Page 1

MAINTENANCE MANUAL

The GO BED

TM

ELECTRIC ACUTE CARE BED

Product Number: FL17E

Product Number for the United States: 2500

TECHNICAL ASSISTANCE AND PARTS

1 800 428-5025 (Service in English in Canada)

1 800 361-2040 (Service in French in Canada)

1 800 327-0770 (In United States)

E-mail (Canada): service@bertec.strykercorp.com

Manufactured by Stryker Bertec Medical Inc 72-0173 R1.0

Printed in Canada

December 2000

Page 2

Page 3

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................................5

1.1 BED SPECIFICATIONS ..................................................................................................................5

1.2 TECHNICAL SUPPORT..................................................................................................................5

1.3 SAFETY...........................................................................................................................................6

Warning / Caution / Note Definition ................................................................................................6

Safety Tips and Guidelines.............................................................................................................6

Static Discharge Precautions..........................................................................................................8

1.4 WARRANTY....................................................................................................................................8

Limited Warranty.............................................................................................................................8

To Obtain Service and/or Parts ......................................................................................................8

To Require Service ......................................................................................................................8

To Order Parts..............................................................................................................................9

Return Authorization.....................................................................................................................10

Damaged Merchandise.................................................................................................................10

1.5 SET-UP PROCEDURE ..................................................................................................................10

Checklist .......................................................................................................................................10

1.6 BED ILLUSTRATION.....................................................................................................................12

2. PREVENTIVE MAINTENANCE..............................................................................................................13

2.1 BED CLEANING AND MATTRESS CARE....................................................................................13

Cleaning Beds...............................................................................................................................13

Bed Mattress Care........................................................................................................................13

2.2 LUBRICATION...............................................................................................................................14

Annual Checklist...........................................................................................................................14

Two Years Time Interval Checklist...............................................................................................14

Five Years Time Interval Checklist...............................................................................................14

Lubrication Points Illustrated.........................................................................................................15

2.3 PREVENTIVE MAINTENANCE PROGRAM.................................................................................16

Checklist .......................................................................................................................................16

PC Board Maintenance Program..................................................................................................17

Recommended Spare Parts .........................................................................................................18

3. TROUBLESHOOTING............................................................................................................................19

3.1 TROUBLESHOOTING GUIDE ......................................................................................................19

4. MAINTENANCE PROCEDURES...........................................................................................................24

4.1 SIDE-RAIL ASSEMBLY REPLACEMENT.....................................................................................24

Foot Side-Rail Assembly Replacement........................................................................................24

Head Side-Rail Assembly Replacement.......................................................................................25

4.2 SIDE-RAIL REPLACEMENT (RAIL ONLY)...................................................................................27

Foot Side-Rail Replacement (Rail Only).......................................................................................27

Head Side-Rail Replacement (Rail Only) .....................................................................................27

4.3 MEMBRANE REPLACEMENT (FOOT BOARD CONTROL PANEL)...........................................28

4.4 MEMBRANE REPLACEMENT ( SIDE-RAIL CONTROL).............................................................29

4.5 NURSE CALL SYSTEM COMPONENT REPLACEMENT............................................................30

4.6 FOOT BOARD CONNECTOR REPLACEMENT...........................................................................32

4.7 FOOT END CASE CONNECTOR REPLACEMENT.....................................................................33

4.8 PC BOARD REPLACEMENT........................................................................................................34

4.9 ON/OFF SWITCH REPLACEMENT..............................................................................................35

Page 4

4.10 BED POWER CORD REPLACEMENT.........................................................................................35

4.11 NIGHT LIGHT SYSTEM COMPONENT REPLACEMENT............................................................36

4.12 120V AUXILIARY OUTLET COMPONENT REPLACEMENT.......................................................38

4.13 MATTRESS SUPPORT SECTION REPLACEMENT....................................................................39

Foot Section Replacement ...........................................................................................................39

Thigh Section Replacement..........................................................................................................40

Center Section Replacement........................................................................................................41

Head Section Replacement..........................................................................................................42

Bed without Optional CPR .........................................................................................................42

Bed with Optional CPR ..............................................................................................................43

4.14 ACTUATOR REPLACEMENT.......................................................................................................45

Knee Gatch Actuator Replacement..............................................................................................46

Head Actuator Replacement.........................................................................................................47

Hi-Lo Actuator Replacement.........................................................................................................48

4.15 ACTUATOR SCREW LUBRICATION PROCEDURE ...................................................................49

Head and Knee Gatch Actuator Screws.......................................................................................49

Head Actuator Screw Guide.........................................................................................................49

Hi-Lo Actuator Screws..................................................................................................................50

4.16 CPR MECHANISM SPRINGS AND/OR DAMPER REPLACEMENT...........................................51

4.17 CPR MICRO SWITCH REPLACEMENT.......................................................................................52

Micro Switch Located Under the Head Section............................................................................52

Micro Switch Located Under the Mattress Support......................................................................53

4.18 AUTO CONTOUR MICRO SWITCH REPLACEMENT.................................................................54

Knee Gatch Micro Switch .............................................................................................................54

Head Section Micro Switch...........................................................................................................54

4.19 BRAKE /STEER PEDAL REPLACEMENT....................................................................................55

4.20 5TH WHEEL MECHANISM COMPONENT REPLACEMENT.......................................................56

5th Wheel Replacement ...............................................................................................................56

5th Wheel Activation Lever Replacement.....................................................................................56

5th Wheel Swing Arm Assembly Replacement............................................................................57

4.21 CASTER REPLACEMENT ............................................................................................................59

4.22 HI-LO LEVER REPLACEMENT ....................................................................................................61

APPENDIX A: CONNECTION DIAGRAM .................................................................................................63

APPENDIX B: BED POSITIONS FOR MAINTENANCE PURPOSE.........................................................64

E

NNOOTTE

Stryker Bertec gives special attention to the quality of the information found in this document. Any

comments on its content will be most welcomed. Please forward your remarks to our Technical Service

department (see section 1.2).

Page 5

Introduction Chapter 1

1. INTRODUCTION

This maintenance manual is designed to assist you with the servicing of the GO BED. Before

servicing the bed, it is important to read and understand all information in this manual. Qualified

maintenance personnel should be able to refer to this manual at all time when servicing the bed.

An operations manual, included in the Customer's Guide, is also available to assist you with the

operation of the bed.

This maintenance manual is an integral part of the unit and should be turned over to the new

user should the bed be sold or transferred.

1.1 BED SPECIFICATIONS *

Maximum Weight Capacity 500 lb including 100 lb of boards and

accessories

227 kg including 45.5 kg of boards and

accessories

Overall Bed Length/Width - Steel Side-rails

Overall Bed Length/Width - Plastic side-rails

93" x 41 9/16" (steel side-rails up)

93" x 38 3/8" (steel side-rails down)

236.2 cm x 105.5 cm (steel side-rails up)

236.2 cm x 97.5 cm (steel side-rails down)

93" x 42 9/16" (plastic side-rails up)

93" x 38 3/4" (plastic side-rails down)

236.2 cm x 108.1 cm (plastic side-rails up)

236.2 x 98.4 cm (plastic side-rails down)

Overall Weight (w/o boards and accessories) 385 lb - 175 kg

Patient Sleeping Surface 35" x 80" extendable to 82" and 84"

89 cm x 203 cm extendable to 208 cm and

213 cm

Minimum/Maximum Bed Height 14" to 29" - 35.5 cm to 74.7 cm

Sound Level

< 58 dBa

Fowler Angle 0° to 65°

Knee Gatch w/o Contour Positioning

Knee Gatch w/Contour Positioning

0° to 32°

0° to 24°

Trendelenburg/Reverse Trendelenburg -14° to +14°

Electrical Requirements - All electrical

requirements meet the CSA standard C22.2 No

125 and UL 544 specifications for Class 2G

100 VAC, 50-60 Hz, 7.5 A

120 VAC, 50-60 Hz, 9.8 A w/o outlet

120 VAC, 50-60 Hz, 14.8 A w/outlet

200 VAC, 50-60 Hz, 3.2 A

220 VAC, 50-60 Hz, 2.9 A

240 VAC, 50-60 Hz, 2.7 A

* Stryker Bertec Medical affords special attention to product improvement and reserve the right to change

specifications without notice.

1.2 TECHNICAL SUPPORT

For questions regarding this product, contact one the following Technical Service department or

your local representative:

In Canada: In the United States:

Stryker Bertec Medical Inc Stryker Medical

Service in English: 1 800 428-5025 1 800 327-0770

Service in French: 1 800 361-2040 6300, Sprinkle Road

E-mail (Canada): service@bertec.strykercorp.com Kalamazoo, MI 49001-9799

70, 5th Avenue, P.O. Box 128 USA

L’Islet (Québec), G0R 2C0, Canada

5

Page 6

Chapter 1 The GO BED Maintenance Manual

WWAARRNNIINNGG

WWAARRNNIINNGG

CCAAUUTTIIOON

N

1.3 SAFETY

Warning / Caution / Note Definition

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully

reviewed.

The personal safety of the patient or user may be involved. Disregarding this information could

result in injury to the patient or user.

These instructions point out special procedures or precautions that must be followed to avoid

damaging the equipment.

E

NNOOTTE

Notes provides special information to make maintenance easier or important instruction clearer.

Safety Tips and Guidelines

The following is a list of safety precautions that must be observed when operating or servicing

the GO BED. They are repeated throuhout the guide, where applicable. Carefully read and

strictly follow them before operating or servicing this unit.

• The GO BED is not intended for pediatric use.

• It is important that all users have been trained and educated on the inherent hazards

associated with the use of manual and electric beds. Bed mechanisms can cause serious

injury to the patient or user. Operate bed only when all people are clear of the mechanisms.

• This bed is equipped with a hospital grade plug for protection against shock hazard. It must

be plugged directly into a properly grounded receptacle. Grounding reliability can be

achieved only when a hospital grade receptacle is used.

• Possible fire hazard exists when this bed is used with oxygen administering equipment other

than nasal, mask type or half bed-length tent type. It is recommended to disconnect the bed

in such circumstances. When using a half bed-length tent type, ensure the side-rails are

outside the oxygen tent and oxygen tent should not extend below the mattress support level.

• Always keep the caster brakes applied when a patient is on the bed (except during

transport). Serious injury could result if the bed moves while a patient is getting in or out of

bed. After the brake pedal is applied, push on the bed to ensure the wheels are locked.

• To help reduce the number and severity of falls by patients, always leave the bed in the

lowest position and side-rails fully up when the patient is unattended. After raising a siderail, pull firmly on the side-rail to ensure it is securely locked into position.

• Always keep side-rails in the fully raised position and the sleeping surface horizontal in its

lowest position when the patient is sleeping unless the patient's medical conditions dictates

otherwise. If the sleeping surface is not in a horizontal position and the bed is equipped with

half-length side-rails, it is strongly recommended that only the head side-rails be kept in

their highest position and the foot side-rails be stored on the side of the bed to avoid the

risks of a patient becoming caught between the two side-rail sections.

6

Page 7

Introduction Chapter 1

CCAAUUTTIIOON

N

• Side-rails, with or without their padded covers or nets, are not intended to serve as restraint

devices to keep patient from exiting the bed. Side-rails are designed to keep a patient from

inadvertently rolling off the bed. It is the responsibility of the attending medical personnel to

determine the degree of restraint necessary to ensure a patient will remain safely in bed.

Failure to utilize the side-rails properly could result in serious patient injury.

• When a patient's condition requires greater safety measures for his security, use the lockout

switches in the foot board control panel to deactivate the side-rail or pendant control

commands and install protective pads on the side-rails.

• When the sleeping surface sections are articulated, ensure that all spaces created by the

raised side-rails are clear in order to avoid the patient's limb becoming trapped between

side-rails or between side-rails and boards.

• When moving the bed with a patient in it, ensure that the bed is in the lowest position with

side-rails fully raised and securely locked in order to reduce risks of injuries to the patient.

• Do not attempt to move the bed directly sideways with the 5th wheel activated. The 5th

wheel can not pivot. Attempting to do so may cause injury to the patient or user.

• The instant CPR release is for emergency use only. When activating the CPR release, all

people and equipment must be removed from the area below and around the head and foot

sections of the bed or serious personal injury or damage to equipment could occur.

• When large fluid spills occur in the area of the circuit board, cables and motors, immediately

unplug the bed. Remove the patient from the bed and clean up the fluid. Have maintenance

completely check the bed. Fluids can have an adverse effect on operational capabilities of

any electrical product. DO NOT put the bed back into service until it is completely dried and

has been thoroughly tested for safe operation.

• Do not steam clean, hose off or ultrasonically clean the bed. Do not immerse any part of the

bed. The internal electrical parts may be damaged by exposure to water. Hand wash

regularly all surfaces of the bed with warm water and a mild detergent. Wipe cleaned

surfaces dry to avoid build up of cleaning substance. Inspect the mattress after each use.

Discontinue use if any cracks or rips are found in the mattress cover which may allow fluid to

enter the mattress. Failure to properly clean the mattress, or dispose of it if defective, may

increase the risk of exposure to pathogenic substances and may cause injury to the patient

or user.

• Always unplug the bed power cord from the wall outlet when cleaning or servicing the bed.

When working under the bed with the bed in the high position, always place blocks under

the frame and lock the casters to prevent injury in case the Bed Down switch is accidentally

pressed.

• When using the emergency crank during a power failure, unplug the power cord from the

wall receptacle so that unexpected resumption of power will not rotate handle. Remove and

store the crank before reconnecting the bed.

• Ensure that any bed malfunction is promptly reported to service personnel for immediate

attention. Preventive maintenance should be performed periodically to ensure all bed

features are functioning properly.

• Never move the bed using the raised side-rails nor hit the side-rails against any object found

in the room, for example: other furniture, walls, door frame, etc. Damage to the equipment

could result from such actions. Use the push/pull handles integrated on the head and foot

boards to move the bed, they provide a solid grip when moving the bed.

7

Page 8

Chapter 1 The GO BED Maintenance Manual

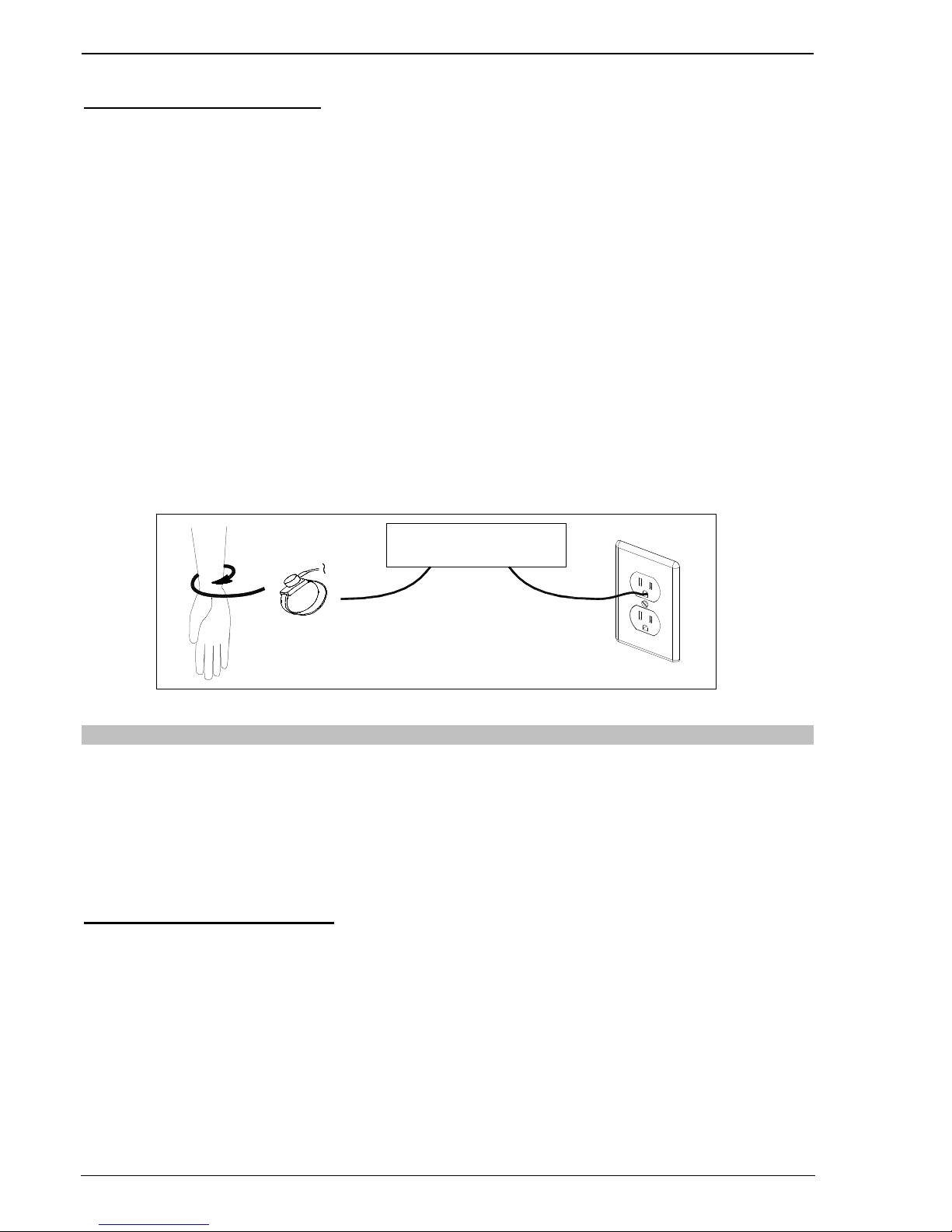

Static Discharge Precautions

The electronic circuits of the bed are protected from static electricity damage only while the bed

is assembled. It is extremely important that all service personnel always use adequate static

protection when servicing the electronic components of the bed.

Static Protection Equipment

The necessary equipment for a proper static protection is:

• 1 static wrist strap

• 1 grounding plug

• 1 test lead with a banana plug on one end and a alligator clip on the other.

Static Protection Procedure

1. Unplug the bed power cord from the wall receptacle.

2. Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the

banana plug of the test lead into the receptacle on the grounding plug. Connect the alligator

clip on the other end of the test lead to a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the clip at the other end of the

wrist strap cord to a ground point on the bed.

BED

GROUNDING DIAGRAM

1.4 WARRANTY

Limited Warranty

All Stryker Bertec products are guaranteed against material or manufacturing defects, improper

operation of mechanisms, and premature wear of bed components under normal use

conditions.

For questions regarding warranty, please contact Stryker Bertec Technical Service department

(see section 1.2) or your local representative.

To Obtain Service and/or Parts

NOTE

Throughout this maintenance guide, the words "right" and "left" refer to the right and left sides of

a patient lying face up on the bed.

To Require Service

To obtain the service of a Stryker Field Service Representative for an on-site diagnosis and/or

repair of a bed malfunction, contact the Stryker Bertec Technical Service department or your

local representative.

8

Page 9

Introduction Chapter 1

To Order Parts

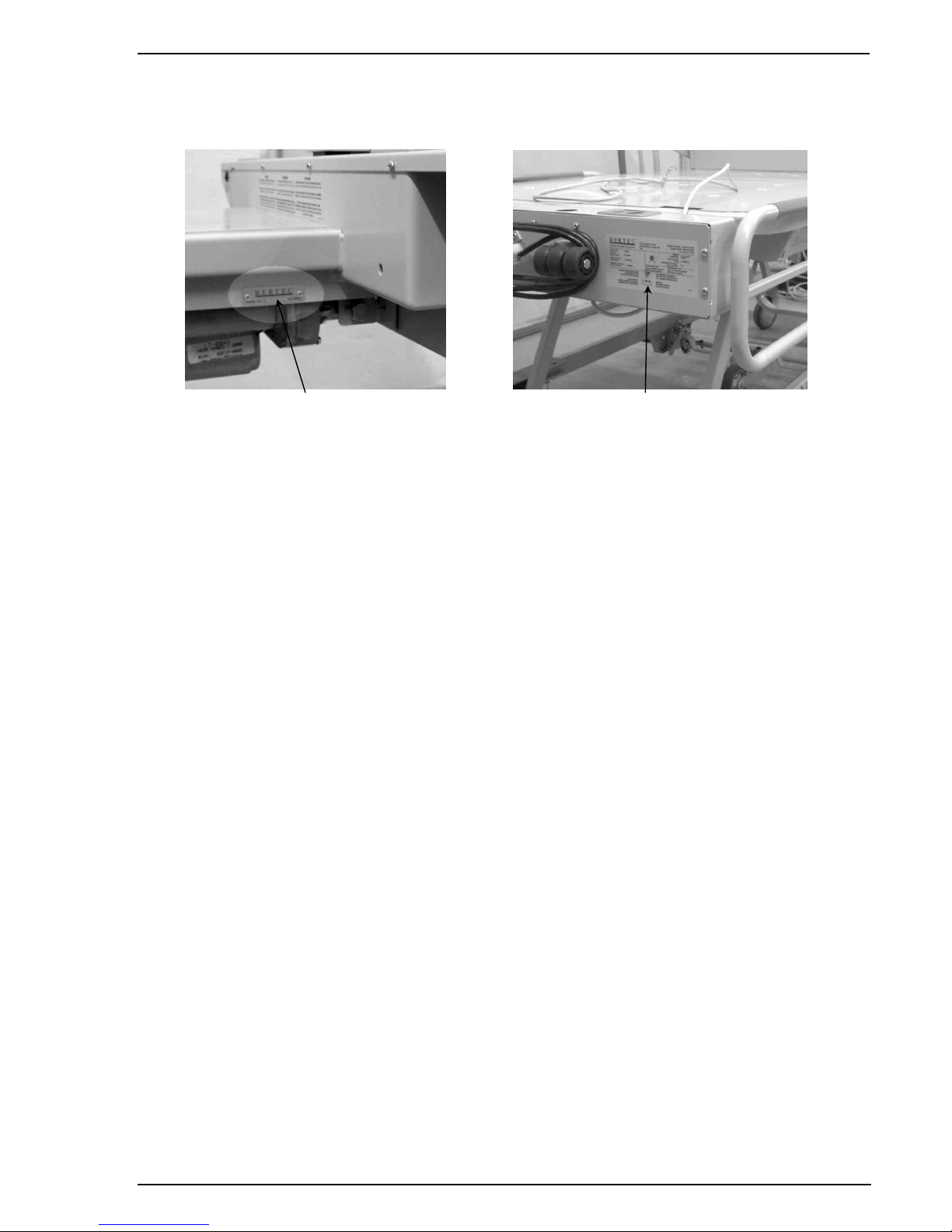

SERIAL NUMBER PLATE

MANUFACTURER'S NAMEPLATE

Figure 1.4

In order to correctly identify and order parts to be replaced, proceed as follow:

• Once you have established the nature of the problem, locate the serial number plate (fig.

1.4) and the manufacturer's nameplate (fig. 1.4) affixed respectively on the right side of the

mobile frame at the foot end of the bed, and on the right side of the head end casing cover.

• Write down the serial number, the production number (e.g. FL17-XXXX) and the bed model

(manufacturer's nameplate). Make sure that the bed is indeed a Stryker Bertec bed. At first

glance, beds manufactured by other companies may resemble ours.

• Locate the Parts Manual or Customer's Guide (containing the Parts Lists needed) number

on the manufacturer's nameplate and refer to its drawings and part lists to identify the

defective part. Write down the name of the part and its part number. Also write down the

problem encountered while using the equipment.

E

NNOOTTE

It is very important that you refer to the Customer's Guide drawings and part lists that are

specific to the bed needing repair.

• Contact Stryker Bertec Technical Service department (see section 1.2) or your local

representative and provide all the previously noted information.

• Bed model

• Serial number and production number

• Name and part number of the defective part

• Problem encountered

E

NNOOTTE

We will do our best to help you identify the parts to be replaced. However, if an error occurs

when ordering, the user remains responsible for identifying parts to change.

Stryker Bertec will take back wrong parts ordered but will not assume shipping charges and

restocking fees will be charged to the user unless a Technical Service representative has been

requested for an on-site diagnosis of the malfunction.

9

Page 10

Chapter 1 The GO BED Maintenance Manual

WWAARRNNIINNGG

Return Authorization

Merchandise cannot be returned without approval from the Stryker Bertec Technical Service

department. An authorization number will be provided, which must be clearly printed on the

returned merchandise. Stryker Bertec reserves the right to charge shipping and restocking fees

on returned items.

Damaged Merchandise

Claims for damaged merchandise must be made with the carrier within fifteen (15) days of

receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt

notification, Stryker Bertec will file a freight claim with the appropriate carrier for damages

incurred. Claims will be limited in amount to the actual replacement cost. In the event that this

information is not received by Stryker Bertec within the fifteen (15) days period following the

delivery of the merchandise, or the damage was not noted on the delivery notice at the time of

receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within 5 days of invoice.

1.5 SET-UP PROCEDURES

Checklist

It is important to ensure that the bed is working properly before it is put into service. The

following list will help ensure that each part of the bed is tested.

q Install the foot and head boards on the bed. Insert the foot board carefully so that the board

connector connects smoothly to the foot end casing connector.

q Plug the power cord into a properly grounded hospital grade wall receptacle and ensure that

the Power LED light at the foot end of the bed comes on when the "On/Off" switch is turned

on.

The bed is equipped with a hospital grade plug for protection against shock hazard. It must be

plugged directly into a properly grounded receptacle. Grounding reliability can be achieved only

when a hospital grade receptacle is used.

q Depress and engage the red "TOTAL BRAKE" side of the pedal at either side of the bed to

set the brakes. Two of the four wheels, diagonally opposed, should lock, ensure it is so.

Ensure brakes disengage when the pedal opposite green "AXIAL STEER" side is depressed

to bring pedal to neutral position (horizontal position).

q Depress the green "AXIAL STEER" side of the pedal on either side of the bed to engage the

5th wheel. Ensure the 5th wheel is engaged.

q Ensure the 5th wheel disengages when the pedal opposite red "TOTAL BRAKE" side is

depressed to bring pedal to neutral position (horizontal).

q Ensure the side-rails raise and lower smoothly and lock in the up position.

q Run through each function on the foot board control panel and ensure that each function is

working properly.

q Ensure all functions are working properly on the side-rail control panels (inner and outer

sides).

10

Page 11

Introduction Chapter 1

q Raise the bed to full up position and activate the Trendelenburg function (see

"Trendelenburg Switch (E)", Operations Manual, page 21). Ensure that the head end lowers

to the full down position.

q Raise the bed to the full up position and activate the reverse Trendelenburg function (see

"Trendelenburg Switch (E)", Operations Manual, page 21). Ensure that the foot end lowers

to the full down position.

q Ensure that the optional Auto Contour function works properly (see "Auto Contour",

Operations Manual, page 21).

q Leaving the bed in the Auto Contour position, pull the instant CPR release handle (optional

equipment) and ensure the Fowler and Knee Gatch will drop with minimal effort. Wait and

listen for the typical noise indicating that the Fowler actuator has reset itself (during the

resetting period, no bed functions are available).

q Check following optional equipment for proper operation: 120V auxiliary outlet, photoelectric

night light, two or three function pendant control, etc.

If any problems are found during bed set-up, contact our Technical Service department (see

section 1.2).

11

Page 12

Chapter 1 The GO BED Maintenance Manual

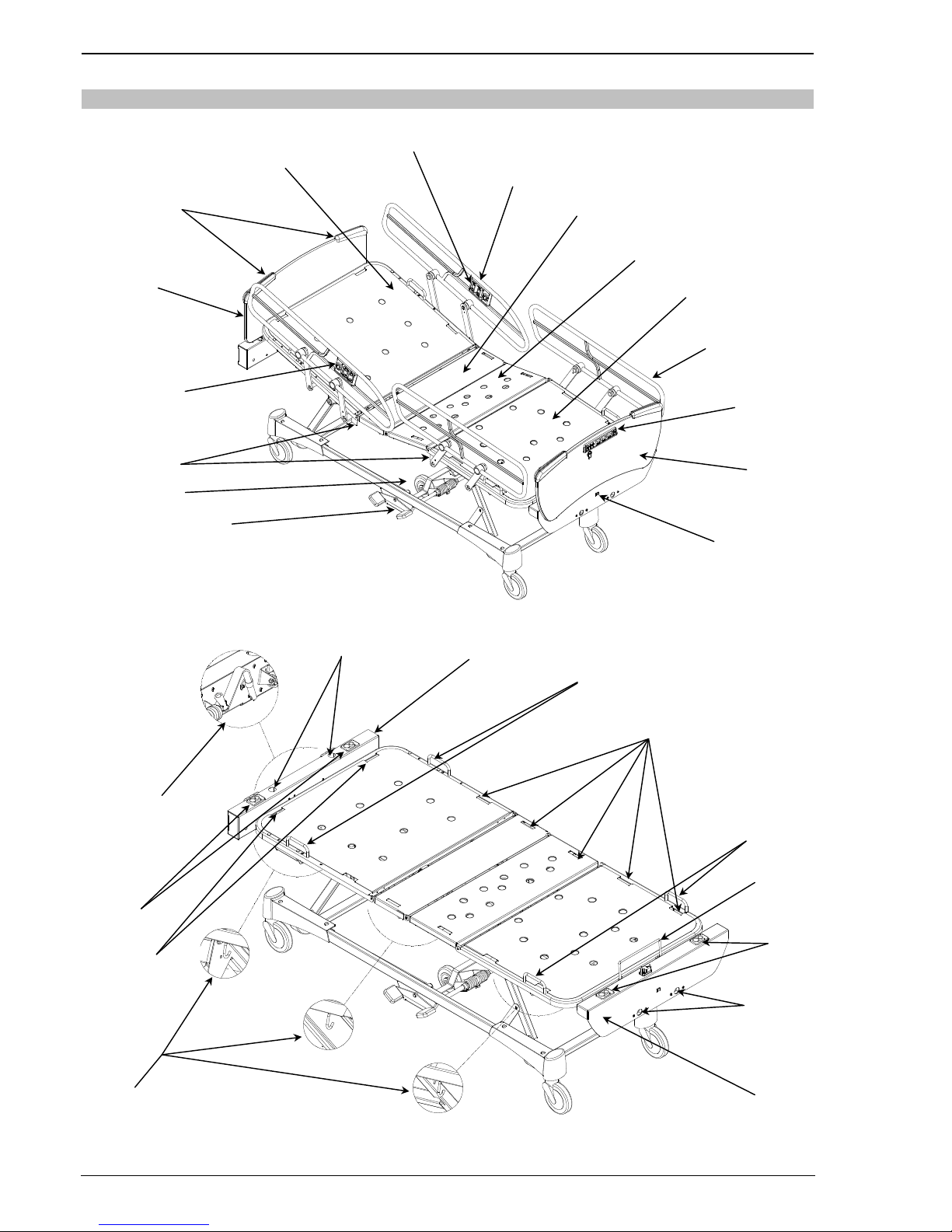

HEAD SIDE

-

RAIL

FOOT SIDE

-

RAIL

CONTROL PANEL

THIGH SECTION

FOOT SECTION

HOLDERS

SIDE MATTRESS

RETAINERS

FOOT MATTRESS

RETAINERS

1.6 BED ILLUSTRATION (Bed may differ from illustration)

SIDE-RAIL INSIDE

HEAD SECTION

PUSH/PULL HANDLE

HEAD BOARD

SIDE-RAIL OUTSIDE

CONTROL PANEL

SIDE-RAIL

LATCH LEVER

FIFTH WHEEL

BRAKE/STEER

PEDAL

PATIENT HELPER

MOUNTING SOCKETS

HEAD END

CASING

CENTRE SECTION

FOOT BOARD

CONTROL PANEL

FOOT BOARD

ON/OFF SWITCH

SIDE MATTRESS

RETAINERS

EMERGENCY

CRANK STORED

HEAD I. V. POLE

RESTRAINT STRAP

LOCATIONS

FOLEY BAG HOOKS

Figure 1.6

RESTRAINT STRAP

LOCATIONS

FOOT I. V. POLE

HOLDERS

EMERGENCY

CRANK OPENINGS

FOOT END

CASING

12

Page 13

Preventive Maintenance Chapter 2

CCAAUUTTIIOON

N

WWAARRNNIINNG

G

2. PREVENTIVE MAINTENANCE

This section contains a recommended spare parts list as well as cleaning instructions and a

checklist to assist with the preventive maintenance and cleaning of your equipment.

In the text, the words "right" and "left" refer to the right and left sides of a patient lying face up on

the bed.

2.1 BED CLEANING AND MATTRESS CARE

Do not use harsh cleaners, solvents or detergents. Do not steam clean, hose off or

ultrasonically clean the bed. Do not immerse any part of the bed. The bed electrical parts may

be damaged by exposure to water.

Germicidal disinfectant, used as directed, and/or Chlorine Bleach products are not considered

mild detergents. These products are corrosive in nature and may cause damage to your bed if

used improperly. If these types of products are used, ensure the beds are rinsed with clean

water and thoroughly dried following cleaning. Failure to properly rinse and dry the beds will

leave a corrosive residue on the surface of the bed, possibly causing premature corrosion of

critical components. Failure to follow the above directions when using these types of cleaners

may void this product warranty.

Cleaning Beds

• Hand wash all surfaces of the bed with a soft cloth moistened with a solution of lukewarm

water and a mild detergent.

• Wipe the bed clean and dry thoroughly to avoid build up of cleaning solution.

Bed Mattress Care

Failure to properly clean mattress or dispose of them if defective will increase the risk of

exposure to pathogenic substances which may cause injury to the patient or user.

Inspection

• Implement local policies to address regular care, maintenance, and cleaning of mattresses

and covers. The cover cleaning and sterilization procedures can be found below and on the

bed label.

• Inspect mattress cover surface (also zip fasteners and cover inner surface if mattresses

have zip fasteners) regularly for signs of damage. If the mattress cover is stained, soiled, or

torn, examine the mattress, and seek instructions from the infection control nurses, as the

mattress may harbour micro-organisms. If the mattress is wet or badly stained, withdraw

the mattress from service.

• Seek the advice of infection control nurse in case of heavy soiling or infection, as general

cleaning procedures are unlikely to be adequate.

Cleaning and Sterilization

• Stains:

Wash with lukewarm water using a mild detergent. Rinse with water and let dry.

• Tough stains and sterilization:

Use bleach diluted with ten parts of water.

13

Page 14

Chapter 2 The GO BED Maintenance Manual

CCAAUUTTIIOON

N

WWAARRNNIINNG

G

2.2 LUBRICATION

Listed below are the lubrication points and their recommended time interval check. When

needed, lubricate these points with OG2 grease (Stryker Bertec part number M0027).

The use of types of grease other than the one recommended (OG2 grease) could lead to

deterioration of critical parts and to mechanism failure, resulting in injury to the patient or user

and damage to the bed.

The GO BED uses oil-impregnated shoulder spacers at hinge points. Do not lubricate these

shoulder spacers. When shoulder spacers are found worn, replace them.

Annual Checklist:

q The Hi-lo lever nylon sliders and their shafts (see fig. 2.2A, page 15). Check that grease is

still present along the course of the sliders (inner surfaces (bottom and side) of the rail).

q Lower mounting points (see fig. 2.2A, page 15) of the lifting system stabilizer.

q Side-rail plungers and plunger springs (see fig. 2.2B, page 15).

q The side-rail arm glide rods (see fig. 2.2B, page 15).

Two Years Interval Checklist:

q The two Hi-lo actuator tubes (see fig. 2.2C, page 15) to facilitate their sliding into the

support tubes. Bring the bed to its highest position before greasing the tubes.

q Head, foot and Hi-lo actuator screws (see fig. 2.2C, page 15).

q Head actuator screw guide (see fig. 2.2C, page 15).

q Clevis pins and nylon washers linking the actuator tubes to the head and Knee Gatch

section lever arms and the two Hi-lo lever arms (see fig. 2.2C, page 15).

q Actuator bolts that hold actuators to their brackets as well as the inner sides of the brackets,

including the pivot pin (see fig. 2.2C, page 15).

q Micro-switch activator (see fig. 2.2E, page 15) of the optional Auto Contour mechanism.

Five Years Interval Checklist:

q The side-rail shafts and transfer plate handles (see fig. 2.2B, page 15).

q Inside of the Hi-lo lever moulded bearings (see fig. 2.2A, page 15).

q The damper bearings, the pivot shaft of the CPR support, and the activation rod pivot sleeve

(see fig. 2.2D, page 15) all from the instant CPR release mechanism.

Serial Number:_______________ _______________ _______________

_______________ _______________ _______________

_______________ _______________ _______________

_______________ _______________ _______________

Completed by:______________________________ Date:_______________

14

Page 15

Preventive Maintenance Chapter 2

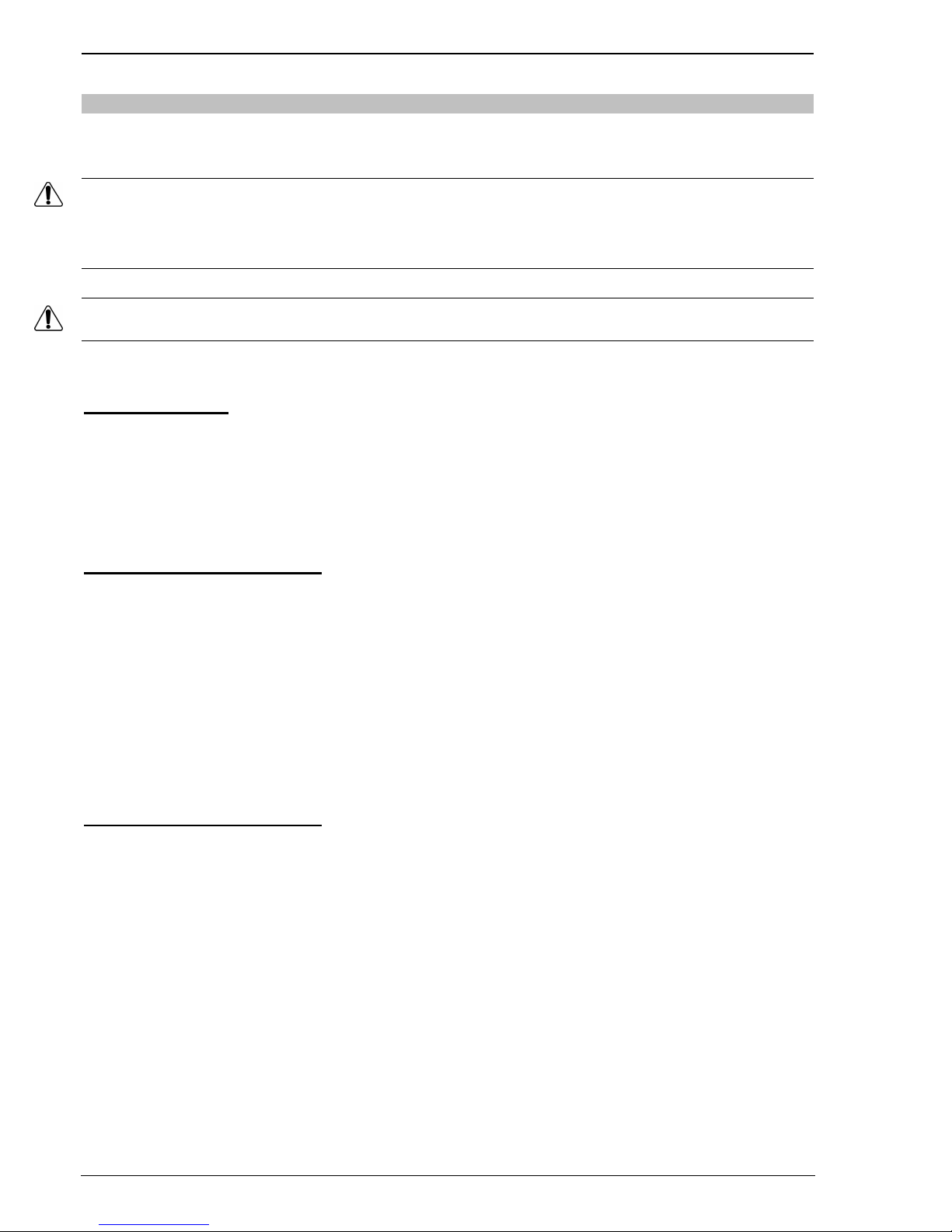

Figure 2.2E

Figure 2.2C

Lubrication Points Illustrated

LEGEND:

1 YEAR 2 YEARS 5 YEARS

Figure 2.2A

Figure 2.2D

Figure 2.2B

Figure 2.2

15

Page 16

Chapter 2 The GO BED Maintenance Manual

CCAAUUTTIIOON

N

WWAARRNNIINNG

G

2.3 PREVENTIVE MAINTENANCE PROGRAM

The following periodic maintenance and inspection program has been devised to ensure a long

and productive life to your GO BED. Each item on the schedule should be checked and any

necessary adjustment made during the preventive maintenance process. Persistence in

performing it annually will help minimize bed failures and reduce downtimes.

Only qualified and authorized maintenance personnel should perform the procedures detailed in

this maintenance guide. Failure to observe this restriction can result in serious damage to

material and/or severe injury to people.

Checklist

The GO BED uses oil-impregnated shoulder spacers at hinge points. Do not lubricate these

shoulder spacers. When shoulder spacers are found worn at preventive maintenance, replace

them.

q Inspection for excessive wear of all the oil-impregnated bronze shoulder spacers found in

the following components of the bed. Replace as needed

q Linkage of the mattress support sections together

q Linkage of the head section lever arms to the head section and the fixed frame

q 5th wheel activation mechanism

q Instant CPR release mechanism

q Inspect and lubricate, if needed, bed lubrication points described in section 2.2

q Inspection of all bolt, locknut and screw tightening, tighten if necessary

q Engage brake pedal and push on the bed to ensure that casters lock securely

q Using the Axial Steer pedal, ensure that the 5th wheel engages and disengages properly

q Side-rails move, latch and stow properly

q All functions on the foot board control panel working properly (give special attention to lock-

out switches and their LED indicators). See "PC Board Integrated Maintenance Program",

next page.

q Check the Fowler, Knee Gatch, Hi-lo, optional Auto Contour, and the Trendelenburg limits to

ensure that actuator built-in limit switches are working properly.

q All functions on side-rail control panels (inner and outer) working properly. See "PC Board

Integrated Maintenance Program", next page.

q On/Off switch and LED power indicator working properly

q Optional 120 volt auxiliary outlet working properly

q Optional photoelectric night light working properly

q Optional instant CPR release working properly

q Optional Auto Contour working properly

q Fowler slides securely in tracks without making noise (grease applied on the assembly line

along the path of the mobile frame wheels and on the wheel shafts should last as long as

the bed life. Should a problem occur with this part of the bed, please contact our Technical

Service department (see section 1.2).

16

Page 17

Preventive Maintenance Chapter 2

q Automatic foot prop rod working properly when Knee Gatch or Auto Contour function is

activated.

q No cracks or splits in head and foot boards

q Head end bumpers tightly secured to frame and working properly

q No rips or cracks in mattress cover

q Power cord not frayed

q No cables worn or pinched

q All electrical connections tight

q All ground secure to the frame

q All casters roll properly. Check caster tire for cuts, wear, tread life, etc

q Ground chain intact and in place

q Measure bed current leakage and ground impedance (check with our Technical Service

department for the acceptable values).

q Measure optional 120V auxiliary ground impedance (check with our Technical Service

department for the acceptable value).

E

NNOOTTE

Preventive maintenance may need to be performed more frequently based on the usage level of

the bed.

Serial Number: _______________ _______________ _______________

_______________ _______________ _______________

_______________ _______________ _______________

_______________ _______________ _______________

Completed By:___________________________________ Date:_______________

PC Board Integrated Maintenance Program

This bed has a PC Board equipped with a maintenance program. To activate and process the

program, perform the following steps:

• Unplug the bed power cord, remove the foot board and the foot end casing cover (see

section 4.7, step 1 through 4 and fig. 4.7A) to gain access to the PC Board.

• Move the board four dip switches to the ON position and replace temporarily the casing

cover and the foot board (do not fasten the cover to the casing for the moment).

• Plug the bed power cord and turn the main power switch on. Note that the LED of the

Trendelenburg function switch may light up, do not mind it.

• Press all function switches of the control panels (foot board and side-rails) one after the

other. The green LED of the Fowler lock-out switch will be the maintenance test indicator. It

should lit up when a function switch is pressed and go out when the same function switch is

pressed again thus indicating that the wiring and the membrane are working properly. If the

LED does not light up when a function switch is pressed, the wiring and/or the membrane

may be defective.

• After completion of the test, unplug the bed power cord, remove the foot board and the

casing cover, readjust the dip switches to their normal position (1= Off; 2= On; 3= Off; 4=

Off), fasten the cover to the foot end casing, and replace the foot board.

17

Page 18

Chapter 2 The GO BED Maintenance Manual

Recommended Spare Parts

The following is a list of recommended on hand spare parts for the GO BED.

Electronic/Electrical Assembly Parts

PC Board QDF14-0990

PC Board stand off pins QDF8011

Strain relief bushing QPNC0604

S.A. power cord 120V/Connector QDF17-0236/QDF8042

Micro switch 1325P003

Night light QDF9539

Actuator Assembly Parts

Hi-lo actuator QDF17-0005

Knee Gatch actuator QDF17-0006

Head actuator 17-0041

Control Panel Assembly Parts

Nurse control plate and membrane QDF17-0180/QDF17-0127

S.A. Fixed 3 way patient control (H-B-F) 13-0220

S.A. Fixed 3 way patient control (F-B-H) 13-0221

S.A. Fixed 2 way patient control (F-H) 17-0193

S.A. Fixed 2 way patient control (H-F) 17-0194

Side-Rail assembly parts

Head side-rail protector 17-0220

Foot side-rail protector 17-0221

3M adhesive tape #950 x 1" QDF7826

Side-rail right handed release 17-0306-P

Side-rail left handed release 17-0307-P

Dome cap DP1250 1-1/4" QDFP1514

Protective cap QPN-18748

Mattress support Assembly

Warm grey mattress retainer QPN-14034-2

Base Assembly Parts

"Tente" caster with locking system RT61C

"Tente" caster without locking system T61CSW

5th wheel RL5

Pedal green treadle tip QPN-18028

Pedal red treadle tip QPN-18029

Anchor washer for 3/16 dia. stud VW00A06

Rue ring cotter dia. 3/8" p.z. QDF7878

Miscellaneous

OG-2 grease M0027

Tread locker - medium strength (blue) M008

"Sand Grey" aerosol spray paint DDCAP-GSP

18

Page 19

Troubleshooting Chapter 3

WWAARRNNIINNG

G

3. TROUBLESHOOTING

This section contains a troubleshooting chart to assist you with the diagnosis of problems with your

equipment.

In the text, the words "right" and "left" refer to the right and left sides of a patient lying face up on the

bed.

3.1 TROUBLESHOOTING GUIDE

Only qualified and authorized maintenance personnel should perform the procedures detailed in

this maintenance guide. Failure to observe this restriction can result in serious damage to

material and/or severe injury to people.

PROBLEM POSSIBLE CAUSES RECOMMENDED ACTION

ON/OFF switch is on, power

LED is off and bed does not

respond to any command.

Power cord loosely or not

connected to wall receptacle.

Bed connected into a defective

Make sure plug fits tightly in

wall receptacle.

Check wall receptacle.

wall receptacle.

Power cord severed. Replace power cord

(see section 4.10).

Bed power cord connector

improperly or not connected to

the PC Board power cord

connector in the head end

casing

PC Board power cord

improperly or not connected to

PC Board

Check cable connection

(see section 4.10). Refer to

Connection Diagram in

Appendix A for proper

connecting position.

Check cable connection

(see section 4.8). Refer to

Connection Diagram in

Appendix A for proper

connecting position.

PC Board power cord

defective

Replace PC Board power

cord. See the "120V

electrical system" parts list

and drawing in the GO BED

Parts List manual.

ON/OFF switch cable

ON/OFF switch or cable

PC Board defective. Replace PC Board (see

disconnected or improperly

connected to PC Board.

defective.

Check cable connection

(see section 4.9). Refer to

Connection Diagram in

Appendix A for proper

connecting position.

Replace ON/OFF switch

and cable (see section 4.9).

section 4.8).

19

Page 20

Chapter 3 The GO BED Maintenance Manual

PROBLEM POSSIBLE CAUSES RECOMMENDED ACTION

ON/OFF switch is on, the bed

responds to commands but

the LED power indicator does

not light up.

ON/OFF switch is on but the

bed fails to respond or

responds erratically to:

* foot board panel control

**side-rail control panels

E

NNOOTTE

In the possible causes

column, one * refers to

causes affecting only the

foot board control panel and

two ** refer to causes

affecting only side-rail

control panels. * **

combined refer to causes

affecting both control panels.

ON/OFF switch LED defective. Replace ON/OFF switch

(see section 4.9).

* Foot board control

membrane cable improperly or

Check cable connection

(see section 4.3).

not connected to the foot

board connector.

* PC Board to foot end casing

connector cable improperly or

not connected to PC Board.

Check cable connection

(see G fig. 4.7A, section

4.7). Refer to Connection

Diagram in Appendix A for

proper connecting position.

* Foot board panel membrane

defective.

* Foot board connector

defective.

Replace membrane (see

section 4.3).

Replace connector (see

section 4.6).

* Foot end casing connector

defective.

** Side-rail panel functions not

activated through the foot

board control panel lock-outs.

** Side-rail bed function cable

not connected to the bed.

Replace connector (see

section 4.7).

Turn the lock-out switches

on (see section 2.16 of the

User Guide).

Connect the side-rail cable

into receptacle located

under the centre section of

the mattress support.

** Side-rail panel membrane

(inner or outer) defective.

** Side-rail control cable

improperly or not connected to

the PC Board.

Replace membrane (see

section 4.4).

Check cable connection

(see section 4.8). Refer to

wiring diagram in Appendix

A for proper connecting

position.

** Side-rail control cable

running from the control panel

to the bed receptacle

Replace cable (see section

4.5, step 13 and note

following it.)

defective.

20

Page 21

Troubleshooting Chapter 3

PROBLEM POSSIBLE CAUSES RECOMMENDED ACTION

* ** PC Board dip switches

improperly set.

Set Dip switches properly.

DIP #1 = off; DIP #2 = on;

DIP #3 = off; DIP #4 = off.

* ** If your bed is equipped

with the optional CPR release

and only the Knee Gatch

functions, the CPR mechanism

may have not returned to

Check CPR mechanism

and both micro switch

assembly. Replace

component as needed (see

section 4.16 and 4.17).

original position and/or the

head section actuator may

have not reset itself after CPR

usage.

* ** Actuator automatic thermal

protection switch has turned

the actuator off.

Refrain from using the bed

for about twenty minutes.

The actuator will then reset

itself.

* ** Actuator cables improperly

or not connected to the PC

Board.

Check actuator connections

(see section 4.8 and 4.14).

Refer to the Connection

Diagram in Appendix A for

proper connecting position.

* ** An actuator defective.

Identify faulty actuator and

replace it (see section

4.14).

* ** PC Board defective.

Replace PC Board

(see section 4.8).

Bed functions operate

without being activated or

don't stop after command

has been released.

Foot board or side-rail panel

membrane defective.

Replace membrane

(see section 4.3 and 4.4).

PC Board defective. Replace PC Board

(see section 4.8).

Instant CPR release does not

function properly: the head

section actuator does not

reset automatically and/or

the Knee Gatch does not

return to horizontal position

following the use of the

instant CPR release.

Micro switches detecting the

mattress support movement

not functioning properly

Check the CPR mechanism

under the head section.

(see section 4.16)

Check that micro switches

and the micro switch

activator(located on the

right side of the fixed

frame) are tightly fastened.

Check wires connected to

micro switches for proper

connection.

Check micro switches.

Replace component as

needed (see section 4.17).

21

Page 22

Chapter 3 The GO BED Maintenance Manual

PROBLEM POSSIBLE CAUSES RECOMMENDED ACTION

The micro switch cable

improperly connected to the

PC Board.

Check cable connection

(see section 4.8). Refer to

Connection Diagram in

Appendix A for proper

connecting position.

The micro switch cable running

from the micro switch to the

PC Board connector defective.

Head or Knee Gatch actuator

defective.

Replace micro switch

cable.

Replace head or Gatch

actuator (see section 4.14).

PC Board defective. Replace PC Board

(see section 4.8).

Fowler and Knee Gatch are

out of synchronization when

optional Contour Positioning

is activated.

Micro switches detecting the

relative positions of the

mattress support sections not

functioning properly.

Check that micro switches

and micro switch activator

(located on the left side of

the fixed frame) are tightly

fastened.

Check micro switches and

wires connected to them for

proper connection. Replace

component as needed (see

section 4.18).

Micro switch cable improperly

connected to the PC Board.

Check cable connection

(see section 4.8). Refer to

Connection Diagram in

Appendix A for proper

connecting position.

Micro switch cable running

from the micro switch to the

Replace micro switch

cable.

PC Board defective

Head or Gatch actuator

defective.

Replace head or Gatch

actuator (see section 4.14)

PC Board defective. Replace PC Board

(see section 4.8)

Nurse call command does

not function.

Nurse call wall connection

cable plugged into a defective

Check wall receptacle.

wall receptacle.

Nurse call wall connection

cable disconnected or

improperly connected to the

Check cable wire

connection to the multiple

connector (see section 4.5).

multiple connector.

Nurse call wall connection

cable severed or defective.

Replace nurse call wall

connection cable (see

section 4.5)

22

Page 23

Troubleshooting Chapter 3

PROBLEM POSSIBLE CAUSES RECOMMENDED ACTION

Nurse call switch defective. Replace nurse call switch

(see section 4.5).

Nurse call switch cable

defective

Safety side-rails jam, move

with difficulty, do not latch in

high position or latch with

difficulty.

Side-rail mechanisms poorly

greased and/or mechanism

parts loosened.

Side-rail parts misaligned

following a blow.

Brake does not engage when

activated or do not release.

Fasteners of the brake

activation mechanism not

secured or parts misaligned.

One or both casters that are

part of the locking mechanism

defective.

Replace nurse call cable

(see section 4.5)

Apply grease on the side-

rail plungers, plunger

springs, arm glide rods and

rail shafts (see section 2.2,

"Lubrication"). Check all

applicable hardware and

parts alignment. Replace

parts as needed (see

section 4.1).

Replace side-rail assembly

(see section 4.1)

Check all applicable

linkage, hardware and parts

alignment. Replace parts

as needed (see sect. 4.19,

"Brake/steer pedal…")

Replace caster (see section

4.21).

Steer wheel (5th wheel) does

not engage when activated or

does not disengage.

Fasteners of the 5th wheel

activation mechanism not

secured or parts misaligned.

Swing arm assembly spring

warped

Check all applicable

linkage, hardware and parts

alignment. Replace parts

as needed (see sect. 4.20).

Replace the 5th wheel

swing arm assembly (see

section 4.20)

23

Page 24

Chapter 4 The GO BED Maintenance Manual

WWAARRNNIINNG

G

CCAAUUTTIIOON

N

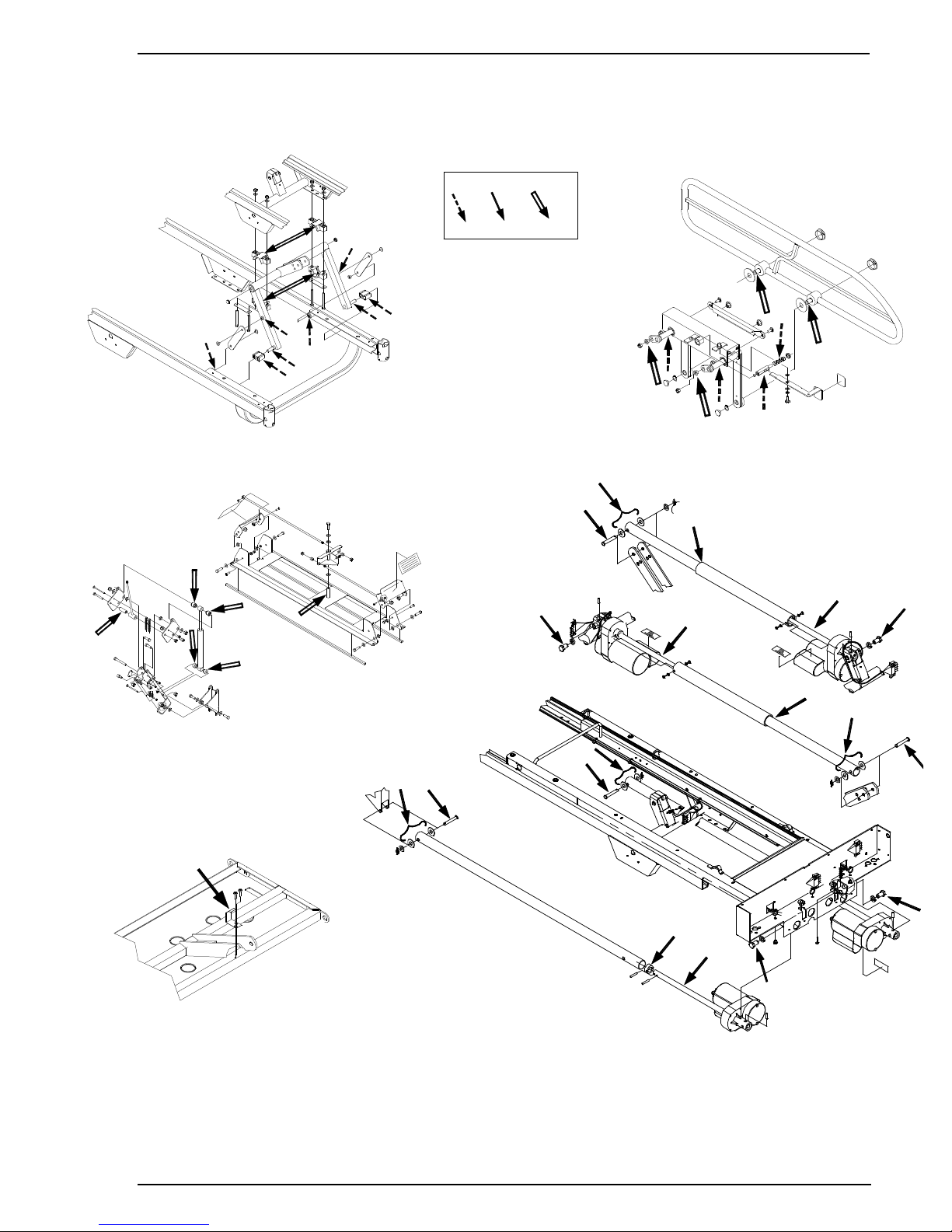

4. MAINTENANCE PROCEDURES

This section contains step-by-step procedures to assist with the maintenance and servicing of

the GO BED.

In the text, the words "right and "left" refer to the right and left sides of a patient lying face up on

the bed.

Only qualified maintenance personnel should perform the procedures detailed in this

maintenance guide. Failure to observe this restriction can result in serious damage to material

and/or severe injury to people.

The use of types of grease other than the one recommended (OG2 grease, Stryker Bertec part

number M0027) could lead to deterioration of critical parts and mechanism failure, resulting in

injury to the patient or user and damage to the bed.

Always unplug the bed power cord from the wall outlet when cleaning or servicing the bed.

The GO BED uses oil-impregnated shoulder spacers at hinge points. Do not lubricate these

shoulder spacers. When shoulder spacers are found worn at preventive maintenance, replace

them.

E

NNOOTTE

Except for rare exceptions, reference points - i.e. A, B, C appearing in sequence of instructions

will refer to a figure immediately preceding this sequence of instructions.

4.1 SIDE-RAIL ASSEMBLY REPLACEMENT

Foot Side-Rail Assembly Replacement

FOOT SECTION

FOOT SIDE-RAIL

1. Raise the bed to the high position and lock casters.

2. Put the head side-rails in the down position and raise the foot side-rails.

3. Raise the Knee Gatch to the high position.

4. Unplug the power cord from the wall receptacle.

24

Figure 4.1A

Page 25

Maintenance Procedures Chapter 4

C C E D

F H G

5. Manually lift and fold the foot section back towards the head end of the bed (see figure 4.1

in Appendix B).

6. Remove the four bolts / lock washers (A) holding the side-rail assembly to the foot section.

E

NNOOTTE

Apply medium strength tread locker (blue) on the bolt treads, before replacing the four bolts.

7. Lift up assembly to disengage from anchor point (B) and remove assembly

8. Reverse the above steps to install the replacement foot side-rail assembly.

9. Test foot side-rail for proper operation before returning the bed to service.

Head Side-Rail Assembly Replacement

E

NNOOTTE

If the bed being maintain is equipped with the nurse call option, be sure to mention it to the

Service representative when ordering a new head side-rail assembly.

1. Raise the bed to the high position and lock casters.

2. Raise head side-rail to be replaced and raise Fowler to high position.

3. Unplug the power cord from the wall receptacle.

4. Unscrew the lock ring of the side-rail cable plug (J, fig. 4.1C, page 25) and remove cable

from the bed receptacle.

5. If the bed being repaired is not equipped with the optional nurse call function, proceed with

step 10.

If the bed being repaired is equipped with the optional nurse call function, and its version is prior

to version 03 (bed with serial number [ C02025), proceed with step 6. For version 03 (bed with

serial number / C02026) and higher of the GO BED (equipped with the optional nurse call

function, proceed with step 10.

AU MUR D'HOPITAL

TO HOSPITAL WALL

Figure 4.1B

6. Remove the fourteen screws (C) holding the head end casing (D) cover and remove the

cover (E).

7. Identify the right (F) or left (G) nurse call cable wires in the head end casing, cut the cable

tie if necessary.

8. Loosen the two screws holding the two groups of red and black wires on the multiple

connector (H), remove both groups of wires and segregate from them the red and black

wires of the nurse call cable involved in the procedure.

25

Page 26

Chapter 4 The GO BED Maintenance Manual

J

HEAD SECTION

K

9. Pull on the cable to slide it out of the cable ties holding it along its path under the bed. It

might be necessary to cut the cable ties to install the new nurse call cable.

HEAD SIDE-RAIL

Figure 4.1C

10. Remove the four bolts/lock washers (K) holding the side-rail assembly to the head section.

Begin with the two bolts located near the latch lever followed by the two others. Support the

assembly when removing the two last bolts.

E

NNOOTTE

Apply medium strength tread locker (blue) on the bolt treads before replacing the four bolts.

11. Lift up assembly to disengage from anchor pin and remove it.

12. Reverse the above steps to install the replacement head side-rail assembly.

E

NNOOTTE

Be sure to connect the side-rail cable to the bed receptacle before testing the bed.

13. Test side-rail motion, all side-rail controls, and if present the nurse call function for proper

operation before returning bed to service.

26

Page 27

Maintenance Procedures Chapter 4

B C

D

4.2 SIDE-RAIL REPLACEMENT (RAIL ONLY)

Foot Side-Rail Replacement (Rail Only)

A

Figure 4.2

1. Raise the bed to the high position and lock casters.

2. Raise side-rail needing a rail replacement.

3. Unplug the power cord from the wall receptacle.

4. Use a small screwdriver to remove the plastic dome caps (A) sealing the front part of the

two rail shafts.

E

NNOOTTE

We recommend that you have some of these dome caps on hand because they can hardly be

removed without damaging them.

5. Use a hammer and a blunt-ended tool to remove the nylon protective caps (B) from the rear

part of the two rail shafts.

6. Remove lock rings (C) from each shaft and remove the defective barrier. Keep the nylon

washers (D).

7. Reverse the above steps to install the replacement rail.

E

NNOOTTE

Apply grease on the rail shafts before installing the rail.

Head Side-Rail Replacement (Rail Only)

Replacing the rail of head side-rail is a complex task requiring a good knowledge of the product.

We recommend that you contact our Technical Service department (see section 1.2) in order for

them to suggest an appropriate solution to the problem.

27

Page 28

Chapter 4 The GO BED Maintenance Manual

A

B

C

D

E

F

Figure 4.3

4.3 MEMBRANE REPLACEMENT (FOOT BOARD CONTROL PANEL )

E

NNOOTTE

The membrane comes with the control panel plate, already affixed to it.

1. Raise the bed to the high position and lock casters.

2. Unplug the power cord from the wall receptacle.

3. Remove the head board and lay it on a workbench

4. Remove the 7 screws (A) securing the support cover (B) to the inner face of the foot

board and remove cover.

5. Remove the screw (C) holding the membrane support to the foot board.

6. Disconnect the defective membrane cable (E) from the board connector (D).

7. Remove the control panel plate (F).

8. Reverse the above steps to install the replacement membrane.

E

NNOOTTE

Be sure to connect the new membrane cable correctly. The side of the membrane connector

bearing the inscription "1" must face the black wire of the foot board connector.

9. Test all the foot board control panel functions for proper operation before returning bed

to service.

28

Page 29

Maintenance Procedures Chapter 4

4.4 MEMBRANE REPLACEMENT ( SIDE-RAIL CONTROL)

C

A

D

A

B

Figure 4.4

1. Raise the bed to high position and lock casters.

2. Raise the head side-rail needing a membrane replacement.

3. Unplug the power cord from the wall receptacle.

4. Remove the four screws (A) holding together the two sections of the side-rail control panel

housing (B).

5. Open the side-rail control panel housing. Both sections of the housing contains a membrane

permanently fixed to it. Changing a side-rail control panel membrane means replacing one

of the two sections of the control panel housing.

6. Disconnect the faulty membrane cable (C) from the side-rail connecting board (D) and

remove the membrane.

7. Reverse the above steps to install the replacement side-rail control membrane.

E

NNOOTTE

Make sure to connect the new membrane cable correctly. The side of the connector bearing the

inscription "1" must face the brown wire of the connecting board.

8. Test all side-rail control panel functions (inner and outer sides) for proper operation before

returning bed to service.

29

Page 30

Chapter 4 The GO BED Maintenance Manual

B

A C

Figure 4.5

F G

D D K

L J H E

CONNECTOR

4.5 NURSE CALL SYSTEM COMPONENT REPLACEMENT

TO WALL

RECEPTACLE

1. Raise the bed to high position and lock casters.

2. Remove the head board.

3. Remove the fourteen screws (C, fig. 4.1 B, page 24) holding the head end casing cover (E

fig. 4.1B, page 24) to the head end casing and remove the cover.

4. Identify the wires (A) of the nurse call wall connector cable (B). Loosen the two screws

holding the cable wires to the multiple connector (C) and remove wires.

E

NNOOTTE

If the wall connector cable is made of three wires, ensure that the red and orange wires are

connected together in the same multiple connector slot.

TO MULTIPLE

5. Test the nurse call wall connector cable.

- if defective, proceed with step 6 through step 8 and end procedure.

- if functioning properly, proceed with step 9.

6. Remove nurse call wall connection cable.

30

Figure 4.5A

Page 31

Maintenance Procedures Chapter 4

7. Reverse the above steps to install the replacement cable.

8. Test nurse call function for proper operation before returning bed to service.

End of procedure.

9. Identify the right (F, fig. 4.5, page 29) or left (G, fig. 4.5, page 29) nurse call cable wires, cut

the cable tie if necessary.

10. Loosen the two screws holding the two groups of red and black wires on the multiple

connector (C, fig. 4.5, page 29), remove both groups of wires and segregate the two red and

black wires of the defective nurse call control.

11. Remove the four screws (D) holding together the two sections of the nurse call control

housing (E).

12. Remove the two screws (H) holding the switch support to the housing. Remove the nurse

call button (J) and clean it as well as its housing, if dirt has accumulated.

13. Test the switch and the two sections of the nurse call cable to determine which is

responsible for the problem. Note that in prior versions of the GO BED (beds with a serial

number [ C02025), the nurse call cable is in one section, running from the nurse call switch

to the multiple connector located in the head end casing.

- if the switch is defective but the cable functions properly, proceed with step 14 through

step 18 and end procedure.

- if one of the cable sections is defective, read the following note and end procedure.

E

NNOOTTE

Replacing a defective nurse call cable is a complex task requiring a good knowledge of the

product. We recommend that you contact our Technical Service department (see section 1.2) in

order for them to suggest an appropriate solution.

End of procedure.

14. Unsolder the two nurse call cable wires (K) from the defective switch (L). Note the position

of each soldered wire on the switch.

15. Unsolder from the replacement switch the two wires of the cable attached to it. Keep the

cable as an on-hand replacement part.

16. Solder to the replacement switch the two wires of the original nurse call cable.

17. Reverse the above steps to install the replacement nurse call switch and finalize installation

of the nurse call assembly.

18. Test nurse call function for proper operation before returning bed to service.

31

Page 32

Chapter 4 The GO BED Maintenance Manual

A B C D E F

4.6 FOOT BOARD CONNECTOR REPLACEMENT

Figure 4.6

1. Raise the bed to high position and lock casters.

2. Remove head board and lay on a workbench.

3. Remove the 7 screws (A) securing the support cover (B) to the inner face of the foot board

and remove cover.

4. Disconnect the foot board control panel membrane (C) from the connector.

5. Remove the two bolts/washers/sleeves/locknuts (D) holding the connector (E) to its support

(F) and remove defective connector.

6. Reverse steps to install replacement foot board connector.

E

NNOOTTE

Make sure to connect the foot board control panel cable correctly. The side of the cable

connector bearing the inscription "1" must be aligned with the black wire of the foot board

connector.

7. Test all foot board control panel functions for proper operation before returning bed to

service.

32

Page 33

Maintenance Procedures Chapter 4

A

A

B

D E F G

L

4.7 FOOT END CASING CONNECTOR REPLACEMENT

C

Figure 4.7A

1. Raise the bed to high position, lock casters and remove the foot board.

2. Unplug the power cord from the wall receptacle.

3. Remove the 12 screws (A, B) holding the foot end casing cover (C) and the two IV pole

holders (E) to the foot end casing (D).

4. Lift up and hold cover while disconnecting from the PC Board the On/Off switch cable (F)

and the PC Board to foot end casing connector cable (G). Note carefully the connecting

positions of the cable connectors to the PC Board connectors (On/Off switch: cable

connector green wire facing pin 11; foot end casing connector cable: connector black wire

facing pin 1). Lay cover on a workbench.

K

H

J

C

H

5. Remove the two bolts/shoulder sleeves/locknuts (H) holding the connector (J) to the foot

end casing cover (C) and remove defective connector. Keep the seal (K).

6. Reverse the above steps to install replacement foot end casing connector.

E

NNOOTTE

Make sure to properly connect the foot casing connector cable to the PC Board connector. See

step 4

7. Test all nursing control functions for proper operation before returning bed to service.

Figure 4.7B

33

Page 34

Chapter 4 The GO BED Maintenance Manual

Figure 4.8

B

C

D

F

4.8 PC BOARD REPLACEMENT

1. Raise the bed to high position and lock casters.

2. Unplug the power cord from the wall receptacle.

3. Remove the foot panel.

4. Properly ground yourself (see "Static Discharge Precautions", page 8).

5. Remove the 12 screws (A, B, fig. 4.7A, page 32) holding the foot end casing cover (C, fig.

4.7A, page 32) and the two IV pole holders (E, fig. 4.7A, page 32) to the foot end casing.

6. Lift up and hold cover while disconnecting from the PC Board the On/Off switch cable (F)

and the PC Board to foot end casing connector cable (G). Note carefully the connecting

positions of the cable connectors to the PC Board connectors (On/Off switch: cable

connector green wire facing pin 11; foot end casing connector cable: connector black wire

facing pin 1). Lay cover aside.

E

D

A

FOOT END CASING

COVER

7. Carefully identify the position of all the cables connected to the PC Board before

disconnecting them. Disconnect cables.

8. Remove locknut (B) holding the PC Board ground wire (C).

9. Remove the two screws (D) holding the PC Board support (E) to the frame and remove the

PC Board.

10. Disengage PC Board from the support stand off pins and remove it.

11. Reverse the above steps to install replacement PC Board.

E

NNOOTTE

Before closing the foot end casing, ensure that the PC Board dip switches are in the following

positions: dip switch #1 = off; dip switch #2 = on; dip switch #3 = off; dip switch #4 = off.

12. Test all bed functions for proper operation before returning bed to service.

34

Page 35

Maintenance Procedures Chapter 4

Figure 4.10

CASING

4.9 ON/OFF SWITCH REPLACEMENT

E

NNOOTTE

Refer to fig. 4.7A, page 33, for illustration of the reference points mentioned in this section.

1. Raise the bed to high position and lock casters.

2. Unplug the power cord from the wall receptacle.

3. Remove the foot panel.

4. Properly ground yourself (see "Static Discharge Precautions", page 8).

5. Remove the 12 screws (A, B) holding the foot end casing cover (C) and the two IV pole

holders (E) to the foot end casing.

6. Lift up and hold cover while disconnecting from the PC Board the On/Off switch cable (F)

and the PC Board to foot end casing connector cable (G). Note carefully the connecting

positions of the cable connectors to the PC Board connectors (On/Off switch: cable

connector green wire facing pin 11; foot end casing connector cable: connector black wire

facing pin 1). Lay cover on a workbench.

7. Remove the On/Off switch (L) by squeezing both sides and passing it through its housing

aperture.

8. Reverse the above steps to install replacement On/Off switch.

9. Test On/Off switch and LED state indicator for proper operation before returning bed to

service.

4.10 BED POWER CORD REPLACEMENT

E

NNOOTTE

Step 9 of this procedure requires that the connector be removed from the extremity of the power

cord in order to remove the cord from the head end casing. The connector does not pass

through the orifice provided for the power cord. A special tool exists that enables the removal of

the connector without damaging the cord wires or the connector female sockets. If this tool is

not available and you have to cut the wires to remove the connector, be sure to order the

connector (P/N QDF8042) in addition to the power cord.

HEAD END

1. Unplug the power cord from the wall receptacle.

2. Remove the head panel.

3. Remove the fourteen screws (C, fig. 4.1B, page 24) holding the head end casing cover (E,

fig. 4.1B, page 24) and remove cover.

35

Page 36

Chapter 4 The GO BED Maintenance Manual

4. Cut cable tie holding wires together.

5. Disconnect the bed power cord connector (A) from the PC Board power cord connector (B).

Note the connecting position of the connectors, white wire opposite white wire, black

opposite black.

6. Remove locknut (C) holding the power cord ground wire (green) (D) to the head end casing.

Note position of the ground wire among the others. Remove wire.

E

NNOOTTE

Replace the power cord ground wire exactly at the same position it was before being

removed.

7. Use pliers to squeeze the strain relief bushing (E) and remove it from its location by pulling

the cable from under the head end casing. Remove bushing from cable.

8. Remove connector (A) from end of power cord to remove power cord from head end casing.

E

NNOOTTE

Do not install connector before having inserted the power cord extremity in the head end

casing through the orifice provided. Remember that the connector does not pass through

the orifice provided for the power cord.

9. Remove defective power cord.

10. Reverse the above steps to install replacement power cord.

11. Test power cord for proper operation before returning bed to service.

4.11 NIGHT LIGHT SYSTEM COMPONENT REPLACEMENT

E

NNOOTTE

The following procedure aims at troubleshooting and replacing a defective part in the

photoelectric night light assembly.

1. Raise bed to maximum elevation and lock casters.

2. Put the head side-rails in the down position and raise the foot side-rails.

3. Raise the Knee Gatch to the high position.

4. Unplug the power cord from the wall receptacle.

5. Remove the head panel.

6. Manually lift and fold the foot section back towards the head end of the bed (see figure 4.1

in Appendix B).

7. Remove night light located on the left rail at the foot end of the bed (see fig. 4.11, page 37).

8. Check bulb and replace if necessary with a 120V, 7W type bulb and/or check that bulb is

correctly inserted into the socket. Plug night light into a 120V wall power receptacle and

mask the photoelectric cell. Does the bulb light up?

NO: Proceed to step 9. YES: Plug night light back into bed socket.

Does night light work properly when plugged back to bed and photo cell masked?

NO: Proceed to step 9. YES: End the procedure.

9. Replace photoelectric night light with a new 120V, 7.5W max. type and test on a 120V wall

power receptacle for proper functioning. Plug night light back into bed socket.

Does night light work properly when plugged back to bed and photo cell masked?

NO: Proceed with step 10. YES: End the procedure.

10. Remove night light from the bed socket.

11. Use the necessary equipment for proper static protection (see "Static Discharge

Precautions, page 8).

36

Page 37

Maintenance Procedures Chapter 4

C

A

12. Remove the 12 screws (A, B, fig. 4.7A, page 32) holding the foot end casing cover (C, fig.

4.7A, page 32) and the two IV pole holders (E, fig. 4.7A, page 32) to the foot end casing.

13. Lift up and hold cover while disconnecting from the PC Board the On/Off switch cable (F, fig.

4.7A, page 32) and the PC Board to foot end casing connector cable (G, fig. 4.7A, page 32).

Note carefully the connecting positions of the cable connectors to the PC Board connectors

(On/Off switch: cable connector green wire facing pin 11; foot end casing connector cable:

connector black wire facing pin 1). Lay cover aside.

D

B

NIGHT LIGHT

FOOT END

CASING

Figure 4.11

14. Disconnect the night light cable connector (A) from the PC Board power cord connector (B).

Note the connecting position of the connectors, white wire facing white wire, black facing

black.

15. Cut the cable tie holding cables together.

16. Remove the 3 screws (C) holding the rail cover (D) to the left rail and slowly remove rail

cover from its location. The night light wiring will follow.

17. Make necessary tests to detect faulty component.

18. Reverse steps to install night light assembly with replacement component.

19. Test night light for proper operation before returning bed to service.

37

Page 38

Chapter 4 The GO BED Maintenance Manual

WWAARRNNIINNG

G

Figure 4.12

A

C

D E

4.12 120V AUXILIARY OUTLET COMPONENT REPLACEMENT

Always unplug the power cord from the wall outlet when cleaning or servicing the bed.

Danger: 120V current.

E

NNOOTTE

The following procedure aims at troubleshooting and replacing a defective part in the 120V

auxiliary outlet assembly.

1. Raise the bed to high position and lock casters.

2. Unplug the power cord from the wall receptacle.

3. Remove the 12 screws (A, B, fig. 4.7A, page 32) holding the foot end casing cover (C, fig.