Page 1

MAINTENANCE MANUAL

ELECTRIC MED/SURG BED

Model FL28EX

TECHNICAL ASSISTANCE AND PARTS

Canada: 1 888 233-6888

United States: 1 800 327 0770

Outside Canada and the United States: Contact your local representative

Manufactured by Stryker

72-0905E REV A MM FL28EX December 2005

F15-44-B Printed in Canada

Page 2

Page 3

TABLE OF CONTENTS

1. INTRODUC TION................................................................................................................... 5

1.1 Specifications .................................................................................................................5

1.2 Technical Support...........................................................................................................6

1.3 Warning, Caution, Note Definition................................................................................... 6

1.4 Static Discharge Precautions.......................................................................................... 6

1.5 Warranty......................................................................................................................... 7

Limited Warran ty.......................................................................................................... 7

To Obtain Service and/or Parts....................................................................................7

Return Authorization.....................................................................................................8

Damaged Merchandise................................................................................................8

1.6 Symbols..........................................................................................................................8

2. PREVENTATIVE MAINTENANCE........................................................................................9

2.1 Bed Cleaning and Mattress Care.................................................................................... 9

2.2 Lubrication Requirements............................................................................................. 10

Actuator Screw Lubrication......................................................................................... 10

2.3 Preventative Maintenance Program.............................................................................. 12

Annual Checklist.........................................................................................................12

Recommended Spare Parts ....................................................................................... 13

3. TROUBLESHOOTING........................................................................................................1 5

3.1 Troubleshooting Guide..................................................................................................15

4. MAINTENANCE PROCEDURES........................................................................................18

4.1 Siderail Maintenance Procedures.................................................................................18

Head Siderail Assembly Replacement........................................................................18

Head Rail Replacement.............................................................................................. 19

Head Siderail Mechanism Replacement..................................................................... 19

Foot Siderail Assembly Replacement......................................................................... 19

Foot Rail Replacement............................................................................................... 20

Foot Siderail Mechanism Replacement...................................................................... 20

Siderail Control Fascia Replacement..........................................................................21

Siderail Outer Control Board Replacement................................................................. 22

Siderail Inner Control Board Replacement.................................................................. 23

Speakerphone Replacement (Optional)...................................................................... 24

4.2 Foot Board Maintenance Procedures............................................................................25

Foot End Control Fascia Replacement....................................................................... 25

Weigh System LCD Display Replacement.................................................................. 25

Foot End Control Board Replacement........................................................................26

4.3 Mattress Support Maintenance Procedures.................................................................. 27

Foot Section Replacement......................................................................................... 27

Thigh Section Replacement........................................................................................28

Seat Section Replacement.........................................................................................28

Head Section Replacement........................................................................................ 29

Fowler Actuator Replacement....................................................................................30

Knee Gatch Actuator Replacement............................................................................ 32

Page 4

Hi-Lo Actuator Replacement.......................................................................................33

Motor Control Board Replacement..............................................................................35

Nurse Call (Optional)/GEN lll Pendant Control (Optional) Control Board Replacement

...................................................................................................................................36

Power Connector Replacement..................................................................................37

Power Connector Fuse Replacement..........................................................................37

Scale Control Board/Bed Exit Buzzer (Optional) Replacement....................................38

Toroidal Transformer Replacement (100/200/220/240V International Series Beds -)..39

Load Cell Replacement...............................................................................................40

Scale Calibration.........................................................................................................41

Verifying the Scale Accuracy....................................................................................41

Scale Calibration ......................................................................................................42

Cardiac Chair and Auto Contour Micro Switch Replacement ......................................44

Cardiac Chair Micro Switch.......................................................................................44

Micro Switch Common to the Cardiac Chair and Auto Contour Mechanisms............45

Auto Contour Micro Switch .......................................................................................45

CPR Micro Switch Replacement.................................................................................46

Micro Switch Attached to the Head Section Lever....................................................46

Micro Switch Attached to the Frame.........................................................................47

CPR Activation Cable Replacement............................................................................47

CPR Pneumatic Cylinder ............................................................................................47

4.4 Base Maintenance Procedures......................................................................................49

Brake/Steer Pedal Replacement.................................................................................49

Steer Wheel Caster Replacement...............................................................................50

Steer Wheel Assembly Replacement..........................................................................50

Steer Wheel Swing Arm Assembly Replacement........................................................51

Bed Caster Replacement............................................................................................52

Brake Rod Replacement.............................................................................................53

Appendix A: Circuit Diagrams...................................................................................................54

Appendix B: Maintenance Menu: Signification of Error Codes and Digital Inputs......................59

Page 5

Introduction Chapter 1

1. INTRODUCTION

This manual is designed to assist in the servicing of the Stryker's FL28EX Med/Surg Beds.

Read it thoroughly before beginning any service on the bed. Qualified maintenance personnel

should be able to refer to this manual at all time when servicing the bed.

This Maintenance Manual is an integral part of the bed and should be included if the bed is sold

or transferred.

1.1 SPECIFICATIONS *

Safe Working Load** 500 lb (227 kg)

Scale System

- Capacity

- Accuracy

- Operating Angular Range

Overall Length/ Width

- Siderails Up

- Siderails Down

Weight w/Boards 472 lb (214.1 kg)

Patient Sleep Surface 35 x 80" (89 x 203 cm) adjustable to 82" (208 cm) a nd

Recommended Mattress Siz e

Mattress Maximum Thickness

Min/Max Bed Height 14 1/2 to 29" (36.8 to 73.7 cm)

Fowler Angle 0 to 61°

Knee Gatch Angle

- with Auto Contour

- without Auto Contour

Trendelenburg/Reverse Tr endelenburg +14 to -14°

Environmental Conditions

- Transport and Storage

- Ambient Temperature

- Relative Humidity

- Atmospheric Pressure

- Operating ***

- Ambient Temperature

- Relative Humidity

- Atmospheric Pressure

Electrical Requirements*** * - all electrical

requirements meet CSA C22.2 No. 601.1,

UL 60601-1 and IEC 6060 1-1, 60601-2-38

specifications.

* Stryker pays special attention to product improvement and reserves the right to change specifications

without notice.

** The Safe Working Load specified is the sum of the mattress and accessory weight (100 lb/45.4 kg) and the

patient's weight.

*** Operating environment recommended to ensure the scale system precision.

**** The device has a 10% duty cycle.

Patients weighing up to 500 lb (22 7 kg)

± 2 % for weight from 100 to 500 lb (45.3 to 227 kg)

± 2 lb for weight under 100 lb (45.3 kg)

-12° to +12°

94 5/8 x 40" (240.34 cm x 101.6 cm)

94 5/8 x 39" (240.34 cm x 99.06 cm)

84" (213 cm)

35 x 80" (89 x 203 cm); 35 x 82" (89 x 208 cm); 35 x

84" (89 x 213 cm)

6" (15.24 cm)

0 to 24°

0 to 32°

-40 to 70°C (-40 to 158°F)

10 to 100%

500 to 1060 hPa

18.3 to 26.7°C (65 to 80°F)

20 to 80% without condensation

700 to 1060 hPa

100V∼, 50-60Hz, 7.5A - Two 250V, 10A Fuses

120V∼, 50-60Hz, 4.0A (9.8A w/120V Optional Auxi li ary

Outlet) - Two 250V, 10A Fuses

200V∼, 50-60Hz, 3.2A -Tw o 250V, 6.3A Fuses

220V∼, 50-60Hz, 2.9A -Tw o 250V, 6.3A Fuses

240V∼, 50-60Hz, 2.7A -Tw o 250V, 6.3A Fuses

5

Page 6

Maintenance Manual

A

A

1.2 TECHNICAL SUPPORT

For questions regarding this product, contact the following Technical Service department or your

local representative:

Stryker Canada Stryker Medical

1 888 233-6888 1 800 327-0770

45, Innovation Drive 3800, East Centre Avenue

Hamilton, Ontario, L9H 7L8 Portage, MI 49002

Canada USA

1.3 WARNING, CAUTION, NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully

reviewed.

WWAARRNNIINNGG

The personal safety of the patient or user may be involved. Disregarding this information could

result in injury to the patient or user.

C

C

UUTTIIOON

N

These instructions point out special procedures or precautions that must be followed to avoid

damaging the equipment.

E

NNOOTTE

Notes provide special information to make maintenance easier or important instruction clearer.

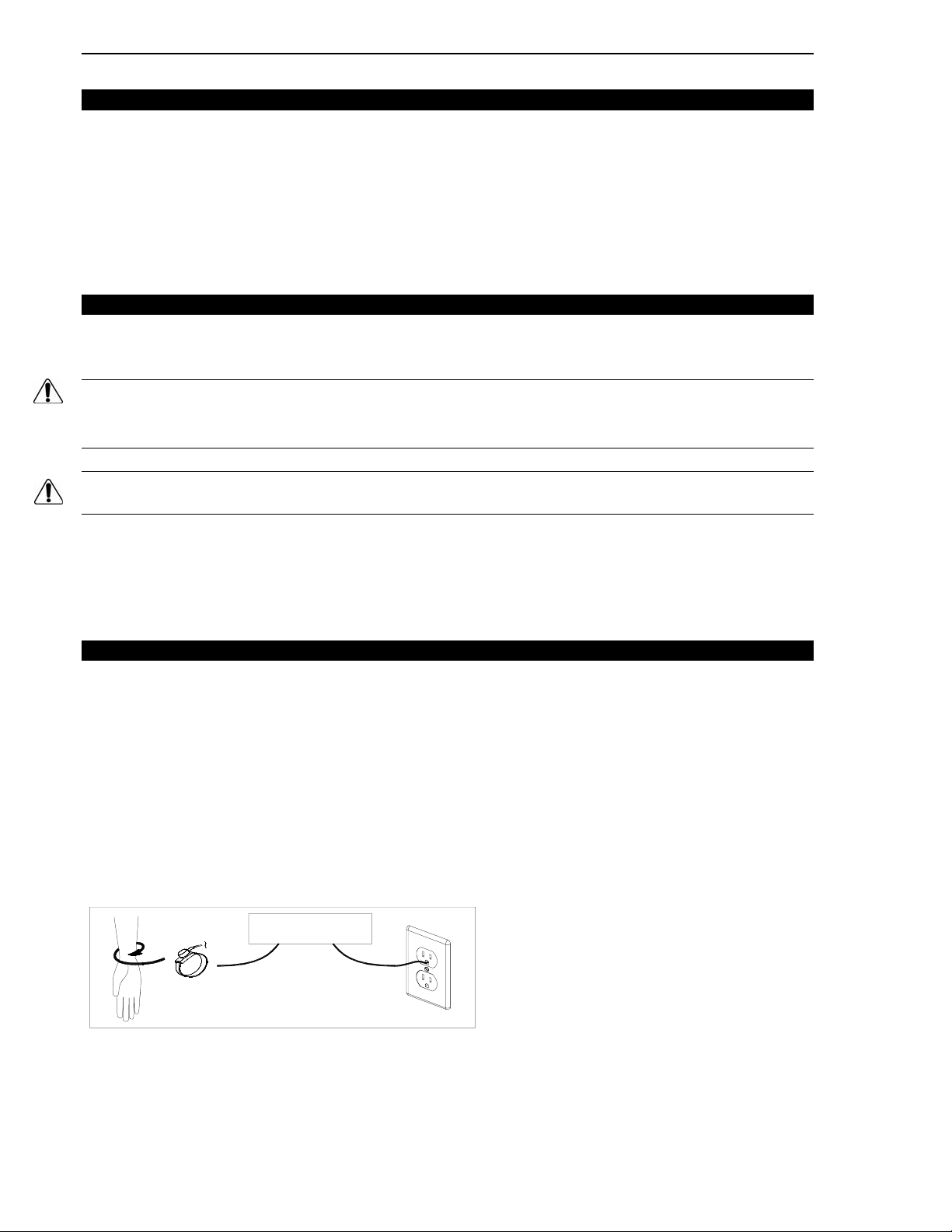

1.4 STATIC DISCHARGE PRECAUTIONS

The electronic circuits of the bed are protected from static electricity damage only while the bed

is assembled. It is extremely important that all service personnel always use adequate static

protection when servicing the electronic components of the bed.

Static Protection Equipment

The necessary equipment for a proper static protection is:

• 1 static wrist strap

• 1 grounding plug

• 1 test lead with a banana plug on one end and an alligator clip on the other.

Static Protection Procedure

1. Unplug the bed power cord from the

BED

wall outlet.

2. Insert the grounding plug into a

properly grounded hospital grade wall

receptacle. Plug the banana plug of

GROUNDING DIAGRAM

the test lead into the receptacle on

the grounding plug. Connect the

alligator clip on the other end of the test lead to a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the clip at the other end of the

wrist strap cord to a ground point on the bed.

6

Page 7

Introduction Chapter 1

A

C

1.5 WARRANTY

LIMITED WA RRANTY

All Stryker products are guaranteed against material or manufacturing defects, improper

operation of mechanisms, and premature wear of bed components under normal use

conditions.

For questions regarding warranty, please contact the Technical Service department (see section

1.2) or your local representative.

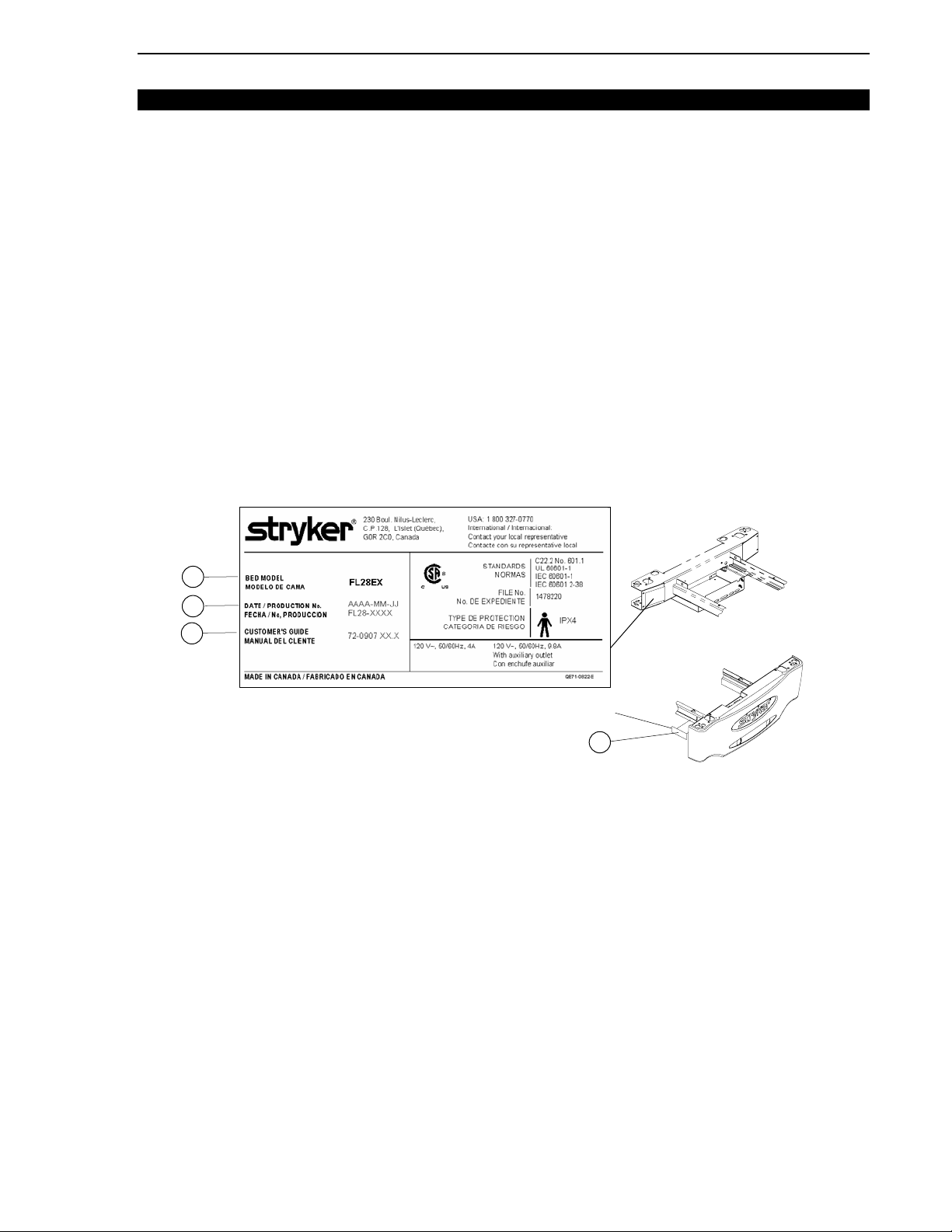

TO OBTAIN SERVICE AND/OR PARTS

• To Require Service

For an on-site diagnosis of a malfunction by one of our Field Service Representative, contact

the Technical Service department (see section 1.2) or your local representative.

• To Order Parts

Contact the Technical Service department (see section 1.2) or your local representative and

provide the following information that can be found on the serial number plate and the

manufacturer's nameplate affixed respectively to the right side of the frame at the foot end of the

bed, and on the right side of the head end casing:

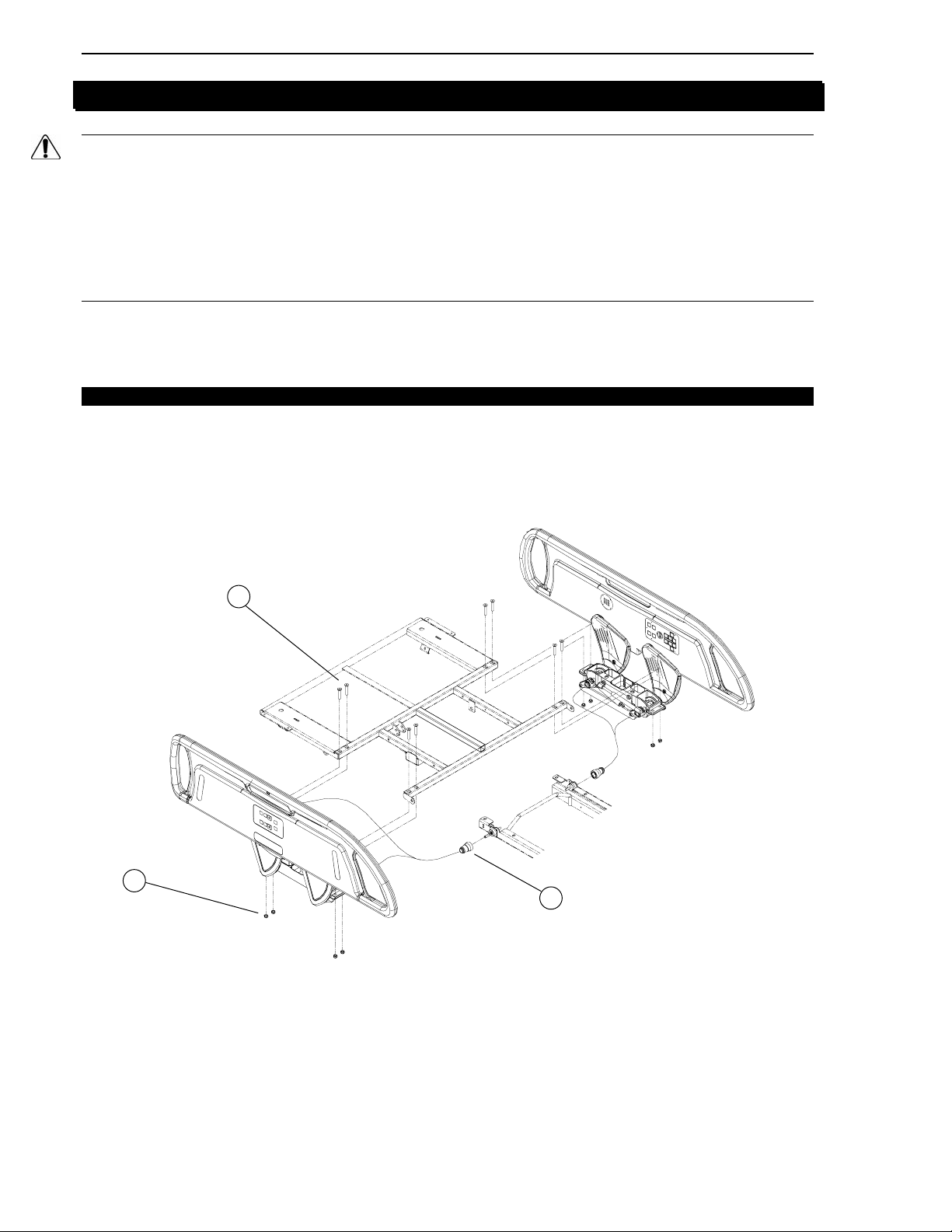

HEAD END

B

D

MANUFACTURER NAMEPLATE

SERIAL NUMBER PLATE

FOOT END

Figure 1.5

• From the serial plate, write down the serial number (A).

• From the manufacturer's nameplate, write down the bed model (B), the production number

(C), ex. FL28-XXXX, and the Customer's Guide number (D).

• Consult the parts lists and the drawings contained in the Customer Guide third section,

“Parts Lists”, to identify the defective part. Write down the information.

• Write down a description of the problem encountered while using the equipment.

E

NNOOTTE

It is very important that you refer to the parts lists and drawings of the Parts Lists manual

specific to the bed needing repair.

The Technical Service representative can help you identify the parts to be replaced. However, if

an error occurs when ordering, the user remains responsible for the parts ordered.

Stryker will take back wrong parts ordered but will not assume shipping charges, and restocking

fees will be charged to the user unless a Field Service Representative has been requested for

an on-site diagnosis of the malfunction.

7

Page 8

Maintenance Manual

A

RETURN AUTHORIZA T ION

Merchandise cannot be returned without approval from the Technical Service department. An

authorization number will be provided, which must be clearly printed on the returned

merchandise. Stryker reserves the right to charge shipping and restocking fees on returned

items.

DAMAGED ME R CHANDISE

Claims for damaged merchandise must be made with the carrier within fifteen (15) days of

receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt

notification, Stryker will file a freight claim with the appropriate carrier for damages incurred.

Claims will be limited in amount to the actual replacement cost. In the event that this information

is not received by Stryker within the fifteen (15) day period following the delivery of the

merchandise, or the damage was not noted on the delivery notice at the time of receipt, the

customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within five (5) days of invoice.

1.6 SYMBOLS

Warning, refer to accompanying documents

Fuse rating for 100V∼ and 120V∼ electric systems

10A 250V

Fuse rating for 200V∼, 220V∼ and 240V∼ electric

6.3A 250V

systems

Protective Earth (ground)

∼

lternating Current

Type B Equipment

IPX4 Protection from liquid splash

8

Page 9

Preventative Maintenance Chapter 2

A

A

2. PREVENTATIVE MAINTENANCE

2.1 BED CLEANING AND MATTRESS CARE

WWAARRNNIINNGG

When large fluid spills occur in the area of the circuit boards, cables and motors, immediately

unplug the bed power cord from the wall outlet, remove the patient from the bed and clean up

the fluid. Have maintenance completely check the bed. Fluids can have an adverse effect on

operational capabilities of any electrical product. DO NOT put the bed back into service until it is

completely dried and has been thoroughly tested for safe operation. Ensure, among other

things, that the plastic components being used as covers for the siderail mechanism arms and

the foot end casing are removed and that the parts they cover are thoroughly dried.

C

C

UUTTIIOON

N

Do not use harsh cleaners, solvents or detergents. Equipment damage could occur. Do not

steam clean, hose off or ultrasonically clean the bed. Do not immerse any part of the bed. The

bed electrical parts may be damaged by exposure to water.

Germicidal disinfectant, used as directed, and/or Chlorine Bleach products are not considered

mild detergents. These products are corrosive in nature and may cause damage to your bed if

used improperly. If these types of products are used, ensure the beds are wiped with clean

water and thoroughly dried following cleaning. Failure to properly rinse and dry the beds will

leave a corrosive residue on the surface of the bed, possibly causing premature corrosion of

critical components. Failure to follow the above directions when using these types of cleaners

may void this product warranty.

CLEANING BEDS

Hand wash all surfaces of the bed with a soft cloth moistened with a solution of lukewarm water

and a mild detergent.

Wipe the bed clean and dry thoroughly to avoid build up of cleaning solution.

MATTRESS CARE

WWAARRNNIINNGG

Inspect the mattress after each use. Discontinue use if any cracks or rips, which may allow fluid

to enter the mattress, are found in the mattress cover. Failure to properly clean the mattress, or

dispose of it if defective, may increase the risk of exposure to pathogenic substances and

bring about diseases to the

patient and user.

may

• Inspection

Implement local policies to address regular care, maintenance, and cleaning of mattresses and

covers. The cover cleaning procedure can be found below and on the bed label.

Inspect the mattress cover inner and outer surfaces and the zip fasteners regularly for signs of

damage. If the mattress cover is heavily stained or soiled, or is torn, remove the mattress from

service.

• Cleaning

Stains: Wash with lukewarm water using a mild detergent. Rinse with water and let dry. For

tough stains, use bleach diluted with ten parts of water.

9

Page 10

Maintenance Manual

A

A

A

2.2 LUBRICATION REQUIREMENTS

The only components of the bed needing periodic verification and lubrication are the four

actuator screws and the clevis pin holding the head actuator to the head section lever. They

should be checked every year and lubricated every two years.

C

C

UUTTIIOON

N

The bed uses oil-impregnated shoulder spacers at hinge points. Do not lubricate these shoulder

spacers. When shoulder spacers are found worn, replace them.

ACTUATOR SCREW LUBRICATION

Required Tools:

No. 2 Phillips Screwdriver 1/4" Ratchet (w/6" extension) and 5/16" socket

OG2 Grease Brush Bungee Cord

Procedure:

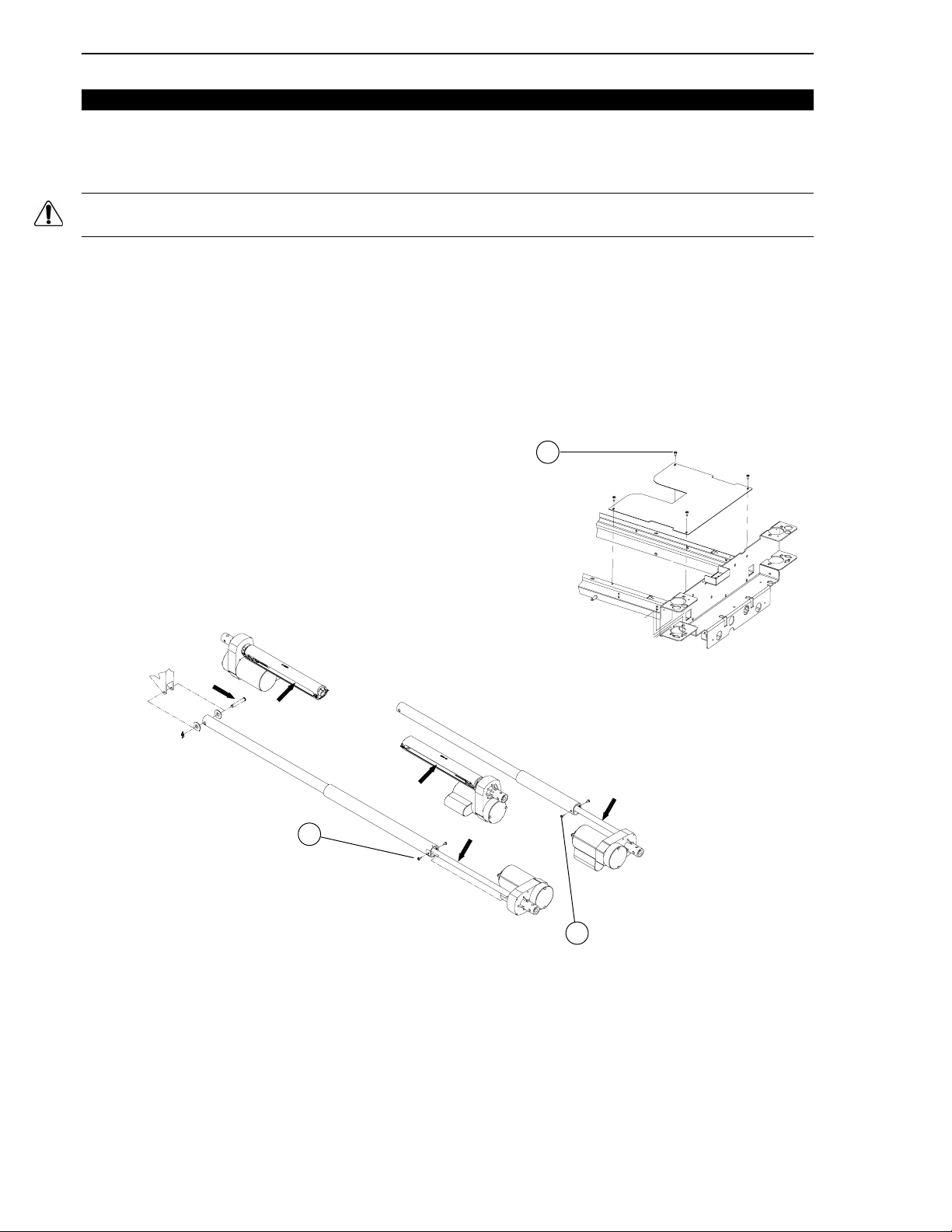

B

B

Figure 2.2

Clevis Pin

1. Raise the bed fully up and apply the brakes.

2. Remove if applicable the head section plastic cover (optional).

3. Fully raise the head section.

4. Remove the head board.

5. Unplug the bed power cord from the wall outlet.

6. Apply grease all over the clevis pin.

10

Page 11

Preventative Maintenance Chapter 2

7. Fully raise and lower the head section several times to spread the grease.

Head and Thigh Actuators

8. Raise the bed fully up and apply the brakes.

9. Remove if applicable the head and foot section plastic covers (optional).

10. Fully raise the head section and flatten the thigh section. Lower the four siderails.

11. Unplug the bed power cord from the wall outlet.

12. Lift and fold back the foot section toward the head end of the bed. Secure the foot section to

the bed using a bungee cord.

13. Using a no. 2 Phillips screwdriver, remove the four screws (A) holding the cover plate to the

frame and remove the plate. Remove the optional night light if present.

14. Using a 1/4" ratchet (w/6" extension) and a 5/16" socket, remove the two screws (B) holding

the dust tube of each actuator. Push the tube back to uncover the screw threads.

15. Using a brush, apply grease on the screw threads. Make sure the grease reaches the

bottom of the threads.

16. Replace the dust tubes.

17. Replace the cover plate.

18. Lower the foot section.

19. Plug in the bed power cord and, using the electric controls, raise and lower several times the

Fowler and Knee Gatch to spread the grease evenly.

Hi-Lo Actuators

1. Lower the bed completely and apply the brakes. Flatten the mattress support.

2. Lower the four siderails.

3. Remove if applicable the head and foot section plastic covers (optional), to reach the Hi-Lo

actuators. Otherwise, fully raise the head section, and lift and fold back the foot section

toward the head end of the bed. Secure the foot section to the bed using a bungee cord.

4. Unplug the bed power cord from the wall outlet

5. Using a brush, apply grease on the threads through the dust tube side openings of both HiLo actuators. Make sure the grease reaches the bottom of the threads.

6. Lower the foot section.

7. Plug in the bed power cord and, using the electric controls, raise and lower the bed several

times to spread the grease evenly.

11

Page 12

Maintenance Manual

A

A

2.3 PREVENTATIVE MAINTENANCE PROGRAM

W

W

RRNNIINNG

G

When servicing use only identical replacement parts provided by Stryker.

ANNUAL CHECKLIST

⎯ All fasteners secure.

⎯ Inspect for excessive wear the oil-impregnated bronze shoulder spacers found at the bed

hinge points. Do not lubricate these spacers. Replace as needed.

⎯ Check the grease present on the components detailed in section 2.2, lubricate if needed

(see section 2.2). Lubricate them at least every two years.

⎯ On both sides of the bed, depress fully down the side of the pedal identified with a red

sticker and ensure that the brakes are applied and the bed is immobilized. Toggle the pedal

to neutral and ensure the brakes are released.

⎯ On both sides of the bed, depress fully down the side of the pedal identified with a green

sticker and ensure that the steer wheel is engaged. Toggle the pedal to neutral and ensure

that the steer wheel disengages.

⎯ Siderails move, latch and stow properly.

⎯ All controls of the foot end panel working properly, including LED's.

⎯ Calibrate the scale (see the scale calibration procedure on page 41).

⎯ All siderail controls working properly.

⎯ Ensure that the nurse call (optional) alarm sounds in the nurse station.

⎯ Ensure that the Communication Package (optional) controls operate properly.

⎯ Verify the CPR emergency release using both CPR release handles: raise the Fowler fully

up and, using the CPR handle, lower the Fowler gradually to flat position by pulling, holding

and releasing the handle several times. Ensure the Knee Gatch (if raised) also starts

flattening when the Fowler is completely down. Following the complete lowering of the

Fowler, wait approximately 30 seconds - the time for the Fowler actuator to reset - and verify

that the actuator has indeed reset itself by raising the Fowler fully up.

⎯ Verify the Fowler, Knee Gatch and Hi-lo movements to ensure that the motion interrupt

switch integrated to the four electric actuators is operating properly.

⎯ Auxiliary outlet (option available only with 120V beds) working properly.

⎯ Night light (optional) working properly.

⎯ No cracks in the boards, siderails, wheel covers, steer wheel hood (optional) and plastic

covers (optional) of the head and foot sections.

⎯ Head end bumpers tightly secured to frame and working properly.

⎯ No rips or cracks in mattress cover. Replace if so.

⎯ Power cord intact.

⎯ No cables pinched or worn.

⎯ All electrical connections tight.

⎯ All grounds secure to the frame.

⎯ All casters roll properly. Check caster for cuts, wear, etc.

⎯ Measure current leakage and grounding continuity of the bed and the auxiliary outlet

(optional). Check with our Technical Service (see section 1.2) for the acceptable values.

12

Page 13

Preventative Maintenance Chapter 2

RECOMMENDED SPARE PARTS

The following is a list of recommended on hand spare parts for the FL28EX bed.

Description Part Number Parts List

• Electric/Electronic Components

Motor Control Board QDF25-0592 OL250001/010

Scale Control Board QDF25-0593 L28-008

S.A. Scale Display QDF25-0463 L28-008

Nurse Call (Optional)/ Gen lll Control Board (Option al) QDF21-1163 OL280002

Foot Board Control Board QDF21-1154 L28-014

Micro Switch 1325P003 L28-013

Push Button Micro Switch QDF9159 L28-013

Power Connector QDF2034 O L28001/010

Fuse - Fast Acting 10A, 250V for 10 0/ 120V Electric Systems QDF8078 OL280001/011

Fuse - Slow Blow 6.3A, 250V for 200/220/240V Electric Sy st ems QDF8068 OL280012/013

/014

Power Cord with Straight N A Molded Plug QDF8066 OL250053

Power Cord with 90° N A Molded P lug (Optional) QDF8066-90D OL250055

Foot Board/Control Board Cable QDF28-0258 OL28001/010

Speakerphone w/Connectors (Optional) QDF26-0111 OL280020

Night Light (Optional) QDF9539 OL250018

Load Cell w/Long Cab le QDF14-1367 L28-028

Load Cell w/Short Cab le QDF25-0218 L28-028

Auxiliary Power Outlet (Optional) QDF8024 OL250029

5A Circuit Breaker (for Optional Auxi li ary Power Outlet) QDF9025 OL250029

Hi-Lo Actuator 25-0567 OL280001/010

Head Section Actuat or 28-0403L OL280001/010

Thigh Section Actuator 28-0377 OL280001/010

Toroidal Transformer (Inter nat ional Series Bed) 14-1160 OL280001/010

Stand Off Pins: Motor Control Board

Stand Off Pins: Scale Control Board

QP23-0258

QDF8011

OL280001/010

L28-008

Strain Relief Bushing QDF9541 OL280001/010

Female Screw Lock QDF2047

• Foot Board Components

Foot End Control Panel Self-Sticking Fascia w/Scale and Bed

QDF25-0461 OP250002

Exit 3 Zone (optional)

Foot End Control Panel Self-Sticking Fascia w/Scale and Bed

QDF25-0528 OP250003

Exit 1 Zone (optional)

Foot End Control Panel Self-Sticking Fascia w/Scale w/o Bed

QDF25-0529 OP250004

Exit (optional)

Round Self-Sticking Scre w Cover QDF28-0334 L28-014

Head/Foot Board Leg Caps QPC21-3855 L28-011-014

• Siderail Components

Siderail Right Patient Ctrl Self-Sticking Fascia w/o Nurse Call

QDF28-0248 OL280019

nor Communications Pack age (O pt ional)

13

Page 14

Maintenance Manual

Siderail Left Patient Ctrl Self-Sticking Fascia w/o Nurse Call no r

QDF28-0249 OL280019

Communications Package (Optiona l)

Siderail Right Patient Ctrl Self-Sticking Fasci a w/Nurse Call, w/o

QDF28-0252 OL280020

Communications Package (Optiona l)

Siderail Left Patient Ctrl Self-Sticking Fasc ia w/Nurse Call, w/o

QDF28-0253 OL280020

Communications Package (Optiona l)

Siderail Right Patient Ctrl Self- St icking Fascia w/Nurse Call and

QDF28-0250 OL280021

Communications Package (Optiona l)

Siderail Left Patient Ctrl Self-Sticking Fasc ia w/Nurse Call and

QDF28-0251 OL280021

Communications Package (Optiona l)

Outer Right Ctrl Panel Self-Sticking Fascia QDF28-0139 L28-001

Outer Left Ctrl Panel Self-Sticking Fascia QDF28-0140 L28-001

Outer Ctrl Panel Control Board QDF21-1151 L28-001

Inner Ctrl Panel Control Board QDF21-1169 L28-001

"Lift To Release" Self-St icking Sticker QDF28-0146 L28-001

Oblong Self-Sticking Screw Cover QDF28-0145 L28-001

• Mattress Support Components

Head Section Plastic Cover (optional) 28-0101 OL280032

Foot Section Plastic Cover (optional) 28-0103 OL280032

Steel Head Section (Opt ional) 28-0197L OL280007

Steel Foot Section (Optional) 28-0196L OL280007

Seat Section 28-0345L OL280032

Thigh section 28-0034L OL280032

CPR Mechanism Lon g Cable Q DF 19-0815 OL280034

CPR Mechanism Short Cable QDF19-0354 OL280034

CPR Mechanism Pn eumatic Cylinder QDF5090 OL280034

Foot End Mattress Retain er 17-0211L OL250022/023

• Hi-Lo Mechanism Components

Right "Stub-Acme" Nut QP13-0677-05 OL280001/ 010

Nut Support QPA25-0380 OL280001/010

• Base Components

Foot End Casing Plastic Cover QP28-0111 L28-005

Plastic Base Tube Cover QP25-0023 L28-020

6" Caster w/Locking Mechanis m R25-0388-13 OL280003

5th Steer Wheel RL5 L28-006

Right Wheel Cover QP28-0299-13 L28-020

Left Wheel Cover QP28-0300-13 L28-020

Brake/Steer Pedal QP28-0130 L28-006

• Miscellaneous

OG2 Grease M0027

Touch-Up Paint - Opal PD018

Ty-rap QDF9518

Nylon Cable Dia. 3/4" QDF953 2

Coupling for Ty-rap QDF9533

14

Page 15

Troubleshooting Chapter 3

3. TROUBLESHOOTING

Please consult the following troubleshooting guide before calling the Technical Service department

(see section 1.2).

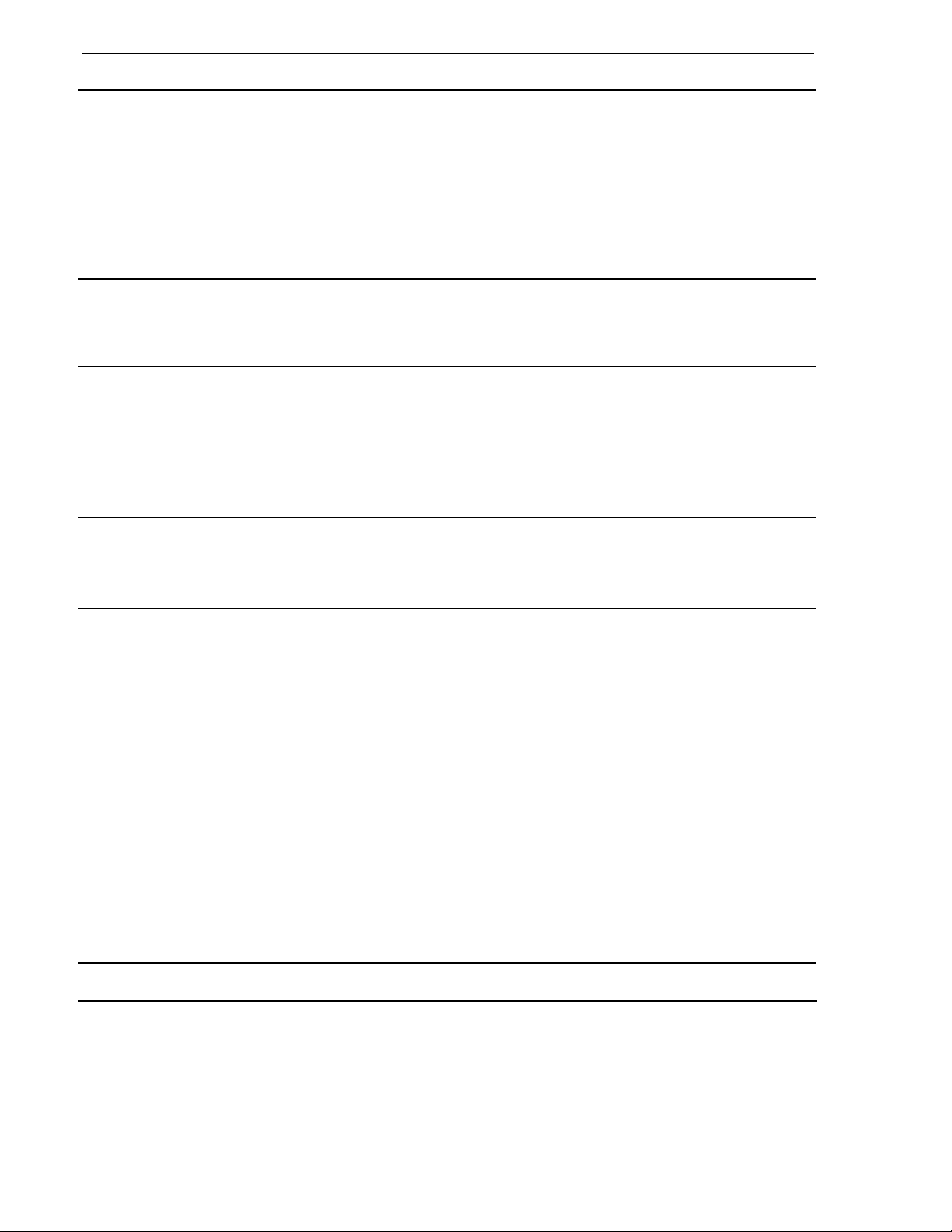

3.1 TROUBLE SHOOTING GUIDE

PROBLEM/FAILURE WHAT TO CHECK

No power to bed

• Is the power cord connected to the power

connector and plugged into the wall outlet?

• Is the bed power switch at the head end of

the bed turned on?

• Is the power cord severed? Replace if

needed.

• Are the two fuses inside the power

connector still operational (see page 37)?

• Verify power at wall outlet.

No bed up or down motion when:

• the siderail command is used

• the foot board command is used

No Fowler up or down motion when:

• the siderail command is used

• the foot board command is used

The Fowler does not fully raise

• Is the total lockout activated (LED (padlock)

on)? If so, deactivate it.

• Is the cable of the siderail control panel

properly connected to the bed receptacle

under the mattress support?

• Check points of the “No power to bed”

problem described above.

• Is the Fowler lockout activated (LED

(padlock) on)? If so, deactivate it.

• Is the total lockout activated (LED (padlock)

on)? If so, deactivate it.

• Is the cable of the siderail control panel

properly connected to the bed connector

under the mattress support?

• Check points of the “No power to bed”

problem described above.

This situation happens when the CPR handle

is used to partly lower the Fowler. The use of

the CPR mechanism for this purpose creates a

situation where the Fowler motor is out of sync

with the actual position of the Fowler. To

correct the situation:

• Completely lower the Fowler using the

CPR handle or the Fowler down control to

enable the Fowler motor to reset itself.

Refer to the "Emergency CPR Release"

section of the Operations Manual for more

information.

15

Page 16

Maintenance Manual

No Knee Gatch up or down motion when:

• the siderail command is used

• the foot board command is used

No Auto Contour motion

Improper operation of the cardiac chair: Fowler

and Knee Gatch raise but final step of the

cardiac chair position not reached (reverse

Trend).

Improper operation of the CPR positioning:

Knee Gatch does not lower and/or the Fowler

actuator does not reset.

The weight shown on the scale display is

incorrect.

• Is the Knee Gatch lockout activated (LED

(padlock) on)? If so, deactivate it.

• Is the total lockout activated (LED (padlock)

on)? If so, deactivate it.

• Is the cable of the siderail control panel

properly connected to the bed connector

under the mattress support?

• Check points of the “No power to bed”

problem described above.

• Is the Knee Gatch or total lockout activated

(LED (padlock) on)? If so, deactivate it.

• Check and replace if needed the two Auto

Contour limit switches (see page 45).

• Check and replace if needed (see pages

44 and 45) the two Cardiac Chair limit

switches.

• Check and replace if needed (see pages

46 and 47) the two CPR limit switches.

• Zero the bed without the patient in it (see

the "Scale System Usage" section in the

Operations Manual).

• Calibrate the scale (see page 41).

Scale display reads OVERLOAD or shows

incorrect weight.

Angle shown on the scale display is incorrect

• The weight present on the bed is superior

to the scale capacity, which is 500 lb (227

kg). If the patient weight is superior to 500

lb (227 kg), do not use the scale.

If not the case, zero the scale after having

removed the patient from the bed. This

situation often results from equipment

added to the bed without using the

add/remove equipment procedure (see the

Operations Manual). The weight of this

equipment is then added to the patient's

weight.

• One or more load cell cable not properly

connected or completely disconnected from

the scale control board (see figure 4.3E,

page 38 for the connecting positions of the

load cell cable).

• Calibrate the scale (see page 41).

16

Page 17

Troubleshooting Chapter 3

Scale display does not turn on when the scale

is activated.

Scale displays "No scale found".

All lockout LEDs (padlock icons) flash or the

word Error appears at the bottom of the LCD

display.

• Press ENTER key twice.

• Turn the main power switch off and turn it

on.

• Lift the foot board and gently replace it into

position taking care to completely push it

down so that the connectors match

correctly.

• Check points of the “No power to bed”

problem described above.

• Scale user interface cable not properly

connected or completely disconnected from

the scale control board (J6 connector, see

drawing L28-008 in the parts list manual).

• Press the ENTER key. If message

persists, contact our Technical Service

(see section 1.2).

If message disappears, data displayed is

correct and current procedure can be

resumed.

• The scale is unable to measure the

weight due to an electrical problem.

Please contact our Technical Service

(see section 1.2).

Bed Exit system (optional) does not operate

properly.

Bed Exit system (optional) does not work at all

or alarm goes off when Bed Exit is activated.

Nurse call (optional) or Bed Exit (optional)

signal does not reach the nurse desk.

• Verify that the load cell cables are properly

connected to the scale control board (see

figure 4.3E, page 38 for the illustration of

the load cell cable connecting positions).

• Check points of the “No power to bed”

problem described above.

• One or more load cell cable are not

properly connected or are completely

disconnected from the scale control board

(see figure 4.3E, page 38 for the load cell

cable connecting positions).

• Check points of the “No power to bed”

problem described above.

• Check the connecting cable.

• Check the wall outlet.

• Contact the Technical Service (see 1.2)

17

Page 18

Maintenance Manual

A

A

4. MAINTENANCE PROCEDURES

WWAARRNNIINNGG

Only field technicians from Stryker or service personnel trained by Stryker should perform the

procedures detailed in this maintenance manual, especially those related to the Scale (option)

and Bed Exit (option) systems. Failure to observe this restriction can result in serious damage to

material and/or severe injury to people.

To prevent injury when working under the bed with the bed in the high position, always place

blocks under the mattress support frame and apply the brakes.

Always unplug the bed power cord from the wall outlet when servicing or cleaning the bed.

NOTE

Throughout this maintenance manual, the words “right” and “left” refer to the right and left sides

of a patient lying face up on the bed.

4.1 SIDERAIL MAINTENANCE PROCEDURES

HEAD SIDERAIL ASSEMBLY REPLACEMENT

Required Tools:

1/2" Wrench 3/16" Allen Key Cutting Pliers

Procedure:

B

B

Figure 4.1

1. Run the bed fully up and apply the brakes.

2. Remove the head section plastic cover (optional). Fully raise the head section and raise the

siderail needing repair.

3. Unplug the power cord from the wall receptacle.

4. Loosen the lock ring (A) and unplug the siderail cable.

5. Using cutting pliers, remove the Ty-raps holding the siderail cable to the frame.

6. Using a 3/16" Allen key and a 1/2" wrench, remove the four locknuts/bolts (B) holding the

siderail assembly to the head section and remove the assembly. Support the assembly

when removing the last bolts.

18

Page 19

Maintenance Procedures Chapter 4

A A

7. Reverse the above steps to install the new siderail assembly.

8. Test the siderail movement and all controls of both control panels, including the nurse call

optional) and the communications package (optional), for proper operation before returning

the bed to service.

HEAD RAIL REPLACEMENT

Please contact the Technical Service (see section 1.2) for information regarding the

replacement of a head end rail.

HEAD SIDERAIL MECHANISM REPLA CEMENT

Please contact the Technical Service (see section 1.2) for information regarding the

replacement of a head end siderail mechanism.

FOOT SIDERAIL ASSEMBLY REPLACEMENT

Required Tools:

1/2" Socket Wrench 1/2" Wrench Bungee Cord

Procedure:

K

G

F

D

B

C

B

E

Figure 4.1B

1. Run the bed fully up and apply the brakes. Raise the siderail needing repair.

2. Run the Knee Gatch fully up and unplug the power cord from the wall receptacle.

3. Remove if applicable the foot section plastic cover (optional). Lift and fold the foot section

back toward the head end of the bed. Secure its position using a bungee cord.

4. Using a 1/2" socket wrench and a 1/2" wrench, remove the four locknuts/bolts (A) holding

the siderail assembly to the support and remove the assembly. Support the siderail

assembly while removing the last bolts.

5. Reverse the above steps to install the new siderail assembly.

6. Test the siderail for proper operation before returning the bed to service.

K

19

Page 20

Maintenance Manual

FOOT RAIL REPLACEMENT

Required Tools:

Small Slotted Head Screwdriver No. 2 Phillips Screwdriver 5/32" Allen Key

Bungee Cord

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.1B on page 19 for the illustration of this procedure

reference points.

1. Run the bed fully up and apply the brakes. Raise the siderail needing repair.

2.

Unplug the bed power cord from the wall outlet.

Using a small slotted head screwdriver, lift and remove the following self-sticking parts: the

3.

three screw-covers (B) and the "Lift to release siderail" label (C) to expose the screws

holding the siderail cover. Proceed gently when inserting the screwdriver under the labels to

avoid scratching the molded rail.

E

NNOOTTE

Do not reuse the self-sticking parts removed since their adhesive coating considerably looses its

efficiency once they are removed. Replace them with new parts.

4. Using a no. 2 Phillips screwdriver, remove the eight screws (D) holding the cover to the

siderail and remove the cover.

WAARRNNIINNGG

W

The eight screws (D) must be replaced with new identical screws because their Scotch-Grip

coating is less efficient once they have been tightened and removed thereafter.

5. Remove the yellow locking lever (E).

Using a no. 2 Phillips screwdriver, remove the screw (F) holding each siderail arm plastic

6.

cover and lift up the covers to remove them.

Using a 5/32" Allen key, remove the two Allen screws (G) holding each pommel to the

7.

siderail arms. Leave one loosened screw on each pommel until ready to remove both

pommels.

While supporting the rail, remove the two last screws, the pommels, the bungee cord and

8.

finally the rail.

E

NNOOTTE

Note the position of the pommel with the lock (left pommel when facing the rail) when the

siderail is fully raised. The rail will not lock in high position if this pommel is positioned

differently.

Reverse the above steps to install the new rail.

9.

Test the siderail for proper operation before returning the bed to service.

10.

FOOT SIDERAIL MECHANISM REPLACEMENT

Required Tools:

Small Slotted Head Screwdriver No. 2 Phillips Screwdriver 5/32" Allen Key

Bungee Cord 1/2" Socket Wrench 1/2" Wrench

Procedure:

1. Follow steps 1 to 8 of the foot end rail replacement procedure above.

2. Using a 1/2" socket wrench and a 1/2" wrench, remove the four locknuts/bolts (K, fig. 4.1B,

page 19) holding the mechanism assembly to the support and remove the assembly.

3. Reverse the above steps to install the new mechanism assembly.

4. Test the siderail for proper operation before returning the bed to service.

20

Page 21

Maintenance Procedures Chapter 4

A

SIDERAIL CONTROL FASCIA REPLACE ME NT

Required Tools:

Small Slotted Head Screwdriver

Procedure:

K

J

I

H

F

A

D

B

A

L

J

B

B

E

G

Figure 4.1C

1. Run the bed fully up and apply the brakes. Raise the siderail needing repair.

2. Unplug the bed power cord from the wall outlet.

3. Using a small slotted head screwdriver, lift and remove the self-sticking fascia (A) of the inner or outer control panel needing to be

replaced. Proceed gently when inserting the screwdriver under the membrane to avoid scratching the rail.

4. Install the new fascia making sure to position the fascia properly over the control board switches.

5. Test all controls of the control panel for proper operation before returning the bed to service.

21

Page 22

Maintenance Manual

SIDERAIL OUTER CO NT RO L BOARD REPLACE MEN T

Required Tools:

Small Slotted Head Screwdriver No. 2 Phillips Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.1C on page 21 for the illustration of this procedure

reference points.

1. Run the bed fully up and apply the brakes. Raise the siderail needing repair.

Unplug the bed power cord from the wall outlet.

2.

Using a small slotted head screwdriver, lift and remove the following self-sticking parts: the

3.

two screw-covers (B), the "Lift to release siderail" label (C) and the control panel membrane

(A) to expose the screws holding the siderail cover. Proceed gently when inserting the

screwdriver under the labels to avoid scratching the molded rail.

E

NNOOTTE

Do not reuse the self-sticking parts removed since their self-adhesive coating considerably

looses its efficiency once they are removed. Replace them with new parts.

4. Properly ground yourself (see section 1.4).

5. Using a no. 2 Phillips screwdriver, remove the eight screws (D) holding the cover to the

siderail. Remove the cover after having disconnected the cable of the control board attached

to the cover.

WAARRNNIINNGG

W

The eight screws (D) must be replaced with new identical screws because their Scotch-Grip

coating is less efficient once they have been tightened and removed thereafter.

E

NNOOTTE

Gather the cables and place them properly before replacing the cover.

6. Remove the yellow locking lever (E).

7. Using a no. 2 Phillips screwdriver, remove the six screws (F) holding the control board to the

cover and remove the control board. Remove the cable connected to the board.

8. Reverse the above steps to install the new control board.

9. Test all controls of the outer control panel for proper operation before reassembling the

siderail and returning the bed to service.

22

Page 23

Maintenance Procedures Chapter 4

SIDERAI L INNER CO N TRO L BO ARD REPLACEME NT

Required Tools:

Small Slotted Head Screwdriver No. 2 and 3 Phillips Screwdrivers Cutting Pliers

Bungee Cord 5/32" Allen Key

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.1C on page 21 for the illustration of this procedure

reference points.

1. Follow steps 1 to 6 of the siderail outer control board replacement procedure above.

2. Secure the siderail needing repair to the adjacent

siderail using a bungee cord (see opposite

illustration).

3. Using side cutters, clip the lower cable tie (G)

holding the bottom part of the grey cable (there

may be two cables) to the aluminum structure. The

loose given to the cable will be necessary for steps

to come.

E

NNOOTTE

Make sure the cable ties are inserted in the aluminum

structure before reinstalling the structure.

4. Using a no. 2 Phillips screwdriver, remove the

screw (H) holding each siderail arm cover and lift

up the covers to remove them.

Using a 5/16" Allen key, remove the two Allen screws (I) holding each pommel to the siderail

5.

arms. Leave one loosened screw on each pommel until ready to remove both pommels.

6. While supporting the rail, remove the two last screws and the bungee cord.

7. Lift the siderail, pass it over the mechanism arms and lay it on the mattress support while

gently pulling on the cables.

8. Using a no. 3 Phillips screwdriver, remove the six screws (J) holding the aluminum structure

to the siderail.

E

NNOOTTE

Do not reuse these Scotch-Grip screws. Replace them with new screws (P/N VV37A1N24).

9. Grasp and lift the upper part of the aluminum structure until it may be secured temporarily to

one of the mechanism arms using a cable tie.

Remove from the defective board the cable connected to it. The nurse call (optional) cable

may also be present, remove it.

10. Using a no. 2 Phillips screwdriver, remove the eight screws (K) holding the control board to

the siderail.

11. Reverse the above steps to install the new control board.

12. Test all controls of the inner and outer control panels for proper operation before

reassembling the siderail and returning the bed to service.

23

Page 24

Maintenance Manual

SPEAKERPHONE REPLACEMENT (OPTIO NAL)

Required Tools:

Small Slotted Head Screwdriver No. 2 and 3 Phillips Screwdrivers Cutting Pliers

Bungee Cord 5/32" Allen Key

Procedure:

1. Follow steps 1 to 9 of the siderail inner control board replacement procedure, described

above.

2. Remove the cables connected to the speakerphone. Note their position before removing

them.

3. Using a no. 2 Phillips screwdriver, remove the four screws (L, fig. 4.1C, page 21) holding the

speakerphone to the siderail.

4. Reverse the preceding steps to install the new speakerphone.

E

NNOOTTE

Before reassembling the different parts of the siderail, we recommend that you check the

continuity at the speakerphone terminals to ensure the circuit operates properly.

5. Test the nurse call and all controls of the inner and outer control panels for proper operation

before reassembling the siderail and returning the bed to service.

24

Page 25

Maintenance Procedures Chapter 4

A

4.2 FOOT BOARD MAINTENANCE PROCEDURES

FOOT END CO NTROL PANEL FASCIA REPLACEMENT

Required Tools:

Small Slotted Head Screwdriver

Procedure:

E

C

C

D

B

Figure 4.2

1. Run the bed fully up and apply the brakes.

2. Unplug the bed power cord from the wall outlet.

3. Using a small slotted head screwdriver, lift and remove the self-sticking fascia (A). Proceed

gently when inserting the screwdriver under the membrane to avoid scratching the molded

board.

4. Install the new fascia making sure to position it properly over the board switches.

5. Test all controls of the foot end control panel for proper operation before returning the bed to

service.

SCALE SYSTEM LCD DISPLAY REPLACEMENT

Required Tools:

Small Slotted Head Screwdriver No. 2 Phillips Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.2 on page 25 for the illustration of this procedure

reference points.

1. Run the bed fully up and apply the brakes.

2. Unplug the bed power cord from the wall outlet.

3. Using a small slotted head screwdriver, lift and remove the five self-sticking round screwcovers (B) located on the foot board cover as well as the self-sticking fascia (A) of the foot

board control panel to expose the screws holding the cover to the foot board.

25

Page 26

Maintenance Manual

E

NNOOTTE

Do not reuse the self-sticking parts removed since their self-adhesive coating considerably

looses its efficiency once they are removed. We recommend that you have replacement stickers

at hand (see Recommended Spare Parts on page 13).

4. Properly ground yourself (see section 1.4).

5. Using a no. 2 Phillips screwdriver, remove the seven screws (C) holding the cover to the foot

board and remove the cover.

6. Using a small slotted head screwdriver, push aside the clips (D) and remove the LCD

display (E) after having disconnected its cable from the control board.

7. Reverse the above steps to install the new LCD display.

8. Test the LCD display for proper operation before replacing the foot board cover and

returning the bed to service.

FOOT END CO NTROL BOARD REPLACEMEN T

Required Tools:

Small Slotted Head Screwdriver No. 2 Phillips Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.2 on page 25 for the illustration of this procedure

reference points.

1. Follow steps 1 to 5 of the scale system LCD display replacement procedure above.

2. Disconnect all cables from the control board. Note the locations of the cables so they will be

reconnected properly to the new control board.

3. Using a no. 2 Phillips screwdriver, remove the 17 screws (E) holding the control board to

the foot board and remove the control board.

4. Remove the scale system ACL display (D) by pushing aside the clips using a small slotted

head screwdriver. Disconnect its cable from the board and install the display on the new

control board.

5. Reverse the above steps to install the new control board.

6. Test all controls of the foot board control panel for proper operation before replacing the

foot board cover and returning the bed to service.

26

Page 27

Maintenance Procedures Chapter 4

A

4.3 MATTRESS SUPPORT MAINTENANCE PROCEDURES

FOOT SECTION REPLACEMENT

Required Tools:

1/2" Wrench No. 2 Phillips Screwdriver Bungee Cord

Procedure:

F

E

C

H

B

G

D

E

Figure 4.3A

1. Run the bed fully up and apply the brakes. Flatten all sections of the mattress support.

2. Unplug the bed power cord from the wall outlet.

3. Lower the siderails.

4. Remove if applicable the foot section plastic cover (optional). Lift and fold back the foot

section toward the head end of the bed and secure it to the bed using a bungee cord.

5. Remove the foot end mattress retainer (A) and install it on the new foot section. Replace the

foot section to horizontal position,

6. Using a 1/2" wrench, remove the two locknuts/washers/shoulder spacers/bolts (B) linking

the foot section to the thigh section and remove the defective section.

7. Reverse the above steps to install the new foot section.

27

Page 28

Maintenance Manual

THIGH SECTION REPLACEMENT

Required Tools:

Long Nose Pliers 1/2" wrench No. 2 Phillips Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3A on page 27 for the illustration of this procedure

reference points.

1. Run the bed fully up and apply the brakes. Flatten all sections of the mattress support.

2. Unplug the bed power cord from the wall outlet.

3. Raise the siderails.

4. Using long nose pliers, remove the rue ring cotter/washers/clevis pin (E fig. 4.3B, page 30)

linking the thigh section lever arms to the thigh actuator tube.

5. Using a 1/2" wrench, remove the four locknuts/washers/shoulder spacers/bolts (B, C) linking

the thigh section to the foot and seat sections.

6. Remove the defective thigh section and lay it upside down on a workbench.

7. Using a no. 2 Phillips screwdriver, remove the two screws (D) holding the micro switch

activator to the thigh section. Install the activator on the new thigh section.

8. Reverse the above steps to install the new thigh section.

9. Test the Knee Gatch as well as the Auto Contour and Cardiac Chair positioning before

returning the bed to service.

E

NNOOTTE

Should the Auto Contour and Cardiac Chair positions not perform properly, check the

positioning of the switch activator on the thigh section.

SEAT SECTION REPLACEMEN T

Required Tools:

1/2" Long Socket Wrench Two 1/2" Wrench No. 2 Phillips Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3A on page 27 for the illustration of this procedure

reference points.

1. Raise the bed fully up and apply the brakes. Flatten the mattress support.

2. Unplug the power plug from the wall outlet.

3. Lower the siderails.

4. Using two 1/2" wrench, remove the locknut/shoulder spacers/bolt holding the mattress

support lever of the CPR mechanism (N, fig. 4.3H, page 46) to the seat section.

5. Using a 1/2" long socket wrench and a 1/2" wrench, remove the four locknuts/washers/bolts

(E) holding the seat section to the frame.

6. Using a 1/2" wrench, remove the four locknuts/washers/shoulder spacers/bolts (C, F) linking

the seat section to the thigh and head section and remove the defective seat section.

7. Using a no. 2 Phillips screwdriver, remove the three screws (G) holding the protective plate

to the seat section.

8. Reverse the preceding steps to install the new seat section.

28

Page 29

Maintenance Procedures Chapter 4

HEAD SECTION REPLACE ME NT

Required Tools:

1/2" Socket Wrench Two 1/2" Wrenches No. 2 Phillips Screwdriver

3/16" Allen Key 7/16" Wrench Strap

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3A on page 27 for the illustration of this procedure

reference points.

WWAARRNNIINNG

G

Under no circumstances should the CPR emergency release handles be activated during this

procedure or serious injury to people or damage to equipment could occur.

1. Fully raise the bed and apply the brakes.

2. Unplug the bed power cord from the wall outlet.

3. Raise the head siderails.

4. Remove if applicable the head section plastic cover (optional) or run fully up the head

section. Secure the head section to the bed using a strap to prevent the head section from

moving once the CPR mechanism is removed.

5. Loosen the lock rings (A, fig. 4.1A, page 18) of both siderail cables and remove the siderail

cables. Using cutting pliers, cut the Ty-raps holding the siderail cables to the frame.

6. Using a 3/16" Allen key and a 1/2" wrench, remove the four locknuts/bolts (B, fig. 4.1A, page

18) holding each head siderail assembly to the head section and remove the siderails.

7. Using a no. 2 Phillips screwdriver, remove the screw holding each cable tie present on both

sides of the head section structure.

8. Remove the two wires (C, fig, 4.3H, page 46) from the micro switch. Note their position

before removing them.

9. Using a 1/2" wrench, remove the nuts/shoulder spacers/bolts (H) holding the head section to

the stabilizer arms. Lay the stabilizer arms down.

10. Using two 1/2" wrench, remove the locknut/shoulder spacers/bolt (L, fig. 4.3H, page 46)

holding each CPR handle to the head section. To remove the cable ends from the handle

slots, loosen the two locknuts holding each CPR cable to its handle using a 7/16" wrench.

E

NNOOTTE

Insert the cable ends inside the handle slots before assembling the handle to the new head

section. Then adjust the two locknuts of each cable in order to have a 1/8" play in the CPR

handle movement.

11. Using two 1/2" wrenches, remove the locknut/bolt (M, fig. 4.3H, page 46) holding the

pneumatic cylinder end fitting to the head section lever arms. Lay the CPR mechanism

down on the frame.

12. Remove the strap and lower the head section while holding it firmly.

13. Using a 1/2" wrench, remove the two locknuts/shoulder spacers/bolts (F) holding the head

section to the seat section.

14. Remove from the defective head section the micro-switch by pressing its two side clips

15. Reverse the above steps to install the new head section.

16. Test the CPR mechanism for proper operation before returning the bed to service.

29

Page 30

Maintenance Manual

A

FOWLER ACTUATOR REPLACEMENT

Required Tools:

Long Nose Pliers No. 2 and 3 Phillips Screwdrivers Pliers

Cutting Pliers 5/16" Socket Wrench

Bungee Cord Small Slott ed Head Screwdriver

Procedure:

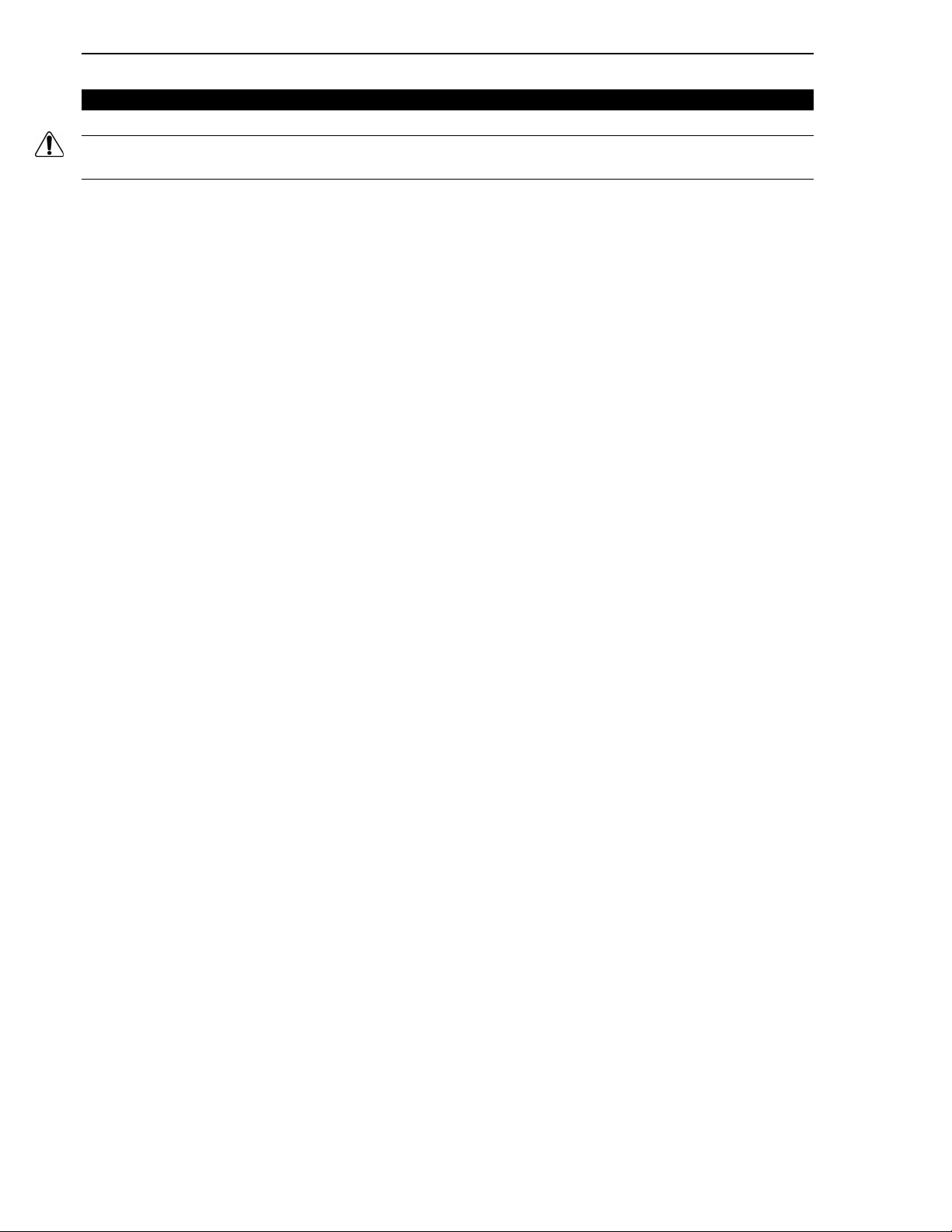

I

J

J

K

E

K

J

B

D

D

C

H

I

J

F

H

G

Figure 4.3B

1. Raise the bed fully up and apply the brakes.

2. Raise the Knee Gatch fully up.

3. Unplug the bed power cord from the wall outlet.

4. Raise the siderails.

5. Remove the head and foot boards.

6. If applicable, remove the foot and head section plastic covers (optional).

7. Lift and fold the foot section back toward the head end of the bed and secure it to the bed

using a bungee cord.

8. Using long nose pliers, remove the rue ring cotter/washers/clevis pin (A) linking the actuator

tube to the seat section lever arms.

30

Page 31

Maintenance Procedures Chapter 4

A

A

9. Using a no. 3 Phillips screwdriver, remove the six screws (A, fig. 4.3C, page 35) holding the

plastic cover to the foot end casing. Grasp both ends of the cover, move them apart to

disengage the inside clips from the round accessory brackets and remove the cover.

10. Using a no. 2 Phillips screwdriver, remove the four screws (B, fig. 4.3C, page 35) holding the

protective plate to the foot end casing.

11. Properly ground yourself (see section 1.4).

12. Using cutting pliers, clip the cable tie holding the head actuator cable to the other cables, if

applicable.

13. Remove the actuator cable (connector J8) from the control board.

14. Using pliers, squeeze the upper part of the strain relief bushing (B) and lift it up to remove it

from its location.

15. Remove the cable from the bushing and pass the cable connector through the rear casing

hole.

16. Using a 5/16" socket wrench, remove the two screws (C) holding the retaining plate to the

actuator support.

17. Remove the two pivot pins (D) holding the actuator to the support. To facilitate the removal

of the pins, insert a small slotted head screwdriver into the opening at the end of the

actuator and push out the pins.

18. Move the actuator toward the centre of the bed to remove it from its location.

19. Reverse the above steps to install the new actuator. Take note of the following caution

before hooking up the actuator tube to the head section lever arms.

C

C

UUTTIIOON

N

It is of utmost importance that the course of the new head actuator be adjusted before

hooking up its tube to the head section lever arms. An improper adjustment can damage the

head section structure.

17. To adjust the course of the replacement head actuator, proceed as follows:

A. Make sure that the actuator cable is connected to the control board and connect the

bed power cord.

B. Grab the new actuator tube and position its holes horizontally. While holding the tube

firmly to prevent it from rotating, press the Fowler up control for a few seconds and

then press the down control until the actuator stops. This will be the lower limit of the

actuator course.

C. Gently turn the tube in either direction to align the tube holes with those of the head

section lever arms. Then raise again the Fowler a few inches while holding firmly the

tube and lower it completely.

D. Check the alig nment of the holes. If the tube holes are not aligned any more with those

of the lever arms, repeat steps B and C until they are. Once the holes aligned, install

the washers and the clevis pin. Slightly raise the head section manually to ease the

insertion of the clevis pin.

E. Before installing the rue ring cotter to finalize the head actuator replacement, raise and

lower completely the Fowler. Check that the actuator stops working as soon as the

head section reaches the frame.

31

Page 32

Maintenance Manual

A

A

KNEE GATCH ACTUATOR REPLACEMENT

Required Tools:

Long Nose Pliers No. 2 and 3 Phillips Screwdrivers Pliers

Cutting Pliers Bungee Cord 5/16" Socket W rench

Small Slotted Head Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3B on page 30 for the illustration of this procedure

reference points.

1. Raise the bed fully up and apply the brakes. Flatten the mattress support.

2. Unplug the bed power cord from the wall outlet.

3. Raise the siderails.

4. If applicable, remove the foot and head section plastic covers (optional).

5. Lift and fold the foot section back toward the head end of the bed. Secure it to the bed using

a bungee cord.

6. Using long nose pliers, remove the rue ring cotter/washers/clevis pin (E) linking the actuator

tube to the thigh section lever arms.

7. Using a no. 3 Phillips screwdriver, remove the six screws (A, fig. 4.3C, page 35) holding the

plastic cover to the foot end casing. Grasp both ends of the cover, move them apart to

disengage the inside clips from the round accessory brackets and remove the cover.

8. Using a no. 2 Phillips screwdriver, remove the four screws (B, fig. 4.3C, page 35) holding the

protective plate to the foot end casing.

9. Properly ground yourself (see section 1.4).

10. Using cutting pliers, clip, if applicable, the cable tie holding the thigh actuator cable to the

other cables.

11. Remove the actuator cable (connector J9) from the control board.

12. Using pliers, squeeze the upper part of the strain-relief bushing (F) and lift it up to remove it

from its location.

13. Remove the cable from the bushing and pass the cable connector through the casing hole.

14. Using a 5/16" socket wrench, remove the two screws (G) holding the retaining plate to the

actuator support.

15. Remove the two pivot pins (H) holding the actuator to the support. To facilitate the removal

of the pins, insert a small slotted head screwdriver into the opening at the end of the

actuator and push out the pins.

16. Move the actuator toward the centre of the bed to remove it from its location.

17. Reverse the above steps to install the new actuator. Take note of the following caution

before hooking up the actuator tube to the thigh section lever arms.

C

C

UUTTIIOON

N

It is of utmost importance that the course of the new thigh actuator be adjusted before

hooking up its tube to the thigh section lever arms. An improper adjustment can damage the

thigh section structure.

17. To adjust the course of the replacement thigh actuator, proceed as follows:

A. Make sure that the actuator cable is connected to the control board and connect the

bed power cord.

32

Page 33

Maintenance Procedures Chapter 4

B. Grab the new actuator tube and position its holes horizontally. While holding the tube

firmly to prevent it from rotating, press the Knee Gatch up control for a few seconds

and then press the down control until the actuator stops. This will be the lower limit of

the actuator course.

C. Gently turn the tube in either direction to align the tube holes with those of the thigh

section lever arms. Then raise again the Knee Gatch a few inches while holding firmly

the tube and lower it completely.

D. Check the alig nment of the holes. If the tube holes are not aligned any more with those

of the lever arms, repeat steps B and C until they are. Once the holes aligned, install

the washers and the clevis pin. Slightly raise the thigh section manually to ease the

insertion of the clevis pin.

E. Before installing the rue ring cotter to finalize the actuator replacement, raise and lower

completely the Knee Gatch. Check that the actuator stops working as soon as the thigh

section reaches the frame.

HI-LO ACTUATOR REPLACEMENT

E

NNOOTTE

In order to preserve the adjustment of the bed lowest position when replacing a Hi-lo actuator, a

special tool kit designed for that purpose must be used. The kit includes alignment jigs. To

obtain this kit, contact our Technical Service department (see section 1.2) and order part

number KR0154.

Required Tools:

Tool Kit KR0154 Cutting Plier s 5/16" Socket Wrench

Angle Indicator Small Slotted Head Screwdriver 1/2" Wrench

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3B on page 30 for the illustration of this procedure

reference points.

1. Position the mattress support sections depending on the location of the Hi-Lo actuator to

replace:

At the foot of the bed: Remove, if applicable, the plastic section (optional) of the foot

section. Fully raise the thigh section, and lift and fold back the foot section toward the head

end of the bed. Finally, using an angle indicator, raise the Fowler by approximately 30°.

At the head of the bed: Remove, if applicable, the plastic cover (optional) of the head

section and fully raise the Fowler.

2. Position the alignment jigs on

the floor right under the Hi-Lo

levers and lower the bed until

the levers come to rest on the

jigs (see opposite illustration).

Use a 3/8" socket wrench with

the 1/2" socket provided in the

kit to lower a defective Hi-Lo

actuator until the lever rests on

L

the jig.

3. Unplug the bed power cord from the wall outlet.

4. Disconnect the actuator cable and clip, using cutting pliers, the cable ties holding it to the

frame.

5. Using a 5/16" socket wrench, remove the two screws (i) holding the retaining plate to the

actuator support.

33

Page 34

Maintenance Manual

6. Remove the two pivot pins (J) holding the actuator to the support. To facilitate the removal

of the pins, insert a small slotted head screwdriver into the opening at the end of the

actuator and push out the pins.

7. Using a 1/2" wrench, remove the two bolts/washers/shoulder spacers (K) holding the

molded nut support to the Hi-Lo lever arms. Remove the molded nut support and keep it for

the replacement Hi-Lo actuator that will have its own molded nut.

E

NNOOTTE

Make sure that the support and the molded nut holes are aligned before screwing in the bolts. If

resistance is felt, stop immediately; the holes then are not aligned.

8. Remove the defective actuator.

9. Reverse the above steps to install the new actuator. Take note of the following caution

before hooking up the molded nut support to the Hi-Lo lever arms.

CCAAUUTTIIOON

N

The course of the new actuator must be adjusted prior to hooking it to the Hi-Lo lever. An

improper adjustment can damage the Hi-Lo mechanism.

10. To adjust the new actuator, proceed as follows:

A. Once the new actuator cable connected, plug the bed power cord and press the bed

down control until the actuator stops. This will be the lower limit of the actuator course.

B. Attach the molded nut support to the Hi-Lo lever arms (see note following step 7).

C. T he alig nment j igs still in position, raise and lower completely the bed to ensure that

the lower limit is properly adjusted.

34

Page 35

Maintenance Procedures Chapter 4

A

MOTOR CONT ROL BO A R D REP LACEMENT

Required Tools:

No. 2 and 3 Phillips Screwdrivers Long-Nose Pliers Cutting Pliers

3/8" Wrench

Procedure:

D

C

B

C

Figure 4.3C

1. Raise the bed fully up and apply the brakes.

2. Unplug the bed power cord from the wall outlet.

3. Remove the foot board.

4. Using a no. 3 Phillips screwdriver, remove the six screws (A) holding the plastic cover to the

foot end casing. Grasp both ends of the cover, move them apart to disengage the inside clips

from the round accessory brackets and remove the cover.

5. Using a no. 2 Phillips screwdriver, remove the four screws (B) holding the protective plate to

the foot end casing.Properly ground yourself (see section 1.4).

6. Properly ground yourself (see section 1.4)

7. Using cutting pliers, clip the cable ties holding together the cables.

E

NNOOTTE

Carefully note the position and the gathering of the cables before clipping the cable ties.

8. Remove all cables connected to the control board. Note their location so they will be

connected properly to the new board. Refer to drawing OL280001 or OL280010 for the

connecting position of the cables on the motor control board

9. Using a 3/8" wrench, remove the nut/screw (C) holding the ground cable to the frame.

35

Page 36

Maintenance Manual

A

10. Using long-nose pliers, pinch the upper part of the stand-off pins and lift the defective board

up and out.

11. Using a 3/8" wrench and a no. 2 Phillips screwdriver, remove the nut/screw (D) holding the

ground cables to the board.

12. Reverse the above steps to install the new control board.

13. Test all the bed functions before returning the bed to service.

NURSE CALL (OPTIONAL)/GEN III PENDANT CONTROL (OPTIONAL) CONTROL BOARD

REPLACEMENT

Required tools:

No. 2 Phillips Screwdriver

Procedure:

B

F

G

B

F

Figure 4.3D

C

D

E

1. Raise the bed fully up and apply the brakes.

2. Unplug the bed power cord from the wall

outlet.

3. Remove the power cord from the power

connector and disengage it from the wire

clip.

4. Properly ground yourself (see section 1.4).

5. Using a no. 2 Phillips screwdriver, remove

the six screws (A) holding the cover to the

head end casing. Keep the cable clips (F).

6. Once the screws removed, pivot the cover

and lay it flat on the bottom of the casing

(see opposite illustration).

36

Page 37

Maintenance Procedures Chapter 4

7. Remove all cables connected to the control board. Note their location so they will be

connected properly to the new board.

8. Pivot the cover to vertical position and, using a Phillips screwdriver, remove the four screws

(B) holding the control board (G) to the head casing cover and remove the board.

9. Reverse the above steps to install the new control board.

10. Test the nurse call (optional) and, if applicable, the GEN lll pendant control (optional) for

proper operation before returning the bed to service.

POWER CONNE CTO R R EPL ACEMENT

Required Tools:

No. 1 and 2 Phillips Screwdrivers

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3D on page 36 for the illustration of this procedure

reference points.

1. Follow steps 1 to 6 of the nurse call/communications package control board replacement

procedure described above.

2. Remove all cables connected to the power connector. Note their location so they will be

connected correctly to the new power connector. Refer to drawing OL280001 or OL280010

for the connecting position of the cables on the power connector.

3. Pivot the cover to vertical position and remove, using a no. 1 Phillips screwdriver, the two

screws (C) holding the power connector to the cover.

4. Press the connector clips and remove it from its location.

5. Reverse the above steps to install the new power connector.

6. Test that the bed is powered before returning it to service.

POWER CONNE CTO R FUS E RE PLACEMENT

Required Tools:

Small Slotted Head Screwdriver

Procedure:

E

NNOOTTE

Unless otherwise indicated, refer to figure 4.3D on page 36 for the illustration of this procedure

reference points.

1. Remove the power cord from the power connector.

2. Using a small slotted screwdriver, open and slide down the power connector door (D).

3. Still using the small screwdriver, remove the fuse holder (E).

4. Remove the defective fuse and replace it by a new one.

E

NNOOTTE

Fuses used in the FL28EX bed, powered by the 120V electrical system, are of the fast acting type

and their rating is 250V, 10A. For beds powered by other electrical system, see section 1.1

“Specifications” for fuse ratings.

5. Replace the fuse holder in its housing and close the door.

E

NNOOTTE

There is only one way to install the fuse holder. The characters 115V (100 and 120V electric