Page 1

STUDER INNOTEC

User and installer Manual

Sine wave Inverter, Battery charger, Transfersystem

COMPACT C 1600-12

COMPACT C 2600-24

COMPACT C 4000-48

Temperature sensor CT-35

Remote control RCC-01

Solar charge controller Cxxxx-S

Remote power sharing RPS-01

AC cable cover CFC-01

IP-23 top cover C-IP23

COMPACT

User manual COMPACT V4.0 E

Page 2

STUDER INNOTEC

Summary

COMPACT

1 G

ENERAL INFORMATION ............................................................................................................... 4

1.1 OPERATING INSTRUCTIONS........................................................................................................................4

1.2 QUALITY AND WARRANTY ..........................................................................................................................4

1.3 W

ARRANTY DISCLAIMER............................................................................................................................4

1.4 LIABILITY DISCLAIMER ...............................................................................................................................4

1.5 PRECAUTIONS….......................................................................................................................................4

1.6 S

PECIAL PRECAUTIONS .............................................................................................................................5

2 INTRODUCTION ............................................................................................................................ 6

2.1 PRINCIPLE SCHEMATIC ..............................................................................................................................6

2.2 D

ESCRIPTION OF MAIN FUNCTIONS .............................................................................................................6

2.2.1 THE INVERTER ..................................................................................................................................6

2.2.2 THE TRANSFER SYSTEM ....................................................................................................................6

2.2.3 T

HE BATTERY CHARGER....................................................................................................................6

2.2.4 THE SOLAR CHARGE CONTROLLER (OPTIONAL) ...................................................................................7

2.2.5 REMOTE CONTROL ............................................................................................................................7

2.3 B

ATTERY CONNECTIONS............................................................................................................................7

2.3.1 PARALLEL CONNECTION .......................................................................................................................7

2.3.2 SERIES CONNECTION ...........................................................................................................................7

2.3.3

PARALLEL- SERIES CONNECTION ..........................................................................................................8

3 ASSEMBLY ................................................................................................................................... 8

3.1 PLACE OF ASSEMBLY.................................................................................................................................8

3.2 F

IXING………….. .....................................................................................................................................8

3.2.1 COMPACT .........................................................................................................................................8

3.2.2 PROTECTION COVER IP23 .................................................................................................................8

3.3 C

ONNECTION .…………………………………………………………………………………………………….8

3.3.1 GENERAL INSTRUCTIONS ON CONNECTING .........................................................................................8

3.3.2 PROTECTION COVER FOR THE TERMINALS CONNECTIONS ....................................................................9

3.4 C

ONNECTING PLAN / FRONT SIDE ..............................................................................................................9

3.5 CABLING/WIRING.....................................................................................................................................10

3.5.1 PRE-INSTALLATION SETTINGS ..........................................................................................................10

3.5.2 C

3.5.3 CONNECTION THE 230VAC-CONSUMER DEVICE (AC OUTPUT) .......................................................10

3.5.4 C

3.5.5 C

3.5.6 C

3.5.7 C

3.5.8 C

ONNECTION TO BATTERY ...............................................................................................................10

ONNECTION THE 230VAC INPUT (AC INPUT) ................................................................................11

ONNECT THE SOLARMODULES: SOLAR +/- (ONLY FOR SOLAR OPTION)...........................................11

ONNECTION TO AUXILIARY CONTACT .............................................................................................11

ONNECTION TO REMOTE CONTROL ................................................................................................11

ONNECTION TO TEMPERATURE SENSOR (TEMP.)............................................................................11

4 OPERATING ...............................................................................................................................12

4.1 DISPLAY AND OPERATING CONTROL ELEMENTS .......…………………………………….…………………….12

4.2 LIGHT EMITTING DIODES ...........................................................................................................................12

USH BUTTONS… ...................................................................................................................................13

4.3 P

4.4 T

URNING KNOBS.....................................................................................................................................13

4.5 THE INVERTER…. ...................................................................................................................................14

4.5.1 C

4.5.2 O

4.5.3 OVERHEATING (OVER TEMP)...........................................................................................................14

4.5.4 BATTERY CONDITION ......................................................................................................................14

4.6 T

4.6.1 CYCLE OF CHARGE..........................................................................................................................15

4.6.2 E

4.6.3 I

4.6.4 CHARGING CURRENT.......................................................................................................................16

4.6.5

4.7 T

4.7.1 SET THE TRANSFER VOLTAGE THRESHOLD........................................................................................17

4.7.2

User manual COMPACT V4.0 E 2

HARGE DETECTION SYSTEM „STANDBY“ .........................................................................................14

VERLOAD .....................................................................................................................................14

HE BATTERY CHARGER..........................................................................................................................15

QUALIZATION CHARGING................................................................................................................15

NPUT CURRENT REPARTITION (POWER SHARING) .............................................................................15

BATTERY CONDITION ......................................................................................................................16

HE TRANSFER SYSTEM ..........................................................................................................................16

FAST (UPS)- MODE FOR THE TRANSFER SWITCH.................................................................................17

Page 3

STUDER INNOTEC

COMPACT

4.7.3 DELAYED MODE OF THE TRANSFER SYSTEM .....................................................................................17

HE SOLAR CHARGE CONTROLLER (OPTION) ............................................................................................17

4.8 T

4.9 T

HE MULTIFUNCTIONAL CONTACT............................................................................................................18

4.10

THE REMOTE CONTROL..........................................................................................................................18

4.11 THE TEMPERATURE SENSOR ...................................................................................................................19

5 PROGRAMMING.......................................................................................................................... 19

5.1 STANDARD SETTING ................................................................................................................................19

5.1.1 WORKING MODE..............................................................................................................................19

5.1.2 BATTERY VOLTAGE..........................................................................................................................19

5.1.3 A

5.2 RESET VALUE…......................................................................................................................................19

5.3 BATTERY VOLTAGES AND ABSORPTION TIME .............................................................................................19

5.3.1 T

5.3.2 SET THE VOLTAGE AND TIMING THRESHOLD ......................................................................................20

5.4 PROGRAMMING THE AUXILIARY CONTACT..................................................................................................20

5.4.1 P

5.4.2 T

5.4.3 EXAMPLES......................................................................................................................................21

5.4.4 M

5.5 D

5.5.1 DIAGRAM OF THE DIFFERENT MODES ...............................................................................................22

UXILIARY CONTACT .......................................................................................................................19

ABLE OF VOLTAGE AND TIMING THRESHOLD ....................................................................................19

RINCIPLE ......................................................................................................................................20

HE PROGRAMMING OF THE AUXILIARY CONTACT IS CARRIED OUT IN THE FOLLOWING STEPS .............20

ANUAL OPERATING OF AUXILIARY CONTACT...................................................................................21

ISABLING SOME OF THE COMPACT FUNCTIONS ........................................................................................21

6 MAINTENANCE ...........................................................................................................................22

7 EC

8 T

COMPLIANCE ....................................................................................................................... 22

ECHNICAL DATA ....................................................................................................................... 23

User manual COMPACT V4.0 E 3

Page 4

STUDER INNOTEC

COMPACT

1 General Information

1.1 Operating instructions

This manual is a part of the delivery package of every COMPACT inverter-charger. It serves as

guidelines for safe and efficient operation of COMPACT. The instructions are only valid for use with

the following devices and options:

COMPACT C 1600-12

COMPACT C 2600-24

COMPACT C 4000-48

Temperature sensor CT-35 AC cable cover CFC-01

Remote Control RCC-01 IP23 cover C-IP23

Power sharing remote control RPS-01 Solar charge controller CxxxxS

Every person who installs a COMPACT and/or works with it must be fully familiar with the contents

of this manual and must follow exactly all the warnings and safety instructions. Installation of or any

work on the COMPACT must be carried out by a qualified and trained staff. Installation and

application must comply with the respective local installations codes and safety regulations.

1.2 Quality and Warranty

During production and assembling, all COMPACT appliances go through many controls and tests.

Fabrication, controls and tests are carried out in accordance with firm and established procedures.

Every COMPACT has its own serial number, which helps to refer back to its original data in the

event of controls or repairs. That is why you should never remove the identification plate showing

the serial number. The production assembly and tests on all COMPACT appliances are totally

carried out in our company in Sion, Switzerland. The warranty for these appliances is valid for uses

and operating possibilities mentioned in this manual.

The warranty period for the COMPACT is 2 Years.

1.3 Warranty Disclaimer

We do not accept any responsibility for any damages occurring through use, manipulation, working

situation and handling, which are not explicitly mentioned in these operating instructions.

Following cases are not covered by the warranty:

- High voltage at INPUT (i.e. 48V at the Battery INPUT of COMPACT 1600-12)

Reverse polarity on Battery connections (+/- reversed)

Running liquid or oxidation through condensation in the appliance

Defects caused by force, physical or mechanical means

Changes not explicitly authorized by Studer INNOTEC

Not or only partly tightened screws and nuts after change of fuses or connecting cables

Connecting other sources of energy such as PV-Modules on the INPUT „SOLAR +/-„

Transport damage, i.e. through bad handling and /or packing.

1.4 Liability Disclaimer

Respecting this manual, servicing and method of installation, functioning, application and

maintenance of the appliance can not be controlled or supervised by Firma Studer INNOTEC.

Hence we do not accept any liability and responsibility for damages, loses and costs which result

through the use of this appliance or which result through incorrect installation, incorrect operation

or wrong application and maintenance or which by some other means maybe connected together

to these. Similarly, we do not accept any responsibility for any violation of the patents rights or

violation of any third party’s rights resulting from the use of this appliance

Studer INNOTEC reserves the right to modify the technical data or these operating instructions

without issuing any prior notice.

1.5 Precautions

This manual must be readily available for the user at all times. The user must be familiar with the

precautions and safety aspects.

User manual COMPACT V4.0 E 4

Page 5

STUDER INNOTEC

During operation of COMPACT, high tensions are generated at the connections and inside of the

appliance which could be deadly fatal. Work on the appliance and on the installation should only

be carried out by qualified and trained personnel.

The whole installation connected with the COMPACT must comply with the respective valid codes

and ordinances.

Persons without the written authorization from Studer INNOTEC are strictly forbidden to carry out

any changes or repairs on the appliances. For authorized changes only original parts are to be

used.

The COMPACT may only be used when it has been installed in accordance with these instructions

and all parts have been correctly assembled and installed.

On the IN- and OUTPUT points of the COMPACT only the already selected energy sources and

consumer devices should be connected.

In order to carry out any maintenance or repair work on the COMPACT without danger, all

connections must be disconnected beforehand.

COMPACT

Caution: Even when a COMPACT has been disconnected from the all connections, at the

OUTPUT point there could still be deadly fatal tensions present. To remove these tensions

you must switch on the COMPACT ON with the ON/OFF switch. After one minute the

electronics are discharged and any work can now be safely carried out.

The COMPACT is only suitable for internal use and under no circumstances should it be subjected

to snow, rain, or any other wet conditions

By installations in motorized vehicles the COMPACT must be protected from water-spray and any

other wet conditions.

The COMPACT may only be connected to lead –acid or lead-gel batteries.

Caution: In normal use lead-acid and lead-gel batteries give out explosive gases. Never smoke

or allow a spark or flame in the vicinity of batteries. The batteries must always be stored or placed

in a well ventilated area, they should be placed in such a way that there is no danger of short

circuiting through carelessness. Never charge frozen batteries.

The COMPACT is not to be used or sold for life support equipment or applications.

1.6 Special Precautions

While working on batteries there should always be a second person close to you or within your

voice range, in case help is needed.

Plenty of fresh water and soap must be ready at hand so that in case of acid coming in contact with

skin, eyes and clothes, the areas in question can be thoroughly washed.

If acid enters the eyes, you must thoroughly wash the eyes with cold running water for at least 15

minutes. It is recommended that you immediately consult a medical doctor.

Baking powder neutralizes battery acid electrolyte. Always keep some at hand.

Special care must be taken when working with metal tools near or on the batteries. With tools such

as screwdrivers, spanners etc. short-circuits can result. Sparks produced by the short circuit can

cause an explosion.

When working on batteries all personal metal items such as rings, necklaces and bracelets must

be removed. Batteries are so powerful that short-circuit with these items can melt them and thus

cause severe burns. Always follow the battery manufacturer instructions.

Under certain conditions COMPACT or a connected generator can start automatically. While

working on an electrical installation you must ensure that these appliances are disconnected

beforehand from the installation.

User manual COMPACT V4.0 E 5

Page 6

STUDER INNOTEC

A

T

R

A

A

A

Ω

A

A

COMPACT

2 Introduction

The COMPACT is a sine wave inverter with integrated battery charger and solar charger controller

with many additional functions, it has been developed to be used as stand-alone (independent of a

grid-system) AC provider, or as continuous / break-free current supply provider.

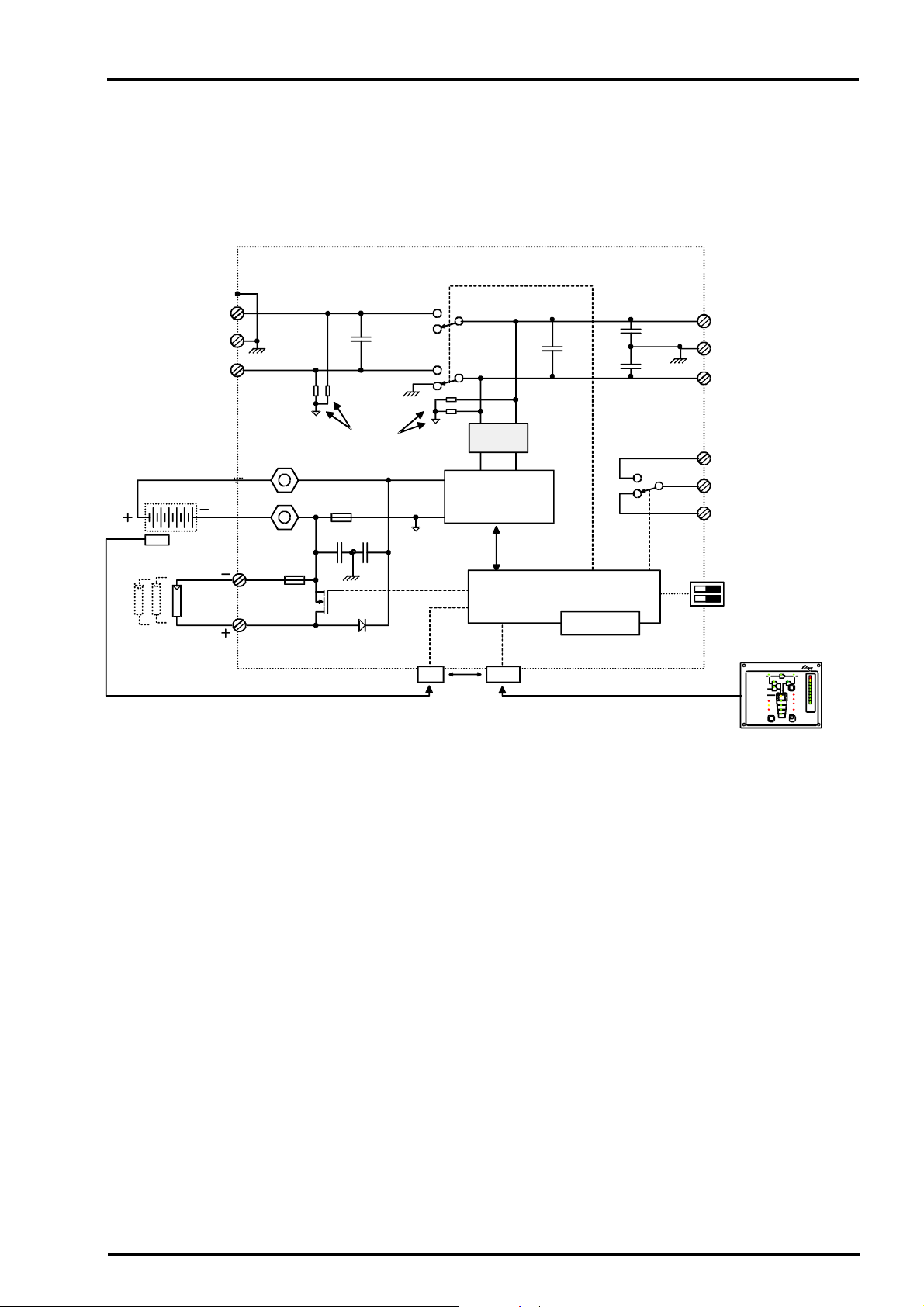

2.1 Principle schematic

C IN

Input

230Vac

L

PE

N

100nF

1uF

10nF

10nF

L

PE

N

C OUT

Output

230Vac

4x2,7M

Filter

UX. CONT

.

Battery

BATTERY

CT35

150A

1uF

1uF

Inverter

Charger

Temp. Sensor

Microprocessor,

SOLAR

Solarmodule

Max. 6m

Temp.

6p 8p

Control, Adjustment

RJ11

Remote control

Display

Max. 40m

Remote control

Remote control

INVERTER - CHARGE

RCC-01

COMPAC

TRANSFER

AC IN

SOLAR CHARGE

EQUALIZE

Program

Contact active

Contact manual

AUXILIARY CONTACT ON/OFF

(Program) (Change sta tus)

%

C OUT

160

130

INVERTERCHARGER

100

70

RESET

80

60

LARM

(Select)

60

50

40

40

20

30

Over Temp.

10

20

Overload

Battery

5

10

Ch

Low/High

Inv

arg

ert

er

er

OFF

2.2 Description of main functions

2.2.1 The Inverter

The sine wave inverter built in the COMPACT generates a sinusoidal AC voltage with an

exceptionally precise voltage and stabilized frequency. In order to start large electric motors, the

user has the possibility to employ a short-start-power which is 3-times the nominal power of the

COMPACT.

The inverter is protected against overload and short circuit. A power-stage with the latest MOSFET power transistors, a toroidal transformer, and a fast regulating system make-up a robust and

reliable inverter with highest efficiency. A 1-20 Watt adjustable charge detection system serves to

provide the smallest energy consumption and ensures a long life for the battery.

2.2.2 The Transfer system

COMPACT can be connected to an AC source. For example a stand-by emergency generator or

the AC network. With the transfer system, on one side you have an alternating voltage at the

output for use by the connected consumer devices. On the other side the batteries are charged.

The distribution of energy between the consumer devices and battery charger is automatic.

2.2.3 The Battery charger

The built-in battery charger is so arranged that it can charge the batteries quick very completely. A

microprocessor controlled, 3 to 4 Step charging process ensures the optimum charging of the

batteries. The desired charging current can be set continuously from 0 – 55A (C 4000-48: 0 - 50A).

The battery charger is meant for the lead-acid and lead-gel batteries. Thanks to the floating charge

system the batteries can remain continuously connected.

User manual COMPACT V4.0 E 6

Page 7

STUDER INNOTEC

2.2.4 The solar charge controller (optional)

With the built-in solar charge controller, the COMPACT is a complete solar-power-center. In a solar

installation this controller ensures that the batteries are charged correctly. With the COMPACT,

batteries can be charged with a generator and with the solar modules at the same time. The

charging of batteries with both energy sources is carried out fully automatically.

2.2.5 Remote control

As an option, a remote control can be connected to COMPACT. All operating elements and

displays with the exception of the level adjustment are available on the remote control. The remote

control is furnished with a 20m long cable. This cable can go to 40m long. On the remote control

output power and charging current are also shown.

COMPACT

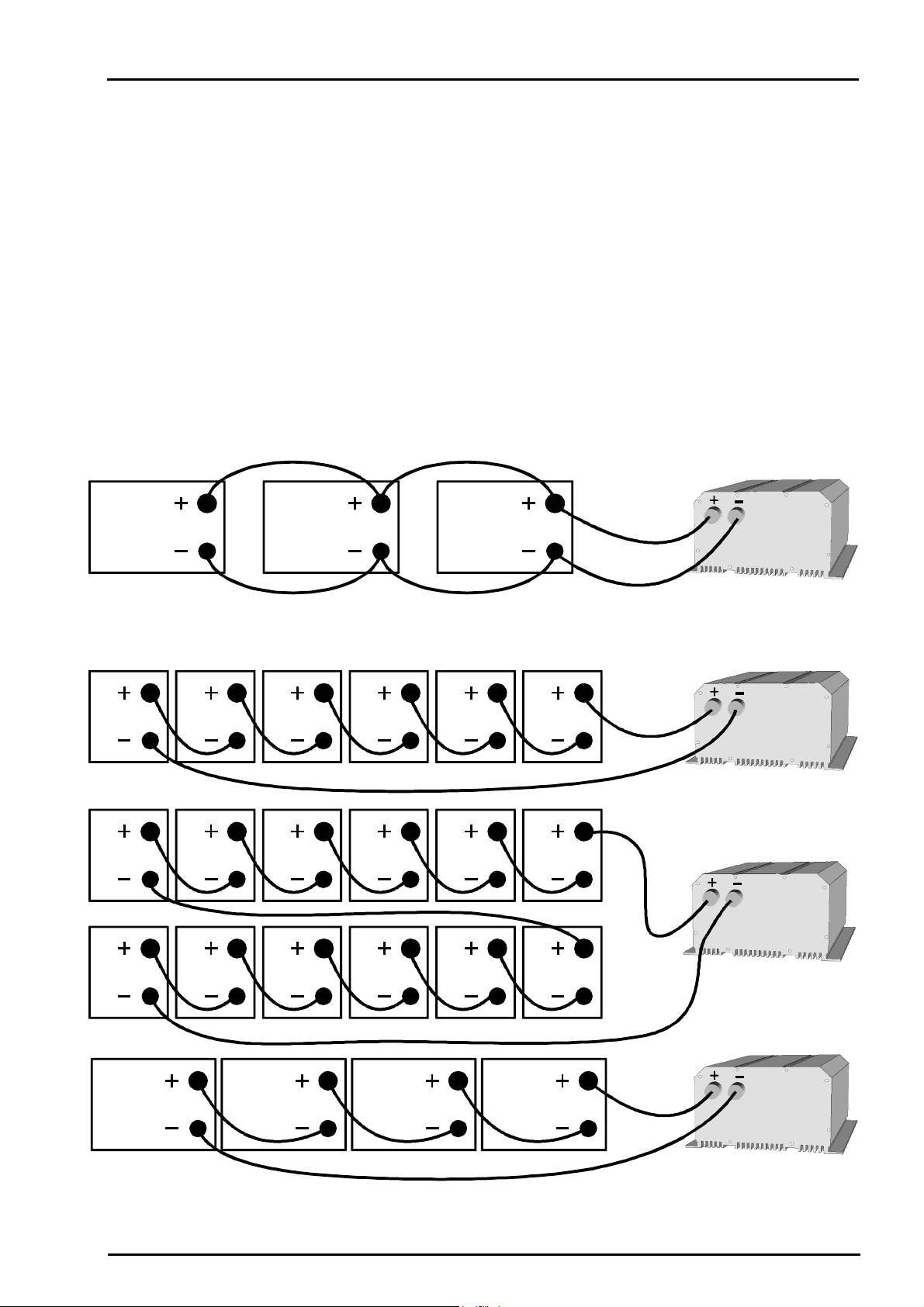

2.3 Battery connections

Lead-acid batteries are normally available in blocks of 2V, 6V or 12V. In most cases, to generate

the necessary operating voltage and the capacity of the batteries for the COMPACT many

batteries have to be connected together in parallel and or in series. Following three examples are

shown:

2.3.1 Parallel Connection

12V 12V 12V

2.3.2 Series Connection

2V 2V 2V 2V 2V 2V

2V 2V 2V 2V 2V 2V

2V 2V 2V 2V 2V 2V

C 1600-12

C 1600-12

C 2600-24

12V 12V 12V 12V

C 4000-48

User manual COMPACT V4.0 E 7

Page 8

STUDER INNOTEC

2.3.3 Parallel- Series Connection

COMPACT

12V 12V 12V 12V

C 2600-24

3 Assembly

3.1 Place of assembly

The location of the COMPACT must be chosen by the following criteria:

Protection from unauthorized handling.

Dry dust free room, no condensation.

Never install directly over the battery and never in a cabinet together with the batteries.

Keep ventilation holes free. The ventilation of COMPACT is designed in such a way that it can only

work efficiently when the appliance is fully laying on its back.

In mobile installation it is important to keep the vibrations down to as low as possible.

3.2 Fixing

3.2.1 Compact

Basically the COMPACT can be installed in any desired location. Preferred is that the appliance be

wall mounted with battery cables downwards. The COMPACT is fixed on the wall with four screws

through the four holes (diameter 5.5mm) which are accessible from the outside. In motor vehicles

COMPACT must be fixed on vibrations reducing elements. The COMPACT must not be fixed on a

combustible base, as the back of the casing can get hot and reach up to 80 degree Celsius.

3.2.2 Protection cover IP23

This cover IP23 (Order ref. CIP-23) can be easily installed after

the fixation of the COMPACT. For that’s release a little the too

screws down and more the tow up. Then it’s possible to pass the

IP 23 cover between the COMPACT and the wall. The cover must

touch the screws. Lock on the four screws, it’s ready.

3.3 Connection

3.3.1 General instructions on connecting

The cable connection on the terminals AC INPUT / AC OUTPUT / 15A 230VAC are carried out

with a screwdriver Nr.1 and the connection on the SOLAR terminal with a screwdriver Nr.2.

The conductor cross section on the terminals AC INPUT / AC OUTPUT / 15A 230VAC of the

connecting cable must be minimum 2.5mm

All connecting cables and also the mounted battery cables, must be fixed with strain relief clamps.

The COMPACT is delivered with battery cables already connected.

The battery cables must never be extended. If the extension is unavoidable then the conductor

cross section must be elevated accordingly.

To protect the battery cable, a fuse corresponding to the conductor cross section must be fixed

directly on to the battery.

All cables must be tightly screwed in place. For safety, a yearly control is recommended. In mobile

installations control must be carried out more often.

Connecting must be done by qualified personnel. Material such as cable, connectors and

distribution boxes, fuses etc. used in the installation must comply with the respective valid lowvoltage installation rules and regulations.

2

.

User manual COMPACT V4.0 E 8

Page 9

STUDER INNOTEC

3.3.2 Protection cover for the terminals

connections

The protection is available as an option (Order ref.

CFC-01) and avoid to do wrong hazardous

connection on the terminals 230Vac. It mounted

with strain relief clamps for the cable.

3.4 Connecting Plan / Front side

COMPACT

Don't open before

disconnect line

and battery

BATTERY

SOLAR

Remote

control

Caution: Check battery

polarity (+/-) before connecting!

A wrong connection could

damage the system.

.

Auxiliary Contact

16A-250Vac

Equalize

Transfer delay

Temp.

N

AC Input

PE

N

Typ:

N°:

L

Ubat:

Pnom: 2300 VA

Uin: 150 - 250 Vac

Uout: 230 V/50 Hz

I Solar:

I Charge: 70A

OM AL

C 2600-24

22-32 Vdc

30A max.

Remote

Power

sharing

AC Output

N

PE

L

B

C

D

EF G

HJ

K

A Battery +/- Battery cable (already installed)

B SOLAR +/- Connecting terminal for Solar modules

C Remote contr. Connecting terminal for Remote Control RCC-01

D Equalize Slide switch for equalization of the Battery

E Transfer delay Slide switch for Transfer Delay

F Temp. Connecting terminal for Temperature sensor CT-35

User manual COMPACT V4.0 E 9

Page 10

STUDER INNOTEC

G Aux. Contact Connecting terminal for Auxiliary Contact

H AC Input Connecting terminal for AC-input. Located directly above

this terminal is the automatic safety cut-out for this

terminal.

J ID Plate Identification plate with Technical data and Serial number

K AC Output Connecting terminal for AC-output

L Caution… Caution: Check Polarity (+/-) before connecting the

battery !

Polarity reversal can damage the COMPACT.

M Don‘t … Do not open without disconnecting all terminals

N 16A Protection 16A Protection switch for the Transfer system

O Remote Power Input current repartition

Sharing

COMPACT

3.5 Cabling/wiring

Connecting of the COMPACT is a very important step in the installation. You must take care that

all connecting work is carried out in a clean and correct manner and under no circumstances that a

cable is connected to a wrong terminal.

Connecting of the COMPACT must be carried out in the following order. In case of dismantling this

order must be reversed.

3.5.1 Pre-installation settings

Before you start with the cabling of the COMPACT you must set the type of battery. In case that

sealed-gel batteries are used then you must set the small slide-switch „Equalize“ which is on the

front with the connecting terminals, to OFF position. In case of „normal“ lead-acid – batteries, these

can handle a higher equalizing charge, the same slide switch can be set to ON position. In case of

doubt leave the setting in OFF position.

3.5.2 Connection to battery

Get the batteries ready for connection: Matching battery terminals, matching fuse on a clamp.

Prepare battery cables, if necessary press on cable tabs/shoes. Connect red cable on Plus (+)Pole and the black cable on the Minus (-) Pole. On connecting the second cable to the battery pole

a spark is produced, because for a short time high current flows in the COMPACT to charge the

capacitors. For this reason follow strictly the safety measures described in this manual. Check if

the red LED OFF (13) is lit. If it is not lit, press shortly on the switch ON/OFF (19), now OFF should

be lit.

On connecting the battery the COMPACT needs 1 – 2 Minutes to calculate the actual capacity of

the battery. During this time the battery condition is shown as 100% charged. (LED 14 – 17 lit).

If the LED 12 Battery Low/High is lit, the battery charge is too low. If the LED 12 Battery Low/High

is blinking, the battery charge is too high.

Caution: With a wrong battery voltage the COMPACT can be destroyed. (for example: connecting

a C 1600-12 to a 48V-Battery).

Nevertheless, if the COMPACT had been connected with reverse polarity, it is highly probable that

the fuse inside the casing is defect. Before opening the casing cover all terminals must be

disconnected including the battery. If the COMPACT does not function after the changing of the

fuse and correcting of the polarity, it means that it is defect and must be sent for repair.

3.5.3 Connection the 230Vac-Consumer Device (AC OUTPUT)

The 230V consumer device must be connected to the screw terminal AC OUTPUT. For this, use a

3-core cable with a conductor cross section of 2.5mm

Neutral, “PE“ Earth, “L“ Live.

2

. Connections are marked as follows “N“

Caution: High tension can by there. By sure that’s the compact is turn off (LED 13 alight) before

the connection.

User manual COMPACT V4.0 E 10

Page 11

STUDER INNOTEC

COMPACT

3.5.4 Connection the 230Vac Input (AC INPUT)

The 230V-supply from network or from a generator must be connected to the screw terminals AC

INPUT. For this use a 3-core cable with a conductor cross section of 2.5mm

2

. Connections are

marked as follows “N“ Neutral, “PE“ Earth, “L“ Live.

3.5.5 Connect the solar modules: SOLAR +/- (Only for solar option)

Solar modules are connected on these terminals. Under no circumstances should any other energy

source i.e. wind generator be connected to these terminals! Only solar modules must be connected

with two cables +/-. Depending on the power of the modules, the cable cross section should be 2.5

up to 6mm

2

. Before connecting it is necessary to check with a Voltmeter that the voltage of the

Module meets the following values:

C 1600-12 17-25V/30A, C 2600-24 34 – 45V/30A,C 4000-48 68 – 90V/20A.

3.5.6 Connection to Auxiliary Contact

On these tree terminals is a potential free change-over contact). The maximal permitted current

and voltage for this is 16A/250Vac. The DEL 5 “Contact active” show the position of them: alight

mind active and off mind non-active. The schematic view of the connections on the front, show the

relay in the non-active mode.

3.5.7 Connection to Remote control

The Remote Control RCC 01 is connected in the terminal marked „Remote control“ with a RJ11/8

connector. The Remote Control can be plugged IN or plugged OUT during any operation situation.

Push in the connector, without forcing it, until you hear the „click“, now the connector is locked in

place. The same applies to the plug in the Remote Control. The length of the cable for Remote

Control should not exceed 40m. We deliver it with 20m cable.

3.5.8 Connection to Temperature Sensor (Temp.)

The Temperature sensor CT-35 is connected in the terminal marked „Temp“ with a RJ11/6

connector. The Temperature Sensor can be plugged IN or plugged OUT during any operating

situation. Push in the connector without forcing it, until you hear a „click“, now the connector is

locked in place. The Temperature Sensor must be glued to the wall of the battery or near it. The

Temperature Sensor cable must not be tied together with the battery cables or laid in a

rope/bundle.

User manual COMPACT V4.0 E 11

Page 12

STUDER INNOTEC

4 Operating

4.1 Display and operating control elements

Inverter

output

power

[%]

200

160

130

100

80

60

40

20

10

25

5

INPUT LIMIT

16A

0

26

Ch a r g e r - I n v e r t e r

CHARGER

70A

22

TRANSFER

150V

230V

23

STANDBY

24

OFF0

20W

POWER

MONITOR

Charge

current

[A]

70

60

50

40

30

20

10

COMPACT

1

8

7

CHARGER INVERTER

SOLAR CHARGE

EQUALIZE

Program

Contact active

Contact manual

2

3

14

4

15

9

20

10

11

12

5

6

16

13

17

AUX. CONTACT

(Program)

21

18

19

AC OUTAC IN

RESET ALARM

Lock (select)

Over Temp

Overload

Batt Low/High

OFF

ON/OFF

(Change status)

User manual COMPACT V4.0 E 12

Page 13

STUDER INNOTEC

COMPACT

4.2 Light Emitting Diodes

LED Marking LED lit LED blinks

1 AC IN Voltage corresponding to self-

adjusted values is at the AC IN

input.

2 CHARGER Battery Charger is working The input voltage is out value

3 SOLAR

CHARGE

4 Program Programming mode for Aux.

5 Contact active Auxiliary Contact is activated

6 Contact manual Aux. Cont. manually activated

7 Transfersystem is active. In-

8 AC OUT There is voltage at the AC OUT

9 INVERTER Inverter is working Forced -Inverter Mode

10 Over Temp. For the time being the COMPACT

11 Overload The COMPACT is out of service

12 Batt. Low/High Battery voltage is too low Battery voltage is too high

13 OFF COMPACT is turned off. Turning it

14 Battery Charger and or Solar

15–18 Charge condition of Battery LED 15 – Absorption time is

25 CURRENT

MONITOR

Connected solar modules are

delivering energy

Contact

coming voltage is being sent

directly to AC OUT outlet

outlet

is out of service because of

overheating.

because of overload or shortcircuit

back on is only possible manually.

Charge Controller are doing an

equalization cycle

Display the value of the output power in % of Pnom (in Inverter Mode)

and the charge current in Amps. (in Charger Mode) In this mode the

200% LED indicate that power sharing is in use.

Voltage, outside of the selfadjusted values is at the AC IN

input.

(voltage or frequency)

The Inverter is in Standby-Mode

COMPACT is for the time being

turned off. Turning it back on will

follow automatically!

running

4.3 Push buttons

19 ON/OFF Turning the COMPACT on and off (Help Button for Programming)

20 RESET Alarm Signal off (Help Button for Programming)

21 Aux. Contact Control Aux. contact (Help Button for Programming)

4.4 Turning Knobs

22 CHARGER Adjustment for max. Charging Current (Not for Solar charge controller)

23 TRANSFER Adjustment for Transfer Voltage Threshold (TRANSFER – INVERTER)

24 STANDBY Adjustment for „Standby“ system

26 INPUT LIMIT Must be adjusted to the maximal available current of your AC INPUT

supply (see on chap.

User manual COMPACT V4.0 E 13

4.6.3)

Page 14

STUDER INNOTEC

COMPACT

4.5 The Inverter

An Inverter is built in the COMPACT, which generates a sinusoidal alternating voltage of a very

high quality. With this Inverter any alternating voltage consuming device 230Vac up to the nominal

power of your COMPACT can be operated. Thanks to the generous dimensioning of the

COMPACT, you can operate appliances requiring higher power than the nominal power of the

COMPACT for a short time. The COMPACT provide up to 3-times the nominal power to start

motors.

The Inverter mode is displayed through LED 9 (Inverter). If the Inverter Mode is disabled (see

chap. 5.5) LED 9 will blink. If the LED 9 is lit, the Inverter is in operation and you have 230Vac at

output AC OUT. The actual power of the connected consumer device is displayed on the power

monitor 25 and on the remote Control.

4.5.1 Charge detection system „Standby“

In order to avoid unnecessary discharge of the battery, the inverter switches OFF automatically if

no consuming device is connected and switches ON automatically again if a consuming device is

connected. The LED 8 blinks if the inverter is in Standby-Mode. The switching-on/starting level can

be adjusted with the turning knob 24 „STANDBY. Adjusting the switching-on level is as follows:

Switch off all consuming devices; turn the Turning Knob 24 to the right until the LED 8 is blinking,

switch on the smallest consuming device (i.e. Mobile phone charger); turn the Turning Knob slowly

to the left until LED 8 is lit.

If the Standby- Mode is not wanted, turn the Turning Knob 24 to the left, to the OFF position.

4.5.2 Overload

If the Inverter is too long or too heavily overloaded, it switches off. The LED 11 „Overload“ is lit and

LED 13 „OFF“ blinks. After ca. 10 seconds the Inverter switches on automatically. If the Inverter is

overloaded four times one after the other in a short time, then it no longer switches on

automatically. The LED 13 remains lit. Press the push button 19 „ON/OFF“ in order to switch on

the Inverter.

4.5.3 Overheating (Over Temp)

If the Inverter has been overloaded for a long time or it has been working at too high surrounding

temperatures, it will switch off. The LED 10 „Over Temp.“ is lit and the LED 13 „OFF“ blinks. After

cooling down, the inverter switches back on automatically. One minute before the inverter switches

off for to high temperature it gives out an acoustic alarm signal. If the Auxiliary Contact has been

programmed to detect the high temperature then it synchronizes the relay with the alarm signal. In

this way, for example, an emergency back up system can be started without any break in the

energy supply.

4.5.4 Battery Condition

Deep discharging of the lead-acid batteries leads to high losses in capacity and early aging. That is

why battery condition is continuously controlled and supervised. With low voltage the inverter

switches off. The LED 12 „L/H Batt.“ is lit and the LED 13 „OFF“ blinks. When the battery voltage

gets up to 12.1V / 24.2V / 48.4V, the Inverter switches on automatically. One minute before the

Inverter switch off due to low voltage it gives out an acoustic alarm signal. If the Auxiliary Contact

has been programmed to detect the low voltage then it synchronizes the aux. contact with the

alarm signal. In this way, for example, an emergency back up system can be started without any

break in the energy supply.

The low voltage is set to 11.8V / 23.6V / 47.2V. These settings are standard for most batteries.

These voltage levels are maintained by the built-in Battery-Management-System of COMPACT by

matching the load and the battery condition.

This setting is comparable with the levels of 10.8V/ 21.6V / 43.2, which are given for most batteries

on nominal load.

All voltage levels can be programmed. See the instructions under the section on Programming.

Check your battery supplier as to which voltage values are necessary to be set.

User manual COMPACT V4.0 E 14

Page 15

STUDER INNOTEC

COMPACT

4.6 The Battery charger

4.6.1 Cycle of charge

The full automatic COMPACT Battery Charger is adjusted at the factory so that most lead-acid and

lead-gel batteries can be charged to the maximum. As soon as the minimum alternating voltage for

the AC IN set on the Turning Knob 23 is available at the input (LED 1 AC IN is lit), the Battery

Charger is switched on automatically (LED 2 CHARGER is lit). The battery is fully automatically

charged matching to the charge level, the adjusted voltage levels and the charge current. Thanks

to the built-in Float Charge System, the batteries can be left connected for unlimited time with the

Battery Charger switched on.

During the charging phase the consuming devices at the outlet AC OUT are continually supplied

with power (LED 8 AC OUT is lit).

The charger functions are shown in the following diagram:

[V/cell]

2.50

2.3

2.1

1.9

A

B

C

D

[A]

70

60

40

20

Equalization

Absorption

Floating

Charging current (adjusted)

Charging time

A

B

Egalization time

C

Absorption time

Floating

D

t

4.6.2 Equalization charging

Before you program the COMPACT for Equalization-charge you must confirm with your supplier

that the batteries are suitable for this process.

Equalization is recommended for the lead-acid batteries in order to mix well the electrolyte fluid

and to clean the lead plates.

Equalization mode should never be used when using Gel-Batteries

If the COMPACT is operating with a lead-acid battery, which is suitable for equalization, the slide

switch „Equalize“ which is on the cable connection side, must be placed in the ON position. In this

setting, at every 25 charge cycles an equalization is carried out for 20 min. (factory setting). During

such a charge cycle the LED 14 is lit. Charge cycle with equalization can be started independently

of the actual program. For this the slide switch must be slid from “OFF” to the “ON” position. The

LED 14 will light up. If the periodic equalization is not required, slide switch must be slid back to the

„OFF“ position after the completion of the manual cycle.

CAUTION: During the equalization process, the batteries produce lot more gas.

DANGER OF AN EXPLOSION !!

4.6.3 Input current repartition (Power sharing)

For manage the power available on the AC INPUT (depend the supply use) the COMPACT is

equipped with a system usually called “Power sharing” or INPUT power distribution. With this

function it’s possible to limit the AC INPUT current assigned to the charger. More current it uses on

User manual COMPACT V4.0 E 15

Page 16

STUDER INNOTEC

the OUTPUT less it’s give to the charger. Priority to the OUTPUT.

When the power sharing is used the LED 200% (red) is lit to point

out that’s the charge is limited.

Caution: If the power use on the OUTPUT is higher than the value

of the INPUT LIMIT (26) the COMPACT limits the current, then the

generator means to stop or the circuit breaker before means to

break.

In option, a remote control (RPS-01, 20m cable) allows the Power

Sharing far from the COMPACT.

4.6.3.1 Set the INPUT LIMIT (26)

The current available for the COMPACT depend of the supply used

i.e. motor generator, network limit in a camping or shore

connections… The value of the turning knobs INPUT LIMIT (26)

must by adjust lower or equal of the current available from the

source.

For example if you have a generator of 2kW you must adjust the

turning knobs 26 to approximately 8.5A. For calculate this, we

divide the nominal power (2000W) by the voltage (230V). If you

have a circuit breaker (i.e. 6A) before the COMPACT, then you set

this value on the turning knobs (26) (i.e. 6A).

Generator

power

500W 2A

900W 4A

1500W 6,5A

2000W 8,5A

3000W 13A

COMPACT

Current

(230V)

4.6.4 Charging current

The maximum charging current for the battery can be adjusted with the Turning Knob 22

(CHARGER). The charging current of the battery should be set to approximately 10 – 20% of the

battery capacity (at C10). This means that the charging current for a battery with 300Ah should be

set between 30 – 60A.

The charging current is displayed on CURRENT MONITOR (25) of the front panel or on the

Remote Control.

4.6.5 Battery Condition

Built-in microprocessor with a specially developed

algorithm calculates the actual state of charge of the

battery and displays it on LED 15 – 18. The LED 14 is

lit when the system is carrying out a charge cycle with

equalization.

For safety reasons, you must get the recommended

charge voltage and charge currents from your battery

supplier. The voltage levels and charge characteristics

can be changed through Programming. The instruction

for programming of battery charger is in the section

„Programming“ (Chap. 5.1.2). The correct charging is

14

15

16

17

18

Equalization cycle

Battery 75 – 100%

Battery 50 – 75%

Battery 25 – 50%

Battery 0 – 25%

indispensable for a safe function and long-life of the

battery.

4.7 The Transfer system

When an ac voltage is at the input AC IN of the COMPACT, the LED 1 AC IN is lit. When this

voltage matches the lowest adjusted value set by the Turning Knob 23 TRANSFER, and the

frequency is between 44Hz and 65Hz, this voltage is switched directly to the battery charger and to

the output AC OUT. The LED 7 TRANSFER is lit. The inverter is switched off and the battery

charger switched on. This process is automatic, unless the charger mode or the transfer mode is

disabled (see Chap. 5.5)

The maximum current of the Transfer switch is 16A. That means through this system, consuming

devices up to a maximum of al 3700 Watt can be operated. When the Battery Charger is working,

part of this power is used for the charging according with the power sharing system.

User manual COMPACT V4.0 E 16

Page 17

STUDER INNOTEC

The Transfer system is protected against overload with an automatic safety fuse on the AC Input

side of the COMPACT. If the system has been overloaded the button/pin of the fuse will pop-out.

To put the automatic safety system back in to operating you must push this pin back.

Note: In the Inverter operation, The COMPACT generates a true sinusoidal and quartz stabilized

output voltage. When, however the COMPACT is supplied from a grid or a generator and the

transfer contact is active, then you have at the output AC OUT the same voltage as that at the

input. This voltage can not be modified by the COMPACT!

4.7.1 Set the transfer voltage threshold

The voltage threshold of the transfer can by adjust between 150 to 230V with the turning knobs

(23). From factory this value is 200V. Most of appliances can work on this voltage. When the Input

voltages reach the settled value on turning knob, the inverter switch off and the AC INPUT go

directly on the AC OUTPUT. When the voltage INPUT is less of 20V the value set, the transfer is

stop and the OUTPUT switch back on the inverter.

Don’t use the turning knobs “TRANSFERT” (23) to adjust the AC OUTPUT voltage!

This is only it’s only a voltage threshold level to enable or disable the transfer.

4.7.2 FAST (UPS)- MODE for the Transfer Switch

The quick and break free Transfer mode is programmed with a slide switch „Transfer Delay“ OFF,

which is on the front side (cable connections side).

The aim of the COMPACT is to supply the consuming device with a break-free alternating voltage.

When the incoming voltage AC IN no longer matches values which have been set with the Turning

Knob 23, the Inverter switches on at once. The transfer is carried out in 0.02 seconds. This quick

transfer ensures a break-free function for most consuming devices. If you have an alternating

voltage back at the input AC IN, transfer system starts up again without any break, and the inverter

is stopped.

COMPACT

4.7.3 Delayed mode of the Transfer System

The delayed mode of the transfer system „Transfer Delay ON“ is programmed with the slide switch

on front with the cable connections. The COMPACT provides a break-free alternating voltage for

the consuming device. A quick transfer switch is not always sensible nor is it always desired. For

example, when the consuming devices are operated by a small back-up generator. An overload of

a short duration on such a generator, i.e. start of a vacuum cleaner etc., has the effect of

decreasing the voltage for a short time. As in such cases the transfer to the Inverter is not

desirable, the transfer system can be programmed with a delay. When the slide switch (Transfer

delay) is in the „On“ position, the transfer to the inverter takes place with a delay of 5 seconds. If

the voltage falls below 100Vac, the transfer takes place without delay! The transfer switching to the

Inverter takes place without any break.

4.8 The Solar charge controller (option)

The COMPACT also has a Solar Charge Controller built in. For charging the batteries, Solar

modules can be connected to the screw terminal SOLAR +/-. The in-built controller is a „Shunt

controller“ for the maximum input current of 30A for C 1600-12 and C 2600-24 and 20A for C 4000-

48. The operating voltage of solar panels to be connected must match the actual operating voltage

of the COMPACT and never exceeds the max. rated value.

Under no circumstances should any other systems such as wind-generator be connected at the

input of the Solar Charge Controller.

The Solar Charge Controller works automatically and is always in operation. As soon as the energy

is delivered from the Solar Charge Controller, LED 3 “SOLAR CHARGE” is lit and the batteries are

being charged. The Solar Charge Controller works even when the Battery Charger is functioning.

The way of working is the principally the same as that of the Battery Charger. The function is

described in the section on Battery Charger. The programming and the adjustments are carried out

in accordance with the same conditions. Check with your battery supplier which adjustments must

be carried out for your battery.

User manual COMPACT V4.0 E 17

Page 18

STUDER INNOTEC

A

COMPACT

4.9 The Multifunctional Contact

In the COMPACT there is a built-in programmable power relay. The potential-free change-over

contact (NO – NC) of this power relay is connected to the screw terminal AUX CONTACT.

Maximum Contact load: -230Vac /16Amp-30Vdc/1A !

With the Push Button 21 „AUXILIARY CONTACT“ the contact can be manually switched on or off

independent of programming and the operating situation. The LED 5 “Contact active” shows the

state of the contact. The drawing up the screw terminal “AUX CONTACT” is the inactive position

mode, LED 5 “Contact active” off.

The switching on and off of this contact can be freely programmed for every operating situation of

the COMPACT witch situation is indicated with a LED. There is no limitation to its application and it

is left to your wishes and desires as to where and how you would like to use it. The example and

the setting of this contact are explained chapter 5.4.2.

In factory we program this for a dysfunction alarm. The contact is active when one of these

situations is detected:

Over temperature (LED 10 lit)

Overload (LED 11 lit)

Over or less voltage of batteries (LED 12 lit or blinking)

COMPACT is turned off manually or with a fault (LED 13 lit)

4.10 The Remote Control

As an option a Remote Control can

be connected to the COMPACT. All

operating controls and displays

except from level adjustment are

available on the Remote Control.

The Remote Control is supplied

with a 20m long cable. It can be

lengthened to 40m. The Remote

Control is suitable for surface

mounting on the wall or on to a

switch board. It is fixed with 4

screws. The COMPACT can also

be programmed with the Remote

CO M PA CT

RCC-01

AC IN

CHARGER

SOLAR CHARGE

EQUALIZE

Program

Contact active

Contact manual

INVERTER - CHARGER

TRANSFER

AC OUT

INVERTER

RESET

ALARM

(Select)

Over Temp.

Overload

Battery

Low/High

OFF

A %

160

130

100

70

60

50

40

30

20

10

Charger

80

60

40

20

10

5

Inverter

Control. The Programming is

ON/

OFF

described in the section „Program-

UXILIARY CONTACT

(Program) (Change status)

ming“.

The output power and the charging

currents are displayed on the

Remote Control.

In the Remote Control there is an

additional Alarm Contact and a Control

Input built in. These two functions are

ON/

OFF

available through Tip-jack RJ11/4 for use.

This Auxiliary Contact is Front / Work

Contact (max. 0.5A!), which is

independent of the Auxiliary Contact of the

COMPACT. This contact is active in case

of an alarm of the COMPACT.

COMPACT

Remote

control

Dry contact

only

! -

batt

!

1 2 3 4

Remote contorl

60V/0,5A

max

.

The Control Input is connected in parallel to the ON/OFF- push button. The COMPACT can be

switched on or off through this input with an impulse button or an impulse contact.

Order Number for Remote Control: RCC-01

Dimensions: H x B x T / 111.5 x 136.5 x 25mm

User manual COMPACT V4.0 E 18

Page 19

STUDER INNOTEC

Caution: No external voltage should be connected to this Input Control.

COMPACT

4.11 The Temperature sensor

Operating voltage of lead-acid batteries change depends on the

temperature. To correct the operating voltages according to the actual

temperatures, a temperature sensor can be connected to the COMPACT.

The compensation through the sensor is –3mV/°C/Cell.

Order Number: CT-35

Dimensions: H x B x T / 58 x 51.5 x 22mm

5 Programming

5.1 Standard setting

The COMPACT is delivered with the default setting following:

5.1.1 Working mode

The working of the charger, the inverter and the transfer are described in chapter 5.3/5.4/5.5.

5.1.2 Battery voltage

Low voltage 11.6V / 23.2V / 46.4V

Float Charge 13.5V / 27.0V / 54.0V

End of Charge Voltage 14.4V / 28.8V / 57.6V

Equalization 15.3V / 30.6V / 61.2V

Absorption Time: 2 Hours

5.1.3 Auxiliary contact

Active in case of defect or manual turn off with the LED 10/11/12/13

5.2 Reset value

When the COMPACT is to be connected to a battery or after an interruption (RESET), it is always

programmed with these standard settings.

In order to get to these settings during operation you must press the three Push Buttons 19/20/21

simultaneously for a minimum of 2 seconds.

5.3 Battery voltages and absorption time

The voltage levels (low voltage, float charge, end of charge and equalization) and the duration of

the absorption charge can be changed.

The display of these voltages and the times in the program mode are in accordance with the

diagram shown below:

5.3.1 Table of voltage and timing threshold

Low voltage

LED 13

LED 12V 24V 48V 12V 24V 48V 12V 24V 48V 12V 24V 48V 12/24/48V

14 12.0 24.0 48.0 13.7 27.4 54.8 16.2 32.4 64.8 16.2 32.4 64.8 4 h

15 11.8 23.6 47.2 13.6 27.2 54.4 15.6 31.2 62.4 15.9 31.8 63.6 3 h

16 11.6 23.2 46.4 13.5 27.0 54.0 15 30 60 15.6 31.2 62.4 2 h

17 11.4 22.8 45.6 13.4 26.8 53.6 14.4 28.8 57.6 15.3 30.6 61.2 1 h

18 11.2 22.4 44.8 13.3 26.6 53.2 14.2 28.4 56.8 15 30 60 0 – 1Min.

The heavy printed values show the standard settings.

Float Charge

LED 12

Absorption

LED 11

Equalization

LED 10

Absorpt.

Time

LED 10->13

User manual COMPACT V4.0 E 19

Page 20

STUDER INNOTEC

COMPACT

5.3.2 Set the voltage and timing

threshold

The programming is done in accordance

with the following steps:

Push and hold down, the Push Button 21

(Program) and the Push Button 19

(Change status) for minimum 2 seconds

simultaneously.

With the Push Button 20 (select) select

3

14

4

5

6

15

16

17

20

10

11

12

13

RESET ALARM

lock

Over Temp

Overload

Batt Low/High

OFF

with of the battery level and the absorption

time to be changed.

21

18

19

ON/OFF

(Change status)

These four red LED show the function set:

Low voltage LED 13

Float charge LED 12

Absorption (End of charge) LED11

Equalization LED 10

Absorptions Time LED 10/11/12/13

With the Push Button 19 (Change status) set the desired parameter (voltage or the time) to modify

(LED 14/15/16/17/18). Push Button 19 (Change status) to set the desired value according to the

table 5.3.1.

If desired, repeat the operation with any other parameter (voltage or time) to be changed.

If during 10 seconds no buttons are pressed, the selected values are automatically stored and the

COMPACT switches back in to the normal operating status.

The voltage levels and times changed through programming are only first active with the next

charge cycle!

The voltage level which are not suitable can greatly reduce the battery life or could even destroy it !

Therefore check beforehand with your battery supplier.

5.4 Programming the auxiliary contact

5.4.1 Principle

The Auxiliary Contact can be basically programmed for any operating situation of the COMPACT

which is indicated with a LED. The programming is possible for one or more operating situations. If

the contact is programmed for many situations, it is activated as soon as the COMPACT finds itself

in any one of the programmed situations. That means that the work of the contact meets that of the

logic OR–Function.

5.4.2 The programming of the Auxiliary Contact is carried out in the following Steps

The Push Button 21 (Program) press down for min. 2 seconds. The LED 4 „Program“ is lit as an

indication, that the COMPACT is in program mode.

A lit LED shows the programmed condition for the auxiliary contact. (LED 10/11/12/13 factory

setting)

With the Push Button 20 (select), select the desired condition in which the contact should be

activated.

With the Push Button 19 (Change status) confirm or change the status for this condition.

If desired, with the Push Button 20 (select) select another condition in which the contact should be

activated.

With the Push Button 19 (Change status) confirm or change the status for this condition.

If during 10 seconds no buttons are pushed, then the settled values are automatically stored and

the COMPACT switches back to normal operating condition.

User manual COMPACT V4.0 E 20

Page 21

STUDER INNOTEC

COMPACT

5.4.3 Examples

5.4.3.1 Auxiliary Contact as generator starter

As per the battery capacity

When in the programming of the Auxiliary Contact, the Battery Capacity (LED 15-18) is used as a

condition, then you must take note of the following requirements.

If you have to start an emergency back-up supply with a battery having a certain residual capacity,

then two battery levels must be programmed. The first (i.e. Battery 25% LED 17) for the starting or

activating the Auxiliary Contact and the second (i.e. Battery 100% LED15) for stopping or

deactivating the Auxiliary Contact. By programming like this the Auxiliary Contact works with the

lowest set condition and stops when it has reached the highest programmed condition through

charging.

As per the inverter output power (not available with some special executions)

Activating the auxiliary contact for the generator start can be programmed also on a predetermined output power of the inverter. The auxiliary contact will be activated if the inverter output

power exceeds 80% of the inverter nominal power during 3 minutes and/or 100% during 30

seconds.

The auxiliary contact will remain activated 30 minutes after the input current has come back to a

value lower than the one adjusted by the “INPUT LIMIT” (chap. 4.6.3). In other words, the contact

will be deactivated 30 minutes after the lighting out of the LED 200%.

This programming is achieved accordingly to chap. 5.4.2 of the user manual and by activating the

contact on LED 100% of “Power Monitor” (25).

5.4.3.2 Auxiliary Contact as Twilight Switch (with solar charger option)

The Auxiliary Contact of the COMPACT can also be used as a twilight switch, i.e. to operate

automatically the exterior lighting. With it the connected solar modules measure the light intensity.

If the COMPACT is operating without solar modules and a twilight-switching function is desired,

you can connect small solar cells with the nominal voltage of the COMPACT on to the SOLAR

terminals for the purpose of measuring the light intensity. To function as a twilight-switch the

Auxiliary Contact must be programmed so that the condition SOLAR CHARGE (LED 3) is active.

Programming must be carried out in steps and in accordance with the description for the

programming of the Auxiliary Contact.

5.4.4 Manual operating of Auxiliary Contact

The Auxiliary Contact can be operated at any time with the Push Button 21 (AUX. CONTACT). The

LED 6 „Contact manual“ lights up as information that the Contact is manually operated, and LED 5

„Contact active“ lights up when the Contact is active. By pushing the Push Button 21 a second

time, the Contact is deactivated. By pushing it the third time, automatic functions are restored.

5.5 Disabling some of the Compact functions

Each different function charger, inverter and transfer can be disabled. This is useful for specific

applications which are required to disable some of these three functions.

If you press the button (20) more than 2 seconds, you can have the access to the different

possibilities shown in the following diagram.

In programming mode the display show only the different types of program with the three LED 2,7

and 9 to each functions. To change the type of programming press shortly the button 20 until your

reach to the right function use according table below. After 10 seconds the COMPACT exit the

programming mode and load the new change.

In user mode, the disabled functions are displayed by blinking LED. So you can see in witch mode

is disabled.

User manual COMPACT V4.0 E 21

Page 22

STUDER INNOTEC

R

R

R

R

5.5.1 Diagram of the different modes

Show an off LED

Show a blinking LED

9

Show a lighted LED

COMPACT

All the functions are enabled. This is the

factory setting.

The inverter is disabled. Only the transfer

switch and the charger will work normally.

Charger and transfer switch are disabled. the

inverter will work continuously even if there is

a correct AC voltage at the input

Inverter and charger are both disabled.

Only the transfer switch function is enabled in

input voltage and frequency is OK.

CHARGE

CHARGE

CHARGE

CHARGE

1

2

1

2

1

2

1

2

7

7

7

7

8

AC OUTAC IN

9

INVERTER

8

AC OUTAC IN

9

INVERTER

8

AC OUTAC IN

9

INVERTER

8

AC OUTAC IN

9

INVERTER

6 Maintenance

Apart from the periodic controls mentioned for the connections, the COMPACT does not need any

maintenance. Keep the appliance clean and from time to time wipe it clean with a damp cloth.

7 EC Compliance

We hereby state that the products described in this user manual meets the following standards:

EN 61000-6-1, EN 61000-6-3, EN 55014, EN 55022, EN 61000-3-2, Dir. 89/336/EEC,

LVD 73/23/EEC

CH-1950 Sion, 31

st

of March 2000 STUDER INNOTEC (R. Studer)

User manual COMPACT V4.0 E 22

Page 23

STUDER INNOTEC

COMPACT

8 Technical Data

Technical

Model

Inverter

Nominal battery voltage

Input voltage range 9.5 - 16V 19 - 32V 38 - 64V

Continuous power @ 25°C 1300VA 2300VA 3500VA

Power 30 min. @ 25°C 1600VA 2600VA 4000VA

Maximum power load 5 sec. 3 x Pnom

Maximum load up to short circuit

Maximum asymmetric load up to Pcont.

Stand-by adjustment 1 to 25W

Cos ϕ

Maximum efficiency 94% 95%

Consumption OFF/Stand-by/ON 0.5/0.6/6W 0.8/0.9/9W 1.2/1.4/12W

Output voltage 230Vac (- 10% / 0)

Output frequency crystal controlled 50Hz +/- 0.05%

Total harmonic distortion < 2%

Dynamic behaviour on load change 0 to 100% 0.5 ms

Overload and short circuit protection Automatic disconnection with 3 time restart attempt

Overheat protection Acoustic warning before shut-off - with automatic restart

Battery charger (4 STEP) I-U-Uo-Equalize (every 25 cycles)

Charging current adjustable 0 - 55A 0 - 55A 0 - 50A

Input current balance adjustment (Power Sharing) 1 - 16A

Maximum input voltage 265Vac

Minimum input voltage Adjustable threshold from 150 to 230Vac

Input frequency 45 - 65Hz

Power Factor Correction (PFC) EN 61000-3-2

Optional solar charger (4 stages) I-U-Uo-Equalize (every 25 cycles)

Maximum PV open circuit voltage (V) 25V 45V 90V

Maximum charge current (A) 30A 30A 20A

Working principle: I-U-Uo-Equalize (every 25 cycles) Shunt

Battery control (thresholds and times adjustable by the user)

Absorption time 0-4 h

End charge cycle voltage 14.4V 28.8V 57.6V

Floating voltage 13.6V 27.2V 54.4V

Equalization voltage 15.6V 31.2V 62.4V

Deep-discharge protection 10.8V 21.6V 43.2V

Temperature compensation (optional CT-35) -3mV / o C / cell

General data

Multifunction contact - potential free (3 points) 16A - 250Vac

Max. current on transfer relay 16A/3.7kVA 16A/3.7kVA 16A/3.7kVA

Transfer time < 20 ms

Weight 16 kg 17.1 kg 29.4 kg

Dimension h x l x L [mm] 124x215x480 124x215x670

Protection index IP20 IP23 with top cover CxxxxIP23

EC conformity

Operating temperature range -20 to 55 oC

Ventilation from 45

Acoustic level without / with ventilation < 10 dB / < 35 dB

Warranty 2 years

Options

Solar charge controller C-xxxx-S

Remote control (112 x 138 x 25mm / 20 m. cable) RCC-01

Remote power sharing (20 m. cable) RPS-01

IP-23 top cover C-xxxx-IP23

AC cable cover CFC-01

Battery temperature sensor (58 x 51.5 x 22mm / 3 m.

cable)

Data may change without any notice

data

C 1600-12 C 2600-24 C 4000-48

12V 24V 48V

0.1 - 1

EN 61000-6-1, EN 61000-6-3, EN 55014, EN 55022,

EN 61000-3-2, Dir. 89/336/EEC, LVD 73/23/EEC

o

C

CT-35

User manual COMPACT V4.0 E 23

Loading...

Loading...