Page 1

InTouch® Critical Care Bed

REF

FL27 (2131/2141)

Version 4.0 with Wi-Fi /

Isolibrium™ (2971) support surface

Maintenance Manual

2018/03 H.0 2141-209-002 REV H www.stryker.com

Page 2

Page 3

General warning

~

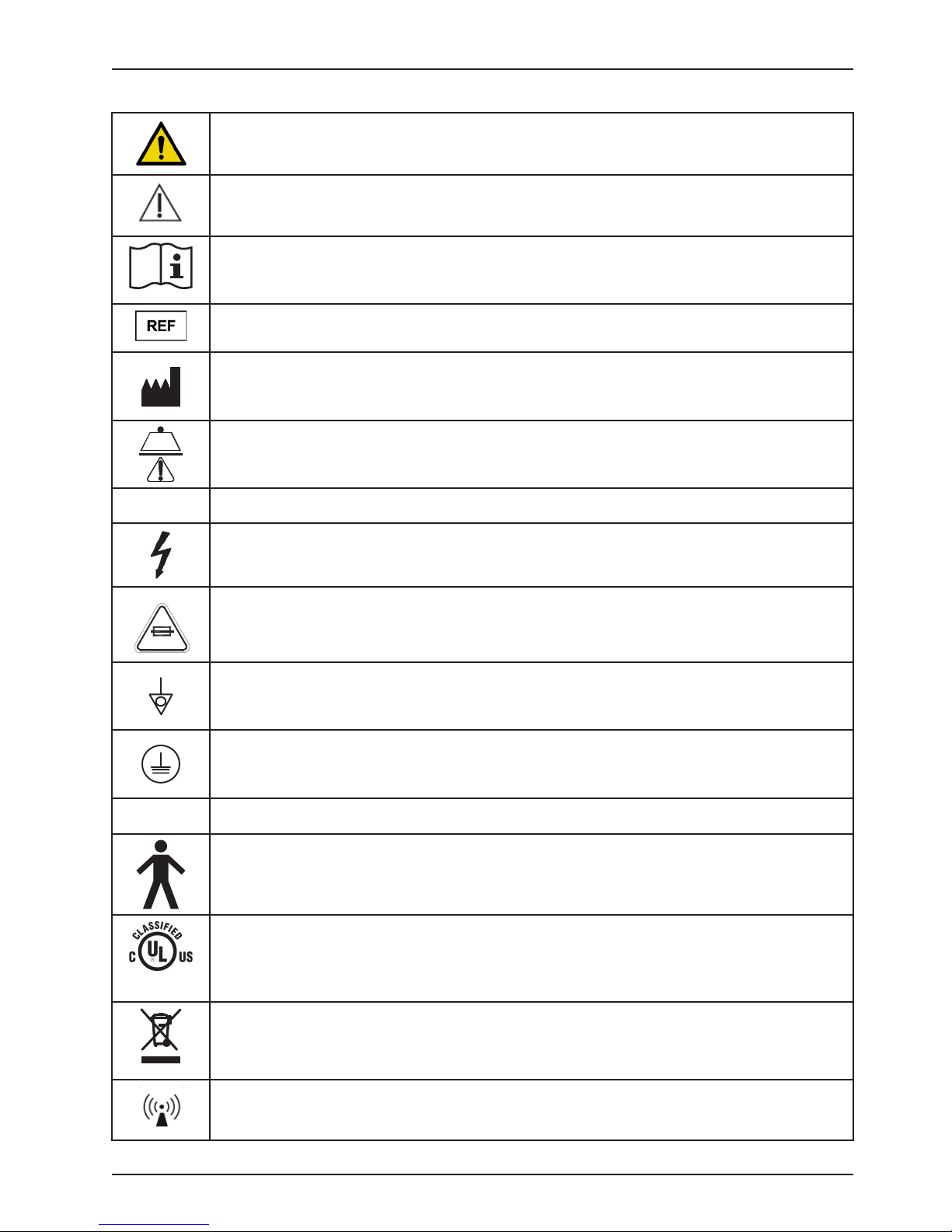

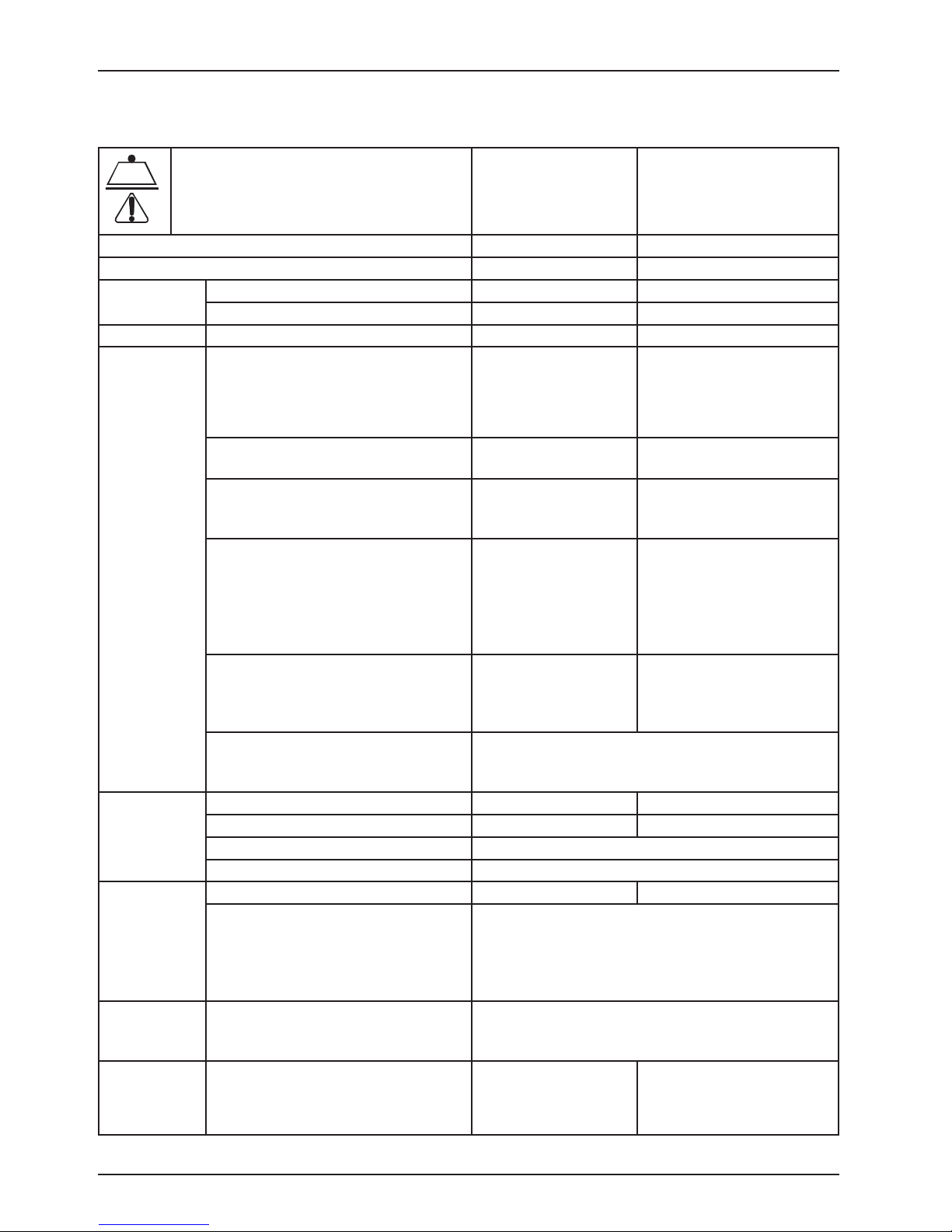

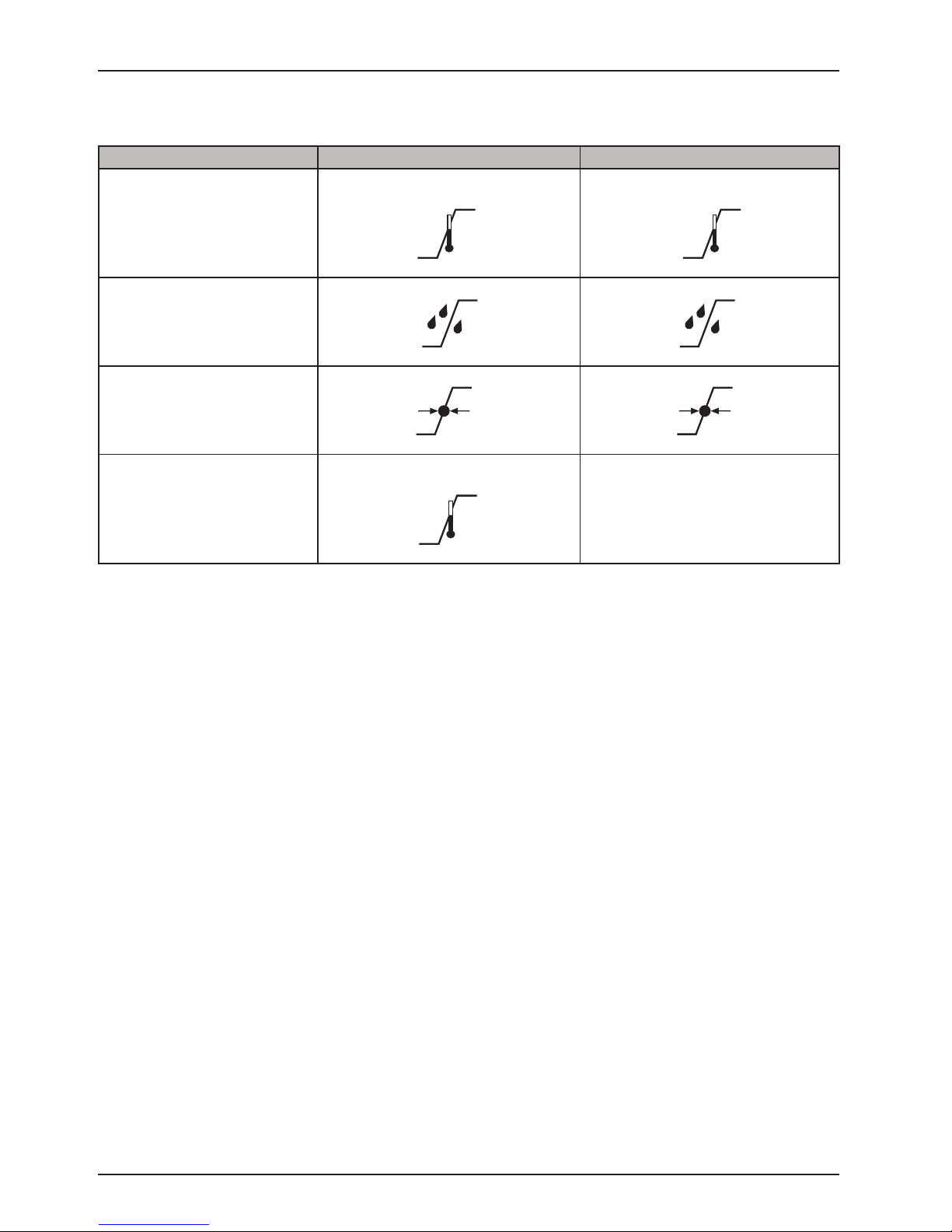

1.6 SYMBOLS

Caution

Consult instructions for use

Catalogue number

Manufacturer

Safe Working Load Symbol

Symbols

10A 250V

IPX4

87VL

Alternating Current

Dangerous Voltage Symbol

Fuse Rating for Beds with the 100V~ or 120V~ Electric System

Potential Equalization

Protective Earth Terminal

Protection from liquid splash

Type B Applied Part

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock, Fire,

and Mechanical Hazards Only in Accordance with ANSI/AAMI ES60601-1: 2005 and CAN/CSA-C22.2

No. 60601-1:08.

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic Equipment,

this symbol indicates that the product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local distributor for return and/or collection systems

available in your country.

www.stryker.com 2141-209-0 02 RE V H 3

Non-ionizing radiation; i.e. RF transmitter (Wi-Fi)

Return To Table of Contents

Page 4

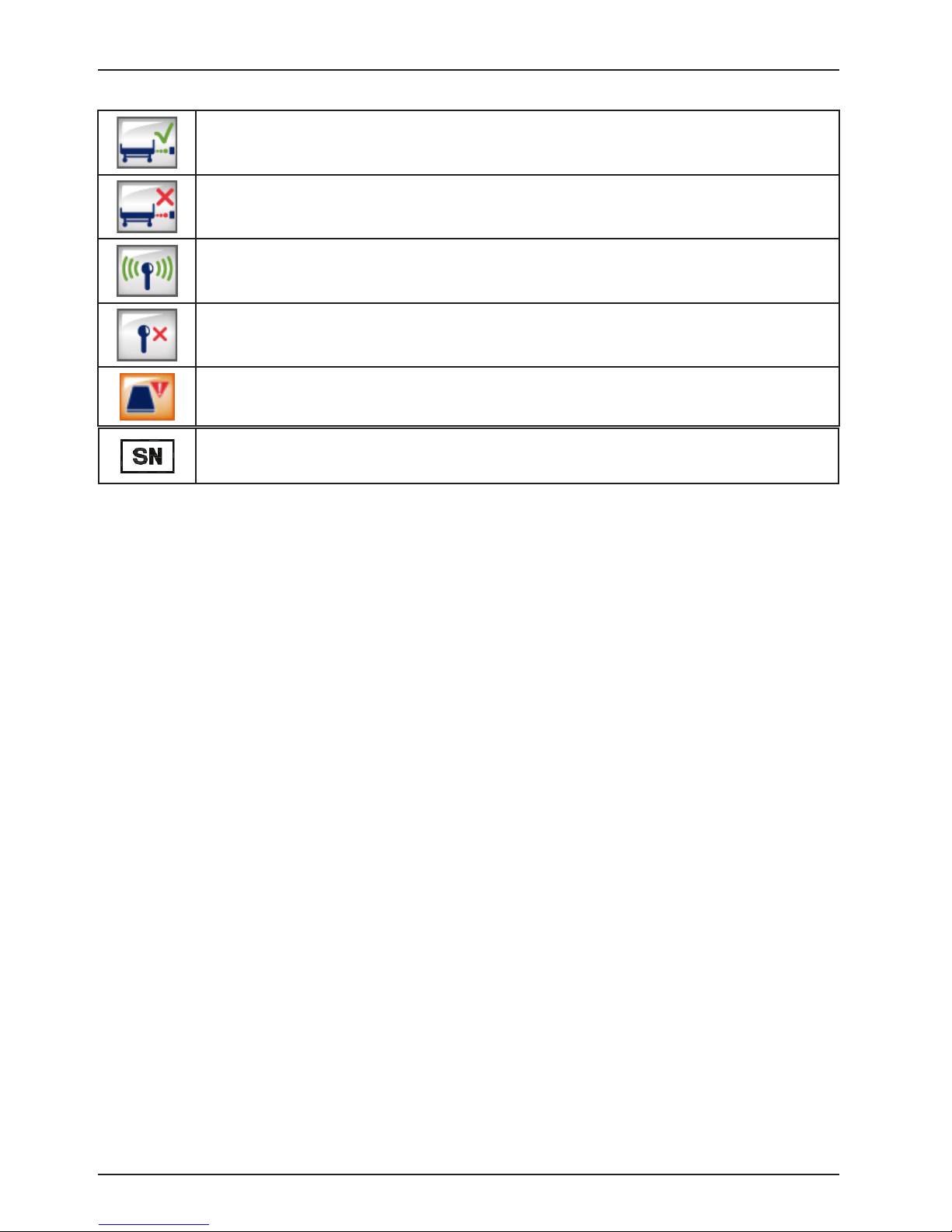

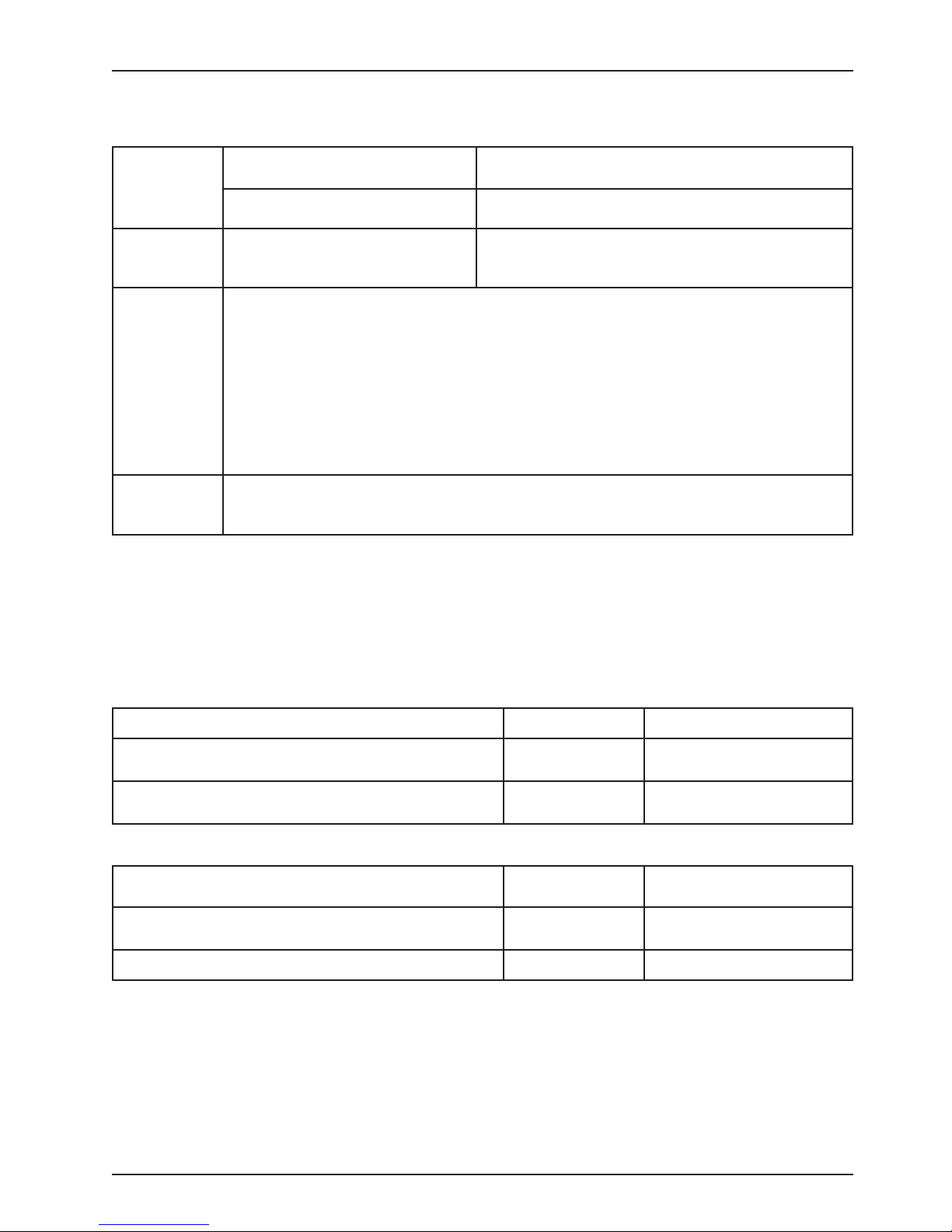

iBed Locator is connected

iBed Locator is not connected

Wireless Network is connected

Wireless Network is not connected

Support surface call maintenance

Serial number

Symbols

Return To Table of Contents

4 2141-2 09 -002 REV H www.stryker.com

Page 5

Table of Contents

Symbols ................................................................................3

Warning / Caution / Note Definition ............................................................9

Introduction ............................................................................10

Product Description ...................................................................10

Intended Use: InTouch Critical Care Bed ....................................................10

Intended Use – iBed® Wireless with iBed Awareness ..........................................11

Expected service life ..................................................................11

Contraindications.....................................................................11

Specifications .......................................................................12

Environmental Conditions...............................................................14

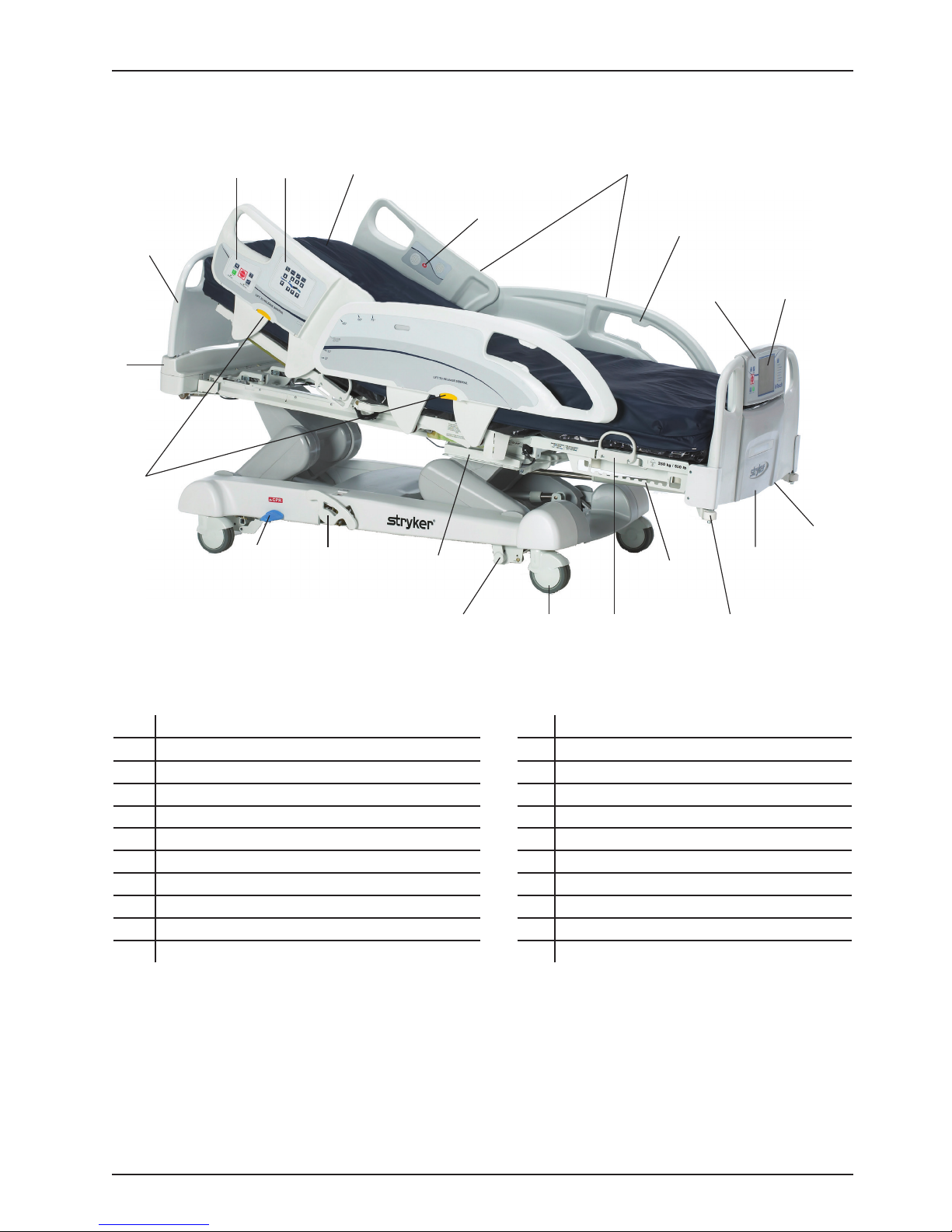

Product Illustration....................................................................15

Contact Information ...................................................................16

Serial Number Location ................................................................16

Specification Label Location ............................................................16

Summary of Safety Precautions .............................................................17

Static Discharge Precautions ...............................................................21

Protecting against Electrostatic Discharge (ESD) .............................................21

Setup .................................................................................22

Installation .............................................................................23

Installing the XPRT Therapy support surface (optional) .........................................23

Installing the PositionPRO support surface (optional) ..........................................23

Installing the Isolibrium support surface (optional).............................................23

Installing iBed Wireless (120V North American only) (optional) ...................................23

Maintenance Menu Guide ..................................................................24

InTouch Configuration Screen............................................................25

A. Bed Calibration .................................................................25

B. Full Diagnostic .................................................................36

C. Touch Screen Calibration .........................................................37

D. Optional Wi-Fi Configuration .......................................................38

E. Bed Options Configuration.........................................................39

F. Serial Number Configuration .......................................................40

Accessing the Isolibrium diagnostic menu...................................................41

Reviewing active Isolibrium errors .........................................................42

Reviewing and Clearing Isolibrium Error History...............................................42

Viewing Advanced Signal Values for Isolibrium ...............................................43

Running a Diagnostic Test for Isolibrium ....................................................44

Cleaning...............................................................................46

Cleaning a support surface .............................................................46

Preventive Maintenance ...................................................................47

Quick Reference Replacement Parts..........................................................49

Troubleshooting .........................................................................51

Bed Troubleshooting ..................................................................51

Scale Troubleshooting .................................................................57

Error Codes ............................................................................58

Error Handling .......................................................................58

Error Messages ......................................................................58

www.stryker.com 2141-209-0 02 RE V H 5

Page 6

Table of Contents

CPU/Power Board - QDF75-0440 ............................................................63

Fuse Specification ....................................................................64

Bed Electrical Diagram ....................................................................65

Service Information.......................................................................84

Bed lift Actuator (Head) Removal and Replacement - (Base).....................................84

Bed lift Actuator (Foot) Removal and Replacement - (Base) .....................................85

Fowler Actuator Removal and Replacement - (Litter) ..........................................86

Gatch Actuator Removal and Replacement - (Litter) ...........................................87

Foot Actuator Removal and Replacement - (Litter) ............................................88

Zoom® Drive Actuator Removal and Replacement (2141 Model Only) - (Base) .......................89

CPU / Power Board Removal and Replacement - (Litter)........................................90

Load Cell (Head End) Removal and Replacement - (Litter)......................................91

Load Cell (Foot End) Removal and Replacement - (Litter) ......................................92

Display Removal and Replacement - (Footboard) .............................................93

Brake Control Board Removal and Replacement - (Footboard) ...................................94

Function Selection/LED Board Removal and Replacement - (Footboard) ...........................95

Touch Screen Removal and Replacement - (Footboard) ........................................96

Battery Removal and Replacement - (Footboard) .............................................97

Brake / Neutral / Drive Potentiometer Removal and Replacement - QDF27-2024 ......................98

Battery Removal and Replacement - (Litter) .................................................99

Fowler Angle Sensor Removal and Replacement - (Litter) .....................................10 0

Gatch Angle Sensor Removal and Replacement - (Litter) ......................................101

Foot Angle Sensor Removal and Replacement - (Litter) .......................................10 2

Base Angle Sensor Removal and Replacement - (Base) .......................................103

Trend Angle Sensor Removal and Replacement - (Litter) ......................................104

Headwall Communication Board Removal and Replacement - (Litter) .............................105

IR Module Removal and Replacement - (Litter) (Optional) ......................................106

Wi-Fi Board Removal and Replacement - (Footboard) (Optional) .................................107

Base Assembly, Hood....................................................................109

Base Assembly, Brake ...................................................................111

Base Assembly, Caster Lock (Model 2131 Only) ................................................114

Base Assembly, Caster Non-Lock (Model 2141 Only).............................................1 15

Angle Sensor Assembly ..................................................................116

Base Assembly, Electrical ................................................................. 1 17

Base Assembly, Zoom® ..................................................................12 3

Base Assembly, Zoom® Drive (Model 2141 Only) ................................................12 5

Bed Labeling ..........................................................................12 7

Lift Assembly ..........................................................................131

Spring Assembly........................................................................13 5

Litter Assembly......................................................................... 13 6

Litter Assembly, Interior Frame .............................................................140

Litter Assembly with Serial Port.............................................................14 3

Litter Assembly, Upper Frame .............................................................14 4

Litter Assembly, Foot End .................................................................146

6 2141-2 09 -002 REV H www.stryker.com

Page 7

Table of Contents

Assembly Drawings (Continued)

Litter Assembly, Standard Cabling...........................................................150

Litter Assembly, Electrical................................................................. 15 1

120V Electric System ....................................................................157

Coiled Power Cord ......................................................................15 8

Litter Assembly, Foot End, with Mattress Connector..............................................15 9

Standard Outlet ........................................................................160

Litter Assembly, Optional Dual 120V Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

CPR Assembly, Mechanical ...............................................................163

Handle Assembly (Model 2131 Only) .........................................................168

Zoom® Handle Assembly (Model 2141 Only) ...................................................169

Zoom® Assembly........................................................................ 171

Optional No Head End Control Panel......................................................... 17 2

Optional Head End Control Panel Assembly ................................................... 17 3

Siderail Mounting Assembly, Head End ....................................................... 17 5

Standard Siderail Assembly, Head End, Right ..................................................17 6

Standard Siderail Assembly, Head End, Left ...................................................18 0

Standard Siderail Assembly, Labeling ........................................................18 4

Optional Siderail Assembly, Head End, with Speaker/iAudio ........................................18 5

Optional Siderail Assembly, Head End, with Speaker/with NC/with iAudio ..............................18 6

Optional Siderail Assembly, Head End, with Speaker/iAudio/IR ......................................18 8

Optional Siderail Assembly, Head End, with Speaker/with NC/with iAudio/with iBed® Wireless...............18 9

Siderail Mounting Assembly, Foot End........................................................193

Standard Siderail Assembly, Foot End, Right ...................................................194

Standard Siderail Assembly, Foot End, Left ....................................................197

Standard Siderail Assembly without iBed......................................................200

Optional Siderail Assembly with iBed ........................................................201

Headboard and Footboard Assembly .........................................................202

Standard Footboard Assembly .............................................................203

Footboard Assembly without iBed ...........................................................205

Footboard Assembly with iBed .............................................................208

Footboard Assembly with iBed and Wi-Fi......................................................211

Bed Extender - FA64234-XXX .............................................................. 214

Bed Extender Pad with Position Pro Mattress - DM64196-XXX ...................................... 2 15

Bed Extender Pad with XPRT™ Mattress - DM64197-XXX .........................................215

Line Management Clip - FA64210-XXX .......................................................216

IV Pole Assembly, Permanent - FA64221-XXX/FA64238-XXX ....................................... 217

IV Pole Ass’y, Dual Head End, Permanent - FA64202-XXX .........................................218

Monitor Tray Assembly - FA64214-XXX .......................................................220

Upright Oxygen Bottle Holder Assembly - FA64187-XXX...........................................221

Right-Fit Oxygen Bottle Holder Assembly - FA64203 .............................................222

Pendant Assembly with Motion Control - FA64228-XXX ..........................................223

Pendant Assembly with Motion Control/NC - FA64226 ...........................................224

Pendant Assembly with Motion Control/Smart TV - FA64227.......................................225

Pendant Assembly with Motion Control/NC/Smart TV - FA64225....................................226

www.stryker.com 2141-209-0 02 RE V H 7

Page 8

Table of Contents

Pendant Clip Assembly - FA64186-XXX ......................................................226

Roller Bumpers.........................................................................227

Traction Sleeve Assembly, 4 in. x 1/2 in. - FA64215-XXX ..........................................228

Traction Sleeve Assembly, 4 in. x 3/4 in. - FA64216-XXX ..........................................229

Traction Sleeve Assembly, 8 in. x 1/2 in. - FA64217-XXX ..........................................230

Traction Sleeve Assembly, 8 in. x 3/4 in. - FA64218-XXX ..........................................231

Traction Sleeve Assembly, 6-1/2 in. x 3/4 in. - FA64219-XXX .......................................232

Wall Saver Cable Assembly - FA64208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

X-ray Cassette Holder Assembly - FA64205-XXX................................................234

Tube Support ..........................................................................236

Recycling Passports .....................................................................237

Warranty .............................................................................249

Limited Warranty ....................................................................249

Warranty exclusion and damage limitations.................................................249

To Obtain Parts and Service ...........................................................249

Return Authorization..................................................................249

Damaged Merchandise ...............................................................249

International Warranty Clause...........................................................249

8 2141-2 09 -002 REV H www.stryker.com

Page 9

Warning / Caution / Note Definition

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation, which if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation, which if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note

This provides special information to make maintenance easier or important instructions clearer.

www.stryker.com 2141-209-0 02 RE V H 9

Return To Table of Contents

Page 10

Introduction

This manual assists you with the operation or maintenance of the Stryker Model FL27 (2131/2141) InTouch® Critical

Care bed. Read this manual thoroughly before operating or maintaining this product. Set methods and procedures to

educate and train your staff on the safe operation or maintenance of this product.

WARNING

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described

in this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

Notes

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current

product information available at the time of printing. There may be minor discrepancies between your product and

this manual. If you have any questions, contact Stryker Customer Service or Technical Support at 1–800–327-0770.

PRODUCT DESCRIPTION

InTouch is an AC-powered, adjustable hospital bed designed to position human patients for procedures, therapy, and

recovery in a healthcare environment, and transport patients between bays and procedural rooms. InTo u c h measures

and displays patient weight. The scale output is not intended to be used to determine diagnosis or treatment. The nurse

call allows patients to alert an operator when the patient requires assistance. There is a 30-degree head of bed (HOB)

button that puts the patient at a 30-degree angle that is calculated relative to the base to assist in ventilator-associated

pneumonia (VAP) prevention. When the Chaperone bed exit system is active, it monitors a chosen zone, and alerts the

operator of a deliberate or non-deliberate bed exit. The bed has 39 prerecorded clinical phrases in 24 languages and

a sound feature that offers various environmental and musical selections.

INTENDED USE: INTOUCH CRITICAL CARE BED

InTouch is intended for use by patients in an acute care setting. The safe working load (the sum of the patient, the

mattress, and accessory weight) for InTouch is 550 lb (249 kg).

InTouch is intended to support a human patient. The frame can come in contact with human skin, but a patient should

never be on the frame without a support surface in use.

InTouch is intended for use in acute care. These settings may include critical care, step down, progressive care, med/

surg, sub-acute care, and post anesthesia care unit (PACU), or other locations, as prescribed. Intended operators are

healthcare professionals (nurses, nurse aids, doctors) that can use all bed operations (such as bed motion functions,

nurse call, siderail communications, bed exit, therapy options), patient and bystander that can use bed motion functions,

nurse call and siderail communications, and trained professionals for installation, service, and calibration.

The product is intended for use in a healthcare environment, including hospitals, surgery centers, long term acute care

centers, and rehabilitation centers.

The product is compatible with 35 in. x 84 in. support surfaces, the facility nurse call system, standard med/surg

equipment, and the facility infrastructure. InTo u c h is intended for use with a 6 in. to 8.5 in. support surface. You may

use a support surface or overlay greater than 6 in. that offers therapeutic value with added patient supervision.

The Chaperone bed exit system is intended only to aid in the detection of a patient exiting the unit. It is not intended

to replace patient monitoring protocol.

Return To Table of Contents

10 2141-209-0 02 RE V H www.stryker.com

Page 11

Introduction

INTENDED USE – iBED® WIRELESS WITH iBED AWARENESS

The intended use for the iBed® Wireless (with iBed® Awareness) is to assist clinical staff to monitor bed parameters

on specific Stryker beds. The desired bed parameters will be set by clinicians at the bedside. The iBed® Wireless

software is intended to be used only with specifically enabled Stryker beds that have been verified and validated with

the iBed® Wireless software, and is not intended to provide bed status information for non-Stryker beds. The iBed®

Wireless software is not intended to communicate any patient status information, nor to permanently store any type

of data. The iBed® Wireless with iBed® Awareness System is not intended to provide automated treatment decisions

or as a substitute for professional healthcare judgment. The iBed® Wireless with iBed® Awareness System is not a

replacement or substitute for vital signs monitoring or alert equipment. All patient medical diagnosis and treatment are

to be performed under direct supervision and oversight of an appropriate health care professional.

EXPECTED SERVICE LIFE

InTouch has a 10 year expected service life under normal use conditions and with appropriate periodic maintenance.

CONTRAINDICATIONS

InTouch is not intended to:

• be used without a support surface

• use the scale output to determine diagnosis or treatment

• be used with an oxygen tent

• support more than one individual at a time

• be used with patients that are 35 in. or less

• be used with patients that weigh 50 lb or less

• be used on patient less than two years old

• be used in a home healthcare environment

• be used in the presence of flammable anesthetics

www.stryker.com 2141-209-0 02 RE V H 11

Return To Table of Contents

Page 12

SPECIFICATIONS

Safe Working Load

Introduction

Note: Safe Working Load indicates the

sum of the patient, mattress and accessory

weight.

Bed Weight 750 lbs 340.2 kg

Overall Bed Length 90 in. 228,6 cm

Overall Bed

Width

Base Underbed Clearance 5 in. 12,7 cm

Litter Patient Surface

Bed Lift

System

Scale System Capacity 550 lbs 249 kg

CPR System Speed to level bed from any position

Zoom®

motorized

drive (Model

2141) (option)

Siderails Up 42 in. 106,7 cm

Siderails Down 40 in. 102,9 cm

• Width

• Length

• Length (with Optional Bed

Extender)

Seat Section

• Depth

Foot Section

• Length

• Angle

Fowler Section

• Length

• Width

• Angle

Gatch Section

• Length

• Width

• Angle

Cardiac Chair

• Standard Cardiac Chair Position

• Enhanced Cardiac Chair Position

Height (high) to top of litter 33 in. 83,8 cm

Height (low) to top of litter 16 in. 40,6 cm

Trendelenburg/Reverse Trendelenburg 12° (± 2°)

Bed Lift Time 35 seconds maximum from lowest to highest position

Accuracy:

• For weight from 100 lb to 550 lb

• For weight from 100 lb to 550 lb

• For weight under 100 lb

• For weight under 100 lb

• Fowler

• Foot and Seat

Speed

• Forward

• Backwards

550 lbs 249 kg

35 in.

84 in.

90 in.

18.5 in. 47 cm

29 in.

0° to 50° (± 5°)

36 in.

34 in. to 35 in.

0° to 70°

(0°-40° and 50°-70° ± 3°)

(40°-50° ± 5°)

18 in.

34 in. to 35 in.

0° to 15° (± 3°)

Head: 65°, Seat: 17°, Foot: 30°, Trend: 3°

Head: 70°, Seat: 19°, Foot: 47°, Trend: 3°

± 2% when in Trendelenburg or Reverse Trendelenburg

± 2% when Flat

± 2 lb when in Trendelenburg or Reverse Trendelenburg

± 2 lb when Flat

15 seconds

60 seconds

2.98 mph

1.79 mph

88,9 cm

213,4 cm

228,6 cm

73,7 cm

0° to 50° (± 5°)

91,4 cm

86,4 cm - 88,9 cm

0° to 70°

(0°-40° and 50°-70° ± 3°)

(40°-50° ± 5°)

45,7 cm

86,4 cm - 88,9 cm

0° to 15° (± 3°)

4.8 km/h

2.88 km/h

Return To Table of Contents

12 2141-209 - 002 REV H www.stryker.com

Page 13

SPECIFICATIONS (CONTINUED)

Introduction

Maximum

Current

Consumption

Electrical

Requirements

iBed® Wireless

radio (optional)

Battery

Note: For Isolibrium specifications, see the Isolibrium operations/maintenance manual.

Without Optional Auxiliary Outlet

(120VAC O n ly)

With Optional Auxiliary Outlet(s)

(120VAC O n ly)

All electrical requirements meet CSA

C22.2 No. 601.1, UL 60601-1 and IEC

60601-1.60601-2-38 specifications.

802.11 b/g, 2.4 GHz

• Minimum Operational Signal Strength: -65 dB

• Supported Security Protocols:

WEP

WPA -PSK (TK I P)

WPA 2-PSK (CC M P/A ES)

WPA2-Enterprise (Only with PEAP-MS-CHAPv2)

802.1x

• PEAP-MS-CHAPv2 (Without certificate)

• Supports IPv4 and DHCPv4

12 V, 17.6 Ahr, Sealed Lead-Acid Battery (Part Number QDF9188)

3.0 V 220mAh Lithium Battery, Size 20mm - Varta Int. CR2032

Coin Cell PC Battery Holder, Size 20mm - MDP Int. BA2032

4.0 Amps

9.8 Amps

120 ± 10% Vac, 50/60Hz - Two 250V, 10A Fuses

120V~, 50-60Hz, 4.0A (9.8A with 120V Optional Auxiliary

Outlet) - Two 250V, 10A Fuses

Recommended Support Surface Size 35” x 84” x 6” 88,9 cm x 213,4 cm x 15,2 cm

• With Bed Extender DM64196

(PositionPRO® and Isolibrium™) (35” x 6” x 4”)

• With Bed Extender DM64197 (XPRT™) (35” x 6” x 5.5”) 35” x 90” x 5.5” 88,9 cm x 228,6 cm x 13,9 cm

Recommended Air Mattress Size 35” x 84” x 6” - 8.5”

• With Bed Extender DM64196

(PositionPRO® and Isolibrium™) (35” x 6” x 4”)

• With Bed Extender DM64197 (XPRT™) (35” x 6” x 5.5”) 35” x 90” x 5.5” 88,9 cm x 228,6 cm x 13,9 cm

www.stryker.com 2141-209-0 02 RE V H 13

35” x 90” x 4” 88,9 cm x 228,6 cm x 10,1 cm

88,9 cm x 213,4 cm x

15,2 cm - 21,6 cm

35” x 90” x 4” 88,9 cm x 228,6 cm x 10,1 cm

Return To Table of Contents

Page 14

50 °F

(1

104 °F

-40 °F

(-40 °C)

158 °F

30%

75%

10

95%

7

1060 hPa

500 hP

1060 hPa

64 °F

(1

77 °F

Introduction

ENVIRONMENTAL CONDITIONS

Environmental Conditions Operation Storage and Transportation

Ambient Temperature

(40 °C)

(70 °C)

0 °C)

Relative Humidity

(Non-Condensing)

%

Atmospheric Pressure

00 hPa

a

(25 °C)

Scale Accuracy

8 °C)

Specifications listed are approximate and may vary slightly from product to product or by power supply fluctuations.

Stryker reserves the right to change specifications without notice.

Return To Table of Contents

14 2141-209- 002 REV H www.stryker.com

Page 15

PRODUCT ILLUSTRATION

ST

Introduction

B

O

N

P

H

G

J

I

R

A

D

L

K

E

F

U

A 110V outlet (optional) L Manual backup brake

B Brake control panel (outside siderail) M Mattress retainer

C Caster N Nurse call (inside siderail) (optional)

D CPR release pedal O Motion control panel (outside siderail)

E Foley bag hooks P Pendant holder

F Footboard Q Roller bumpers

G Footboard control panel R Siderail release levers

H Headboard S Siderails

I Head end control panel (optional) T Support surface (optional)

J InTouch touch screen U Zoom drive system (model 2141) (optional)

K Isolated foley bag hooks

C

M

Q

www.stryker.com 2141-209-0 02 RE V H 15

Return To Table of Contents

Page 16

Introduction

CONTACT INFORMATION

Contact Stryker Customer Service or Technical Support at 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

USA

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical

Support. Include the serial number in all written communication.

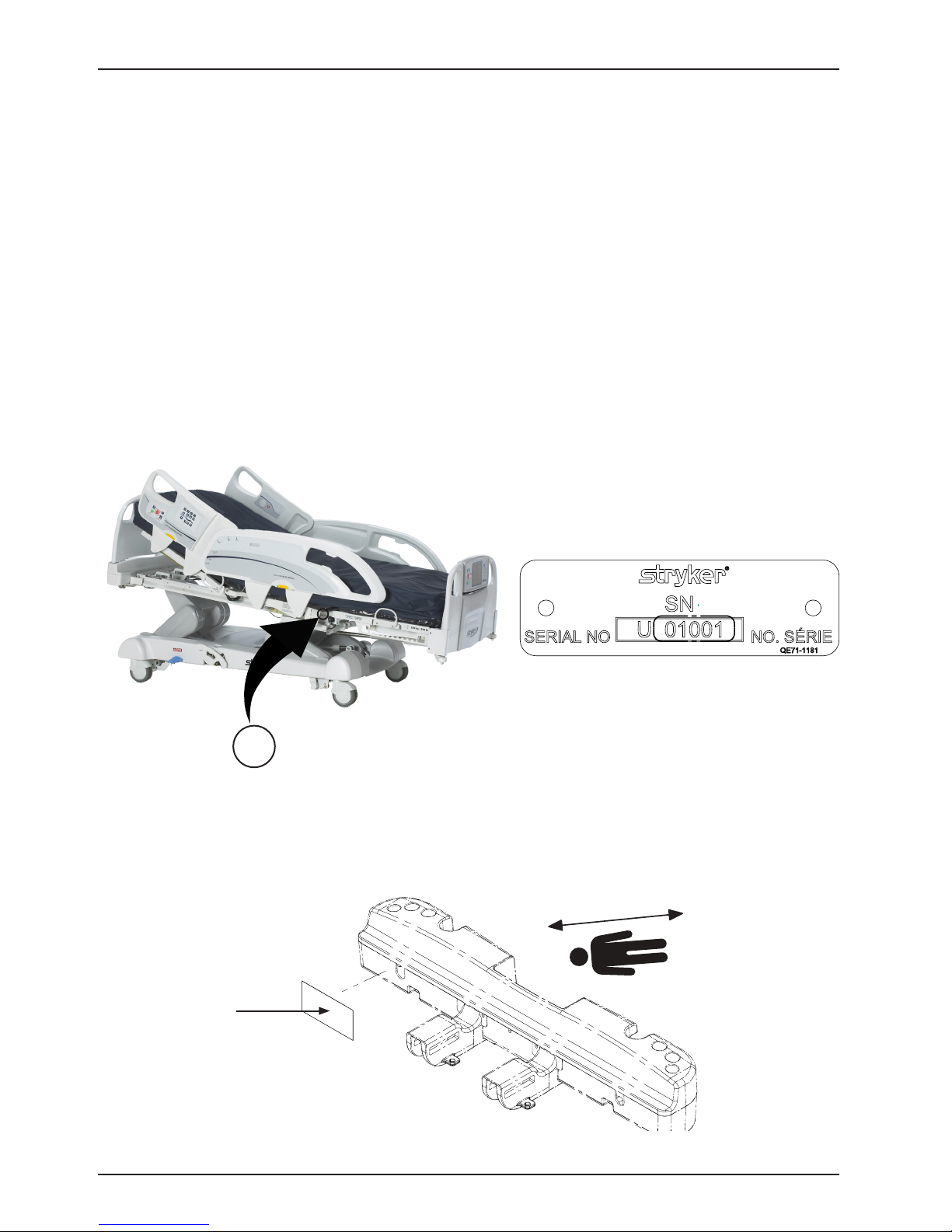

SERIAL NUMBER LOCATION

You can find the serial number plate behind the patient right siderail near the foot end of the product.

A

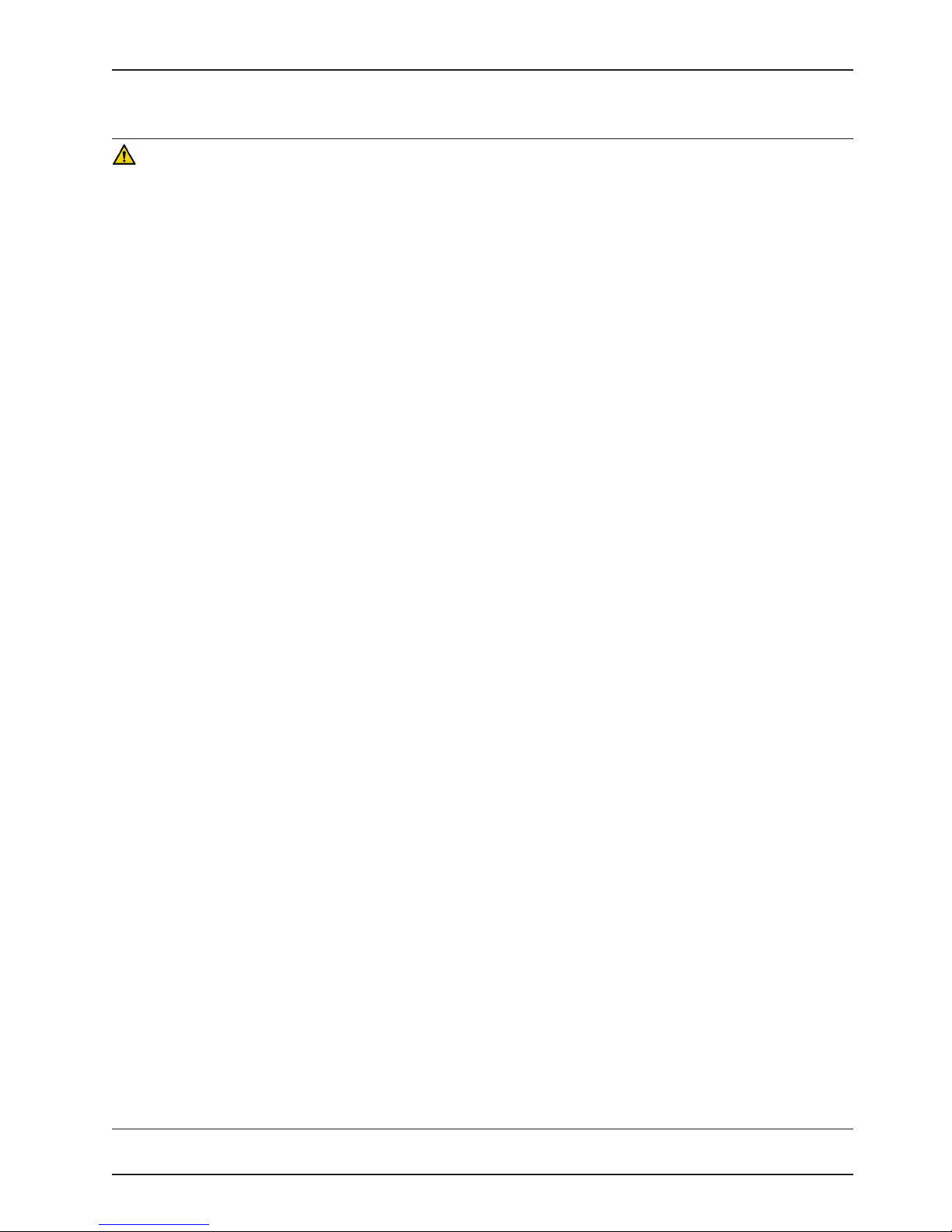

SPECIFICATION LABEL LOCATION

You can find the specification label behind the head end cover on the patient right side of the product.

Return To Table of Contents

16 2141-209 -002 RE V H www.stryker.com

Page 17

Summary of Safety Precautions

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WARNING

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described

in this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Always allow the product to reach room temperature before conducting any setup or testing functional operations

to prevent permanent product damage.

• Always operate the product when all operators are clear of the mechanisms.

• Always plug the product directly into a properly grounded, three-prong receptacle. You can only achieve grounding

reliability when you use a hospital-grade receptacle. This product is equipped with a hospital-grade plug for

protection against electric shock hazard.

• Always properly handle the power cord to avoid the risk of entanglement, damage to the power cord, or potential

shock hazards. If the power cord is damaged, immediately remove the product from service and contact the

appropriate maintenance personnel.

• Do not attach the power cord to any moving parts of InTouch.

• Always unplug the power cord, turn the battery switch to the OFF (O) position, press the N/Brake Off button, and

call maintenance if unanticipated motion occurs.

• Always unplug the product power cord from the wall when using oxygen administering equipment. Possible fire

hazard exists when this product is used with oxygen administering equipment other than nasal, mask type, or half

bed-length tent type.

• The optional iBed® Wireless function is only intended to provide remote information of product status and parameter

conditions. It is not intended to replace patient monitoring protocol.

• The line of sight between an iBed Locator and the head end of bed must be free of obstruction at all times. Any

interference could interrupt communication between the iBed Locator and the IR module.

• You must use an iBed® Wireless compatible footboard with an iBed® Wireless compatible product. You will lose

iBed® Wireless functionality if you use an older version of the footboard.

• You must verify all iBed® Wireless functionality after installation. Verify that the iBed locator communicates the

product’s positions, and that iBed® Wireless communicates with the wireless access point. Failure to do may result

in the loss of information or the transmission of incorrect information.

• You must install the iBed Locators more than 71” apart from one another in the same room (such as in a

semiprivate room with more than one product). Failure to do may result in the product transmitting information to

the incorrect iBed Locator.

• Do not use iBed® Wireless to replace the existing nurse call system. iBed® Wireless products are only intended

to transmit product information. They are not intended to transmit nurse call information.

• Always correctly associate or map the iBed Locator to the room or location to provide accurate location information.

Failure to properly map the iBed Locator to the room or location may result in the product transmitting incorrect

information.

• If you move an iBed Locator after it has been installed and mapped, you must remap to the new room or location

in which it is moved to. You must also remap the iBed Locator if you change the room or location information after

initial installation.

• Always wash your hands after handling a battery. Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Properly dispose of batteries when required.

• Power save mode activates after one hour on battery power with no motion release switch activation. Bed exit,

scale, and product motion stops operating when the product enters the power save mode.

• Always keep feet clear from the area above the base cover or below the base cover when lowering the product or

when applying the brakes or releasing the brakes.

• Always apply the brakes when a patient is getting in the product or out of the product to avoid instability.

• Always apply the brakes when the patient is unattended.

• Do not apply the electronic brake to slow or stop the product while it is in motion.

• Always keep the product in a low, horizontal position with the siderails fully raised and locked when transporting a

patient.

www.stryker.com 2141-209-0 02 RE V H 17

Return To Table of Contents

Page 18

Summary of Safety Precautions

WARNING (CONTINUED)

• Do not use the Zoom motorized drive when the batteries become discharged. Press N/Brake Off to place the drive

wheel in neutral and push the product manually. Recharge the batteries before using the Zoom motorized drive

again to avoid the risk of battery damage and the drive wheel getting stuck in the down position.

• Use caution while maneuvering the product with the drive wheel activated. Always make sure that there are no

obstacles near the product while the Zoom motorized drive is activated. Injury to the patient, user or bystanders or

damage to the frame or surrounding equipment could occur if you collide with an obstacle.

• Make sure that the brakes are completely released before attempting to move the product. Attempting to move the

product with the brakes applied could result in injury to the patient or operator.

• Do not attempt to move the product manually when you activate the Zoom motorized drive. Always place the drive

wheel into the neutral position and release the brakes before attempting to move the product manually.

• Always make sure that all persons and equipment are away from the area below and around the product before

you activate the CPR release. The CPR release is for emergency use only.

• Always determine the proper use of the restraint straps and restraint strap locations. Improperly adjusted restraint

straps can cause serious injury to a patient. Stryker is not responsible for the type or use of restraint straps on

any of Stryker’s products.

• Only use hospital-grade electric equipment consuming 5A or less with the auxiliary power outlet (optional). The

use of standard electric equipment may bring the current leakage to a level unacceptable for hospital equipment.

• Always keep the siderails in the fully raised position and the sleep surface horizontal in its lowest position unless

the patient’s medical condition dictates otherwise.

• Do not use siderails, with or without their padded covers, as restraint devices to keep patient from exiting the

product. Siderails are designed to keep a patient from inadvertently rolling off the product. It is the responsibility

of the attending medical personnel to determine the degree of restraint necessary to ensure a patient’s safety.

Failure to use the siderails properly could result in serious patient injury.

• Always keep the siderails outside of the oxygen tent.

• The scale system is intended to assist in the monitoring of the patient’s weight variation. Under no circumstances

should its reading be used as sole reference for medical treatment.

• Bed exit is intended only to aid in the detection of a patient exiting the product. It is not intended to replace patient

• onitoring protocol.

• Bed exit is not designed to be used with patients weighing less than 50 lb (23 kg).

• Do not use extension cords with support surfaces. Support surfaces are only intended to be powered by InTouch

with the power cord supplied.

• Do not route cables between the support surface and InTouch.

• Always make sure that all of the patient’s limbs are within the raised and locked siderails when the support surface

is articulating to avoid the risk of patient injury.

• Always center the patient on the support surface. Align the patient’s head toward the headboard before starting

functions. Check the patient frequently to make sure that you maintain the proper positioning.

• Always make sure that the tubing and wiring that is connected to the patient is long enough, stable, and secure

during Lateral Rotation or Turn Assist.

• Always raise all of the InTouch bed siderails before starting Turn Assist or Lateral Rotation functions.

• Do not exceed the safe working load of the Isolibrium support surface. Excess weight could cause unpredictable

safety and performance of this system.

• Always use extra caution when reading radiology images taken of a patient on a support surface because internal

components can cause artifacts and distort readings.

• Do not extubate or intubate patients during Lateral Rotation or Turn Assist. The functions could interfere with the

performance of the ancillary devices.

• Do not zero the bed scales or weigh the patient with Lateral Rotation or Turn Assist active. Motion from the support

surface functions may adversely affect the scale system performance.

• Do not arm bed exit with Lateral Rotation or Turn Assist active. The patient motion and position that results from

the support surface may adversely affect bed exit system performance.

• Do not leave the patient unattended during Turn Assist.

• Always deflate the Isolibrium support surface before beginning CPR.

Return To Table of Contents

18 2141-209 -002 RE V H www.stryker.com

Page 19

Summary of Safety Precautions

WARNING (CONTINUED)

• Always lock the control panel when the patient is unattended, or when a patient’s condition requires greater safety

measures for their condition.

• Do not use iBed® Awareness as a lock indicator for siderails. iBed® Awareness is only intended to detect the

position of the siderails. It is not intended to replace patient monitoring protocol.

• The iBed® Awareness LED light bars are only intended to monitor the product status and parameter conditions. It

is not intended to replace patient monitoring protocol.

• You must physically verify that the siderails are locked before arming iBed® Awareness.

• Always securely set the footboard connector on the optional bed extender into the footboard connector slot at the

foot end of the product.

• Do not pinch the power cord or cables when installing the optional bed extender.

• Do not sit on the optional bed extender. This may cause the product to flip.

• Do not allow the optional line management clip to interfere with a mechanical or electronic mechanism of the

product.

• Do not pinch tubes inside the clip.

• Do not clean the clip with a liquid solution.

• Always adjust the scale or bed exit system if an option is added while the scale or bed exit system is armed.

• Do not place objects that exceed 40 lb (18 kg) onto the optional monitor tray.

• Do not exceed the 150 lb (68 kg) load capacity for the tray support pole.

• Do not clean, service, or perform maintenance while the product is in use.

• Always unplug the power cord and turn the battery switch to the OFF (O) position before cleaning, servicing, or

performing maintenance.

• Always immediately unplug the power cord from the wall outlet when large spills occur near the circuit boards,

cables, and motors. Remove the patient from the product, clean up the fluid, and have service personnel completely

inspect the product. Fluids can cause unpredictable operation and decreased functionality of any electrical product.

Do not return the product to service until it is completely dry and has been thoroughly tested for safe operation.

www.stryker.com 2141-209-0 02 RE V H 19

Return To Table of Contents

Page 20

Summary of Safety Precautions

CAUTION

• Always plug the product into a wall outlet (regulated AC power source) when not in use to maintain a sufficient

battery charge and to maximize product performance while operating on battery power.

• Always immediately replace batteries that have corrosion at the terminals, display cracking, have expanded or

bulging sides, or no longer can maintain a full charge.

• Always use only Stryker authorized batteries when replacing the batteries. Use of non-Stryker batteries may lead

to unpredictable system performance.

• Upon a Battery Low alarm (Battery Low LED on Footboard and audible beep), stop using the Zoom motorized drive

and recharge the batteries immediately. Ignoring the Battery Low alarms may cause your batteries to degrade

quicker than normal and may decrease battery life.

• Always clean Velcro® after each use. Saturate Velcro with disinfectant and allow disinfectant to evaporate.

Appropriate disinfectant for nylon Velcro should be determined by the hospital.

• Do not move footboards from one product to another. Individual products may have different options. Mixing

footboards could result in unpredictable operation of the product.

• Do not use the siderails to move the product. Move the product using the integrated handles in the headboard and

footboard.

• Do not use pencils, pen caps, pen tips, or other pointed objects to tap the touch screen display. Using excessive

pressure may damage the footboard control panel and the touch screen display.

• Always use extra supervision when using a mattress or support surface thicker than six in. (15,4 cm).

• Do not allow sharp objects to come into contact with the support surface that could puncture, tear, or cut the cover.

• Make sure that you set the desired product parameters before enabling iBed® Awareness.

• Do not use accessories that cover the footboard and outside siderail LED light bars.

• Do not turn off the iBed® Awareness alarm. You will lose access to the event manager that displays the compromised

parameter condition.

• Do not hang IV bags that exceed 22 lb (10 kg) onto the IV pole.

• Always make sure that the IV pole is at a low height to pass safely through door openings.

• Do not use the IV pole as a push/pull device.

• Always make sure that the clip is stable when installed.

• Do not inset tubes that are larger than 0.75 in. into the line management clip.

• Always sterilize the clip after each use.

• Always make sure that the clip is stable when installed.

• Always unplug the product before cleaning or servicing.

• Always unplug the product, set the brakes, and place blocks under the litter frame for support when working under

the product.

• Always make sure that you wipe each product with clean water and thoroughly dry each product after cleaning.

Some cleaning products are corrosive in nature and may cause damage to the product if you use them improperly.

If you do not properly rinse and dry the product, a corrosive residue may be left on the surface of the product that

could cause premature corrosion of critical components. Failure to follow these cleaning instructions may void

your warranty.

• Do not steam clean, pressure wash, ultrasonically clean, or immerse any part of the product in water. Exposure to

water may damage the internal electric parts. These methods of cleaning are not recommended and may void this

product’s warranty.

Return To Table of Contents

20 2141-209-0 02 RE V H www.stryker.com

Page 21

Static Discharge Precautions

PROTECTING AGAINST ELECTROSTATIC DISCHARGE (ESD)

CAUTION

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

• All electronic service parts will be shipped in static shielding bags. Do not open the bags until you have completed

steps 2 and 3 of the Static Protection Procedure.

Note: Always ship back circuit boards to Stryker in the same antistatic bags that the new boards were

originally shipped in.

The electronic circuits in the product are completely protected from static electricity damage when factory assembled.

Always use adequate static protection when servicing the electronic systems of the product. All service personnel must

use static protection whenever they are touching wires.

Static Antistatic Protection Equipment Includes:

• 1 antistatic wrist strap

• 1 grounding plug

• 1 test lead with a banana plug on one end and an alligator clip on the other end

Static Protection Procedure

1. Unplug the power cord from the power source.

2. Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the banana plug of the

test lead into the receptacle on the grounding plug. Connect the alligator clip on the other end of the test lead to

a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the alligator clip at the other end of the wrist strap cord

to a ground point on the bed.

BED

GROUNDING DIAGRAM

www.stryker.com 2141-209-0 02 RE V H 21

Return To Table of Contents

Page 22

Setup

To unpack your product, see the unpacking instructions that are attached to the product inside of the shipping crate.

WARNING

• Always allow the product to reach room temperature before conducting any setup or testing functional operations

to prevent permanent product damage.

• Always operate the product when all operators are clear of the mechanisms.

• Always properly handle the power cord to avoid the risk of entanglement, damage to the power cord, or potential

shock hazards. If the power cord is damaged, immediately remove the product from service and contact the

appropriate maintenance personnel.

• Do not attach the power cord to any moving parts of InTouch.

• Always unplug the power cord, turn the battery switch to the OFF (O) position, press the N/Brake Off button, and

call maintenance if unanticipated motion occurs.

CAUTION

Always plug the product directly into a properly grounded, three-prong receptacle. You can only achieve grounding

reliability when you use a hospital-grade receptacle. This product is equipped with a hospital-grade plug for protection

against electric shock hazard.

To turn on the product:

1. Plug the power cord into a properly grounded, hospital-grade wall outlet.

2. Turn the battery switch to the ON (|) position.

Before placing the product into service, make sure that these components are working properly:

1. Visually inspect the product for any signs of shipping damage.

2. Flip down and depress the manual brake pedal and make sure that the neutral, drive, and brake functions of the

manual brake pedal hold.

3. Press BRAKE on each control panel and make sure that the neutral, drive, and brake functions of the electronic

brake hold.

4. Test the Zoom drive system (Model 2141).

5. Raise and lower the siderails to make sure that they move smoothly and lock securely in the full up position.

6. Press each button on the head end control panel (optional), motion control panel, brake control panel, footboard

control panel, and patient control pendant (optional) to make sure that each function operates properly.

7. Make sure that the footboard operates properly.

8. Make sure that the scale system operates properly.

9. Make sure that the bed exit system operates properly.

10. Make sure that the CPR release pedal operates properly.

11. Make sure that the support surface operates properly (optional).

12. Make sure that optional accessories are installed and operate as described.

WARNING

Always unplug the product power cord from the wall when using oxygen administering equipment. Possible fire hazard

exists when this product is used with oxygen administering equipment other than nasal, mask type, or half bed-length

tent type.

Return To Table of Contents

22 2141-209-0 02 RE V H www.stryker.com

Page 23

Installation

INSTALLING THE XPRT THERAPY SUPPORT SURFACE (OPTIONAL)

To install the XPRT support surface option onto InTouch, see the installation instructions in the XPRT support surface

operations manual.

INSTALLING THE POSITIONPRO SUPPORT SURFACE (OPTIONAL)

To install the PositionPRO support surface option onto InTouch, see the installation instructions in the PositionPRO

support surface operations manual.

INSTALLING THE ISOLIBRIUM SUPPORT SURFACE (OPTIONAL)

To install the Isolibrium support surface option onto InTouch, see the installation instructions in the Isolibrium support

surface operations manual.

INSTALLING IBED WIRELESS (120V NORTH AMERICAN ONLY) (OPTIONAL)

WARNING

• The optional iBed® Wireless function is only intended to provide remote information of product status and parameter

conditions. It is not intended to replace patient monitoring protocol.

• The line of sight between an iBed Locator and the head end of bed must be free of obstruction at all times. Any

interference could interrupt communication between the iBed Locator and the IR module.

• You must use an iBed® Wireless compatible footboard with an iBed® Wireless compatible product. You will lose

iBed® Wireless functionality if you use an older version of the footboard.

• You must verify all iBed® Wireless functionality after installation. Verify that the iBed locator communicates the

product’s positions, and that iBed® Wireless communicates with the wireless access point. Failure to do may result

in the loss of information or the transmission of incorrect information.

• You must install the iBed Locators more than 71” apart from one another in the same room (such as in a semiprivate room with more than one product). Failure to do may result in the product transmitting information to the

incorrect iBed Locator.

• Do not use iBed® Wireless to replace the existing nurse call system. iBed® Wireless products are only intended to

transmit product information. They are not intended to transmit nurse call information.

You must install the iBed Locator on the wall at the head end of the bed. The iBed Locator communicates with the IR

Module that is installed onto the product.

To mount the iBed Locator, see the installation instructions that were included with your iBed Locator Installation kit.

After you install the iBed Locator, you must configure the wireless connection settings for the iBed Server application.

To configure the iBed Server application, see the installation and configuration instructions in the iBed Server

Installation/Configuration manual.

WARNING

• Always correctly associate or map the iBed Locator to the room or location to provide accurate location information.

Failure to properly map the iBed Locator to the room or location yields incorrect remote information.

• If you move an iBed Locator after it has been installed and mapped, you must remap to the new room or location

in which it is moved to. You must also remap the iBed Locator if you change the room or location information after

initial installation.

If you have any problems during the iBed Wireless installation process, contact Stryker Technical Support at

1–800–327−0770.

www.stryker.com 2141-209-0 02 RE V H 23

Return To Table of Contents

Page 24

Maintenance Menu Guide

The Maintenance Menu is accessed through the Touch Screen and contains additional features of the product. This

menu provides an interface to the user and/or service personnel in order to provide the ability to control and access

maintenance features.

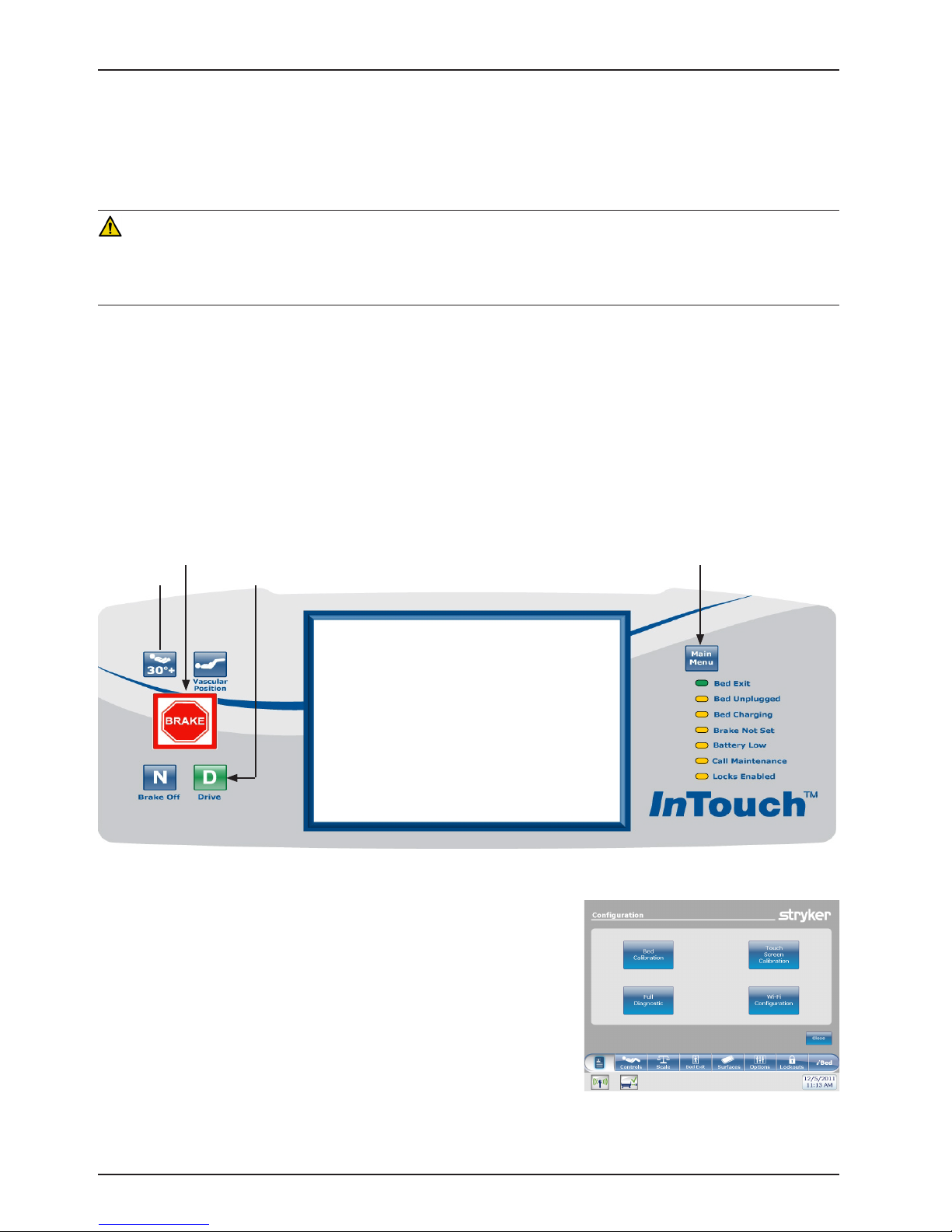

ACCESSING THE CONFIGURATION SCREEN

WARNING

Please ensure patient is not in the bed prior to starting bed calibration. In calibration mode, the software does not control

the interferences between the mechanical parts of the bed. Mechanical damage could occur without supervision. Only

qualified personnel should perform the calibration.

Note

Verify that the bed is on a level surface which does not have any slopes or inclines prior to entering into the calibration

mode.

1. Unseat and reseat the footboard and wait until the main control screen is displayed.

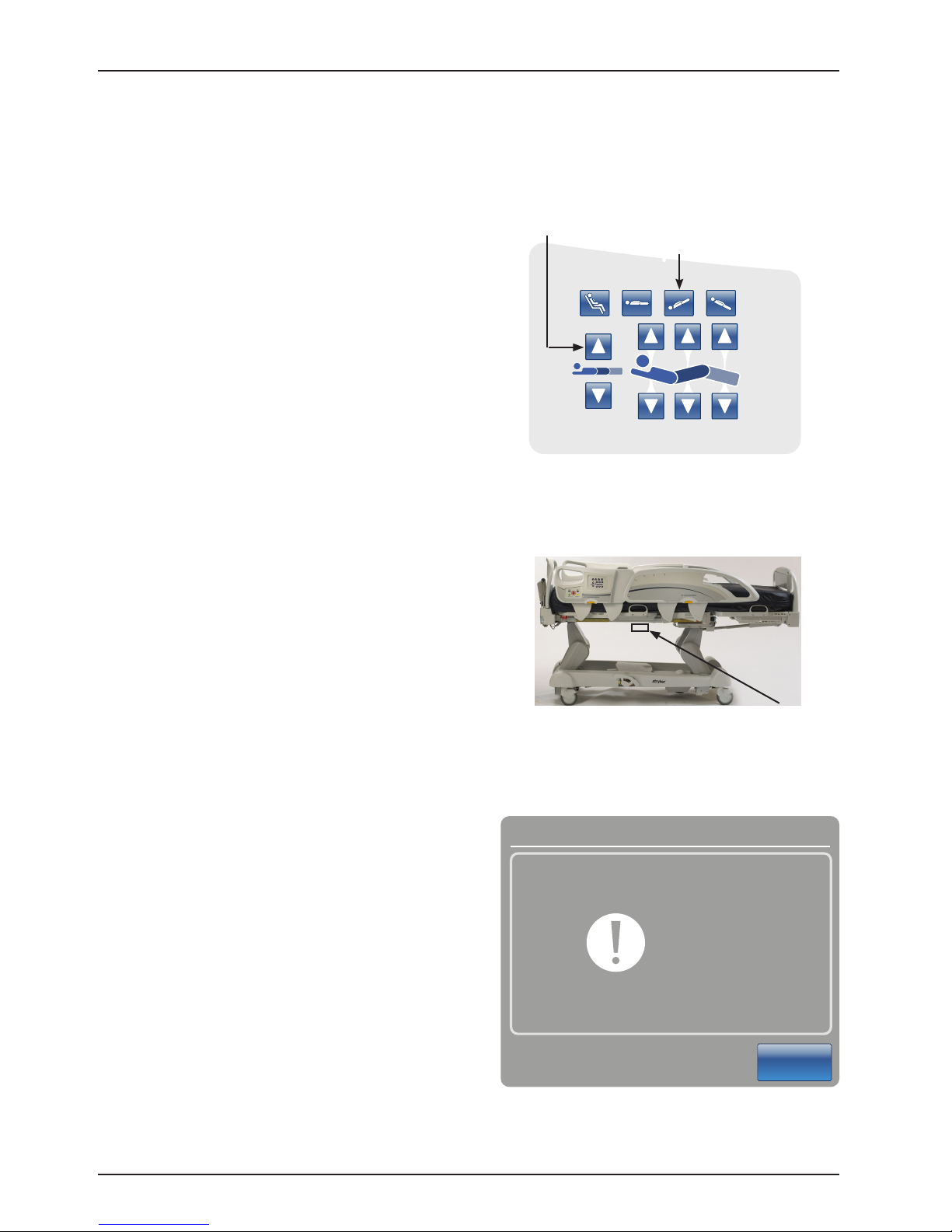

2. Push and hold the Main Menu button located in the upper right corner of the footboard control panel

(see Figure 1 below). Continue pressing on the Main Menu button while executing steps 3-5.

3. Push and hold the Brake button for 5 seconds and then release.

4. Push the HOB 30o+ button once and release.

5. Push the Drive button once and release.

6. Release the Main Menu button and you will be taken into the Configuration Screen shown in Figure 2.

HOB

Brake

Main Menu

Drive

Figure 1: Footboard Control Panel

Return To Table of Contents

24 2141-209-0 02 RE V H www.stryker.com

Figure 2: Configuration Screen

Page 25

Maintenance Menu Guide

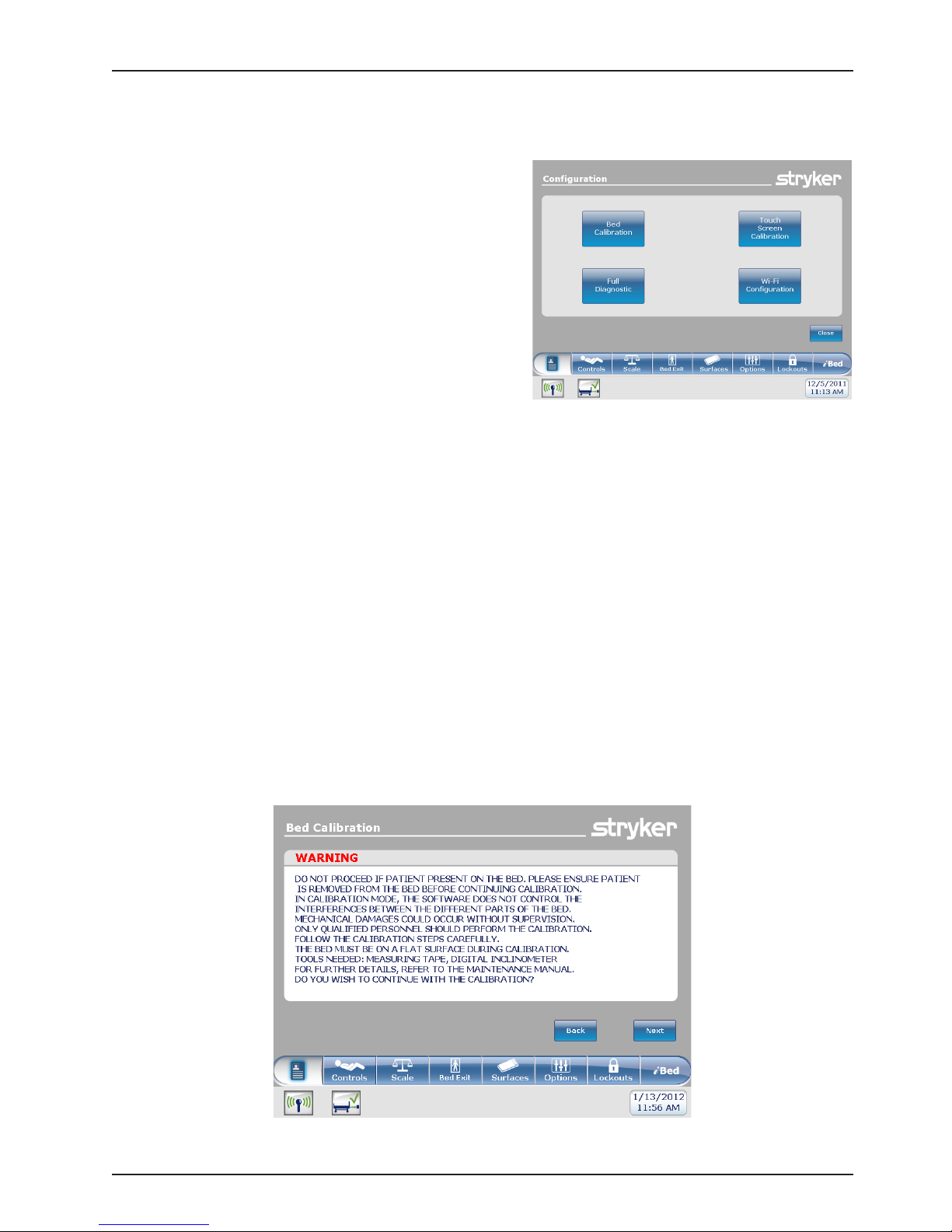

INTOUCH CONFIGURATION SCREEN

The following items A, B, and C are configuration buttons

available and displayed on the Configuration screen

(Figure 3).

A. Bed Calibration

B. Full Diagnostic (see page 36)

C. Touch Screen Calibration (see page 37)

D. Optional Wi-Fi Configuration (see page 38)

The following items D and E are configuration options

available but are not displayed on the Configuration

screen To access these configuration options, follow the

procedures identified on page listed below.

E. Bed Options Configuration (see page 39)

F. Serial Number Configuration (see page 40)

Figure 3: Configuration Screen Menu Items

A. Bed Calibration

Note: During calibration, if the backlight shuts off touch the screen to continue.

1. Connect the bed to an A/C outlet.

2. Place the mattress onto the frame.

3. Press the Bed Calibration button on the Configuration Screen (refer to Figure 3).

4. After pressing the Bed Calibration button, Figure 4 will be displayed. Press “NEXT” to continue with

calibration.

www.stryker.com 2141-209-0 02 RE V H 25

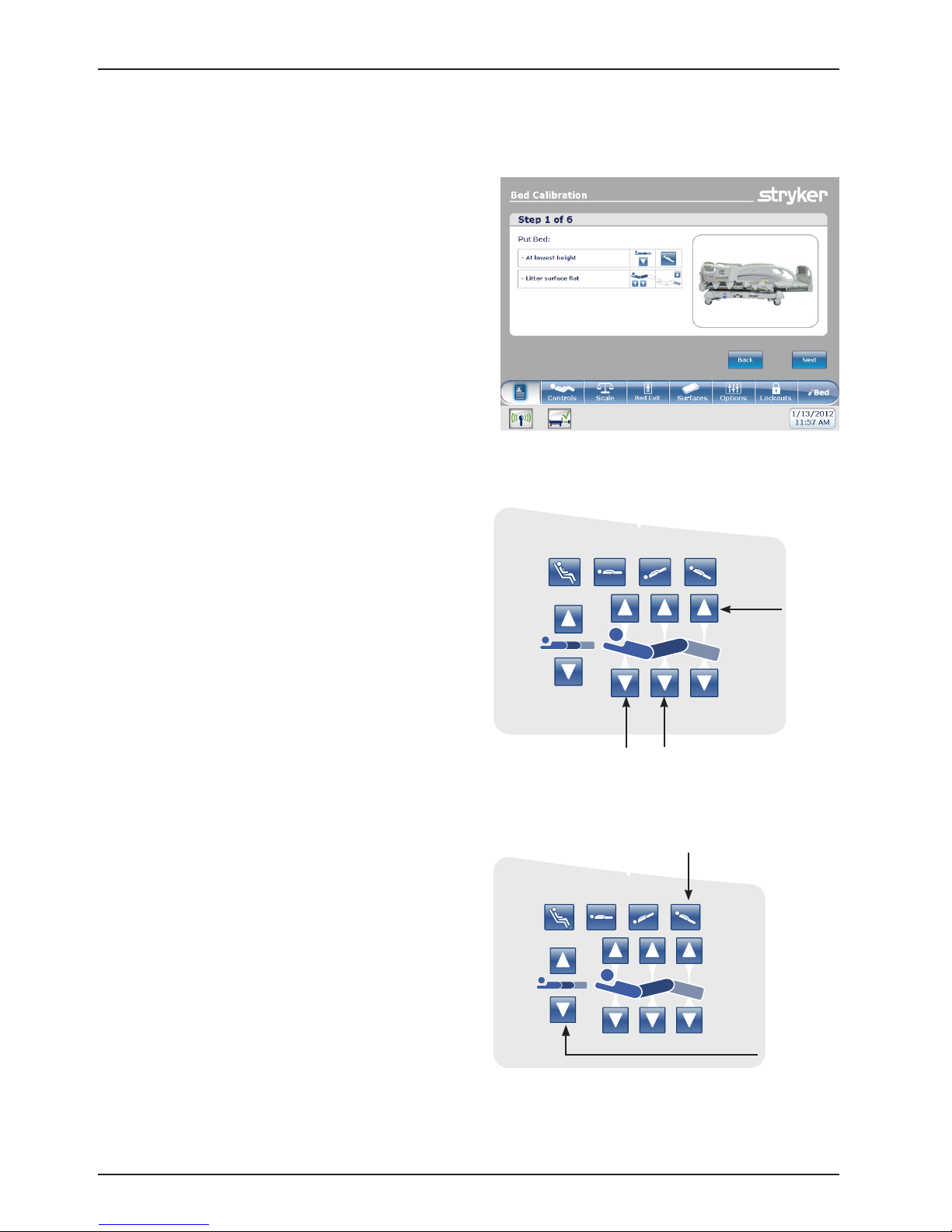

Figure 4: Bed Calibration - WARNING

Return To Table of Contents

Page 26

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

5. After pressing Next to continue calibration,

Figure 5 will appear.

Figure 5: Bed Calibration - Step #1 of 6

6. Place the Litter surface to a flat position by

pressing simultaneously the Foot Up, Fowler

Down and Gatch Down buttons as shown in

Figure 6.

7. Lower the bed to the lowest position. Press

the Bed Height Down (Head Lift Down) and

Reverse Trendelenburg (Foot Lift Down)

buttons simultaneously as shown in Figure 7.

Foot Up

QDF27-2237

Fowler Down

Gatch Down

Figure 6: HE Siderail Control Panel - (Right Side Shown)

Reverse Trendelenburg

(Foot Lift Down)

Bed Height

Down

(Head Lift

Down)

QDF27-2237

Figure 7: HE Siderail Control Panel - (Right Side Shown)

Return To Table of Contents

26 2141-209 -002 REV H www.stryker.com

Page 27

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

Bed Calibration

Do Not

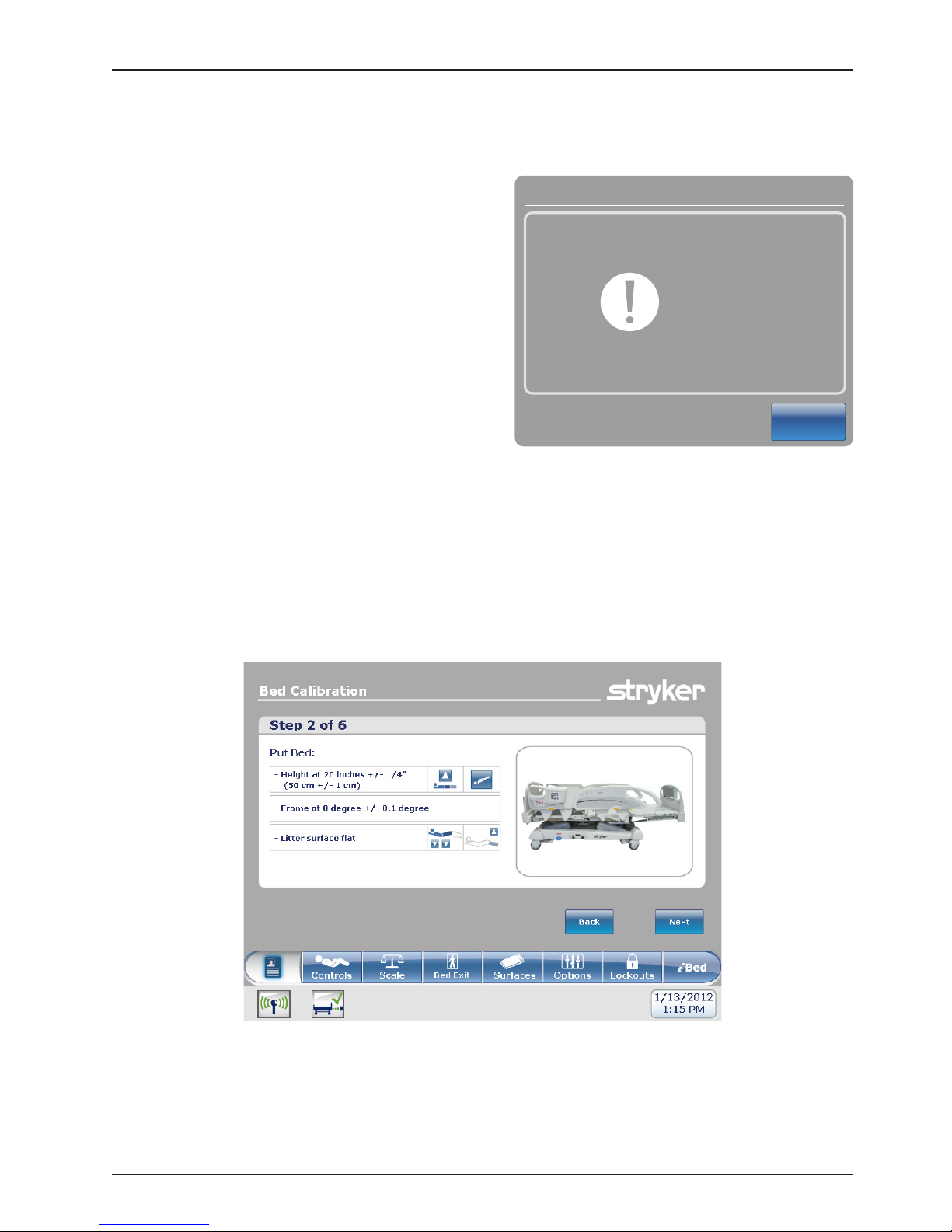

8. Press the Next button when done. The “Do Not

Touch Bed

Touch Bed” screen will appear as shown in Figure

8.

Cancel

Figure 8

9. When step 1 of the calibration procedure has completed, step 2 of the calibration procedure will begin and

Figure 9 will be displayed.

www.stryker.com 2141-209-0 02 RE V H 27

Figure 9: Bed Calibration - Step 2

Return To Table of Contents

Page 28

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

10. Raise the bed height to 20 inches measuring

from the top of the seat section to the floor.

Press the Bed Height Up (Head Lift Up) and

Trendelenburg (Foot Lift Up) buttons as

shown in Figure 10.

11. Standing on either side of the bed at the fowler

section, raise the foot siderail and then position

the digital level/inclinometer on the bottom of

the litter below the mattress retainer (refer to

Figure 11). Using the digital level/inclinometer,

verify the bed is level (0.0 +/- 0.1).

Bed Height Up

(Head Lift Up)

Trendelenburg

(Foot Lift Up)

Figure 10: Head Siderail Control Panel

(Right Side Shown)

QDF27-2237

Note: Cycle power on the digital level/

inclinometer prior to placing it on the

bottom of the litter frame and do not zero/

calibrate the digital level/inclinometer.

12. Press the Next button when done. The “Do

Not Touch Bed” screen will appear as shown

in Figure 12.

Placement

on Litter

Figure 11: Inclinometer placement

Bed Calibration

Do Not

Touch Bed

Cancel

Figure 12: Do Not Touch Bed Screen

Return To Table of Contents

28 2141-209 -002 REV H www.stryker.com

Page 29

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

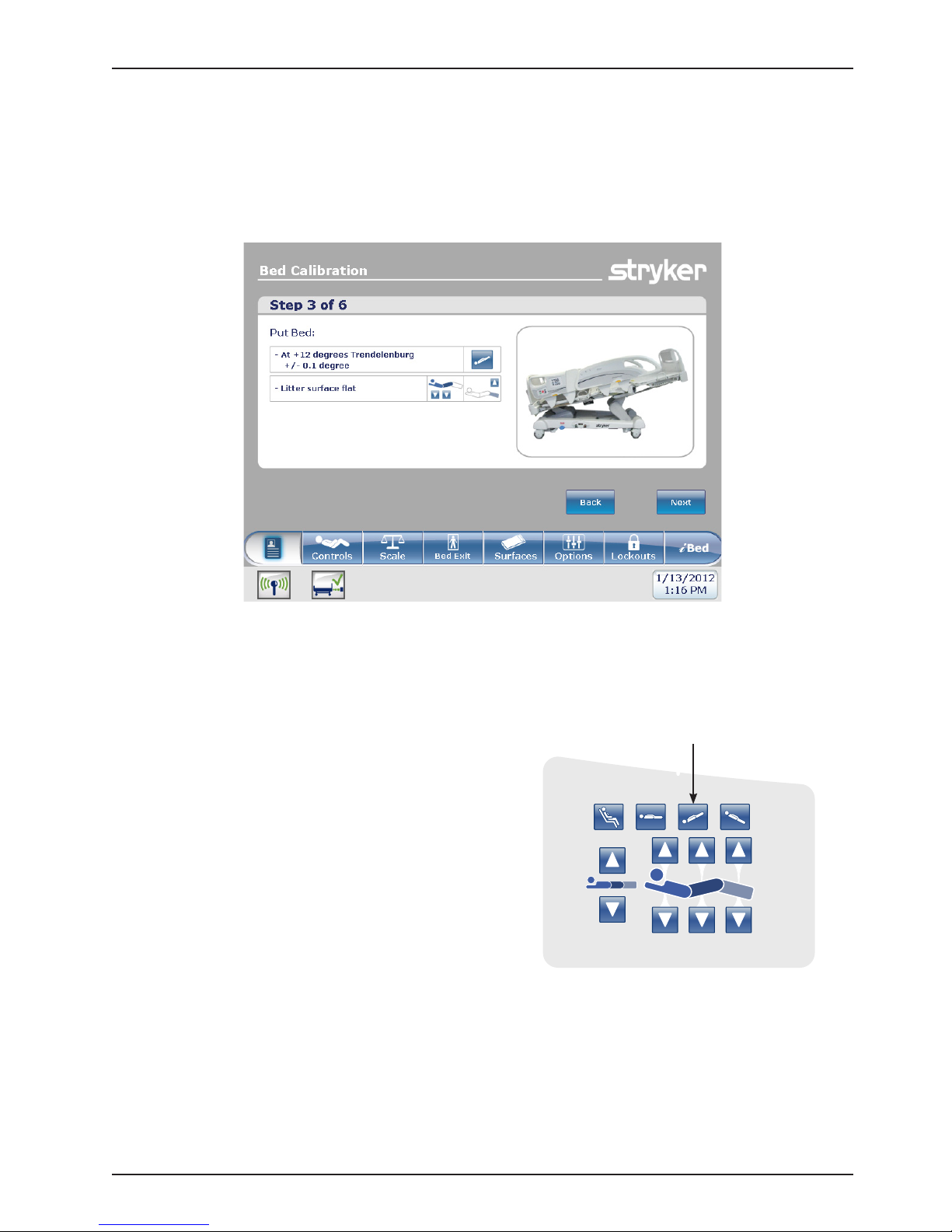

13. When step 2 of the calibration procedure has completed, step 3 of the calibration procedure will begin and

Figure 13 as shown below will appear on the screen.

Figure 13: Bed Calibration - Step 3

14. Place the bed at +12 degrees Trendelenburg by pressing

the Trendelenburg (Foot Lift Up) button as shown in

Figure 14. Verify +12 degrees +/- 0.1 with the inclinometer

you previously placed on the litter frame in step 11.

Trendelenburg

(Foot Lift Up)

QDF27-2237

Figure 14: Head Siderail Control Panel

www.stryker.com 2141-209-0 02 RE V H 29

Return To Table of Contents

Page 30

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

15. Press the Next button when done.

16. The “Do Not Touch Bed” screen will appear as

shown in Figure 15.

Bed Calibration

Do Not

Touch Bed

Cancel

Figure 15: Do Not Touch Bed Screen

17. When step 3 of the calibration procedure has completed, step 4 of the calibration procedure will begin and

Figure 16 will be displayed as shown below.

Figure 16: Bed Calibration - Step 4

Return To Table of Contents

30 2141-209- 0 02 REV H www.stryker.com

Page 31

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

18. Level the bed back out to zero degrees by pushing

the Reverse Trendelenburg button until the litter

is level while referencing the inclinometer. Note:

Confirm inclinometer reads zero degrees.

19. Place the bed at -12 degrees Reverse Trendelenburg

by pressing the Bed Height Up (Head Lift Up) button

as shown in Figure 17 below. Verify -12 degrees +/-

0.1 with the inclinometer you previously placed on the

bottom of the litter frame in step 11.

Bed Height Up

(Head Lift Up)

QDF27-2237

Figure 17: Head Siderail Control Panel -

(Right Side Shown)

20. Press the Next button when done.

21. The “Do Not Touch Bed” screen will appear as

shown in Figure 18.

Bed Calibration

Do Not

Touch Bed

Cancel

Figure 18: Do Not Touch Bed Screen

www.stryker.com 2141-209-0 02 RE V H 31

Return To Table of Contents

Page 32

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

22. When step 4 of the calibration procedure has completed, step 5 of the calibration procedure will begin and

Figure 19 will appear on the screen as shown below.

Figure 19: Bed Calibration - Step 5

23. Place the bed at the highest height by pressing

simultaneously the Trendelenburg (Foot Lift Up)

button and Bed Height Up (Head Lift Up) button as

shown in Figure 20.

Trendelenburg

(Foot Lift Up)

Bed Height Up

(Head Lift Up)

QDF27-2237

Figure 20: Head Siderail Control Panel -

(Right Side Shown)

Return To Table of Contents

32 2141-209 -002 REV H www.stryker.com

Page 33

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

Gatch Up

24. Press the Fowler Up button until the Fowler reaches

the highest height, next press the Gatch Up button

until the Gatch reaches its highest height, lastly

press the Foot Up button until the foot section

reaches its highest height (refer to Figure 21

below). The foot section should be at a flat position.

25. Press the Next button when done.

Fowler Up

Figure 21: Head Siderail Control Panel -

(Right Side Shown)

Bed Calibration

Foot Up

QDF27-2237

26. The “Do Not Touch Bed” screen will appear as

shown in Figure 22.

Do Not

Touch Bed

Cancel

Figure 22: Do Not Touch Bed Screen

Return To Table of Contents

www.stryker.com 2141-209-0 02 RE V H 33

Page 34

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

27. When step 5 of the calibration procedure has completed, step 6 of the calibration procedure will begin and

Figure 23 will be displayed as shown below.

Figure 23: Bed Calibration - Step 6

28. Place the bed at the highest height by pressing

simultaneously the Trendelenburg (Foot Lift Up)

button and Bed Height Up (Head Lift Up) button (see

Figure 24).

29. Place the Fowler and Gatch section of the bed at the

highest height by first pressing the Fowler Up button

then the Gatch Up button (See Figure 24).

30. Place the foot at the lowest position by pushing the

Foot Down button until limit is met (see Figure 24) .

CAUTION: The Gatch must be raised to the highest

height prior to running the Foot Down or damage

could occur.

Bed Height Up

(Head Lift Up)

Fowler Up

Trendelenburg

(Foot Lift Up)

Gatch Up

Figure 24: Calibration Complete

Foot Down

QDF27-2237

Return To Table of Contents

34 2141-209 -002 RE V H www.stryker.com

Page 35

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

31. When the calibration procedure is completed, Figure 25 will be displayed as shown below.

32. Press the Close button to exit the Calibration Procedure Menu.

33. Level the litter flat using the CPR pedal. Verify all display readings are zero degrees while the bed is at

33” (84 cm) (highest height). Lower the bed to 16” (41 cm) (lowest height) and verify the display readings

maintain a constant reading of zero degrees with no fluctuations. When the bed reaches it lowest height at

16”, verify the display readings are still at zero degrees.

Note: If readings are not all zero, you will need to recalibrate the bed by repeating steps 1-30.

Figure 25: Calibration Complete

Return To Table of Contents

www.stryker.com 2141-209-0 02 RE V H 35

Page 36

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN

(CONTINUED)

B. Full Diagnostic

1. From the Configuration Screen, press the

Full Diagnostic button. Figure 26 will appear.

2. The following menu items may be selected

by pressing their button.

a. BOARDS (Figure 27a)

Provides information on the switch

boards and the touch screen’s

software version.

b. ERROR CODES (Figure 27b)

Provides information on errors which

the CPU board has identified.

c. INPUT STATES (F igure 2 7c)

Provides information on the status of

all switches and jumpers on the bed.

d. MOTORS (Figu r e 27d)

Provides information on what a motor is doing when a function button is pushed.

Note: This requires assistance to press the buttons on the head siderails or at the head end control.

e. BUTTONS PRESSED (Figu r e 27e)

Provides information on when the CPU has detected a button being pressed.

Note: This requires assistance to press the buttons on the head siderails or at the head end control.

f. SIGNAL VALUES (Figure 27f)

Provides information on CPU voltages, load cell values, and angle sensor values.

Figure 26: Full Diagnostic Screen

Boards Connected

Nurse A.0 A.1

Nurse (SRH) A.1

Nurse (SRL) A.1

Nurse (SRR) A.1

Power board B.37

Room Interface A.1

TouchScreen D.3

Figure 27a: Board

Motors

Gatch - Reverse

Hilo Foot - Forward

Foot - Forward

Figure 27d: Motor

Close

Close

Figure 27c: Input StatesFigure 27b: Error Codes

Buttons Pressed

Nurse SRR - Trend

Footboard - Hob

Nurse Head - Leg up

Close

Figure 27e: Pressed Buttons Figure 27f: Signal Values

Return To Table of Contents

36 2141-209-0 02 REV H www.stryker.com

Page 37

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

C. Touch Screen Calibration

Ensure patient is not present on the bed before performing the Touch Screen Calibration.

1. From the Configuration Screen, press the Touch Screen Calibration button. Figure 28 will appear.

NOTE: If the touch screen will not respond, you will need to push the HOB 300+, Brake and Drive buttons

on the footboard at the same time (this will enable you to get directly into the touch screen calibration).

CAUTION: When pushing the buttons above the fowler, brakes, or drive, actuators may activate.

2. Carefully press and briefly hold a stylus or your finger on the center of the cross hair shown on the screen.

3. Repeat as the target moves around the screen. There will be five different locations to press: center, lower

right, upper right, upper left, and lower left.

4. When the last cross hair has been touched, Figure 29 displays ‘New calibration settings have been measured’.

5. Tap the screen to register saved data.

6. If you do not want to save the new data, wait for 30 seconds to cancel saved data and keep the current setting.

Figure 28: Touch Screen Calibration: Start Figure 29: Touch Screen Calibration: Completed

NOTE: The TOUCH SCREEN CALIBRATION SCREEN is a validation of the touch screen’s calibration. When the

user presses anywhere on the screen, the coordinates x and y are displayed on the lower part of the screen.

Return To Table of Contents

www.stryker.com 2141-209-0 02 RE V H 37

Page 38

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

D. Optional Wi-Fi Configuration

CAUTION

These settings should only be modified by trained personnel. Changing these settings may disable the wireless feature.

These settings should only be changed or updated with the aid of the hospital’s IT department or the appropriate

maintenance personnel.

1. From the Configuration Screen, tap Wi-Fi Configuration to configure wireless settings for the bed.

2. Tap Wi-Fi OFF to toggle the wireless network connection on.

3. Tap the appropriate tab, and then tap the pencil icon to configure the network settings (Figure 30 - Figure 33).

4. Tap Save to save the network settings.

5. After saving the configured network settings, a power cycle notification appears.

6. Unplug the power cord from the wall outlet.

7. Turn the battery switch to the OFF (O) position.

8. Plug the power cord into the wall outlet.

9. Turn the battery switch to the ON (|) position.

Note: After you cycle power, InTouch reboots to the Patient Information screen.

Figure 30: Network Parameters

Figure 32: Security

Return To Table of Contents

38 2141-209- 0 02 REV H www.stryker.com

Figure 31: User Authentication

Figure 33: Advanced

Page 39

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

E. Bed Options Configuration

Access the configuration screen as shown on page 24. Once in the configuration screen, follow the steps below to

access the options screen or the serial number screen.

To access the Bed Options screen:

1. Press and hold the HOB 30 button and the BRAKE button at the same time for 5 seconds, then release both

buttons. The Bed Options screen (Figure 34) will be displayed.

NOTE: When the European Community message window displays, push the Close button to close out

of the message. That is not applicable in this configuration.

Figure 34: Bed Options screen

2. Select all of the options shown on the Bed Options screen that apply to the bed configuration then, press Continue.

NOTE: In Figure 34, the options selected are iBed, iAudio, iDoc and Wi-Fi. All of the options selected will turn

green.

3. After pressing Continue in step 2, a confirmation screen

as shown in Figure 35 will be displayed verifying the

options you selected.

a. If the options on the confirmation screen do not

match the options on the bed, press the Back

button.

b. If the options on the confirmation screen match the

options on the bed, press the OK button.

4. After pressing the OK button, the options will be saved

and the screen will return to the configuration screen.

Press the Close button to close the configuration

screen.

5. After pressing the Close button, a cycle power screen

(Figure 38) will be displayed stating to cycle power on

the bed.

6. To cycle power on the bed, turn the battery disconnect

switch to OFF (O) then unplug the power cord from the

wall outlet. Plug the power cord back into the wall outlet

then turn the battery disconnect switch back ON (|).

7. Test bed functionality prior to returning the bed into service.

Figure 35: Bed Options Confirmation Screen

www.stryker.com 2141-209-0 02 RE V H 39

Return To Table of Contents

Page 40

Maintenance Menu Guide

INTOUCH CONFIGURATION SCREEN (CONTINUED)

F. Serial Number Configuration

To access the Serial Number screen:

1. Press and hold the HOB 30 button and the Vascular Position button at the same time for 5 seconds then release

both buttons. The Bed Configuration - Serial Number screen (Figure 36) will be displayed.

Pencil icon

Press to edit

Figure 36: Bed Configuration Serial Number Screen

2. Enter or confirm the serial number of the bed (Figure 36).

a. To enter the serial number:

i. Press the pencil button located to the right of the serial

number field. The Edit screen will be displayed.

ii. Enter the serial number of the bed in the serial number

field, then press the OK button. You will be returned to

the serial number main screen as shown in Figure 36.

iii. Press the Continue button and proceed to step 3.

b. To confirm the serial number:

i. Review the serial number displayed in the serial number

field.

ii. If serial number is correct, press the Back button and

proceed to step 6.

iii. If the serial number is incorrect, press the pencil icon

button to open the Edit screen then enter the correct

serial number.

iv. Press the OK button and you will be returned to the

serial number main screen.

v. Press the Continue button and proceed to step 3.

3. After pressing the Continue button, the serial number will be

saved and the serial number confirmation screen (Figure 37) will

be displayed. Press the OK button.

4. After pressing the OK button, a cycle power screen (Figure 38)

will be displayed stating to cycle power on the bed.

5. To cycle power on the bed, turn the battery disconnect switch to

OFF (O) then unplug the power cord from the wall outlet. Plug

the power cord back into the wall outlet then turn the battery

disconnect switch back ON (|).

6. Test bed functionality prior to returning the bed into service.

Figure 37: Serial Number

Confirmation Screen

Figure 38: Cycle Power Screen

Return To Table of Contents

40 2141-209 -002 REV H www.stryker.com

Page 41

Maintenance Menu Guide

A B

ACCESSING THE ISOLIBRIUM DIAGNOSTIC MENU

WARNING

• Electrical shock risk. Refer all servicing to qualified personnel.

• Do not perform diagnostic test with a patient or other weight on the support surface.

CAUTION

Do not touch the support surface while performing diagnostics test. Failure to do so could lead to inaccurate diagnostic

results.

Note: Make sure that you plug the support surface power

cord into the InTouch auxiliary mattress outlet (A) and the

integration cable to the mattress connector (B) (Figure

39).

The service display and its functions are for use by

authorized service personnel only to avoid the risk of

equipment malfunction. The entry to this menu is through a

key combination in the Support Surface menu.

To access the diagnostic menu:

Figure 39: InTouch auxiliary mattress outlet and

integration cable

1. Unplug the InTouch bed and turn the battery switch to off and wait one minute.

2. Turn the battery switch to on and plug the InTouch bed into a wall outlet.

3. Tap Support Surfaces.

4. Enter the following key combination within 5 minutes of the support surface connection (Figure 40):

a. Lock (A) (lock is activated)

b. Low Air Loss (B) (press and hold for a minimum of 5 seconds)

c. Therapy History (C) (press and hold for a minimum of 5 seconds)

B

Figure 40: Diagnostic Entry Combination

5. If you have entered into the diagnostic menu and need to exit, tap X (Figu r e 41).

A

C

www.stryker.com 2141-209-0 02 RE V H 41

Figure 41: Diagnostic Main Screen Sample

Return To Table of Contents

Page 42

Maintenance Menu Guide

REVIEWING ACTIVE ISOLIBRIUM ERRORS

Note: For Isolibrium error codes, see the Isolibrium operations/maintenance manual.

To enter the Active Errors screen, tap the Active Errors tab on the Service Diagnostic screen (Figure 42).

Figure 42: Active Errors