Page 1

Studer OnAir 500

Digital Mixing Console

Operating Instructions

Page 2

Safety Information

I

A Safety Information

To reduce the risk of electric shock, do not remove covers. No userserviceable parts inside. Refer servicing to qualified service personnel

(i.e., persons having appropriate technical training and experience necessary to be aware of hazards to which they are exposed in performing a

repair action, and of measures to minimize the danger of themselves).

This symbol alerts the user to the presence of un-insulated dangerous

voltage within the equipment that may be of sufficient magnitude to constitute a risk of electric shock to a person.

This symbol alerts the user to important instructions for operating and

maintenance in this documentation.

Assemblies or sub-assemblies of this product can contain opto-electronic

devices. As long as these devices comply with Class I of laser or LED

products according to EN 60825-1:1994, they will not be expressly

marked on the product. If a special design should be covered by a higher

class of this standard, the device concerned will be marked directly on

the assembly or sub-assembly in accordance with the above standard.

A1 First Aid

In Case of Electric Shock: Separate the person as quickly as possible from the electric power

source:

• By switching off the equipment,

• By unplugging or disconnecting the mains cable, or

• By pushing the person away from the power source, using dry,

insulating material (such as wood or plastic).

• After having suffered an electric shock, always consult a doctor.

Warning! Do not touch the person or his clothing before the power is turned

off, otherwise you stand the risk of suffering an electric shock as

well!

If the Person is Unconscious: • Lay the person down

• Turn him to one side

• Check the pulse

• Reanimate the person if respiration is poor

• Call for a doctor immediately.

CLASS I

LASER PRODUCT

CLASS I

LED PRODUCT

Page 3

Installation/Maintenance/ESD

II

B General Installation Instructions

Please consider besides these general instructions also any product-specific

instructions in the “Installation” chapter of this manual.

B1 Unpacking

Check the equipment for any transport damage. If the unit is mechanically

damaged, if liquids have been spilled or if objects have fallen into the unit,

it must not be connected to the AC power outlet, or it must be immediately

disconnected by unplugging the power cable. Repair must only be per-

formed by trained personnel in accordance with the applicable regulations.

B2 Installation Site

Install the unit in a place where the following conditions are met:

• The temperature and the relative humidity of the environment must be

within the specified limits during operation of the unit. Relevant values

are the ones at the air inlets of the unit.

• Condensation must be avoided. If the unit is installed in a location with

large variation of ambient temperature (e.g. in an OB-van), appropriate

precautions must be taken before and after operation (for details on this

subject, refer to Appendix 1).

• Unobstructed air flow is essential for proper operation. Air vents of the

unit are a functional part of the design and must not be blocked in any

way during operation (e.g. by objects placed upon them, placement of

the unit on a soft surface, or installation of the unit within a rack or

piece of furniture).

• The unit must not be heated up by external sources of heat radiation

(sunlight, spot lights).

B3 Earthing and Power Supply

Earthing of units with mains supply (class I equipment) is performed via

the protective earth (PE) conductor integrated in the mains cable. Units

with battery operation (< 60 V, class III equipment) must be earthed separately.

Earthing the unit is one of the measures for protection against electrical

shock hazard (dangerous body currents). Hazardous voltage may not only

be caused by a defective power supply insulation, but may also be introduced by the connected audio or control cables.

If the unit is installed with one or several external connections, its earthing

must be provided during operation as well as while the unit is not operated.

If the earthing connection can be interrupted, for example, by unplugging

the mains plug of an external power supply unit, an additional, permanent

earthing connection must be installed using the provided earth terminal.

Avoid ground loops (hum loops) by keeping the loop surface as small as

possible (by consequently guiding the earth conductors in a narrow, parallel way), and reduce the noise current flowing through the loop by inserting

an additional impedance (common-mode choke).

Page 4

ESD/Repair

III

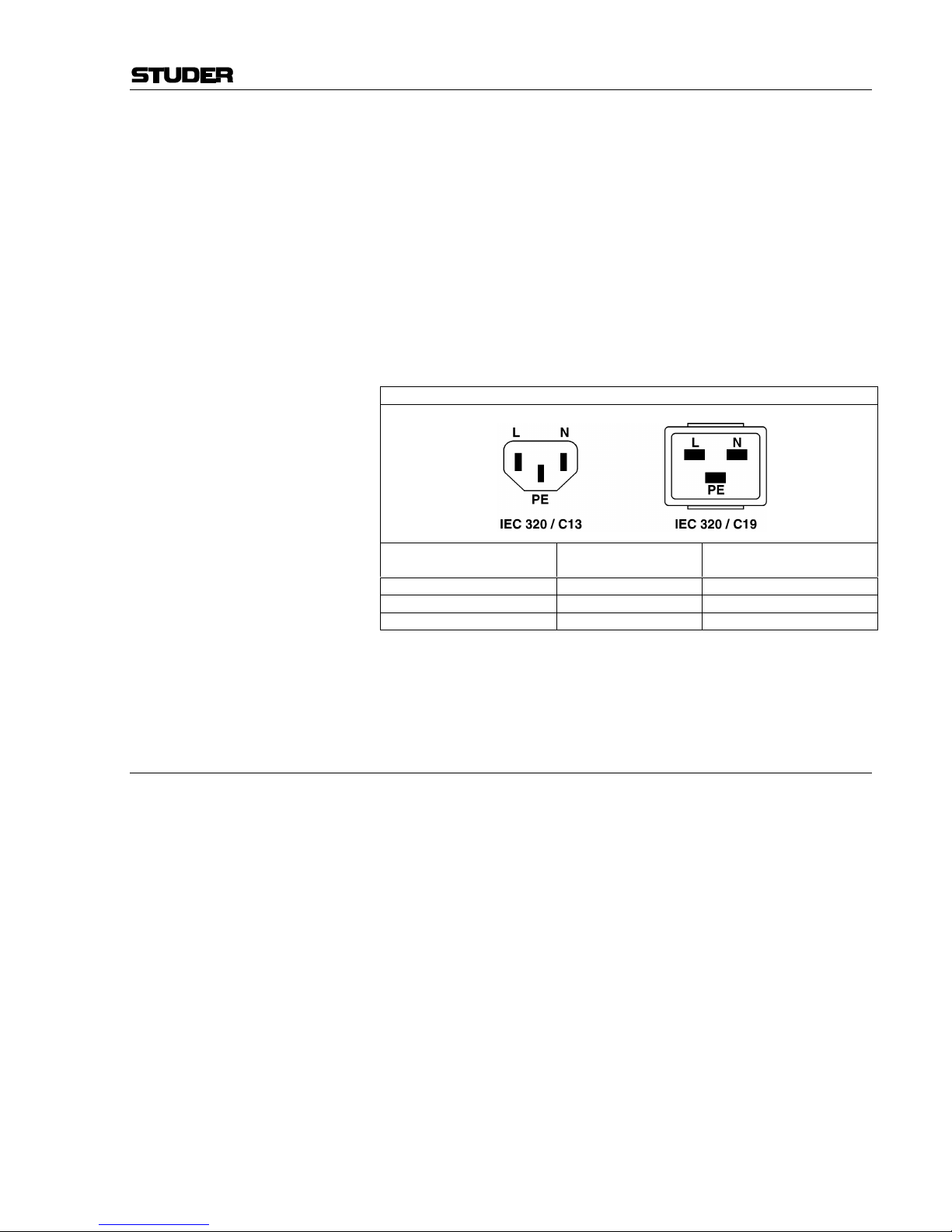

Class I Equipment (Mains Operation)

Should the equipment be delivered without a matching mains cable, the

latter has to be prepared by a trained person using the attached female plug

(IEC320/C13 or IEC320/C19) with respect to the applicable regulations in

your country.

Before connecting the equipment to the AC power outlet, check that the

local line voltage matches the equipment rating (voltage, frequency) within

the admissible tolerance. The equipment fuses must be rated in accordance

with the specifications on the equipment.

Equipment supplied with a 3-pole appliance inlet (protection conforming to

class I equipment) must be connected to a 3-pole AC power outlet so that

the equipment cabinet is connected to the protective earth.

For information on mains cable strain relief please refer to Appendix 2.

Female Plugs (IEC320), Front-Side View:

European Standard

(CENELEC)

North American Standard

(NAS)

Brown L (Live) Black

Blue N (Neutral) White

Green/Yellow PE (Protective Earth) Green (or Green/Yellow)

Class III Equipment (Battery Operation up to 60 VDC)

Equipment of this protection class must be earthed using the provided earth

terminal, if one or more external signals are connected to the unit (see explanation at the beginning of this paragraph).

B4 Electromagnetic Compatibility (EMC)

The unit conforms to the protection requirements relevant to electromagnetic phenomena that are listed in guidelines 89/336/EC and FCC, part 15.

• The electromagnetic interference generated by the unit is limited in such

a way that other equipment and systems can be operated normally.

• The unit is adequately protected against electromagnetic interference so

that it can operate properly.

The unit has been tested and conforms to the EMC standards of the specified electromagnetic environment, as listed in the following declaration.

The limits of these standards ensure protection of the environment and corresponding noise immunity of the equipment with appropriate probability.

However, a professional installation and integration within the system are

imperative prerequisites for operation without EMC problems.

For this purpose, the following measures must be followed:

• Install the equipment in accordance with the operating instructions. Use

the supplied accessories.

• In the system and in the vicinity where the equipment is installed, use

only components (systems, equipment) that also fulfill the EMC standards for the given environment.

• Use a system grounding concept that satisfies the safety requirements

(class I equipment must be connected with a protective ground conduc-

Page 5

Installation/Maintenance/ESD

IV

tor) and that also takes into consideration the EMC requirements. When

deciding between radial, surface, or combined grounding, the advantages and disadvantages should be carefully evaluated in each case.

• Use shielded cables where shielding is specified. The connection of the

shield to the corresponding connector terminal or housing should have a

large surface and be corrosion-proof. Please note that a cable shield

connected only single-ended can act as a transmitting or receiving antenna within the corresponding frequency range.

• Avoid ground loops or reduce their adverse effects by keeping the loop

surface as small as possible, and reduce the noise current flowing

through the loop by inserting an additional impedance (e.g. commonmode choke).

• Reduce electrostatic discharge (ESD) of persons by installing an appropriate floor covering (e.g. a carpet with permanent electrostatic filaments) and by keeping the relative humidity above 30%. Further measures (e.g. conducting floor) are usually unnecessary and only effective if

used together with corresponding personal equipment.

• When using equipment with touch-sensitive operator controls, please

take care that the surrounding building structure allows for sufficient

capacitive coupling of the operator. This coupling can be improved by

an additional, conducting surface in the operator’s area, connected to the

equipment housing (e.g. metal foil underneath the floor covering, carpet

with conductive backing).

C Maintenance

All air vents and openings for operating elements (faders, rotary knobs)

must be checked on a regular basis, and cleaned in case of dust accumulation. For cleaning, a soft paint-brush or a vacuum cleaner is recommended.

Cleaning the surfaces of the unit is performed with a soft, dry cloth or a

soft brush.

Persistent contamination can be treated with a cloth that is slightly humidified with a mild cleaning solution (soap-suds).

For cleaning display windows, commercially available computer/TV

screen cleaners are suited. Use only a slightly damp (never wet) cloth.

Never use any solvents for cleaning the exterior of the unit! Liquids must

never be sprayed or poured on directly!

For equipment-specific maintenance information please refer to the corresponding chapter in the Operating and Service Instructions manuals.

D Electrostatic Discharge during Maintenance and Repair

Caution: Observe the precautions for handling devices sensitive to electrostatic dis-

charge!

Many semiconductor components are sensitive to electrostatic discharge

(ESD). The life-span of assemblies containing such components can be

drastically reduced by improper handling during maintenance and repair

work. Please observe the following rules when handling ESD sensitive

components:

• ESD sensitive components should only be stored and transported in the

packing material specifically provided for this purpose.

• When performing a repair by replacing complete assemblies, the removed assembly must be sent back to the supplier in the same packing

Page 6

ESD/Repair

V

material in which the replacement assembly was shipped. If this should

not be the case, any claim for a possible refund will be null and void.

• Unpacked ESD sensitive components should only be handled in ESD

protected areas (EPA, e.g. area for field service, repair or service bench)

and only be touched by persons who wear a wristlet that is connected to

the ground potential of the repair or service bench by a series resistor.

The equipment to be repaired or serviced as well as all tools and electrically semi-conducting work, storage, and floor mats should also be connected to this ground potential.

• The terminals of ESD sensitive components must not come in uncontrolled contact with electrostatically chargeable (voltage puncture) or

metallic surfaces (discharge shock hazard).

• To prevent undefined transient stress of the components and possible

damage due to inadmissible voltages or compensation currents, electrical connections should only be established or separated when the

equipment is switched off and after any capacitor charges have decayed.

E Repair

Removal of housing parts, shields, etc. exposes energized parts. For this

reason the following precautions must be observed:

• Maintenance may only be performed by trained personnel in accordance

with the applicable regulations.

• The equipment must be switched off and disconnected from the AC

power outlet before any housing parts are removed.

• Even if the equipment is disconnected from the power outlet, parts with

hazardous charges (e.g. capacitors, picture tubes) must not be touched

until they have been properly discharged. Do not touch hot components

(power semiconductors, heat sinks, etc.) before they have cooled off.

• If maintenance is performed on a unit that is opened and switched on, no

un-insulated circuit components and metallic semiconductor housings

must be touched, neither with your bare hands nor with un-insulated

tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic capacitors and

power semiconductors (watch the component’s polarity. Do not short

battery terminals. Replace batteries only by the same type).

• Implosion hazard from evacuated display units.

• Radiation hazard from laser units (non-ionizing), picture tubes (ionizing).

• Caustic effect of display units (LCD) and components containing liquid

electrolyte.

Such components should only be handled by trained personnel who are

properly protected (e.g. safety goggles, gloves).

Page 7

Repair/Disposal

VI

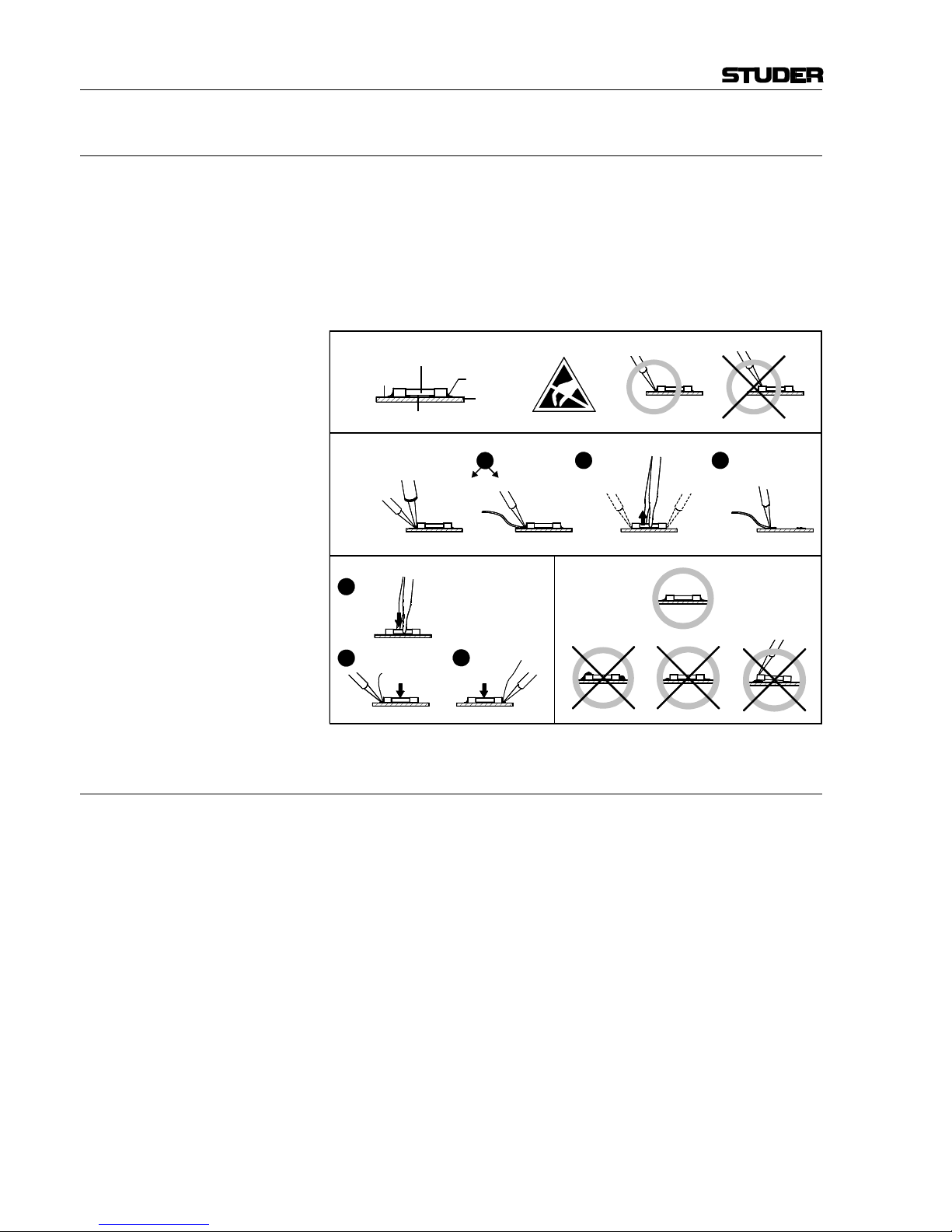

E1 SMD Components

Studer has no commercially available SMD components in stock for service purposes. For repair, the corresponding devices have to be purchased

locally. The specifications of special components can be found in the service manual.

SMD components should only be replaced by skilled specialists using appropriate tools. No warranty claims will be accepted for circuit boards that

have been damaged. Proper and improper SMD soldering joints are illustrated below.

F Disposal

Disposal of Packing Materials The packing materials have been selected with environmental and disposal

issues in mind. All packing material can be recycled. Recycling packing

saves raw materials and reduces the volume of waste.

If you need to dispose of the transport packing materials, please try to use

recyclable means.

Disposal of Used Equipment Used equipment contains valuable raw materials as well as materials that

must be disposed of professionally. Please return your used equipment via

an authorized specialist dealer or via the public waste disposal system, ensuring any material that can be recycled is.

Please take care that your used equipment cannot be abused. To avoid

abuse, delete sensitive data from any data storage media. After having disconnected your used equipment from the mains supply, make sure that the

mains connector and the mains cable are made useless.

32

Dismounting

Mounting

Examples

Solder

SMD

Component

Copper

Track

Adhesive

Soldering Iron

Desoldering

Iron

Desolder

Wick

Heat and Remove Cleaning

Solder

Ø 0.5...0.8 mm

Heating Time < 3 s per Side

Soldering

Iron

Desolder

Wick

1

3

2

1

PCB

Page 8

Conformity

VII

G Declarations of Conformity

G1 Class A Equipment - FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at his own

expense.

Caution: Any changes or modifications not expressly approved by the manufacturer

could void the user's authority to operate the equipment. Also refer to relevant information in this manual.

G2 CE Declaration of Conformity

We,

Studer Professional Audio GmbH,

CH-8105 Regensdorf,

declare under our sole responsibility that the product

Studer OnAir 500, Digital Mixing Console

(starting with serial no. 1001)

to which this declaration relates, according to following regulations of EU

directives and amendments

• Low Voltage (LVD):

73/23/EEC + 93/68/EEC

• Electromagnetic Compatibility (EMC):

89/336/EEC + 92/31/EEC + 93/68/EEC

is in conformity with the following standards or normative documents:

• Safety:

EN 60950:2000 (Class I equipment)

• Safety of laser products:

EN 60825-1:1994 + A11 + A2, EN60825-2:2000

• EMC:

EN 55103-1/-2:1996, electromagnetic environments E2 and E4.

Regensdorf, July 21, 2003

B. Hochstrasser, President P. Fiala, Manager QA

Page 9

Appendix

VIII

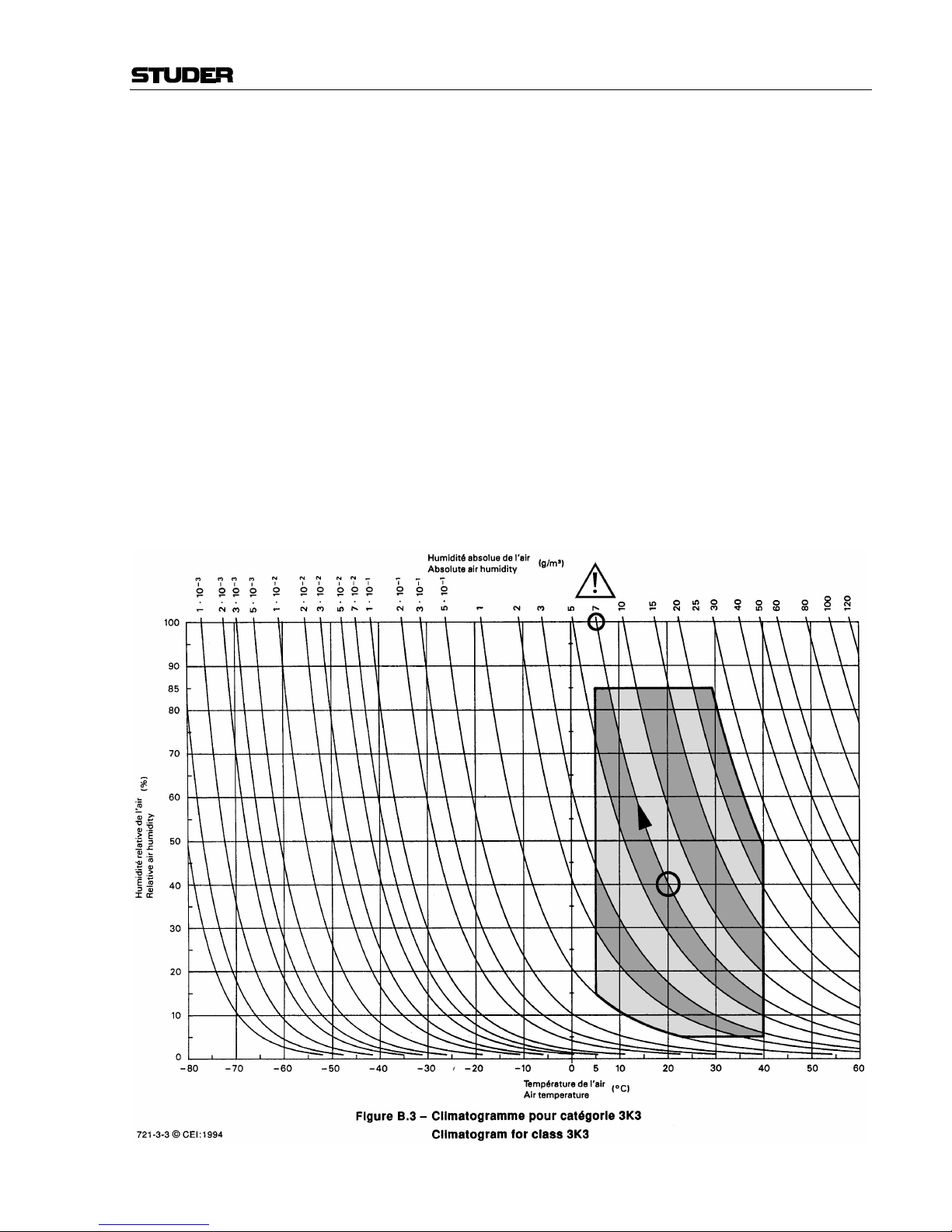

Appendix 1: Air Temperature and Humidity

General

Normal operation of the unit or system is warranted under the following

ambient conditions defined by EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters, the most

important of which are: ambient temperature +5...+40 °C, relative humidity

5...85% (i.e., no formation of condensation or ice); absolute humidity

1...25 g/m³; rate of temperature change < 0.5 °C/min. These parameters are

dealt with in the following paragraphs.

Under these conditions the unit or system starts and works without any

problem. Beyond these specifications, possible problems are described in

the following paragraphs.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient temperature range (i.e. temperature of the incoming air) of +5...+40 °C. When

rack mounting the units, the intended air flow and herewith adequate cooling must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semiconductor components is 0 °C to +70 °C (commercial temperature range

for operation).

• The air flow through the installation must provide that the outgoing air

is always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing

for an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air flow of 2.65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air flow of 0.8 * 2.65 m³/min

which corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failure or illumination with spot lamps), the outgoing air temperature

must be measured directly above the modules at several places within

the rack. The trigger temperature of the sensors should be 65 to 70 °C.

Frost and Dew

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible

with the naked eye will already lead to malfunctions. In practice, reliable

operation can be expected in a temperature range above –15 °C, if the following general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches 100%, condensation will arise, usually in the boundary layer between the air and a cooler surface, together with formation of ice or dew at

sensitive areas of the system (contacts, IC pins, etc.). Once internal condensation occurs, trouble-free operation cannot be guaranteed, independent

of temperature.

Before putting into operation, the system must be checked for internal formation of condensation or ice. Only with a minute formation of ice, direct

Page 10

Appendix

IX

evaporation (sublimation) may be expected; otherwise the system must be

heated and dried while switched off.

A system without visible internal formation of ice or condensation should

be heated up with its own heat dissipation, as homogeneously (and subsequently as slow) as possible; the ambient temperature should then always

be lower than the one of the outgoing air.

If it is absolutely necessary to operate the cold system immediately within

warm ambient air, this air must be dehydrated. In such a case, the absolute

humidity must be so low that the relative humidity, related to the coldest

system surface, always remains below 100%.

Ensure that the enclosed air is as dry as possible when powering off (i.e.

before switching off in winter, aerate the room with cold, dry air, and remove humid objects as clothes from the room).

These relationships are visible from the following climatogram. For a controlled procedure, thermometer and hygrometer as well as a thermometer

within the system will be required.

Example 1: An OB-van having an internal temperature of 20 °C and relative humidity

of 40% is switched off in the evening. If temperature falls below +5 °C,

dew or ice will be forming.

Example 2: An OB-van is heated up in the morning with air of 20 °C and a relative

humidity of 40%. On all parts being cooler than +5 °C, dew or ice will be

forming.

Page 11

Appendix

X

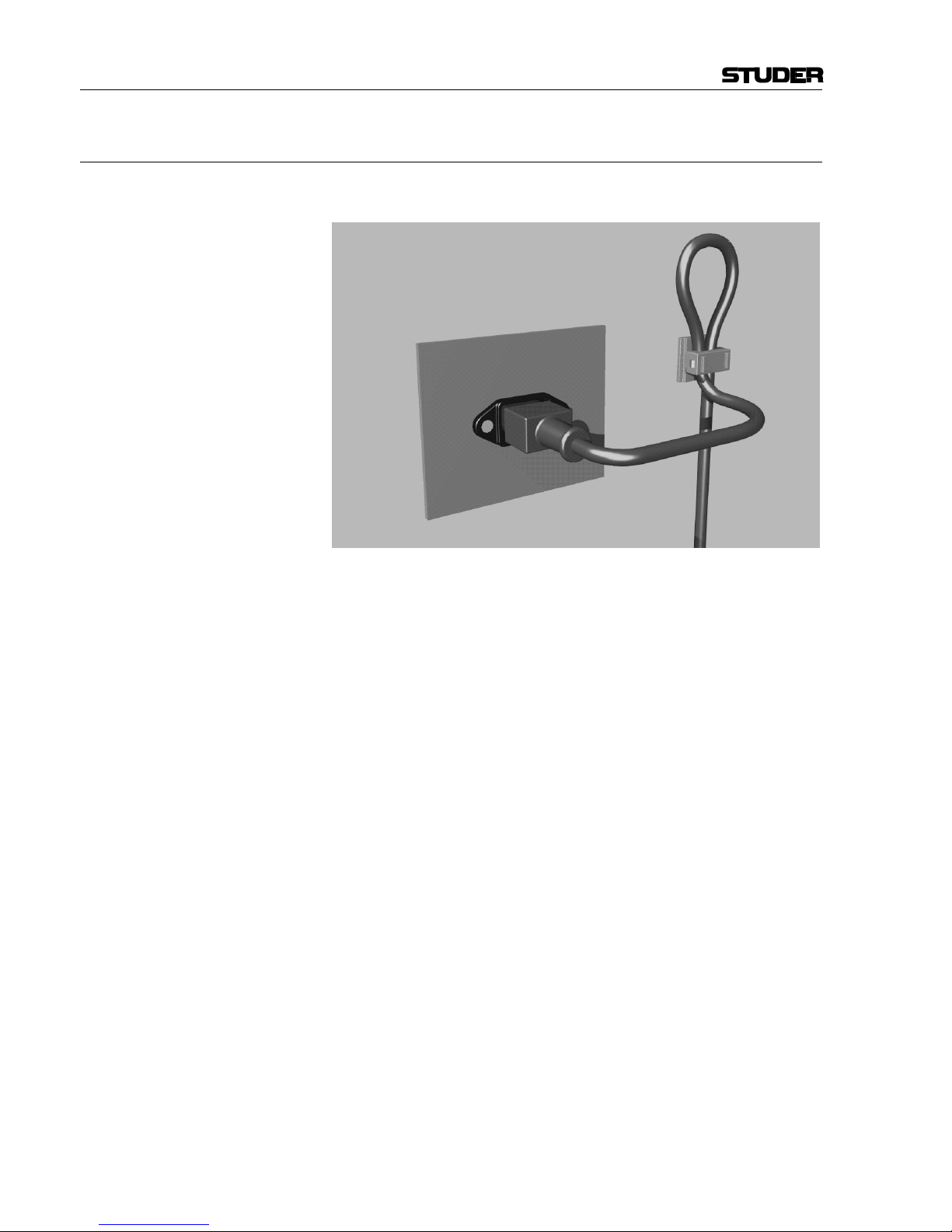

Appendix 2: Mains Connector Strain Relief

For anchoring connectors without a mechanical lock (e.g. IEC mains connectors), we recommend the following arrangement:

Procedure: The cable clamp shipped with your unit is auto-adhesive. For mounting

please follow the rules below:

• The surface to be adhered to must be clean, dry, and free from grease,

oil, or other contaminants. Recommended application temperature range

is +20...+40 °C.

• Remove the plastic protective backing from the rear side of the clamp

and apply it firmly to the surface at the desired position. Allow as much

time as possible for curing. The bond continues to develop for as long as

24 hours.

• For improved stability, the clamp should be fixed with a screw. For this

purpose, a self-tapping screw and an M4 bolt and nut are included.

• Place the cable into the clamp as shown in the illustration above and

firmly press down the internal top cover until the cable is fixed.

Page 12

Appendix

XI

Appendix 3: Software License

Use of the software is subject to the Studer Professional Audio Software

License Agreement set forth below. Using the software indicates your acceptance of this license agreement. If you do not accept these license terms,

you are not authorized to use this software.

Under the condition and within the scope of the following Terms and Conditions, Studer Professional Audio GmbH (hereinafter “Studer”) grants the

right to use programs developed by Studer as well as those of third parties

which have been installed by Studer on or within its products. References

to the license programs shall be references to the newest release of a license program installed at the Customer’s site.

Programs Covered by the Agreement

License Programs of Studer The following Terms and Conditions grant the right to use all programs of

Studer that are part of the System and/or its options at the time of its delivery to the Customer, as well as the installation software on the original data

disk and the accompanying documentation (“License Material”). In this

Agreement the word “Programs” shall have the meaning of programs and

data written in machine code.

Using the software indicates your acceptance of this license agreement. If

you do not accept these license terms, you are not authorized to use this

software.

Programs of Third Parties Programs of third parties are all programs which constitute part of the

System and/or its options at the time of delivery to the Customer but have

not been developed by Studer. The following conditions are applicable to

programs of third parties:

• The right to use third parties’ programs is governed by the License

Agreement attached hereto (if applicable), which is an integral part of

this Agreement. The Customer shall sign any and all License Agreements for all further programs of third parties installed on the system.

The Customer shall be deemed to have received all License Agreements

upon delivery of the system and/or its options.

• Studer shall accept no responsibility or liability for, and gives no warranties (express or implied) as to the programs of third parties. The

Customer waives any and all claims versus Studer for any consequential

damages, which might occur due to defects of these programs.

Right of Use

Principle Studer grants the Customer the non-exclusive right to use the License Ma-

terial in one copy on the system and/or its options as laid down by the

Sales Agreement concluded between the parties and all Terms and Conditions which shall be deemed to form and be read and construed as part of

the Sales Agreement. This right is assignable according to the “Assignability” paragraph hereinafter.

Customized Configurations The Customer is not entitled to alter or develop further the License Mate-

rial except within the expressly permitted configuration possibilities given

by the software installed on the system or elsewhere. All altered programs,

including but not limited to the products altered within the permitted configuration possibilities, are covered by this License Agreement.

Page 13

Appendix

XII

Reverse Engineering Reverse engineering is only permitted with the express consent of Studer.

The consent of Studer can be obtained but is not limited to the case in

which the interface-software can not be provided by Studer. In any case

Studer has to be informed immediately upon complete or partial reverse

engineering.

Copying the License Material The Customer is entitled to make one copy of all or parts of the License

Material as is necessary for the use according to this Agreement, namely

for backup purposes. The Customer shall apply the copyright of Studer

found on the License Material onto all copies made by him. Records shall

be kept by the Customer regarding the amount of copies made and their

place of keeping. The responsibility for the original program and all copies

made lies with the Customer. Studer is entitled to check these records on

first request. Copies not needed anymore have to be destroyed immediately.

Disclosure of License Material The License Material is a business secret of Studer. The Customer shall not

hand out or in any way give access to parts or the complete License Material to third parties nor to publish any part of the License Material without

prior written consent of Studer. The Customer shall protect the License

Material and any copies made according to the paragraph above by appropriate defense measures against unauthorized access. This obligation of

non-disclosure is a perpetual obligation.

Third parties are entitled to have access to the License Material if they use

the License Material at the Customer’s site in compliance with this Agreement.

Under no circumstance are third parties entitled to have access to the installation software on the original data media. The Customer shall safeguard the original data media accordingly.

Assignability The rights granted to the Customer according to this License Agreement

shall only be assignable to a third party together with the transfer of the

system and/or its options and after the prior written consent of Studer.

Rights to License Material

With the exception of the right of use granted by this License Agreement

all proprietary rights to the License Material, especially the ownership and

the intellectual property rights (such as but not limited to patents and copyright) remain with Studer even if alterations, customized changes or

amendments have been made to the License Material.

Studer’s proprietary rights are acknowledged by the Customer. The Customer shall undertake no infringements and make no claims of any patent,

registered design, copyright, trade mark or trade name, or other intellectual

property right.

Warranty, Disclaimer, and Liability

For all issues not covered herewithin, refer to the “General Terms and

Conditions of Sales and Delivery” being part of the sales contract.

Page 14

OnAir 500 Digital Mixing Console

Contents 0-1Date printed:

30.07.04

CONTENTS

1 Introduction ....................................................................................................................................................................1-1

1.1 Key Features ............................................................................................................................................................. 1-2

1.2 Feature Overview .....................................................................................................................................................1-3

1.3 Studer OnAir 500 Block Diagram ............................................................................................................................1-4

2 General ............................................................................................................................................................................2-1

2.1 Utilization for the Purpose Intended ........................................................................................................................2-1

2.2 First Steps .................................................................................................................................................................2-1

2.2.1 Unpacking and Inspection .................................................................................................................................2-1

2.2.2 Installation .........................................................................................................................................................2-1

2.2.3 Adjustments, Repair ..........................................................................................................................................2-2

2.3 Technical Specifications ...........................................................................................................................................2-3

2.3.1 Typical Values .................................................................................................................................................... 2-3

2.3.2 Mechanical Dimensions ....................................................................................................................................2-4

3 Operating Elements........................................................................................................................................................3-1

3.1 Power Switch ............................................................................................................................................................3-1

3.2 Channel Strip ............................................................................................................................................................3-3

3.3 Edit Strip...................................................................................................................................................................3-5

3.4 Monitoring Section ...................................................................................................................................................3-9

3.5 Master Section ........................................................................................................................................................3-11

3.6 Meter Bridge ..........................................................................................................................................................3-14

4 The Menu Pages .............................................................................................................................................................4-1

4.1 Analog Inputs ...........................................................................................................................................................4-2

4.2 Assign Channel .........................................................................................................................................................4-4

4.3 Auto Muting ............................................................................................................................................................. 4-6

4.4 Channel Phases ......................................................................................................................................................... 4-7

4.5 Clock Source ............................................................................................................................................................4-8

4.6 Digital Outputs .........................................................................................................................................................4-9

4.7 Digital Out Adv. (Advanced) .................................................................................................................................4-10

4.8 Display Settings ......................................................................................................................................................4-12

4.9 External IP (Input) Gain ......................................................................................................................................... 4-12

4.10 Guest Headphones Level ........................................................................................................................................4-13

4.11 HPF Frequency ....................................................................................................................................................... 4-13

4.12 Input Naming ..........................................................................................................................................................4-14

4.13 Line/CF Outputs .....................................................................................................................................................4-14

4.14 Lockout PIN ...........................................................................................................................................................4-17

4.15 Lockout Setup .........................................................................................................................................................4-18

4.16 Lockout Status ........................................................................................................................................................4-19

4.17 Machine Starts ........................................................................................................................................................4-20

4.18 Master Faders .........................................................................................................................................................4-22

4.19 MIDI Backup ..........................................................................................................................................................4-22

4.20 Mono Output ..........................................................................................................................................................4-24

4.21 CUE Autocancel ..................................................................................................................................................... 4-24

Page 15

OnAir 500 Digital Mixing Console

0-2 Contents Date printed:

30.07.04

4.22 RCS Channel Sel ....................................................................................................................................................4-25

4.23 RCS Setup ..............................................................................................................................................................4-25

4.24 Remote Inputs .........................................................................................................................................................4-26

4.25 Software Version ....................................................................................................................................................4-27

4.26 System ....................................................................................................................................................................4-27

4.27 Talkback Assign .....................................................................................................................................................4-28

4.28 TDIF Outputs .........................................................................................................................................................4-29

4.29 TDIF Out Adv.........................................................................................................................................................4-30

4.30 2nd Meter Source ...................................................................................................................................................4-31

5 Talkback ..........................................................................................................................................................................5-1

5.1 Scenario 1 - Presenter in Control Room (Talkback Swap Off) ............................................................................... 5-1

5.2 Scenario 2 - Presenter in Studio (Talkback Swap On) ............................................................................................. 5-2

6 Dynamics .........................................................................................................................................................................6-1

6.1 Gate ..........................................................................................................................................................................6-1

6.2 Compressor ...............................................................................................................................................................6-2

6.3 Limiter ......................................................................................................................................................................6-3

6.4 Compressor + Gate / Limiter + Gate ........................................................................................................................6-3

6.5 Assigning the Dynamics Processors.........................................................................................................................6-3

6.6 Adjusting Dynamics Processor Settings .................................................................................................................. 6-4

6.7 Dynamics Presets .....................................................................................................................................................6-5

6.7.1 Storing and Naming a Dynamics Preset ............................................................................................................ 6-5

6.7.2 Recalling a Dynamics Preset .............................................................................................................................6-5

6.7.3 Deleting a Dynamics Preset...............................................................................................................................6-6

7 Lexicon™ Effects ...........................................................................................................................................................7-1

7.1 Selecting an Effect ....................................................................................................................................................7-1

7.2 Applying the Effect to a Signal ................................................................................................................................7-2

7.3 Editing, Storing and Renaming an Effect .................................................................................................................7-2

7.4 Deleting an Effect .....................................................................................................................................................7-3

8 Presets ..............................................................................................................................................................................8-1

8.1 Storing a Snapshot Preset .........................................................................................................................................8-2

8.2 Renaming a Snapshot Preset ....................................................................................................................................8-2

8.3 Recalling a Snapshot Preset .....................................................................................................................................8-3

8.4 Deleting a Snapshot Preset ....................................................................................................................................... 8-4

8.5 Recalling the Factory Default Preset........................................................................................................................8-4

9 Timer Operation ............................................................................................................................................................. 9-1

9.1 Manual Operation .....................................................................................................................................................9-1

9.2 Automatic Operation ................................................................................................................................................9-1

Page 16

OnAir 500 Digital Mixing Console

Contents 0-3Date printed:

30.07.04

10 Automation Operation ................................................................................................................................................ 10-1

10.1 OnAir 500 and Studer DigiMedia ..........................................................................................................................10-1

10.1.1 Control Connections and Setup .......................................................................................................................10-1

10.1.2 Audio Connections ..........................................................................................................................................10-2

10.1.3 Operation .........................................................................................................................................................10-2

10.2 OnAir 500 and RCS System ...................................................................................................................................10-3

10.2.1 Connections and Setup ....................................................................................................................................10-3

10.2.2 Operation .........................................................................................................................................................10-4

11 Software Update / Re-Initializing ............................................................................................................................... 11-1

11.1 SW Update ............................................................................................................................................................. 11-1

11.1.1 Preparing the Hardware ................................................................................................................................... 11-1

11.1.2 Preparing the PC ..............................................................................................................................................11-2

11.1.3 Transferring the Software ................................................................................................................................ 11-3

11.2 Re-Initializing the OnAir 500 ................................................................................................................................11-5

11.2.1 Total Reset of the OnAir 500 ..........................................................................................................................11-5

11.2.2 Effects/Dynamics Presets Reset ......................................................................................................................11-5

11.2.3 Snapshot Presets Reset .................................................................................................................................... 11-6

11.2.4 Restoring the Factory Default Preset .............................................................................................................. 11-6

12 Connectors, Test Hookup ........................................................................................................................................... 12-1

12.1 Connector Panel .....................................................................................................................................................12-1

12.1.1 Connector Set ..................................................................................................................................................12-2

12.2 Connector Pin Assignments....................................................................................................................................12-2

12.2.1 Audio Inputs ....................................................................................................................................................12-2

12.2.2 Audio Outputs ..................................................................................................................................................12-2

12.2.3 Miscellaneous Audio Inputs/Outputs ..............................................................................................................12-3

12.2.4 Control Inputs/Outputs ....................................................................................................................................12-4

12.2.5 External 24 VDC Supply ...................................................................................................................................12-6

12.3 Test Hookup ...........................................................................................................................................................12-7

12.3.1 Before you Start ...............................................................................................................................................12-7

12.3.2 Audio Test Hookup..........................................................................................................................................12-7

12.3.3 Input Assignment .............................................................................................................................................12-8

12.3.4 Input Naming ...................................................................................................................................................12-8

12.3.5 Connecting an Input .........................................................................................................................................12-9

12.3.6 Channel Output Assignment ............................................................................................................................12-9

12.3.7 Add some EQ to the Signal .......................................................................................................................... 12-10

12.3.8 Add some Reverb to the Signal .................................................................................................................... 12-10

12.3.9 Return to the Normal Configuration .............................................................................................................12-11

13 Index ............................................................................................................................................................................. 13-1

Page 17

OnAir 500 Digital Mixing Console

0-4 Contents Date printed:

30.07.04

Page 18

OnAir 500 Digital Mixing Console

Introduction 1-1

Date printed:

30.07.04

1 INTRODUCTION

The Studer OnAir 500 is designed first and foremost as a broadcast radio

console, which can simply drop in to any existing setup with a minimum of

fuss. This might be as a replacement for older analog equipment, or integration into a totally digital environment. The instantly familiar “analog” control style of the Studer OnAir 500 ensures that users do not have to fight with

the technology in order to start using the powerful features on offer. The

added benefits of automation to the professional radio presenter are obvious

– simple single-key recall of a complete console state with effects, routing

and EQ all configured, according to the user’s preferences. Whether in a

studio or in an outside broadcast vehicle, the Studer OnAir 500 will offer the

user repeatable, detailed control over a powerful feature set, in a simple and

efficient manner.

All of this control would have been little use without the intuitive interface

incorporating the edit strip, which allows fast access to all audio parameters

on the console when used in conjunction with the EDIT key present on each

channel. The “Tap and Adjust” functionality of the Studer OnAir 500 provides even the first-time operator with a familiar channel strip and a meter

bridge equipped with bar graph meters.

Page 19

OnAir 500 Digital Mixing Console

1-2 Introduction Date printed:

30.07.04

Each channel has full access to the edit strip, which offers three-band EQ

with semi-parametric midrange equalization, variable high-pass filter and

two auxiliary sends, a digital trim control with a range of ±12 dB, and a pan/

balance control. Every channel has an assignable stereo dynamics processor

offering a choice of compression, limiting and gating facilities.

The on-board Lexicon™ effects processor can be accessed from any channel

by configuring either the AUX 1 or AUX 2 send to operate as an effects send.

Immediacy is critical in the broadcast environment and so it was important

to have controls on each channel, like input 2 switching. Also included are

advanced but simple-to-use functions, like how the channel ON keys or fader

movements can trigger remote equipment, and how the PFL key can activate

talkback to cleanfeeds if required. Comprehensive talkback facilities and

compatibility with existing systems ensure that the user is never out of touch

even during the most complex of outside broadcast links.

The built-in MIDI ports allow full backup and restore of console presets via

MIDI system-exclusive data transfers.

1.1 Key Features

The Studer OnAir 500 offers the following features:

• Six assignable 100 mm faders

• Meter bridge with choice of VU or PPM metering

• Built-in cue/reverse talkback loudspeaker

• Two flexible timers for logging and scheduling

• Flexible routing of inputs

• Easy to use “analog” style user interface

• External monitor muting and equipment control via assignable contact switch

outputs

• External control inputs for cough muting and enabling reverse talkback

• Independently assignable line/talkback/cleanfeed outputs with “mix-minus”

facility

• Built-in LexiconTM digital effects processor with 128 available FX presets

• Assignable channel dynamics

• 128 desk presets for storage and recall of digital console parameters

• Backup and restore of snapshot, dynamic and FX presets via MIDI

• Software upgrades via built-in RS232 port

• Backlit LCD screen for parameter editing, global setup and configuration

• Integrated, auto-ranging power supply unit (100...240 VAC, 50...60 Hz)

• Input connector for 24 VDC supply, can be used for first-level PSU redundancy.

Page 20

OnAir 500 Digital Mixing Console

Introduction 1-3

Date printed:

30.07.04

1.2 Feature Overview

Analog Inputs The Studer OnAir 500 offers four assignable mic/line inputs, using digitally

controlled mic pre-amps. Two mic/line Inputs have an analog insert point

using a stereo jack plug, and all have a gain range from 0 to +60 dB, with

switchable 48 V phantom power. Two stereo inputs are also available with a

gain range from 0 to +18 dB. For monitoring purposes, there are four external stereo inputs accessible via a 37-pin D-type connector, with a gain range

from 0 to +18 dB. All of the above inputs are electronically balanced and

feature 24 bit, 128 × oversampling A/D converters.

A further eight analog inputs can be achieved by connecting an external mic/

line input interface box to the TDIF port found on the rear of the Studer

OnAir 500.

Analog Outputs The Studer OnAir 500 offers an array of analog outputs. There are electroni-

cally balanced XLR outputs for the PROG and AUD mix buses, and unbalanced outputs for control room and studio monitors. Outputs for guest, studio, and control room headphones are supplied, with a duplicate control room

headphone socket located at the front.

Outputs for AUX buses 1 and 2, line/clean-feed buses 1 and 2, stereo PFL,

mono PFL and cue speaker are located on the 37 pin D-type connector.

A further eight analog outputs can be achieved by connecting an external

analog output interface box to the TDIF port found on the rear of the Studer

OnAir 500.

Digital Inputs Four dedicated AES/EBU inputs and one S/PDIF input for connecting CD,

MiniDisc and DAT units are provided on the rear of the Studer OnAir 500.

Additional digital inputs are accessed by an eight-channel TDIF connector.

With the exception of the TDIF inputs, all other digital inputs are equipped

with sample rate converters, simplifying the setup and eliminating the need

for all devices in the system to share a common wordclock. All digital inputs

can be routed freely to any channel in exactly the same way as the analog

inputs, and therefore have the same access to the edit strip (there are, however, limitations regarding the routing of the S/PDIF input - see chapter 4.2

for details).

A further four AES/EBU inputs (four stereo or eight mono) can be achieved

by connecting an AES/EBU input interface box to the TDIF port.

Digital Outputs There are two AES/EBU digital outputs provided on male XLR connectors,

and one S/PDIF output via an RCA/Cinch connector. The TDIF connector

also provides eight additional digital outputs that can be configured to output a variety of mono or stereo sources.

A further four AES/EBU outputs (four stereo or eight mono) can be achieved

by connecting an AES/EBU output interface box to the TDIF port.

Meters The Studer OnAir 500 has two stereo bargraph meters with a correlation

indicator above each of them. On the METER 1, three easily selected modes

show either the PROG or AUD output buses or the control room selection;

for METER 2, the same sources are menu-selectable. Metering can be specified at the time of ordering with either VU or PPM characteristics.

(continued on page 1-6)

Page 21

OnAir 500 Digital Mixing Console

1-4 Introduction Date printed:

30.07.04

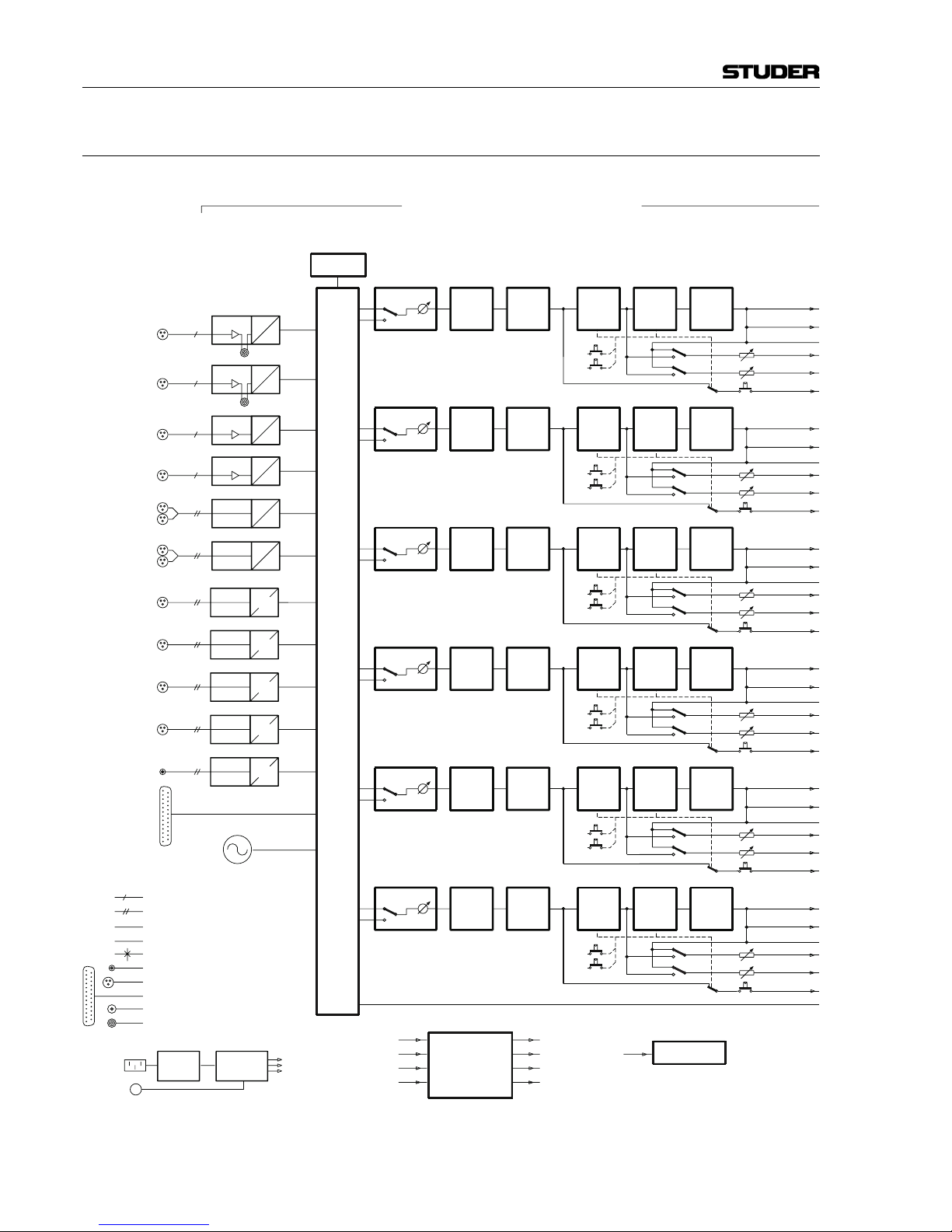

1.3 Studer OnAir 500 Block Diagram

A

PRE 1 A

D

D

PRE 2

PRE 3

D

A

A

D

MIC/LINE 1

MIC/LINE 2

D

D

DYN

EQ

FADER

AUX2

AUX1

STEREO IN 1

HL IN 1

a

a

a

a

AES IN 1d

SFC

AUX 1

AUX 2

CUE

AES 1

INSERT

MONO

STEREO

ANALOG SIGNAL

DIGITAL SIGNAL (AES/EBU)

CONFIG. SELECTION

d

a

PF

AF

XLR CONNECTOR

D-TYPE CONNECTOR

Σ AUDITION

Σ PROGRAM

TRS JACK SOCKET, STEREO, UNBAL

ON

CH

MIC/LINE 3

MIC/LINE 4

a

D

PRE 4 A

STEREO IN 2

aDHL IN 2 A

AES 2

dDAES IN 2

D

SFC

AES 4

d

AES 3

d

SFC

D

AES IN 4

D

D

AES IN 3

D

SFC

S/PDIF

d

SFC

D

S/PDIF IN

D

TDIF IN

1

8

INP SEL

HPF PAN/

BAL

GAIN

AF

PF

DIR OUT

ON

OFF

AF

PF

AUX 2

AUX 2

CUE

INP SEL GAIN

DYN

HPF

EQ BAL

AF

PF

FADER

AUX 1

PAN/

DIR OUT

AUX 1

Σ AUDITION

Σ PROGRAM

AF

PF

AUX 2

AUX 2

CUE

INP SEL GAIN

DYN

HPF

EQ BAL

AF

PF

FADER

AUX 1

PAN/

DIR OUT

AUX 1

Σ AUDITION

Σ PROGRAM

INP SEL GAIN

DYN

HPF

EQ BAL

PF

AF

PF

AF

FADER

AUX 2

AUX 1

AUX 2

CUE

AUX 1

DIR OUT

PAN/

Σ PROGRAM

Σ AUDITION

AF

PF

AUX 2

AUX 2

CUE

INP SEL GAIN

DYN

HPF

EQ BAL

AF

PF

FADER

AUX 1

PAN/

DIR OUT

AUX 1

Σ AUDITION

Σ PROGRAM

INP SEL GAIN

DYN

HPF

EQ BAL

PF

AF

PF

AF

FADER

AUX 2

AUX 1

AUX 2

CUE

AUX 1

DIR OUT

PAN/

Σ PROGRAM

Σ AUDITION

CINCH/RCA CONNECTOR

TRS JACK SOCKET, MONO, BAL

TALKBACK

INSERT

CONFIG. BY

LCD SCREEN

POWER

SUPPLY

MAINS

24 VDC

POWER

CONVERTER

FADER START 1...6

INPUT 1/2 LOGIC

EXT. REV TB SWITCH

EXT. COUGH SWITCH A/B

RELAY CONTACTS 1...12

TIMER CONTROL 1/2

REV TB ENABLE

A/B COUGH

OFF

ON

CH

ON

ON

OFF

CH

ON

ON

OFF

CH

ON

ON

OFF

CH

ON

ON

OFF

CH

ON

1 kHz GEN

INPUT/FADER CHANNELSINPUTS

INPUT ROUTER

LOGIC

CONTROL

TIMERS 1 & 2

Page 22

OnAir 500 Digital Mixing Console

Introduction 1-5

Date printed:

30.07.04

17.06.03/STI

OA500_V1.0

ON AIR 500 V1.0

AUDIO BLOCK DIAGRAM

REGENSDORF

SWITZERLAND

0

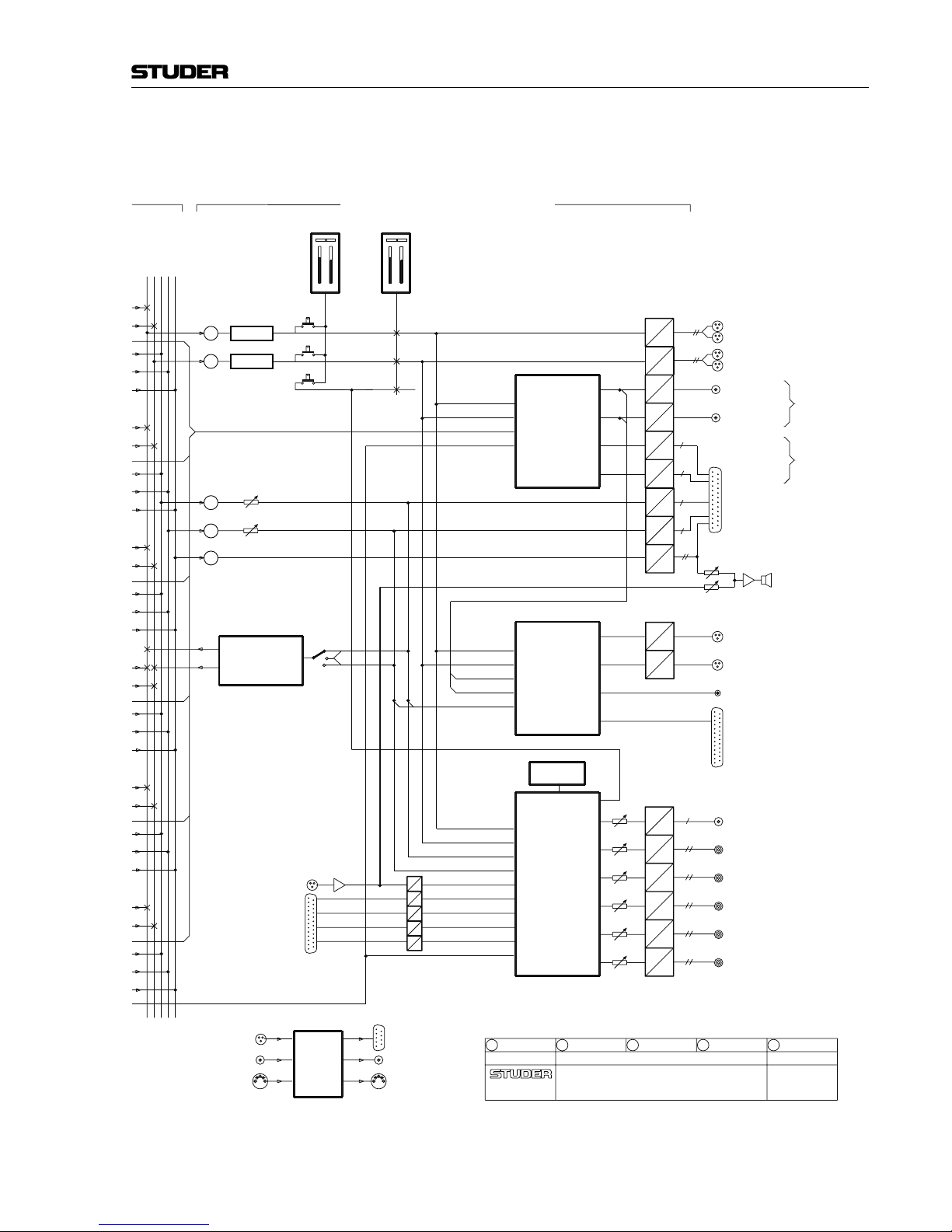

AUX 1 MASTER

AUX 2 MASTER

D

A

DAa

a

a

CUE/TB

AUX2

AUX1

METER 2

a

METER 1

D

A

Σ AUDITION

Σ PROGRAM A

Σ FADER

Σ FADER

+

+

PROGRAM

AUDITION

+

+

A

D

DAa

+

CUE

L

EXT IN 2

R

EXT IN 1

EXT IN 3

EXT IN 4

R

L

R

L

R

L

D

A

A

D

A

A

D

D

REV TB MIC IN

D

A

D

A

A

D

A

D

A

D

LINE OUT/

CLEANFEED 3

CLEANFEED 4

LINE OUT/

STEREO

LINKABLE

a

a

CLEANFEED 2

LINE OUT/

CLEANFEED 1

LINE OUT/

STEREO

LINKABLE

DIR OUT

AUD

PGM

INT TB

C/FEED 1/2

PGM

AUD

D

AES

AES

D

d

d

1

8

TDIF OUT

AES 1 OUT

AES 2 OUT

S/PDIF OUT

d

D

a

A

A

D

A

a

D

D

A

D

A

A

D

MONO MIX OUT

CR OUT

CR PHONES OUT

a

STUDIO OUT

a

STUDIO PHONES OUT

a

GUEST PHONES OUT

a

C/FEED 3/4

AUX 1/2

MONITOR

REV TB

AUX 2

AUX 1

AUD

PGM

INT TB

EXT 4

EXT 3

EXT 1

EXT 2

CONFIG. BY

LCD SCREEN

AUX 1/2

AUX 1

AUX 2

AES SYNCIN

MIDI IN

WORDCLOCK

RS232

MIDI OUT

WORDCLOCK

MAIN OUTPUTS

MASTER AND MONITORING

LINE OUTPUT

ROUTER

MIX MINUS

GENERATOR

ROUTER

OUTPUT

DIGITAL

MONITOR

&

SECTION

SOURCE

SELECT

/

LEXICON

FX

CPU

Page 23

OnAir 500 Digital Mixing Console

1-6 Introduction Date printed:

30.07.04

(cont.) Faders The 100 mm long-throw faders found on the Studer OnAir 500 work just as

you would expect on an analog console. The top end of the fader is calibrated

at 0 dB (unity gain). The master faders can be bypassed via the setup menu

so that both the PROG and AUD bus outputs are fixed at unity gain.

Edit Strip The edit strip places the main controls found on a conventional analog chan-

nel strip in one central, easy-to-access area. The edit strip has three-band

equalization, variable high-pass filter, two stereo-linkable AUX sends which

can be switched either pre- or post-channel fader, a digital gain control and a

pan/balance control together with PROG and AUD assignment keys.

Lexicon™ Effects Processor The Studer OnAir 500 features a built-in Lexicon™ stereo FX processor that

includes reverb, delay, chorus and flange effects and is fed from AUX sends

1 and 2. Customized effects can be stored in user libraries for later recall.

Stereo Dynamics Processors Each channel has a dynamics processor that is automatically configured de-

pending on the channel source, for either mono or stereo operation. It is positioned before the digital EQ and gain controls so that limiting can occur

during signal peaks.

Snapshot Presets Complete recall of all console settings can be stored in up to 128 preset

memory locations for recall.

Audio Quality All analog inputs and outputs on the Studer OnAir 500 have 24-bit 128 ×

oversampling A/D and D/A converters, ensuring wide dynamic range and

superb sonic performance.

Power Supply The OnAir 500 features both AC and DC supply. The internal supply unit is

auto-ranging, for supply voltages of 100...240 VAC, 50...60 Hz. A DC supply

input for connecting an external supply unit, a battery, or an uninterruptible

power supply (UPS) is provided as well. Both supply variants can be used

simultaneously for redundancy. A power alarm indicator on the front panel is

illuminated and warns the operator as soon as either one, the AC or DC supply fails while the other one keeps up running the console.

Page 24

OnAir 500 Digital Mixing Console

General 2-1

Date printed:

02.08.04

2 GENERAL

2.1 Utilization for the Purpose Intended

The OnAir 500 mixing console is intended for professional use.

It is presumed that the unit is operated only by trained personnel. Servicing

is reserved to skilled technicians.

The electrical connections may be connected only to the voltages and signals

designated in this manual.

2.2 First Steps

2.2.1 Unpacking and Inspection

Your new mixing console is shipped in a special packing that protects the

unit against mechanical shock during transit. Care should be exercised when

unpacking so that the surfaces do not get marred.

Verify that the content of the packing agrees with the items listed on the

enclosed shipping list.

Check the condition of the equipment for signs of shipping damage. If there

should be any complaints you should immediately notify the forwarding

agent and your nearest Studer distributor.

Please retain the original packing material because it offers the best protection in case your equipment ever needs to be transported.

2.2.2 Installation

Primary Voltage: The power supply unit is auto-ranging; it can be used for mains voltages in a

range of 100 to 240 VAC, 50 to 60 Hz.

DC Operation: The console can be operated from a 24 VDC source (battery, external supply

unit, UPS) through the respective 24 VDC connector provided on the rear

panel.

For DC operation it is mandatory that a UL approved, external fuse is connected in series with one of the supply lines (T 3.15 A H 250 V UL/CSA).

The power switch next to the power inlet only switches the mains voltage; for

DC operation, an external power switch has to be foreseen by the installer.

General Precautions: Do not use the unit in conditions of excessive heat or cold, near any source of

moisture, in excessively humid environments, or in positions where it is

likely to be subjected to vibration or dust. The ambient temperature range for

normal operation of the unit is +5...+40° C.

Unobstructed air flow is essential for proper operation. The air vents on the

top and bottom of the unit are a functional part of the design and must not be

blocked in any way (e.g. by a manual or a computer screen).

Page 25

OnAir 500 Digital Mixing Console

2-2 General Date printed:

02.08.04

Cleaning: Do not use any liquids to clean the exterior of the unit. A soft, dry cloth or

brush will usually do. Never use any solvent for cleaning any surface of your

unit!

For cleaning the display windows, most of the commercially available window or computer/TV screen cleaners are suited. Use only a slightly damp

(never wet) cloth. Never use any solvent!

Power Connection: The attached female IEC 320/C13 mains cable socket has to be connected to

an appropriate mains cable by a trained technician, respecting your local

regulations. Refer to the “Installation, Operation, and Waste Disposal” chapter at the beginning of this manual.

In case of 24 VDC operation, use an appropriate connection to the external

DC supply unit or battery, equipped on one end with the attached 10-pole

cable socket.

For DC operation it is mandatory that a UL approved, external fuse is connected in series with one of the supply lines (T 3.15 A H 250 V UL/CSA).

For pin assignment of the 24 VDC connector please refer to chapter 12.2.5.

Please check your DC supply cable for correct polarity before connecting it

to the console.

Earthing: This equipment must be earthed, due to the mains input filter network being

connected to the mains earth. Also in case of DC operation, earthing of the

unit is mandatory.

Some consideration should be given to the earthing arrangement of the system, at the center of which is the console. The console chassis is earthed to

the mains earth via the power supply and/or the dedicated earth connection

bolt. Ground loops may occur where signal processing equipment, patched

to the console, has its signal earth commoned to the equipment chassis.

2.2.3 Adjustments, Repair

Danger: All internal adjustments as well as repair work on this product must be per-

formed by trained technicians!

Supply Unit Replacement: The primary fuse is located within the power supply unit and cannot be

changed. In case of failure, the complete supply unit must be replaced. Please

contact your nearest Studer representative.

Page 26

OnAir 500 Digital Mixing Console

General 2-3

Date printed:

02.08.04

2.3 Technical Specifications

2.3.1 Typical Values (subject to change without notice)

Microphone/Line Level Inputs

Input Sensitivity: –42...+18 dBu for 0 dB

FS

Input impedance: 2.2 kΩ

Frequency response: ±0.5 dB, 20 Hz…20 kHz

Phantom power, switchable: 48 V

A/D converter: 24 bit (128 x oversampling)

Dynamic range: typ. 106 dB (unweighted, analog in-to-analog out)

Equivalent input noise: –127 dBu (150 Ω @ max. gain)

THD: < –80 dB (1 kHz @ 30 dB gain)

Stereo Line Level Inputs

Input sensitivity: 0…+18 dBu for 0 dB

FS

Frequency response: ±0.5 dB, 20 Hz…20 kHz

Input impedance: > 10 kΩ

A/D converter: 24 bit (128 x oversampling)

Dynamic range: 106 dB (unweighted, analog in-to-analog out)

THD: < –86 dB (1 kHz @ 0 dB gain)

Analog Outputs D/A converter: 24 bit (128 × oversampling)

Dynamic range: 106 dB (unweighted, analog in-to-analog out)

Frequency response: ±0.5 dB (20 Hz…20 kHz)

Output impedance: 50 Ω

Equalizer Treble control (hi): 10 kHz: ±10 dB

Equalizer (mid): 500 Hz...8 kHz: ±10 dB

Bass control (low): 100 Hz: ±10 dB

Power Supply Mains voltage: 100...240 V, 50/60 Hz (auto-ranging)

Power consumption: 80 VA typ.

DC operating voltage: 24 V / 3 A typ.

Weight 15 kg

Page 27

OnAir 500 Digital Mixing Console

2-4 General Date printed:

02.08.04

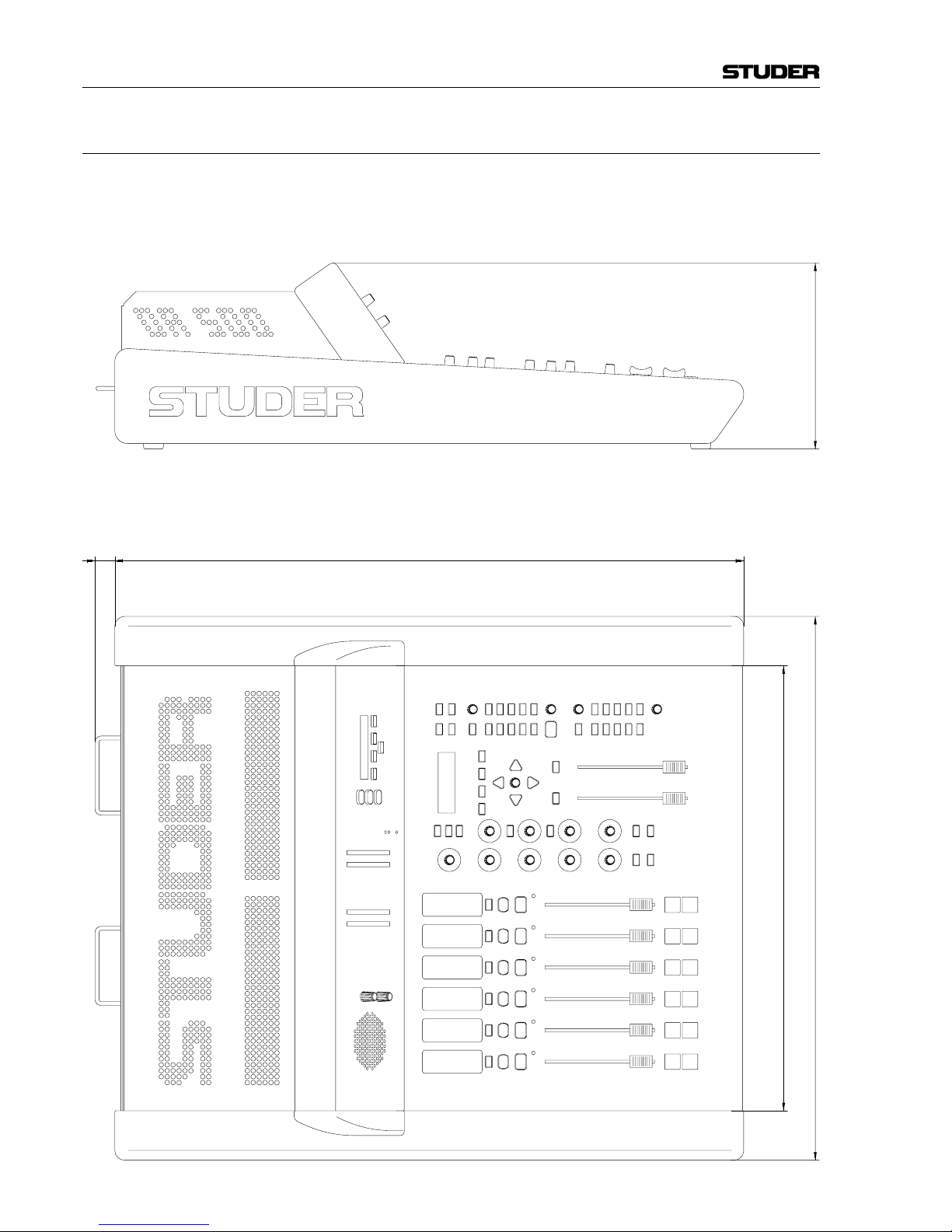

550 mm

636 mm

450 mm

20 mm

188 mm

2.3.2 Mechanical Dimensions

Page 28

OnAir 500 Digital Mixing Console

Operating Elements 3-1

Date printed:

30.07.04

3 OPERATING ELEMENTS

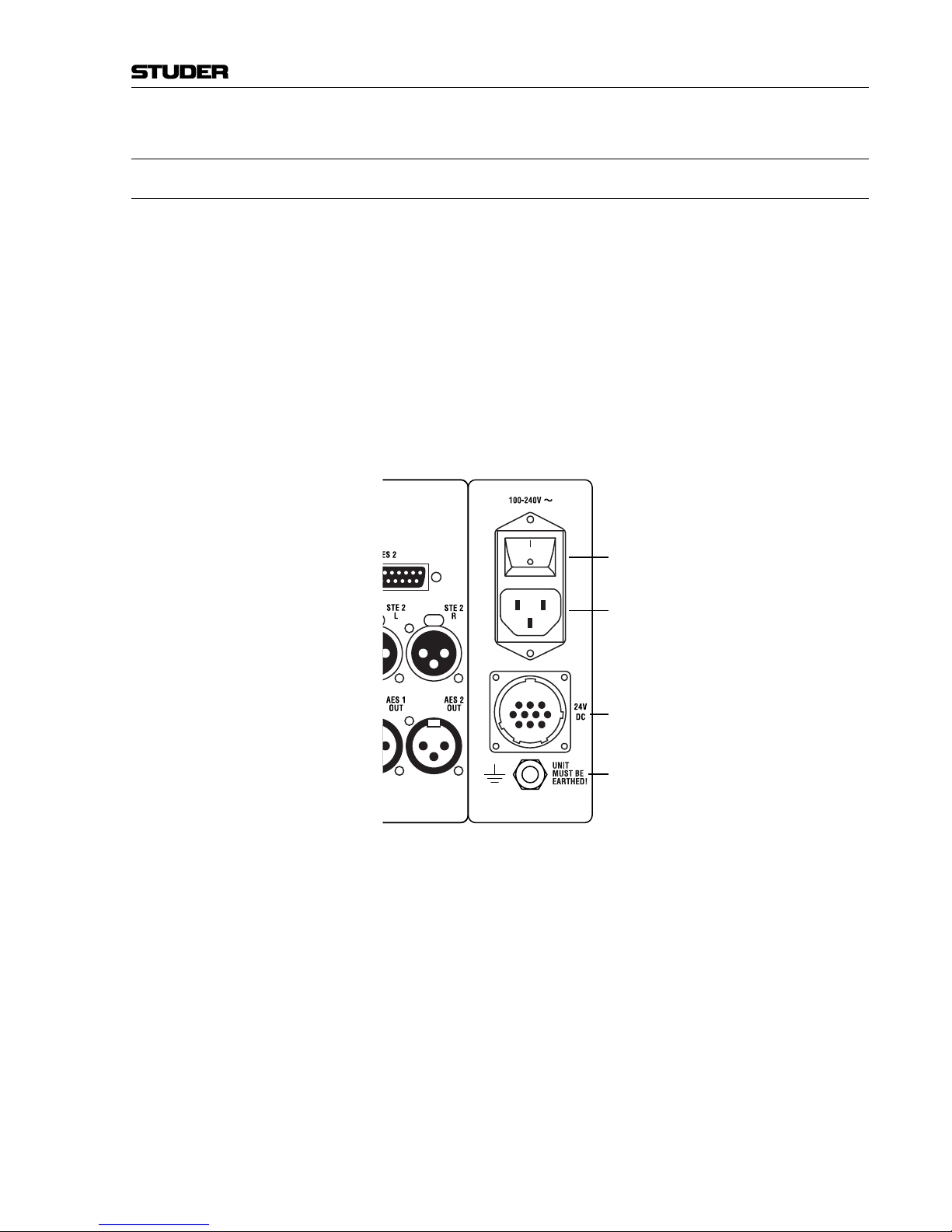

3.1 Power Switch

The mains power switch is located on the rear side of the console, next to the

power inlet.

In case of DC operation of the console using an external power supply, a

battery or an UPS, the power switch is without function. In such a case, an

external power switch has to be foreseen by the installer.

The mains inlet and the DC supply inlet can be used at the same time for

quasi-redundant operation.

In case of quasi-redundant operation, the POWER ALARM LED on the meter

bridge illuminates and warns the operator as soon as either one, the AC or

the DC supply fails while the other one keeps up running the console. In

addition, a power alarm signal is active on one of the pins of the 24V DC

connector.

For pin assignment of the 24V DC connector refer to chapter 12.2.5.

213

9810

47

132

2

132

1

Power Switch (active for Mains Supply only)

IEC Mains Inlet

DC Supply Inlet

Earthing Lug

Page 29

OnAir 500 Digital Mixing Console

3-2 Operating Elements Date printed:

30.07.04

[1]

[3]

[4]

[5]

[6]

[7]

[2]

[8]

Page 30

OnAir 500 Digital Mixing Console

Operating Elements 3-3

Date printed:

30.07.04

3.2 Channel Strip

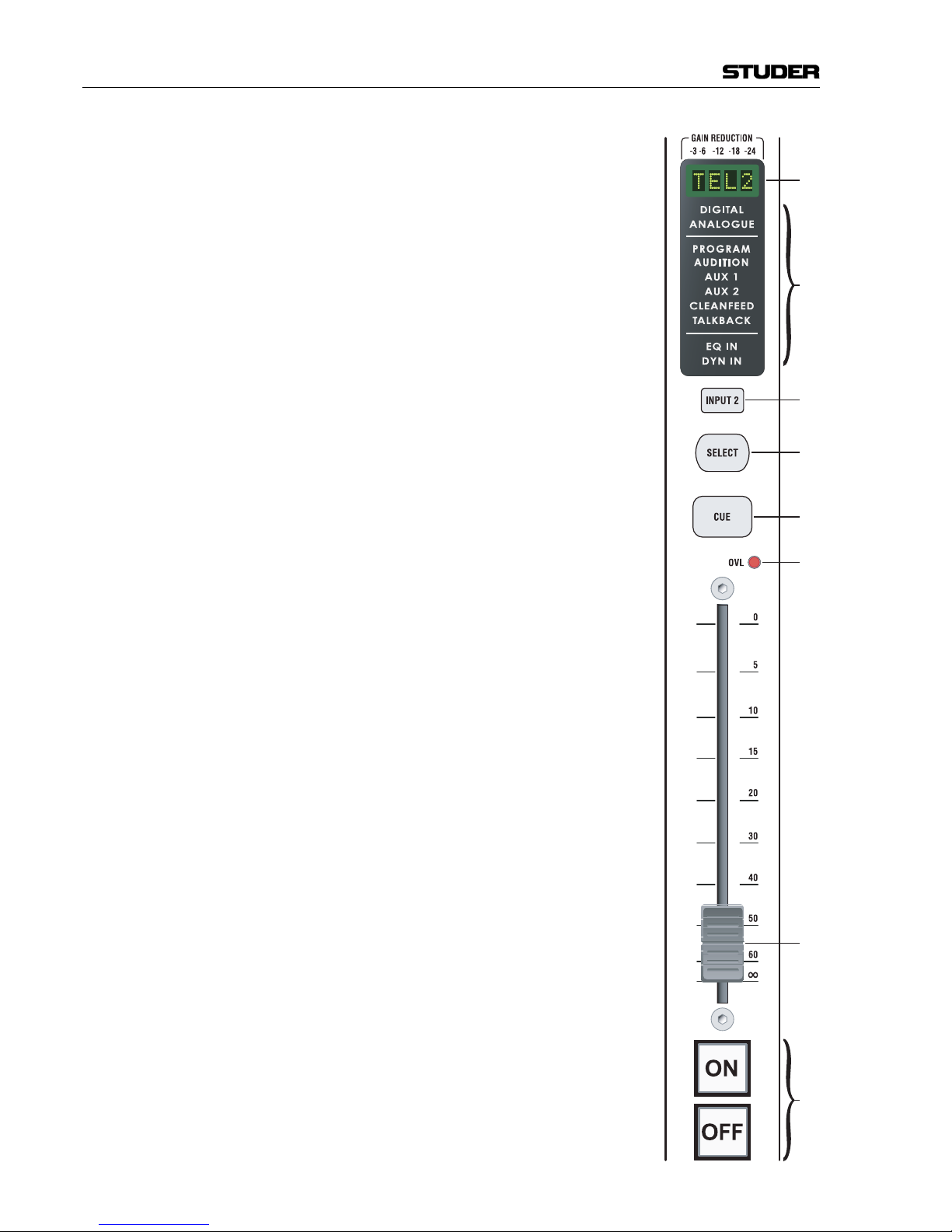

Input Display [1] This four-character display normally indicates the currently active channel

input (the name of which can be edited, refer to chapter 4.12). If the channel’s

dynamics processor is active, it indicates compressor/limiter gain reduction

and gate activity instead (see chapter 6).

Status Window [2] The status window contains individual displays that give constant visual in-

formation on:

• Whether the input source is ANALOGUE or DIGITAL.

• Whether the channel is assigned to the PROGRAM or AUDITION out-

puts.

• Whether the AUX 1 or AUX 2 sends are active on the selected channel

(the legend will illuminate as soon as either of the AUX 1 or AUX 2 sends

are opened).

• Whether the channel has been configured as a CLEANFEED source.

• Whether the channel has been configured as the TALKBACK channel

• Whether the EQ IN button is active on the channel

• Whether the channel’s dynamics processor is active or not (DYN IN).

INPUT 2 [3] The INPUT 2 button indicates whether input 1 or input 2 is the current input

source for the channel. If the INPUT 2 button is dark, then input 1 is active. If

the INPUT 2 button is illuminated then input 2 is active.

Note: The REV TB1 (reverse talkback input) and the four external monitoring in-

puts (on the ANALOGUE I/O 37-pin D-type connector) cannot be used as

channel inputs.

SELECT [4] When the SELECT button is pressed, the edit strip will be assigned to the

selected channel. The SELECT button is also used in conjunction with some

of the setup menus, for fast configuration of console functions.

CUE [5] The CUE button routes the channel source to the CUE/PFL bus. This allows

the presenter to listen to any channel source before the fader is opened. The

CUE button can also be used together with the TALK button [34] to send

talkback, usually the presenter’s microphone, to a designated cleanfeed output. The CUE button can be latched by giving it a short press; alternatively it

can have a momentary action by holding it down.

OVL LED [6] The OVL LED indicates clips occurring in the digital domain.

Channel Fader [7] The channel fader is a high-quality, 100 mm fader with a logarithmic scale.

Any channel fader can be configured in the Assign Channels menu to start

external equipment and to trigger the timers (refer to chapters 4.17 and 9.2).

ON / OFF [8] The large ON and OFF buttons are used to switch the channel on and off.

They may also be configured for triggering external devices using the remote relay port (refer to chapter 4.17).

Page 31

OnAir 500 Digital Mixing Console

3-4 Operating Elements Date printed:

30.07.04

[9]

[10]

[13]

[12]

[11]

[14]

[15]

[17]

[18]

[16]

[19]

Page 32

OnAir 500 Digital Mixing Console

Operating Elements 3-5

Date printed:

30.07.04

3.3 Edit Strip

The edit strip is a central panel offering all of the usual facilities you would

expect to find on a standard channel strip. The edit strip can be applied to any

channel by pressing the channel’s SELECT button [4]. It will remain active

on the selected channel until the SELECT button of another channel is

pressed.

AUX MASTER [9] Used in conjunction with the AUX 1 and AUX 2 buttons, this control adjusts

the overall send level for either the AUX 1 or AUX 2 bus. When the associated STE button is pressed, both AUX 1 and AUX 2 buttons illuminate, indicating that they are now linked as a stereo pair (AUX 1 = L, AUX 2 = R). In

this case, the AUX MASTER control will adjust the send level as a stereo pair.

The red STE LED found next to the AUX 1 send control will illuminate, showing that stereo link mode is active.

Note: The AUX MASTER control and its associated buttons are always active, re-

gardless of which channel is currently selected to the edit strip.

HF [10] The HF control has a shelving characteristic and offers 10 dB of cut/boost at

a frequency of 10 kHz.

LF [11] The LF control has a shelving characteristic and offers 10 dB of cut/boost at

a frequency of 100 Hz.

MF [12] The MF control has a semi-parametric characteristic and offers 10 dB of cut/

boost. The center frequency is adjusted with the FREQ control [13].

FREQ [13] The FREQ control selects the frequency of the MF EQ band in a range of

500 Hz to 8 kHz.

HPF [14] The HPF button inserts the variable high-pass filter into the channel. This is

useful for reducing unwanted low frequency interference. The choice of cutoff frequencies for the high-pass filter is 80, 100, 150, 200, 250 Hz.

EQ IN [15] The EQ IN button switches the EQ section on and off, excluding the high-

pass filter (HPF) which is not affected by this control.

AUX 1, AUX 2 [16] Each channel can be routed to the AUX 1 and AUX 2 buses. Turning either

control clockwise will activate the AUX send, and the corresponding AUX

legend in the status window of the selected channel will illuminate.

Turning either control fully anti-clockwise (–∞) will mute the AUX send,

and the corresponding AUX legend in the status window will extinguish.

The AUX MASTER control determines the overall level of the AUX 1 or

AUX 2 bus output.

The PRE button next to each AUX control switches the AUX send between