Page 1

MMVV33™™ BBaarriiaattrriicc BBeedd

MMaaiinntteennaannccee MMaannuuaall

5900

5900-009-002 Rev A.0

EN

2019/08

Page 2

Page 3

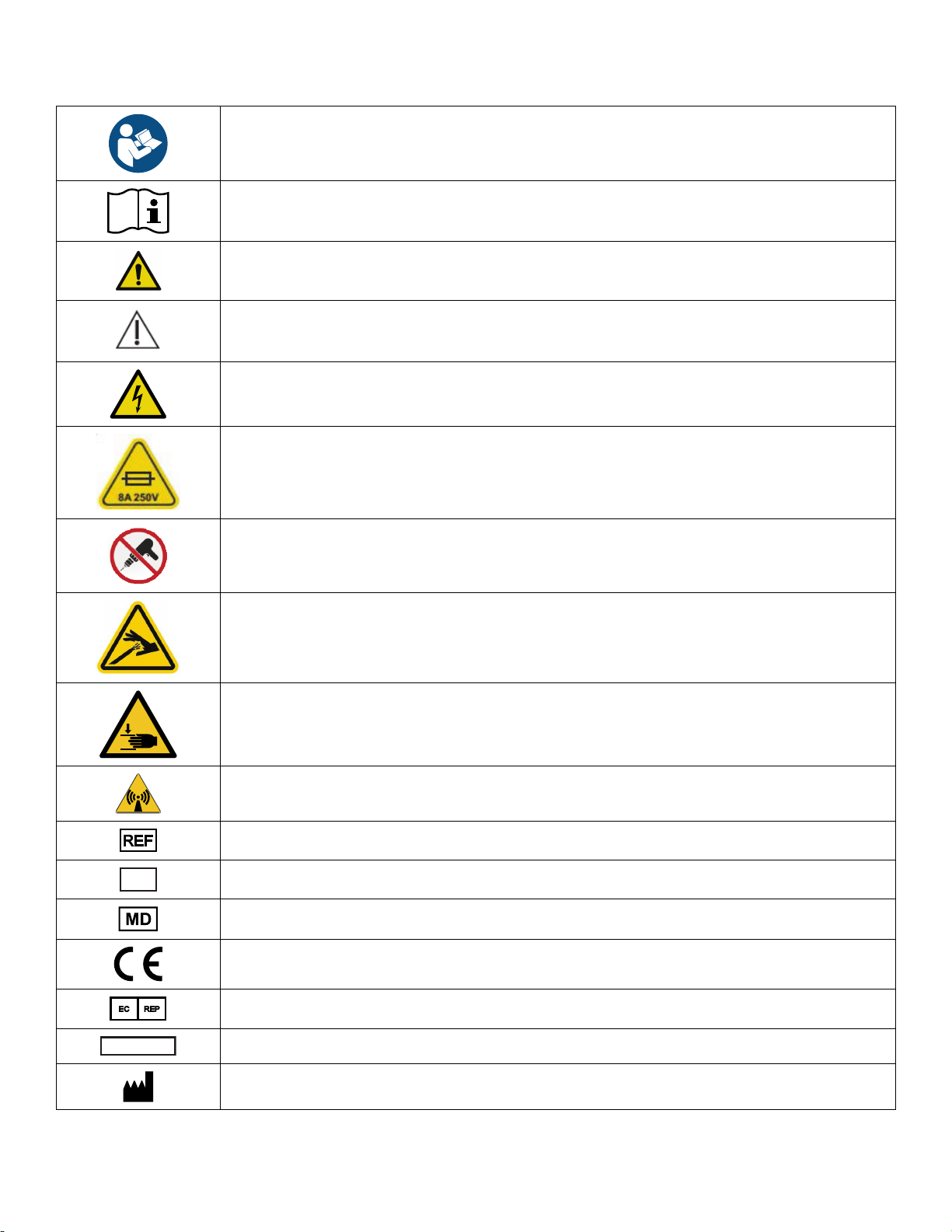

SSyymmbboollss

Refer to instruction manual/booklet

Operating instructions/Consult instructions for use

General warning

Caution

Warning; electricity

Fuse rating

Do not drill

Hydraulic oil pressure

Pinch/crush hazard

Non-ionizing radiation

Catalogue number

Serial number

European medical device

CE mark

5900-009-002 Rev A.0 EN

Authorized representative in the European Community

For US Patents see www.stryker.com/patents

Manufacturer

Page 4

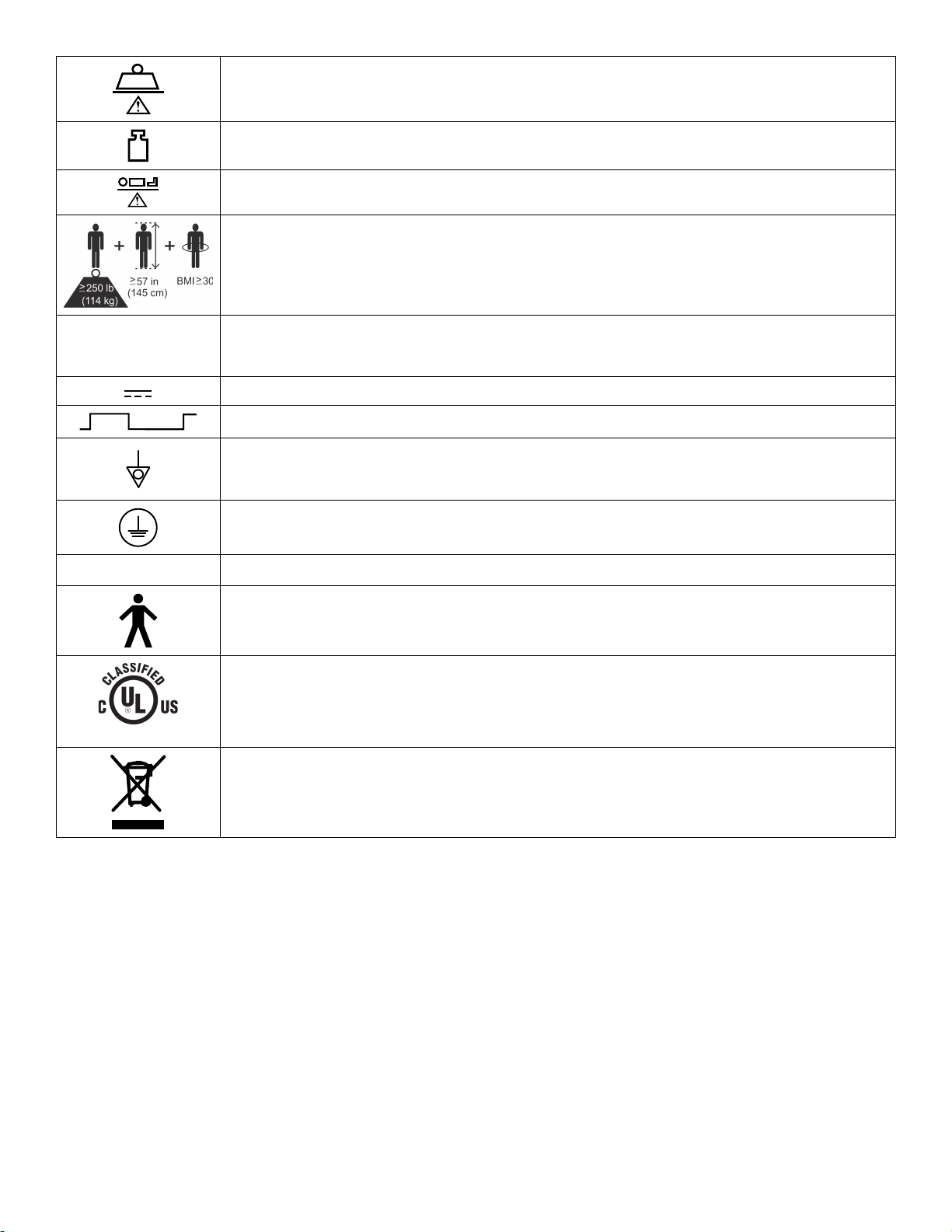

Safe working load

~

≤2m ≥18m

87VL

Mass of equipment

Maximum patient weight

Adult patient biometrics

Alternating current

Direct current

Duty cycle of product

Unit provides terminal for connection of a potential equalization conductor. The potential

equalization conductor provides direct connection between the unit and potential equalization

busbar of the electrical installation.

Protective earth ground

IIPPXX44

Protection from liquid splash

Type B applied part

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock,

Fire, and Mechanical Hazards Only in Accordance with ANSI/AAMI ES60601-1:2005/(R)2012

and A1:2012 C1:2009/(R)2012 and A2:2010/(R)2012, CAN/CSA-C22.2 No. 60601-1:14, IEC

60601-2-52:2009/A1:2015, CAN/CSA-C22.2 No. 60601-2-52:11 with Amendment 1:2017.

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic

Equipment (WEEE) as amended, this symbol indicates that the product should be collected

separately for recycling. Do not dispose of as unsorted municipal waste. Contact local distributor

for disposal information. Ensure infected equipment is decontaminated prior to recycling.

EN 5900-009-002 Rev A.0

Page 5

TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................3

Summary of safety precautions ................................................................................................................................4

Introduction ...............................................................................................................................................................5

Product description .................................................................................................................................................5

Indications for use ...................................................................................................................................................5

Clinical benefits ......................................................................................................................................................5

Expected service life ...............................................................................................................................................5

Disposal/recycle.................................................................................................................................................5

Contraindications ....................................................................................................................................................6

Specifications .........................................................................................................................................................6

Product illustration ..................................................................................................................................................8

Contact information .................................................................................................................................................8

Serial number location.............................................................................................................................................9

Preventive maintenance .........................................................................................................................................10

Error codes ............................................................................................................................................................. 12

Electrical diagram ................................................................................................................................................... 18

Cable routing...........................................................................................................................................................19

Maintenance menu ................................................................................................................................................. 20

Language............................................................................................................................................................. 20

Set clock .............................................................................................................................................................. 20

Actuator maintenance ...........................................................................................................................................21

Scale maintenance ............................................................................................................................................... 21

Calibrate scale .................................................................................................................................................22

Angle maintenance ...............................................................................................................................................22

Calibrate angles ...............................................................................................................................................22

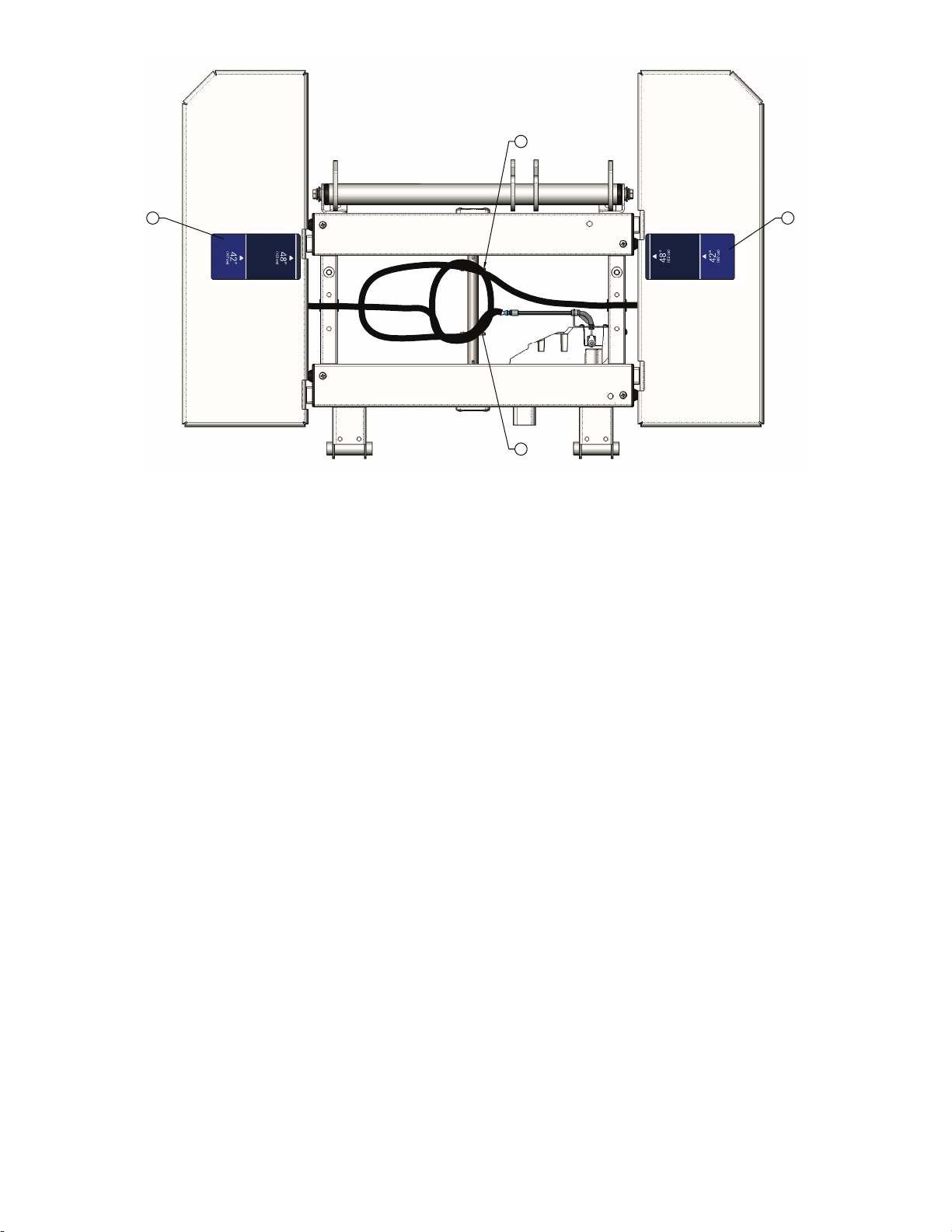

Width maintenance ...............................................................................................................................................23

Calibrate deck widths........................................................................................................................................ 23

Patient station....................................................................................................................................................... 24

Test modes ..........................................................................................................................................................24

Battery maintenance .............................................................................................................................................24

Service ....................................................................................................................................................................25

Protecting against electrostatic discharge (ESD) .....................................................................................................25

Battery replacement ..............................................................................................................................................25

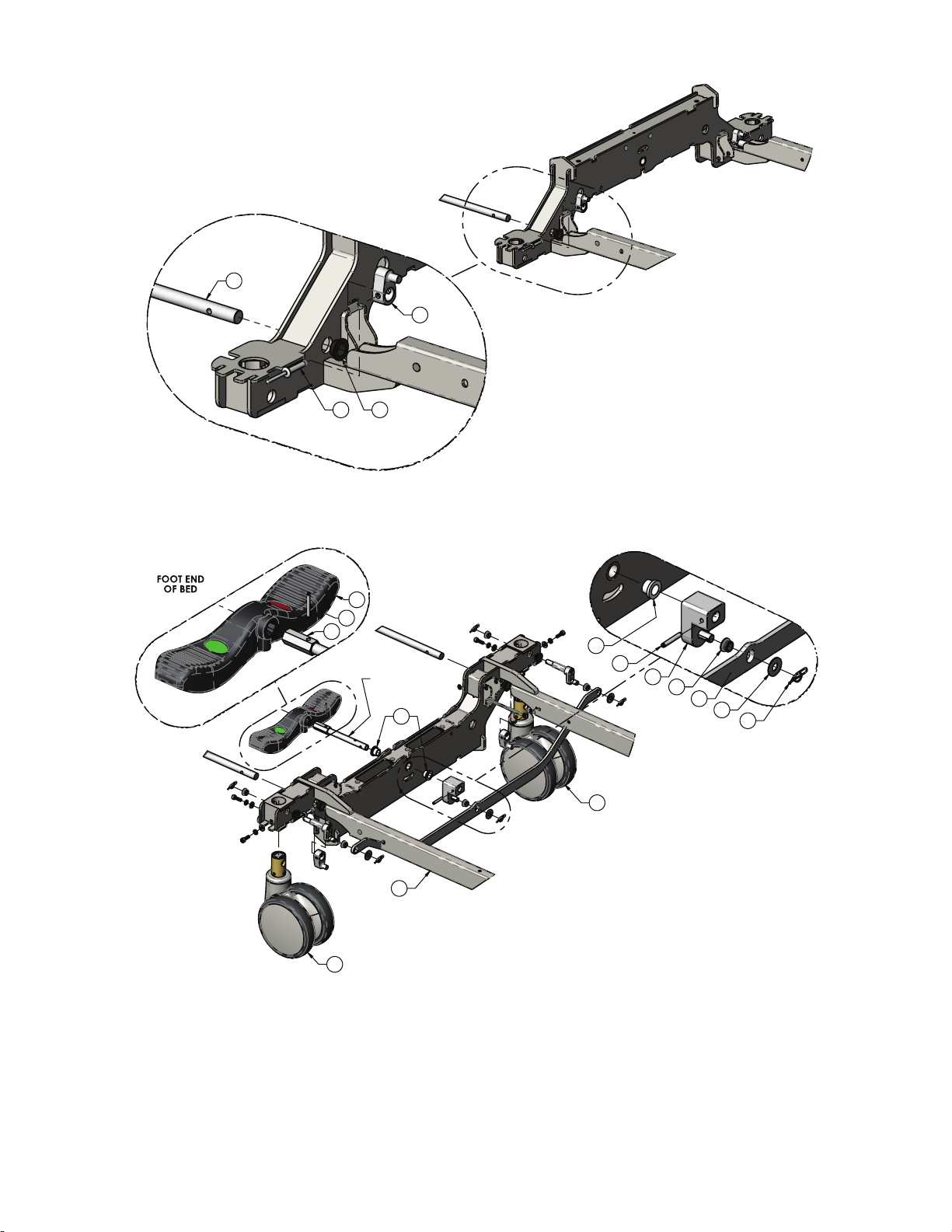

Caster replacement...............................................................................................................................................26

Main control board replacement .............................................................................................................................26

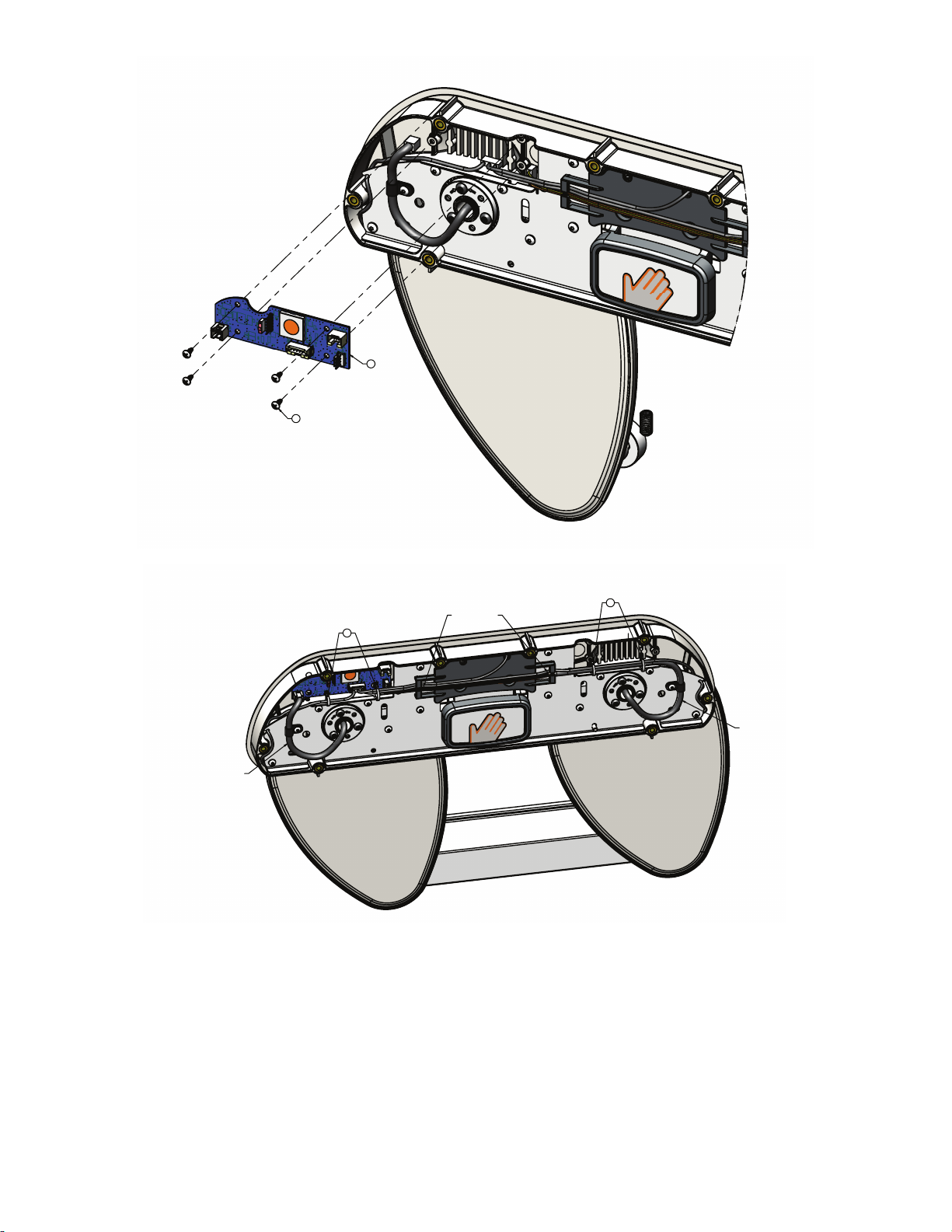

AVB board replacement ........................................................................................................................................27

Footboard keypad/display replacement ..................................................................................................................28

Footboard main cable replacement ........................................................................................................................28

Fowler actuator replacement.................................................................................................................................. 29

Gatch actuator replacement................................................................................................................................... 29

Thigh actuator replacement ...................................................................................................................................30

Lift actuator replacement (head/foot) ...................................................................................................................... 31

Load cell board replacement, head end and foot end ............................................................................................... 31

Load cell assembly replacement ............................................................................................................................ 32

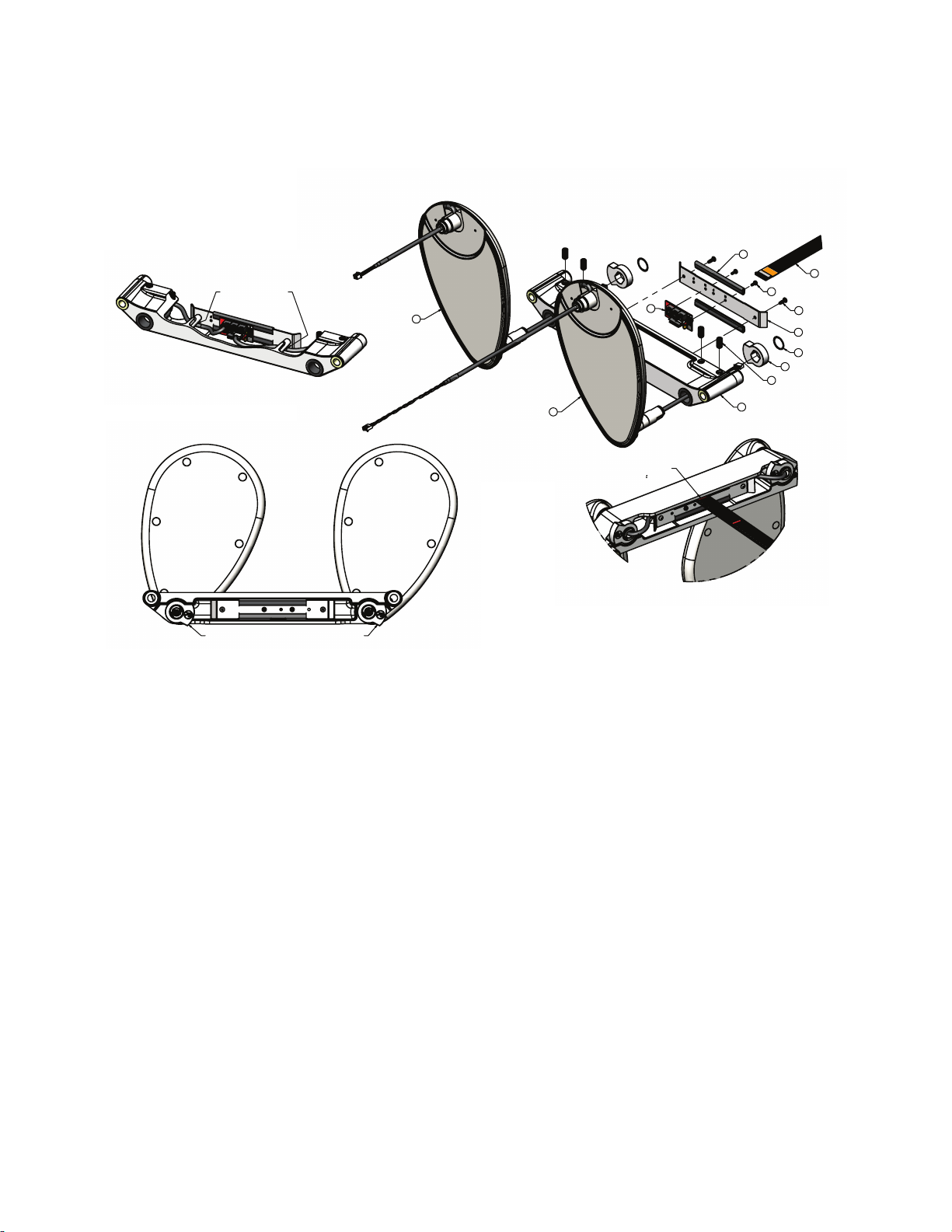

Siderail replacement, head end..............................................................................................................................33

Siderail replacement, foot end................................................................................................................................33

IV pole attachment ................................................................................................................................................34

Patient helper attachment ......................................................................................................................................34

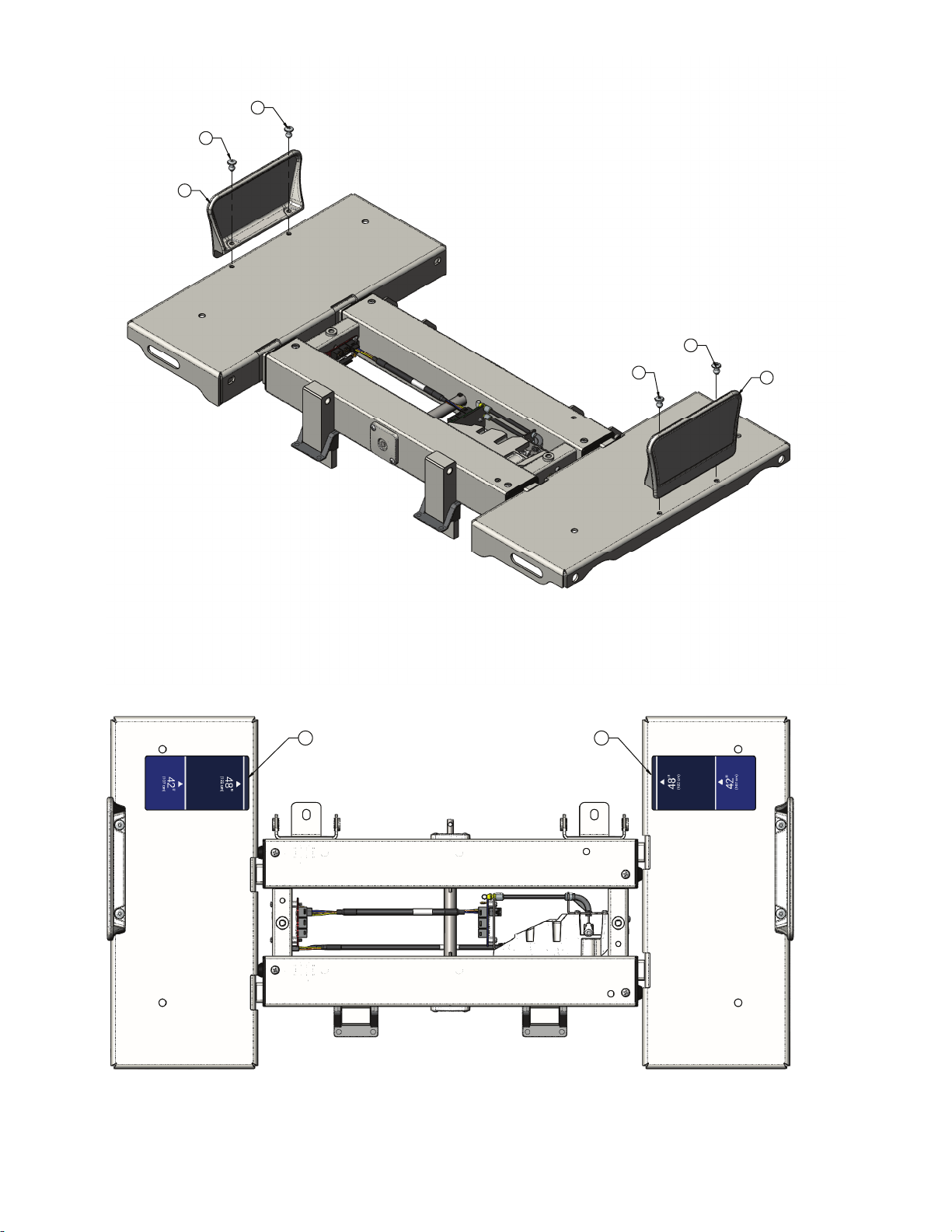

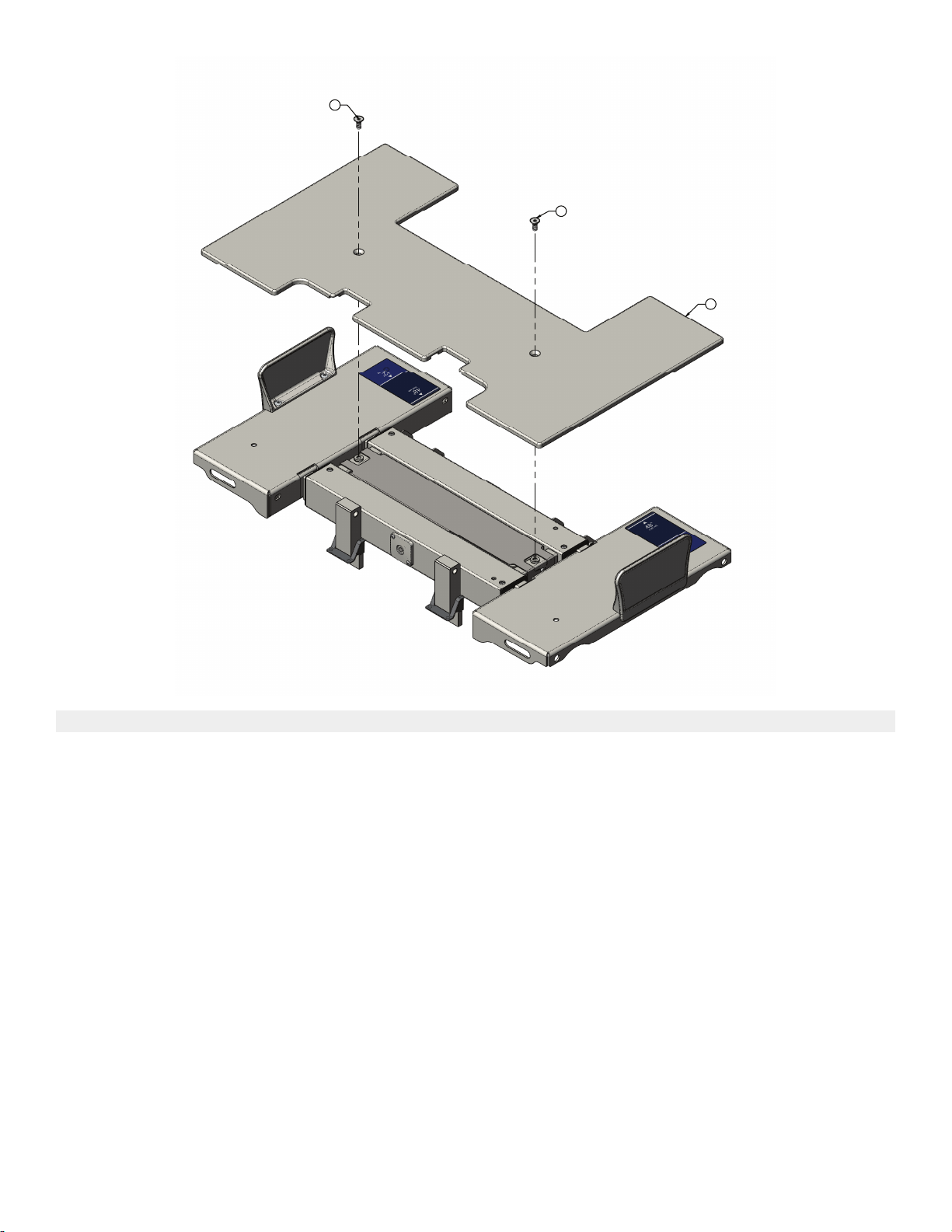

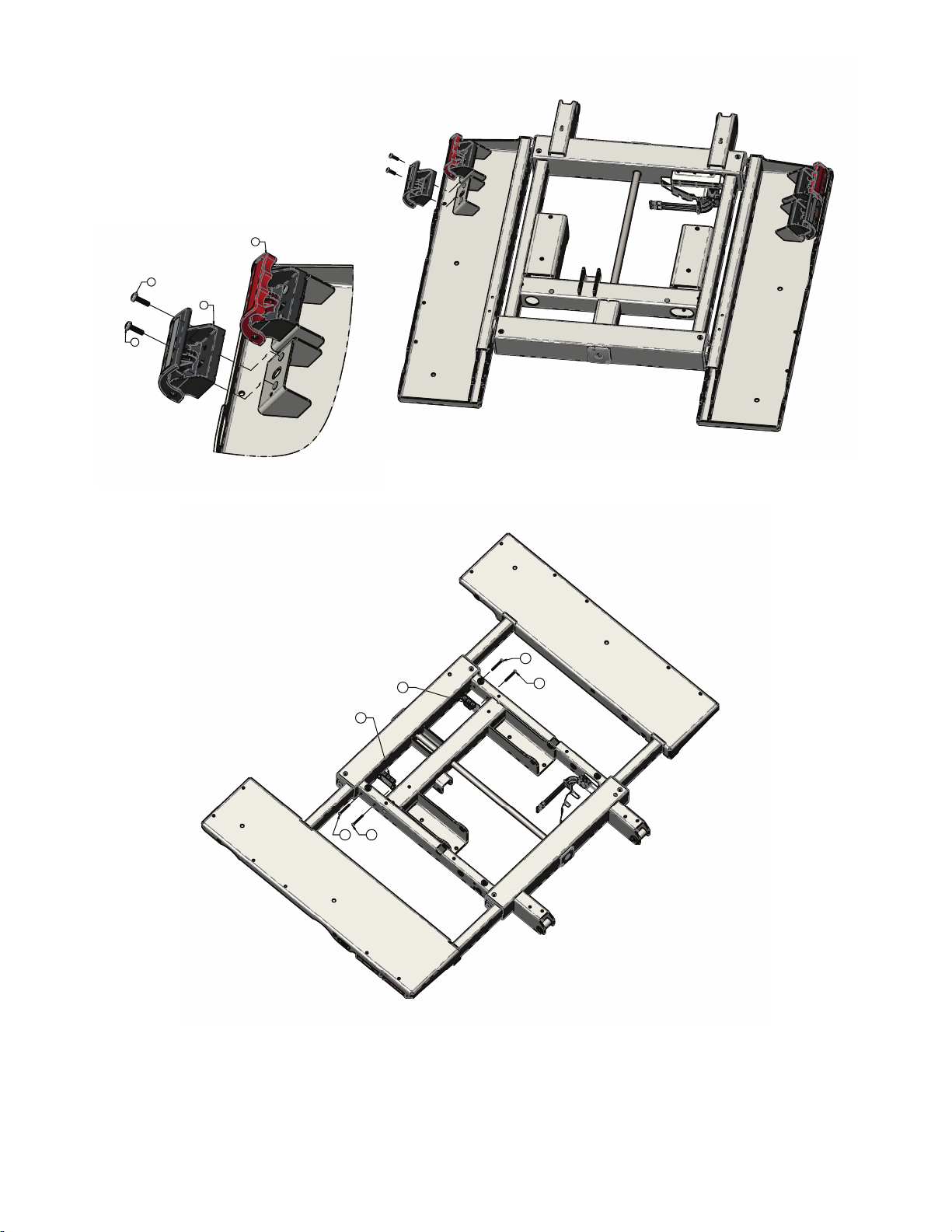

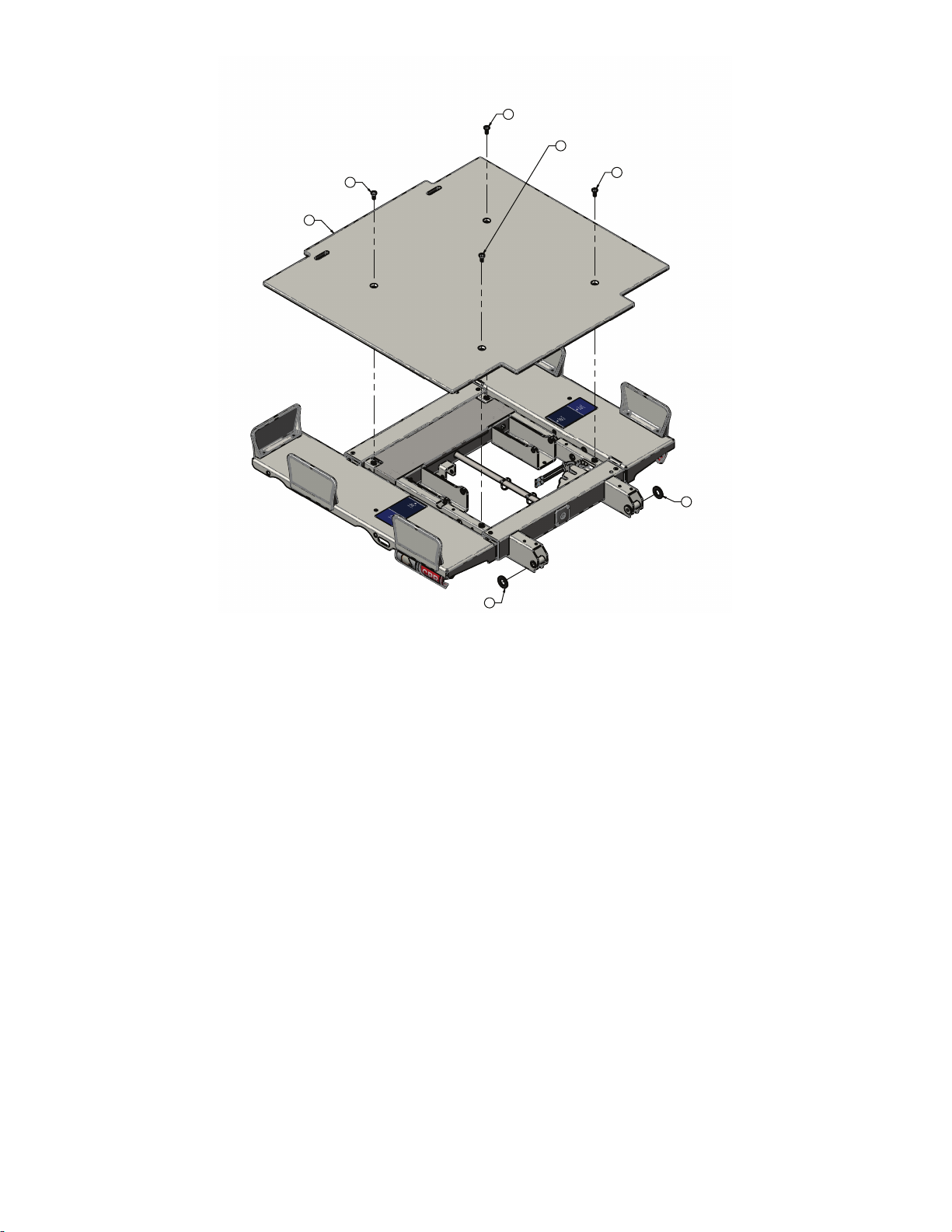

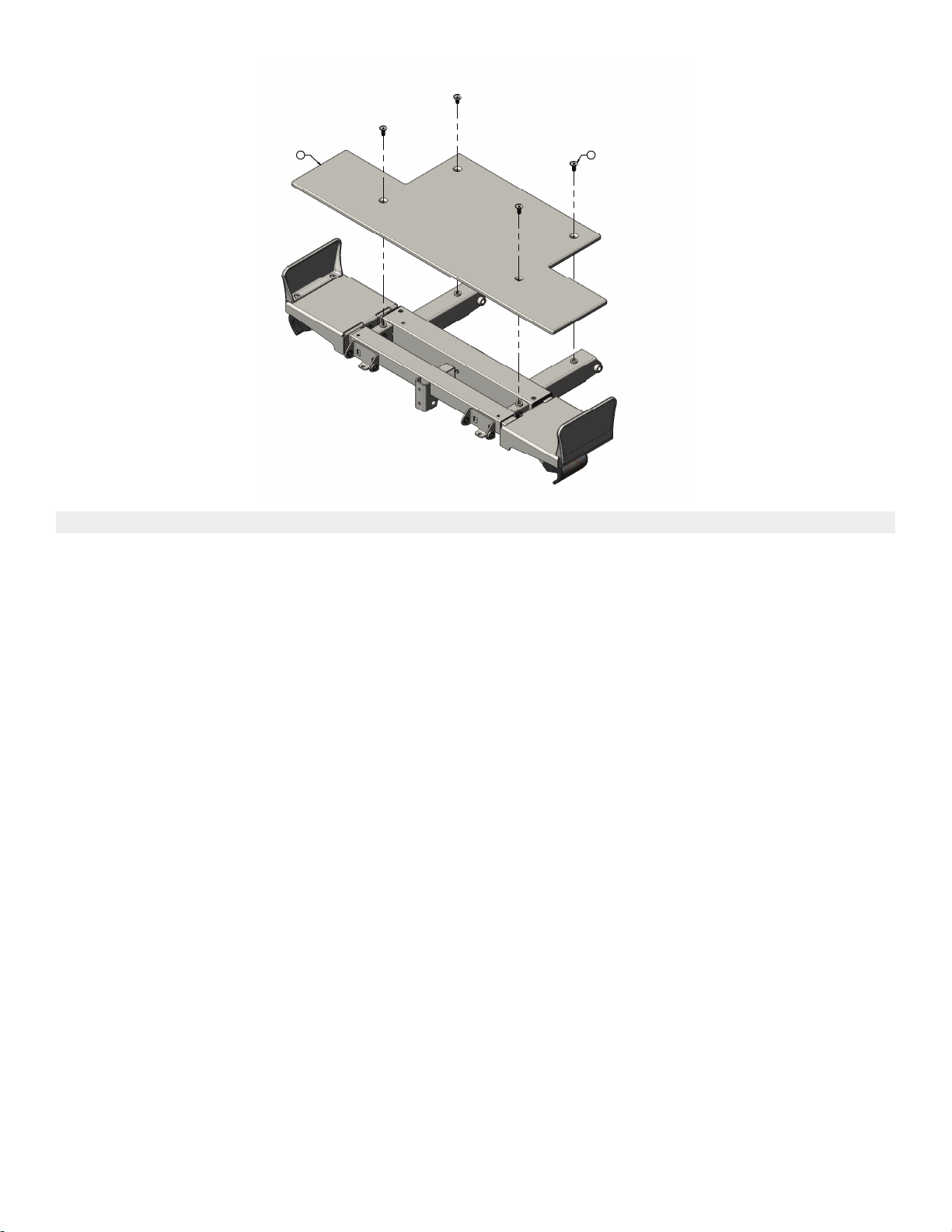

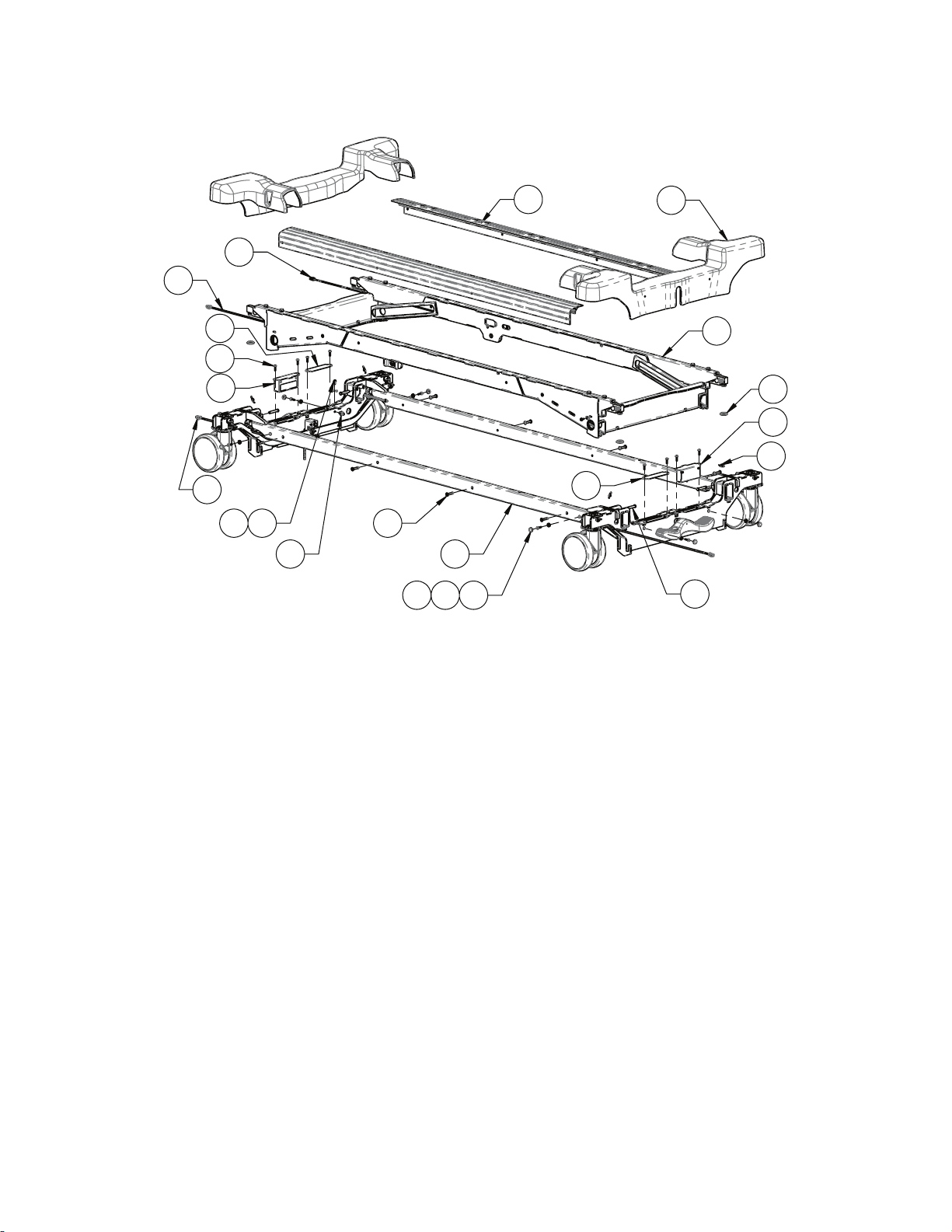

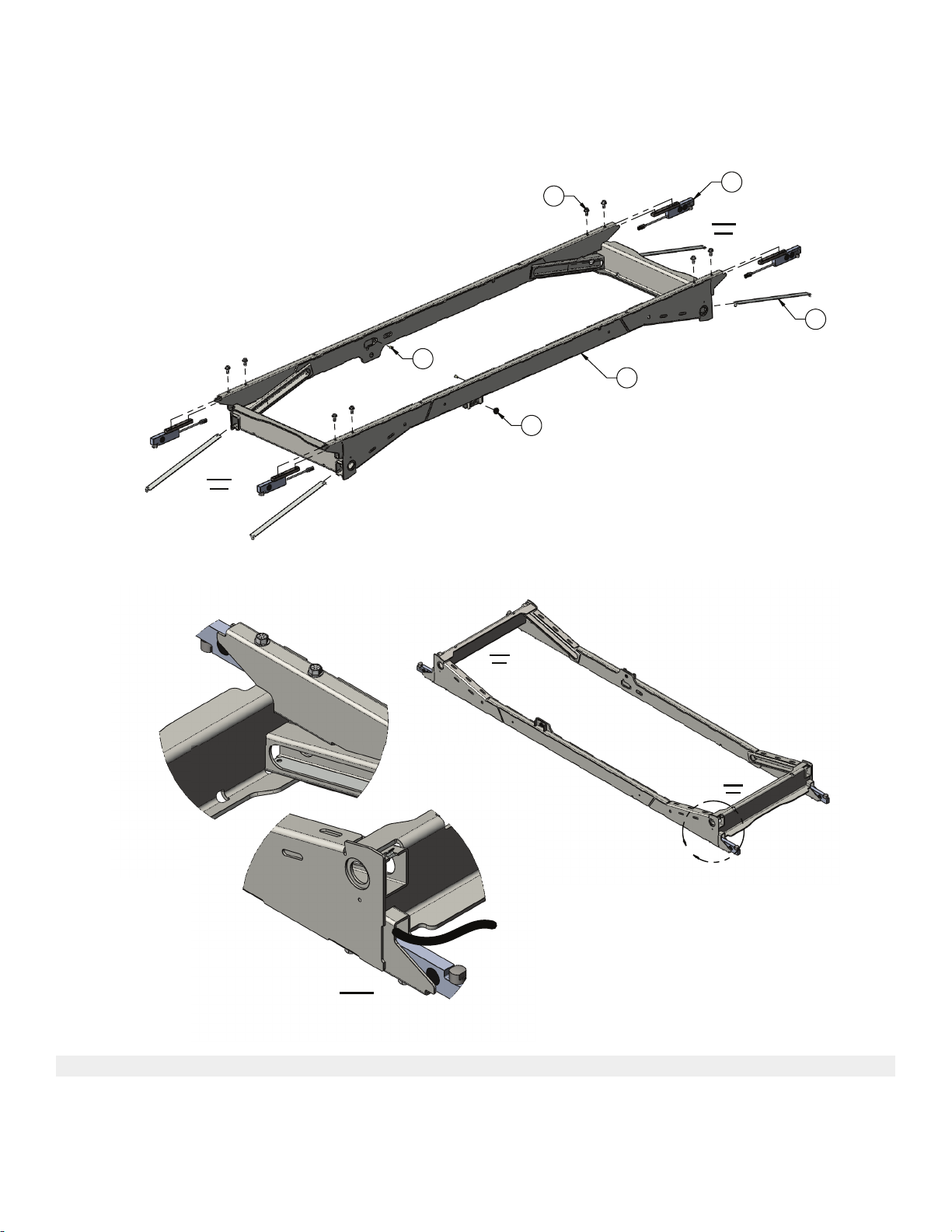

Top level assembly .................................................................................................................................................36

Upper frame assembly............................................................................................................................................ 41

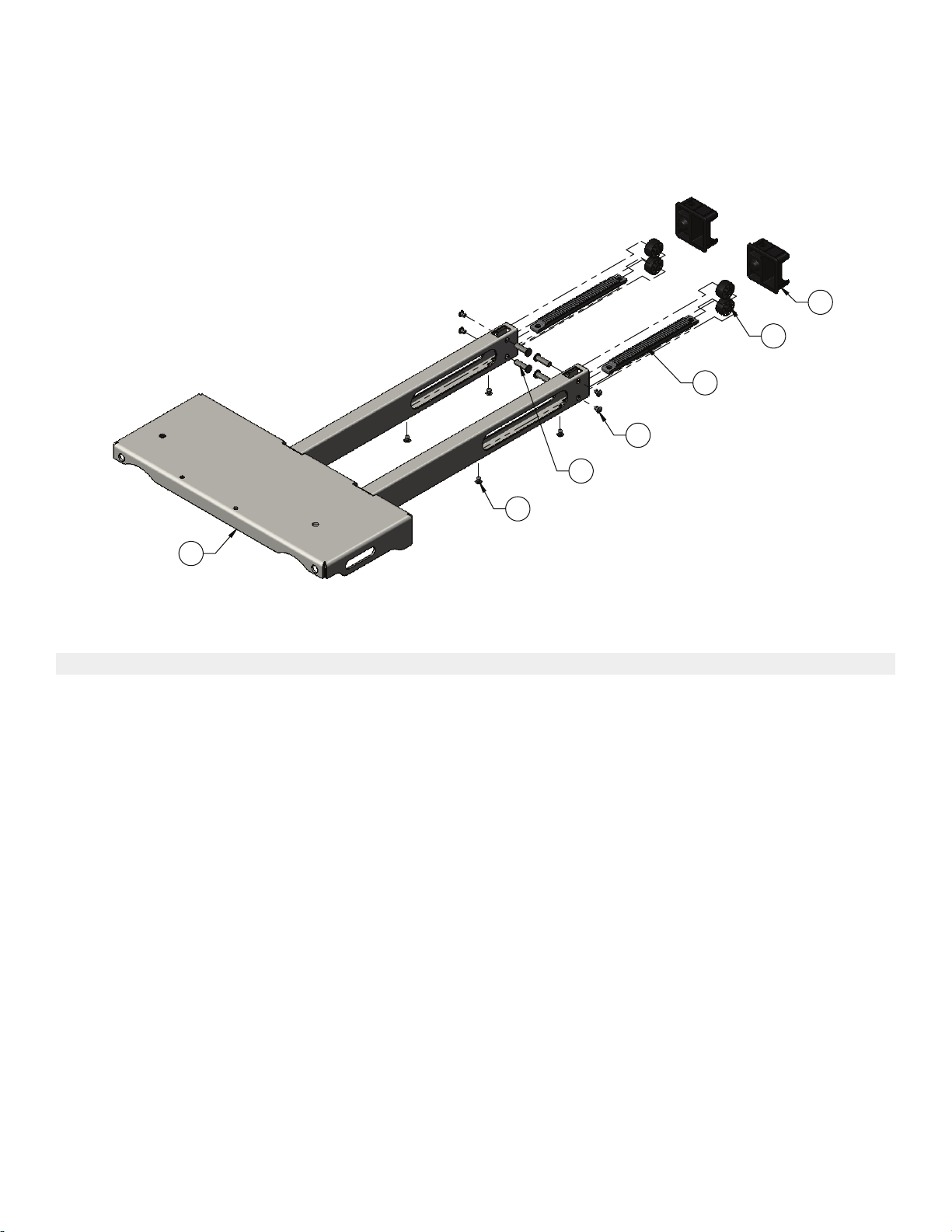

Deck assembly, seat section .................................................................................................................................. 47

Deck pan assembly, seat deck, patient right.......................................................................................................... 54

5900-009-002 Rev A.0 1 EN

Page 6

Deck pan assembly, seat deck, patient left ............................................................................................................ 55

Deck assembly, head section ................................................................................................................................. 56

Deck pan assembly, head deck, patient right......................................................................................................... 65

Deck pan assembly, head deck, patient left ...........................................................................................................66

Lock assembly, head deck position........................................................................................................................ 67

Deck assembly, knee section .................................................................................................................................68

Deck pan assembly, knee deck, patient right.........................................................................................................72

Deck pan assembly, knee deck, patient left ...........................................................................................................73

Deck assembly, foot section ...................................................................................................................................74

Deck pan assembly, foot deck, patient right...........................................................................................................81

Deck pan assembly, foot deck, patient left .............................................................................................................82

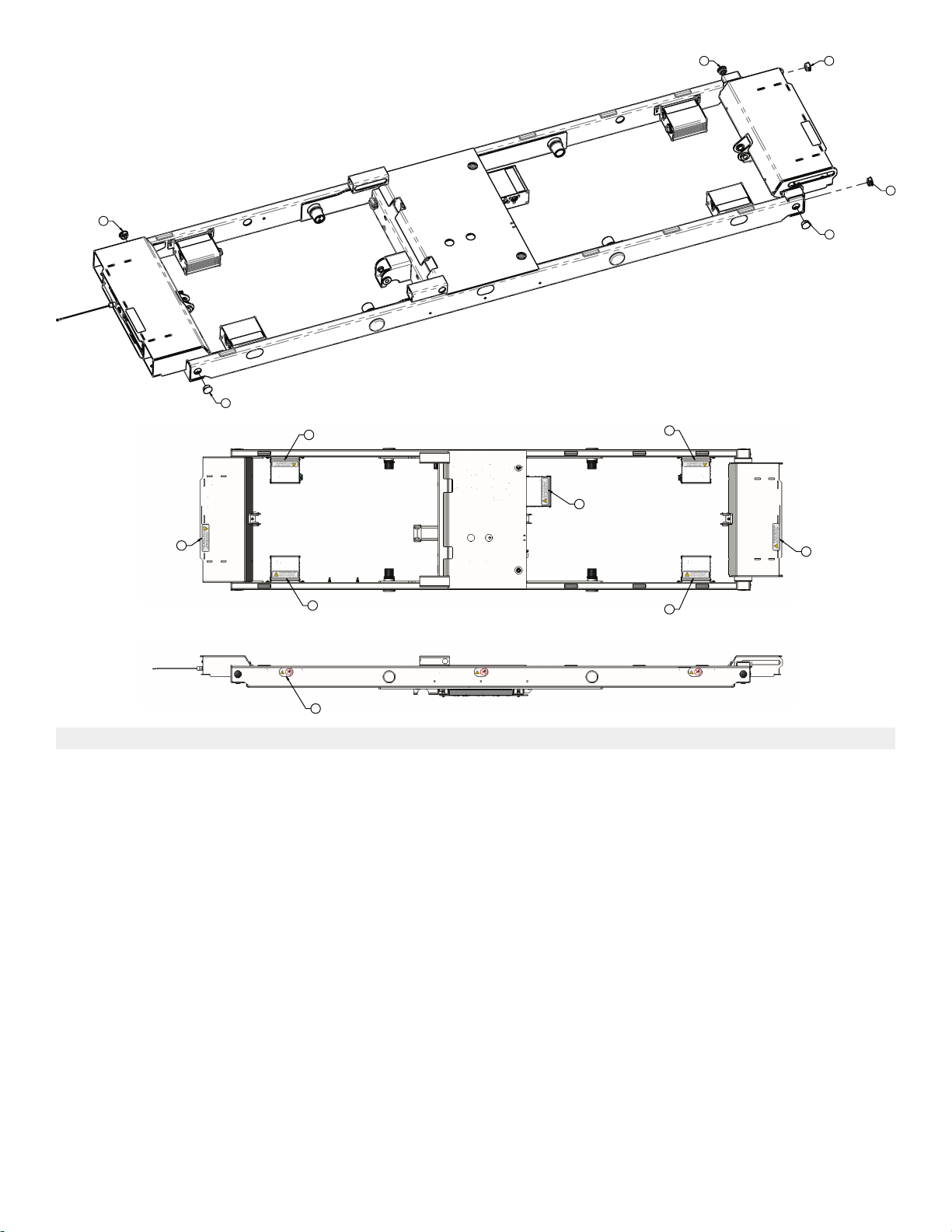

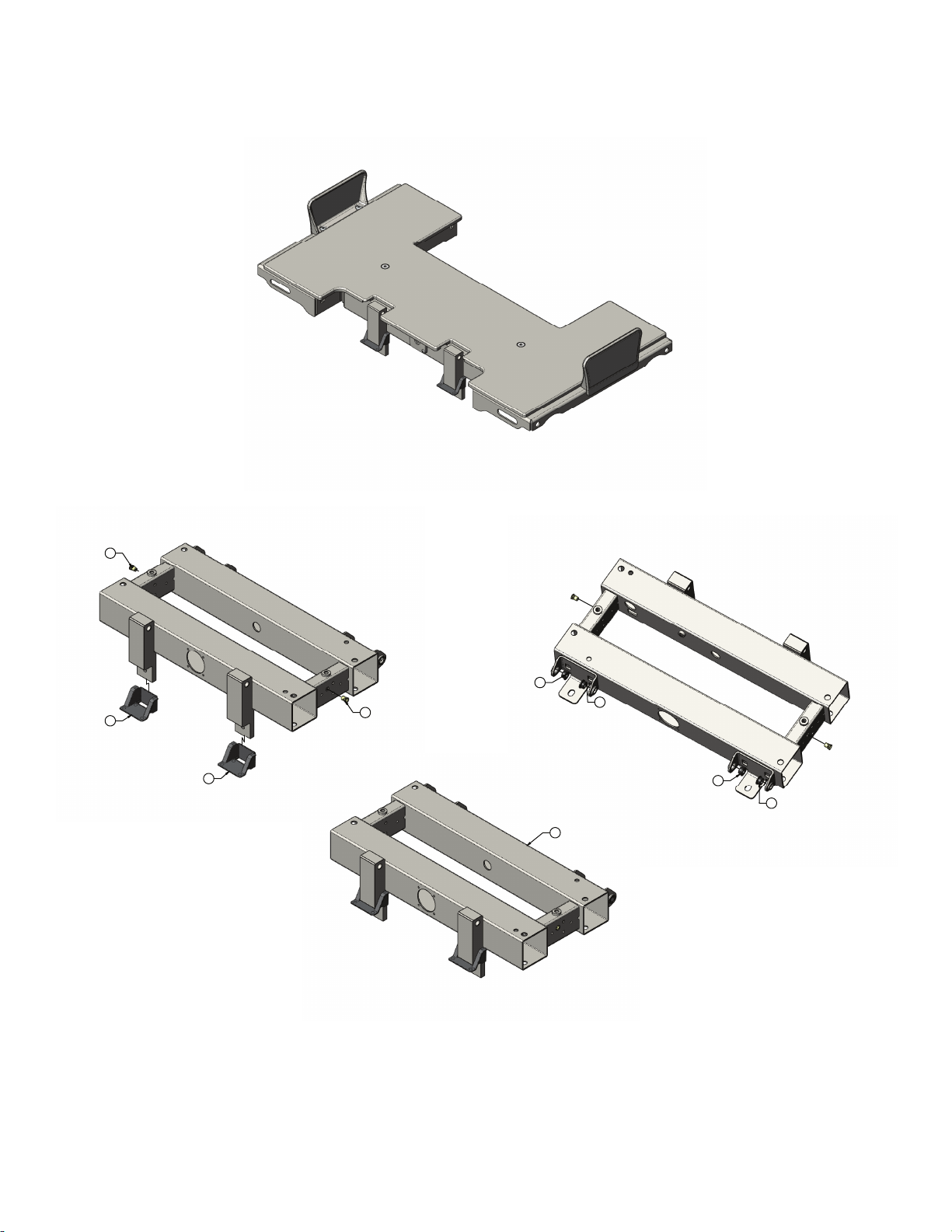

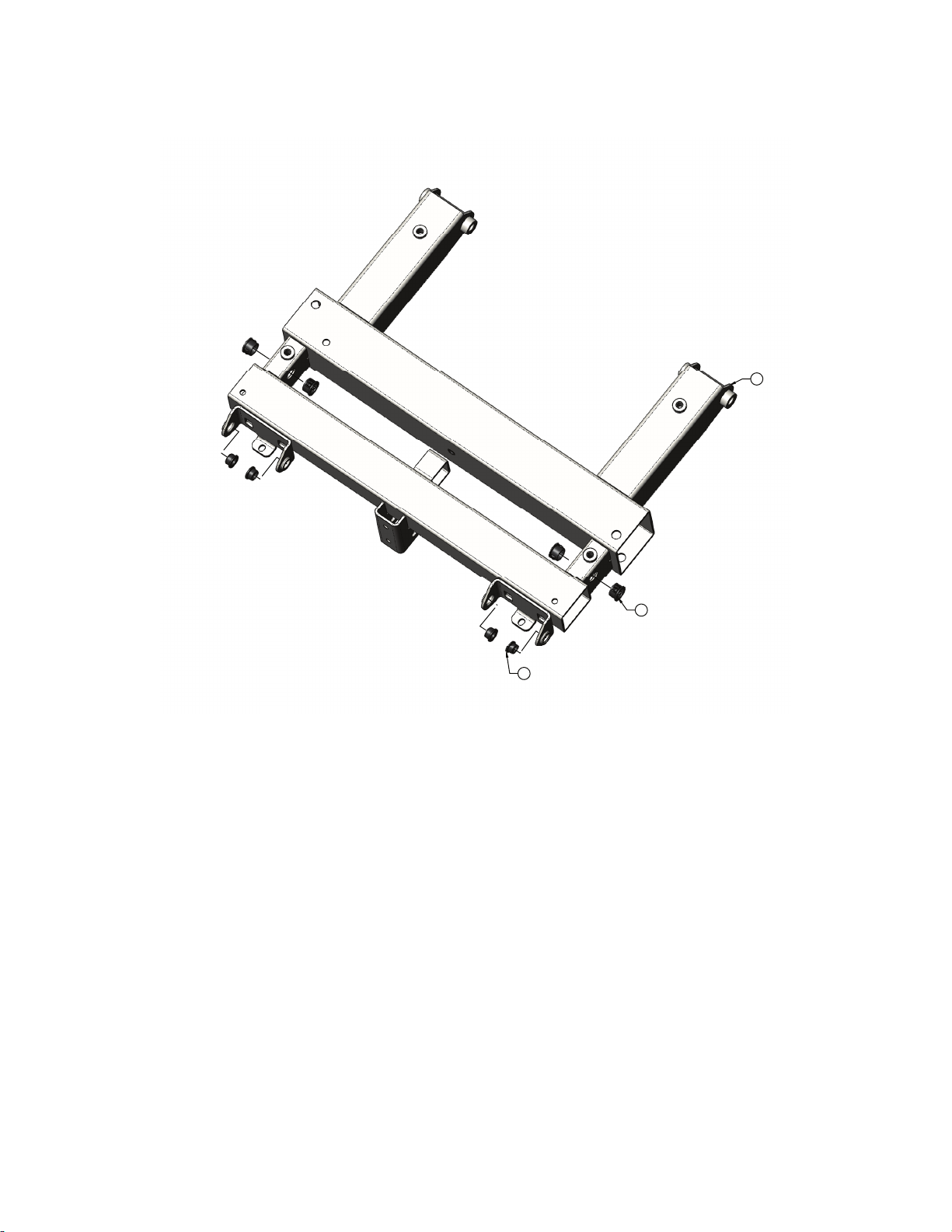

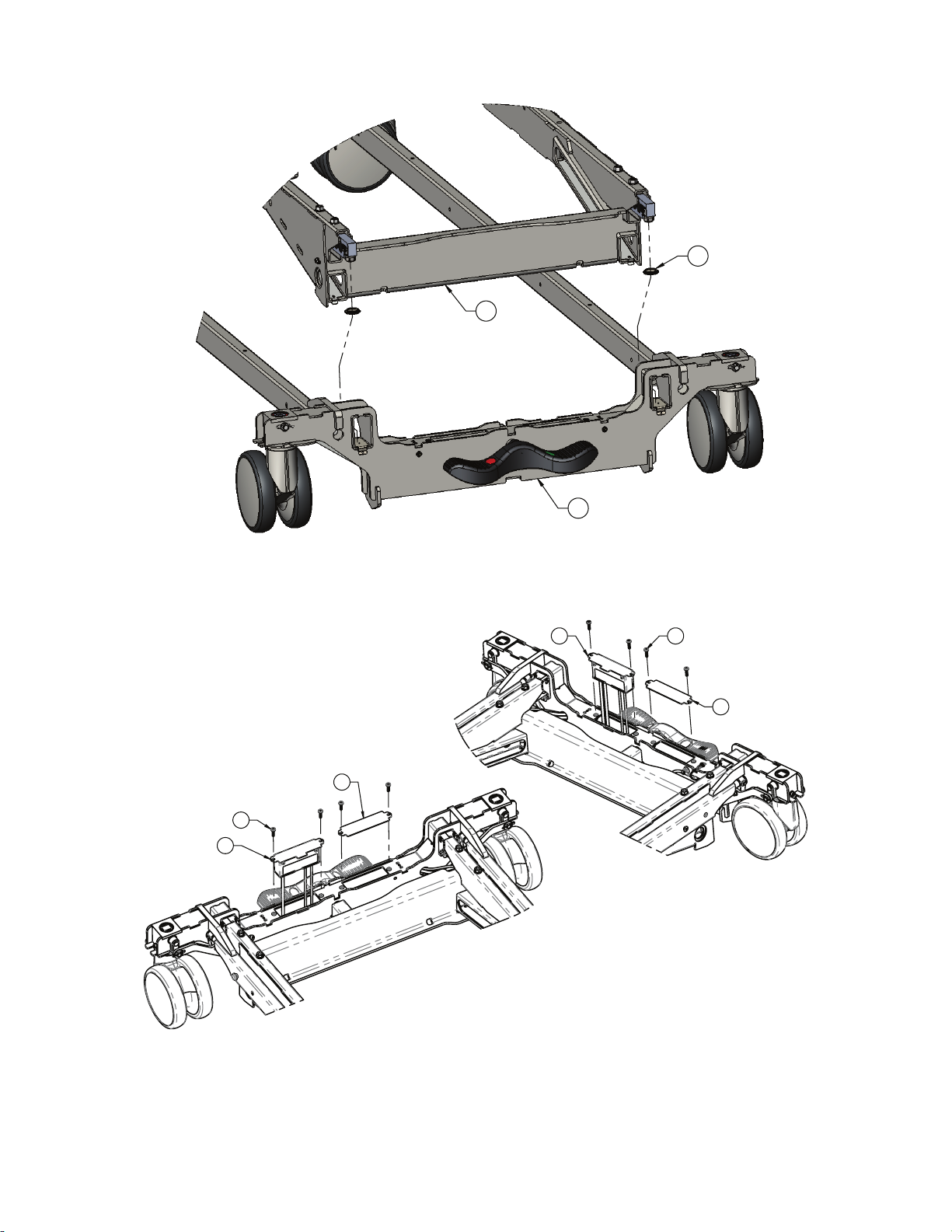

HILO frame assembly ............................................................................................................................................. 83

Lower frame assembly............................................................................................................................................ 87

Caster frame assembly........................................................................................................................................... 89

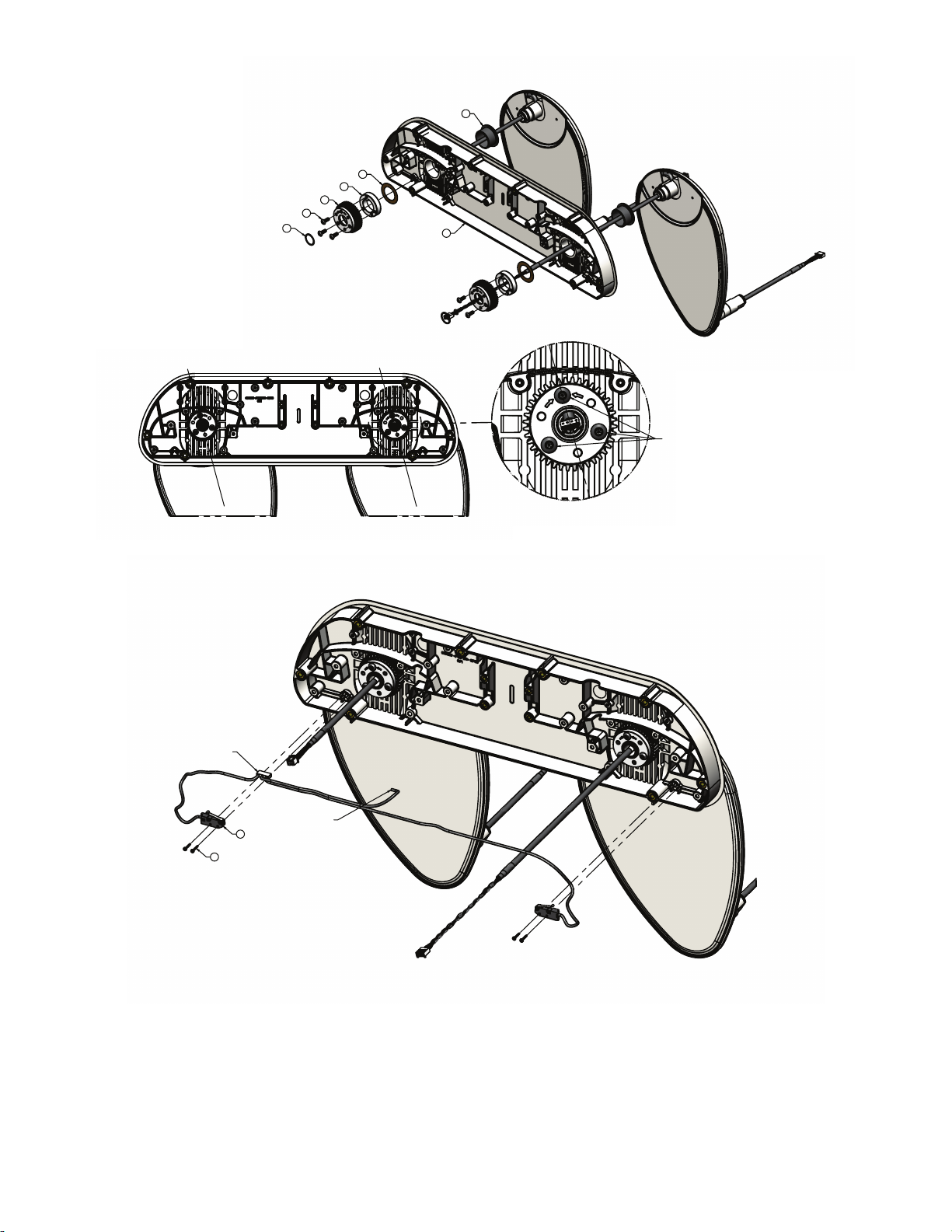

Rail assembly, head ...............................................................................................................................................93

Rail assembly, foot ............................................................................................................................................... 101

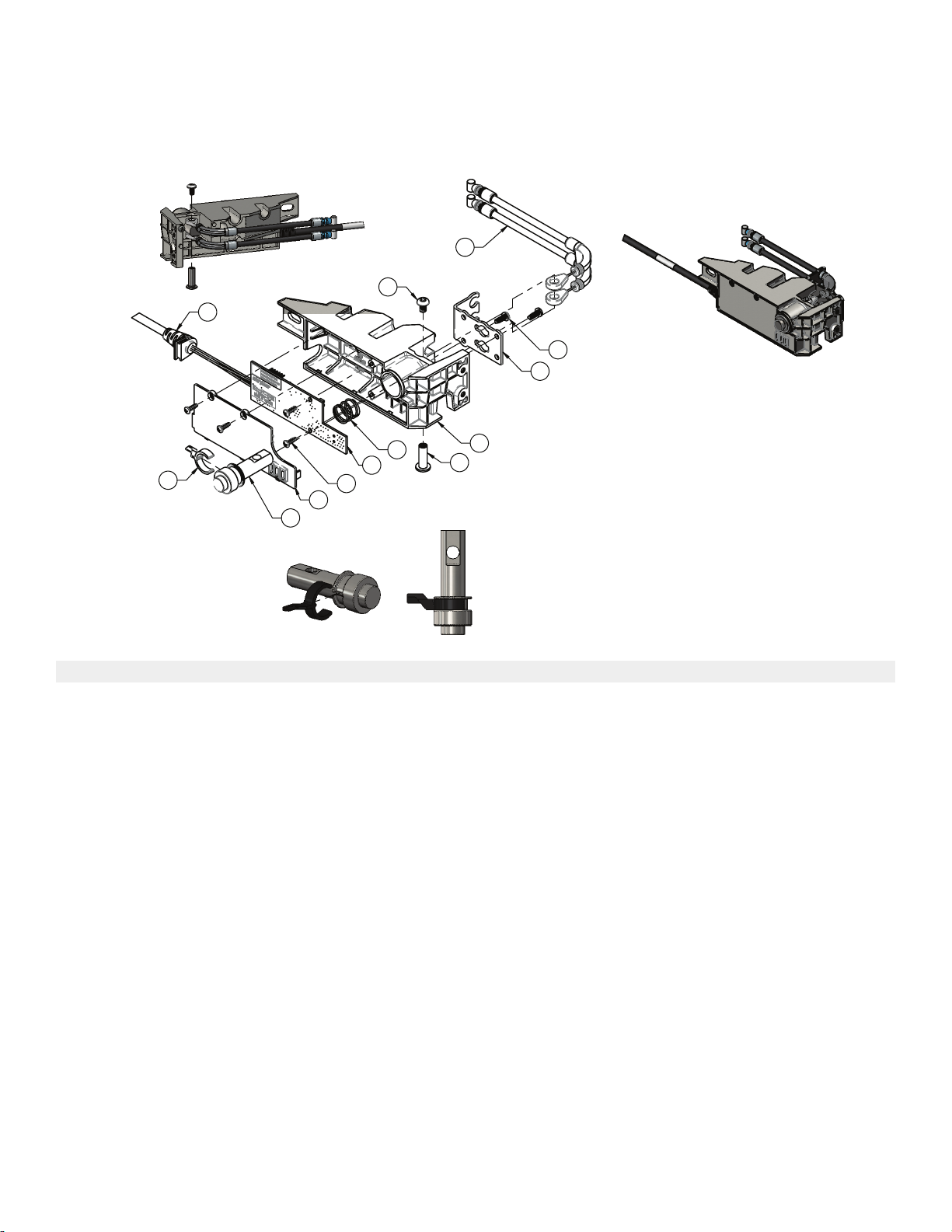

Timing link assembly ............................................................................................................................................ 108

Rail arm assembly, power/communication........................................................................................................... 109

Rail arm assembly, nurse call/speaker................................................................................................................. 110

Rail arm assembly, no cable................................................................................................................................. 111

Bracket assembly, lower rail slide ........................................................................................................................ 112

Latch lock assembly, left head/right foot - 5900200023....................................................................................... 113

Latch lock assembly, right head/left foot - 5900200024....................................................................................... 114

Power supply cord ................................................................................................................................................ 115

Accessory cord, type B 120V................................................................................................................................ 116

Footboard assembly - 5900200025...................................................................................................................... 117

Expandable headboard assembly - 5900200026................................................................................................. 120

EMC information ................................................................................................................................................... 123

0039-254-000 ....................................................................................................................................................... 128

5900400037, 5900400040.................................................................................................................................... 129

5900400038.......................................................................................................................................................... 130

5900470017.......................................................................................................................................................... 131

5900470018, 5900470019.................................................................................................................................... 132

EN 2 5900-009-002 Rev A.0

Page 7

WWaarrnniinngg//CCaauuttiioonn//NNoottee DDeeffiinniittiioonn

The words WWAARRNNIINNGG, CCAAUUTTIIOONN, and NNOOTTEE carry special meanings and should be carefully reviewed.

WWAARRNNIINNGG

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CCAAUUTTIIOONN

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and effective

use of the device and the care necessary to avoid damage to a device that may occur as a result of use or misuse.

NNoottee -- Provides special information to make maintenance easier or important instructions clearer.

5900-009-002 Rev A.0 3 EN

Page 8

SSuummmmaarryy ooff ssaaffeettyy pprreeccaauuttiioonnss

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WWAARRNNIINNGG

• Always use this product for bariatric use only per the details on the product labeling and specifications from this manual.

• Do not use this product for psychiatric, pediatric, or home health care use.

• Do not use this product in an oxygen rich environment.

• Always use Stryker approved mattresses that have been tested for compatibility with the product frame to avoid the risk

of patient entrapment.

• Do not lower the litter too low or the litter may not be supported.

• The use of accessories, transducers, and cables, other than those specified or provided by the manufacturer, could

result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper operation.

• Portable RF communications equipment, including peripherals such as antenna cables and external antennas, should

be no closer than 12 inches (30 cm) to any part of MMVV33, including cables specified by the manufacturer.

• Avoid stacking or placing equipment adjacent with other equipment to prevent improper operation of the products. If

such use is necessary, carefully observe stacked or adjacent equipment to make sure that they are operating properly.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Always make sure that the product is clear of obstacles before you use motion functions.

• Always calibrate the product angles when you replace the main control board or any actuator or product damage may

occur.

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

• Always perform this procedure in a secure location with the floor jack secure to the base frame before you remove the

caster to prevent the risk of injury.

• Do not put your hands or feet below the caster when you remove or attach the caster to prevent the risk of injury.

• Always leave the bolts loose in the support holes, so the bolt head is out far enough to stop the lift mechanism slide

block.

EN 4 5900-009-002 Rev A.0

Page 9

IInnttrroodduuccttiioonn

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or maintenance

of this product.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

NNoottee

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current product

information available at the time of printing. There may be minor discrepancies between your product and this manual. If

you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

PPrroodduucctt ddeessccrriippttiioonn

The Stryker model 5900 MMVV33™™ bariatric hospital bed is an AC-powered adjustable hospital bed designed to be utilized with

a patient support surface matching the deck size of the bed frame. MMVV33 consists of a Fowler and knee Gatch to aid in the

adjustment of the surface contour of the bed, moveable and latchable siderails, and electronic controls located in the

footboard and siderails. The

positioning and provides visual alerts when those parameters set by the health care professional (HCP) are altered.

ii

BBeedd®® Awareness system allows users to set various bed parameters to monitor bed

IInnddiiccaattiioonnss ffoorr uussee

WWAARRNNIINNGG

• Always use this product for bariatric use only per the details on the product labeling and specifications from this manual.

• Do not use this product for psychiatric, pediatric, or home health care use.

• Do not use this product in an oxygen rich environment.

The MMVV33 bariatric bed is intended to provide a patient support surface for medical purposes and to provide a method of

transporting patients within a healthcare facility. It is intended to be used with bariatric, adult, non-behavioral health patients

with a BMI of 30 kg/m² or greater and weighing 250 lb (113.4 kg) or more.

CClliinniiccaall bbeenneeffiittss

Patient treatment, patient positioning, and diagnostic

EExxppeecctteedd sseerrvviiccee lliiffee

The 5900 MMVV33 bariatric bed has an eight year expected service life under normal use conditions and with appropriate

periodic maintenance.

The backup batteries have a one year expected service life under normal use conditions.

DDiissppoossaall//rreeccyyccllee

Always follow the current local recommendations and/or regulations governing environmental protection and the risks

associated with recycling or disposing of the equipment at the end of its useful life.

5900-009-002 Rev A.0 5 EN

Page 10

CCoonnttrraaiinnddiiccaattiioonnss

None known.

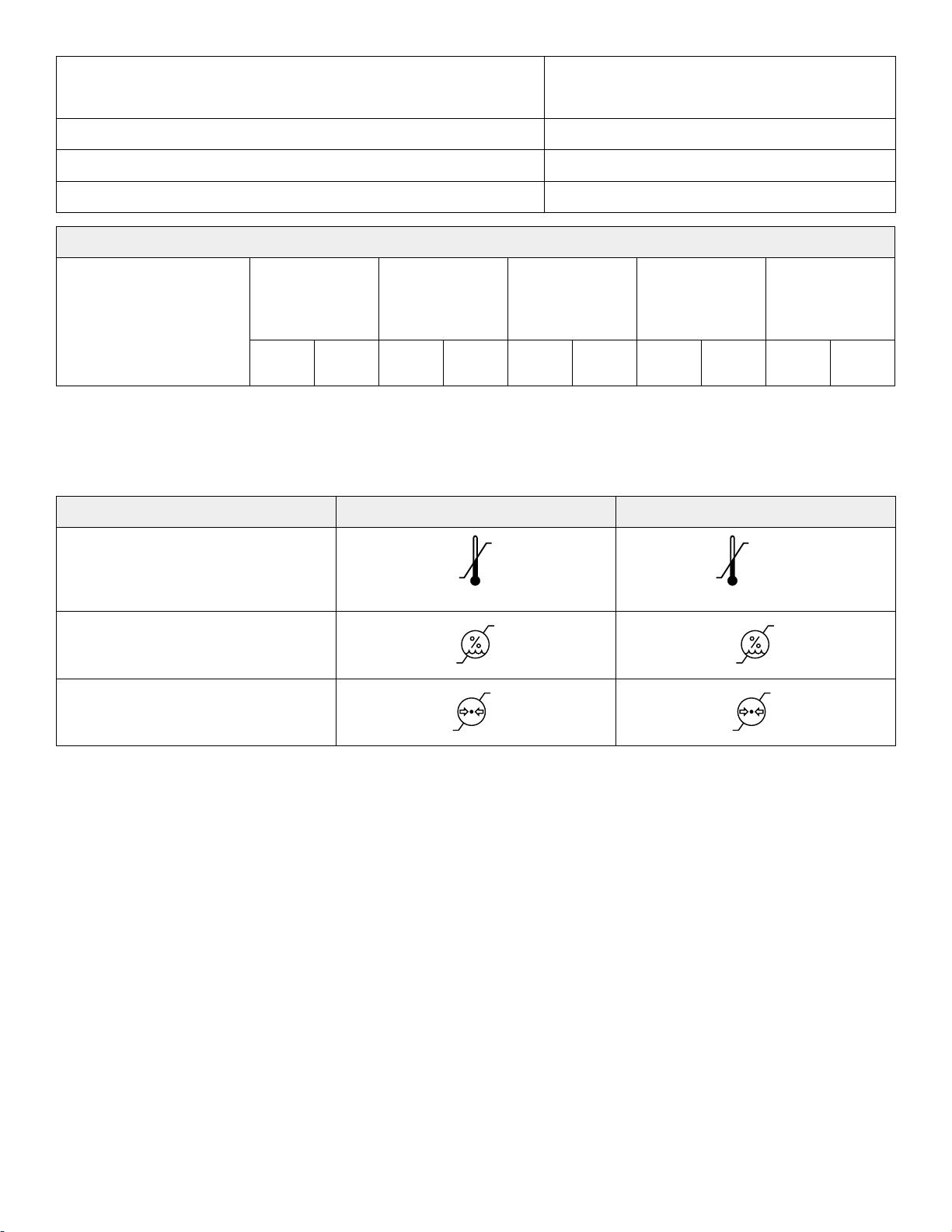

SSppeecciiffiiccaattiioonnss

WWAARRNNIINNGG -- Always use Stryker approved mattresses that have been tested for compatibility with the product frame to

avoid the risk of patient entrapment.

Safe working load

NNoottee:: Safe working load indicates the sum of the

occupant, accessories, and mattress weight.

1102 lb

500 kg

Maximum patient weight

Product weight

Scale system capacity maximum 1102 lb 500 kg

± 4.4 lb (2 kg) for patients weighing 225 (102 kg)

to 882 lb (400 kg)

Scale system accuracy

± 6.6 lb (3 kg) for patients weighing 886 (402 kg)

to 1102 lb (500 kg)

92 in. x 38.3 in. 233.7 cm x 97.2 cm

Overall length and width

Patient sleep surface

Siderails stowed

Siderails at low,

intermediate, and high

position

36 in. (91.4 cm) deck

position

42 in. (106.7 cm) deck

position

92 in. x 42 in. 233.7 cm x 106.7 cm

92 in. x 48 in. 233.7 cm x 121.9 cm

92 in. x 40.5 in. 233.7 cm x 102.9 cm

92 in. x 46.5 in. 233.7 cm x 118.1 cm

92 in. x 52.5 in. 233.7 cm x 133.4 cm

80 in. x 34.5 in.

80 in. x 40.5 in.

1027 lb

902 lb

203.2 cm x 87.6 cm

203.2 cm x 102.9 cm

465.8 kg

409.1 kg

48 in. (121.9 cm) deck

position

Bed height to top of seat litter

Knee Gatch position 0° to 20° ± 2°

Fowler position

Foot position

Trendelenburg and reverse Trendelenburg

Electrical requirements

NNoottee -- Class I Electrical Equipment: Protection against electrical

shock relies on connection to protective earth of an appropriately

rated hospital grade outlet.

Hospital grade GFCI auxiliary outlet

EN 6 5900-009-002 Rev A.0

80 in. x 46.5 in.

12 in. to 28 in. 30.5 cm to 71.1 cm

0° to 60° ± 2°

0° to 13° ± 2°

+12° to -12°

120 VAC, 60 Hz, 8A 230 VAC, 50 Hz, 4A

120 VAC, 60 Hz, 6A

203.2 cm x 118.1 cm

230 VAC, 50 Hz, 3A

Page 11

Battery voltage

95 °F

(35 °C)

50 °F

(10 °C)

140 °F

(60 °C)

-40 °F

(-40 °C)

80%

20%

95%

10%

106 kPa

70 kPa

106 kPa

50 kPa

NNoottee -- Always replace with Stryker approved batteries.

12 VDC (x2) (Stryker part number: 5900280025)

Duty cycle

2 minutes ON, 18 minutes OFF

Application environments 1, 2, 3, and 5 per IEC 60601-2-52

Maximum acoustic sound pressure

< 60 dBA

CCoommppaattiibbllee mmaattttrreessss

Bariatric non-powered

support surface

Length

Width Thickness

Bolster width,

patient right and

patient left

Bolster

thickness,

patient right and

patient left

(28850555001)

79.5

in.

201.9cm45 in. 114.3cm7 in. 17.8

cm

6 in. 15.2

cm

7 in. 17.8

NNoottee -- Minimum mattress firmness: ILD at 50% - minimum of 108 lbf

Stryker reserves the right to change specifications without notice.

Specifications listed are approximate and may vary slightly from product to product or by power supply fluctuations.

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss

OOppeerraattiioonn SSttoorraaggee aanndd ttrraannssppoorrttaattiioonn

Ambient temperature

cm

Relative humidity (non-condensing)

Atmospheric pressure

5900-009-002 Rev A.0 7 EN

Page 12

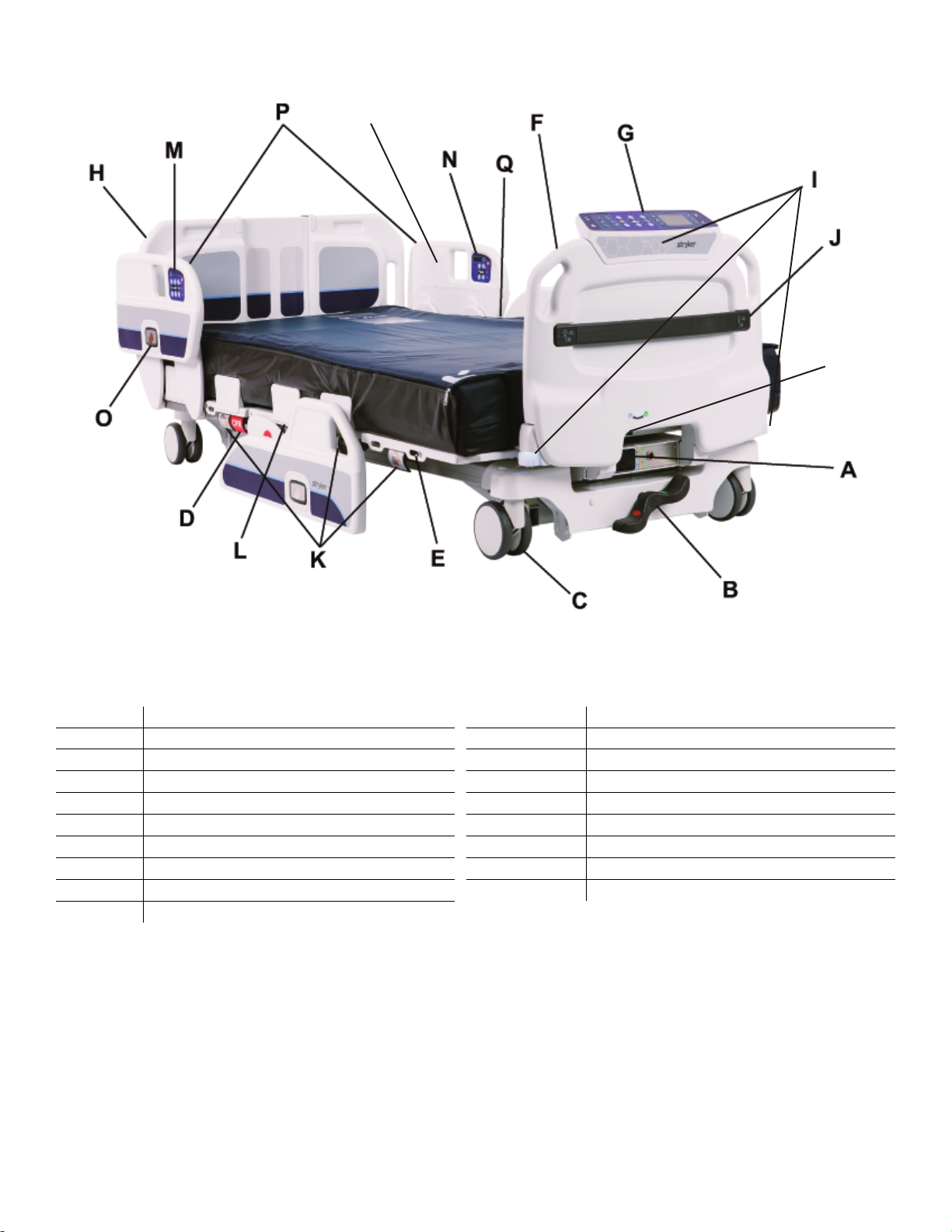

PPrroodduucctt iilllluussttrraattiioonn

R

S

FFiigguurree 11 –– MMooddeell 55990000 MMVV33 bbaarriiaattrriicc bbeedd

A

B

C Caster M

D CPR release handle N

E

F Footboard P Siderails

G

H Headboard R

I

J

120/230 VAC hospital grade GFCI outlet

Brake/steer pedal

Foley bag hooks

Footboard control panel

ii

BBeedd Awareness lights

Integrated pump rack

K

L Mattress retainer

O Siderail release button

Q

S Footboard lock switch

Mattress deck expansion handle

Operator control panel

Patient control panel

Support surface

Nurse Call speaker

CCoonnttaacctt iinnffoorrmmaattiioonn

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

EN 8 5900-009-002 Rev A.0

Page 13

NNoottee -- The user and/or the patient should report any serious product-related incident to both the manufacturer and the

A

Competent authority of the European Member State where the user and/or patient is established.

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

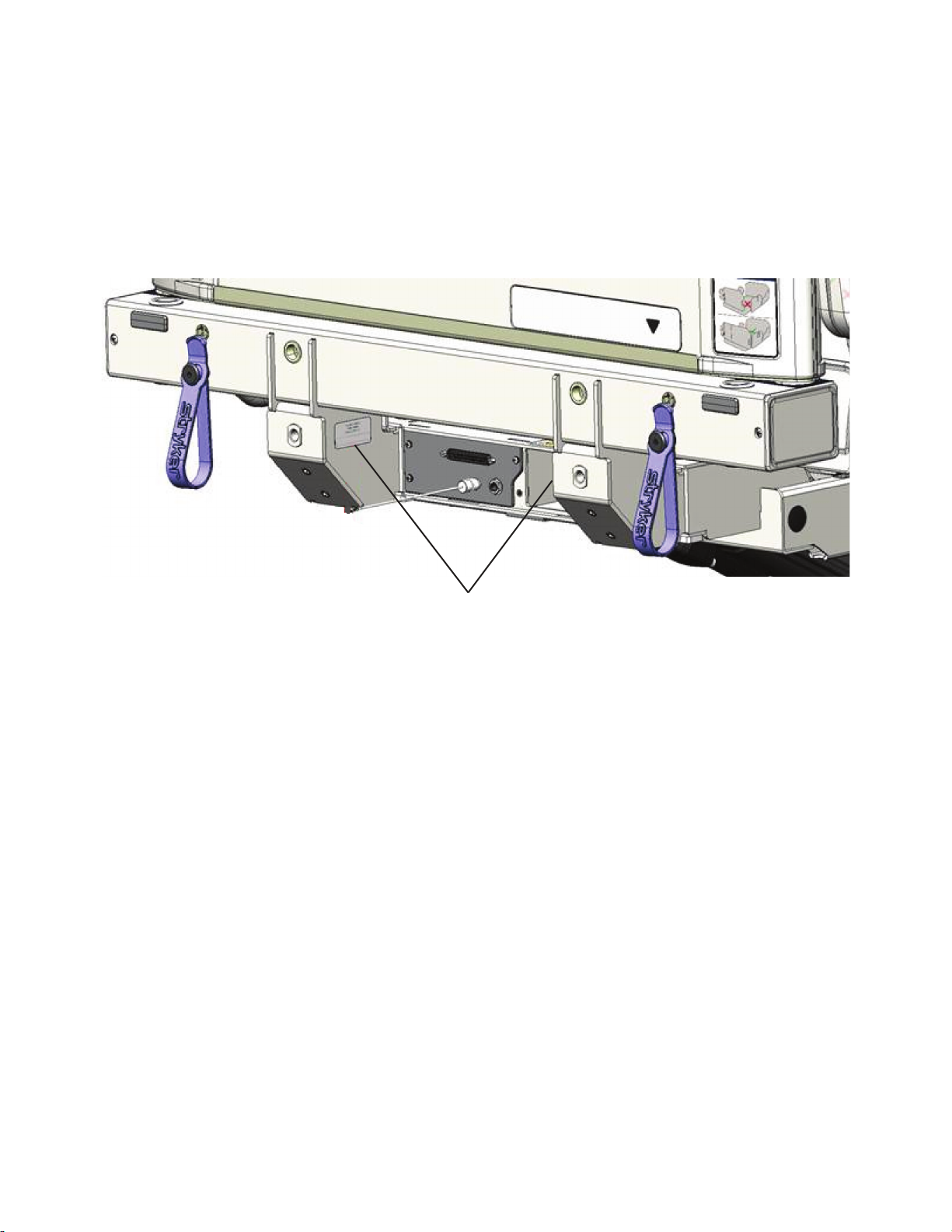

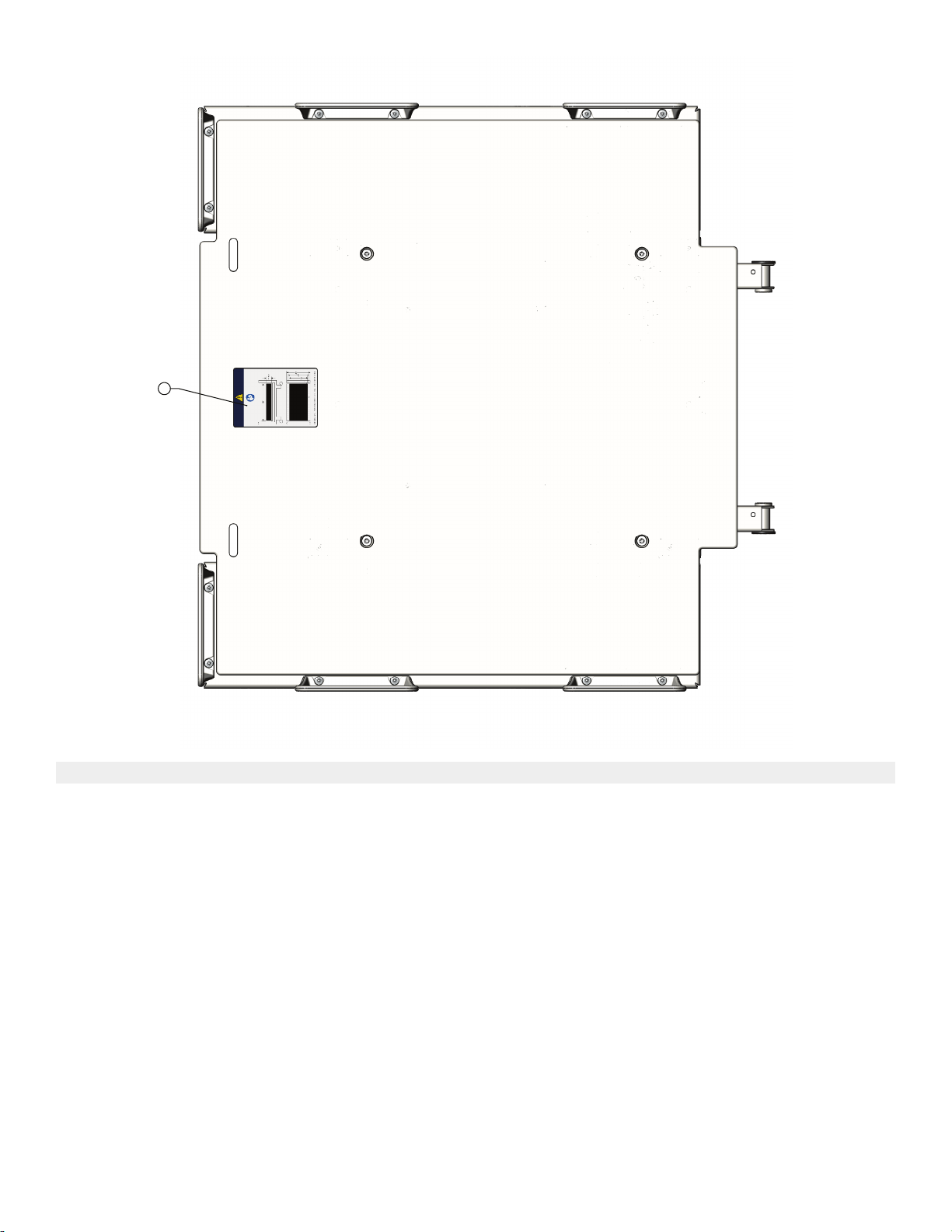

SSeerriiaall nnuummbbeerr llooccaattiioonn

You can find the serial number (A) below the headboard at the head of the bed (Figure 2).

FFiigguurree 22 –– SSeerriiaall nnuummbbeerr llooccaattiioonn--ooppeerraattoorr vviieeww

5900-009-002 Rev A.0 9 EN

Page 14

PPrreevveennttiivvee mmaaiinntteennaannccee

Remove the product from service before you perform the preventive maintenance inspection. Make sure that all items listed

during annual preventive maintenance for all Stryker Medical products. You may need to perform preventive maintenance

checks more often based on your level of product usage. Service only by qualified personnel.

NNoottee -- Clean and disinfect the exterior of the support surface before inspection, if applicable.

Inspect the following items:

All welds

All fasteners are secure

Casters lock with brake pedal applied

Casters are secure and swivel

Casters are free of wax and debris

Center light LED and bumper LEDs flash when brakes are released

Steer function works

Siderails move, latch, and stow

Deck expands, retracts, and locks in all positions

CPR release operates

IV pole is intact and operates (option)

Foley bag hooks intact

No cracks or splits in headboard, footboard or siderail panels

No rips or cracks in mattress cover

All functions on head end siderails operate (includes LEDs)

All functions on footboard operate (includes LEDs)

No cracks or damage to control overlays

Scale system calibrated

Night light operates

Power cords and plug not frayed or damaged

No cables worn or pinched

No damage to nurse call connections

All electrical connections tight

All ground strap cables are secure to the frame

Ground impedance not more than 200 mΩ (milliohms)

Current leakage not more than 300 µA (microamps)

Apply grease to the litter grease points (see maintenance manual for locations)

Ground chains intact

Trendelenburg/reverse Trendelenburg angle accuracy is minimum +12° to -12°

Fowler angle accuracy is 0° - 60° ± 2°

Fowler holds position at 30° with weight

Siderail switches operate (iiBBeedd Awareness)

Center light LED and bumper LEDs operate (iiBBeedd Awareness)

Inspect footboard control labels for signs of degradation

EN 10 5900-009-002 Rev A.0

Page 15

Inspect hi-lo actuators for oil leaks

Inspect footboard connector housing for cracks or damage

All motions function

Nurse call functions

Auxiliary outlets function (test ground fault interrupter)

Replace batteries (one year expected service life)

Set clock to local date and time

Product serial number:

Completed by:

Date:

5900-009-002 Rev A.0 11 EN

Page 16

EErrrroorr ccooddeess

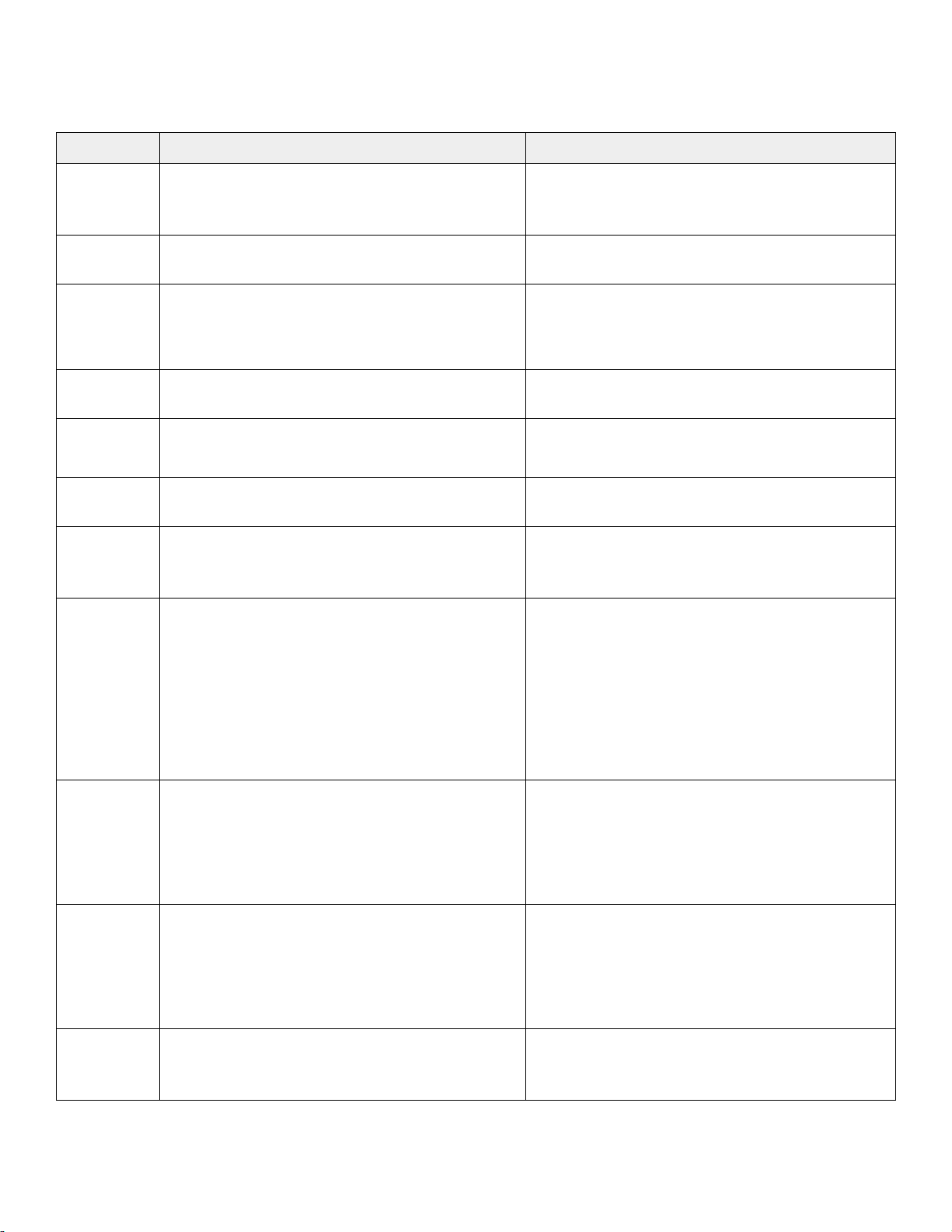

Error codes are detailed in the table below.

EErrrroorr ccooddee CCaauussee

0.02 Error on non volatile memory

(nvm)

0.03 Watchdog switch in wrong position or broken

(comWatchdogDisabled)

0.04 Software version mismatched or missing board

(softwareVersionMismatch)

0.05 Brake switch malfunction

(brake)

0.06 Obstruction switch malfunction

(obstruction)

0.07 CPR switch/cable malfunction

(cprHandle)

0.08 FSC_KPD board is not responding

(FSC_KPD_missing)

TTrroouubblleesshhoooottiinngg

1. Reboot product

2. Replace MCU

1. Toggle watchdog switch on MCU

1. Reboot product

2. Check for a missing board error, if missing take

corrective action on cable or board

1. Check brake cable and switch

1. Check each of the four obstruction switches and

cables

1. Check CPR switch, cable, and head actuator

1. Check cable

2. Check AVB board (electrical issue)

0.09 FSC_GUI board is not responding

(FSC_GUI_missing)

0.1 SRK PL board is not responding

(SRK_PL_missing)

0.11 SRK PR board is not responding

(SRK_PR_missing)

0.12 PSI board is not responding

(PSI_missing)

1. Check cable

2. Check FSC_KPD

• Software in bootloader mode

• Software incorrect

• Electrical issue

3. AVB board (electrical issue)

1. Check cables

2. Check junction boards

3. Check SRK board

4. Check SRC (software and electrical)

1. Check cables

2. Check junction boards

3. Check SRK board

4. Check SRC (software and electrical)

1. Check cables

2. Check junction boards

EN 12 5900-009-002 Rev A.0

Page 17

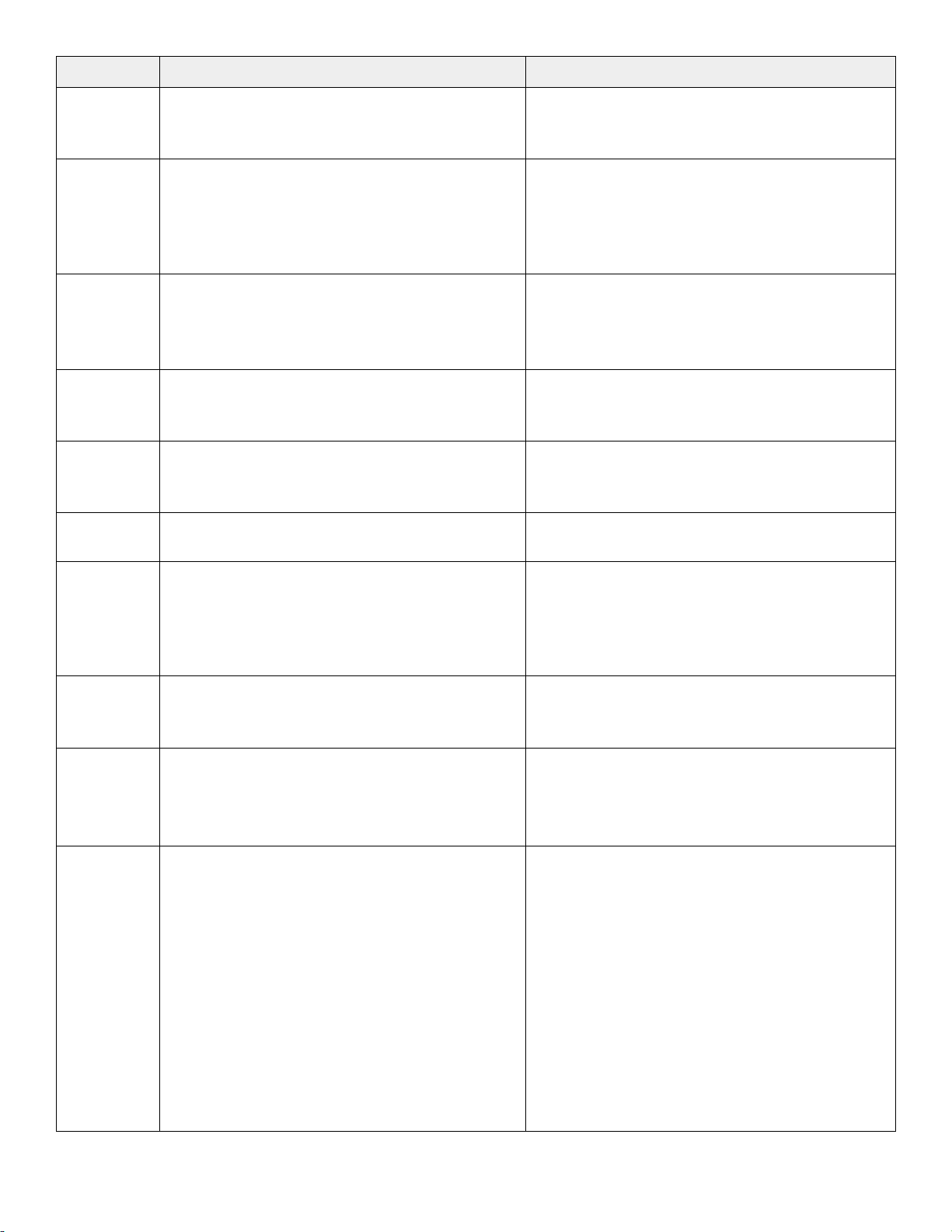

EErrrroorr ccooddee CCaauussee

TTrroouubblleesshhoooottiinngg

0.13 ACB HILO foot board is not responding

(ACB_HILO_FT_missing)

0.14 ACB HILO head board is not responding

(ACB_HILO_HD_missing)

0.15 ACB foot board is not responding

(ACB_FT_missing)

0.16 ACB head board is not responding

(ACB_HD_missing)

0.17 ACB knee board is not responding

(ACB_KN_missing)

0.18 SRC foot patient left board is not responding

(SRC_FT_PL_missing)

0.19 SRC head patient left board is not responding

(SRC_HD_PL_missing)

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

0.2 SRC foot patient right board is not responding

(SRC_FT_PR_missing)

0.21 SRC head patient right board is not responding

(SRC_HD_PR_missing)

0.22 DPM foot board is not responding

(DPM_FT_missing)

0.23 DPM head board is not responding

(DPM_HD_missing)

0.24 DPM MID board is not responding

(DPM_MID_missing)

0.25 SMB foot board is not responding

(SMB_FOOT_missing)

0.26 SMB head board is not responding

(SMB_HEAD_missing)

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

1. Check cables

2. Check junction boards

5900-009-002 Rev A.0 13 EN

Page 18

EErrrroorr ccooddee CCaauussee

TTrroouubblleesshhoooottiinngg

0.27 AVB board is not responding

(AVB_missing)

0.29 Real Time Clock is not responding

(RTC chip fail)

0.3 CPR handle switch stuck

(StuckCPRhandle)

1.05 24V is out of range

(24V)

1.08 Battery not connected to the system or completely

depleted

(batteryMissing)

1.09 Damaged battery

(batteryShort)

1. Check cables

2. Check junction boards

1. Reboot product

2. Replace MCU, if 0.02 is present, also issue with

PMB charger chip

3. Replace PMB

1. Check CPR handle

2. Check pull cable

3. Check head actuator

1. Power cable issue

2. PMB ciruit error, replace PMB

1. Check cables

2. Replace battery

1. Replace batteries

1.1 Unable to communicate with accelerometer

(Accelerometer error)

1.11 HILO foot configuration error

(HiloFoot config)

1.12 HILO foot drive circuit error

(HiloFoot Drive ckt)

1.13 HILO head configuration error

(HiLo Head config)

1. Reboot product

2. Replace MCU, if 0.02 is present, also issue with

PMB charger chip

3. Replace PMB

1. WD switch position

2. Reboot product

1. Check 24V cable to ACB

2. Disconnect actuator from ACB

3. Replace ACB

1. WD switch position

2. Reboot product

3. Check HILO head potentiometer cable (30159)

4. Check HILO head counts in actuator

maintenance menu

5. Check HILO head counts in angle maintenance

menu

• Check if counts are between 1024-1033 or

not moving

6. Check HILO foot potentiometer cable (30124)

7. Recalibrate angles

EN 14 5900-009-002 Rev A.0

Page 19

EErrrroorr ccooddee CCaauussee

TTrroouubblleesshhoooottiinngg

1.14 HILO head drive circuit error

(HiLo Head Drive Ckt)

1.15 Foot actuator configuration error

(Foot config)

1.16 Foot drive circuit malfunction

(Foot Drive ckt)

1.17 Head actuator configuration error

(Head config)

1. Check 24V cable to ACB

2. Disconnect actuator from ACB

3. Replace ACB

1. WD switch position

2. Recalibrate angles

3. Reboot product

4. Check foot counts in angle maintenance menu

• Check if foot counts are stored between

power cycles

• If they are not stored, EEPROM error

5. Replace board

1. Check 24V cable to ACB

2. Disconnect actuator from ACB

3. Replace ACB

1. WD switch position

2. Reboot product

3. Check head potentiometer cable (30141)

4. Check head counts in actuator maintenance

menu

1.18 Head drive circuit malfunction

(Head Drive ckt)

1.19 Knee actuator configuration error

(Knee config)

1. Check 24V cable to ACB

2. Disconnect actuator from ACB

3. Replace ACB

1. WD switch position

2. Reboot product

3. Check knee counts in actuator maintenance

menu

• Check if knee counts are stored between

power cycles

• If they are not stored, EEPROM error

• Replace board

• Recalibrate angles

4. Check HILO foot counts in actuator

maintenance menu

• Check if counts are between 1024-1033 or

not moving

5. Check HILO foot potentiometer cable (30124)

6. Recalibrate angles

5900-009-002 Rev A.0 15 EN

Page 20

EErrrroorr ccooddee CCaauussee

TTrroouubblleesshhoooottiinngg

1.2 Knee drive circuit malfunction

(Knee Drive ckt)

1.21 PSI configuration error

(PSI config)

1.22 Patient left foot SRC configuration error

(SRC PL Foot config)

1.23 Patient left head SRC configuration error

(SRC PL Head config)

1.24 Patient right foot SRC configuration error

(SRC PR Foot config)

1. Check 24V cable to ACB

2. Disconnect actuator from ACB

3. Replace ACB

1. Replace switch if this appears only in some

positions

2. WD switch position

1. Replace switch if this appears only in some

positions

2. WD switch position

1. Replace switch if this appears only in some

positions

2. WD switch position

1. Replace switch if this appears only in some

positions

2. WD switch position

1.25 Patient right foot SRC configuration error

(SRC PR Head config)

1.26 DPM foot configuration error

(DPM FT config)

1.27 DPM head configuration error

(DPM HD config)

1.28 DPM MID configuration error

(DPM MID Config)

1. Replace switch if this appears only in some

positions

2. WD switch position

1. Calibration error

2. Trim error

• If values from DPM maintenance screen are

at 36 and less than 600, this error bit is set

3. WD switch position

1. Calibration error

2. Trim error

• If values from DPM maintenance screen are

at 36 and less than 600, this error bit is set

3. WD switch position

1. Calibration error

2. Trim error

• If values from DPM maintenance screen are

at 36 and less than 600, this error bit is set

3. WD switch position

EN 16 5900-009-002 Rev A.0

Page 21

EErrrroorr ccooddee CCaauussee

TTrroouubblleesshhoooottiinngg

1.29 SMB head configuration error

(SMB Head Config)

1.3 SMB foot configuration error

(SMB Foot Config)

1.31 AVB configuration error

(AVB Foot Config)

1. Load cell missing

2. EEPROM error on board

3. Secondary scale missing (also will set 0.25)

4. WD switch position

1. Load cell missing

2. EEPROM error on board

3. Secondary scale missing (also will set 0.25)

4. WD switch position

1. WD switch position

5900-009-002 Rev A.0 17 EN

Page 22

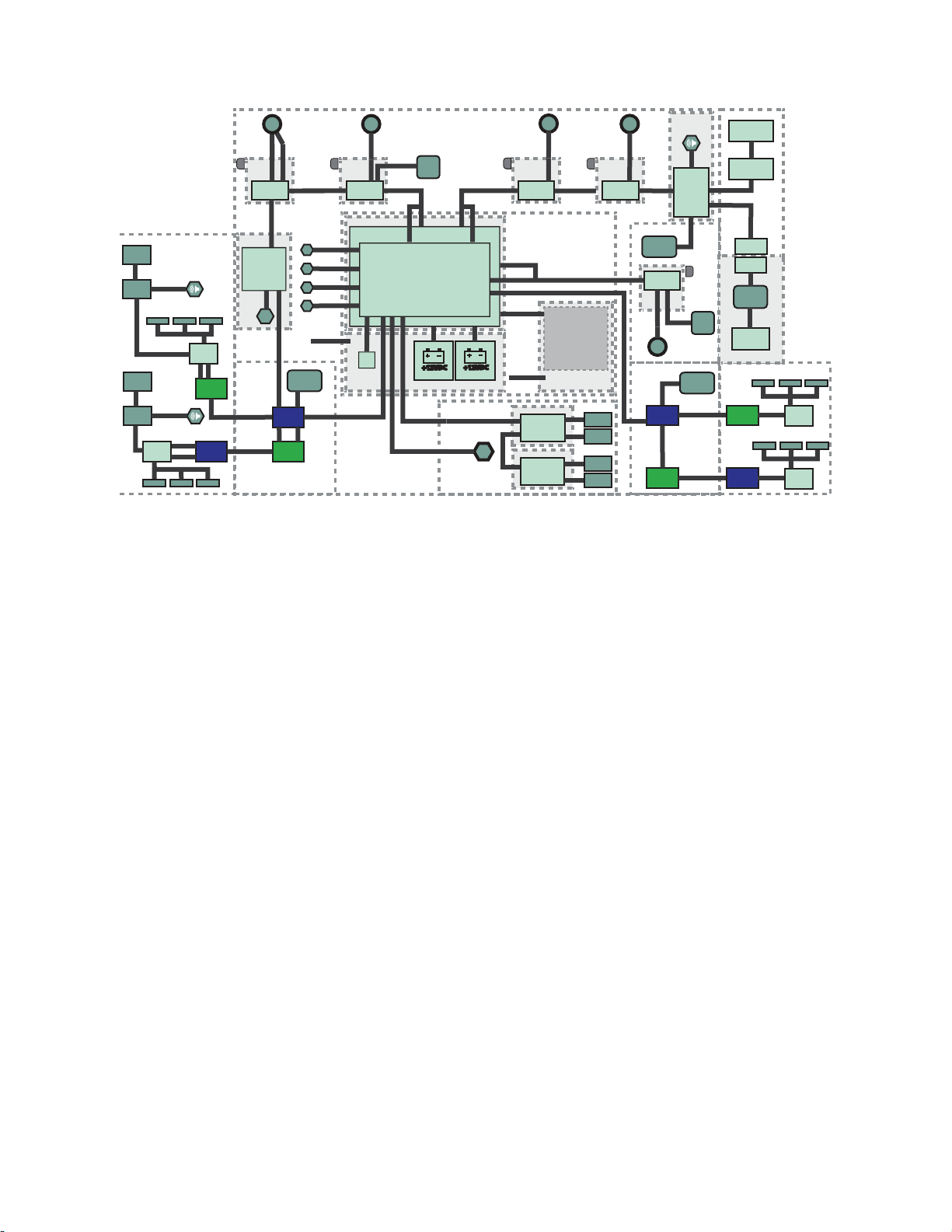

EElleeccttrriiccaall ddiiaaggrraamm

AVB 5900280034

+12VDC+12VDC

J21

MAINS AC TO DC

POWER SUPPLY

5900410023

+12VDC+12VDC

5900430029

USB

5900410022

DC POWER - 5900280025

AC POWER - 5900280026

SMB HEAD - 5900280039

2

5

PEIZO SPE

AKER

5900280035

MID DECK FRAME (SEAT)

HEAD DECK FRAME

(FOWLER)

5900430156

5900410002 5900410002

5900410002

ALT TUCK

LOCKTUCK

5900430156

5900410002 5900410002

5900410002

ALT TUCK

LOCKTUCK

5900430156

5900410002 5900410002

5900410002

ALT TUCK

LOCKTUCK

5900430156

5900410002 5900410002

5900410002

ALT TUCK

LOCKTUCK

PCBA, S1 JCTN

PL-OUT PR-IN

5900400052

5900430059

5900430059

PCBA, S1 JCTN

PL-IN PR-OUT

5900400051

PL HEAD

RAIL SRC

590040004201

PR HEAD

RAIL SRC

590040004202

PR PATIENT

RAIL SRK

5900470018

PR STAFF

RAIL SRK

5900470025

5900430044

PL PATIENT

RAIL SRK

5900470019

PL STAFF

RAIL SRK

5900470026

5900430044

59002

80009

SPEAKER

5900430036

FOOT DECK FRAME

5900430060

5900430060

UPPER LITTER FRAME

5900200094

3 1

4

UNDERBED ENCLOSURE

LOWER FRAME

UPPER

BLINDMATE

LOWER

BLINDMATE

PCBA

S1 IOM AVB

5900400039

PCBA, S1 IOM PSI

5900400038

[DB37 BED PORT]

1/4

JACK

EHA

5900430118

LA31

EHA

5900430118

PCBA, S1 JCTN

PL-OUT PR-IN

5900400052

iBED BUMPER

LIGHT ASSY

5900280053

iBED BUMPER

LIGHT ASSY

5900280053

iBED LIGHT

5900400032

5900430131

5900430148

5900430162

5900430133

5900200152

5900430161

5900410022

5900430146

5900430146

5900430083

5900430146

5900430147

5900430030

5900430091

5900430092

5900430144

5900430159

5900430124

5900430155

590043012

3

5900430141

590043014

2

HEAD ACTUATOR W/ CPR

5900420009

HILO HEAD ACTUATOR

5900420010

HILO FOOT ACTUATOR

5900420010

FOOT ACTUATOR

5900420011

KNEE ACTUATOR

5900420012

5900430123

590043012

1

5900430122

IOM ACB (KNEE)

5900280045

IOM ACB (FOOT)

5900280046

IOM ACB (HILO FOOT)

5900280043

5900430121

PCBA

S1 IOM SMB

HEAD

590040003501

RS485

9V

INT

LC2

LC1

5900430160

59

00430042

5900430119

5900430138

5900430120

5900430149

5900430047

LA34

FSC

5900470017

PCBA, S1 JCTN

PL-IN PR-OUT

5900400051

LA31

DECK POSITION

SENSOR (SEAT)

590040004102

IOM ACB (HEAD)

5900280044

IOM ACB (HILO HEAD)

5900280042

ROTARY

POT

5900410034

PCBA, S1 MCU

5900400037

5900400040

PCBA, S1 IOM PMB

OBS1

OBS2

OBS3

OBS4

J21

J15

J1

J2

J3

J8

J9

J4

J25

J24

J23

J6

J5J10

5900410004

5900410004

OBS

OBS

OBS

OBS

5900430130

5900430129

5900430130

5900430130

5900410022

5900410022

5900410022

ACB

590040004403

5900430140

ACB

5900400044041

ACB

590040004402

ACB

590040004405

5900430151

5900430136

5900430135

5900200051

DECK POSITION

SENSOR (HEAD)

590040004101

5900200153

DECK POSITION

SENSOR (FOOT)

590040004103

PCBA

S1 IOM SMB

FOOT

590040003502

RS485

9V

INT

LC2

LC1

SMB FOOT - 5900280040

ACB

590040004401

BRAKE

5900430137

5900430134

PCBA, S1 JCTN

PL-OUT PR-IN

5900400052

PCBA, S1 JCTN

PL-IN PR-OUT

5900400051

5900430132

FOOTBOARD 5900200025

FOOT BRACKET 5900200135

PSI DB37

5900280033

2

5900280051

5900430142

ROTARY

POT

5900410034

PCBA, S1 JCTN

PL-OUT PR-IN

5900400052

5900430059

5900430059

PCBA, S1 JCTN

PL-IN PR-OUT

5900400051

PL FOOT

RAIL SRC

590040004203

PR FOOT

RAIL SRC

590040004204

5900280009

SPEAKER

5900430036

HEAD RAIL

S

FOOT RAILS

5900430157

5900430143

5900430143

LOAD CELL

5900280027

LOAD CELL

5900280027

LOAD CELL

5900280027

LOAD CELL

5900280027

EN 18 5900-009-002 Rev A.0

Page 23

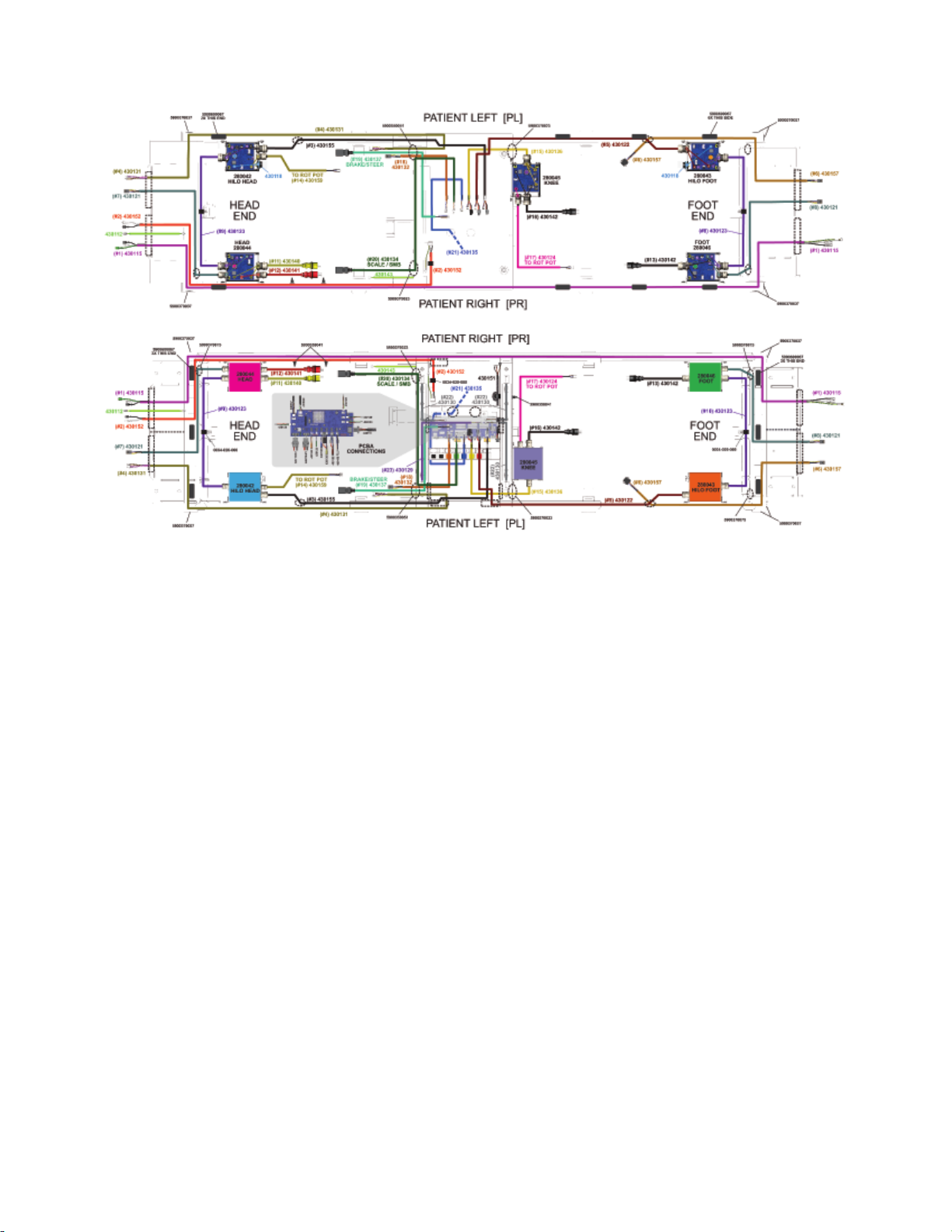

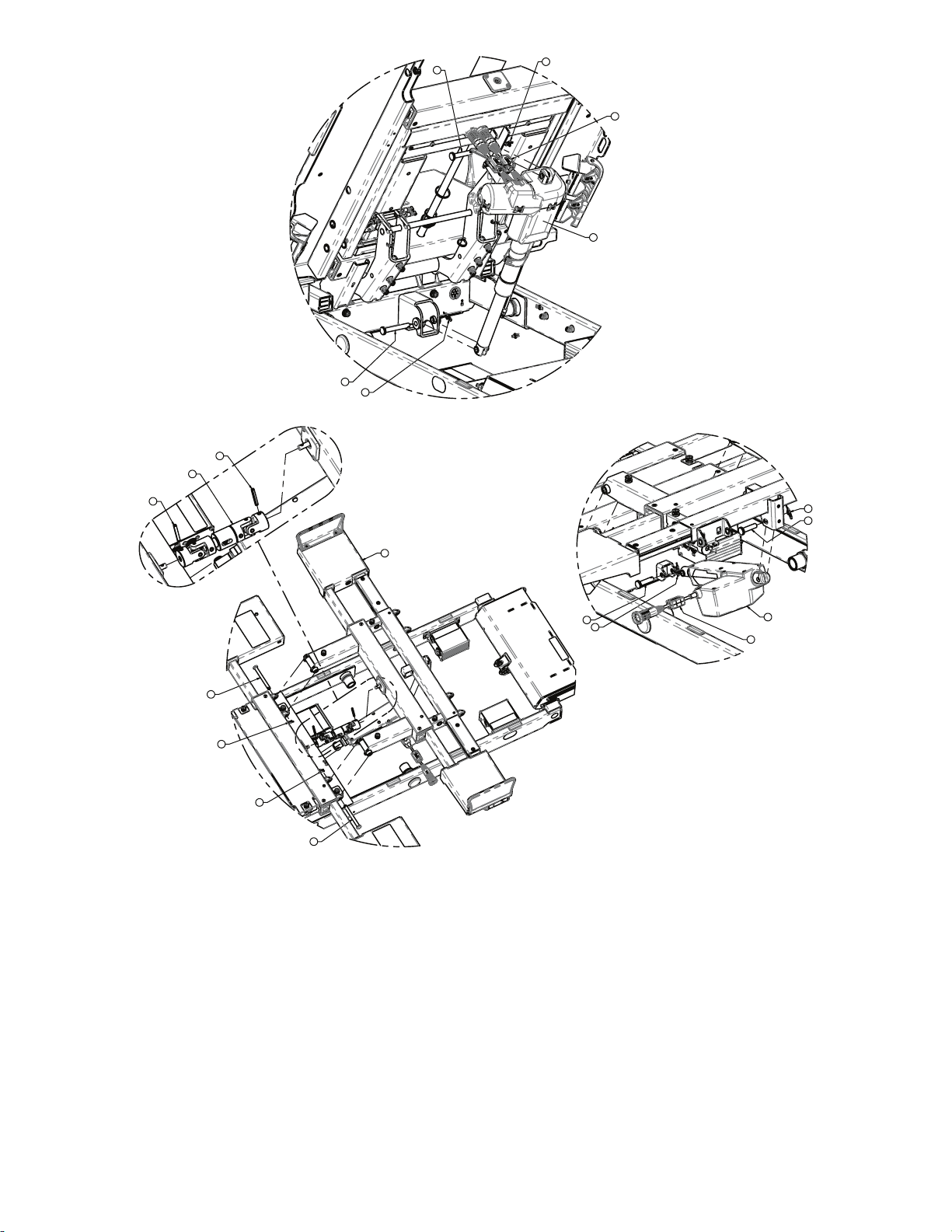

CCaabbllee rroouuttiinngg

5900-009-002 Rev A.0 19 EN

Page 24

MMaaiinntteennaannccee mmeennuu

The maintenance menu provides access to the following settings:

• Language

• Set clock

• Actuator maintenance

• Scale maintenance

• Angle maintenance

• Width maintenance

• Patient station

• Maintenance log

• Clear maintenance log

• Test modes

• Battery maintenance

To access the maintenance menu:

1. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

2. Highlight MMaaiinntteennaannccee and press EEnntteerr.

3. Use the up and down arrow buttons to highlight each number.

4. Press EEnntteerr to increase the number.

NNoottee -- The number will increase to 9 until it resets to 0.

5. The maintenance code is as follows: 2, 4, 6

6. Highlight PPrroocceeeedd and press EEnntteerr to access the maintenance menu.

LLaanngguuaaggee

To change the display language:

1. Enter the

2. Highlight LLaanngguuaaggee and press EEnntteerr.

3. Highlight the desired language and press EEnntteerr.

Maintenance menu

(page 20).

SSeett cclloocckk

To change the product clock:

1. Enter the

2. Highlight SSeett cclloocckk and press EEnntteerr.

3. In the clock setting menu you will see the following options:

• Year

• Month

• Day

• Hour

• Minute

4. Use the up and down arrow buttons to highlight each option and press EEnntteerr to set.

Maintenance menu

(page 20).

EN 20 5900-009-002 Rev A.0

Page 25

5. Highlight PPrreessss √√ ttoo sseett and press EEnntteerr to set the product clock.

AAccttuuaattoorr mmaaiinntteennaannccee

CCAAUUTTIIOONN -- Always make sure that the product is clear of obstacles before you use motion functions.

Actuator maintenance allows you to bypass the set limits of the product actuators for testing and troubleshooting.

To access actuator maintenance:

1. Enter the

2. Highlight AAccttuuaattoorr mmaaiinntt.. and press EEnntteerr.

3. In actuator maintenance you will see the following options:

• Both hilos up

• Both hilos down

• Hilo foot up

• Hilo foot down

• Hilo head up

• Hilo head down

• Foot up

• Foot down

• Head up

• Head down

• Knee up

• Knee down

4. Use the up and down arrow buttons to highlight a movement and press and hold EEnntteerr to move the actuator.

Maintenance menu

(page 20).

SSccaallee mmaaiinntteennaannccee

Scale maintenance provides access to the following:

• Gross weight

• Net weight

• Center of gravity

• Load cells foot end

• Load cells head end

• Enable NAWI Scale

• Calibrate scale

To access scale maintenance:

1. Enter the

2. Highlight SSccaallee mmaaiinntt.. and press EEnntteerr.

3. Use the up and down arrow buttons to highlight each number.

4. Press EEnntteerr to increase the number.

NNoottee -- The number will increase to 9 until it resets to 0.

5. The scale maintenance code is as follows: 4, 3, 2

Maintenance menu

(page 20).

5900-009-002 Rev A.0 21 EN

Page 26

6. Highlight PPrroocceeeedd and press EEnntteerr to access scale maintenance.

CCaalliibbrraattee ssccaallee

NNoottee -- Make sure that the product litter deck is flat and horizontal before you calibrate the scale.

TToooollss rreeqquuiirreedd::

• 91 kg (200 lb) calibrated weight

PPrroocceedduurree::

1. Enter the

2. Enter

3. Highlight CCaalliibbrraattee ssccaallee and press EEnntteerr.

4. Remove all weight from the product and press EEnntteerr.

NNoottee -- All weight includes the mattress and accessories.

5. Place the calibrated weight at the head left outer corner and press EEnntteerr.

NNoottee

• Do not touch the product during calibration.

• Make sure that the product is not against a wall during calibration.

6. Place the calibrated weight at the foot left outer corner and press EEnntteerr.

7. Place the calibrated weight at the foot right outer corner and press EEnntteerr.

8. Place the calibrated weight at the head right outer corner and press EEnntteerr.

9. The product screen displays CCoommpplleettee and sends you to the scale maintenance menu when calibration is complete.

Maintenance menu

Scale maintenance

(page 20).

(page 21).

AAnnggllee mmaaiinntteennaannccee

Angle maintenance provides access to the following:

• Foot hilo angle (counts)

• Head hilo angle (counts)

• Foot act position (counts)

• Head act position (counts)

• Knee act position (counts)

• Inclinometer

• Calibrate angles

1. Enter the

2. Highlight AAnnggllee mmaaiinntt.. and press EEnntteerr.

CCaalliibbrraattee aanngglleess

CCAAUUTTIIOONN

• Always calibrate the product angles when you replace the main control board or any actuator or product damage may

occur.

• Always make sure that the product is clear of obstacles before you use motion functions.

Maintenance menu

(page 20).

NNoottee -- Make sure that the product litter deck is flat and horizontal before you calibrate the angles.

Calibrate angles allows you to set the motion limits for the product actuators.

EN 22 5900-009-002 Rev A.0

Page 27

To calibrate the angles:

1. Enter the

2. Enter

3. Highlight CCaalliibbrraattee aanngglleess and press EEnntteerr.

4. Raise the product to high height and press EEnntteerr.

5. Lower the product to low height and press EEnntteerr.

6. Lower the product knee and foot actuators and press EEnntteerr.

7. The product screen displays CCoommpplleettee and sends you to the angle maintenance menu when calibration is complete.

Maintenance menu

Actuator maintenance

(page 20).

(page 21).

WWiiddtthh mmaaiinntteennaannccee

Width maintenance provides access to the following:

• Head State

• Mid State

• Foot State

• Head raw position

• Mid raw position

• Foot raw position

• Calibrate deck widths

• Trim Foot

• Trim Mid

• Trim Head

To access width maintenance:

1. Enter the

2. Highlight WWiiddtthh mmaaiinntt.. and press EEnntteerr.

Maintenance menu

(page 20).

CCaalliibbrraattee ddeecckk wwiiddtthhss

NNoottee -- Make sure that all siderails are in the full up position when you perform this procedure.

To calibrate the deck widths

1. Enter the

2. Enter

3. Highlight CCaalliibbrraattee ddeecckk wwiiddtthhss and press EEnntteerr.

4. Put all decks to the 36” position and press EEnntteerr.

5. Manipulate each siderail and press EEnntteerr.

6. Put all decks to the 42” position and press EEnntteerr.

7. Manipulate each siderail and press EEnntteerr.

8. Put all decks to the 48” position and press EEnntteerr.

9. Manipulate each siderail and press EEnntteerr.

10.The product screen displays CCoommpplleettee and sends you to the width maintenance menu when calibration is complete.

Maintenance menu

Width maintenance

(page 20).

(page 23).

5900-009-002 Rev A.0 23 EN

Page 28

PPaattiieenntt ssttaattiioonn

The patient station menu allows the user to set the product to patient station interface.

Patient station provides access to the following settings:

• Priority call on alarm: a priority call will occur at the nursing station on bed exit alarm

• Nurse call on alarm: a nurse call will occur at the nursing station on bed exit alarm

• Priority call on iBed alertL a priority call will occur at the nursing station on iBed alert

• Cord out relay closed: set the cord out relay

• Audio transfer relay closed: set the audio transfer relay

• Nurse call interlock relay close: set the nurse call interlock relay

• Select nurse call type: select normally open/closed nurse call

To access the patient station settings:

1. Enter the

2. Highlight PPaattiieenntt ssttaattiioonn and press EEnntteerr.

Maintenance menu

(page 20).

TTeesstt mmooddeess

The test mode menu provides access to the following settings:

• Lamp test: turns on all lamps, with either dim or bright backlight

• Siderail display: leaves the siderail angle display on continuously

To access test modes:

1. Enter the

2. Highlight TTeesstt mmooddeess and press EEnntteerr.

Maintenance menu

(page 20).

BBaatttteerryy mmaaiinntteennaannccee

Battery maintenance provides access to the following:

• Charge state

• PMB Bus V

• PMB IIN

• IBAT

• Battery voltage

To access battery maintenance:

1. Enter the

2. Highlight BBaatttteerryy MMaaiinntt.. and press EEnntteerr.

Maintenance menu

(page 20).

EN 24 5900-009-002 Rev A.0

Page 29

SSeerrvviiccee

PPrrootteeccttiinngg aaggaaiinnsstt eelleeccttrroossttaattiicc ddiisscchhaarrggee ((EESSDD))

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

NNoottee -- Always ship back circuit boards to Stryker in the same antistatic bags that the new boards were originally shipped in.

The electronic circuits in the product are completely protected from static electricity damage when factory assembled.

Always use adequate static protection when servicing the electronic systems of the product. All service personnel must use

static protection whenever they are touching wires.

Sample antistatic protection equipment includes:

• 1 antistatic wrist strap

• 1 grounding plug

• 1 test lead with a banana plug on one end and an alligator clip on the other end

Make sure that you follow the ESD manufacturer’s instructions for appropriate protection against static discharge.

BBaatttteerryy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 5/32” hex driver

• #2 Phillips screwdriver

• 3/8” nut driver

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Push down on the brake pedal to apply the brake.

6. Using a 5/32” hex driver, remove the two screws and flat washers that secure the motion interrupt pan to the litter

weldment. Remove the motion interrupt pan.

7. Using a #2 Phillips screwdriver, remove the two screws from the power supply mounting bracket closest to the center of

the bed.

8. Using a #2 Phillips screwdriver, remove the two screws from the power supply mounting bracket closest to the outside

of the bed.

9. Hinge the batteries down.

10.Unplug the two battery supply cables from the main control board.

11.Unplug the USB cable from the main control board.

12.Using a 3/8” nut driver, remove the nut that secures the ground cable to the battery mounting plate.

13.Lift up to remove the battery mounting plate assembly from the litter.

14.Reverse steps to reinstall.

15.Verify proper operation of the product before you return it to service.

5900-009-002 Rev A.0 25 EN

Page 30

CCaasstteerr rreeppllaacceemmeenntt

CCAAUUTTIIOONN

• Always perform this procedure in a secure location with the floor jack secure to the base frame before you remove the

caster to prevent the risk of injury.

• Do not put your hands or feet below the caster when you remove or attach the caster to prevent the risk of injury.

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Small flat head screwdriver

• 5 mm hex wrench

• Small floor jack

PPrroocceedduurree::

1. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

2. Highlight SShhuuttddoowwnn and press EEnntteerr.

3. Unplug the power cord from the wall outlet.

4. Using a small flat head screwdriver, remove and save the four base cover screw caps.

5. Using a #2 Phillips screwdriver, remove and save the four screws that secure the base cover to the base frame.

Remove and save the base cover.

NNoottee -- Set the brakes to the neutral position.

6. Using a small floor jack, raise the base frame high enough to remove the caster.

7. Using a 5 mm hex wrench, remove and save the caster locating screw. Remove and discard the caster.

8. Reverse steps to reinstall.

NNoottee -- The caster stem has a red and green half. Face the red half of the caster stem toward the foot end of the bed.

9. Verify proper operation of the product before you return it to service.

MMaaiinn ccoonnttrrooll bbooaarrdd rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 5/32” hex driver

• #2 Phillips screwdriver

• 3/8” nut driver

• ESD system

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Push down on the brake pedal to apply the brake.

6. Using a 5/32” hex driver, remove the two screws and flat washers that secure the motion interrupt pan to the litter

weldment. Remove the motion interrupt pan.

7. Using a #2 Phillips screwdriver, remove the two screws from the power supply mounting bracket closest to the center of

the bed.

EN 26 5900-009-002 Rev A.0

Page 31

8. Using a #2 Phillips screwdriver, remove the two screws from the power supply mounting bracket closest to the outside

of the bed.

9. Hinge the batteries down.

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

10.Unplug the two battery supply cables from the main control board.

11.Unplug the USB cable from the main control board.

12.Using a 3/8” nut driver, remove the nut that secures the ground cable to the battery mounting plate.

13.Lift up to remove the battery mounting plate assembly from the litter.

14.Unplug all cables from the main control board. Make note of how the cables are labeled and plugged in.

15.Using a #2 Phillips screwdriver, remove the two screws that secure the main control board assembly to the litter.

16.Grasp the main control board mounting bracket where you removed the two screws and pull down.

17.Reverse steps to reinstall.

18.Verify proper operation of the product before you return it to service.

AAVVBB bbooaarrdd rreeppllaacceemmeenntt

This procedure applies to both the head end and foot end AVB board.

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• ESD system

PPrroocceedduurree::

1. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

2. Highlight SShhuuttddoowwnn and press EEnntteerr.

3. Unplug the power cord from the wall outlet.

4. Push down on the brake pedal to apply the brake.

5. Using a #2 Phillips screwdriver, remove and save the three screws that secure the AVB board assembly to the litter

frame.

6. Remove the AVB board assembly from the litter frame.

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

7. Disconnect all cables from the AVB board assembly.

8. Using a #2 Phillips screwdriver, remove and save the two screws that secure the beeper to the AVB board assembly.

Remove and save the beeper.

9. Discard the AVB board assembly.

10.Reverse steps to reinstall.

11.Verify proper operation of the product before you return it to service.

5900-009-002 Rev A.0 27 EN

Page 32

FFoooottbbooaarrdd kkeeyyppaadd//ddiissppllaayy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Pick

• ESD system

PPrroocceedduurree::

1. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

2. Highlight SShhuuttddoowwnn and press EEnntteerr.

3. Unplug the power cord from the wall outlet.

4. Push down on the brake pedal to apply the brake.

5. Using a pick, remove and save the front label from the footboard.

6. Using a #2 Phillips screwdriver, remove the three screws that secure the back panel to the footboard.

7. Remove and save the back panel.

8. Using a #2 Phillips screwdriver, remove and save the six screws and six washers that secure the keypad/display to the

footboard.

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

9. Disconnect the keypad/display cable. Remove and discard the keypad display.

10.Reverse steps to reinstall.

11.Verify proper operation of the product before you return it to service.

FFoooottbbooaarrdd mmaaiinn ccaabbllee rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Pick

• ESD system

PPrroocceedduurree::

1. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

2. Highlight SShhuuttddoowwnn and press EEnntteerr.

3. Unplug the power cord from the wall outlet.

4. Push down on the brake pedal to apply the brake.

5. Using a pick, remove and save the front label from the footboard.

6. Using a #2 Phillips screwdriver, remove the three screws that secure the back panel to the footboard. Remove and save

the back panel.

7. Using a #2 Phillips screwdriver, remove and save the six screws and six washers that secure the keypad/display to the

footboard.

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

EN 28 5900-009-002 Rev A.0

Page 33

8. Disconnect the keypad/display cable. Remove and save the keypad display.

9. Remove the footboard from the product.

10.Using a #2 Phillips screwdriver, remove and save the two screws that secure the footboard main cable to the bottom of

the footboard.

11.Remove the footboard main cable from the footboard and discard.

12.Reverse steps to reinstall.

13.Verify proper operation of the product before you return it to service.

FFoowwlleerr aaccttuuaattoorr rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• Needle nose pliers

• Small flat screwdriver

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Push down on the brake pedal to apply the brake.

6. Raise both head end siderails to the up and locked position.

7. Pull the CPR release handle to lower the fowler down.

8. Using needle nose pliers, remove both rue ring retaining clips from the clevis pins that attach the actuator to the litter

weldment and fowler weldment.

9. While supporting the actuator with one hand, remove the head end clevis pin and then lower the actuator down.

NNoottee -- Apply a thin coat of Syn-Tech grease to the clevis pin when you reinstall.

10.Using a small flat screwdriver, unlock the gray CPR pull retainer from the red CPR pull to loosen the CPR pull retainer.

11.Using a small flat screwdriver, remove the gray CPR pull retainer from the red CPR pull. A white spacer between the

CPR pull and the CPR cable retaining bracket will fall out. Save the white spacer.

12.Remove the CPR cables from the CPR cable retaining bracket.

13.Using a small flat screwdriver, release the retaining ring from the power and sensor cable quick connects and

disconnect the cables from the actuator. When re-connecting the cables, fully seat and lock the cable quick connector

retaining ring.

14.While supporting the actuator with one hand, remove the foot end clevis pin and then lower the actuator down.

NNoottee -- Apply a thin coat of Syn-Tech grease to the clevis pin when you reinstall.

15.Reverse steps to reinstall.

16.Verify proper operation of the product before you return it to service.

GGaattcchh aaccttuuaattoorr rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• Needle nose pliers

• Small flat screwdriver

5900-009-002 Rev A.0 29 EN

Page 34

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Push down on the brake pedal to apply the brake.

6. Raise both foot end siderails to the up and locked position.

7. Using a small flat screwdriver, release the power/sensor cable quick connect and disconnect the cable from the

actuator. When re-connecting the cables, fully seat and lock the cable quick connector retaining ring.

8. Using needle nose pliers, remove both rue ring retaining clips from the clevis pins that attach the actuator to the litter

weldment and fowler weldment.

9. While supporting the actuator with one hand, remove the head end clevis pin and foot end clevis pin and then lower the

actuator down.

NNoottee -- Apply a thin coat of Syn-Tech grease to the clevis pin when you reinstall.

10.Reverse steps to reinstall.

11.Verify proper operation of the product before you return it to service.

TThhiigghh aaccttuuaattoorr rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• Needle nose pliers

• Small flat screwdriver

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Push down on the brake pedal to apply the brake.

6. Raise both foot end siderails to the up and locked position.

7. Using needle nose pliers, remove the rue ring retaining clip from the head end clevis pin that attaches the actuator to the

litter weldment.

8. Using needle nose pliers, remove the circle ring retaining ring from the foot end clevis pin that attaches the actuator to

the thigh weldment.

9. While supporting the actuator with one hand, remove the head end clevis pin and the foot end clevis pin and then lower

the actuator down.

NNoottee -- Apply a thin coat of Syn-Tech grease to the clevis pin when you reinstall.

10.Using a small flat screwdriver, release the power/sensor cable quick connect and disconnect the cable from the

actuator. When re-connecting the cables, fully seat and lock the cable quick connector retaining ring.

11.Reverse steps to reinstall.

NNoottee -- Route the power/sensor cable over the top of the actuator when you reinstall the actuator.

12.Verify proper operation of the product before you return it to service.

EN 30 5900-009-002 Rev A.0

Page 35

LLiifftt aaccttuuaattoorr rreeppllaacceemmeenntt ((hheeaadd//ffoooott))

TToooollss rreeqquuiirreedd::

• Needle nose pliers

• (2) 3/8” x 1” grade 8 bolt and nut

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Run the actuator up or down to remove the litter load from the actuator.

2. Raise both siderails to the up and locked position at either the head end or foot end.

3. If the activator still runs:

a. Raise the product to the highest height position to expose the base weldment support holds on both sides.

CCAAUUTTIIOONN -- Always leave the bolts loose in the support holes, so the bolt head is out far enough to stop the lift

mechanism slide block.

b. Insert two 3/8” bolts through the support holes in the base weldment from the inside out and then thread the nuts

onto the bolts to keep the bolts from falling out.

WWAARRNNIINNGG -- Do not lower the litter too low or the litter may not be supported.

c. Lower the litter until the lift mechanism slides touch the 3/8” bolt heads. You should be able to wiggle the actuator by

hand after you remove the litter load from the litter surface. If not, lower the litter more until the actuator is loose.

4. If the activator does not run:

a. Put the bed into the Maintenance mode (limits bypassed) and then go to the Actuator Maintenance Menu. Select the

actuator that needs to be moved and see if it will run.

b. See step 2a.

5. If the actuator will not run with the limits bypassed in step 4a, use a hoist, with a strap around and under the litter, to

remove the litter load from the actuator and support the litter surface on the end that has failed.

6. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

7. Highlight SShhuuttddoowwnn and press EEnntteerr.

8. Unplug the power cord from the wall outlet.

9. Using the cable quick connector release, unlock the cable from the motor control box so that it is loose.

10.Using needle nose pliers, remove both rue ring retaining clips from the clevis pins that attach the actuator to the litter

weldment and lift weldment.

11.While supporting the actuator with one hand, remove the head end clevis pin and foot end clevis pin and then lower the

actuator down.

NNoottee -- Apply a thin coat of Syn-Tech grease to the clevis pin when you reinstall.

12.Reverse steps to reinstall.

13.Verify proper operation of the product before you return it to service.

LLooaadd cceellll bbooaarrdd rreeppllaacceemmeenntt,, hheeaadd eenndd aanndd ffoooott eenndd

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Small flat head screwdriver

• ESD system

5900-009-002 Rev A.0 31 EN

Page 36

PPrroocceedduurree::

1. Push down on the brake pedal to apply the brake.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Using a small flat head screwdriver, remove and save the four base cover screw caps.

6. Using a #2 Phillips screwdriver, remove and save the four screws that secure the base cover to the base frame.

Remove and save the base cover.

7. Using a #2 Phillips screwdriver, remove and save the two screws that secure the load cell board assembly to the base

weldment. Remove the load cell board assembly.

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

8. Disconnect the communication cable and the two load cells from the load cell board assembly. Discard the load cell

board assembly.

9. Reverse steps to reinstall.

10.Recalibrate the scale (

11.Verify proper operation of the product before you return it to service.

Calibrate scale

(page 22)).

LLooaadd cceellll aasssseemmbbllyy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Small flat head screwdriver

• Needle nose pliers

• Ratchet

• 1/2” socket

• Small floor jack

PPrroocceedduurree::

1. Push down the brake pedal to apply the brake.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.

4. Unplug the power cord from the wall outlet.

5. Using a small flat head screwdriver, remove and save the four base cover screw caps.

6. Using a #2 Phillips screwdriver, remove and save the four screws that secure the base cover to the base frame

weldment. Remove and save the base cover.

7. Using a small floor jack, near the load cell that you need to replace, push downward on the jack’s lever to raise the lift

support tube upward.

8. Using needle nose pliers. remove and save the rue clip and pin from the base frame weldment.

9. Using a ratchet and 1/2” socket, remove and save the two bolts that secure the load cell assembly to the base frame

weldment..

NNoottee -- When you reinstall the load cell assembly, orient the load cell assembly up, so you can secure the bolts by hand

to start.

10.Using needle nose pliers, remove the load cell assembly from the base frame weldment.

EN 32 5900-009-002 Rev A.0

Page 37

11.Using a #2 Phillips screwdriver, remove and save the two screws that secure the inspection cover to the base frame

weldment. Remove and save the inspection cover.

12.Using a #2 Phillips screwdriver, remove and save the two screws that secure the board assembly to the base frame

weldment. Remove and save the board assembly.

13.Disconnect the load cell assembly and remove the cable from the base frame weldment. Discard the load cell assembly.

NNoottee -- Note the routing of the load cell cable for reinstallation.

14.Reverse steps to reinstall.

15.Recalibrate the scale (

16.Verify proper operation of the product before you return it to service.

Calibrate scale

(page 22)).

SSiiddeerraaiill rreeppllaacceemmeenntt,, hheeaadd eenndd

TToooollss rreeqquuiirreedd::

• T15 Torx driver

• T27 Torx driver

• Needle nose pliers

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. Raise the Fowler to the full upright position.

3. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

4. Highlight SShhuuttddoowwnn and press EEnntteerr.

5. Unplug the power cord from the wall outlet.

6. Push down on the brake pedal to apply the brake.

7. Expand all litter decks to the 48 in. position.

8. Raise the siderail to the up and locked position.

9. Using a T15 Torx driver, remove the two screws that secure the junction board assembly to the siderail carrier. Remove

the junction board assembly.

10.Unplug the two siderail cables from the junction board assembly.

11.Using a T27 Torx driver, remove the screw that secures the guide rod to the litter.

12.Push the siderail release button to lower the siderail to the lowest stowed position.

13.Using needle nose pliers, from under the litter surface, slide each glide rod out.

NNoottee -- Save the two rubber washers on each glide rod, one on both sides of the siderail carrier, to reinstall. Use SynTech grease to lube the glide rod, if required.

14.While supporting the rail with one hand, remove both glide rods and remove the siderail assembly.

15.Reverse steps to reinstall.

16.Verify proper operation of the product before you return it to service.

SSiiddeerraaiill rreeppllaacceemmeenntt,, ffoooott eenndd

TToooollss rreeqquuiirreedd::

• T15 Torx driver

• T27 Torx driver

5900-009-002 Rev A.0 33 EN

Page 38

• Needle nose pliers

• Syn-Tech grease (3000-200-719)

PPrroocceedduurree::

1. Raise the product to the highest height position.

2. On the footboard control panel, press EEnntteerr to access the SSeettttiinnggss menu.

3. Highlight SShhuuttddoowwnn and press EEnntteerr.