Page 1

MX-PRO® R3

6082

Operations/Maintenance Manual

2013/02 A.0 6082-209-001 REV A www.stryker.com

Page 2

Page 3

Table of Contents

Introduction .............................................................................6

Specifications ........................................................................6

Warning / Caution / Note Definition.........................................................7

Product Illustration ........................................................................8

Symbols and Definitions ....................................................................9

Warranty ..............................................................................10

Stryker EMS Return Policy ..............................................................11

Return Authorization...................................................................11

Damaged Merchandise ................................................................11

International Warranty Clause............................................................11

Patent Information ....................................................................11

Summary of Safety Precautions .............................................................12

Setup Procedures........................................................................14

Vehicle Safety Hook Selection ..............................................................15

Vehicle Safety Hook Installation .............................................................16

Vehicle Configuration..................................................................16

Required Hardware for Installation of the Safety Hook (Not Supplied) ..............................16

Front to Back Positioning of the Safety Hook ................................................17

Side to Side Positioning of the Safety Hook .................................................18

Installing the Safety Hook...............................................................18

Cot Positions ...........................................................................19

Cot Operations..........................................................................20

Using Patient Restraint Straps ...........................................................20

Pedi-Mate® Infant Restraint System Attachment Instructions (Optional Equipment) ....................22

Operating Guidelines ..................................................................24

Transferring the Patient to the Cot ........................................................24

Rolling the Cot ......................................................................24

Raising/Lowering the Cot ..............................................................24

Loading the Cot into a Vehicle with Two Operators ............................................25

Loading an Empty Cot into a Vehicle with One Operator ........................................26

Unloading The Cot From a Vehicle with Two Operators .........................................27

Unloading an Empty Cot From a Vehicle with One Operator .....................................27

Using Additional Assistance .............................................................28

Operating the Optional Wheel Lock(s) .....................................................29

Adjusting the Wheel Locking Force........................................................30

Changing the Cot Height with Two Operators ................................................31

Changing The Height of an Empty Cot With One Operator ......................................32

Adjusting the Leg Rest.................................................................33

Operating the Backrest ................................................................34

Operating the Siderails.................................................................34

Operating the Breakaway Head Section ....................................................35

Operating the Two-Stage I.V. Pole (Optional Equipment) ........................................36

Operating the Three-Stage I.V. Pole (Optional Equipment).......................................37

www.stryker.com 6082-209 -001 REV A 3

Page 4

Table of Contents

Cleaning...............................................................................38

Washing Limitations ...................................................................38

Removal of Iodine Compounds ...........................................................39

Preventative Maintenance ..................................................................40

Checklist ...........................................................................40

Base Lubrication .....................................................................41

Pneumatic Backrest Adjustment ..........................................................42

Maintenance Record......................................................................43

Training Record .........................................................................44

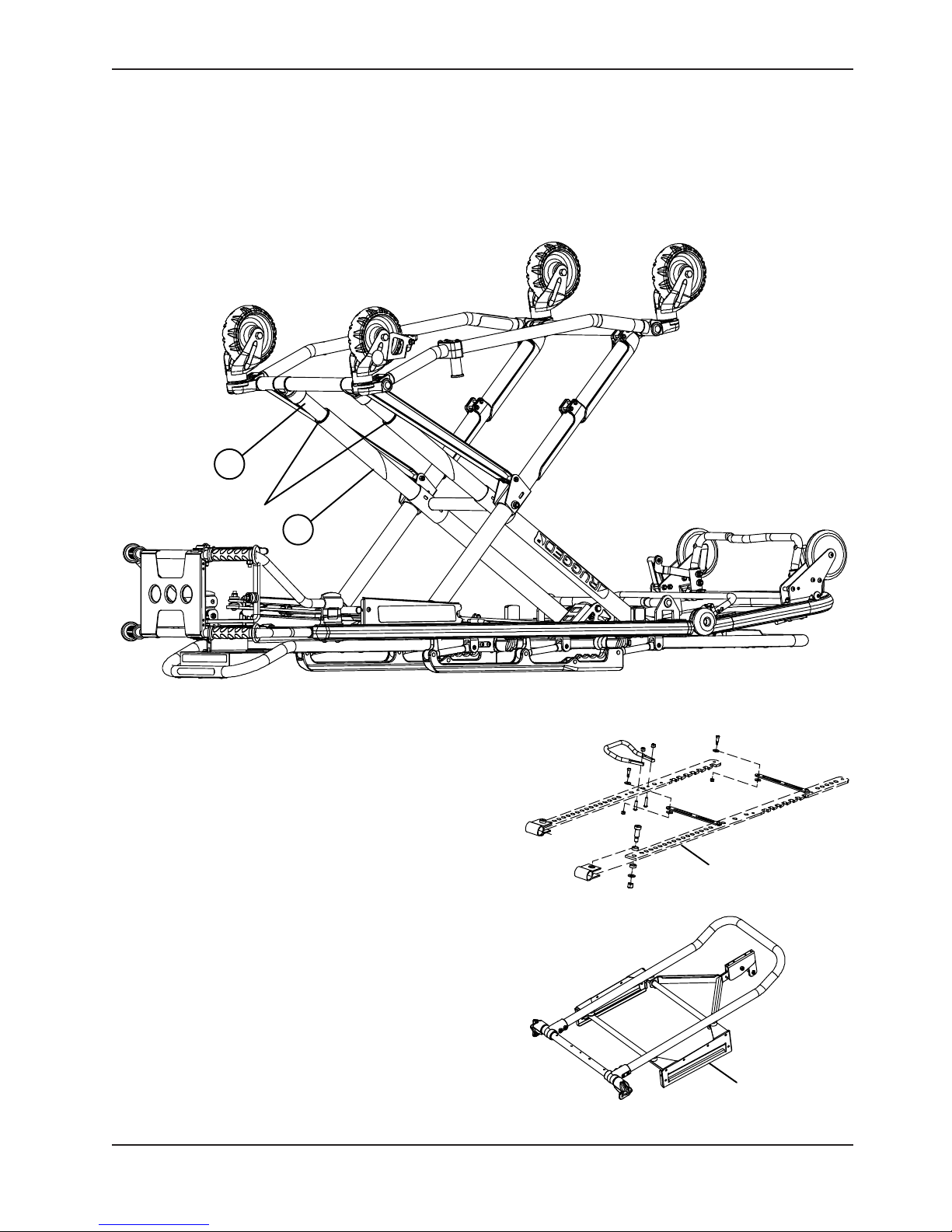

Cot Assembly ...........................................................................45

Base Assembly..........................................................................51

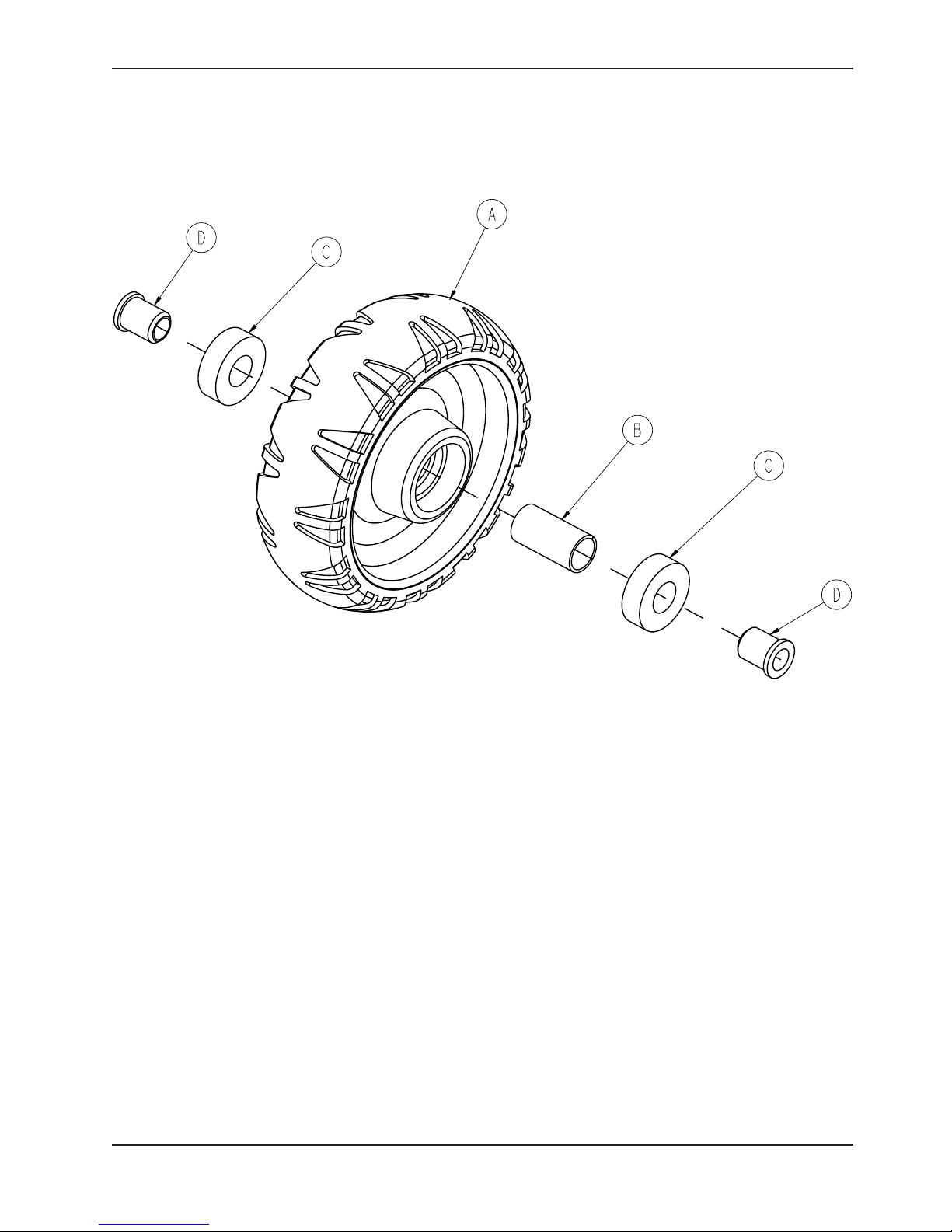

Wheel Assembly - 6060-002-010 ............................................................55

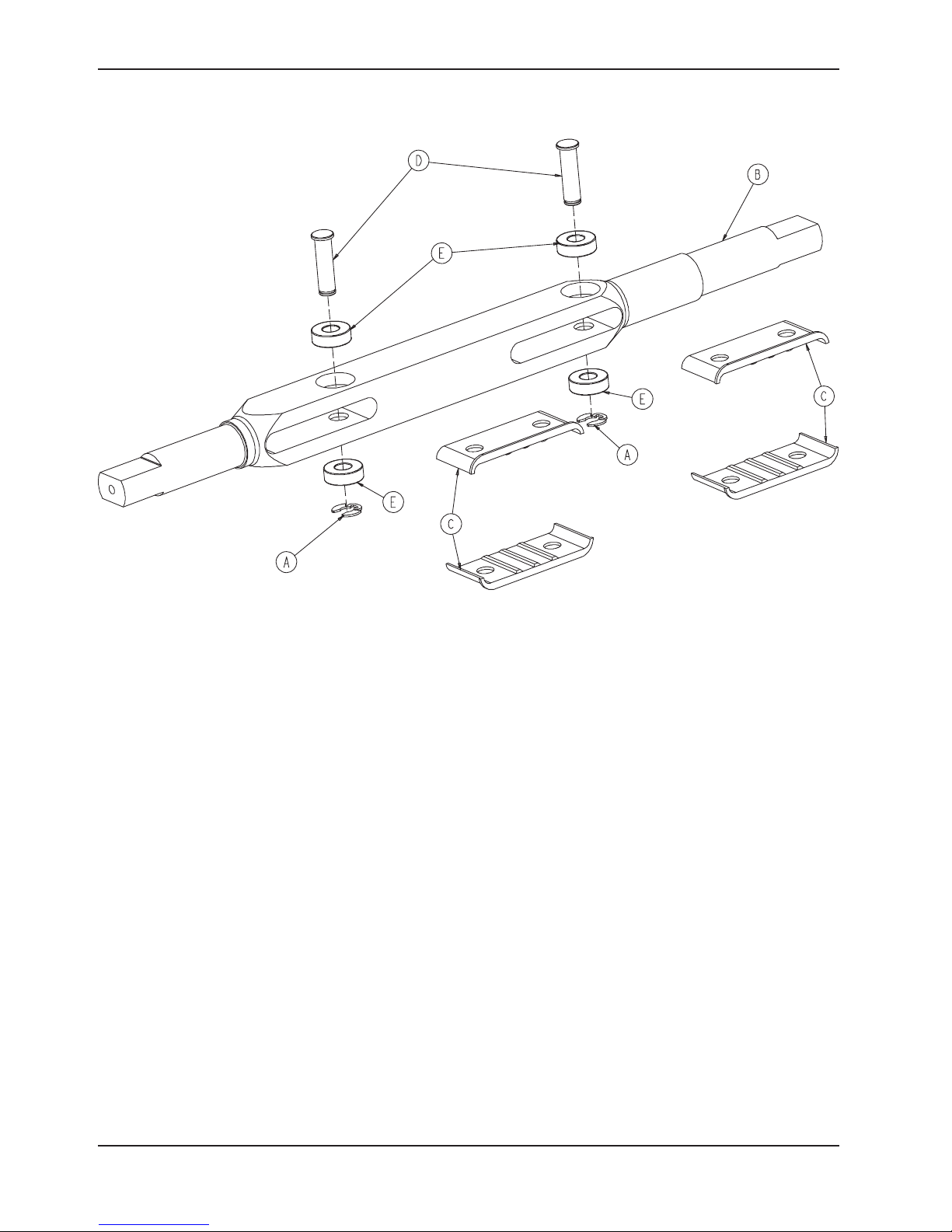

Base Pivot Outer Lift Tube Assembly - 6082-201-067..............................................56

Base Pivot Inner Lift Tube Assembly - 6082-001-069 ..............................................57

Lock Bar Assembly - 6082-005-056 ..........................................................58

Adjustable Caster Lock Assembly - 6082-200-010 ................................................59

Optional Single Wheel Lock Assembly - 6082-501-010.............................................60

Optional Dual Wheel Lock Assembly - 6082-502-010..............................................60

No Wheel Lock Option ....................................................................61

Dual Diagonal Wheel Lock Option............................................................61

Four Wheel Lock Option...................................................................61

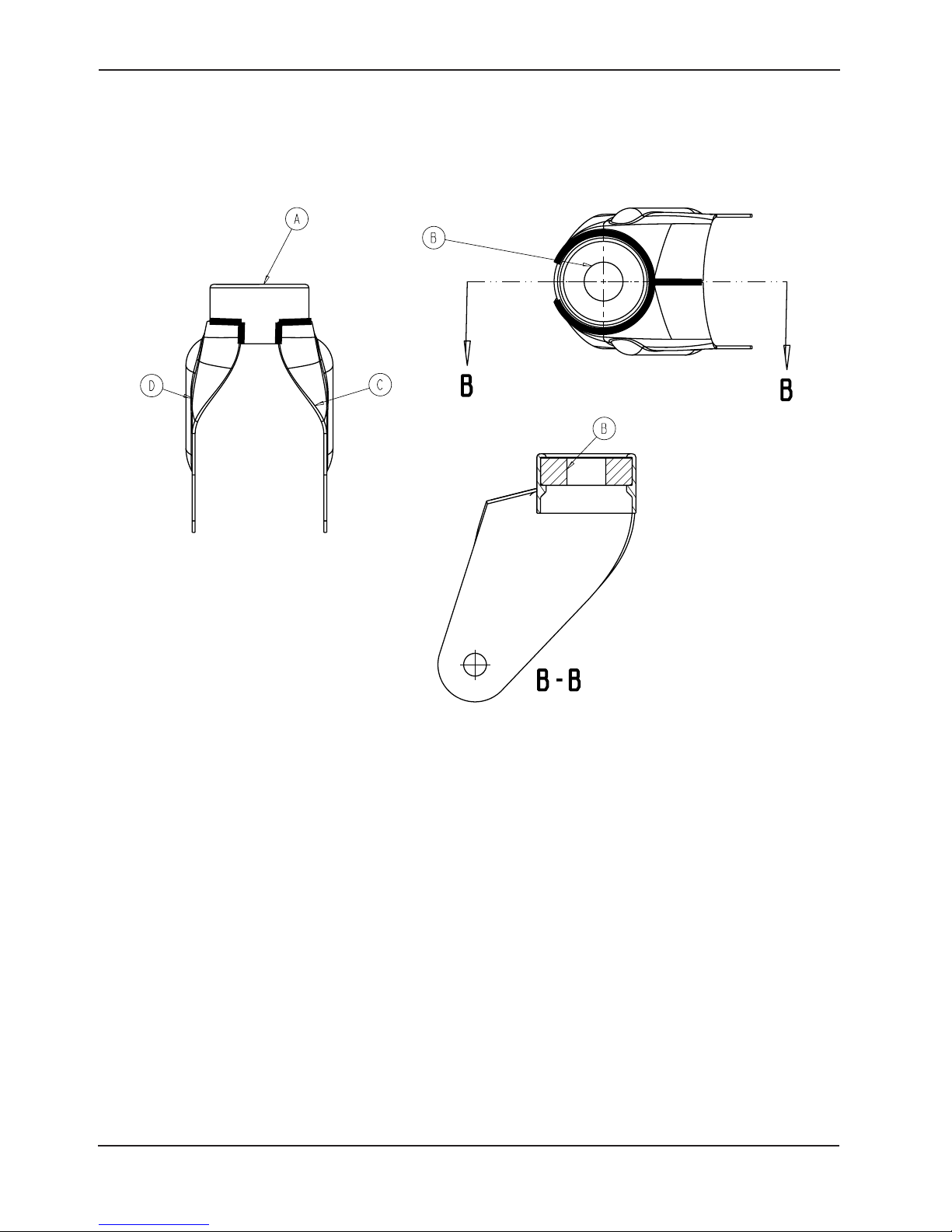

Caster Horn Assembly ....................................................................62

Litter/Base Adapter Assembly, Right - 6082-205-050 ..............................................63

Litter/Base Adapter Assembly, Left - 6082-205-053 ...............................................64

Litter Assembly..........................................................................65

Siderail Assembly - 6082-026-010............................................................72

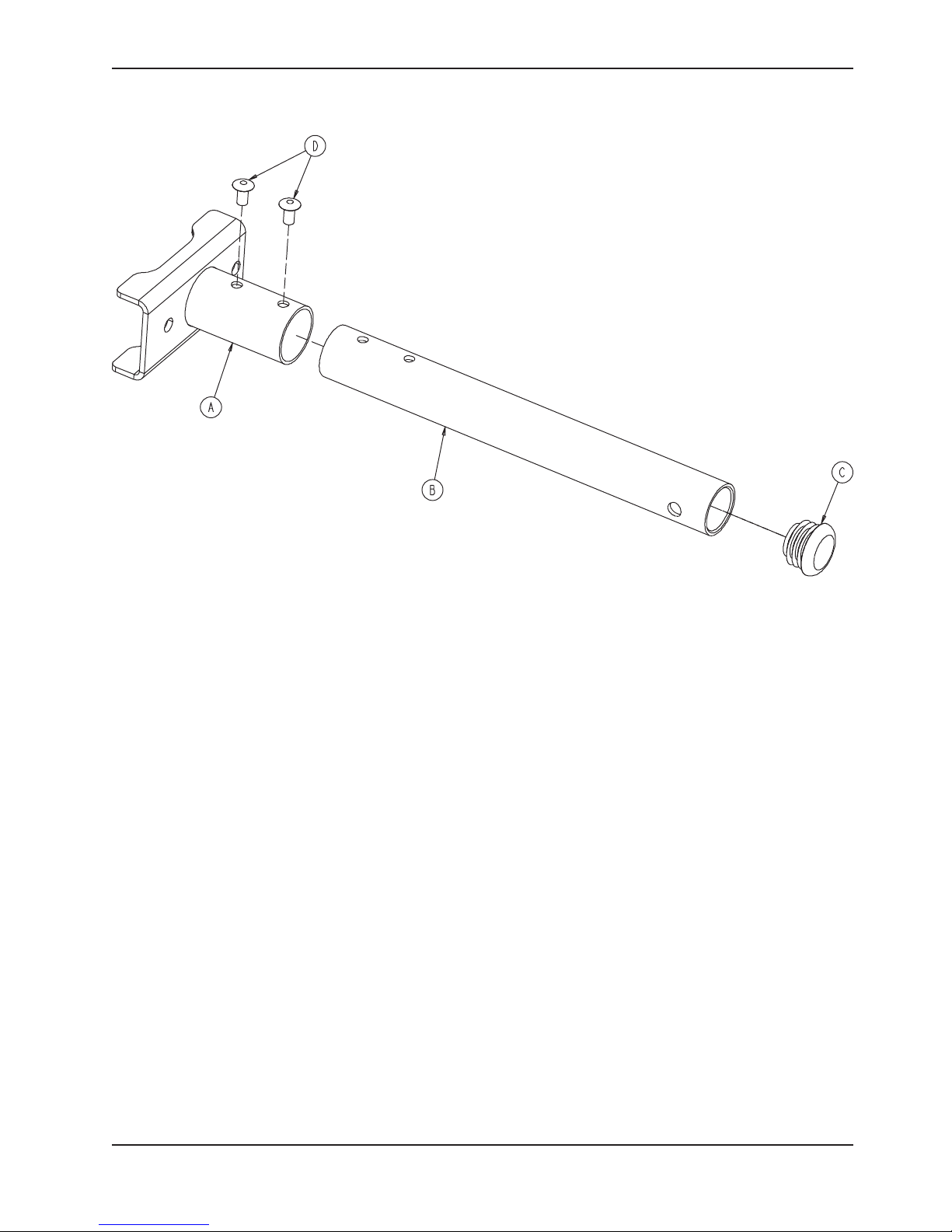

Optional Lift Tube Assembly, Left Side Release - 6082-140-059 ......................................73

Optional Lift Tube Assembly, Right Side Release - 6082-140-060 .....................................75

Release Handle Assembly, Left - 6082-040-061 .................................................77

Release Handle Assembly, Right - 6082-040-062 ................................................78

Breakaway Head Assembly .................................................................79

Optional Two-Stage I.V. Pole Assembly, Right - 6080-210-010

Optional Three-Stage I.V. Pole Assembly, Right - 6080-215-010 ......................................84

Optional Two-Stage I.V. Pole Assembly, Right - 6080-210-020 .......................................85

Optional Three-Stage I.V. Pole Assembly, Right - 6080-215-020 ......................................86

Optional Two-Stage I.V. Pole Assembly, Left - 6080-211-010

Optional Three-Stage I.V. Pole Assembly, Left - 6080-216-010 .......................................87

Optional Two-Stage I.V. Pole Assembly, Left - 6080-211-020 ........................................88

Optional Three-Stage I.V. Pole Assembly, Left - 6080-216-020.......................................89

Optional Two-Stage I.V. Pole Assembly - 6070-210-070 ............................................90

Optional Three-Stage I.V. Pole Assembly - 6070-215-070...........................................91

Optional Three-Stage I.V. Pole Assembly - 6070-115-030 ...........................................92

Patient Right Assembly, No I.V. Pole Option - 6080-212-010 .........................................93

4 60 82-209-0 01 REV A www.stryker.com

Page 5

Table of Contents

Patient Left Assembly, No I.V. Pole Option - 6080-213-010..........................................94

Optional Oxygen Bottle Holder, Removable - 6080-140-000 .........................................95

Optional Oxygen Bottle Holder, Foot End - 6070-140-000 ..........................................96

Optional Oxygen Bottle Holder Tray Assembly, Foot End - 6060-140-020 ...............................97

Optional Oxygen Bottle Holder, Head End - 6082-140-000 .........................................98

Optional Oxygen Bottle Holder Tray Assembly, Head End - 6082-140-040 ..............................99

Optional Pull Handle Assembly - 6080-155-000 .................................................100

Optional Base Lift Bar Assembly - 6080-157-010 ................................................10 1

Optional Base Storage Tray Assembly - 6082-150-015............................................102

Optional X-Frame Guard Assembly (Pair) - 6080-145-000 .........................................103

Optional Pedi-Mate Restraint Assembly - 6080-300-010 ..........................................104

Optional Retaining Post, Right - 6082-200-000 .................................................105

Optional Retaining Post, Dual - 6082-190-000 ..................................................106

Optional Storage Tray, Head End - 6082-128-000 ...............................................107

Optional Tray Assembly, Head End - 6082-128-020 ..............................................10 8

Optional Head Extension Kit Assembly - 6100-044-000 ...........................................109

Optional Head Extension Assembly - 6100-044-012 ..............................................1 10

Base Storage Net - 6080-150-010 ...........................................................111

Optional Backrest Pouch Assembly - 6500-130-000..............................................1 12

Optional Defibrillator Platform Assembly - 6082-170-000 .......................................... 1 13

Optional Equipment Hook - 6500-147-000 .....................................................114

Transfer Flat - 6005-001-001 ..............................................................1 15

Standard Restraint Strap Package - 6082-260-010 ..............................................116

Chest Restraint - 6060-260-046 ............................................................116

Optional Restraint Extender, 3’ - 6082-160-050 .................................................117

Optional Head End Storage Pouch - 6082-128-010/6082-128-012....................................118

Optional Accessory Strap Assembly - 6082-160-052 .............................................1 18

Bolster Mattress - 6090-041-010 ............................................................119

Flat Mattress - 6090-042-010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Safety Hook, Short - 6060-036-017/Safety Hook, Long - 6060-036-018/Safety Hook, J - 6092-036-018 .......121

Quick Reference Replacement Part List ......................................................122

www.stryker.com 6082-209 -001 REV A 5

Page 6

Introduction

This manual is designed to assist you with the operation and maintenance of the MX-PRO® R3 Ambulance Cot. Read

it thoroughly before using the equipment or beginning any maintenance on it.

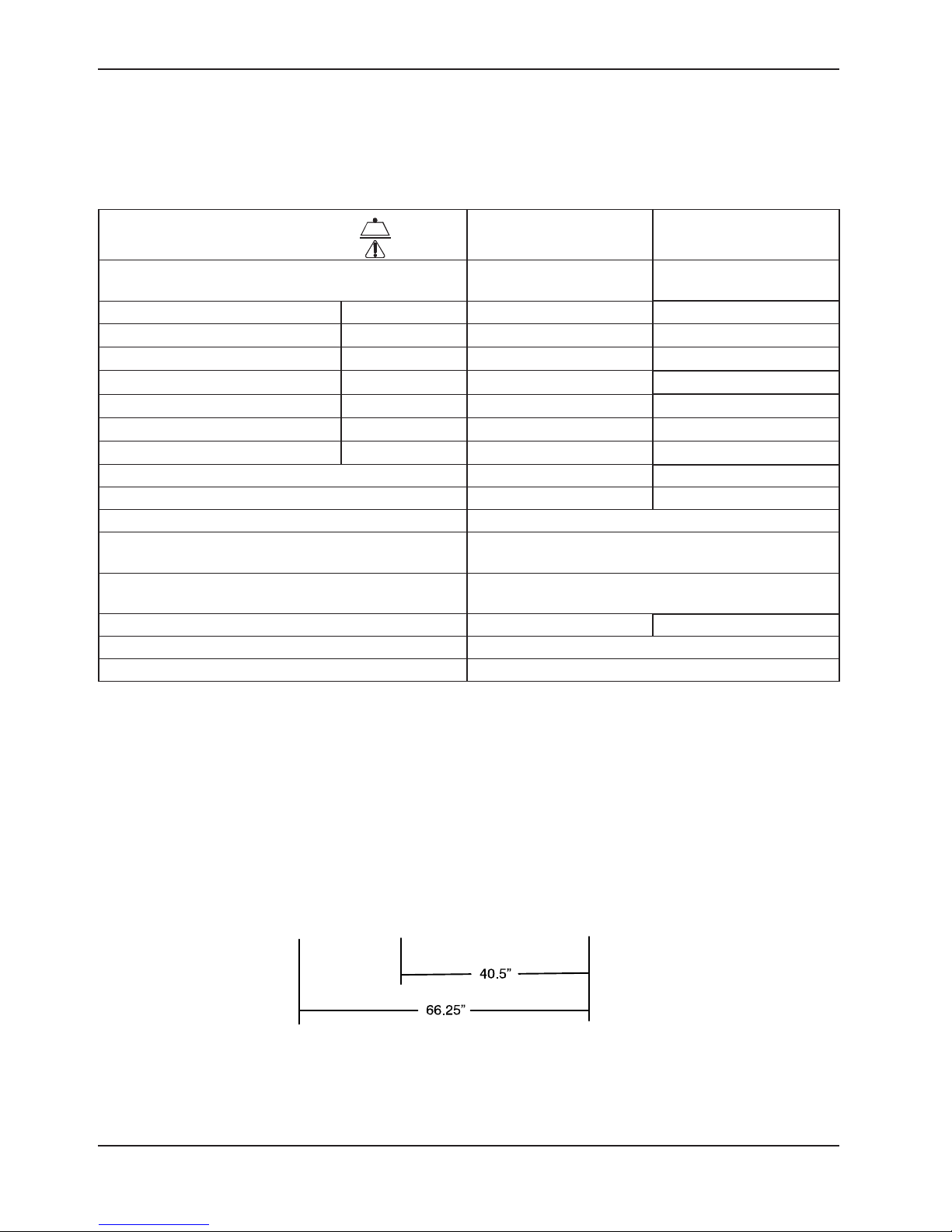

SPECIFICATIONS

Maximum Cot Load Capacity 650 pounds 294,8 kg

Overall Length/Minimum Length/Width 80.5" / 62" / 23" 204,5 cm /

157,5 cm / 58,4 cm

1

Height

See page 19 for positions. Position 2 21.0” 53,3 cm

2

Weight

Caster Diameter/Width 6" / 2" 15,2 cm / 5,1 cm

Backrest Articulation/Shock Position 2° to 73° / +14°

Minimum Operators Required for Loading/

Unloading an Occupied Cot

Recommended Fastener Systems Model 6370/6377/6378 Floor Mount Type

Recommended Floor Height

3

Roll-In Style Yes

Single Wheel Lock / Double Wheel Lock Optional

Position 1 13. 5" 34,3 cm

Position 3 25.5” 64,8 cm

Position 4 29.0” 73,7 cm

Position 5 32.0” 81,3 cm

Position 6 35.0” 88,9 cm

Position 7 37.5 ” 95,3 cm

81 pounds 37,7 kg

2

Model 6371 Wall Mount Type

Up to 32" 81,3 cm

1

Height measured from bottom of mattress at seat section to ground level.

2

Cot is weighed without mattress and restraints.

3

Cot may be loaded from any height and a height limiting kit (p/n 6060-202) is available to limit the load height of the cot.

Stryker reserves the right to change specifications without notice.

The MX-PRO is designed to conform to the Federal Specification the Star-of-Life Ambulance KKK-A-1822-F.

The yellow and black color scheme is a proprietary trademark of Stryker Corporation.

Return To Table of Contents

6 60 82-209-0 01 REV A www.stryker.com

Page 7

Introduction

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

NOTE

Provides special information to make maintenance easier or important instructions clearer.

www.stryker.com 6082-209 -001 REV A 7

Return To Table of Contents

Page 8

Product Illustration

Height Adjustment

Release Handle

(1 of 3)

Foot Rest

Backrest (Head Section)

Siderail Release Handles

Breakaway

Head Section

Release Bar

Backrest Adjustment

Release Handle

HEAD END

Breakaway

Head Section

Safety Bar

Release

Lever

Loading Wheels

(1 of 2)

Lifting Bar

Return To Table of Contents

8 60 82-209-0 01 REV A www.stryker.com

Foot Rest

Release

Handle

Transport Wheels

J Safety Hook

Stryker part number

6092−036−018

Wheel Lock

(Optional)

Figure 2 − 6082 MX−PRO R3 Cot

Long Safety Hook

Stryker part number

6060−036−018

Transport Wheels

Short Safety Hook

Stryker part number

6060−036−017

Page 9

Symbols and Definitions

Warning, consult accompanying documentation

Safe Working Load Symbol

Manufacturer

www.stryker.com 6082-209 -001 REV A 9

Return To Table of Contents

Page 10

Warranty

Stryker EMS, a division of the Stryker Corporation, offers two distinct warranty options in the United States:

One (1) year parts and labor. Under this option, Stryker EMS warrants to the original purchaser that its products

should be free from manufacturing non-conformances that affect product performance and customer satisfaction for

a period of one (1) year after date of delivery. Stryker’s obligation under this warranty is expressly limited to supplying

replacement parts and labor for, or replacing, at its option, any product that is, in the sole discretion of Stryker, found

to be defective.

Two (2) year parts. Under this option, Stryker EMS warrants to the original purchaser that non-expendable components

of its products should be free from manufacturing non-conformances that affect product performance and

customer satisfaction for a period of two (2) years after date of delivery. Stryker’s obligation under this warranty

as expressly limited to supplying replacement parts for, or replacing, at its option, any product which is, in the sole

discretion of Stryker, found to be defective. Expendable components, i.e. mattresses, restraints, I.V. poles, storage

nets, storage pouches, oxygen straps, and other soft goods, have a one (1) year limited warranty with this option.

Under either warranty option, Stryker EMS products are designed for a 5 year expected service life under normal use,

conditions, and with appropriate periodic maintenance as described in the maintenance manual for each device. Stryker

warrants to the original purchaser that the welds on its EMS products will be free from structural defects for the expected

5 year life of the EMS product as long as the original purchaser owns the product. Original purchasers will also obtain a

three (3) year limited parts warranty for the X-frame components of the MX-PRO R3 stretcher provided they also purchase

X-frame guards at the time of the original purchase and the guards are installed on the MX-PRO before it is put into service.

If Stryker requests, products or parts for which an original purchaser makes a warranty claim, the purchaser shall

return the product or part prepaid freight to Stryker’s factory.

Any improper use or alteration or repair by unauthorized service providers in such a manner as in Stryker’s judgment

affects the product materially and adversely, shall void this warranty. Any repair of Stryker products using parts not

provided or authorized by Stryker shall void this warranty. No employee or representative of Stryker is authorized to

change this warranty in any way.

This statement constitutes Stryker EMS’s entire warranty with respect to the aforesaid equipment. STRYKER MAKES NO

OTHER WARRAN TY OR REPRESENTATION EITHER EX PRESSED OR IMPLIED, EXCEPT AS SET FORTH H EREIN. THERE

IS NO WARRANTY OF MERCHANTABILITY AND THERE ARE NO WARRANTIES OF FITNESS FOR ANY PARTICULAR

PURPOSE. IN NO EVENT SHALL STRYKER BE LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING FROM OR IN ANY MANNER RELATED TO SALES OR USE OF ANY SUCH EQUIPMENT.

Return To Table of Contents

10 6082-209 -001 REV A www.stryker.com

Page 11

Warranty

STRYKER EMS RETURN POLICY

Cots, Stair Chairs, Evacuation Chairs, Cot Fasteners and Aftermarket Accessories may be returned up to 180 days of

receipt if they meet the following guidelines:

Prior to 30 Days

• 30daymoneybackguaranteeineffect

• StrykerEMSisresponsibleforallcharges

• Returnswillnotbeapprovedonmodifieditems

Prior to 90 Days

• Productmustbeunused, undamaged and in the original packaging

• Customerisresponsiblefora10%restockingfee

Prior to 180 Days

• Productmustbeunused, undamaged and in the original packaging

• Customerisresponsiblefora25%restockingfee

RETURN AUTHORIZATION

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization

number will be provided which must be printed on the returned merchandise. Stryker reserves the right to charge

shipping and restocking fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

DAMAGED MERCHANDISE

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen (15)

days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE IS NOTED

ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt notification, Stryker will file a freight claim

with the appropriate carrier for damages incurred. Claim will be limited in amount to the actual replacement cost. In

the event that this information is not received by Stryker within the fifteen (15) day period following the delivery of

the merchandise, or the damage was not noted on the delivery receipt at the time of receipt, the customer will be

responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

INTERNATIONAL WARRANTY CLAUSE

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by country. Please contact your local

Stryker Medical representative for additional information.

PATENT INFORMATION

The Stryker MX-PRO R3 cot is covered by one or more of the following patents:

United States 5,537,700 5,575,026 6, 908,133 7,100 , 224

Other patents pending

www.stryker.com 6082-209 -001 REV A 11

Return To Table of Contents

Page 12

Summary of Safety Precautions

The following is a list of safety precautions that must be observed when operating or servicing this unit. The precautions

are repeated throughout the manual, where applicable. Carefully read this list before using or servicing the unit.

WARNING

• Improper usage of the cot can cause injury to the patient or operator. Operate the cot only as described in this

manual.

• Install the safety hook at least 1/8 inch from the edge of the rear ambulance door. After installation, verify the cot

legs lock into the load position without contacting the ambulance bumper.

• Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can result in

injury to the patient or operator or damage to the unit.

• Failure to install the vehicle safety hook can result in injury to the patient or operator. Install and use the safety

hook as described in this manual.

• To avoid injury, verify the safety bar has engaged the safety hook before removing the cot from the patient

compartment.

• Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot and

be injured.

• To avoid accidental release of the Pedi−Mate™, and possible injury to the infant, ensure the buckle is located away

from obstructions on the cot or head end storage pouch.

• Siderails are not intended to serve as a patient restraint device. See page 20 for proper restraint strap usage.

Failure to utilize the siderails properly could result in patient injury.

• Never leave a patient unattended on the cot or injury could result. Hold the cot securely while a patient is on the

cot.

• Never apply the optional wheel lock(s) while a patient is on the cot. Tipping could occur if the cot is moved while

wheel locks are applied, resulting in injury to the patient or operator and/or damage to the cot.

• Wheel locks are only intended to help prevent the cot from rolling while unattended. Wheel locks may not provide

sufficient resistance on all surfaces or under loads.

• Never install or use wheel locks on a cot with excessively worn wheels. Installing or using wheel locks on wheels

with less than a 6” diameter could compromise the holding ability of the wheel lock, resulting in injury to the patient

or operator and/or damage to the cot or other equipment.

• Be sure the undercarriage has engaged and locked before removing the loading wheels from the patient

compartment floor of the vehicle. An unlocked undercarriage will not support the cot and injury to the patient and/

or operator could result.

• Grasping the cot improperly can cause injury. Grasp only the lifting bars to lift the cot. Keep hands, fingers and

feet away from moving parts. To avoid injury, use extreme caution when placing your feet near the base tubes

while raising and lowering the cot.

• Do not pull or lift on the safety bar when unloading the cot. Damage to the safety bar could result and injury to

the patient or operator could occur.

• The one person loading and unloading procedures are for use only with an empty cot. Do not use the procedures

when unloading a patient. Injury to the patient or operator could result.

• The cot must have at least 5/8” of clearance between the ambulance bumper and the cot to disengage the safety

bar when unloading the cot from the ambulance. Verify the cot legs lock into the load position before disengaging

the safety bar from the safety hook. Failure to properly lock the cot into position can cause injury to the patient or

operator and/or damage to the cot.

• Do not allow untrained helpers to assist in the operation of the cot. Untrained technicians/helpers can cause injury

to the patient or themselves.

• When the optional head end storage pouch is being used, ensure it does not interfere with the operation of the

safety bar and safety hook. Injury to the patient or operator could occur.

• Use any appropriate personal safety equipment (goggles, respirator, etc.) to avoid the risk of inhaling contagion.

Use of power washing equipment can aerate contamination collected during the use of the cot.

• Do not ride on the base of the cot. Damage to the cot could occur, resulting in injury to the patient or operator.

• Failure to properly clean or dispose of contaminated mattress or cot components will increase the risk of exposure

to bloodborne pathogens and may cause injury to the patient or the operator.

Return To Table of Contents

12 6082-209 -001 REV A www.stryker.com

Page 13

Summary of Safety Precautions

WARNING (CONTINUED)

• Do not modify the cot. Modifying the cot can cause unpredictable operation resulting in injury to the patient or

operator. Modifying the cot will also void its warranty.

• Operating the cot with the breakaway head section lowered may cause injury to the patient or operator or damage

to the cot. Use only positions 5−7 (see page 19) when using this configuration.

• High obstacles such as curbing, steps or rough terrain can cause the cot to tip, possibly causing injury to the patient

or operator. Transporting the cot in lower positions reduces the potential of a cot tip. If possible, obtain assistance

or take an alternate route.

CAUTION

• Height limit kit is recommended for ambulance deck heights less than 30 inches (76 cm) − Stryker part number

6060−202−000.

• Damage to the cot can occur if the cot is lowered in the shortened position. Use only positions 5−7 (see page

19) when the cot is shortened.

• Do not allow the cot undercarriage to drop unassisted (commonly known as a “hot drop”) when removing the cot

from the vehicle. Repeated hot dropping will cause premature wear or damage to the cot.

• Do not store items under the cot mattress. Storing items under the mattress can interfere with the operation of

the cot.

• The weight of the I.V. bags or equipment must not exceed 40 pounds.

• Improper maintenance can cause injury or damage to the unit. Maintain the cot as described in this manual. Use

only Stryker approved parts and maintenance procedures. Using unapproved parts and procedures could cause

unpredictable operation and/or injury and will void the product warranty.

• The weight of the monitoring equipment must not exceed 75 pounds (34 kg) with the defibrillator platform (if

equipped). Monitoring equipment should not be stored on the cot or on the defibrillator platform when in the

ambulance vehicle.

www.stryker.com 6082-209 -001 REV A 13

Return To Table of Contents

Page 14

Setup Procedures

Unpack the cartons and check all items for proper operation. It is important that the cot is working properly before it

is put into service. Have a qualified service person use the following list and the operation instructions to check the

cot before it is put into service.

Note: Ensure that all shipping and packaging materials have been removed from the product(s) prior to use.

• All fasteners secure (reference all assembly drawings)

• All welds intact, not cracked or broken

• No bent or broken tubing or sheet metal

• No debris in wheels

• All wheels secure, rolling and swivelling properly

• Siderails move and latch properly

• Backrest operating properly

• Optional accessories intact and operating properly

• Height positioning latch functioning properly

• Cot secure in each height position

• Undercarriage folds properly

• Breakaway head section operating properly

• Safety bar operating properly

• Foot rest operating properly

• No rips or cracks in mattress cover

• Body restraints intact and working properly

• Wheel lock(s) operating properly (optional equipment)

• Does the vehicle safety hook engage the safety bar so that the cot loads and unloads easily from the vehicle?

• Is there an approved crash−stable fastener (Stryker part number 6370/6377/6378 or 6371 − not included) installed

in the vehicle?

The patient compartment of the vehicle in which the Cot will be used must have:

• A smooth rear edge for cot loading.

• A level floor large enough for the folded cot.

• Stryker 6370/6377/6378/6379 or 6371 crash stable cot fastener (not included).

• 32” (81 cm.) maximum loading height.

• Space to install the safety hook.

When necessary, modify the vehicle to fit the cot. Do not modify the cot.

WARNING

Do not modify the cot. Modifying the cot can cause unpredictable operation resulting in injury to the patient or operator.

Modifying the cot will also void its warranty (see page 10).

Return To Table of Contents

14 6082-20 9-001 REV A www.stryker.com

Page 15

Vehicle Safety Hook Selection

The vehicle safety hook is a device that ships with the cot. The cot safety bar and vehicle safety hook are designed

to keep the cot from being accidentally removed from the vehicle and to provide increased operator assurance and

confidence when loading and unloading. The safety hook was designed for compatibility and proper operation when

loading and unloading the cot from a vehicle that is compliant with Federal Regulation KKK-A-1822.

Stryker offers three different types of safety hooks that are ordered and shipped with your ambulance cot. These

safety hook types are designed to meet the needs of various emergency vehicle configurations, specifically the length

and location of the floor structure support that is located in the rear of the vehicle.

Consider the following information when selecting

which safety hook is appropriate for your vehicle

configuration:

• Determine the location of the floor structure

support where there is adequate room to mount

the safety hook.

• Ensure that the safety hook can be securely

mounted into the back of the vehicle while

providing adequate bumper clearance to allow the

cot to be loaded and unloaded from the vehicle.

• Note the differences in vehicle design. Each safety

hook provides a different mounting location option

to maintain the appropriate distance between the

face of the safety hook and the edge of the door

sill.

Long Safety Hook

6060-036-018

Short Safety Hook

6060-036-017

J-Style Safety Hook

6092-036-018

Due to the differences in vehicle dimensions and the

floor structure support locations, each safety hook

requires a different mounting location. See “Vehicle

Safety Hook Installation” to determine the correct

positioning for safety hook installation.

Safety Hook Types

Note: When replacing an existing safety hook with a new style, adjust the mounting location to maintain the proper

position of the safety hook face.

www.stryker.com 6082-209 -001 REV A 15

Return To Table of Contents

Page 16

Vehicle Safety Hook Installation

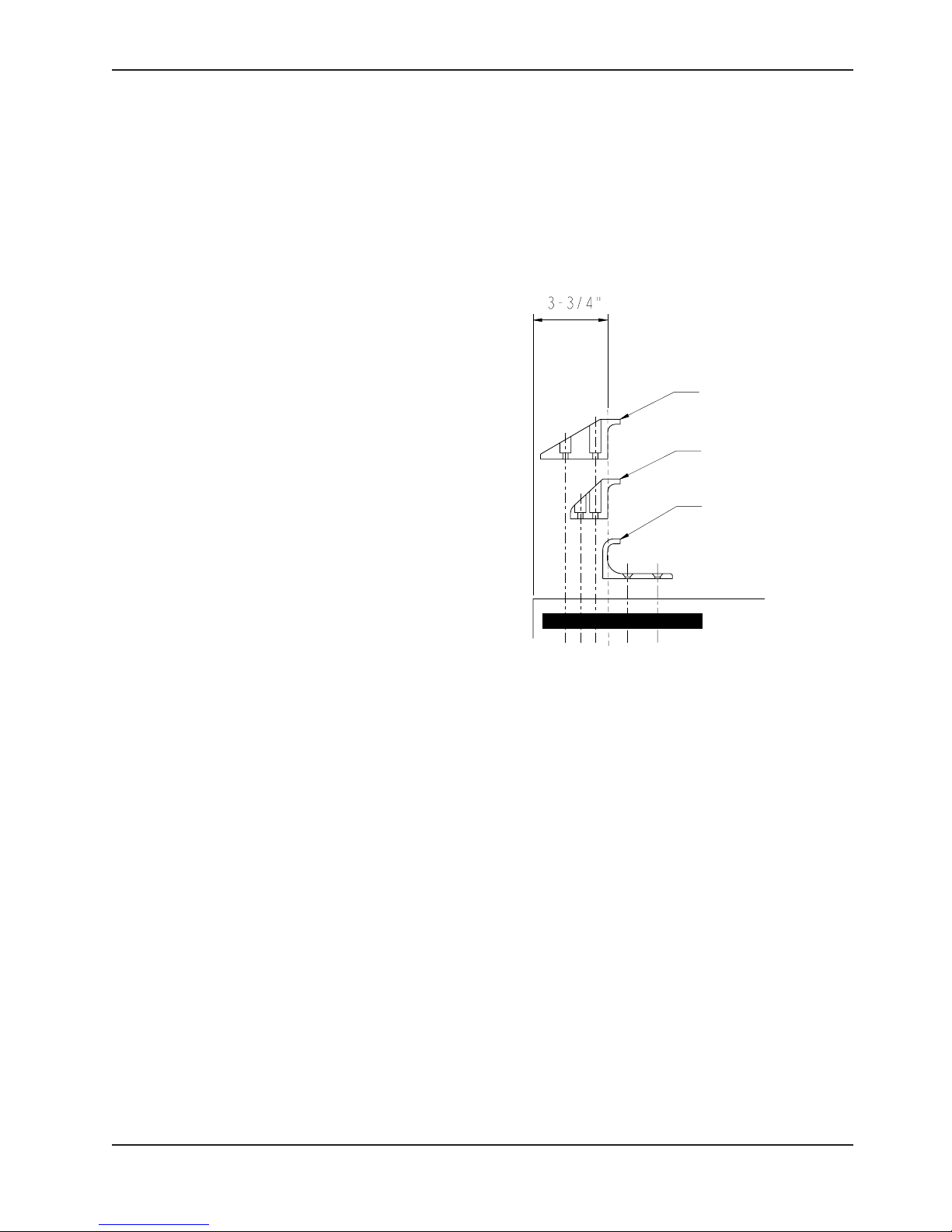

VEHICLE CONFIGURATION

According to federal regulations (reference KKK-A-1822), the bumper height of the vehicle shall be installed equidistant

± 5 cm (2 inches) from the vehicle floor to the ground level, which is defined as the vehicle deck height. The bumper

step shall have a minimum depth of 13 cm (5 inches) and a maximum depth of 25 cm (10 inches). If the bumper depth

is greater than 18 cm (7 inches), then the bumper must be able to fold. Installation of the safety hook into any vehicle

compliant with this federal specification provides adequate clearance for the cot base to lower to its fully extended

position. The cot is compatible with all vehicle deck heights (see specifications for maximum load height) as long as

the vehicle meets the federal specifications that are outlined in KKK-A-1822.

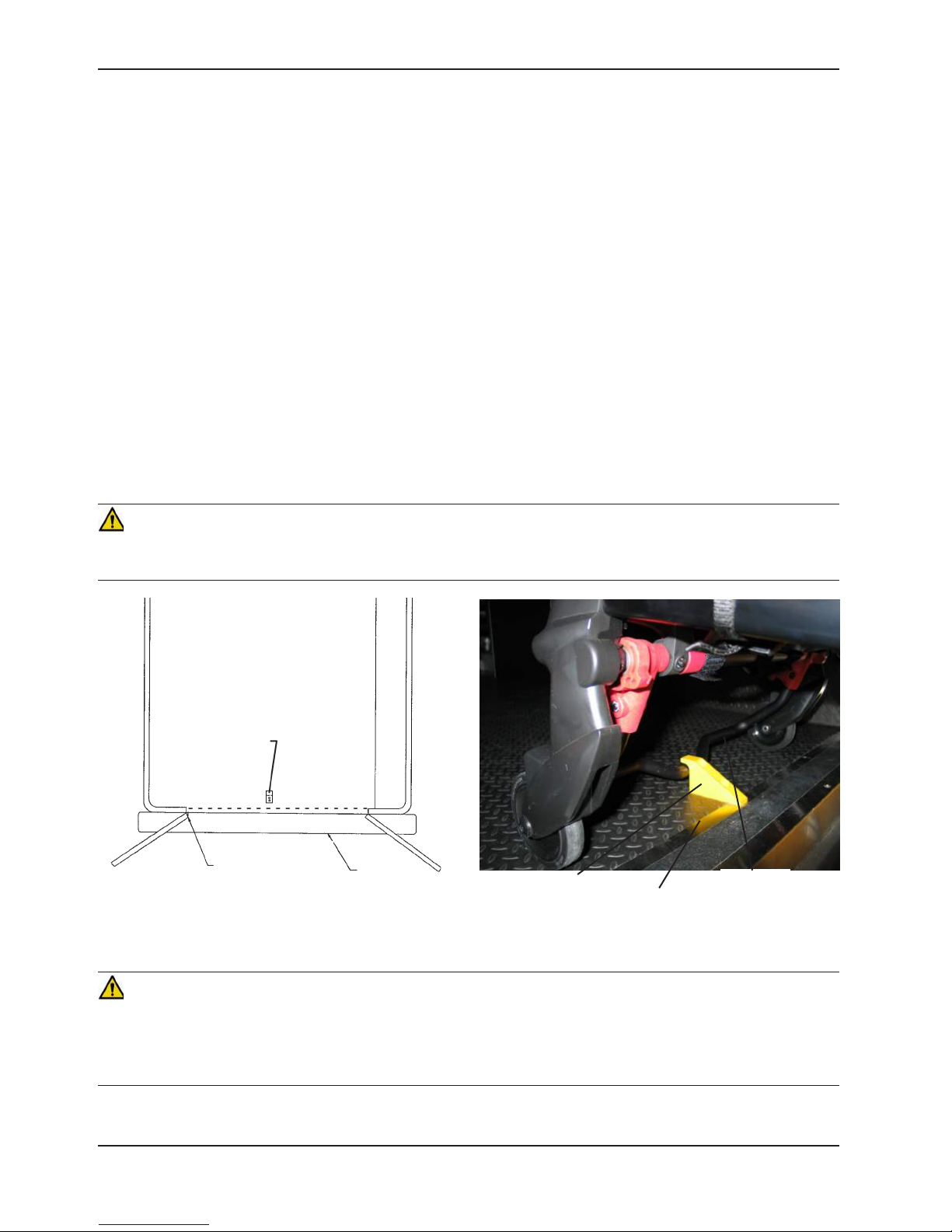

Sill Edge

Sill

DH

2

2

Vehicle Deck Height

Safety Hook

Vehicle Deck Height

CAUTION

• Set the cot load height to the proper stop height prior to operation.

• Installation of the safety hook should be done by a certified mechanic familiar with ambulance vehicle construction.

Consult the vehicle manufacturer before installing the safety hook and be sure that the installation of the safety hook

does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank or electrical wiring of the vehicle.

REQUIRED HARDWARE FOR INSTALLATION OF THE SAFETY HOOK (NOT SUPPLIED)

(2) Grade 5, 1/4”-20 Socket Head Cap Screws*

(2) Grade 5, 1/4”-20 Flat Socket Head Cap Screws*

(2) Flat Washers

(2) Lock Washers

(2) 1/4”-20 Nuts

* The length of the socket head cap screws depends on the thickness of the vehicle floor. Use screws that are long

enough to go completely through the patient compartment floor, washer and nut by at least two full threads.

Return To Table of Contents

16 608 2-209 -001 REV A w ww.stryker.com

Page 17

Vehicle Safety Hook Installation

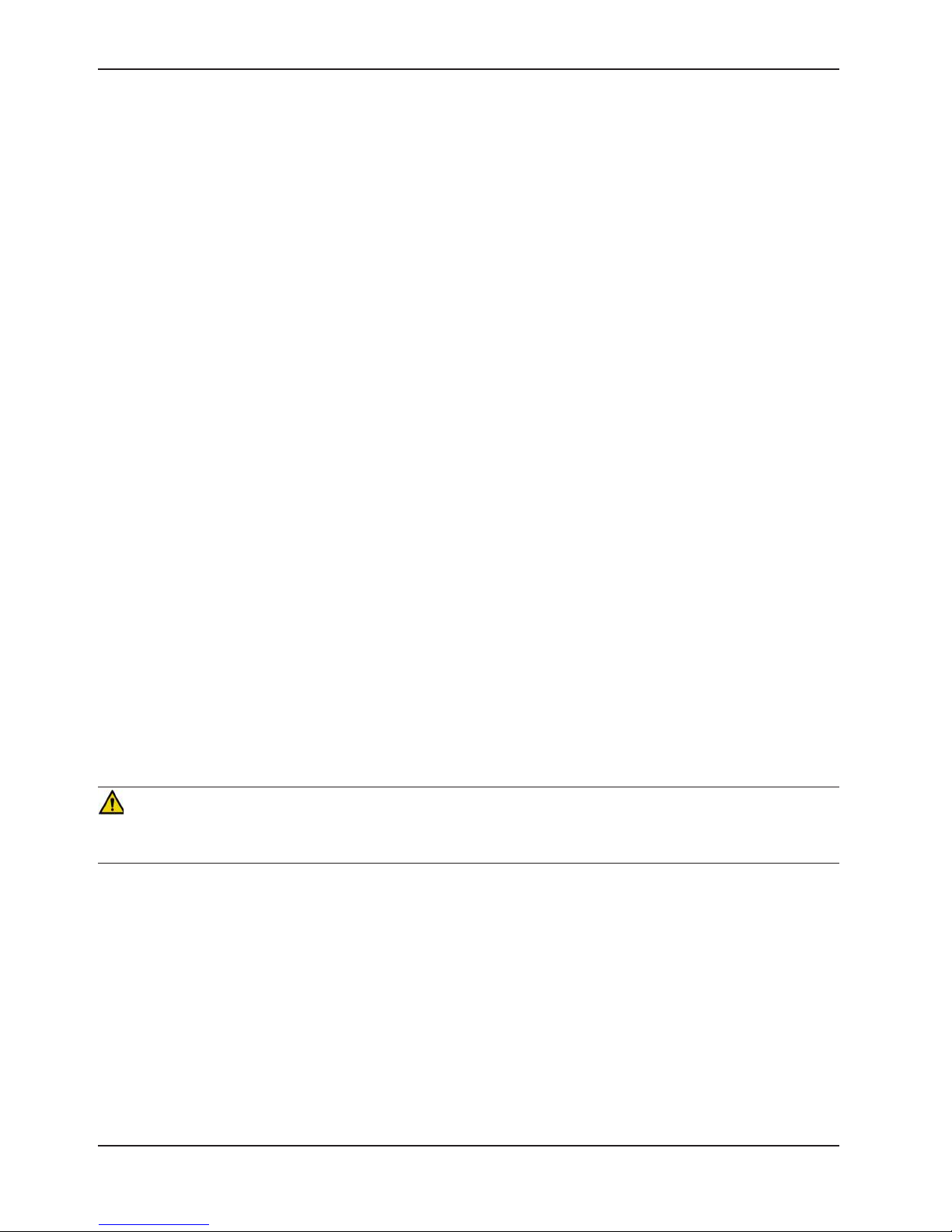

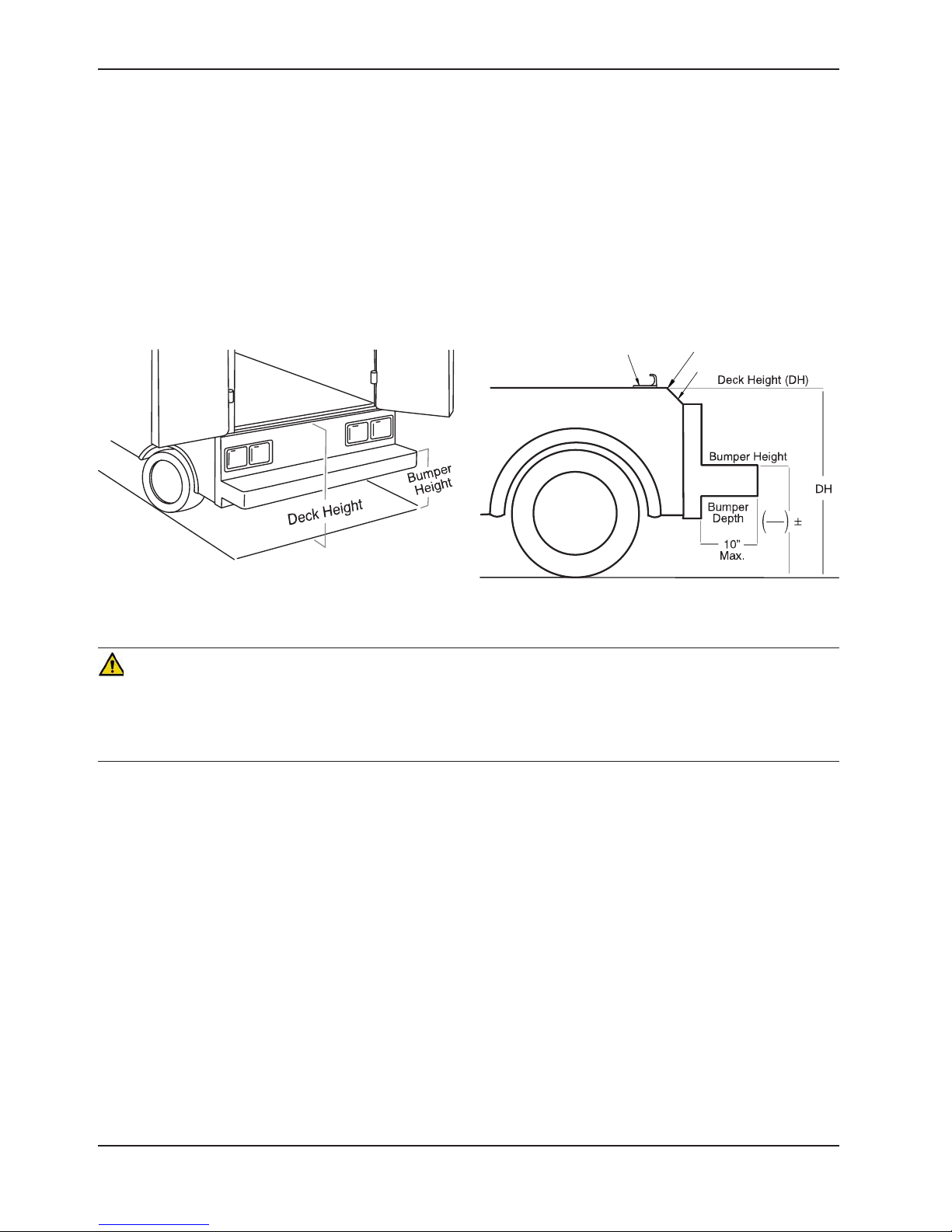

WARNING

• Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can cause injury

to the patient or operator and/or damage to the cot.

• Failure to install the safety hook can cause injury to the patient or operator.

• The face of the safety hook that engages the safety bar should be located at least 3-3/4” from the leading edge

of the door sill. After installation, verify that the cot legs lock into the load position without contacting the vehicle

bumper.

• To avoid injury, verify that the safety bar has engaged the safety hook before removing the cot from the patient

compartment.

Note: Stryker recommends that, prior to installation, the certified mechanic plan the placement of the safety hook in

the rear of the vehicle.

Before installing the safety hook into your vehicle, check the front to back and side to side positioning when unloading

and loading the cot to ensure that the safety hook will be installed properly. The cot safety bar must engage the safety

hook every time, regardless of cot position.

FRONT TO BACK POSITIONING OF THE SAFETY HOOK

1. Select the appropriate safety hook for your vehicle configuration.

2. Position the safety hook at least 3-3/4” from the leading edge of the door sill.

3. Ensure that the safety hook can be securely mounted into the back of the vehicle while providing adequate bumper

clearance to allow the cot to be loaded and unloaded from the vehicle.

4. See “Side to Side Positioning of the Safety Hook” to confirm the side to side placement.

Long Safety Hook

6060-036-018

Short Safety Hook

6060-036-017

J-Style Safety Hook

6092-036-018

Safety Hook Placement

Return To Table of Contents

www.stryker.com 6082-209 -001 REV A 17

Page 18

Vehicle Safety Hook Installation

SIDE TO SIDE POSITIONING OF THE SAFETY HOOK

1. Remove the cot from the fastener and unload it from the vehicle.

2. While the cot is being removed, note the position of the load wheels and the safety bar.

3. Mark the center of the cot safety bar on the vehicle floor.

4. Verify that the position marked in Step 3 is where the safety bar engages the safety hook every time when

unloading the cot in a variety of positions (all the way to the left and all the way to the right), regardless of cot

position.

• If the cot safety bar does not engage the safety hook in any of these positions (left, center, or right), modify

the vehicle, not the cot or safety hook.

• If the cot safety bar engages the safety hook every time, install the safety hook.

INSTALLING THE SAFETY HOOK

1. Determine the correct safety hook front to back and side to side positioning, so the cot safety bar engages the

safety hook every time.

2. Drill the holes for the socket head cap screws.

3. Fasten the safety hook to the patient compartment floor and verify that the safety hook always engages the cot

safety bar regardless of how the cot is unloaded from the vehicle.

WARNING

Verify that the safety hook always engages the cot safety bar regardless of how the cot is unloaded from the vehicle or

injury to the patient or operator and/or damage to the cot may occur.

Top View of Vehicle

Bumper

Squad Bench

Safety Hook

Floor Edge

Safety Bar Engaging Safety Hook

Safety Bar

Safety Hook

Door Frame

Safety Hook Placement

(For Reference Only)

WARNING

The cot must have at least 5/8” of clearance between the vehicle bumper and the cot to disengage the safety bar when

unloading the cot from the vehicle. Verify that the cot legs lock into the load position before disengaging the safety bar

from the safety hook. Failure to properly lock the cot into position can cause injury to the patient or operator and/or

damage to the cot.

Return To Table of Contents

18 608 2-209 -001 REV A w ww.stryker.com

Page 19

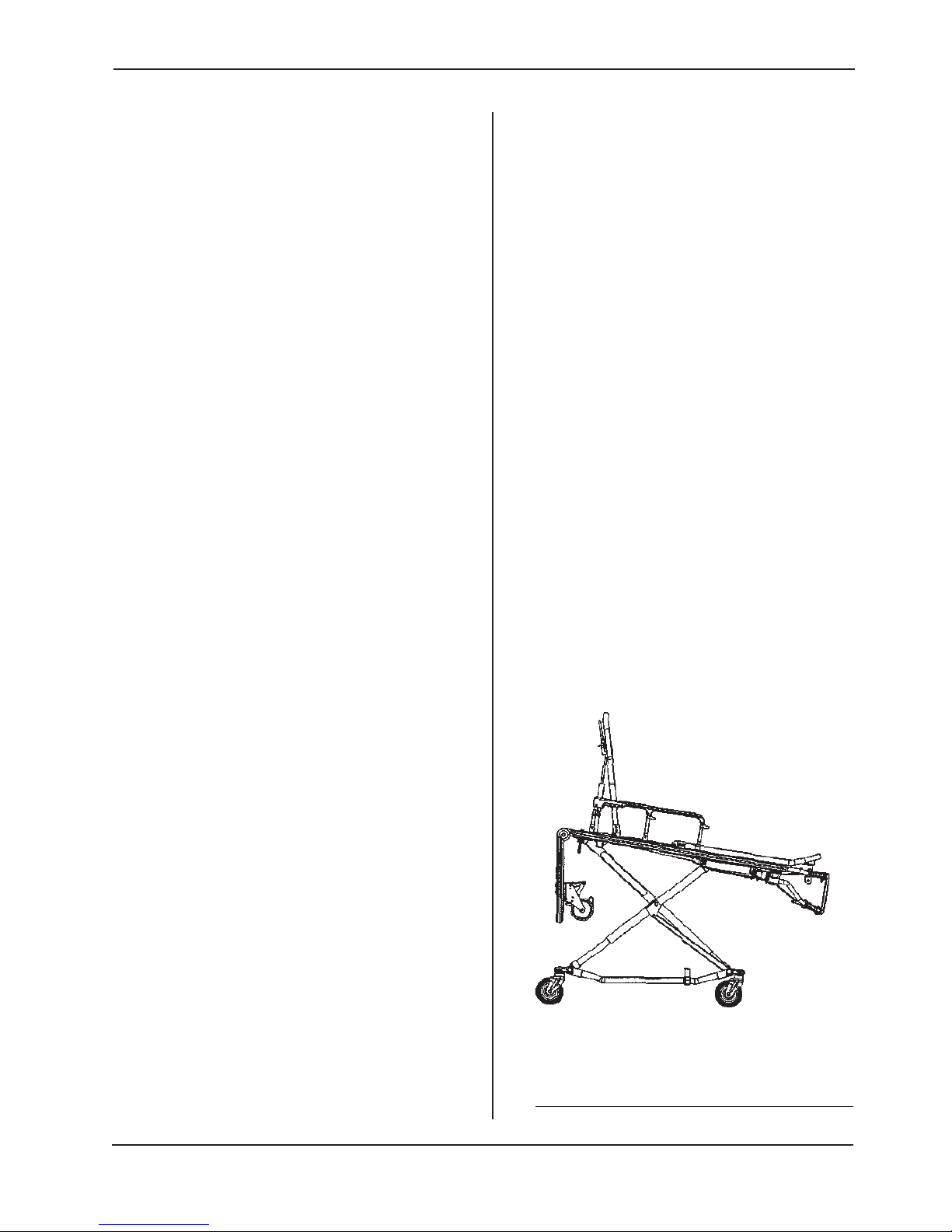

Cot Positions

Position 1 - Use for patient transfer.

Position 2 - Use for patient transfer/cot rolling.

Position 6 - Use for patient transfer/cot rolling.

Position 3 - Use for patient transfer/cot rolling.

Position 4 - Use for patient transfer/cot rolling.

Position 5 - Use for patient transfer/cot rolling.

Position 7 - Use for patient transfer/cot rolling.

WARNING - Operating the cot with the breakaway

head section lowered may cause injury to the

patient or operator or damage to the cot. Use only

positions 5-7 when using this configuration.

www.stryker.com 6082-209 -001 REV A 19

Return To Table of Contents

Page 20

Cot Operations

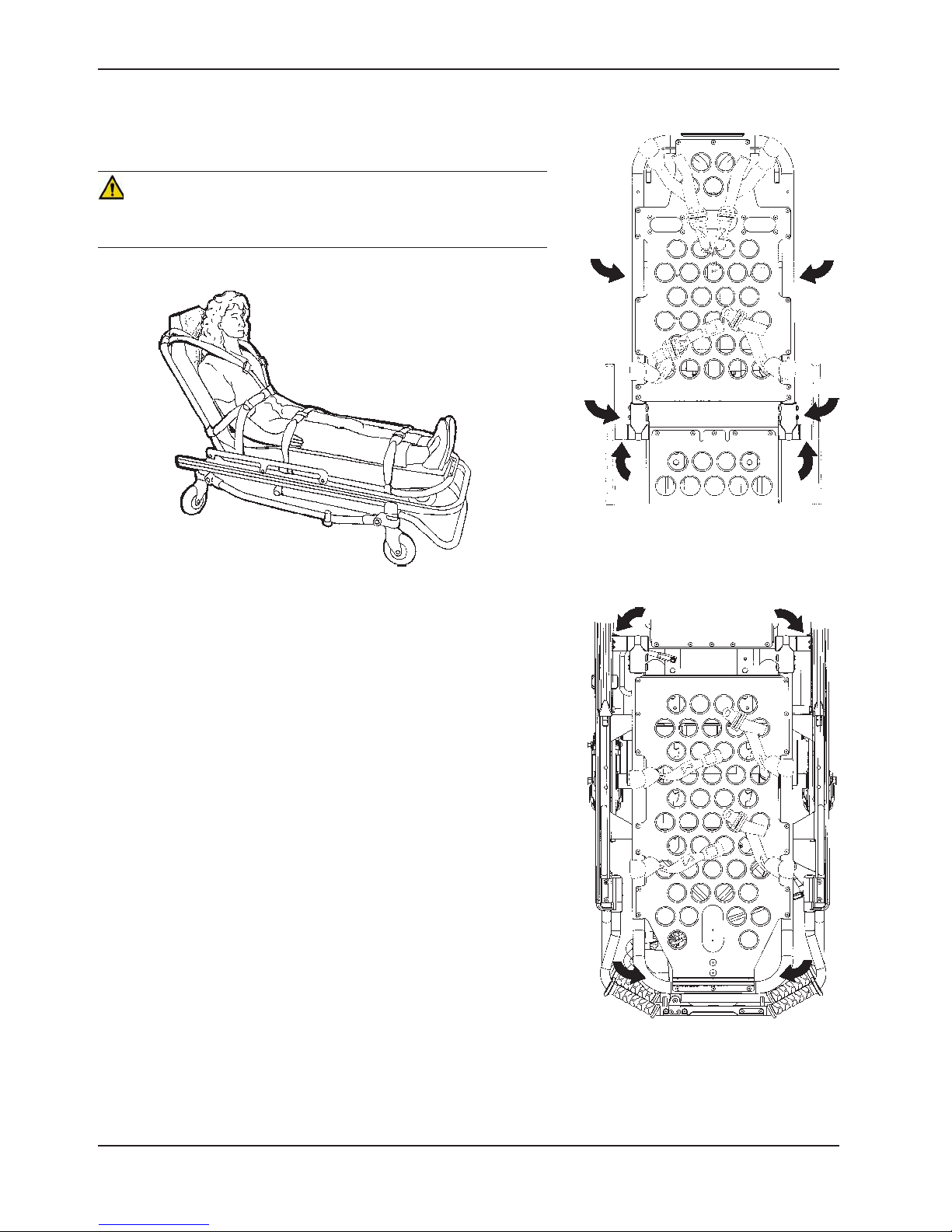

USING PATIENT RESTRAINT STRAPS

WARNING

Always use all restraint straps to secure the patient on the cot. An

unrestrained patient may fall from the cot and be injured.

Figure 6 - Safety Restraints

Always secure the patient on the cot with all the restraint straps. Buckle

the restraints across the patient’s chest/shoulders, waist and legs as

shown in Figure 6. Keep the restraint straps buckled when the cot is not

being used with a patient to avoid damage to the buckles and straps.

When attaching the restraint straps to the cot, keep in mind the

attachment points should provide strong anchorage and proper restraint

position while not interfering with equipment and accessories. Wrap

the strap around the cot frame and back through the loop on the end

of the strap as shown in Figures 7 and 8. The arrows indicate alternate

attachment areas.

Figure 7 - Back Rest Restraints

Return To Table of Contents

20 6082-209 -001 REV A www.stryker.com

Figure 8 - Foot Section Restraints

Page 21

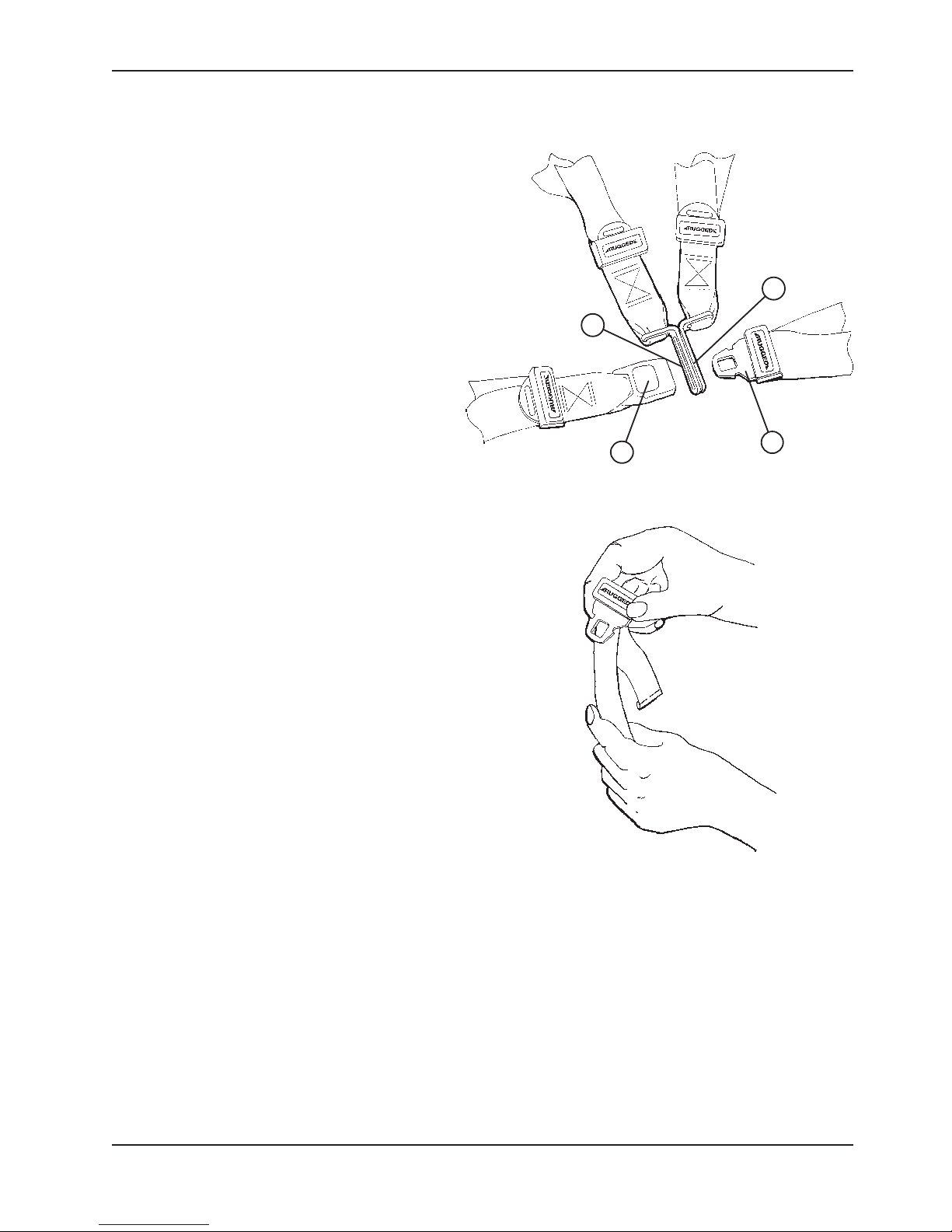

Cot Operations

USING PATIENT RESTRAINT STRAPS (CONTINUED)

When the cot is put into service, the restraints are

opened and placed to either side of the cot until

the patient is positioned on the cot mattress. The

restraint is lengthened, buckled around the patient

and shortened until the required tightness is achieved.

To Open the Safety Restraint:

• Press the red button (A) on the front of the buckle

”receiver”. This releases the buckle tang” (B)

which can then be pulled out of the receiver as

shown in Figure 9.

To Close the Safety Restraint:

• Push the tang into the receiver until a ”click” is

heard. When fastening the chest restraint, be

sure the tang passes through both links (C) on

the shoulder strap as shown in Figure 9.

To Lengthen the Safety Restraint:

• Grasp the buckle tang, turn it at an angle to the

webbing, then pull it out as shown in Figure 10. A

hemmed tab at the end of the webbing prevents

the tang from coming off the strap.

To Shorten the Safety Restraint:

• Grasp the hemmed tab and pull the webbing back

through the tang until the required tightness is

achieved as shown in Figure 11.

Note:

• Whenever a restraint is buckled on a patient, the

attendant should check to be sure the tang is

fully engaged and that the extra webbing is not

tangled in the cot or hanging loose.

• Inspection of the restraints should be done at

least once a month (more frequently if used

heavily). Inspection should include checking for

a bent or broken receiver or tang, torn or frayed

webbing, etc. Any restraint showing wear or not

operating properly must be replaced immediately.

C

C

A

B

Figure 9 - Buckling the Safety Restraints

Figure 10 - Lengthening the Safety Restraint

www.stryker.com 6082-209 -001 REV A 21

Figure 11 -

Shortening the Safety

Restraint

Return To Table of Contents

Page 22

Cot Operations

PEDI-MATE® INFANT RESTRAINT SYSTEM ATTACHMENT INSTRUCTIONS (OPTIONAL EQUIPMENT)

Refer to the Pedi-Mate® users manual for the manufacturer’s recommendations for the use, operation and care of the

Pedi-Mate® Infant Restraint System.

Securing the Pedi-Mate® to the cot:

1. Remove any restraints already attached to the cot.

2. Raise the cot backrest to the full upright position.

3. Position the Pedi-Mate® pad flat on the backrest with the black backrest straps out (see Figure 12).

Figure 12 - Positioning the Pedi-Mate®

4. Wrap the straps around the backrest and insert the ends of the straps through the brackets. Securely fasten the

buckle (see Figure 13).

Figure 13 - Fastening the Pedi-Mate® Buckle

WARNING

To avoid accidental release of the Pedi-Mate®, and possible injury to the infant, ensure the buckle is located away from

obstructions on the cot or head end storage pouch.

Return To Table of Contents

22 6082-209 -001 REV A www.stryker.com

Page 23

Cot Operations

PEDI-MATE® INFANT RESTRAINT SYSTEM ATTACHMENT INSTRUCTIONS (CONTINUED)

5. Pull firmly on the end of the adjustable backrest strap and tighten it securely.

6. Insert the mainframe straps between the cot frame and the mattress. To ensure the release button is toward

the foot end of the cot, insert the buckle behind the litter crossbrace and bring it up in front of the crossbrace.

Secure the buckle around the crossbrace, leaving a little slack in the strap for final adjustment (see Figure 14).

Figure 14 - Securing the Safety Restraints on a Cot

WARNING

To avoid accidental release of the Pedi-Mate®, and possible injury to the infant, ensure the buckle is located away from

obstructions on the cot.

7. Verify all the straps are snug and fastened securely (see Figure 15).

Figure 15- Pedi-Mate® Strapped to a Cot

Note:

• These are general instructions for installation of the Pedi-Mate®. Safe and proper use of the Pedi-Mate® is solely

at the discretion of the user. Stryker recommends all users be trained on the proper use of the Pedi-Mate® before

using it in an actual situation.

• Retain these instructions for future reference. Include them with the product in the event of transfer to new users.

• Pedi-Mate® is a trademark of Ferno-Washington Inc.

www.stryker.com 6082-209 -001 REV A 23

Return To Table of Contents

Page 24

Cot Operations

OPERATING GUIDELINES

• Use the cot only as described in this manual.

• Read all labels and instructions on the cot before using the cot.

• Use a minimum of two operators to manipulate the cot while a patient is on the cot.

• Do not adjust, roll or load the cot without advising the patient. Stay with the patient and control the cot at all times.

• Never apply the optional wheel lock while a patient is on the cot.

• Always use the restraint straps and keep the siderails up when a patient is on the cot.

• Use properly trained helpers when necessary to control the cot and patient.

TRANSFERRING THE PATIENT TO THE COT

1 Roll the cot to the patient.

2 Place the cot beside the patient and raise/lower the cot to the patient’s level.

3 Lower the siderails and open the restraint straps.

4 Transfer the patient to the cot using accepted EMS procedures.

5 Use all the restraints to secure the patient to the cot (see page 20 for restraint strap usage instructions).

6 Raise the siderails and adjust the backrest and leg rest as necessary.

WARNING

• Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot and

be injured.

• Never apply the optional wheel lock while a patient is on the cot. Tipping could occur if the cot is moved while the

wheel lock is applied, resulting in injury to the patient or operator and/or damage to the cot.

ROLLING THE COT

1. Make sure all the restraint straps are securely buckled around the patient (see page 20 for restraint strap usage

instructions).

2. Place the cot in positions 2−7 for rolling (see page 19 for cot positions).

3. When rolling the cot, position an operator at the foot end and one at the head end at all times.

Note:

• Loose items or debris on the patient compartment floor can interfere with the operation of the safety hook and cot

fastener. Keep the patient compartment floor clear.

• The cot can be loaded with the siderails down only if the restraint belts are properly buckled around the patient.

WARNING

Operating the cot with the breakaway head section lowered may cause injury to the patient or operator or damage to the

cot. Use only positions 5−7 (see page 19) when using this configuration.

RAISING/LOWERING THE COT

1. Both users must lift weight up off the base.

2. The user at the foot end must pull the release handle.

3. Both users must lower the cot to the ground or raise the cot up.

Return To Table of Contents

24 6082-209 -001 REV A www.stryker.com

Page 25

Cot Operations

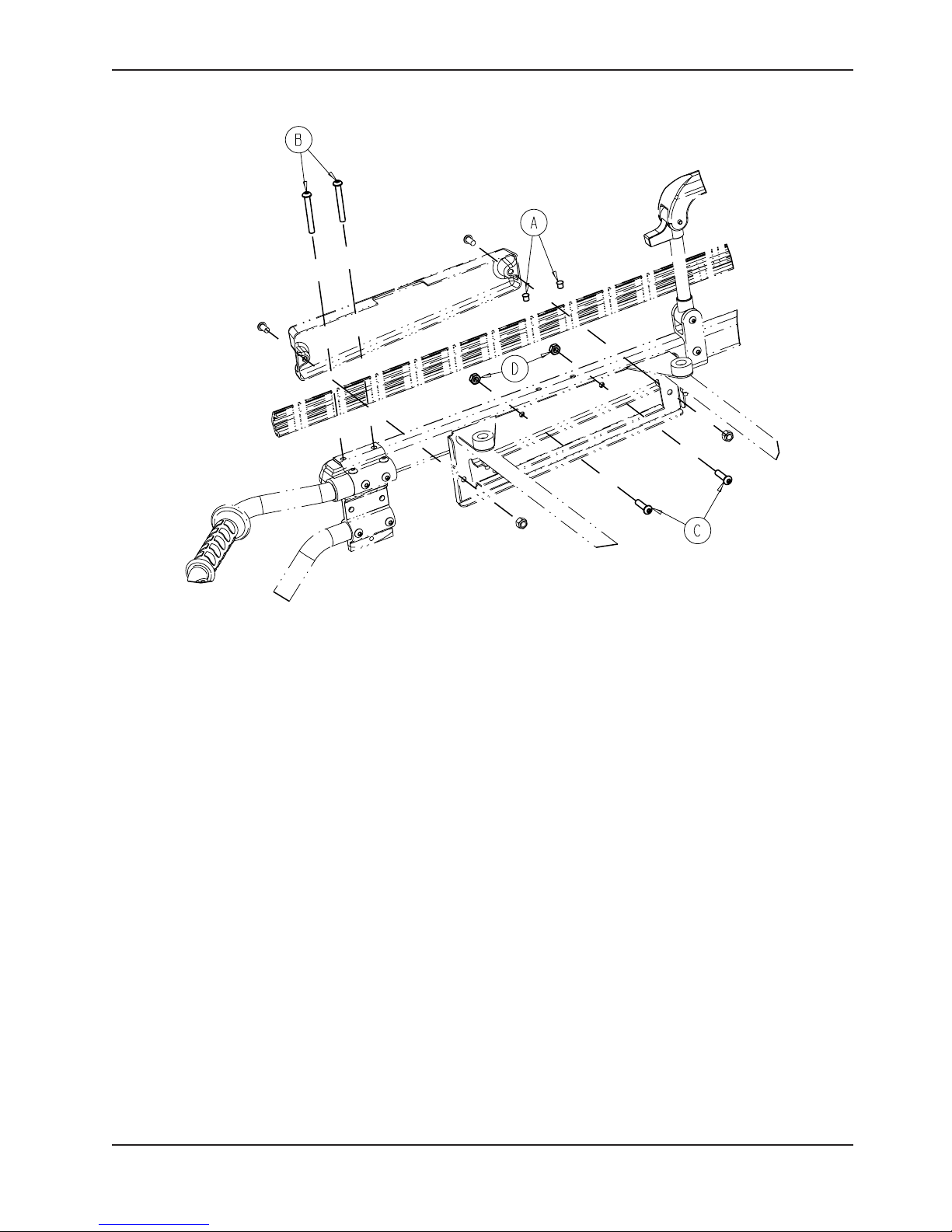

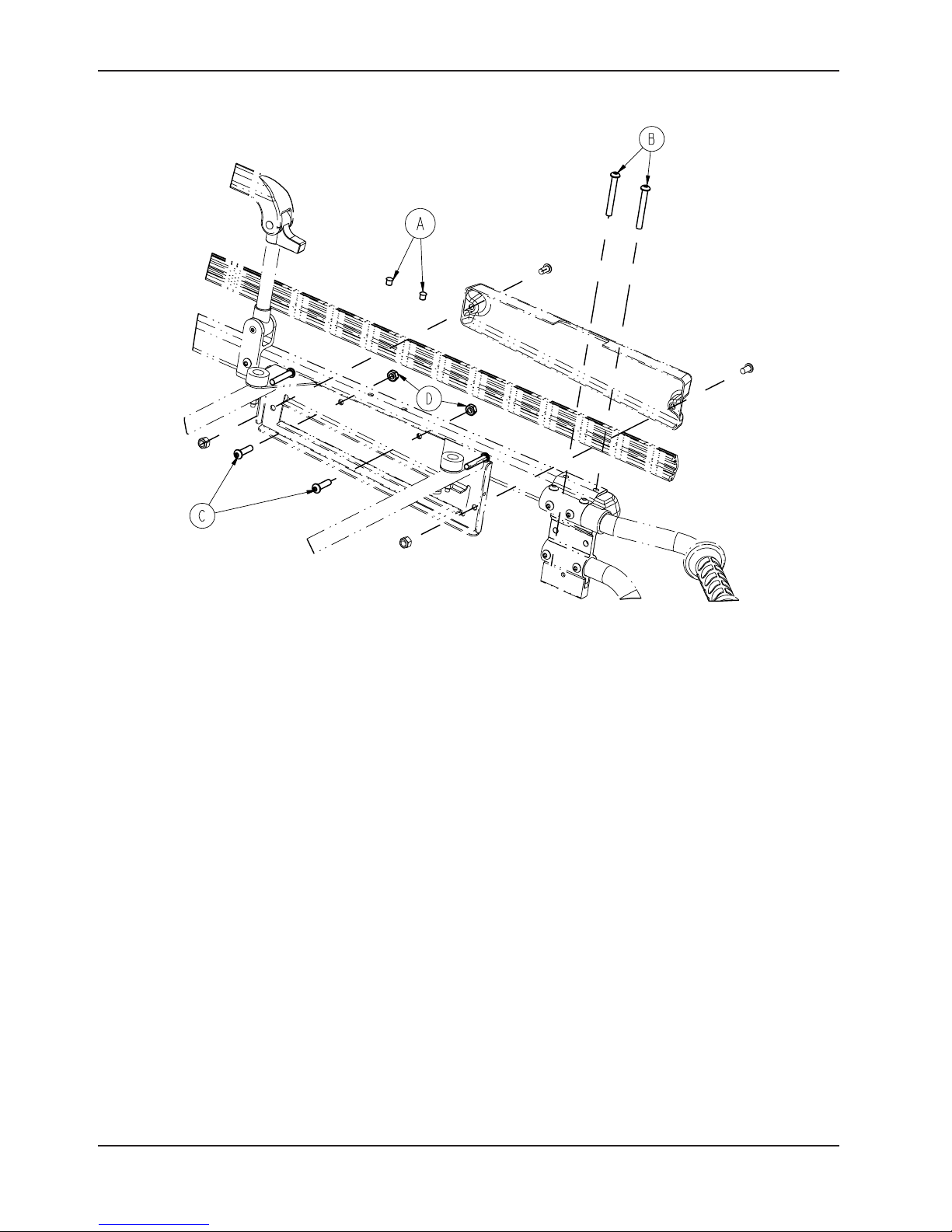

LOADING THE COT INTO A VEHICLE WITH TWO OPERATORS

When loading the cot into a vehicle, an operator should

remember the following important issues:

• Two operators must be present when the cot is occupied.

• There must be a safety hook properly installed in the

vehicle so that the bumper does not interfere with the front

legs of the base frame. (See for safety hook installation

instructions.)

• Operators must be able to lift the total weight of the

patient, cot and any items on the cot.

• The higher an operator must lift the cot, the more difficult

it becomes to hold the weight. An operator may need help

loading the cot if he/she is too short or if the patient is too

heavy to lift safely. The operator must be able to lift the

cot high enough for the cot’s legs to unfold completely and

lock when the cot is unloaded. A shorter operator will have

to raise his/her arms higher to enable the undercarriage

to unfold.

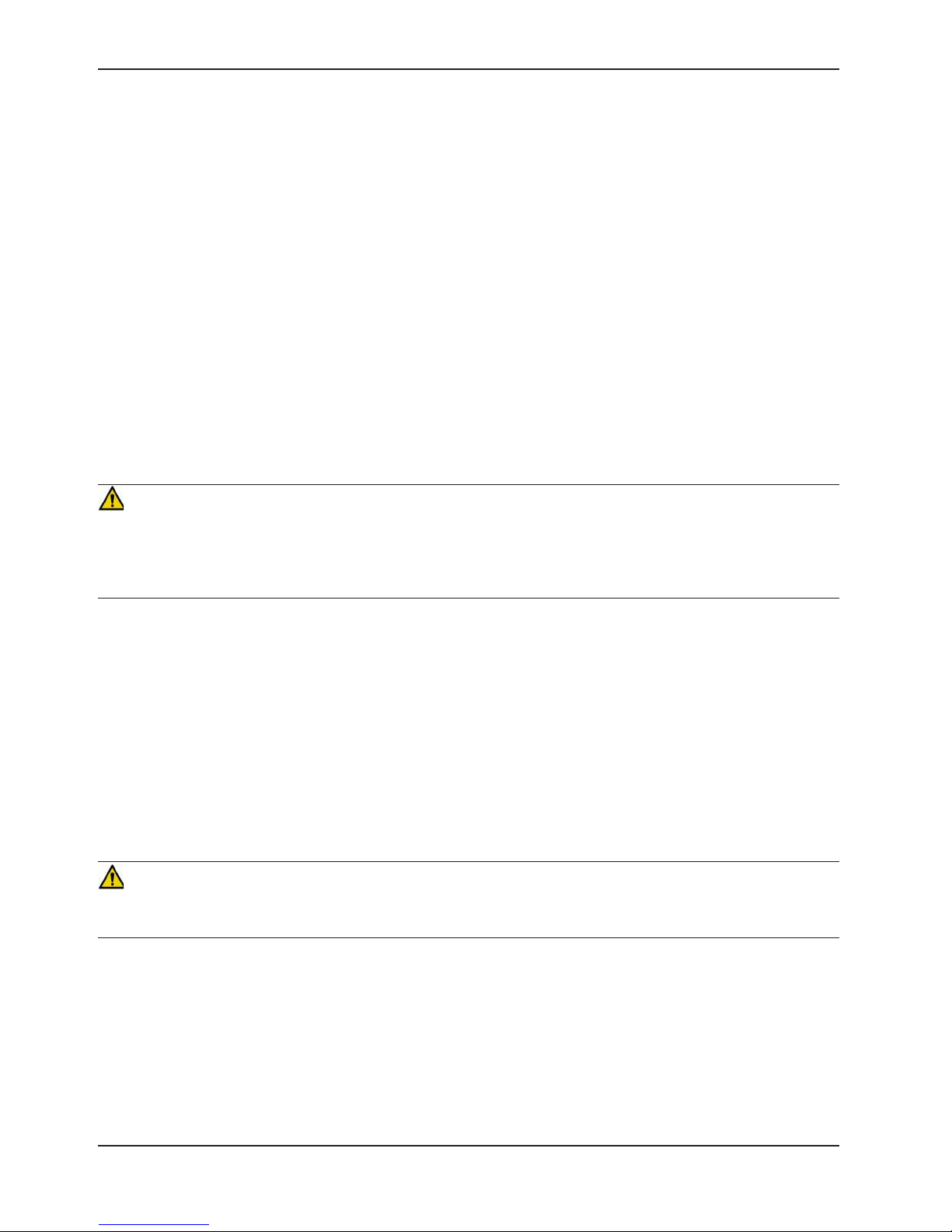

Figure 16 - Safety Bar Engaging Safety Hook

WARNING

Failure to use the safety hook can result in injury. Install and use

the hook as described in this manual.

1. Place the cot in a loading position (any position where

the loading wheels meet the vehicle floor height). Roll the

cot to the open door of the patient compartment. Lift the

vehicle bumper to the raised position (if possible).

2. Push the cot forward until the loading wheels are on the

patient compartment floor and the safety bar passes the

safety hook as shown in Figure 16.

3. For maximum clearance to lift the base, pull the cot back

until the safety bar engages the safety hook. Operator two

should verify that the bar engages the safety hook.

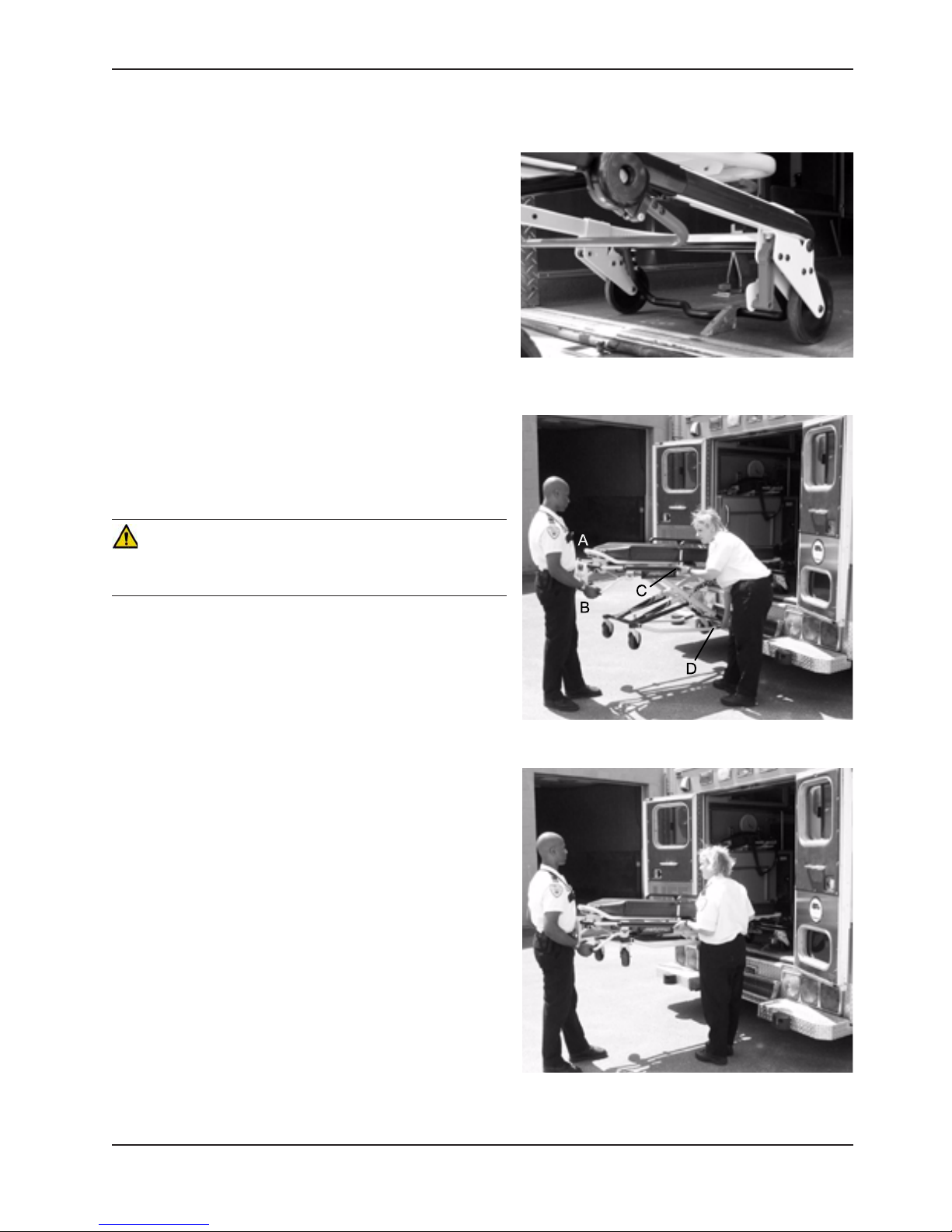

4. Operator 1 − Grasp the cot frame at the foot end. Lift

the foot end of the cot until the weight is off the latching

mechanism. Squeeze and hold the release handle

(location A or B).

5. Operator 2 − Stabilize the cot by placing your hand on

the outer rail (location C). Grasp the base frame where

indicated (location D). After the foot end operator has

lifted the cot and squeezed the release handle, raise the

undercarriage until it stops in the uppermost position and

hold it there (Figure 17).

6. Both Operators − Push the cot into the patient compartment

(Figure 18), engaging the cot fastener (not included).

Figure 17 - 2 Operators - One Lifting the Base

www.stryker.com 6082-209 -001 REV A 25

Figure 18 - 2 Operators - Base Full Up

Return To Table of Contents

Page 26

Cot Operations

LOADING AN EMPTY COT INTO A VEHICLE WITH ONE OPERATOR

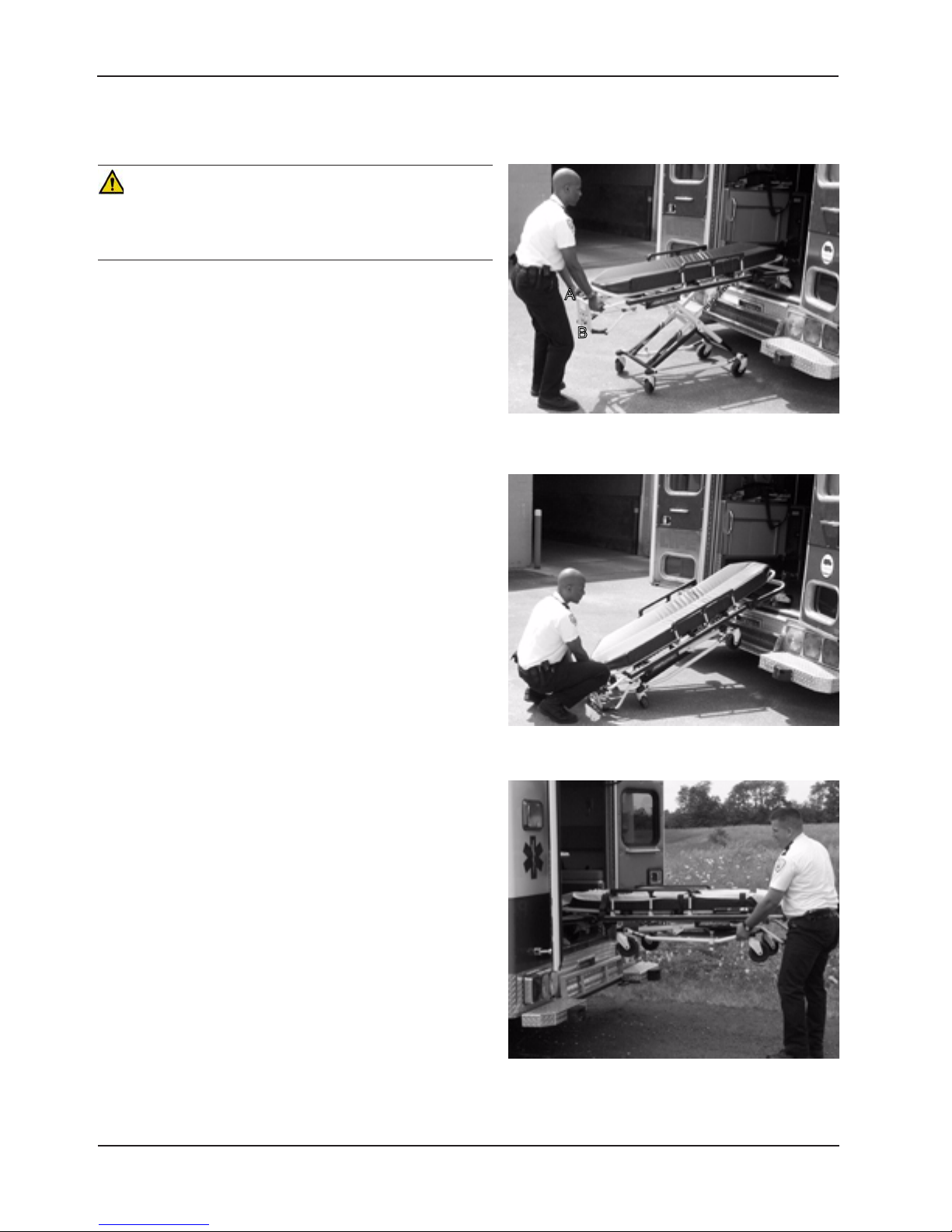

WARNING

This procedure is for use only with an empty cot. Do not use

this procedure when loading a patient. Injury to the patient and/

or operator could result.

1. Place the cot in a loading position (any position in which

the load wheels meet the vehicle floor height – see page

19).

2. Roll the cot to the open door of the patient compartment.

3. Lift the vehicle bumper to the raised position (if possible).

4. Push the cot forward until the loading wheels are on the

compartment floor and the safety bar passes the safety

hook.

5. Pull the cot back until the safety bar engages the safety

hook.

6. Grasp the cot frame at the foot end and squeeze and hold

the release handle (A or B) (Figure 19).

7. Lower the foot end of the cot to the ground, making sure

the cot locks in position 1 (Figure 20).

8. Lift the foot end of the cot until it is level with the

compartment floor.

9. Grasp the base of the cot with one hand and pull up the

base of the cot towards the litter, reducing the space

between the base and the litter (Figure 21).

10. Push the cot into the patient compartment, guiding it into

the cot fastener.

Figure 19 - Squeeze the Release Handle

Figure 20 - Lower the Foot End of the Cot

Figure 21 - Pull Up the Base of the Cot

Return To Table of Contents

26 6082-209 -001 REV A w ww.stryker.com

Page 27

Cot Operations

UNLOADING THE COT FROM A VEHICLE WITH TWO OPERATORS

WARNING

Failure to use the safety hook can cause injury to the patient or operator. Install and use the safety hook as described

in this manual. To avoid injury, verify the safety bar has engaged the safety hook before removing the cot from the patient

compartment.

1. Disengage the cot from the cot fastener. (For more detailed instructions, reference the Cot Fastener Operations

Manual − Model 6370).

2. Operator 1 − Grasp the cot frame. Pull the cot out of the patient compartment until the safety bar engages the

safety hook.

3. Operator 2 − Grasp the base frame where indicated, lift slightly, and lower the base frame to its fully extended

position while operator 1 squeezes and holds the release handle.

4. Operator 1 − Let go of the release handle and be sure the undercarriage locks into place.

5. Operator 2 − Disengage the safety bar from the safety hook by pushing the safety bar release lever forward.

6. Remove the cot loading wheels from the vehicle. Place the cot in a rolling position (cot positions 2−7 − see page

19).

CAUTION

Do not allow the cot undercarriage to drop unassisted (commonly known as a “hot drop”) when removing the cot from

the vehicle. Repeated hot dropping will cause premature wear or damage to the cot.

WARNING

Be sure the undercarriage has engaged before removing the loading wheels from the patient compartment floor of the

vehicle. An unlocked undercarriage will not support the cot and injury to the patient or operator could result.

UNLOADING AN EMPTY COT FROM A VEHICLE WITH ONE OPERATOR

WARNING

This procedure is for use only with an empty cot. Do not use this procedure when unloading a patient. Injury to the

patient and/or operator could result.

1. Lift the vehicle bumper to the raised position (if possible).

2. Grasp the cot frame at the foot end; pull the cot from the vehicle until the safety bar engages the safety hook.

3. Lower the foot end of the cot to the ground (see Figure 20 on page 26).

4. Squeeze and hold the release handle (A or B − see Figure 21 on page 26) and raise the foot end of the cot

back to a level position with the compartment floor.

5. Disengage the safety bar from the safety hook by pushing the safety bar release lever forward and roll the cot out

of the vehicle.

www.stryker.com 6082-209 -001 REV A 27

Return To Table of Contents

Page 28

Cot Operations

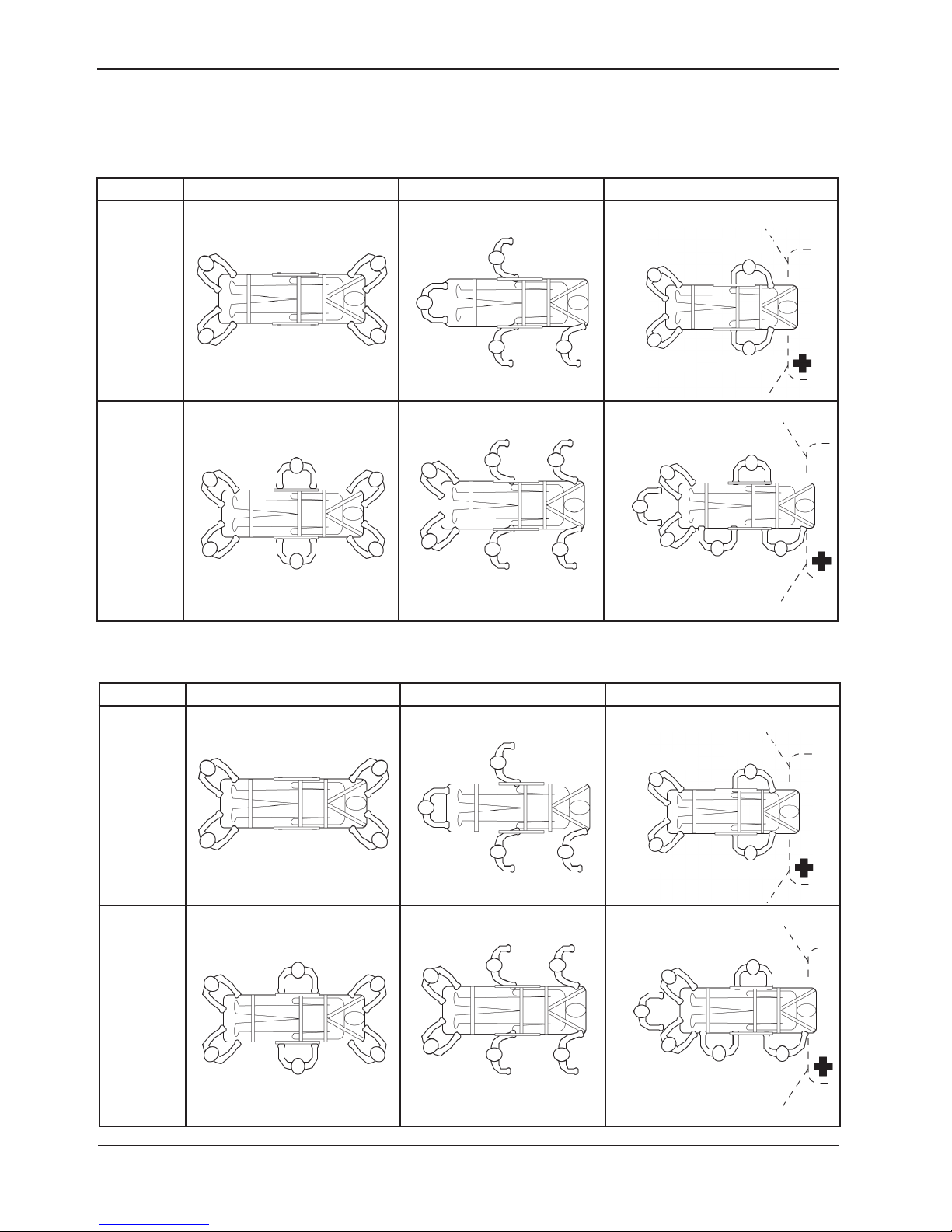

USING ADDITIONAL ASSISTANCE

IF EQUIPPED WITH THE RIGHT HAND RELEASE OPTION

Changing Levels Rolling Loading/Unloading

Helper

Helper

Helper Helper

Helper

Two

Operators

Two

Helpers

Two

Operators

Four

Helpers

Helper

Operator

Helper

Operator

Helper

Helper

Operator

Helper

Operator

Helper

Operator

Helper

Operator

IF EQUIPPED WITH THE LEFT HAND RELEASE OPTION

Operator

Operator

Helper

Operator

Helper

Helper

Operator

Helper

Operator

Helper

Helper

Operator

Changing Levels Rolling Loading/Unloading

Operator

Two

Operators

Two

Helpers

Helper

Operator

Two

Operators

Four

Helpers

Helper

Return To Table of Contents

28 6082-209 -001 REV A w ww.stryker.com

Helper

Helper

Operator

Helper

Operator

Helper

Operator

Operator

Helper

Helper

Helper

Helper Helper

Helper

Operator

Operator

Operator

Helper

Operator

Helper

Helper

Helper

Operator

Helper

Helper

Operator

Page 29

Cot Operations

OPERATING THE OPTIONAL WHEEL LOCK(S)

A

Figure 22 - Wheel Lock

1. To activate the optional wheel lock(s), press down fully on the pedal (A) until it stops.

2. To release the optional wheel lock(s), depress the upper face of the pedal with your foot or lift up with your toe

under the pedal. The upper portion of the pedal will rest against the caster frame when the wheel lock is released.

WARNING

• Never apply the optional wheel lock(s) while a patient is on the cot. Tipping could occur if the cot is moved while

a wheel lock is applied, resulting in injury to the patient or operator and/or damage to the cot.

• Wheel lock(s) are only intended to help prevent the cot from rolling while unattended. A wheel lock may not

provide sufficient resistance on all surfaces or under loads.

• Never leave a patient unattended on the cot or injury could result. Hold the cot securely while a patient is on the

cot.

• Never install or use a wheel lock on a cot with excessively worn wheels. Installing or using a wheel lock on a wheel

with less than a 6” diameter could compromise the holding ability of the wheel lock, possibly resulting in injury to

the patient or operator and/or damage to the cot or other equipment.

www.stryker.com 6082-209 -001 REV A 29

Return To Table of Contents

Page 30

Cot Operations

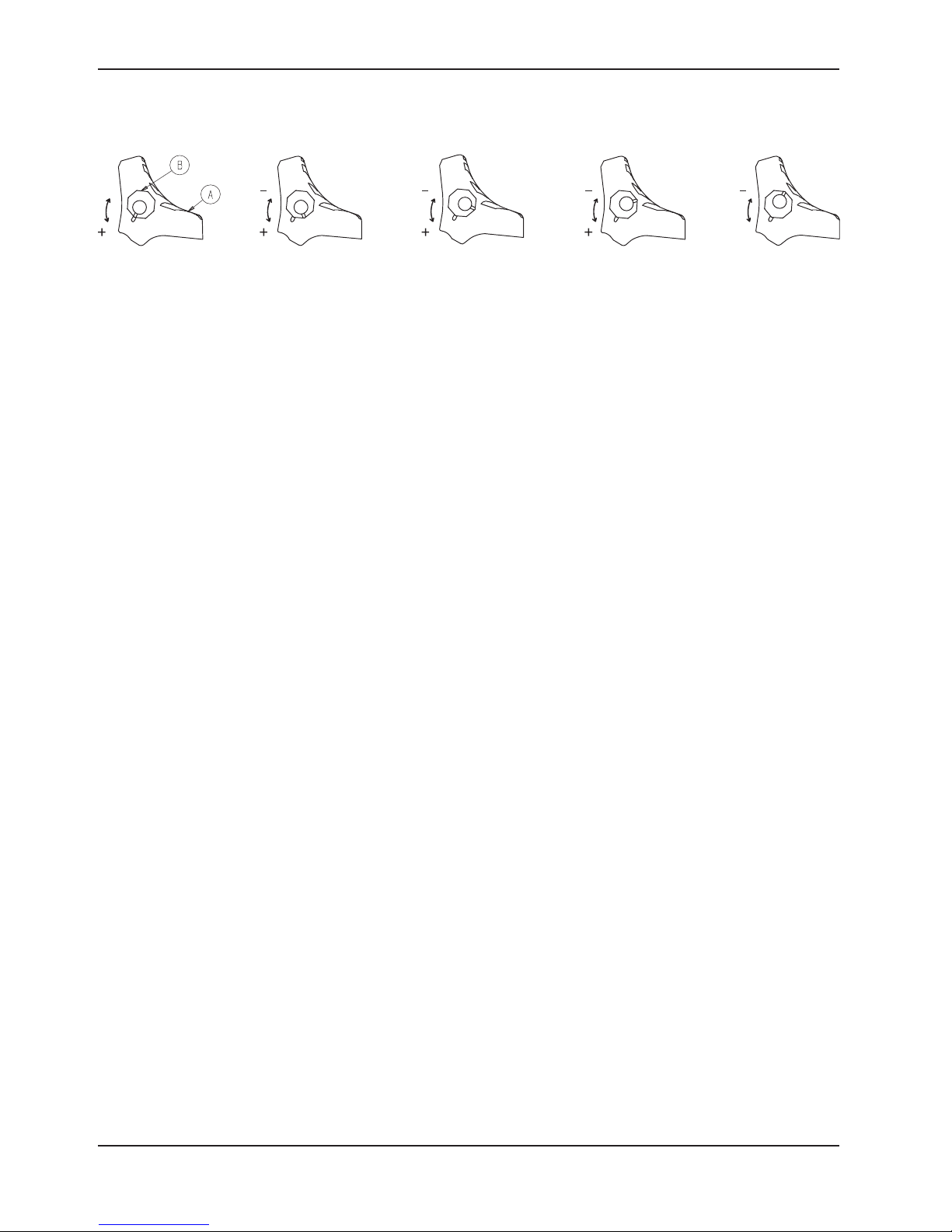

ADJUSTING THE WHEEL LOCKING FORCE

MINIMUM MAXIMUM

Figure 26 - Wheel Locking Force Adjustment

1. To adjust the wheel locking force, remove the socket screw from the center of the lock pedal. The wheel lock is

initially assembled with the pedal set at the minimum locking force. The marker on the pedal (item A) is aligned

with the marker on the octagonal sleeve (item B).

2. Remove the sleeve (B). Rotate the sleeve counterclockwise to increase the pedal locking force and clockwise to

decrease the locking force. Insert the sleeve into the pedal. Reinstall the socket screw.

3. Test the pedal locking force and verify the pedal holds properly before returning the cot to service.

Return To Table of Contents

30 6082 -209-001 RE V A ww w.stryker.com

Page 31

Cot Operations

CHANGING THE COT HEIGHT WITH TWO OPERATORS

C

FOOT END

B

A

Figure 24 - Release Handle Locations

Note: Changing the height while a patient is on the cot requires a minimum of two operators, positioned at both ends

or on each side of the cot. Each operator must grasp the cot frame securely.

To lower the cot from the ends, the operator at the foot end of the cot positions his/her hands so the release handle

(A or B) can be squeezed while a secure grip is maintained on the lifting bars. Both operators must lift the cot until

the weight is off the latching mechanism (approximately 1/4”). The operator at the foot end squeezes and holds the

release handle and both operators then raise or lower the cot together. The handle is released when the desired

position is reached. Both operators should maintain a secure grip on the litter frame until the latching mechanism is

securely locked into position.

To lower the cot from the sides, the operator on the patient’s right positions his/her hands so he/she can reach the

release handle at the midpoint of the litter (C). Both operators must lift the cot until the weight is off the latching

mechanism (approximately 1/4”). The operator at the patient’s right squeezes and holds the release handle. Both

operators then raise or lower the cot together. The handle is released when the desired position is reached. Both

operators should maintain a secure grip on the litter frame until the latching mechanism is securely locked into position.

WARNING

Grasping the cot improperly can cause injury. Grasp only the litter frame or the lifting bar to lift the cot. Keep hands,

fingers and feet away from moving parts. To avoid injury, use extreme caution when placing your feet near the base

tubes while raising and lowering the cot.

www.stryker.com 6082-209 -001 REV A 31

Return To Table of Contents

Page 32

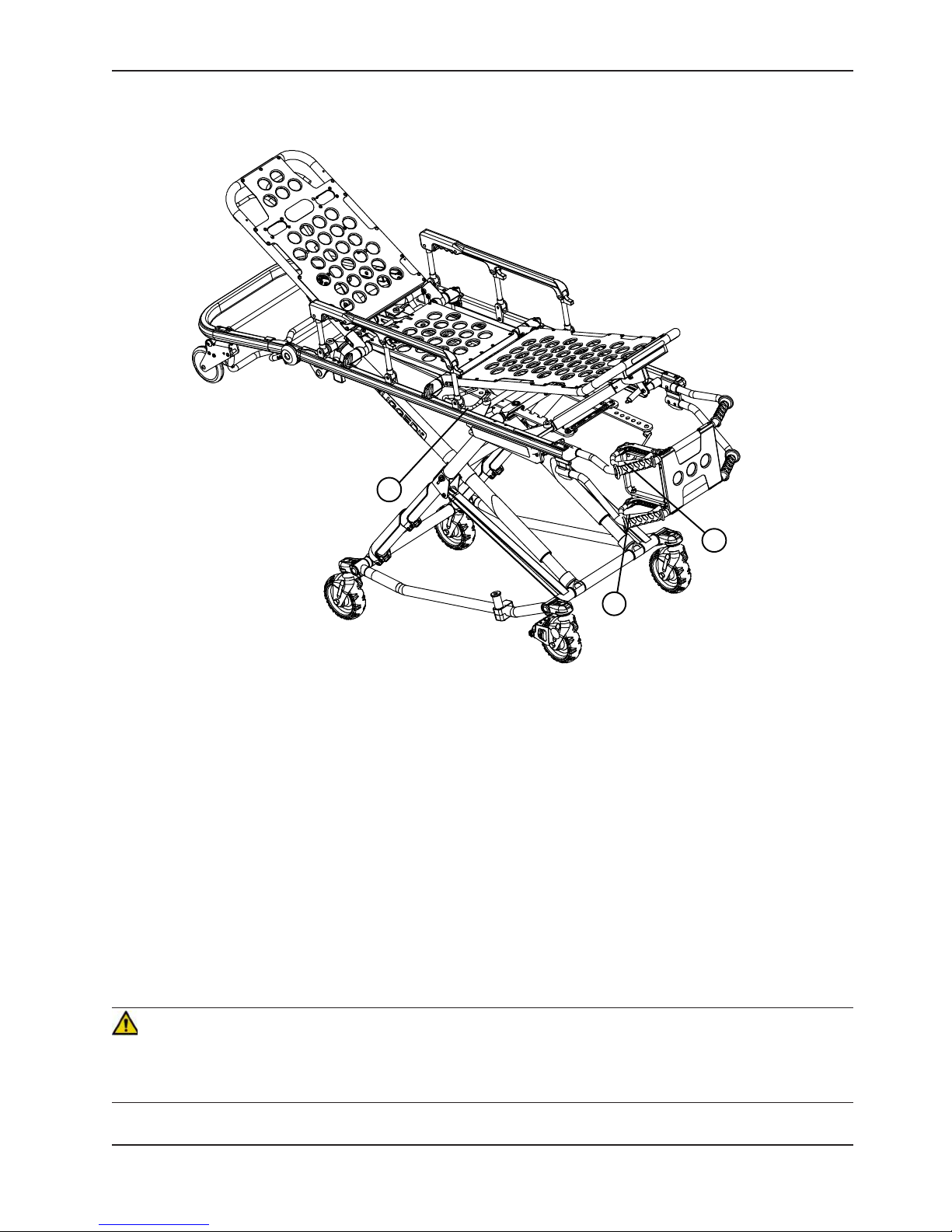

Cot Operations

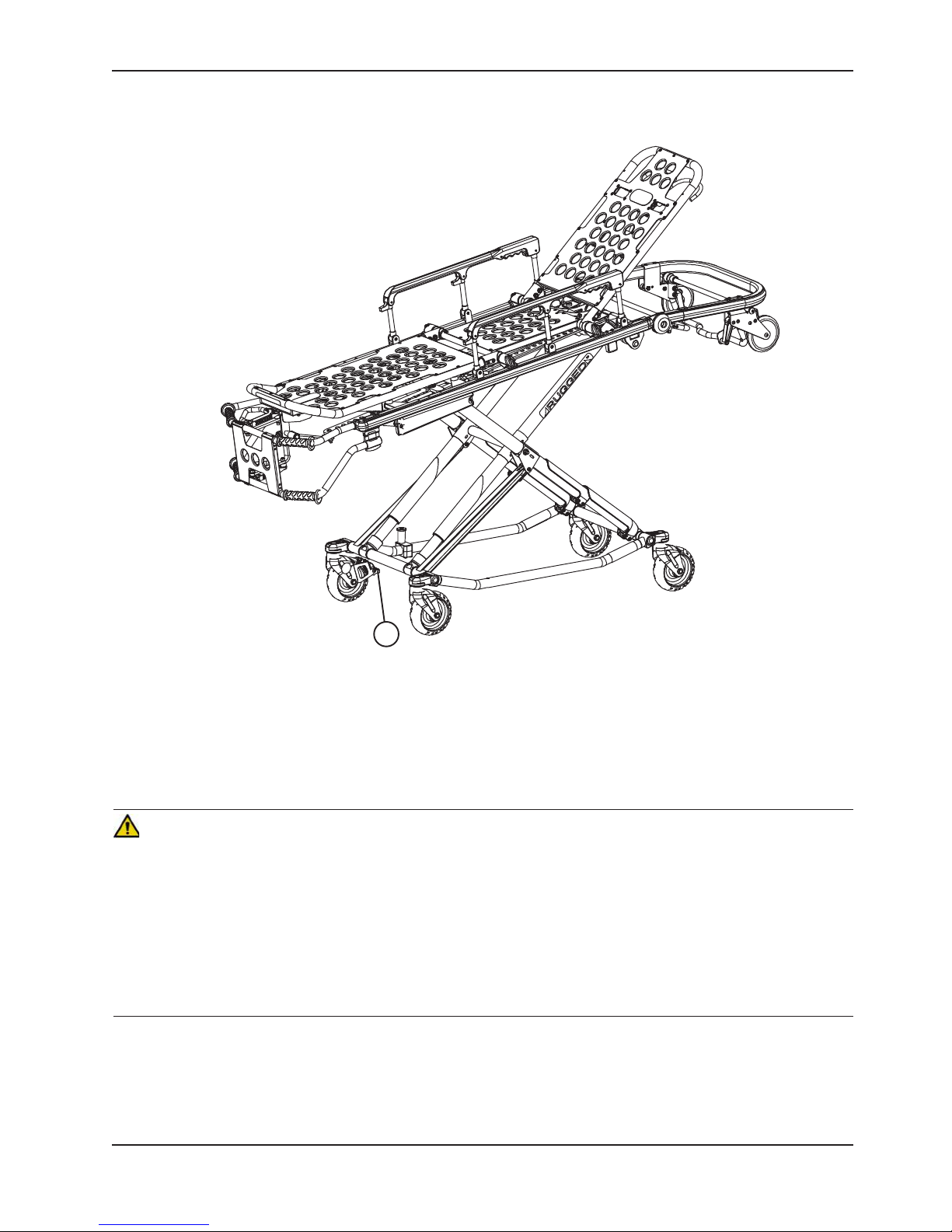

CHANGING THE HEIGHT OF AN EMPTY COT WITH ONE OPERATOR

To raise/lower the cot from the foot end:

1. Standing at the foot end of the cot, grasp the lower foot end lift tube.

2. Tip the cot up onto the load wheels (Figure 25).

3. Squeeze and hold the release handle and raise or lower the foot end to the desired position.

4. Lower the cot back onto the four base wheels (Figure 26).

Figure 25 - Cot Tipped on Load Wheels Figure 26 - Cot Lowered to Ground

To raise/lower the cot from the side:

1. Place one foot on the outer base tube.

2. Grasp the side release handle with one hand. Place your other hand on the outer support rail to help stabilize the

cot (Figure 27).

3. Squeeze the side release handle and raise or lower the cot to the desired position.

WARNING

If lowering the cot to the lowest position (position 1), remove your foot from the base tube or injury could result (Figure

28).

Figure 27 - Holding Outer Support Rail

Return To Table of Contents

32 6082-209 -001 R EV A w ww.stryker.com

Figure 28 - Lowering Cot From Side

Page 33

ADJUSTING THE LEG REST

Cot Features

A

B

FOOT END

Figure 29 - Leg Rest Elevated

The leg rest is adjustable to allow for elevation of the patient’s legs.

To raise the leg rest, lift the leg rest frame (A) as high as possible. The support bracket will engage automatically.

Release the frame after the support bracket has engaged.

To lower the leg rest, lift the leg rest frame (A) and, while holding the frame, lift up on the release handle

(B) until the bracket disengages. Lower the leg rest until flat.

www.stryker.com 6082-209 -001 REV A 33

Return To Table of Contents

Page 34

Cot Features

OPERATING THE BACKREST

To raise, squeeze handle (A) for pneumatic assist in lifting the Backrest to the desired height. Remove hand(s) from

handle when desired height is achieved.

To l ow er, squeeze handle (A) and push down on the Backrest frame until the Backrest has reached the desired height.

Remove hand(s) from handle when desired height is achieved.

A

B

HEAD END

Figure 30 - Backrest Elevated and Siderails Raised

OPERATING THE SIDERAILS

To raise, lift up until the latch clicks and the siderail locks into place. When a patient is on the cot, always keep the

siderails in the raised position unless the patient is being transferred.

To l ow er, squeeze handle (B) to release the siderail latch. Guide the siderail down toward the foot end until flat.

WARNING

Siderails are not intended to serve as a patient restraint device. Refer to page 20 for proper restraint strap usage.

Failure to utilize the siderails properly could result in patient injury.

Return To Table of Contents

34 608 2-209 -001 REV A w ww.stryker.com

Page 35

Cot Features

OPERATING THE BREAKAWAY HEAD SECTION

The head end of the cot litter folds down to shorten the length of the cot and allow for maneuvering when space is

limited in elevators, halls, etc.

The breakaway head section should only be used when the cot is in positions 5−7 (see page 19).

WARNING

Operating the cot with the breakaway head section lowered may cause injury to the patient or operator or damage to the

cot. Use only positions 5−7 (see page 19) when using this configuration.

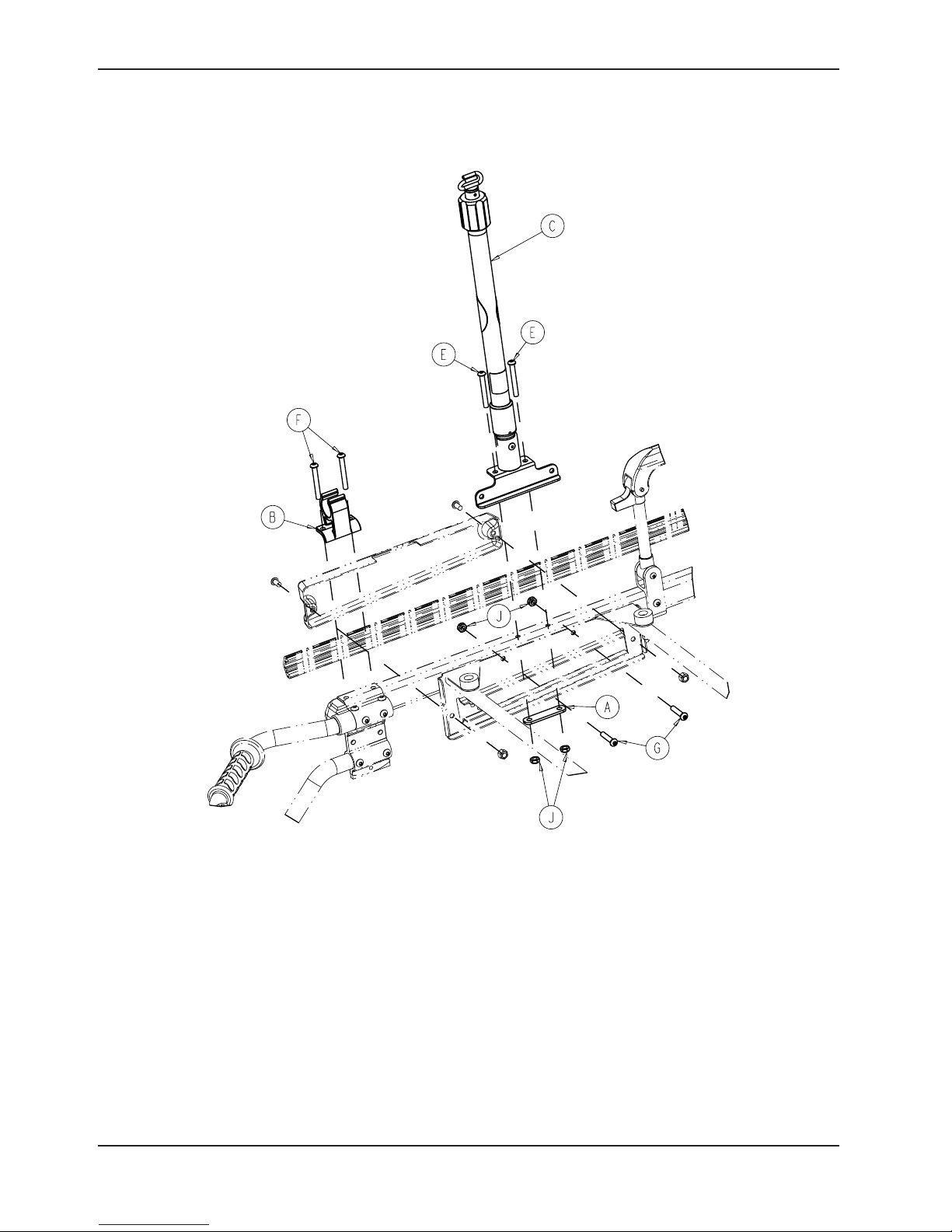

A

Figure 31 - Breakaway Head Section Release Bar

To lower the breakaway head section, raise the backrest to its uppermost position (see page 35 for backrest

operation instructions). Squeeze the release bar (A) at the head end of the cot with one hand while supporting the

head section with the other hand. Lower the head section.

To raise the breakaway head section, lift the breakaway head section until the release bar clicks and the head section

locks into place.

Figure 32 - Lowered Breakaway Head Section

CAUTION

Damage to the cot can occur if the cot is lowered in the shortened position. Use only positions 5−7 (see page 19)

when the cot is shortened.

www.stryker.com 6082-209 -001 REV A 35

Return To Table of Contents

Page 36

Cot Features

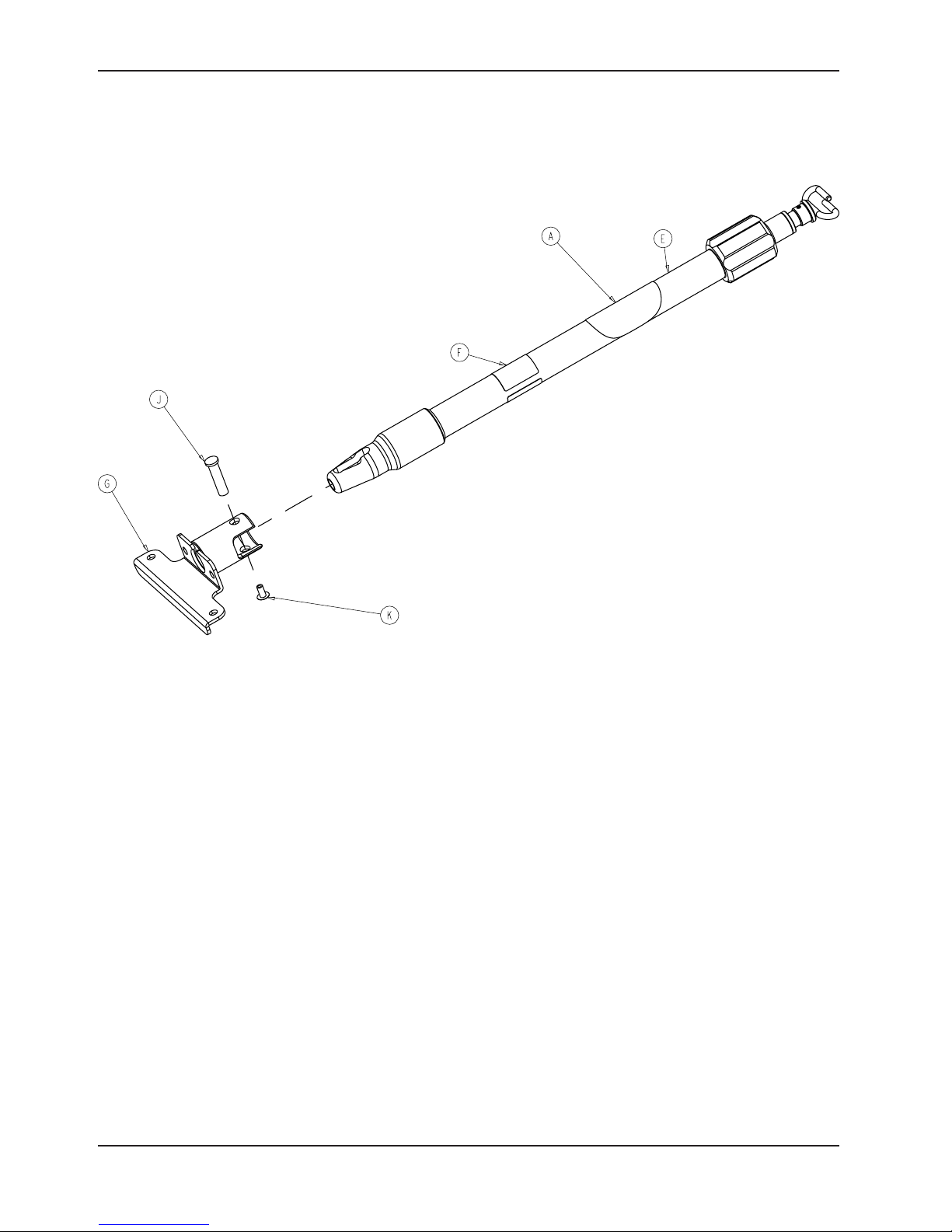

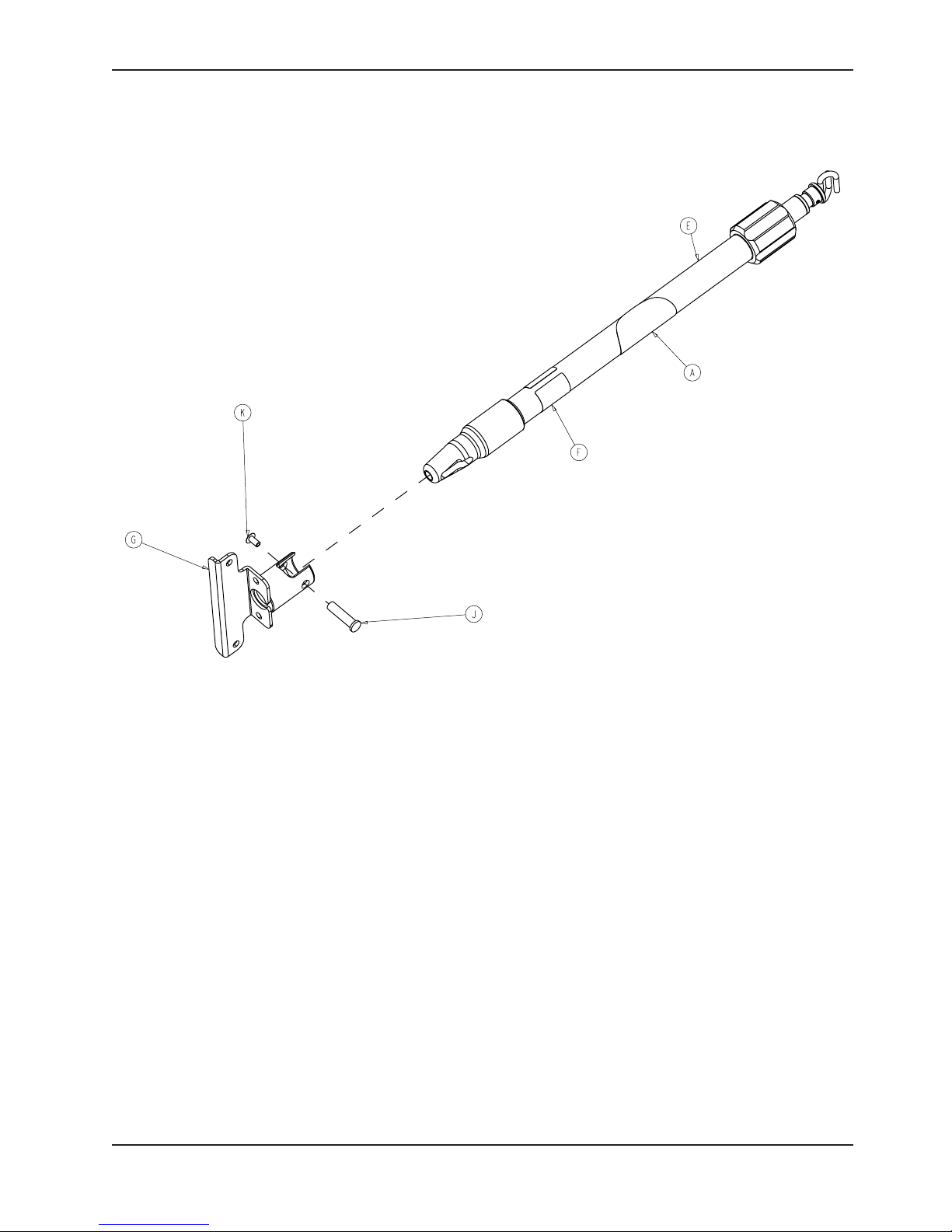

OPERATING THE TWO-STAGE I.V. POLE (OPTIONAL EQUIPMENT)

D

C

B

Figure 33 - Two-Stage I.V. Pole Storage Position

A

Figure 34 - Two-Stage I.V. Pole

1. Lift and pivot the pole from the storage position and push down until it is locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B) counterclockwise and pull up on the telescoping portion

(C) of the pole to raise it to the desired height.

3. Turn the lock actuator (B) clockwise to lock the telescoping portion in place.

4. Hang I.V. bags on the I.V. hook (D).

CAUTION

The weight of the I.V. bags or equipment must not exceed 40 pounds.

Return To Table of Contents

36 6082-209 -001 RE V A www.stryker.com

Page 37

Cot Features

OPERATING THE THREE-STAGE I.V. POLE (OPTIONAL EQUIPMENT)

1. Lift and pivot the pole from the storage position and push down until it is

locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B) counterclockwise

and pull up on the bottom telescoping portion (C) of the pole to raise it to

the desired height.

3. Turn the lock actuator (B) clockwise to lock the bottom telescoping portion

in place.

4. For a higher I.V. pole, pull up on section (D) until the spring clip (E) engages.

5. Hang I.V. bags on the I.V. hook (F).

6. To lower the I.V. pole, push in on the spring clip (E) and slide section (D)

down into section (C). Turn the lock actuator (B) counterclockwise and

slide section (C) into the bottom tube.

7. Lift up and pivot the pole down into the storage position.

CAUTION

The weight of the I.V. bags or equipment must not exceed 40 pounds.

F

D

E

C

B

Figure 35 - Three-Stage I.V. Pole Storage Position

www.stryker.com 6082-209 -001 REV A 37

A

Figure 36 - Three-Stage I.V. Pole

Return To Table of Contents

Page 38

Cleaning

The cot is designed to be power washable. The unit may show some signs of oxidation or discoloration from continuous

washing, however, no degradation of the cot’s performance characteristics or functionality will occur due to power

washing as long as the proper procedures are followed.

Clean Velcro AFTER EACH USE. Saturate Velcro with disinfectant and allow disinfectant to evaporate. (Appropriate

disinfectant for nylon Velcro should be determined by the hospital.)

WASHING LIMITATIONS

WARNING

Use any appropriate personal safety equipment (goggles, respirator, etc.) to avoid the risk of inhaling contagion. Use of

power washing equipment can aerate contamination collected during the use of the cot.

CAUTION

• DO NOT STEAM CLEAN OR ULTRASONICALLY CLEAN THE UNIT

• Maximum water temperature should not exceed 180°F/ 82°C.

• Maximum air dry temperature (cart washers) is 240°F /115°C.

• Maximum water pressure should not exceed 1500 psi/130.5 bar. If a hand held wand is being used to wash the

unit, the pressure nozzle must be kept a minimum of 24 inches/61 cm from the unit.

• Towel dry all casters and interface points.

• After washing the cot, follow the lubrications procedure on page 41.

• Failure to comply with these instructions may invalidate any/all warranties.

Return To Table of Contents

38 6082 -209 -001 RE V A ww w.stryker.com

Page 39

Cleaning

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or quaternary

(excluding Virex® TB) type disinfectants can be used. Iodophor type disinfectants are not recommended for use

because staining may result.

Suggested cleaners for the cot surface:

• Quaternary Cleaners (active ingredient - ammonium chloride)

• Phenolic Cleaners (active ingredient - o-phenylphenol)

• ChlorinatedBleachSolution(5.25%-lessthan1partbleachto100partswater)

Avoid over saturation and ensure the product does not stay wet longer than the chemical manufacturer’s guidelines

for proper disinfecting.

WARNING

• SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO THE PRODUCT IF

USED IMPROPERLY. If the products described above are used to clean Stryker patient care equipment, measures

must be taken to insure the cots are wiped with a cloth soaked in clean water and thoroughly dried following

cleaning.

• Failure to properly rinse and dry the cots will leave a corrosive residue on the surface of the cots, possibly causing

premature corrosion of critical components.

Note: Failure to follow the above directions when using these types of cleaners may void this product’s warranty.

REMOVAL OF IODINE COMPOUNDS

Use a solution of 1-2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area. Clean as soon

as possible after staining occurs. If stains are not immediately removed, allow solution to soak or stand on the surface.

Rinse surfaces which have been exposed to the solution in clear water before returning unit to service.

WARNING

Failure to properly clean or dispose of contaminated mattress or cot components will increase the risk of exposure to

blood borne pathogens and may cause injury to the patient or the operator.

www.stryker.com 6082-209 -001 REV A 39

Return To Table of Contents

Page 40

Preventative Maintenance

Operation Schedule Procedure

Cleaning and Disinfecting Each Use. See page 38

For 1-25 calls per month, inspect cot

every 6 months

Inspection

Note: Keep up to date maintenance records using the Maintenance Record form on page 43.

For 26-200 calls per month, inspect

cot every 3 months

For 200+ calls per month, inspect cot

monthly.

See below for checklist

CHECKLIST

_____ All fasteners secure (reference all assembly drawings)

__ ___ All welds intact, not cracked or broken

__ ___ No bent or broken tubing or sheet metal

__ ___ No debris in wheels

__ ___ All wheels secure, rolling and swiveling properly

__ ___ Optional wheel lock holds wheel securely when on and clears wheel when off

__ ___ Siderails move an latch properly

_____ Backrest operating properly

_____ Optional accessories intact and operating properly

_____ Height positioning latch functioning properly

__ ___ Cot secure in each height position

_____ Undercarriage folds properly

_____ Breakaway head section operating properly

__ ___ Safety bar operating properly

_____ Foot rest operating properly

__ ___ No rips or cracks in mattress cover

__ ___ Body restraints intact and working properly

_____ Lubricate base tubes (optional)

Serial Number:

Completed by: _______________________________________ Date: _________________

Return To Table of Contents

40 6082-209-001 REV A www.stryker.com

Page 41

Preventative Maintenance

BASE LUBRICATION

Note: The MX−PR O® has been designed to operate without the need for lubrication. Tri−Flow™ with Teflon® lubricant

may be used to reduce the force required to raise the undercarriage and to minimize wear. Do not use silicone,

WD−40™, or lithium grease. They could harm the moving parts of the cot.

FOOT END

B

APPLY LUBRICATION

A

Figure 37 - Base Lubrication Locations

1. Place the cot in the highest position.

2. Turn the cot upside down with the base legs facing up.

3. Using the plastic applicator tube, spray Tri−Flow™ with

Teflon® lubricant (Stryker part number 6082−199−12) in

the gap between the upper (item A) and lower lift tubes

(item B) on both foot end legs.

4. Apply Tri−Flow™ to right and left height adjustment

Height Adjustment Racks racks providing an even

application.

5. Apply Tri−Flow™ to the right and left slide plates

providing an even application.

6. Let the cot sit for 5 minutes.

7. Turn the cot back over. Raise and lower the cot a

few times to work the lubricant throughout the applied

areas.

8. Wipe any excess lubricant from the base tubes. Slide

Plates

Height Adjustment Racks

Slide Plates

www.stryker.com 6082-209 -001 REV A 41

Return To Table of Contents

Page 42

Preventative Maintenance

PNEUMATIC BACKREST ADJUSTMENT

Tools Required:

1/2” Wrench 5/32” Allen Wrench Locktite 3/32” Allen Wrench

Adjustment Procedure:

1. For easier access, move the backrest to 75 degrees.

Note: Before continuing with the backrest adjustment procedure, be sure the cylinder (item A) is completely

threaded into the yoke (item B) so no threads are showing on the shaft of the cylinder. If threads are showing,

use a 3/32” Allen wrench to remove the set screw (item C) in the center of the yoke and remove the E−clip and

pin (items D & E) holding the bottom of the pneumatic cylinder. Thread cylinder shaft (item A) completely into

yoke (item B). Replace the E−clip and pin (items D & E) and replace the set screw (item C) using Locktite.

2. Using a 1/2” wrench, loosen the hex nut (item F) on the backrest pivot (item J) while holding the set screw (item

H) fixed in the pivot.

3. Using a 5/32” Allen wrench, turn the set screw (item H) until there is no play between the backrest release handle

A

K

J

H

F

C

B

D

E

Figure 38 - Pneumatic Cylinder and Fowler Crossbrace

(item K) and the pneumatic cylinder release button.

4. Be sure the backrest will travel from flat to at least 75 degrees. If it doesn’t, turn the set screw (item H) clockwise

1/2 turn. Repeat until at least 75 degrees of travel is achieved.

5. Lower the backrest to a 5−10 degree angle and release the handle. Apply approximately 50 pounds downward

force to the end of the backrest. If the backrest drifts down, turn the set screw (item H) counterclockwise. Repeat

until the backrest does not drift downward.

6. Using the 1/2” wrench, tighten the hex nut (item F) while holding the set screw (item H) fixed in the pivot.

Return To Table of Contents

42 6082-209 -001 REV A www.stryker.com

Page 43

Maintenance Record

Date Maintenance Operation Performed By Hours

www.stryker.com 6082-209 -001 REV A 43

Return To Table of Contents

Page 44

Training Record

Training Date Training Method

Trainee Name Basic

Training

Refresher

Update

Owner’s Manual, In-Service,

Formal Class, Etc.

Return To Table of Contents

44 6082-209-001 RE V A ww w.stryker.com

Page 45

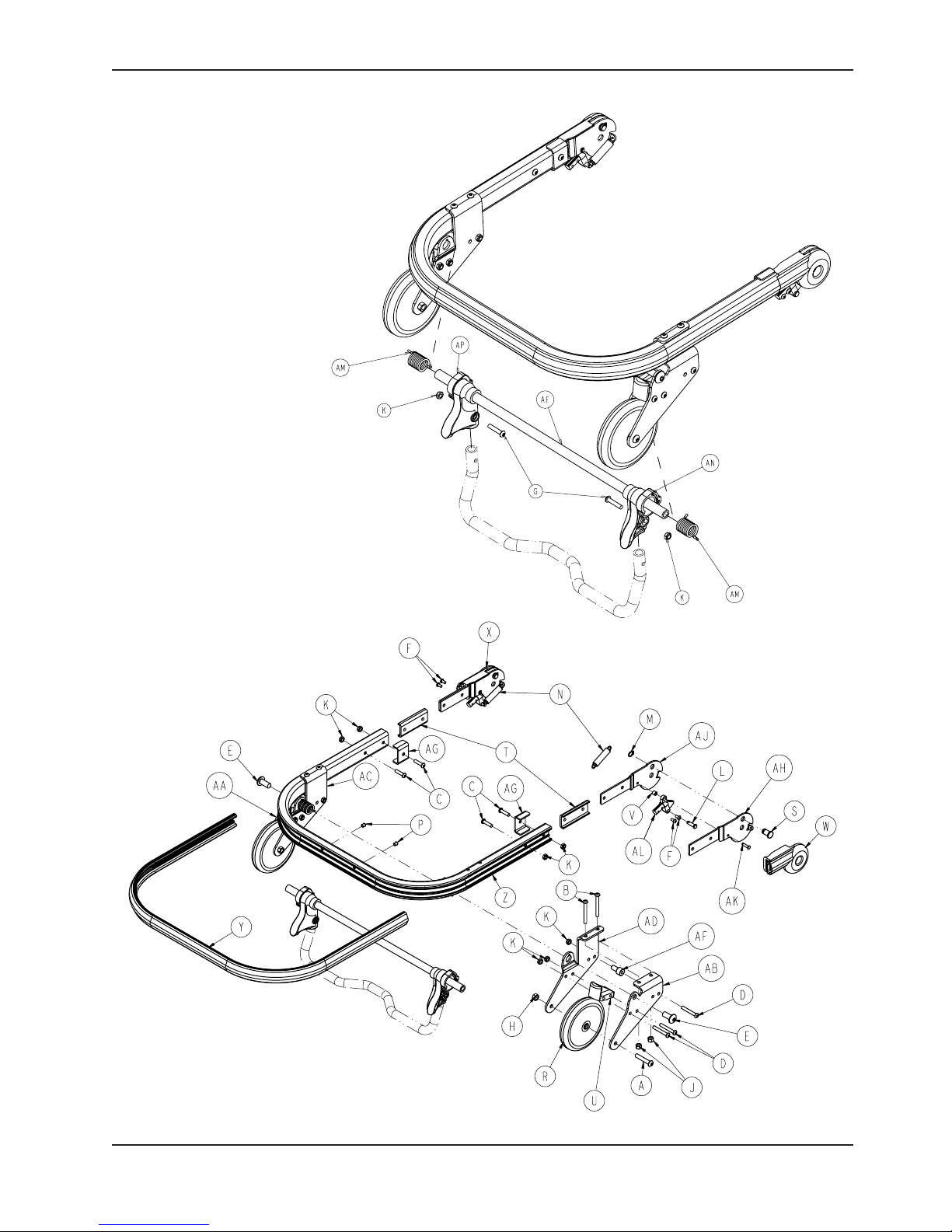

6082-150-011 Rev P (Reference Only)

Cot Assembly

www.stryker.com 6082-209 -001 REV A 45

Return To Table of Contents

Page 46

Cot Assembly

Return To Table of Contents

46 6082-209-001 REV A www.stryker.com

Page 47

Cot Assembly

www.stryker.com 6082-209 -001 REV A 47

Return To Table of Contents

Page 48

Cot Assembly

Return To Table of Contents

48 6082- 209- 001 REV A www.stryker.com

Page 49

Cot Assembly

www.stryker.com 6082-209 -001 REV A 49

Return To Table of Contents

Page 50

Cot Assembly

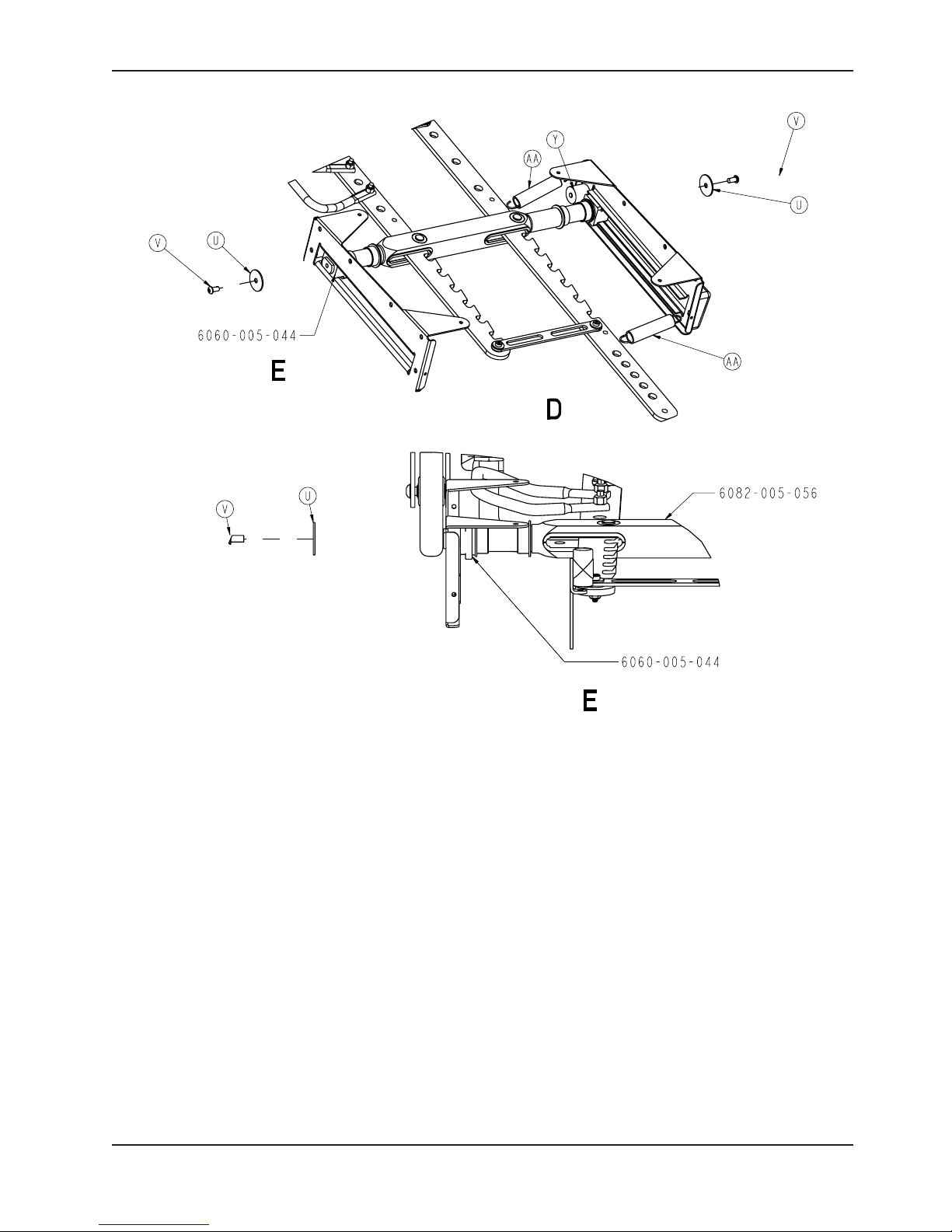

Cot Assembly - 6082-150-011 Rev P (Reference Only)

Item Part No. Part Name Qty.

A 6082-101-011 Base Assembly (page 51) 1

B 6082-205-050 Litter/Base Adapter Assy., Right

(page 63) 1

C 6082-205-053 Litter/Base Adapter Assy., Left

(page 64) 1

D 6082-205-060 Litter/Base Adapter Spacer Sleeve 2

E 6082-130-011 Litter Assembly (page 65) 1

F 0004-135-000 Button Head Cap Screw 2

G 0004-204-000 Button Head Cap Screw 2

H 6060-037-026 Pivot Spacer Plate 2

J 6060-037-035 Outer Rail End Cap 2

K 6082-037-010 Breakaway Head Section Assembly 1

L 0004-198-000 Button Head Cap Screw 7

M 0016-028-000 Hex Nut 10

N 1010-031-077 Gas Spring 1

P 0014-021-000 Washer 2

Q 6082-031-046 Litter/Base Interface Pivot Spacer 2

R 0011-448-000 Washer 2

S 6082-031-031 Clevis Pin 1

T 0028-181-000 Truarc Ring 1

U 0011-355-000 Washer 2

V 0004-325-000 Button Head Cap Screw 2

W 6082-033-037 Retainer Plate Cover, Right 1

X 6082-033-036 Retainer Plate Cover, Left 1

Y 0037-082-000 Vibration Mount 2

Z 6080-030-043 Litter Frame Bumper 2

AA 0038-508-000 Extension Spring 2

AB 6060-090-002 Serial Number Tag 1

AC 0025-079-000 Blind Rivet 2

AE 6082-090-043 Label, Stryker 2

AF 6060-090-004 Label, Small 1

AG 6060-090-114 Label, Keep Hands Clear 2

AH 6070-090-107 Label, Lift to Release 1

AJ 6082-090-045 Label, MX-PRO R3 1

AK 6080-090-108 Label, Lift Here 2

AL 6080-090-009 Label, Warning 1

AM 6082-090-110 Label, MX−PRO R3 2

AN 6082-090-040 Label, MX-PRO Tube, Left 1

AP 0946-001-155 Bumper 2

AR 0025-133-000 Blind Rivet 2

AS 0008-033-000 Socket Head Shoulder Bolt 1

AT 0016-028-000 Hex Nut 1

AU 6082-040-025 Link Bushing 2

AV 0011-352-000 Washer 1

AX 6082-090-039 Label, MX−PRO Tube, Right 1

AZ 6082-090-004 Label, Side Release 1

BA 0025-132-000 Flange Rivet 4

BB 6082-001-085 2” Adhesive Loop Pile 2

BC 6082-090-046 Label, 650 lb Weight Capacity 2

Return To Table of Contents

50 6082-209 -001 REV A www.stryker.com

Page 51