Page 1

Rebuilding your Transmission

If you still have transmission in your Samurai,

chances are very good that it makes a little noise in

at least one of the forward gears... You have a few

choices. You can try and find a dealer money. Our

kit was purchased from Petroworks.

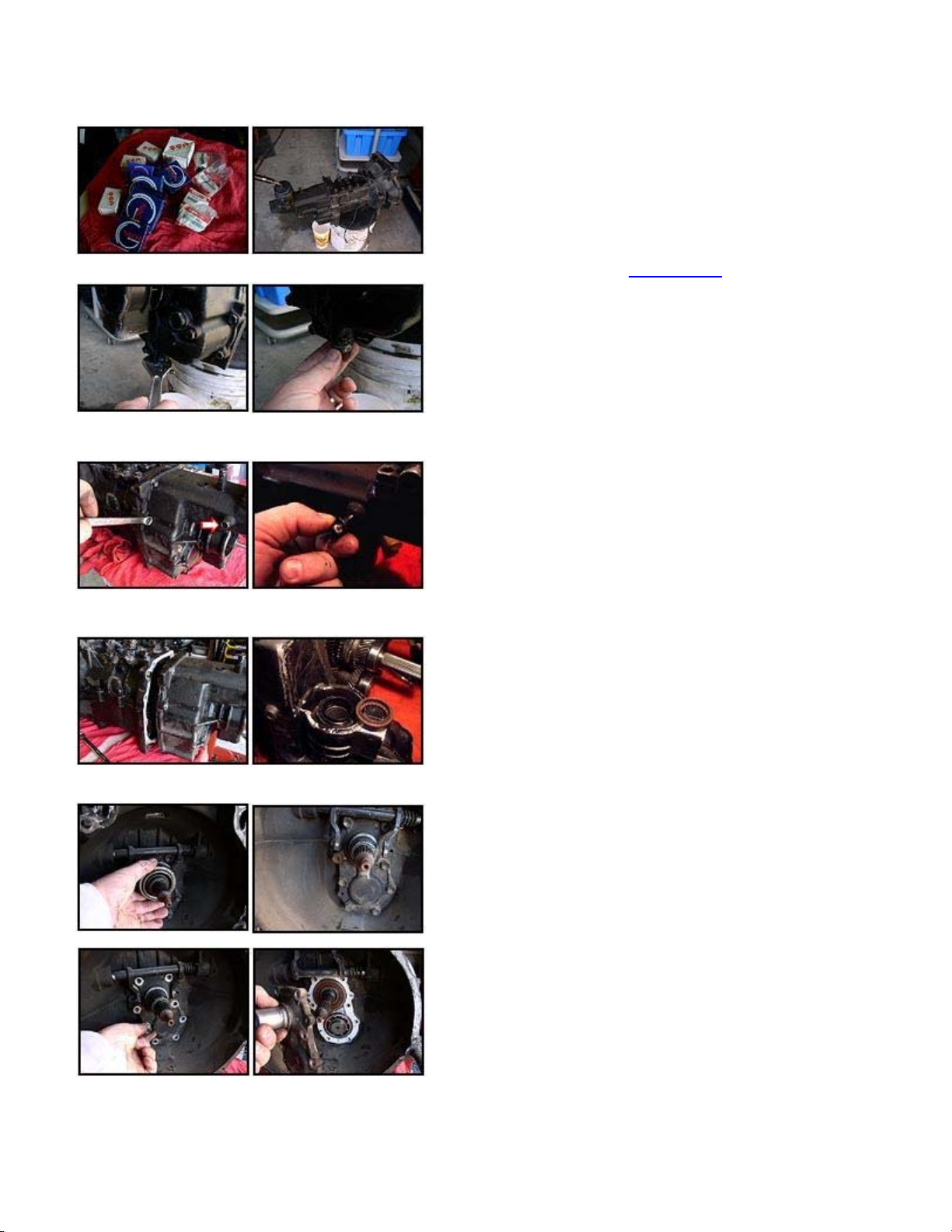

Everything starts with simply draining the oil. Check

the oil as it comes out for metal shavings or flakes.

Large metal chunks could be a bad thing depending

on where they came from. If the shifter locator pin

has broken off in the past it will eventually end up

down here in the bottom of the case. If it got

wedged in the gearing on the way down, then you

may have more to replace than you planned on.

Next it's time to go inside to check out the condition

of the components. To do that you can start at the

back and remove all the bolts holding the tail

housing to the main section. Don't forget to remove

the reverse shift rim bolt. You can see the arrow

pointing at it in the photo on the left. When you

remove it you will notice that it looks pretty

unique... Don't lose it, we will talk more about this later.

Separate the tail shaft housing (extension case)

from the main section and turn it up on end. Here

you see the tail shaft seal. You should take this

time to replace it and then clean out the case. Then

set it aside for later.

Next we go to the front of the transmission and remove

the clutch release bearing. Now you can see the 8

bolts that hold the input shaft bearing retainer in place.

You will also note that even when the bolts have been

removed, it is very difficult to remove the retainer.

There are three small bolt holes that look unused,

these will help. Use 3 conventional 6mm bolts to 'pop'

the retainer from its home.

Page 2

Here is the input shaft seal. It is the other seal that

needs to be replaced during a rebuild. Replace it and

then set it aside and turn your attention back to the

case.

Next we remove all the bolts holding the upper and

lower cases together.

Removing the upper case reveals the main shaft

assembly. This can now be lifted easily from the case

and set aside for now.

Back at the lower case, you can easily remove the

reverse gear shaft and idler gear. Set it aside. Next

we turn our attention to the countershaft.

Using a bearing puller, remove the countershaft

rear bearing. This is the first of three bearings you

will replace on the countershaft.

Being careful not to damage the gear teeth, remove

the countershaft 5th gear and the countershaft

reverse gear. They both just slide off of the

countershaft.

Now we go to the opposite end of the countershaft

and remove the c-clip from the end of the

countershaft, and the large c-clip that surrounds the

countershaft front bearing.

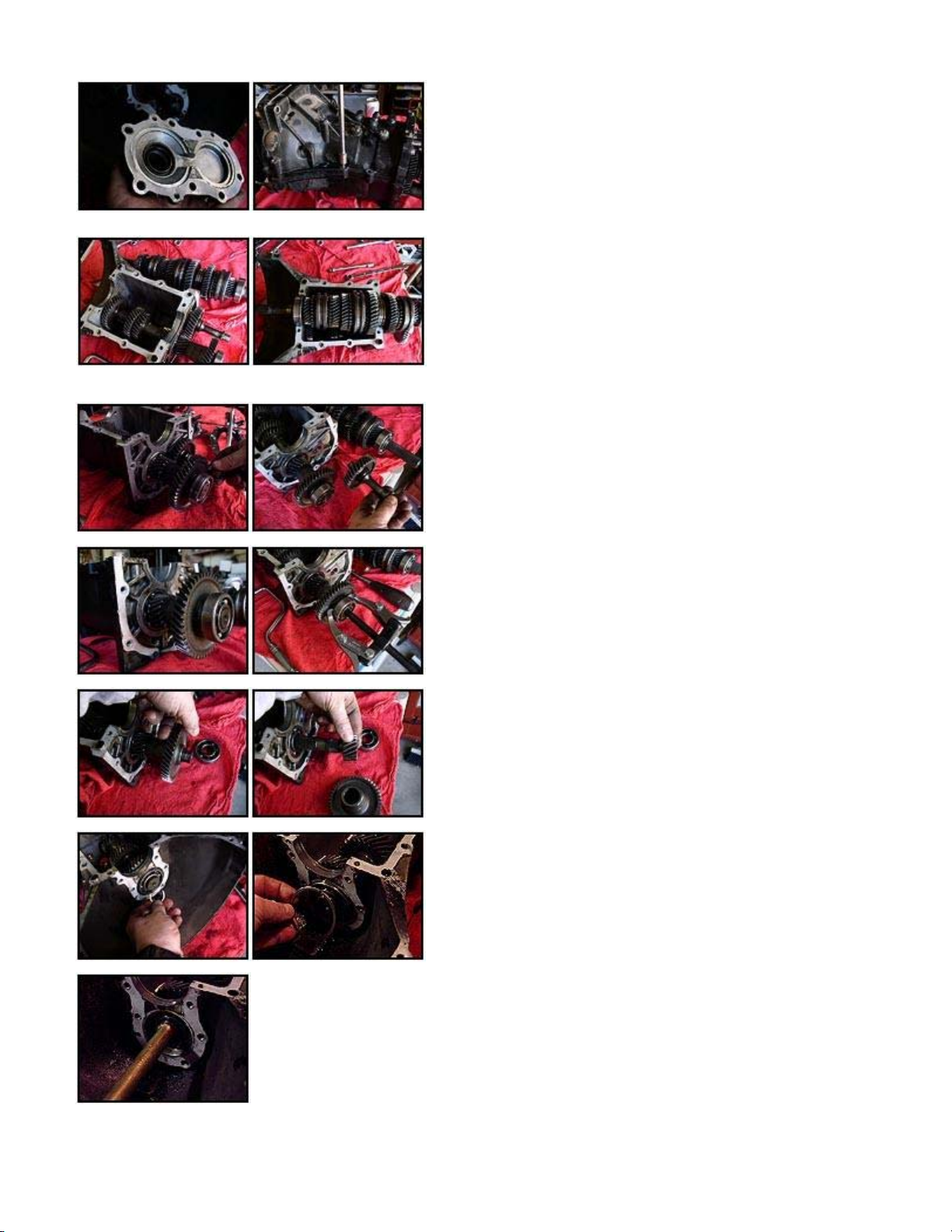

The factory service manual says to press out the countershaft using a

hydraulic press. I accomplished the same thing using a brass drift and a

small sledge hammer. Do not use the hammer by itself, you WILL

damage the countershaft and you run the risk of cracking the case if you

miss...

Page 3

You can see the progress at the other end as the

other bearing slides out. Be careful as the bearings

leave the casting, do not damage the gear as it

enters the race.

Using the bearing puller again, remove the bearing

without damaging the gear behind it.

You can then pull the countershaft up and out of the

lower case. Then remove the remaining bearing

with the bearing puller and then reverse what you

just did. Install new bearings and reassemble the

countershaft and reinstall it in the lower case. Set

the whole assembly aside and turn your attention to

the main shaft again.

When you first look at the main shaft, it may appear

very daunting. But as long as you have a large

workbench where you can lay everything out in

order (and you have your Factory Service Manual

handy) it's not really tough. This is actually two

shafts. The main shaft has the input shaft at one

end. You can see it being carefully removed in the

photo to the right. The high-speed synchronizer ring may be loose on the end of the input shaft

when you separate the shafts, be sure to keep the parts in order. We will come back to this

later.

On the end of the main shaft (where the input shaft

had been) you will find a needle bearing. This is

unlike the larger bearings you have already

replaced because there are no ball bearings in it.

This kind of bearing is for close quarters, looking

more like a sleeve, it uses long cylindrical bearings

that ride on a larger surface. Set this aside, keeping

the components in a line to insure the right order of assembly.

Remove the circlip, and pull the third gear,

synchonizer low speed hub and needle bearing off

all at once. You can keep them together to make it

easier, but remember to replace the needle bearing

with a new one from the rebuild kit. Set it face down

on the workbench in its place in the order.

Page 4

Starting at the other end of the main shaft, carefully

remove each bearing, and its set of gears and put

them in line on the table.

There are circlips along the way that retain each

gear set, so don't force anything until you have

checked for one of these suckers.

Your rebuild kit should include all of the main

bearings as well as the needle bearings, so

remember to swap in the new components as you

go.

As you (carefully) pull the main shaft assembly

apart, you will notice three (3) ball bearings in the

mix. Don't lose these. Also, don't try to remove a

component if there is a ball holding the component

in place. Carefully remove the ball and place it in

the assembly order.

Once the shaft has been disassembled, go back

through the parts you have removed and make sure

you replace all of the bearings with new

components that look identical.

For a reminder of the order, take a look at this. The main bearings will

need to be pressed back into place, so be careful not to lose track of the

ball bearings shown above.

Then reassemble the shaft in the reverse order that

you took it apart. This is where keeping everything

in order makes the difference.

Page 5

The needle bearings should slide easily with no

obstructions. And don't forget the circlips as you go.

Remember the input shaft we set aside earlier?

You will need to replace the bearing on the end of

the input shaft. Use a bearing puller for removal

and then press the new bearing into its place. Then

slide the input shaft back onto the main shaft over

the new needle bearing.

As you carefully place the main/input shaft back

into place, be sure to notice the circlips on the main

bearings. These ride in a slot that will keep the

bearing race from moving after assembly. Make

sure everything rotates smoothly.

Bolt the upper case back into place and torque to

factory specs. Put the idle gear/ reverse gear shaft

back into place.

Bolt the extension case back into place and don't

forget the reverse shift rim bolt that we pointed out

earlier. Then we concentrate on the shift tower.

The shifter locating bolt is a commonly replaced

item, as it is very prone to wear. There are two

different sizes based on the model year of your

transmission. You can see an example of each

shifter to the right. The shifter on the left of the

photo is a newer model, as it has the wider slot to

accept a larger locating pin. On the right, you can

see an older model that has also been outfitted with a new poly shifter 'sheet'. These

replacement shifter sheets are available from many of the aftermarket distributors. Planning

ahead, we got this one from North Coast Offroad during the ZookiMelt last year.

Page 6

Here you can see the shifter tower after a cleanup

and lube. A new locating bolt has been installed

and because this is an older model shifter tower,

we used the shifter handle with the new shifter

sheet described above.

If your shift tower needs to be replaced, maybe the threads for the

locating bolt are stripped out - or you have an older model and would like

to take advantage of the larger diameter locating bolt of the newer

model, you can get a complete tower kit from Hawk Strictly Suzuki.

Here we finally close up the case by replacing the

input shaft housing.

Finally a new clutch release bearing (aka - the

throwout bearing) tops off the input shaft.

Remember to replace the pilot bearing in your

flywheel also, or you may experience a situation

where the vehicle still wants to move with the clutch

depressed. Sometimes it's the little things that get

you!

Important things to note here...

Every rebuild kit is not created equal, make sure you are getting all of the seals and

bearings to do the job right the first time.

If you experience problems shifting smoothly from one gear to another while the drivetrain

is in motion, the synchronizer rings may be worn out. These are not usually sold as a part of

a rebuild kit. You may have to ask your distributor for them separately.

And last but not least, everyone is not mechanically inclined. So if you think you may need

help with this, get help first. Nobody likes having to fish through a box of transmission parts

from an unfinished job.

Loading...

Loading...