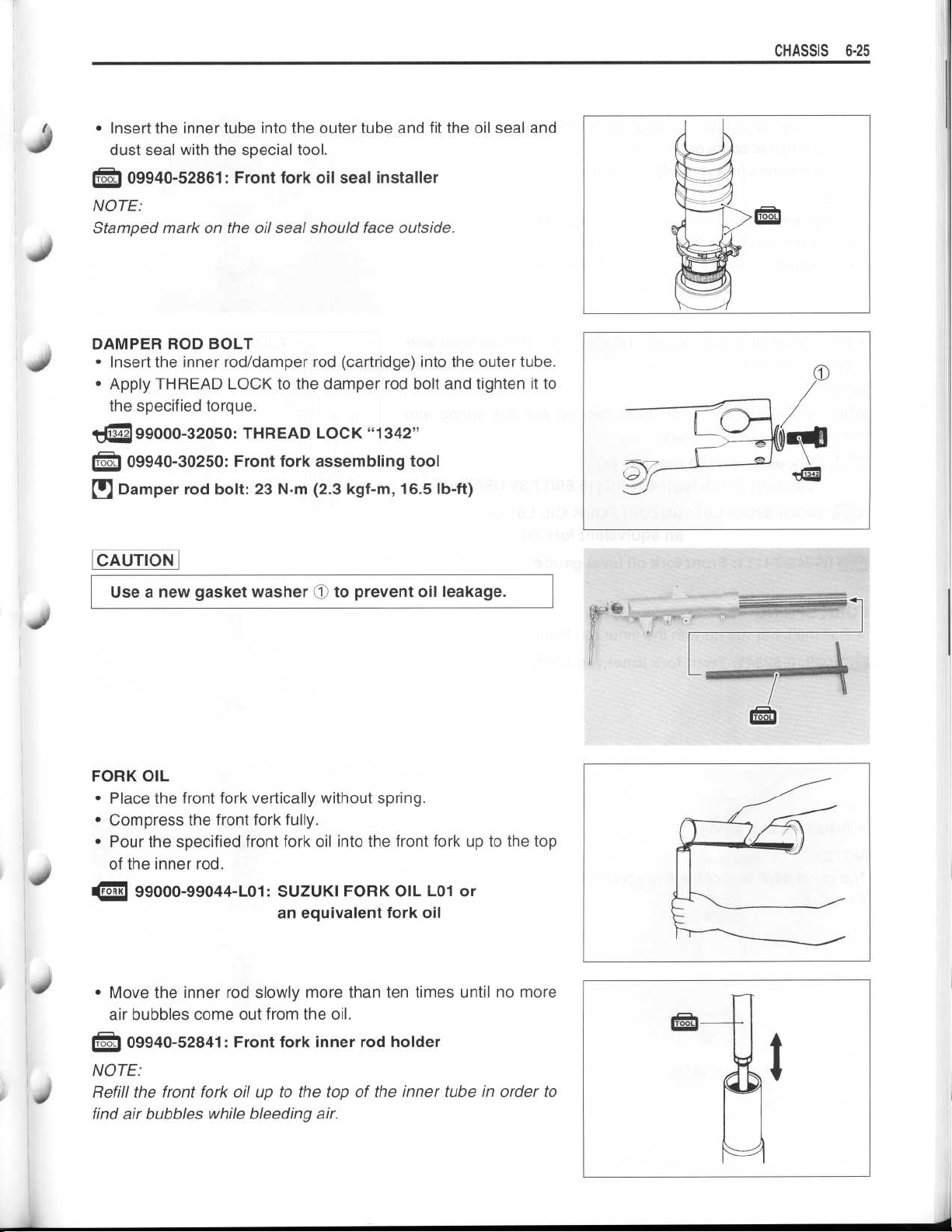

•

Insert the inner tube into the outer tube and fit the oil seal and

dust seal with the special tool

. .

09940-52861

NOTE

:

Stamped mark on the oil seal should face outside

i

DAMPER ROD BOLT

•

Insert the inner rod/damper rod (cartridge) into the outer tube

•

Apply THREAD LOCK to the damper rod bolt and tighten it to

the specified torque

: Front fork oil seal installer

.

.

.

.

99000-32050

09940-30250

Damper rod bolt

0

CAUTION

Use a new gasket washerDto prevent oil leakage

FORK OIL

Place the front fork vertically without spring

•

•

Compress the front fork fully

Pour the specified front fork oil into the front fork up to the top

•

of the inner rod

99000-99044-LOl

: THREAD LOCK "1342"

: Front fork assembling tool

: 23 N

.m (2 .3 kgf-m, 16

.

.

: SUZUKI FORK OIL L01 or

an equivalent fork oil

.5 Ib-ft)

.

.

im

Move the inner rod slowly more than ten times until no more

•

air bubbles come out from the oil

09940-52841

NOTE

:

Refill the front fork oil up to the top of the inner tube in order to

find air bubbles while bleeding air

: Front fork inner rod holder

.

.

~

~

~

~

~

6-26

CHASSIS

•

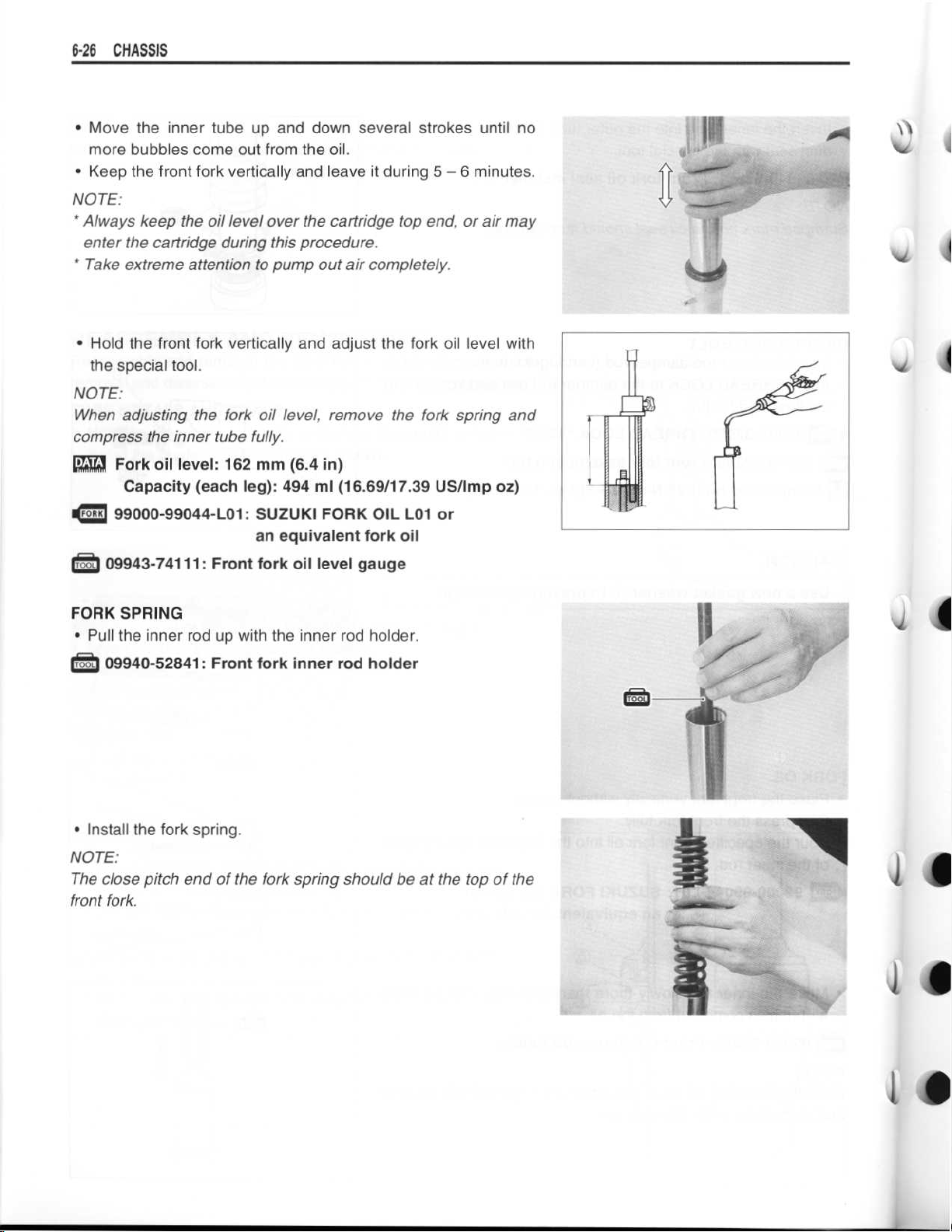

Move the inner tube up and down several strokes until no

more bubbles come out from the oil

•

Keep the front fork vertically and leave it during 5 - 6 minutes

NOTE

:

.

.

* Always keep the oil level over the cartridge top end, or air may

enter the cartridge during this procedure

* Take extreme attention to pump out air completely

•

Hold the front fork vertically and adjust the fork oil level with

the special tool

NOTE

:

.

.

.

When adjusting the fork oil level, remove the fork spring and

compress the inner tube fully

.

Fork oil level

Capacity (each leg)

99000-99044-LOl

: 162 mm (6

.4 in)

: 494 ml (16 .69/17

: SUZUKI FORK OIL L01 or

.39 US/Imp oz)

an equivalent fork oil

09943-74111

: Front fork oil level gauge

FORK SPRING

•

Pull the inner rod up with the inner rod holder

.

.

09940-52841

•

Install the fork spring

NOTE

:

: Front fork inner rod holder

.

.

The close pitch end of the fork spring should be at the top of the

front fork

.

~

~

~

~

~

CHASSIS 6-27

a/

40

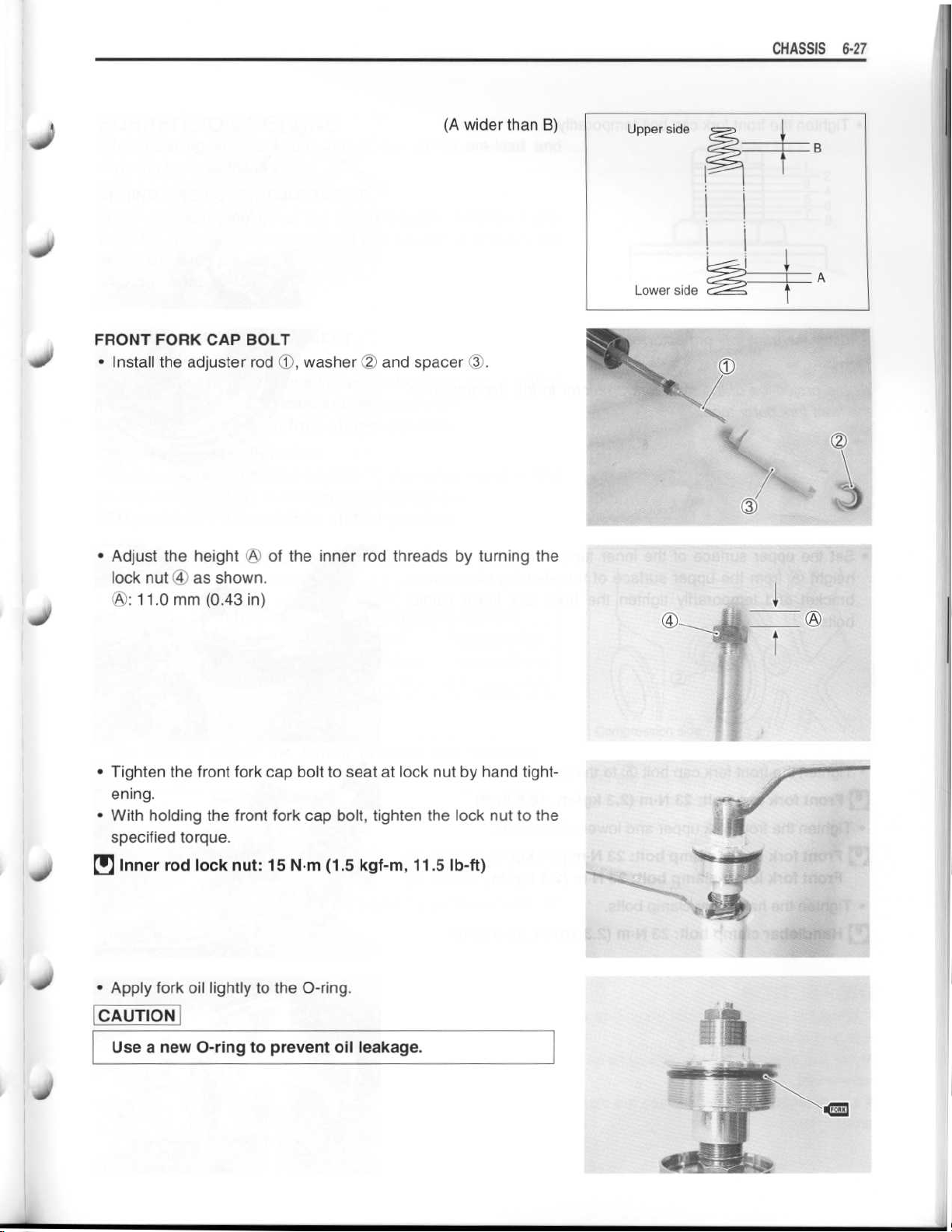

(A wider than B)

FRONT FORK CAP BOLT

0

•

Install the adjuster rodO,washer 02 and spacer

•

Adjust the heightOof the inner rod threads by turning the

lock nut ® as shown

:

OA

11

.0 mm (0

.

.43 in)

(T

.

Upper side

Lower side

1

10

40

•

Tighten the front fork cap bolt to seat at lock nut by hand tightening

.

•

With holding the front fork cap bolt, tighten the lock nut to the

specified torque

Inner rod lock nut

0

•

Apply fork oil lightly to the 0-ring

CAUTION

Use a new O-ring to prevent oil leakage

.

: 15 N

.m (1

.5 kgf-m, 11

.

.5 Ib-ft)

.

~

~

~

~

~

~

~

~

6-

2 8

CHASSIS

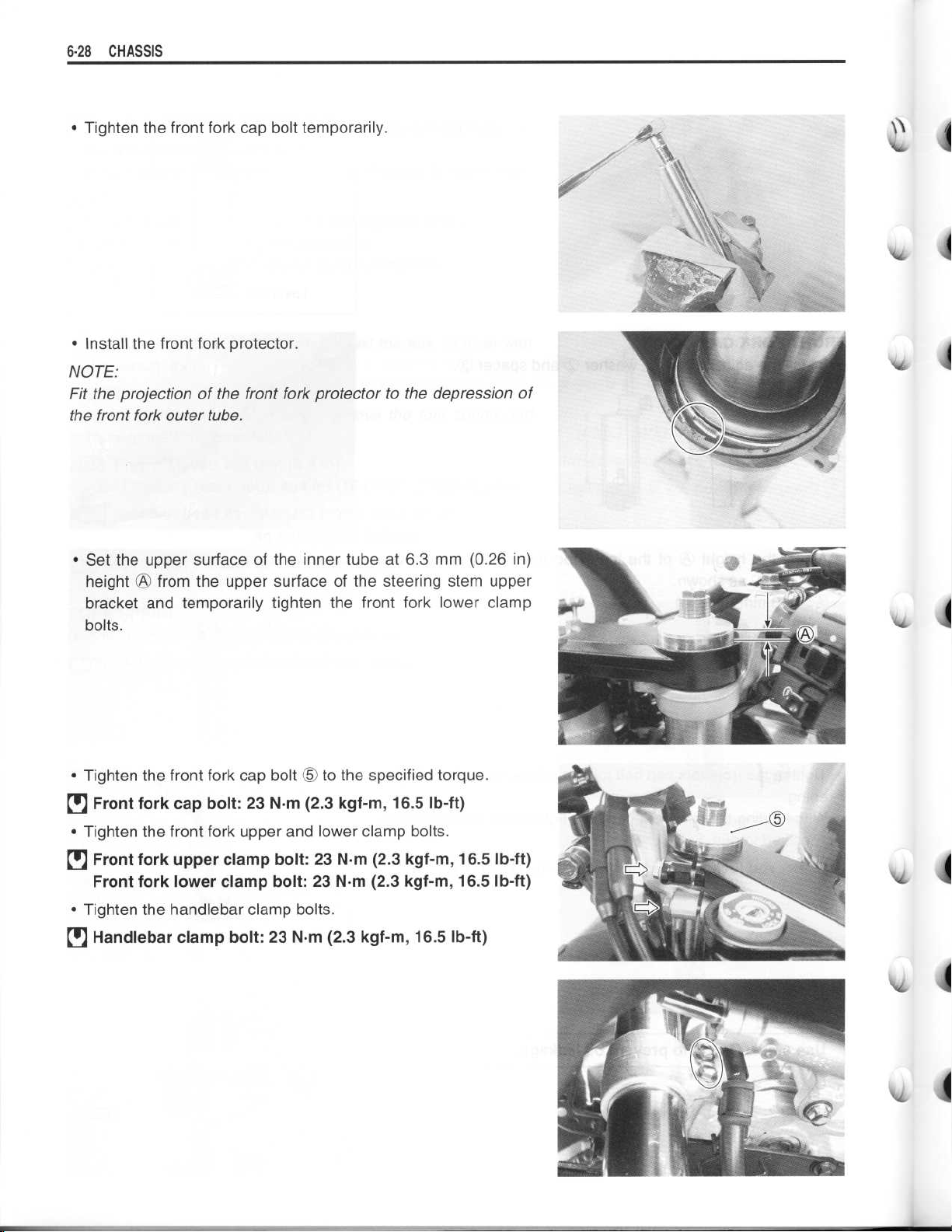

Tighten the front fork cap bolt temporarily

•

•

Install the front fork protector

NOTE

:

Fit the projection of the front fork protector to the depression of

the front fork outer tube

Set the upper surface of the inner tube at 6

•

height AO from the upper surface of the steering stem upper

bracket and temporarily tighten the front fork lower clamp

bolts

.

.

.

.

.3 mm (0

.26 in)

•

Tighten the front fork cap bolt

•

Front fork cap bolt

•

Tighten the front fork upper and lower clamp bolts

Front fork upper clamp bolt

•

Front fork lower clamp bolt

•

Tighten the handlebar clamp bolts

Handlebar clamp bolt

•

: 23 N

OO

to the specified torque

.m (2

.3 kgf-m, 16

: 23 N

.m (2

: 23 N-m (2

.

: 23 N

.m (2 .3 kgf-m, 16

.5 lb-ft)

.

.3 kgf-m, 16

.3 kgf-m, 16

.5 lb-ft)

.5 lb-ft)

.5 lb-ft)

.

14

~

~

~

~

~

4

.rte

S

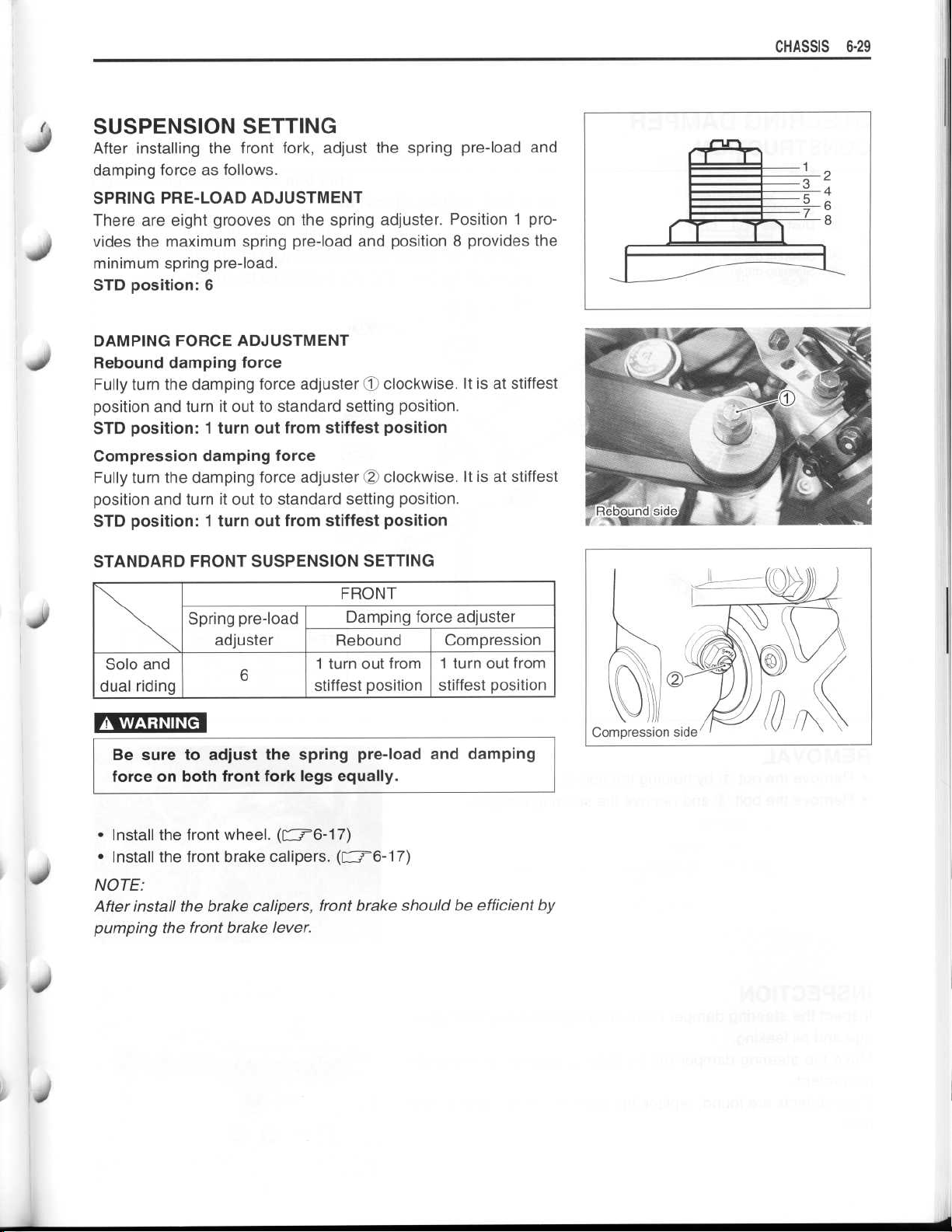

SUSPENSION SETTING

After installing the front fork, adjust the spring pre-load and

damping force as follows

SPRING PRE-LOAD ADJUSTMENT

There are eight grooves on the spring adjuster

vides the maximum spring pre-load and position 8 provides the

minimum spring pre-load

STD position

DAMPING FORCE ADJUSTMENT

Rebound damping force

Fully turn the damping force adjuster 1O clockwise

position and turn it out to standard setting position

STD position

Compression damping force

Fully turn the damping force adjuster 02 clockwise

position and turn it out to standard setting position

STD position

: 6

: 1 turn out from stiffest position

: 1 turn out from stiffest position

.

. Position 1 pro-

.

. It is at stiffest

.

. It is at stiffest

.

CHASSIS 6-29

1

2

3

4

5

6

7

8

4

STANDARD FRONT SUSPENSION SETTING

FRONT

Spring pre-load

adjuster

Solo and

dual riding

WARNING

A

Be sure to adjust the spring pre-load and damping

force on both front fork legs equally

•

Install the front wheel

•

Install the front brake calipers

NOTE

:

After install the brake calipers, front brake should be efficient by

pumping the front brake lever

6

. (CIr6-17)

Damping force adjuster

Rebound

1 turn out from 1 turn out from

stiffest position stiffest position

.

.

(r

--

r6-17)

.

Compression

~

~

~

~

6-30

CHASSIS

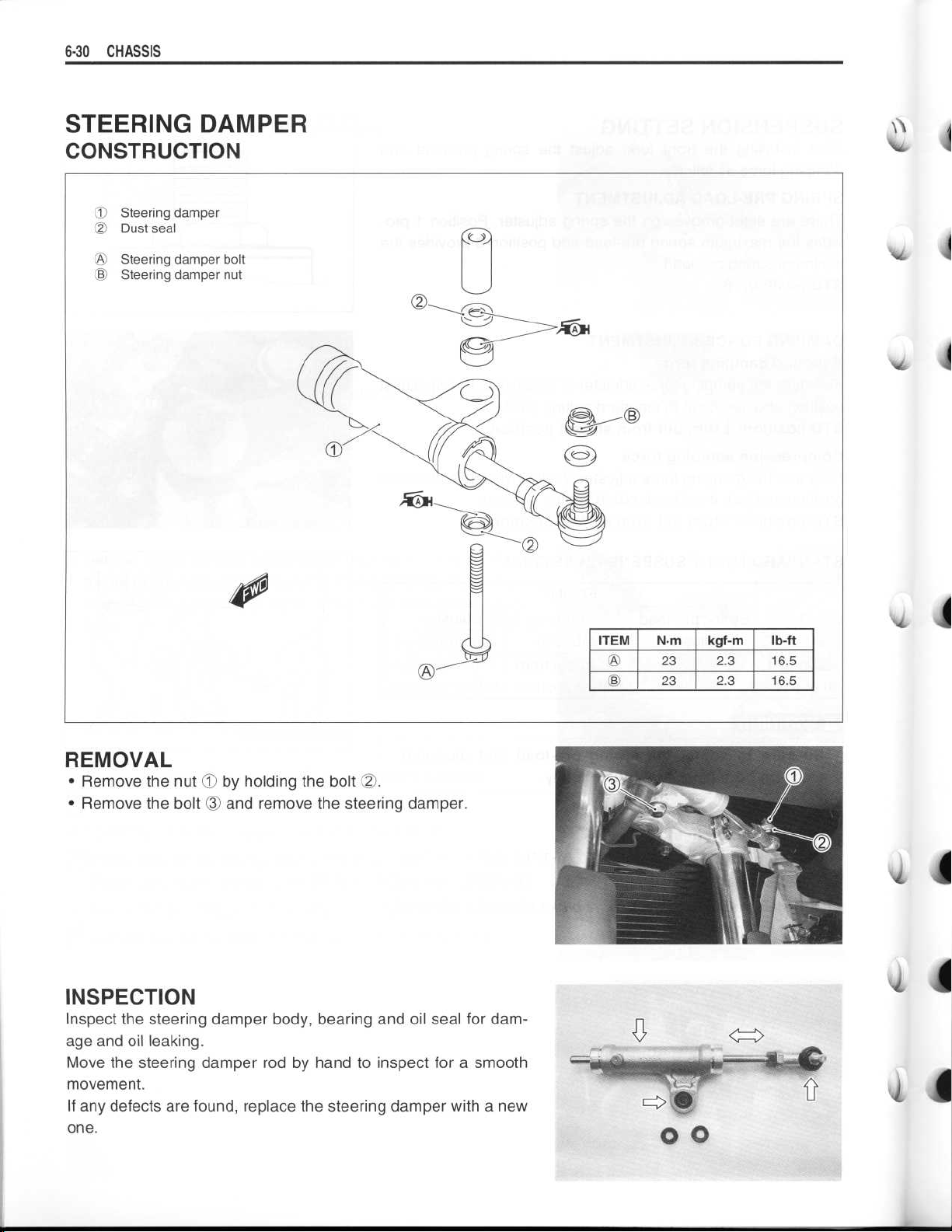

STEERING DAMPER

CONSTRUCTION

T

Steering damper

(2

Dust seal

•

Steering damper bolt

Steering damper nut

•

ITEM N

OO

©

REMOVAL

•

Remove the nut 90 by holding the bolt 02

•

Remove the bolt 03 and remove the steering damper

.

.

INSPECTION

Inspect the steering damper body, bearing and oil seal for damage and oil leaking

Move the steering damper rod by hand to inspect for a smooth

movement

.

If any defects are found, replace the steering damper with a new

one

.

.

23

23

•m

kgf-m

2

.3

2

.3

Ib-ft

16

.5

16

.5

Loading...

Loading...