Page 1

MedSurg Bed

Model FL23SE

(Electric)

Maintenance Manual

For Parts or Technical Assistance:

USA: 1-800-327-0770 (option 2)

Canada: 1-888-233-6888

2008/08 72-1048E MM FL23SE REV A www.stryker.com

Page 2

Page 3

Table of Contents

Introduction...............................................................................7

Intended Use ..........................................................................7

Product Illustration ......................................................................7

Specifications .........................................................................8

Warning / Caution / Note Definition ..........................................................9

Symbols ................................................................................10

Electrical Service Information ................................................................11

Connection Diagram ...................................................................11

Preventative Maintenance ................................................................... 13

Annual Checklist ......................................................................13

Cleaning................................................................................14

Bed Cleaning .........................................................................14

Mattress Care ........................................................................14

Troubleshooting Guide......................................................................15

Quick Reference Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation Guide ..........................................................................19

Maintenance Procedures ................................................................19

Static Discharge Precautions .............................................................19

Service Information ........................................................................20

Siderail Replacement ...................................................................22

Half-Length Rail Replacement.............................................................22

Half-Length Siderail Assembly Replacement ..................................................24

Transfer Plate Replacement ..............................................................25

Full-Length Siderail Pivot Tube Replacement ..................................................27

Full-Length Rail Replacement ............................................................28

Full-Length Siderail Assembly Replacement ..................................................29

Full-Length Siderail Release Handle Replacement ..............................................30

Full-Length Siderail Locking Hook Replacement................................................31

Foot End Control Panel Replacement .......................................................32

Foot End Casing Connector Replacement (Optional) ............................................33

Foot Board Control Panel Replacement (Optional) ..............................................34

Foot Board Connector Replacement (Optional) ................................................35

Siderail Control Panel Membrane Replacement ................................................36

Mattress Support Replacement ............................................................37

Foot Section Replacement ...............................................................38

Thigh Section Replacement ..............................................................39

Seat Section Replacement ..............................................................40

Head Section Replacement...............................................................41

Fowler Actuator Replacement .............................................................43

Knee Gatch Motor Replacement ...........................................................45

Bed Lift Motor Replacement ..............................................................47

www.stryker.com 72-1048E MM FL2 3SE REV A 3

Page 4

Table of Contents

Service Information (Continued)

Toroidal Transformer Replacement (International Series Models) ...................................49

Motor Control Board Replacement .........................................................50

Power Connector and Fuse Replacement ....................................................51

Auto Contour Micro Switch Replacement (Optional) ............................................52

CPR Micro Switch Replacement (Optional) ...................................................54

CPR Activation Cable Replacement (Optional) .................................................56

CPR Pneumatic Cylinder Replacement (Optional) ..............................................57

Brake/Steer Pedal Replacement ..........................................................58

Fifth Wheel Caster Replacement (Optional) ..................................................59

Fifth Wheel Assembly Replacement (Optional) ................................................60

Fifth Wheel Swing Arm Assembly Replacement (Optional) ........................................61

Bed Caster Replacement ................................................................62

Brake Rod Replacement ................................................................64

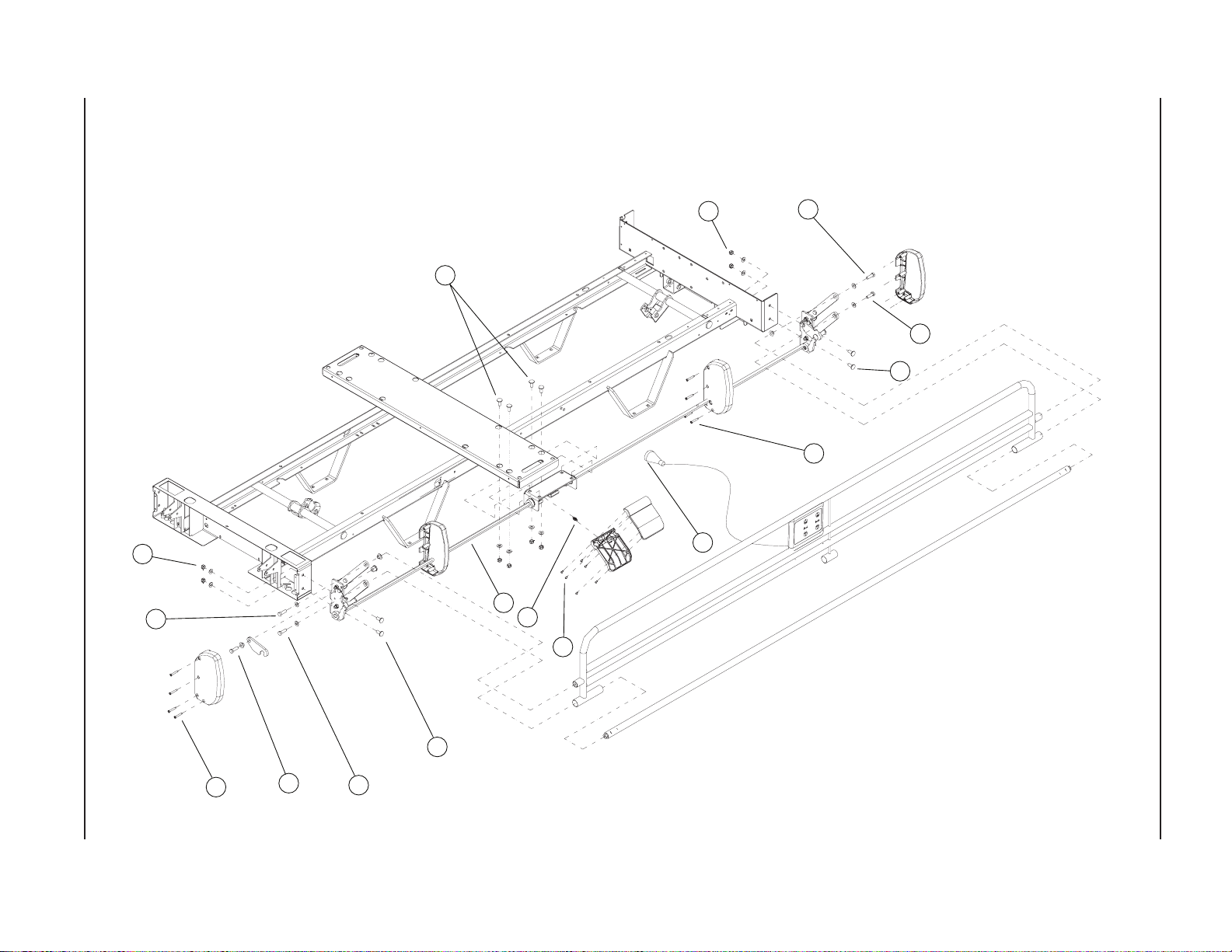

Assembly Drawings

Base ...............................................................................65

Wheel Covers ........................................................................66

Brake Mechanism without Fifth Wheel.......................................................68

5” Casters without Fifth Wheel ............................................................70

6” Casters without Fifth Wheel ............................................................71

Brake Mechanism with Fifth Wheel .........................................................72

6” Casters with Fifth Wheel ..............................................................74

Fifth Wheel ..........................................................................75

Bed Lift Mechanism ....................................................................78

Frame ..............................................................................80

120V Electric System ...................................................................82

100V Electric System ...................................................................86

International Electric System..............................................................87

200V Electric System ...................................................................92

220V Electric System ...................................................................93

240V Electric System ...................................................................94

Auto Contour Positioning.................................................................96

Bed Lift Motors Screw Covers.............................................................98

Mattress Support ..................................................................... 10 0

Foot End Control Panel................................................................. 10 2

Control Panel on Frame for Full-Length .....................................................10 4

Foot End and Foot Board Control Panels ....................................................106

Foot End and Foot Board Control Panels - Full-Length Siderail ....................................108

Without CPR Emergency Release .........................................................110

CPR Emergency Release ............................................................... 112

Stickers French/English ................................................................116

4 72-1048E MM FL23SE REV A w ww.stryker.com

Page 5

Table of Contents

Assembly Drawings (Continued)

Stickers English/Spanish ...............................................................118

BNQ Certification ..................................................................... 12 0

120V Auxiliary Outlet .................................................................. 12 2

Night Light ..........................................................................12 4

Cable and Phone Plug 1/4” ............................................................. 12 5

Power Cord with 90° North American Grade Plug .............................................. 131

Power Cord with Straight Molded North American Hospital Grade Plug .............................. 13 1

Power Cords and Plugs ................................................................ 13 2

Full-Length Retractable Siderail........................................................... 13 3

Retractable Full-Length Siderail without Pendant .............................................. 13 7

PVC Protector for Full-Length Siderail ...................................................... 141

Retractable Half-Length Siderails with Fixed Control ............................................ 142

Retractable Siderails with Removable Controls ................................................ 14 8

PVC Protector - Half-Length Retractable Siderails ............................................. 15 3

Fixed Control Panel without Nurse Call ..................................................... 154

Fixed Control Panel with Nurse Call........................................................ 15 5

Control with Nurse Call Normally Open (N.O.) ................................................ 15 6

Control with Nurse Call Normally Closed (N.C.) ............................................... 157

Post Set............................................................................15 8

Melamine Boards without Control Panel..................................................... 15 9

MDF Laminated Boards without Control Panel ................................................160

MDF Laminated Boards with Control Panel .................................................. 161

Solid Wood Board without Control Panel ....................................................163

Solid Wood Boards with Control Panel......................................................165

Solid Core Boards with Flat Top and Control Panel.............................................167

Optional Bed Accessories ..................................................................169

Removable I.V. Pole - FDTSH ............................................................ 17 0

Bed Extender - FA64152 ................................................................ 17 1

Emergency Crank - FA64161............................................................. 17 4

Removable Two-Sided, Two Function Pendant Control - FA64160 .................................. 17 5

P&D Two-Function Pendant Control - FA64155 ................................................ 17 6

Half an Inch Diameter Stryker Removable I.V. Pole - FA64135 ..................................... 17 7

Half-Length Siderail Protective Pads - DM64232 .............................................. 17 8

Full-Length Siderail Protective Pads - DM64176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 8

Half-Length Siderail Protective Pads - DM64233 .............................................. 17 9

Full-Length Siderail Protective Pads - DM64178 ............................................... 17 9

One Inch Diameter Removable I.V. Pole - FA61002-G ...........................................18 0

Oxygen Bottle Holder - FA64036-G ........................................................ 181

Upright Oxygen Bottle Holder - FA64117 ....................................................18 2

Overhead Trapeze - FA64145 ............................................................ 184

www.stryker.com 72-1048E MM FL2 3SE REV A 5

Page 6

Table of Contents

Optional Bed Accessories

Monitor Tray - FA64153................................................................. 18 6

One Inch Diameter Fixed I.V. Pole - FA64157 ................................................. 187

Recycling Passport .......................................................................188

Warranty...............................................................................190

Limited Warranty .....................................................................190

To Obtain Parts and Service ............................................................. 19 0

Service Contract Coverage .............................................................. 190

Service Contract Programs .............................................................. 19 1

Return Authorization................................................................... 19 1

Damaged Merchandise.................................................................191

International Warranty Clause ............................................................19 1

6 72-1048E MM FL23SE REV A w ww.stryker.com

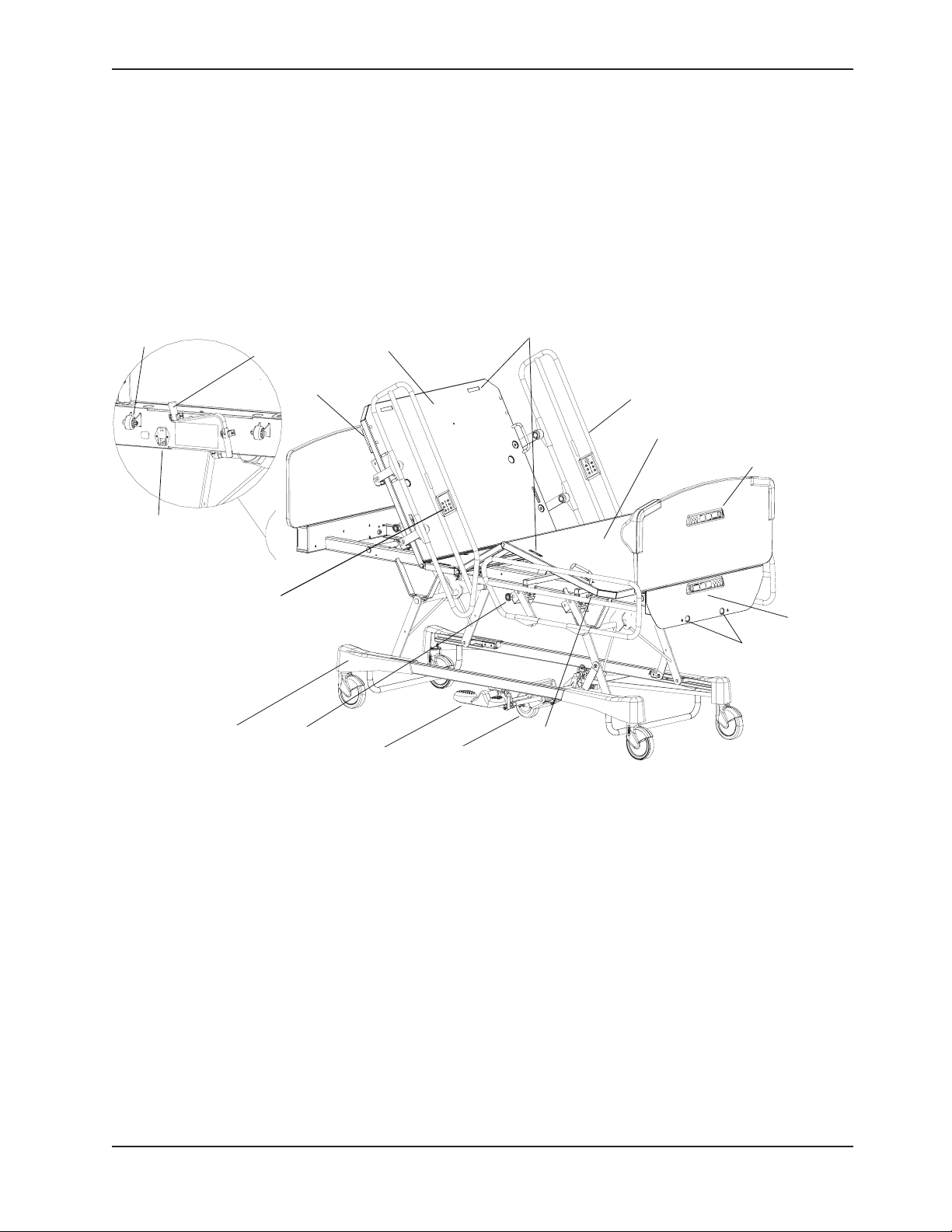

Page 7

Introduction

RESTRAINT STRAP

LOCATIONS

HALF

-

LENGTH

SIDERAIL

FOOT SECTION

FOOTBOARD CONTROL

PANEL

(

OPTIONAL

)

EMERGENCY CRANK

OPENINGS

FOOT END

CONTROL PANEL

DRAINAGE BAG

HOOK

BRAKE

/

STEER

PEDAL

5

TH WHEEL

(

OPTIONAL

)

WHEEL COVER

(

OPTIONAL

)

SIDERAIL RELEASE

LEVER

MAIN SW ITCH

(

POWER

CONNECTOR

)

STORED

EMERGENCY

CRANK

(

OPTIONAL

)

BUMPER

HEAD SECTION

CPR RELEASE

HANDLE

OPTIONAL

FIXED SIDERAIL

CONTROL PANEL

(

OPTIONAL

)

INTENDED USE

This manual is designed to assist you with the maintenance of Stryker Model FL23SE Electrical MedSurg Bed. Carefully

read this manual thoroughly before using the equipment or beginning maintenance on it. To ensure safe operation of this

equipment, it is recommended that methods and procedures be established for educating and training staff on the safe

operation of this bed.

PRODUCT ILLUSTRATION

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 7

Page 8

SPECIFICATIONS

Safe Working Load

Introduction

Note: Safe Working Load indicates the sum

of the patient, mattress, and accessory

weight.

Overall

Length/Width

Weight with Head/Foot Boards 390 lbs 177 kg

Patient Sleep Surface 35” x 78” 88,9 x 198,1 cm

Recommended

Mattress Size

Maximum

Thickness

Minimum/

Maximum

Bed Height

Fowler Angle 0° to 62°

Knee Gatch

Angle

Trendelenburg/Reverse Trendelenburg +17° to -17°

Environmental

Conditions

Electrical

Requirement

Half-Length Siderails Raised

Full-Length Siderails Raised

Length/Width 35” x 78” or 80” 88,9 x 198,1 cm

BNQ

Standard

Non-BNQ Standard 5” 12,7 cm

With diameter 12,7 cm (5”) casters

With diameter 15,2 cm (6”) casters

With Auto Contour 0° to 25°

Without Auto Contour 0° to 32°

Transport and Storage

Operating

Complies with the following standards:

CSA C22.2 No. 601.1, UL 60601-1,

IEC 60601-1, 60601-2-38 and BNQ

6641-120 : 2003.

Bed with diameter

12.7 cm (5”) casters

Bed with diameter

15.2 cm (6”) casters

Ambient Temperature•

Relative Humidity•

Atmospheric Pressure•

Ambient Temperature•

Relative Humidity•

Atmospheric Pressure•

90,4” x 41,3”

90,4” x 39,9”

6” 15,2 cm

5” 12,7 cm

11,75” to 29” 29,8 to 737 cm

12,75” to 30” 32,4 to 76,2 cm

-40° to 158°F

10 to 100%

500 to 1060 hPa

50° to 104°F

5 to 95% without condensation

700 to 1060 hPa

100V~, 50-60Hz, 7.5A - Two 250V, 10A Fast Acting Fuses

120V~, 50-60Hz, 4A (9.8A with 120V Optional Auxiliary

200V~, 50-60Hz, 3.2A - Two 250V, 6.3A Slow Blow Fuses

220V~, 50-60Hz, 2.9A - Two 250V, 6.3A Slow Blow Fuses

240V~, 50-60Hz, 2.7A - Two 250V, 6.3A Slow Blow Fuses

500 lbs 227 kg

229,6 x 104,9 cm

229,6 x 101,3 cm

or 203,2 cm

-40° to 70°C

10° to 40°C

Outlet) - Two 250V, 10A Fast Acting Fuses

Stryker reserves the right to change specifications without notice.

Specifications listed are approximate and may vary slightly from unit to unit or by power supply fluctuations.

*This device has a 10% duty cycle.

Note

The Safe Working Load for the BNQ beds is of 390 lbs (177 kg).

Return To Table of Contents

8 72-1048E MM FL23SE REV A w ww.stryker.com

Page 9

Introduction

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation, which if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation, which if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note

This provides special information to make maintenance easier or important instructions clearer.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 9

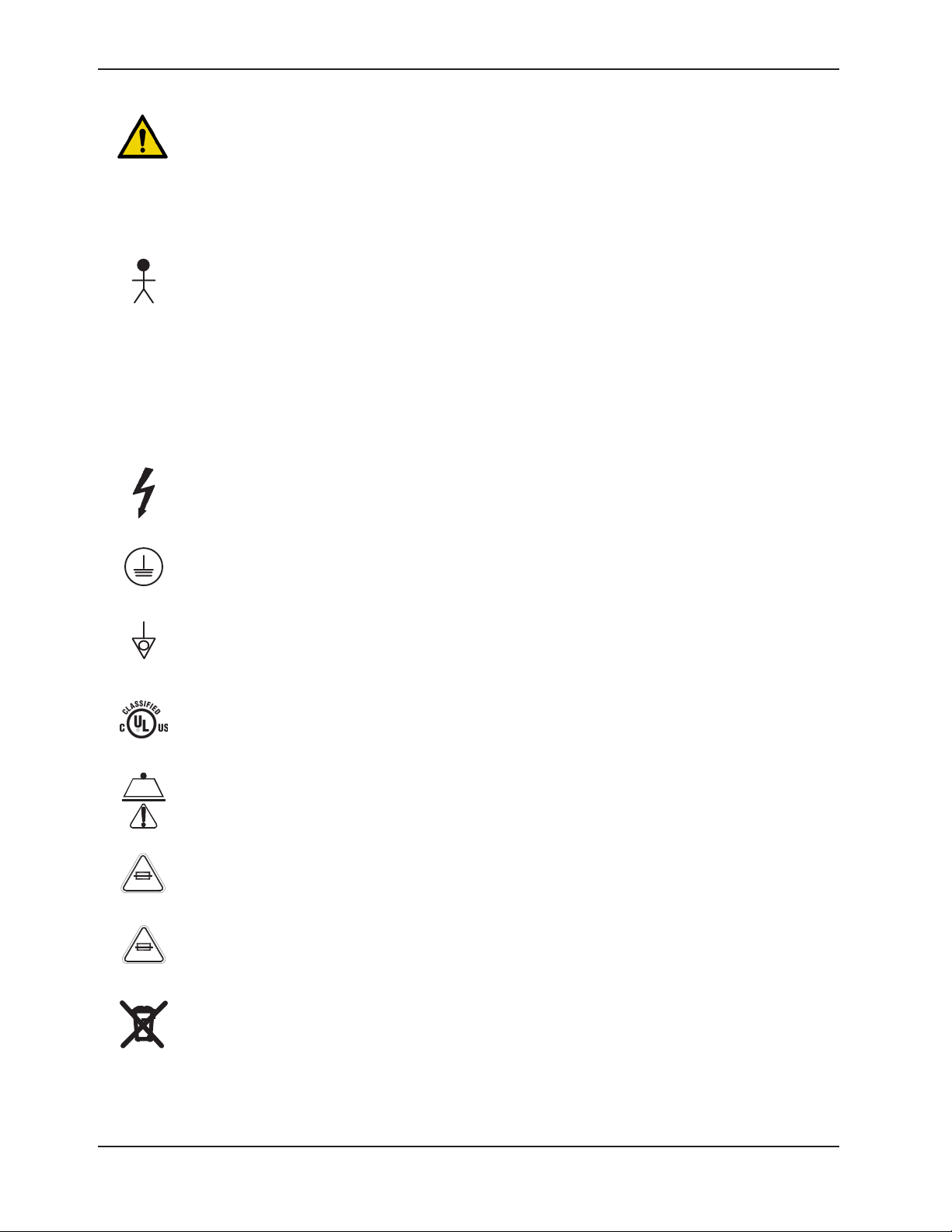

Page 10

Symbols

~

10A 250V

6.3A 250V

Warning, Refer to Accompanying Documentation

Alternating Current

Type B Equipment: Equipment providing a particular degree of protection against electric shock,

particularly regarding allowable leakage current and reliability of the protective earth connection.

Class 1 Equipment: Equipment in which protection against electric shock does not rely on basic insulation

only, but which includes an additional safety precaution in that means are provided for the connection of

the equipment to the protective earth conductor in the fixed wiring of the installation in such a way that

accessible metal parts cannot become live in the event of a failure of the basic insulation.

IPX4

Protection from liquid splash

Dangerous Voltage Symbol

Protective Earth Terminal

Potential Equalization Symbol

Medical Equipment Classified by Underwriters Laboratories Inc. with respect to Electric Shock, Fire,

Mechanical and Other Specified Hazards Only in Accordance with UL 60601-1, First Edition (2003) and

CAN/CSA C22.2 No. 601.1-M90 with updates 1 and 2.

Safe Working Load Symbol

Fuse rating for bed with 100V~ and 120V~ electric systems.

Fuse rating for bed with 200V~, 220V~ and 240V~ electric systems.

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE), this symbol indicates that the product must not be disposed of as unsorted municipal waste,

but should be collected separately. Refer to your local distributor for return and/or collection systems

available in your country.

Return To Table of Contents

10 72-1048E MM FL2 3SE REV A www.stryker.com

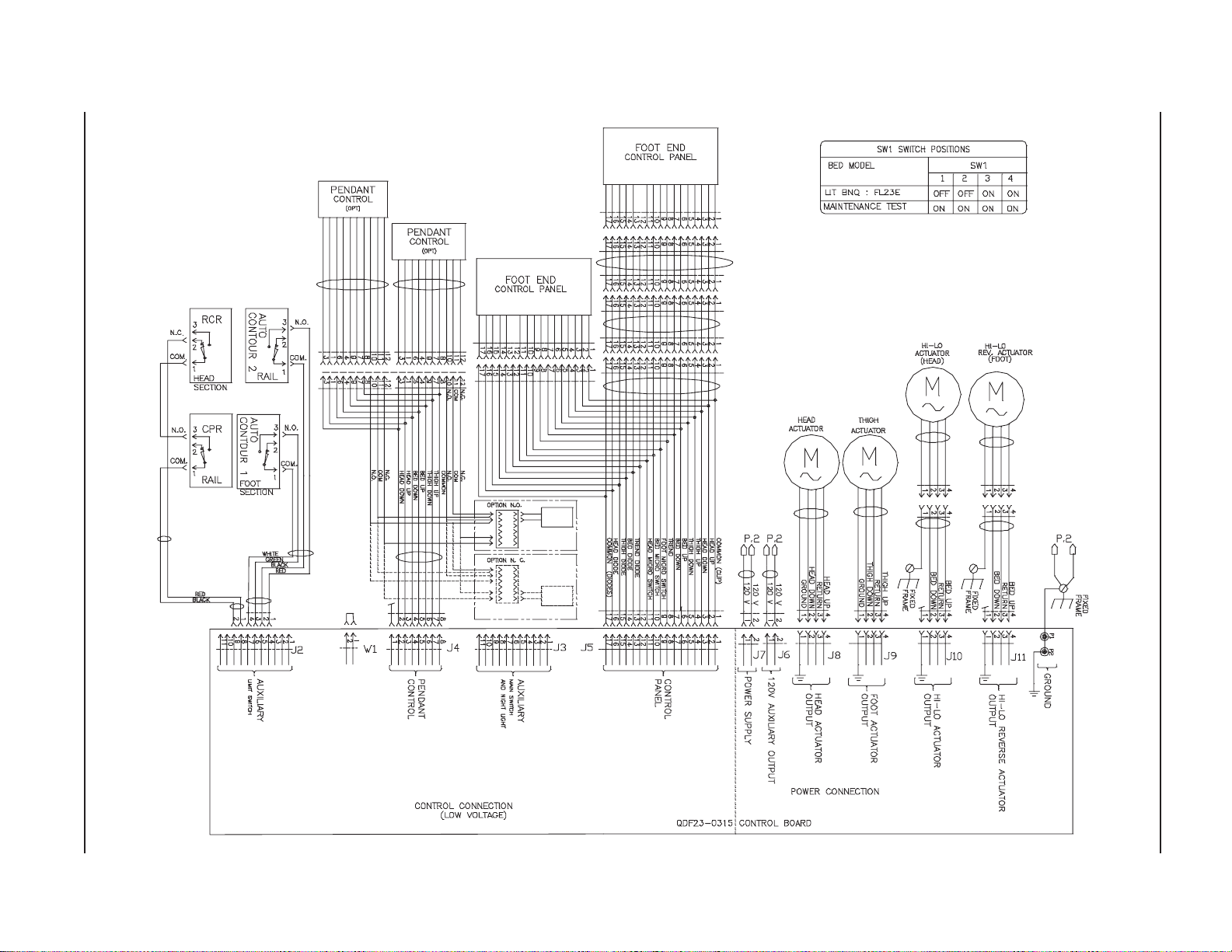

Page 11

www.stryker.com 72-1048E MM FL2 3SE REV A 11

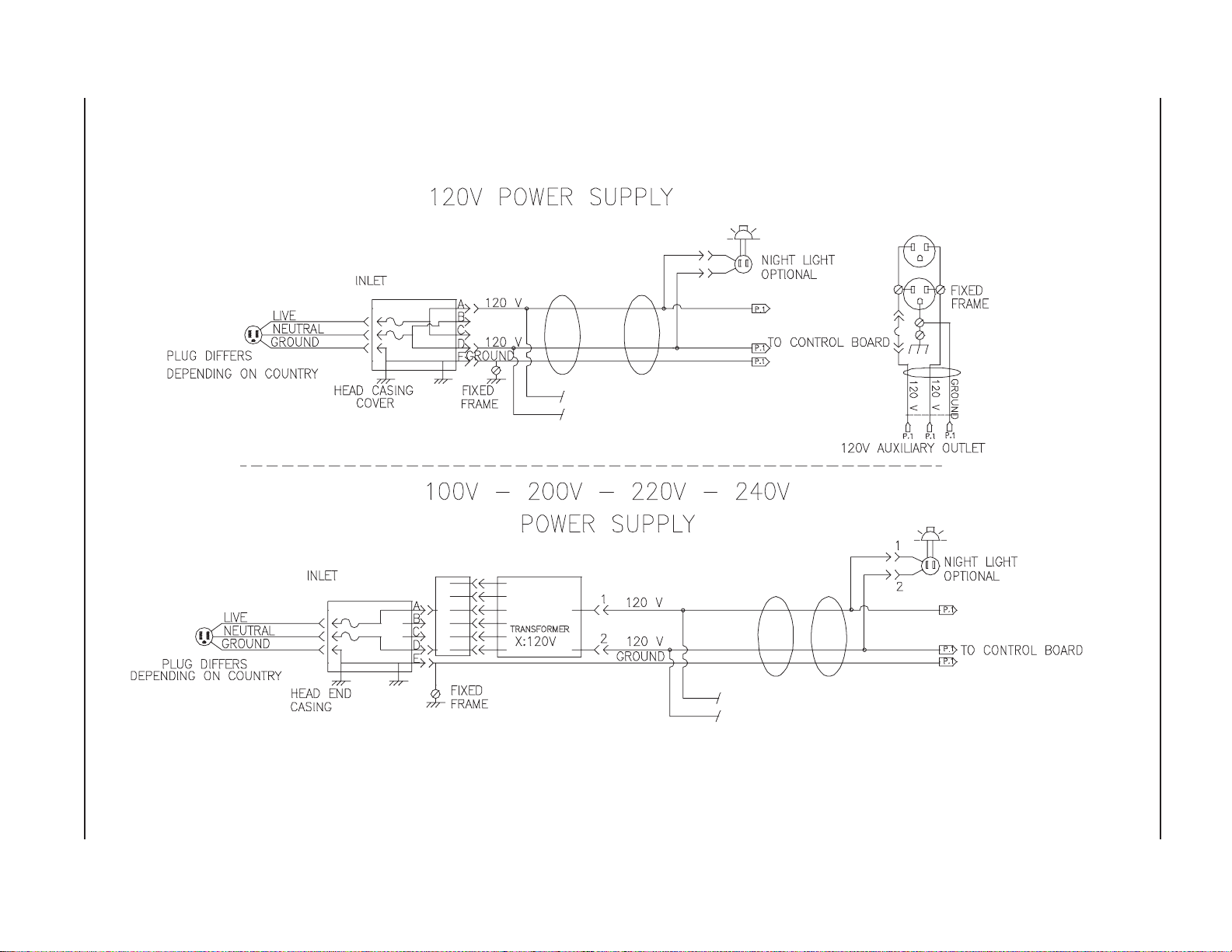

CONNECTION DIAGRAM

Electrical Service Information

Return To Table of Contents

Page 12

12 72-1048 E MM FL 23SE REV A www.stryker.com

Return To Table of Contents

CONNECTION DIAGRAM (CONTINUED)

Electrical Service Information

Page 13

Preventative Maintenance

WARNING

Use only replacement parts provided by Stryker.

ANNUAL CHECKLIST

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

All fasteners secure.

Inspect for excessive wear the oil-impregnated bronze shoulder spacers found at the bed hinge points.

Replace as needed. Do not lubricate these spacers.

On both sides of the bed, depress fully down the side of the pedal identified with a red sticker and ensure

that the brakes are applied and the bed immobilized. Toggle the pedal to neutral and ensure the brakes

are released.

On both sides of the bed, depress fully down the side of the pedal identified with a green sticker and ensure

that the steer mode (fifth wheel (optional) or bed wheel) is engaged. Toggle the pedal to neutral and ensure

that the steer mode disengages.

Siderails move smoothly and latch properly in high position.

Ensure that each control of the inner and outer head siderail control panels (optional) and those of the

removable pendant control (optional) are working properly.

All controls of the foot end panel and those of the foot board panel (optional) working properly, including

Trendelenburg and lockout LED’s.

Fowler and Knee Gatch (if raised) flatten and the Fowler control motor resets itself automatically when the

two CPR handles (optional) are pulled until Fowler is flattened. Wait about 30 seconds, the time for the

Fowler motor to reset itself, and then raise the Fowler to ensure that the resetting of the motor has indeed

occurred.

Verify the Fowler, Knee Gatch and Hi-Lo movements to ensure that the motion interrupt switch integrated

to the four electric actuators is operating properly.

Auxiliary outlet (option available only with 120V beds) working properly.

Night light (optional) working properly.

Head end bumpers tightly secured to frame and working properly.

No rips or cracks in mattress cover.

Power cord is not frayed. Replace if the protective sleeve is cut or torn.

No cables worn or pinched.

All electrical connections tight.

All grounds secured to the frame.

All casters roll properly. Check caster for cuts, wear, etc.

Measure current leakage and grounding continuity of the bed and the optional auxiliary outlet. Check with

our Technical Service department for the acceptable values.

Bed Serial Number:

Completed by: _______________________________________ Date: _________________

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 13

Page 14

Cleaning

BED CLEANING

CAUTION

Do not use harsh cleaners, solvents or detergents. Equipment damage could occur. • Do not steam clean, hose off

or ultrasonically clean the bed. Do not immerse any part of the bed. The bed electrical parts may be damaged

by exposure to water.

Germicidal disinfectant, used as directed, and/or Chlorine Bleach products are not considered as mild detergents. •

These products are corrosive in nature and may cause damage to your bed if used improperly. If these types of

products are used, ensure the beds are wiped with clean water and thoroughly dried following cleaning. Failure to

properly rinse and dry the beds will leave a corrosive residue on the surface of the bed, possibly causing premature

corrosion of critical components. Failure to follow the above directions when using these types of cleaners may void

the product’s warranty.

Procedure:

Hand wash all surfaces of the bed with a soft cloth moistened with a solution of lukewarm water and a mild detergent.

Wipe the bed clean and dry thoroughly to avoid build up of cleaning solution.

MATTRESS CARE

WARNING

Inspect the mattress after each use. Discontinue use if any cracks or rips, which may allow fluid to enter the mattress,

are found in the mattress cover. Failure to properly clean the mattress, or dispose of it if defective, may increase the risk

of exposure to pathogenic substances and may bring about diseases to the patient and user.

Inspection

Implement local policies to address regular care, maintenance, and cleaning of mattresses and covers. The cover •

cleaning procedure can be found below and on the bed label.

Inspect mattress cover surface, interior and exterior, as well as zip fasteners and cover inner surface if mattresses •

have zip fasteners, regularly for signs of damage. If the mattress cover is heavily stained or soiled, or is torn, remove

the mattress from service.

Cleaning

Stains: Wash with lukewarm water using a mild detergent. Rinse with water and let dry. For tough stains, use bleach

diluted with ten parts of water.

Return To Table of Contents

14 72-1048E MM FL23 SE REV A www.stryker.com

Page 15

Troubleshooting Guide

Problem/Failure Recommended Action

No power to bed Is the bed power switch at the head end of the bed •

turned on?

Is the power cord connected to the power connector •

and plugged into the wall outlet?

Is the power cord severed? Replace if so. •

Are the two fuses inside the power connector still •

operational (see pg. 51)?

Verify power at the wall outlet.•

No bed up or down motion when:

The removable pendant control (optional) is used. •

The foot board command is used.•

No Fowler up or down motion when:

The siderail (optional) or removable pendant control •

(optional) is used.

The foot board command is used.•

The Fowler does not fully raise. This situation arises when the CPR emergency release

No Knee Gatch up or down motion when:

The siderail (optional) or removable pendant control •

(optional) is used.

The foot board command is used.•

Is the Hi-Lo lockout activated (LED off)? If so, deactivate •

it (LED on).

Is the cable of the removable pendant control (optional) •

properly connected to the bed connector under the

mattress support?

Check points of the “No power to bed” problem •

described above.

Is the Fowler lockout activated (LED off)? If so, deactivate •

it (LED on).

Is the cable of the siderail control panel (optional) or •

of the removable pendant control (optional) properly

connected to the bed connector under the mattress

support?

Check points of the “No power to bed” problem •

described above.

(optional) is used to partially lower the Fowler. The use

of the CPR for this purpose creates a situation where the

Fowler motor is out of sync with the actual position of the

Fowler. To correct the situation:

Lower the Fowler • completely using a CPR handle or

the Fowler electric control to enable the Fowler motor

to reset itself and thus synchronize its course with the

actual position (flatten) of the Fowler.

Is the Knee Gatch lockout activated (LED off)? If so, •

deactivate it (LED on).

Is the cable of the siderail control panel (optional) or •

of the removable pendant control (optional) properly

connected to the bed connector under the mattress

support?

Check points of the “No power to bed” problem •

described above.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 15

Page 16

Troubleshooting Guide

Problem/Failure Recommended Action

The positioning mechanisms of the Fowler, and/or

the Knee Gatch, and/or the bed height operate with

difficulty.

No Auto Contour (optional) motion. Is the Knee Gatch lockout activated (LED off)? If so, •

Improper operation of the CPR emergency release

(optional): Knee Gatch does not lower and/or the Fowler

actuator does not reset.

Check the four actuator screws to verify their lubrication •

condition and apply grease if needed (see pg. 20).

deactivate it (LED on).

Check and replace if needed the two Auto Contour limit •

switches (see pg. 52).

Check and replace if needed the two CPR mechanism •

limit switches (see pg. 54).

Return To Table of Contents

16 72-1048E MM FL23SE REV A www.stryker.com

Page 17

Quick Reference Replacement Parts List

Note

The parts and accessories listed on this page are all currently available for purchase. Some of the parts identified on

the assembly drawing parts in this manual may not be individually available for purchase. Please call Stryker Customer

Service USA: 1-800-327-0770 (Option 2) or Canada: 1-888-233-6888 for availability and pricing.

Part Name Part Number

Electric/Electronic Components

Motor Control Board QDF23-0315

Micro Switch 1325P003 / QDF9159

Fuse - Fast Acting 10A, 250V (100/120V) QDF8078

Fuse - Slow Blow 6.3A, 250V (200/220/240V) QDF8068

Power Cord with Straight North American Molded Plug QDF8066

Night Light (Optional) QDF9539

5A Circuit Breaker for Auxiliary Outlet (optional) QDF9025

Hi-Lo Actuator 23-0702

Head Section Actuator 23-0335

Thigh Section Actuator 23-0336

Toroidal Transformer - International Series Beds QDF14-1160

Stand-Off Pins: Motors Control Board QP23-0735

Strain-Relief Bushing QDF9541

Support for the Foot End Control Panel Membrane QP17-0127-07

Foot End Control Panel Membrane QDF17-0693 / QDF17-0180

Siderail Components

Protective Cap QDFP1514

Transfer Plate - Half-Length Siderail 23-0777G / 23-0778G

23-0817G / 23-0818G

Left Inner Membrane without Nurse Call

Right Inner Membrane without Nurse Call

Right Inner Membrane with Nurse Call

Left Inner Membrane with Nurse Call

Left Outer Membrane QDF23-0405

Right Outer Membrane QDF23-0406

PVC Protector for Painted Head Half-Length Siderails 23-0476

QDF23-0392 / QDF23-0393

QDF23-0396 / QDF23-0397

PVC Protector for Painted Foot Half-Length Siderails 23-0478

PVC Protector for Painted Full-Length Siderails 23-0641

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 17

Page 18

Quick Reference Replacement Parts List

Part Name Part Number

Mattress Support Components

Lateral Mattress Retainer QP14034-07

I.V. Pole Holder QP17-0121

Caster

6” with Lock Mechanism RD25038807

6” without Lock Mechanism RD25049307

6” with Steer Mechanism RD25049607

5” with Lock Mechanism RD25049407

5” without Lock Mechanism RD25039107

5” with Steer Mechanism RD25049507

Fifth Wheel Mechanism 5” Caster (Optional) RL5

Base Components

Rue Ring Cotter Diameter 3/8” QDF7878

Green Sticker - Fifth Wheel QE71-0496

Red Sticker - Brake QE71-0511

Wheel Cover - Right (Optional) QP28-0299-07

Wheel Cover - Left (Optional) QP28-0300-07

Brake/Steer Pedal QP23-0627

Velcro Fastener 25-0550

Miscellaneous

Grey Spray Paint DDCAP-GSP

Shoulder Spacer QDF17-0020

Nylon Cable Tie QDF9518

Return To Table of Contents

18 72-1048E MM FL23SE REV A www.stryker.com

Page 19

GROUNDING DIAGRAM

BED

Operation Guide

MAINTENANCE PROCEDURES

WARNING

Always unplug the bed power cord when cleaning or servicing the bed.•

To prevent injury when working under the bed with the bed in the high position, always place blocks under the Hi-Lo •

levers and apply the brakes. Always unplug the bed power cord from the wall outlet when servicing or cleaning the

bed.

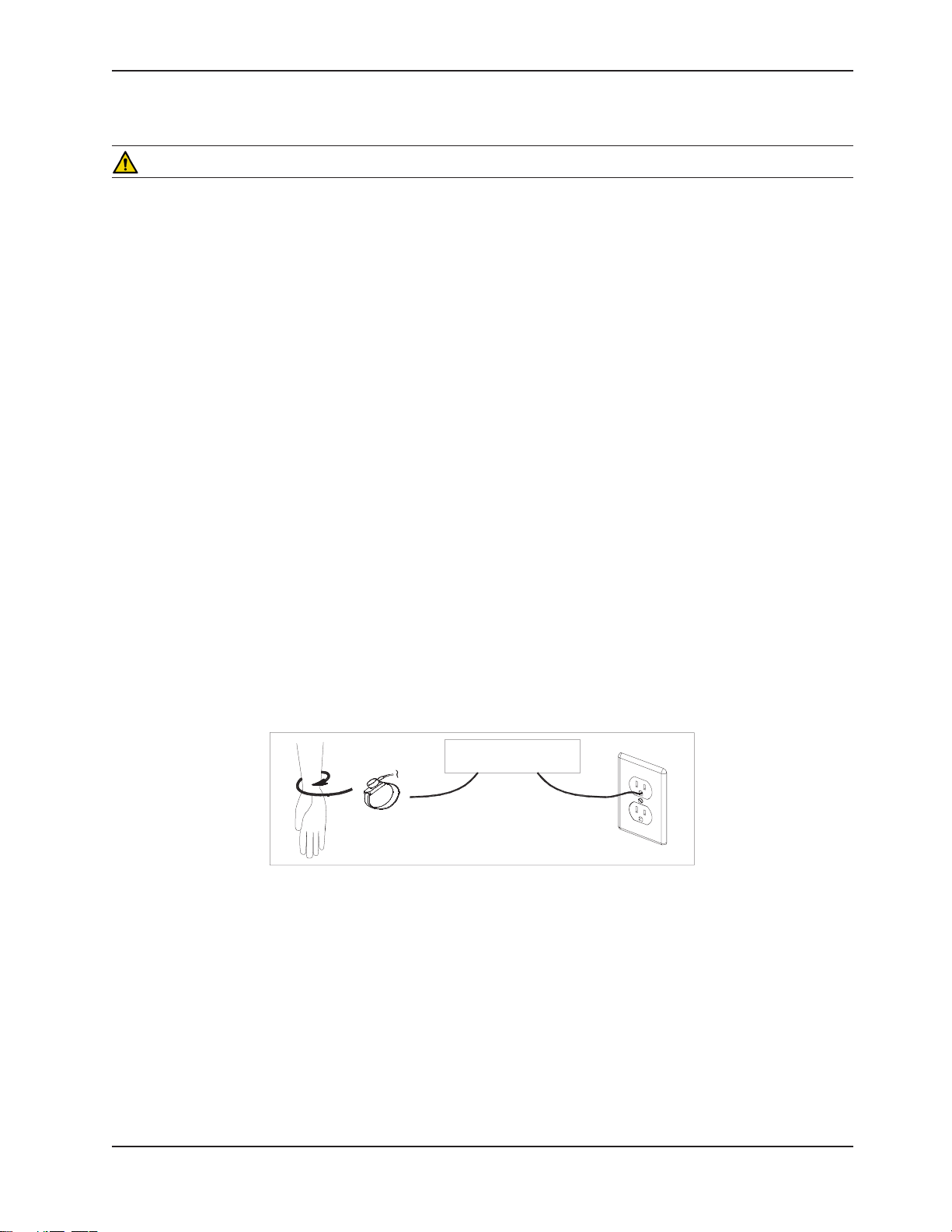

STATIC DISCHARGE PRECAUTIONS

The electronic circuits of the bed are protected from static electricity damage only while the bed is assembled. It is

extremely important that all service personnel always use adequate static protection when servicing the electronic

components of the bed.

STATIC PROTECTION EQUIPMENT

The necessary equipment for a proper static protection is:

1 static wrist strap •

1 grounding plug •

1 test lead with a banana plug on one end and an alligator clip on the other.•

STATIC PROTECTION PROCEDURE

Unplug the bed power cord from the wall outlet. 1.

Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the banana plug of the test 2.

lead into the receptacle on the grounding plug. Connect the alligator clip on the other end of the test lead to a

ground point on the bed.

Place the static control wrist strap on your wrist. Connect the clip at the other end of the wrist strap cord to a ground 3.

point on the bed.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 19

Page 20

Service Information

C

B

Screw Covers Shown Are Optional

A

WARNING

Always unplug the bed power cord when cleaning or servicing the bed.•

To prevent injury when working under the bed with the bed in the high position, always place blocks under the Hi-Lo •

levers and apply the brakes. Always unplug the bed power cord from the wall outlet when servicing or cleaning the

bed.

ACTUATOR LUBRICATION

Note

In compliance with the service life requirement of the BNQ 6641-120/2003 standard, this unit was designed maintenance

free with regard to lubrication. However, if the bed is used improperly or cleaned without following the recommendations

set forth in the Maintenance Manual (presence of cleaning detergent on the actuator screws), a lubrication of the

actuator could be necessary.

Tools Required:

No. 2 Phillips Screwdriver •

1/4” Ratchet (with 6” extension) and 5/16” Socket •

Bungee Cords •

OG2 Grease•

Brush •

Screw Covers

Shown are Optional

Figure 2.2

Return To Table of Contents

20 72-1048E MM FL2 3SE REV A www.stryker.com

Page 21

Service Information

ACTUATOR LUBRICATION (CONTINUED)

Procedure:

Head and Thigh Actuators

Completely raise the bed and apply the brakes. 1.

Completely raise the head section and flatten the thigh section to expose maximum screw threads on both actuators. 2.

Lower the four siderails.

Unplug the power cord from the wall outlet. 3.

Lift and fold back the foot section toward the head end of the bed. Attach it to the bed using bungee cords. 4.

Using a no. 2 Phillips screwdriver, remove the four screws (A) holding the cover plate to the frame and remove the 5.

plate. Remove the optional night light if present.

a. Using a 1/4” ratchet (with 6” extension) and a 5/16” socket, remove the two screws (B) holding the dust tube 6.

of each knee gatch actuator. Push the tube to free it.

b. For the head actuator, remove the two screws, spring washer (C) holding the dust tube of the actuator. Push

the tube to free the threads.

Using a brush, apply grease on the screw threads. Make sure the grease reaches the bottom of the threads.7.

Replace the dust tubes. 8.

Using the electric controls, raise and lower several times the Fowler and Knee Gatch to spread the grease evenly. 9.

Replace the cover plate.10.

Hi-Lo Actuators

Lower the bed completely. 1.

Completely raise the head and foot sections, then lift and fold back the foot section toward the head end of the 2.

bed.

Unplug the power cord from the wall outlet. 3.

Using a brush, apply grease on the threads of the bed lift actuators screws. Optional dust tubes may be present, if 4.

so, simply apply grease through the dust tube side openings.

Using the electric controls, raise and lower the bed several times to spread the grease evenly.5.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 21

Page 22

I

I

J

A

SIDERAIL REPLACEMENT

E

H

G

K

E

F

A

D

C

J

I

HALF-LENGTH RAIL REPLACEMENT

Tools Required:

3/8” Drive Ratchet•

Small Slotted Head Screwdriver •

Long Nose Pliers •

Retaining Ring Pliers •

Rubber Mallet•

7/16” Socket•

Service Information

Right Head Siderail Shown

Return To Table of Contents

22 72-1048E MM FL2 3SE REV A www.stryker.com

Figure 4.1 A

Page 23

Service Information

SIDERAIL REPLACEMENT (CONTINUED)

HALF-LENGTH SIDERAIL

Procedure:

Completely raise the bed and apply the brakes. 1.

Position all the mattress support sections to flat. 2.

Unplug the bed power cord from the wall outlet. 3.

Raise the siderail needing repair. 4.

Using a small slotted head screwdriver and long nose pliers, remove the two protective caps (A). Be careful while 5.

using the tools not to damage the siderail paint.

Note

Replace the caps using a rubber mallet. The removal of the caps may damage them; make sure you have some on

hand.

a. For a head siderail, using the retaining ring pliers, remove the retaining ring on one arm and using the 7/16” 6.

socket, remove the nut, spring washer and spacer holding the rail in place.

b. For a foot siderail, remove using the 7/16” socket the nut, the spring washer and the spacer holding

the siderail in place (B).

Note

Inspect the self-lubricating bearings for wear and replace them if need be.

Reverse the above steps to install the replacement rail. 7.

Verify the siderail movement for proper operation before returning the bed to service.8.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 23

Page 24

Service Information

HALF-LENGTH SIDERAIL ASSEMBLY REPLACEMENT

Tools Required:

3/8” Drive Ratchet•

7/16” Socket •

7/16” Combination Wrench•

Diagonal Pliers •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 A on pg. 22 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Depending on the position of the siderail needing repair, place the mattress support sections as follows: 2.

Head Siderail: Completely raise the head section. •

Foot Siderail: Lower completely the head section. Completely raise the thigh section, then lift and fold back the •

foot section toward the head end of the bed.

Unplug the bed power cord from the wall outlet. 3.

Raise the siderail needing repair. 4.

Using diagonal pliers, cut, if applicable, the cable ties holding the siderails fixed control cable (optional). Loosen the 5.

lock ring (D) and unplug the cable.

Note

Note the position and the gathering of the cable before cutting the cable ties to make sure the replacement cable will

be connected correctly.

Using the 7/16” socket and 7/16” combination wrench, remove the two locknuts and bolts (E) holding the two half 6.

bushings (F), the stopper (G) and the siderail mechanism to each of the two siderail support (H). Remove the

half bushings and the mechanism from their location, hold the bushings tightly to prevent them from falling to the

ground.

Note

First, remove the two locknuts and bolts at one end of the assembly and, while holding the assembly, finish with the ones

at the opposite end.

Reverse the above steps to install the replacement siderail assembly. 7.

Verify the siderail for proper operation before returning the bed to service.8.

Return To Table of Contents

24 72-1048E M M FL23SE REV A www.stryker.com

Page 25

Service Information

TRANSFER PLATE REPLACEMENT

Tools Required:

3/8” Drive Ratchet•

7/16” Socket •

7/16” Combination Wrench •

Torque Wrench •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 A on pg. 22 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Depending on the siderail position, place the mattress support sections as follows: 2.

Head Siderail: Completely raise the head section. •

Foot Siderail: Lower completely the head section. Completely raise the thigh section, then lift and fold back the •

foot section toward the head end of the bed.

Unplug the bed power cord from the wall outlet. 3.

Lower the siderail needing repair. 4.

Using the 7/16” socket and 7/16” combination wrench, remove the two locknuts, bushings, washers and bolts (I) 5.

holding the transfer plate (J) to the siderail mechanism.

Note

At assembly, tighten the two locknuts to a 75 in/lb torque using the torque wrench.

Reverse the above steps to install the replacement transfer plate. 6.

Verify the siderail for proper operation before returning the bed to service.7.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 25

Page 26

26 72-1048E MM FL23SE REV A www.stryker.com

A

D

F

J

C

F

C

E

F

A

B

D

F

G

H

I

Return To Table of Contents

Service Information

Figure 4.1 B

Page 27

Service Information

FULL-LENGTH SIDERAIL PIVOT TUBE REPLACEMENT

Tools Required:

1/2” Combination Wrench •

Rubber Mallet •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 B on pg. 26 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Lower the siderail needing repair. 3.

Using the 1/2” combination wrench, remove the two bolts and washers (A) holding the pivot tube ends to the siderail 4.

mechanism arms. Use a rubber mallet to free the tube ends from the arms.

Slide the tube out of its location.5.

Note

Apply grease on a 4” distance from both ends of the tube.

Reverse the above steps to install the replacement pivot tube. 6.

Verify the siderail movement before returning the bed to service.7.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 27

Page 28

Service Information

FULL-LENGTH RAIL REPLACEMENT

Tools Required:

1/2” Combination Wrench •

Rubber Mallet •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 B on pg. 26 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Raise the siderail needing repair. 3.

Loosen, if applicable, the lock ring (B) and unplug the removable pendant control (optional) cable. Remove the 4.

pendant control from the siderail by sliding it out its supports.

Using the 1/2” combination wrench, remove the four bolts and washers (A, C) holding the rail to the siderail 5.

mechanism arms. Use a rubber mallet to free the tube ends from the arms.

Note

Hold the rail firmly when removing the last bolts.

Reverse the above steps to install the replacement rail. 6.

Verify the siderail movement before returning the bed to service.7.

Return To Table of Contents

28 72-1048E MM FL23SE REV A www.stryker.com

Page 29

Service Information

FULL-LENGTH SIDERAIL ASSEMBLY REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver•

Two 1/2” Combination Wrenches•

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 B on pg. 26 for the following replacement procedure.

Completely raise the bed and raise the siderail needing repair. 1.

Unplug the bed power cord from the wall outlet.2.

Remove the head and foot boards. 3.

Using two 1/2” combination wrenches, remove the two locknuts and bolts (K, Figure 4.3 C, 4. pg. 43) holding the two

bumpers to their supports at the head end of the bed.

Using the no. 2 Phillips screwdriver, remove the seven screws (Q, Figure 4.3 C, 5. pg. 43) holding the cover to the head

end casing. Remove the cables connected to the power connector after having noted their location and remove the

cover.

Using the no. 2 Phillips screwdriver, remove the 10 screws (A, Figure 4.2 A, 6. pg. 32) holding the cover and the I.V.

pole holders to the foot casing. Lift and remove the cover while taking care to disconnect the control panel cable

(B, Figure 4.2 A, pg. 32) from the control board and, if applicable, the foot end casing connector cable (C, Figure

4.2 A, pg. 32) (optional).

Using the no. 2 Phillips screwdriver, remove the four screws (D) holding together the two parts of both siderail 7.

mechanism covers. Remove the covers.

Using the 1/2” combination wrench, remove the four nuts, washers and bolts (E) holding the siderail release handle 8.

to the seat section.

Using the 1/2” combination wrench, remove the two nuts, washers and bolts (F) holding each end of the full-length 9.

siderail to the head end and foot end casings.

Reverse the above steps to install the replacement siderail assembly. 10.

Verify the siderail for proper operation before returning the bed to service.11.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 29

Page 30

Service Information

FULL-LENGTH SIDERAIL RELEASE HANDLE REPLACEMENT

Tools Required:

Needle Nose Pliers •

No. 1 Phillips Screwdriver •

Bungee Cord •

7/16” Combination Wrench •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 B on pg. 26 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Raise both siderails. 3.

Using needle nose pliers, remove the return spring (G). 4.

Attach the siderail needing repair to the other siderail using a bungee cord. 5.

Using the No. 1 Phillips screwdriver, remove the six screws (H) holding both parts of the release handle. Hold the 6.

lower part to prevent it from falling.

Using the 7/16” combination wrench, remove the upper part of the handle by turning the lock rod (I) towards the 7.

floor.

Note

Use the same procedure to insert the upper part of the new handle on the rod, but this time turn the lock rod up.

Reverse the above steps to install the replacement release handle. 8.

Verify the release handle for proper operation before returning the bed to service.9.

Return To Table of Contents

30 72-1048E MM FL23SE RE V A www.stryker.com

Page 31

Service Information

FULL-LENGTH SIDERAIL LOCKING HOOK REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver•

Bungee Cord•

Two 1/2” Combination Wrenches•

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.1 B on pg. 26 for the following replacement procedure.

Completely raise the bed and raise the siderail needing repair.1.

Unplug the bed power cord from the wall outlet. 2.

If the hook is at the head end of the bed, follow steps 3 to 6, then go to step 8.

If the hook is at the foot end of the bed, go directly to step 7.

Head End

Remove the head board.3.

Raise the defective siderail.4.

Using the two 1/2” combination wrenches, remove the two locknuts and bolts (K, Figure 4.3 C, 5. pg. 43) holding the

bumpers to their support.

Using the No. 2 Phillips screwdriver, remove the seven screws (Q, Figure 4.3 C, 6. pg. 43) holding the cover of the head

box. Remove cables connected to power connector taking note of their position then remove cover.

Foot End

Using the No. 2 Phillips screwdriver, remove the 10 screws (A, Figure 4.2 A, 7. pg. 32) holding the cover as well as

the two I.V. poles to the foot box. Raise and remove the cover taking care to disconnect the electronic board first,

the cable (B, Figure 4.2 A, pg. 32) of the control panel and, if applicable, the cable (C, Figure 4.2 A, pg. 32) of the

connector from the foot box (optional).

Using the No. 2 Phillips screwdriver, remove the four screws (D) holding the two parts of the plastic cover over the 8.

siderail mechanism. Remove cover.

Using the two 1/2” combination wrenches, remove locknut, shoulder spacer and bolt (J) holding the locking hook 9.

to the plate. Remove hook.

Reverse the preceding steps to install the new hook.10.

Verify siderail for proper operation before returning the bed to service.11.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 31

Page 32

A

A

A

B

C

D

E

F

Service Information

FOOT END CONTROL PANEL REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver •

Note

The control panel is made of a membrane and its support. Both parts should be ordered for this replacement procedure.

Refer to the “Quick Reference Replacement Parts List” section on pg. 17.

Procedure:

Figure 4.2 A

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Remove the foot board. 3.

Using the No. 2 Phillips screwdriver, remove the 10 screws (A) holding the cover and the I.V. pole holders to the foot 4.

casing.

Use the Static Discharge Precautions procedure (see 5. pg. 19).

Lift and remove the cover taking care to disconnect the electronic board, the cable (B) from the control panel and, 6.

if applicable, the foot casing connector cable ((optional), C). Lay the cover on a workbench.

Using the No. 2 Phillips screwdriver, remove the three screws, washers and spacers (D) holding the panel to the 7.

cover.

Reverse the above steps to install the new control panel. 8.

Verify all the controls of the foot end control panel before returning the bed to service.9.

Return To Table of Contents

32 72-1048E MM FL23SE REV A www.stryker.com

Page 33

Service Information

FOOT END CASING CONNECTOR REPLACEMENT (OPTIONAL)

Tools Required:

No. 2 Phillips Screwdriver •

3/8” Combination Wrench•

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.2 A on pg. 32 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Remove the foot board. 3.

Using the No. 2 Phillips screwdriver, remove the 10 screws (A) holding the cover and the two I.V. pole holders to the 4.

foot casing.

Lift and remove the cover taking care to disconnect the electronic board, the control panel cable (B) and the foot 5.

casing connector cable (C). Lay the cover on a workbench.

Using the 3/8” combination wrench, remove the two locknuts, shoulder spacers and screws (E) holding the connector 6.

and the seal (F) to the cover. Remove the defective connector using the 3/8” combination wrench and No. 2 Phillips

screwdriver. Keep the seal for the replacement connector.

Reverse the above steps to install the new connector. 7.

Verify all the controls of the foot end control panel for proper operation before returning the bed to service.8.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 33

Page 34

A

B

C

D

A

Service Information

FOOT BOARD CONTROL PANEL REPLACEMENT (OPTIONAL)

Tools Required:

No. 2 Phillips Screwdriver •

Double-Sided Tape •

Procedure:

Note

The control panel is made of a membrane and its support. Both parts should be ordered for this replacement procedure.

Refer to the “Quick Reference Replacement Parts List” section on pg. 17.

Figure 4.2 B

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Remove the foot board and lay it on a workbench. 3.

Using the No. 2 Phillips screwdriver, remove the seven screws (A) holding the support cover to the inner face of the 4.

foot board and remove the cover.

Disconnect the foot board panel cable (B). 5.

Using the No. 2 Phillips screwdriver, remove the last screw (C) holding the control panel to the foot board. Remove 6.

the panel. A small part of the panel cable is stuck to the inner face of the panel with a small double-sided tape. Do

the same at reassembly.

Reverse the above steps to install the replacement foot board panel. 7.

Verify all the controls of the foot board panel for proper operation before returning the bed to service. 8.

Return To Table of Contents

34 72-1048E MM FL23SE REV A www.stryker.com

Page 35

Service Information

FOOT BOARD CONNECTOR REPLACEMENT (OPTIONAL)

Tools Required:

No. 2 Phillips Screwdriver •

9 mm Combination Wrench •

Procedure:

Note

This connector is present when the bed is equipped with a foot board control panel.

Unless otherwise indicated, refer to Figure 4.2 B on pg. 34 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.

Remove the foot board and lay it on a workbench. 3.

Using the No. 2 Phillips screwdriver, remove the seven screws (A) holding the support cover to the inner face of the 4.

foot board and remove the cover.

Disconnect the foot board connector cable (B). 5.

Using the 9 mm combination wrench and No. 2 Phillips screwdriver, remove the two locknuts, washers, sleeves and 6.

screws (D) holding the connector to its support. Remove the defective connector.

Reverse the above steps to install the replacement connector. 7.

Verify the foot board controls for proper operation before returning the bed to service.8.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 35

Page 36

A

C

B

B

A

Service Information

SIDERAIL CONTROL PANEL MEMBRANE REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver•

Note

The replacement of a membrane implies that the one facing it on the inner or outer control panel also has to be replaced.

Service kits, including both membranes are available.

Figure 4.2 C

Procedure:

Completely raise the bed and apply the brakes. Bring the head section to horizontal position. 1.

Unplug the bed power cord from the wall outlet. 2.

Raise the head siderail needing repair. 3.

Properly ground yourself (see 4. pg. 19).

Detach the two membranes (A) from their mounting plates and let them hang down. 5.

Using a No. 2 Phillips screwdriver, remove the eight screws (B) holding together the two sections of the control 6.

panel housing.

Open the housing, disconnect the defective membrane cable (C) and remove the membrane. 7.

Reverse the above steps to install the new control panel membranes.8.

Note

Make sure to connect the membrane cables before fastening together the two sections of the control panel housing.

Stick the membranes to the support at the end of the replacement procedure.

Verify all the siderail functions for proper operation before returning the bed to service.9.

Return To Table of Contents

36 72-1048E M M FL23SE REV A www.stryker.com

Page 37

www.stryker.com 72-1048E MM FL2 3SE REV A 37

I

G

H

F

E

D

A

B

C

K

L

M

J

MATTRESS SUPPORT REPLACEMENT

Service Information

Return To Table of Contents

Figure 4.3 A

Page 38

Service Information

FOOT SECTION REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver •

1/2” Combination Wrench •

Bungee Cords •

Procedure:

Completely raise the bed and apply the brakes. Flatten all sections of the mattress support. 1.

Unplug the bed power cord from the wall outlet. 2.

Lower the siderails. 3.

Lift and fold back the foot section toward the head end of the bed. Secure the section to the bed using a bungee 4.

cord.

Using the No. 2 Phillips screwdriver, remove the two lateral mattress retainers (A). 5.

Remove the foot end mattress retainer (B). 6.

Remove the foot prop rod (C). 7.

Remove the bungee cord and replace the foot section to horizontal position. 8.

Using the 1/2” combination wrench, remove the two locknuts, washers, shoulder spacers and bolts (D) linking the 9.

foot section to the thigh section and remove the defective section.

Reverse the above steps to install the new foot section.10.

Return To Table of Contents

38 72-1048E MM FL23SE RE V A www.stryker.com

Page 39

Service Information

THIGH SECTION REPLACEMENT

Tools Required:

Needle Nose Pliers •

1/2” Combination Wrench •

Bungee Cords •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.3 A on pg. 37 for the following replacement procedure.

Completely raise the bed and apply the brakes. Flatten all sections of the mattress support. 1.

Unplug the bed power cord from the wall outlet. 2.

Lower the siderails. 3.

Lift and fold back the foot section toward the head end of the bed. Secure the section to the bed using a bungee 4.

cord.

Using needle nose pliers, remove the rue ring cotter, washers and clevis pin (D, Figure 4.3 C, 5. pg. 43) linking the thigh

section lever arms to the thigh actuator tube.

Note

Before linking back the thigh actuator tube to the thigh section lever arms, verify that the actuator course was preserved.

To do so, refer to the caution that follows step 16 of the “Knee Gatch Actuator Replacement Procedure” on pg. 45 and

proceed with step 17 of the procedure.

Remove the bungee cord and bring the foot section back to flat position. 6.

Using the 1/2” combination wrench, remove the four locknuts, washers, shoulder spacers and bolts (D, E) linking the 7.

thigh section to the foot and seat sections and remove the thigh section.

Reverse the above steps to install the replacement thigh section.8.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 39

Page 40

Service Information

SEAT SECTION REPLACEMENT

Tools Required:

3/8” Drive Ratchet•

1/2” Socket - Deep Well •

Torque Wrench •

1/2” Combination Wrench •

No. 2 Phillips Screwdriver •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.3 A on pg. 37 for the following replacement procedure.

Completely raise the bed and apply the brakes. Flatten the mattress support. 1.

Unplug the power plug from the wall outlet. 2.

Lower the siderails. 3.

Using the 1/2” socket, remove the four thread rolling bolts (F) holding the seat section to the frame.4.

Note

At reassembly, screw the bolts in manually and then tighten applying a 135 lb/in torque.

Using the 1/2” combination wrench, remove the four locknuts, washers, shoulder spacers and bolts (E, G) linking 5.

the seat section to the thigh and head sections and remove the seat section.

Using the Phillips No. 2 screwdriver turn the seat section up side down and remove the three screws (H) holding the 6.

protective plate to the seat section. Keep the plate for the replacement seat section.

Remove the four rubber caps (K) covering the screws (L) holding the stops (M) to the defective section and replace 7.

the parts on the replacement section.

Reverse the above steps to install the replacement seat section.8.

Return To Table of Contents

40 72-1048E MM FL23 SE REV A www.stryker.com

Page 41

Service Information

A

B

HEAD SECTION REPLACEMENT

Tools Required:

No. 2 Phillips Screwdriver •

Strap•

Two 1/2” Combination Wrenches•

Two 7/16” Combination Wrenches •

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.3 A on pg. 37 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

If the bed is equipped with full-length siderails, lower them. If equipped with half-length siderails, raise the head 2.

siderails and lower the foot ones.

Remove the head board. 3.

Completely raise the head section and attach it securely to the bed using a strap. 4. It must not move during the

procedure.

Unplug the bed power cord from the wall outlet. 5.

Using the No. 2 Phillips screwdriver, remove the two lateral mattress retainers (I) and keep them for the replacement 6.

head section.

If the bed is not equipped with the CPR emergency release (optional), proceed with steps 7 to 14. Otherwise, proceed

with steps 15 to 24.

www.stryker.com 72-1048E MM FL2 3SE REV A 41

Figure 4.3 B

Return To Table of Contents

Page 42

Service Information

HEAD SECTION REPLACEMENT (CONTINUED)

Using two 1/2” combination wrenches, remove the locknut, spacer and bolt holding the upper part of the compression 7.

bar to the head section and lay it down.

Using two 1/2” combination wrenches, remove the locknut, shoulder spacers and bolt (B) linking the mattress 8.

support lever to the head section and remove the lever-compression bar assembly.

Remove the strap and manually lower the head section completely. 9.

If the bed is equipped with half-length siderails, lower the head siderails and use the No. 2 Phillips screwdriver 10.

to remove the four screws (K, Figure 4.1 A, pg. 22) holding the two siderail supports to the head section. Let the

support-siderail assembly rest on the frame.

Using the 1/2” combination wrench, remove the two locknuts, flat washers, shoulder spacers and bolts (G) linking 11.

the head section to the seat section. Remove the defective head section.

Using the no. 2 Phillips screwdriver, remove the two screws (J) holding the micro switch activator (optional) to the 12.

head section.

Note

This activator is present only if the bed is equipped with the optional Auto Contour positioning. Remember the position of

the micro switch activator before removing the screws. Properly positioned, the blade of the Auto Contour micro switch

is pushed in by the activator when the Fowler is in flat position.

Reverse the above steps to install the replacement head section. 13.

Verify the Auto Contour positioning (optional) for proper operation before returning the bed to service. 14.

End of the procedure for beds with Auto Contour.

Note

Unless otherwise indicated, refer to Figure 4.3 A on pg. 37 for the following replacement procedure.

Disconnect the two wires (A, Figure 4.3 F, 15. pg. 54) from the micro switch located on the head section lever. Note

their position before doing so.

Using two 7/16” combination wrenches, remove the locknut and bolt (O, Figure 4.3 F, 16. pg. 54) holding the cylinder

end fitting to the head section.

Using two 1/2” combination wrenches, remove the nut, shoulder spacers and bolt (P, Figure 4.3 F, 17. pg. 54) holding

the upper part of the section lever to the head section.

Using a 7/16” combination wrench, remove the two locknuts and bolts (Q, Figure 4.3 F, 18. pg. 54) holding each CPR

release handle to the head section.

Remove the strap and manually lower the head section completely. 19.

If the bed is equipped with half-length siderails, lower the head siderails and use the No. 2 Phillips screwdriver 20.

to remove the four screws (K, Figure 4.1 A, pg. 22) holding the two siderail supports to the head section. Let the

supports-siderails assembly rests on the frame.

Using the 1/2” combination wrench, remove the two locknuts, shoulder spacers, washers and bolts (G) holding the 21.

head section to the seat section. Remove the defective head section.

Using the No. 2 Phillips screwdriver, remove the two screws holding the activator (J) to the head section.22.

Note

Note the position of the activator before removing the screws. Properly positioned, the blade of the CPR and Auto

Contour (optional) micro switches are pushed in by the activator when the Fowler is in flat position.

Reverse the above steps to install the replacement head section. 23.

Verify the CPR emergency release and the Auto Contour positioning (optional) for proper operation before returning 24.

the bed to service.

End of the procedure for beds with CPR and Auto Contour.

Return To Table of Contents

42 72-1048E MM FL23SE REV A www.stryker.com

Page 43

A

D

B

C

E

F

G

H

I

H

I

J

N

O

P

FOWLER ACTUATOR REPLACEMENT

Q

Q

C

C

L

M

Tools Required:

Needle Nose Pliers•

No. 2 Phillips Screwdriver •

Diagonal Pliers •

5/16” Socket •

Small Regular Head Screwdriver •

Pliers•

Bungee Cord •

1/4” Drive Ratchet•

Procedure:

Service Information

Figure 4.3 C

www.stryker.com 72-1048E MM FL2 3SE REV A 43

Return To Table of Contents

Page 44

Service Information

FOWLER ACTUATOR REPLACEMENT (CONTINUED)

Completely raise the bed and apply the brakes. Completely raise the Knee Gatch section and flatten the Fowler 1.

section.

Unplug the bed power cord from the wall outlet. 2.

Raise the siderails. 3.

Manually lift and fold the foot section back toward the head end of the bed. Attach it securely to the bed using a 4.

bungee cord.

Using needle nose pliers, remove the rue ring cotter, washers and clevis pin (A) linking the head actuator tube to 5.

the section lever arms.

Remove the foot board. 6.

Using the No. 2 Phillips screwdriver, remove the 10 screws (A, Figure 4.2 A, 7. pg. 32) holding the cover and the two

I.V. pole holders to the foot casing.

Lift up and remove the cover, taking care first to disconnect, from the control board, the control panel cable 8.

(B, Figure 4.2 A, pg. 32) and, if applicable, the foot casing connector cable ((optional), C, Figure 4.2 A, pg. 32).

Properly ground yourself (see 9. pg. 19).

Using cutting pliers, cut the cable tie holding the head actuator cable to the other cables. 10.

Disconnect the actuator cable (connector J8) from the control board and remove the cable from the foot end 11.

casing.

Using the 5/16” socket, remove the two screws (B) holding the retaining plate to the actuator support.12.

Remove the two pivot pins (C) holding the actuator to the support. To facilitate the removal of the pins, insert a small 13.

slotted head screwdriver into the opening at the end of the actuator and push out the pins.

Move the actuator toward the centre of the bed to remove it from its location. 14.

Reverse the above steps to install the replacement actuator. Take note of the following caution before hooking 15.

up the actuator tube to the head section lever arms.

CAUTION

It is of utmost importance that the course of the replacement head actuator be adjusted before hooking up its tube to

the head section lever arms. An improper adjustment can damage the head section structure.

To adjust the course of the replacement head actuator, proceed as follows: 16.

Make sure that the actuator cable is connected to the control board, and then connect the bed power cord. A.

Grab the replacement actuator tube and position its holes horizontally. While firmly holding the tube with one B.

hand to prevent it from rotating, press the Fowler up control for a few seconds using the other hand, then press

the down control until the actuator stops. This will be the lower limit of the Fowler actuator course.

Gently turn the tube in either direction to align the tube holes with those of the head section lever arms. Then, C.

still holding firmly the tube, raise again the Fowler a few inches, and lower it completely.

Check the alignment of the holes. If the tube holes are not aligned any more with those of the lever arms, repeat D.

steps B and C until they are. Once the holes are aligned, install the washers and the clevis pin. Slightly raise

the head section manually to ease the insertion of the clevis pin.

Before installing the rue ring cotter to finalize the head actuator replacement, raise and lower completely the E.

Fowler. Check that the actuator stops working as soon as the head section reaches the frame.

Return To Table of Contents

44 72-1048E MM FL23SE RE V A www.stryker.com

Page 45

Service Information

KNEE GATCH MOTOR REPLACEMENT

Tools Required:

Bungee Cord •

Needle Nose Pliers •

No. 2 Phillips Screwdriver •

Pliers •

Diagonal Pliers •

Small Regular Head Screwdriver •

5/16” Socket •

1/4” Drive Ratchet•

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.3 C on pg. 43 for the following replacement procedure.

Completely raise the bed and apply the brakes. Flatten the mattress support. 1.

Unplug the bed power cord from the wall outlet. 2.

Raise the siderails. 3.

Manually lift and fold the foot section back toward the head end of the bed. Attach it securely to the bed using a 4.

bungee cord.

Using needle nose pliers, remove the rue ring cotter, washers and clevis pin (D) linking the thigh actuator tube to 5.

the thigh section lever arms.

Using the No. 2 Phillips screwdriver, remove the 10 screws (A, Figure 4.2 A, 6. pg. 32) holding the cover and the two

I.V. pole holders to the foot casing.

Lift up and remove the cover, taking care to first disconnect the control panel cable (B, Figure 4.2 A, 7. pg. 32) and, if

applicable, the foot casing connector cable ((optional), C, Figure 4.2 A, pg. 32) from the control board.

Properly ground yourself (see 8. pg. 19).

Using diagonal pliers, cut the cable tie holding the thigh actuator cable to the other cables. 9.

Disconnect the motor cable (connector J9) from the control board. 10.

Using pliers, squeeze the upper part of the black strain-relief bushing (E) holding the actuator cable to the foot 11.

casing and raise the bushing to disengage it from its location.

Disengage the cable from the strain-relief bushing and remove the cable from the foot casing. 12.

Using the 5/16” socket, remove the two screws (F) holding the retaining plate to the actuator support. 13.

Remove the two pivot pins (G) holding the motor to the support. To facilitate the removal of the pins, insert a small 14.

regular head screwdriver into the opening at the end of the actuator and push out the pins.

Push on the defective actuator toward the centre of the bed to remove it from its location. 15.

Reverse the above steps to install the replacement actuator. Take note of the following caution before hooking up 16.

the actuator tube to the thigh section lever arms.

CAUTION

It is of utmost importance that the course of the replacement thigh actuator be adjusted before hooking up its tube to

the thigh section lever arms. An improper adjustment can damage the thigh section structure.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 45

Page 46

Service Information

KNEE GATCH MOTOR REPLACEMENT (CONTINUED)

To adjust the travel of the replacement knee gatch motor, proceed as follows: 17.

Make sure that the motor cable is connected to the control board, then connect the bed power cord.A.

Grab the replacement motor tube and position its holes horizontally. While firmly holding the tube with one hand B.

to prevent it from rotating, press the Knee Gatch up control for a few seconds using the other hand, then press

the down control until the actuator stops. This will be the lower limit of the Knee Gatch actuator course

Gently turn the tube in either direction to align the tube holes with those of the thigh section lever arms. Then, C.

still holding firmly the tube, raise again the Knee Gatch a few inches, and lower it completely.

Check the alignment of the holes. If the tube holes are not aligned any more with those of the lever arms, repeat D.

steps B and C until they are. Once the holes are aligned, install the washers and the clevis pin. Slightly raise

the head section manually to ease the insertion of the clevis pin.

Before installing the rue ring cotter to finalize the head actuator replacement, raise and lower completely the E.

Knee Gatch. Check that the actuator stops working as soon as the thigh section reaches the frame.

Return To Table of Contents

46 72-1048E M M FL23SE REV A www.stryker.com

Page 47

Service Information

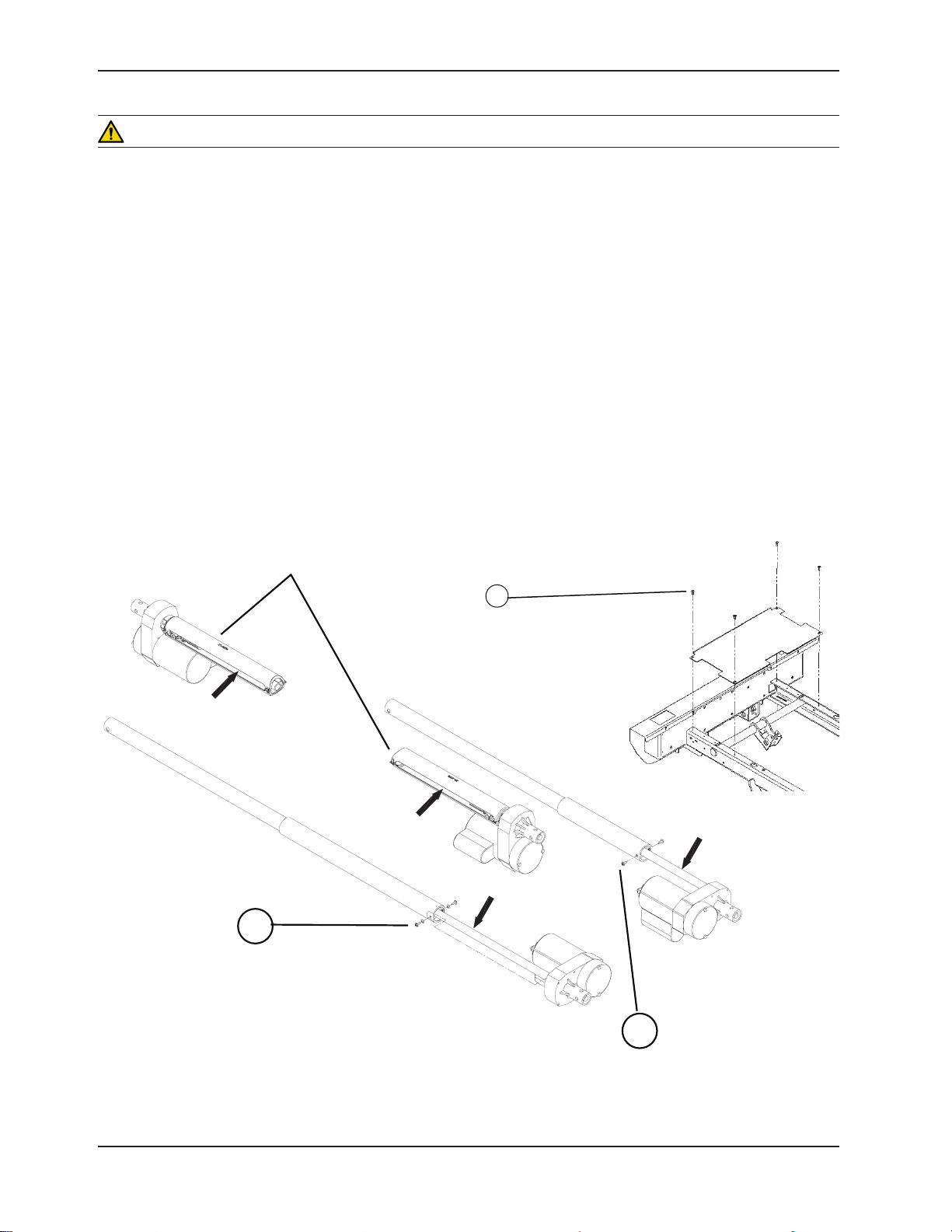

BED LIFT MOTOR REPLACEMENT

Tools Required:

1/4” Drive Ratchet•

KR0121 Tool Kit •

Diagonal Pliers •

5/16” Socket •

Small Regular Head Screwdriver •

No. 2 Phillips Screwdriver •

1/2” Combination Wrench•

Bungee Cord •

Procedure:

Note

In order to preserve the adjustment of the bed’s lowest position when replacing a bed lift motor, a special tool kit

designed for that purpose must be used. The kit includes alignment jigs. To obtain this kit, contact our Customer Support

department and order part number KR0121.

Unless otherwise indicated, refer to Figure 4.3 C on pg. 43 for the following replacement procedure.

Position the mattress support sections depending on the location of the bed lift motor to replace: 1.

At the A. foot of the bed: Completely raise the thigh section, then lift and fold back the foot section toward the

head end of the bed. Attach it securely to the bed using

a bungee cord. Finally completely raise the Fowler.

At the B. head of the bed: Completely raise the Fowler.

Position the alignment jigs on the floor, on a plane surface, 2.

right under the two transversal tubes supporting the link arms

of both bed lift levers. Lower the bed until the tubes come to

rest on the jigs (see opposite Figure). Use the 3/8” ratchet

wrench with the 1/2” socket provided in the kit to lower a

defective bed lift motor until the tube rests on the jig.

Unplug the bed power cord from the wall outlet. 3.

Raise the siderails. 4.

Disconnect the motor cable and cut, using diagonal pliers, 5.

the cable ties holding it to the frame.

Using the 5/16” socket, remove the two screws (H) holding 6.

the retaining plate to the actuator support.

Remove the two pivot pins (I) holding the motor to the support. To facilitate the removal of the pins, insert the small 7.

regular head screwdriver into the opening at the end of the actuator and push out the pins.

Using the 1/2” combination wrench, remove the two bolts and washers (J) holding the molded nut support to the 8.

Hi-Lo lever. Remove the molded nut support and keep it for the replacement actuator.

Note

Make sure that the support and the molded nut holes are aligned before screwing in the bolts. If resistance is felt, it

means that the holes are not aligned.

Remove the defective motor. 9.

Using the No. 2 Phillips screwdriver, remove the two screws holding together the two parts of the screw cover 10.

(optional) and keep it for the replacement actuator.

Reverse the above steps to install the replacement actuator. Take note of the following caution before hooking up 11.

the motor to the bed lift lever.

Return To Table of Contents

www.stryker.com 72-1048E MM FL2 3SE REV A 47

Page 48

Service Information

HI-LO ACTUATOR REPLACEMENT (CONTINUED)

CAUTION

The course of the replacement motor must be adjusted prior to hooking it to the bed lift lever. An improper adjustment

can damage the bed lift mechanism.

To adjust the replacement motor, proceed as follows:12.

Once the replacement motor cable is connected, plug the bed power cord and press the bed down control until A.

the motor stops. This will be the lower limit of the actuator course.

Link the motor to the bed lift lever. B.

The alignment jigs still in position, completely raise and lower the bed to ensure that the lower limit has been C.

preserved following the motor replacement.

Return To Table of Contents

48 72-1048E MM FL23SE RE V A www.stryker.com

Page 49

Service Information

TOROIDAL TRANSFORMER REPLACEMENT (INTERNATIONAL SERIES MODELS)

Tools Required:

No. 2 Phillips Screwdriver •

1/2” Combination Wrench•

Procedure:

Note

Unless otherwise indicated, refer to Figure 4.3 C on pg. 43 for the following replacement procedure.

Completely raise the bed and apply the brakes. 1.

Unplug the bed power cord from the wall outlet. 2.