Page 1

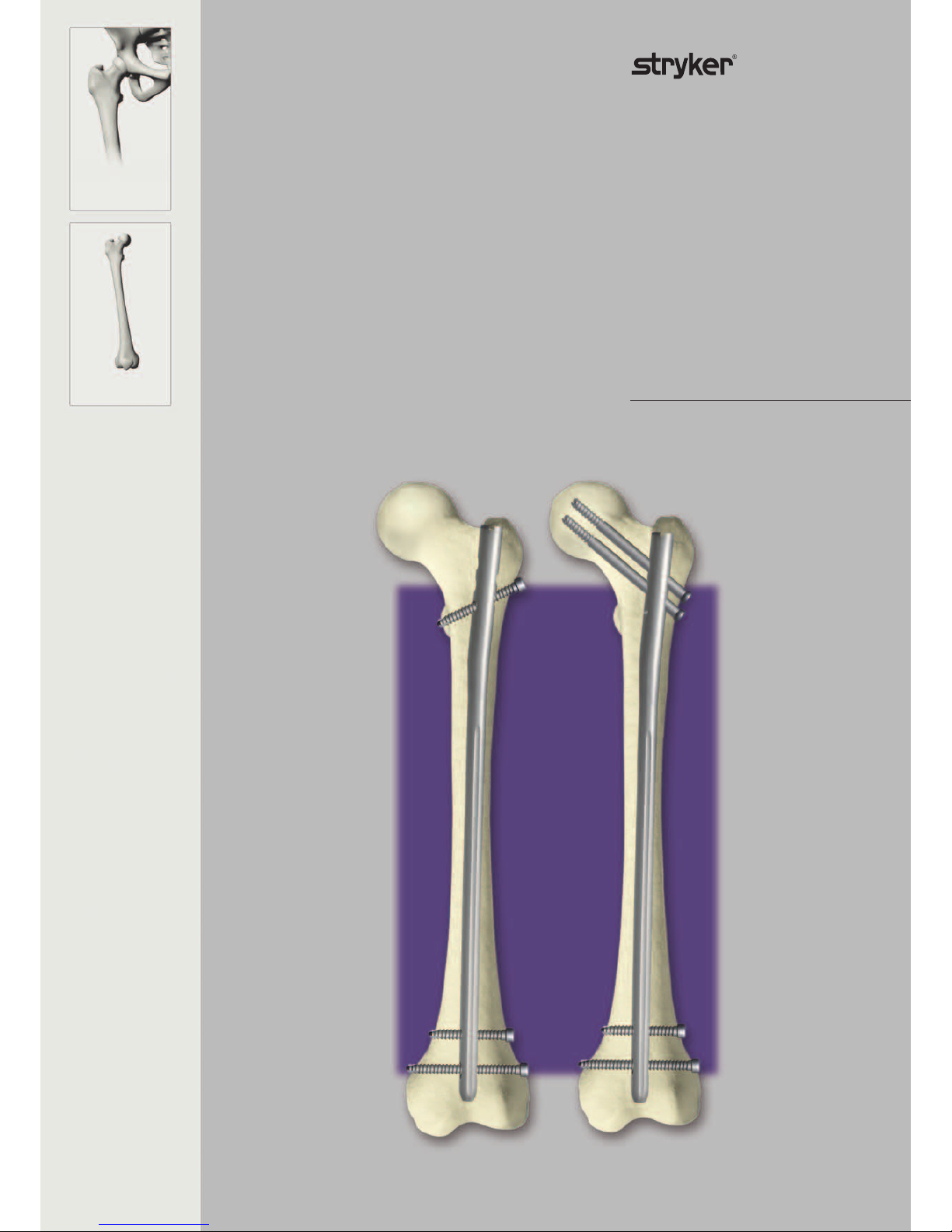

Operative Technique

KnifeLight

Carpal Tunnel Ligament Release

T2

Recon Nailing System R2.0

Operative Techn ique

Hip & Femur Fractures

Hip

Femur

Page 2

T2 Recon Nailing System

We greatly acknowledge and

appreciate the contributions to this

operative technique made by:

Kevin W. Luke, M.D.

Parkview Orthopaedic Group

Assistant Clinical Professor

Department of Orthopaedic Surgery

University of Illinois

Illinois, Chicago

USA

Anthony T. Sorkin, M.D.

Rockford Orthopaedic Associates, LLP

Clinical Instructor

Dep. of Surgery University of Illinois

College of Medicine

Director Orthopaedic Traumatology

Rockford Memorial Hospital

Rockford, Illinois

USA

Ariaan D.P. van Walsum, MD

Trauma surgeon

Medical Spectrum Twente

Enschede

Netherlands

Don Weber, MD, FRCSC

Associate Clinical Professor of

Orthopaedics

Chief of Orthopaedics

University of Alberta Hospital

Edmonton, Alberta

Canada

Contributing Surgeons

2

Page 3

This publication sets forth detailed

recommended procedures for using

Stryker Osteosynthesis devices and

instruments.

It offers guidance that you should

heed, but, as with any such technical

guide, each surgeon must consider

the particular needs of each patient

and make appropriate adjustments

when and as required.

A workshop training is required prior

to first surgery.

All non-sterile devices must be

cleaned and sterilized before use.

Follow the instructions provided in

our reprocessing guide (L24002000).

Multi-component instruments must

be disassembled for cleaning. Please

refer to the corresponding assembly/

disassembly instructions.

See package insert (L22000007) for

a complete list of potential adverse

effects, contraindications, warnings

and precautions. The surgeon must

discuss all relevant risks, including

the finite lifetime of the device, with

the patient, when necessary.

Warn ing :

Fixation Screws:

Stryker Osteosynthesis bone

screws are not approved or

intended for screw attachment

or fixation to the posterior elements (pedicles) of the cervical,

thoracic or lumbar spine.

3

Page 4

Contents

Page

1. Introduction & Features 5

Implant Features 5

Technical Specifications 6

Instrument Features 7

2. Indications, Precautions & Contraindications 8

3. Pre-operative Planning 9

4. Locking Options 10

5. Operative Technique 11

Patient Positioning and Fracture Reduction 11

Incision 11

Entry Point 12

Re a ming 14

Nail Selection 16

Assembly of the Targeting Device and the Nail 17

Nail Insertion 18

Final Seating with Impactor 18

Guided Locking for the Recon Mode 19

Guided Locking for Antegrade Femoral Mode 29

Freehand Distal Locking 32

Set Screw or End Cap Insertion 34

Nail Removal 34

Ordering Information – Implants 35

Ordering Information – Instruments 37

4

Page 5

Introduction

Over the past decades antegrade

and retrograde femoral nailing have

become widely accepted choices for

the treatment of femoral fractures.

The T2 Recon nail is one of the first

femoral nailing systems to offer a

greater trochanter entry point with

both recon and antegrade locking

options.

Through the development of a

common, streamlined instrument

system and intuitive surgical approach,

both in principle and in detail, the T2

Recon Nail offers the potential for

more efficient treatment of fractures

as well as simplifying the training

requirements for all person nel

involved.

Furthermore, the T2 Recon Nail offers

the following competitive advantages:

• Versatility-offerstheabilityto

switch from antegrade to a recon

option without changing either

the nail or targeting arm.

• ReconSetScrew-thisoptional

screw sets the most proximal

Lag Screw thus minimizing

the potential for screw sliding

(Z-effect).

• LockingOptions-distaloptions

include dynamic as well as static.

• DistalTargeting-eliminatesthe

need for freehand locking of either

the static or dynamic modes.

RequiresoptionalGamma3/T2

ReconDTSR2.0

The T2 Recon Nail is the realization

of excellent biomechanical intramedullary stabilization for internal

femoral fixation with several locking

options to address fracture variability.

As with all other T2 Nails, the T2

Recon Nail is made of Type II

anodized Titanium Alloy (Ti6Al4V)

for enhanced biomechanical and

biomedical performance*.

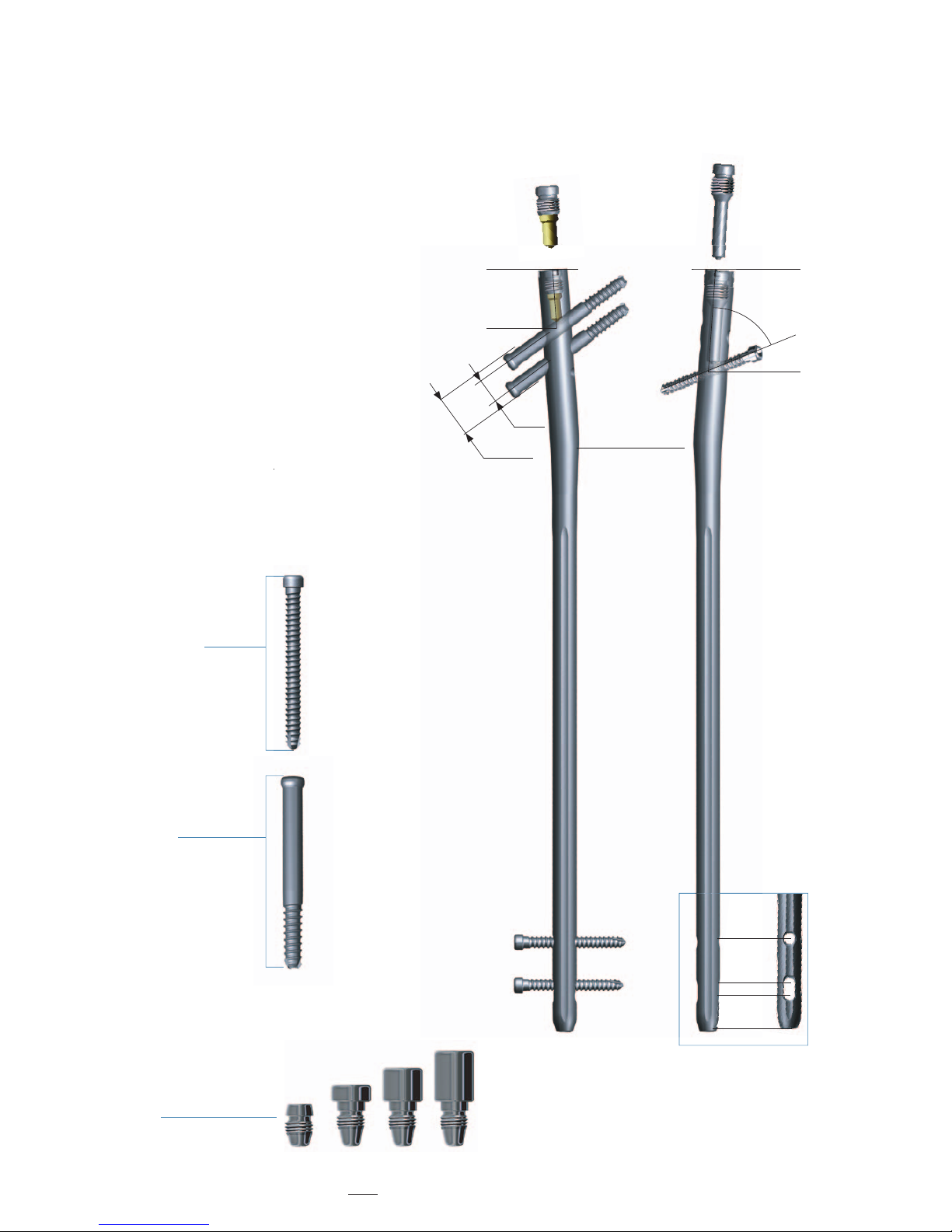

The T2 Recon Nail features a 125°

CCDanglewitha10°anteversion

angle. The 2 proximal holes, each

utilize 6.5mm cannulated Lag

Screws. This CCDangle allows easy

insertion of the 2 lag screws into the

femoral head.

Alternatively a proximal 70° Oblique

hole with 7° retroversion provides

a 5mm Fully Threaded Screw for

targeting the lesser trochanter in the

Femoral Antegrade mode.

The 6.5 mm Cannulated Lag Screws

have a unique thread design that

provide an excellent grip. Improved

front cutting flutes allow for lesser

insertion torque and thinner flanks for

less bone removal.

Secure placement of the Lag Screws

within small neck diameters can be

achieved due to 10mm separating the

two 6.5mm lag screws or 17mm outer

distance between the 6.5mm Lag screws.

Two Set Screws are available:

- Recon Set Screw: Tightens the

6.5mm proximal Lag Screw (Recon

Mode) and

- Antegrade Set Screw: Tightens the

oblique 5mm Fully Threaded Screw

(Femoral Antegrade Mode).

Available as left and right versions,

the T2 Recon Nail incorporates an

antecurvature radius of 2.0M, as

well as a 4° medial lateral bend for

trochanteric insertion.

The distal locking configuration

features a round and an oblong hole to

allow for staticand/ordynamic

distal locking.

Low profile 5mm cortical screws,

common to the T2 Nailing System,

are designed to simplif y the surgical

procedure and promote a minimally

invasive approach.

5mm Fully Threaded Locking Screws

are available for distal locking (Recon

or Femoral Antegrade Mode) and

for the proximal locking in Femoral

Antegrade Mode.

End Caps are available in various

lengths to provide a better fit.

See the detailed chart on the next page

for the design specifications and size

offerings.

Implant FeaturesIntroduction

* Axel Bauman n, Nils Zander, Ti6Al4V with

Anodization Type II: Biological Behaviour and

Biomecha nical Effects, White Paper, March 2005.

5

Page 6

Introduction

NailDiameter 9, 11, 13 and 15mm

(Left and Right)

Sizes 280−480mm,

in 20mm increments

Note:

• Proximal diameter is 13mm for

the 9 and 11mm Nails and 15mm

for the 13 and 15mm Nails.

• Check with your local

representative regarding

availability of nail sizes.

5.0mm Fully Threaded

Locking Screws

L = 25–120mm

6.5mm Cannulated

Lag Screws

L = 65–130mm

Antegrade Set Screw

End Caps

Stand ard +5mm +10mm +15mm

0mm

Antecurvature

radius 2.0M

40mm

20mm

15mm

0mm

4° Medial Lateral bend

44mm

70°

125°Nail angle

0mm

26mm

10.5 mm

Technical Specifi cations

Recon Set Screw

17.0 mm

Note:

Screw length is measured

from top of head to tip.

6

Page 7

Introduction

Instrument Features

A major advantage of the T2

instrument platform is the integration

of core instruments that can be

used not only for the complete T2

Nailing System, but for future Stryker

Osteosynthesis nailing systems,

thereby, reducing complexity and

inventory.

The T2 instrument platform offers

precision and usability, as well as

ergonomically styled targeting devices.

Except for the addition of a small

number of dedicated instruments, the

T2 Femur instrument platform is used

for the T2 Recon Nail.

The T2 Recon targeting device is

designed to provide two proximal locking

options: Recon or Antegrade Femoral

Modes.

Reconmode: Provides two (2)

proximal holes targeting the femoral

neck and head:

• B Targets the Proximal Recon

6.5 mm Lag Screw

• A Targets the Distal Recon

6.5 mm Lag Screw

Antegrade Femoral Mode : Provides a

single 5mm Oblique Screw targeting

the lesser trochanter. LEFT is used for

a left nail and RIGHT for a right nail.

With the exception of the carbon

fi ber targeting device, dedicated

instruments for the recon mode are

color coded with “bronze”.

This makes it easy to differentiate

them from the core T2 instrument

platform.

Drills

Drillsfeaturecolorcodedrings:

4.2mm = Green

(Consistent with the Gamma3 and

T2 Instrument Plat form, this drill

features a green color ring.)

The 4.2mm drills are used for 5.0mm

Fully Threaded Locking Screws (either

for distal locking or for proximal

oblique locking).

6.5mm

The Solid Stepdrill for the Lag Screw

is color coded with “bronze”.

Targeting holes

for Recon Mode

B

A

Targeting holes

for Antegrade

Femoral Mode

Left

Right

7

Page 8

Indications, Precautions & Contraindications

Indications

The T2 Recon Nail is indicated for:

• Subtrochanteric fractures

• Intertrochanteric fractures

• Ipsilateral neck/shaft fractures

• Comminuted proximal femoral

shaft fractures

• Femoral fi xation required as a

result of pathological disease

• Temporary stabilization of

fractures of the femoral shaft ranging from the femoral neck to

the supracondylar regions of the

femur.

Precautions

Contraindications

The physician’s education, training

and professional judgement must

be relied upon to choose the most

appropriate device and treatment.

Conditions presenting an increased

risk of failure include:

• Any active or suspected latent

infection or marked local

infl ammation in or about the

affected area.

• Compromised vascularity that

would inhibit adequate blood

supply to the fracture or the

operative site.

• Bone stock compromised by

disease, infection or prior

implantation that can not provide

adequate support and/or fi xation

of the devices.

• Material sensitivity, documented

or suspected.

• Obesity. An overweight or obese

patient can produce loads on the

implant that can lead to failure

of the fi xation of the device or to

failure of the device itself.

Stryker Osteosynthesis systems have

not been evaluated for safety and use

in MR environment and have not been

tested for heating or migration in the

MR environment, unless specified

otherwise in the product labeling or

respective operative technique.

Antegrade Mode

Recon Mode

• Patients having inadequate tissue

coverage over the operative site.

• Implant utilization that would

interfere with anatomical

structures or physiological

performance.

• Any mental or neuromuscular

disorder which would create an

unacceptable risk of fi xation

failure or complications in

postoperative care.

• Other medical or surgical

conditions which would preclude

the potential benefi t of surgery.

8

Page 9

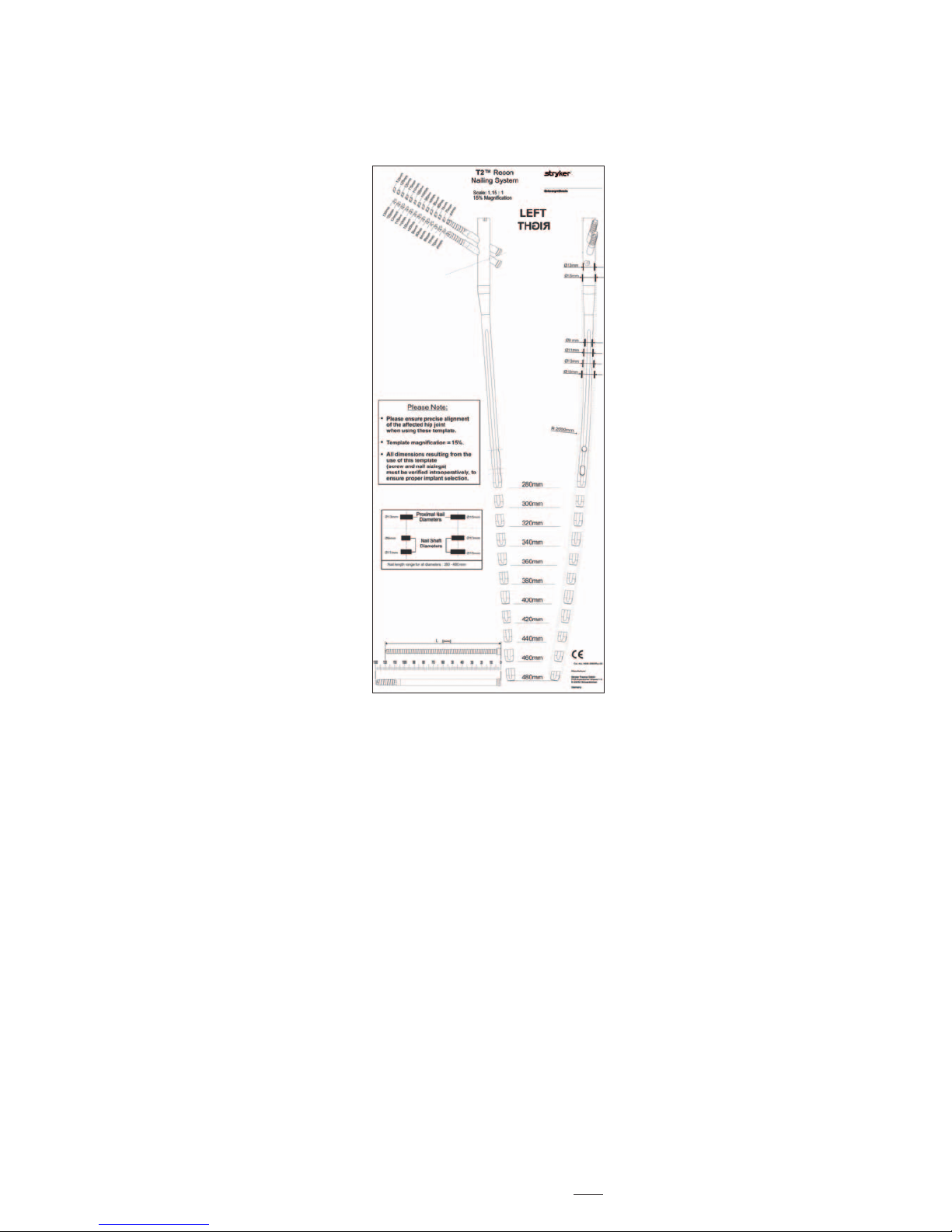

An X-Ray Recon Template (1806-3080)

is available for pre-operative planning.

Thorough evaluation of pre-operative

radiographs of the affected extremity

is critical. Careful radiographic

examination of the trochanteric

region and neck regions can reduce

the potential of intra-operative

complications.

Note:

TheX-RayReconTemplate

features a scale of 1.15:1 which

is adapted to conventional

analoguousX-Rays.Fordigital

X-Rays,attentionhastobe

paid that the magnification is

corresponding with the template.

According to the fracture type either

Recon or Antegrade Femoral Mode

can be chosen.

Evaluation of the femoral neck

angle on the pre-operative X-Rays is

mandatory as the T2 Recon Nail has a

fixed 125° neck angle for the two Lag

Screws. Proper placement of both Lag

Screws in the femoral head is essential.

If possible, X-Rays of the contralateral

side should be used to determine the

normal neck angle and length of the

femur.

The proper nail length should extend

from the tip of the greater trochanter

to the epiphyseal scar.

Note:

Check with your local

representative regarding

availability of nail sizes.

Pre-Operative Planning

9

Page 10

Locking Options

The T2 Recon Nail can be locked

proximally with two 6.5mm Lag

Screws (Recon Mode, Fig. 1) or with

one 5mm Fully Threaded Screw

(Antegrade Femoral Mode, Fig. 2).

For both Recon and Antegrade

Femoral applications, depending

on fracture pattern, either static or

dynamic distal locking can be used.

Fig. 1

Fig. 2

Recon Mode

Antegrade Femoral Mode

10

Page 11

Operative Technique

Fig. 3

Fig. 5

Fig. 4

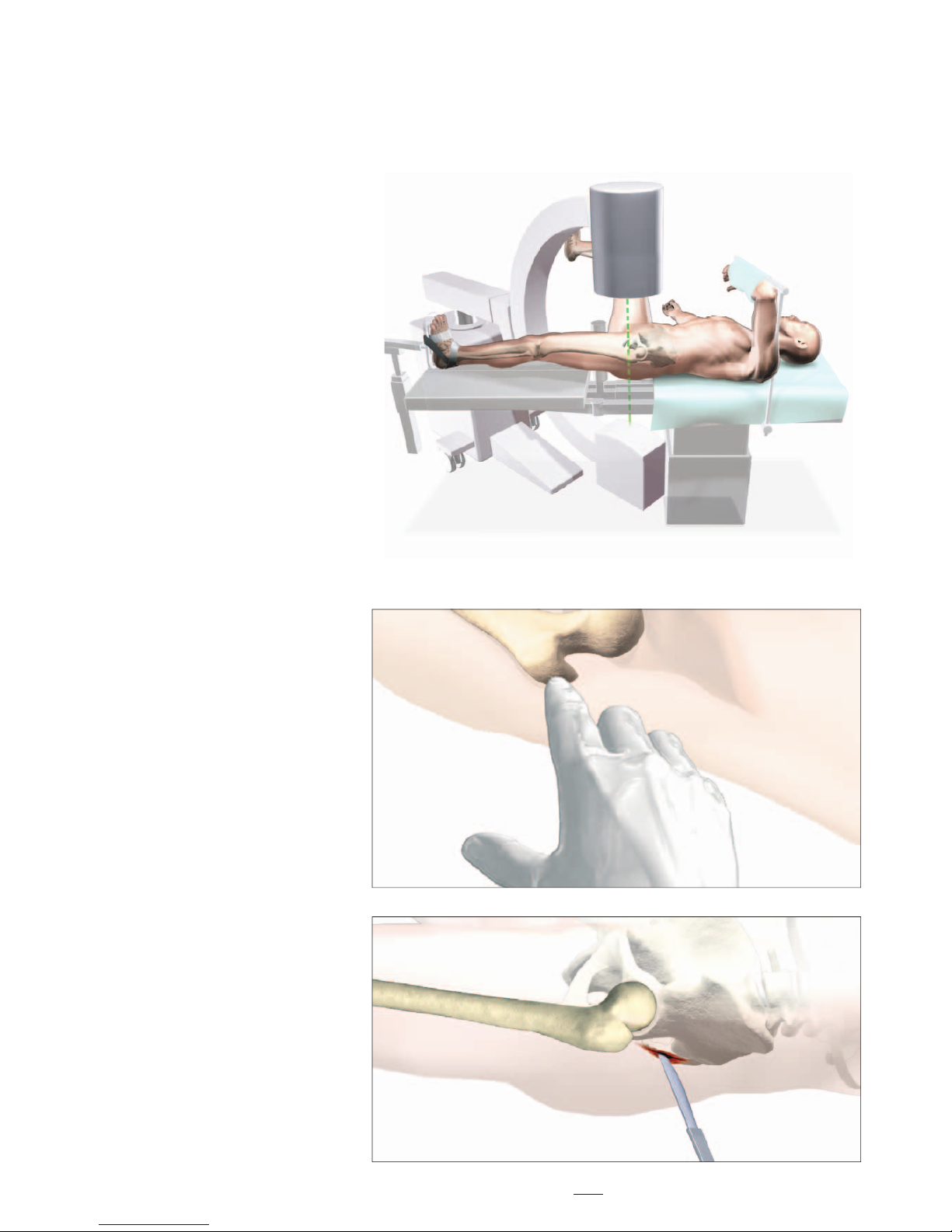

Patient positioning for T2 Recon

Nail insertion is surgeon dependent.

However, it is recommended that

patients are positioned in either the

supine or lateral position on a fracture

table to allow closed reduction of the

frac ture (Fig. 3).

Manipulate and reduce the fracture

in the usual fashion, according to the

fracture type. Reduction should be

achieved as anatomically as possible.

If this is not possible, reduction in

one plane should be complete, leaving

reduction in the other plane to be

achieved prior to reaming and nail

insertion.

The unaffected leg is abducted as far

as possible to ease image intensifi er

positioning. This will also allow easier

access to entry point.

Patient Positioning and Fracture Reduction

Incision

The design of the T2 Recon Nail, with

a 4° medial lateral bend, will only

allow for insertion through the tip of

the greater trochanter.

With experience, the tip of the greater

trochanter can be identifi ed by

palpation (Fig. 4).

A longitudinal skin incision of

approximately 3−5cm is made starting

just above the greater trochanter to the

iliac crest (Fig. 5). The incision is then

deepened to expose the tip of greater

trochanter.

Smaller or larger incisions may be

used based on individual patients

anatomy and at the surgeon’s

discretion.

Note:

The targeting instruments of the

T2ReconNailhavebeendesigned

to allow for a more percutaneous

approach.

11

Page 12

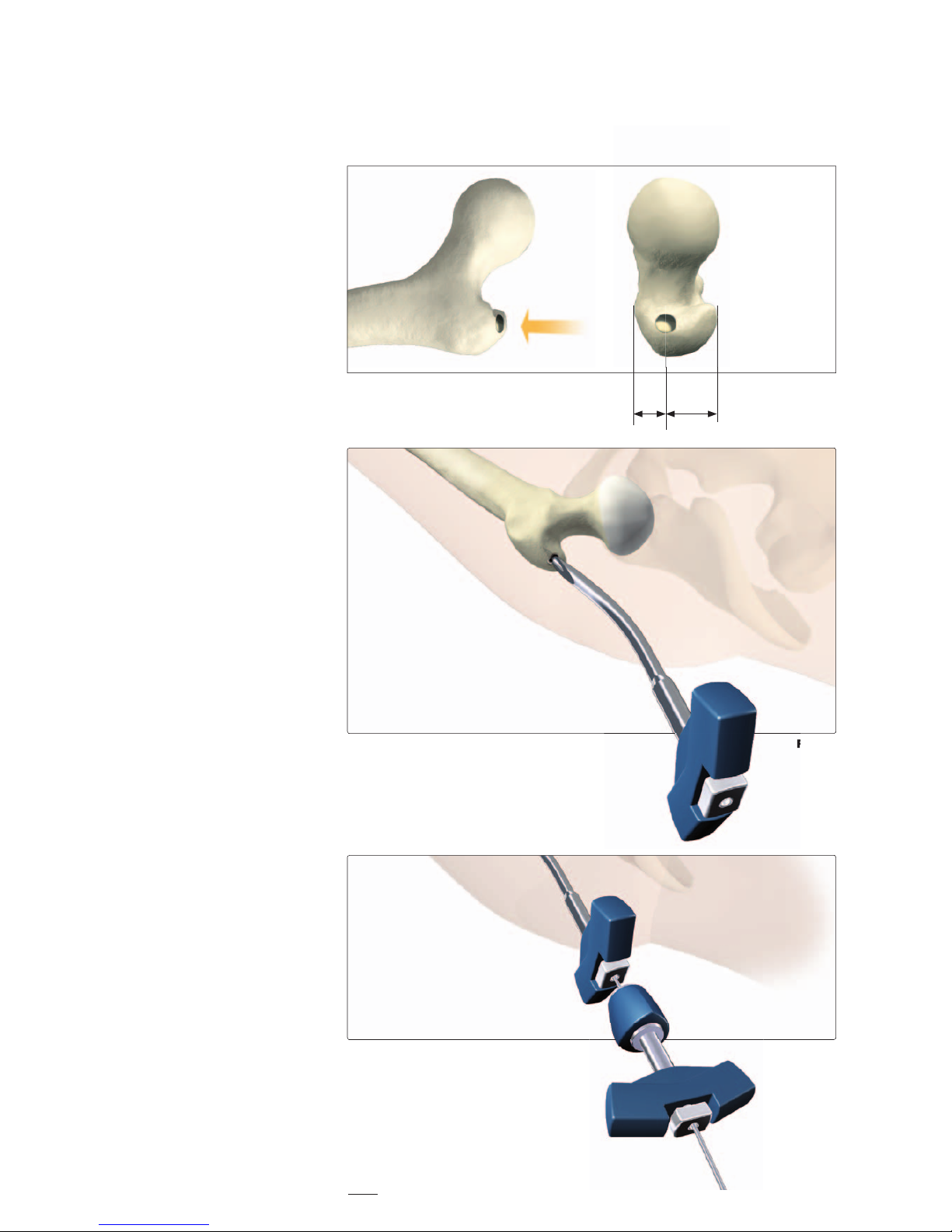

The entry point is located at the

junction of the anterior third and

posterior two-thirds of the greater

trochanter on the medial edge of the tip

itself (Fig. 6).

Note:

Before opening the tip of greater

trochanter, image intensifi er

views(A/PandM/L)should

be used to confi rm correct

identifi cation of the entry point.

The medullary canal can be opened

with the

• CurvedAwl/CurvedAwl,90°

Handle or

• OneStepConicalReamer.

Note:

Densecorticalbonemayblock

the tip of the Awl during opening

of the entry portal. Inserting

fi rst the optional Awl Plug into

the Awl will avoid penetration of

bone debris into the cannulated

Awl shaft. The Awl Plug is

thenremovedforGuideWire

insertion.

• Entry point with Curved Awl

Once the tip of the greater trochanter

has been opened (Fig. 7a), the

Ø3 × 1000mm Ball Tip Guide Wire

may be advanced through the

cannulation of the Curved Awl with

the Guide Wire Handle and Chuck

(Fig. 7 b).

The proximal femur may then be

prepared with the One Step Conical

Reamer.

anterior posterior

1

/

3

2

/

3

Fig. 6

Fig. 7a

Fig. 7b

Operative Technique

Entry Point

• The Tip of the

Greater Trochanter

Fig. 7a

12

Page 13

Fig. 9

Fig. 8

K-Wire

Fig. 8a

Operative Technique

• Entry point with

One Step Conical Reamer

Alternatively, the 13mm diameter

One Step Conical Reamer for the

9 and 11mm nails or the 15mm

diameter Reamer for the 13 and 15mm

nails may be used for opening the

medullary canal and reaming of the

trochanteric region.

Under image intensifi cation control,

the entry point is made with a

Ø3.2 × 400mm Recon K-Wire which

is attached to the Guide Wire Handle

and advanced into the medullary

canal. Confi rm its placement within

the center of the medullary canal

on A/P and lateral image intensifi er

views.

Note:

TheReconK-Wireusedforthe

entry point should not be used

again for the Lag Screw insertion.

It is recommended that a new

K-Wirebeutilized.

The Recon Protection Sleeve and

Multi-hole Trocar are positioned with

the central hole over the K-Wire.

Note:

The Multi-hole Trocar has a

special design for more precise

insertionoftheØ3.2mmRecon

K-Wire(Fig.8).Besidethecentral

hole, 4 other holes are located

eccentrically at different distances

from the center (Fig. 8a) to easily

revise insertion of the guiding

K-Wireintheproperposition

(entry point).

When correct placement of the guiding

Recon K-Wire is confi rmed on image

intensifi er views (A/P and lateral),

keep the Tissue Protection Sleeve

in place and remove the Multi-hole

Trocar.

The T-Handle is attached to the

One Step Conical Reamer and hand

reaming is performed over the Recon

K-Wire through the Tissue Protection

Sleeve (Fig. 9).

The Recon K-Wire is then removed

and replaced with the Ø3 × 1000mm

Ball Tip Guide Wire.

13

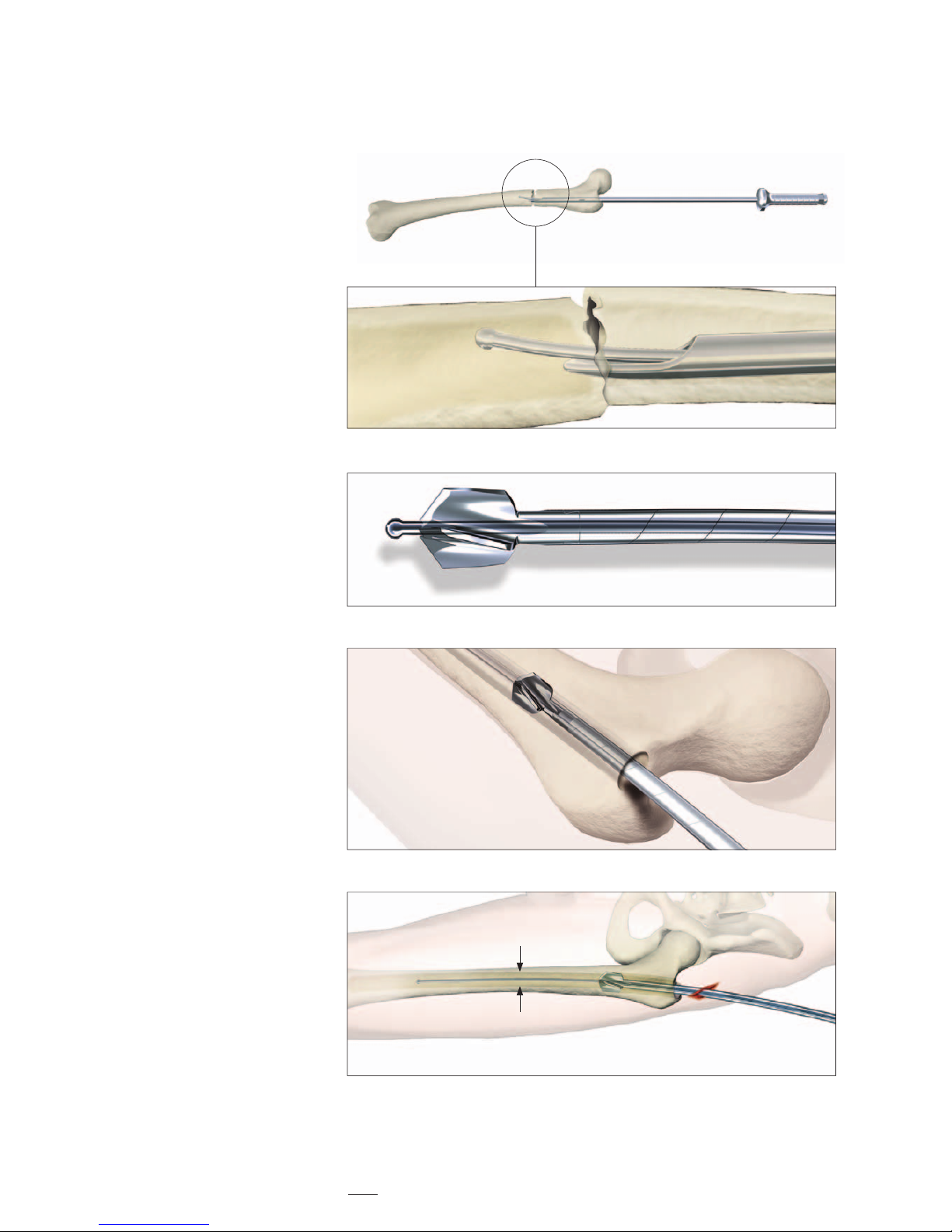

Page 14

The Ø 3 × 1000mm Ball Tip Guide

Wire is inserted with the Guide

Wire Hand le throug h the frac tu re site

to the level of the epiphyseal scar.

The Ø 9mm Universal Rod with

Reduction Spoon may be used as a

fracture reduction tool to facilitate

Guide Wire insertion through the

fracture site (Fig. 10).

Note:

The Ball Tip at the end of the

GuideWirewillstoptheBixcut

reamer* head (Fig. 11).

Caution:

Prior to reaming, it is important

to check the centered

intramedullary position of the

GuideWirewiththeimagein-

ten sifi er. Lateral displacement

oftheGuideWirecouldleadto

resection of more bone on the

lateral side of the wire, which in

turn will lead to an offset position

of the nail and increase the risk of

a shaft fracture.

Note:

Make sure that the reduction

is maintained throughout the

reaming process.

Reaming is commenced in 0.5mm

in crements until cortical contact

occurs (Fig. 12).

For easier nail insertion, the

medullary canal should be reamed at

least 2mm more than the diameter of

selected nail (Fig. 13).

Fig. 10

Fig. 12

Fig. 13

Fig. 11

Operative Technique

Reaming

* see pages 36-37 for additiona l Bixcut Reamer

system details

+ 2mm more than the

selected nail diameter

14

Page 15

Note:

TheT2ReconNailmaybeinser-

ted without reaming of the

subtrochanteric and diaphyseal

region of the femur, particularly

in eldery patients with wide

medullary canals. If appropriate,

after the trochanteric region has

been prepared with the One Step

ConicalReamer,thenailcanbe

inserted without further reaming

of the medullary canal.

Operative Technique

The Guide Wire Pusher can be used to

keep the Guide Wire in position

during reamer shaft extraction. The

metal cavity at the end of the blue

Elastosil handle may be placed on the

end of Guide Wire. Applying pressure

to hold the Guide Wire in place while

removing the drill under power.

(Fig. 14).

When close to the Guide Wire end,

place the Guide Wire Pusher with its

funnel tip at the end of the power tool

cannulation (Fig. 15).

While removing the power tool the

Guide Wire Pusher will keep the

Guide Wire in place.

Guide Wire Pusher (1806- 0271)

Fig. 15

Fig. 14

Reaming of the trochanteric region is

needed (Fig. 13) as the proximal nail

diameter (driving end) is larger than the

nail diameter (13mm for the 9 and

11mm diameter nails and 15mm for

the 13 and 15mm diameter nails).

For both reamed or unreamed

applications, the proximal 5cm of the

trochanteric region must be opened to at

least 13mm or 15mm, depending on the

proximal diameter of the nail.

15

Page 16

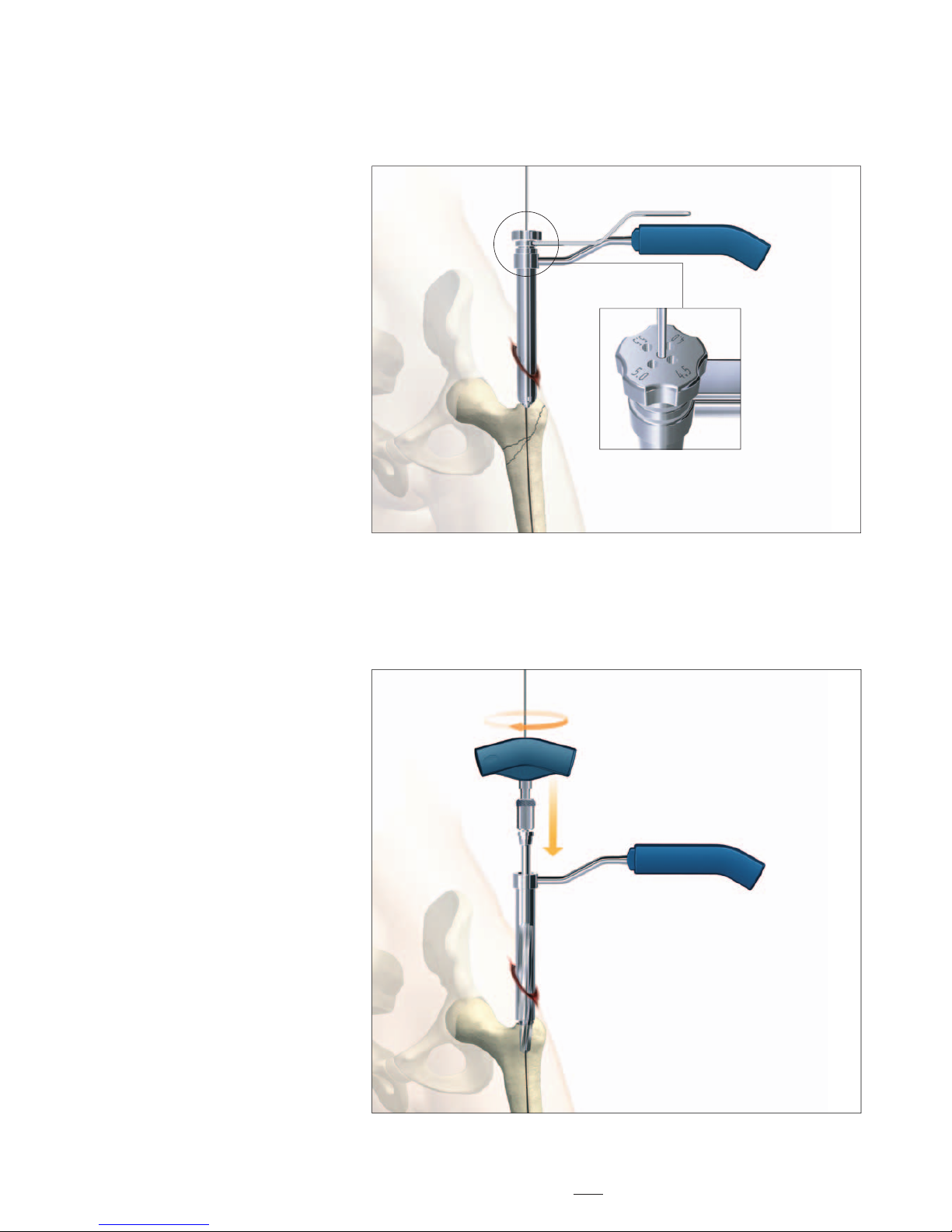

Fig. 17a

Fig. 16a

Diameter

The diameter of the selected nail

should be at least 2.0mm smaller than

that of the last reamer used.

Length

Nail length may be determined by

measuring the remaining length of the

Guide Wire. The Guide Wire Ruler

may be used by placing it on the Guide

Wire and reading the correct nail

length at the end of the Guide Wire on

the Guide Wire Ruler (Fig. 16a, b).

Upon completion of reaming, the

appropriate size nail is ready for

insertion. A unique design feature

of the T2 Recon Nail is that the

Ø3 × 1000mm Ball Tip Guide Wire

does not need to be exchanged.

The selected nail is assembled onto the

Targeting Arm with the Nail Holding

Screw (Fig. 17a). Be sure to securely

tighten the Nail Holding Screw with

the Screwdriver Shaft, Ball Tip and

T-Handle so that it does not loosen

during nail insertion.

Caution:

Prior to the nail insertion,

check the correct assembly

by passing the Stepdrill for

LagScrewthroughtheRecon

Tissue Protection Sleeve and

DrillSleeve,Recon(placedin

the corresponding hole of the

Targeting Arm) and through the

holes of the nail (Fig. 17b).

For the Antegrade Femoral

Mode, use the targeting hole

for Antegrade with the Tissue

ProtectionSleeveandDrill

Sleeve assembly to pass the

Ø4.2×340mmDrillthroughthe

oblique hole of the nail.

Operative Technique

Nail Selection

Fig. 17b

Fig. 17a

Tissue Protection Sleeve and

DrillSleeve,Recon(placedin

the corresponding hole of the

Targeting Arm) and through the

holes of the nail (Fig. 17b).

For the Antegrade Femoral

Mode, use the targeting hole

for Antegrade with the Tissue

ProtectionSleeveandDrill

Sleeve assembly to pass the

Ø4.2×340mmDrillthroughthe

oblique hole of the nail.

Fig. 16b

End of Guide Wire Ruler

is measurement reference

16

Page 17

Fig. 18a Fig. 18b Fig. 18c

First, assemble the Knob to the Targeting Device by aligning the arrow on

the Knob with the white line on the

Target Sleeve, (Fig. 18a) then push

hard to click it.

By turning the Knob clockwise to the

position labeled (A), the sleeve inserted

in target (A) position, which is the

distal Recon Mode targeting hole, can

be locked. (Fig. 18b)

By further turning the Knob clockwise

to the position labeled (A+B), both

sleeves inserted in (A) and (B), which

are the both proximal and distal recon

mode targeting holes, can be locked.

(Fig. 18c)

Operative Technique

Assembly of Targeting Device

17

Page 18

Fig. 19

Operative Technique

The nail is advanced through the

entry point passing the fracture site to

the appropriate level.

If dense bone is encountered, fi rst

re-evaluate that suffi cient reaming

has been achieved, then, if necessary,

the Strike Plate can be attached to

the Targeting Arm and the Slotted

Hammer may be used to further insert

the nail (Fig. 19).

Caution:

The nail must progress smoothly,

without excessive force. If too

much resistance is encountered,

removal of the nail and additional

reaming is recommended.

Note:

RemovetheGuideWirepriorto

drillingorK-Wireinsertion.

The carbon fi ber guide should never

be struck as it may break or become

deformed. The impactor that is

provided can be utilized to assist with

fi nal seating of the nail. Gentle tapping

will produce small adjustments (in

the nail position) that can help to

optimize the ultimate position of the

lag screw in the femoral head. The nail

holding screw should be re-tightened

following any use of the impactor.

The impactor should not be utilized

to force the nail down the canal. If

the nail cannot be seated manually

or if there is no advancement each

time the impactor is tapped, A/P and

Lateral fl uoroscopic X-Rays should

be reviewed to determine the cause

of the impingement - there may be a

mismatch between the nail geometry

and the medullary canal. The starting

position, the femoral bow and the

canal diameter should all be examined

to ensure that the leading end of the

nail is not impinging on the medial

or anterior cortex and that the canal

itself has been suffi ciently reamed.

Nail Insertion

Final Seating with Impactor

Periodically, nail removal and further

reaming of the diaphysis may be

required.

The proximal metaphyseal fl air may

be undersized (particularly in young

patients or those of short stature) and

serve to prevent nail advancement. If

this situation is encountered, a fl exible

reamer may be used to further widen

this area to the level of the lesser

trochanter.

To facilitate manual passage, the

nail internally rotated 90° until the

fracture has been passed.

18

Page 19

Nail / La g S crews Posit ioning

Drive the T2 Recon Nail to the depth

that correctly aligns the proxi mal

screw holes parallel with the femoral

head and neck under fluoroscopic

control (Fig. 20) .

Two aspects regarding the Nail/Lag

Screws position must be carefully

checked with the image intensifier

before drilling into the femoral head:

- Alignment of the anteversion (M//L

view)

- Depth of nail insertion (A/P view).

The distal Lag Screw should run along

the calcar region (on the A/P view) and

centered into the femoral neck and

head (on the M/L view).

Note:

TheuseoftheOneShotDevice

(1213-3010) is recommended to

predetermine the optimal Lag

Screwplacement.Detailsare

described on Page 20 to 21.

Fig. 20

Fig. 20a

Operative Technique

Guided Locking for the Recon Mode

19

Page 20

Now attach the Recon Paddle Trocar

to the T-Handle, AO Medium

Coupling (Fig. 21).

Then, advance them together with the

Recon Tissue Protection Sleeve to the

skin through the hole on the Target

Device labeled (A). Make a small skin

incision and push the assembly

through until it is in contact with the

lateral cortex. Then turn the Knob

clockwise to the position labeled (A)

(Fig. 22).

Remove the Trocar and then insert the

Recon K-Wire Sleeve through the

Tissue Protection Sleeve. Place a Recon

K-Wire into the K-Wire Inserter and

attach it to the T-Handle.

The K-Wire is then man u ally

advanced through the K-Wire Sleeve

until it reaches the subchon dral bone

of the femoral head (Fig. 23).

Alternatively, the K-Wire Inserter can

be attached to a Power Tool and the

Recon K-Wire is inserted to the same

depth.

Fig. 22

Fig. 23

Fig. 21

Operative Technique

20

Page 21

Operative Technique

Note:

With the image intensifier, verify

iftheK-Wireisplacedalongthe

calcarregionintheA/Pview

and central on the lateral view

(correct anteversion) (Fig. 24).

If the K-Wire is incorrectly positioned,

the first step is to remove it and then

to correct the nail position.

More commonly, the nail is posi tioned

too proximal and correction of the

nail should be carried out either by

hand or by using the Strike Plate

placed into the Target Device. If a

higher position is required, the

Universal Rod and Slot ted Hammer

may then be at tached to the Strike

Plate to carefully and smoothly extract

the assembly (Fig. 25).

The new position is checked again

with the image intensifier as described

above.

Fig. 24

Fig. 25

21

Page 22

Nail/Lag Screws Positioning

with the One Shot Device

The use of the One Shot device

(1213-3010) is recommended to

predetermine the optimal Lag Screw

placement* (Fig. 26). The One Shot

Device is made of carbon fiber

and works by providing a target to

indicate the position of the K-Wire

on the fluoroscope screen. The

target contains 3 radio-opaque wires

embedded in the arm – a dashed inner

wire and two solid outer wires. These

wires work like a gun sight to indicate

the position of the K-Wire.

The One Shot Device is attached

by slightly pressing the grip and

releasing it when positioned onto the

Tissue Protection Sleeve. To correct

the position or remove the device, the

grip must be pressed.

Note:

TheuseoftheOneShotDevice

should not replace any steps in the

T2ReconOperativeTechnique.

While pressing the attachment grip,

the device is positioned between the

anterior aspect of the patient’s hip and

the fluoroscope screen positioned for

an A/P view of the hip (Fig. 26, 27).

Note:

It is important to drape the patient

so that the OneShotDevicedoes

not interfere with any drapes

anterior to the patient’s hip.

When positioned correctly, the target

will appear in the f luoroscopic image

(A/P view) with the dashed inner wire

in the middle of the two solid outer

wires (Fig. 27). If it does not, the One

Shot Device should be moved towards

or away from the patient by pressing

the grip slightly until the target is seen

as described above.

* Tokunaga et al, Correct lag screw positioning

for the Gamma Nail: Development for the

targeting device for inser tion, Osteo Trauma

Care 2005; 13:14-17

Operative Technique

Fig. 27

optimal nail position

too cranial nail position

A/Pview

too caudal nail position

Fig. 26

22

Page 23

Operative Technique

To identify the accurate position, the

dashed wire of the target must appear

between the two solid wires at the

desired position. If the position is

incorrect the T2 Recon Nail position

may be corrected by ei ther pulling

backwards or pushing forwards

(Fig. 28).

The K-Wire can then be placed into

the femur and the targeting arm

is held in place until the K-Wire’s

position in the lateral view has

been determined. When positioned

correctly, the target will appear in the

fluoroscopic lateral view (Fig. 29).

If the dashed wire of the target ap pears between the two solid wires,

then advance the Recon Tissue

Protection Sleeve and Trocar as shown

in Fig. 21.

Warn ing :

PriortoadvancingtheK-Wire,

check the correct guidance

throughtheK-WireSleeve.Do

notusebentK-Wires.

Note:

TheK-Wireinsertedintothemost

distal Lag Screw hole of the nail

helps in achieving the correct

positioning of the nail (depth and

rotation) with minimal resection

of bone in case correction of the

position is needed.

Lateral view

Fig. 2 9

Fig. 2 8

23

Page 24

Operative Technique

Solid Stepdrill Technique

For the insertion of proximal screws

in Recon Mode, the Solid Stepdrill

Technique, which is mentioned in this

chapter, is the recommended method

to optimize the proximal targeting

accuracy.

Attach the Recon Paddle Trocar to the

T-Handle, AO Medium Coupling as

demonstrated in Fig. 21. Then slide the

Tissue Protection Sleeve together with

the Paddle Trocar assembly to the

skin through the proximal target hole

labeled (B).

A small skin incision is made and the

assembly is pushed through until it

is in contact with the lateral cortex.

When the tip of the sleeve is in contact

with the lateral cortex, lock the sleeve

by turning the knob further to the

position labeled (A+B) (Fig. 30).

Then remove the Trocar assembly

and insert the Drill Sleeve for the

Recon Solid Stepdrill while the distal

K-Wire and K-Wire Sleeve are still

left in place. The Drill Sleeve for

the Recon Solid Stepdrill is inserted

through the proximal target hole

labeled (B) of the Targeting Device.

The Ø6.5mm Solid Stepdrill for Recon

Lag Screw is forwarded through the

Tissue Protection Sleeve and Drill

Sleeve assembly and pushed onto the

lateral cortex. There is a dedicated

Drill Sleeve for the Solid Stepdrill

Technique. This Sleeve is marked “Use

with Solid Step Drill“ as shown

(Fig. 31b).

Reaming is performed under

fluoroscopic control just until the tip

of the Solid Stepdrill for Lag Screw

reaches the subchondral bone. The

required length of the Lag Screw can

be read directly off the Recon Solid

Stepdrill for Lag Screw at the end of

the Drill Sleeve (Fig. 31a).

Fig. 31

Fig. 31a

Fig. 31b

Fig. 30

24

Page 25

Operative Technique

Using the Recon Screwdriver the

correct Lag Screw is inserted through

the Tissue Protection Sleeve and

threaded up to the subcondral part

of the femoral head. The screw is

near its proper seating position when

the groove around the shaft of the

screwdriver is approaching the end of

the Tissue Protection Sleeve (Fig. 32,

32a). The required length of the

second Lag Screw can be measured

using the Recon Lag Screw Gauge.

Remove the Distal K-Wire and K-Wire

Sleeve. Then insert the Sleeve for the

solid Stepdrill into the distal Tissue

Protection Sleeve.

Repeat the same surgical steps for

drilling and insertion of the distal Lag

Screw without K-Wire guidance.

After the completion of the distal Lag

Screw insertion, move on to the distal

locking procedure.

Fig. 32

Fig. 32 a

25

Page 26

Operative Technique

Alternatively, the K-Wire can be used

prior to drilling with the Solid Drill.

Place a second Recon K-Wire into the

K-Wire Inserter and attach it to the

T-Handle or power tool. The K-Wire

is then advanced through the K-Wire

Sleeve until it reaches the subchondral

bone of the femoral head.

Warn ing :

CorrectplacementoftheK-Wire

tip in subchondral bone must be

checked with image intensifier in

bothA/PandM/Lviews.

The required length of the Lag Screw

is measured using the Recon Lag

Screw Gauge.

Note:

Before starting to measure, ensure

that the Tissue Protection Sleeve

andK-WireSleeveassemblyis

firmly pressed against the lateral

cortex of the femur (Fig. 32b).

Take the Recon Lag Screw Gauge and

place it directly under the K-Wire

and against the K-Wire Sleeve (Fig.

32c). The correct Lag Screw length

corresponds to the measurement

indicated at the end of the K-Wire on

the Lag Screw Gauge.

After the measurement, remove the

K-Wire and drill the channel with the

Solid Stepdrill according to the Solid

Stepdrill technique described on

page 22.

Fig. 32 b

Fig. 32c

26

Page 27

Operative Technique

Fig. 35

Fig. 33

Fig. 34

The required length of the Lag Screw

is measured using the Recon Lag

Screw Gauge (1806-3035). Before

start ing to measure, ensure that the

Tissue Protection Sleeve and K-Wire

Sleeve assembly is fi rmly pressed

against the lateral cortex of the femur.

Take the Recon Lag Screw Gauge

and place it directly under the distal

K-Wire and against the K-Wire Sleeve

(Fig. 34).

As the Cannulated Stepdrill technique

was also discussed in a previous

version of the operative technique,

the insertion of the proximal screws

in Recon Mode using this method

will also be mentioned as a potential

option.

After achieving a satisfactory position

of the fi rst Recon K-Wire slide the

second Recon Tissue Protection Sleeve

together with the Recon K-Wire Sleeve

into the proximal target hole on the

Targeting Arm, labeled (B).

A small skin incision is made and the

assembly is pushed through until it

is in contact with the lateral cortex

(Fig. 33).

Place a second Recon K-Wire into the

K-Wire Inserter and attach it to the

T-Handle or power tool. The K-Wire

is then advanced through the K-Wire

Sleeve until it penetrates the

subchondral bone of the

femoral head.

Caution:

CorrectplacementoftheK-Wire

tip in subchondral bone must be

checked with image intensifi er in

bothA/PandM/Lviews.

Cannulated Stepdrill Technique

The correct Lag Screw length

corresponds to the measurement

indicated at the end of the K-Wire on

the Lag Screw Gauge. This length will

then be set on the cannulated Recon

Stepdrill for Lag Screw (Fig. 35).

27

Page 28

Operative Technique

Fig. 38

Caution:

Before proceeding with drilling

for the selected Lag Screw, check

theA/Pfluoroscopicviewsto

seeifthetwoReconK-Wiresare

parallel.

The distal K-Wire Sleeve is removed

while the Tissue Protection Sleeve

remains in position (Fig. 36a). The

cannulated Ø6.5mm Recon Stepdrill

for Lag Screw (REF 1806-3025)

is forwarded through the Tissue

Protec tion Sleeve and pushed onto

the lateral cortex. The stop on the

drill will only allow drilling up to

5mm before the K-Wire ends (Fig.

36b).

Warn ing :

Donotusethecannulated

ReconStepdrillforLagScrew

overadeflectedK-Wire.

Using the Recon Screwdriver, the

selected Lag Screw is inserted

through the Tissue Protection Sleeve

and threaded up to the subchondral

bone of the femoral head. The screw

is near its proper seating position

when the groove around the shaft of

the screw driver is approaching the

end of the Tissue Protection Sleeve

(Fig. 37).

Alternatively, the Recon Screwdriver

Shaft may be assembled into the

T-Handle and used for the Lag Screw

insertion.

The required length of the second

Lag Screw is measured using the

Recon Lag Screw Gauge. Repeat the

same surgi cal steps for drilling and

insertion of the proximal Lag Screw

(Fig. 38).

After the completion of the distal

Lag Screw insertion, move on to the

proximal locking procedure.

Fig. 36b

Fig. 36a

Fig. 37

28

Page 29

Operative Technique

Fig. 40

Now attach the Paddle Trocar,

Antegrade and the AO T-Handle

Medium Coupling (Fig. 39). Then,

advance them together with the Long

Tissue Protection Sleeve through

the targeting hole for the Antegrade

Femoral Mode (left or right) by

pressing the safety clip (Fig. 40). The

mecha nism will keep the sleeve in

place and prevent it from falling out.

It will also prevent the sleeve from

sliding during screw measurement. To

release the Tissue Protection Sleeve,

the safety clip must be pressed again.

A small skin incision is made and the

assembly is pushed through by manipulating the T-Handle until the Tissue

Protection Sleeve is in contact with the

lateral cortex (Fig. 41).

Guided Locking for Antegrade Femoral Mode

Fig. 41

Fig. 41

Fig. 39

29

Page 30

Pre-drilling the lateral cortex

Fig. 4 5a

65mm

65mm

Fig. 4 4

Fig. 4 5

Fig. 42

Fig. 4 3

Operative Technique

Pre-drilling opens the lateral cortex

for the drill entry. Pre-drilling helps

to prevent a possible slipping of the

drill on the cortex and may avoid

deflection within the cancellous bone.

The Paddle Trocar Assembly is

then removed and the Drill Sleeve

is inserted through the Long Tissue

Protection Sleeve (Fig. 42). With the

Long Tissue Protection Sleeve firmly

engaged in the cortex, the lateral

cortex should be opened using the

centered tip green coded 4.2mm Drill.

The Drill can be connected with

the AO Teardrop Handle Coupling

allowing pre-drilling by hand (Fig.

43). It also can be done using power.

Note:

For optimal stability, the tip

of the oblique screw should be

positioned at the level of the lesser

trochanter (Fig. 44).

Then use the center-tipped, calibrated

Ø4.2 × 340mm Drill and drill through

both cortices (Fig. 45).

The screw length may be read directly

from the Calibrated Drill at the end of

the Drill Sleeve (Fig. 45a).

Caution:

Start the drill before touching

the bone and then keep a gentle

pressure on the pre-dri lled c ortex

to ensure ac cu rate drilling.

Note:

The position of the drill end, as

it relates to the far cortex, is the

same position where the screw

will end.

30

Page 31

Operative Technique

Therefore, if the end of the Drill

is 3mm beyond the far cortex, the

end of the screw will also be 3mm

beyond (Fig. 46). Check the position

oftheendoftheDrillwithimage

intensification before measuring

the screw length. If the screw

measurement using the Long Screw

Gauge is preferred, first remove the

Long Drill Sleeve and read the screw

length directly at the end of the Long

Tissue Protection Sleeve.

Note:

• Before starting to measure,

ensure that the Tissue Protection

Sleeve/DrillSleeveAssemblyand

K-WireSleeveassemblyisfirmly

pressed against the lateral cortex

of the femur (Fig. 46, 47).

• TheLongScrewGaugeis

calibrated so that with the bend

at the end pulled back flush with

the far cortex, the screw tip will

end 3mm beyond the far cortex

(Fig. 47).

When the Drill Sleeve is removed,

the correct Locking Screw is inserted

through the Tissue Protection Sleeve

using the Long Screwdriver Shaft with

Teardrop Handle (Fig. 48). The screw

is ad vanced through both cortices.

The screw is near its proper seating

posi tion when the groove around the

shaft of the screwdriver is approach ing the end of the Tissue Protection

Sleeve (Fig. 48a).

Fig. 47

65mm

Fig. 46

Fig. 4 8

Fig. 4 8a

31

Page 32

The freehand technique is used to insert

Fully Threaded Locking Screws into

both distal transverse holes in the nail.

Rotational alignment must be checked

prior to locking the nail. This is

performed by checking a lateral view

at the hip and a lateral view at the

knee. The anteversion should be the

same as on the contralateral side.

Multiple locking techniques and

radiolu cent drill devices are available

for freehand locking. The critical step

with any freehand locking technique,

proximal or distal, is to visualize a

perfectly round locking hole with the

C-Arm.

The center-tipped ø4.2 × 180mm

Drill is held at an oblique angle to the

center of the locking hole (Fig. 49).

Upon X-Ray verification, the Drill is

placed perpendicular to the nail and

drilled through the lateral and medial

cortices (Fig. 50). Confirm in both the

A/P and lateral views by X-Ray that

the Drill passes through the hole in

the nail.

After drilling both cortices, the screw

length may be read directly off of the

Long Screw Scale at the green ring on

the center-tipped ø4.2 × 180mm Drill

(Fig. 51).

Alternatively, the Screw Gauge for

freehand technique can be used insted

of the Long Screw Scale to

determine the screw length.

Routine Locking Screw insertion

is employed with the assembled Long

Screwdriver Shaft and Teardrop Handle.

Note:

The Screwdriver Shaft can be used

in conjunction with the Long

Screw Capture Sleeve.

Operative Technique

Freehand Distal Locking

Fig. 49

Fig. 50

Fig. 51

Green Ring

32

Page 33

Operative Technique

Fig. 52

Repeat the locking procedure for the

insertion of the second 5mm Fully

Threaded Locking Screw into the

oblong hole in a static position

(Fig. 52).

The T2ReconNail may be used in the

dynamic locking mode. When the

fracture pattern permits, dynamic

lock ing may be utilized for transverse,

rotationally stable fractures. While

dynam ic locking can only be

performed at the end of the nail, this

will require a freehand distal targeting

of the oblong hole in a dynamic

position. This al lows the nail to move

and the fracture to settle while

torsional stability is maintained.

Note:

As an alternative for distal

locking, the guided distal

targeting system can be used. For

details, please refer to the separate

operativetechniques(Distal

TargetingSystemGamma3Long

NailR2.0,T2ReconnailR2.0)or

askStrykerRepresentativefor

further assistance.

Release the Nail Holding Screw using

the Screwdriver Shaft, Ball Tip and

T-Handle. Then remove the Targeting

Arm to complete surgery.

33

Page 34

End Caps

Stand ard +5mm +10mm +15mm

Operative Technique

After removal of the Target Device,

a Set Screw or End Cap can be used.

Two different Set Srews are available

(Fig. 53a):

- a ReconSetScrewto tighten

down on the Proximal Lag Screw

for the Recon Mode

- an Antegrade Set Screw to

tighten down on the oblique Fully

Threaded Screw for the Femoral

Antegrade Mode

Note:

If a Set Screw is used, an End Cap

can no longer be inserted.

Four different sizes of End Caps are

available to adjust nail length and to

reduce the potential for bony ingrowth

into the proximal thread of the nail

(Fig. 53b) .

The Set Screw or End Cap is inserted

with the Long Screwdriver Shaft and

Teardrop Handle after intra-operative

radio graphs confirm satisfactory

reduction and hardware implantation

(Fig. 54). Be sure to fully seat the End

Cap or Set Screw to minimize the

potential risk for loosening.

Nail Removal

The Set Screw or End Cap is removed

with the Long Screwdriver Shaft and

Tear drop Handle (Fig. 55).

The Universal Rod is inserted into

the driving end of the nail.

Alternatively, the Conical Extraction

Rod, can be attached to the Universal

Rod to facilitate extraction of the

nail. All 5mm Fully Threaded Locking Screws are removed with the

Screwdriver, Selfholding. The optional

Long Screw Capture Sleeve may be

used on the Screwdriver Shaft. For

removal of the Lag Screws, the Recon

Screwdriver or the Recon Screwdriver

Shaft and T-Handle are to be used.

The Slotted Hammer is used to ex tract

the nail in a controlled man ner (Fig. 56).

Set Screw or End Cap Insertion

Set Screw,

Antegrade

Set Screw,

Recon

Fig. 53b

Fig. 54

Fig. 55

Fig. 56

Fig. 53a

34

Page 35

Ordering Information – Implants

Titanium Diameter Length

REF mm mm

1846-0928S 9.0 280

1846-0930S 9.0 300

1846-0932S 9.0 320

1846-0934S 9.0 340

1846-0936S 9.0 360

1846-0938S 9.0 380

1846-0940S 9.0 400

1846-0942S 9.0 420

1846-0944S 9.0 440

1846-0946S 9.0 460

1846-0948S 9.0 480

184 6 -112 8S 11.0 280

184 6 -113 0S 11.0 30 0

184 6 -1132S 11.0 32 0

184 6 -113 4S 11. 0 34 0

184 6 -1136S 11.0 360

184 6 -1138S 11.0 380

184 6 -1140S 11.0 40 0

184 6 -1142S 11.0 420

184 6 -1144S 11.0 44 0

184 6 -1146S 11.0 46 0

184 6 -1148S 11.0 480

1846-1328S 13.0 280

1846-1330S 13.0 300

1846-1332S 13.0 320

1846-1334S 13.0 340

1846-1336S 13.0 360

1846-1338S 13.0 380

1846-1340S 13.0 400

1846-1342S 13.0 420

1846-1344S 13.0 440

1846-1346S 13.0 460

1846-1348S 13.0 480

1846-1528S 15.0 280

1846-1530S 15.0 300

1846-1532S 15.0 320

1846-1534S 15.0 340

1846-1536S 15.0 360

1846-1538S 15.0 380

1846-1540S 15.0 400

1846-1542S 15.0 420

1846-1544S 15.0 440

1846-1546S 15.0 460

1846-1548S 15.0 480

T2 Recon Nail, Left T2 Recon Nail, Right

Titanium Diameter Length

REF mm mm

1847-0928S 9.0 280

1847-0930S 9.0 300

1847-0932S 9.0 320

1847-0934S 9.0 340

1847-0936S 9.0 360

1847-0938S 9.0 380

1847-0940S 9.0 400

1847-0942S 9.0 420

1847-0944S 9.0 440

1847-0946S 9.0 460

1847-0948S 9.0 480

1847-1128S 11.0 28 0

1847-1130S 11.0 300

1847-1132 S 11.0 32 0

1847-1134S 11.0 340

184 7-1136 S 11 . 0 36 0

184 7-11 3 8S 11. 0 38 0

184 7-114 0 S 11.0 40 0

184 7-114 2 S 11 . 0 42 0

184 7-114 4 S 11.0 4 4 0

184 7-114 6 S 11.0 46 0

184 7-114 8 S 11 . 0 48 0

1847-1328S 13.0 280

1847-1330S 13.0 300

1847-1332S 13.0 320

1847-1334S 13.0 340

1847-1336S 13.0 360

1847-1338S 13.0 380

1847-1340S 13.0 400

1847-1342S 13.0 420

1847-1344S 13.0 440

1847-1346S 13.0 460

1847-1348S 13.0 480

1847-1528S 15.0 280

1847-1530S 15.0 300

1847-1532S 15.0 320

1847-1534S 15.0 340

1847-1536S 15.0 360

1847-1538S 15.0 380

1847-1540S 15.0 40 0

1847-1542S 15.0 420

1847-1544S 15.0 440

1847-1546S 15.0 460

1847-1548S 15.0 480

Note:

Check with your local representative regarding availability of nail

sizes.

35

Page 36

Ordering Information – Implants

Implants are in steri le pack aging.

Outside of the U. S., Locki ng Screws may be ordered

non-ster ile w ithout t he “S” at the end of the correspondi ng catalog number.

5mm Fully Threaded Locking Screws

6.5mm Lag Screws

Titanium Diameter Length

REF mm mm

1897-6065S 6.5 65

1897-6070S 6.5 70

1897-6075S 6.5 75

1897-6080S 6.5 80

1897-6085S 6.5 85

1897-6090S 6.5 90

1897-6095S 6.5 95

1897- 6100S 6 .5 100

1897- 6105S 6.5 10 5

1897-6110S 6.5 110

1897-6115S 6.5 115

1897-6120S 6.5 120

1897-6125S 6.5 125

1897-6130S 6.5 130

Titanium Diameter Length

REF mm mm

1847-0001S 8.0 Set Screw, Recon

1847-0003S 8.0 Set Screw, Antegrade

Titanium Diameter Length

REF mm mm

1822-0003S 8.0 Standard

1847-0005S 13.0 + 5mm

1847- 0010S 13.0 +10mm

1847-0015S 13.0 +15mm

Titanium

REF

1896-5025S

1896-5030S

1896-5035S

1896-5040S

1896-5045S

1896-5050S

1896-5055S

1896-5060S

1896-5065S

1896-5070S

1896-5075S

1896-5080S

1896-5085S

1896-5090S

1896-5095S

1896-5100 S

1896-5105S

1896-5110S

1896-5115 S

1896-5120S

5.0 25.0

5.0 30.0

5.0 35.0

5.0 40.0

5.0 45.0

5.0 50.0

5.0 55.0

5.0 60.0

5.0 65.0

5.0 70.0

5.0 75.0

5.0 80.0

5.0 85.0

5.0 90.0

5.0 95.0

5.0 100.0

5.0 105.0

5.0 110.0

5.0 115.0

5.0 120.0

End Caps Set Screws

DiameterLeng th

mm mm

Note:

Check with your local representative regarding availability of nail

sizes.

36

Page 37

REF Description

Ordering Information – Instruments

**Caution:

The coupling of Elastosil handles contains

a mechanism with one or multiple ba ll

bearings. In case of applied a xial stress on

the Elastosil handle, those components

are pressed into t he surrounding cyl inder

resulting in a complete blockage of t he

device and possible bending.

To help avoid intra- operative complications and promote long-term functionality, we mandate that Elastosi l handles be

usedonlyfortheirintendeduse.DONOT

HITthem.

*** item s a r e part of T2 B a si c L on g In s t rument

set (1806-9901); however, not used for

T2ReconNailingsurgery

T2 Basic Long

Teardrop Hand le, AO Coupling**

Protection Sleeve, Retrograde***

Guide Wire Ruler

Awl Plug

Awl

Universal Rod

Reduction Spoon

Wrench 8mm/10mm

Ins er tion Wrench, 10mm***

Stri ke Plate

Slotted Hammer

Tissue Protection Sleeve, Long

Screwdriver, Self-Holding, Extra Short (3.5)

Drill Sleeve, Long

Screwdriver Sha ft AO, Long

Screwdriver, Self-Holding, Long (3.5)

Screwdriver Shaft, Compression (hex3.5)***

Guide Wire Pusher

Trocar, Long***

Screw Gauge, Long

Screw Gauge (20-120mm)

Extraction Rod, Conical (Ø8mm)

Screw Scale, Long

Guide Wire Handle

Guide Wire Handle Chuck

Rigid Rea mer Ø12mm***

T2 Basic Long Inst rument Tray

T2 Basic Long Inst rument Set,

Completely f illed

702429

703165

1806- 0 022

1806- 0 032

180 6-0 041

180 6 -0110

1806- 0125

1806- 013 0

1806- 0135

1806- 015 0

1806-0170

1806- 0185

1806- 0203

1806- 0215

1806- 0227

1806- 0233

1806- 0268

1806- 0271

180 6 - 0315

1806- 0325

180 6 - 0331

1806- 0350

1806- 0365

180 6 -1095

180 6 -1096

180 6 -2014

1806-9900

1806-9901

37

Page 38

Ordering Information – Instruments

180 6 -310 0

180 6-3101

1806-3005

1806-3010

1806-3015

1806-3026S

1806-3030S

180 6-30 31S

1806-3035

1806-3040

1806-3041

1806-3045

1806-3050

1806-3055

1806-3057

1806-3060

1806-3070

1806-3090

1806- 0294

1806-4290S

1806- 4260 S

1806- 4270S

1806- 8018S

Target Device

Knob for Target Device

Nail Holding Screw, Recon

One Step Conical Reamer Ø13, Recon

One Step Conical Reamer Ø15, Recon

Solid Stepdri ll for Lag Screw*

Recon K-Wire, Recon*

K-Wire, Recon, CoCr

Lag Screw Gauge, Recon

K-Wire Sleeve, Recon

Dril l Sleeve for Solid Stepdri ll

Tissue Protection Sleeve, Recon

Screwdriver Sha ft, Recon

Multihole Trocar

Protection Sleeve, Antegrade

Screwdriver, Recon

K-Wire Inserter

Screwdriver Sha ft, AO, Ball Tip

Screwdriver Sha ft, Self holding, 3.5 × 85mm

Dril l Ø4.2 × 230 mm, AO*

Dril l Ø4.2 × 34 0mm, AO*

Dril l Ø4.2 × 180m m, AO*

Drill Ø4.2 × 250mm , oblique AO*

* For non-sterile, leave “S” off the REF number

when ordering.

REF Description

T2ReconInstruments

38

Page 39

REF Description

Optional Instruments

REF Description

Spare Parts

Ordering Information – Instruments

1806-0040

1806-3025

1806-0240

1806- 0292

1806-0480

1806-9993

1806-9992

1806-9995

1806-9996

1320-5375

Awl, Cu r ved

Stepdrill for Lag Screw, Recon

Screw Capture Sleeve, Long

Screwdriver Sha ft, 3.5 x 85mm

Screw Gauge, Femur

T2 Recon Instrument Tray Insert

T2 Recon Silicone Mat Free Space

T2 Recon Drill Rack

T2 Recon Insert for Reamer Heads****

DTS Tray Calibration Stand

* For non-sterile, leave “S” off the REF number

when ordering.

**Caution:

The coupling of Elastosil handles contains

a mechanism with one or multiple ba ll

bearings. In case of applied a xial stress on

the Elastosil handle, those components

are pressed into t he surrounding cyl inder

resulting in a complete blockage of t he

device and possible bending.

To help avoid intra- operative complications and promote long-term functionality, we mandate that Elastosi l handles be

usedonlyfortheirintendeduse.DONOT

HITthem.

**** Bixcut Modular Head 9, 10, 11, 12, 13, 14,

15, 16, 17 and 2 additional Modular Heads

can be stored. See page 37 for details.

1213-3010

702628

1806-3065

1806- 0085S

1806-3047

1806-3048

1806-3080

1806-9990

1806-9991

One Shot Device

T-Handle, AO Medium Coupling**

Extraction Screwdriver

Guide Wire, Ball Tip, Ø3 × 1000mm, steri le*

T2 Paddle Trocar Recon Mode

T2 Paddle Trocar Antegrade Mode

X-Ray Template, Recon

T2 Recon Instrument Tray

T2 Recon Instrument Set,

completely f illed

REF Description

T2ReconInstruments

39

Page 40

Complete range of modular and

fixed-head reamers to match

surgeon preference and optimize

O.R.efficiency,presentedinfully

sterilizable cases.

Studies

1

have demonstrated that

the pressures developed within

the medullary cavity through the

introduction of unreamed IMnails can

be far greater than those devel oped

during reaming − but this depends

very much upon the design of the

reamer.

After a three year development study2

involving several universities, the

factors that determine the pressures

and temperatures developed during

reaming were clearly established.

These factors were applied to the de velopment of advanced reamers that

demonstrate significantly better per form ance than the best of previous

designs3.

1

Ja n Paul M. Frolke, e t al. ;

Intramedullary Pressure in Rea med Femor al

Nail ing with Two Different Rea mer Designs.,

Eur. J. of Trauma, 2001 #5

2

Medhi Moussavi, et al.;

Pressure Changes Duri ng Reaming w ith Di fferent

Parameters a nd Reamer Designs,

Clinical Orthopaedics a nd Related Research

Number 373, pp. 295-303, 2000

3 Andrea s Speit ling;

Intra medul lar y Reamers, commented slides of

internal test repor t, Sep 1999

Large c learance rate resulting f rom reduced number

of reamer blades coupled with reduced length of

reamer head to allow for ef fect ive relief of pressure

and effi cient removal of materia l

3

.

Cutti ng fl ute geometry optimized to lower pressure

generation

3

.

Forwa rd- and side-cut ting face combination produces

effi cient material removal and rapid clearance

3

.

Double-wound shaf t tra nsmits torque effectively a nd

with h igh reliabi lity. Low-fric tion surface fi nish aids

rapid debris clea ranc e

3

.

Smal ler, 6 and 8mm shaf t diameters a re designed to

reduce IM pressure.

Typical Standard

Ream erØ14 mm

Clea ra nc e are a :

32% of cross section

Bixcut

Ream erØ14 mm

Clea ra nc e are a :

59% of cross sec tion

Ordering Information – Instruments

Bixcut

Bixcut

40

Page 41

REF Description Diameter

mm

BIXCUT MODULAR HEAD

REF Diameter Length

mm mm

BIXCUT FIXED HEAD − AO FITTING**

REF Description Length

mm

BIXCUT SHAFTS (STERILE)

1,2, 3, 4

REF Description

SHAFT ACCESSORIES

REF Description

BIXCUT TRAYS EMPTY

Ordering Information – Instruments

REF Description

OPTIONAL INSTRUMENTS

0227- 0060 Hand Reamer 6 mm

w/Mod Trinkle connection

0227-0070 Hand Reamer 7 mm

w/Mod Trinkle connection

0227-0080 Hand Reamer 8 mm

w/Mod Trinkle connection

0227-0090 Hand Reamer 9 mm

w/Mod Trinkle connection

1806-6520 Curved Reduction Rod 8.5 mm

w/Mod Trinkle connection

1806- 6500 T-Handle w/Mod Trink le connection

0226-3090

0226-3095

0226 -3100

0226-3105

0226 -3110

0226 -3115

0226 -3120

0226 -3125

0226 -3130

0226-3135

0226 -3140

0226 -3145

0226 -3150

0226-3155

0226 -3160

0226 -3165

0226 -3170

0226 -3175

0226 -3180

022 6-4185

0226 -4190

0226 -4195

0226-4200

0226-4205

0226- 4210

0226- 4215

0226-4220

0226-4225

0226-4230

0226-4235

0226-4240

0226-4245

0226-4250

0226-4255

0226-4260

0226-4265

0226-4270

0226-4275

0226-4280

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

Bixcut Head

9.0

9.5

10.0

10.5

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14. 5

15.0

15.5

16.0

16.5

17.0

17. 5

18.0

18.5

19.0

19.5

20.0

20.5

21.0

21.5

22.0

22.5

23.0

23.5

24.0

24.5

25.0

25.5

26.0

26.5

27. 0

27. 5

28.0

0227-8240S Mod. Trink le 284

0227-3000S Mod. Trink le 448

0227-8 510S Mod. Tri n k le 510

0227-8885S Mod. Trinkle 885

0226-8240S AO 284

0226-3000S AO 448

0225-6000 Tray, Modular Head

(up to size 22.0mm)

0225-6001 Tray, Modular Head

(up to size 28.0mm)

0225-8000 Tray, Fixed Head

(up to size 18.0mm)

0225-6040 Mini Trauma Tray

(for modular heads 9-18)

0225-6050 Mini Revision Tray

(for modular heads 9-28)

0225-5060

0225-5065

0225-5070

0225- 6075

0225-6080

0225-6085

0225-6090

0225-6095

0225- 6100

0225-6105

0225 -6110

0225 -8115

022 5-8120

0225-8125

022 5-813 0

0225-8135

0225 -8140

0225 -8145

022 5-815 0

0225-8155

0225-8160

0225-8165

022 5-8170

022 5-8175

022 5-8180

6.0*

6.5*

7.0 *

7.5

8.0

8.5

9.0

9.5

10.0

10.5

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14. 5

15.0

15.5

16.0

16.5

17.0

17. 5

18.0

400

400

400

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

480

3212-0-210 Grommet (pack of 25)

3212-0-220 Grommet inserter/extractor

0225-6010 Grommet Case

Note:

Bixcut Fi xedHead−ModiedTrinkletting available in same diameters and leng th as the

AOFitting(REFNo :0227-xxxx)

* Use with 2.2mm × 800mm Smooth Tip and 2.5mm × 800mm Ball Tip Guide Wires only.

**

Use with Stryker power equipment.

1. Non-Sterile shafts supplied without Grommet. Use new Grommet for each surgery. See shaft

accessories.

2. Sterile shafts supplied with grommet pre-assembled.

3. For non-sterile leave “S” off the REF Number when ordering (510 and 885mm available only sterile

Modified Trinkle Fitting).

4. non-sterile, AO Fitting Shafts in 510 and 885mm are available as build to order items:

• CM810921 AO Fitting Shaft, length 510mm

• CM810923 AO Fitting Shaft, length 885mm.

41

Page 42

Notes

42

Page 43

Notes

43

Page 44

Manufactured by:

Stryker Trauma GmbH

Prof.-Küntscher-Strasse 1-5

D-24232 Schönkirchen

Germany

www.osteosynthesis.stryker.com

This document is intended solely for the use of healthca re professional s. A surgeon must a lways rely on his or her own

professional cl inical judg ment when deciding whether to use a par ticular product when treating a particular patient .

Stryker does not dispense medica l advice and recommend s that surgeon‘s be trained in the use of any part icular

product before usi ng it in surgery. The information presented in this brochure is intended to demonstrate a Str yker

product. Alway s refer to the package ins ert, product label and /or user inst ructions includi ng the instr uctions for

Clean ing and Steri lization (if applicable) before u sing any Stryker products. Product s may not be available in a ll

markets. Product ava ilabilit y is subject to the regulatory or medical prac tices that govern ind ividual markets. Please

contact your Stryker representative if you have question s about the avai lability of St ryker products in you r area.

Stryker Cor poration or its divisions or other corporate af filiated ent ities own, use or have applied for the followi ng

trademarks or serv ice marks : Bixcut, Gam ma, Gamma3, Stryker, T2. A ll other trademark s are trademarks of their

respec tive owners or holders.

The produc ts listed above are CE ma rked.

Literat u re Num be r : B1000 084Re v1

1/11

Copyright © 2011 Stryker

Loading...

Loading...