Page 1

DRAFT

DRAFT

CrossFlow™ Integrated Arthroscopy Pump

0450000000

Page 2

DRAFT

Page 3

Table of Contents

Warnings ...........................................................................................................................................3

Operator Prole �������������������������������������������������������������������������������������������������������������������������������������������� 3

Prior to Surgery ��������������������������������������������������������������������������������������������������������������������������������������������� 3

During Surgery ��������������������������������������������������������������������������������������������������������������������������������������������� 4

After Surgery ��������������������������������������������������������������������������������������������������������������������������������������������������4

Cautions ............................................................................................................................................5

About Your Product .........................................................................................................................6

Product Description/Intended Use ��������������������������������������������������������������������������������������������������������6

Indications ������������������������������������������������������������������������������������������������������������������������������������������������������ 7

Contraindications ����������������������������������������������������������������������������������������������������������������������������������������� 7

Package Contents ���������������������������������������������������������������������������������������������������������������������������������������� 7

Part Numbers and Available Accessories* ������������������������������������������������������������������������������������������ 7

Approved Resection Consoles ����������������������������������������������������������������������������������������������������������������7

Front Panel ������������������������������������������������������������������������������������������������������������������������������������������������������8

Rear Panel �������������������������������������������������������������������������������������������������������������������������������������������������������8

Setup and Device Conguration ..................................................................................................9

Operation ........................................................................................................................................12

Starting a Procedure ���������������������������������������������������������������������������������������������������������������������������������12

During a Procedure �����������������������������������������������������������������������������������������������������������������������������������15

After a Procedure ���������������������������������������������������������������������������������������������������������������������������������������18

DRAFT

Menu Features ...............................................................................................................................20

Opening and Closing the Main Menu ������������������������������������������������������������������������������������������������20

Programming the Wash and Clear Functions Settings ��������������������������������������������������������������������������������� 20

Programming the Resection Integration Settings �������������������������������������������������������������������������21

Programming the Footswitch and Formula Shaver Settings �����������������������������������������������������22

Loading User Preference Files����������������������������������������������������������������������������������������������������������������24

Navigating to the Settings Menu ���������������������������������������������������������������������������������������������������������25

Navigating to the Help Menu ����������������������������������������������������������������������������������������������������������������27

System Feedback ...........................................................................................................................27

Audible Feedback ��������������������������������������������������������������������������������������������������������������������������������������27

Error Messages ��������������������������������������������������������������������������������������������������������������������������������������������27

Troubleshooting ............................................................................................................................29

Cleaning, Maintenance, and Disposal .......................................................................................32

Clean the Components ����������������������������������������������������������������������������������������������������������������������������32

Replace the Fuses ���������������������������������������������������������������������������������������������������������������������������������������32

Perform Annual Inspection ��������������������������������������������������������������������������������������������������������������������33

Perform Preventive Maintenance and Calibration �������������������������������������������������������������������������35

Expected Life �����������������������������������������������������������������������������������������������������������������������������������������������35

Disposal ���������������������������������������������������������������������������������������������������������������������������������������������������������35

Technical Specications ...............................................................................................................36

Equipment Information ���������������������������������������������������������������������������������������������������������������������������36

EN-1

Page 4

Electromagnetic Compatibility �������������������������������������������������������������������������������������������������������������37

Regulatory Information ���������������������������������������������������������������������������������������������������������������������������38

Symbols and Terminology ...........................................................................................................40

DRAFT

EN-2

Page 5

Please read this manual and follow its instructions carefully� The words warning, caution, and note

carry special meanings and should be carefully reviewed:

• Warning: Indicates risks to the safety of the patient or user� Failure to follow warnings may result

in injury to the patient or user�

• Caution: Indicates risks to the equipment� Failure to follow cautions may result in product

damage�

• Note: Provides special information to clarify instructions or present additional useful information�

Warnings

Operator Prole

1� Federal (USA) law restricts this device to sale by or on the order of a physician�

2� The operator of the CrossFlow™ system should be a qualied health care professional having complete

knowledge of the use of this equipment and awareness of the risks associated with arthroscopic

procedures�

3� The operator of the system should be experienced in arthroscopic practices and techniques�

4� The operator of the system should read this manual thoroughly and be familiar with its contents prior to

operating the equipment�

DRAFT

Prior to Surgery

1� Carefully unpack the CrossFlow Integrated Arthroscopy Pump and ensure that all components listed in

the “Package Contents” section of this manual are accounted for and remain undamaged from shipment�

If damage to any component is detected, refer to the standard warranty�

2� Install the system in an operating room that complies with all applicable IEC, CEC, and NEC requirements

for safety of electrical devices�

3� Install and use the system according to the information provided in the “Electromagnetic Compatibility”

section of this manual�

4� If the pump is installed with other equipment in a stacked conguration, observe the pump to verify

normal operation�

5� Portable and mobile RF communications equipment may interrupt system operation� When the

pump is in use, the conducted and radiated electrical elds may interfere with other electrical medical

equipment� If this occurs, power down all electrical equipment not in use, increase distance of other

electrical equipment, and/or connect the pump and other equipment into dierent outlets�

6� Place the pump at the same height as the joint to ensure accurate pressure readings.

7� Ensure the proper connection of the primary power cord of the pump to a grounded receptacle with

the correct mains voltage� To prevent the risk of electric shock, do not use extension cords or portable

multiple socket outlets that are not a part of a certied hospital cart� The use of a portable multiple

socket outlet can lead to a reduced level of safety�

8� Position any cables extending from the pump to avoid contact with the patient, electrodes, other cables,

and any electrical leads which provide paths for high frequency current�

9� Do not connect items which are not specied as part of the system� The use of accessories, transducers,

and cables other than those specied in this manual may result in increased emissions, decreased

immunity of the equipment, or unintended, unsafe operation of the system�

10� Examine all electrical connections to the pump before use� Improper connection may result in

malfunction or unintended surgical eects�

11� Do not touch or insert any objects, other than the cassettes, inside of the cassette holders as this may

EN-3

Page 6

damage the pressure sensor or cause injury� Place only the cassettes in the cassette holders�

12� Set the alarm volume to a level that is audible in the operating room environment�

13� Ensure the system functions as outlined in this manual prior to a surgical procedure� The system was fully

tested at the factory before shipment�

During Surgery

1� Using uid to distend the joint carries the possibility of uid extravasation into surrounding tissue� Select

the optimal pressure based on the patient prole, including, but not limited to, blood pressure, height,

weight, age, and tissue quality� Recommended pressure settings are included in this manual; however,

these are only suggestions, and each surgery and each patient may require dierent parameters�

2� The Wash function may cause high pressure within the joint, which may lead to uid extravasation�

Carefully monitor joint pressure when using this function�

3� The Clear function may cause excessive uid usage� Monitor the use of this function and the uid level in

the irrigation bags�

4� Use the scope and cannula as selected on the pump� Incorrect scope and cannula use can cause

overpressure if it does not match the selected scope and cannula�

5� Start the pump with the inow tubing outside of the joint, all of the inow tubing clamps open, and no

hardware attached� Failure to remove air from the tubing can cause overpressure in the joint�

6� The pump is only intended for use with exible uid containers� Do not use glass containers as they

might implode due to the vacuum being generated inside of the container�

7� Do not use this system in the presence of oxidizing agents or ammable materials (e�g� anaesthetics,

gases, uids, skin prepping agents, and tinctures)� Observe appropriate re precautions at all times�

8� Keep the pump dry� If liquid has accidentally leaked into the pump from the cassette(s), change the

cassette(s), restart the system, and verify operation�

9� Keep the LCD screen and speaker in the eld of view and hearing at all times during use� These are

important safety features�

10� Failure of the system may result in an unintended increase or decrease in ow and/or pressure� Carefully

the monitor the joint when using the system�

11� Do not allow extended exposure of suction to tissue associated with procedures that require either no or

low-ow suction� Always consider the type of tissue associated with the surgical procedure before using

this system� Failure to comply may result in severe injury�

DRAFT

After Surgery

1� Do not remove the cover of the console as this could cause electric shock and product damage.

2� Disconnect the pump from the electrical output when cleaning, servicing, or inspecting fuses�

3� Do not make any internal repairs or adjustments� Units requiring repair should be returned to Stryker�

Decontaminate the pump and accessories prior to returning them to Stryker� Stryker may refuse to carry

out repairs if the products are contaminated�

4� Do not use ammable agents for cleaning and disinfecting the system�

5� Do not sterilize the pump�

6� Follow the instructions in the “Disposal” section of this manual to adequately dispose of system

accessories�

EN-4

Page 7

Cautions

1� No modication of this equipment is allowed�

2� Insert the cassette prior to spiking the saline bag� Failure to do so may damage the pump or the cassette�

3� Do not remove the cassettes while the pump is in use� The pump or the cassette may be damaged� The

cassettes can only be removed when the pump is stopped�

4� Stryker does not accept any liability for direct or consequential damages if:

• the pump or the accessories are used improperly,

• the instructions and rules in the manual are not followed,

• the pump or the accessories are improperly connected and maintained,

• non-authorized persons perform repairs, adjustments, or alterations to the pump or accessories,

• non-authorized persons open the pump,

• the prescribed inspection and maintenance schedules are not followed�

The warranty is void if any of these warnings or cautions is disregarded�

DRAFT

EN-5

Page 8

About Your Product

Product Description/Intended Use

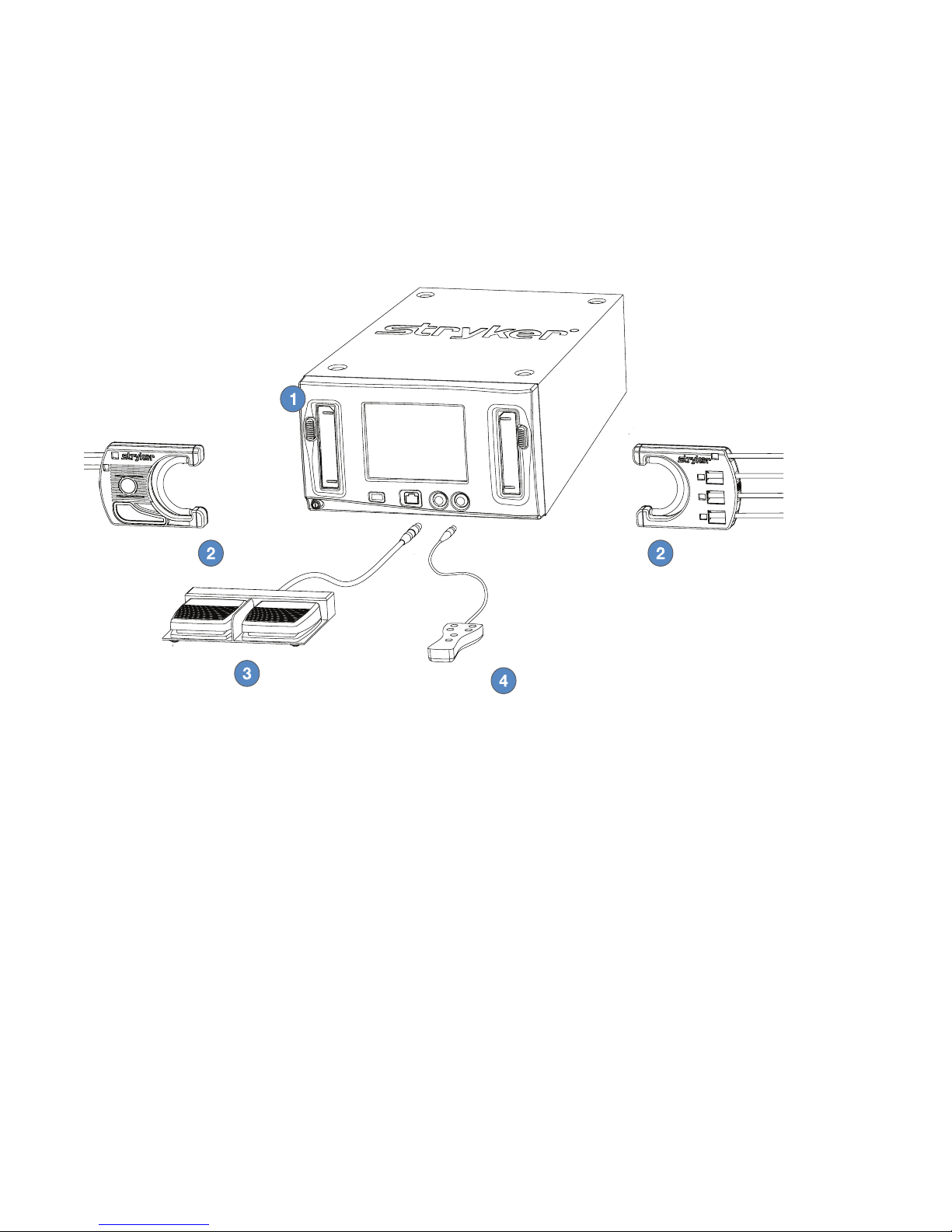

The Stryker CrossFlow Integrated Arthroscopy Pump is a uid management system� Illustrated below, the

system is composed of a pump console with inow-only and inow/outow modes, disposable cassette

tubing, a wired hand control, and a wired footswitch� The system integrates with approved resection

consoles�

DRAFT

1� CrossFlow Integrated Arthroscopy Pump (featured in this manual) - Compatible with the Crossre

Console, CrossFlow Footswitch, Autoclavable Hand Control, iSwitch Wireless Universal Foot Control,

Stryker rewire-compatible devices, and approved resection consoles�

2� CrossFlow Cassette Tubing - Compatible with the CrossFlow Integrated Arthroscopy Pump, 4-bag

adapter with inow cassettes, luer-lock connectors, standard irrigation uids, suction connectors, and

waste management systems� The user may elect to employ one of two modes of operation:

• Inow-Only Mode: utilizes only the inow function of the pump via the Inow Cassette Tubing or

the Day-Use Inow Cassette/Patient-Use Tubing

• Inow Cassette Tubing - The Inow Cassette Tubing transmits uid from saline bags to the

inow cannula at the surgical site and is disposed of after each case�

• Day-Use Inow Cassette/Patient-Use Tubing - The Day-Use Inow Cassette Tubing is used for

a single day’s cases, and the Patient-Use Tubing is connected to the Day-Use Inow Cassette

Tubing for a single case, then removed and discarded�

• Inow/Outow Mode: utilizes both the inow and outow functions of the pump via the Inow

Cassette Tubing and Outow Cassette Tubing�

3� CrossFlow Footswitch (optional) - Provides remote foot control of pump operation�

4� Autoclavable Hand Control (optional) - Provides remote hand control of pump operation�

EN-6

Page 9

Indications

The CrossFlow Integrated Arthroscopy Pump is a dual arthroscopic pump system intended to provide uid

distension and irrigation of the knee, shoulder, hip, elbow, and ankle and wrist joint cavities and uid suction

during diagnostic and operative arthroscopic procedures�

Contraindications

The use of the CrossFlow Integrated Arthroscopy Pump is prohibited whenever arthroscopy is

contraindicated�

Package Contents

Carefully unpack the CrossFlow Integrated Arthroscopy Pump and ensure all components are accounted

for and remain undamaged from shipment� If damage to any component is detected, refer to the standard

warranty�

• (1) CrossFlow pump

• (1) Hospital power cord

• (2) Approved resection console power cord

• (1) User manual

• (1) Warranty and return policy

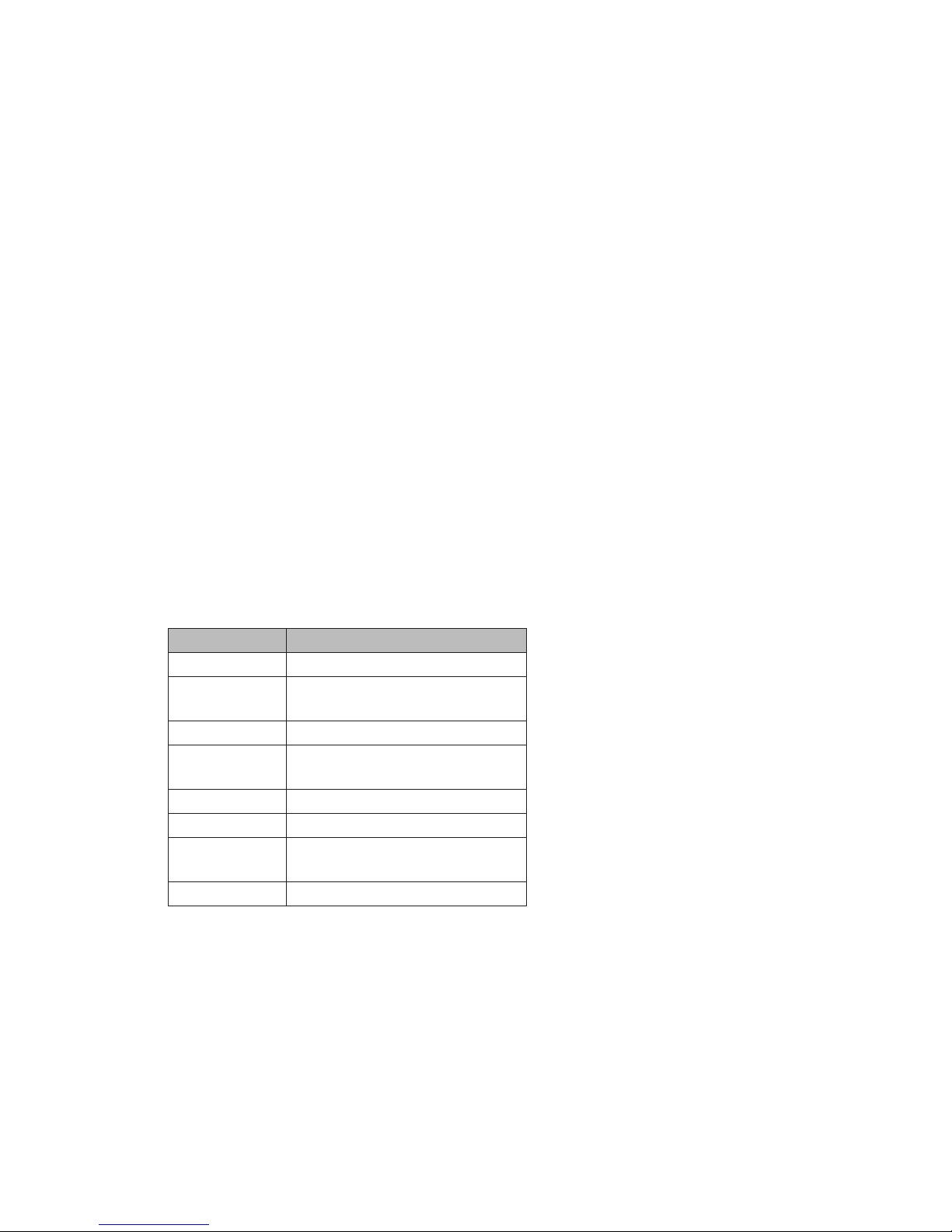

Part Numbers and Available Accessories*

The CrossFlow Integrated Arthroscopy Pump is featured in this manual� Refer to individual manuals for all

other products and accessories�

DRAFT

Part Number Description

0350220000 Autoclavable Hand Control*

0450000000 CrossFlow Integrated Arthroscopy

Pump

0450000100 CrossFlow Inow Cassette Tubing

0450000110 CrossFlow Day-Use Inow Cassette

Tubing

0450000120 CrossFlow Patient-Use Tubing

0450000200 CrossFlow Outow Tubing

0450000300 CrossFlow Integrated Cassette

Tubing

0450000500 CrossFlow Footswitch*

Approved Resection Consoles

The CrossFlow system is compatible with the following consoles� (Contact Stryker Endoscopy for

compatibility requirements for any non-approved resection consoles�)

• Arthrex APS II • Dyonics Power • Stryker CORE

• Arthrex OPES • Dyonics Power II • Stryker SERFAS

• Arthrocare ATLAS • Linvatec Advantage • Stryker TPS

• Arthrocare Quantum • Mitek VAPR

• Arthocare Quantum II • Smith and Nephew Vulcan

EN-7

Page 10

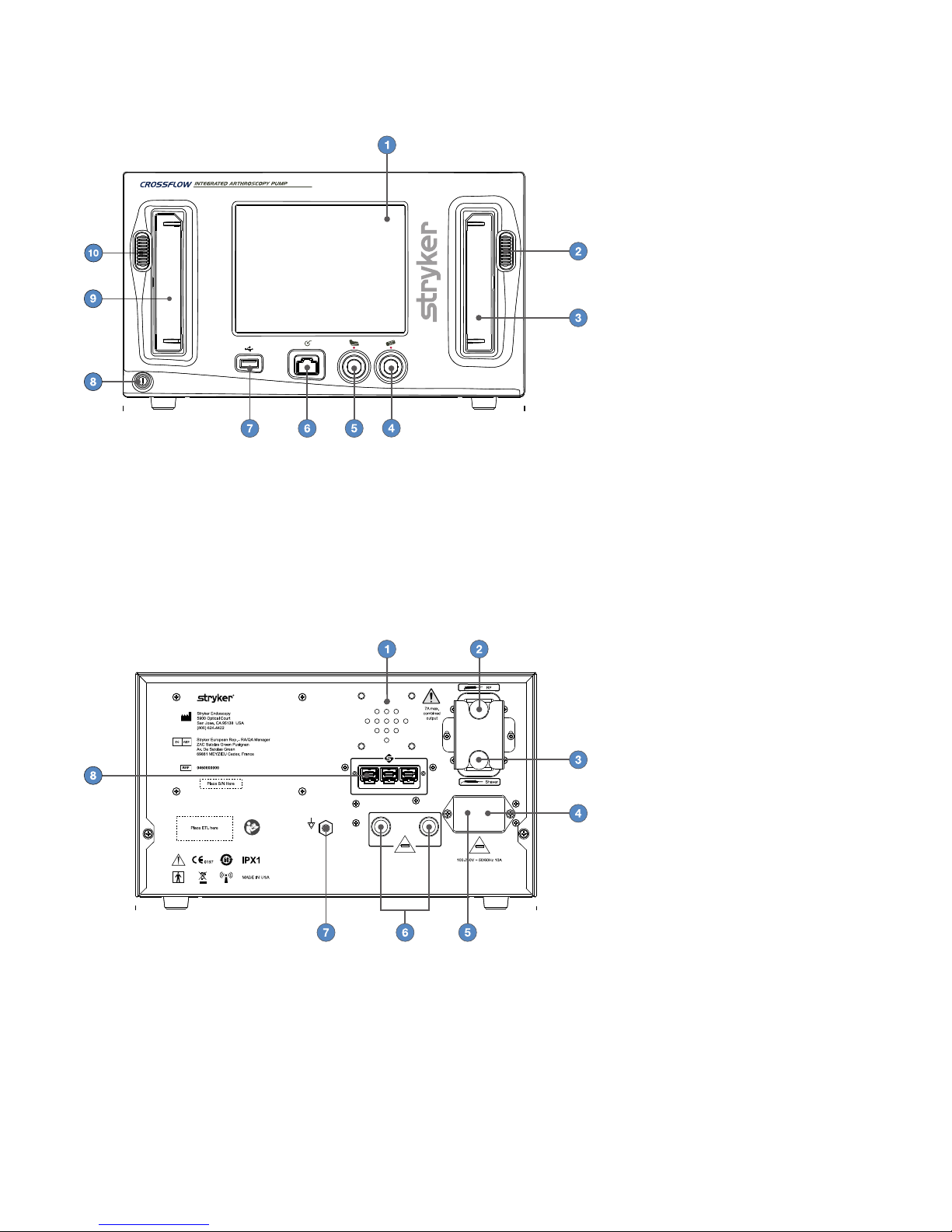

Front Panel

1� LCD Touchscreen 2� Outow Cassette Ejection Button

3� Outow Cassette Holder 4� Hand Control Receptacle

5� Footswitch Receptacle 6� Auxiliary Receptacle

7� USB Port 8� Power Button

9� Inow Cassette Holder 10� Inow Cassette Ejection Button

DRAFT

Rear Panel

FCC ID: SSH-XFLOW

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

IC: 4919C-XFLOW

1� Speaker 2� Power Outlet for Approved Resection RF

3� Power Outlet for Approved Resection

Shaver Console

5� Fuse Drawer 6� Global Fuse Holders

7� Equipotentiality Ground Plug 8� SFB Connector Ports

T10A 250V

T3A 250V

Console

4� AC Power Inlet

EN-8

Page 11

Setup and Device Conguration

Stryker Endoscopy considers instructional training an integral part of the CrossFlow system� Your Stryker

Endoscopy representative will perform at least one in-service at your convenience to help you set up your

equipment and instruct you and your sta on its operation and maintenance� Please contact your local

Stryker Endoscopy representative to schedule an in-service after your equipment has arrived�

1� Choose a location for the CrossFlow pump�

• Place the pump on a Stryker cart or other sturdy platform near a hospital grade outlet�

• Place the pump at the same height as the joint to ensure accurate pressure readings.

• Provide at least four to six inches of space around the sides of the pump to ensure proper ventilation

and allow access to the power cord�

Warning

RF and other mobile communications equipment may aect the normal function of the

CrossFlow pump� When placing the pump, follow the instructions located in the “Electromagnetic

Compatibililty” section of this manual�

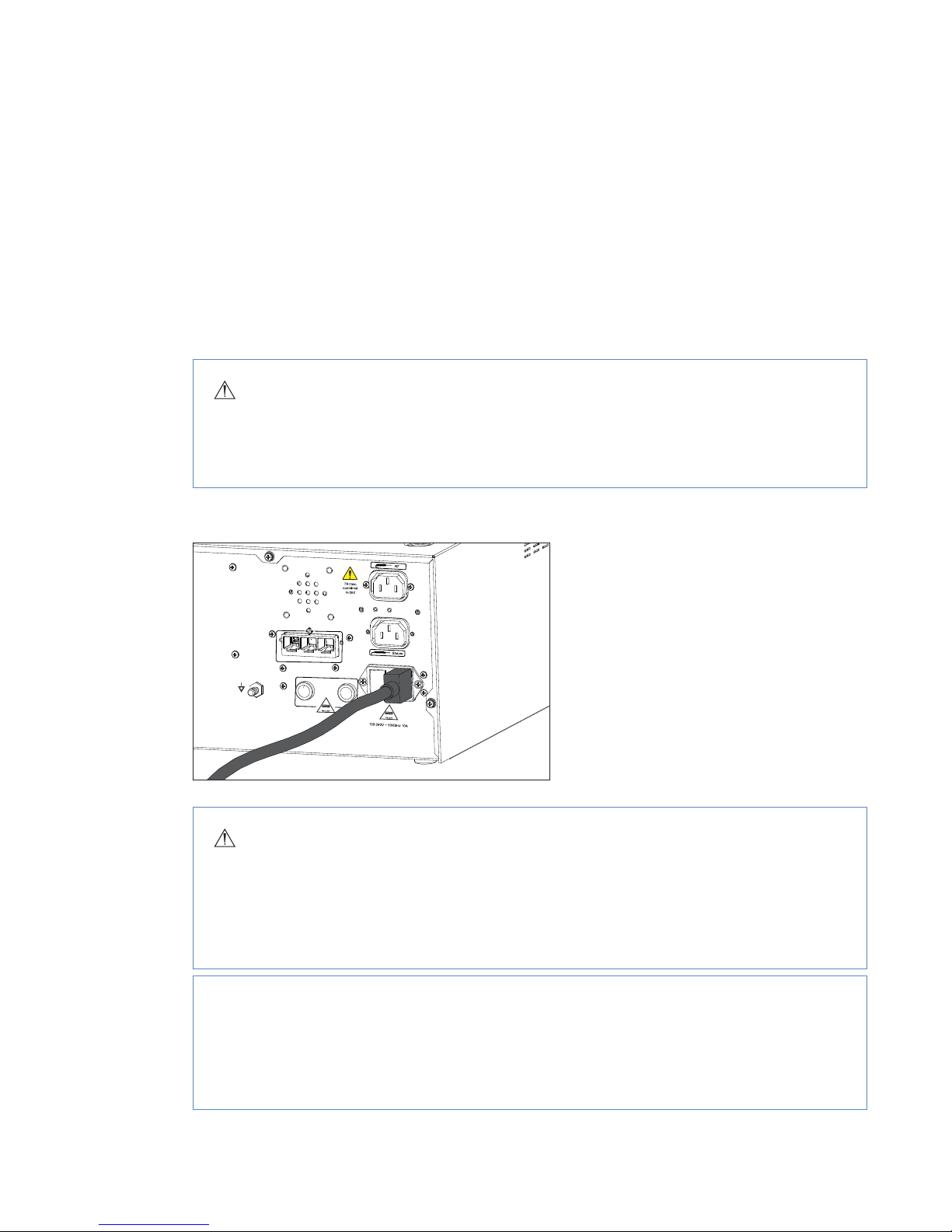

2� Connect the AC power�

• Connect the provided hospital power

DRAFT

cord to the AC inlet on the rear console

panel�

• Connect the other end to a hospital-grade

power outlet�

Warning

• Check the device label on the rear of the pump to determine the operating voltage of the

device�

• Check the power cord assembly periodically for damaged insulation or connectors�

• To avoid risk of electric shock, this equipment must only be connected to a supply mains with

protective earth�

Caution

• When connecting or disconnecting a cable, hold the cable by its connector (its plug, not the

cord)� Failure to comply may result in damage to the cable or pump�

• Connect the power cords directly to the AC inlet or outlet� Do not connect any of the power

cords together�

If required, connect the pump to a Stryker Firewire-compatible device using one of the SFB connector

EN-9

Page 12

ports on each device�

Note: Refer to the manual supplied with each Firewire-compatible device for connection information�

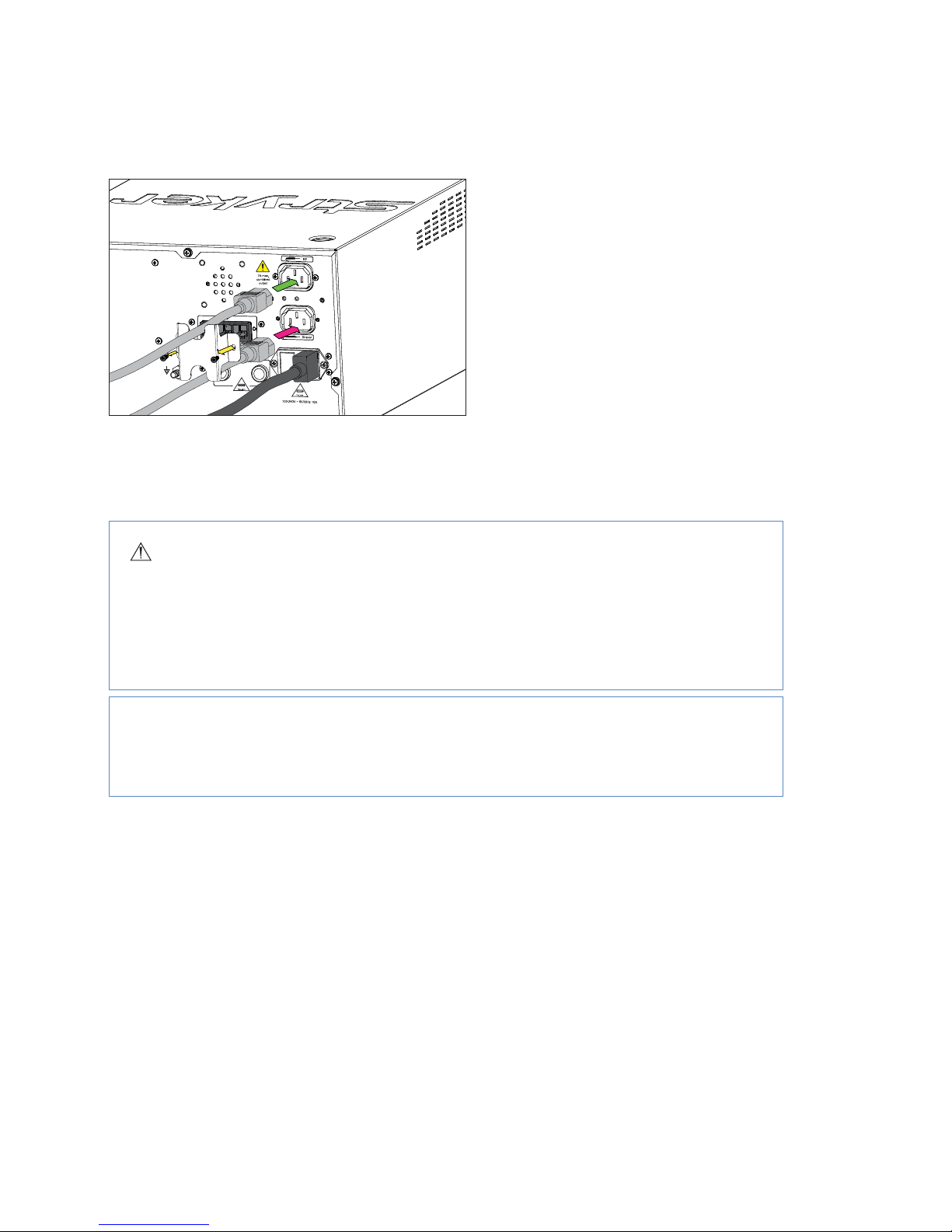

3� If required, connect the approved resection console(s) according to the interconnection diagram�

• Using a #1 Phillips screwdriver, unscrew

and remove the power cord bracket�

• Connect the approved resection power

cord to the AC inlet on the approved

resection console� Refer to the manual

supplied with each approved console for

connection information�

• Connect the other end to the power cord

to the power outlet for the approved

resection console on the rear panel of the

CrossFlow pump, as marked�

• Using a #1 Phillips screwdriver, attach and

secure the power cord bracket�

Note: The pump’s screen will display the specic components that are connected when the device is

powered on�

Warning

When the CrossFlow pump is interconnected with other electrical devices, leakage currents may

be additive, resulting in electromagnetic emissions that can interfere with the normal function

of electronic medical equipment� To properly control electromagnetic emissions and avoid

potential harm to the patient or user, ensure all electrical devices are installed and interconnected

according to the requirements of IEC 60601-1-1�

Caution

Ensure the approved resection consoles are connected to the correct power outlets on the rear

panel of the pump�

DRAFT

EN-10

Page 13

4� If required, connect the hand control, footswitch, and/or USB drive according to the interconnection

diagram�

Note: Stryker recommends using the SIDNE USB2�0 Flash Disk, 512MB (P/N 0105-201-529)�

Note: The pump’s screen will display the specic components that are connected when the device is

powered on�

Caution

• Do not connect an ethernet cable to the auxiliary port�

• Turn the connector of the hand control and footswitch so that the red dot points up�

• Do not thread or twist the cable connector for insertion or removal� It is a push/pull connector

and may be damaged by twisting it into or out of place�

5� For tubing connection instructions, refer to the CrossFlow Inow and Outow Cassette Tubing and the

CrossFlow Day-Use Inow Cassette and Patient-Use Tubing manuals�

DRAFT

EN-11

Page 14

Operation

Note: Refer to the “Symbols and Terminology” section in this manual for button and icon denitions and

commonly used terms�

Starting a Procedure

To start a procedure, perform the following steps:

1� Power the Pump On and O

2� Insert the Inow/Outow Cassette

3� Select the User Preference File

4� Select the Joint

5� Prime the Inow Tubing and Operate the Pump

Power the Pump On and O

1� Press

the front panel to power on the pump� When

this button is illuminated by a green LED, the

system is powered on� The pump will display

a splash screen while the software is loading�

2� To power o the system, press

located at the bottom left corner of

DRAFT

Insert the Inow/Outow Cassette

Warning

The choice of irrigation uid should be determined by the physician, based on the operation method

to be employed�

Caution

again�

The cassettes are color-coded� When inserting the cassettes, make sure to insert them as indicated by

the color-coding�

EN-12

Page 15

1� Align the colored side of the cassette(s)

with the colored button(s) on the pump as

depicted in the diagram� The Inow Cassette

is blue and the Outow Cassette is red�

2� Insert the cassette(s)� Push with your thumb

until it clicks into place�

• When the Inow Cassette is inserted,

a green check mark will appear on the

cassette, and the screen will advance to

the User Preference File Selection screen�

• When the Outow Cassette is inserted,

“Outow” will appear at the bottom of the

screen� A green check mark will appear

on the cassette if it is inserted before the

DRAFT

3� Connect the tubing:

Inow Cassette (depicted in this scenario)�

• For the Inow and Outow Cassette

Tubing, refer to the instructions in the

CrossFlow Inow and Outow Cassette

Tubing manual�

• For the Day-Use Inow Cassette

and Patient-Use Tubing, refer to the

instructions in the CrossFlow Day-Use

Inow Cassette and Patient-Use Tubing

manual�

Select the User Preference File

User preference les can be selected through the CrossFlow Pump interface� Select from “Standard Settings”

provided with the pump, or contact your Stryker representative to program your own, including settings for

pressure and ow rate and button assignments for the hand control and footswitch�

EN-13

Page 16

Select the Joint

1� To scroll up and down the user preference le

list, press

2� Press the name of the desired user preference

le to highlight it�

In this scenario, “Doctor 1” is highlighted�

3� When the desired user preference le is

highlighted, press

selection and advance to the next screen�

1� Select the joint:

• Press

• Press

• Press

• Press

2� When the desired joint is highlighted, the

screen will advance to the next screen�

Note: Press

preference le selection screen�

and

to select the shoulder;

to select the knee;

to select the hip;

to select the small joint�

�

to conrm the

to return to the user

DRAFT

Prime the Inow Tubing and Operate the Pump

Warning

• Start the pump with the inow tubing outside of the joint, all of the inow tubing clamps open,

and no hardware attached� Failure to remove air from the tubing can cause overpressure in the

joint�

1� Press

to

inow tubing�

Note: This step must be performed each time

a new Inow Cassette is inserted into the

pump�

remove air from the

EN-14

Page 17

1� Press

2� Once the air has been removed and tubing is

3� Open the pinch clamps or stopcock to

4� Press

to

inow tubing� The

the pump is operating�

Note: This step must be performed each time

a new Inow Cassette is inserted into the

pump�

completely lled with uid, close the pinch

clamps or stopcock�

proceed with pump operation�

remove air from the

icon indicates that

to start/stop the pump�

During a Procedure

Changing the Pressure and Flow

Note: Follow these instructions to select or change pressure and ow settings if the user preference le does

not specify these settings� Adjusting the settings will override the default and user preference le settings�

The system will select the following default settings for the following application areas:

Joint Default Settings

Knee 45mmHg

Shoulder 50mmHg

Hip 50mmHg

Small 35mmHg

DRAFT

Note: Default pressure settings are only suggestions, and each procedure and each patient may require

dierent parameters� Select the optimal pressure based on the patient prole, including, but not limited to,

blood pressure, height, weight, age, and tissue quality�

1� If necessary, press

or decrease the Set Pressure (adjust in

increments of 5mmHg from 15–150mmHg)

and Flow or Suction (adjust in increments of

10% from 0–100%)�

In this scenario, the pump is operating in

Inow/Outow mode� The Set Pressure is set

at 45mmHg, and the Suction is set at 50%�

Note: A green box will surround the suction/

ow value when the pump reaches the ow

limit� The pump is operating in constant ow

mode� Once the ow limit is reached, it will

operate in constant ow mode� (The pump

will attempt to operate at the set pressure

until the ow limit is reached�)

and

to increase

EN-15

Page 18

Changing the User Preference File or Joint Selections

1� If the pump is running, press

stop the pump�

2� Press

the screen�

3� Press

le selection menu� Press

the Run Screen�

4� Follow the instructions in the “Select the User

Preference File” and “Select the Joint” section

to change the user preference le and/or

joint�

Changing the Hardware Combination Selections

Note: Adjusting the settings will override the default and user preference le settings�

The system will select the following default hardware combination if “Standard Settings” is selected:

Hardware

option

Alternate hardware combination

selections

Low Flow x ≤ 1

Medium Flow 1 > x ≥ 2

High Flow x > 2

Joint Default combination

Knee Stryker 5�8mmx140mm cannula with 4�0mm scope

Shoulder Stryker 5�8mmx140mm cannula with 4�0mm scope

Hip Stryker 5�0mmx165mm cannula (bridge) with 4�0mm scope

Small Stryker 4�0mmx75mm cannula with 2�7mm scope

— None

DRAFT

Cannula diameter-scope diameter = x

in the lower left-hand corner of

to return to the user preference

to return to

to

Note: If the user preference le does not specify a hardware combination, follow these instructions to

change a hardware combination�

EN-16

1� If the pump is running, press

stop the pump�

2� Press the hardware combination selection to

return to the hardware combination selection

menu�

to

Page 19

3� Select the scope/cannula combination

for option

hardware combination list, press

4� Press the desired hardware combination to

highlight it�

In this scenario, “5�8mmx140mm cannula

with 4�0mm scope” is highlighted� (Select

Low, Medium, or High Flow if the desired

hardware combination does not appear on

the list�)

5� If no other hardware combination options are

required, proceed to step 6�

6� If necessary, press

combinations for these options�

Note: Hardware

enabled if the hip joint is selected�

7� Repeat steps 3 and 4 to select the scope/

cannula combination for options

and/or

In this scenario, “4�0x120mm cannula with

2�7mm scope” is highlighted for option

DRAFT

8� When the desired hardware combinations

are highlighted, press

selections and advance to the Run screen�

;

�

to view the available scope/cannula

�

to scroll up and down the

and

,

and

, and/or

are only

,

to conrm the

,

�

Swapping Between Hardware Combination Selections During the Case

The “Hot Swap” function allows the user to switch the cannula through which the inow tubing is attached

without requiring recalibration� Depending on the surgical site, up to four cannulas can be utilized by this

function�

Warning

Use the scope and cannula as selected on the pump� An incorrect scope and cannula selection may

cause overpressure in the joint�

EN-17

Page 20

1� Press

box will briey appear displaying the new

hardware combination selection�

2� Ensure the correct hardware combination

is displayed� If the incorrect hardware

combination selection is displayed, or to

change the hardware combination selection,

follow the instructions in the “Change

Hardware Combination Selections” section�

3� Press

combination

Performing the Wash Function

The Wash function increases the set pressure and ow limit by a user-specied percentage over a userspecied duration (for Inow-only mode), or increases set pressure and suction by a user-specied

percentage over a user-specied duration (for Inow/Outow mode)�

to change to option

to change to hardware

�

� A green

1� While the pump is running, press

perform the Wash function� Follow the

instructions in the “Program the Wash and

Clear Function Settings” section to adjust the

default settings�

2� Press

DRAFT

Performing the Drain Function

The Drain function is only available in the Inow/Outow mode� It operates the outow pump to remove

uid from the surgical site for 30 seconds or until the user stops the pump�

1� Press

2� Press

3� Press

to

to remove uid from the joint�

to repeat or stop the Drain function�

stop the pump�

function�

to repeat or stop the Wash

to

After a Procedure

Remove the Cassettes

Caution

• Do not remove the cassettes while the pump is in use� The pump or the cassette may be damaged�

The cassettes can only be removed when the pump is stopped�

• Do not attempt to remove the Outow Cassette if it gets stuck as it may damage the pump or the

cassette� Follow the instructions in the “Troubleshooting” section in this manual to resolve this

problem�

1� Press

2� Close all pinch clamps�

EN-18

to

stop the pump�

Page 21

3� Refer to the CrossFlow Day-Use Inow Cassette and Patient-Use Tubing and the CrossFlow Inow and

Outow Cassette Tubing manual on instructions on how to disconnect and discard the tubing� Always

maintain a sterile technique�

4� Press the Inow Cassette Ejection button (blue) and/or the Outow Cassette Ejection button (red) on the

front panel of the pump to eject the cassette(s)�

5� Discard the cassettes and tubing appropriately�

DRAFT

EN-19

Page 22

Menu Features

Opening and Closing the Main Menu

1� If the pump is running, press

stop the pump�

2� Press

3� Press

to open the Main Menu�

to close the Main Menu�

to

Programming the Wash and Clear Functions Settings

Note: Adjusting the settings will override the default and user preference le settings�

DRAFT

1� Press

2� Press

Setting Function

Wash • Inow-only mode: Increases set pressure and ow limit by user-specied percentage over

Clear • Inow-only mode: Increases ow limit by user-specied percentage over user-specied

to open the Main Menu�

to open the Wash and Clear Settings Menu�

user-specied duration� By default, the set pressure will increase by 50% of the current

setting, and the ow limit will increase by 100% of the current setting for 30 seconds�

• Inow/Outow mode: Increases set pressure and suction by user-specied percentage

over user-specied duration� By default, the set pressure will increase by 50% of the current

setting, and the suction will increase by 100% of the current setting for 30 seconds�

duration� By default, the ow limit will increase by 100% of the current setting for 30

seconds�

• Inow/Outow mode: Increases suction rate by user-specied percentage over userspecied duration� By default, the outow will increaseby 100% of the current setting for

30 seconds�

EN-20

Page 23

Wash Function Settings

Clear Function Settings

1� Press to program the settings for the

Wash function�

2� Press and to adjust the Pressure,

Flow, or Duration�

In this scenario, the pressure will increase by

50% and the ow will increase by 100% for 30

seconds�

1� Press

Clear function�

2� Press

Duration�

In this scenario, the ow will increase by 100%

for 30 seconds�

to program the settings for the

and

to adjust the Flow or

DRAFT

Programming the Resection Integration Settings

Note: Adjusting the settings will override the default and user preference le settings�

1� Press

2� Press

to open the Main Menu�

to open the Resection Integration Settings Menu�

EN-21

Page 24

Shaver Console Settings

RF Console Settings

1� Press

• Press

• Press

• Press

In this scenario, the CrossFire console is

selected�

2� Press

the Suction (adjust in increments of 10% from

0–100%)�

In this scenario, the Suction is set at 50%�

1� Press

• Press

• Press

DRAFT

• Press

In this scenario, an approved resection

console with a suction probe is selected�

2� Press

the Suction (adjust in increments of 10% from

0–100%)�

In this scenario, the Suction is set at 50%�

to specify the shaver console:

console;

resection console;

use�

and

to specify the RF console:

console;

resection console

(Press “Suction” if the RF probe is a suction

probe�);

and

to select the CrossFire

to select an approved

if no shaver console is in

to increase or decrease

to select the CrossFire

to select an approved

if no RF console is in use�

to increase or decrease

Programming the Footswitch and Formula Shaver Settings

1� Press

2� Press

Setting Function

Wash • Inow-only mode: Increases set pressure and ow limit by user-specied

Clear • Inow-only mode: Increases ow limit by user-specied percentage over user-

Drain • Operates the outow pump to remove uid from the surgical site for 30

EN-22

to open the Main Menu�

to open the Footswitch/Formula Shaver Settings Menu�

percentage over user-specied duration�

• Inow/Outow mode: Increases set pressure and suction by user-specied

percentage over user-specied duration�

specied duration�

• Inow/Outow mode: Increases the suction by user-specied percentage over

user-specied duration�

seconds or until the user stops the pump�

Page 25

Pressure Up/Down • Increases/decreases the set pressure�

Hot Swap • Switches between selected arthroscope/cannula combinations�

Start/Stop • Starts/stops the pump�

Flow Up/Down • Inow-only mode: Increases/decreases the ow limit�

• Inow/Outow mode: Increases/decreases suction�

None • No function�

CrossFlow Footswitch

iSwitch Footswitch

1� Press the CrossFlow button

settings for the CrossFlow Footswitch�

2� Press the black foot pedal (highlighted with

green border) to select its function�

3� Press

function list�

4� Press the function of choice to assign the

function to the pedal�

In this scenario, the “Wash” function is

selected�

5� Repeat steps 2–4 to program the red foot

pedal�

and

DRAFT

1� Press the iSwitch icon

settings for the iSwitch Footswitch�

2� Press the appropriate button/pedal

(highlighted with green border) to select its

function�

3� Press

function list�

4� Press the function of choice to assign the

function to the button/pedal�

In this scenario, the “Flow Up” function is

selected for Button I�

5� Repeat step 2–4 to program each button/

pedal�

and

to program

to scroll up and down the

to program

to scroll up and down the

EN-23

Page 26

Crossre Footswitch

Formula Shaver

1� Press the Crossre icon

settings for the Crossre Footswitch�

2� Select a button/pedal in the left-hand menu

to program it�

Note: Only one button or pedal may be

assigned a function�

3� Press

function list�

4� Press the function of choice to assign the

function to the button/pedal�

In this scenario, the “Wash” function is

selected for Button I�

1� Press the Formula icon

settings for the hand control�

2� Select a button in the left-hand menu to

DRAFT

program it�

In this scenario, Button III is selected�

Note: Only one button or pedal may be

assigned a function�

3� Press

function list�

4� Press the function of choice to assign the

function to the button/pedal�

In this scenario, the Flow Down is selected for

Button III�

and

and

to scroll up and down the

to scroll up and down the

to program

to program

Loading User Preference Files

1� Press

2� Press

EN-24

to open the Main Menu�

to open the User Preference Menu�

Page 27

Transferring Files to/from a USB drive

1� Press

USB drive�

2� Connect the USB drive according to the

instructions in the “Setup and Device

Conguration” section�

3� Press

le list�

4� Select the le to transfer or delete�

In this scenario, the “Doctor 1” le is selected�

5� Press

the USB drive to/from the pump�

6� Press

delete the selected le�

7� To delete the selected le, press

cancel the operation, press

to upload/download les to/from a

and

and

below the USB or pump list to

DRAFT

to scroll up and down the

to transfer les to/from

� To

�

Transferring Files to the Crossre System

Navigating to the Settings Menu

1� Press

2� Press

to open the Main Menu�

to open the Settings Menu�

1� Press

the Crossre system�

2� Press

le list�

3� Select the le to transfer�

Note: Only preference les containing

Crossre settings will appear in this menu�

4� Press

system�

to transfer a user preference le to

and

to transfer the le to the Crossre

to scroll up and down the

EN-25

Page 28

Adjusting the Volume, Brightness, and Language, and Upgrade Software

Adjusting the Actual Pressure Display

DRAFT

1� Press

Menu�

2� Adjust the Volume

3� Adjust the Brightness

4� Press

preference�

5� To upgrade the software:

• Connect the USB drive according to the

• Press

1� Press

selection menu�

2� Select the desired display icon� The selection

will be highlighted with a green box�

to open the General Settings

�

�

and

instructions in the “Setup and Device

Conguration” section� The current

software version appears in the box�

In this scenario, version 00�02�10 is

installed�

system will automatically restart once the

software is succesfully upgraded�

to open the Actual Pressure Display

to select the language

to upgrade the software� The

Accessing the Stryker Settings Menu (For Stryker use only)

EN-26

Only authorized Stryker representatives have

access to this menu�

1� Press

2� Enter a password�

3� To conrm, press

to open the Stryker Settings Menu�

� To cancel, press

�

Page 29

Navigating to the Help Menu

1� Press

to open the Help Menu on any screen�

System Feedback

Audible Feedback

Audible Feedback Event Implication

Three high-tone beeps Fault error Refer to “Error Messages”

Three high-tone beeps,

pause, two beeps

One medium-tone

beep

Two medium-tone

beeps

One low-tone beep Touchscreen/Hand control/

Three (medium, low,

high-tone) beeps

Lockdown error Refer to “Error Messages”

Accessory connection Refer to “Connect the Components” and “Insert

the Inow/Outow Cassette”

Accessory removal Refer to “Connect the Components” and “Insert

the Inow/Outow Cassette”

N/A

Footswitch operation

Hot swap Refer to “Swap between Hardware Combination

Selections”

Error Messages

DRAFT

The words caution, fault, and lockdown carry special meanings and should be carefully reviewed:

• Caution: Visual popup error is displayed for ve seconds; user may clear the message when the problem

is resolved�

• Fault: The pump will stop; user may clear the message when the problem is resolved�

• Lockdown: The pump will stop; reboot system�

Error Message Cause Possible Solution

CAUTION Cassette about to expire (two hours left

before expiration)�

CAUTION Preventative Maintenance required; the

unit has reached its recommended service

interval�

CAUTION Inow/Outow RFID read failure: The

Inow or Outow RFID tag cannot be

detected while the pump is stopped�

FAULT Priming Error: No uid in the tubing after

ten seconds�

• Replace the cassette�

• Contact your Stryker

representative�

• Ensure the Inow or Outow

Cassette is fully inserted�

• If the problem persists, replace

the cassette�

• If the problem persists, contact

your Stryker representative�

• Ensure the pinch clamps on the

saline bags are open�

• Ensure the Inow Cassette is

fully inserted�

EN-27

Page 30

Error Message Cause Possible Solution

FAULT Instrument recognition error: The stopcock

on the cannula is closed, the lower clamp

on inow tubeset is closed, or no hardware

is attached to the tubing�

FAULT Inow and/or Outow Cassette not fully

inserted�

FAULT Cassette is expired (after 24 hours of use)� • Replace the cassette�

FAULT The connection to the Crossre console or

approved resection console is lost�

FAULT The Crossre console is specied in the

user preference le, but it is improperly or

DRAFT

not connected to the pump�

LOCKDOWN Hardware fault detected • Reboot the system�

LOCKDOWN Motor defective • Reboot the system�

LOCKDOWN Pressure Transducer out of calibration:

If the pressure is at a value greater than

20mmHg for ve seconds when no

cassette is inserted�

LOCKDOWN Possible Overpressure: The pressure is

sustained at 750mmHg for more than one

second, or a hardware failure or pressure

transducer malfunction has occurred�

• Check the inow tubing

from the bags to the joint

and ensure the hardware is

properly attached�

• Open any closed clamps or

stopcocks�

• Repeat the priming step�

• Remove and reinsert the

cassette until it clicks into

place�

• Ensure the consoles are

properly connected to the

pump� Follow the instructions

in the “Setup and Device

Conguration” section in this

manual�

• Reboot the system�

• If the problem persists, contact

your Stryker representative or

return the console for repair�

• Ensure the console is properly

connected to the pump� Follow

the instructions in the “Setup

and Device Conguration”

section in this manual�

• Reboot the system�

• If the problem persists, contact

your Stryker representative or

return the console for repair�

• If the problem persists, contact

your Stryker representative or

return the console for repair�

• If the problem persists, contact

your Stryker representative or

return the console for repair�

• Reboot the system�

• If problem persists, contact

your Stryker representative�

• Reboot the system�

• If the problem persists, contact

your Stryker representative or

return the console for repair�

EN-28

Page 31

Troubleshooting

Problem Cause Possible Solution

The pump does not

power on (no approved

resection console(s) are

attached to the pump)�

The pump does not

turn on (approved

resection console(s) are

attached and turn on)�

The pump turns on,

but approved resection

console(s) do not�

Neither the pump or

approved resection

consoles turn on�

The pump is plugged

in, the fuses are

functional and/or have

been replaced, and the

pump still does not

turn on�

The cassette(s) are

inserted, but the Run

Screen does not appear,

and the pump does not

start�

The pump turns on, but

there is no image on

the screen or the screen

is frozen�

The hand control or

the footswitch are

plugged in, but are not

activating�

The pump is not plugged in, or the

global or main fuses are out�

There is a power supply failure, or the

main fuses are out�

There is a problem with the approved

resection console(s)�

The pump is not plugged in, or the

main fuses are out�

A hardware error occurred� • Plug the pump in to a dierent main

DRAFT

The Inow or Outow RFID tag cannot

be detected�

A hardware error occurred� • Reboot the system�

The devices are improperly connected

to the pump�

The settings in the Footswitch/Formula

Shaver Settings Menu are set to “None�”

The device(s) have reached their

expected lifetime�

• Ensure the pump is plugged in to the

main outlet�

• Inspect the all fuses�

• Replace the fuse if it is out of service�

• Inspect the main fuses in the fuse

drawer�

• Replace the fuses if it is out of service�

• If the problem persists, contact your

Stryker representative�

• Inspect the approved resection

console(s)�

• If the problem persists, contact your

Stryker representative or return the

console for repair�

• Ensure the pump is plugged in to the

main outlet�

• Inspect the main fuses in the fuse

drawer�

• Replace the fuses if they are out of

service�

outlet�

• If the problem persists, contact your

Stryker representative�

• Ensure the Inow or Outow Cassette is

fully inserted�

• If the problem persists, replace the

cassette�

• If the problem persists, contact your

Stryker representative�

• If the problem persists, contact your

Stryker representative�

• Ensure the devices are properly

connected according to the

instructions in the “Setup and Device

Conguration” section of this manual�

• Check the settings in the Footswitch/

Formula Shaver Settings Menu�

• Reset the settings to the Default

settings�

• Replace the device(s)�

EN-29

Page 32

There are abnormal

pressure or ow rate

uctuations�

The pump stops

pumping uid, and

the pressure indicator

continues to blink�

The pinch valves are

not engaging�

Bubbles appear in the

joint�

The pump cannot

achieve the set

pressure�

There is insucient

pressure in the surgical

site�

There is no suction

while the pump is

running�

There is a pressure sensor error� • Reboot the system�

A hardware fault is detected�

The pressure is too high� The actual

pressure exceeds 200mmHg for

15seconds or greater than 250mmHg

for ve seconds�

There is a pinch valve or hardware

error�

There is no more irrigation uid� • Replace or add additional saline bags�

The tubing connection is loose� • Ensure the tubing is securly connected�

A priming error occurred� • Ensure the pinch clamps on the saline

DRAFT

The suction level is set too high� • Decrease the suction level�

There is a hardware setup error, the

ow limit is set too low, or the suction

level is set too high�

An irrigation problem exists� • Check the stopcock on the arthroscope

The hardware set up is incorrect� • Ensure the hardware is properly

The approved resection consoles are

improperly connected�

The tubes on the Outow Cassette are

improperly connected�

• If the problem persists, contact your

Stryker representative, or return the

console for repair�

• Open the valve at the outow tube, the

drainage tube, or the stopcock on the

instrument to reduce the pressure�

• Examine the pinch valves to ensure

they are functioning properly�

• Reboot the system�

• Ensure the pinch clamp is open on the

irrigation tube, or the stopcock is open�

• If the problem persists, replace the

tubing�

bags are open�

• Ensure the Inow or Outow Cassette is

fully inserted�

• Remove the hardware from the tubing

and repeat the priming step�

• If the problem persists, replace the

cassette�

• Verify the luer-lock is tightly closed,

the correct hardware is selected and

properly connected, and the dual

stopcock cannula is properly set up�

• Increase the ow limit or the set

pressure setting�

• Decrease the suction level�

• Press Run/Stop to restart the pump�

and the clamps under the saline bags�

selected and set up�

• Ensure the consoles and the tubes

are properly connected according to

the instructions in Setup and Device

Conguration section of this manual�

Unable to upload les

to/from USB drive�

EN-30

A hardware fault occurred� • Ensure the USB drive is functioning

properly and the correct les are on

the drive� If the drive is not functioning

properly, replace the USB drive�

• Reboot the system�

Page 33

Sporadic electrical

interference is aecting

the pump�

The touch screen

is unresponsive or

inaccurate�

Electrical, RF, and/or mobile

communications equipment is

aecting the normal function of the

pump�

Touch screen is not properly calibrated

for the user�

A hardware or software error occurred�

• Power down all electrical equipment

not in use�

• Increase the distance of other electrical

equipment�

• Connect the pump and other

equipment into dierent outlets�

• Reboot the system�

• If the problem persists, contact your

Stryker representative or return the

console for repair�

A user preference

le was accidentally

deleted from the pump�

The pump is stopped,

but the Outow

Cassette is stuck and

cannot be ejected�

“Service Pump Soon” The pump is 95% through the current

Unintentional deletion of a user

preference le�

The pinch valves do not retract� • Do not attempt to remove the cassette

maintenance period�

DRAFT

• Transfer the user preference le from

a USB drive to the pump according to

the instructions in the “Transfer Files

to/from a USB drive” section of this

manual�

as it may damage the pump or the

cassette�

• Reboot the system�

• If the problem persists, contact your

Stryker representative�

• Contact your Stryker service

representative�

EN-31

Page 34

Cleaning, Maintenance, and Disposal

Warning

• Do not remove the cover of the console as this could cause electric shock and product damage.

• To avoid electric shock and potentially fatal injury, unplug the pump from the electrical outlet

before cleaning�

Caution

To prevent product damage:

• when cleaning the pump, do not spray cleaning liquid directly onto the pump; spray on the cloth

before wiping the pump,

• do not immerse the pump in any liquid,

• do not use corrosive cleaning solutions to clean the pump,

• do not sterilize the pump�

Clean the Components

Pump

Should the pump need cleaning:

1� Spray cleaning liquid onto a dry, sterile cloth� Avoid excess liquid or drips�

2� Wipe the pump�

3� Take extra care when cleaning the front LCD screen� Excess liquid or drips that enter the bottom of the screen

may result in product damage�

DRAFT

Footswitch

Warning

Clean the footswitch prior to rst use and after every subsequent use�

Consult the footswitch manual (P17862) for cleaning instructions�

Hand control

Warning

Clean and sterilize the hand control prior to rst use and after every subsequent use to minimize risk

of infection�

Consult the hand control manual for cleaning and reprocessing instructions�

Replace the Fuses

1� Disconnect the pump from the electrical output and remove the power cord from the rear of the pump�

2� Remove the appropriate fuse holder; with a straight blade screwdriver, unlatch the fuse drawer, or turn the

global fuse holders in a counter clockwise direction until the spring pushes out�

3� Remove the fuse(s)�

4� Replace the fuse(s) with a fuse of the same value and rating as indicated on the rear of the pump�

EN-32

Page 35

5� Follow these steps in reverse for assembly�

• Push in the the fuse drawer until it clicks into place�

• Turn the global fuse holders in a clockwise direction until they are fully pushed in and secure in their

original position�

Perform Annual Inspection

Stryker recommends inspections of the system on an annual basis� These inspections evaluate whether the

product currently or in the near future may fail in a manner that aects device performance�

Safety Test

Visually inspect the device and its components to ensure the:

• fuses correspond with the specications on the pump,

• labels and device markings are legible,

• mechanical condition of the system (wires, hardware, etc�) allows for its safe use, and

• the system is clean for safe and proper use�

Basic Function Test

Perform a basic function test to analyze the features, displays, and performance of the system�

1� Power

• Power on the pump according to the instructions in “Power the CrossFlow Pump On and O” section

of this manual� The power button will be illuminated by a green LED, indicating the system has

powered on�

2� Stepper motor

• Insert the cassettes according to the instructions in “Insert the Inow/Outow Cassette” section of

this manual�

• Visually inspect the stepper motors located in the cassette holder; they will be disengaged�

• Remove air from the inow tubing according to the instructions in “Prime the Inow Tubing” section

of this manual�

• Visually inspect the stepper motors; two motors will be engaged�

• Stop the pump�

• Visually inspect the stepper motors; they will be disengaged�

• Remove the cassettes according to the instructions in “Remove the Cassettes” section of this manual�

3� Device Detection

• Connect the components (for example, the hand control, footswitch, CrossFire system, etc�)

according to the instructions in “Connect the Components” section of this manual�

• Ensure the console displays the icon in the bottom of the screen of each component that is

connected when the device is powered on�

4� Pressure Sensor

DRAFT

EN-33

Page 36

1 m / 39 in

• Gather the following equipment:

• disposable Inow Cassette tube set

• container lled with water

• uid bag (3L)

• Follow the instructions in this manual to power on the pump,

insert the Inow Cassette, select a preference le, and select a

joint�

• Suspend a uid bag 1m/39in on its holder and connect the

h

bag to the tubing according to the diagram�

• Discard the protective cap on the tubing (if needed), and

immerse the end of the tubing into a container lled with

water�

• Set the Pressure to 50mmHg and Flow to 20%, according to the

instructions in the “Set the Pressure and Flow” section of this

manual�

• Remove air from the inow tubing according to the instructions

in the “Prime the Inow Tubing” section of this manual�

• Press

• Press

• Remove the tubing from the container and hold it at a given

completely ll with uid�

will show approximately 0–5 mmHg�

water column height (h) indicated in the table below� Ensure

the tubing in the water column is completely lled with uid�

to start the pump� Allow the tubing to

to stop the pump� The actual pressure display

DRAFT

• Read the actual pressure displayed on the pump� The test has

been successfully completed if the actual pressure on the pump

is within the range indicated in the table below for a given

height of the water column�

Height of water column (h)

Inches Centimeters

12 30 20–25

18 45 30–35

24 60 40–45

46 90 65–70

5� Inow Flow Rate

• Gather the following equipment:

• disposable Inow Cassette tube set

• uid bag (3L)

• stopwatch

• one 1L measuring cup

• Follow the instructions in this manual to power on the pump, insert the Inow Cassette, select a

preference le, and select a joint�

• Suspend a uid bag 1m/39in on its holder and connect the bag to the tubing according to the

diagram�

• Discard the protective cap on the tubing (if needed), and place the end of the tubing into a container

lled with water�

• Set the pressure to 150mmHg and ow to 50%�

• Remove air from the inow tubing according to the instructions in the “Prime the Inow Tubing”

section of this manual�

• Clamp o the tubing in the measuring cup without stopping the pump�

Acceptable actual

pressure (mmHg)

EN-34

Page 37

• Empty the measuring cup�

• Unclamp the tubing and place it in the cup� Start the stopwatch once the tubing is placed back in

the cup�

• Once the measuring cup is lled with 1 liter of uid, press

• The test has been successfully completed if the time it takes to ll the measuring cup with 1 liter of

uid is within the range specied in the table below�

Flow (%) Time (seconds)

50 70

to stop the pump�

Perform Preventive Maintenance and Calibration

Caution

Stryker does not accept any liability for direct or consequential damages if:

• the pump or the accessories are improperly prepared and maintained,

• non-authorized persons perform repairs, adjustments, or alterations to the pump or accessories,

• non-authorized persons open the pump,

• the prescribed inspection and maintenance schedules are not followed�

When the pump is 95% through the current maintenance period, a “Service Pump Soon” notication

will appear on the screen� An authorized Stryker service technician must inspect and service the device

according to the maintenance and calibration schedule below to maintain product functionality�

Component Maintenance/Calibration Period

Motors 2years

Pinch valves 2years

Pressure transducer 2years

DRAFT

Expected Life

Equipment Expected Life

Console Fiveyears

Footswitch Threeyears

Hand Control Oneyear

Inow, outow, patient-use tubing Single-use

Day-use cassette Tencases, eighthours of active use, or 24hours after point of rst

use

Disposal

This product contains electrical waste or electronic equipment� It must not be disposed of as unsorted

municipal waste and must be collected separately in accordance with applicable national or institutional

related policies relating to obsolete electronic equipment�

Dispose of any system accessories and irrigation uid according to normal institutional practice relating to

potentially contaminated items�

EN-35

Page 38

Technical Specications

Equipment Information

Size Pump Dimensions:

• 12�528in� (318�2mm) width

• 7�025in� (178�4mm) height

• 16�990in� (431�6mm) depth

Pump Weight: 24lbs� (10�9kg)

Hospital power cord: (p/n 0105-033-001) 2m

Approved resection console power cord: (p/n P17275) 2m

Power

Connection

Frequency 47–63Hz

Power/Current

Consumption

Electrical Safety

Classication

Environmental

Specications

Safety and EMC

Compliance

Pump Capacity 3�0L/min

Pressure range 0-150mmHg

Max suction by

pressure relief

Measuring

accuracy

Display/Color

Touch Screen

Volume

Adjustment

Input Voltage: 80–275V

Inlet Fuse: 10A, 250V

Maximum power consumption: 269W

Maximum current consumption: 80V: 3�4A; 275V: 0�98A

Motor output maximum speed: 650RPM

RF output waveform: 13�56MHz (ISO15693)

Class I equipment

Type BF Part

Water ingress protection, IPX1

Continuous Operation

Operating Temperature: 5 – 40°C

Operating Humidity: 30 – 95% RH (non-condensing)

Shipping Temperature: -18° – 60°C

Shipping Humidity: 15 – 90% RH

• UL 60601-1: 2006

• IEC 60601-1-2: 2007

• IEC 60601-1-4: 2000

• IEC 60601-1-6: 2010

• IEC 60601-1-8: 2006

• IEC 60601-1: 2005 + Corr 2006 + Corr 2007

• IEC 60601-1-1: 2005 + Corr 2006 + Corr 2007

• CAN/CSA-C 22�2 No� 60601-1-2: 2003 + A1: 2006

500mmHg

Pressure: ≤2%

Flow: ±10%

160° viewing angle

6�5inch diagonal active LCD

Resolution 800 (horizontal) x 480 (vertical)

12:8 aspect ratio

16-bit color

Dimensions: 153mm (width) x 118mm (height)

0-85dBA

DRAFT

• IEC 62304: 2006

• IEC 62366: 2007

• CAN/CSA-C 22�2 No� 601�1-M90: 2003

• CAN/CSA 22�2 No� 60601-1: 2002

• AS/NZS 3200�1�0: 1998

EN-36

Page 39

Connections Wired Hand Control

Wired Footswitch

USB 1�1 port

Stryker Firewire Backbone (SFB)

Electromagnetic Compatibility

Like other electrical medical equipment, CROSSFLOW INTEGRATED ARTHROSCOPY PUMP requires special precautions to ensure electromagnetic compatibility with other electrical

medical devices� To ensure electromagnetic compatibility (EMC), CROSSFLOW INTEGRATED ARTHROSCOPY PUMP must be installed and operated according to the EMC information

provided in this manual�

The CROSSFLOW INTEGRATED ARTHROSCOPY PUMP has been designed and tested to comply with IEC 60601-1-2 requirements for EMC with other devices�

Caution: Portable and mobile RF communications equipment may aect the normal function of the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP�

Caution: Do not use cables or accessories other than those provided with the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP, as this may result in increased electromagnetic

emissions or decreased immunity to such emissions�

Caution: If the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP is used adjacent to or stacked with other equipment, observe and verify normal operation of the CROSSFLOW

INTEGRATED ARTHROSCOPY PUMP in the conguration in which it will be used prior to using it in a surgical procedure� Consult the tables below for guidance in placing the

CROSSFLOW INTEGRATED ARTHROSCOPY PUMP�

Guidance and Manufacturer’s Declaration: Electromagnetic Emissions

CROSSFLOW INTEGRATED ARTHROSCOPY PUMP is intended for use in the electromagnetic environment specied below� The customer or the user of CROSSFLOW INTEGRATED

ARTHROSCOPY PUMP should ensure that it is used in such an environment�

Emissions test Compliance Elec tromagnetic Environment - guidance

RF emissions CISPR 11 Group 1

RF emissions CISPR 11 Class A

Harmonic emissions IEC61000-3-2 Not applicable

Voltage Fluctuations/ icker

emissions IEC61000-3-3

Not applicable

CROSSFLOW INTEGRATED ARTHROSCOPY PUMP uses RF energy only for its internal function; therefore, its

RF emissions are very low and are not likely to cause any interference in nearby electronic equipment�

CROSSFLOW INTEGRATED ARTHROSCOPY PUMP is suitable for use in all establishments, other than

domestic and those directly connected to the public low-voltage power supply network that supplies

buildings used for domestic purposes�

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

CROSSFLOW INTEGRATED ARTHROSCOPY PUMP is intended for use in the electromagnetic environment specied below� The customer or the user of CROSSFLOW INTEGRATED

ARTHROSCOPY PUMP should ensure that it is used in such an environment�

Immunity Test IEC 60601 test

Electrostatic Discharge (ESD)

IEC61000-4-2

Electrical fast transient/burst

IEC61000-4-4

Surge IEC61000-4-5 ±1kV dierential

Voltage dips, short

interruptions and voltage

variations on power supply

input lines IEC61000-4-11

Power frequency (50/60Hz)

magnetic eld IEC 61000-4-8

NOTE UT is the a�c� mains voltage prior to application of the test level�

DRAFT

level

±6kV contact

±8kV air

±2kV for power

supply lines

±1kV for input/

output lines

mode

±2kV common

mode

<5% UT (>95% dip

in UT) for 0�5 cycle

40% UT (60% dip

in UT) for 5 cycles

70% UT (30% dip

in UT) for 25 cycles

<5% UT (>95% dip

in UT) for 5 sec

3A/m 3A/m Power frequency magnetic elds should be at levels characteristic of a typical

Compliance Level Elec tromagnetic

±6kV contact

±8kV air

±2kV for power supply lines Mains power quality should be that of a typical commercial or hospital

±1kV for input/output lines

±1kV dierential mode Mains power quality should be that of a typical commercial or hospital

±2kV common mode

<5% UT (>95% dip in UT) for 0�5 cycle Mains power quality should be that of a typical commercial or hospital

40% UT (60% dip in UT) for 5 cycles

70% UT (30% dip in UT) for 25 cycles

<5% UT (>95% dip in UT) for 5 sec

Environment - guidance

Floors should be wood, concrete or ceramic tile� If oors are covered with

synthetic material, the relative humidity should be at least 30%�

environment�

environment�

environment� If the user of CROSSFLOW INTEGRATED ARTHROSCOPY

PUMP requires continued operation during power mains interruptions, it

is recommended that CROSSFLOW INTEGRATED ARTHROSCOPY PUMP be

powered from an uninterruptible power supply or a battery�

location in a typical commercial or hospital environment�

EN-37

Page 40

Guidance and Manufacturer’s Declaration--Electromagnetic Immunity

The CROSSFLOW INTEGRATED ARTHROSCOPY PUMP system is intended for use in the electromagnetic environment specied below� The user of the CROSSFLOW INTEGRATED

ARTHROSCOPY PUMP system should ensure that it is used in such an environment�

Immunity Test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

NOTE 1: At 80MHz and 800MHz, the higher frequency range applies�

NOTE 2: These guidelines may not apply in all situations� Electromagnetic propagation is aected by absorption and reection from structures, objects, and people�

(a) Field strengths from xed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM radio broadcast and

TV broadcast cannot be predicted theoretically with accuracy� To assess the electromagnetic environment due to xed RF transmitters, an electromagnetic site survey should be

considered� If the measured eld strength in the location in which the CROSSFLOW INTEGRATED ARTHR OSCOPY PUMP system is used exceeds the applicable RF compliance level

above, the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP system should be observed to verify normal operation� If abnormal performance is observed, additional measures

may be necessary, such as reorienting or relocating the CROSSFLOW INTEGRATED AR THROSCOPY PUMP unit�

(b) Over the frequency range 150kHz to 80MHz, eld strengths should be less than 3V/m�

IEC 60601 Test

Level

3Vrms

150kHz to 80MHz

3V/m

80MHz to 2�5GHz

Compliance Level Electromagnetic Environment--Guidance

Portable and mobile RF communications equipment should be used no closer to any part of the CROSSFLOW

INTEGRATED ARTHROSCOPY PUMP system, including its cables, than the recommended separation distance

calculated from the equation applicable to the frequency of the transmitter�

3Vrms

3V/m d = 1�2√P 80MHz to 800MHz

Recommended Separation Distance:

d = 1�2√P

d = 2�3√P 800MHz to 2�5GHz

where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation distance in meters (m)�

Field strengths from xed RF transmitters, as determined by an electromagnetic site survey (a), should be less

that the compliance level in each frequency range (b)�

Interference may occur in the vicinity of equipment marked with the following symbol:

Recommended Separation Distances Between Portable and Mobile RF Communications Equipment and the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP System

The CROSSFLOW INTEGRATED ARTHROSCOPY PUMP system is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled� The user of

the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP system can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the CROSSFLOW INTEGRATED ARTHROSCOPY PUMP system as recommended below, according to the maximum output power of

the communications equipment�

Separation distance (m) according to frequency of transmitter

Rated maximum output power

(W) of transmitter

0�01 0�12 0�12 0�23

0�1 0�38 0�38 0�73

1 1�2 1�2 2�3

10 3�8 3�8 7�3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance (d) in meters (m) can be estimated using the equation applicable to

the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer�

NOTE 1: At 80MHz and 800MHz, the separation distance for the higher frequency range applies�

NOTE 2: These guidelines may not apply in all situations� Electromagnetic propagation is aected by absorption and reection from structures, objects, and people�

150kHz to 80MHz

d = 1�2√P

DRAFT

80kHz to 800MHz

d = 1�2√P

800kHz to 2�5GHz

d = 2�3√P

Regulatory Information

Federal Communications Commission (FCC)

FCC ID: SSH-XFLOW

Trade Name: CrossFlow Integrated Arthroscopy Pump

Type or Model: 0450000000

This device complies with Part 15 of the FCC rules� Operation is subject to the following two conditions:

• this device may not cause harmful interference, and

• this device must accept any interference received, including interference that may cause undesired

operation�

Note: FCC regulations provide that changes or modications not expressly approved by Stryker Endoscopy

could void your authority to operate this equipment�

EN-38

Page 41

Frequency of transmission: 13�56MHz

Type of frequency / characteristics of the modulation: 10%ASK

Subcarrier: 423�75kHz, Manchester coding

Eective radiated power: 50µW

Industry Canada (IC)

IC: 4919C-XFLOW

Trade Name: CrossFlow Integrated Arthroscopy Pump

Type or Model: 0450000000

This device complies with Industy Canada license-exempt RSS standard(s)� Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device�

The term “IC” before the radio certication number only signies that Industry Canada technical

specications were met�

R&TTE Declaration of Conformity

We, Name of company: Stryker Endoscopy

Address: 5900Optical Court, San Jose, CA 95138

Authorized representative: Jean-Yves Carentz

Contact detail of authorized representative: Stryker France, ZAC Satolas Green Pusignan, Av� de

Satolas Green, 69881 MEYZIEU Cedex, France