GARANTIE LIMIT É E

VALABLE A TRAVERS LE MONDE

GARANTIE LIMITÉE. Superwinch, Inc. (le “Vendeur”) garantit à l’acheteur d’origine (“vous”) que

toutes les pièces et composants, à l’exception du câble métallique, sont sans vice de matériaux ou

de fabrication, et ce, pendant une période d’un (1) an à compter de la date d’achat prouvable.

Tout produit Superwinch défectueux sera réparé ou remplacé sans dépenses de votre part si vous

respectez ces procédures. Les garanties énoncées par les présentes sont exclusives tiennent lieu de

toutes autres garanties

PROCÉDURE DE RECOURS À LA GARANTIE LIMITEE.

Dès découverte d’un produit Superwinch défectueux, vous devrez envoyer à Superwinch, à l’usine

ou à un Centre de réparation autorisé par l’usine, une notification écrite dudit défaut et vous

devrez envoyer par courrier ou autre service de livraison le Superwinch défectueux, port et frais

postaux payés à l’avance. Les réparations ou remplacements par le Vendeur conformément à la

présente Garantie

tion du Superwinch défectueux. Le Vendeur ou ses Agents autorisés peut facturer des frais

raisonnables pour les pièces et la main d’oeuvre en cas de réparation non couverte par la présente

Garantie limitée.

LIMITATIONS ET EXCLUSIONS EN CE QUI CONCERNE LA GARANTIE ET LES REMÈDES.

La réparation et/ou le remplacement de tout Superwinch défectueux ou de tout composant d’un

tel Superwinch tel que convenu par les présentes est votre remède exclusif. Les exclusions et limitations de garanties et les limitations de REMEDES ci-dessous seront expressément applic

A. Garanties expresses . Le Vendeur garantit que le Superwinch est tel qu’il est décrit dans le

“Mode d’emploi Superwinch” fourni avec la présente; aucune autre garantie expresse n’est donnée en ce qui concerne le Superwinch. Si un modèle ou échantillon vous a été montRé, ledit modèle ou échantillon a été utilisé à des fins d’illustration uniquement et ne sera

garantie que le Superwinch sera conforme au modèle ou à l’échantillon. LE VENDEUR NE DONNE

AUCUNE GARANTIE EXPRESSE EN CE QUI CONCERNE LE

DUIT.

B. Garantie implicite . LA GARANTIE IMPLICITE DE L’APTITUDE À LA VENTE ET TOUTE AUTRE

GARANTIE IMPLICITE S’APPLIQUERA UNIQUEMENT POUR UNE DURÉE D’UN (1) AN À COMPTER DE

LA DATE D’ACHAT PROUVABLE. LE CABLE MÉTALLIQUE EST VENDU “TEL QUEL” SANS AUTRE

GARANTIE IMPLICITE. CERTAINS ÉTATS AMÉRICAINS NE PERMETTENT PAS DE LIMITER LA DURÉE

DES GARANTIES IMPLICITES; IL EST DONC POSSIBLE QUE LA LIMITATION CI-DESSUS NE S’APPLIQUE

PAS À VOTRE CAS.

C. Dommages indirects. SUJET AUX OBLIGATIONS DE LA GARANTIE LIMITÉ

ÉNONCÉES DANS LE PRÉSENT DOCUMENT, LE VENDEUR NE SERA AUCUNEMENT RESPONSABLE DE

DOMMAGES INDIRECTS, DE QUELQUE NATURE QUE CE SOIT, NI DE DOMMAGES INDIRECTS À LA

PROPRIÉTÉ, NI DE PERTES DE PROFITS, NI DE PERTES D’UTILISATION POUVANT SURVENIR À CAUS

D’UN DÉFAUT, D’UN MAUVAIS FONCTIONNEMENT OU D’UNE PANNE QUELCONQUE DU SUPERWINCH CI-JOINT. CERTAINS ÉTATS AMÉRICAINS NE PERMETTENT PAS D’EXCLURE OU DE LIMITER

LES DOMMAGES INDIRECTS; IL EST DONC POSSIBLE QUE LA LIMITATION CI-DESSUS NE S’APPLIQUE

PAS À VOTRE CAS.

D. Condition

garantie fournies par les présentes si la cause du défaut, du mauvais fonctionnement ou de la

panne du Superwinch est un dommage (ne résultant pas de composants défectueux ou qui fonctionnent mal) ou une utilisation déraisonnable par vous. Le terme Utilisation déraisonnable comprend mais ne est pas limité au manquement à la maintenance, à l’installation et à l’utilisation

raisonnables et nécessaires conformément aux consignes contenues dans le Mode

Superwinch, et à l’utilisation du Superwinch pour des charges supérieures à celle figurant dans le

Mode d’emploi pour le modèle en question. La responsabilité du Vendeur sous la présente

garantie ou pour toute

coût de correction des défauts du produit Superwinch ou de remplacement de celui-ci, et lors de

l’expiration de la période de garantie, toute telle responsabilité prendra fin. Les agents, distributeurs et employés du Vendeur ne sont pas autorisés à modifie

d’autres garanties complémentaires obligatoires pour le Vendeur. Toute déclaration supplémentaire, qu’elle soit écrite ou orale, ne constituera donc pas une garantie et ne devra pas être considérée comme valable.

REMEDES LÉGAUX DE L’ACHETEUR. Cette garantie limitée vous donne des droits légaux spécifiques et il est possible que vous ayez d’autres droits qui varient d’un état à l’autre aux Etats-Unis

et d’un pays à l’autre. Vous avez également des droits de garantie implicite. En cas de probl

avec le service ou la performance suivant la garantie limitée, il est possible que vous puissiez intenter une action en justice devant la

d’état ou devant le tribunal fédéral des Etats-Unis ou dans une autre juridiction appropriée en

dehors des Etats-Unis.

QUESTIONS. Toute question en ce qui concerne le respect des garanties énoncées dans les

présentes doit être envoyée, par écrit, à : Superwinch, Inc., Winch Drive, Putnam, CT 06260 U.S.A.

ou à Superwinch Limited, Abbey Rise, Whitchu

de la garantie. Le Vendeur ne sera pas tenu de se conformer aux obligations de

expresses ou implicites.

s’effectueront normalement dans les quinze (15) jours ouvrables suivant récep-

ables :

pas considéré une

CABLE MÉTALLIQUE INCORPORÉ AU PRO-

E DU VENDEUR

d’emploi

perte du produit Superwinch ou dommage à celui-ci ne dépassera pas le

r la présente garantie ni à donner

ème

Cour des Prudhommes (“small claims court”), devant le tribunal

rch Road, Tavistock, Devon PL 19 9DR, England

OWNER’S MANUA L

INSTALLATION • OPERATION • MAINTENANCE

E

SAFETY PRECAUTIONS • REPAIR PARTS

S4000 and S5000

12 & 24 Volt DC Electric Winches

With Remote Control

CAUTION

!

READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION

AND OPERATION OF YOUR SUPERWINCH PRODUCT.

Ratings assume a 10% coefficient of friction.

* A 10% slope is a rise of one foot in ten feet. Slope in approximate degrees is also shown above.

** All loads shown are for single-line operation. Double-line operation with optional pulley block

(see Figure 3) approximately doubles capacity of winch.

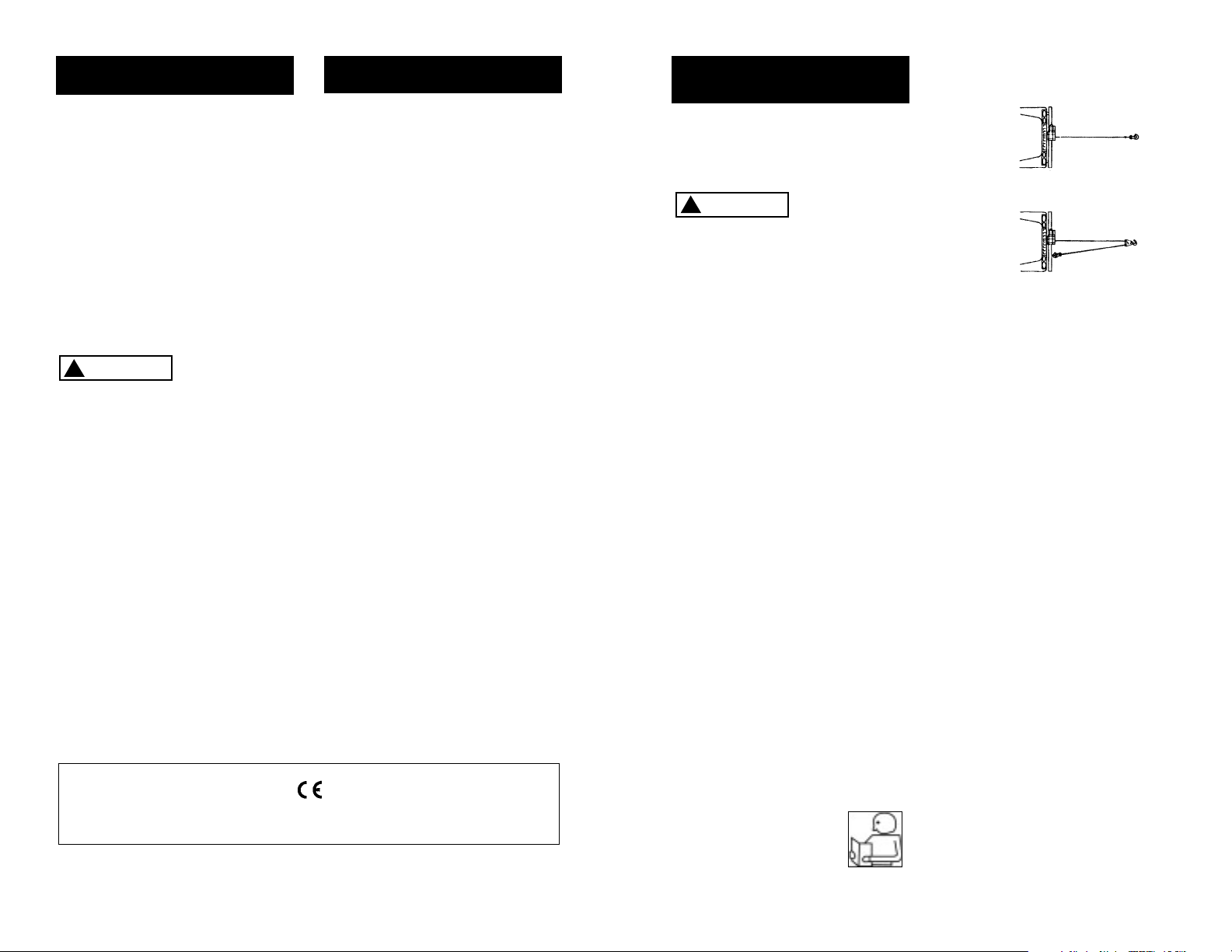

Figure 1

Freespool Clutch

In-Drum Brake

Remote Switch

Receptacle

Permanent

Magnet Motor

GENERAL DESCRIPTION

Integrated Solenoids

32

Thank you for purchasing an S series winch from Superwinch. It has been designed and

manufactured to provide years of trouble-free operation. We hope you will be pleased

with its performance. If you are not, for any reason, please contact our Customer Service

Department: (860) 928-7787 USA; (1822) 614101 England.

When requesting information or ordering replacement parts; always give the

following information:

1. Winch Part Number

2. Serial Number (found on housing)

3. Part Number (found in Replacement Parts List section)

4. Part Description

Please read and understand this Owner’s Manual before installing your winch. Pay particular

attention to the General Safety Information. Your winch is a very powerful machine. If used

unsafely or improperly, there is a possibility that property damage or personal injury could

result. We have included several features in the winch to minimize this possibility; however,

your safety ultimately depends on your caution when using this product.

The responsibility for safe operation of this winch ultimately rests with you, the operator.

Read and understand all safety precautions and operating instructions before installing

and operating the winch. Careless winch operation can result in serious injury and/or

property damage.

Throughout this manual, you will find notations with the following headings:

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. This notation is also used

to alert against unsafe practices.

The following symbols on the product and in the Owner's manual are used:

Note

: Indicates additional information in the installation and operation procedures

of your winch.

Correct installation of your winch is a requirement for proper operation.

Please Note: The Superwinch S series winch is designed primarily for intermittent duty

general use. This winch is not designed to be used in industrial or hoisting applications

and Superwinch does not warrant it to be suitable for such use. Superwinch manufactures

a separate line of winches for industrial/commercial use. Please contact our Customer Service

Department for further information.

Congratulations on your choice!

INTRODUCTION

Roller Fairlead

ROLLING LOAD CAPACITIES

S4000

Working Load* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,000 lb. (1814 kg)

Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7/32" x 60'

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 12V or 24VDC 1.8 hp (1.34 kW) peak

Gear Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159:1

S5000

Working Load* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,000 lb. (2268 kg)

Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4" x 50'

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 12V or 24VDC 2.1 hp (1.57 kW) peak

Gear Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159:1

* Based on first layer performance

SPECIFICATIONS

S5000

S4000

Slope* 10% (6º) 20% (11º) 30% (17º) 100% (45º)

Lbs.**

kg**

17,588

7,978

11,905

5,400

9,138

4,145

4,499

2,041

Slope* 10% (6º) 20% (11º) 30% (17º) 100% (45º)

Lbs.**

kg**

22,613

10,257

15,306

6,943

11,749

5,329

5,784

2,624

Read Owner's

Manual

Always Use

Handsaver

Keep clear of winch,

wire rope and hook

while operating

Never use winch

to lift or move

people

Never use

winch to hold

loads in place

SAFETY PRECAUTIONS

DANGER

!

WARNING

!

CAUTION

!

Description Quantity

Winch assembly with wire rope including lead wires 1

Circuit breaker assembly with hardware 1

Handsaver 1

Mounting hardware kit 1

Remote pendant 1

Owner’s manual 1

This carton contains the following items. Please unpack carefully.

Read instructions before beginning.

UNPACKING

DIMENSIONS

S4000, S5000

Figure 2

PERFORMANCE

Wire Rope Max. Pulling Capacity

Layer lbs. kg

1 4,000 1814

2 3,000 1361

3 2,600 1179

4 2,000 907

Motor

Load Speed Current

lbs. kg ft/min m/min Amps

0 0 21.6 6.6 30

1,000 454 16.0 4.9 90

2,000 907 12.4 3.8 155

2,500 1134 10.6 3.2 180

3,000 1361 8.8 2.7 215

3,500 1588 6.2 1.9 250

4,000 1814 4.5 1.4 311

Wire Rope Max. Pulling Capacity

Layer lbs. kg

1 5,000 2268

2 4,000 1814

3 3,500 1588

4 2,900 1315

Motor

Load Speed Current

lbs. kg ft/min m/min Amps

0 0 17.5 5.3 36

1,000 454 14.5 4.4 80

2,000 907 12.0 3.7 135

3,000 1361 9.5 2.9 200

4,000 1814 7.3 2.2 265

5,000 2268 4.5 1.4 350

S4000

S5000

* Based on first layer performance

NOTES

1. All dimensions are in inches [millimeters].

2. Typical mount is to flat surface capable of handling the loads. Bolts to be Grade 5 or better.

6.0

(152)

15.1

(383)

7.2

(183)

7.1

(180)

3.1

(79)

5.9

(150)

3.69

(93.7)

1.24

(31.5)

ROLLER FAIRLEAD

SCREWS

DRUM SUPPORT

PLATE SCREWS

MOTOR

SCREWS

4 5

DRUM SUPPORT

PLATE

Your S series winch is a very powerful

machine. Treat it with respect, use it

with caution and always follow the

safety guidelines.

The wire rope

may break

before the winch stalls. For heavy

loads, use a pulley block to reduce

the load on the wire rope.

1. The S4000 and S5000 winch is

rated at 4,000 and 5,000 pounds

(1814 and 2268 kg) (single line)

capacity on the wire rope layer

closest to the drum. DO NOT

OVERLOAD. DO NOT ATTEMPT

PROLONGED PULLS AT HEAVY

LOADS. Do not maintain power

to the winch if the motor stalls.

Overloads can damage the winch

and/or the wire rope and create

unsafe operating conditions. FOR

LOADS OVER

2

/3RATED CAPACITY, WE RECOMMEND THE USE OF

THE OPTIONAL PULLEY BLOCK TO

DOUBLE LINE THE WIRE ROPE

(Figures 3 & 15). This reduces the

load on the winch and the strain

on the wire rope by approximately

50%. If attaching back to vehicle,

attach to the frame or other load

bearing part. The vehicle engine

should be running during winch

operation to minimize battery drain

and maximize winch power and

speed. If considerable winching is

performed with the engine off,

the battery may be too weak to

restart the engine.

2. AFTER READING AND UNDERSTANDING THIS MANUAL, LEARN

TO USE YOUR WINCH.

After installing the

winch, practice

using it so you

will be familiar with it when the

need arises.

3. DO NOT “move” your vehicle to

assist the winch in pulling the

load. The combination of the

winch and vehicle pulling together

could overload the wire rope and

the winch.

4. KEEP WINCHING AREA CLEAR. Do

not allow people to remain in the

area during winching operations.

ALWAYS STAND CLEAR OF WIRE

ROPE, HOOK AND WINCH. IN THE

UNLIKELY EVENT OF ANY COMPONENT FAILURE, IT IS BEST TO

BE OUT OF HARM‘S WAY.

5. INSPECT WIRE ROPE AND EQUIPMENT FREQUENTLY. A FRAYED

WIRE ROPE WITH BROKEN

STRANDS SHOULD BE REPLACED

IMMEDIATELY. Always replace

wire rope with the manufacturer‘s

identical replacement part (see

Replacement Parts List).

Periodically check the winch

installation to ensure that all

bolts are tight.

6. USE HEAVY LEATHER GLOVES

when handling wire rope. DO

NOT LET WIRE ROPE SLIDE

THROUGH YOUR HANDS EVEN

WHEN WEARING GLOVES.

WARNING

!

7

GENERAL SAFETY

INFORMATION

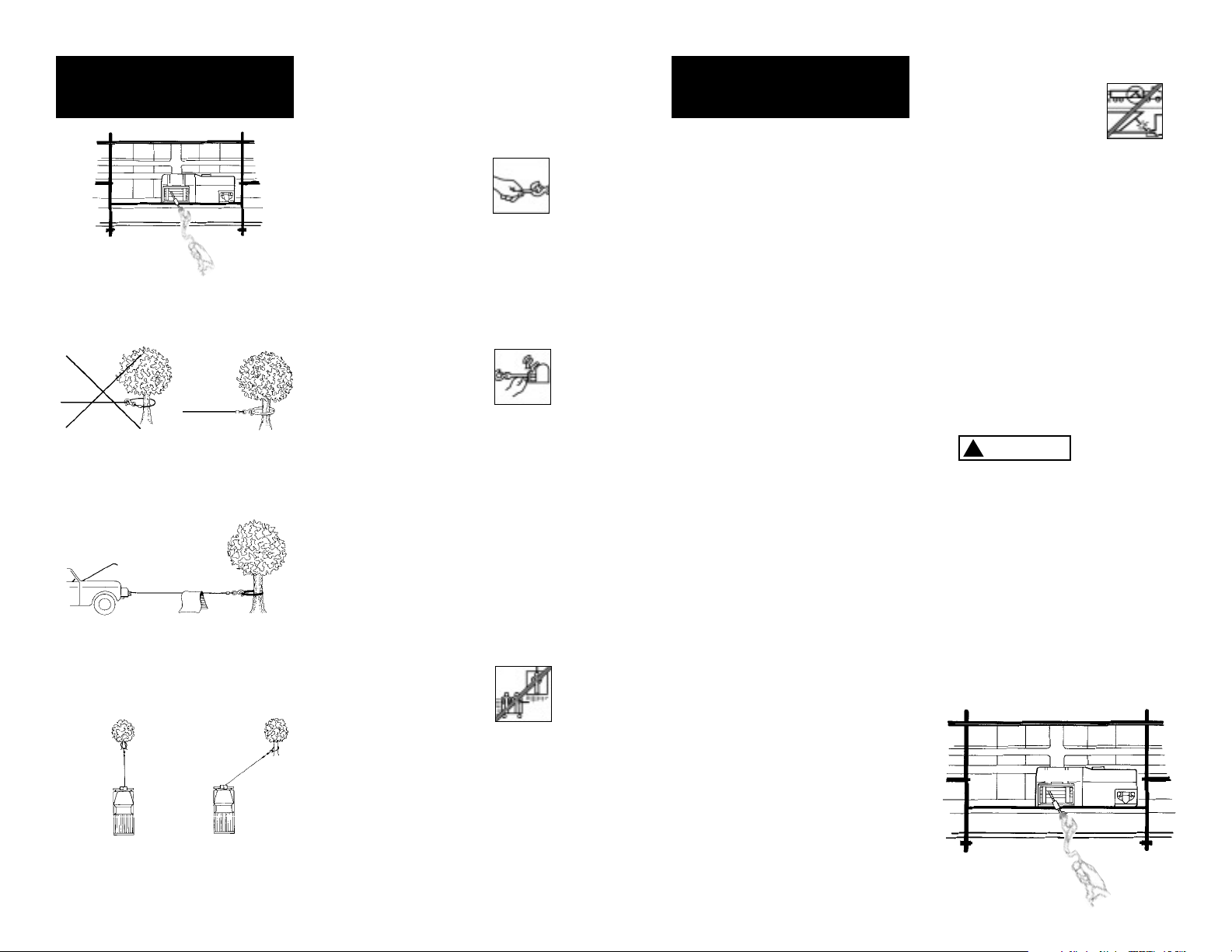

Figure 3

Single Line

Double Line

INTERMITTENT DUTY

An electric winch is like any other

motor driven power tool such as

an electric drill or saw. The electric

motor should not be allowed to

become excessively hot. Normal

precautions will extend the life

of your motor. Keep the duration

of pulls as short as possible.

If

the end of the motor becomes

uncomfortably hot to touch

,

stop winching and allow the

motor to cool down.

If the winch

motor stalls,

do not continue to apply power

to the winch.

6

FEATURES

Electric Motor – 1.8 (S4000),

2.1 (S5000) peak hp, 1.34 (S4000),

1.57 (S5000) kW) 12V or 24V

Permanent Magnet.

Braking – A wrap spring brake

which will hold 50% of rated load

on the first wrap. Reducing by

approximately 10% per layer

thereafter.

Drum – Die cast aluminum running

in maintenance free bearings.

Freespool Clutch – Operated by

an easy action lever which disengages the gearbox to allow the

wire rope to be pulled out without

using electric power. A tension

plate reduces backlash and snarling

when pulling out the wire rope.

Remote Switch – 30' (9.14 m)

handheld pendant switch assembly

with toggle switch.

Mounting – Optional custom

engineered mounting kits are available

for vehicle frame attachment.

European Union

Noise The noise level of this winch in operation is below 92 dB(A).

Battery Isolator In order to conform to Machinery Directive 89/392/EEC, each machine installation must be

fitted with an Isolator (Part Number 8370) whereby the machine can be brought safely to a complete stop.

CAUTION

!

7. NEVER WINCH WITH LESS THAN

5 TURNS of wire rope AROUND

THE WINCH DRUM since the

wire rope end fastener will NOT

withstand a load. ALWAYS USE

THE HANDSAVER

when guiding the

wire rope in or

out (see Figure 4).

8. KEEP CLEAR OF WINCH, TAUT

WIRE ROPE AND HOOK WHEN

OPERATING WINCH. Never put

your finger through the hook. If

your finger should become

trapped in the hook, you could

lose your finger.

Never guide a wire

rope onto the drum

with your hand.

9. NEVER HOOK THE WIRE ROPE

BACK ONTO ITSELF because you

could damage the wire rope.

Use a nylon sling (Figure 5).

10. It is a good idea to lay a heavy

blanket or jacket over the wire

rope near the hook end when

pulling heavy loads (Figure 6). If

a wire rope failure should occur,

the cloth will act as a damper

and help prevent the rope from

whipping. Raise the hood of the

vehicle for added protection.

11. NEVER USE YOUR

WINCH FOR LIFTING

OR MOVING PEOPLE.

12. Your winch is not designed or

intended for overhead hoisting

operations.

13. AVOID CONTINUOUS PULLS

FROM EXTREME ANGLES as this

will cause the wire rope to pile

up at one end of the drum

(Figure 7). This can jam the wire

rope in the winch, causing damage

to the rope or the winch.

14. NEVER OBSCURE THE WARNING

INSTRUCTION LABELS.

15. Always operate winch with an

unobstructed view of the winching operation.

16. Equipment such as tackle, hooks,

pulley blocks, straps, etc. should

be sized to the winching task

and should be periodically

inspected for damage that could

reduce their strength.

17. NEVER RELEASE FREESPOOL

CLUTCH WHEN THERE IS A LOAD

ON THE WINCH.

18. STORE THE REMOTE PENDANT

ASSEMBLY IN A SAFE PLACE

when not in use to prevent use

by children or other unauthorized persons.

19. DO NOT OPERATE WINCH

WHEN UNDER THE INFLUENCE

OF DRUGS, ALCOHOL OR

MEDICATION.

20. ALWAYS UNPLUG THE REMOTE

PENDANT BEFORE WORKING IN

OR AROUND THE FAIRLEAD OR

WINCH DRUM (THE DANGER

ZONE) so that the winch cannot

be turned on accidentally.

21. When moving a load, slowly

take up the wire rope slack until

it becomes taut. Stop, recheck

all winching connections. Be

sure the hook is properly seated.

If a nylon sling is used, check the

attachment to the load.

22. When using your winch to move

a load, place the vehicle transmission in neutral, set vehicle parking brake and chock all wheels.

23. DO NOT USE THE WINCH TO

HOLD LOADS IN PLACE.

Use other means of securing

loads such as tie down straps.

Superwinch offers a

wide variety of tie

downs. Contact your

local Superwinch

dealer.

24. USE ONLY FACTORY APPROVED

SWITCHES, REMOTE CONTROLS

AND ACCESSORIES. Use of nonfactory approved components

may cause injury or property

damage and could void your

warranty.

25. DO NOT MACHINE OR WELD

ANY PART OF THE WINCH. Such

alterations may weaken the

structural integrity of the winch

and could void your warranty.

26. Do not power the winch out for

more than 50 feet (15.2m) or

longer than 2 minutes.

The drum

and wire rope

may get very hot (Figure 8).

27. DO NOT CONNECT WINCH TO

EITHER 110V AC HOUSE CURRENT OR 220V MAINS AS WINCH

BURNOUT OR FATAL SHOCK

MAY OCCUR!

28. Never allow shock loads to be

applied to winch or wire rope.

29. Use caution when pulling or

lowering a load up and down a

ramp or incline. Keep people,

pets and property clear of the

path of the load.

GENERAL SAFETY

INFORMATION

(CONT.)

Figure 8

9

8

GENERAL SAFETY

INFORMATION

(CONT.)

Wrong Right

Right

Wrong

Figure 7

Figure 5

Figure 6

Figure 4

HOT!

WARNING

!

MOUN T I N G

YOU R WINCH

Superwinch mounting (fitting) kits

are available for most popular vehicles. If you can‘t locate a kit locally

contact Superwinch at the address

listed on the front of this manual

for the name of a Superwinch dealer

near you.

Detailed Mounting instructions are

provided with each mounting kit.

Read and follow directions carefully

to ensure proper winch alignment

and trouble free operation.

WARNING

!

ed with the wire rope in the underwind direction. Improper mounting

could damage your winch and void

your warranty.

DRUM SUPPORT

PLATE SCREWS

6.0

(152)

This winch

MUST be mou

nt-

I N S TA L L AT I O N

MINIMUM ELECTRICAL

REQUIREMENTS

For 12 volt winches, a 60 ampere

alternator and battery with 440

cold-cranking amperes capacity are

the minimum recommended power

sources. If the winch is in heavy use,

an auxiliary battery and heavy duty

alternator are recommended.

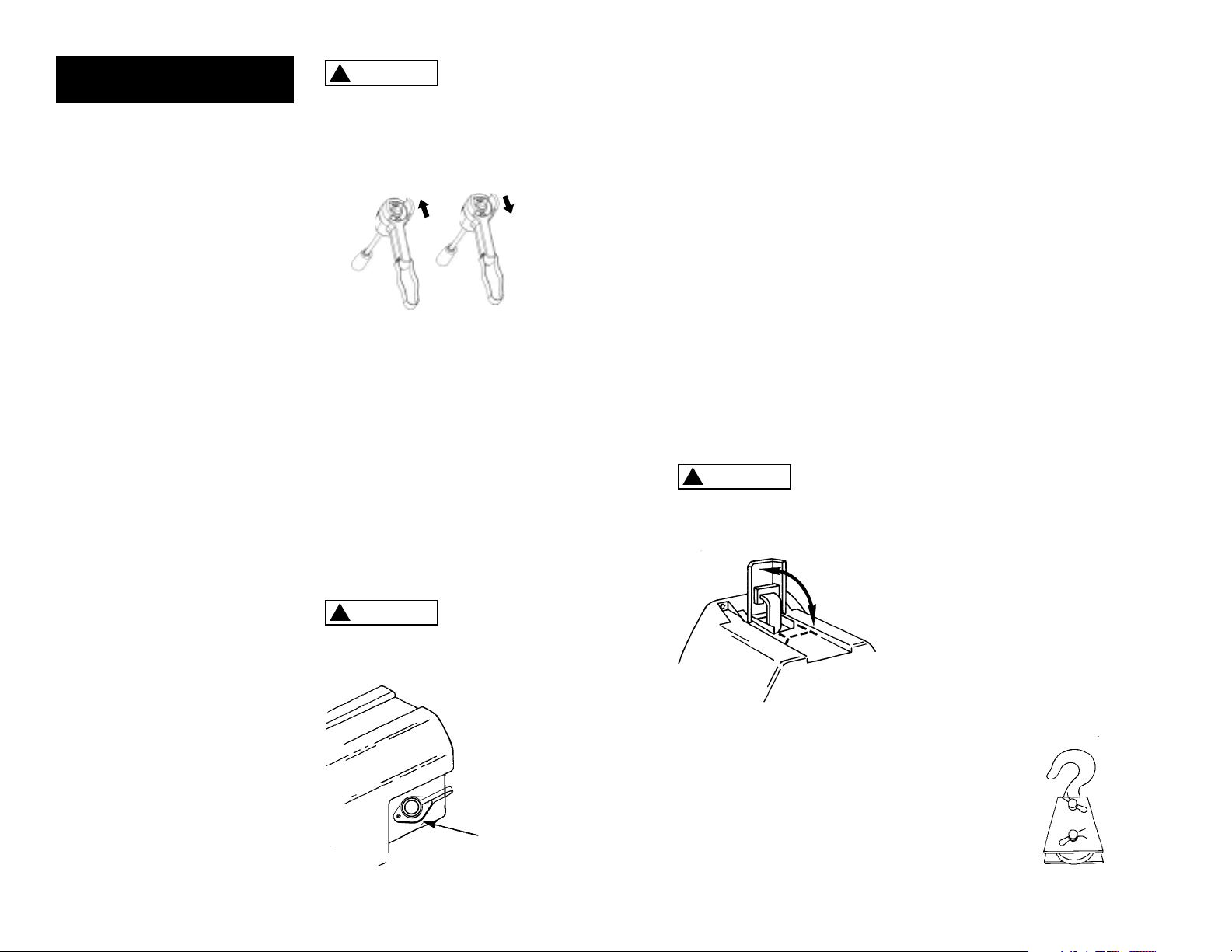

Step (1)

Install mounting kit or structural

s

upport for winch.

Step (2)

When mounting the winch, pull the

freespool clutch lever into the freespool

position. Unwind 25-30 feet of rope

from the drum. This will provide the

access needed to install the mounting

bolts into the base plate mounting holes.

Mount the winch to the mount that

you have designed. Mounting bolts

supplied are the

correct length for

use with up to a

1/4”(6.3 mm)

thick plate.

strength grade weaker than

grade 5.

When attaching wires to the motor

terminals and solenoid (relay), hold

the inner nut when tightening the

outer nut. Do not allow the motor

terminals to rotate for it may cause

internal wire breakage or part misalignment. Be especially careful in

preventing the solenoid (relay)

terminals from rotating. Any

rotation can damage the solenoid

(see Figure 10).

Figure 10

Step (3)

Disconnect the vehicle battery

leads.

I N S TA L L AT I O N

C O N T.

WARNING

!

Do not substitute any

DANGER

!

contain gasses which are flammable

and explosive. Wear eye protection

during installation and remove all

metal jewelry. Do not lean over

battery while making connections.

Figure 11

Automobile

batteries

Be Prepared

Step (4)

Route the two (2) wires through

the vehicle grille to the battery. To

ensure against insulation abrasion

and/or cutting, apply several layers

of electrical tape where wiring may

come in contact with sharp metal

parts of the vehicle. Attach the circuit breaker assembly to the end of

the red wire. Wrap the circuit

breaker assembly with electrical tape

to prevent accidental short circuits.

Attach other end of circuit breaker

assembly to battery positive terminal.

ROLLER FAIRLEAD

SCREWS

Figure 9

1.24

(31.5)

3.69

(93.7)

5.9

(150)

3.1

(79)

7.1

NOTES

1. All dimensions are in inches [millimeters].

2. Typical mount is to flat surface capable of handling the loads. Bolts to be Grade 5 or better.

(180)

15.1

(383)

DRUM SUPPORT

PLATE

MOTOR

SCREWS

7.2

(183)

10

11

PULLING OUT THE WIRE ROPE

The wire rope has been installed on

your winch under minimal load at

the factory. The wire rope must be

respooled onto the drum under

load so that the outer layers will

not draw down into the inner ones,

thereby damaging the wire rope.

Lift the clutch lever to the “Free”

position as shown in Figure 13. If

there is a load on the wire rope,

the clutch lever may not turn easily.

DO NOT FORCE THE CLUTCH LEVER.

Release tension on the wire rope

by jogging out some of the wire

rope. Releasing the clutch and pull

out the wire rope and secure to

anchor or load. Check that there

are at least five (5) turns of wire

rope left on the drum. Re-engage

the drum by returning the clutch

lever to the “Engaged” position

(see Figure 14).

Lever must

be in the

“Engaged” position and locked

before winching.

TIPS FOR EXTENDING THE LIFE OF

YOUR WINCH

1. KEEP THE WIRE ROPE TIGHTLY

WOUND ON THE DRUM. Do not

allow the wire rope to become

loosely wound. A loosely-wound

spool allows a wire rope under

load to work its way down into

the layers of wire rope on the

drum. When this happens, the

wire rope may become wedged

within the body of the windings

damaging the wire rope. To prevent this problem, keep the wire

rope tightly and evenly wound

on the drum at all times. A good

practice is to rewind the wire

rope under tension after each

use. One way to do this is to

attach the hook to a stationary

object at the top of a gradual

incline and winch your vehicle

up the incline.

2. DO NOT ALLOW WINCH MOTOR

TO OVERHEAT. Remember, the

winch is for intermittent use only.

During long or heavy pulls the

motor will get hot. For pulling

at rated capacity, allow motor

to cool after 20 seconds of “On”

time. At loads less than 50

% of

rated capacity, allow to cool after

2 minutes of “On” time. KEEP THE

ENGINE RUNNING TO RECHARGE

THE BATTERY during this break.

3. USE A PULLEY BLOCK FOR HEAVY

LOADS. To maximize winch and

wire rope life, use a pulley block

to double line heavier loads

(Figure 15).

13

Figure 14

FREE

ENGAGED

Figure 15

Note: If you choose to locate the

winch at a greater distance than

the wires provided will permit,

it may be necessary to purchase

a larger gauge wire to get the

best performance from your winch.

If the total length of additional

wire to be added to the system

exceeds 10' (3m), use a larger wire

gauge size.

Attach the circuit breaker directly

to the battery positive terminal,

and reattach the terminal to the

battery. If your vehicle is equipped

with side pole terminals, it may

be necessary to obtain auxiliary

side terminal bolts from your

localauto parts dealer to make

these connections.

Connect the remaining wire to the

battery negative terminal, and connect the terminal to the battery.

Step (5)

Lift the freespool clutch lever to

the “Free” position. Pull several

feet of wire rope off the drum.

Return the clutch lever back to

the “Engaged” position. Plug in

the remote pendant control. Press

the switch trigger to the “RopeOut” position momentarily to

check wire rope drum rotation and

direction. If the drum rotates in

the wrong direction, recheck your

wiring. The Handheld pendant

switch activates a solenoid that

activates power to the winch

motor. One solenoid is for “Rope

Out” motor direction and the

other is for the “Rope In” motor

direction (Fig. 12).

To prevent

unauthorized

use of the winch, remove pendant

control and store in a clean dry area

such as the glove box.

PENDANT OPERATION

The handheld pendant switch

activates a solenoid that activates

power to the winch motor. To connect the pendant control, remove

the cover on the plug receptacle

(Figure 13) and insert the plug

end of remote switch. The plug

on the pendant control cord is

keyed and will fit into the socket

only one way. The switch trigger

returns to the “Off” position when

released. To change direction,

move the toggle in the other

direction. (Fig.12)

The switch

assembly must

be kept free of dirt and moisture

to ensure safe operation.

12

INSTALLATION

CONT.

Figure 12

Cable In

Cable Out

A

B

DUST

COVER

Figure 13

CAUTION

!

CAUTION

!

CAUTION

!

HOT!

BRAKE OPERATION

Your S Series winch has a wrap

spring brake that stops and holds

loads up to 50

% rated capacity on

the first layer of wire rope closest

to drum.

Each additional layer of wire rope

reduces brake capacity approximately 10%. When powering the

winch in, the brake is disengaged

and does not become activated

until the motor is turned off and

the load tries to pull the wire rope

off the drum. When the winch is

powered out, as in releasing a load,

the brake is engaged and the motor

must over power the brake drag to

rotate the drum. Therefore, it is

normal for the winch to operate

faster in one direction than the

other. The brake is designed for the

wire rope to be used in the underwind position only. DO NOT OVERWIND. Powering against the brake

will cause heat to build up in the

drum and may transfer heat to the

wire rope (Figure 19). DO NOT

POWER OUT FOR MORE THAN 50

FEET (15.2m) OR 2 MINUTES.

The drum and

wire rope may

get very hot.

When wire rope is removed from

the drum, as in bringing the hook

to the load, the freewheel feature

of the winch should be used.

WARNING

!

15

Figure 19

4. The pull required to start a load

moving is often much greater

than the pull required to keep

it moving. AVOID FREQUENT

STOPS AND STARTS during pull.

5. PREVENT KINKS BEFORE THEY

OCCUR.

a. This is the start of a kink. At

this time, the wire rope should

be straightened.

b. The wire rope was pulled and

the loop has tightened to a

kink. The wire rope is now permanently damaged and must

be replaced.

c. Kinking causes the wire strands

under the greatest tension to

break and thus reduces the

load capacity of the wire rope.

The wire rope must be replaced.

6. EQUIPPING THE WINCH WITH A

ROLLER FAIRLEAD will substantially

reduce wear on the wire rope

during angle pulls (Figure 17).

The rollers eliminate heavy rubbing and abrasion to the wire rope.

Periodically check tightness of

mounting bolts and electrical connections. Remove any dirt or corrosion that may have accumulated

on the electrical connections.

Repair should be done by

Authorized Superwinch Repair

Centers ONLY. Do not attempt

to disassemble the gearbox.

Disassembly will void warranty.

LUBRICATION

The gearbox and drum bearing are

permanently lubricated with a high

performance gear lube. If relubrication is necessary (after repair or

disassembly) only use Shell Alvenia

EP2 or equivalent.

REPLACING THE WIRE ROPE

Never substitute a heavier or lighter

wire rope. Never use rope made of

any material other than wire.

Always replace damaged wire

rope with manufacturer’s identi-

cal replacement part

(see

Replacement Parts list). Pass attaching end of wire rope through the

fairlead (if equipped) and attach it

to the drum. When inserting the

wire rope into the drum, insert it

into the correct end of the hole

provided (Figure 18). Tighten the

set screw securely.

It is important that the wire rope be

wound tightly onto the drum. A

good way to do this is to attach the

wire rope hook to a fixed object at

the top of a slight incline, then

winch the vehicle up the incline.

14

MAINTENANCE

AND REPAIRS

Figure 16

a

b

c

Figure 17

Figure 18

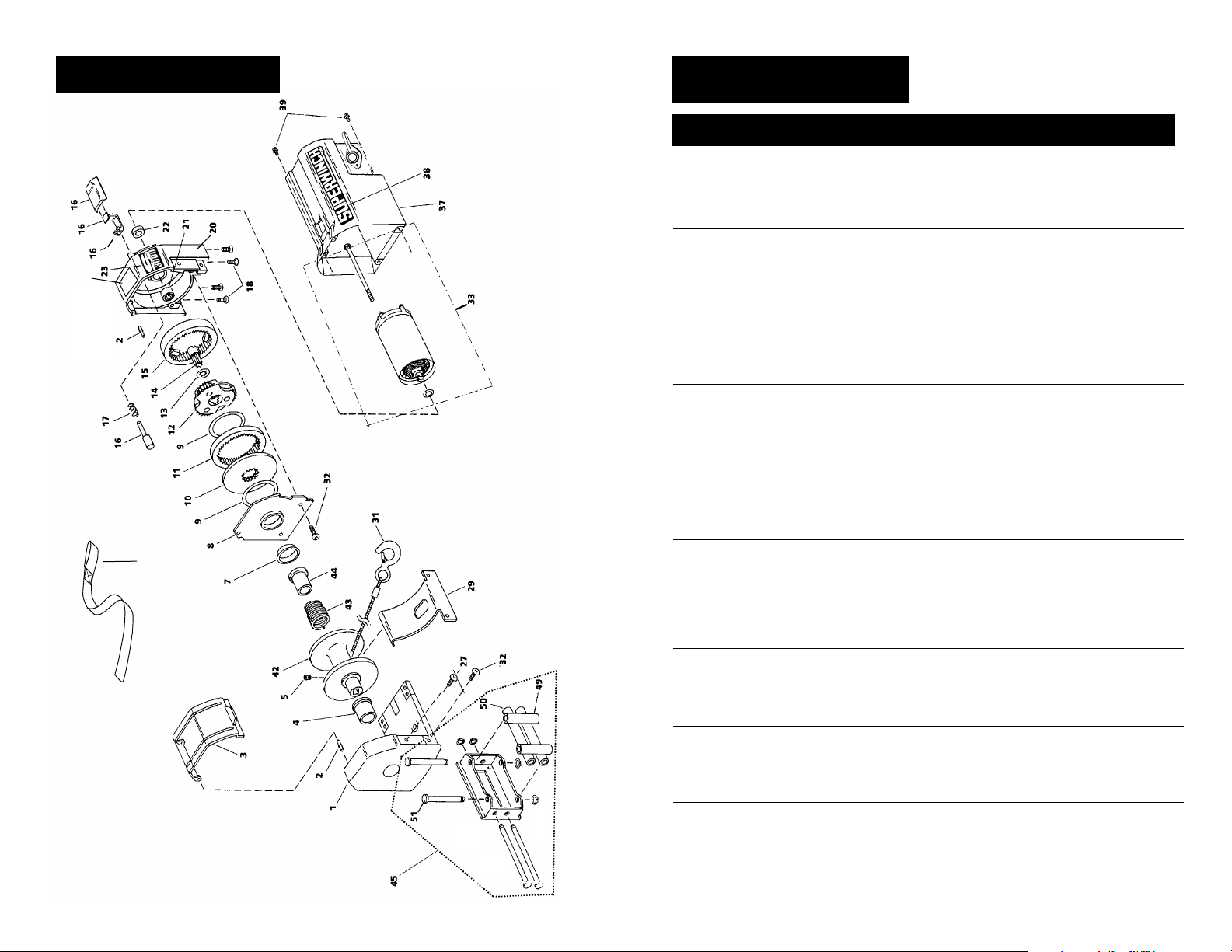

W INC H ASSEMBLY

REPLACEMEN T

PA R T S L I S T

Reference

5 M6 x 1 x 8mm Cup Pt. Set Screw 90-23164-12 1

52

Safety

(Includes Shaft, Lever, Handle, and Rivet)

18 M6 x 1 x 16mm Flat Head Screw 89-22291-01 4

20 Housing Assembly (includes 21 & 22) 89-40104 1

21 Needle Bearing (.8125 x 1.125 x .750) 89-23263-03 1

27 M6 x 1 x 13mm Button Head Screw 89-22290-01 2

30

31 Wire Rope Assembly w/hook 1/4"x50' (S5000) 1577A 1

Wire Rope Assembly w/hook 7/32"x60' (S4000) 1514A 1

32 M6 x 1 x 16mm Button Head Screw 89-22290-02 5

33 12 Volt Complete Motor (S5000) 90-33294 1

12 Volt Complete Motor (S4000) 90-33295 1

38 “Superwinch” 177222-98etalpemaN

39 M4 x 0.7 x 6mm Hex Washer Head Screw 89-22292-01 4

ytQrebmuN traPnoitpircseDrebmuN

112025-98esaB1

210-30332-98niP evoorG2

186223-98drauG elbaC3

186222-98gniraeB niaM4

196222-98gniraeB murD7

129004-98troppuS murD8

247521-09rehsaW tsurhT9

136223-98etalP evirD01

156223-98raeG gniR gnitatoR11

114122-98ylbmessA reirraC yratenalP21

130333-98raeG nuS41

166223-98raeG gniR yranoitatS51

108501-98tiK riapeR leehW eerF61

180-25132-09gnirpS leehW eerF71

120021-98gniraeB tfahS rotoM22

123371-98ogoL 0005S32

113371-98ogoL 0004S

159223-98gnirpS noisneT elbaC92

102113-78 revasdnaH03

189233-98 rotoM etelpmoC tloV 42

181333-09rotoM etelpmoC tloV 42

142025-98revoC rotoM73

158004-98 murD24

124322-98gnirpS ekarB34

178222-98retpadA ekarB44

12235daelriaF relloR54

16

240-86521-09relloR 253.2 x 8/594

260-86521-09relloR 537.4 x 8/505

210-43322-98)trohS( tfahS daelriaF relloR15

103302-98lebaL ytefaS25

17

53

58

61

54

55

57

59

60

62

63

19

REPLACEMENT

PARTS LIST

Reference

Number Description Part Number Qty

TORQUE SPECIFICATIONS

Drum Support Plate 50-60 lb in

Screws

Hawse (Roller Fairlead) 45-55 lb in

Screws

Base Screws 65-75 lb in

Motor 35-40 lb in

TORQUE SPECIFICATIONS

Over torquing

could damage

your winch and void your warranty.

WARNING

!

53 Leadwire spacer kit 89-24430 1

54 Buss bar kit 89-24431 1

55 Black 2 gage wire (-), S5000 12V 89-22635-61 1

Black 6 gage wire (-), S4000, S5000 24V 89-23292-38 1

57 Band clamp 89-14459 2

58 Red 2 gage wire (+), S5000 12V 89-22635-60 1

Red 6 gage wire (+), S4000, S5000 24V 89-23292-37 1

59 Socket 90-14140 1

60 Type 6 solenoid with bracket, 12V 89-24429 1

Type 6 solenoid with bracket, 24V 89-24467 1

61 Handheld remote control 90-33450-02 1

62 Ground jumper wire 18 gage 89-23283 1

63 Terminal adapter 89-14458 1

18

ROLLER FAIRLEAD

SCREWS

MOTOR

SCREWS

DRUM SUPPORT

PLATE SCREWS

DRUM SUPPORT

PLATE SCREWS

SOLENOID ASSEMBLY

Motor will not operate or

runs in one direction only

Winch will not shut off

Motor runs extremely hot

Motor runs but with

insufficient power or line

speed

Motor runs but drum

doesn’t turn

Winch runs backwards

Winch will not hold load

1. Damaged or stuck

solenoid

2. Switch inoperative

3. Broken wires or bad

connection

4. Damaged motor

5. Solenoids not grounded

1. Solenoid stuck “On”

1. Long period of operation

2. Damaged motor

3. Damaged brake

1. Weak battery

2. Battery to winch wire too

long

3. Poor battery connection

4. Poor ground

5. Damaged brake

1. Clutch not engaged

1. Motor wires reversed

2. Solenoids wired

incorrectly

1. Excessive load

2. Worn or damaged brake

1.

CAUTION Disengage

clutch before performing

this test to prevent powering the wire rope

drum. If a solenoid sticks

once, it is likely to stick

again and must be

replaced immediately.

Tap solenoid to free stuck

contacts. Check by applying voltage to the small

solenoid terminal. Be

sure solenoid is grounded

back to source. A solenoid that is not stuck will

make an audible “click”

when first energized.

2. Replace switch

3. Check for poor connections:

CAUTION Always use

2 wrenches (spanners)

(see Fig. 11)

4. Replace or repair motor

5. Check the ground path

between battery negative and solenoid base

1. If a solenoid sticks on,

reverse direction and

hold trigger switch until

the power lead can be

disconnected. A safety

disconnect switch is available as an accessory

1. Allow to cool

2. Replace or repair motor

3. Replace or repair brake

1.

Recharge or replace battery.

Check charging system

2. Use larger diameter wire

3. Check battery terminals

for corrosion. Clean as

required

4. Check and clean

connections

5. Repair or replace brake

1. Engage clutch

1. Recheck wiring

2. Recheck wiring

1. Reduce load or double

line

2. Repair or replace brake

Symptom Possible Cause(s) Corrective Action

USA

Superwinch Inc.

Winch Drive

Putnam, CT 06260

phone: 860-928-7787

repair@superwinch.com

Electric Motor Repair

2010 North 4th Street

Minneapolis, MN 55411

phone: 612-588-4693

Berens & Associates

124 Hegenberger Loop

Oakland, CA 94621

phone: 800-540-2858

berens94621@yahoo.com

Zorko’s Alternator Service

241 Wells Road

Home, PA 15747

phone: 800-468-5055

zasapw@microserve.net

Electric Motors of Iowa City

50 Commercial Court

Iowa City, IA 52246

phone: 319-354-4040

emic4040@aol.com

CANADA

Demand Electric

228-39th St. N.E.

Calgary, AB T2E 2M5

403-230-2709

Harold Supply

3 Southerland Ave.

Sudbury, Ont. P3C 3A7

705-761-4455

Explora Industries Ltd.

9605-5th Ave.

Edmonton, AB T6E 0B2

780-430-8591

Dayworth Sales

1 Saunders Rd. Unit 2

Barrie, Ont. 9A7 9A7

705-726-7778

Les Equipment Twin

10401 Parkway Blvd.

Ville D’Anjou, PQ H1J 1R4

514-353-1190

Buffalo Industries

251-253 Princess Street

Winnipeg, Manitoba R2C 1M1

204-942-1951

Power Plus Tool Repair

57 Millenium Ave.

Moncton, NB E1E 2G2

560-855-8665

Muskoka Auto Parts

11 King William St.

Huntsville, Ont. P1H 2K8

705-789-2321

Lou Dennis Auto

Hiway 11 South

Sundridge, Ont. P0A 1Z0

705-384-5345

Outdoors Plus

128 Regional St.

P.O. Box 1349

Port Aux Basques, NF A0M 1C0

709-695-7533

Bobcaygeon Auto and Marine

91 Main St.

Bobcaygeon, Ont. K0M 1A0

705-738-2317

MAP Bracebridge

19 Taylor Rd.

Bracebridge, Ont. P1L 1W3

705-645-8785

MAP Fenelon Falls

165 Lindsay St.

Fenelon Falls, Ont. K0M 1N0

705-887-6232

Central Electric Motor Rewind

#1-1960 Windsor Rd.

Kelowna, NC V1Y 2Y3

250-860-4415

jnelsoncentral@netscape.net

Delta Tool Repair Limited

114-7533, 135th St.

Surrey, BC V3W 0N6

604-591-3230

Ted's Power Tool Repair

426-44th St. East

Saskatoon, SK S7K OW1

306-934-6155

Bob's Electric Truck Servise

845-B Macdonald Ave.

Regina, SK S4N 2X5

306-721-4148

Off Road Canada

251-12th St. "B" North

Lethbridge, AB T1H 2K8

403-327-7722

Gary's Starter & Alternator

P.O.Box 7 Site 4

RR 1 Mount Uniacke B0N 1Z0

Contact: Gary Thorne

902-757-2388

Power Blitz Mftg. & Maintenance

577 Edgeley Blvd. Unit 6

Concord, Ont. L4K 4B2

905-669-8209

ali@powerblitz.com

Bruce's Recreaction

92 Balbo Dr.

Shoal Harbour Nfld A5A 4A8

709-466-3355

Atlantic Recreation & Marine

5 School St.

Sydney, Nova Scotia

B1S 3G1

902-567-1697

sbidart@thearm.ca

UNITED KINGDOM

Superwinch, LTD

Abbey Rise, Whitchurch road

Tavistock, Devon PL19 9DR

+44 (0) 1822 614101

WORLDWIDEContact your Local

Superwinch Distributor or call Superwinch.

21

WARRANTY REPAIR CENTERS

20

TROUBLESHOOTING CHART

If a problem arises, contact your nearest

Superwinch dealer or repair center.

L IMIT E D WARR ANTY

VALID WOR LDWIDE

LIMITED WARRANTY

Superwinch Inc. (“Seller”) warrants to the original buyer (“YOU”) all parts and components except

wire rope to be free of defects in materials and workmanship for a period of ONE (1) year from

provable date of purchase. Any Superwinch product which is defective will be repaired or replaced

without charge to you, upon compliance with these procedures. The warranties set forth herein

are exclusive and in lieu of all other warranties, whether oral or written, express or implied.

WARRANTY PERFORMANCE PROCEDURE

LIMITED

Upon discovery of a defective Superwinch product, you shall mail to the Seller at his factory or to

any Factory Authorized Service Center written notice of such defect and mail, ship or otherwise

deliver the defective Superwinch, postage or shipping prepaid. Repairs or replacements by Seller

under this Limited Warranty will normally be accomplished within fifteen (15) business days after

receipt of the defective Superwinch. Seller or its Authorized Agents may make reasonable charges

for parts and la

WARRANTY AND REMEDY LIMITATIONS AND EXCLUSIONS

Repair and/or replacement of the defective Superwinch or component part thereof as provided

herein is the exclusive remedy for you. The following exclusions or limitations of warranties and

limitations of remedies shall be expressly applicable:

A. Express Warranties. Seller Warrants that the Superwinch is as described in the ”Superwinch

Owner’s Manual” provided herewith; no other express warranty is made in respect to

Superwinch. If any model or sample was shown to you, such model or sample was used for illustrative purposes only, and shall not be construed as a warranty that the Superwinch will conform to

the sample or model. SELLER MAKES NO EXPRESS WARRANTY WITH RESPECT TO THE WIRE ROPE

INCORPORATED IN THE PRODUCT.

B. Implied Warranty. The implied warranty of merchantability and all other implied warranties

shall only extend from the provable date of purchase for one (1) year. The wire rope is sold

without any implied warranties. Some states within the U.S.A. do not allow limitations on how

long an implied warranty lasts, so the above limitation may not apply to you.

C. Incidental and Consequential Damages. SUBJECT TO THE SELLER’S LIMITED WARRANTY OBLIGATIONS SET FORTH HEREIN, SELLER SHALL NOT BE

ANY KIND, OR FOR CONSEQUENTIAL DAMAGES TO PROPERTY, LOSS OF PROFITS AND LOSS OF USE

WHICH MAY BE CAUSED BY ANY DEFECT IN, OR MALFUNCTION, OR FAILURE

SUPERWINCH. SOME STATES WITHIN THE USA DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU.

D. Condition of Warranty. Seller shall not be required to comply with its warranty duties provided

herein if the defect, malfunction, or failure of the Superwinch was caused by damage (not resulting

from defective or malfunctioning components) or unreasonable use by you. Unreasonable use shall

include, but not be limited to, the failure to provide reasonable and necessary maintenance or

installation or use of the Superwinch without compliance with the instructions contained in the

Superwinch Owner’s Manual, and subjecting the Superwinch to loads in excess of the load listed in

the Owner’s Manual for the particular model number. Seller’s liability under this warranty or for any

loss or damage to the Superwinch product shall not exceed the

replacing the Superwinch product, and upon expiration of the warranty period, all such liability

shall terminate. The agents, dealers and employe

cations to this warranty, or additional warranties binding on the Seller. Accordingly, additional statements, whether oral or written, do not constitute warranties and should not be relied upon.

LEGAL REMEDIES OF BUYER

This Limited Warranty gives you specific legal rights, and you may also have other rights which

may vary from state to state within the USA and from country to country. You also have implied

warranty rights. In the event of a problem with Limited Warranty service or performance, you may

be abl

priate jurisdictions outside the USA.

INQUIRIES

Any inquiries regarding compliance with warranties provided herein may be addressed in writing

to: Superwinch Inc., Winch Drive, Putnam, CT 06260, USA or to: Superwinch Ltd., Abbey Rise,

Whitchurch Road, Tavistock, Devon PL 19 9DR, England.

bor for repairs not covered by this Limited Warranty.

the

”as is,”

RESPONSIBLE FOR INCIDENTAL DAMAGES OF

OF THE ENCLOSED

cost of correcting the defects in or

es of the Seller are not authorized to make modifi-

e to go to small claims court, a state court, or federal district court in the USA or to appro-

MANUAL DEL PROPIETARIO

INSTALACIÓN • OPERACIÓN • MANTENIMIENTO

PRECAUCIONES DE SEGURIDAD • PIEZAS DE

REPUESTO

S4000 y S5000

Cabrestantes Eléctrico de 12 y 24 Volts CD

Con control remoto

PRECAUCION

!

LEA Y ENTIENDA ESTE MANUAL ANTES

DE INSTALAR Y OPERAR SU PRODUCTO SUPERWINCH

Las especificaciones asumen un 10% de coeficiente de fricción.

* Una pendiente de 10% es una elevación de 30.48 cm en 3.048 m (1 ft en 10 ft). Arriba se muestra

una pendiente en grados aproximados.

** Todas las cargas mostradas son para operación de línea sencilla. La operación de línea doble

con el bloque de poleas opcional duplica aproximadamente la capacidad del cabrestante.

25

Figura 1

DESCRIPCIÓN GENERAL

24

Gracias por comprar un cabrestante Serie S de Superwinch. Éste ha sido diseñado y fabricado para proporcionar años de operación sin problemas. Esperamos que esté satisfecho con

su rendimiento. Si no lo está por cualquier motivo, por favor comuníquese con nuestro

Departamento de Servicio al Cliente al: (860) 928-7787 en E.U.A.; (1822) 614101 en Inglaterra.

Cuando solicite información o piezas de refacción, siempre dé la siguiente información:

1. Número de Pieza del cabrestante

2. Número de Serie (se encuentra en la carcasa)

3. Número de Pieza (se encuentra en la lista de piezas de este manual)

4. Descripción de la pieza

Por favor lea y entienda este manual del propietario antes de instalar su cabrestante. Ponga

particular atención a la Información General de Seguridad. Su es una máquina mu poderosa.

Si se usa sin precaución o inadecuadamente existe la posibilidad de causar daños a la propiedad

o lesiones personales. Hemos incluido varias características en el malacate para reducir esta

posibilidad. No obstante, su seguridad depende en última instancia en su pre caución al usar

este producto.

La responsabilidad de la operación segura de este cabrestante reside en última instancia en usted,

el operador. Lea y entienda todas las precauciones de seguridad e instrucciones de uso antes de

instalar y de utilizar el cabrestante. Si se lo utiliza sin precaución, podría ocasionar lesiones graves

y/o daños materiales.

En este manual, encontrará notas con los títulos siguientes:

Indica una situación de peligro inminente que, de no evitarse,

dará como resultado muerte o lesiones graves.

Indica una situación de peligro potencial que, de no evitarse,

podría dar como resultado muerte o lesiones graves.

Indica una situación de peligro potencial que, de no evitarse,

puededar como resultado lesiones leves o moderadas. Esta nota

se utiliza también para alertarle sobre prácticas inseguras.

Se usan los siguientes símbolos en el producto y en el Manual del Propietario:

Nota: Indica información adicional en los procedimientos de instalación y operación de su

cabrestante.

La instalación correcta de su cabrestante es un requisito para su operación correcta. Si

piensa instalar su cabrestante en el extremo delantero de su vehículo, use el juego de

montaje (adaptación) que ha sido diseñado y manufacturado por Superwinch para

recibir su malacate y adaptarse a su vehículo.

Por favor tome nota: El cabrestante Serie S de Superwinch está diseñado esencialmente

para uso general intermitente. Este cabrestante no está diseñado para usarse en aplicaciones industriales ni de grúa ni Superwinch garantiza que sea idóneo para tal uso.

Superwinch fabrica una línea separada de cabrestantes para uso industrial y comercial. Para

mayor información, por favor comuníquese con nuestro Departamento de Servicio al Cliente.

¡Felicidades por su elección!

INTRODUCCIÓ N

Embrague

Freno

Receptáculo del

Conmutador

Remoto

Moteur con Imán

Permanente

Solenoides Integrados

Guia de entrada

con rodillos

S4000

Carga de trabajo* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,000 lb. (1814 kg)

Cable de alambre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7/32" x 60'

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 12V or 24VDC 1.8 hp (1.34 kW) peak

Relación de engranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159:1

S5000

Carga de trabajo* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,000 lb. (2268 kg)

Cable de alambre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4" x 50'

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 12V or 24VDC 2.1 hp (1.57 kW) peak

Relación de engranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159:1

*Basado en el rendimiento de la primera capa

SPECIFICATIONS

CAPACIDADES DE CARGA RODANTE

S5000

S4000

Slope* 10% (6º) 20% (11º) 30% (17º) 100% (45º)

Lbs.**

kg**

17,588

7,978

11,905

5,400

9,138

4,145

4,499

2,041

Slope* 10% (6º) 20% (11º) 30% (17º) 100% (45º)

Lbs.**

kg**

22,613

10,257

15,306

6,943

11,749

5,329

5,784

2,624

PELIGRO

!

ADVERTENCIA

!

PRECAUCION

!

Leer el Manual

del Propietario

Siempre use la

barra protectora

para manos

Manténgase alejado

del cabrestante, el

cable de alambre y

el gancho durante

la operación

Nunca use el

cabrestante para

levantar o mover

personas

Nunca use el

cabrestante para

sostener cargas

PRECAUCIONES DE

SEGURIDAD

Descripción Cantidad

Embrague de Carrete Libre 1

Solenoides Integrados 1

Motor de Imán Permanente 1

Receptáculo del interruptor Remoto 1

Freno de Tambor Interno 1

Manual del propietario 1

Esta caja contiene los siguientes artículos. Por favor desempáquelos

cuidadosamente. Lea las instrucciones antes de comenzar.

DISEMPACADO

DIMENSIONES

S4000, S5000

RENDIMIENTO

*Basado en el rendimiento de la primera capa

Capa del Capacidad Máxima de Tiro

Cable lbs. kg

1 4,000 1814

2 3,000 1361

3 2,600 1179

4 2,000 907

Carga Corriente

Velocidad del Motor

lbs. kg pies/min m/min Amperes

0 0 21.6 6.6 30

1,000 454 16.0 4.9 90

2,000 907 12.4 3.8 155

2,500 1134 10.6 3.2 180

3,000 1361 8.8 2.7 215

3,500 1588 6.2 1.9 250

4,000 1814 4.5 1.4 311

Capa del Capacidad Máxima de Tiro

Cable lbs. kg

1 5,000 2268

2 4,000 1814

3 3,500 1588

4 2,900 1315

Carga Corriente

Velocidad del Motor

lbs. kg pies/min m/min Amperes

0 0 17.5 5.3 36

1,000 454 14.5 4.4 80

2,000 907 12.0 3.7 135

3,000 1361 9.5 2.9 200

4,000 1814 7.3 2.2 265

5,000 2268 4.5 1.4 350

S4000

S5000

26 27

NOTAS:

1. Todas las dimensiones están en pulgadas [milímetros].

2. La instalación típica se realiza sobre una superficie plana capaz de soportar las cargas. Los pernos

deben ser Grado 5 o mejores.

6.0

(152)

15.1

(383)

7.2

(183)

7.1

(180)

3.1

(79)

5.9

(150)

3.69

(93.7)

1.24

(31.5)

Tornillos de la base

Tornillos

del escobén

(Guía de rodillos)

Tornillos de la placa

base del tambor

Tornillos del motor

Figura 2

2. DESPUÉS DE LEER Y ENTENDER

ESTE MANUAL, APRENDA A USAR

SU CABRESTANTE.Después de

instalar el cabrestante, practique

usándolo para que esté

familiarizarse con su

operación cuando surja

la necesidad de usarlo.

3. NO «mueva» su vehículo para

ayudar al cabrestante a tirar de la

carga. La combinación del

cabrestante y el vehículo tirando

a la vez puede sobrecargar el

cable de alambre y el cabrestante.

4. MANTENGA EL ÁREA DE MANIOBRAS LIBRE DE OBSTRUCCIONES.

No permita que permanezcan

personas en el área durante las

operaciones de tirado. SIEMPRE

MANTÉNGASE ALEJADO DEL

CABLE, EL GANCHO Y EL

CABRESTANTE. EN EL REMOTO

CASO DE FALLA DE CUALQUIER

COMPONENTE, ES MEJOR ESTAR

LEJOS DEL PELIGRO.

5. INSPECCIONE FRECUENTEMENTE

EL CABLE DE ALAMBRE Y EL

EQUIPO. UN CABLE DE ALAMBRE

DESHILACHADO CON HILOS

ROTOS DEBE REEMPLAZARSE

INMEDIATAMENTE. Siempre

reemplace el cable de alambre

con la pieza de repuesto del fabricante idéntica (vea la lista de

piezas). Revise periódicamente la

instalación del Cabrestante para

asegurarse de que los tornillos

estén firmes.

6. USE GUANTES DE CUERO PESADOS AL manejar el cable. NO

DEJE QUE EL CABLE DE ALAMBRE

SE DESLICE EN SUS MANOS NI

AÚN CUADO USE GUANTES.

29

INFORMACIÓN GENERAL

DE SEGURIDAD

Figura 3

Un sólo cable

Cable doble

28

SERVICIO INTERMITENTE

Un cualquier otra herramienta

motorizada, como por ejemplo un

taladro o una sierra eléctrica. No se

debe permitir que el motor eléctrico se caliente excesivamente. Las

precauciones normales extenderán

la vida de su motor. Mantenga la

duración de los tiros tan breve

como sea posible.

Si el extremo

del motor se calienta de modo

que resulte incómodo tocarlo

,

deje de operar el cabrestante y permita que el motor se enfríe.

Si el motor del

cabrestante se

para, no siga aplicándole energía al

cabrestante.

Unión Europea

Ruido El nivel de ruido de este cabrestante en operación está por debajo de los 92 dB. (A).

Aislante de la Batería Para cumplir con la Directiva de Maquinaria 89/392/EEC, todas las instalaciones de

máquinas deben estar equipadas con un aislante (Número de pieza 8370) con la cual la máquina puede detenerse

completamente con seguridad.

Motor Eléctrico - 1.8 (S4000), 2.1

(S5000) hp, 1.34 (S4000), 1.57

(S5000) kW) pico, con imán

permanente de 12 V ó 24 V.

Freno - Un freno de resorte para

el enrollamiento, que mantendrá

el 50% de la carga nominal en la

primera vuelta. A partir de ese

momento, ese porcentaje se

reducirá en aproximadamente

el 10% por cada capa.

Tambor – De aluminio fundido

sostenido por rodamientos sin mantenimiento.

Embrague de carrete libre –

Operado por una palanca de acción

fácil que desembraga el motoreductor para permitir que el cable de

alambre sea sacado sin usar corriente eléctrica. Una placa de tensión

reduce el latigueo y el tironeo

cuando se tira del cable de alambre.

Interruptor Remoto – 9.14 m (30')

Conjunto de interruptor de mano

tipo pendiente con interruptor

de reversa con interbloqueo y

disparador.

Montaje – Se ofrecen juegos de

montaje opcionales, diseñados a la

medida, para instalaciones sobre el

chasís del vehículo.

Un cabrestante eléctrico es como

CARACTERÍ STICAS

Su cabrestante Serie S es una

máquina muy poderosa. Trátelo

con respeto, úselo con precaución

y siempre siga los lineamientos

de seguridad

.

El cable puede

romperse

antes de que el cabrestante entre

en pérdida. Para cargas pesadas use

un bloque de poleas para reducir la

carga sobre el cable de alambre.

1. El cabrestante S4000 y S5000 tiene

una capacidad nominal de 4,000 y

5,000 libras (1814 y 2268 kg) (en

línea sencilla) en la capa de cable

de alambre más cercana al tambor. NO LO SOBRECARGUE.

NO TRATE DE TIRAR CARGAS

PESADAS DE FORMA PROLONGADA. No mantenga encendido el

cabrestante si el motor entra en

pérdida. Las sobrecargas pueden

dañar el cabrestante o el cable de

alambre y causar condiciones de

operación inseguras. PARA CARGAS MAYORES DE 2/3 LA CAPACIDAD NOMINAL, RECOMENDAMOS EL USO DEL BLOQUE DE

POLEAS OPCIONAL PARA LA

OPERACIÓN DEL CABLE DE

ALAMBRE EN LÍNEA DOBLE

(Figuras 3 y 15). Esto reduce la

carga sobre en el cabrestante y el

esfuerzo sobre el cable de alambre en aproximadamente el 50%.

Si lo monta en la parte trasera del

vehículo, sujételo al chasís u otra

parte que soporte carga. El motor

del vehículo debe estar funcionando durante la operación del

cabrestante para reducir el desgaste de la batería y aumentar la

potencia y velocidad del

cabrestante. Si se activa el

cabrestante durante considerables

periodos de tiempo con el motor

apagado, la batería podría descargarse demasiado, de modo que ya

no pueda arrancar el motor.

ADVERTENCIA

!

PRECAUCION

!

chos, bloques de poleas, cintas, etc.,

deben ser del tamaño de la tarea

de levantamiento y debe inspeccionar periódicamente que no tengan daños que puedan reducir su

resistencia.

17. NUNCA SUELTE EL EMBRAGUE DEL

CARRETE LIBRE CON UNA CARGA

EN EL CABRESTANTE.

18. ALMACENE EL CONJUNTO DE PEN-

DIENTE REMOTO EN UN LUGAR

SEGURO cuando no se use para evitar que lo usen los niños u otras personas no autorizadas.

19. NO OPERE EL CABRESTANTE CUAN-

DO ESTÉ BAJO LA INFLUENCIA DE

DROGAS, ALCOHOL

O MEDICAMENTOS.

20. SIEMPRE DESCONECTE EL PENDI-

ENTE REMOTO ANTES DE TRABAJAR

EN LA GUÍA DE RODILLOS Y EL

TAMBOR DEL CABRESTANTE O A SU

ALREDEDOR (LA ZONA DE

PELIGRO), para que no se pueda

encender el cabrestante

accidentalmente.

21. Cuando mueva una carga, recoja el

exceso de cable de alambre con

cuidado hasta que el cable de alambre esté tenso. Deténgase, vuelva a

verificar todas las conexiones de levantado. Asegúrese de que el gancho

esté bien asentado. Si se usa una

eslinga de nilón, revise la sujeción

a la carga.

22. Cuando use su cabrestante para

mover una carga, coloque la transmisión de su vehículo en neutral,

ponga el freno de mano y bloquee

todas las ruedas.

23. NO USE EL CABRESTANTE PARA

RETENER CARGAS EN UN SÓLO

SITIO. Use otros medios para asegurar cargas, como tirantes para atar.

Superwinch ofrece una

amplia variedad de ataduras.

Comuníquese con su distribuidor local Superwinch.

24. SÓLO USE INTERRUPTORES, CONTROLES REMOTOS Y ACCESORIOS

APROBADOS POR LA FÁBRICA. El

uso de componentes no aprobados

por la fábrica puede ocasionar

lesiones o daños a la propiedad, y

puede anular su garantía

25. NO MAQUINE NI SUELDE PARTE

ALGUNA DEL CABRESTANTE. Tales

alteraciones pueden debilitar la

integridad estructural del

cabrestante y pueden anular la

garantía.

26. No saque el cable con el motor del

cabrestante en longitudes mayores

de 15.2 metros (50 pies) o durante

periodos mayores de 2 minutos.

El tambor

y el cable

pueden calentarse mucho

(Figura 8).

27. NO CONECTE EL CABRESTANTE A

LA CORRIENTE RESIDENCIAL DE 110

VCA O DE 220 VCA, YA QUE SE

PUEDE QUEMAR EL CABRESTANTE

O ¡RECIBIR UN CHOQUE ELÉCTRICO

FATAL!

28. Nunca permita que se apliquen cargas de choque al cabrestante o al

cable de alambre.

29. Tenga precación al bajar o tirar de

una carga hacia arriba o hacia

abajo por una rampa o pendiente.

Mantenga a la gente, mascotas y

bienes lejos del camino de la carga.

ADVERTENCIA

!

31

INFORMACIÓN GENERAL

DE SEGURIDAD

(CONT.)

7. NUNCA USE EL CABRESTANTE CON

MENOS DE 5 VUELTAS de cable de

alambre en el tambor, ya que es

posible que el cable de alambre y su

sujeción no resistan la carga completa. Siempre use la barra para manos

cuando guíe el cable de

alambre hacia adentro o

afuera (ver la Figura 4).

8. MANTÉNGASE ALEJADO DEL

CABRESTANTE, EL CABLE TENSO Y

EL GANCHO AL OPERAR EL

CABRESTANTE. Nunca introduzca su

dedo a través del gancho. Si su dedo

llega a quedar atrapado en el gancho, podría perderlo.

Nunca guíe el cable hacia

el tambor con la mano.

9. NUNCA ENGANCHE EL CABLE DE

ALAMBRE SOBRE SÍ MISMO PORQUE

PODRÍA DAÑAR EL CABLE DE

ALAMBRE. Use una eslinga de nilón

(Figura 5).

10. Es una buena idea poner una frazada pesada o abrigo sobre el cable de

alambre cerca del extremo del gancho al tirar de cargas pesadas

(Figura 6). En el caso de que el cable

de alambre falle, la tela actuará

como atenuador para evitar que el

cable de alambre latiguee. Levante

la capota del motor del vehículo

para aumentar la protección.

11. NUNCA USE SU

CABRESTANTE PARA LEVANTAR O MOVER GENTE.

12. Su cabrestante no ha sido diseñado

para operaciones de izado.

13. EVITE TIRAR CONTINUAMENTE

DESDE ÁNGULOS EXTREMOS, ya

que esto causará que el cable de

alambre se apile en un extremo del

tambor (Figura 7). Esto puede atorar

el cable de alambre en el

cabrestante, dañando tanto el cable

de alambre como el cabrestante.

14. NUNCA TAPE LAS ETIQUETAS DE

INSTRUCCIONES DE ADVERTENCIA.

15. Siempre opere el cabrestante

teniendo una vista sin obstrucciones

del área de operaciones.

16. Los equipos como aparejos, gan-

30

INFORMACIÓN GENERAL

DE SEGURIDAD

(CONT.)

Incorrecto

Correcto

Figura 7

Figura 5

Figura 6

Figura 4

Correcto Incorrecto

Figura 8

¡

CALIENTE!

MONTAJE DE S U

CABRESTANTE

Se ofrecen juegos de montaje

(adaptación) de Superwinch para la

mayoría de los vehículos más populares. Si usted no puede localizar un

juego localmente, comuníquese con

Superwinch a la dirección anotada

al frente de este manual para

obtener el nombre del distribuidor

Superwinch más cercano.

Se proporcionan instrucciones detalladas de montaje con cada juego de

montaje. Lea y siga

las instrucciones cuidadosamente

para asegurar la alineación correcta

del cabrestante y su operación sin

problemas.

ADVERTENCIA

!

DEBE montarse con el cable en la

dirección de desenrollado por

abajo. El montaje indebido podría

dañar su cabrestante y anular su

garantía.

Tornillos de

la placa base

del tambor

6.0

(152)

Figura 9

Este

cabrestante

Tornillos

del escobén

(Guía de rodillos)

INSTALACI Ó N

REQUISITOS ELÉCTRICOS

MINIMOS

La capacidad mínima de las fuentes

de energía recomendadas para un

cabrestantes de 12 volts, es un alternador de 60 amperes y una batería

con 440 amperes de arranque en

frío. Si el cabrestante está sometido

a uso pesado, se recomienda utilizar una batería auxiliar y un alternador para servicio pesado.

Paso (1)

Instale el juego de montaje sobre el

apoyo estructural del cabrestante.

Paso (2)

Monte el cabrestante a la base que haya

longitud correcta para usarse con una

placa de hasta 1/4” (6.3mm).

15.1

(383)

Tornillos del motor

INSTALACI Ó N

(CONT. )

ADVERTENCIA

!

grado de resistencia menor a

grado 5.

Al conectar cables a las terminales

del motor y solenoides (relevador),

sostenga la tuerca interna al apretar la tuerca exterior. No permita

que giren las terminales del motor

porque puede romper los cables

internos o desalinear la pieza.

Tenga especial cuidado en evitar

que gire el solenoide (relevador)

Cualquier giro puede dañar el solenoide (vea la Figura 10).

Paso (3)

Desconecte los conductores de la

batería del vehículo.

No sustituya

por ningún

Figura 10

PELIGRO

!

contienen gases que son inflamables y explosivos. Use protección

para los ojos durante la instalación

y quítese toda la joyería de metal.

No se incline sobre la batería al

hacer las conexiones.

Figura 11

Las baterías de

los automóviles

Esté preparado

Paso (4)

Pase dos (2) cables a través de la

rejilla del vehículo a la batería. Para

proteger contra desgaste del aislamiento o cortes, aplique varias

capas de cinta aislante en lugares

donde el cableado pueda tocar

piezas agudas del vehículo. Ponga

el cortacircuitos en el extremo del

cable rojo. Envuelva el conjunto del

cortacircuitos con cinta aislante para

evitar cortocircuitos accidentales.

Conecte el otro extremo del conjunto

de interruptor de circuito al terminal

positivo de la batería.

1.24

(31.5)

3.69

(93.7)

5.9

(150)

7.1

3.1

(180)

(79)

NOTAS:

1. Todas las dimensiones están en pulgadas [milímetros].

2. La instalación típica se realiza sobre una superficie plana capaz de soportar las cargas. Los pernos

deben ser Grado 5 o mejores.

Tornillos de la base

7.2

(183)

32

33

35

CÓMO SACAR EL CABLE

El cable ha sido instalado en la

fábrica en su cabrestante bajo carga

mínima. El cable debe ser rebobinado al tambor bajo carga de modo

que las capas exteriores no se

inserten a las interiores, dañándose. Levante la palanca de

embrague a la posición «Free»

(Libre) como se muestra en la Figura

13. Si hay una carga en el cable de

alambre, es posible que la palanca

del embrague no gire fácilmente.

NO FUERCE LA PALANCA DE

EMBRAGUE. Suelte la tensión sobre

el cable, sacando lentamente un

poco de cable. Suelte el embrague,

saque el cable y asegúrelo al anclaje

o la carga. Revise que haya por lo

menos cinco (5) vueltas de cable de

alambre en el tambor. Vuelva a

embragar el tambor devolviendo la

palanca del embrague a la posición

de «Acoplado» (vea la Figura 14).

La palanca

debe estar en

la posición de «Acoplado» y estar

cerrada antes de operar el

cabrestante.

CONSEJOS PARA INCREMENTAR

LA VIDA ÚTIL DE SU CABRESTANTE

1. MANTENGA EL CABLE DE ALAMBRE ARROLLADO FIRMEMENTE

EN EL TAMBOR. No permita que

se afloje el cable de alambre. Un

carrete arrollado flojamente permite que el cable de alambre

tenso baje por las capas de cable

de alambre del tambor. Cuando

esto sucede, el cable de alambre

puede deformarse como cuña

dentro del cuerpo del enrollado

dañándose. Para evitar este problema, mantenga siempre el cable

de alambre embobinado firme y

uniformemente en . Una buena

práctica es enrollarlo bajo tensión

después de cada uso. Una manera

de hacerlo es sujetar el gancho a

un objeto estacionario hasta arriba de una pendiente gradual y

tirar de su vehículo hacia arriba

en la pendiente.

2. NO PERMITA QUE EL MOTOR

DEL CABRESTANTE SE SOBRECALIENTE. Recuerde, el cabrestante

se ha diseñado usarse sólo intermitentemente. Durante sesiones

de tirado largas o pesadas, el

motor se calentará. Para tirar a la

capacidad nominal, deje enfriar

el motor después de 20 segundos

de estar conectado (On). Para

cargas menores del 50% de la

capacidad nominal, deje enfriar

después de 2 minutos de estar

conectado (On).

3. USE UN BLOQUE DE POLEAS

PARA CARGAS PESADAS. Para

aumentar la vida del cabrestante

y del cabe de alambre, use un

bloque de poleas para tirar con

línea doble las cargas más

pesadas. (Figura 15)

PRECAUCION

!

Figura 14

LIBRE

ACOPLADO

34

Nota: Si decide ubicar el cabrestante

a una distancia mayor que la que

permiten los cables provistos, quizás

sea necesario comprar cable más

grueso para lograr el mejor

rendimiento de su cabrestante. Si la

longitud total del cable adicional a

conectar al sistema excede los 3.04

m (10'), use un cable de mayor calibre.

Conecte el interruptor directamente

a la terminal positiva de la batería,

y reconecte la terminal a la batería.

Si su vehículo está equipado con

terminales laterales quizás sea necesario obtener pernos para terminales laterales de su refaccionaria

local para hacer estas conexiones.

Conecte el otro cable a la terminal

negativa de la batería, y conecte la

terminal a la batería.

Paso(5)

Cambie la posición de la palanca del

embrague a la posición «Free»

(Libre). Saque varios pies de cable

de alambre del tambor. Coloque

nuevamente la palanca del

embrague en posición «Engaged»

(Trabado). Enchufe el control de

pendiente remoto. Presione

momentáneamente el obturador

del interruptor hacia la posición de

“Cable Afuera” para verificar la

rotación y dirección del tambor con

cable metálico. Si el tambor rota en

la dirección equivocada, revise nuevamente la instalación de los cables.

El interruptor pendiente de mano

activa un solenoide que le aplica

corriente al motor del cabrestante.

Un solenoide es para la dirección

«Rope Out» (Sacar Cable) del motor

y el otro es para la dirección «Rope

In» (Tirar Cable)(Fig. 12).

Para evitar el

uso no autorizado del cabrestante, quite el control

pendiente y almacénelo en un lugar

limpio y seco, como la guantera.

OPERACIÓN DEL PENDIENTE

El gatillo interruptor vuelve a la

posición «Off» (Apagado) cuando se

suelta (Figura 12, Artículo A). El

botón deslizante del reverso del

interruptor determina la dirección

de giro del tambor para funcionar

tirando o sacando cable (Figura 12,

Artículo B). El interruptor deslizador

está dotado de un sistema de

interbloqueo para que el motor no

pueda ponerse en marcha atrás si se

oprime el gatillo. Para cambiar la

dirección, suelte el gatillo, mueva el

botón deslizante y vuelva a oprimir

el gatillo. (Fig. 12)

El conjunto

del interruptor

debe mantenerse libre de tierra

y humedad para asegurar su

operación segura.

Para conectar el control de pendiente, levante la tapa guardapolvos

del receptáculo del enchufe (Vea la

Figura 13). La clavija del control de

pendiente está codificada y entrará

en el enchufe solamente en una

dirección.

PRECAUCION

!

PRECAUCION

!

INSTALACIÓ N

(CONT.)

TAPA

ANTI-POLVO

Figure 13

Figura 15

Cable hacia adentro

Cable hacia afuera

Figure 12

erlo es sujetar el gancho del cable

de alambre a un punto fijo en una

pendiente ligera y arrollarlo tirando

del vehículo.

OPERACIÓN DEL FRENO

Su cabrestante Serie S posee un

freno de resorte para el enrollamiento, que detiene y mantiene

cargas de hasta el 50% de la

capacidad nominal en la primera

capa de cable de alambre más cercana al tambor. Cada capa adicional

de cable de alambre redecirá la

capacidad de frenado en 10%

aproximadamente. Al arrollar el

cable con el motor, el freno no está

acoplado y no se activa sino hasta

que se apaga el motor y la carga

trata de tirar del cable hacia afuera

del tambor. Cuando se apaga el

cabrestante, como al soltar una

carga, el freno se acopla y el motor

deberá sobreponerse a la resistencia

del freno para girar el tambor. Por

lo tanto, es normal que el

cabrestante opere más rápidamente

en una dirección que en la otra. El

freno se ha diseñado para que el

cable se use sólo en la posición de

enrollado por debajo. NO lo enrolle

por encima. Tirar contra el resorte

hará que se acumule el calor y es

posible que éste se transmita al

cable de alambre (Figura 20). NO

SAQUE CABLE CON EL MOTOR POR

MÁS DE 15.2 METROS (50 PIES) O

POR 2 MINUTOS.

El tambor

y el cable de

alambre pueden calentarse mucho.

Cuando sale el cable de alambre del

tambor, como para llevar el gancho

a la carga, debe usarse la caracterís-

tica de rueda libre.

ADVERTENCIA

!

37

4. El tirón requerido para comenzar

a mover una carga a menudo es

mayor que el que se requiere

para mantenerla en movimiento.

EVITE PARADAS Y COMIENZOS

FRECUENTES DURANTE EL TIRO.

5. EVITE TORCEDURAS ANTES DE

QUE OCURRAN.

a. Este es el comienzo de una

torcedura. En este momento

debe enderezarse el cable de

alambre.

b. Se ha tirado del cable de alam-

bre y el rizo se ha apretado a

una retorcedura. Ahora el cable

de alambre ya está dañado permanentemente y debe ser

reemplazado.

c. Las torceduras hacen que se

rompan los hilos de alambre

bajo tensión y sí reducen la

capacidad de carga del cable

de alambre. El cable de alambre debe ser reemplazado.

6. EQUIPAR EL CABRESTANTE CON

UNA GUÍA DE ENTRADA CON

RODILLOS reduce sustancialmente

el desgaste del cable durante

sesiones de tirado en ángulo

(Figura 18). Los rodillos eliminan

el roce pesado y las abrasiones

sufridas por el cable.

Revise periódicamente la firmeza de

los tornillos de montaje y las conexiones eléctricas. Quite toda la tierra

o corrosión que se haya acumulado

en las conexiones eléctricas.

Las reparaciones deben hacerlas

los centros autorizados de

reparaciones Superwinch solamente. No trate de desarmar el

motoreductor. Si lo hace, anulará la garantía.

LUBRICACIÓN

La motoreductor y el cojinete del