Page 1

READ AND UNDERSTAND ALL STEPS OF THESE INSTRUCTIONS

BEFORE BEGINNING THIS INSTALLATION.

SUZUKI SAMURAI

For kit no. K600

using (1) Weber 32 DGAV

(Legal in California ONLY for racing vehicles which may NEVER be used upon a highway.)

Tools and equipment needed: Parts supplied with installation kit:

Combination, box or open end wrenches 1- 32 DGAV Weber Carburetor

(metric) 1- Manifold Adapter

Socket set with 12mm socket 1- Air Cleaner Adapter

Screwdriver (regular and phillips) 1- Cable Bracket

Pliers 1- Hardware Kit

Gasket scraper

Cleaning solvent and rags

Knife

Gasket sealer

Tune-Up Specifications

All tune-up specifications for the Weber Carburetor remain the same as those specified by the

Factory for the original unit. Emissions tune-up should be carried out by a suitably qualified dealer

or independent garage, using infrared gas analyzing equipment.

NOTE: late model vehicles fitted with Emission Control Systems have many vacuum lines and

electrical connections in their fuel systems. It is essential when dismantling, that disconnected lines

be identified with a corresponding number tag or label system. To establish function, locate and

identify the source of each line. Use the under hood emissions diagram, or the factory service

manual for reference when identifying hoses.

Page 2

Disassembly

1. Disconnect the vehicle’s battery.

2. Remove the gas cap.

3. Drain approximately one (1) quart of engine coolant.

CAUTION: Hot water may be present.

4. Using either the map inside the vehicle’s engine compartment, or a factory service manual

for your year/make vehicle: tag each hose, vacuum line and electrical wire/connector

attached to the original carburetor and air filter assembly for proper identification during

reassembly. Disconnect all connections once they are identified.

5. Disconnect and remove the flexible connector and the sheet metal elbow between the

carburetor and the air cleaner housing.

6. Disconnect the fuel line from the original carburetor.

Plug the end of the fuel line to prevent leakage.

7. Disconnect the throttle cable from the throttle lever and the cable bracket.

8. Remove the four (4) nuts that secure the carburetor to the intake manifold. Remove the

carburetor and the spacer/gasket. Insert a clean rag into the intake ports to prevent dirt

and gasket material from entering the engine.

9. Remove the stock carburetor mounting studs from the intake manifold. NOTE: For correct

stud removal or installation, use stud removal/installation tool or the “double-nut” method.

DOUBLE-NUT METHOD: Install two nuts approximately half way down the stud. Lock the

nuts together. Turn the lo

wer nut for removal and the upper nut for installation.

10. Clean the intake manifold flange surface thoroughly.

ASSEMBLY

11. Remove the rag from the intake manifold.

12. Apply Loc-Tite (supplied) to the 8mm end of the stud into the two holes of the manifold

closer to the passenger side fenderwell.

13. Using appropriate gasket sealer, slide the smaller of the supplied adapter gaskets over the

two studs so that the larger hole is closer to the valve cover.

14. Slide the manifold adapter over the two studs in the same manner as the gasket and using

Loc-Tite (supplied) on the tow allen bolts supplied secure it to the manifold.

Torque the bolts to 7 ft/lbs.

15. Install 8mm studs into threaded holes of the manifold adapter (apply Loc-Tite to the studs)

insuring that the studs go no further than flush with the bottom of the adapter.

16. Slide the remaining gasket over the studs (with the large hole facing the valve cover), fol-

lowed by the Weber carburetor (insuring that the linkage faces the firewall). The AntiBackfire Valve bracket may require bending for clearance.

17. Slide the supplied cable bracket over the two (2) adapter studs closer to the valve cover.

18. Using the nuts and washers supplied, secure the carburetor to the manifold and adapter;

and tighten, in a criss-cross fashion to 7 ft/lbs.

Page 3

19. Re-route the throttle cable so that it runs from the firewall to the front of the valve cover and

back around to the installed bracket. (Run cable under and through the PCV hoses and tee.)

Install the cable on to the cable bracket and throttle lever.

20. Remove the throttle pedal stop adjustment bolt and nut from the floor of the passenger

compartment.

21. Adjust throttle cable at the cable bracket so that full throttle can be achieved, AND, the

throttle returns fully to an idle position (choke plates should be held open to bypass idle

kick-up of choke linkage).

CHECK THROTTLE OPERATION FOR FREE MOVEMENT. IF THERE IS ANY BINDING

OR STICKING, CORRECT AS NECESSARY BEFORE PROCEEDING.

22. Remove the original water choke hose from the back of the intake manifold. Using the new

hose and clamps supplied, install the hose between the fitting at the back of the manifold

and the upper fitting of the water choke housing on the Weber carburetor. Connect the

remaining original water hose to the lower fitting of the water choke housing.

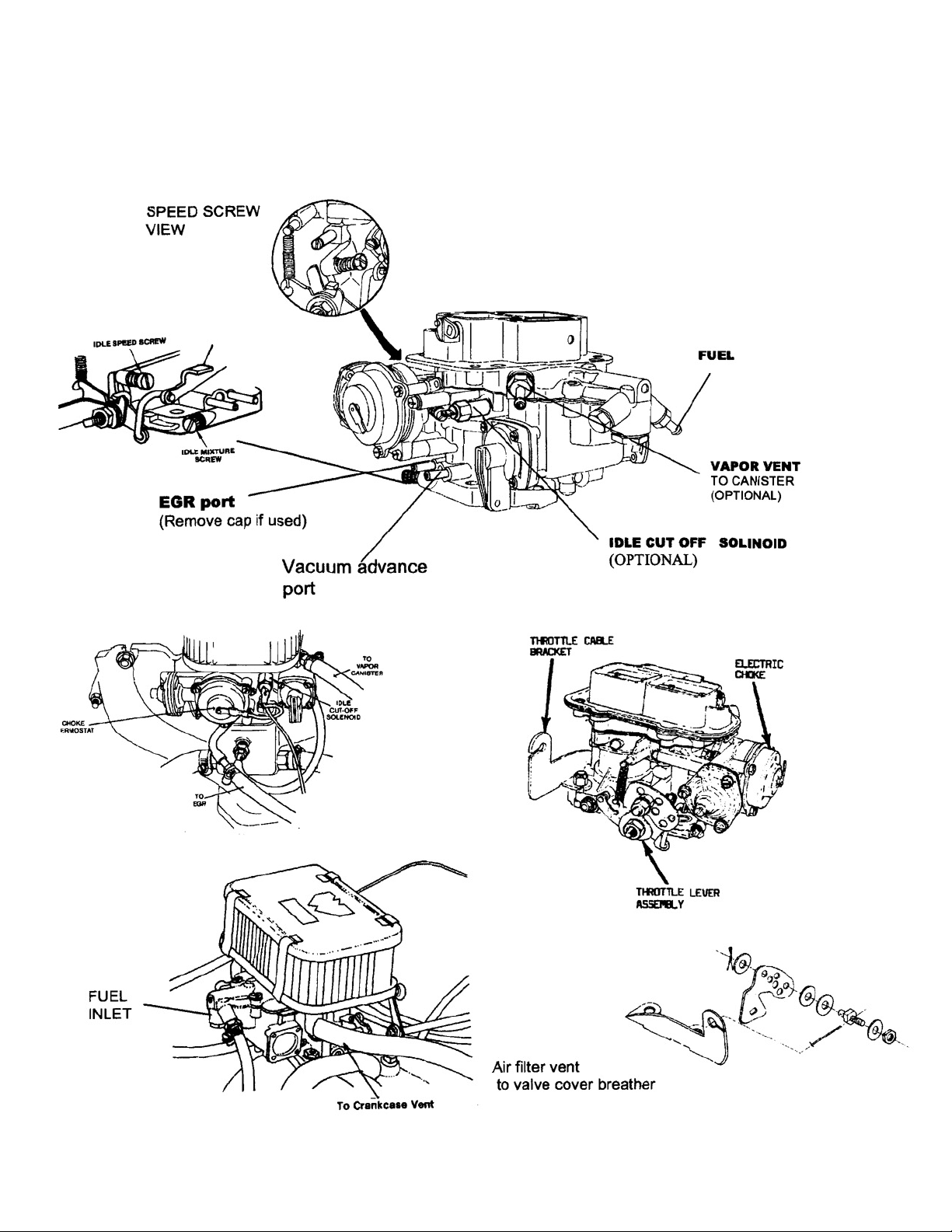

23. Connect the supplied vacuum hose between the vacuum advance unit of the distributor and

vacuum fitting on the base of the Weber carburetor that faces the passenger side fenderwell.

24. Connect the original float bowl vent hose to the 90 degree fitting on the passenger side of

the Weber carburetor.

25. Remove the plug from the original fuel line and connect the line to the fitting on the driver’s

side of the Weber carburetor.

26. Cap off any exposed vacuum fittings from hose removal in step 4. (One (1) 1/4” vacuum cap

is included to cap the larger fitting on the EGR Valve.)

27. Install air cleaner adapter using supplied washers between the adapter and the 5mm allen

bolts for adapter. Torque bolts to 10 in/lbs.

28. Re-install the flexible connector and the sheet metal elbow removed in step 5. (The elbow

may require modification in order to fit flush to the air cleaner adapter.) Use the supplied

6mm bolt and the original sealing washer to secure the elbow to the adapter.

29. Reconnect the battery and replace the gas cap.

30. Depress the throttle pedal once to initiate the choke unit and start the engine. (Realize that

the float bowl is empty and it will require cranking the engine a few moments in order to fill

the bowl with enough fuel to start the engine.)

31. A. Check for leaks around the carburetor mounting base and the fuel line connection.

Correct as necessary.

B. Warm engine to operating temperature and recheck step A.

C. Set idle speed and mixture to factory specifications.

32. CHECK FOR ADEQUATE HOOD CLEARANCE BEFORE CLOSING THE HOOD.

Page 4

Page 5

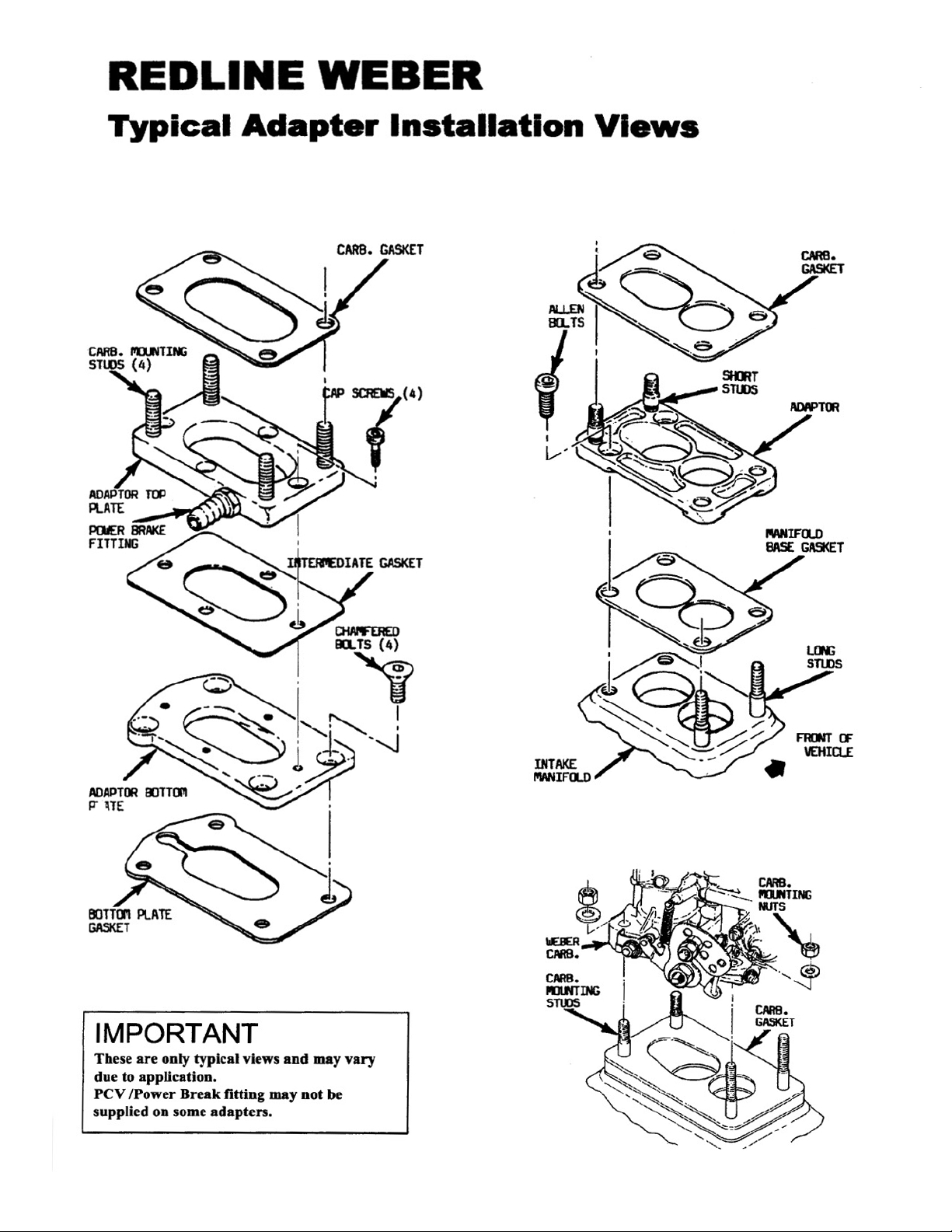

REDLINE WEBER

TYPICAL DGV CARB INSTALL VIEWS

These views may vary depending on application. For general assembly assistance only.

Page 6

Page 7

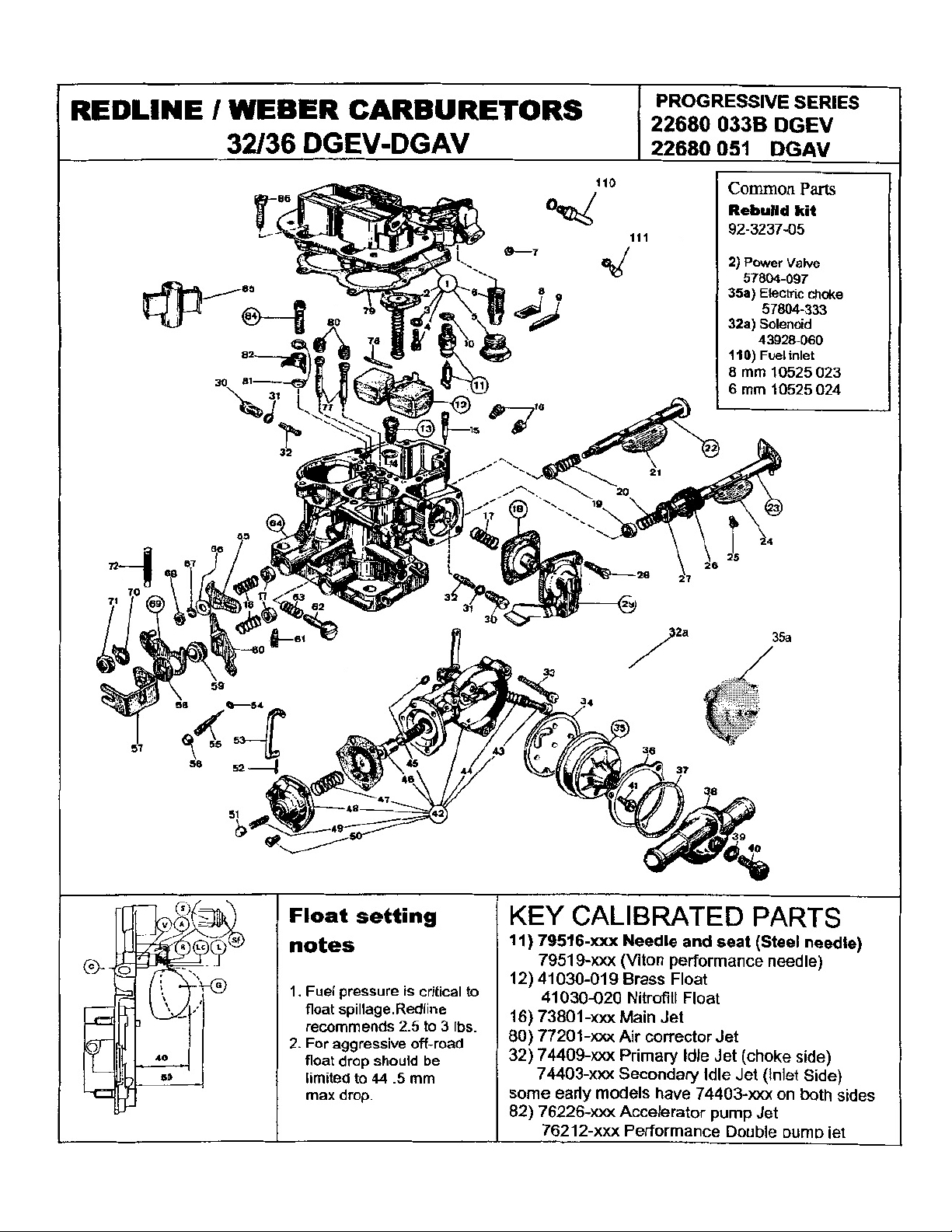

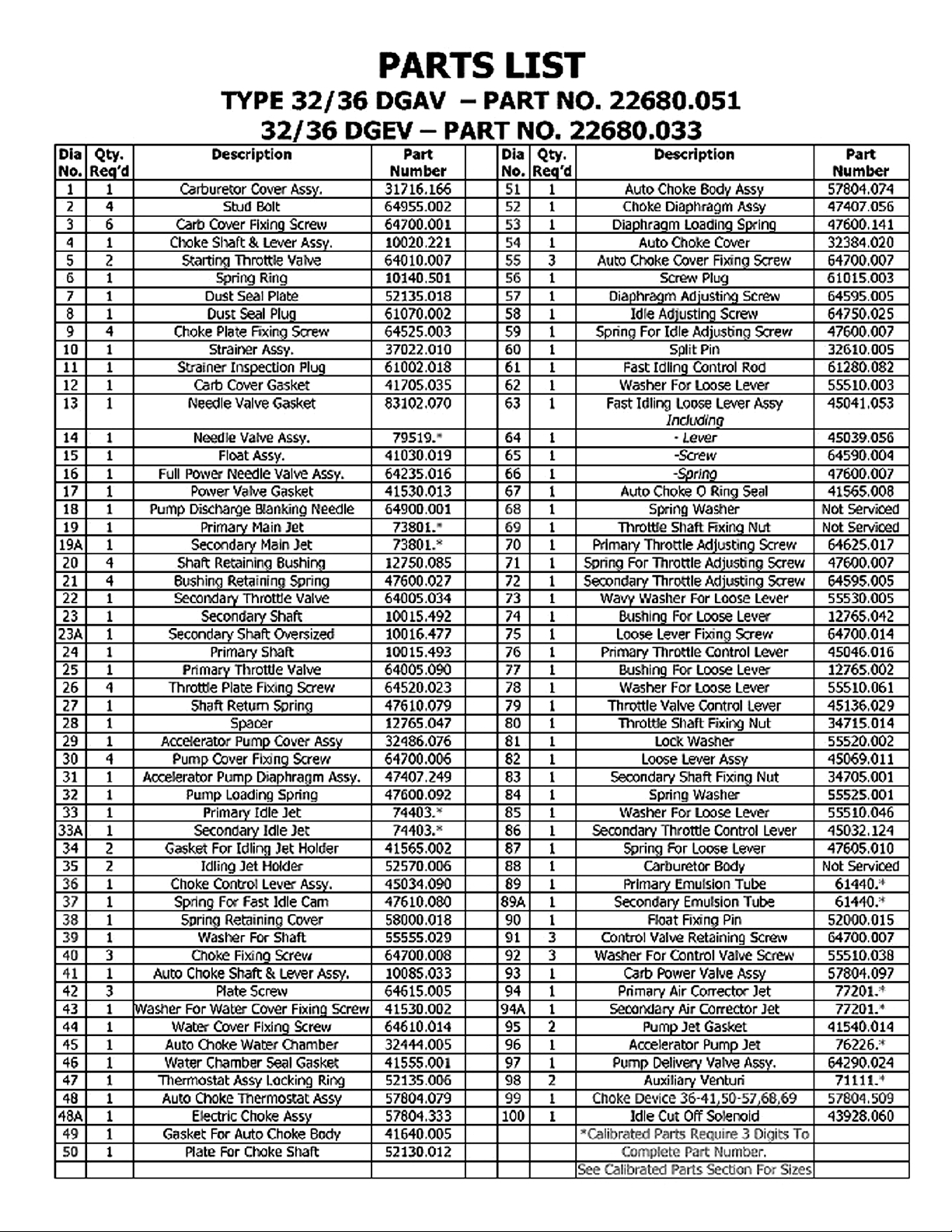

32/36 DGAV

Part Number

22680.051

Water Choke

32/36 DGEV

Part Number

22680.033

Electric Choke

Page 8

Page 9

It is important to follow all linkage and lever installation instructions. The number one and two

reasons for tuning errors are improper linkage installations and over tightened linkage nut,

causing a binding in linkage assembly.

CALIBRATIONS MAY VARY DUE TO REGIONAL FUELS AND STATE OF ENGINE TUNE

AND PERFORMANCE. POOR RUNNING QUALITY DOES NOT MEAN A DEFECT IN THE

CARBURETOR. AN ADVANTAGE OF THE WEBER CARBURETOR IS ITS EASE OF

ADJUSTMENT AND TUNING.

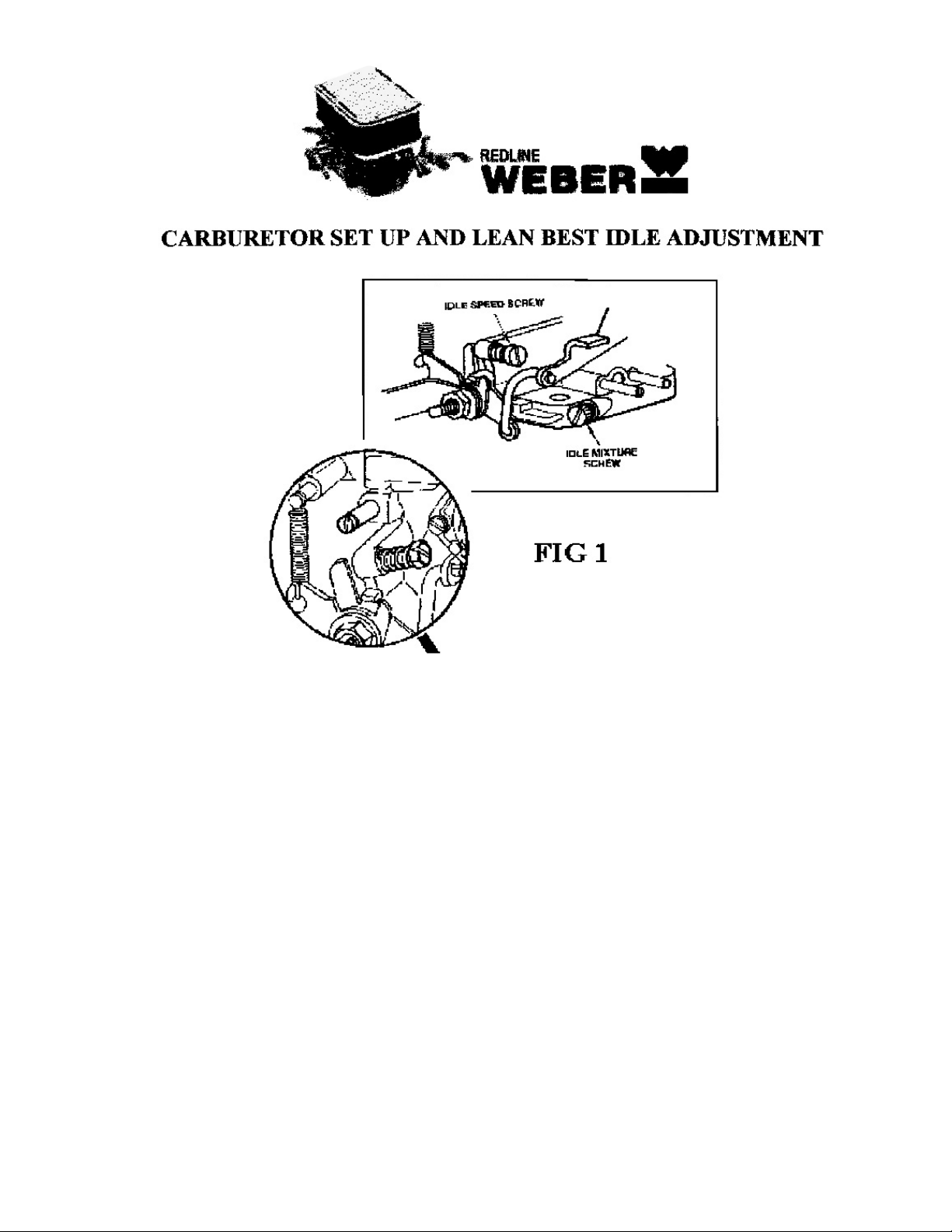

SET UP ADJUSTMENTS

Start set up by confirming carb base line settings. Do not depend on the factory delivered settings.

Check them before the carb is installed.

1. All settings are done with choke disengaged or warmed up so that the choke is fully opened

and disengaged. This is done on automatic choke carburetors by first opening the choke

butterfly by hand and inserting a wood block or wedge of some kind to hold open while the

linkage is cycled (linkage operated through its full movement) to clear the choke cam. (You

will hear a metallic click as the cam is released. You can check the fast idle screw under the

choke assembly to confirm that it is not in contact with the choke fast idle cam.)

Page 10

2. Set the Idle stop screw (speed screw see fig 1)

by backing out the Idle speed screw until it is

not in contact with the throttle stop lever. Cycle

the linkage again to be sure that the linkage

comes to close without any assistance.

(Checking for linkage bind) Now bring screw

back into contact with the lever and continue

to open or screwing in 1 turn no more than

1 1/2 turns.

3. Set the mixture screw (see fig 1) by first

screwing in until the screw stops, bottoms out.

DO NOT FORCE OR BIND AS THIS WILL

CAUSE DAMAGE TO THE SCREW AND IT’S

SEAT IN THE BODY OF CARBURETOR.

Back out the screw 2 full turns.

4. TUNING

BE SURE TO FOLLOW THE NEXT INSTRUCTIONS IN THE PROPER SEQUENCE,

DEVIATION WILL CAUSE THE CARBURETOR TO NOT FUNCTION TO ITS IDEAL

SPECIFICATIONS AND MAY NOT PROVIDE THE PERFORMANCE AND FUEL

ECONOMY AS DESIGNED.

4a Start the engine, the engine will run very slowly more like a tractor. As long as the engine

stays running idle speed is not important at this point.

4b The first thing to do is not set up the idle speed, but to set the idle mixture screw to lean

best idle setting. First, turn in the mixture screw until the engine dies or runs worse, then

back out the screw (recommend turning 1/4 to 1/2 turn at a time). The engine should pick up

speed and begin to smooth out. Back out 1/2 turn more, or until the screw does nothing or

runs worse then turn back to the point where it ran its best. Use your ear, not a scope or

tuning instruments at this point. You want to tune the engine by sound. Adjust to best, fastest

and smoothest running point.

4c Now that the mixture screw is at its best running location, you can adjust the idle speed with

the screw. The screw will be sensitive and should only take 1/4 to 1/2 turns to achieve the

idle speed you like.

Check and set idle to your driving preference. put the car in gear and apply slight load, (AC

on) and set the Idle as you like it. Don’t set it too high, as this will cause excessive clutch

and brake wear. The Idle only needs to be 700 to 900 RPMs with light load or AC on.

5. Recheck timing and vacuum hook ups. Recheck mixture screw to lean best idle again. If all

is still best and smoothest idle, then confirm and note the final settings.

To confirm settings with the engine running: Start by screwing in the mixture screw and

count the number of turns it takes to bottom out and note if the engine dies. If Idle Mixture

screws are with in 1/2 turn of base line setting then all is well and have fun. Also check the

speed screw and note how many total turns from initial contact. You may have opened

(turned in) the speed screw.Your final setting should be under 2 full turns. Reset the screws

(back in) to the best final settings (per your notes) and go on a test drive and have fun. If the

settings are other than described then you may want to recalibrate the idle circuit (low

speed circuit) to your engines needs. This is done by following the rule of thumb below.

(see next page...)

Page 11

Simple Rules for low speed calibration

If the mixture screw is more than 2 1/2 turns out, then the idle jet is too lean (too small). When

the mixture screw is less than 1 1/2 turns, then the idle jet is too rich (too large). These assumptions

are based on the fact that the speed screw setting is not opened more than 1 1/2 turns. If the

speed screw has to be opened 2 or more turns then this is also an indication of a lean condition

usually requiring greater change. At times it may appear to be showing signs of richness or

flooding it is really a lean condition. See pictures and notes in the tech 2 article supplied in the

kit instructions, view and please understand the need to keep throttle plate as near to closed as

possible so as not to prematurely expose the transition holes. This is what causes the visible rich

condition, and confirms the need to increase the jet size. JET KITS are available if needed.

EXAMPLE: With the speed screw set at no more than two (2) turns in after contact with the stop

lever; and the best idle occurring with the mixture screw set at 3 turns from bottom, indicates the

need for a larger Idle jet. Achieving the best idle at under 2 turns indicates the need for a smaller

idle jet.

The secret to understanding the critical nature of the carburetor set up and the advantages of a

WEBER over the other carburetors is the idle circuit. Referred to as the low speed circuit by

Weber, this circuit is responsible for 80% of the driving operation. This is the reason that the

Weber should give a fuel economy improvement over most factory carbs along with significant

performance gains. In the worst case you should not see a significant fuel economy loss over

stock, while improving HP and drivability.

The Weber Carburetor is a sequentially timed device to the motor like the distributor. Time taken

in the setup will provide more fun later.

Page 12

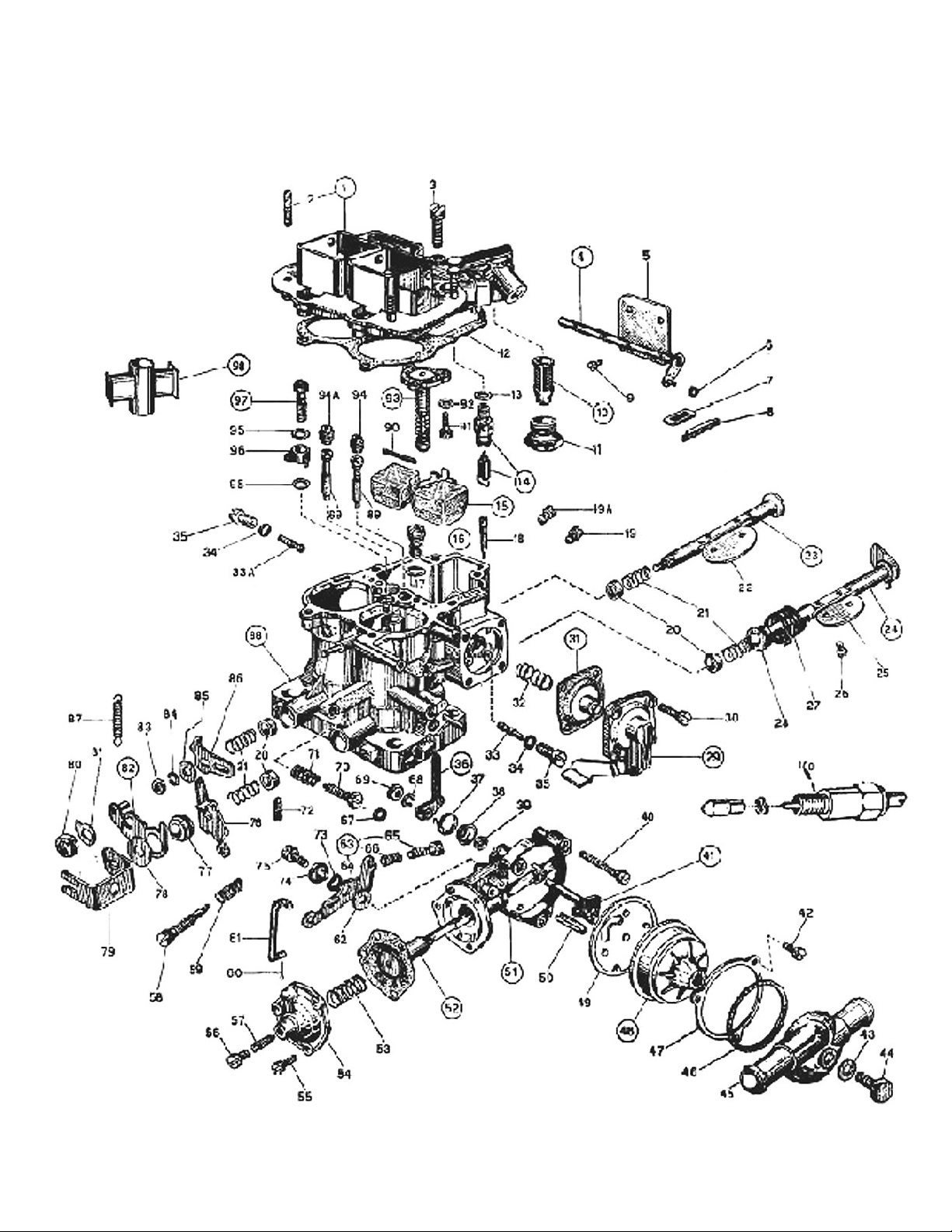

DUAL-DOWNDRAFT REPAIR:

DGAV

The DGAV carburetor is representative of the family of downdraft Weber

carburetors with two venturis and two

parallel throttle shafts. The dual-venturi,

vertical carburetor is standard equipment

on most Italian cars that do not use horizontal Webers such as the DCOE. It is a

favorite conversion carburetor for every

vehicle from Austin to Volkswagen.

The DGAV uses a progressive linkage

from the primary throttle shaft to operate

the secondary throttle, and there is an

automatic choke, power enrichment valve

and accelerator pump to enrich the fuel

mixture as needed. The main casting

includes the two venturis and carries all

the jets and their drilled passages. The

float bowl cover casting carries the power

enrichment valve and float assembly.

DISASSEMBLY

See the sidebar, page 45, for information on special Weber tools. It’s not practical to disassemble this carburetor completely just to fix one part, because you

can do more accidental damage than

could ever result form normal wear. A

little extra time spent diagnosing the

problem can save the grief of breaking a

good part during disassembly.

1. Carburetor-cover assembly

2. Stud bolt

3. Carburetor-cover fixing screw

4. Choke shaft-&-lever assembly

5. Starting throttle valve

6. Retaining ring

7. Dust-seal plate

32/36 DGAV. Drawing courtesy Redline, Inc.

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

should its long spring be broken or corroded. Renew it as required.

Jets–Blow compressed air through the

main jets, the air-correction jets, emulsion tubes and accelerator-pump jet to

clean them. Never use a wire to probe or

clean a jet; it will disturb the flow characteristics. Blow air through both sides of

the accelerator-pump delivery jet. It is a

one-way valve, so you should be able to

blow through it only one way.

Press down on the center needle of the

full-power valve to make sure it moves

freely against its return spring.

If you removed the auxiliary venturis,

blow through the passage and remove any

burrs or dirt on their surfaces.

Main Casting–Check for any damage

to the main casting. Use a straightedge to

check the base of the carburetor for

excessive warpage.

Remove the idle jets from their holders

and check each jet by holding it up to a

light. Blow through the jet if it’s clogged.

Check the diaphragm of the accelerator

pump for damage.

The automatic choke assembly contains a lot of levers. Check that all operate freely. The bimetallic spring should

not be bent or broken. Check the water

chamber for signs of leakage.

Throttle Shafts–The throttle shafts

should be straight, with no visible wear

where they bear on the nylon seals.

Double-check the threads on the end of

the primary throttle shaft and the threads

on both shafts where the valves are

attached. The throttle valves should have

smooth edges and be flat.

The springs that slide onto the throttle

shafts should be strong and not deformed. Replace the nylon shaft seals

whether or not they show any evidence of

wear.

REASSEMBLY

The disassembly of the DGAV is, in

itself, a lesson on reassembly. After all

the components have been inspected and

damaged parts replaced, begin

reassembling the major components

first. The disassembly photos will be

helpful during assembly. Start with

either the float bowl cover or main casting. The following notes give the most

important points to remember in

reassembly.

Throttle Shafts–There are two dangers

in reassembling the throttle valves;

bending the throttle shafts and not positioning the valves correctly. The first

danger requires only care; the second,

some strategy.

The holes in the valves are oversize so

they can be positioned for a perfect seat

in the bores. The auxiliary venturis

should be removed to give free access to

the attaching screws for this operation.

Install the throttle shafts with all their

linkages and springs in place, then tighten the end nuts before installing the

valves. This strategy assures that the

valves are not moved while you’re

installing anything else on the throttle

shafts. On the primary shaft, working

outward from the innermost part, the

order is:

Nylon washer

Spring

Arm

Shoulder washer, shoulder side to

carburetor casting

Arm

Washer

Throttle bellcrank

Lock tab

Nut

On the secondary shaft, working outward, the order is:

Nylon washer

Spring

Arm–Engage arm with slotted arm

on the primary shaft before slipping

it onto the secondary shaft.

Washer

Lock washer

Nut

Shaking throttle-shaft screws requires that you support throttle shaft. End of screw

presents itself at an angle, so a dead-center punch is impossible. Note hammer used

weighs less than five pounds. Shaft support is drive side of 1/4-in. drive socket, or

short section of solid metal rod.

Page 25

Page 26

Pierce Manifolds is the largest distributor of WEBER carburetors,

WEBER parts, and WEBER conversions in the USA. Pierce

Manifolds manufactures intake manifolds for WEBER carburators,

MGB cylinder heads, and air filters for all WEBER carbs. Pierce

Manifolds rebuilds vintage WEBER carbs to original specs. They

also have the largest inventory of linkages for WEBER carbs.

http://www.piercemanifolds.com

Carburetor Repair Kits

Carburetor Type Rebuild Kit Gasket Set

32 DGAV, DGEV 92.3237.05 92.0108.05

32/36 DFV, DFAV, DFEV 92.3230.05 92.0073.05

32/36 DGAV, DGEV 92.3237.05 92.0108.05

32/36 DGV 92.3238.05 92.0108.05

Page 27

Suzuki Samurai SJ413 General Specifications (stock)

Vehicle type Two-door, hard and soft top

Vehicle class Sport / utility

Powertrain layout Front engine, four-wheel drive

Body structure Body with chassis frame

Body material Steel

Seating capacity Four

Suspension (Front and Rear): Leaf spring solid axle

Shock Absorber Specifications Stock Samurai front replacement shocks measure 10.125” collapsed and

15.25” extended, the rear measures 11.75” collapsed and 18.” extended.

Steering

Turning radius 16.7 ft. (5.1 m)

Toe in 0.08 - 0.24 in. (2 - 6 mm)

Caster angle 3° 30'

King pin angle 9° 00'

Brakes Type: Power-assisted hydraulic

Front Disc, floating caliper

Rear Drum leading and trailing

Parking brake Lever-hand operated

Wheels and Tires 15 x 5" Steel Wheels (381 x 127 mm)

Tire type All-season, steel-belted radial

Tire size P205/70R15 (Full-size Spare)

Front hubs JA and JX: Manual/Automatic

Restraint System Safety belts: Front and rear lap / shoulder belts

Fuel Economy (EPA Estimates) City: 23 MPG Highway: 25 MPG

Engine Type

The engine is an aluminum-block, steel-sleeve 1.3L (81 c.i.) four-cylinder, in-line, 8-valve OHC,

weighs about 200lbs. and generates 64 hp and 74 ft. lbs. of torque.

Bore x Stroke 2.91 in. x 3.03 in. (74 mm x 77 mm)

Displacement 80.8 cu. in. (1.3 liter)

Compression ratio 8.9:1

Induction system 2bbl Carburetor

Horsepower (SAE net) 60 hp @ 6500 rpm (45 kw)

Torque (SAE net) 74 lb.-ft. @ 3500 rpm

Manual Transmission Five-speed, all synchromesh

Clutch Dry, single disc, diaphragm spring

Gear r

atios

1st 3.652 Transfer gear ratios

2nd 1.947 Low (4WD) 2.268

3rd 1.423 High 1.409

4th 1.000

5th 0.795 Diff

erential ratio 373:1

Reverse 3.466 373:1

Capacities / Calculated Data

Engine oil 3.7 qts (7.4 U.S. pt.) (3.5 liters)

Fuel tank 10.6 U.S. gal. (40.3 liters)

Engine coolant 1.34 gal (10.69 U.S. pt.) (5 liters)

Transmission oil Manual (4WD) 2.76 U.S. pt. (1.3 liters)

Differential gear oil Front 4.2 U.S. pt. (2.0 liters)

Differential gear oil Rear 3.2 U.S. pt. (1.5 liters)

Transfer gear box oil 1.7 U.S. pt. (0.8 liter)

Page 28

Samurai VIN # Codes:

first 3 characters = manufacturer's ID (JS4)

next character = car line

next character = series, chassis and restraint system type

next character = engine type

next character = design sequence

next character = body type

next character = "check digit" (tells you what city the vehicle was originally sent to to be sold.)

10th character = model year (G=86, H=87, J=88, K=89, L=90, M=91, N=92, P=93, R=94, S=95)

next character = assembly plant

next six digits = sequential number

Replace the plugs at least every 30,000 miles. Gap them to .028-.032

Timing: 10 degrees BTDC. Firing order is 1-3-4-2

Wiper blades are 12” Idle speed should be 750-850 rpm

Exterior Dimensions Interior Dimensions - Rear cargo

Wheelbase 79.9 in. (2030 mm) Length = 32.5 in (826 mm)

Tread width Front 51.2 in. (1300 mm) Width = 50.0 in. (1270 mm)

Tread width Rear 51.6 in. (1310 mm) Height = 40.2 in (1021 mm)

Overall Length 135.0 in. (3430 mm)

Overall Width (Body) 60.2 in. (1530 mm)

Overall Height 65.6 in. (1665 mm)

1 Asian Auto Parts of Arizona

1-877-885-9341

http://asianautopartsofaz.com

2 Calmini

http://www.calmini.com

3 Hawk Suzuki Parts

1-888-SAMURAI (1-888-726-8724)

http://www.hawksuzukiparts.com/index.html

hawkins@hawksuzukiparts.com

4 North Coast OffRoad

1-866-4X4PART (1-800-494-7278)

http://www.northcoastoffroad.com

5 PetroWorks Off-Road Products

1-800-952-8915

http://www.petroworks.com

6 Pierce Manifolds

(Source for Weber Carb parts)

http://www.piercemanifolds.com

7 Roadless Gear (formerly Giri Trading Co.)

1-208-660-6905

http://www.roadlessgear.com

8 Rocky Road Outfitters

1-888-801-7271

http://www.rocky-road.com/suzuki.html

9 Rod's Samurai Parts

Rod Reyerson - Marshalltown, Iowa

Email: Rey55@prodigy.net

Phone: 641-751-2468 or 641-752-2150

http://www.izook.com/spy/rods/rods.htm

10 Sky Manufacturing

1-541-736-3743

http://www.sky-manufacturing.com

11 Spidertrax

http://www.spidertrax.com/index.html

12 Suzuki John

http://suzukijohn.hypermart.net/index.html

suzukijohn@aol.com

13 Trail Tough

1-877-SUZUKIS (1-877-789-8547)

http://www.trailtough.com

14 Wheeler’s Off-Road

1-541-474-2879

http://www.wheelersoffroad.com

15 Zuki South Samurai parts

http://www.zukisouth.com

Suzuki Parts & Supplies

(Web pages / Phone numbers)

Loading...

Loading...