Superwinch TALON SERIES WINCH User Manual [en, es, fr]

WINCH USER’S GUIDE

SAFETY PRECAUTIONS

Please record the following information:

Model |

|

Serial No. |

|

Date |

READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND OPERATION OF YOUR SUPERWINCH.

Superwinch LLC. |

Superwinch Ltd. |

Winch Drive |

Union Mine Road |

Putnam, CT 06260, USA |

Pitts Cleave, Tavistock, |

tel: (860) 928 -7787 |

Devon, PL19 0PW, UK |

fax: (860) 9630811 |

tel: +44 (0) 1822 614101 |

e-mail: info@superwinch.com |

fax: + 44 (0) 1822 615204 |

www.superwinch.com |

e-mail: sales@superwinch.net |

|

www.superwinch.com |

87-14468 Rev01/07/10

1

INTRODUCTION

Thank you for purchasing a winch from Superwinch. It is designed and manufactured to provide years of trouble-free operation. We hope you are pleased with it’s performance. If, for any reason you are not, please call our Customer Service Department. Contact information included on the cover of this User’s Guide.

When requesting information or ordering replacement parts, please provide the Model Number and Serial Number.

SAFETY PRECAUTIONS

The responsibility for safe operation with this winch ultimately rests with you,

the operator. Read and understand all safety precautions and operating instructions before installing and operating the winch. Careless winch operation can result in serious injury and/or property damage.

Throughout this manual, you will find notations with the following headings:

!DANGER

!WARNING

!CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. This notation is also used to alert against unsafe practices.

ThefollowingsymbolsontheproductandintheOwnersmanualareused:

Read Owner's |

Always Use |

Keep clear of winch, |

Never use winch |

Never use |

Manual |

Handsaver |

rope and hook |

to lift or move |

winch to hold |

|

|

while operating |

people |

loads in place |

Note: Indicates additional information in the installation and operation procedures of your winch.

Correct installation of your winch is a requirement for proper operation.

Please Note: Winch is designed primarily for intermittent applications. This winch is not designed to be used in industrial or hoisting applications and Superwinch does not warrant it to be suitable for such use. Superwinch manufactures a separate line of winches for industrial/ commercial use. Please contact Customer Service Department for further information.

Congratulations on you choice!

2

APPLICATION INFORMATION

This winch is designed to move a load at ground level or up an incline. It is neither designed nor intended for hoisting.

This winch is not to be used to lift or move people.

This winch is for intermittent use due to heat build up characteristics of various components.

SAFETY PRECAUTIONS

1.Operator must be alert. Do not operate the winch under the influence of drugs, alcohol or medication.

2.The best way to get acquainted with how the winch operates is to make practice runs before you need it in an emergency situation.

|

|

Never connect DC powered winches to AC current. Motor |

|

! |

DANGER |

||

damage or fatal shock may occur. |

|||

|

|

||

! |

WARNING |

Stand clear of rope and load during winching. Keep |

|

|

|

helpers and spectators at a safe distance. |

If a wire rope pulls loose or breaks under load, it can lash back with dangerous force.

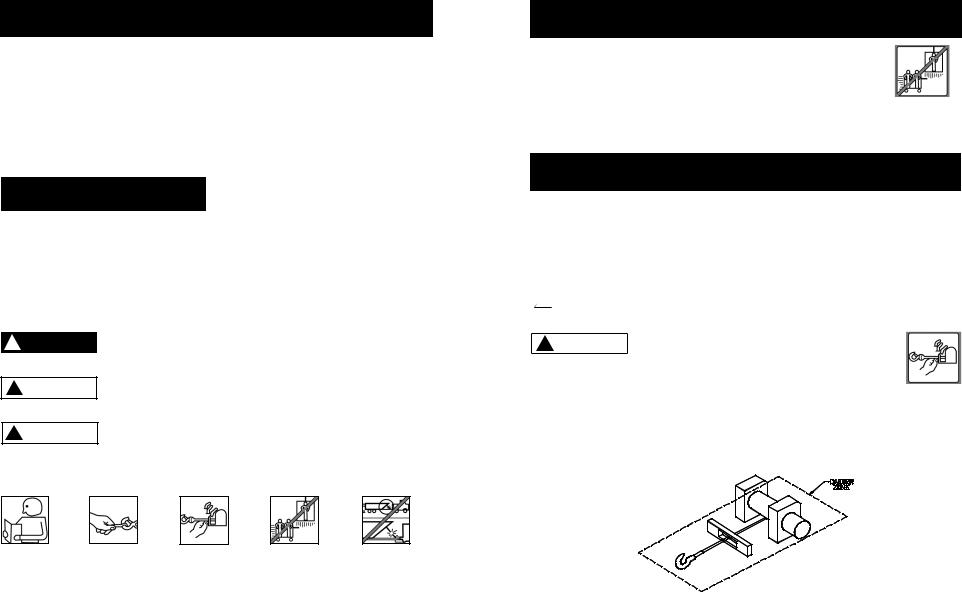

3. Beware of the danger zone. The danger zone is the area of the rotating rope drum, the fairlead (if fitted), the rope, the hook, and motor (see Fig 1. ) First relieve tension on load then disconnect the control switch before putting hands in or around the danger zone. Disconnect power leads to battery before working in or around drum.

Fig. 1

4.It is recommended that if you are within four feet of the winch, do not hold rope and remote (if equipped) at the same time.

5.USE ONLY FACTORY APPROVED SWITCHES, REMOTE CONTROLS AND ACCESSORIES. Use of non-factory approved components may cause injury or property damage and could void your warranty.

3

INSTALLING THE WINCH |

|

WIRE ROPE |

|

|

|

|

Be aware that vehicle batteries contain gases that are flammable |

! DANGER |

|

|

and can explode violently. The following precautions should be |

|

taken before making battery connection:

*Wear eye protection.

*Remove all jewlery.

*Follow wiring diagram included in installation instructions.

*Keep spectators away.

In the event of a battery explosion, acid should be flushed away immediately. Seek medical help as soon as possible.

1.Mount the winch to a firm base. Be sure that your structural support is strong enough to support the rated pulling forces of the winch.

2.While mounting attitude is at your discretion, always remember that your winch is to be operated with the rope in an under wound orientation on the rope drum. Your winch is designed to ROPE IN and ROPE OUT in one direction. DO NOT attempt to reverse the operation of winch.

Fig. 2

Underwind |

|

Overwind |

1.The life of the wire rope is directly related to the care it receives. The wire rope on a new winch, and any replacement ropes, should be respooled under a minimum of 100 lb. load before using the winch. Failure to do this will result in wire rope damage.

Inspect wire rope before use. Mashed, pinched, frayed or kinked areas severely reduce the load-carrying capability. Replace damaged wire rope.

2.Prevent kinks before they occur.

|

|

|

|

|

|

|

|

|||

(a.) This is the start of a kink. At this time, the wire |

|

|

|

a. |

||||||

rope should be straightened. |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

(b.) The wire rope was pulled and the loop has |

|

|

|

|

|

|

|

|||

tightened to a kink. The rope is now permanently |

|

|

|

|

|

|

|

|||

damaged and should not be used. |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

(c.) |

The result of kinking is that each strand pulls a |

|

|

b. |

||||||

|

|

|

|

|

|

|

||||

different amount causing the strands under great- |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

est tension to break and reduce load capacity of |

|

|

|

|

|

|

|

|||

the wire rope. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

c. |

|||||

|

SYNTHETIC ROPE |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Sharp edges and abrasion will significantly shorten rope life. |

||||||||

! |

DANGER |

|||||||||

Inspect entire length of rope and protective sleeve before each |

||||||||||

|

|

|||||||||

use. Any rope that exhibits cut strands, fused or melted fibers, inconsistent stiffness over the length of the rope, chemical contamination, flat areas or lumps that are not eliminated by flexing the rope, or is otherwise visibly damaged must be replaced immediately. Failure to do so can result in rope failure and personal injury.

|

Do not weld or machine any part of the winch. Machining or |

|

! CAUTION |

|

|

welding may weaken the structural integrity of the winch and |

|

|

will void your warranty. |

|

|

3. If you do not understand an instruction, or if you have a question that is not cov- |

|

|

ered in the manuals with your winch or mounting kit, please contact the Superwinch |

DANGER |

|

Customer Service Department. |

||

! WARNING

!• Do not knot or tie the rope to secure to a load, or to repair a broken rope.

•Do not expose the rope to heat sources or chemicals.

•Do not pull the rope over rough surfaces or sharp edges.

•Do not pull the rope around non-rotating sheaves or rollers.

|

Do not mount the winch inverted (base upward) or put the winch |

! CAUTION |

|

|

mounting hardware in a direct tension condition. In all |

|

installations, the unit must be mounted so that the rope feeds through the hawse or roller fairlead on the front of the winch and does not rub across housings.

1. Synthetic Winch Rope Installation:

Pull the rope through hole, (enough line so it reaches opposite end of drum). Position inserted line lengthwise down the drum as shown. Using duct tape or similar, secure end of line to drum, taping around drum. Setscrew is not used in this installation. You are ready to wind on the line. (Be sure that line is wound on from underneath drum.

Line should come off drum on bottom).

4 |

5 |

2. Synthetic Winch Rope Inspection:

When rope is new, it has a smooth finish (a.). When the rope is first used, the outer filaments of the rope will roughen and give the rope a slightly ,“fuzzy” appearance (b.). This condition of the outer filaments creates a rougher rope surface and actually helps to protect the fibers underneath. Rope must be replaced when approximately 25% of the visible outer fibers exhibit abrasion (c.).

a. |

b. |

c. |

New Rope |

Used Rope |

Rope must be replaced |

Examine both inner and outer fibers. Open the strands of the rope by compressing the rope length-wise (e.) and look for powdered fiber and abrasion - this is a sign of internal wear of the rope. Estimate internal fiber loss to include in your determination of overall abrasion fiber loss of the rope.

d. |

e. |

Glossy or glazed rope |

Compressing Rope Length-wise |

Glossy or glazed areas in the rope (d.) can be the result of 2 different conditions. The most common form of glossing or glazing is caused by compression, which can occur when the rope is wound on the winch drum, or through a pulley block. Compressing the rope length-wise (e.) will generally make the rope more pliable and begin to resemble normal rope. If the glazed section remains hardened, this can be a sign of heat damage, and the rope must be replaced.

Tips for prolonging the life of your synthetic rope:

It is your responsibility to exercise proper care to prolong the life of your synthetic winch rope.

1.) Minimize rope abrasion. Use the movable abrasion sleeve whenever the rope comes in contact with rocks or other objects. Slide the sleeve up and down the rope as required. Abrasion will reduce rope life.

2.) Keep the rope clean. Allowing dirt and debris to enter the rope will lead to abrasion of the rope.

3.) Avoid sharp bends. A sharp bend in the rope decreases it’s strength substantially under load and may cause rope damage or failure.

3.When it is necessary to respool the rope under no load after use, hold the remote switch lead in one hand and the rope in the other. Start from as far from the vehicle as the remote switch will allow, activate the switch, walk in several feet of rope and release switch. Repeat the process. Always release the switch before your hand comes within four feet from the fairlead ( the physical opening through which the rope passes ).

4.Be sure the rope is distributed evenly and tightly on the drum. A loosely wound drum allows the rope to work it’s way down into the layers of rope on the drum and become wedged.

5.It is not advisable to grease or oil the wire rope due to dirt contamination that will reduce the wire rope life.

|

|

PREPARING THE WINCH |

|

|

|

|

|

Wear heavy leather gloves when handling rope. Do not let the |

! |

DANGER |

|

|

|

rope slip through your hands, even with gloves on. When |

|

|

handling the hook, always use handsaver (Fig. 4). Never put your fingers into the hook. Placing finger(s) in hook could result in injury.

Fig. 4

WRONG

1. When anchoring the pulling vehicle, set the parking brake and block or chock the wheels. Keep the vehicle’s foot brake depressed and place the automatic or manual transmission in neutral.

|

|

Inspect switch and wiring for cracks, pinched spots, frayed, or |

! |

WARNING |

|

|

|

loose connections. A damaged, shorted lead could cause the |

|

|

winch to run as soon as it is plugged in.

2. When using the remote switch inside a vehicle, always pass it through a window to avoid pinching the wire in the door.

6 |

7 |

WINCHING

|

|

Never touch the rope or hook while they are in tension or under |

! |

DANGER |

|

|

|

load. Even at rest, the winch may have the rope in tension. Never |

|

|

guide a rope under tension onto the drum with your hands (see Fig. 5).

Fig. 5

WRONG

1.Winch with at least five wraps of wire rope or at least eight wraps of synthetic rope around the winch drum. With fewer wraps the rope could pull loose from the drum under load.

2.When pulling a load, place a blanket, jacket or tarpaulin over the wire rope near the hook end (see Fig. 6). This will slow the snap back of a broken wire rope and help to

prevent serious injury. Raise hood to protect windshield.

Fig. 6

Fig. 6

! WARNING Note the winch’s rated capacity and do not exceed it.

3. Double line with a pulley block ( see Fig. 7 ) to reduce the load on the winch, rope and battery. Double lining will also reduce winch line speed. Be sure all equipment used meets the winch’s maximum line pull rating. When double-lining, pulley blocks should be rated to a minimum of two times the winch’s line pull rating.

|

Pulley |

|

|

Block |

|

|

.1/2Load |

|

|

Approx |

|

load |

load |

|

Approx. |

||

|

||

|

1/2 Load |

|

|

Winch |

Anchor

Anchor Point

Point

Winch

( Single Line ) |

Fig. 7 |

( Double Line ) |

4.If you install a tow hook for double lining, it should be attached to the vehicle frame.

5.Equipping the winch with a fairlead will reduce wear on the rope during angle pulls ( see Fig. 8 ). The rollers reduce rubbing and abrasion to the rope.

Fig. 8

Roller Fairlead |

Hawse Fairlead |

6.Pull as straight as possible to reduce the buildup of rope on one end of the drum.

7.The vehicle’s engine should be running during winching operation. If considerable winching is performed with the engine off, the battery may be too weak to restart the engine.

Use a pulley block to avoid winching at sharp angles. Uneven ! CAUTION layering will cause serious damage to the winch and rope. It

can be corrected by securing load, spooling out the rope and repositioning it to the opposite end of the drum.

Do not disengage clutch under load. If your winch is equipped

! DANGER with a freespool clutch, be certain that there is no tension on the rope when you disengage the clutch. Before winching a load, be sure the clutch is fully engaged.

Use the winch to move the load. Do not attempt to assist the

! WARNING winch by moving the vehicle. The combination of the winch and and vehicle pulling could overload the rope and the load could break the winch.

! DANGER Never rely on the winch to hold a load in place.  None of our winches are designed for load-holding

None of our winches are designed for load-holding

applications and may unwind or fail due to shock loading as the

load is being transported. The load should be secured by other means, and the winch hook detached from the load.

8 |

9 |

|

|

RIGGING |

|

|

|

|

|

Take your time when rigging and include a reasonable factor for |

! |

WARNING |

|

|

|

safety. Improper rigging can result in damage to vehicle and |

|

|

equipment. It can also cause injury.

1. Never handle the rope or rigging while anyone else is at the control switch.

|

Use a nylon sling when attaching the rope to an anchor point. |

|

! CAUTION |

||

|

Do not attach the hook back on to the rope. Doing so can cause |

|

the rope to break. |

||

|

Fig. 9 |

|

Right |

Wrong |

! WARNING |

Always use the handsaver ( see Fig. 10 ). Do not hold |

|

the hook with your hand. This is important not only |

when reeling rope in but also when removing rope from the winch under power.

Fig. 10

2. Run the winch intermittently to take up rope slack. When using a pulley block, be sure the rope is running properly in all pulley rollers before applying a load.

|

|

Do not re-engage clutch while winch is running. |

! |

WARNING |

|

|

|

Always operate winch with an unobstructed view of the winching |

|

|

|

! |

WARNING |

|

|

|

operation. Never obscure warning and instruction labels. |

|

|

3. Figure (11.) Illustrates the most commonly used rigging. A nylon sling is used to protect the tree when it is used as an anchor, and the rope is attached to the sling. The use of a chain or rope is not recommended due to the damage it could cause to the tree.

Fig. 11

4. Figure (12.) Illustrates a method of rigging used to obtain a mechanical advantage. The use of a pulley block will almost double pulling capacity.

Pulley

Block

Block

Fig. 12

Winch

Vehicle

Anchor point |

Load |

|

|

||

|

|

|

5. Figure (13.) Illustrates the use of a pulley block to change the direction of the pull. Mechanical advantage can be obtained by attaching a pulley block to the nylon sling with a shackle and running the rope to the anchor point.

Fig. 13

|

Equipment such as tackle, hooks, pulley, blocks, straps, etc., |

! CAUTION |

|

|

should be properly sized and rated and should be inspected |

|

|

periodically for damage that could reduce their strength. |

|

10 |

11 |

Loading...

Loading...