S101622 Rev. 1 superwinch.com | info@superwinch.com 1

User’s Manual

SI Series, Hydraulic 8,000 & 10,000

Safety Precautions

S101622 Rev. 1 superwinch.com | info@superwinch.com 2

READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND

OPERATION OF YOUR SUPERWINCH

Table of Contents

1 INTRODUCTION

2 GENERAL SPECIFICATION DATA

INSTALLATION

3 HYDRAULIC SYSTEM

4 WINCH

5 ROPE

COMMISSIONING AND USE

6 FREESPOOL USE

7 TIPS FOR EXTENDING THE LIFE OF YOUR WINCH

MAINTENANCE

8 RUNNING IN, MAINTENANCE & SERVICING

9 HYDRAULIC SYSTEM TROUBLESHOOTING

PARTS

10 ACCESSORIES

11 WARRANTY

S101622 Rev. 1 superwinch.com | info@superwinch.com 3

1. INTRODUCTION

From all of us at Superwinch, “thank you.” We’ve built this winch to perform and

we’ve built this manual to help you get the most from your Superwinch.

Please read and understand this owner’s manual before installing your SI Series winch. You

industrial winch is a very powerful machine. If used unsafely or improperly, there is a possibility

that property damage or personal injury can result. We have included several unique features in

the Hydraulic Industrial winch to minimize this possibility; however, your safety ultimately

depends on your caution when using the product.

Pay particular attention to the caution notes preceded with the symbol shown here. The notes

contain advice for your safety and protection.

Please Note: The Superwinch SI Series winches are designed for total reliability. This winch is not

designed to be used in hoisting applications and Superwinch does not warrant it to be suitable

for such use.

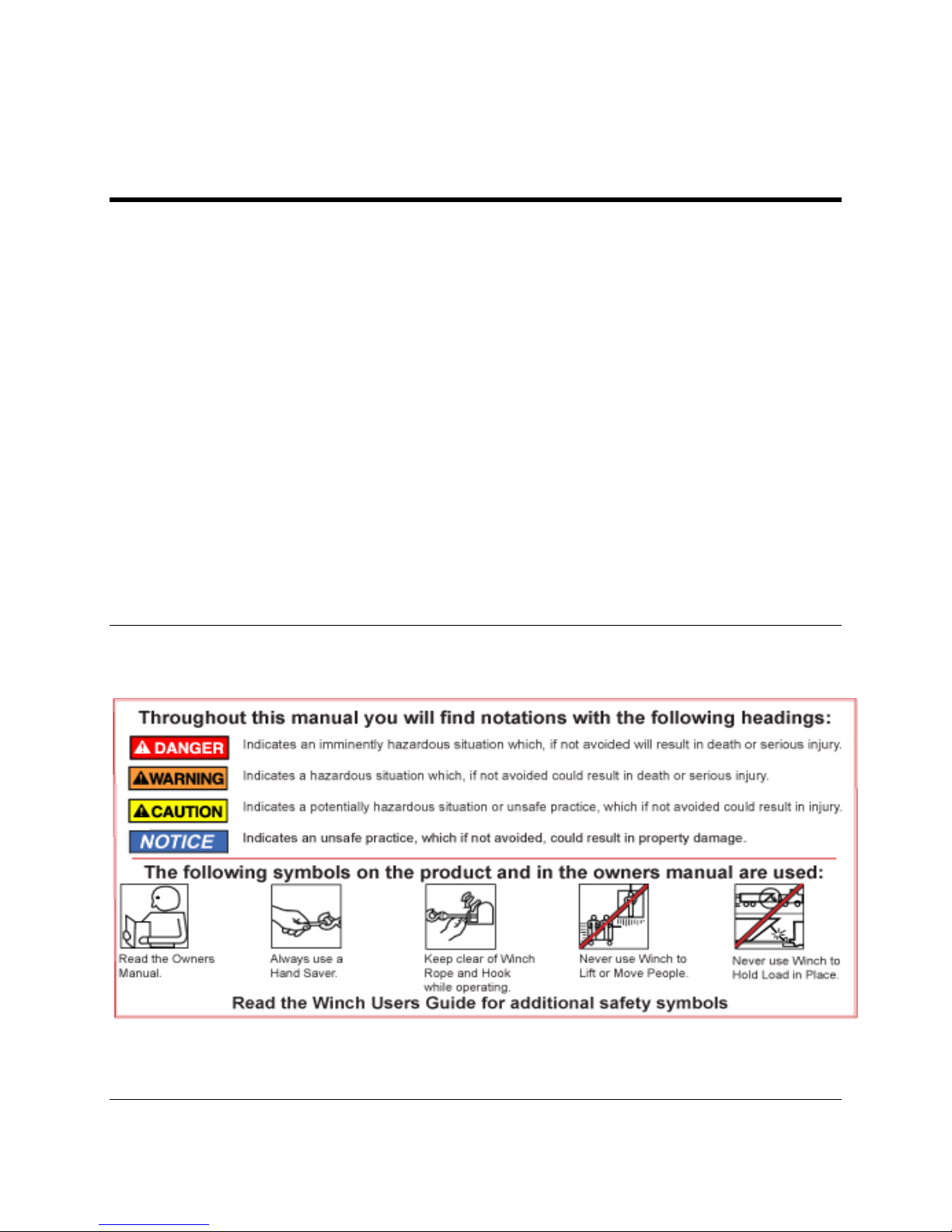

WARNING, CAUTIONS AND NOTES

These warnings, cautions and notes are given throughout these instructions in the following

forms:

REPAIRS AND REPLACEMENTS

S101622 Rev. 1 superwinch.com | info@superwinch.com 4

Before contacting Superwinch or your nearest authorized Superwinch dealer, please have the

following information:

Part Number:

Serial Number of the Winch:

POISONOUS SUBSTANCES

Many liquids and other substances used should under no

circumstances be consumed, and should be kept away from

open wounds. These substances include (among others)

hydraulic oil.

SYNTHETIC RUBBER

Many ‘O’ ring seals, flexible pipes and similar items, when

subjected to fire or heat can become highly corrosive. Handle

with seamless industrial gloves only. Should skin contact occur,

remove contaminated clothing immediately and obtain medical assistance without delay.

RECYCLING AND THE ENVIROMENT

It is illegal to dispose of used oil in the ground, down sewers or

drains, or into waterways.

Dispose of used oil through an authorized waste disposal

contractor or recycling center. If in doubt contact your local authority for advice on how to

dispose of the oil or disposal facilities.

S101622 Rev. 1 superwinch.com | info@superwinch.com 5

2. GENERAL SPECIFICATION DATA

Type: Hydraulic Industrial

Gear Reduction: Planetary

Gear Ratio: 16:1

Drum: Steel Drum

Braking: Integral bi-directional, full load holding, hydraulically released,

spring applied brake.

Load Control: Optional Superblock Load Control Valve provides dynamic brake to

give a controlled stop on winch-out, under load. Brake opening

also assisted by Superblock.

Freespool: Operated either by an ergonomically designed handle, a cable

system, or by integral pneumatic device. Can be mounted to winch

side or top.

Mounting: Designed to meet most industry standard dimensions, 4 ½” x 10”

(254mm x 114.3mm). See 4) Winch Installation section of this

manual for more information.

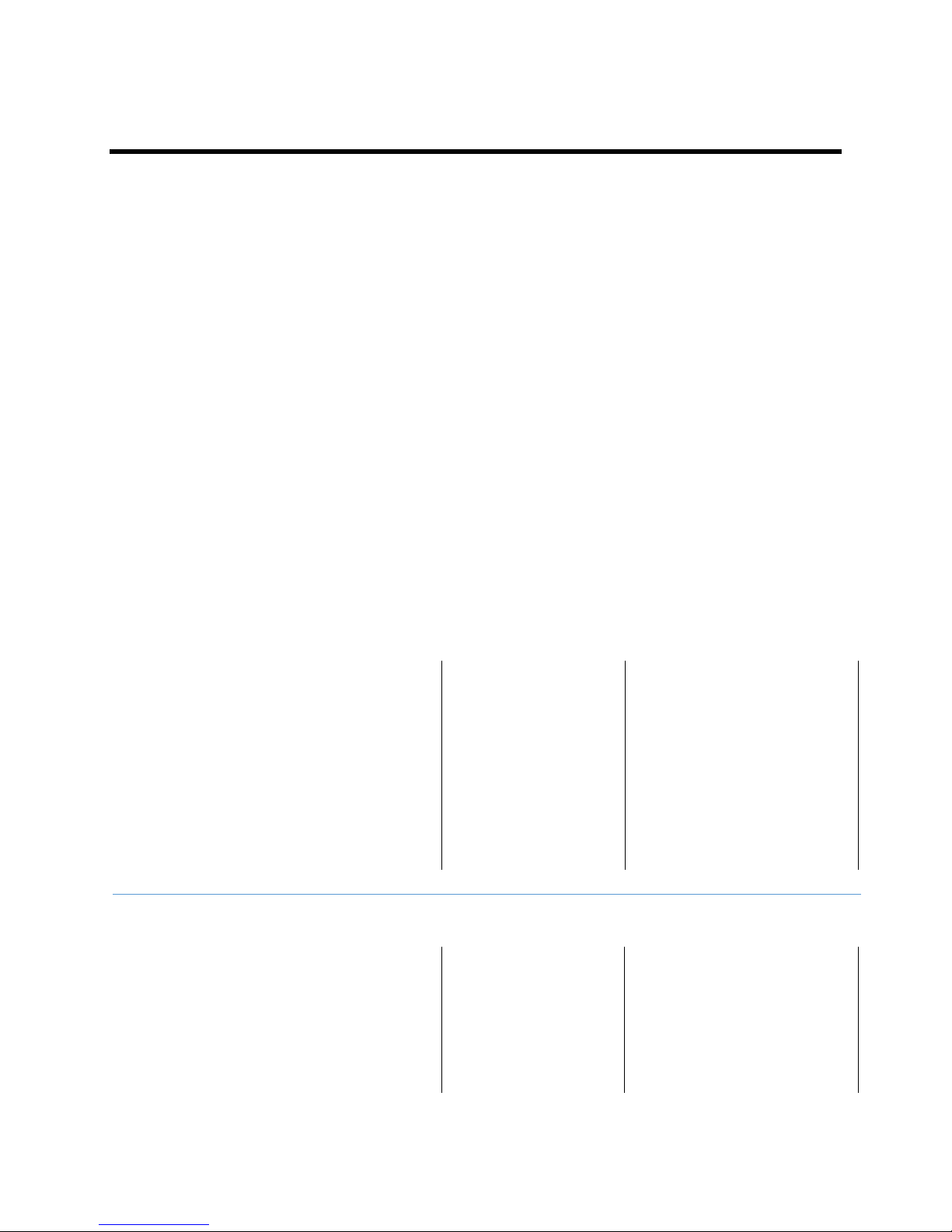

STANDARD DRUM MODELS

Model Designation

SI- 8K Hyd.

SI- 10K Hyd.

Part Number

S100419

S100420

Weight (Less Rope)

107 lbs. / 48.5 kg

109 lbs. / 49.4 kg

Recommended Rope Diameter

3/8" / 9.5mm

3/8" / 9.5mm

Drum Capacity

169' / 51.5m

169' / 51.5m

Drum Diameter

3.5"/ 88.9mm

3.5"/ 88.9mm

Line Speed (1st Layer, No Load)

52 FPM / 15.8 MPM

31.5 FPM/ 9.6 MPM

Line Pull (Bottom Layer)

8,000 lbs. / 3628 kg.

10,000 lbs. / 4536 kg.

Operating Pressure

2200 PSI / 152 Bar

2050 PSI / 141 Bar

Oil Flow

15 GPM / 56.8 LPM

15 GPM / 56.8 LPM

LONG DRUM MODELS

Model Designation

SI- 8K Hyd.

SI- 10K Hyd.

Part Number

S100425

S100426

Weight (Less Rope)

111 lbs. / 50.3 kg

113 lbs. / 51.3 kg

Recommended Rope Diameter

3/8" / 9.5mm

3/8" / 9.5mm

Drum Capacity

202' / 61.5m

202' / 61.5m

Drum Diameter

3.5"/ 88.9mm

3.5"/ 88.9mm

Line Speed (1st Layer, No Load)

52 FPM / 15.8 MPM

31.5 FPM/ 9.6 MPM

S101622 Rev. 1 superwinch.com | info@superwinch.com 6

Line Pull (Bottom Layer)

8,000 lbs. / 3628 kg.

10,000 lbs. / 4536 kg.

Operating Pressure

2200 PSI / 152 Bar

2050 PSI / 141 Bar

Oil Flow

15 GPM / 56.8 LPM

15 GPM / 56.8 LPM

SHORT DRUM MODELS

Model Designation

SI- 8K Hyd.

SI- 10K Hyd.

Part Number

S100422

S100423

Weight (Less Rope)

105 lbs. / 47.6 kg

107 lbs. / 48.5 kg

Recommended Rope Diameter

3/8" / 9.5mm

3/8" / 9.5mm

Drum Capacity

135' / 41.1m

135' / 41.1m

Drum Diameter

3.5"/ 88.9mm

3.5"/ 88.9mm

Line Speed (1st Layer, No Load)

52 FPM / 15.8 MPM

31.5 FPM/ 9.6 MPM

Line Pull (Bottom Layer)

8,000 lbs. / 3628 kg.

10,000 lbs. / 4536 kg.

Operating Pressure

2200 PSI / 152 Bar

2050 PSI / 141 Bar

Oil Flow

15 GPM / 56.8 LPM

15 GPM / 56.8 LPM

HYDRAULIC SYSTEM RECOMMENDATIONS

Note: These parts are listed as minimum expectations for the Superwinch SI Series to perform to

its fullest.

System Type Open system with filtered return line

Relief Valve Set at winch operating pressure

Pump A max oil supply of 15 gallons per minute (57 Liters/ per minute) at top

motor RPM. The pump must be capable of delivering a pressure of 2320

PSI or 160 bar.

Reservoir Must be fitted with an oil filler device comprising of a strainer, an air filter,

and a dip stick. The capacity of the tank should be at least 15.8 gal (60 L).

Note: Do not fill the tank to the top, since there must be space for

expansion in the tank. Suitable hydraulic oil is Castrol CRML or

equivalent. Typical viscosity rating of 150 – 175 CST at 100 degrees C

Hoses Hoses should have a working pressure of 2900 psi (200 bar) or greater.

Pressure and flow loss is increased as hose length increases and/or bore

sizes decreases. Pressure and return lines in excess of 11.5 ft. (3.5 m)

should be compensated with an increase in nominal bore size.

Control Valve 4- way, 3- position self-centering with ports A & B to tank in the neutral

position and built in relief valve. The relief valve must be set at the winch

operating pressure. The valve should be mounted as close to the winch

as possible.

Loading...

Loading...