Page 1

2017/12 836002-5210 V3.4 www.stryker.com

EOLE DC Powered Support Surface

2871

Operations/Maintenance Manual

Page 2

Page 3

www.stryker.com 836002-5210 V3.4 3

Table of Contents

Symbols and Denitions................................................................ 4

Symbols ......................................................................... 4

Warning/Caution/Note Denition ...................................................... 5

Technical Specication................................................................. 6

Introduction.......................................................................... 7

Contraindications.................................................................. 7

Intended Use of Product ............................................................ 7

Expected Service Life .............................................................. 7

Product Description ................................................................ 7

Contact Information ................................................................ 7

Product Serial Number Location/Identication ........................................... 8

Summary of Safety Precautions.......................................................... 9

Product Description .................................................................. 10

Control Unit Front................................................................. 10

Control Unit Rear ................................................................. 10

Control Panel .................................................................... 10

Instructions ..........................................................................11

Installing the Control Unit............................................................11

Product Functions ................................................................ 12

Transport mode .................................................................. 13

Storage ........................................................................ 13

Cleaning and Disinfection.............................................................. 14

Troubleshooting ..................................................................... 15

Service Information .................................................................. 16

Top Cover Replacement ........................................................... 16

Air Cell Replacement .............................................................. 16

Control Unit Replacement .......................................................... 16

Hose Replacement ............................................................... 16

CPC Tube Replacement ........................................................... 16

Filter Replacement................................................................ 16

Preventive Maintenance............................................................... 17

Checklist ....................................................................... 17

Appendix A: EMC Information .......................................................... 19

Guidance and Manufacturer’s Declaration- Electromagnetic Emissions: ...................... 19

Guidance and Manufacturer’s Declaration- Electromagnetic Immunity: ....................... 20

Warranty........................................................................... 22

Limited Warranty ................................................................. 22

To Obtain Parts and Service ........................................................ 22

Return Authorization .............................................................. 22

Damaged Merchandise ............................................................ 22

International warranty clause........................................................ 22

Page 4

4 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

Symbols and Denitions

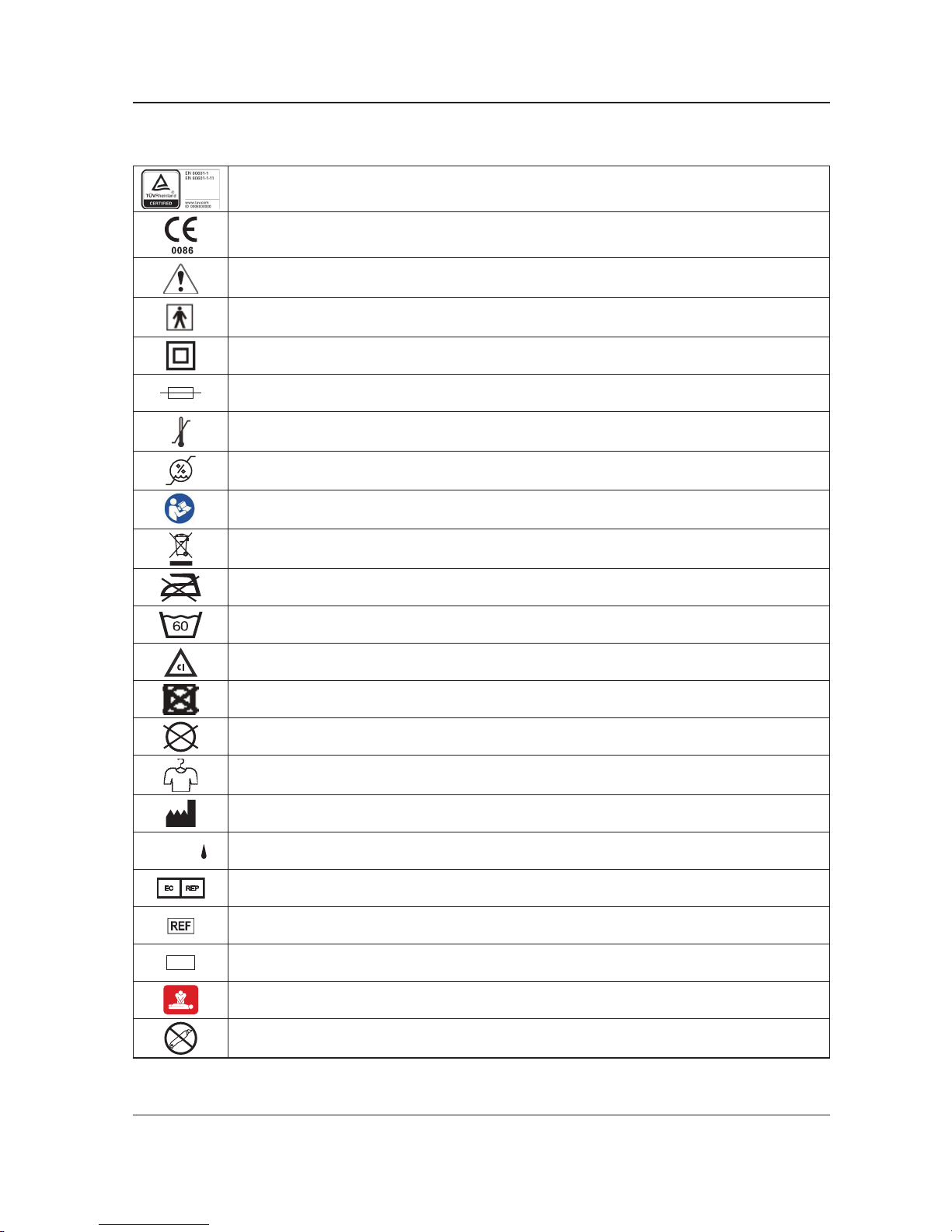

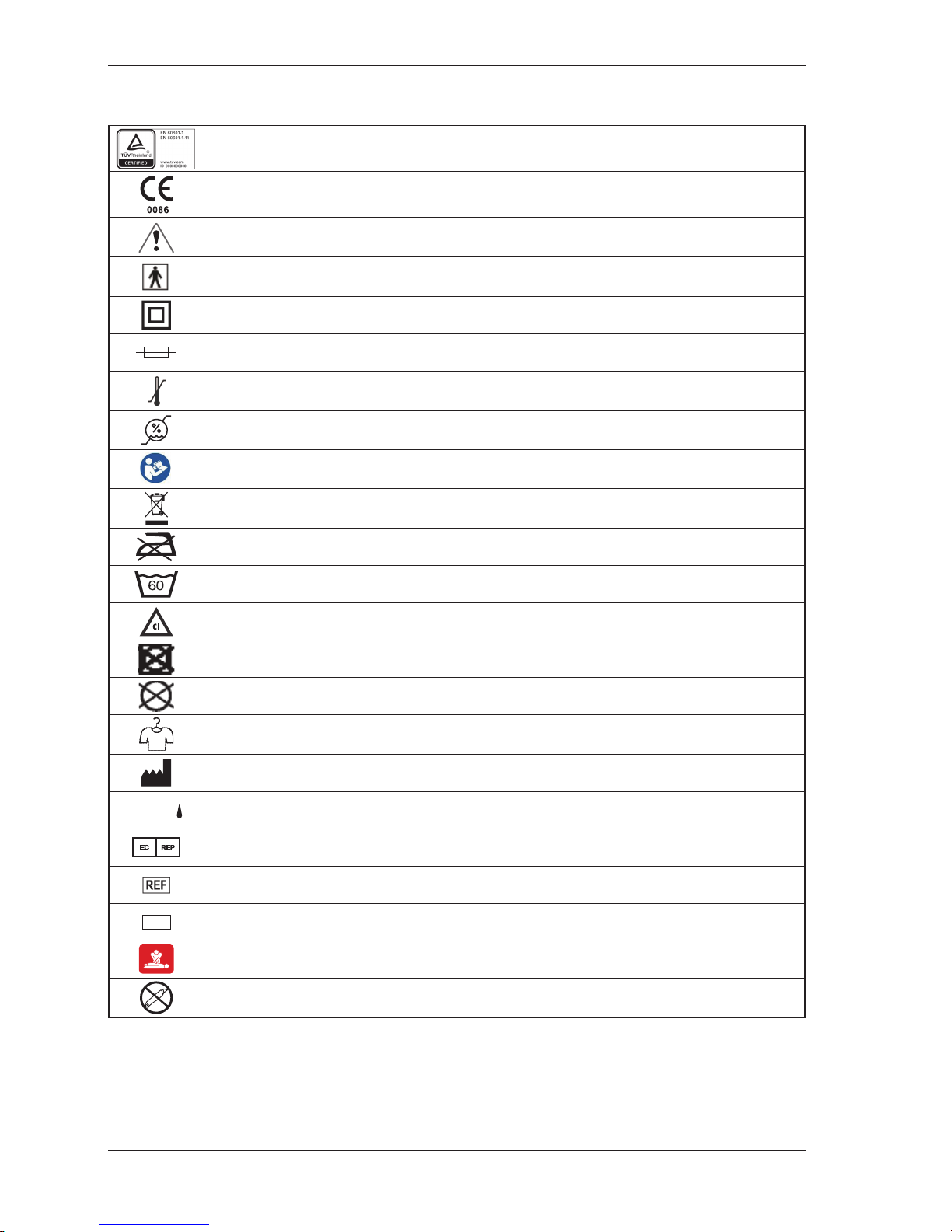

SYMBOLS

TUV marking

CE marking

Warning / Caution, consult accompanying documentation

Type BF equipment

Double Insulation

Fuse

Temperature Limitation, Operating: 10°C to 40°C, Storage: -15°C to 50°C

Humidity Limitation, 10% - 90%

Refer to instruction manual/ booklet

Disposal: Contact local distributor who will take the necessary steps according to your

national market.

Do Not Iron

Maximum washing temperature 60°C, normal process, only for top cover of mattress.

Chlorinated Bleach

Do Not Tumble Dry

Do Not Dry Clean

Allow to Completely Air Dry

Manufacturer

IP24

First Digit (Solids) Protected against touch by ngers (>12.5mm); Second Digit (Liquids)

Water splashing against the enclosure from any direction shall have no harmful effect.

Authorized representative in the European community

Catalogue Number (model)

SN

Serial Number

CPR

Do Not Open with Cutter

Page 5

www.stryker.com 836002-5210 V3.4 5

Return To Table of Contents

WARNING/CAUTION/NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alert the reader about a situation which, if not avoided, could result in death or serious injury. It may also

describe potential serious adverse reactions and safety hazards.

CAUTION

Alert the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury to the user or patient or damage to the equipment or other property. This includes special care necessary

for the safe and effective use of the device and the care necessary to avoid damage to a device that may

occur as a result of use or misuse.

NOTE

Provide special information to make maintenance easier or important instructions clearer.

Symbols and Denitions

Page 6

6 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

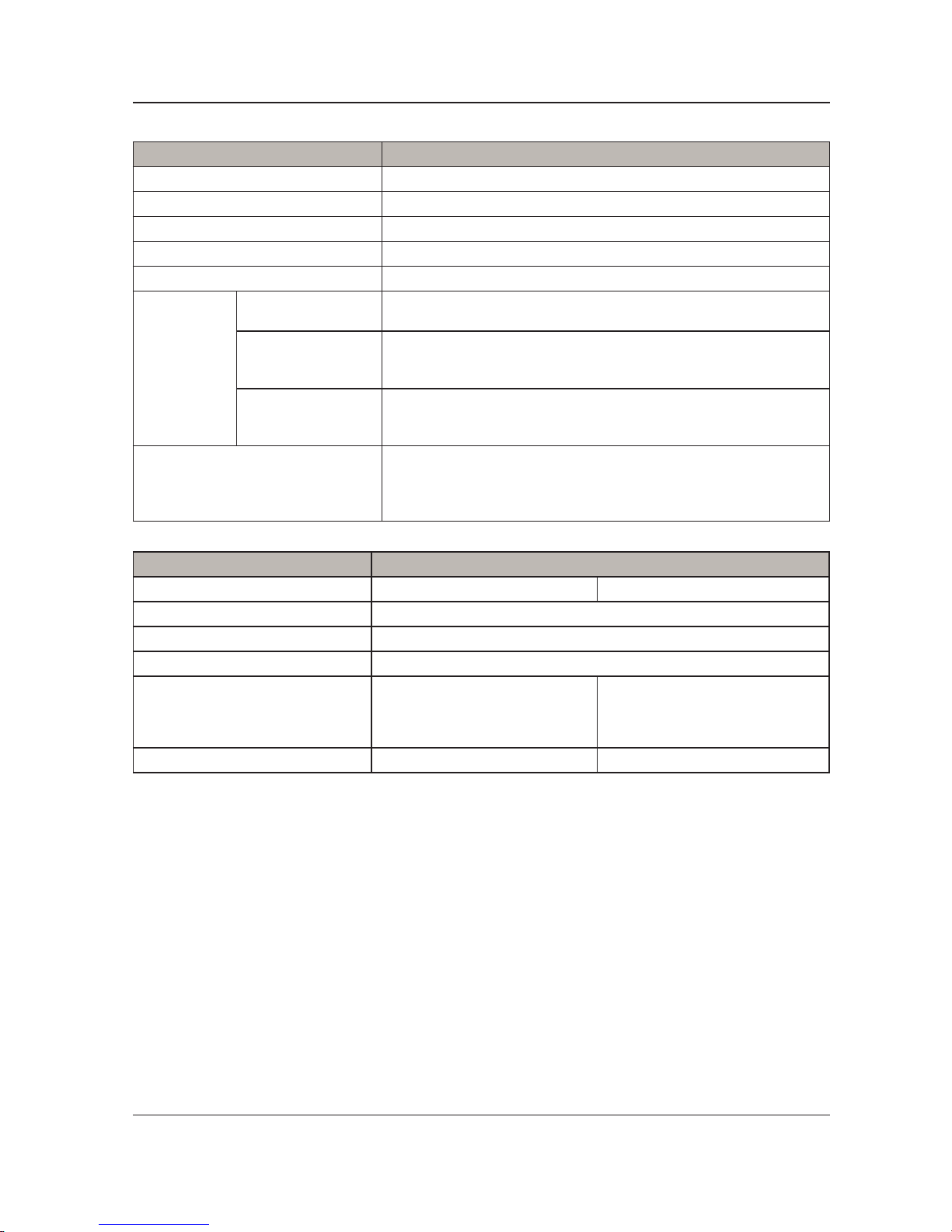

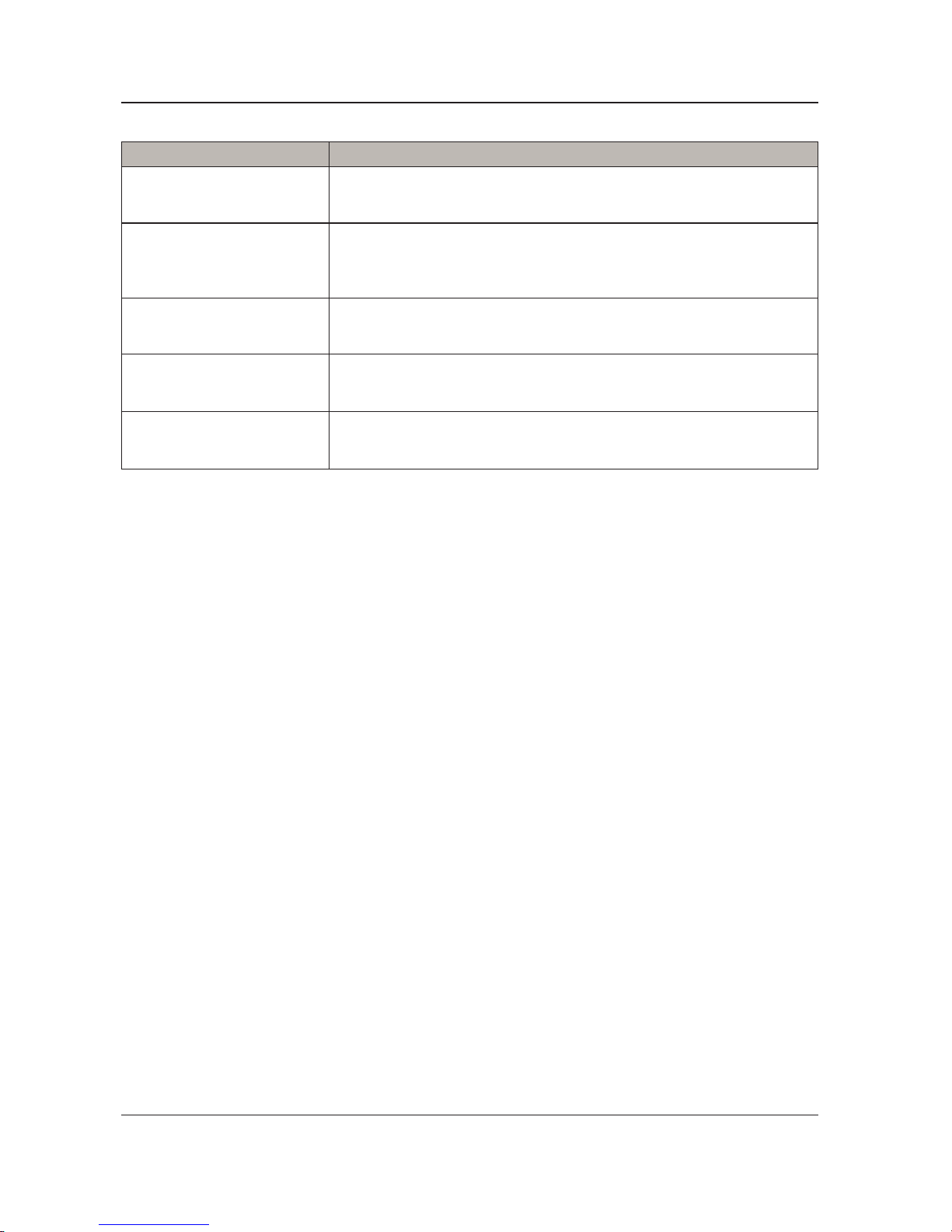

Item Specication

Power Supply AC 230V, 50Hz, 0.07A

Fuse Rating T1AL, 250V

Dimension (L x W x H) 29.5 x 14.5 x 19.2 cm / 11.5” x 5.7” x 7.6”

Weight 2.4 kg / 5.3 lb

Cycle Time 12 minutes

Environment

Atmospheric

Pressure

Operation: 70-106 hPa

Temperature

• Operation: 10°C to 40°C (50°F to 104°F)

• Storage: -15°C to 50°C (5°F to 122°F)

• Shipping: -15°C to 70°C (5°F to 158°F)

Humidity

• Operation: 10% to 90% non-condensing

• Storage: 10% to 90% non-condensing

• Shipping: 10% to 90% non-condensing

Classication

• Class II, Type BF, IP24

• Applied Part: Air Mattress

• Not suitable for use in the presence of a ammable anesthetic

mixture (No AP or APG protection)

Air Mattress Specication

Model EOLE DC 32” (80cm) EOLE DC 35” (90cm)

Model Number 2871

Flame Retardant Standards EN 597-1 and EN 597-2

Safe Working Load 200 kg / 441 lb

Dimension (L x W x H)

200 X 80 X 20 cm

78.74 X 32 X 7.84 inches

200 X 90 X 20 cm

78.74 X 35.43 X 7.84 inches

Weight 4.75 kg / 10.47 lb 5.45 kg / 12 lb

Technical Specication

Page 7

www.stryker.com 836002-5210 V3.4 7

Return To Table of Contents

This manual is designed to assist with the operation and maintenance of the EOLE DC Powered Support

Surface. Carefully read this manual thoroughly before using or beginning maintenance on the support

surface. To ensure safe operation of this equipment, it is recommended that methods and procedures are

established for educating and training staff.

CONTRAINDICATIONS

None known.

INTENDED USE OF PRODUCT

EOLE DC is a constant low pressure powered support surface intended to provide pressure redistribution to

aid in the prevention and treatment of pressure ulcers. The system consists of a control unit combined with

an alternating air cell mattress. The air cells redistribute the weight of the patient over the surface and aid in

the reduction of tissue interface pressure. It is recommended that the product be operated by personnel who

are qualied to perform general nursing procedures and have received adequate training in the prevention

and treatment of pressure ulcers.

This support surface is intended to be used with human patients in a general hospital, nursing home or

homecare environment and for patients at risk of developing pressure ulcers, as well as those who require

therapy for pre- existing pressure ulcers. The safe working load for EOLE DC is 200 kg/ 441 lb; the patient

must not exceed safe working load specied by the support surface, frame, and accessories. Patients shall

meet the minimum age requirement of 2 years old.

EOLE DC shall be used with a mattress cover at all times.

The support surface is not intended to be a sterile product nor is it intended to include a measuring function.

EXPECTED SERVICE LIFE

The products are intended to offer safe and reliable operation when in use or installed according to the

instructions provided by Stryker Medical. Stryker Medical recommends that the system be inspected and

serviced by authorized technicians if there are any signs of wear or concerns with device function and

indication on products. Otherwise, service and inspection of the devices generally should not be required.

The control unit thereof has an expected service life of 3 years and the mattress thereof has an expected

service life of 2 years.

PRODUCT DESCRIPTION

EOLE DC is powered support surface focusing on equalizing pressure and enhancing comfort.

Introduction

Page 8

8 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

CONTACT INFORMATION

Contact Stryker Customer Service or Technical Support at: (800) 327-0770 or (269) 324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

Please have the serial number (A) of your Stryker product available when calling Stryker Customer Service

or Technical Support. Include the serial number in all written communication.

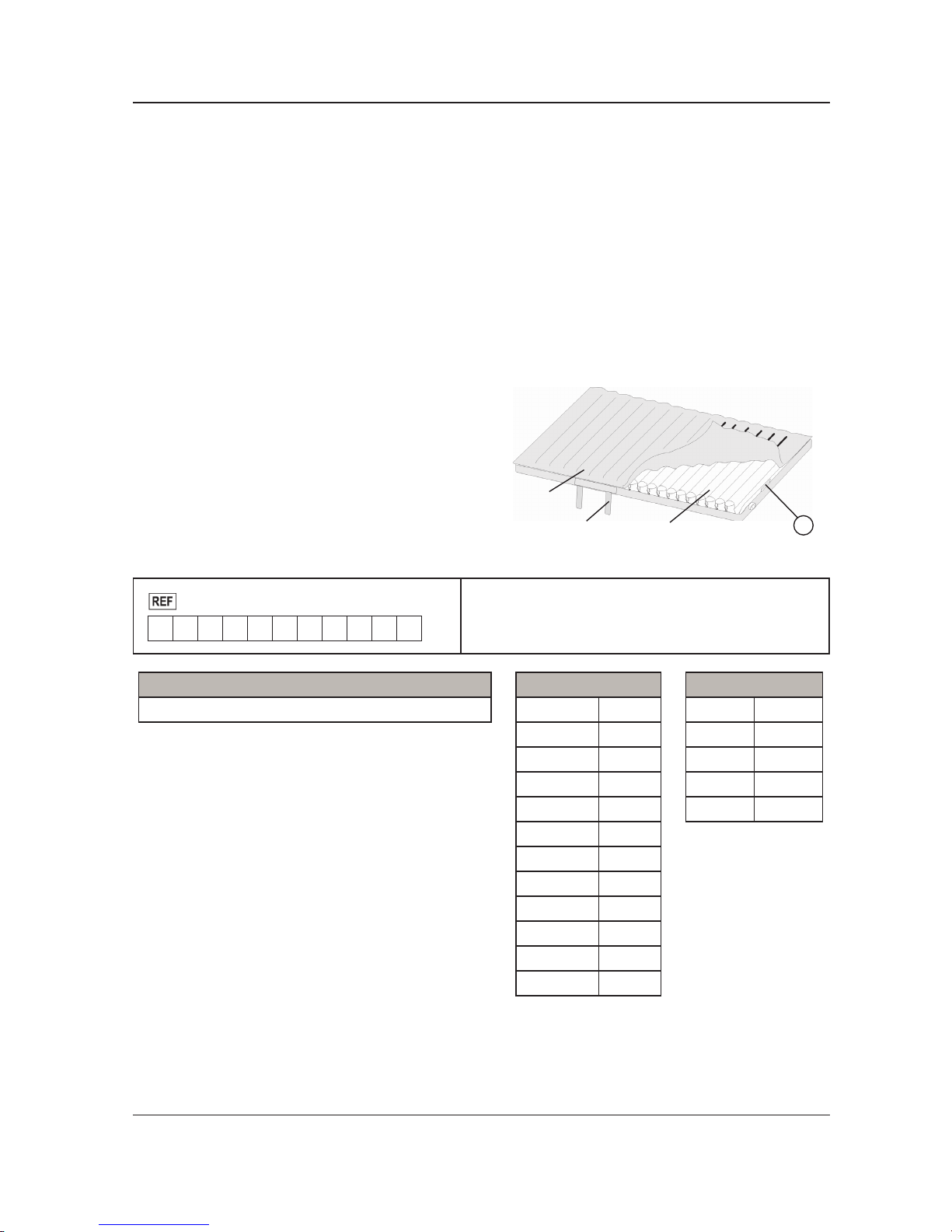

PRODUCT SERIAL NUMBER LOCATION/IDENTIFICATION

The serial number (A) is located at the mattress

cover near foot right corner of the mattress as shown

in Figure 1. To access the serial number, unzip the

cover about one foot.

▼

Figure 1

EOLE DC

Mattress

Air CellCPR

A

Format:

2871

M Y Y M M - S S S S S

• M = Mattress

• YY = Year

• MM = Month

• SSSSS = Sequence (Numeric)

Model Number Legend (X)

2871 EOLE DC

Month Legend (MM)

January 01

February 02

March 03

April 04

May 05

June 06

July 07

August 08

September 09

October 10

November 11

December 12

Year Legend (YY)

2014 14

2015 15

2016 16

2017 17

2018 18

Introduction

Page 9

www.stryker.com 836002-5210 V3.4 9

Return To Table of Contents

WARNING

• Check patient’s skin regularly. Consult physician if any redness or skin break occurs. Serious injury could

result if the patient’s skin condition is left untreated.

• Do not place the control unit in the patient’s bed, in contact with the patient, or under sheets or other

coverings. Doing so could cause serious injury or could affect control unit performance.

• Do not use in the presence of a ammable anesthetic mixture or with oxygen (O2) or nitrous oxide (N2O).

• Verify bed side rails are compatible with bed frame and existing mattress. A risk assessment must be

performed by a suitably qualied person, especially when side rails are prescribed, to ensure that the

bed meets the IEC 60601-2-52 bed standard.

• Use with appropriate top sheet and minimize layers of bedding between patient and mattress.

• Assess patient’s risk of entrapment according to protocols and monitor accordingly.

• Close supervision is necessary when this product is used on or near children. Electrical burns or choking

may result from a child swallowing a small part detached from the device.

• Use this product only for its intended use as described in this manual.

• Do not operate product if the power cord or plug has been damaged.

• Keep the power cord away from heated surfaces.

• Never block any air openings of this product or place it on soft surfaces, where openings may be blocked.

Keep the air opening free of lint, hair, and other similar particles.

• Do not modify this equipment without the authorization of the manufacturer.

• Mattress covers have passed skin sensitization and skin irritation tests. However, if you suspect that

the patient or caregiver you may have had or is having an allergic reaction, please consult a physician

immediately.

• The power cord to the Control Unit should be positioned to avoid a strangulation hazard and/or damage

to the cord. Careful consideration is required when routing the power cable. It is recommended that placing the cord under the bed frame and attaching it to an electrical outlet at the head of bed.

• Serious injury or death can result from the use (potential entrapment) or non-use (potential patient falls)

of side rails or other restraints. The safe use of the support surface is maximized when used in conjunction with side rails; there may be an increased risk of falls when side rails are not present. Local policies regarding the use of side rails should be taken into account. Whether and how to use side rails is a

decision that should be based on each patient’s individual needs and should be made by the physician,

operators, and responsible parties.

• When cleaning the support surface, ensure that no liquid is allowed to seep into the zipper area and

watershed cover barrier (underside); uids allowed to come in contact with the zipper may leak into the

support surface.

• Do not expose the mattress to excessive moisture. Personal injury or equipment damage could occur.

• The use of quaternaries containing glycol ethers and/or accelerated hydrogen peroxides may compro-

mise the cover integrity and legibility.

• Be aware of devices or equipment placed on the top of the support surface. Damage to the surface

may occur due to the weight of the equipment, heat generated by the equipment, or sharp edges on the

equipment.

• Do not put overlays or accessories inside the cover. Doing so may reduce pressure redistribution

performance.

• It is the responsibility of the caregiver team to evaluate the appropriate CPR protocol to be used with the

surface.

• If there is a possibility of electro-magnetic interference with mobile phones, please increase the distance

(3.3m/10.8 feet) between devices or turn off the mobile phone.

• Ensure the waterproof cap to the power switch is present and unbroken before use. Failure to do so could

increase risk of electric shock.

• Mattress contains metal snap buttons and delrin zippers and should not be exposed under X-rays entirely.

Always use X-ray cassette during portable X-ray procedure.

NOTE

The EOLE DC support surface must be used with a mattress cover at all times. The support surface cover

may interact with all external skin.

Summary of Safety Precautions

Page 10

10 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

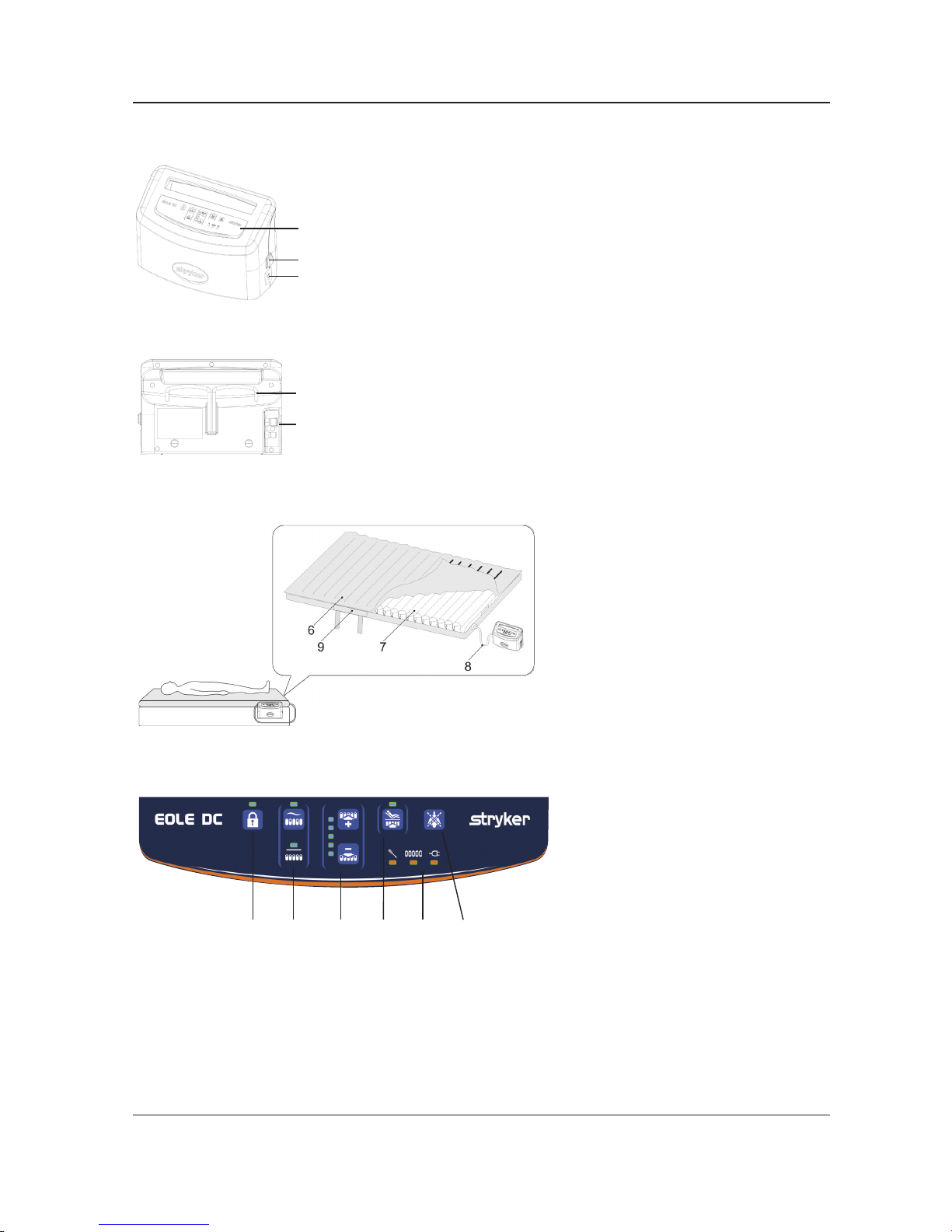

CONTROL UNIT FRONT

2

1

3

◄

Figure 2

1. Power Switch On/Off

2. Front Panel

3. Power Socket

CONTROL UNIT REAR

4

5

◄

Figure 3

4. Hanger

5. CPC Connector

◄

Figure 4

6. EOLE DC Mattress

7. Air Cell

8. Air Hose

9. CPR Strap

CONTROL PANEL

10 11 12 13 14 15

◄

Figure 5

10. Lock/Unlock

11. Mode Selection

12. Comfort Level

13. Maxrm/Seat mode

14. Alarm

15. Mute

Product Description

Page 11

www.stryker.com 836002-5210 V3.4 11

Return To Table of Contents

INSTALLING THE CONTROL UNIT

1. Place control unit on at surface or suspend control unit on end of bed using attached hooks. See Fig-

ure 2 and Figure 3. Remove the plug to disconnect the device. Do not position the equipment such that

it is difcult to operate the disconnecting device.

2. Position the mattress on bed frame.

3. Connect the hose assembly between the mattress air cell and the control unit. Connect the adaptor

from control unit onto the air valve.

4. Plug the power cord and Maxrm/Seat mode will be inated automatically. Note: The unit will take

approximately 40 minutes to inate the mattress. Nurse can adjust the comfort level or mode with the

patient on the initial stage.

5. After installation, make sure the ap is not folding upwards to avoid uid seeping through mattress

cover.

NOTE

Make sure the control unit is suitable for the local power voltage and frequency.

6. Position patient on the mattress.

WARNING

Deate before CPR or CPR could be ineffective.

To deate mattress for CPR:

When there is an emergency to perform CPR on the patient, quickly pull the CPR strap from the mattress

to release air. The quick connector on the pump unit can be disconnected for even faster deation. The

air cell will deate in approximately 15 seconds. Proceed with CPR procedures.

Resetting CPR:

After CPR, re-plug CPR and make sure the CPR plug is xed on the mattress.

Instructions

Page 12

12 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

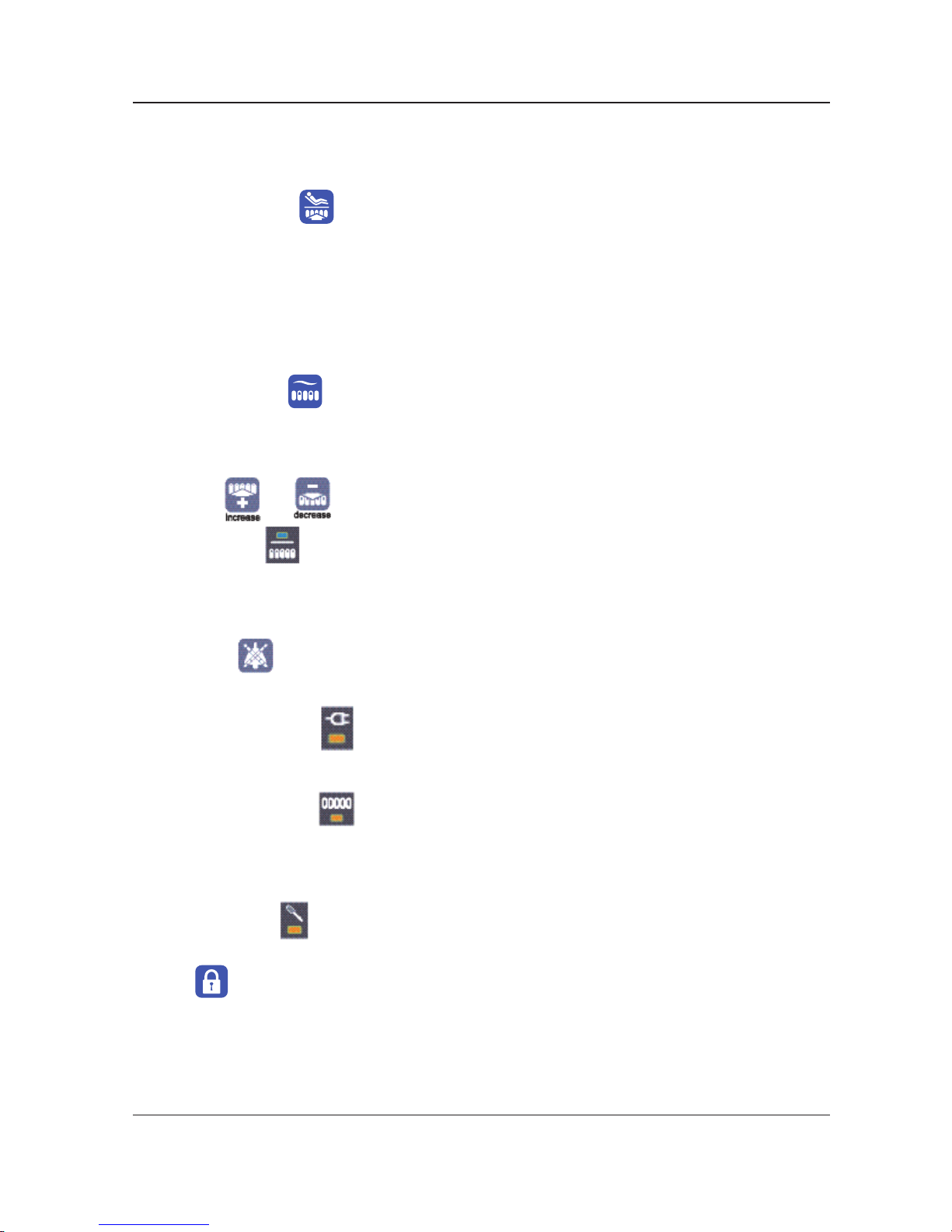

PRODUCT FUNCTIONS

THERAPY

1. Maxrm / Seat mode

When connected to the power for the rst time, the control unit automatically inates to maximum ination

and the indicator light of Maxrm/Seat comes on. This insures the control unit is able to reach its maximum

operating pressure. Once the maximum pressure level is reached, the pump will automatically switch

into alternating mode. User can also use this function as full mattress ination while ingress/egress the

patient for better support. Nurse or professional operator can adjust the comfort level manually at the

maxrm stage.

On the alternating or static mode, nurse can operate the maxrm button to implement the maxrm or

return to the former stage.

a. Alternate mode

In Alternate therapy mode, the mattress system will alternate every 12 minutes. User can select for

best comfort.

b. Comfort level:

Press

and to adjust the pressure level for the patient’s comfort.

c. Static mode

Press THERAPY button to suspend alternating function, if needed. The pressure inside of air cells will

be adjusted to the same softness. Press the THERAPY button again; it will switch back to alternating

mode. Under the static mode, cell pressure level will be lowered compare to the same pressure level

from alternating mode.

2. Alarm Mute

Press alarm mute to deactivate the alarm sound. If the problem continues, the alarm sounds again after

3 minutes.

a. Power Failure Alarm

During power failure situation, the Power Failure indicator will light on with sound. Upon power

restoration, press the power switch to disable the audible and visual alarm and LED.

b. Low Pressure Alarm

The audible low pressure alarm is not active during initial mattress ination. The audible alarm will be

active after approximately 50 minutes has elapsed from the time the unit has been turned on.

If there is a loss of mattress pressure with the unit ON and the alarm switch activated, an alarm will

sound and ash intermittently. In addition, the low pressure light will be illuminated.

c. Service Alarm

This feature will light during mechanical failure situation. User can notify the technician for repair.

3. Lock

Patient or caregiver can hold the lock button 3 seconds to activate or deactivate lock mode. In lock mode,

Patient or caregiver can press Maxrm/Seat button for maximum ination.

The panel of control unit will be lock automatically without any operation after 3 minutes.

Instructions

Page 13

www.stryker.com 836002-5210 V3.4 13

Return To Table of Contents

TRANSPORT MODE

In case of power failure or transport: Disconnect the CPC connector and

interconnect Male to Female part of the air hose connector to slow deation.

For transport purpose, interconnect Male to Female part of the air hose

connector. When a “click” is felt or heard, the connection is completed and

secured; then air from mattress is sealed off.

STORAGE

1. To quickly deate the mattress for storage, take off the CPR

strap and the CPC connectors. It will make the air release

quickly.

2. Lay the mattress out at and upsides down.

3. Fold in half and place the control unit inside.

4. Roll from the head end towards the foot end.

5. The power cord could be wrapped around the pump bumper on

the back of pump.

6. Place the whole system into the carrying bag.

Instructions

Page 14

14 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

Cleaning and Disinfection

The control unit housing, tubing, and mattress should be cleaned between patients.

• To clean, use water and a clean cloth to wipe down the Control Unit, power cord, hoses, mattress top

cover, and bottom cover. Do not use abrasive cleaners on the mattress. Note: Blood and other body

uids must be thoroughly cleaned from all surfaces before applying disinfectants.

• Apply disinfectants to the external surfaces of the control unit, hoses and mattress top cover, and bottom cover by wiping. Stryker recommends a chlorine-based solution with a concentration less than or

equal to 1000 ppm or 70% alcohol twice a week.

• To wash the top cover of mattress by washing machine with normal process under the temperature

60°C in 45 minutes.

• It is not recommended to disinfect the internal parts of the mattress on a regular basis, but only as

needed for particular instance, the air cell could be wiped with a cloth and disinfectants as recommended above.

• Wipe down the mattress with a clean, dry cloth to remove any excess of disinfectant.

• If other detergent or other cleaning agent is used, choose one that will not have adverse chemical ef-

fects on the surface of the plastic case of the control unit, mattress cover and any other component of

the device.

• When cleaning or disinfecting the support surface, ensure that no liquid is allowed to seep into the zipper area and watershed cover barrier (underside); uids allowed to come in contact with the zipper may

leak into the support surface.

• Avoid dust and proximity to dusty areas.

• All components should be air dried thoroughly before use.

The waterproof cap of power switch should be on the power switch.

• Avoid using sharp tools on the waterproof cap over the power switch.

• Please reply to your distributor if the cap is broken or missed off.

WARNING

• Do not use phenolic based products for cleaning.

• Do no dry the mattress in direct sunlight.

Page 15

www.stryker.com 836002-5210 V3.4 15

Return To Table of Contents

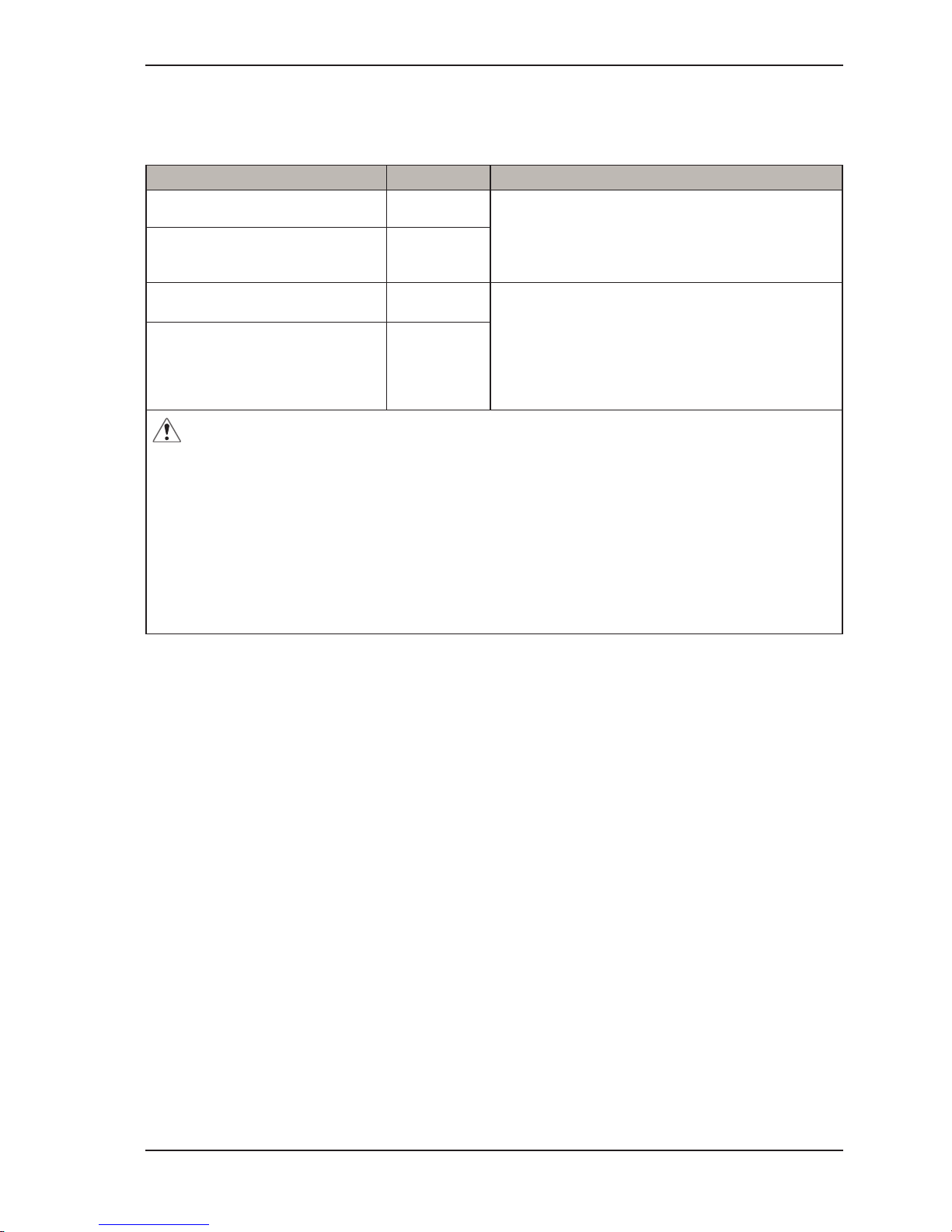

Troubleshooting

Problem Solution

Loss of power Check if the plug is connected to mains.

Low pressure alarm noises

1. Check if the CPR is sealed.

2. Check if the air cell is broken.

3. Check if the connection tube is tightly secured.

4. Check if there is any leakage on air cells.

Patient is bottoming out

Pressure setting might be inadequate for the patient. Adjust comfort range

1 to 2 levels higher and wait for a few minutes for best comfort.

Air Mattress is not secure

1. Check if all the snap buttons or straps of mattress are all securely

fastened.

2. Check if the mattress is xed to the bed frame by elastic straps.

Air cells fail to inate

Make sure the air hose is not kinked, cracked, or split. Verify that the power

switch is illuminated, signifying the control unit has power. Verify that the

air hoses are fully inserted with a positive connection.

Page 16

16 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

TOP COVER REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose assembly between the mattress air cell and control unit.

2. Unzip the top cover.

3. Discard the old cover.

4. Place the new cover.

5. Carefully zip the cover.

6. Verify proper operation of the unit before returning it to service.

AIR CELL REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose assembly from the air valve of mattress.

2. Unzip 2-way zipper from either way to remove the top cover and remove the CPC tubes.

3. Remove and discard the old air cell.

4. Place the new air cell, connect the tubes and zip the cover to close.

5. Verify proper operation of the unit before returning it to service.

CONTROL UNIT REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the plug from mains power and hose.

2. Discard the old control unit.

3. Place the new control unit and connect the plug to mains power and hose.

4. Verify proper operation of the unit before returning it to service.

HOSE REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose from control unit and mattress.

2. Discard the old hose.

3. Connect the new hose to control unit and mattress.

4. Verify proper operation of the unit before returning it to service.

CPC TUBE REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the tube from control unit and mattress.

2. Discard the old tube.

3. Connect the new tube to control unit and mattress.

4. Verify proper operation of the unit before returning it to service.

FILTER REPLACEMENT

Tools Required: None

Procedure:

1. Discard the old lter.

2. Verify proper operation of the unit before returning it to service.

WARNING

Any replacement of non-authorized or wrong parts may cause the unpredictable risk rise. Please check the

replaced part is suitable for Stryker Medical’s EOLE DC Powered Support Surface, Model 2871.

Service Information

Page 17

www.stryker.com 836002-5210 V3.4 17

Return To Table of Contents

Preventative maintenance should be performed annually, at a minimum. A preventative maintenance

program should be established for all Stryker Medical equipment. Preventative maintenance may need to be

performed more frequently based on the usage level of the product.

CHECKLIST

_______ Cover zipper opens and closes properly and has no visible damage.

_______ No tears, rips, holes, cracks, or other openings in the mattress cover.

_______ Check labels for legibility, proper adherence, and integrity.

_______ Support surface cover straps and snaps are intact and are not damaged.

_______ Straps properly secure the support surface assembly to the crib.

_______ Components have not degraded or come apart.

_______ Check main power cord and do not plug if there is an abrasion or excessive wear.

_______ Check airow from the air hose.

_______ Check the air hose if there is kink or breaks

_______ Verify proper operation of the unit before returning it to service.

_______ Check the waterproof cap of power switch.

Preventive Maintenance

Product Serial Number:

Completed by: ___________________________________________ Date: _____________________

Page 18

18 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

The parts and accessories listed on this page are currently available for purchase. Some of the parts identied

on the assembly drawing parts in this manual may not be individually available for purchase. Please call

Stryker Customer service USA at 1-800-327-0770 for availability and pricing.

Product Part Number

EOLE DC POWERED SUPPORT SURFACE 32” (80cm) 2871-000-002

EOLE DC POWERED SUPPORT SURFACE 35” (90cm) 2871-000-001

EOLE DC Control Unit 2871-001-000

Service Part Name Part Number

Manual, EOLE DC 2871-009-001

Mattress, Top Cover 32” (80cm) 2871-019-006

Single Air Cell, Orange PU 32” (80cm) 2871-019-007

Single Air Cell, Clear 32” (80cm) 2871-019-008

Mattress, Top Cover 35” (90cm) 2871-002-000

Single Air Cell, Orange PU 35” (90cm) 2871-004-001

Single Air Cell, Clear 35” (90cm) 2871-004-002

Air hose, PVC, EOLE DC 2871-004-003

Plug, Replacement, QTY 1 2871-004-004

Manifold 2871-004-005

Pump, Button Overlay, EOLE DC 2871-001-001

Pump, Fuse 2870-001-002

Tube, CPC 2870-001-003

Pump, Compressor 2870-001-004

Air Filter 2870-001-005

Accessory Part Number

Pump, UK Plug 2870-019-001

Transport Bag 2870-019-002

Pump, FR Plug 2870-019-003

Quick Reference Replacement Parts

Page 19

www.stryker.com 836002-5210 V3.4 19

Return To Table of Contents

Appendix A: EMC Information

GUIDANCE AND MANUFACTURER’S DECLARATION- ELECTROMAGNETIC EMISSIONS:

This device is intended for use in the electromagnetic environment specied below. The user of this device

should make sure it is used in such an environment.

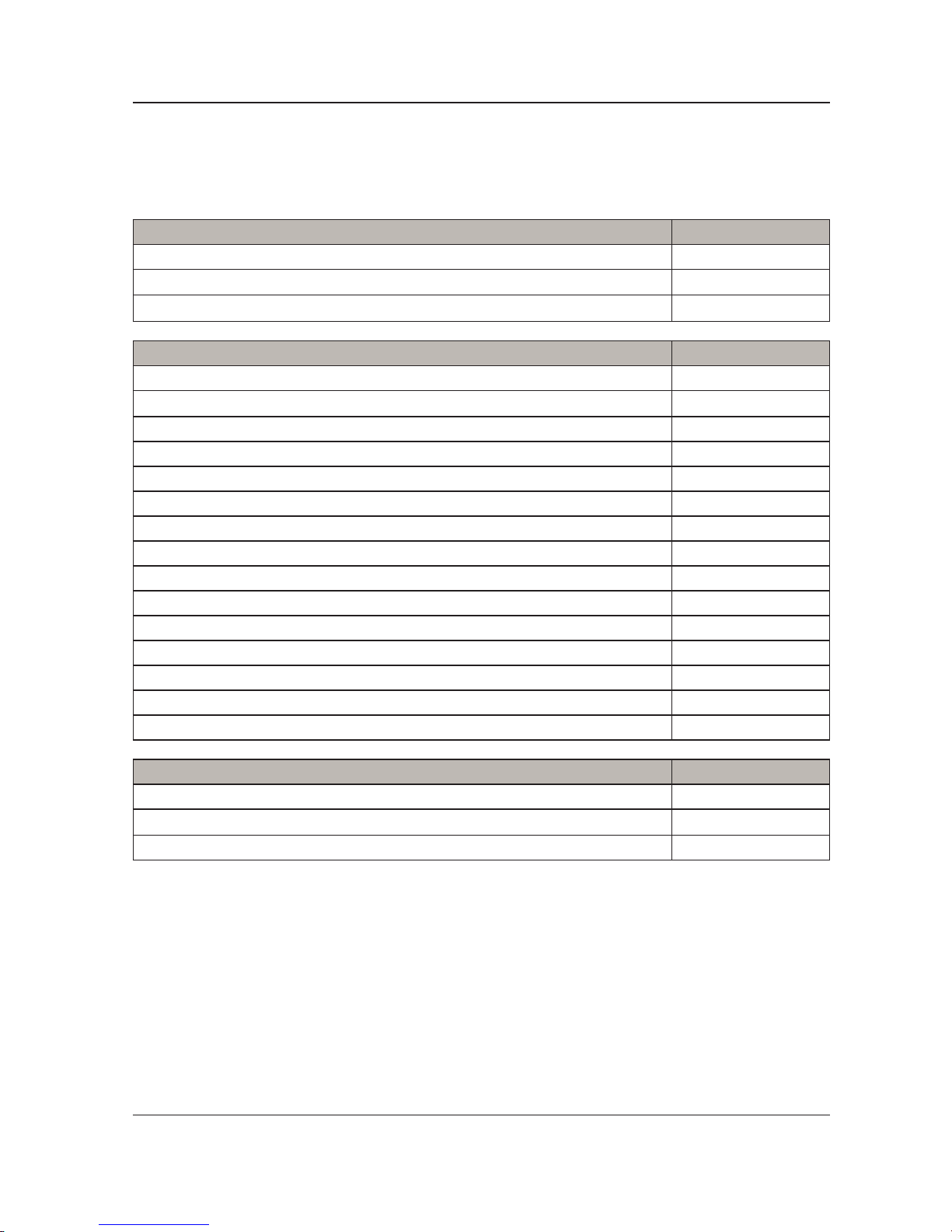

Emissions Test Compliance Electromagnetic Environment-Guidance

RF emissions

CISPR 11

Group1

The device uses RF energy only for its internal

function. Therefore, its RF emissions are very

low and are not likely to cause any interference in

nearby electronic equipment

RF emissions

CISPR 11

Class B

Harmonic emissions

IEC61000-3-2

Class A

The device is suitable for use in all establishments,

including domestic establishments and those

directly connected to the public low-voltage power

supply network

Voltage uctuations / Flicker

emissions

IEC61000-3-3

Complies

WARNING

1. The device should not be used adjacent to or stacked with other equipment. If adjacent or stacked use

is necessary, the device should be observed to verify normal operation in the conguration in which it will

be used.

2.Use of accessories, transducers and cables other than those specied or provided by the

manufacturer of this equipment could result in increased electromagnetic emissions or decreased

electromagnetic immunity of this equipment and result in improper operation.

3. Portable RF communications equipment (including peripherals such as antenna cables and external

antennas) should be used no closer than 30 cm (12 inches) to any part of the Pump, including cables

specied by the manufacturer. Otherwise, degradation of the performance of this equipment could result.

Page 20

20 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

Appendix A: EMC Information

GUIDANCE AND MANUFACTURER’S DECLARATION- ELECTROMAGNETIC IMMUNITY:

This device is intended for use in the electromagnetic environment specied below. The user of this device

should make sure it is used in such an environment.

Basic EMC

standard

Immunity Test Levels Compliance

Levels

Electromagnetic

Environment-Guidance

HOME HEALTHCARE

ENVIRONMENT

Electrostatic

Discharge (ESD)

IEC61000-4-2

±8kV contact

±15kV air

±8kV contact

±15kV air

Floors should be wood, concrete or

ceramic tile. If oors are covered

with synthetic material, the relative

humidity should be at least 30 %.

Electrical fast

transient/ burst

IEC61000-4-4

±2kV for power supply line

±1kV for input/output line

±2kV for power

supply line

±1kV for input/

output line

Mains power quality should be that

of a typical commercial or hospital

environment

Surge

IEC61000-4-5

± 1 kV line(s) to

line(s)

± 2 kV line(s) to earth

± 1 kV line(s) to

line(s)

Mains power quality should be that

of a typical commercial or hospital

environment.

Voltage dips,

short interruptions

and voltage

variations on

power supply

input lines

IEC61000-4-11

Voltage Dips:

i) 100% reduction for 0.5

period,

ii) 100% reduction for 1

period,

iii) 30% reduction for 25/30

period,

Voltage Interruptions:

100% reduction for 250/300

period

230V (UT)

(1)

Voltage Dips:

i) 100%

reduction for 0.5

period,

ii) 100%

reduction for 1

period,

iii) 30%

reduction for

25/30 period,

Voltage

Interruptions:

100% reduction

for 250/300

period

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of this

device requires continued operation

during power mains interruptions,

it is recommended that the device

be powered from an uninterruptible

power supply or a battery.

Power frequency

(50/60Hz)

magnetic eld

IEC61000-4-8

30 A/m 30 A/m Power frequency magnetic elds

should be at levels characteristic

of a typical location in a typical

commercial or hospital environment.

Conducted RF

IEC 61000-4-6

3 Vrms

0,15 MHz – 80 MHz

6 Vrms in ISM and amateur

radio bands between

0,15 MHz and 80 MHz

80 % AM at 1 kHz

(4)

6Vrms Portable and mobile RF

communications equipment should

be used no closer to any part of this

device, including cables, than the

recommended separation distance

calculated from the equation

applicable to the frequency of the

transmitter.

Page 21

www.stryker.com 836002-5210 V3.4 21

Return To Table of Contents

Appendix A: EMC Information

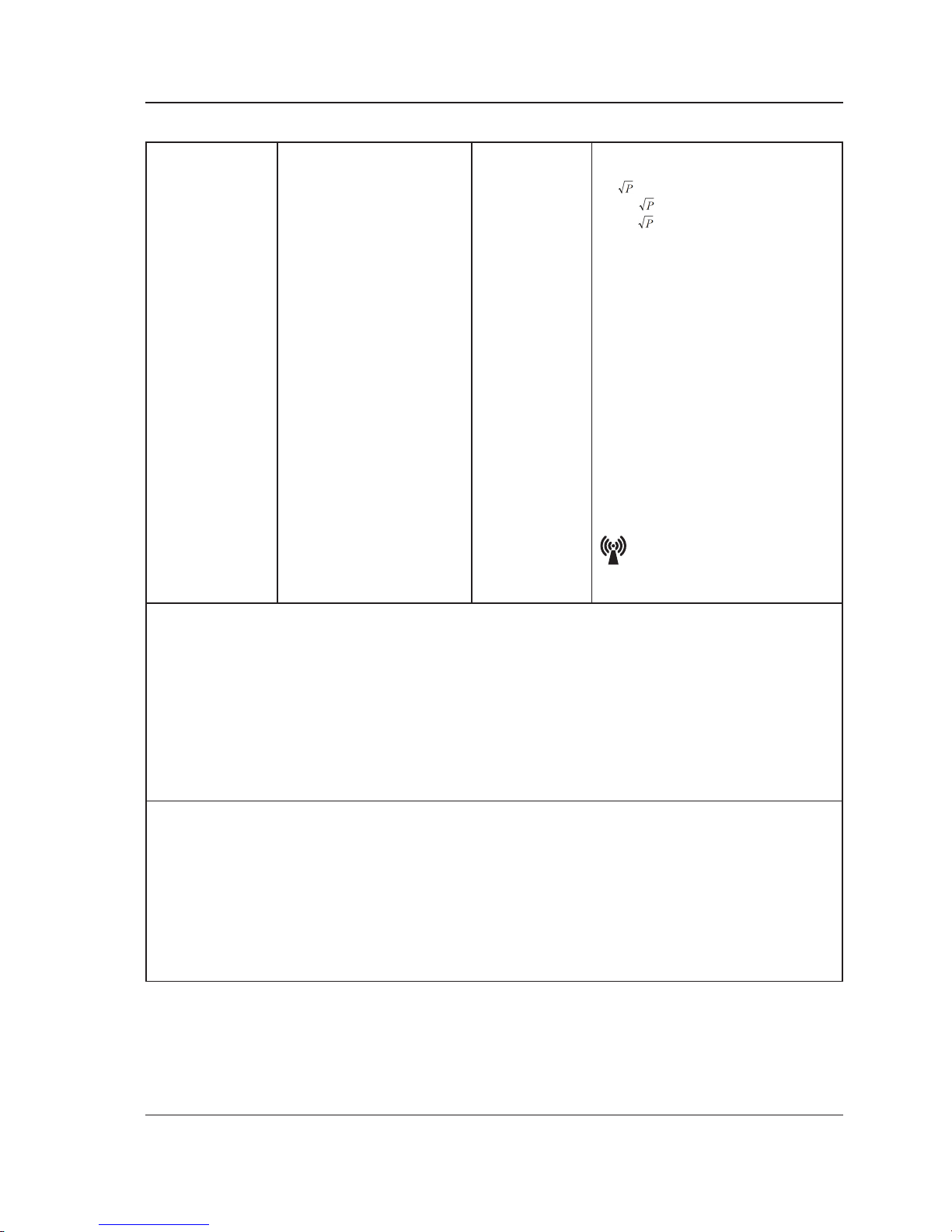

Radiated RF EM

Fields

IEC61000-4-3

10 V/m 80 MHz to 2,7 GHz

80 % AM at 1 kHz

385-6000 MHz, 9-28V/m,

80% AM(1kHz) pulse mode

and other modulation

10V/m

Recommended separation distance

d= 150kHz to 80MHz

d=0.6 80MHz to 800MHz

d=1.2 800 MHz to 2.7G Hz

Where P is the maximum output

power rating of the transmitter

in watts (W) according to the

transmitter manufacturer and d

is the recommended separation

distance in meters (m).

b

Field strengths from xed RF

transmitters, as determined by

an electromagnetic site survey ,a

should be less than the compliance

level in each frequency ranged.

Interference may occur in the

vicinity of equipment marked with

the following symbol:

NOTE 1: UT is the a.c. mains voltage prior to the application of the test level

NOTE 2: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 3: These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reection from structures, objects and people

NOTE 4:The ISM (industrial, scientic and medical) bands between 0.15 MHz and 80 MHz are 6.765 MHz

to 6.795 MHz; 13.553 MHz to 13.567 MHz; 26.957 MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz.

The amateur radio bandsbetween 0.15 MHz and 80 MHz are 1.8 MHz to 2.0 MHz, 3.5 MHz to 4.0 MHz,

5.3 MHz to 5.4 MHz, 7 MHz to 7.3 MHz,10.1 MHz to 10.15 MHz, 14 MHz to 14.2 MHz, 18.07 MHz to 18.17

MHz, 21.0 MHz to 21.4 MHz, 24.89 MHz to 24.99MHz, 28.0 MHz to 29.7 MHz and 50.0 MHz to 54.0

MHz.

a)Field strengths from xed transmitters, such as base stations for radio (cellular/cordless) telephones

and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted

theoretically with accuracy. To assess the electromagnetic environment due to xed RF transmitters, an

electromagnetic site survey should be considered. If the measured eld strength in the location in which

the device is used exceeds the applicable RF compliance level above, the device should be observed to

verify normal operation. If abnormal performance is observed, additional measures may be necessary,

such as reorienting or relocating the device.

b) Over the frequency range 150 kHz to 80 MHz, eld strengths should be less than 10 V/m.

Page 22

22 836002-5210 V3.4 www.stryker.com

Return To Table of Contents

LIMITED WARRANTY

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser EOLE DC

Powered Support Surface, Model 2871 to be free from defects in material and workmanship for a period

of two (2) years for the support surface assembly and the control unit after date of delivery under normal

use*. Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor

for, or replacing, at this option, any product which is, in the sole discretion of Stryker, found to be effective. If

requested by Stryker, products or parts for which a warranty claim is made shall be returned to the factory.

Any improper use or any alteration or repair by others in such manner as in Stryker’s judgment affects

the product materially and adversely shall void this warranty. Any repair of Stryker products using parts

not provided or authorized by Stryker shall void this warranty. No employee or representative of Stryker is

authorized to change this warranty in any way.

CONDITIONS AND LIMITATIONS

Stryker Medical’s EOLE DC Powered Support Surface, Model 2871 is designed for an expected service life

as listed below under normal use conditions, and with appropriate periodic maintenance as described in the

operations/maintenance manual for each device.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. Stryker makes

no other warranty or representation, either expressed or implied, except as set forth herein. There

is no warranty of merchantability and there are no warranties of tness for any particular purpose.

in no event shall Stryker be liable here under for incidental or consequential damages arising from

or in any manner related to sales or use of any such equipment. This warranty does not extend to,

nor cover:

• Normal wear and tear; or

• Damage or product failure due to causes beyond Stryker’s control such as, but not limited to abuse,

theft, re, ood, wind , lightning, freezing, clogging of mattress pores due to tobacco smoke, unusual

atmosphere conditions, material degradation due to exposure to moisture; or

• Damage to support surface or support surface handles through the use of the support surface for patient transfer or transport.

* Normal use is dened as normal hospital or facility usage. Damages arising from abnormal use such as

those caused by needle punctures, burns, chemicals, negligent use or improper care or improper cleaning or

staining resulting from it are exempt from warranty coverage.

TO OBTAIN PARTS AND SERVICE

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives.

These representatives are factory trained, available locally, and carry a substantial spare parts inventory

to minimize repair time. Simply call your local representative or call Stryker Customer Service USA at

1-800-327-0770.

RETURN AUTHORIZATION

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An

authorization number will be provided which must be printed on the returned merchandise. Stryker reserves

the right to charge shipping and restocking fees on return merchandise. Special, modied, or discontinued

items not subject to return.

DAMAGED MERCHANDISE

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fteen

(15) days of receipt of merchandise. Do not accept damaged shipments unless such damage is noted

on the delivery receipt at the time of receipt. Upon prompt notication, Stryker will le a freight claim with

the appropriate carrier for damages incurred. Claim will be limited in amount to the actual replacement cost.

In the event that this information is not received by Stryker within the fteen (15) days period following the

delivery of the merchandise, or the damage was not noted on the delivery receipt at the time of receipt, the

customer will be responsible for payment of the original invoice in full. Claims for any short shipment must be

made within thirty (30) days of invoice.

INTERNATIONAL WARRANTY CLAUSE

This warranty reects U.S. domestic policy. Warranty outside the U.S. may vary by country. Please contact

your local Stryker Medical representative for extra information.

Warranty

Page 23

www.stryker.com 836002-5210 V3.4 23

Return To Table of Contents

Page 24

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

USA

www.stryker.com

Stryker European Operations B.V.

Herikerbergweg 110

Amsterdam

1101 CM

Netherlands

Page 25

2017/12 836002-5210 V3.4 www.stryker.com

Surface de soutien alimentée en DC EOLE

2871

Guide d'utilisation/de maintenance

Page 26

Page 27

www.stryker.com 836002-5210 V3.4 3

Sommaire

Symboles et dénitions ................................................................ 4

Symboles ........................................................................ 4

Avertissement/Attention/Remarque : Dénition........................................... 5

Spécications techniques............................................................... 6

Introduction.......................................................................... 7

Contre-indications ................................................................. 7

Utilisation prévue du produit ......................................................... 7

Durée de vie prévue................................................................ 7

Description du produit .............................................................. 7

Informations de contact ............................................................. 8

Emplacement du numéro de série du produit/Identication ................................. 8

Récapitulatif des précautions de sécurité .................................................. 9

Description du produit ................................................................ 10

Panneau avant de l'unité de commande ............................................... 10

Panneau arrière de l'unité de commande .............................................. 10

Panneau de commande............................................................ 10

Instructions ..........................................................................11

Installation de l'unité de commande....................................................11

Fonctionnalités du produit .......................................................... 12

Mode de transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stockage ....................................................................... 13

Nettoyage et désinfection.............................................................. 14

Dépannage......................................................................... 15

Informations de maintenance ........................................................... 16

Remplacement du protège-matelas supérieur .......................................... 16

Remplacement de la cellule d'air ..................................................... 16

Remplacement de l'unité de commande ............................................... 16

Remplacement du tuyau ........................................................... 16

Remplacement du tube CPC ........................................................ 16

Remplacement du ltre ............................................................ 16

Maintenance préventive ............................................................... 17

Liste de contrôle.................................................................. 17

Annexe A : Information relative à la compatibilité électromagnétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Directive et déclaration du fabricant - Émissions électromagnétiques:........................ 19

Directive et déclaration du fabricant - Immunité électromagnétique:.......................... 20

Garantie ........................................................................... 22

Limite de garantie ................................................................ 22

Méthode d'obtention de pièces de rechange et de prestations de maintenance ................ 22

Autorisation de retour.............................................................. 22

Marchandise endommagée ......................................................... 22

Clause de garantie internationale .................................................... 22

Page 28

4 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

Symboles et dénitions

SYMBOLES

Marquage TÜV

Marquage CE

Avertissement/Attention : consulter la documentation fournie

Équipement BF

Isolation double

Fusible

Limites de température - De fonctionnement : 10 °C à 40 °C - De stockage : -15 °C à 50 °C

Limites d'humidité : 10 % - 90 %

Voir le manuel d'instructions

Mise au rebut : contacter le distributeur local, qui prendra les mesures nécessaires, en

fonction du pays concerné.

Ne pas repasser

Température de lavage maximale : 60 °C, lavage normal (uniquement du protège-matelas).

Blanchiment chloré

Ne pas utiliser de sèche-linge

Ne pas nettoyer à sec

Laisser l'appareil sécher totalement à l'air

Fabricant

IP24

Premier chiffre (Solides) P ro t ec ti o n co nt r e l e c on t a ct av e c l es doi g ts (>12 , 5 m m) ; Deuxième

chiffre (Liquides) Les éclaboussures d'eau sur le boîtier sont sans conséquence.

Représentant agréé au sein de la Communauté européenne

Numéro catalogue (modèle)

SN

Numéro de série

CPR

Ne pas ouvrir avec un cutter

Page 29

www.stryker.com 836002-5210 V3.4 5

Retour au Sommaire

AVERTISSEMENT/ATTENTION/REMARQUE : DÉFINITION

Les termes AVERTISSEMENT, ATTENTION et REMARQUE ont des signications spéciques et une

attention particulière doit y être apportée.

AVERTISSEMENT

Alerter le lecteur au sujet d'une situation qui, s'il n'était pas possible de l'éviter, risquerait d'entraîner des

blessures graves, voire mortelles. Description de réactions indésirables potentielles et de risques de sécurité

graves.

ATTENTION

Alerter le lecteur quant aux situations potentiellement dangereuses risquant d'entraîner des blessures légères

à modérées de l'utilisateur ou du patient, ou encore d'endommager l'équipement ou d'autres dispositifs. Une

attention particulière doit être apportée an d'utiliser l'équipement de façon sécurisée et efcace, et d'éviter

d'endommager l'équipement suite à une mauvaise utilisation de ce dernier.

REMARQUE

Fournir des informations spéciques visant à faciliter la maintenance ou la compréhension des instructions

importantes.

Symboles et dénitions

Page 30

6 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

Article Spécication

Alimentation CA 230 V, 50 Hz, 0,07 A

Calibre des fusibles T1AL, 250 V

Dimensions (l x L x H) 29,5 x 14,5 x 19,2 cm

Poids 2,4 kg

Durée d'un cycle 12 minutes

Environnement

Pression

atmosphérique

De fonctionnement : 70-106 hPa

Température

• De fonctionnement : 10 °C à 40 °C

• De stockage : -15 °C à 50 °C

• D'expédition : -15 °C à 70 °C

Humidité

• De fonctionnement : 10 % à 90 %, sans condensation

• De stockage : 10 % à 90 %, sans condensation

• D'expédition : 10 % à 90 %, sans condensation

Classication

• Classe II, Type BF, IP24

• Pièce : Matelas à air

• Non adapté à une utilisation en présence d’un mélange de

produits anesthésiques inammables (absence de protection

AP ou APG)

Matelas à air Spécication

Modèle EOLE DC 32” (80cm) EOLE DC 35” (90cm)

Référence modèle 2871

Normes applicables aux produits

ignifuges

EN 597-1 et EN 597-2

Charge maximale 200 kg

Dimensions (l x L x H) 200 X 80 X 20 cm 200 X 90 X 20 cm

Poids 4,75 kg 5,45 kg

Spécications techniques

Page 31

www.stryker.com 836002-5210 V3.4 7

Retour au Sommaire

Ce manuel a pour objectif de faciliter l'utilisation et la maintenance du produit Surface de soutien alimentée en

DC EOLE. Lisez-le attentivement avant d'utiliser l'équipement ou d'effectuer des opérations de maintenance.

Pour garantir un fonctionnement de l'appareil dans de bonnes conditions de sécurité, il est recommandé de

mettre en œuvre des méthodes et des procédures visant à former le personnel.

CONTRE-INDICATIONS

Aucune connue.

UTILISATION PRÉVUE DU PRODUIT

EOLE DC est une surface de soutien à alimentation continue basse pression permettant de prévenir et

de traiter les escarres. Ce système se compose d'une unité de commande et d'un matelas à cellules d'air

à pression alternée. Les cellules d'air redistribuent le poids du patient sur la totalité de la surface, permettant

ainsi de réduire la pression sur les tissus. L'utilisation du produit doit être conée à un personnel qualié,

capable d'exécuter des soins inrmiers classiques, et formé en matière de prévention et de traitement des

escarres.

Ce dispositif est destiné aux patients hospitalisés, ou se trouvant dans des environnements de maisons

de soins inrmiers ou de soins à domicile, ainsi qu'aux patients risquant de développer des escarres ou

nécessitant un traitement pour des escarres préexistants. La charge maximale d'EOLE DC est de 200 kg ;

le patient ne doit pas dépasser le poids spécié pour la surface, le cadre et les accessoires. Les patients

doivent être âgés au minimum de 2 ans.

EOLE DC doit en permanence être utilisé avec un protège-matelas.

Il ne s'agit ni d'un appareil stérile, ni d'un dispositif de mesure.

DURÉE DE VIE PRÉVUE

Ces produits offrent un fonctionnement able et sécurisé lorsqu'ils sont utilisés ou installés conformément

aux instructions fournies par Stryker Medical. Stryker Medical recommande de faire inspecter et entretenir

le système par des techniciens agréés, en cas de signes d'usure ou de problèmes de fonctionnement ou

de signalisation sur le produit. Dans tous les autres cas, ces opérations ne sont pas nécessaires. L'unité de

commande a une durée de vie prévue de 3 ans, et le matelas de 2 ans.

DESCRIPTION DU PRODUIT

EOLE DC est une surface à air motorisée permettant d'égaliser la pression exercée et de maximiser le

confort des patients.

Introduction

Page 32

8 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

INFORMATIONS DE CONTACT

Contactez le service d'assistance clientèle ou le support technique de Stryker, au numéro suivant :

(800) 327-0770 ou (269) 324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

ÉTATS - U NIS

Munissez-vous du numéro de série (A) de votre produit Stryker lorsque vous appelez le service d'assistance

clientèle ou le service de support technique de Stryker. De la même façon, mentionnez le numéro de série

du produit dans tous vos envois de courriers.

EMPLACEMENT DU NUMÉRO DE SÉRIE DU PRODUIT/IDENTIFICATION

Le numéro de série (A) se trouve sur le protègematelas, dans l'angle inférieur droit, comme l'illustre

la Figure 1. Pour accéder à ce numéro de série,

ouvrir légèrement (de 30 cm) la fermeture éclair du

protège-matelas.

▼

Figure 1

Matelas

EOLE DC

Cellule d’airCPR

A

Format :

2871

M A A M M - S S S S S

• M = Matelas

• AA = Année

• MM = Mois

• SSSSS = Séquence (Numérique)

Légende Référence modèle (X)

2871 EOLE DC

Légende Mois (MM)

Janvier 01

Février 02

Mars 03

Avril 04

Mai 05

Juin 06

Juillet 07

Août 08

Septembre 09

Octobre 10

Novembre 11

Décembre 12

Légende Année

(AA)

2014 14

2015 15

2016 16

2017 17

2018 18

Introduction

Page 33

www.stryker.com 836002-5210 V3.4 9

Retour au Sommaire

AVERTISSEMENT

• Vérier régulièrement la peau du patient. En cas de rougeur ou d'altération de la peau, consulter un médecin.

L'absence de traitement de ces altérations de la peau risquerait d'entraîner de graves blessures pour le patient.

• Ne pas placer l'unité de commande dans le lit du patient, au contact avec ce dernier ou sous les draps ou

couvertures. En effet, cela risquerait d'entraîner de graves blessures ou de diminuer les performances

de l'unité de commande.

• Ne pas utiliser en présence d'un mélange anesthésiant inammable ou comportant de l'oxygène (O2) ou

de l'oxyde d'azote (N2O).

• Vérier que les rails latéraux du lit sont compatibles avec le cadre du lit et avec le matelas existant. Une

évaluation des risques doit être effectuée par une personne habilitée, et tout particulièrement lorsque des rails

latéraux sont prescrits, an de garantir que le lit soit conforme aux dispositions de la norme IEC 60601-2-52.

• Utiliser avec un drap approprié et minimiser les couches entre le patient et le matelas.

• Évaluer le risque de piégeage du patient, conformément aux protocoles en vigueur, et effectuer les

vérications correspondantes.

• Une surveillance étroite est requise lors de l'utilisation du produit avec des enfants ou à proximité

d'enfants. Des brûlures électriques ou une suffocation peuvent se produire si un enfant avale une petite

pièce s'étant détachée de l'appareil.

• N'utiliser ce produit que pour les utilisations prévues, décrites dans le présent manuel.

• Ne pas utiliser ce produit si le cordon ou la prise d'alimentation a été endommagé(e).

• Maintenir le cordon d'alimentation à distance des surfaces chauffées.

• Ne jamais bloquer les ouvertures d'air du produit, ne jamais le placer sur des surfaces risquant d'obturer les

ouvertures. Veiller à ce que les ouvertures ne soient pas obturées par des particules (peluches, cheveux ou autres).

• Ne pas apporter de modication à cet équipement sans l'autorisation du fabricant.

• Les protège-matelas ont été soumis à des tests de sensibilisation et d'irritation de la peau. Toutefois,

si vous pensez que le patient ou le soignant est susceptible d'avoir une réaction allergique, consultez

immédiatement un médecin.

• Le cordon d'alimentation reliant l'unité de commande doit être positionné de façon à éviter tout risque

de strangulation et/ou de détérioration du cordon. Une attention particulière doit être accordée lors du

déplacement du câble d'alimentation. Il est recommandé de placer le cordon sous le cadre du lit et de le

brancher sur une prise électrique au niveau de la tête du lit.

• Des blessures graves, voire mortelles, pourraient avoir lieu en cas d'utilisation (piégeage potentiel)

ou de non utilisation (chute potentielle) de rails latéraux ou d'équipements similaires. La sécurité de

l'équipement est maximisée en cas d'utilisation avec des rails latéraux. Un risque de chute accru est

présent en cas d'absence de rails. Les politiques locales en matière d'utilisation de rails latéraux doivent

être prises en considération. La décision d'utiliser ou non des rails latéraux doit s'appuyer sur les besoins

de chaque patient ; elle incombe au médecin, aux opérateurs et aux responsables concernés.

• Lors du nettoyage de l'équipement, vérier qu'aucun liquide ne coule : en effet, les uides entrant en

contact avec la fermeture risqueraient de couler dans l'équipement.

• Ne pas exposer le matelas à un degré d'humidité excessif. Cela risquerait d'entraîner des blessures ou

des détériorations de l'appareil.

• L'utilisation de quaternaires contenant des éthers de glycol et/ou du peroxyde d'hydrogène accéléré

risque d'endommager le protège-matelas.

• Surveiller les équipements placés sur l'appareil. Ils risquent d'endommager le matelas, en raison de leur

poids, de la chaleur qu'ils dégagent ou de leurs aspérités.

• Ne pas placer d'accessoires dans le protège-matelas. Cela risquerait de diminuer les performances de

répartition de pression.

• Il incombe à l'équipe en charge du patient d'évaluer le protocole CPR approprié pour l'équipement.

• En cas de possible interférence électromagnétique avec les téléphones mobiles, augmenter la distance

(3,3 m) entre les équipements ou mettre le téléphone hors tension.

• Vérier avant utilisation que le capuchon étanche de l'interrupteur est présent et en bon état de fonctionnement. Sinon, cela augmenterait le risque d'électrocution.

• Le matelas contient des boutons et des fermetures métalliques et ne doit donc pas être exposé entièrement

aux rayons X. Veiller à utiliser systématiquement un support pour cassette radiographique pendant les

procédures de radiographie portable.

REMARQUE

EOLE DC doit en permanence être utilisé avec un protège-matelas. Ce protège-matelas peut être en contact

avec toute la surface externe de la peau.

Récapitulatif des précautions de sécurité

Page 34

10 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

PANNEAU AVANT DE L'UNITÉ DE COMMANDE

2

1

3

◄

Figure 2

1. Interrupteur On/Off

2. Panneau avant

3. Prise d'alimentation

PANNEAU ARRIÈRE DE L'UNITÉ DE COMMANDE

4

5

◄

Figure 3

4. Suspension

5. Connecteur CPC

◄

Figure 4

6. Matelas EOLE DC

7. Cellule d'air

8. Tuyau d'air

9. Sangle CPR

PANNEAU DE COMMANDE

10 11 12 13 14 15

◄

Figure 5

10. Verrouiller/Déverrouiller

11. Sélection du mode

12. Niveau de confort

13. Maxrm/Seat mode (Mode de

fermeté maximale)

14. Alarme

15. Son coupé

Description du produit

Page 35

www.stryker.com 836002-5210 V3.4 11

Retour au Sommaire

INSTALLATION DE L'UNITÉ DE COMMANDE

1. Placer l'unité de contrôle sur une surface plane, ou la suspendre à l'extrémité du lit, à l'aide des

crochets joints. Voir les Figures 2 et 3. Retirer la prise pour débrancher l'appareil. Ne pas positionner

l'équipement de telle sorte qu'il soit difcile de le débrancher.

2. Placer le matelas sur le cadre du lit.

3. Placer le tuyau entre les cellules d'air du matelas et l'unité de commande. Brancher l'adaptateur de

l'unité de commande sur la soupape d'air.

4. Brancher le cordon d'alimentation : le mode de fermeté maximale (Maxrm/Seat) est automatiquement

sélectionné. Remarque : le matelas se gone ; cette opération prend environ 40 minutes. L'inrmière

peut régler le niveau de confort ou le mode avec le patient lors de l'étape initiale.

5. Une fois l'installation effectuée, vérier que le rabat n'est pas relevé, an d'éviter tout déversement de

liquide sur le protège-matelas.

REMARQUE

Vérier que l'unité de commande est compatible avec la tension d'alimentation et la fréquence locales.

6. Positionner le patient sur le matelas.

AVERTISSEMENT

Dégoner le matelas avant d'effectuer le CPR, sinon ce dernier risquerait d'être inefcace.

Pour dégoner le matelas avant d'effectuer le CPR, procéder comme suit :

En cas de besoin urgent de pratiquer un CPR sur le patient, retirer rapidement la sangle CPR du matelas

pour libérer l'air. Le connecteur rapide situé sur l'unité de pompe peut être débranché, pour dégoner plus

rapidement la cellule d'air. Elle sera dégonée en 15 secondes environ. Exécuter les procédures CPR.

Réinitialisation du CPR :

Une fois le CPR effectué, rebrancher le CPR et vérier que la prise CPR correspondante est correctement

xée sur le matelas.

Instructions

Page 36

12 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

FONCTIONNALITÉS DU PRODUIT

THERAPY (THÉRAPIE)

1. Maxrm/Seat mode (Mode de fermeté maximale)

Lors de sa mise sous tension initiale, l'unité de commande gone automatiquement l'équipement jusqu'au

niveau maximal, et l'indicateur lumineux du mode Maxrm/Seat s'allume. Cela permet de s'assurer que

l'unité de commande est capable d'atteindre la pression maximale de fonctionnement. Une fois le niveau

maximal atteint, la pompe passe automatiquement en mode alternatif. L'utilisateur peut également utiliser

cette fonction pour goner totalement le matelas pour un meilleur soutien du patient lors des accès/

sorties. L'inrmière ou l'opérateur peut régler manuellement le degré de confort au niveau maximal.

En mode alternatif ou statique, l'inrmière peut utiliser le bouton Maxrm (Fermeté maximale) pour

sélectionner la fermeté maximale, ou revenir à l'étape antérieure.

a. Mode Alternate (Alternatif)

En mode Alternate (Alternatif), les fonctions du matelas alternent toutes les 12 minutes. L'utilisateur

peut sélectionner le meilleur confort.

b. Niveau de confort :

Appuyer sur

et sur pour régler le niveau de pression adapté au confort du patient.

c. Mode Static (Statique)

Appuyer sur le bouton THERAPY (Thérapie) pour arrêter l'alternance entre les fonctions, en cas de

besoin. La pression dans les cellules d'air est réglée au même niveau. Appuyer de nouveau sur le

bouton THERAPY (Thérapie) : le mode d'alternance entre les fonctions reprend. Lorsque le mode

statique est activé, le niveau de pression des cellules est abaissé par rapport au même niveau en

mode Alternate (Alternatif).

2. Alarm Mute (Alarme muette)

Appuyer sur Alarm Mute (Alarme muette) pour désactiver le son de l'alarme. Si le problème persiste,

l'alarme retentit de nouveau après un délai de 3 minutes.

a. Alarme de panne de courant

En cas de panne de courant, l'indicateur de panne s'allume et un son est émis. Une fois le courant

rétabli, appuyer sur l'interrupteur pour désactiver l'alarme sonore et visuelle, ainsi que la DEL

correspondante.

b. Alarme basse pression

L'alarme basse pression n'est pas active pendant le gonement initial du matelas. L'alarme sonore est

active après un délai d'environ 50 minutes à compter de la mise sous tension de l'unité.

En cas de perte de pression dans le matelas pendant que l'unité est sous tension (ON) et que l'alarme

est activée, une alarme retentit et clignote. Par ailleurs, le voyant de basse pression s'allume.

c. Alarme de maintenance

Cette alarme s'allume en cas de panne mécanique. L'utilisateur peut alors contacter le technicien en

vue d'une réparation.

3. Bouton Lock (Verrouillage)

Le patient ou le soignant peut maintenir ce bouton enfoncé pendant 3 secondes pour activer ou désactiver

le mode de verrouillage. En mode de verrouillage, le patient ou le soignant peut appuyer sur le bouton

Maxrm/Seat (Fermeté maximale) pour obtenir un niveau maximal de gonage.

Le panneau de l'unité de commande est automatiquement verrouillé en cas d'inactivité de plus de

3 minutes.

Instructions

Page 37

www.stryker.com 836002-5210 V3.4 13

Retour au Sommaire

MODE DE TRANSPORT

En cas de panne de courant ou de transport : débrancher le connecteur

CPC et brancher ensemble les parties mâle et femelle du connecteur du

tuyau d'air, pour ralentir le gonement.

Pour le transport, brancher ensemble les parties mâle et femelle du

connecteur du tuyau d'air. Lorsqu'un « clic » retentit, cela signie que le

branchement est effectué de façon sécurisée ; ensuite, l'air du matelas est

bloqué hermétiquement.

STOCKAGE

1. Pour dégoner rapidement le matelas à des ns de stockage,

retirer la sangle CPR et les connecteurs CPC. Cela permet de

libérer l'air rapidement.

2. Etendre à plat le matelas et le tourner à l'envers.

3. Plier le matelas en deux et insérer l'unité de commande.

4. Rouler le matelas du haut vers le bas.

5. Le cordon d'alimentation peut être enroulé autour du support

de la pompe (à l'arrière de cette dernière).

6. Placer l'intégralité du système dans la sacoche de transport.

Instructions

Page 38

14 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

Nettoyage et désinfection

Le boîtier de l'unité de commande, les tubes et le matelas doivent être nettoyés entre chaque patient.

• Pour effectuer le nettoyage, utiliser de l'eau et un chiffon propre pour essuyer l'unité de commande,

le cordon d'alimentation, les tuyaux, la partie supérieure et la partie inférieure du protège-matelas.

Ne pas utiliser de produits nettoyants abrasifs sur le matelas. Remarque : le sang et les autres uides

corporels doivent être soigneusement nettoyés sur toutes les surfaces avant application des produits

désinfectants.

• Appliquer les produits désinfectants sur les surfaces externes de l'unité de commande, sur les tuyaux

et sur les parties supérieure et inférieure du matelas, en essuyant. Stryker recommande l'utilisation

deux fois par semaine d'une solution à base de chlore, d'une concentration inférieure ou égale à 1 000 ppm

ou 70 % d'alcool.

• Pour nettoyer le protège-matelas à la machine, sélectionner un programme normal d'une température

inférieure à 60°C, d'une durée de 45 minutes.

• Il n'est pas recommandé de désinfecter régulièrement les parties internes du matelas, mais uniquement

en cas de besoin ; la cellule d'air peut être essuyée à l'aide d'un chiffon et des produits désinfectants

recommandés ci-avant.

• Essuyer le matelas à l'aide d'un chiffon propre et doux, an d'éliminer tout excès de désinfectant.

• En cas d'utilisation d'un autre produit nettoyant ou détergent, choisir un produit n'ayant pas d'effets

chimiques néfastes sur la surface en plastique de l'unité de commande, du protège-matelas ou des

autres composants de l'appareil.

• Lors du nettoyage ou de la désinfection de l'équipement, vérier qu'aucun liquide ne coule : en effet,

les uides entrant en contact avec la fermeture éclair risqueraient de couler dans l'équipement.

• Éviter la poussière et la proximité de zones poussiéreuses.

• Tous les composants doivent être totalement secs avant utilisation.

Le capuchon étanche d'alimentation doit être positionné sur l'interrupteur.

• Ne pas utiliser d'outils pointus sur le capuchon étanche de l'interrupteur.

• Si le capuchon est cassé ou manquant, contacter le distributeur.

AVERTISSEMENT

• Ne pas utiliser de produits à base de substances phénoliques pour le nettoyage.

• Pour faire sécher le matelas, ne pas l'exposer à la lumière directe du soleil.

Page 39

www.stryker.com 836002-5210 V3.4 15

Retour au Sommaire

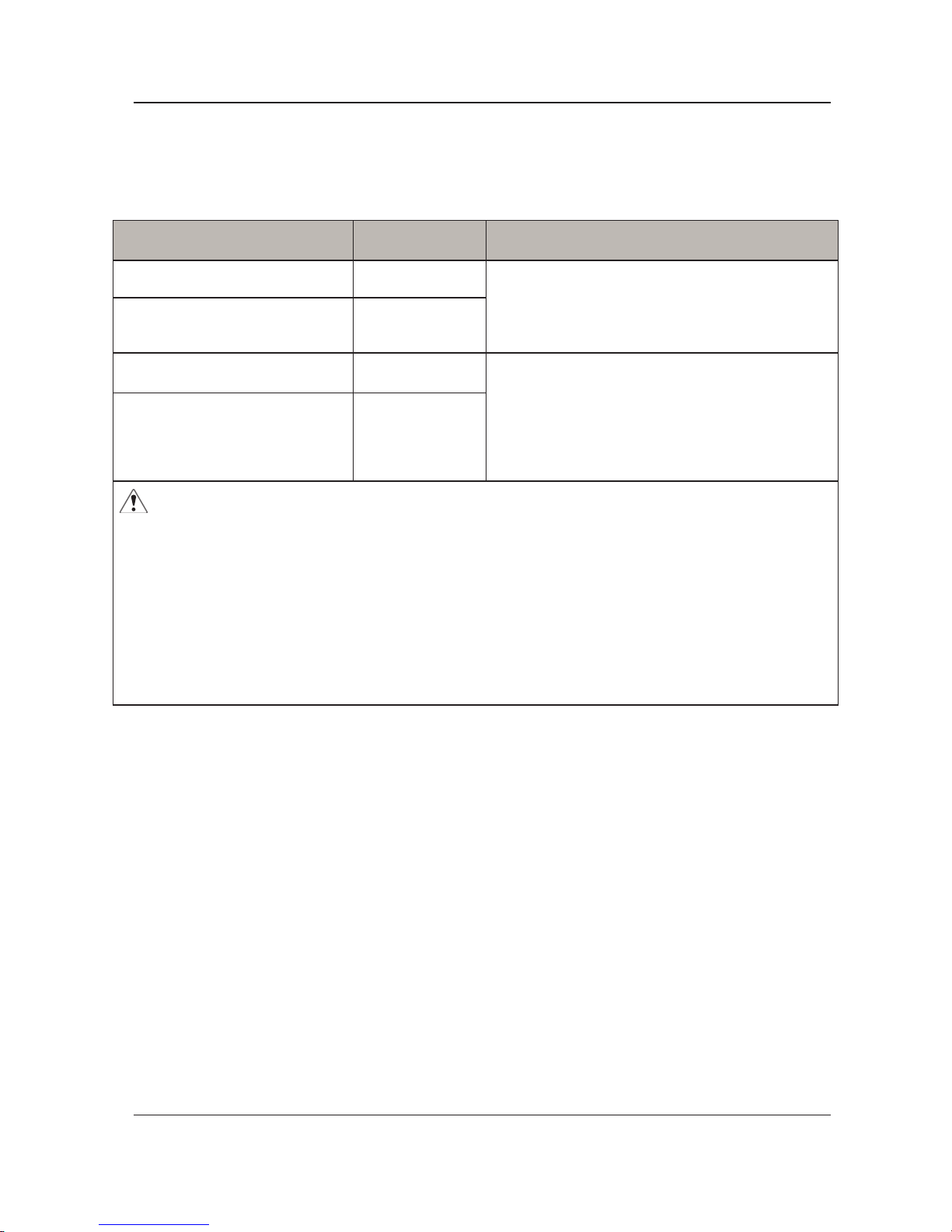

Dépannage

Problème Solution

Panne d'électricité Vérier si la prise est branchée à l'alimentation principale.

L'alarme basse pression retentit

1. Vérier si le CPR est fermé hermétiquement.

2. Vérier que la cellule d'air n'est pas endommagée.

3. Vérier que le tube de raccordement est correctement xé.

4. Vérier l'absence de fuite au niveau des cellules d'air.

Le patient est dans le creux du

matelas

Le réglage de pression est peut-être inapproprié pour ce patient. Régler

la plage de confort en sélectionnant un confort situé 1 à 2 niveaux

au-dessus et attendre quelques minutes que le confort s'améliore.

Le matelas d'air n'est pas sécurisé

1. Vérier que tous les boutons et sangles du matelas sont

correctement xés.

2. Vérier la xation du matelas au cadre de lit par des sangles

élastiques.

Les cellules d'air ne se gonent

pas

Vérier que le tuyau d'air n'est pas écrasé, coudé ou endommagé.

Vérier que le voyant d'alimentation est allumé, ce qui indique que

l'unité de commande est sous tension. Vérier que les tuyaux d'air sont

totalement insérés et raccordés.

Page 40

16 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

REMPLACEMENT DU PROTÈGE-MATELAS SUPÉRIEUR

Outils requis : aucun

Procédure :

1. Débrancher le tuyau situé entre les cellules d'air du matelas et l'unité de commande.

2. Ouvrir le protège-matelas.

3. Jeter le protège-matelas existant.

4. Placer le nouveau protège-matelas.

5. Refermer soigneusement le protège-matelas.

6. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

REMPLACEMENT DE LA CELLULE D'AIR

Outils requis : aucun

Procédure :

1. Débrancher le tuyau de la soupape d'air du matelas.

2. Ouvrir la fermeture éclair des deux côtés pour retirer le protège-matelas et retirer les tubes CPC.

3. Retirer et jeter l'ancienne cellule d'air.

4. Placer la nouvelle cellule d'air, raccorder les tubes et refermer le protège-matelas.

5. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

REMPLACEMENT DE L'UNITÉ DE COMMANDE

Outils requis : aucun

Procédure :

1. Débrancher la prise d'alimentation principale et retirer le tuyau.

2. Jeter l'ancienne unité de commande.

3. Placer la nouvelle unité de commande et brancher la prise sur l'alimentation principale et le tuyau.

4. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

REMPLACEMENT DU TUYAU

Outils requis : aucun

Procédure :

1. Retirer le tuyau de l'unité de commande et du matelas.

2. Jeter le tuyau existant.

3. Raccorder le nouveau tuyau sur l'unité de commande et le matelas.

4. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

REMPLACEMENT DU TUBE CPC

Outils requis : aucun

Procédure :

1. Retirer le tube de l'unité de commande et du matelas.

2. Jeter l'ancien tube.

3. Raccorder le nouveau tube sur l'unité de commande et le matelas.

4. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

REMPLACEMENT DU FILTRE

Outils requis : aucun

Procédure :

1. Jeter l'ancien ltre.

2. Vérier le bon fonctionnement de l'unité avant de la remettre en service.

AVERTISSEMENT

Tout remplacement de pièces non autorisées risque d'entraîner une augmentation de risque imprévisible.

Vérier que la pièce remplacée est adaptée au produit Surface de soutien alimentée en DC EOLE de Stryker

Medical (Modèle 2871).

Informations de maintenance

Page 41

www.stryker.com 836002-5210 V3.4 17

Retour au Sommaire

La maintenance préventive doit être effectuée chaque année au minimum. Un programme de maintenance

préventive doit être élaboré pour tous les équipements Stryker Medical. Une maintenance préventive plus

fréquente peut être nécessaire en fonction du niveau d'utilisation du produit.

LISTE DE CONTRÔLE

_______ La fermeture du protège-matelas fonctionne bien et ne comporte pas de détérioration visible.

_______ Aucune usure, déchirure, craquelure, aucun trou ou autre ouverture ne gure au niveau du

protège-matelas.

_______ Les étiquettes sont lisibles, collent correctement et sont en bon état.

_______ Les sangles et attaches sont intactes, non endommagées.

_______ Les sangles permettent de xer correctement l'équipement au support.

_______ Les composants ne se sont pas détériorés ou détachés.

_______ Le cordon d'alimentation est en bon état (ne pas brancher en cas d'usure).

_______ L'air sort correctement du tuyau d'air.

_______ Le tuyau d'air n'est pas endommagé ou coudé

_______ Vérier le bon fonctionnement de l'unité avant de la remettre en service.

_______ Vérier le capuchon étanche d'alimentation.

Maintenance préventive

Numéro de série du produit :

Réalisé par : ___________________________________________ Date : _____________________

Page 42

18 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

Les pièces et accessoires répertoriés sur cette page sont actuellement disponibles. En revanche, certaines

pièces illustrées dans les croquis de ce guide peuvent ne pas être disponibles. Pour connaître les disponibilités

et les prix, appeler le service d'assistance clientèle de Stryker États-Unis au 1-800-327-0770.

Produit Référence

SURFACE DE SOUTIEN ALIMENTÉE EN DC EOLE 32” (80cm) 2871-000-002

SURFACE DE SOUTIEN ALIMENTÉE EN DC EOLE 35” (90cm) 2871-000-001

Unité de commande EOLE DC 2871-001-000

Pièce Référence

Manuel, EOLE DC 2871-009-001

Matelas, protège-matelas 32” (80cm) 2871-019-006

Cellule d'air unique, Orange PU 32” (80cm) 2871-019-007

Cellule d'air unique, transparente 32” (80cm) 2871-019-008

Matelas, protège-matelas 35” (90cm) 2871-002-000

Cellule d'air unique, Orange PU 35” (90cm) 2871-004-001

Cellule d'air unique, transparente 35” (90cm) 2871-004-002

Tuyau d'air, PVC, EOLE DC 2871-004-003

Prise, Remplacement, Qté 1 2871-004-004

Collecteur 2871-004-005

Pompe, afchage bouton, EOLE DC 2871-001-001

Pompe, fusible 2870-001-002

Tube, CPC 2870-001-003

Pompe, compresseur 2870-001-004

Filtre à air 2870-001-005

Accessoire Référence

Pompe, prise UK 2870-019-001

Sacoche de transport 2870-019-002

Pompe, prise FR 2870-019-003

Pièces de rechange - Guide de référence rapide

Page 43

www.stryker.com 836002-5210 V3.4 19

Retour au Sommaire

Annexe A : Information relative à la compatibilité électromagnétique

DIRECTIVE ET DÉCLARATION DU FABRICANT - ÉMISSIONS ÉLECTROMAGNÉTIQUES:

L’appareil doit être utilisé dans un environnement électromagnétique indiqué ci-dessous. L’utilisateur de cet

appareil doit garantir que l’appareil est utilisé dans un environnement approprié.

Test d'émissions Conformité Environnement électromagnétique - Directive

Emissions RF CISPR 11 Groupe 1

L’appareil utilise de l’energie RF uniquement pour

son fonctionnement interne. Par

consequent, les emissions RF sont tres faibles et ne

devraient pas causer d’interferences

avec l’equipement electronique environnant.

Emissions RF CISPR 11 Classe B

Rayonnements harmoniques CEI

61000-3-2

Classe A

L’appareil peut etre utilise dans dans toutes les

installations, y compris les installations

domestiques et celles directement raccordees au

reseau public de distribution a basse

tension qui fournit de l’electricite aux batiments

utilises a des ns domestiques.

Emissions dues aux uctuations

de tension/au papillotement CEI

61000-3-3

Conforme

ATTENTION :

1. L’appareil ne doit pas être utilisé à proximité ou empilé avec d’autres équipements. Si une utilisation

adjacente ou empilée est nécessaire, le dispositif doit être observé pour vérier le fonctionnement normal

dans la conguration dans laquelle il sera utilisé.

2. L’utilisation d’accessoires, de transducteurs et de câbles autres que ceux spéciés ou fournis par le

fabricant de cet équipement peut entraîner une augmentation des émissions électromagnétiques ou une

diminution de l’immunité électromagnétique de cet équipement et entraîner un fonctionnement incorrect.

3. Les appareils de communication RF portables (y compris les périphériques tels que les câbles

d’antenne et les antennes externes) doivent être utilisés à une distance de 30 cm (12 pouces) de

toute partie de la Pompe, y compris les câbles spéciés par le fabricant. Sinon, une dégradation des

performances de cet équipement pourrait en résulter.

Page 44

20 836002-5210 V3.4 www.stryker.com

Retour au Sommaire

Annexe A : Information relative à la compatibilité électromagnétique

DIRECTIVE ET DÉCLARATION DU FABRICANT - IMMUNITÉ ÉLECTROMAGNÉTIQUE:

L’appareil doit être utilisé dans un environnement électromagnétique indiqué ci-dessous. L’utilisateur de cet

appareil doit garantir que l’appareil est utilisé dans un environnement approprié.

Norme EMC de

base

Niveau du test

d'immunité

Niveau du