Superwinch Tiger Shark 9500- 4309 Installation [en, es, fr]

+-

INSTALLATION GUIDE

MEMBER

SUPERWINCH®, SUPERWINCH® (design) and S SUPERWINCH® are registered trademarks of SUPERWINCH LLC.

SUPERWINCH LLC., 359 Lake Road, Dayville CT 06241, USA © 2012

TIGER SHARK

™

SERIES WINCH

READ AND UNDERSTAND THIS MANUAL BEFORE

INSTALLATION AND OPERATION OF YOUR

SUPERWINCH.

Superwinch LLC.

359 Lake Road

Dayville, CT 06241, USA

tel: 1.800.323.2031

fax: 1.860.963.0811

info@superwinch.com

www.superwinch.com

90-14517 Rev - 2/13/2012

Superwinch LTD.

Union Mine Road

Pitts Cleave

Tavistock, Devon

PL19 0NS, UK

tel: +44 (0) 1822 614101

fax: + 44 (0) 1822 615204

sales@superwinch.net

www.superwinch.com

1

SAFETY PRECAUTIONS

The responsibility for safe installation and operation of this winch ultimately rests with

you, the operator. Read and understand all safety precautions and operating instructions before installing and operating the winch. Careless winch operation can result

in serious injury and/or property damage. Never obscure or remove the warning or

instruction labels.

(NOTES,

NOTAS)

DANGER

!

WARNING

!

CAUTION

!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. This notation

is also used to alert against unsafe practices.

Note: Indicates additional information in the installation and operation procedures of

your winch.

The following symbols on the product and in the Owners manual are used:

Read Owner's

Manual

Always Use

Handsaver

Keep clear of winch,

rope and hook

while operating

Never use winch

to lift or move

people

Never use

winch to hold

loads in place

Correct installation of your winch is a requirement for proper operation.

Please Note: Winch is designed primarily for intermittent applications. This winch is not

designed to be used in industrial or hoisting applications and Superwinch does not

warrant it to be suitable for such use. Superwinch manufactures a separate line of

winches for industrial/commercial use. Please contact Customer Service Department

for further information.

Congratulations on your choice!

AFTER READING AND UNDERSTANDING THIS MANUAL, LEARN TO USE

YOUR WINCH. After installing the winch, practice using it so you will be

familiar with it when the need arises.

2

27

(NOTES,

NOTAS)

MOUNTING YOUR WINCH

MOUNTING KITS

SUPERWINCH RECOMMENDS THE USE OF A MOUNT KIT FOR SECURE MOUNTING TO

YOUR VEHICLE. For information on available kits, contact your Superwinch product

dealer or go to www.superwinch.com for the most current list of kits.

If you choose not to purchase a mounting kit, your Superwinch needs to be attached

to a secure and at mounting location. Note that your winch may not be able to be

operated safely without some equipment included in the kit. If you choose not to

purchase a mounting kit, contact Superwinch for recommended accessories and the

name of a dealer near you.

Detailed mounting instructions for your specic vehicle are provided with each mounting kit. Read and follow directions carefully.

D R

CAUTION

!

and void your warranty.

!

Fig. 1

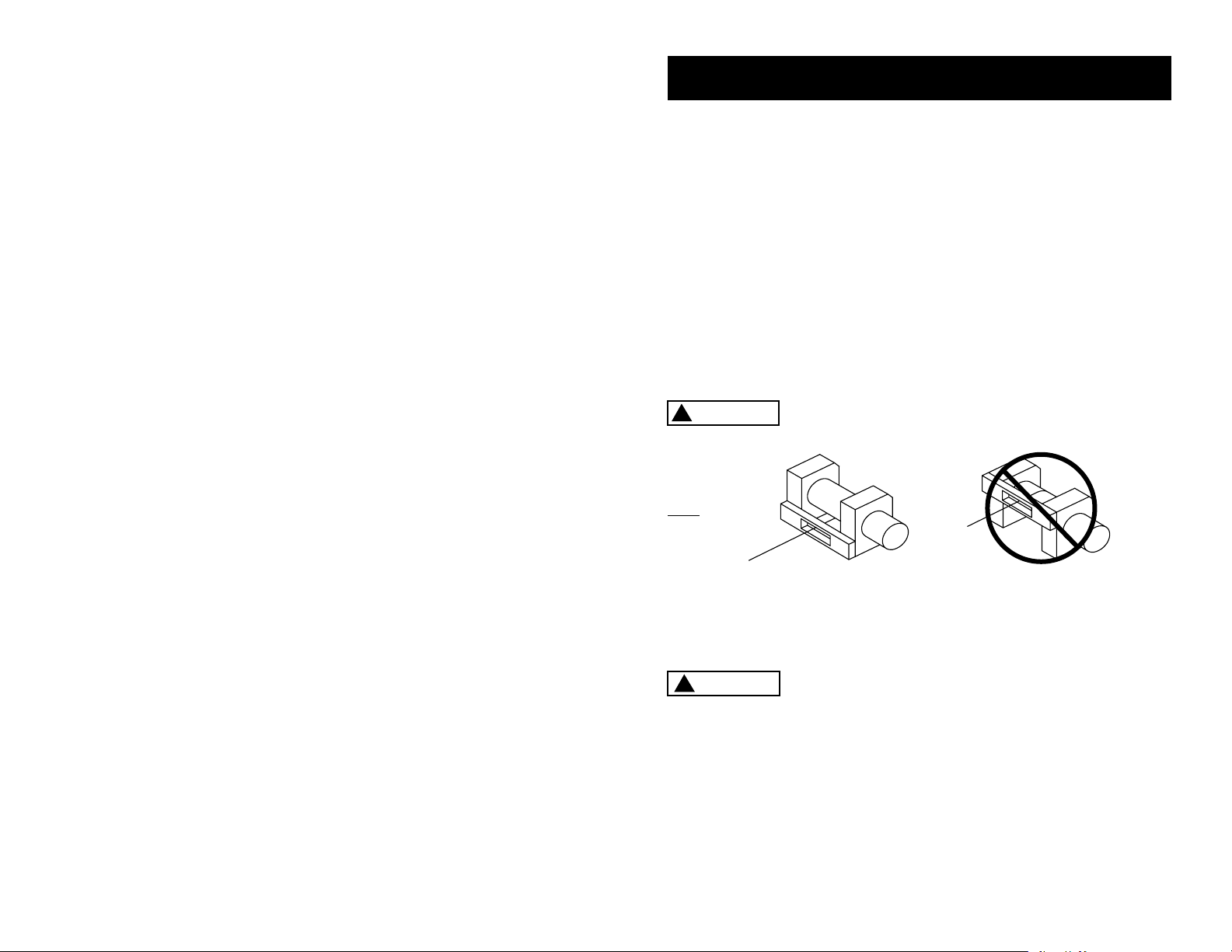

Note: Your winch is designed to ROPE IN and ROPE OUT in one direction. Do not at-

tempt to reverse the operation of your winch.

Do not mount winch inverted (base upward) or put the

CAUTION

!

winch mounting hardware in direct tension condition. In all

installations, the unit must be mounted so the rope feeds through the hawse or

roller fairlead on the front of the winch and does not rub across housings.

For winch capacities, a complete parts list, and an exploded diagram of your specic

Superwinch, refer to the Technical Data Sheet included in this package.

For instructions on safe winch operation and tips for prolonging the life of your winch,

refer to the User’s Guide included in this package.

This winch must be mounted with the rope in the under wound

direction ( Fig. 1 ) Improper mounting could damage your winch

Underwind

Overwind

26

3

Improper mounting

WARNING

!

can cause personal

!

injury. Improper mounting could

damage your winch and void the warranty.

MINIMUM ELECTRICAL REQUIREMENTS

A 60 amp. alternator and battery with

440 cold-cranking amperes capacity

are the minimum recommended power

sources. If the winch is in heavy use, an

auxiliary battery is recommended.

Under some circumstances, it may be

appropriate to install additional circuit

protection devices (circuit breakers). If

in

doubt, seek appropriate advice.

Superwinch recommends that all winch

electrical systems can be readily and

quickly isolated from their electrical supply in the event of an emergency. The

winch electrical’s system should always

be isolated when the winch is not in use.

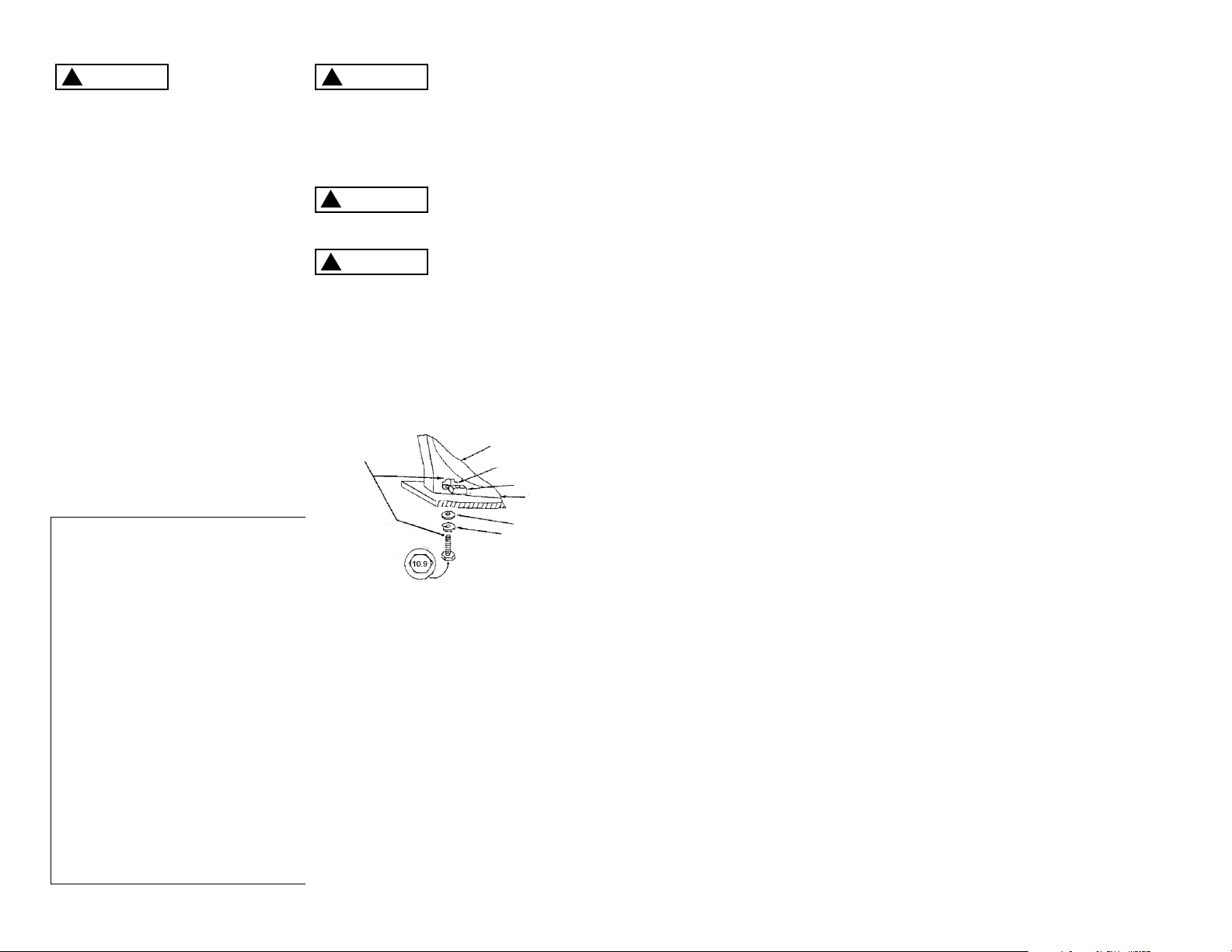

1. Install mounting kit or structural sup-

port for the winch.

2. Mount the winch to a mounting plate

or to a mount that you have properly

designed.

If not using a Superwinch mounting

accessory, follow the general

guidelines listed below.

For 9.5 and 11.5 models:

Mounting plate must be minimum 1/4”

(6.3mm) thick. Mounting bolt threads must

fully engage nut, but bolt must not contact

opposite side of nut pocket in casting. All 4

mounting bolts must be used to secure the

winch.

(see Fig 2 insert)

Your winch is a very

WARNING

!

!

powerful machine.

To protect yourself and property, the

winch must be properly mounted to a

structural support capable of withstanding the high pulling capacity of

the winch.

Do not substitute

WARNING

!

!

any strength grade

weaker than SAE Grade 8 (ISO 10.9).

CAUTION

!

If remote mounting,

the soleniod box, the solenoid pack

may be mounted in any configuration

EXCEPT inverted (i.e. solenoid studs

facing down). Inverted mounting may

cause erratic operation. Use properly

sized wire or contact Superwinch for

remote mount kit options.

(Must not touch)

M

Support Casting

Mounting Pocket

Bolt

Nut

Mounting Plate

Flat Washer

Lock Washer

(NOTES,

NOTAS)

For 13.5 and 15.5, 17.5 models:

Mounting hardware suppied with winch is

sized for a 5/16” (8mm) thick mounting plate.

For thicker mounting plates, minimum 18mm

(0.700”) bolt engagement in casting is

required. Bolts must not bottom out in the

tapped holes before being fully tightened. All

8 mounting bolts should be used when

possible. Minimum of 4 bolts required.

6.5” x 10” (165.1mm x 254mm) pattered is prefered

4.5“ x 10” (114.3mm x 254mm) pattern is acceptable.

4

INSTALLATION

Figure 2

25

Le Treuil de Collection de Requin de tigre

TELEGRAPHIER DIAGRAMME pour Le Treuil de Requin de tigre Modèle; 9,500 11,500

Contrôle de poche :

Rouge-à-le blanc = Hors

Rouge-à-le noir = En

!

PRUDENCE

Le circuit de commutation de

Requin de tigre est conçu pour

l'usage avec le contrôle de

poche qui est fourni avec le treuil.

Il ne peut pas être compatable avec

les autres contrôleurs de treuil,

connectés ou la radio.

Utiliser seulement des contrôles

de Superwinch qui sont conçus

pour l'usage avec ce produit de

treuil de Requin de Tigre. L'usage

d'aucuns autres fabricants contrôle

le système annulera votre garantie

et peut causerdes dommages à l'un

/ou de treuil systèmesaccessoires.

TELEGRAPHIER DIAGRAMME pour Le Treuil

de Requin de tigre Modèle;

Contrôle de poche :

Rouge-à-le blanc = Hors

Rouge-à-le noir = En

!

PRUDENCE

Le circuit de commutation de

Requin de tigre est conçu pour

l'usage avec le contrôle de

poche qui est fourni avec le treuil.

Il ne peut pas être compatable avec

les autres contrôleurs de treuil,

connectés ou la radio.

Utiliser seulement des contrôles

de Superwinch qui sont conçus

pour l'usage avec ce produit de

treuil de Requin de Tigre. L'usage

d'aucuns autres fabricants contrôle

le système annulera votre garantie

et peut causerdes dommages à l'un

/ou de treuil systèmesaccessoires.

Hors

blanc

de Pouvoir

Brown

Power

Out

Hors

brun de

Pouvoir

Rouge + 12VDC 2 AGW

Le Pouvoir

noir En

Le Pouvoir

rouge

de Douille

Le Sol noir de

Solénoïde

2 AWG/LES

AUTOBUS

BARRENT

2 AWG/LES AUTOBUS BARRENT

2 AWG/LES AUTOBUS BARRENT

Le Pouvoir

bleu de

Douille

C B

Le Pouvoir

jaune En

Un

2 AWG/LES AUTOBUS BARRENT

D

2 AWG/LES AUTOBUS BARRENT

Positif Négatif

Pile

LA VIS DE SOL DE

MOTEUR DE TREUIL

13,500 15,500 17,500

Positif Négatif

Rouge + 12VDC 2 AGW

LA VIS DE SOL DE

MOTEUR DE TREUIL

Le Sol noir de

Solénoïde

2 AWG/LES

AUTOBUS

BARRENT

Le noir Fonde 2 AWG

Pile

Le noir Fonde 2 AWG

24

If different length

WARNING

!

!

bolts, nuts, washers

and other hardware are required for

your installation, always use hardware that equals or exceeds the

strength grade of the supplied hardware. In no circumstance should the

end of the mounting bolts touch the

inside of the casting mount pockets.

WARNING

!

!

Automobile batteries

contain gasses

which are and explosive.

Wear eye protection during installation and remove all metal jewelry.

Do not lean over battery while making connections.

3. Disconnect the vehicle negative and

positive battery leads. Route the long

red and black color coded wires to the

battery. To ensure against insulation

abrasion and/or cutting, apply several

layers of electrical tape where wiring

may come in contact with sharp parts

on the vehicle. Attach the red color

coded wire to the battery positive and

reattach the terminal to the battery.

If your vehicle is equipped with side

pole terminals, it may be necessary

to obtain auxiliary side terminal bolts

from your local auto parts dealer to

make these connections.

Connect the black color coded wire to

the battery negative terminal, then

connect the terminal to the battery.

4.

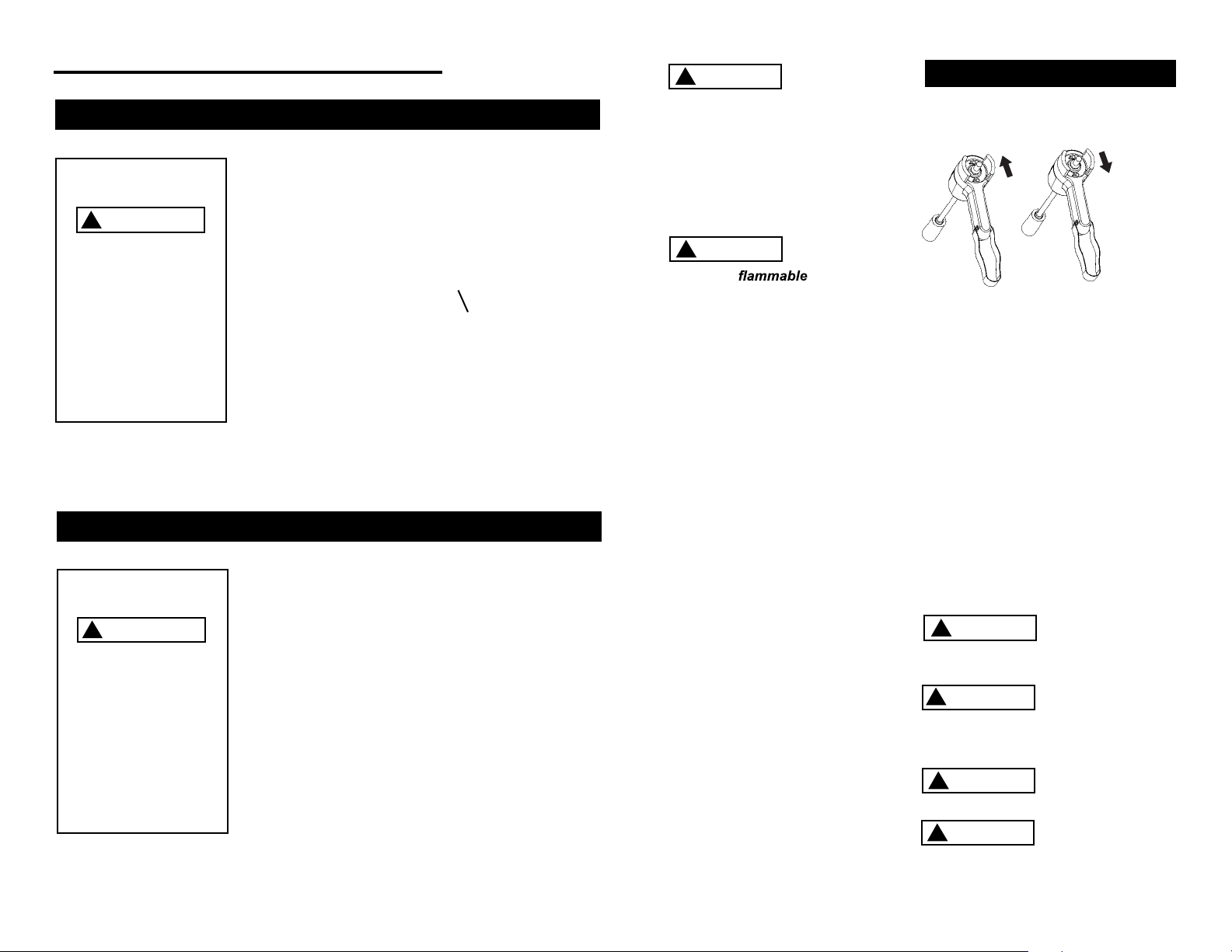

Pull and turn the freespool clutch lever

to the, “disengaged” position. Pull sev-

eral feet of wire rope off the drum.

Return the clutch lever back to the,

“engaged” position. Plug in remote

pendant control. Push button momen tarily to check rope drum rotation

direction. If drum rotates in the wrong

direction, recheck your wiring.

OPERATION

PENDANT OPERATION

Rope Out

Figure 3

The handheld pendant switch

activates a solenoid that activates

power to the winch motor.

To connect the pendant control,

remove the cover on the plug

receptacle and insert the plug end

of remote switch. The plug on the

pendant control cord is keyed and

will fit into the socket only one

way.

The switch trigger returns to the

“Off” position when released.

To change direction, move the

toggle in the other direction.

The switch assem-

CAUTION

!

free of dirt and moisture to ensure

safe operation.

W

ARNING

!

break before the

winch stalls. For heavy loads use a

pulley block to reduce the load on

the wire rope.

If the winch motor

CAUTION

!

stalls, do not continue to apply power to the winch.

CAUTION

!

orized use of

winch, remove the pendant control

and store it in a clean dry area such

as the glove box.

Rope In

bly must be kept

The wire rope may

To prevent unauth-

the

5

Loading...

Loading...