OWNER’S MANUAL

INSTALLATION • OPERATION • MAINTENANCE

SAFETY PRECAUTIONS • REPAIR PARTS

MODEL X1 & X1F

12 & 24 Volt DC Electric Winches

READ AND UNDERSTAND THIS MANUAL

BEFORE INSTALLATION AND OPERATION

OF YOUR SUPERWINCH PRODUCT.

90-10884 Rev- 05/08/03

Superwinch, Inc. Superwinch, Ltd.

Winch Drive Abbey Rise, Whitchurch Road

Putnam, CT 06260 Tavistock, Devon PL 19 9DR

U.S.A. England

Tel. (860) 928-7787 Tel. (1822) 614101

Fax (860) 928-1143 Fax (1822) 615204

3

2

Thank you very much for purchasing a Superwinch product. We hope and

expect that you will be pleased with the performance and reliability of this

unit. If you are not, for any reason, please contact our Customer Service

Department: (860) 928-7787 USA; (1822) 614101 England.

When requesting information or ordering replacement parts; always give the

following information:

1. Winch Part Number

2. Part Number (found in Replacement Parts List section)

3. Part Description

It is extremely important that you read and understand this Owner’s Manual

prior to installing and using your winch. Pay particular attention to “General

Safety Information” and be sure that anyone else who might use your winch

also studies this section.

Pay particular attention to the caution notes preceded

with this symbol. The notes contain advice for your

protection.

Description Quantity

Winch assembly with wire rope and hook installed 1

Switch and harness assembly with two 5' long 8-gauge wires 1

Handsaver 1

Circuit breaker assembly with hardware 1

Poly bag containing: 2 bolts, 2 washers, 2 nuts, 1

4 flat washers and 5 cable ties

INTRODUCTION

UNPACKING: This carton contains the following items. Please unpack carefully. Read instructions before beginning.

PERFORMANCE

Motor

Volt Load Speed Current

DC lbs kg Ft/min m/min Amps

12 0 0 25 7.6 30

2,000 907 9 2.7 200

24 0 0 25 7.6 20

2,000 907 9 2.7 100

Working Load . . . . . 2,000 lbs. (907 kg)

Stall Load . . . . . . . 2,500 lbs. (1,134 kg)

Wire Rope . . . . . . . . . 3/16” x 25 ft.

Voltage . . . . . . . . 12 or 24 Volt DC

Motor . . . . . . . . . . . . . . . . . .1.3 hp

Gear Ratio . . . . . . . . . . . . . . . 123:1

Weight . . . . . . . . . . 18 lbs. (8.2 kg)

SPECIFICATIONS

GENERAL SAFETY

INFORMATION

Your new Superwinch is a powerful

machine. Treat it with respect, use it

with caution and always follow

these safety guidelines.

1. The X1 winch is rated at 2,000

lbs. (single-line) capacity. DO NOT

OVERLOAD. DO NOT ATTEMPT

PROLONGED PULLS AT HEAVY

LOADS. DO NOT MAINTAIN

POWER TO THE WINCH IF THE

MOTOR STALLS. Overloads can

damage the winch and/or the

wire rope and create unsafe

operating conditions. FOR

HEAVY LOADS, WE RECOMMEND THE USE OF THE

OPTIONAL PULLEY BLOCK AND

HOOK ASSEMBLY (PART NO.

2227) TO DOUBLE-LINE THE

WIRE ROPE (Figure 1). This

reduces the load on the winch

and the strain on the wire rope

by approximately 50%.

2. AFTER READING AND UNDER-

STANDING THIS MANUAL,

LEARN TO USE YOUR WINCH.

Practice using it so you will be

familiar with it when the need

arises. Periodically check the

winch installation to assure that

all bolts are tight.

3. DO NOT “move

”

your vehicle to

assist the winch in pulling a load.

The combination of the winch

and vehicle pulling together

could overload the wire rope and

the winch itself.

4. KEEP WINCHING AREA CLEAR.

Do not allow people to remain in

the area during winching operations. Do not step over a taut

wire rope or allow anyone else to

do so. Do not stand between the

winch and load.

5. INSPECT WIRE ROPE AND

EQUIPMENT FREQUENTLY. A

FRAYED WIRE ROPE WITH BROKEN STRANDS SHOULD BE

REPLACED IMMEDIATELY.

Always replace wire rope

with the manufacturer’s identical replacement part, (see

Replacement Parts List). Never

replace the wire rope with any

kind of rope other than the type

and size specified in the Wire

Rope section of this manual.

6. USE HEAVY LEATHER GLOVES

when handling wire rope. DO

NOT LET WIRE ROPE SLIDE

THROUGH YOUR HANDS. A bro-

ken strand could seriously injure

your hands.

7. KEEP CLEAR OF THE WINCH,

WIRE ROPE, AND HOOK WHEN

OPERATING WINCH. NEVER put

your fingers through the hook

when reeling in the last few feet

of line. If your finger should

become trapped in the hook, you

could lose your finger. Use the

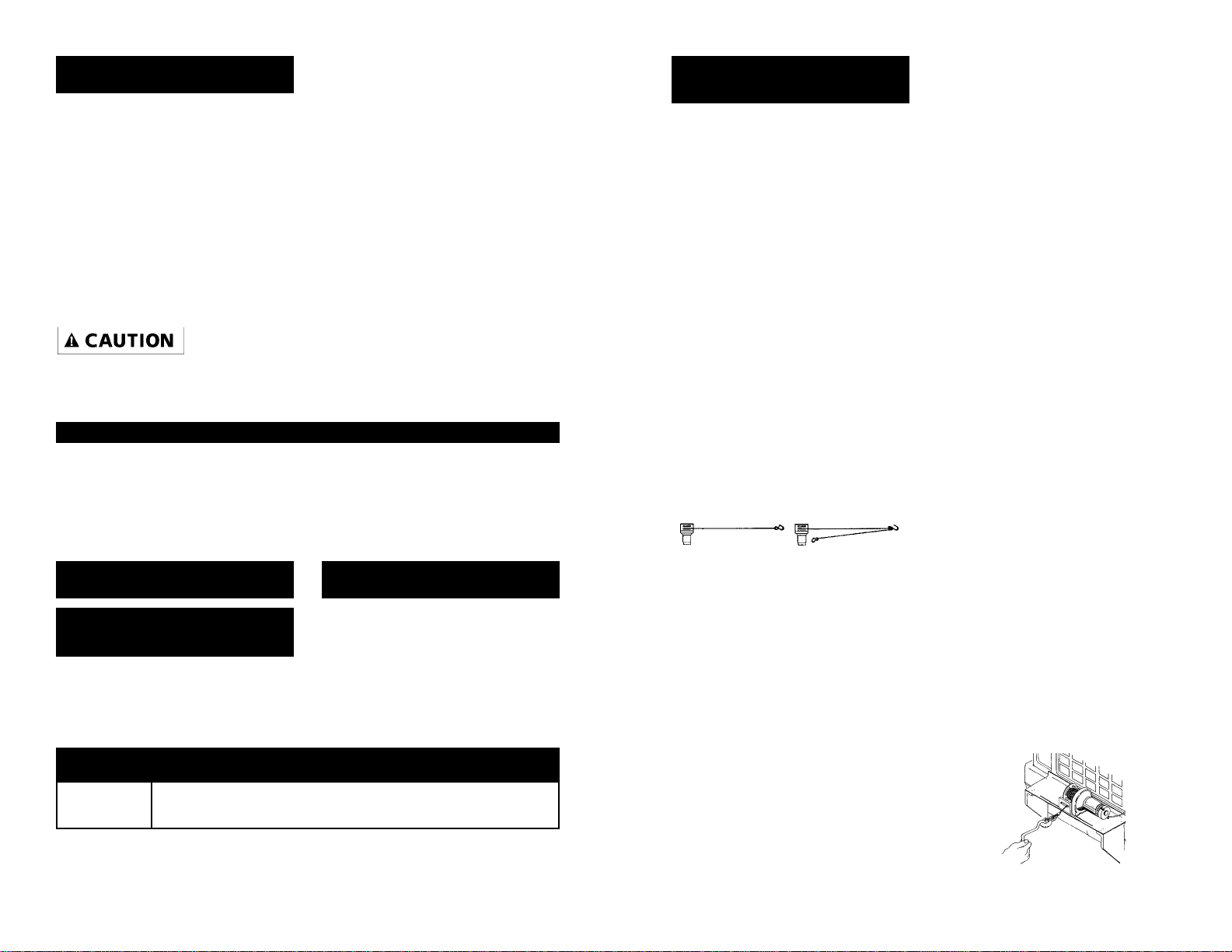

HAND SAVER BAR (Figure 2) to

guide the hook within the last

few feet. Never guide a wire rope

on or off the drum with your hand.

Figure 2

Slope* 10% (6º) 20% (11º) 30% (17º) 100% (45º)

Lbs.**

kg**

10,000

4535

6,800

3084

5,200

2359

2,600

1179

Ratings assume a 10% coefficient of friction.

* A 10% slope is a rise of one foot in ten feet. Slope in approximate degrees is also shown above.

** All loads shown are for single-line operation (see Figure 1). Double-line operation with optional

pulley block (P/N 2227) approximately doubles capacity of winch (see Figure 1).

ROLLING LOAD CAPACITY**

Figure 1

Single Line

Double Line

5

4

8. NEVER HOOK THE WIRE ROPE

BACK ONTO ITSELF. Use a nylon

sling (Superwinch Part No. 1509).

Hooking the wire rope onto itself

can damage the rope (Figure 3).

9. It is a good idea to lay a heavy

blanket or jacket over the wire

rope near the hook end when

pulling heavy loads (Figure 4). If

a wire rope failure should occur,

the cloth will act as a damper

and help prevent the rope from

whipping. Raise the hood of the

vehicle for added safety.

10. NEVER USE YOUR WINCH FOR

LIFTING OR MOVING PEOPLE.

The winch is not designed nor

intended for use in lifting or

moving people.

11. Your winch is not designed or

intended for overhead hoisting

operations.

12. DO NOT ATTEMPT PULLS

FROM ANGLES WITHOUT

USING OPTIONAL FAIRLEAD,

P/N 1507 OR 1560, as damage

to winch and wire rope may result.

13. AVOID CONTINUOUS PULLS

FROM EXTREME ANGLES as

this will cause the wire rope to

pile up at one end of the drum

(Figure 5). This can jam the wire

rope in the winch, causing damage to the wire rope or winch

itself.

14. Always operate winch with an

unobstructed view of the winching operation.

15. IT IS RECOMMENDED THAT A

FAIRLEAD BE USED to guide

the wire rope onto the winch.

Two types of fairleads are

offered: the Hawse Fairlead,

Part No. 1507, and the Roller

Fairlead, Part No. 1560.

16. DO NOT OPERATE WINCH

WHEN UNDER THE INFLUENCE

OF DRUGS, ALCOHOL OR

MEDICATION.

17. ALWAYS REMOVE THE

SWITCH BEFORE WORKING IN

OR AROUND THE WIRE ROPE,

FAIRLEAD, OR WINCH DRUM

(THE DANGER ZONE) so that

the winch cannot be turned on

accidentally.

18. NEVER WORK ON OR

AROUND THE FAIRLEAD OR

WINCH DRUM, WHEN WINCH

IS UNDER LOAD.

19. When using your winch to move

a load, place the vehicle transmission in neutral, set vehicle

parking brake, chock all wheels,

and keep the engine running.

20. DO NOT USE THE WINCH TO

HOLD LOADS IN PLACE.

Use other means of securing

loads such as tie down straps.

Superwinch offers a wide variety

of tie down straps. Contact your

local Superwinch dealer.

21. USE ONLY FACTORY

APPROVED SWITCHES,

REMOTE CONTROLS, AND

ACCESSORIES. Use of non-fac-

tory approved components may

cause injury or property damage

and could void your warranty.

22. DO NOT MACHINE OR WELD

ANY PART OF THE WINCH.

Such alterations may weaken

the structural integrity of the

winch and could void your warranty.

23. Maintain 5 turns of wire rope

around wire rope drum to prevent the wire rope from pulling

off under load.

24. NEVER INSTALL WINCH IN

SUCH A WAY THAT THE

WARNING AND INSTRUCTION

LABELS ARE OBSCURED.

Someone who had not read this

manual may need to see them

to understand the proper operation of the winch. ALWAYS

CHECK FOR CORRECT DIRECTION OF ROTATION BEFORE

USING WINCH. The winch must

be properly wired to ensure correct direction of rotation.

25. When moving a load, slowly

take up the wire rope slack until

it becomes taut. Stop, recheck

all winching connections. Be

sure the hook is properly seated.

If a nylon sling is used, check the

attachment to the load.

26. Always install winch in such a

way that the operator will be

standing with a comfortable

posture, with unobstructed

access to, and a clear view of the

winch, its labels, and its controls.

TOOLS NEEDED FOR MOUNTING

AND WIRING

Open End Wrenches – 9/16", (2), or

small adjustable wrenches, wire

strippers, or cutters, terminal

crimpers (pliers), torque wrench, Pair

3/8" bolts and nuts, four flat and

two lock washers.

MOUNTING

The mounting location for the

winch must be capable of handling

the loads of the job you intend the

winch to do. Suggested locations

are: a flat front or rear bumper of a

vehicle, on a pickup truck bed or the

winch stand on a trailer.

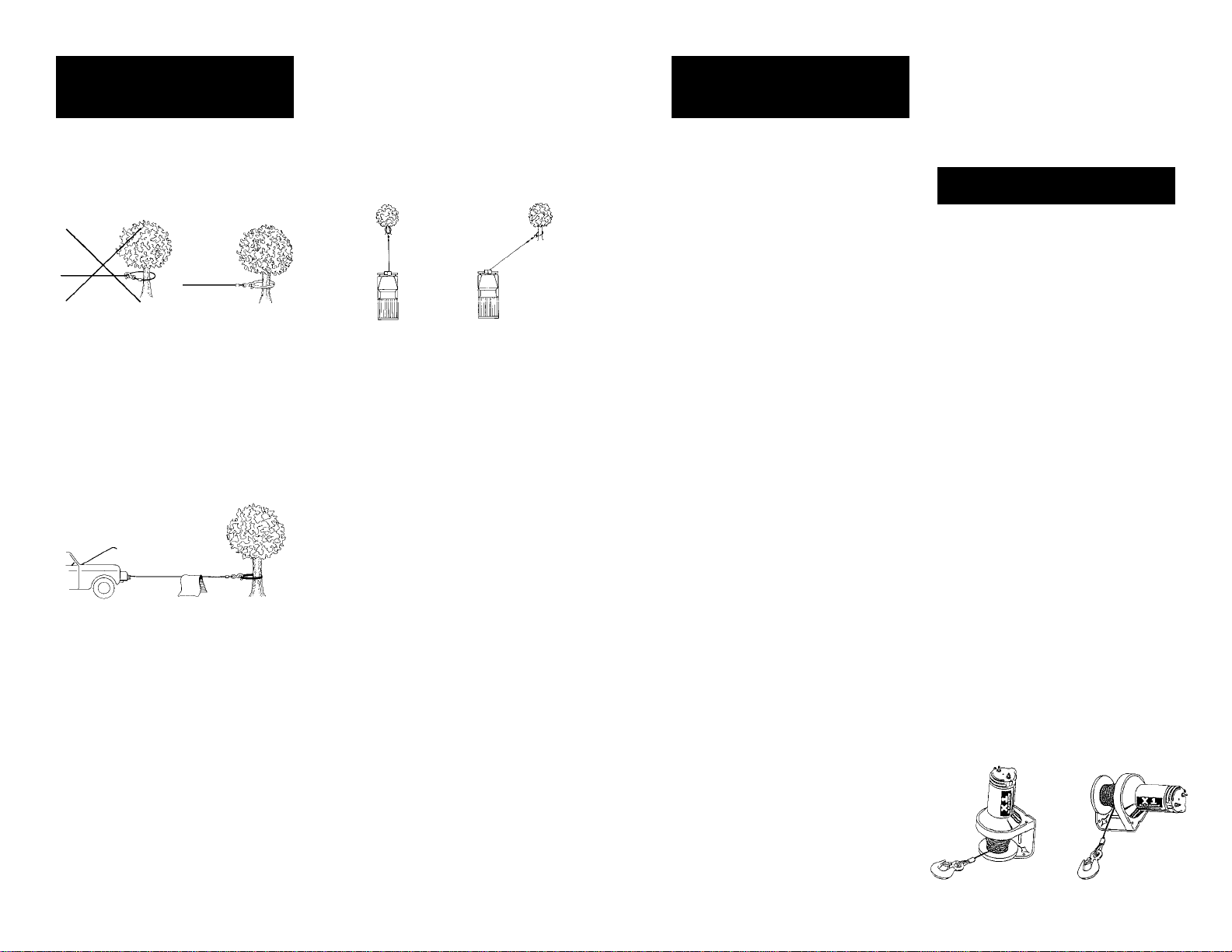

The winch can be mounted in a horizontal or vertical position (Figure

6). Do not mount the winch where

there would be the possibility of it being submerged in water.

The winch is weather resistant but

not waterproof.

Superwinch mounting (fitting) kits

are available for most popular vehicles. If you can’t obtain a kit locally,

contact Superwinch at the address

listed in this manual for the name of

a Superwinch dealer near you.

GENERAL SAFETY

INFORMATION

(CONT.)

Wrong Right

GENERAL SAFETY

INFORMATION

(CONT.)

Right

Wrong

Figure 5

Figure 3

Figure 4

INSTALLATION

Horizontal

Vertical

Figure 6

7

6

MOUNTING (CONT.)

Drill two 7/16" (12mm) diameter

holes with center lines exactly

3-11/16" (93.66mm) apart (Figure 7)

in the support chosen for the

winch. Attach the winch to the support with two (2) 3/8-16 Hex Head

Bolts. Be sure the hardware is

assembled as shown. Tighten the

hardware to 35 lb. ft. torque.

ELECTRICAL INSTALLATION

This winch operates on standard

automotive 12-or 24-volt Direct

Current.

Do not

connect winch

to 110 Volt house current. Motor

damage or fatal shock may occur.

Automobile

batteries contain gasses which are flammable and

explosive. Wear eye protection during installation and remove all metal

jewelry. Do not lean over the battery while making connections.

The red wire from the switch is

connected to the circuit protector

terminal using the hardware provided. The other end of the circuit

protector is connected to the battery positive terminal. The black

wire from the switch is connected

to the battery negative terminal

(Figure 8). Be sure connections are

clean and tight. Do not connect the

switch or wiring to any other power

source in the vehicle.

Starting at the winch, feed the

wires into the engine compartment.

If possible, use the routing and support for the existing wiring.

If it is necessary to drill holes, to

feed the wires, be sure the wires

are protected from damage by

using a grommet (Figure 9). Use

cable ties to secure wires along the

route.

When you make the ground connection, be sure to scrape off any

dirt from the bolt that would prevent a good connection.

Note: If the winch is mounted at

the rear of the vehicle, a special

wiring kit (P/N 1520) is available

from Superwinch.

When extending the lead wires for

rear vehicle mount, always use 8

gauge wire or heavier to extend the

existing wires to the battery.

If connection to the battery positive

terminal is not possible because of

the terminal design, connect the

circuit protector to the starter

solenoid “hot” side. Determine the

“hot” side by tracing the battery

cable to the solenoid connection.

Connect the red supply wire to the

same terminal to which the battery

cable is connected (Figure 10).

Note: Special adapters are available

from your local Auto Parts Dealers

for making connections to Side Post

Batteries.

The switch and motor end are

designed so the switch will mount

properly only when installed as

shown in Figure 11. Do not attempt

to install the switch in the opposite

direction. If the switch is installed

incorrectly and electrical contact

made, the winch will run in a direction opposite that is indicated on

the product label resulting in possible operator injury.

Secure the switch to the motor by

tightening the round thumb screw

on the outside of the switch (Figure

12). The screw threads into the

tapped hole between the brass

motor contact (Figure 11). Do not

use pliers or over-tighten the thumb

screw.

After the switch is in place, remove

excess slack from the wiring harness

in the vehicle by doubling over

slack areas and tying securely. Do

not leave any dangling or loose

wiring.

Figure 7

Bolt

Flat Washer

Support

Flat Washer

Lock Washer

Nut

Figure 9

Grommet

Tie Strap

Circuit

Protector

From Switch

Figure 10

Battery

Cable

Circuit

Protector

Red

Solenoid

Figure 11

Switch

Wires

Figure 12

Be Prepared

Figure 8

Circuit

Protector

Chassis

Ground

Red

Black

9

8

Periodically check tightness of the

mounting bolts and electrical connections. Remove any dirt or corrosion that may have accumulated on

the electrical connection.

LUBRICATION

Your new winch has lifetime lubrication. There will be some grease

leaking out of the winch, especially

during the first few operations. This

is normal and it is not necessary to

grease or oil any part of the winch

at any time.

WIRE ROPE

A part of your winch that will

require periodic attention and

eventual replacement is the wire

rope. Inspect the wire rope for wear

frequently. If fraying exists, replace

the wire rope at once. Your winch

uses 3/16" diameter galvanized aircraft type 7 x 9 wire rope (4,200 lb.

breaking strength). Always replace

the wire rope with Superwinch

replacement wire rope, P/N 1511

(See pages 12 and 13).

FREE SPOOL OPERATION MODEL X1F

To disengage the clutch for freewheeling the wire rope out, pull

the knob at the wire rope end of

the winch straight out and rotate

the knob 90° (1/4 turn). The wire

rope can be pulled out by hand

(Figure 15). Avoid jerking the wire

rope off the drum when freespooling as this can cause the wire rope

to backlash and snarl on the drum.

Note: The clutch cannot be

released if there is a load on the

wire rope.

To engage the clutch, turn the

clutch knob until the square key

drops into the inner drum shaft

(Figure 16). Activate the control

switch on the winch until the key

drops into the outer drum shaft.

Check that the key is fully engaged

before applying a load to the wire

rope.

SWITCH OPERATION

When the switch springs back to the

“OFF” position, an electrical shunt provides dynamic braking action which

prevents the winch from coasting

(Figure 13). THIS BRAKING ACTION IS

NOT A LOAD HOLDING DEVICE.

When the switch is centered in the

“OFF” position, the shunt reduces the

action of a load backdriving the winch.

However, a load can cause the winch

to creep. With the switch removed

from the winch, there is a greater tendency for a load to backdrive the

winch.

The winch is

not designed

as a load holding device.

The switch should be removed from

the winch when unattended to prevent unauthorized operation. A

Quickconnect (Superwinch P/N 1551) is

also available as an accessory to disarm

the winch. Because the winch will not

hold a load, in trailing or load holding

applications, tie down ropes or straps

must be used to secure loads.

Remote operation of the switch

(Figure 14) can be achieved by tying

one end of a cord through each “ear”

of the switch.

Periodically check tightness of the

mounting bolts and electrical connections. Remove any dirt or corrosion

that may have accumulated on the

electrical connections.

LUBRICATION

Your new winch has lifetime lubrication. There will be some grease leaking

out of the winch, especially during the

first few operations. This is normal and

it is not necessary to grease or oil any

part of the winch at any time.

WIRE ROPE

A part of your winch that will require

periodic attention and eventual

replacement is the wire rope. Inspect

the wire rope for wear frequently. If

fraying exists, replace the wire rope at

once. Your winch uses 3/16" diameter

galvanized aircraft type 7 x 19 wire

rope that is 25 feet long (4,200 lb.

breaking strength). Always replace the

wire rope with Superwinch replacement wire rope, P/N 1511 (see

Replacement Parts List).

OPERATION

Figure 13

Off

Rope In

Rope Out

MAINTENANCE

MAINTENANCE

Figure 14

Figure 15 Figure 16

11

10

5. PREVENT KINKS BEFORE THEY

OCCUR.

6. EQUIPPING THE WINCH WITH A

ROLLER FAIRLEAD, P/N 1560,

Figure 19, will substantially

reduce wear on the wire rope

during angle pulls. The rollers

eliminate heavy rubbing and

abrasion to the wire rope.

a

b

c

a. This is the start of a kink. At this time,

the wire rope should be straightened.

b.The wire rope was pulled and loop has

tightened into a kink. Wire rope is now

permanently damaged and must be

replaced.

c. The result of kinking is that each

strand pulls a different amount causing

strands under greatest tension to break

and reduce load capacity of the wire

rope. The wire rope must be replaced.

Figure 19

Figure 18

If the winch motor labors and then

stops, the load is too great.

Evidence of this will be a motor

almost too hot to touch. Repeated

occurrence of this condition indicates that the load exerted on your

winch is beyond its capacity and

may burn out the winch motor. Use

of the accessory pulley block, P/N

2227, will increase the winch‘s

capacity.

MOTOR DOES NOT OPERATE

Follow these steps in order. Make

sure your vehicle engine is running

and then try operating your winch

after each step.

1. Remove switch, then replace it on

the motor, making certain that it

is aligned properly over brass

motor connectors and that thumb

screw is snug.

2. If motor does not operate, check

all electrical connections on battery and ground, making sure

that they are clean and tight.

3. Check the wiring harness to

determine if all insulation is

intact. Damaged insulation could

cause a short circuit.

TIPS F0R EXTENDING THE LIFE OF

YOUR WINCH

1. KEEP A TIGHTLY AND EVENLY

WOUND WIRE ROPE DRUM. Do

not allow the wire rope to

become loosely wound. A looselywound drum allows a wire rope

under load to work its way down

into the layers of wire rope on

the drum. When this happens,

the wire rope may become

wedged within the body of the

windings, damaging the wire

rope. To prevent this problem,

keep the wire rope tightly and

evenly wound on the drum at all

times. During winching, periodically check to see that the wire

rope is winding on evenly. A

good practice is to rewind the

wire rope under tension after

each use. One way to do this is to

attach the hook to a stationary

object at the top of a small hill or

incline and winch your vehicle up

the incline.

2. DO NOT ALLOW MOTOR TO

OVERHEAT. Remember, the

winch is only for intermittent use.

During long or heavy pulls the

motor will get hot. The internal

parts will be hotter than the case.

To check the motor temperature,

stop winching and carefully touch

the motor. If the motor is uncomfortably warm, allow the motor

to cool before continuing. Keep

the engine running to recharge

the battery during this break.

3. USE A PULLEY BLOCK FOR

HEAVY LOADS. To maximize

winch and wire rope life, use a

pulley block, P/N 2227, to doubleline heavier loads.

4. The pull required to start a load

moving is often much greater

than the pull required to keep it

moving. AVOID FREQUENT

STOPPING AND STARTING

DURING A PULL.

TROUBLE SHOOTING

Figure 17

13

12

Reference

Number Description Part Number Qty

1 Handsaver 89-32300 1

2 Rotating Drive Shaft Assembly 90-32057-01 1

3 Drum Assembly 90-32054 1

4 Perimeter Bearing 90-23137 1

5 Carrier Bearing 90-23140 1

6 Planetary Gear Assembly 90-23138 1

7 Nylon Step Washer 90-12418 1

8 10 Tooth Sun Gear 90-22865 1

9 Flat Thrust Washer 90-23120-08 1

10 1.3 HP 12 Volt Motor w/Gearbox & Needle Bearing 90-32425 1

1.3 HP 24 Volt Motor w/Gearbox & Needle Bearing 90-32429 1

10A Stationary Gear w/Needle Bearing 90-12454 1

11 Washer 90-23120-11 1

13 Freespooling Knobshaft Assembly 90-12534 1

14 5/16" Socket Head Cap Screw 90-23056-02 1

15 Pair of 3.8" Bolts & Nuts, 4 Flat Washers & 90-22892 1

2 Locking Washers

16 Base Plate 90-32067 1

17 Outboard Housing 90-32058 1

20 Flange Bushing 90-23167-01 1

21 Cable Tension Set 90-12536 1

22 3/16" x 25' Wire Rope & Hook Assembly

(Model 1141, 1142) 1511 1

3/16" x 50' WIre Rope w/out Hook (Model 1177) 1511E 1

Clevis Hook (Model 1177) 90-22812 1

3/16" x 50' Wire Rope & Hook Assembly 1511A 1

(Model 1181A)

AR denotes “As Required”

Reference

Number Description Part Number Qty

REPLACEMENT

PARTS LIST

REPLACEMENT

PARTS LIST

REPLACEMENT

PARTS LIST

1 Handsaver 89-32300 1

2 Rotating Gear Drum 90-32038 1

3 Perimeter Bearing 90-23137 1

4 Carrier Bearing 90-23140 2

5 Planetary Gearing Assembly 90-23138 1

6 Nylon Step Washer 90-12418 1

7 10-Tooth Sun Gear 90-22865 1

8 Flat Thrust Washer 90-23120-08 1

9A Stationary Ring Gear w/ Needle Bearing 90-12629 1

9 12 Volt Motor w/Ring Gear & Needle Bearing 90-32425 1

24 Volt Motor w/Ring Gear & Needle Bearing 90-32429 1

11 Shim Washer 90-23120-05 AR

12 Bushing 90-12174 1

13 5/16" Socket Head Cap Screw 90-23056-02 2

14 Main Frame Base Plate 90-41019 1

15 Repair Switch Assembly w/ two 3 ft. leads (includes 1519A 1

two butt splices for connecting to old harness)

16 3/16" x 25' Cable & Hook Assembly 1511 1

17 12V Circuit Breaker Assembly 90-22873 1

24V Circuit Breaker Assembly 90-22873-01 1

18 Rope Retainer 90-12419 1

19 Pair of 3/8" Bolts & Nuts, 4 Flat Washers &

2 Locking Washers 90-22892 1

20 Handsaver Label 90-12417 1

NS Pulley Block 2227 1

AR denotes “As Required”

14

25 Freewheel Label 90-12520 1

26 Handsaver Label 90-12417 1

27 Repair Switch with 3' Leads 1519 1

28 Assembly of two Circuit Breakers on bracket (12V) 90-22873 1

Assembly of two Circuit Braekers on bracket (24V) 90-22873-01 1

29 Cable Retainer 90-23164-04 1

NS Pulley Block 2227 1

REPLACEMENT

PARTS LIST

REPLACEMENT

PARTS LIST (CONT.)

Reference

Number Description Part Number Qty

Loading...

Loading...