Page 1

EOLE / EOLE DC Pump

REF

REF

2870

2871

Service Manual

2 017/10 A . 0

836 00 4 -5 210 V1.1

www.stryker.com

Page 2

Page 3

Table of Contents

Troubleshooting .............................................................................................................................................................................. 2

Quick Reference Replacement Parts....................................................................................................................................... 2

Service ............................................................................................................................................................................................. 3

Pumping set replacement ....................................................................................................................................................................... 3

Air cell replacement .................................................................................................................................................................................. 5

Check internal tubing ................................................................................................................................................................................ 5

Fuse replacement ...................................................................................................................................................................................... 6

Main PCBA replacement .........................................................................................................................................................................6

Timing motor module replacement ...................................................................................................................................................... 8

Micro switch replacement ....................................................................................................................................................................... 9

Front Panel PCBA replacement ........................................................................................................................................................... 10

Filter replacement ....................................................................................................................................................................................10

Pressure Calibration ................................................................................................................................................................................11

Pressure test ..............................................................................................................................................................................................13

www.stryker.com 836 00 4 -5 210 V1.1 1

Page 4

Troubleshooting

Problem/Failure Possible Cause Recommended Action

Low pressure alarm Pump performance degradation Replace pumping set

Replace filter

CPR control is not fully closed Close CPR control

There is a leak in the mattress Replace broken tube

The tubing of mattress is

not connected properly

Tubing inside the pump is

not connected properly

Power failure alarm Fuse is burnt Replace fuse

No power Make sure the unit is plugged into ground outlet

Transformer fail Replace main PCBA

Main PCBA fail Replace main PCBA.

Service alarm Main PCBA fail Replace main PCBA

Timing motor fail Replace timing motor module

Micro switch fail Replace micro switch

Panel display error Button or LED fail Replace front panel PCBA

Cannot stop buzzer beeping Forget to switch off power button Switch off power switch

The buzzer wire is not connected

to the correct position

Check the tubing connectors and make

sure they are securely connected

Open the pump housing and connect

the internal tubing properly.

Check the wire connections on front

panel and on main PCBA

Quick Reference Replacement Parts

Part Name Part Number For product model

Pumping set (50Hz, 8 Liter) 2870001016 EOLE DC/EOLE

Timing motor module 2870001017 EOLE DC/EOLE

Compressor 2870001004 EOLE DC/EOLE

Micro switch 2870001018 EOLE DC/EOLE

Main PCBA 2871001002 EOLE DC

Main PCBA 2870001014 EOLE

Front panel PCBA 2870001015 EOLE DC/EOLE

Filter 2870001019 EOLE DC/EOLE

Fuse (T1AL/250V) 2870001002 EOLE DC/EOLE

Label, Stryker, front enclosure 2870001006 EOLE DC/EOLE

Screw cover, rubber 2870001007 EOLE DC/EOLE

Screw, M3 x 20 mm 2870001008 EOLE DC/EOLE

Screw, M3 x 10 mm 2870001011 EOLE DC/EOLE

Air outlet assembly, with CPC connector 2870001009 EOLE DC/EOLE

Switch assembly, with PVC switch cap 2870001010 EOLE DC/EOLE

Front case enclosure 2870001012 EOLE DC/EOLE

Mattress bottom cover 32” (80cm) 2871019009 EOLE DC

Back Case 2870001013 EOLE/EOLE DC

Pump Service Manual for Eole and Eole DC 2870009002 EOLE/EOLE DC

2 836 00 4 -5 210 V1.1 www.stryker.com

Page 5

Service

PUMPING SET REPLACEMENT

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

● Threadlocker (LOCTITE 290)

PROCEDURE:

1. Take out the 8 rubbers and remove 8 screws on the rear case. Take off the rear case.

2. Remove 6 screws on the base.

3. Remove wire connections to power switch and front panel PCBA. Take out the module set from the

case.

4. Pumping set is inside the compressor. Unscrew the 4 screws on the compressor and open the case.

5. Remove the screw of pumping set.

6. Take out the pumping set.

www.stryker.com 836 00 4 -5 210 V1.1 3

Page 6

Service

7. Keep the rubbers, screw, and washer. Replace pumping set with a new one and discard the old one.

Assemble the pumping set:

1. Use your thumb to push back the pumping set and hold on this position, and then tighten the screw.

2. Press the vibration rods to make sure they will not touch the front object.

3. Apply threadlocker around the screw to set for the best bond.

4 836 00 4 -5 210 V1.1 www.stryker.com

Page 7

Service

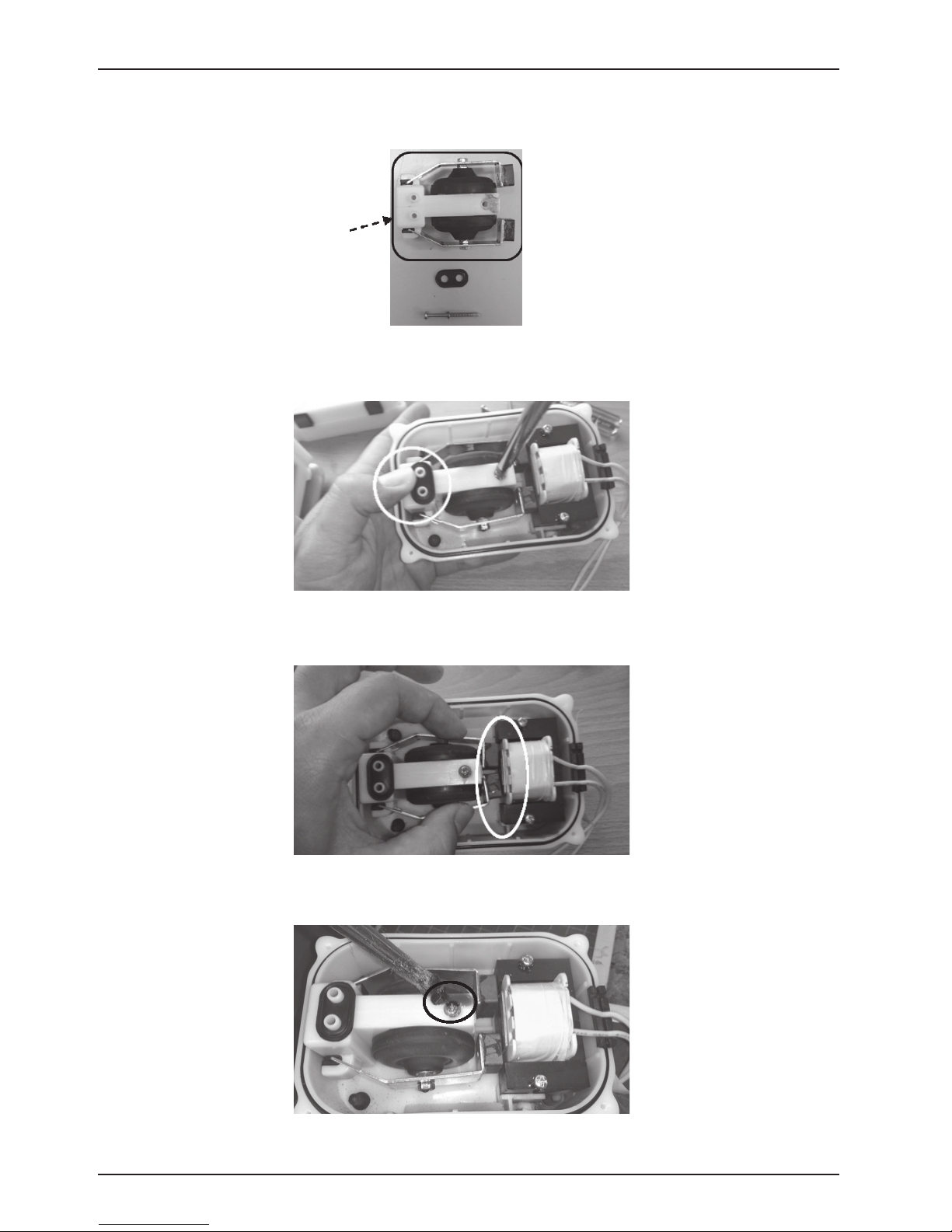

AIR CELL REPLACEMENT

TOOLS REQUIRED:

● Soap water and a container

PROCEDURE:

1. Infalte the air cells. Wipe soap water on the air cells.If you see bubbles on the air cells, there is an air

leakage. If there is a leakage, replace the air cell.

Photo is for reference only.

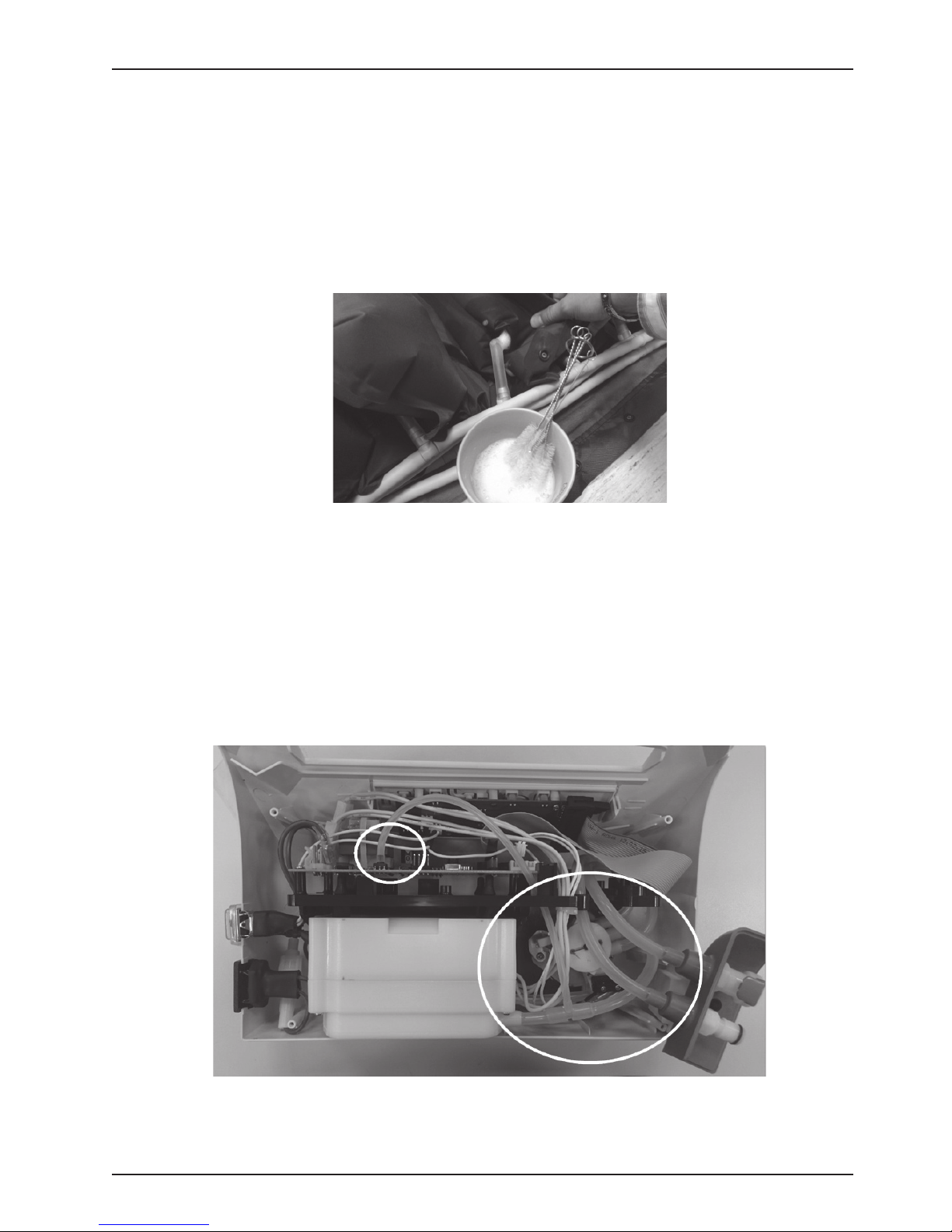

CHECK INTERNAL TUBING

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Inspect for the tubing connections. Make sure that each tube is attached to its connector.

www.stryker.com 836 00 4 -5 210 V1.1 5

Page 8

Service

FUSE REPLACEMENT

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Push the fuse holder together with turning counterclockwise to open it.

3. Replace the fuse and discard the old one.

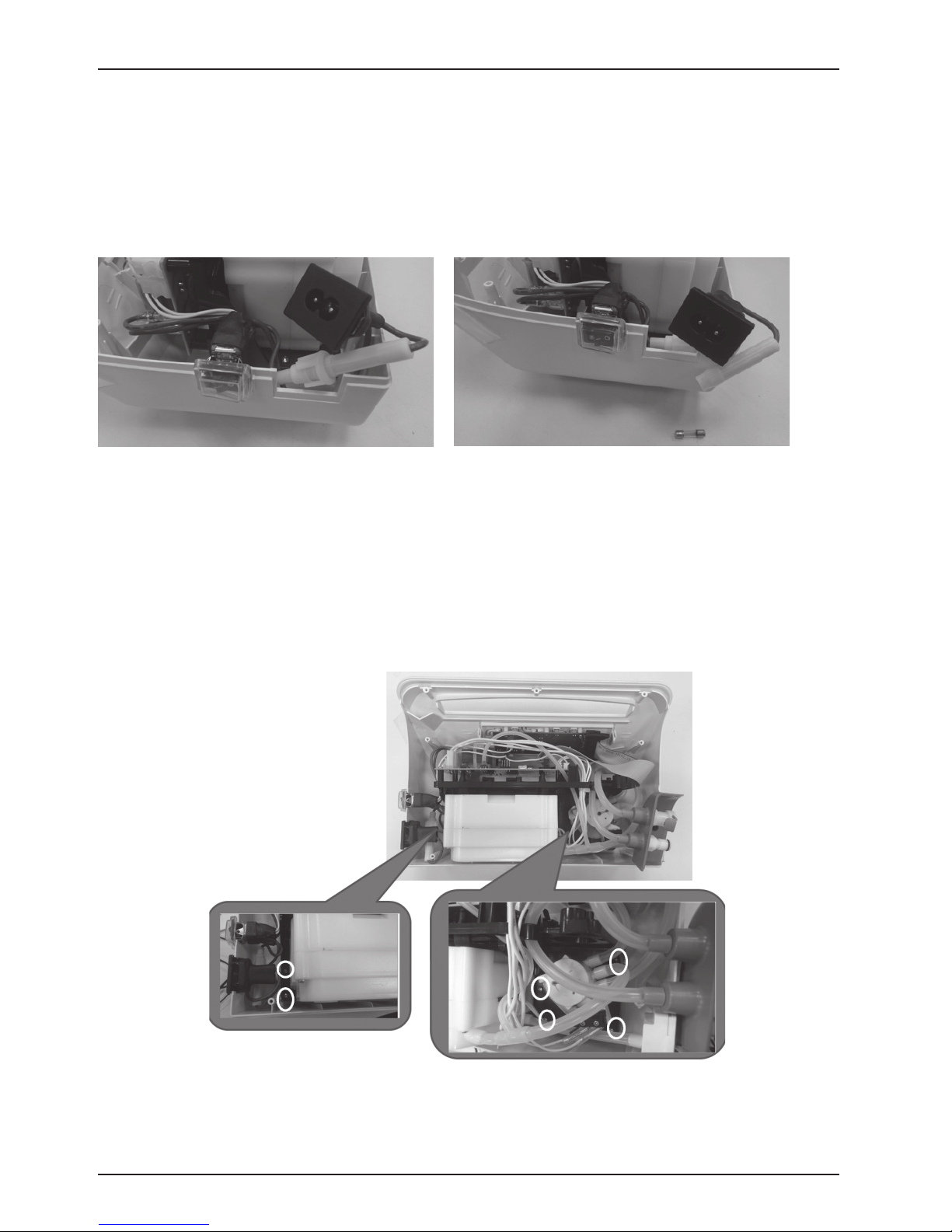

MAIN PCBA REPLACEMENT

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Remove 6 screws on the base.

6 836 00 4 -5 210 V1.1 www.stryker.com

Page 9

Service

3. Remove wire connections between power switch and main PCBA, front panel PCBA and main PCBA .

Take out the module set from the case.

4. Remove the 2 screws and all wire connections on the main PCBA.

5. Take out the main PCBA. Replace with a new one and discard the old one.

6. The wire connections on the main PCBA are as below.

7. After replacement, perform pressure calibartion. Refer to Pressure Calibration section.

www.stryker.com 836 00 4 -5 210 V1.1 7

Page 10

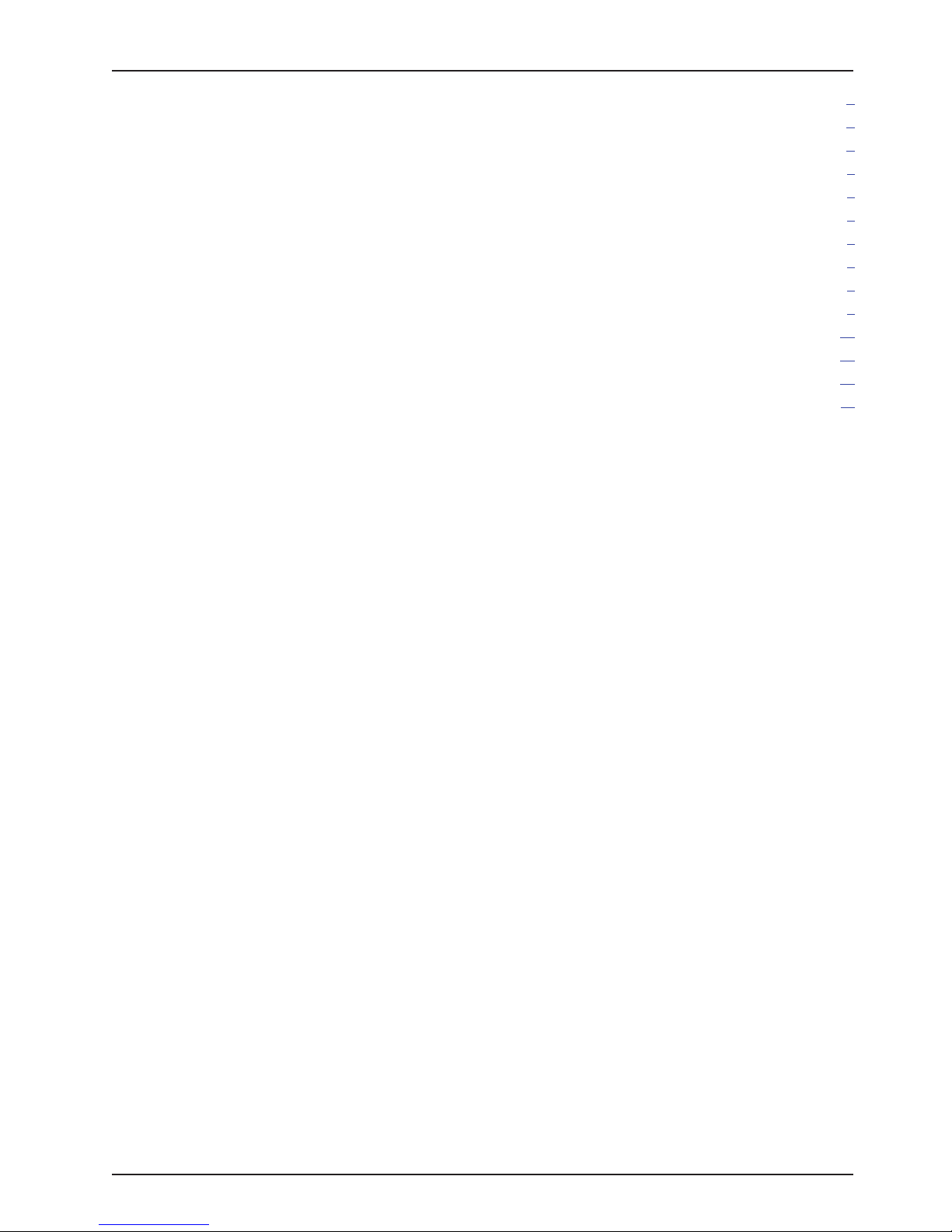

Service

TIMING MOTOR MODULE REPLACEMENT

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Remove the tubes and wire connections from timing motor module.

3. Remove the 2 screws on the motor assembly.

4. Remove the wire of timing motor module from the main PCBA.

5. Take out the timing motor module. Replace with a new one and discard the old one.

8 836 00 4 -5 210 V1.1 www.stryker.com

Page 11

Service

MICRO SWITCH REPLACEMENT

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Remove the wire connections from micro switch.

3. Remove the 2 screws on the micro switch and then take out the micro switch. Replace with a new one

and discard the old one.

www.stryker.com 836 00 4 -5 210 V1.1 9

Page 12

Service

FRONT PANEL PCBA REPLACEMENT

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

PROCEDURE:

1. Remove the 8 rubber stops. Using a Philips screwdriver, remove the 8 screws that hold the rear case.

Remove the rear case.

2. Remove the tubes and wire connections from front panel PCBA.

3. Remove the 5 screws on the front panel PCBA.

FILTER REPLACEMENT

PROCEDURE:

1. Open the filter case. 2. Take out the filter. Replace with a new one and discard the old one.

10 836 00 4 -5 210 V1.1 www.stryker.com

Page 13

Service

PRESSURE CALIBRATION

TOOLS REQUIRED:

● Phillips screwdriver for M3 screws

● Syringe

● Pressure meter

● Tubing

Note: Pressure Meter suggested

Specification

±2psi or ±5psi range

Resolution: 0.001psi

Accuracy: ±0.3% FS

PROCEDURE:

1. Take out the 8 rubbers and unscrew 8 screws on the rear case. Remove the rear case.

2. Connect the deivce to power supply and switch on power switch.

3. In order press ABCA, then it goes into calibration mode.

ABC

4. For timing motor to be in position, there will be a long beep.

5. Press “A”. There will be a long beep.

6. After 10 seconds, press “A” again. There will be a long beep.

7. Remove the sensor tube from the main PCBA.

8. Connect the tubing of the calibration tool onto the sensor on the main PCBA.

www.stryker.com 836 00 4 -5 210 V1.1 11

Page 14

Service

9. Push (or pull) the loading piece of the syringe until the pressure meter shows and holds 10 mmHg, and

then press “A”. There will be a long beep.

10. Push (or pull) the loading piece of the syringe until the pressure meter shows and holds 33 mmHg, and

then press “A”. There will be a long beep.

11. Push (or pull) the loading piece of the syringe until the pressure meter shows and holds 63 mmHg, and

then press “A”. There will be a long beep. After about 5 seconds, another long beep (total 2 beeps). The

calibration is completed.

12. Switch off the power.

13. Remove the calibration tubing and put the sensor tube on senor.

14. Close the rear case and tighten all screws.

Note: Once you displace the main PCBA, you must complete the pressure calibration and pressure

test.

12 8 36 004 -5210 V1.1 ww w.stryker.com

Page 15

Service

PRESSURE TEST

TOOLS REQUIRED:

● Air cells with air loss x2

● Pressure meter

● PVC tubes and connector.

Note: Pressure Meter suggested

Specification

±2psi or ±5psi range

Resolution: 0.001psi

Accuracy: ±0.3% FS

PROCEDURE:

1. Connect the pressure test tool to the pump.

Photo is for reference only

2. Switch on power

3. After inflation is completed, change mode to “Static”.

4. Choose leve1, and after the pressure is stable, check the pressure meter. The pressure should be 20 ±

3 mmHg.

5. Choose level 5, and after the pressure is stable, check the pressure meter. The pressure should be 32

± 5 mmHg.

Note: If the pressure is out of range, please repeat the calibration process.

www.stryker.com 836 00 4 -5 210 V1.1 13

Page 16

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

USA

Stryker European Operations B.V.

Herikerbergweg 110

Amsterdam

110 1 CM

Netherlands

2 017/10

836 00 4 -5 210 V1.1

www.stryker.com

Loading...

Loading...