Page 1

T/PUMP®

Series Localized Temperature

Therapy System

TP600 & TP700

Service Manual

2014/06 E.3 101176 REV E www.stryker.com

Page 2

Page 3

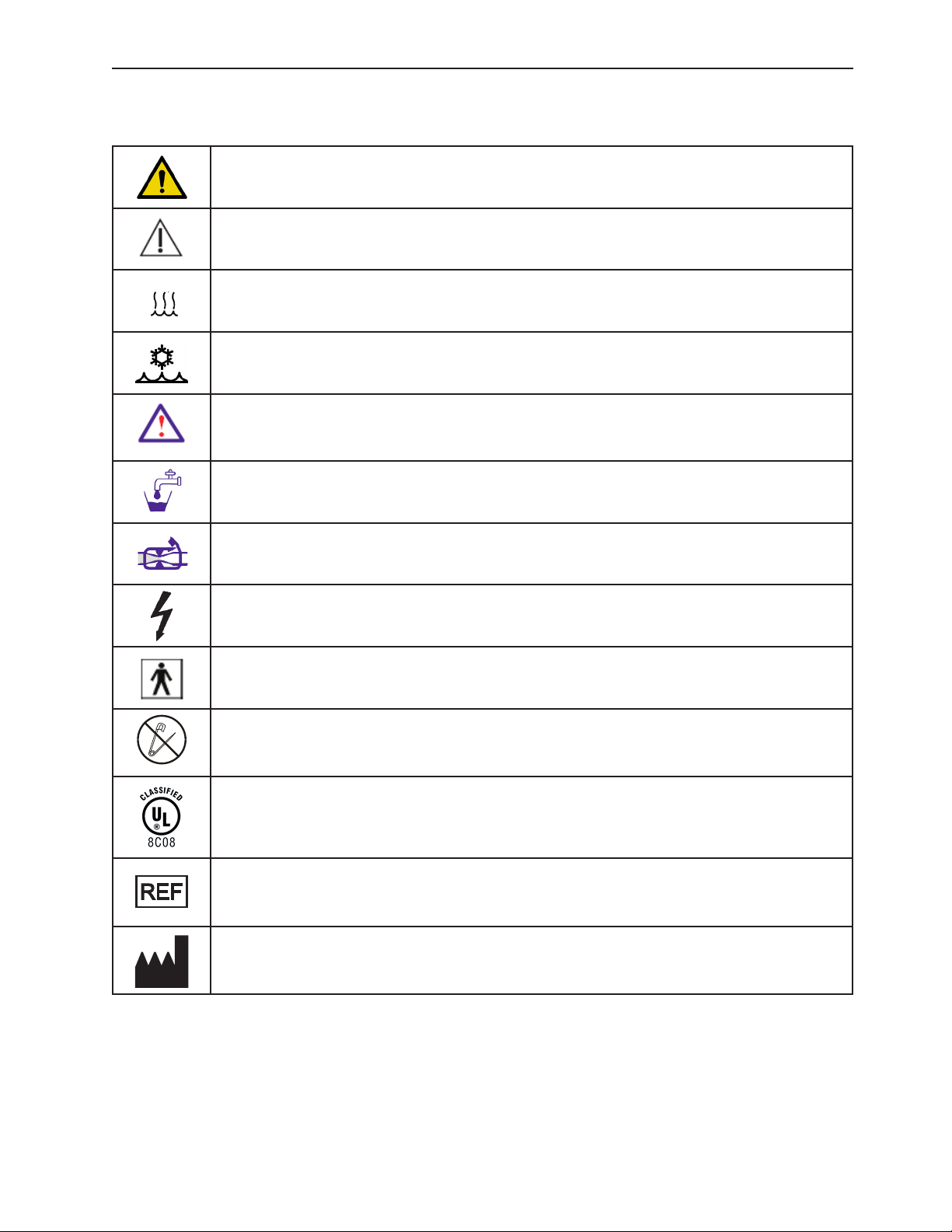

SYMBOLS

Symbols and Definitions

General Warning

Caution

Warm Water Fill Line

Cold Water Fill Line

Attention, consult Operator’s Manual

Water Levels

Water Flow

Dangerous Voltage

Type BF Applied Part

Do not penetrate with sharp object

Medical Electrical Equipment with Respect to Electrical Shock, Fire, and Mechanical hazards in accordance with UL 60601-1, and CAN/CSA C22.2 No. 601.1, ASTM F 2196-2002

Model or Catalog Number

Manufacturer

Page 4

Table of Contents

Symbols and Definitions ....................................................................3

Symbols ............................................................................3

Safety Precautions ........................................................................5

Introduction .............................................................................6

Before You Begin......................................................................6

Receiving Inspection ...................................................................6

To Return Pumps To Factory For Repair Or Exchange...........................................6

Introduction ..........................................................................7

Connecting the Pads ...................................................................7

Catalog Descriptions ...................................................................8

Features................................................................................9

Pump Features .......................................................................9

Keypad Features TP600 Series ..........................................................10

Keypad Features TP700 Series ..........................................................11

Keypad Features TP702 Series ..........................................................12

Specifications...........................................................................13

Operating Instructions.....................................................................14

Clik-Tite Connectors...................................................................14

Quick Disconnects....................................................................15

Start-Up Procedure ...................................................................16

Shutdown Procedure ..................................................................16

Cleaning...............................................................................17

Storage / Cleaning....................................................................17

Institutional (Hospital) Cleaning Instructions .................................................18

Pads / Accessories ...................................................................18

Water Temperature Control .................................................................19

Theory of Operation ......................................................................20

Functional Check ........................................................................21

Disassembly / Reassembly .................................................................26

Troubleshooting .........................................................................28

Troubleshooting .........................................................................31

Parts Illustration .........................................................................32

Parts Illustration .........................................................................33

Replacement Parts List....................................................................34

Warranty ..............................................................................36

Warranties..........................................................................36

Pump .............................................................................36

Pad, Single Patient Use ................................................................36

Pad, Reusable .......................................................................36

Parts ..............................................................................36

4 101176 REV E www.stryker.com

Page 5

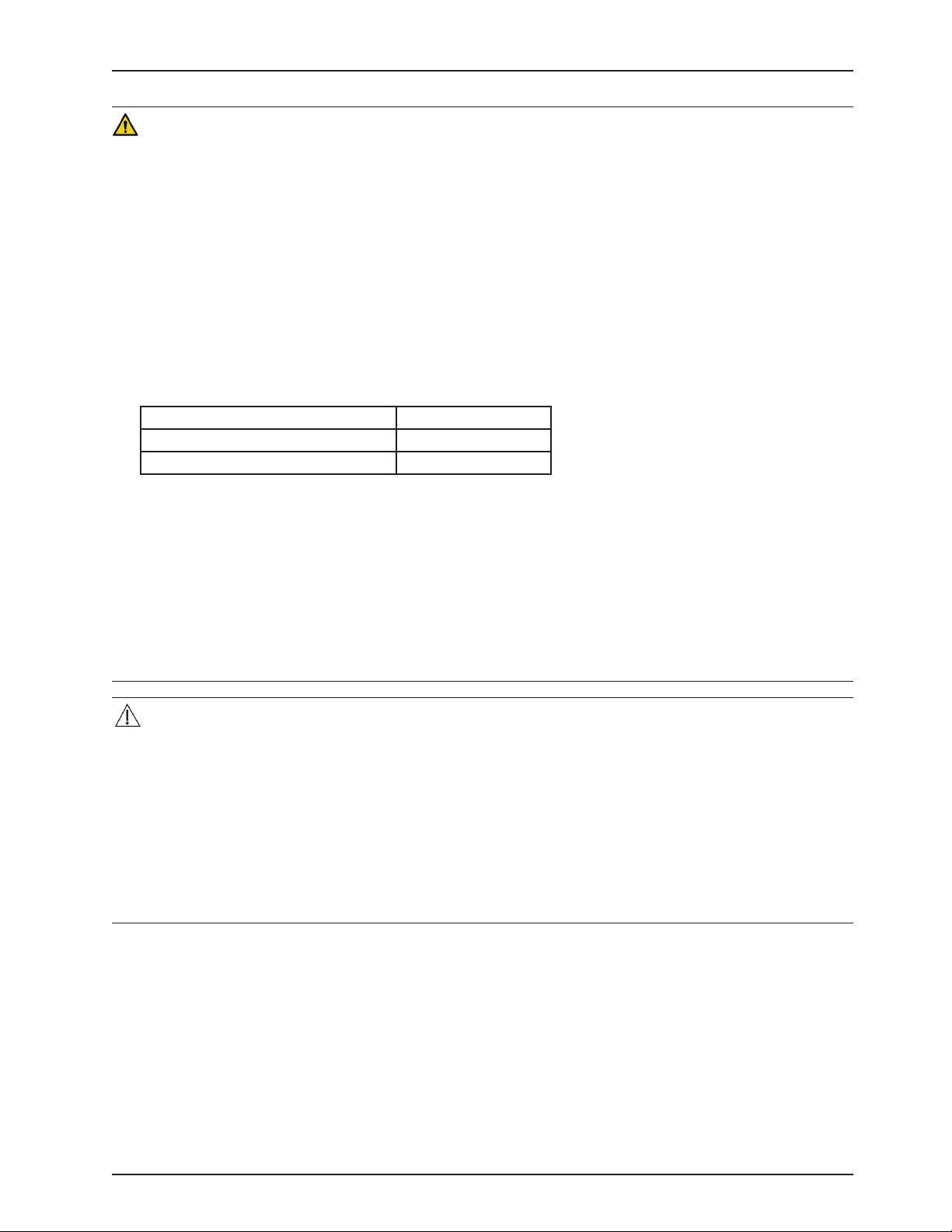

Safety Precautions

WARNING

• Risk of explosion. Do not use in the presence of flammable anesthetics.

• Risk of electric shock. Disconnect power before servicing the T/Pump.

• Do not attach the power cord to any moving parts of the bed frame or any location that may be a pinch point or

cause power cord damage. If routed improperly, the power cord may become pinched and could cause electrical

shock.

• This device pumps temperature controlled water through a pad. Set the pad temperature only as directed by and

under the guidance of the prescriber.

• Check the skin integrity of the body surface to which therapy is applied. Evaluate patient response to temperature

application.

• Check patient’s skin for adverse reactions every 30 minutes or as directed by the prescriber. Patients at greatest

risk are those who are unconscious, diabetic, and/or incapacitated.

• Failure to adhere to these warnings could result in patient injury.

• The following Groups/Conditions require additional surveillance:

Group/Condition at risk Potential Injury

Patients with impaired circulation Ischemia

Areas of application under pressure Ischemia

• Only qualified medical service personnel should repair the T/Pump. Improper repair may result in death or serious

injury, equipment damage, or malfunction.

• UseT/PumpTP600&TP700seriescontrolswithMul•T•Pads®. For catalog numbers and descriptions, see page

8.

• Do not place additional heat sources between the patient and pad. Skin damage may result.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to the patient or operator. Modifying the product aslo voids the product warranty.

• Do not use accessories other than those specified by Stryker. Using competitor accessories may result in

unpredictable operation resulting in injury to the patient or operator or damage to the product.

• To avoid the risk of shock, unplug the unit before filling the reservoir.

CAUTION

• U.S. Federal law restricts this device to sale by or on the order of a physician.

• Set fluid temperature and monitor patient’s temperature and skin condition as directed by a physician to prevent

injury.

• Additional surveillance required for pediatric patients and patients with impaired circulation.

• Closely monitor areas of application under pressure as well as with use with topical solutions and other heat

sources to prevent injury.

• The use of quaternary disinfectant products may cause damage to the product.

• Frequent or prolonged exposure to higher concentration disinfectant solutions may result in damage to the product.

• Do not cover the control unit with blankets, pillows or other insulating materials. Air flow is required to maintain

system performance.

www.stryker.com 101176 REV E 5

Page 6

Introduction

BEFORE YOU BEGIN

Read and understand this T/PUMP OPERATOR’S MANUAL and all SAFETY PRECAUTIONS

(see page 5) prior to using the T/Pump.

Only qualified medical service personnel should repair or perform function tests on the T/Pump. Contact your dealer

or Stryker’s Technical Service Department for assistance:

Telephone: 1-800-327-0770

RECEIVING INSPECTION

Check the shipping carton for damage immediately upon receipt. If package damage is discovered, the device should

be unpacked with the carrier’s agent present. Any claims for shortage or damage must be filed with the delivering

carrier by the purchaser. Do not return pumps that were damaged in shipment to Stryker without contacting our

Technical Service Department for advice (see phone numbers below). If damaged goods are returned to Stryker

without notifying the carrier, Stryker will assume the repairs will be made at the customer’s expense.

TO RETURN PUMPS TO FACTORY FOR REPAIR OR EXCHANGE

Merchandise returned to Stryker must be accompanied by a Return Goods Number (RG#), issued by Stryker,

authorizing goods to be returned. Contact Customer Service at:

Customer Service: 1-800-327-0770

6 101176 REV E www.stryker.com

Page 7

Introduction

INTRODUCTION

WARNING

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to the patient or operator. Modifying the product aslo voids the product warranty.

• Do not use accessories other than those specified by Stryker. Using competitor accessories may result in

unpredictable operation resulting in injury to the patient or operator or damage to the product.

CAUTION

• U.S. Federal law restricts this device to sale by or on the order of a physician.

• Do not cover the control unit with blankets, pillows or other insulating materials. Air flow is required to maintain

system performance.

Heat therapy is effective in the dilation of blood vessels, thereby increasing the blood flow to the heated area. Heat

therapy has a variety of uses, the most common being treatment of aches and pains in joints and muscles.

Cooling therapy assists in vasoconstriction, decreasing blood flow and decreasing the metabolism in the affected area.

Cooling therapy is applied in the acute phase of injury minimizing blood loss, inflammation of the tissue, and can be

effective in pain management.

The Stryker T/Pump® Localized Temperature Therapy System provides therapy by warming or cooling the enclosed

water,andcirculatingitthroughtheStrykerMul•T•Pad.ThepadisconnectedtotheStrykerT/Pumpwith

easy-to-use Clik-Tite® or quick disconnects.

TheMul•T•Pad® provides the interface for delivering the temperature therapy. The unique button design allows water

to flow and provides trouble-free operation when the pad is folded to form a customized fit. This reduces the number

of pads your facility must keep in inventory. The pads are applied to the part of the body requiring therapy, and the

circulating water maintains the pad at the setpoint temperature. The setpoint temperature (TP700 series only) can be

locked to prevent tampering.

CONNECTING THE PADS

TheMul•T•Pads® can be interconnected using Clik-Tite® connectors to provide therapy to more than one body site at

a time.

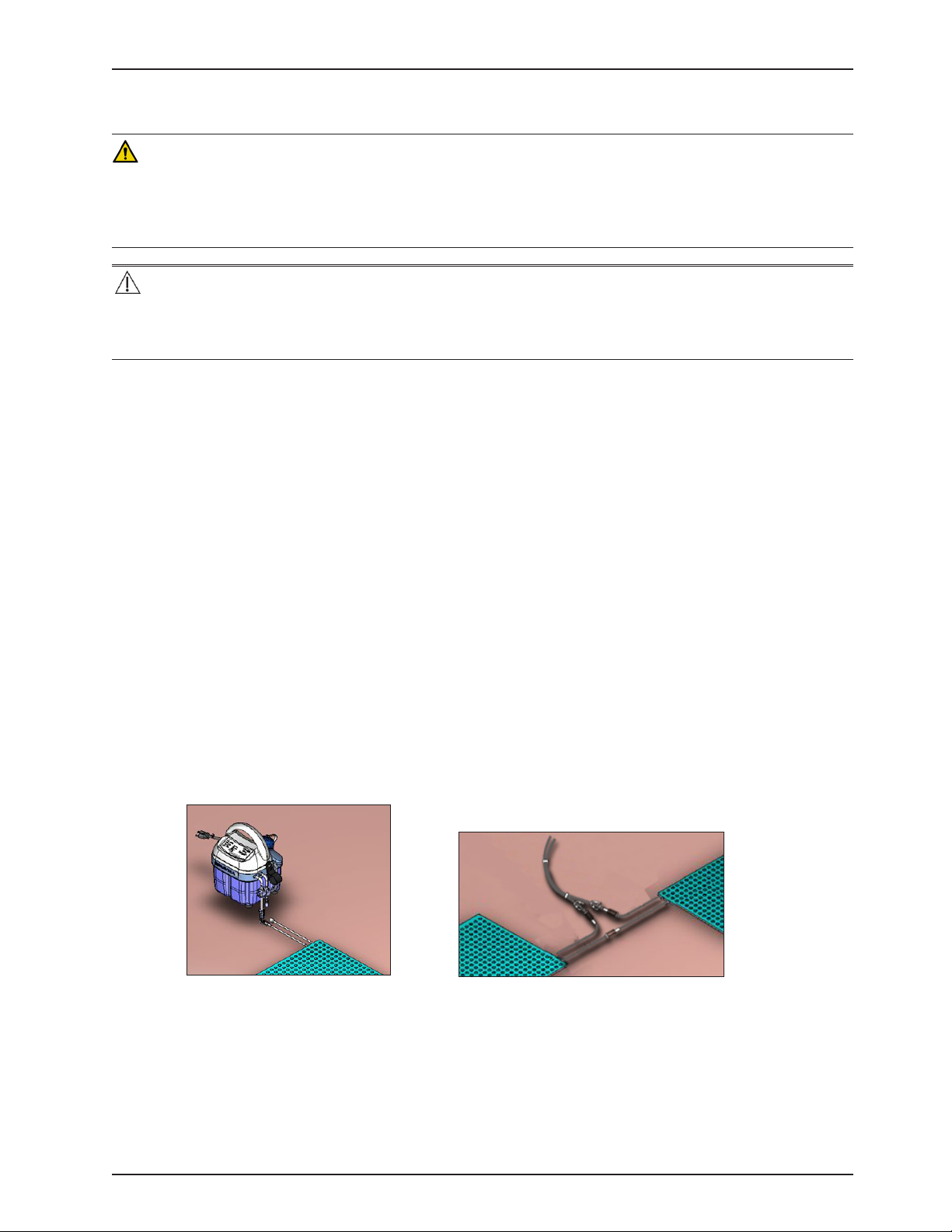

Figure 1A: Localized

Temperature Therapy System

with Single Pad with the TP650

and TP700.

www.stryker.com 101176 REV E 7

Figure 1B: Localized Temperature

Therapy System with Multiple Pads.

Page 8

Introduction

CATALOG DESCRIPTIONS

Catalog # Product Name

TP650 Classic Control Unit

TP700/TP702 Professional Control Unit

TP22B* Mul•T•Pad®: 15"w x 22"l (38cm x 56cm)

All Polymer. 10 per carton

TP22C Mul•T•Pad®: 15"w x 22"l (38cm x 56cm)

Nonwoven fabric on one side, pliable polymer on the other side. 1 per carton

TP3E* Mul•T•Pad®: 3"w x 23"l (8cm x 58cm)

Nonwoven fabric on one side, pliable polymer on the other side. 10 per carton

TP12E Mul•T•Pad®: 13"w x 18"l (33cm x 46cm)

Nonwoven fabric on one side, pliable polymer on the other side. 20 per carton

TP22E Mul•T•Pad®: 15"w x 22"l (38cm x 56cm)

Nonwoven fabric on one side, pliable polymer on the other side. 20 per carton

TP26E Mul•T•Pad®: 18"w x 26"l (46cm x 66cm)

Nonwoven fabric on one side, pliable polymer on the other side. 10 per carton

TP22G Mul•T•Pad®: 15"w x 22"l (38cm x 56cm)

Heavy Polymer, Reuseable. 10 per carton

TP650C Classic Control Unit with quick disconnects

TP700C Professional Control Unit with quick disconnects

TP612E Mul•T•Pad®: 13"w x 18"l (33cm x 46cm)

Nonwoven fabric on each side with quick disconnects. 10 per carton

TP622E Mul•T•Pad®: 15"w x 22"l (38cm x 56cm)

Nonwoven fabric on each side with quick disconnects. 10 per carton

TP626E Mul•T•Pad®: 18"w x 26"l (33cm x 46cm)

Nonwoven fabric on each side with quick disconnect. 10 per carton

*Non-CE Products

To order any of these products contact your dealer or Stryker’s Customer Service Department at:

Telephone: 1-800-327-0770

Or, visit our website at www.stryker.com

8 101176 REV E www.stryker.com

Page 9

Features

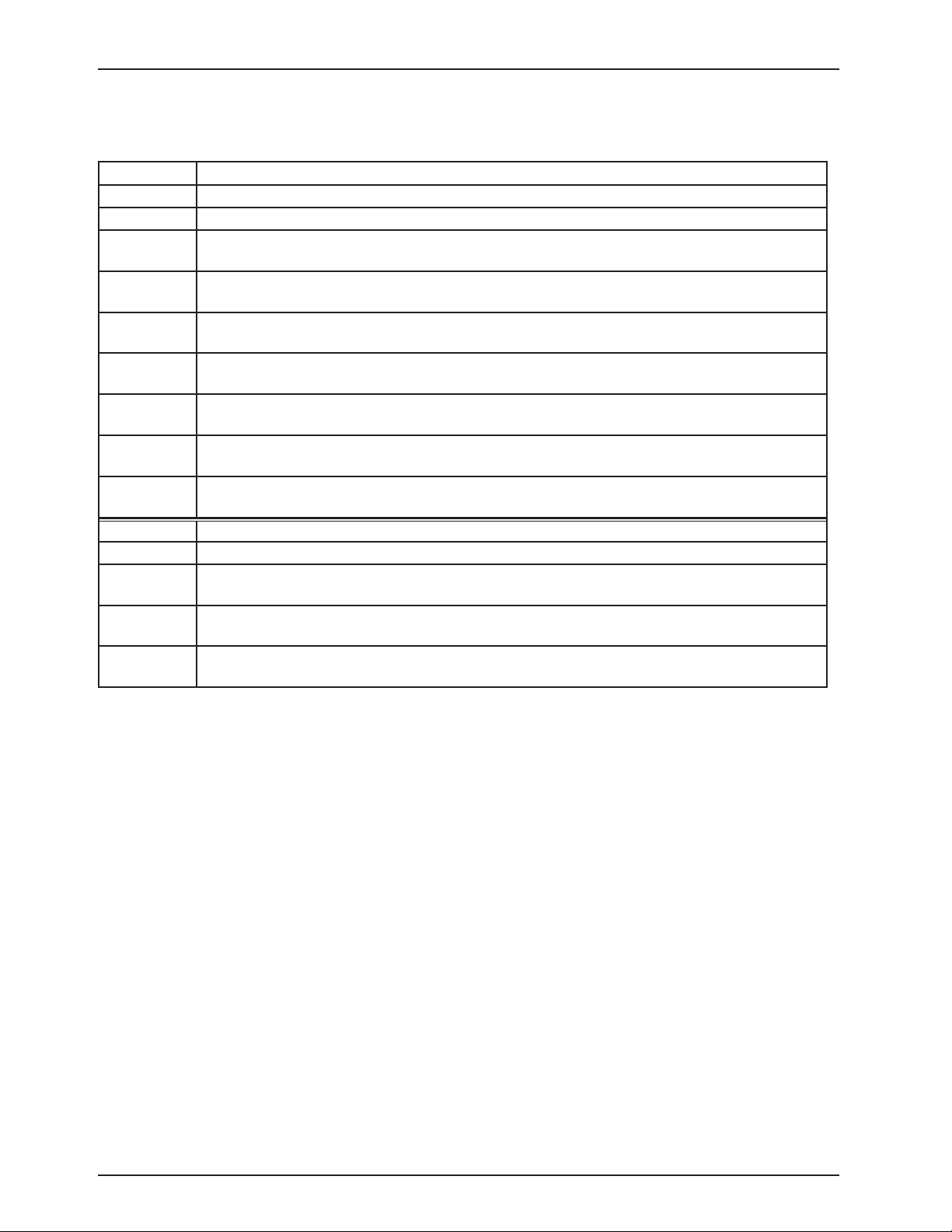

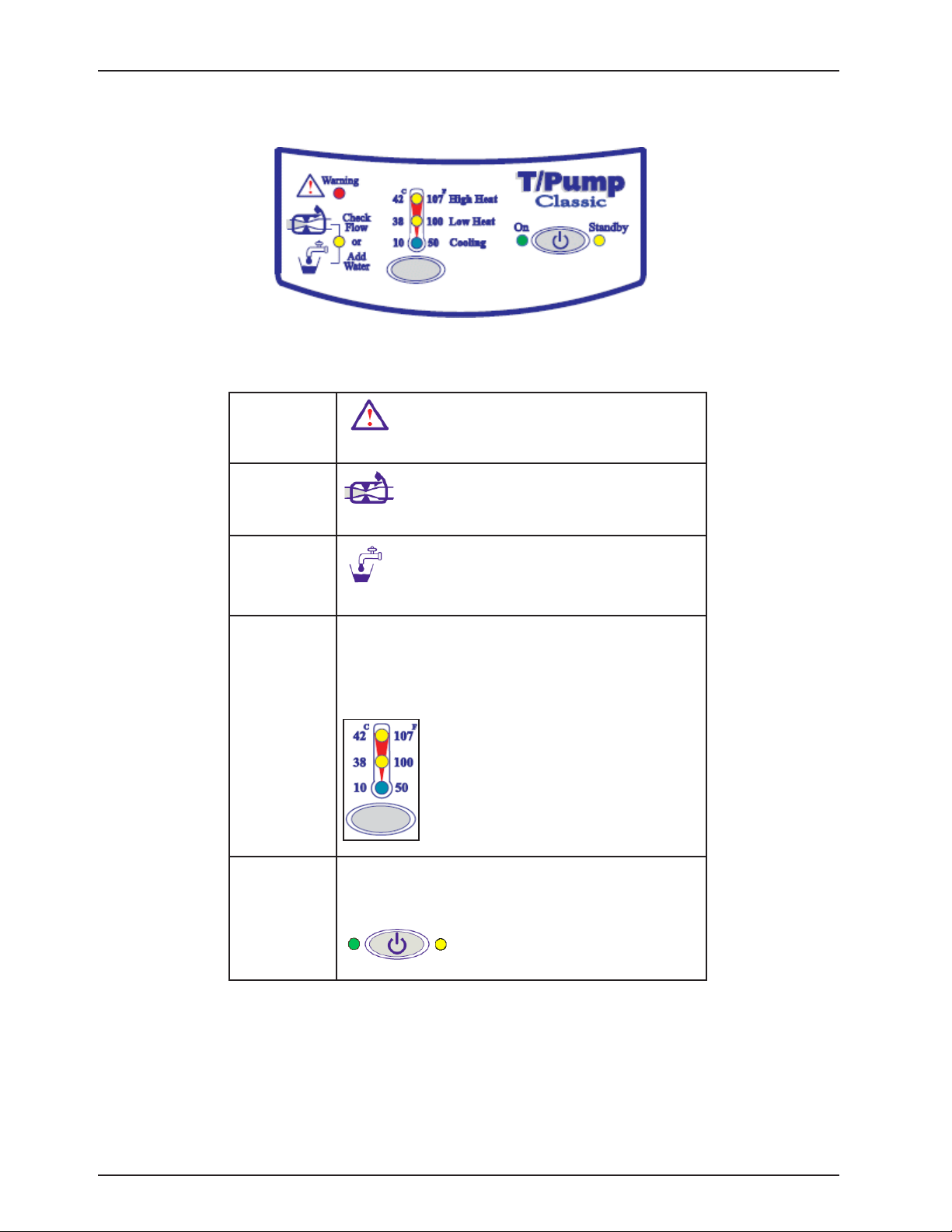

PUMP FEATURES

Easy to Use Keypad See KEYPAD FEATURES on page 10 (TP600 series) and page 11 (TP700 series).

Attached hose 10 ft (305 cm) dual hose. Connectors allow pads to be connected to the pump (Figures 1A

and 1B, page 7).

Flow indicator Indicates no flow. Turns off heater if pump is tipped.

Warm/Cool Delivery Three setpoints on the TP600 series.

Four temperature setpoints on the TP700 series.

Therapy Cycles (TP700

Choose from 20-minute, 30-minute, or Continuous cycles.

series only)

On/Standby Button Indicates power is supplied to the unit.

Over Temp Safety

Limit thermostat shuts off heater if the high temperature limit is exceeded.

Thermostat

Self Check Automatic system check at startup.

Hose/cord Management Convenient and easy storage areas for hose and cord.

Comfortable

Designed for a more comfortable grip when moving the pump.

Handle Design

Dual Micro Processor Two electronic circuits, one over temperature sensing circuit.

Tethered Easy-Open

Prevents misplacing the cap. Only 1/4 of a turn is needed to remove or secure the cap.

Cap

Handle Vents The vents in the handle allow air flow to keep the motor and heater inside the unit cool.

Easy to Use Keypad

On/Standby Button

Comfortable Handle

Handle Vents

Flow Indicator

Tethered Easy-Open Cap

Cord storage

Temperature

Setpoints for warm

or cool delivery

Therapy Time Cycles

(TP700 series only)

Hose Connections

Hose storage

Figure 2: T/Pump Features

www.stryker.com 101176 REV E 9

Page 10

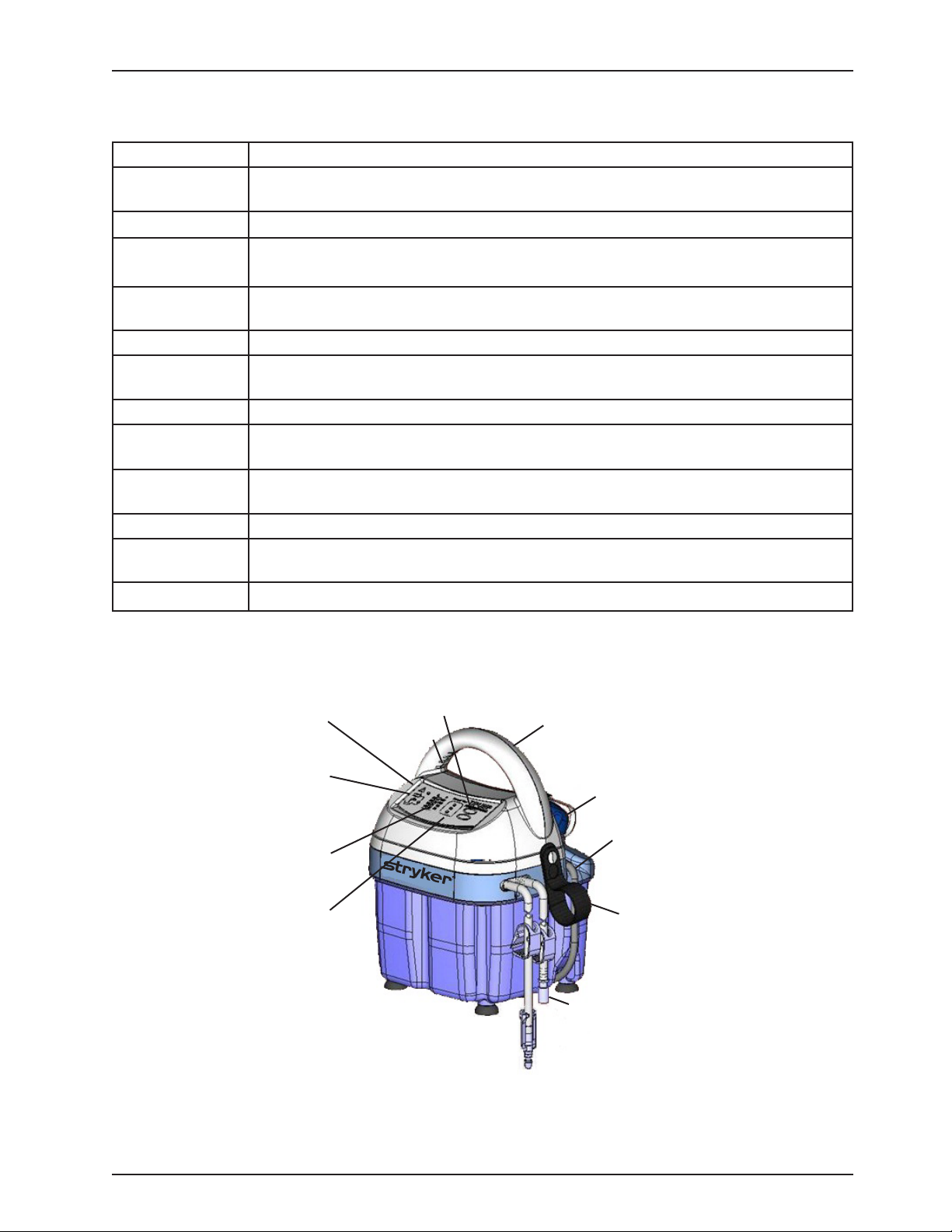

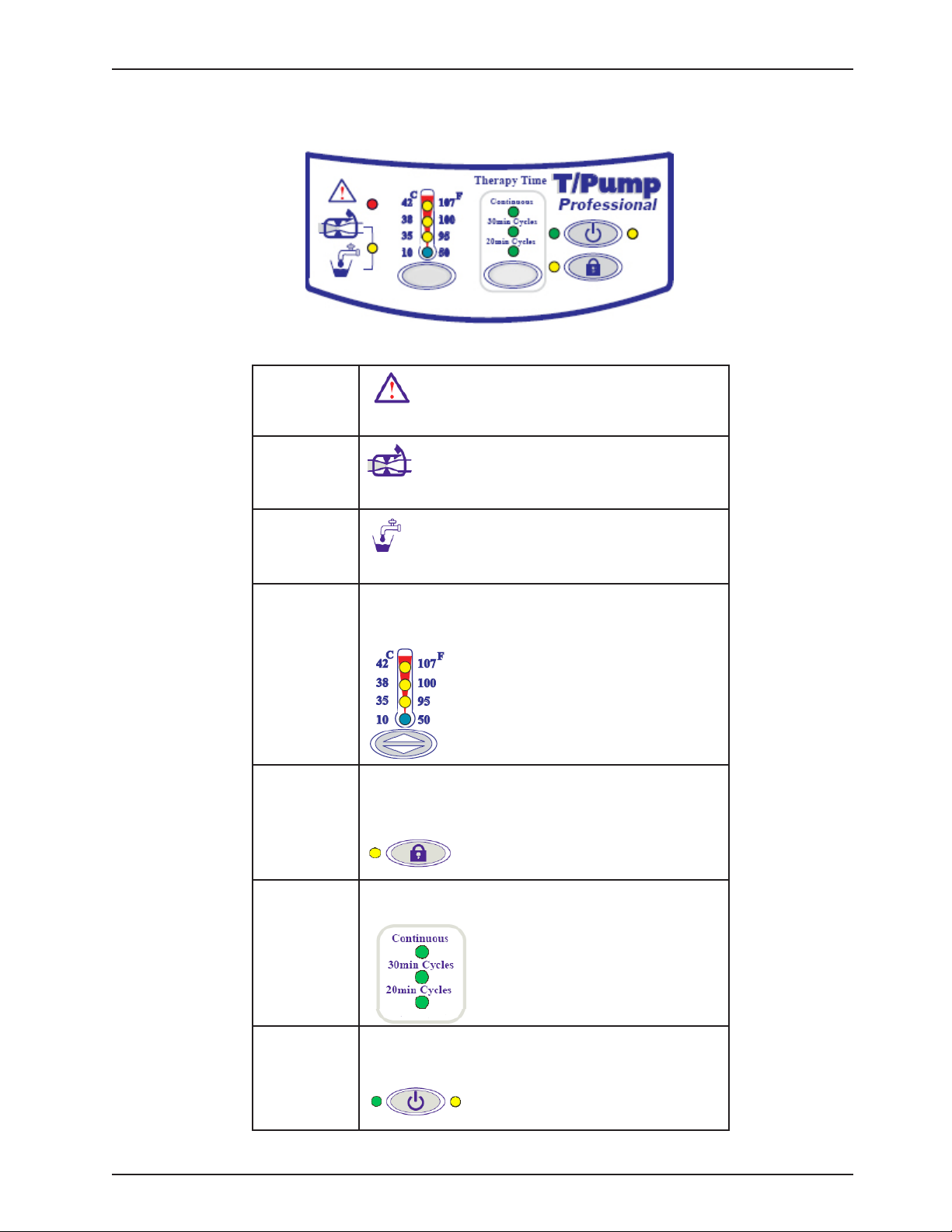

KEYPAD FEATURES TP600 SERIES

Indicator/

Warning Light

Features

Figure 3: TP600 Series Keypad

See the Troubleshooting section on page 28.

Water Flow

Check hoses and clamps for kinks or occlusions.

Water Level

Check water level.

Setpoints Press the button at the bottom of the setpoint indicator to

toggle through the three setpoints.

High Heat is 107°F (42°C).

Low Heat is 100°F (38°C).

Cooling is 50°F (10°C).

On/Standby

Button

Green indicates the unit is on.

Yellow indicates power is supplied to the unit but the unit

is not on.

10 101176 REV E www.stryker.com

Page 11

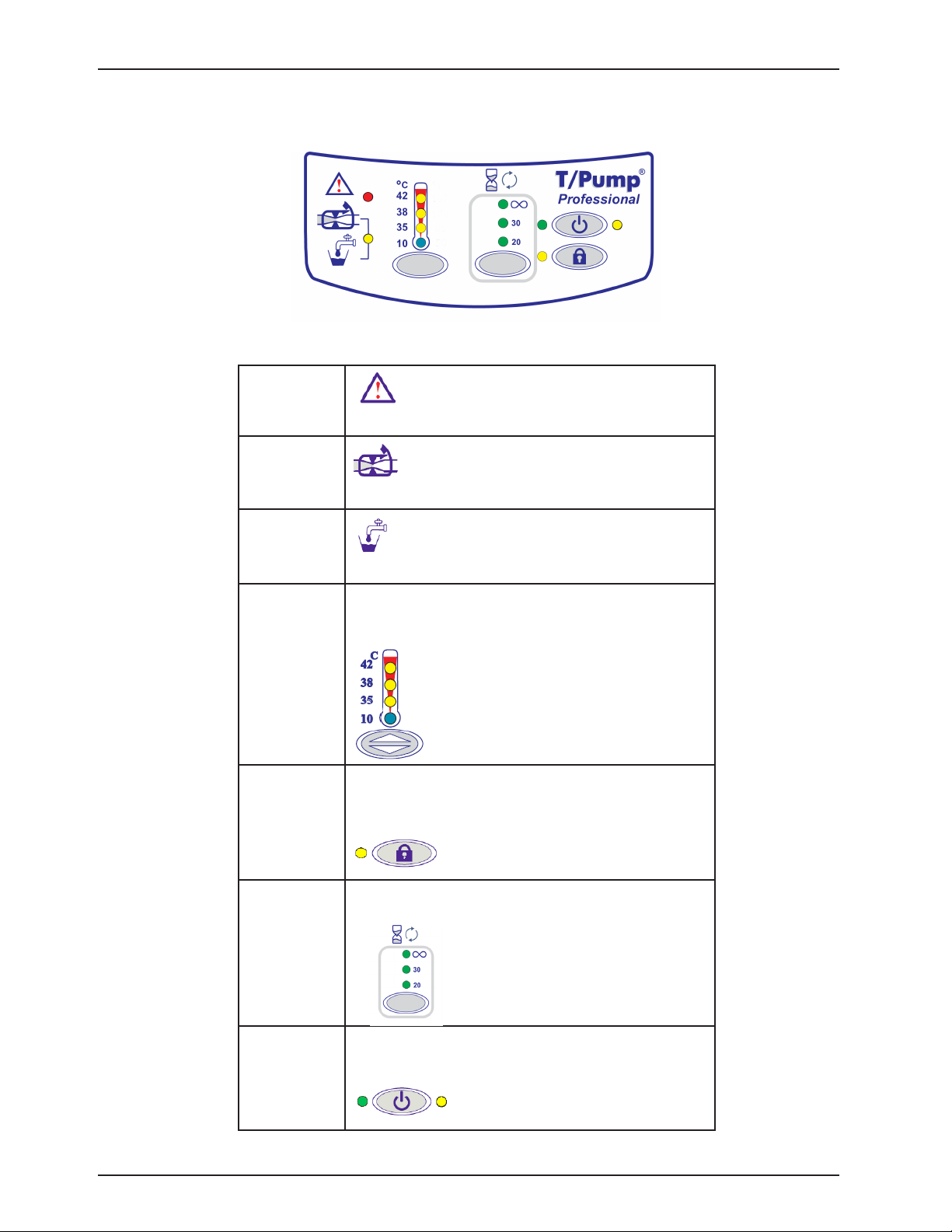

KEYPAD FEATURES TP700 SERIES

Indicator/

Warning Light

Features

Figure 4: TP700 Series Keypad

See the Troubleshooting section on page 28.

Water Flow

Check hoses or clamps for kinks or occlusions.

Water Level

Check water level.

Setpoints Press the button at the bottom of the setpoint indicator

to toggle through the four setpoints. Temperatures are

identified in °C and °F.

Setpoint Lock Prevents tampering.

Press and hold for 2 seconds to lock or unlock the

setpoint.

Therapy

Cycles

Continuous cycle, 30-minute cycle or 20-minute cycle.

On/Standby

Button

www.stryker.com 101176 REV E 11

Green indicates the unit is on.

Yellow indicates power is supplied to the unit but the unit

is not on.

Page 12

KEYPAD FEATURES TP702 SERIES

Indicator/

Warning Light

Features

Figure 5: TP702 Keypad

See the Troubleshooting section on page 28.

Water Flow

Check hoses or clamps for kinks or occlusions.

Water Level

Check water level.

Setpoints Press the button at the bottom of the setpoint indicator

to toggle through the four setpoints. Temperatures are

identified in °C.

Setpoint Lock Prevents tampering.

Press and hold for 2 seconds to lock or unlock the

setpoint.

Therapy

Cycles

Continuous cycle, 30-minute cycle or 20-minute cycle.

On/Standby

Button

12 101176 REV E www.stryker.com

Green indicates the unit is on.

Yellow indicates power is supplied to the unit but the unit

is not on.

Page 13

Specifications

120V Models 230V Models

Electrical Classification Class I equipment with Type BF applied part suitable for continuous operation. Not

classified for protection against ingress of liquid. Not classified for use in the presence

of flammable anesthetics.

Size (approx.) 11.5” x 8” x 8”

29.2cm x 20.3cm x 20.3cm

Weight 6.5 lbs (2.9 kg) when empty

9 lbs (4.0 kg) with unit filled with water to heating level

Reservoir capacity 93 oz (2.75 l) maximum

Flow rate 7 gph (26.5 lph) minimum with pad attached

Ambient operating

temperature

Environmental conditions

for transport and storage

Temperature setpoints TP650 Classic

Average temperature

accuracy

Maximum Contact

Surface Temperature

High Limit Safety

Temperature

Power cord International (harmonized) 3-wire cordset Modular

Current leakage 300 microamperes maximum 500µA Max

Ground resistance 0.5 ohm max

Electrical requirements

Voltage (VAC)

Frequency (Hz)

Current (amps)

Certifications MEDICAL ELECTRICAL EQUIPMENT WITH

60°F to 90°F (15.6°C to 32.2°C )

-20°F to 120°F (-28°C to 48°C )

At uncontrolled RH

107°F (42°C) High heat

100°F (38°C) - Low heat

50°F (10°C) - Cooling

TP700 Professional

107°F (42°C)

100°F (38°C)

95°F (35°C)

50°F (10°C)

±2°F at 107°F (±1°C at 42°C)

107°F (42°C)

110°F to 120°F

(43.3°C to 49°C)

120±10%

60

3.1 amperes

RESPECT TO ELECTRICAL SHOCK, FIRE,

AND MECHANICAL HAZARDS ONLY IN

ACCORDANCE WITH UL 60601-1, AND CAN/

CSA C22.2 NO 601.1, ASTM F 2196-2002

TP702

42ºC

38ºC

35ºC

10ºC

230+ 10%

50 Hz

1.6 A

EN 60601-1-2

IEC 60601-1

EN 60601-1

EN 60601-1-2

www.stryker.com 101176 REV E 13

Page 14

Operating Instructions

CLIK-TITE CONNECTORS

The TP600 & 700 Series T/Pump is supplied with Clik-Tite® connectors.

To connect and disconnect Clik-Tite® connectors from hose to pad:

1. Insert male fittings into female fittings with a twisting motion

(Figures 6A and 6B).

2. When fittings are fully inserted, snap locking ring into place

(Figures 6C and 6D).

3. To disconnect, reverse the procedure.

4. To open or close the hose pinch clamps:

•Open the clamp by pushing the serrated end (Figure 7B).

•Close the clamp by pressing the clamp together (Figure 7C).

Note: Refer to Figure 1B on page 7 when connecting multiple pads.

6A

6C

7B

6B

6D

7C

Figure 6: Clik-Tite® Connectors

14 101176 REV E www.stryker.com

Page 15

Operating Instructions

QUICK DISCONNECTS

To connect and disconnect quick disconnects to a pad:

1. Push the male coupling onto the female coupling. When you hear an audible click, the connectors are joined

(Figure 7A).

2. To open or close the hose pinch clamps:

•Open the clamp by pushing the serrated end (Figure 7B).

•Close the clamp by pressing the clamp together (Figure 7C).

3. To disconnect, press down on the thumb tab of the female coupling. The couplings will partially disconnect.

4. Pull the male coupling out fully to disconnect (Figure 7D).

7A

7B 7C

7D

Figure 7: Quick disconnects

www.stryker.com 101176 REV E 15

Page 16

Operating Instructions

START-UP PROCEDURE

WARNING

• Pump must be filled with water prior to operation.

• To avoid the risk of shock, unplug the unit before filling the reservoir.

1. Before filling the pump, attach a pad to the connector hose. Make sure that

there are no kinks in the hose or pad. Open the hose clamps.

2. Open the fill cap on top of the pump.

3. To fill for cooling:

a. Fill with cold water to the Cooling water line.

b. Fill with ice to the full capacity of the reservoir.

4. To fill for heating, fill with room temperature

water to the Heating water line.

5. Plug the T/Pump into a properly grounded Hospital Grade receptacle.

6. Press the On/Standby button. The light next to the selected temperature begins to flash.

7. Use the keypad to set the temperature as directed by the prescriber. For the TP700 only, after setting the

temperature, press and hold the lock Temperature Setpoint button for 2 seconds to lock the setpoint.

Note: If you toggle past the desired setpoint, keep toggling to start at the beginning of

the setpoint column. The selected water temperature will be reached in approximately

15 minutes and the light next to the selected temperature becomes steady.

8. Check the water level. If it drops below the operating level, add water.

9. ApplytheMul•T•Padtothepatientasprescribed.FollowtheMul•T•Padinstructions.

10. Position the pump at or above the level of the pad.

Note: If the pump is placed below the pads, water will drain into the pump when it is shut off. If

the pump has been overfilled or if multiple pads are connected, excess water can leak.

11. When using for cooling, the ice will eventually melt and the setpoint will start flashing. Press on/

standby button so the standby light is lit. Unplug pump from power receptacle. Open fill cap and

invert pump over sink to drain water. Refer back to step #3 and follow through procedure.

SHUTDOWN PROCEDURE

1. Press the On/Standby button so that the Standby light is lit.

2. Unplug the T/Pump.

3. Close all hose clamps.

4. Disconnect pads from pump.

Note: To prevent water spillage, always disconnect pad from pump with connectors raised above the level of the

pad and pump.

5. Coil the hose, and attach the Clik-Tite® connectors together on the hose (See Figure 6, page 14), where

applicable.

6. Secure the hose to the T/Pump using the tube set strap.

7. Wrap the power cord around the unit.

16 101176 REV E www.stryker.com

Page 17

Cleaning

STORAGE / CLEANING

Storage (Short term) Less than 1 day

1. Close the hose clamps.

2. Disconnect the pad.

3. Connect ends of the connector hoses together, where applicable.

4. Open the hose clamps.

5. Leave water in the reservoir.

6. Coil and fasten the hose using the tube set strap and wrap the power cord around the unit.

Storage (Long term)

1. Drain the pump. (See instructions below.)

2. Coil the hose, rather than folding it, to prevent hose kinks.

3. Fasten the hose using the tube set strap and wrap the power cord around the unit.

Draining

1. Disconnect the T/Pump from AC power.

2. Clamp the hose clamps.

3. Disconnect the pad or hoses from one another, keeping hoses at or above the level of the T/Pump.

4. Open the hose clamps.

5. Remove the fill cap and invert the T/Pump over a sink.

6. When all fluid has drained from the hoses and reservoir, replace the fill cap.

7. Connect the hoses together, where applicable.

www.stryker.com 101176 REV E 17

Page 18

Cleaning

INSTITUTIONAL (HOSPITAL) CLEANING INSTRUCTIONS

CAUTION

• The use of quaternary disinfectant products may cause damage to the product.

• Frequent or prolonged exposure to higher concentration disinfectant solutions may result in damage to the product.

Note: Change the water monthly or more often depending on use.

Clean the outer surfaces of the T/Pump with one of the following:

•A damp cloth and soapy water.

•Phenolic Disinfectant or 10% bleach solution.

Note: If water is contaminated or not changed for a month, please follow the internal cleaning procedure below.

1. Prepare a germicidal solution according to the manufacturer’s instructions. Stryker, product catalog MTA33.

2. Drain the pump.

3. Connect hose set together, where applicable, or attach a pad to the connector hose.

4. Fill the reservoir to the Heating water line on the back of the reservoir.

5. (TP650) Select Low Heat on the keypad.

(TP700) Select the 95°F (35°C) temperature setpoint on the keypad.

6. Start the T/Pump, and circulate the solution for one hour.

7. Drain the solution and refill the pump with clean water.

Note: In a home environment, perform only step 2 and the refill instructions in step 7.

PADS / ACCESSORIES

OnlyuseMul•T•Pads®. The unique button design allows optimal water flow and provides trouble-free operation when

the pad is folded. This reduces the number of different sizes of pads your facility must keep in inventory.

TheMul•T•PadswithClik-Tite® connectors can be interconnected to provide therapy to more than one body site at

a time (Figure 1B, page 7). Refer to Catalog Descriptions on page 8 for a list of various pads and ordering

information.

18 101176 REV E www.stryker.com

Page 19

Water Temperature Control

WATER TEMPERATURE CONTROL

There are three devices that control the operation of the heater in the Stryker T/Pump:

• The temperature is thermistor controlled (Figure 8, item 8). This temperature is selectable from the

operator’s keypad (Figure 8, item 10). To prevent unauthorized temperature setting changes, a lockout

key is available on the TP700 / TP702 “Professional” model.

• The limit thermostat (Figure 8, item 2) is mounted on the brass manifold block (figure 8, item 6).

This thermostat senses water temperature flowing to the pad and will shut off the heater if the water

temperature exceeds specific limits (120ºF). The purpose of the limit thermostat is to prevent the pump

from providing water at too high a temperature to the pad.

• The control of the selected temperature is performed by a dual thermistor (Figure 8, item 1) Dual

Processor design. The Control Processor reads its thermistor and determines if heat is required. If heat

is required it sends a signal to an Over Temperature Processor. The Over Temperature Processor reads

its thermistor, and insures the temperature is below the over temperature value, before it allows the

heater (Figure 8, item 5) to turn on.

FLUID SYSTEM

The pump is a sump configuration magnetically coupled to an impedance protected, shaded pole AC Motor (Figure 8,

item 3).

The return hose fitting (Figure 8, item 7) is machined internally to act as an orifice. This maintains a back pressure in

the pad to make it resistant to flow restrictions.

www.stryker.com 101176 REV E 19

Page 20

10

Theory of Operation

1

9

2

3

8

7

6

4

5

Item Description

1 PC Board (Temperature

Controller)

2 Manifold Backup Limit

Thermostat

3 Pump Motor

4 Tray Assembly

5 Cartridge Heater

6 Brass Manifold Block

7 Return Hose Fitting

8 Temperature Sensor

9 Housing Front Assembly

10 Ribbon to Front Keypad

Figure 8: T/Pump Components

20 101176 REV E www.stryker.com

Page 21

Functional Check

FUNCTIONAL CHECK - INTERNAL REQUIRED EQUIPMENT

WARNING

• Only qualified service personnel should perform this Functional Check. Improperly fol-

lowing the test procedure may result in equipment damage.

• Do not perform this Functional Check with an empty reservoir. Damage to the T/Pump may result.

• Read through and understand each step before performing the test.

• After any field service, the functional check must be completed to ensure operation.

To assure optimum performance, dependability and safety, the following Functional Check should be performed once

per year (or as specified in the facility's preventive maintenance program).

•TPT9 is used to measure the temperature and the flow of the water entering the pad. (To use quick

disconnects, also order adapter hose P/N 77926000)

•Stop Watch

•Mul•T•Pad

•Test Probe, T/Pump P/N:100925000

•Current Leakage meter

•Ohm Meter

Note:ToorderaTPT9,TestProbeandMul•T•Pad,contactyourdealerorStryker'sCustomerServiceDepartment.

Plug into a properly

grounded outlet.

NOTE: If the ow meter is

connected in reverse, the ow

meter will indicate no ow.

Reverse the pump connections

so that the male tting (with black

O ring) is on the supply side.

Fitting and tube

closest to front of

T/Pump

T/Pad, size "12" or

"22": Be sure pad

is at and at same

level as pump.

Male Clik-Tite

connector

(black O ring)

Figure 9a: Functional Check Setup (Clik-Tite)

T/Pad, size "12" or

"22": Be sure pad is at

and at same level as

pump.

NOTE: If the ow meter is

connected in reverse, the

ow meter will indicate no

ow. Reverse the pump hose

connections to change the

direction of ow.

TPT9:

7 gph (26.5 lph)

minimum.

Read at top

of oat.

TPT9:

7 gph (26.5 lph)

minimum.

Read at top

of oat.

Fitting and tube closest

Plug into a properly

grounded outlet.

www.stryker.com 101176 REV E 21

to front of T/Pump

Figure 9b: Functional Check Setup (quick disconnects)

Adaptor Hose

Assembly

Page 22

Functional Check

OPERATING TEMPERATURES, FLOW AND OVER-TEMPERATURE SAFETY CIRCUIT CHECK

This section provides a complete check of all T/Pump functions. Refer to Functional Check and Safety Inspection

Form to record test data. Follow the steps in this section carefully, paying particular attention to each step, and its

expected result. If at any time the expected result can not be verified, press the On/Standby button to stop the test,

then restart the procedure. If after a second attempt the expected result can not be verified, press the On/Standby

button to stop the test, then unplug the T/Pump and call your dealer or Stryker’s Technical Service Department for

assistance.

PHYSICAL CONDITION CHECK

1. Examine the plug and line cord along its entire length for physical damage, such as cuts or cracked insulation. A

damaged line cord should be replaced rather than repaired. Check the quality of the strain relief of the line cord.

2. Examine membrane panel for cuts or cracks. If damaged, replace.

3. Visually inspect pump. Check for cracked or damaged plastic parts.

Be sure unit is unplugged. Remove four (4) screws securing upper housings to tray. (reference #13 Parts Illustration - (1) screw by power cord, (1) screw by hose strap and (2) screws in front corners). Perform visual inspection

of all internal parts. Remove any accumulated dirt with a vacuum cleaner or compressed air hose.

4. Check connectors for cracks, missing O rings, or other damage. Replace connectors if necessary.

FLOW & OPERATING TEMPERATURE TEST

Note: Stay present for the full duration of the test to observe all readings and to prevent damage to the T/Pump.

Perform this test on a fully assembled unit.

1. ConnecttheT/PumptotheTPT9andMul•T•PadasshowninFigure9a,9b.Un-kinkthepadandhose.Open

the hose clamps.

2. Open the fill cap on top of the pump.

3. Fill with room temperature water to the Heating water line.

4. Plug the T/Pump into a properly grounded Hospital Grade receptacle.

The T/Pump performs its self test of the lights and audible alarm, with light pattern and short audible beep.

The T/Pump goes to Standby mode with only the Standby light on.

5. Press the On/Standby button.

6. Set the temperature to 107ºF (42ºC). For TP700 Series pumps, select Continuous Therapy Mode. Allow

temperature to stabilize. Stabilization is indicated by a steady (not flashing) light at the temperature setpoint.

7. After stabilization, allow 5 minutes before proceeding. The T/Pump controls to 107°F (42°C) at the inlet to the pad

for the duration of the test.

8. On the TPT9, take a temperature reading every 1/2 minute for 5 minutes, average the 10 readings and record the

flow reading from the TPT9. Verify the average temperature is at 107°F +/- 2°F (42ºC+/-1°C) and flow is 7 gph

(26.5 lph) minimum.

Note: If the T/Pump does not reach the temperature and flow, press the On/Standby button, unplug the unit,

check the pad and hoses for kinks and start over.

9. Press the On/Standby button and unplug the unit.

Note: If at any time the Function test needs to be stopped, press the On/Stanby button.

22 101176 REV E www.stryker.com

Page 23

Functional Check

BACKUP LIMIT THERMOSTAT TEST

This test is used to insure the temperature at the pad stays below a safe level in an over temperature condition.

Figure 10: Connection of Test Temperature Sensor

Test Procedure:

1. To perform this test you will need to separate the upper housing from the center tray assembly by removing 4

screws (reference #13 parts illustration (1) screw by power cord, (1) screw by hose strap and (2) screws in front

corners to install the Test probe, as shown in figure 10). Be sure to position test probe away from motor fan.

2. Plug the T/Pump into a properly grounded Hospital Grade receptacle.

The T/Pump performs its self test of the lights and audible alarm, with light pattern and short audible beep.

The T/Pump goes to Standby mode with only the Standby light on.

3. Press the On/Standby button. The T/Pump starts running at the default Setpoint of 100ºF (38ºC). Note: The

Control & Over Temperature processor are reading the room temperature. This makes the system “believe” it

will always require the heater due to the temperature the processors read is below the required Setpoint. This

will drive the water flowing through the system to a temperature that will “trip” the thermostat (in approximately

10 to 15 minutes). Record the peak temperature read by the thermometer. The temperature recorded must be

between 110ºF (43.3ºC) and 120ºF (49ºC). If the thermostat operates outside its intended range, it must be

replaced. After the thermostat “Trips” the system will cool down to a temperature that resets the thermostat

(in approximately 20 to 25 minutes). This “Trip”/Reset cycle will continue until the unit is put back into Standby

mode.

4. Press the On/Standby button. The T/Pump goes into Standby mode.

5. Unplug the T/Pump.

6. Unplug the Test probe, and plug the Original Temperature Sensor back in.

7. Close the unit. Reinstall screws removed in step #1 and tighten to secure.

www.stryker.com 101176 REV E 23

Page 24

Functional Check

LEAK TEST

• Immediately upon completion of the previous test, tilt unit towards you so the front is down. Hold for three (3)

minutes.

• Return the unit to upright position and carefully check the reservoir tray joint for leaks. Repeat process turning

pump on back face. If leakage is found, refer to DISASSEMBLY/REASSEMBLY, Reservoir section.

GROUND RESISTANCE CHECK

WARNING

Risk of electrical shock. Be sure unit is unplugged when performing the ground resistance test.

1. Use a ground resistance meter to measure the resistance between the ground pin on the plug and the brass

manifold block (Figure 8, item 6). Contact is available through the hole where the hoses connect to the pump.

This value should not be more than 0.5 ohm.

CURRENT LEAKAGE CHECK

It will be convenient to check current leakage at this point since the unit is full and connected to a pad.

1. Measure the maximum current leakage in all combinations of heater “ON” or “OFF” and On/Standby “ON” or

Standby. Access to chassis ground for current leakage testing is available through the hole where the hose

connects to the pump. The highest reading is typically less than 100 microamperes (200 microamperes for 230

volt model). Record the highest reading.

2. Disconnect leakage meter setup.

This completes the recommended functional test for the Stryker T/Pump. If the pump passes all the requirements of

this section and the Functional Check and Safety Inspection Form, the pump should be considered operational and

suitable for return to service.

24 101176 REV E www.stryker.com

Page 25

Functional Check

Inspection forms vary from hospital to hospital. The following sample form is intended as a guide so that the important

parameters are recorded.

T/Pump Functional Check and Safety Inspection Form

Date:_______________

Model Number:___________________ Serial Number:___________________

Item Value Okay Action

1

Inspect physical condition (line cord, plug, housing)

Inspect hose connections and connectors

2

Measure flow, >7 gph (26.5 lph)...indicate value

3

Measure operating temperature @ 107ºF +2ºF

(42ºC+1ºC)...Indicate average

4

Backup limit test 110ºF - 120ºF (43.3ºC - 49ºC)

5

Leak Test

6

Measure ground resistance, <0.5 ohm...indicate value

Needed?

(check one)

Action

Taken

7

Measure current leakage, <100µA (120 V), <200µA (230

V)

Signature:______________________________________________________________________

www.stryker.com 101176 REV E 25

Page 26

Disassembly / Reassembly

RESERVOIR

•Unplug the Unit.

•Drain the Reservoir.

•Remove the nine (9) screws which retain the Reservoir to the Tray assembly.

•Lift the Tray assembly from the Reservoir and set aside.

Note: Be careful to keep the Upper Housing with the tray. It can be lifted from the tray, but there are wires

connecting the two parts.

UPPER FRONT & REAR HOUSING

•Perform the Steps for Reservoir disassembly.

•Remove the four (4) screws from the back of the Upper Housing handle.

•Remove the Rear Housing to the Tray, or Front Housing.

PC BOARD

•Perform the steps for Reservoir and Upper Front &Rear Housing disassembly.

•Lift the Upper Front Housing from the Tray assembly.

•Remove the Keypad Ribbon cable (Figure 8, Item 10) from the PC Board (Figure 8, item 1).

•Remove the Temperature Sensor (Figure 8, Item 8) from the PC Board.

•Remove the 6 wires from the PC Board.

•Remove the 3 Screws from the PC Board.

HEATER KIT ASSEMBLY

•Perform the Steps for Reservoir and Upper Front & Rear Housing disassembly.

•Remove the two (2) screws from the Manifold backup limit thermostat (Figure 8, Item 2).

•Remove the 2 wires from the Cartridge Heater. One goes to the PC-Board, the other goes to a neutral

wiring connector.

•Remove the Temperature Sensor (Figure 8, Item 8) from the Brass Heater Manifold.

•Cut the Gray Hose connected to the Brass Heater Manifold.

•Remove the two (2) brass fittings on the bottom of the Tray assembly which hold the brass manifold block

to the tray.

•Discard the two (2) o-rings between the brass heater manifold and the tray assembly.

26 101176 REV E www.stryker.com

Page 27

Disassembly / Reassembly

HEATER ASSEMBLY

Perform the Steps for Reservoir and Upper Front & Rear Housing disassembly.

Remove the 2 wires from the Cartridge Heater. One goes to the PC-Board, the other goes to a neutral wiring connector.

Remove the (2) brass fittings on the bottom of the Tray assembly which holds the brass manifold block to the tray.

To assemble, reverse the disassembly steps. Special attention is required for the following:

1. Gray hose can be placed in warm water (<50°C) to facilitate installation on manifold fittings.

2. All o-rings must be seated. The reservoir o-ring is shaped, and shape must be aligned with the reservoir.

3. All fittings on the manifold should have teflon tape applied to prevent leaks.

4. Insure wires are cleared from between enclosures and away from enclosure screws.

5. Insure wires are routed away from the cooling fan blades.

6. For proper screw size and location for reservoir and housing, refer to parts illustration and replacement parts list.

7. Transfer the serial number to the new reservoir and cover with serial number label window.

8. When needed, the membrane ribbon must be routed as shown in Figure 11. This prevents interference between

the ribbon and moving components.

Membrane Ribbon

Front Housing

PCB Kit

Figure 11: Ribbon Cable Routing

www.stryker.com 101176 REV E 27

Page 28

Troubleshooting

Problem Possible Cause Remedy

T/Pump will NOT Turn ON. The electrical cord is NOT plugged into

a properly grounded Hospital Grade

receptacle.

Damaged cord or plug.

Defective PC Board.

Defective Membrane Panel.

T/Pump will NOT Pump. Water level is LOW or reservoir is EMPTY

Loss of POWER to motor.

Defective Motor / Defective Impeller

magnet or magnet driver assembly.

Insert the plug fully into the properly

grounded Hospital Grade receptacle.

Visually check the power cord for any

defects. If defective, replace the power

cord.

Refer to T/PUMP will NOT heat.

Replace the Membrane Panel.

Refill with room temperature water to

proper level.

Check the POWER (TP650(C)/TP700(C)

- 120V ± 10% or TP702 - 230V ± 10% )

across the motor connections. If present

check for defective motor / defective

impeller magnet or magnet driver

assembly. If there is NO power, replace

the PC Board.

Replace the motor if the fan is NOT

spinning when the unit is plugged in

and in run mode. Otherwise, check the

impeller for any obstruction or replace the

Impeller magnet assembly.

Warning indicator ON with

unit in Standby Mode.

Temperature or Therapy

Time buttons DO NOT

Work (TP700 Series Only).

Unit shut down in an OVER temperature

condition.

The buttons have been LOCKED.

Defective Membrane Panel.

If the fan is spinning and there is no

defect on the impeller magnet assembly,

check the magnet driver assembly to

see if the screw holding the driver magnet

to the motor shaft is tight.

Empty the reservoir and refill with room

temperature water.

Make sure all clamps are OPEN.

Press the On/Standby button.

Verify flow through the pad.

The Warning light will turn OFF within 5

minutes.

Press and hold the lock button for two (2)

seconds.

Replace the Membrane Panel.

28 101176 REV E www.stryker.com

Page 29

Troubleshooting

Problem Possible Cause Remedy

Flow indicator and Standby

indicator are ON with

T/Pump NOT pumping.

Flow indicator light is ON. Water flow to pad or hose is

Warning indicator &

Audible alarm (Flash /

Beep).

Unit detected a Flow warning for more

than 5 minutes, thus goes to Standby.

RESTRICTED.

Clamp is CLOSED.

Water level is low or reservoir is EMPTY.

T/Pump is filled with water that is too

HOT.

A High Heat (107°F / 42°C) or Cooling

Setpoint was selected

(50°F / 10°C).

Loss of Power while unit was in a

Therapy mode. (Possible Power Fail.)

Reference “Flow indicator light is ON”

(see below).

Correct the problem, and press the On/

Standby to put the unit back into Run

mode.

Straighten the hose.

Open the clamp.

Refill with room temperature water to

proper level.

Refill with room temperature water to

proper level.

Indication only: A Setpoint outside body

temperature range is selected.

Insert the plug fully into the receptacle,

place the unit into Standby mode, then

unplug the

T/Pump. If Power is removed while unit

is in On-Mode, the Power Fail alarm will

beep for approximately 10 minutes.

Both the Temperature and

Therapy Cycle Setpoint

lights are BLINKING

(TP700 Series Only).

Temperature Setpoint light

BLINKING.

Indication only to indicate an “ON”

Unit is running after a 20- or 30- minute

“OFF" Therapy Cycle period, has reached

the desired Setpoint, and is now timing

the 20- or 30- minute ON cycle period

(TP700 Series only).

The unit just went into, or came out of

Lock mode (TP700 Series only).

Unit is in “OFF” Therapy Cycle time. Indication only.

Unit is warming up to the selected

Setpoint.

Unit is in Cooling mode, for longer than

40 minutes.

Therapy Cycle period is timing.

Indication only.

Indication only.

Follow the "shutdown" procedure. Drain

the water in reservoir to ice fill level,

and refill with ice. Follow the "start-up"

procedure.

www.stryker.com 101176 REV E 29

Page 30

Troubleshooting

Problem Possible Cause Remedy

T/Pump will NOT Heat. Reservoir is EMPTY.

Flow is BLOCKED.

Therapy Cycle is OFF.

Heater is NOT receiving Power, or is

defective.

Refill with room temperature water to

proper level.

Reference “Flow indicator light is ON”

above.

Wait for Therapy Cycle ON.

Check if the Set Point is set too low.

Remove cover and check Power

(TP650(C)/TP700(C) - 120V ± 10% or

TP702 - 230V ± 10% ) to the heater at

J2 on the PCB (See Figure 12). NOTE:

Power to J2 cycles ON and OFF.

If Power is present and thermostat is

CLOSED, heater is probably defective.

Cold heater resistance is approximately

49 ohms (120V) or 180 ohms (230V).

Replace heater if required.

If Power is present and thermostat is

OPEN, thermostat is probably defective.

Replace thermostat if it does not pass

Backup Limit Thermostat Test from

Functional check.

T/Pump will NOT Cool. Reservoir is EMPTY.

Flow is BLOCKED.

Ice is DEPLETED.

Water LEAKS from hose

connectors.

Damaged O-ring.

Locking ring on Clik–Tite® connector is

NOT snapped into place (See Figure 6)

Quick disconnect NOT seated properly.

If there is NO Power to the heater,

replace the PC Board.

Refill with room temperature water to

proper level.

Reference “Flow indicator light is ON”

section (see PG. 27).

Drain excess water to Cooling water

line and fill remainder of reservoir with

ice.

Replace Clik–Tite® connector.

Male: P/N: 03887001

Female P./N: 03884001

Snap Clik–Tite® connector SHUT.

Secure pad connection to pump (See

quick disconnects). Replace connectors

or pad if defective.

30 101176 REV E www.stryker.com

Page 31

Troubleshooting

Figure 12: Wiring Diagram

www.stryker.com 101176 REV E 31

Page 32

Parts Illustration

1K

19

2K

6K

3K

4K

5K

Figure 13: Parts Illustration for Kits

32 101176 REV E www.stryker.com

Page 33

53

12

39

33

37

15

40

Parts Illustration

21

44

43

25

14

52

3

41

16

49

38

51

26

12

17

2

8

28

5

6

11

28

36

12

13

9

29

16

1

7

7

1

10

31

50

27

32

30

20

18

Figure 14: Parts Illustration Continued

www.stryker.com 101176 REV E 33

Page 34

Replacement Parts List

Item PN Qty Description

1K

2K

3K

4K

5K

6K 100820000 1 KIT: Reservoir Assembly. Includes Reservoir, Gasket, Rubber Feet, Label.

10 81002048 1 Tubing, PVC,Panacea 1/4 ID x 3/8 OD x 6" LG

11 90018029 1 Screw, Machine 4-40 x 1/2" FH Phillips

12 90018075 9 Screw Mach PH CR 8-32 UNC 2A x 3/8 LG S

13 90018082 4 Screw, Machine Pan HD #8-32 x 1 SST

14 90049005 2 LockWasher, Spring #6 SST

15 90076018 1 Bushing, Straight Thru (HEYCO #1210)

16 90295019 2 O-Ring

17 90295020 1 O-Ring, Silicone

18 90385000 4 Cup, Suction

19 90514002 3 Screw Type "BT" Thread Cutting Pan HD SST. #4 x 5/16" LG

20 90514013 4 Screw Type "BT" Thread Cutting Pan HD SST. #6 x 7/8" LG

21 90514020 4 Screw Type "BT" Thread Cutting #8 x 3/4" LG

22 90603000 1 Label Ground Identification

23 91275059 1 Screw, Mach, Flat C'Sunk HD, CR SST 6-32 x 3/8 LG

24 91390000 1 Toroid, Ferrite Ring

25 91454052 2 Screw, Mach, Fillister Head #6-32 x 1/4 LG SST

26 100092000 2 Connector Lever Nut 3 Terminal

27 100127000 1 Reservoir

100822002 1 KIT: Upper front & Rear Housing. Includes both Front & Rear plastic housing, Label, Membrane Panel

100822001 1 KIT: Upper front & Rear Housing. Includes both Front & Rear plastic housing, Label, Membrane Panel

100822000 1 KIT: Upper front & Rear Housing. Includes both Front & Rear plastic housing, Label, Membrane Panel ( TP702 ).

100898000 1 KIT: PC Board/Sensor Assembly - This assembly comes with a pre-calibrated sensor and PCB assembly. They

100898001 1 KIT: PC Board/Sensor Assembly - This assembly comes with a pre-calibrated sensor and PCB assembly. They

100819000 1 KIT: Upper Rear Housing Assembly. Includes Rear Plastic Housing with Label ( TP650(c) ).

100819001 1 KIT: Upper Rear Housing Assembly. Includes Rear Plastic Housing with Label ( TP700(c), TP702 )

100818000 1 KIT: Upper Front Housing Assembly. Includes Front Plastic Housing with Membrane Panel ( TP650(c) ).

100818001 1 KIT: Upper Front Housing Assembly. Includes Front Plastic Housing with Membrane Panel ( TP700(c) ).

100818002 1 KIT: Upper Front Housing Assembly. Includes Front Plastic Housing with Membrane Panel ( TP702 ).

100821001 1 KIT: Heater Assembly. Includes Brass Manifold, 2 O-Rings, 4 Fittings. ( TP650(c), TP700(c) ).

100821000 1 KIT: Heater Assembly. Includes Brass Manifold, 2 O-Rings, 4 Fittings ( TP702 ).

1 03394000 1 Fitting, Manifold

2 03791001 2 Strap Assembly - Hose

3 04152000 1 Fan

5 08086000 1 Hose Assembly - Clik Tites

6 08648000 6 Hose Assembly - quick disconnects (colder)

7 Source

Locally

8 Source

Locally

9 81002028 1 Tubing, PVC, Panacea 1/4 ID x 3/8 OD x 3 1/2" LG

(TP650(c)).

(TP700(c)).

are a "Matched" set. Do not use the old sensor with the new PC Board or the old PC Board with the new sensor

( TP650(c), TP700(c)).

are a "Matched" set. Do not use the old sensor with the new PC Board or the old PC Board with the new sensor

( TP702 ).

3 Tape, Teflon, 1/4" Wide

5 Ty-Wrap, Self Locking

34 101176 REV E www.stryker.com

Page 35

Replacement Parts List

28 100129000 1 Tray Assembly (TP650(c), TP700(c) )

100129001 1 Tray Assembly ( TP702 )

29 101157000 1 Impeller/Magnet Assembly

30 100132000 1 Impeller Housing Bottom

31 100133000 1 Impeller Housing Top

32 100134000 1 Pin, Impeller

33 100139000 1 Housing, Front Assembly

36 100152000 1 O-Ring, Reservoir

37 100261000 1 Motor/Plate Assembly (TP650(c), TP700(c) )

100261001 1 Motor/Plate Assembly (TP702 )

38 100267000 1 Cord, Power Assy (TP650(c),TP700(c) )

39,40 100269001 1 Membrane Panel - Professional (TP700(c) )

100269002 1 Membrane Panel - Classic (TP650(c) )

100269003 1 Membrane Panel - CE ( TP702 )

41 100275000 1 Cap, Tethered, Rivet Assembly

42 101158000 1 Magnet Driver Assembly (Not Shown)

43 100288000 1 Label, Instruction Classic (TP650 )

44 100288001 1 Label, Instruction Professional (TP700 )

45-48 100289000 1 Label, Ratings Classic (TP650 )

100289001 1 Label, Ratings Professional (TP700 )

100289002 1 Label, Ratings Classic W/quick disconnects (TP650c )

100289003 1 Label, Ratings Professional W/quick disconnects (TP700c )

100289004 1 Label, Ratings CE Professional (TP702 )

49 100292000 1 Clip, Cord

50 100378000 1 Cap (for Impeller Pin)

51 100578000 1 Label, Danger

52 100256002 1 Heater Assembly 230 VAC (TP702)

100256001 1 Heater Assembly 120 VAC

53

PC001 1 Power Cord (Continental Europe) - (TP702)

PC002 1 Power Cord (United Kingdom) - (TP702)

PC003 1 Power Cord (Australia) - (TP702)

www.stryker.com 101176 REV E 35

Page 36

Warranty

WARRANTIES

Stryker equipment and products are warranted against defects in material and workmanship under normal use, and

operation from the date of purchase, for the time periods listed below for the respective equipment and products.

Except for such warranty, Stryker disclaims all other expressed and/or implied warranties including, but not limited to,

the implied warranties of merchantability and of fitness for a particular purpose.

PUMP

All labor performed and parts provided free of charge for a period of one (1) full year from the date of purchase,

provided the equipment is returned with prior authorization prepaid to Stryker. The expected service life for this

product is two (2) years.

PAD, SINGLE PATIENT USE

Free replacement of product where defects in materials and/or workmanship are evident at time of delivery, provided

the product is returned with prior authorization prepaid to Stryker.

PAD, REUSABLE

Free replacement of product where defects in materials and/or workmanship occur within 90 days from date of

delivery, provided the product is returned with prior authorization prepaid to Stryker.

PARTS

Defective parts will be exchanged free of charge where defects in materials and/or workmanship occur within 90 days

from date of delivery, provided the parts are returned with prior authorization prepaid to Stryker.

36 101176 REV E www.stryker.com

Page 37

Page 38

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

USA

2014/ 06 101176 Rev E www.stryker.com

Loading...

Loading...