Page 1

InTouch® Critical

REF

White letters and

outline with

transparent

rectangle

Care Bed

Model FL27 (2131/2141)

Version 2.5

Maintenance Manual

For Parts or Technical Assistance:

USA: 1-800-327-0770

2012/04 B.1 2131-509-002 REV B www.stryker.com

Page 2

Page 3

Table of Contents

Symbols and Definitions ....................................................................7

Warning / Caution / Note Definition.........................................................8

Introduction .............................................................................9

Intended Use .........................................................................9

Brief Product Description and Intended Use Statement ..........................................9

Product Illustration....................................................................10

Specifications .......................................................................11

Summary of Safety Precautions .............................................................13

Optional Zoom® Drive System (Model 2141) .................................................15

Static Discharge Precautions ...............................................................16

Setup Procedures........................................................................17

Optional XPRT™ Therapy Mattress .......................................................18

Optional PositionPRO™ Repositioning Mattress option .........................................18

Optional Zoom® Drive System (Model 2141) .................................................19

Maintenance Menu Guide ..................................................................20

Configuration Screen ..................................................................21

A. Bed Calibration .................................................................21

B. Full Diagnostic .................................................................32

C. Touch Screen Calibration .........................................................33

D. Bed Options Configuration.........................................................34

E. Serial Number Configuration .......................................................35

Preventative Maintenance ..................................................................36

Checklist ...........................................................................36

Cleaning...............................................................................37

Troubleshooting Guide ....................................................................39

Scale Troubleshooting .................................................................45

Maintenance Error Messages ...............................................................46

Error Handling .......................................................................46

Error Messages ......................................................................46

Quick Reference Replacement Parts List ......................................................49

Quick Reference Replacement Parts List ......................................................50

CPU/Power Board - QDF75-0450 ............................................................51

Fuse Specification ....................................................................52

Bed Electrical Diagram ....................................................................53

Service Information.......................................................................70

Bed lift Actuator (Head) Removal and Replacement - (Base) .....................................70

Bed lift Actuator (Foot) Removal and Replacement - (Base) .....................................71

Fowler Actuator Removal and Replacement - (Litter) ..........................................72

Gatch Actuator Removal and Replacement - (Litter) ...........................................73

Foot Actuator Removal and Replacement - (Litter) ............................................74

Zoom® Drive Actuator Removal and Replacement (2141 Model Only) - (Base) .......................75

CPU / Power Board Removal and Replacement - (Litter)........................................76

Load Cell (Head End) Removal and Replacement - (Litter)......................................77

Load Cell (Foot End) Removal and Replacement - (Litter) ......................................78

Display Removal and Replacement - (Footboard) .............................................79

www.stryker.com 2131-509- 002 RE V B 3

Page 4

Table of Contents

Service Information (Continued)

Brake Control Board Removal and Replacement - (Footboard) ...................................80

Function Selection/LED Board Removal and Replacement - (Footboard) ...........................81

Touch Screen Removal and Replacement - (Footboard) ........................................82

Battery Removal and Replacement - (Foot Board).............................................83

Brake / Neutral / Drive Potentiometer Removal and Replacement - QDF27-2024 ......................84

Battery Removal and Replacement - (Litter) .................................................85

Fowler Angle Sensor Removal and Replacement - (Litter) ......................................86

Gatch Angle Sensor Removal and Replacement - (Litter) .......................................87

Foot Angle Sensor Removal and Replacement - (Litter) ........................................88

Base Angle Sensor Removal and Replacement - (Base) ........................................89

Trend Angle Sensor Removal and Replacement - (Litter) .......................................90

Headwall Communication Board Removal and Replacement - (Litter) ..............................91

Base Assembly, Hood.....................................................................92

Base Assembly, Brake ....................................................................95

Base Assembly, Caster Lock (2131 Model Only) .................................................98

Base Assembly, Caster Non-Lock (2141 Model Only) .............................................100

Angle Sensor Assembly - 27-2477...........................................................102

Base Assembly, Electrical .................................................................10 3

Base Assembly, Zoom® ..................................................................109

Base Assembly, Zoom® Drive (2141 Model Only) ...............................................111

Bed Labeling .......................................................................... 1 13

Lift Assembly ..........................................................................1 17

Spring Assembly........................................................................ 121

Litter Assembly.........................................................................123

Litter Assembly, Interior Frame .............................................................12 7

Litter Assembly with Serial Cable ...........................................................13 0

Litter Assembly, Upper Frame ..............................................................13 2

Litter Assembly, Foot End .................................................................13 4

Litter Assembly, Electrical .................................................................13 9

120V Electric System ....................................................................14 6

120V Straight Plug - OL250053.............................................................147

Optional 120V 90 Degree Plug - OL250055 ....................................................148

Litter Assembly, Foot End, without Mattress Connector - OL270165 ..................................149

Litter Assembly, Foot End, with Mattress Connector - OL270166 ....................................15 0

Standard Outlet - OL270247 ............................................................... 151

Litter Assembly, Optional Dual 120V Outlet ....................................................152

Optional 100V Electric System .............................................................15 4

Optional 110V Electric System .............................................................15 5

Optional 200V Electric System .............................................................156

Optional 220V Electric System .............................................................157

Optional 240V Electric System .............................................................158

CPR Assembly, Mechanical ...............................................................159

Handle Assembly (Model 2131 Only).........................................................164

Handle Assembly (Zoom® Model 2141 Only) ..................................................165

4 2131-50 9- 002 REV B www.stryker.com

Page 5

Table of Contents

Assembly Drawings (Continued)

Zoom® Assembly........................................................................167

Optional No Head End Control Panel.........................................................168

Optional Head End Control Panel Assembly ...................................................169

Head End Siderail Mounting Assembly ....................................................... 17 1

Standard Siderail Assembly, Head End, Right ..................................................172

Standard Siderail Assembly, Head End, Left ...................................................17 6

Standard Siderail Assembly, Labeling ........................................................180

Optional Siderail Ass’y, HE, without Speaker/without NC ..........................................181

Optional Siderail Ass’y, HE, with Speaker/without NC .............................................18 2

Optional Siderail Ass’y, HE, with Speaker/iAudio ................................................183

Optional Siderail Ass’y, HE, with Speaker/with NC ...............................................18 4

Optional Siderail Ass’y, HE, with iAudio - OL270164 .............................................185

Optional Siderail Ass’y, HE, with Speaker/with NC/with iAudio ......................................186

Foot End Siderail Mounting Assembly ........................................................188

Standard Siderail Assembly, Foot End, Right - Common...........................................189

Standard Siderail Assembly, Foot End, Left - Common............................................192

Standard Siderail Assembly without iBed......................................................195

Optional Siderail Assembly with iBed ........................................................196

Headboard and Footboard Assembly.........................................................197

Standard Footboard Assembly - Common .....................................................198

Footboard Assembly without iBed ...........................................................200

Footboard Assembly with iBed .............................................................203

Footboard USB Assembly ................................................................206

Optional Bed Accessories.................................................................207

Bed Extender - FA64234-XXX..............................................................208

Bed Extender Pad with Position Pro Mattress - DM64196..........................................209

Bed Extender Pad with XPRT™ Mattress - DM64197 .............................................209

Line Management System Assembly - FA64210.................................................210

I.V. Pole Assembly, Permanent - FA64221/FA64238 ..............................................211

I.V. Pole Ass’y, Dual Head End, Permanent - FA64202 ............................................2 12

Monitor Tray Assembly - FA64214 ........................................................... 214

Upright Oxygen Bottle Holder Assembly - FA64187 .............................................. 215

Right-Fit Oxygen Bottle Holder Assembly - FA64203 .............................................216

Pendant Assembly with Motion Control - FA64209 .............................................. 2 17

Pendant Assembly with Motion Control/NC - FA64226 ...........................................218

Pendant Assembly with Motion Control/Smart TV - FA64195 ....................................... 219

Pendant Assembly with Motion Control/NC/Smart TV - FA64225....................................220

Pendant Clip Assembly - FA64186 ..........................................................221

Traction Sleeve Assembly, 4” x 1/2” - FA64215 .................................................222

Traction Sleeve Assembly, 4” x 3/4” - FA64216 .................................................223

Traction Sleeve Assembly, 8” x 1/2” - FA64217 .................................................224

Traction Sleeve Assembly, 8” x 3/4” - FA64218 .................................................225

Traction Sleeve Assembly, 6-1/2” x 3/4” - FA64219 ..............................................226

Wall Saver Cable Assembly - FA64208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

www.stryker.com 2131-509- 002 RE V B 5

Page 6

Table of Contents

Service Information (Continued)

X-Ray Cassette Holder Assembly - FA64205 ...................................................228

Standard Mattress Retainer - OL270223 ......................................................230

Tube Support - OL270224-XXX.............................................................231

Recycling Passports .....................................................................232

Warranty .............................................................................248

Limited Warranty ....................................................................248

To Obtain Parts and Service ...........................................................248

Service Contract Coverage ............................................................248

Service Contract Programs ............................................................249

Return Authorization..................................................................249

Damaged Merchandise ...............................................................249

International Warranty Clause...........................................................249

6 2131-50 9- 002 REV B www.stryker.com

Page 7

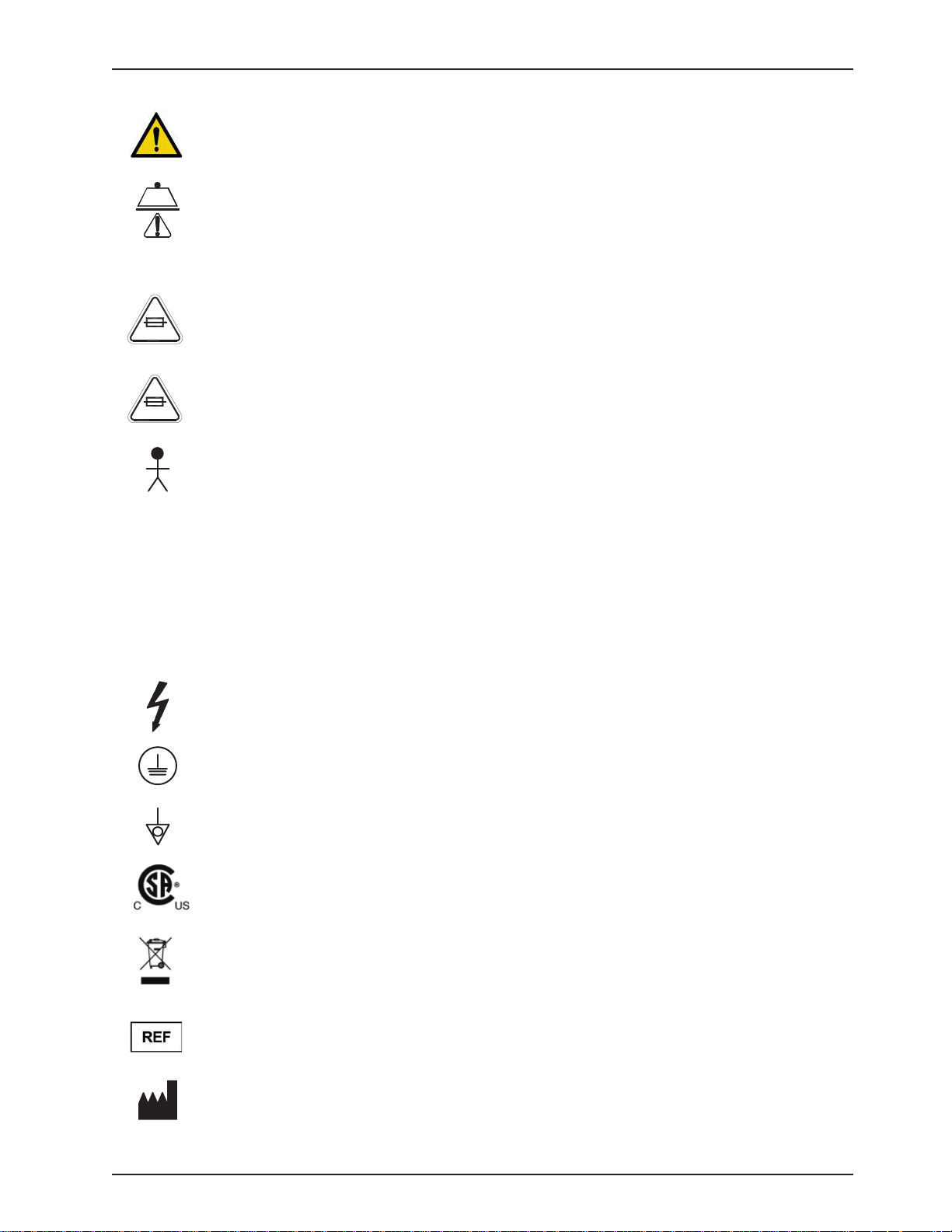

Symbols and Definitions

1.6 SYMBOLS

1.6 SYMBOLS

~

Warning/Caution, consult accompanying documentation

Safe Working Load

Alternating Current

10A 250V

6.3A 250V

IPX4

Fuse Rating for Beds with the 100V~ or 120V~ Electric System

Fuse Rating for Beds with the 200V~ or 220V~ or 240V~ Electric System

Type B Equipment: equipment providing a particular degree of protection against electric shock,

particularly regarding allowable leakage current and reliability of the protective earth connection.

Class 1 Equipment: equipment in which protection against electric shock does not rely on BASIC

INSULATION only, but which includes an additional safety precaution in that means are provided for the

connection of the EQUIPMENT to the protective earth conductor in the fixed wiring of the installation in

such a way that ACCESSIBLE METAL PARTS cannot become live in the event of a failure of the BASIC

INSULATION.

Mode of Operation: Continuous

Protection from liquid splash

Dangerous Voltage

Protective Earth Terminal

Potential Equalization

Medical Equipment approved by the Canadian Standards Association with Respect to Electric Shock,

Fire, Mechanical and Other Specified Hazards.

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this

symbol indicates that the product must not be disposed of as unsorted municipal waste, but should be

collected separately. Refer to your local distributor for return and/or collection systems available in your

country.

Model Number

Manufacturer

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 7

Page 8

Symbols and Definitions

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation, which if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation, which if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note

This provides special information to make maintenance easier or important instructions clearer.

Return To Table of Contents

8 2131-50 9- 002 REV B www.stryker.com

Page 9

Introduction

INTENDED USE

This manual is designed to assist you with the maintenance of the Stryker InTouch® Critical Care Bed, Model FL27

(2131/2141). Carefully read this manual thoroughly before using the equipment or beginning maintenance on it. To

ensure safe operation of this equipment, it is recommended that methods and procedures be established for educating

and training staff on the safe operation of this bed.

This Maintenance Manual is an integral part of the bed and should be included if the bed is sold or transferred.

BRIEF PRODUCT DESCRIPTION AND INTENDED USE STATEMENT

INTENDED MEDICAL INDICATIONS: In-touch is an AC-powered adjustable hospital bed designed to position patients

for procedures, therapy, and recovery in healthcare environment, transport patients between bays and procedural

rooms, provide patient security, measure and display patient weight, allow patients to alert caregiver when the patient

requires emergency assistance or any assistance to improve comfort levels, and monitor patient position to alert

caregiver of a deliberate exit or potential fall. The bed has thirty-nine prerecorded clinical phrases in 24 languages and

offers music therapy.

INTENDED PATIENT POPULATION: The intended patient population is acute-care human patients. The safe working

load (i.e. the sum of the patient, the mattress, and accessory weight) for InTouch is 550lbs (250kg). This bed is not

intended for use with patients 35 inches or less and/or patients that weigh less than 50 pounds.

INTENDED PART OF THE BODY: InTouch is intended to support a patient. It is intended to be used with a sleep surface.

The Frame can come in contact with human skin but a patient should never be on the frame without a support surface.

INTENDED USER PROFILE: InTouch is intended for use in Acute Care settings. These settings may include critical

care, step down, progressive care, med/surg, sub-acute care, and post anesthesia care unit (PACU) or other locations

as prescribed. Intended operators are health care professionals (nurses, nurse aids, doctors) which can use all bed

operations (e.g., bed motion functions, nurse call, siderail communications, bed exit, therapy options), patient and

bystander, which can use bed motion functions, nurse call & siderail communications, and trained professionals for

installation, service, and calibration.

INTENDED CONDITION OF USE AND EXPECTED LIFE: Stryker Medical Bed products are designed for a 10 year

expected service life under normal use, conditions, and with appropriate periodic maintenance as described in the

maintenance manual for each device. Stryker warrants to the original purchaser that the welds on its Bed products

will be free from structural defects for the expected 10 year life of the Bed product as long as the original purchaser

owns the products.

The product is intended to be used in a healthcare environment, including hospitals, surgery centers, long term acute

care centers, and rehabilitation centers. The intended environmental conditions are 10 to 40 degrees Celsius and

30 to 75% RH. The product is compatible with 35” x 84” surfaces, the facility nurse call system, standard Med-Surg

equipment, and the facility infrastructure. InTouch is intended to be used with a 6”-8.5” sleep surface; asleep surface

or overlay greater than 6” that offers therapeutic value may be used with, patient supervision.

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 9

Page 10

PRODUCT ILLUSTRATION

Introduction

Headboard

Siderail

Release

Levers

Brake Control

Panel

Nurse Control

Panel

Nurse Call

Siderails

Footboard

Control Panel

InTouch®

Screen

CPR Emergency

Release Pedal

Manual

Backup

Return To Table of Contents

10 2131-509- 002 RE V B www.stryker.com

®

Drive Wheel

Zoom

(Model 2141 only)

(Under base -

not shown)

Casters

Foley Bag

Hooks

Footboard

Page 11

SPECIFICATIONS

Safe Working Load

Introduction

Note: Safe Working Load indicates the

sum of the patient, mattress and accessory

weight.

Bed Weight 750 lbs 340.2 kg

Overall Bed Length 90” 228,6 cm

Overall Bed

Width

Base Underbed Clearance 5” 12,7 cm

Litter Patient Surface

Fowler Length 36.5” 92,7 cm

Bed Lift

System

Scale System Capacity 550 lbs 249 kg

Siderails Up 42” 106,7 c m

Siderails Down 40” 102,9 cm

• Width

• Length

• Length (with Optional Bed

Extender)

Seat Section

• Depth

Foot Section

• Length

• Angle

Fowler Section

• Length

• Width

• Angle

Gatch Section

• Length

• Width

• Angle

Cardiac Chair

• Standard Cardiac Chair Position

• Enhanced Cardiac Chair Position

Height (high) to top of litter 33” 83,8 cm

Height (low) to top of litter 16” 40,6 cm

Trendelenburg/Reverse Trendelenburg 12°

Bed Lift Time 35 seconds maximum from lowest to highest position

Accuracy:

• For weight from 100 lb to 550 lb

• For weight from 100 lb to 550 lb

• For weight under 100 lb

• For weight under 100 lb

550 lbs 249 kg

35”

84”

90”

18.5” 47 cm

29”

0° to 50°

36”

34” to 35”

0° to 70°

18”

34” to 35”

0° to 15°

Head: 65°, Seat: 17°, Foot: 30°, Trend: 3°

Head: 70°, Seat: 19°, Foot: 47°, Trend: 3°

+/- 2% when in Trendelenburg or Reverse Trendelenburg

+/- 2% when Flat

+/- 2 lb when in Trendelenburg or Reverse Trendelenburg

+/- 2 lb when Flat

88,9 cm

213,4 cm

228,6 cm

73,7 cm

0° to 50°

91,4 c m

86,4 cm - 88,9 cm

0° to 70°

45,7 cm

86,4 cm - 88,9 cm

0° to 15°

CPR System Speed to level bed from any position

• Fowler

• Foot and Seat

Drive System Speed (Optional Zoom® Drive)

• Forward

• Backwards

www.stryker.com 2131-509- 002 RE V B 11

15 seconds

60 seconds

3.6 mph

2.5 mph

5.8 km/h

4.0 km/h

Return To Table of Contents

Page 12

SPECIFICATIONS (CONTINUED)

Introduction

Mattress

Maximum

Current

Consumption

Environmental

Conditions

Electrical

Requirements

Battery

Recommended Mattress Size

•With Bed Extender DM64196

(PositionPRO) (35” x 6” x 4”)

•With Bed Extender DM64197

(XPRT™) (35” x 6” x 5.5”)

Recommended Air Mattress Size

•With Bed Extender DM64196

(PositionPRO) (35” x 6” x 4”)

•With Bed Extender DM64197

(XPRT™) (35” x 6” x 5.5”)

Without Optional Auxiliary Outlet

(120VAC O nly )

With Optional Auxiliary Outlet(s)

(120VAC O nly )

Storage

• Ambient Temperature

• Relative Humidity

• Atmospheric Pressure

Operating

• Ambient Temperature

• Relative Humidity

• Atmospheric Pressure

• Scale Accuracy

All electrical requirements meet CSA

C22.2 No. 601.1, UL 60601-1 and IEC

60601-1.60601-2-38 specifications.

12 V, 17.6 Ahr, Sealed Lead-Acid Battery (Part Number QDF9188)

3.0 V 220mAh Lithium Battery, Size 20mm - Varta Int. CR2032

Coin Cell PC Battery Holder, Size 20mm - MDP Int. BA2032

35” x 84” x 6” 88,9 cm x 213,4 cm x 15,2 cm

35” x 90” x 4” 88,9 cm x 228,6 cm x 10,1 cm

35” x 90” x 5.5” 88,9 cm x 228,6 cm x 13,9 cm

35” x 84” x 6” - 8.5”

35” x 90” x 4” 88,9 cm x 228,6 cm x 10,1 cm

35” x 90” x 5.5” 88,9 cm x 228,6 cm x 13,9 cm

4.8 Amps

9.8 Amps

-40°F to 158°F

10 to 100%

500 to 1060 hPa

50°F to 104°F

30 to 75%

700 to 1060 hPa

18 °C to 25 °C

100V~, 50-60Hz, 7.5A - Two 250V, 10A Fuses

120 ± 10% Vac, 50/60Hz - Two 250V, 10A Fuses

120V~, 50-60Hz, 4.0A (9.8A with 120V Optional Auxiliary

Outlet) - Two 250V, 10A Fuses

200V~, 50-60Hz, 3.2A -Two 250V, 10A Fuses

220V~, 50-60Hz, 2.9A -Two 250V, 10A Fuses

240V~, 50-60Hz, 2.7A -Two 250V, 10A Fuses

88,9 cm x 213,4 cm x

15,2 cm - 21,6 cm

-40°C to 70°C

10°C to 40°C

64 °F to 77 °F

Stryker reserves the right to change specifications without notice.

Specifications listed are approximate and may vary slightly from unit to unit or by power supply fluctuations.

Return To Table of Contents

12 2131-509- 002 REV B www.stryker.com

Page 13

Summary of Safety Precautions

Before operating the bed, it is important to read and understand all information in this manual. Carefully read and

strictly follow the safety guidelines listed below.

Note

To ensure safe operations of the bed, methods and procedures must be established for educating and training hospital

staff on the intrinsic risks associated with the usage of electric beds.

WARNING

• To prevent permanent damage to this unit, the unit must reach room temperature prior to conducting any setup

and/or unit operations.

• The Weigh system is intended to assist in the monitoring of the patient’s weight variation. Under no circumstances

should its reading be used as sole reference for medical treatment.

• Preventative maintenance should be performed at least once a year to ensure all bed features are functioning

properly.

• This bed is not intended for pediatric use, i.e., for any patient measuring 35 inches (88,9 cm) or less.

• This bed is equipped with a hospital grade plug for protection against shock hazard. It must be plugged directly into

a properly grounded receptacle. Grounding reliability can be achieved only when a hospital grade receptacle is used.

• Shock Hazard - Improper handling of the power cord may result in damage to the power cord and potential shock

hazards. If damage has occurred to the power cord, immediately remove the bed from service and contact the

appropriate maintenance personnel. Failure to do so could result in serious injury or death.

• Serious injury can result if caution is not used when operating the bed. Operate the bed only when all people and

equipment are clear of the electrical and mechanical systems.

• Always apply the brakes when a patient is on the bed or entering/exiting the bed. Serious injury could result if the bed

moves while a patient is getting on or off the bed. Once the brake pedal is engaged, push on the bed to ensure the

brakes are securely applied. Do the same test when using the electrical brake.

• To help reduce the number and severity of a potential fall when the patient is unattended, keep the siderails in the

fully raised position and the sleep surface horizontal in its lowest position, unless his/her medical condition dictates

otherwise. When raising the siderails, be sure that you hear the “click” that signals the locked condition. Pull firmly

on the siderail to ensure it is locked into position.

• When the sleep surface sections are articulated, ensure that all the patient’s limbs are within the raised siderails to

avoid patient injury.

• When a patient’s condition requires greater safety measures for his/her security, use the lockout controls in the

footboard control panel to inhibit the siderail functions or remove any optional pendant control and install protective

pads on the siderails.

• Siderails, with or without their padded covers, are not intended to serve as restraint devices to keep a patient from

exiting the bed. Siderails are designed to keep a patient from inadvertently rolling off the bed. It is the responsibility of

the attending medical personnel to determine the degree of restraint necessary to ensure a patient will remain safely

in bed. Failure to use the siderails properly could result in serious patient injury.

• To reduce the risk of injury, ensure the sleep surface is horizontal and in the lowest position with the siderails fully

raised and locked when moving the bed with a patient in it.

• To avoid injury to the patient and/or user, do not attempt to move the bed laterally with the steer mode engaged. The

steer wheel cannot swivel.

• The CPR emergency pedal is for emergency use only. When activating the CPR pedal, all people and equipment must

be removed from the area below and around the head, thigh and foot sections of the bed or serious personal injury

and/or equipment damage could occur.

• To stop the fowler from moving down, the CPR pedal can be released at anytime during activation.

• The manual backup brake is for emergency use only. It should not be used for any other situation than an emergency

or it might get overused when the time comes to use it for an emergency.

• Possible fire hazard exists when this bed is used with oxygen administering equipment other than nasal, mask type

or half bed-length tent type. Unplug the bed power cord from the wall when oxygen administering equipment is used.

• When using a half bed-length tent type, ensure that the siderails are outside the oxygen tent and that the tent does

not extend below the mattress support level. Do not route the power cord between the mattress and the bed frame.

• Do not attach the power cord to any moving parts of the bed frame.

• The power cord could be pinched and may cause electrical shock if a bed extender is used.

• The Bed Exit system is not designed to be used with patients weighing less than 50 lbs (23 kg).

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 13

Page 14

Summary of Safety Precautions

WARNING (CONTINUED)

• The Bed Exit system is intended only to aid in the detection of a patient exiting the bed. It is not intended to replace

patient monitoring protocol. The Bed Exit system signals when a patient is about to exit the bed. The addition or

removal of equipment with the Bed Exit system armed must be done using the “Adding or Removing Equipment

with the System Armed” procedure, otherwise the sensitivity of the system may be affected and the readings of the

patient’s movements in the bed may be erroneous.

• Do not steam clean, hose off or ultrasonically clean the bed. Do not immerse any part of the bed. The internal

electrical parts may be damaged by exposure to water. Hand wash regularly all surfaces of the bed with warm water

and a mild detergent. Wipe cleaned surfaces dry to avoid build-up of cleaning substances. Inspect the mattress

after each use. Discontinue use if any cracks or rips, which may allow fluid to enter the mattress, are found in the

mattress cover. Failure to properly clean the mattress, or dispose of it if defective, may increase the risk of exposure

to pathogenic substances and may bring about diseases to the patient and user.

• Always unplug the bed power cord from the wall socket when servicing or cleaning the bed. When working under the

bed with the bed in the high position, always apply the brakes and place blocks under the Bed Lift levers to prevent

injury in case the Bed Down switch is accidentally pressed.

• Please ensure patient is not in the bed prior to starting bed calibration. In calibration mode, the software does

not control the interferences between the mechanical parts of the bed. Mechanical damage could occur without

supervision. Only qualified personnel should perform the calibration.

• Battery posts, terminals and related accessories contain lead and lead compounds - chemicals known to the state

of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

• Do not modify the InTouch® bed. Modifying the unit can cause unpredictable operation resulting in injury to the

patient or user. Modifying the unit will also void this warranty.

CAUTION

• When using a mattress thicker than 6 inches (15,24 cm) or a mattress overlay, extra caution and/or patient supervision

may be required to reduce the likelihood of occurrence of a patient fall.

• Preventative maintenance should be performed at least once a year to ensure all bed features are functioning

properly. Ensure that any bed malfunction is promptly reported to your service personnel for immediate attention.

• When large fluid spills occur in the area of the circuit boards, cables and motors, immediately unplug the bed power

cord from the wall socket, remove the patient from the bed and clean up the fluid. Have maintenance completely

check the bed. Fluids can have an adverse effect on operational capabilities of any electrical product. DO NOT

put the bed back into service until it is completely dried and has been thoroughly tested for safe operation. Ensure,

among other things, that the plastic components being used as covers for the siderail mechanism arms and the foot

end casing are removed and that the parts they cover are thoroughly dried.

• To avoid damage to the siderail mechanisms, do not move the bed using the raised siderails. Move the bed using the

handles integrated to the boards.

• Because individual beds may have different options, footboards should not be moved from one bed to another.

Mixing footboards could result in unpredictable bed operation.

• The mattress thickness should not exceed 6 inches (15,24 cm).

• When servicing, use only identical replacement parts provided by Stryker.

• SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO THE PRODUCT IF

USED IMPROPERLY. If the products described above are used to clean Stryker patient care equipment, measures

must be taken to ensure the beds are wiped with a damp cloth soaked in clean water and thoroughly dried following

cleaning. Failure to properly rinse and dry the beds will leave a corrosive residue on the surface of the bed, possibly

causing premature corrosion of critical components. Failure to follow the above directions when using these types

of cleaners may void this product’s warranty.

Note

• Throughout this Operations Manual, the words “right” and “left” refer to the right and left sides of a patient lying on

his/her back on the bed.

• The addition of accessories affects the motion of the bed.

• The iBed option is only used as an informational feature and is not supposed to replace normal patient monitoring

protocol.

Return To Table of Contents

14 2131-509-002 REV B ww w.stryker.com

Page 15

Summary of Safety Precautions

OPTIONAL ZOOM® DRIVE SYSTEM (MODEL 2141)

In addition to the previous warnings and cautions, all of the following warnings and cautions apply to units equipped

with the Zoom®.

WARNING

• The 2141 InTouch® Bed is intended for use by trained hospital personnel only. Failure to properly train personnel

could result in injury.

• USE CAUTION while maneuvering the unit with the drive wheel activated. Always ensure there are no obstacles

near the unit while the drive wheel is activated. Injury to the patient, user or bystanders or damage to the frame or

surrounding equipment could occur if the unit collides with an obstacle.

• Use caution when transporting the unit down halls, through doors, in and out of elevators, etc. Damage to the

siderails or other parts of the unit could occur if the unit comes in contact with walls or door frames.

• Put the drive wheel in the neutral position and release the brake before pushing the unit manually. For 2141 models;

push the Brake Off button to disengage drive wheel (Zoom®) before pushing the unit manually. Do not attempt

to push the unit manually with the drive wheel engaged. The unit will be difficult to push and injury could result.

• If unanticipated motion occurs, unplug the power cord from the wall socket, push the battery power on/off switch

to the “OFF” (0) position (the LED will not be illuminated), actuate the drive wheel pedal to the neutral position

and call maintenance.

• The power save mode is activated after one hour on battery power with no motion release switch activation.

Functions including Bed Exit, Scale and Motion will cease to operate when the unit enters the power save mode.

Injury to the patient could occur if proper patient monitoring protocol is not observed.

• Always unplug the power cord and push the battery power on/off switch to the “OFF” (0) position before service

or cleaning. When working under the frame, always support the litter frame to prevent injury in case the Bed Down

switch is accidently activated.

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 15

Page 16

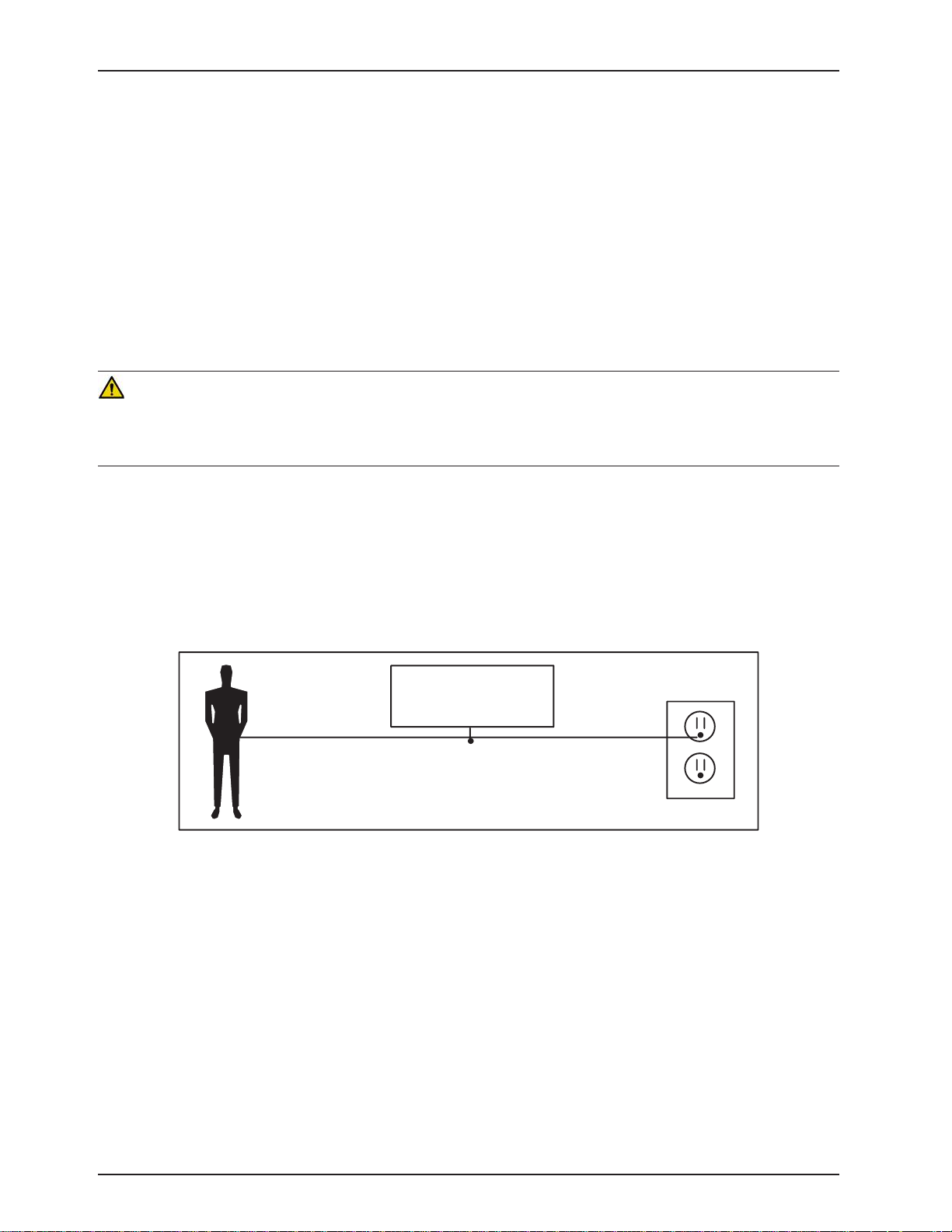

Static Discharge Precautions

The electronic circuits in the InTouch® Critical Care Bed are completely protected from static electricity damage only

while the bed is assembled. It is extremely important that all service personnel always use adequate static protection

when servicing the electronic systems of the InTouch® Critical Care Bed. You should be using static protection

whenever you are touching wires.

Static Protection Equipment

The necessary equipment for proper static protection is:

• 1 static wrist; 3M part number 2214 or equivalent,

• 1 grounding plug; 3M part number 61038 or equivalent,

• 1 test lead with a banana plug on one end and an alligator clip on the other; Smith part number N132B699 or

equivalent.

CAUTION

All electronic service parts will be shipped in static shielding bags. Do not open the bags until you have completed steps

2 and 3 of the following procedure. Do not place unprotected circuit boards on the floor. All circuit boards to be returned

to Stryker Medical should be shipped in the static shielding bags the new boards were shipped in.

Static Protection Procedure

1. Unplug the power cord from the power source.

2. Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the banana plug of the

test lead into the receptacle on the grounding plug. Connect the alligator clip on the other end of the test lead to

a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the alligator clip at the other end of the wrist strap cord

to a ground point on the bed.

BED

GROUNDING DIAGRAM

Return To Table of Contents

16 2131-50 9- 002 RE V B www.stryker.com

Page 17

Setup Procedures

To prevent permanent damage to this unit, the unit must reach room temperature prior to conducting any setup

and/or unit operations.

It is important to ensure that the bed is working properly before it is put into service. The following list will help

ensure that each part of the bed is checked.

• Install the foot and head boards on the bed. Insert the footboard carefully so that the footboard and the casing

connectors fit in smoothly.

CAUTION

Because individual beds may have different options, footboards should not be moved from one bed to another. Mixing

footboards could result in unpredictable bed operation.

• Plug the power cord to the bed connector at the head end of the bed and into a properly grounded hospital grade

wall outlet.

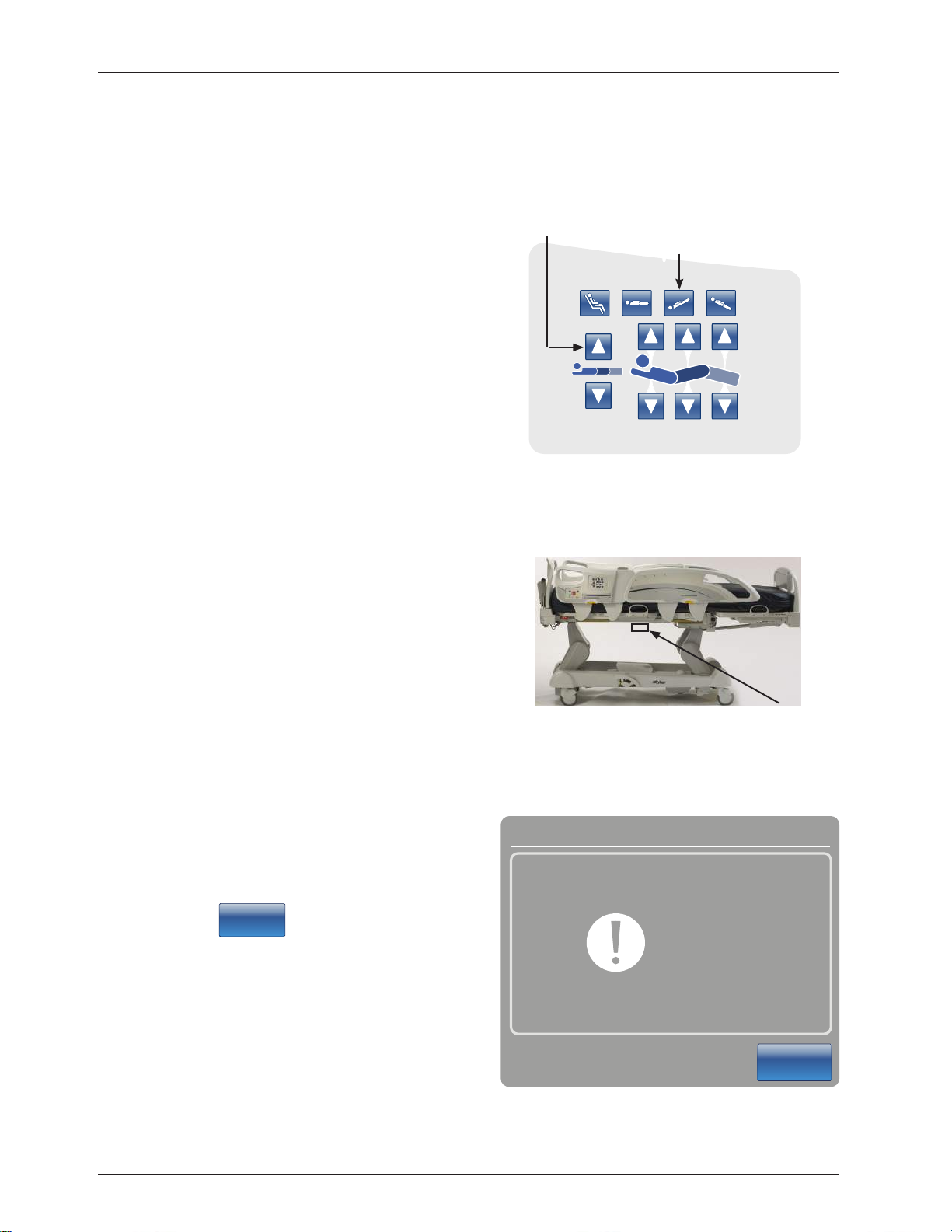

• Turn the battery power switch to the “ON” (1) position (located below the litter surface at patient right side).

• Set the time and date through the touch screen (refer to the InTouch® Operations Manual for procedures).

WARNING

This bed is equipped with a hospital grade plug for protection against shock hazard. It must be plugged directly into a

properly grounded receptacle. Grounding reliability can be achieved only when a hospital grade receptacle is used.

• To test the manual backup brake (located on the patient’s right side only), flip the manual backup brake pedal

outward and depress down fully on the foot end side of the pedal. The word BRAKE in red will be visible in the

clear window located on the base next to the pedal and the Brake symbol will be flashing on the footboard control

panel. The brakes should now be applied.

• To test the electric brake; engage the brake by pressing the brake button on the siderail or footboard control panel.

Try moving the bed to ensure the brakes are applied. Press the Neutral or Brake button on the siderail control panel

or on the footboard to disengage the brake.

• For Model 2141 Beds only: On the patient’s right side, flip the manual backup brake pedal outward and depress

down fully on the head side of the pedal. The letter D in GREEN should be visible in the clear window located on

the base next to the pedal. The Zoom® Drive wheel should now be engaged. Depress down fully on the center

of the pedal until the letter N in BLUE is visible in the clear window. The Zoom® Drive wheel should now be

disengaged.

• Ensure that the siderails raise, lock in the fully raised position and lower smoothly.

• Run through each control on the footboard.

• Verify the scale system and the Bed Exit system for proper operation.

• Run through each control on both inner and outer control panels of the head siderails. If the bed is equipped with

the optional Siderail Communication Pendant, plug the provided cable to the 37-pin connector located at the head

end of the bed and into the proper wall outlet.

• Raise the bed completely and activate the Trendelenburg function. Ensure the head end lowers to the full down

position (refer to the InTouch® Operations Manual for procedures). Level the bed using the Bed Lift system

controls.

• Raise the bed completely and activate the reverse Trendelenburg function. Ensure the foot end lowers to the full

down position (refer to the InTouch® Operations Manual for procedures). Level the bed using the Bed Lift system

controls.

• Verify functionality of the CPR emergency release: raise the fowler up then depress down on the CPR pedal

located on either side of the bed at the head end of the base. The fowler will lower towards a flat position until

the pedal is released.

• Ensure the Knee Gatch (if raised) also starts flattening when the Fowler is completely down. Following the

complete lowering of the Fowler, wait approximately 30 seconds (the time for the Fowler control motor to reset)

and verify that the motor has indeed reset by raising the Fowler fully up using the “Fowler Up” control.

• Verify the following optional equipment for proper operation: 120V Auxiliary Outlet, Head End Nurse Controls,

Pendant, Roller Bumpers, Zoom® Handles, etc.

• To prevent permanent damage to the bed, ensure the unit reaches room temperature prior to use.

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 17

Page 18

Setup Procedures

OPTIONAL XPRT™ THERAPY MATTRESS

If your bed is equipped with the XPRT™ Therapy Mattress option, perform the following setup procedures to install

the Mattress. For graphic representation of the setup procedures, refer to the XPRT™ Therapy Mattress Operations

Manual.

CAUTION

When using a mattress thicker than 6 inches (15,24 cm) or a mattress overlay, extra caution and/or patient supervision

may be required to reduce the likelihood of occurrence of a patient fall.

1. Place mattress over bed litter with printed logo at head end of the bed.

2. Fold back foot end section of mattress.

3. Place foot box on foot end of bed litter.

4. Connect the two (2) color coded connectors on the foot box to the corresponding color coded connectors on the

mattress. Connect black connection on foot box to cable adapter 2950-001-180 and then to the bed frame.

5. Turn the locking collars clockwise to secure the connections.

6. Connect the other end of the black connector to the bed (left side of litter at foot end behind the accessory outlet).

7. Connect the air line from the mattress to the corresponding fitting on the foot box.

8. Fasten the two (2) retaining clips to the two (2) D-Rings on the foot box.

9. Lower the foot section of mattress over the foot box. Attach the mattress to the bed frame using the mattress

tie-downs.

10. Apply linens utilizing the “D” rings for the flat sheet.

11. To secure linens, to mattress, thread four corners through D-Rings attached to mattress.

12. To ensure proper therapy, do not pull linens taut. The linens should remain loose and wrinkly on the surface of

the mattress.

13. Plug the mattress power cord into a properly grounded, hospital grade receptacle.

Note

The InTouch® bed will detect when the mattress has been connected as well as what type of mattress it is. This will

be shown on the InTouch® screen.

WARNING

• Do not route the power cord between the mattress and the bed frame.

• Do not attach the power cord to any moving parts of the bed frame.

• The power cord could be pinched and may cause electrical shock if a bed extender is used.

OPTIONAL POSITIONPRO™ REPOSITIONING MATTRESS OPTION

If your bed is equipped with the PositionPRO™ Patient Repositioning Mattress option, perform the following setup

procedures to install the mattress. For graphic representation of the setup procedures, refer to the PositionPRO™

Mattress Operations Manual.

CAUTION

When using a mattress thicker than 6 inches (15,24 cm) or a mattress overlay, extra caution and/or patient supervision

may be required to reduce the likelihood of occurrence of a patient fall.

1. Place the mattress onto the bed.

2. Flip the foot section towards the head end.

3. Place the control box (upside down) into the opening in the foot section.

4. Connect outer transparent tubes to manifold, matching the color coding.

Return To Table of Contents

18 2131-50 9- 002 RE V B www.stryker.com

Page 19

Setup Procedures

OPTIONAL POSITIONPRO™ REPOSITIONING MATTRESS (CONTINUED)

5. Connect tilt sensor cables.

a. Align the white dots.

b. Twist clockwise to fasten.

6. Connect pendant cable.

7. Connect power cord (4’) and turn the switch to on.

Note: The switch is hidden under the power cord.

8. Fasten straps over the power cord.

9. Install the power cord in the two (2) retaining clips.

10. Fasten the three (3) retaining straps.

11. Carefully rotate the foot end control box and the mattress into the flat position.

CAUTION

Gently lower the foot end section to not damage the control box.

12. Fasten the retaining straps to secure the mattress to the bed frame (four (4) straps total).

13. Connect the power cord to the 110V outlet on the bed.

Applying the linens

1. Apply the linens using the “D” rings for the flat sheet.

2. To effectively use the “Turn Assist”, do not pull linens taut. Linens should remain loose and wrinkly on surface of

the mattress.

WARNING

Ensure that you have always access to the CPR straps.

Note

If any problems are found during bed setup, contact our Technical Service department at USA: 1-800-327-0770 (option

2).

OPTIONAL ZOOM® DRIVE SYSTEM (MODEL 2141)

If your bed is equipped with the Zoom® drive, run through the preceding setup procedures and continue with the

procedures listed below.

• With the battery power switch in the “ON” (1) position and the drive wheel in the neutral position (not touching the

floor), ensure the “Engage Drive Wheel” LED on the head end control panel is illuminated.

• Run through the operation of the drive wheel (refer to InTouch® Operations Manual for procedures) to ensure it

is operating properly.

• On both sides of the bed, flip the manual backup brake pedal outward and depress down fully on the head side of

the pedal. The letter D in GREEN should be visible in the clear window located on the base next to the pedal. The

Zoom® drive (2141 Model only) should now be engaged. Depress down fully on the center of the pedal until the

letter N in BLUE is visible in the clear window. The Zoom® drive should now be disengaged.

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 19

Page 20

Maintenance Menu Guide

The Maintenance Menu is accessed through the Touch Screen and contains additional features of the product. This

menu provides an interface to the user and/or service personnel in order to provide the ability to control and access

maintenance features.

ACCESSING CONFIGURATION SCREEN

WARNING

Please ensure patient is not in the bed prior to starting bed calibration. In calibration mode, the software does

not control the interferences between the mechanical parts of the bed. Mechanical damage could occur without

supervision. Only qualied personnel should perform the calibration.

Note

Verify that the bed is on a level surface which does not have any slopes or inclines prior to entering into the

calibration mode.

1. Unseat and reseat the footboard and wait until the main control screen is displayed.

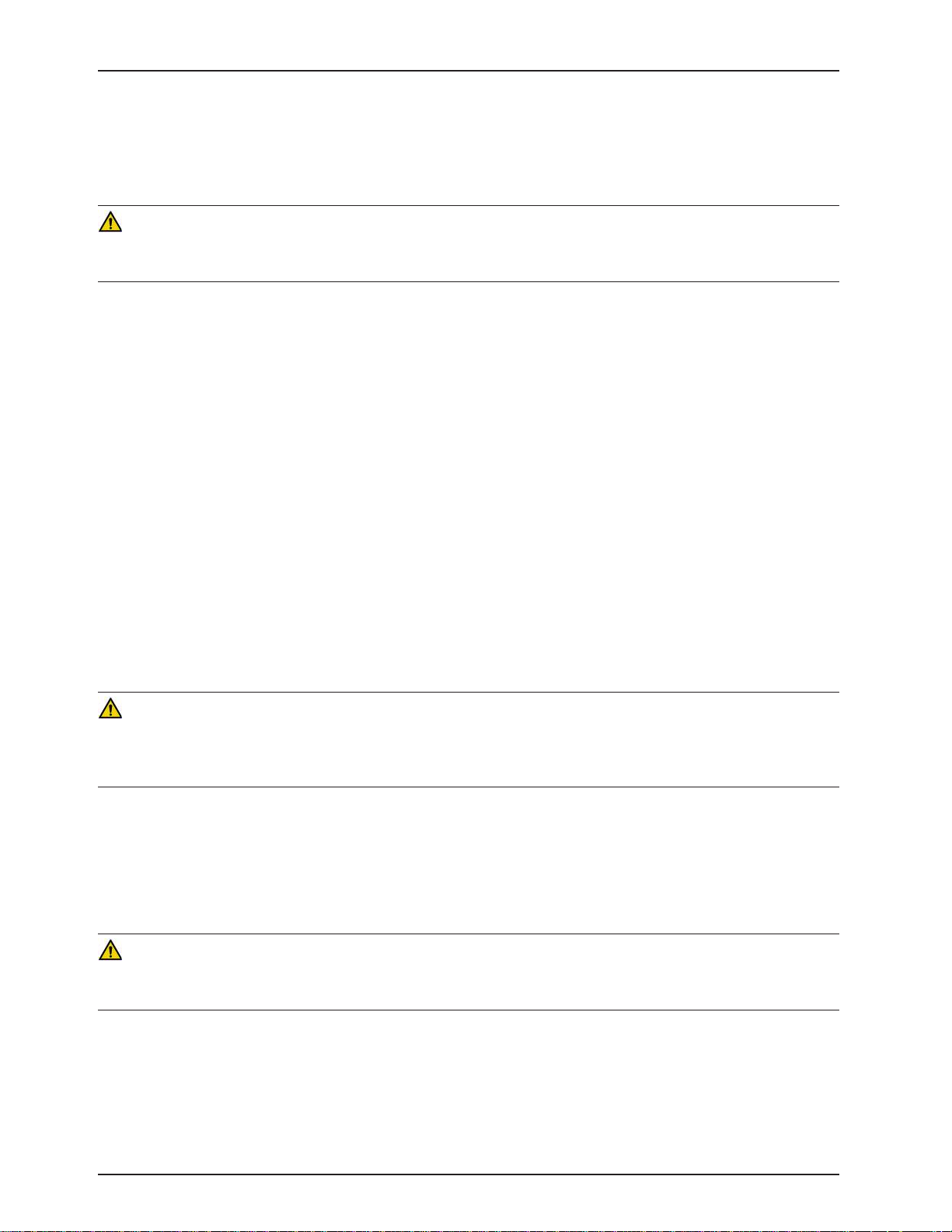

2. Push and hold the Main Menu button located in the upper right corner of the footboard control panel

(see Figure 1 below). Continue pressing on the Main Menu button while executing steps 3-5.

3. Push and hold the Brake button for 8-10 seconds and then release.

4. Push the HOB 30o+ button once and release.

5. Push the Drive button once and release.

6. Release the Main Menu button and you will be taken into the Conguration Screen shown in Figure 2.

HOB

Brake

Main Menu

Drive

Figure 1: Footboard Control Panel

Figure 2: Conguration Screen

Return To Table of Contents

20 2131-509-002 REV B www.stryker.com

Page 21

Maintenance Menu Guide

CONFIGURATION SCREEN

The following items A, B, and C are configuration buttons

available and displayed on the Configuration screen

(Figure 3).

A. Bed Calibration

B. Full Diagnostic (see page 32)

C. Touch Screen Calibration (see page 33)

The following items D and E are configuration options

available but are not displayed on the Configuration

screen To access these configuration options, follow the

procedures identified on page listed below.

D. Bed Options Configuration (see page 34)

E. Serial Number Configuration (see page 35)

Figure 3: Configuration Screen Menu Items

A. Bed Calibration

Note: During calibration, if the backlight shuts off touch the screen to continue.

WARNING

Refer to Figure 4 for WARNING details.

1. To start the bed calibration, press the Bed Calibration button on the Configuration Screen (refer to Figure 3).

2. After pressing the Bed Calibration button, Figure 4 will be displayed. Press “NEXT” to continue with

calibration.

Figure 4: Bed Calibration - WARNING

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 21

Page 22

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

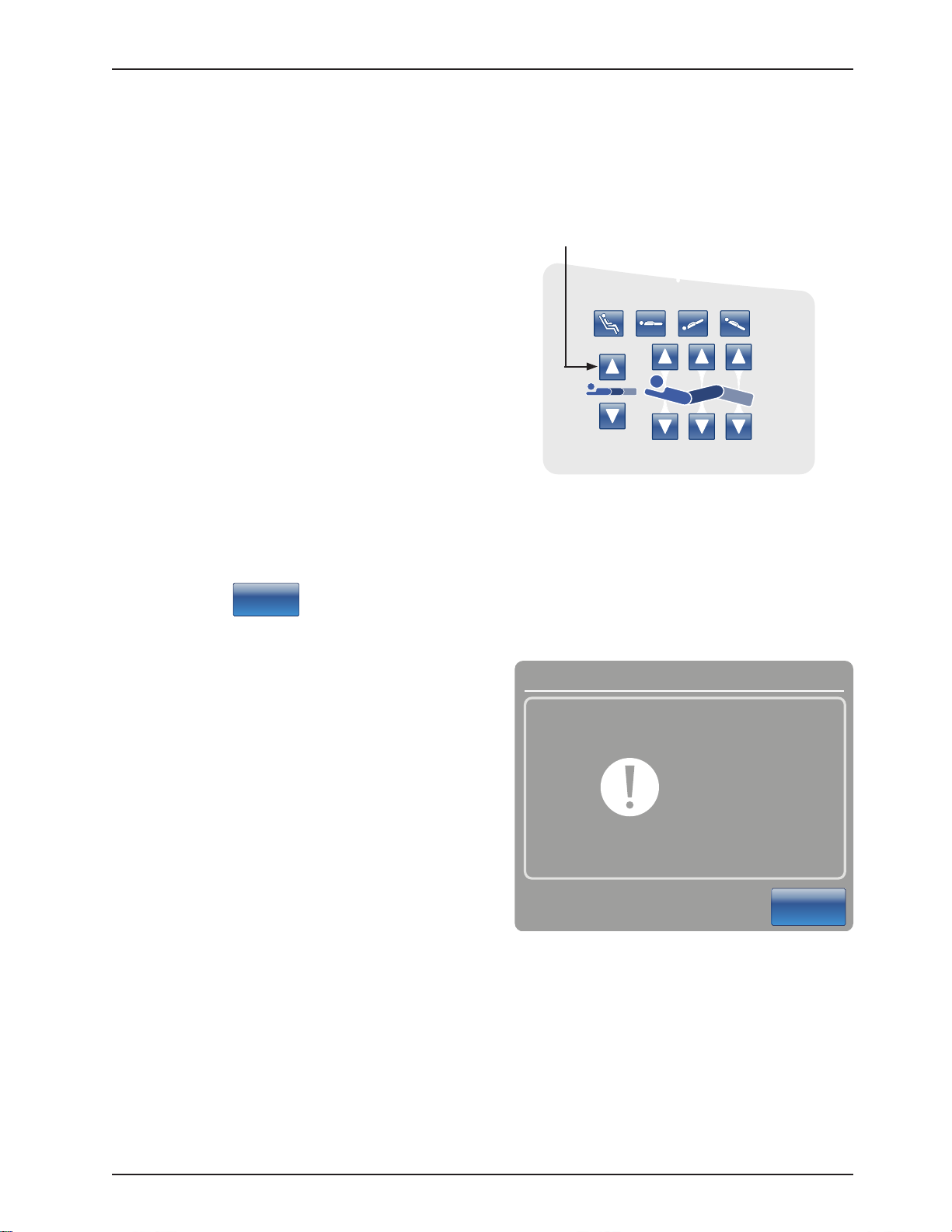

3. After pressing “NEXT” to continue calibration,

Figure 5 will appear.

Figure 5: Bed Calibration - Step #1 of 6

4. Place the Litter surface to a flat position

by pressing simultaneously the Foot Up,

Fowler Down and Gatch Down buttons as

shown in Figure 6.

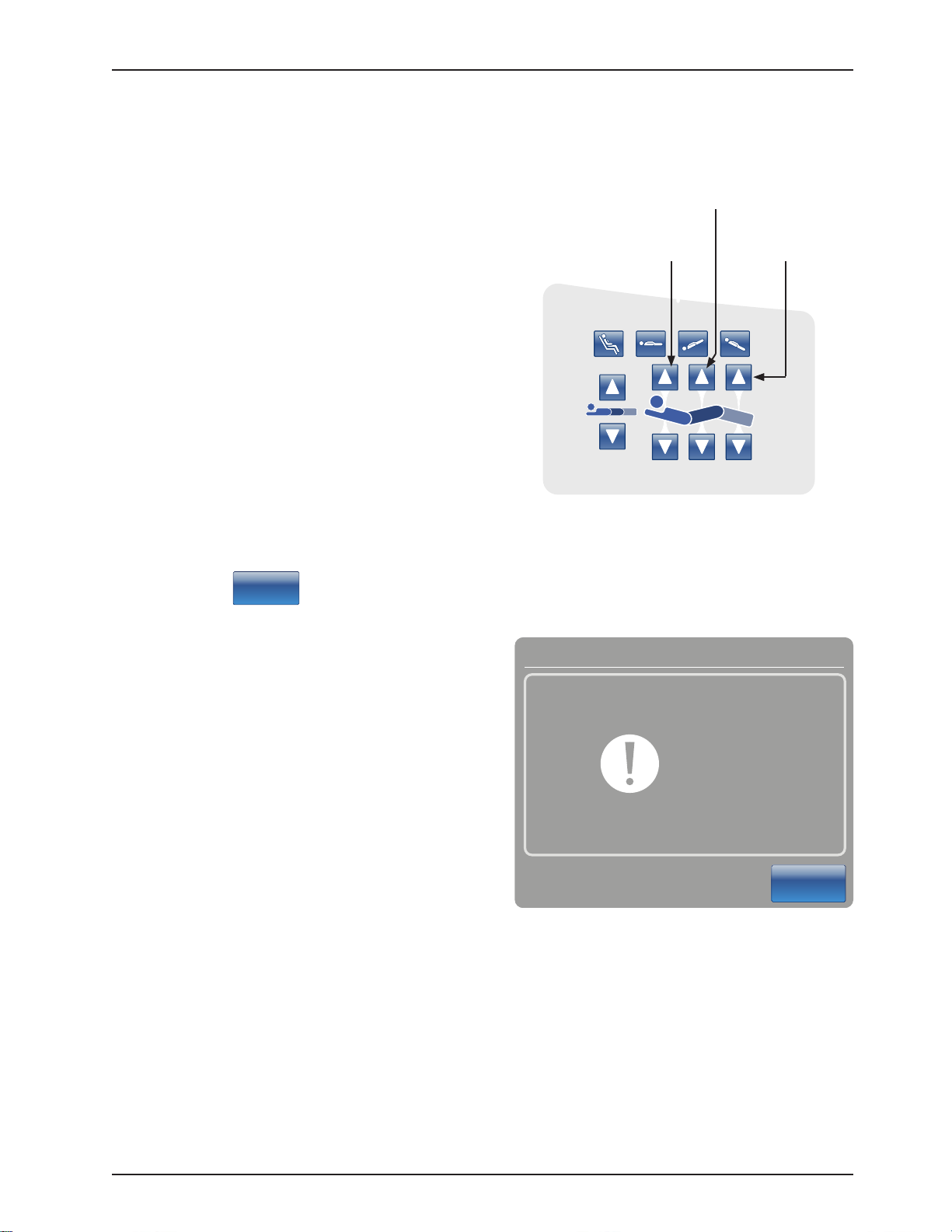

5. Lower the bed to the lowest position. Press

the Bed Height Down (Head Lift Down) and

Reverse Trendelenburg (Foot Lift Down)

buttons simultaneously as shown in Figure 7.

Foot Up

QDF27-2237

Fowler Down

Gatch Down

Figure 6: HE Siderail Control Panel - (Right Side Shown)

Reverse Trendelenburg

(Foot Lift Down)

Bed Height

Down

(Head Lift

Down)

QDF27-2237

Figure 7: HE Siderail Control Panel - (Right Side Shown)

Return To Table of Contents

22 2131-50 9- 002 RE V B www.stryker.com

Page 23

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

Bed Calibration

Do Not

Touch Bed

6. Press the

Next

button when done. The “Do

Not Touch Bed” screen will appear as shown in

Figure 8.

Cancel

Figure 8

7. When step 1 of the calibration procedure has completed, step 2 of the calibration procedure will begin and

Figure 9 will be displayed as shown below.

Figure 9: Bed Calibration - Step 2

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 23

Page 24

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

8. Raise the bed height to 20 inches measuring

from the top of the seat section to the floor.

Press the Bed Height Up (Head Lift Up) and

Trendelenburg (Foot Lift Up) buttons as

shown in Figure 10.

9. Standing on either side of the bed at the fowler

section, raise the foot siderail and then position

the digital level/inclinometer on the bottom of

the litter below the mattress retainer (refer to

Figure 11). Using the digital level/inclinometer,

verify the bed is level (0.0 +/- 0.2).

Bed Height Up

(Head Lift Up)

Trendelenburg

(Foot Lift Up)

Figure 10: Head Siderail Control Panel

(Right Side Shown)

QDF27-2237

Note: Cycle power on the digital level/

inclinometer prior to placing it on the

bottom of the litter frame and do not zero/

calibrate the digital level/inclinometer.

10. Press the

Next

button when done. The

“Do Not Touch Bed” screen will appear as

shown in Figure 12.

Placement

on Litter

Figure 11: Inclinometer placement

Bed Calibration

Do Not

Touch Bed

Cancel

Figure 12: Do Not Touch Bed Screen

Return To Table of Contents

24 2131-509- 002 RE V B w ww.stryker.com

Page 25

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

11. When step 2 of the calibration procedure has completed, step 3 of the calibration procedure will begin and

Figure 13 as shown below will appear on the screen.

Figure 13: Bed Calibration - Step 3

12. Place the bed at +12 degrees Trendelenburg by pressing

the Trendelenburg (Foot Lift Up) button as shown in

Figure 14. Verify +12 degrees +/- 0.1 with the inclinometer

you previously placed on the litter frame in step 9.

Trendelenburg

(Foot Lift Up)

QDF27-2237

Figure 14: Head Siderail Control Panel

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 25

Page 26

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

Bed Calibration

13. Press the

Next

button when done.

Do Not

Touch Bed

14. The “Do Not Touch Bed” screen will appear as

shown in Figure 15.

Cancel

Figure 15: Do Not Touch Bed Screen

15. When step 3 of the calibration procedure has completed, step 4 of the calibration procedure will begin and

Figure 16 will be displayed as shown below.

Figure 16: Bed Calibration - Step 4

Return To Table of Contents

26 2131-50 9- 002 REV B www.stryker.com

Page 27

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

16. Level the bed back out to zero degrees by pushing

the Reverse Trendelenburg button until the litter

is level while referencing the inclinometer. Note:

Confirm inclinometer reads zero degrees.

17. Place the bed at -12 degrees Reverse Trendelenburg

by pressing the Bed Height Up (Head Lift Up) button

as shown in Figure 17 below. Verify -12 degrees +/-

0.1 with the inclinometer you previously placed on the

bottom of the litter frame in step 9.

18. Press the

19. The “Do Not Touch Bed” screen will appear as

shown in Figure 18.

Next

button when done.

Bed Height Up

(Head Lift Up)

QDF27-2237

Figure 17: Head Siderail Control Panel -

(Right Side Shown)

Bed Calibration

Do Not

Touch Bed

Cancel

Figure 18: Do Not Touch Bed Screen

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 27

Page 28

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

20. When step 4 of the calibration procedure has completed, step 5 of the calibration procedure will begin and

Figure 19 will appear on the screen as shown below.

Figure 19: Bed Calibration - Step 5

21. Place the bed at the highest height by pressing

simultaneously the Trendelenburg (Foot Lift Up)

button and Bed Height Up (Head Lift Up) button as

shown in Figure 20.

Trendelenburg

(Foot Lift Up)

Bed Height Up

(Head Lift Up)

QDF27-2237

Figure 20: Head Siderail Control Panel -

(Right Side Shown)

Return To Table of Contents

28 2131-509- 002 REV B www.stryker.com

Page 29

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

Gatch Up

22. Press the Fowler Up button until the Fowler reaches

the highest height, next press the Gatch Up button

until the Gatch reaches its highest height, lastly

press the Foot Up button until the foot section

reaches its highest height (refer to Figure 21

below). The foot section should be at a flat position.

23. Press the

Next

button when done.

24. The “Do Not Touch Bed” screen will appear as

shown in Figure 22.

Fowler Up

Figure 21: Head Siderail Control Panel -

(Right Side Shown)

Bed Calibration

Do Not

Touch Bed

Foot Up

QDF27-2237

Cancel

Figure 22: Do Not Touch Bed Screen

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 29

Page 30

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

25. When step 5 of the calibration procedure has completed, step 6 of the calibration procedure will begin and

Figure 23 will be displayed as shown below.

Figure 23: Bed Calibration - Step 6

26. Place the bed at the highest height by pressing

simultaneously the Trendelenburg (Foot Lift Up)

button and Bed Height Up (Head Lift Up) button (see

Figure 24).

27. Place the Fowler and Gatch section of the bed at the

highest height by first pressing the Fowler Up button

then the Gatch Up button (See Figure 24).

28. Place the foot at the lowest position by pushing the

Foot Down button until limit is met (see Figure 24) .

CAUTION: The Gatch must be raised to the highest

height prior to running the Foot Down or damage

could occur.

Bed Height Up

(Head Lift Up)

Fowler Up

Trendelenburg

(Foot Lift Up)

Gatch Up

Figure 24: Calibration Complete

Foot Down

QDF27-2237

Return To Table of Contents

30 2131-509-002 REV B w ww.stryker.com

Page 31

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

A. Bed Calibration (Continued)

29. When the calibration procedure is completed, Figure 25 will be displayed as shown below.

30. Press the Close button to exit the Calibration Procedure Menu.

31. Level the litter flat using the CPR pedal. Verify all display readings are zero degrees while the bed is at

33” (84 cm) (highest height). Lower the bed to 16” (41 cm) (lowest height) and verify the display readings

maintain a constant reading of zero degrees with no fluctuations. When the bed reaches it lowest height

at 16”, verify the display readings are still at zero degrees.

Note: If readings are not all zero, you will need to recalibrate the bed by repeating steps 1-30.

Figure 25: Calibration Complete

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 31

Page 32

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

B. Full Diagnostic

1. From the Configuration Screen, press the

Full Diagnostic button. Figure 26 will appear.

2. The following menu items may be selected

by pressing their button.

a. BOARDS (Figure 27a)

Provides information on the switch

boards and the touch screen’s

software version.

b. ERROR CODES (Figure 27b)

Provides information on errors which

the CPU board has identified.

c. IN PUT STAT ES (Figure 27c)

Provides information on the status of

all switches and jumpers on the bed.

d. MOTORS (Figure 27d)

Provides information on what a motor is doing when a function button is pushed.

Note: This requires assistance to press the buttons on the head siderails or at the head end control.

e. BUTTONS PRESSED (Figure 27e)

Provides information on when the CPU has detected a button being pressed.

Note: This requires assistance to press the buttons on the head siderails or at the head end control.

f. SIGNAL VALUES (Figure 27f)

Provides information on CPU voltages, load cell values, and angle sensor values.

Figure 26: Full Diagnostic Screen

Boards Connected

Nurse A.0 A.1

Nurse (SRH) A.1

Nurse (SRL) A.1

Nurse (SRR) A.1

Power board B.37

Room Interface A.1

TouchScreen D.3

Figure 27a: Board

Motors

Gatch - Reverse

Hilo Foot - Forward

Foot - Forward

Figure 27d: Motor

Close

Close

Figure 27c: Input StatesFigure 27b: Error Codes

Buttons Pressed

Nurse SRR - Trend

Footboard - Hob

Nurse Head - Leg up

Close

Figure 27e: Pressed Buttons Figure 27f: Signal Values

Return To Table of Contents

32 2131-509- 002 REV B www.stryker.com

Page 33

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

C. Touch Screen Calibration

Ensure patient is not present on the bed before performing the Touch Screen Calibration.

1. From the Configuration Screen, press the Touch Screen Calibration button, Figure 28 will appear.

NOTE: If the touch screen will not respond, you will need to push the HOB

300+, Brake and Drive buttons on the footboard at the same time (this will

enable you to get directly into the touch screen calibration).

CAUTION: When pushing the buttons above the fowler, brakes, or drive actuators may activate.

2. Carefully press and briefly hold a stylus or your finger on the center of the target (cross-hair) shown on the

screen. Repeat as the target moves around the screen. There will be four different locations to press: upper

center, lower center, center left and center right.

3. When the last target has been touched, the Figure 29 will be displayed to inform you the ‘New calibration

settings have been measured’.

4. Tap the screen to register saved data.

Figure 28: Touch Screen Calibration: Start Figure 29: Touch Screen Calibration: Completed

5. If you do not want to save the new data, wait for 30 seconds to cancel saved data and keep the current setting.

NOTE: The TOUCH SCREEN CALIBRATION SCREEN is a validation of the touch screen’s calibration. When the

user presses anywhere on the screen, the coordinates x and y are displayed on the lower part of the screen.

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 33

Page 34

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

D. Bed Options Configuration

Access the configuration screen as shown on page 20 . Once in the configuration screen you will need to follow the

steps below to access the options screen or the serial number screen.

To access the Bed Options screen:

1. Press and hold the HOB 30 button and the BRAKE button at the same time for 25 seconds then release both

buttons. The Bed Options screen (Figure 30) will be displayed.

NOTE: When the European Community message window displays, push the Close button to close out

of the message. That is not applicable in this configuration.

Figure 30: Bed Options screen

2. Select all of the options shown on the Bed Options screen that apply to the bed configuration then press the

Continue button.

Note: In Figure 30, the options selected are Zoom, iBed and iAudio. All of the options selected will turn

green.

3. After pressing Continue in step 2, a confirmation screen

as shown in Figure 31 will be displayed verifying the

options you selected.

a. If the options on the confirmation screen do not

match the options on the bed, press the Back

button.

b. If the options on the confirmation screen match the

options on the bed, press the OK button.

4. After pressing the OK button, the options will be saved

and the screen will return to the configuration screen.

Press the Close button to close the configuration

screen.

5. Cycle the power to the bed by first turning the battery

disconnect switch to OFF (O) then unplug the power

cord from the wall outlet. Plug the power cord back

into the wall outlet and then turn the battery disconnect

switch back ON (|).

6. Test bed functionality prior to returning the bed into service.

Figure 31: Bed Options Confirmation Screen

Return To Table of Contents

34 2131-50 9- 002 REV B www.stryker.com

Page 35

Maintenance Menu Guide

CONFIGURATION SCREEN (CONTINUED)

E. Serial Number Configuration

To access the Serial Number screen:

1. Press and hold the HOB 30 button and the Vascular Position button at the same time for 25 seconds then release

both buttons. The Bed Configuration - Serial Number screen (Figure 32) will be displayed.

Pencil icon

Press to edit

Figure 32: Bed Configuration Serial Number Screen

2. Enter or confirm the serial number of the bed (Figure 32).

a. To enter the serial number:

i. Press the pencil button located to the right of the serial

number field. The Edit screen will be displayed.

ii. Enter the serial number of the bed in the serial number

field, then press the OK button. You will be returned to

the serial number main screen as shown in Figure 32.

iii. Press the Continue button and proceed to step 3.

b. To confirm the serial number:

i. Review the serial number displayed in the serial number

field.

ii. If serial number is correct, press the Back button and

proceed to step 6

iii. If the serial number is incorrect, press the pencil icon

button to open the Edit screen then enter the correct

serial number.

iv. Press the OK button and you will be returned to the

serial number main screen.

v. Press the Continue button and proceed to step 3.

3. After pressing the Continue button, the serial number will be

saved and the serial number Confirmation screen (Figure 33)

will be displayed. Press the OK button.

4. After pressing the OK button a Cycle Power screen (Figure 34)

will be displayed stating to cycle power on the bed.

5. To cycle power on the bed, turn the battery disconnect switch to

OFF (O) then unplug the power cord from the wall outlet. Plug

the power cord back into the wall outlet then turn the battery

disconnect switch back ON (|).

6. Test bed functionality prior to returning the bed into service.

Figure 33: Serial Number

Confirmation Screen

Figure 34: Cycle Power Screen

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 35

Page 36

Preventative Maintenance

Beds require an effective maintenance program. We recommend checking these items annually. Use this sheet for

your records. Keep on file.

CHECKLIST

____ _ All fasteners secure (reference all assembly prints).

__ ___ Engage brake pedal and push on the bed to ensure all casters lock securely.

__ ___ “Brake Not Set” LED on the footboard and head end siderails when brakes are not engaged.

____ _ Locking steer caster engages and disengages properly (2131 Model only).

__ ___ Siderails move, latch and stow properly.

__ ___ CPR release working properly.

__ ___ I.V. pole working properly (if on bed).

__ ___ No cracks or splits in head or footboards.

__ ___ No rips or cracks in mattress cover.

__ ___ All functions on head end siderails working properly (including LED’s).

__ ___ All functions on footboard working properly (including LED’s).

__ ___ Scale and bed exit system working properly.

__ ___ Night light working properly.

__ ___ Power cord not frayed.

__ ___ No cables worn or pinched.

__ ___ All electrical connections tight.

__ ___ All grounds secure to the frame.

__ ___ Ground impedance not more than 100 milliohms.

____ _ Current leakage not more than 300 microamps.

__ ___ Engage drive wheel and ensure it is operating properly (Zoom® option - 2141 model only).

____ _ Motion release switches working properly (Zoom® option - 2141 model only).

__ ___ Confirm head end Zoom® handle functionality (2141 model only).

__ ___ Confirm battery powered functionality.

__ ___ Ensure ground chains are clean, intact, and have at least two links touching the floor.

__ ___ Check fowler angle for accuracy 00 - 700.

__ ___ Check gatch angle for accuracy 00 - 150.

__ ___ Check foot section angle for accuracy 00 - 500.

__ ___ Siderail switches working properly (iBED Awareness option).

_____ iBED Awareness Light Bar LED’s on footboard and siderails working properly (iBED Awareness option).

__ ___ Inspect footboard control labeling for signs of degradation.

__ ___ Ensure calibration of the touch screen is accurate.

__ ___ Ensure calibration of the bed is accurate.

Bed Serial Number:

Completed by: _______________________________________ Date: _________________

Return To Table of Contents

36 2131-509- 002 RE V B www.stryker.com

Page 37

Cleaning

Hand wash all surfaces of the bed with warm water and mild detergent. Dry thoroughly. Do not steam clean or hose off

the InTouch® Critical Care Bed. Do not immerse any part of the bed. Some of the internal parts of the bed are electric

and may be damaged by exposure to water.

Suggested cleaners for bed surfaces:

Quaternary Cleaners (active ingredients - ammonium chloride)

Phenolic Cleaners (active ingredient - o-phenylphenol)

Chlorinated Bleach Solution (5.25% - less than 1 part bleach to 100 parts water)

Avoid over saturation and ensure the product does not stay wet longer than the chemical manufacturer’s guidelines

for proper disinfecting.

CAUTION

SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO THE PRODUCT IF USED

IMPROPERLY. If the products described above are used to clean Stryker patient care equipment, measures must be

taken to ensure the beds are wiped with a damp cloth soaked in clean water and thoroughly dried following cleaning.

Failure to properly rinse and dry the beds will leave a corrosive residue on the surface of the bed, possibly causing

premature corrosion of critical components. Failure to follow the above directions when using these types of cleaners

may void this product’s warranty.

For mattress cleaning instructions, please see the tag on the mattress, or contact the mattress manufacturer.

Clean Velcro® after each use. Saturate Velcro® with disinfectant and allow disinfectant to evaporate. (Appropriate

disinfectant for nylon Velcro® should be determined by the hospital.)

Return To Table of Contents

www.stryker.com 2131-509- 002 RE V B 37

Page 38

Troubleshooting Guide

Note

See “Bed Circuit Boards” section for an outline of bed PCB’s and voltage test points.

Problem / Failure Recommended Action

No Power to Bed.

(On wall voltage 120VAC)

COUNTRY VOLTAGE (CV) TABLE

VO LTAGE FUSE

100V 10A

110V 10A

120V 10A

1. Verify the bed is plugged into a functional wall outlet.

A. Check your country voltage option at wall outlet.

I. If your country voltage option is present, go to step 2.

II. If 1your country voltage option is not present, contact

hospital maintenance staff and try another outlet.

2. Verify the Bed main power fuses are good, located in drawer where

power cord plugs into the bed.

A. Check for continuity of each 10A fuse.

I. If each fuse (see CV Table) is good, go to step 3.

II. If either fuse (see CV Table) does not have continuity,

replace the fuse.

200V 10A

220V 10A

230V 10A

240V 10A

3. Verify there is power at the transformer connection (J11) on the

CPU/Power board at the foot end.

A. Check for 24VAC at J11 between the blue and red wires.

I. If 24VAC is present, go to step 4.

II. If 24VAC is not present, check the 25 Amp fuse in the fuse

holder on the red wire from the transformer. If bad, replace

the fuse.

III. If 24VAC is not present, check the power cable quick

connection going to the transformer for (see CV Table)

VAC. If no voltage, follow the cable and repair or replace

the damaged component.

IV. If (see CV Table) VAC is present, replace the transformer

assembly.

4. A. Check for 30VAC at J11 between the yellow and orange wires

for the transformer.

I. If 30VAC is present, go to step 5.

II. If 30VAC is not present, check the power cable quick

connection going to the transformer for (see CV Table)

VAC. If no voltage, follow the cable and repair or replace

the damaged component.

III. If (see CV Table) VAC is present, replace the transformer

assembly.

5. A. Check fuse F1 on the CPU/Power board.

I. If fuse is good, replace CPU/Power board.

II. If fuse does not have continuity, replace the fuse (littelfuse

215008.P).

Return To Table of Contents

38 2131-509- 002 REV B w ww.stryker.com

Page 39

Problem / Failure Recommended Action

No Bed Up Motion.

No Bed Down Motion.

FOOT

HEAD

FOOT

Troubleshooting Guide

1. Put the bed into the Bed Calibration menu.

A. Using one of the head siderails, push the trend button.

I. If the foot lift motor runs up, recalibrate the bed (refer to

the Bed Calibration procedures located on page 21).

a. If recalibration does not work, replace the litter angle

sensor and recalibrate.

II. If the foot lift motor does not run up, check for 24VDC at

connector J6 while pressing the trend button. Black lead

to pin 1, red lead to pin 2.

a. If voltage is present, replace the motor.

b. If voltage is not present, replace the CPU/Power board.

1. Put the bed into the Bed Calibration menu.

A. Using one of the head siderails, push the bed up button.

I. If the head lift motor runs up, recalibrate the bed (refer to

the Bed Calibration procedures located on page 21).

a. If recalibration does not work, replace the litter angle

sensor and recalibrate.

II. If the head lift motor does not run up, check for 24VDC at