Page 1

Booms and Lights

Installation and Service Manual

July 2011 1004-400-061 REV YB www.stryker.com

Page 2

Page 3

Stryker Booms and Lights

Installation and Service Manual

is manual contains condential information that shall not be disclosed or duplicated for any reason other than to use and maintain a

Stryker Booms and Lights. is restriction does not limit the right to use information contained in this manual, if it is obtained from another source without restriction. e information subject to this restriction is contained in all pages of this manual.

© June 2011 Stryker Communications. All rights reserved. Information in this document is subject to change without notice. Stryker,

Stryker logo, Visum®, and StrykeCam® 2 are registered trademarks of Stryker

All rights reserved.

Stryker Booms and Lights Installation and Service Manual

1004-400-061 REV YB

Page 4

Page 5

S

Contents

1. Warnings and Cautions ........................................................................................................................................ 10

1.1 Safeguards and Precautions............................................................................................... 10

1.2 Warnings .......................................................................................................................... 10

2. Product Symbol Denition .................................................................................................................................. 11

3. Tool List ............................................................................................................................................................... 13

3.1 Required Tools .................................................................................................................. 13

3.2 Optional Tools ................................................................................................................... 13

4. Unpacking ........................................................................................................................................................... 14

4.1 Halogen Light ................................................................................................................... 14

4.1.1 Suspension Box .........................................................................................................14

4.1.2 Accessory Box ...........................................................................................................14

4.1.3 Light Head Boxes ......................................................................................................14

4.2 LED Light .......................................................................................................................... 15

4.2.1 Suspension Box .........................................................................................................16

4.2.2 Accessory Box ...........................................................................................................16

4.2.3 Light Head Boxes 1 and 2 ...........................................................................................16

4.3 Flat Panel Arms ................................................................................................................ 17

4.4 Booms .............................................................................................................................. 17

5. Preparing the Mounting (Interface) Plate............................................................................................................ 18

6. Preparing the Suspensions .................................................................................................................................. 19

6.1 Installing the Cable Kit for Lights ....................................................................................... 19

6.2 Surgical Lights .................................................................................................................. 20

6.2.1 Standard Horizontal Arm ...........................................................................................20

6.2.2 Extended Horizontal Arm...........................................................................................20

6.2.3 Alternate Light Installation Instructions.....................................................................21

6.3 Flat Panel ......................................................................................................................... 22

6.4 Booms .............................................................................................................................. 22

6.5 Routing Cables .................................................................................................................. 24

7. Installing the Suspension and Boom Arms .......................................................................................................... 25

7.1 Alternate Light Installation Instructions (Continued) ........................................................... 26

5

Page 6

S

8. Installing Light Heads ......................................................................................................................................... 27

8.1 LED and Halogen ............................................................................................................... 27

8.1.1 Standard Light ..........................................................................................................27

8.1.2 Low Ceiling Light ......................................................................................................28

9. Powering the System .......................................................................................................................................... 31

9.1 Halogen Lights .................................................................................................................. 31

9.1.1 Electrical and Data Connections .................................................................................31

9.2 LED Lights ......................................................................................................................... 32

9.2.1 Power Supply Box Wall Mount (Optional) ....................................................................32

9.3 Power Supply Box Connections ........................................................................................... 33

9.3.1 Power ......................................................................................................................34

9.3.2 Control .....................................................................................................................34

9.3.3 Wall Control Unit Port ...............................................................................................35

9.3.4 SORN ........................................................................................................................35

9.3.5 SIDNE .......................................................................................................................35

9.3.6 Expansion Port (Optional) ..........................................................................................35

9.4 Visum LED New Installation Setup ...................................................................................... 36

9.4.1 Required Tools ..........................................................................................................36

9.4.2 Installing USB to RS-232 Adapter (for laptops without Serial Ports) ..............................36

9.4.3 Connecting a Laptop to the SIDNE Port on Visum LED System .......................................37

9.4.4 Visum LED Main Menu ...............................................................................................39

9.4.5 New Installation .......................................................................................................39

10. Monitor Assembly ............................................................................................................................................. 40

10.1 Light Flat Panel or Single Panel installation ....................................................................... 40

10.2 Adjusting the Yoke ............................................................................................................ 41

10.2.1 Adjusting the Width ..................................................................................................41

10.2.2 Adjusting the Height .................................................................................................45

10.3 Attaching the Monitor ....................................................................................................... 46

10.4 Balancing the Monitor ....................................................................................................... 48

10.5 Adjusting the Brakes ......................................................................................................... 50

11. Boom Shelf Attachment and Adjusting Brakes/Stops ....................................................................................... 51

11.1 Boom Shelf and Accessories Attachment ............................................................................. 51

11.1.1 FLEXiS Shelf Installation ............................................................................................51

6

Page 7

S

11.1.2 FLEXiS Handle to MFR Bracket Installation ..................................................................54

11.1.3 FLEXiS Handle to Service Head Installation .................................................................56

11.1.4 Installing Auxiliary Plates ..........................................................................................58

11.1.5 Installing Other Accessories .......................................................................................59

11.1.6 Installing GCX Accessory Track on OSC600 Down Tube ...................................................59

11.1.7 Drawer Installation ...................................................................................................59

11.2 Lights and Flat Panel Arms ................................................................................................. 60

11.2.1 Height Adjustment ...................................................................................................60

11.2.2 Tension Adjustment ..................................................................................................62

11.2.3 Adjusting the Friction Brakes .....................................................................................62

11.2.4 Adjusting the Brake Force of the Extension and Spring Arms ........................................64

11.2.5 Adjusting Down Tube Screws ......................................................................................64

11.3 Adjusting the Cardanic Suspension .................................................................................... 66

11.4 Boom Arms ....................................................................................................................... 67

11.4.1 OSC400 .....................................................................................................................67

11.4.2 OSC600 .....................................................................................................................70

12. Installing Covers ................................................................................................................................................ 72

12.1 Lights and Flat Panel Suspension ....................................................................................... 72

12.2 Booms .............................................................................................................................. 72

12.3 Tandem ............................................................................................................................ 73

12.4 Cable Covers ...................................................................................................................... 75

12.4.1 Flat Panel/Light/Light Suspension .............................................................................75

12.4.2 Light/Flat Panel Suspension - Teacup Installation .......................................................75

12.4.3 MMP200, OSC400, and OSC600 ...................................................................................76

12.4.4 Mounting Motor Ring Covers ......................................................................................77

12.4.5 Replacing Rear End Spring Arm Covers ........................................................................77

12.5 Installing a Flexstrip Kit (Dual Flat Panel Arm Only) ............................................................. 78

13. Accessories ........................................................................................................................................................ 79

13.1 Lights ............................................................................................................................... 79

13.1.1 Halogen In-Light Camera and Weighted Light Handle Assemblies ................................79

13.1.2 LED In-Light Camera and Weighted Light Handle Assemblies .......................................79

13.1.3 Field Upgrade for StrykeCam In-Light Camera .............................................................79

13.1.4 Power Supply Box Components .................................................................................81

13.1.5 Camera Installation ..................................................................................................82

7

Page 8

S

14. Legacy ............................................................................................................................................................... 84

14.1 Suspension Installation ..................................................................................................... 84

14.2 Installing Spring Arms (if necessary for lights only suspension) ............................................ 84

14.3 Standard Width Yoke ......................................................................................................... 87

14.4 Halogen Light Flat Panel Stop Replacement ........................................................................ 87

14.5 Variant ............................................................................................................................. 89

14.6 Installing GCX Accessory Track on OSC400 Service Head ........................................................ 89

15. Cleaning and Completion .................................................................................................................................. 93

16. Servicing the Visum 600/450 ............................................................................................................................. 94

16.1 Electronic Control System .................................................................................................. 94

16.2 Power Supply Box ............................................................................................................. 96

16.2.1 Halogen Power Supply Box Troubleshooting Guide ......................................................96

16.3 Wall Control ..................................................................................................................... 99

16.4 Plug Layout of the Electronic Control System .................................................................... 101

16.5 Plug Allocation ............................................................................................................... 101

16.5.1 Location of the Plug and Diagnostic LEDs on the Terminal ..........................................102

16.5.2 Plug Allocation Operating Console and Diagnostic LEDs .............................................103

16.5.3 Plug Locations of the Power Box ..............................................................................103

16.5.4 Connections at the front: ......................................................................................... 104

16.5.5 Connections at the back: .........................................................................................105

16.5.6 Connection Structure of Systems ..............................................................................107

16.6 Can Bus Troubleshooting ................................................................................................. 110

16.6.1 Light Block Diagram ................................................................................................ 110

17. Servicing Booms .............................................................................................................................................. 114

17.1 System operation ........................................................................................................... 114

17.2 Troubleshooting ............................................................................................................. 114

17.2.1 Air Leaks .................................................................................................................115

17.3 Miscellaneous Hardware Parts List ................................................................................... 117

17.4 Replacing the Trim Strip .................................................................................................. 119

17.5 Replacing Med Gas .......................................................................................................... 120

17.5.1 Replacing a Nitrogen Regulator ...............................................................................120

17.5.2 Replacing Med Gas Plate..........................................................................................120

8

Page 9

S

17.6 Replacing the Brake Bladder ............................................................................................ 121

17.7 Reassembling the Service Head ........................................................................................ 127

17.7.1 Removing and Attaching the Front and Back Plates ...................................................127

17.7.2 Removing and Attaching the MFR ............................................................................128

17.7.3 Removing Extrusions ...............................................................................................129

17.7.4 Installing Extrusions ...............................................................................................129

17.7.5 Removing Modules .................................................................................................130

17.7.6 Installing Modules ..................................................................................................132

17.8 Replacing the Motor ........................................................................................................ 133

17.9 Electro-Pneumatic (EP) Module ........................................................................................ 135

17.9.1 Removing the Electro-Pneumatic (EP) Module ..........................................................135

17.9.2 Installing an Electro-Pneumatic (EP) Module ............................................................135

17.10 Generation 1 Service Head ............................................................................................... 136

17.10.1 Replacing a Shelf with Brake ...................................................................................136

17.10.2 Replacing the Brake Button ..................................................................................... 138

18. Servicing the LED ............................................................................................................................................ 140

19. Replacement Part Numbers ............................................................................................................................. 141

20. Contact Information ........................................................................................................................................ 144

9

Page 10

S

1. Warnings and Cautions

Please read this manual and follow its instructions carefully. The words WARNING, CAUTION, and

Note carry special meanings and should be carefully reviewed:

Warning e personal safety of service personnel may be involved. Disregarding

this information could result in injury to the patient.

Caution Special service procedures or precautions must be followed to avoid dam-

aging the equipment.

Warning A warning with a lightening bolt warns of hazardous voltage. All service

must be performed by authorized personnel.

Note Special information to make maintenance easier or important information more

clear.

1.1 Safeguards and Precautions

Stryker trained personnel are the only personnel authorized to install the equipment described in this

manual.

Incorrect operation or negligence of safety measures may cause damage to the equipment, bodily injury or death. oroughly read this manual before use.

• Do not add additional weight to the surgical lights.

• Do not place anything over the surgical lights.

• Do not look directly into the surgical light while powered on.

1.2 Warnings

1. Be a qualied/trained installer for this equipment.

2. Test this equipment prior to release for use by hospital personnel.

3. Disconnect the unit from the electric outlet before inspecting or servicing system components.

Note that more than one electrical supply may be used. Disconnect all power sources before

inspecting.

4. e electrical installation of the operating room must comply with any applicable IEC, CEC,

NEC requirements as well as the local codes and pre-installation manual.

Caution Carefully unpack the unit and check to ensure that no damage occurred

during shipment. If damage has occurred, please contact Stryker Communications.

10

Page 11

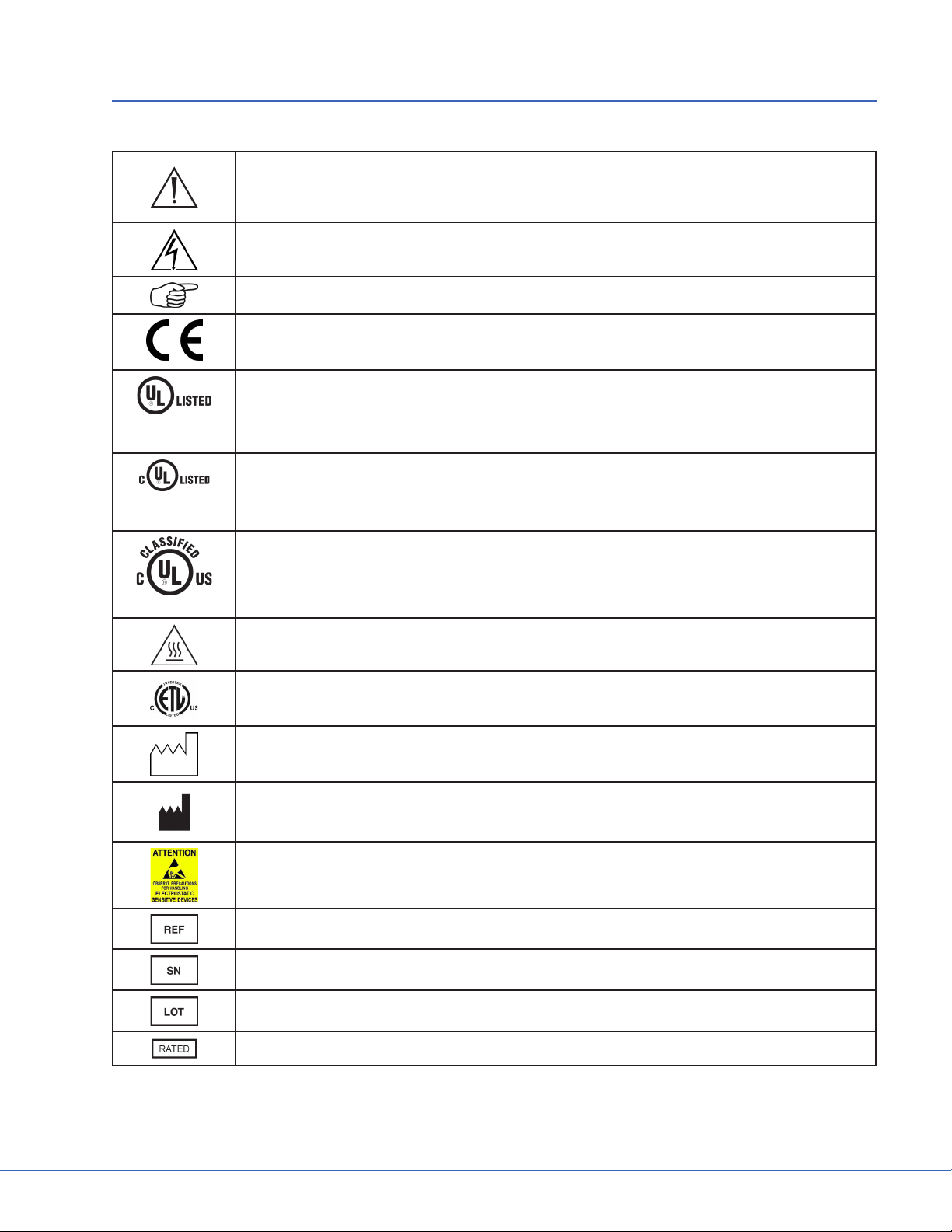

2. Product Symbol Denition

e following symbols may be found on the Stryker Booms and Lights equipment:

An exclamation mark within a triangle is intended to alert the user to the presence

of important operating and maintenance (service) instructions in the literature accompanying the product.

A lightning bolt within a triangle indicates the presence of hazardous voltage. Refer

all service to authorized personnel.

Denotes usage tips and useful information.

Denotes compliance to European Community Directive 93-42-EEC.

Indicates the product is compliant “Medical Electrical Equipment with Respect to

Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1.

EDS

(29AZ)

Indicates the product is compliant “Medical Electrical Equipment with Respect to

EDS

(29AZ)

(13PZ)

Electrical Shock, Fire, and Mechanical Hazard only in accordance with CAN/CSA

C22.2 No601.1.

Indicates the product is compliant “Medical Electrical Equipment with Respect to

Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1,

CAN/CSA C22.2 No601.1.

Indicates hot surfaces.

S

Denotes compliance to CSA Standard C22.2, 60601.1 - M90, AS 3200, IEC 60601,

IEC 60601-2-41, UL 60601, EN 60601

Denotes the date the equipment was manufactured.

Denotes the manufacturer of the device.

A yellow box with a hand within a triangle is intended to warn the user of the presence of an electrostatic sensitive device. Follow ESD prevention procedures.

Denotes product/part number.

Denotes product/serial number.

Denotes lot or batch number.

e acceptable wattage input range for this product.

11

Page 12

S

In accordance with European Community Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this symbol indicates that the product must not be

disposed of as unsorted municipal waste but should be collected separately.

Note: e device does not contain any hazardous materials.

Legal regulations may include specications regarding the disposal of this product. We request that you contact Stryker when you plan to withdraw this device

from service for discard.

12

Page 13

3. Tool List

3.1 Required Tools

• Genie li or equipment li, SLC-12 or equivalent

• Torpedo level

• Metric allen set (Shortened 3mm)

• Small and large phillips head

• Small and Large at head screwdriver

• 24mm (15/16 inch) wrench

• Snap ring plier (adjustable to 15mm)

• Torque Wrench (in. lbs.)

• Torque Wrench (. lbs.)

3.2 Optional Tools

• Porta band saw

• Large hand le

• 1/2 inch Drill/Driver

• Tape measure

• Drill bit set

• Hand tool pouch

• Adjustable wrench

• Roofer’s square

S

13

Page 14

S

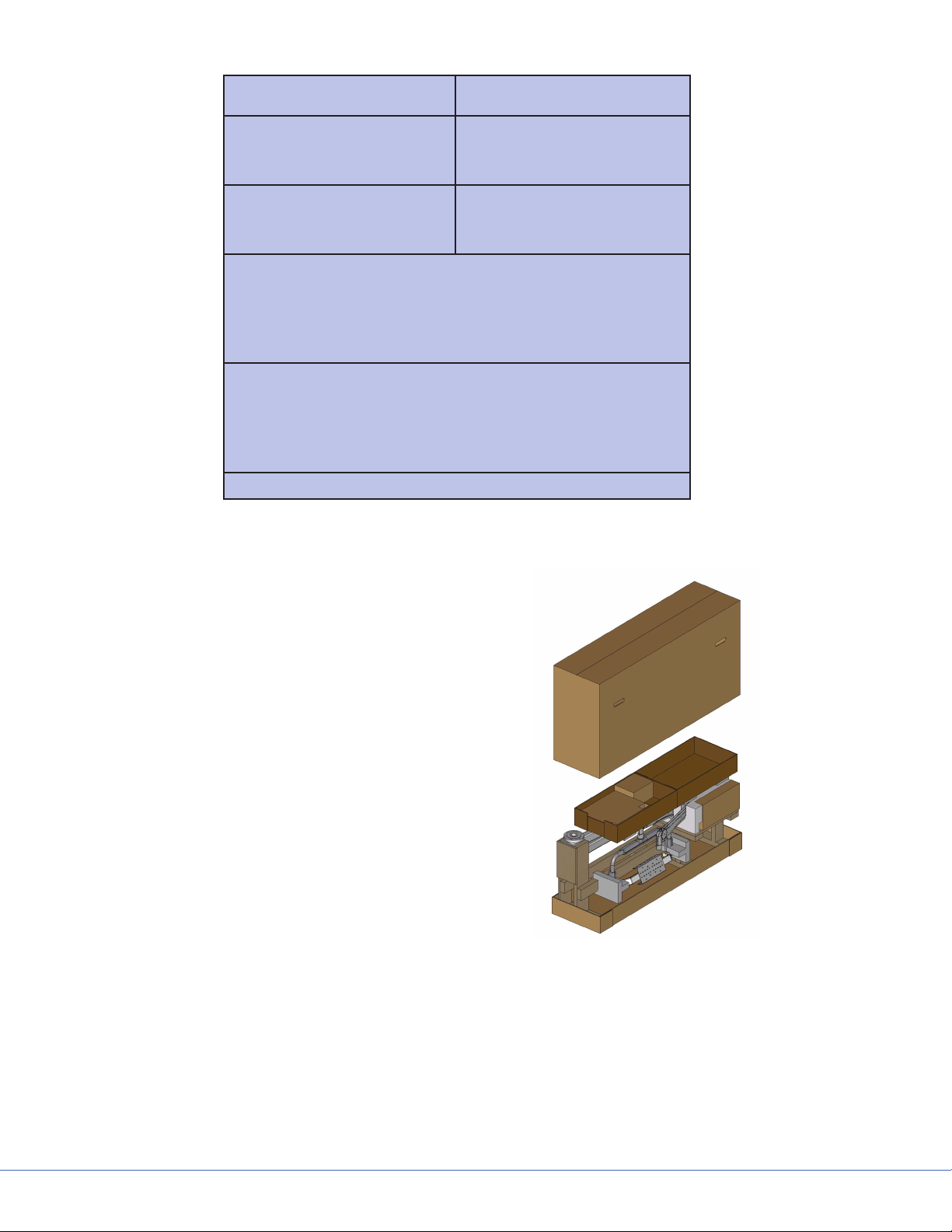

4. Unpacking

4.1 Halogen Light

Warning Use caution when liing heavy objects to avoid serious bodily injury or

damage to the equipment.

e equipment will arrive in shipping boxes on two separate pallets and may be arranged as depicted

in the images below. e shipping boxes should contain all the necessary components required to install the halogen light system. Use the image and list below to determine where each component of the

light suspension is packaged.

Down Tubes

Suspension

Suspension

Pallet

Ceiling

Covers

4.1.1 Suspension Box

• Light Suspension

• Suspension (Single, Dual, or Triple)

• Spring Arms

• Installation Hardware

• Flat Panel Cable Kit

Accessory Box

Light Head

Light Head

Light Head

Light Head

Pallet

4.1.2 Accessory Box

• Wall Control Unit and Cable Kits

• Power Supply Box

4.1.3 Light Head Boxes

• Halogen light heads

• Light Handle Assemblies

• StrykeCam® In-Light Camera (if purchased)

• Sterilizable Light Handle

• Sterilizable Camera Handle (if StrykeCam was ordered)

If any parts are missing, contact the Shipping and Receiving Department to verify whether a shipping

box(es) was le behind. If all boxes were delivered and parts are unaccounted for, call and inform your

Project Manager of the missing items.

14

Page 15

S

Use box cutters to open the shipping box along the seams.

Note Notice that the boxes have “break away” panels to allow easy access to the parts.

Verify that all parts are present and visibly undamaged.

4.2 LED Light

Warning Use caution when liing heavy objects to avoid serious bodily injury or

damage to the equipment.

e equipment will arrive in shipping boxes and may be arranged as depicted in the image below. e

shipping boxes should contain all the necessary components required to install the Visum® LED light

system. Use the image and list below to determine where each component of the light suspension is

packaged.

Light Head Light Head

Light Head Light Head

Suspension Accessory Box

Suspension Accessory Box

Pallet

*e outlined boxes represent a double shipment of supplies.

Orientation of packaging may arrive dierently.

15

Page 16

S

Accessory Box Accessory Box

Light Head Light Head

Light Head Light Head

Suspension

Suspension

Pallet

4.2.1 Suspension Box

• Light Suspension

• Suspension (Single, Dual, or Triple)

• Spring Arms

• Installation Hardware

• Flat Panel Cable Kit

• Tea Cup (EHA only)

4.2.2 Accessory Box

(ere are three boxes within the Accessory Box)

• Ceiling Cover (Box 1)

• Wall Control Unit and Light Cable Kits

(Box 2)

• Power Supply Box and Bezel (Box 3)

• Down Tub e

Extended Horizontal Arm Packaging

4.2.3 Light Head Boxes 1 and 2

• LED light heads

• Light Handle Assemblies

• StrykeCam® 2 In-Light Camera (if purchased)

• Sterilizable Light Handle

• Sterilizable Camera Handle (if StrykeCam 2 was ordered)

16

Page 17

S

If any parts are missing, contact the Shipping and Receiving Department to verify whether a shipping

box(es) was le behind. If all boxes were delivered and parts are unaccounted for, call and inform your

Project Manager of the missing items.

Use box cutters to open the shipping box along the seams.

Note Notice that the boxes have “break away” panels to allow easy access to the parts.

Verify that all parts are present and visibly undamaged.

4.3 Flat Panel Arms

e equipment will arrive in a shipping box on one pallet. e shipping box should contain the Flat

Panel Arm System and Ceiling Covers.

e Flat Panel Arm will be fully assembled and completely wired out of the crate. Uncrate pallet and

open the shipping box.

Use box cutters to open the shipping box along the seams.

Verify that all parts are present and visibly undamaged.

4.4 Booms

Each Boom will arrive in a shipping box on one pallet. e shipping box should contain a Boom Arm,

Service Head, shelves (if applicable), and Ceiling Covers.

Use box cutters to open the shipping box along the seams.

Verify that all parts are present and visibly undamaged.

17

Page 18

S

5. Preparing the Mounting (Interface) Plate

Remove the hardware bag from the suspension box.

Note Ensure all-thread rods do not interfere with the application of ceiling cover by

performing a dry t. e all-thread rods should not extend below the base of the

cover. If they do, cut the rods back.

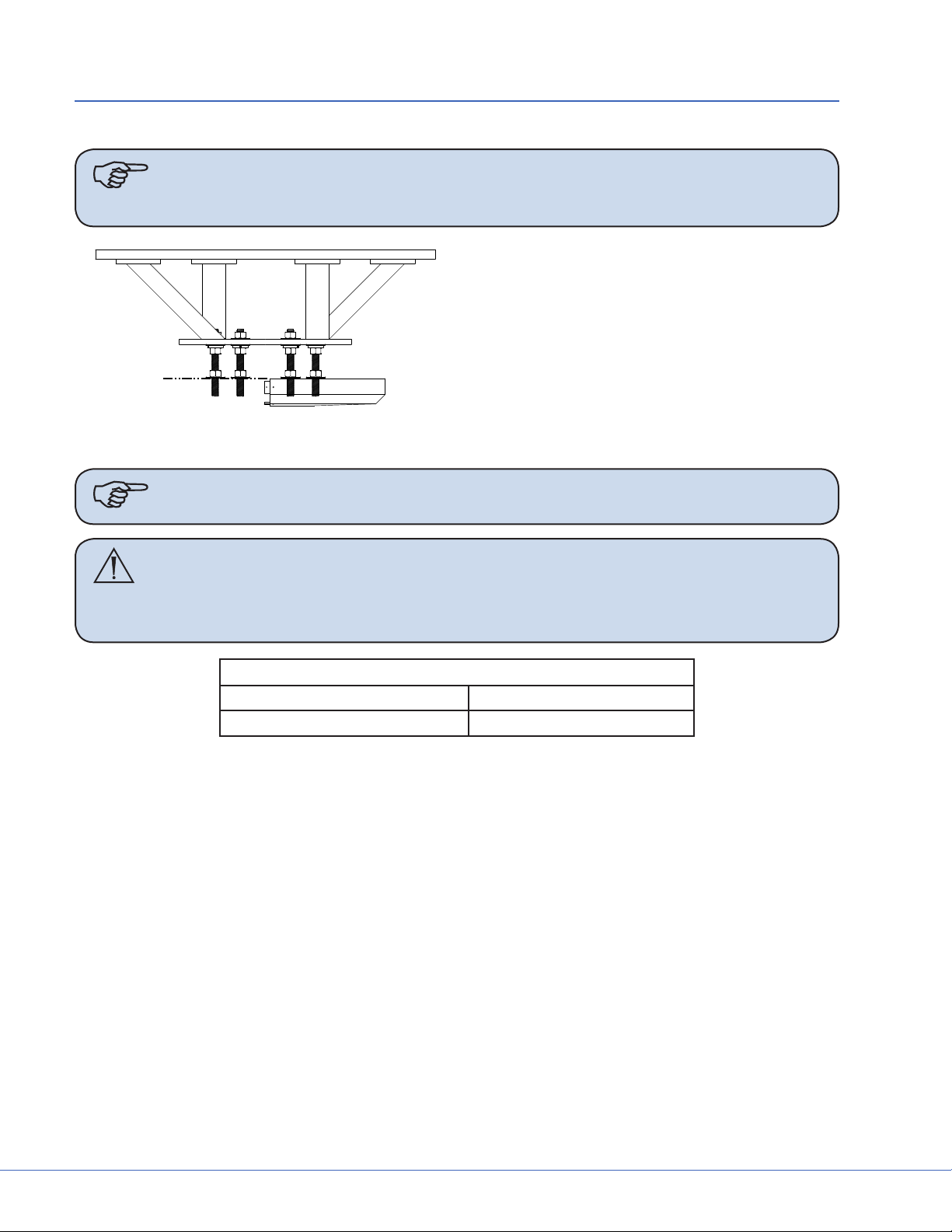

1. Install six hex nuts below Mounting (Interface) Plate to align ange top approximately even with the bottom of nished ceiling.

2. Use a Torpedo Level to verify that the nuts

are level. Measure two sets at a time.

3. Place at washers and Plastic Isolation Discs (required in Europe) below each hex nut to hold in

place.

Note Plastic Isolation Discs are only required in Europe.

Caution No more than 8 inches of exposed all-thread rod is allowed between the Pre-

installation Plate and the down tube ange for Seismic considerations. No

more than 2 inches of exposed all-thread rod is allowed for Zone 4 installations.

Cover Size

180 mm (7 inches) 153 mm (6 inches)

80 mm (3 inches) 64 mm (2.5 inches)

18

Page 19

S

6. Preparing the Suspensions

6.1 Installing the Cable Kit for Lights

1. Route the power and control cables between the power supply box and the suspension structure.

Verify that the light connectors remain near the ceiling plate, as shown in the gure below.

2. (For LED only) Route the S-Video cable through the pre-installed conduit between the super

structure and video output location.

Note Consult your Project Engineer and/or room drawings to determine the video

output location.

3. Pull the cable between the wall control unit and the power supply box.

One end of the wall control unit cable is unterminated.

4. Cut the wall control unit cable to length and terminate it. Connect the wires into the female

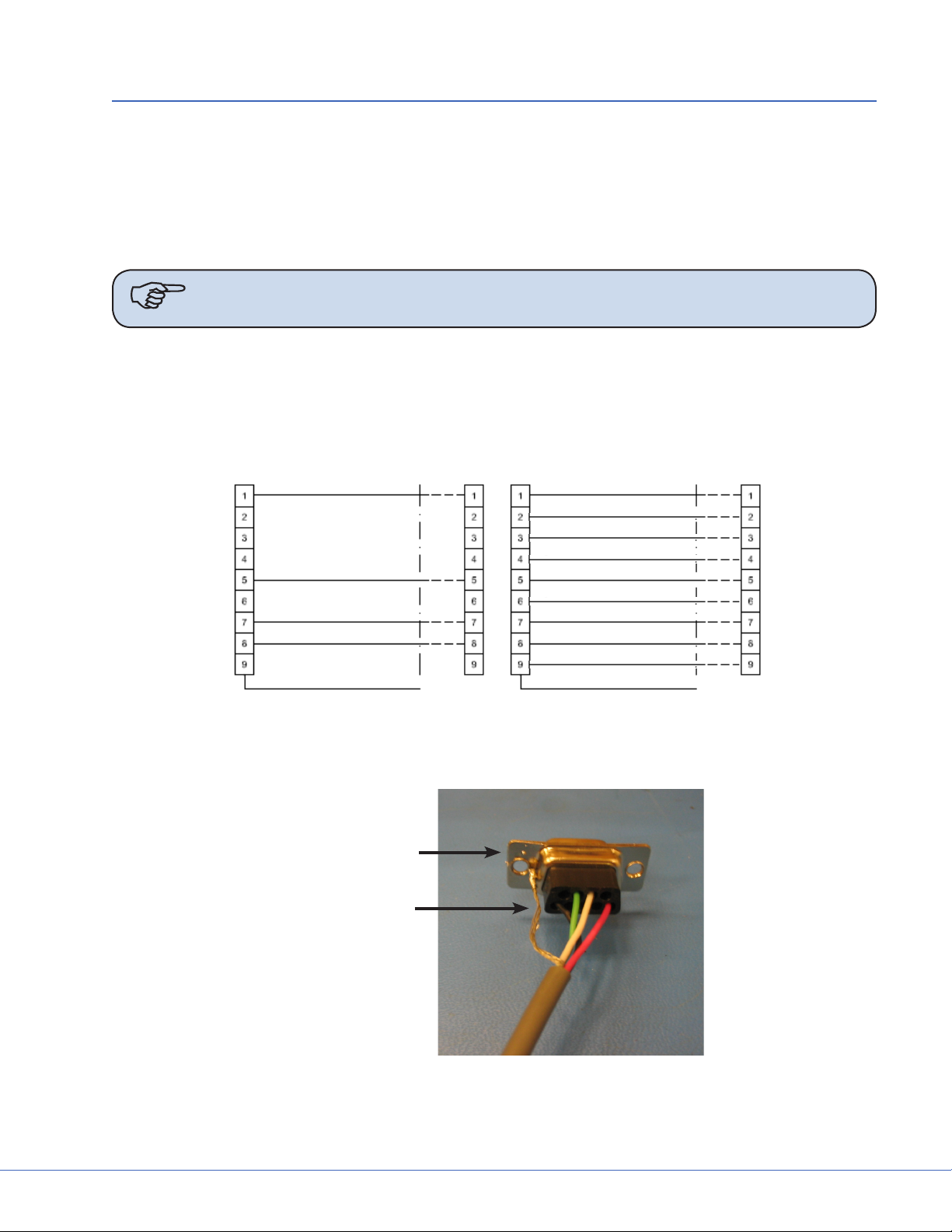

connector according to the schematic chart shown below.

P1 P2

RED

BLK

WHT

GRN

SHLD

Schematic

P1 P2

SHLD

Schematic

Wall Control Unit Cable Pin Conguration - LED (le) Halogen (right)

5. Solder the Shield Conductor to the DB9 female connector chassis as shown below.

DB9 Female

Connector

Shield Conductor

Soldered Shield Conductor

19

Page 20

S

6.2 Surgical Lights

6.2.1 Standard Horizontal Arm

1. Load the suspension shipping box onto a heavy machinery li device.

2. Cut cardboard 9 inches from the top of the box to facilitate hanging suspension. Be careful not

to cut cables or scratch the suspension.

3. Mount down tube onto suspension. Use the six at head socket cap screws (taped to down tube)

to attach the down tube to the central axis spindle. Tighten all screws with a torque wrench set

to 100 lb-in (8.33 lb-, 11.3 Nm). Once all screws have been tightened, retighten each screw to

ensure correct torque is set.

If you are installing a at panel along with a dual light suspension, verify that the at panel cable

kit is routed through the opening in the down tube.

4. Position the suspension assembly directly below the mount site.

5. Go to Section 7, “Installing the Suspension” to complete installation.

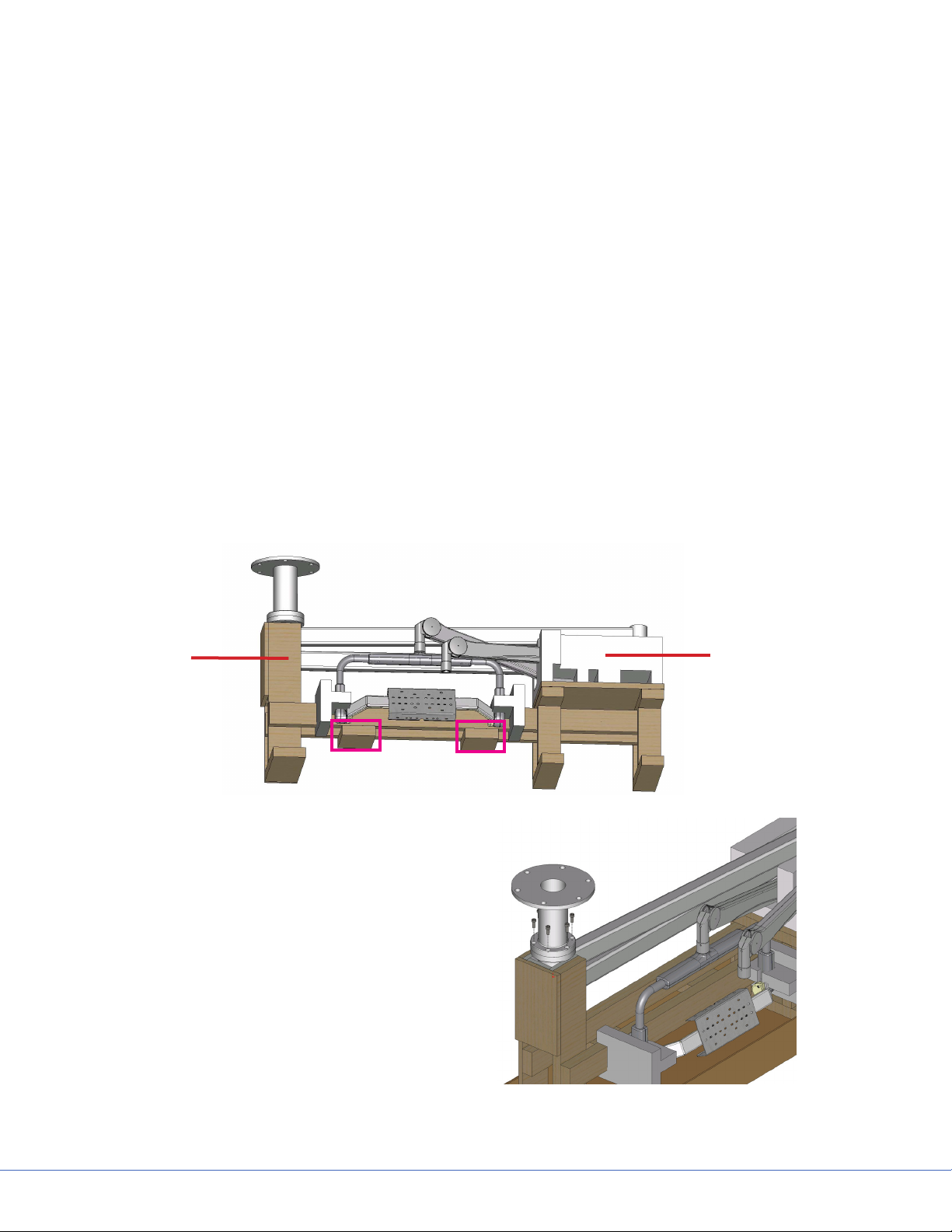

6.2.2 Extended Horizontal Arm

1. Remove all accessories and the cardboard box.

2. Position Genie Life so that forks are underneath the highlighted areas shown in the following

gure.

Brown

packaging is

wood

3. Mount down tube onto suspension. Use

the six socket cap screws to attach the

down tube to the central axis spindle.

Tighten all screws with a torque wrench

set to 354 lb-in (29.5 lb-, 40 N-m). Once

all screws have been tightened, retighten

each screw to ensure correct torque is set.

If you are installing a at panel along with

a dual light suspension, verify that the at

panel cable kit is routed through the opening in the down tube.

White

packaging is

styrofoam

4. Position the suspension assembly directly

below the mount site.

20

Page 21

S

6.2.3 Alternate Light Installation Instructions

1. Load the suspension shipping box onto a heavy machinery li device.

2. Cut cardboard 9 inches from the top of the box to facilitate hanging suspension. Be careful not

to cut cables or scratch the suspension.

Hex Nut

Flat Washer

Lock Washer

Hex Nut

Note When necessary, Plastic Isolation Discs surround the mounting plate, but are only

required in Europe.

3. Raise the down tube toward the mount site.

4. Guide the all-thread rods through the holes located on the down tube ange.

e down tube ange must press lightly against the hardware assembly.

5. Place a at washer on alternating all-thread rods followed by a hex nut; tighten the hex nut.

6. Use a Torpedo Level to verify the down tube ange is level across three horizontal planes. If the

ange is not level, adjust the hex nuts until the Torpedo Level indicates the down tube ange

is level across three horizontal planes. Conrm that the down tube is also level by placing the

Torpedo Level on the down tube at three, evenly-spaced locations.

7. Install a at washer, lock washer, and hex nut on the remaining all-thread rods.

Note Plastic Isolation Discs are only required in Europe.

8. Tighten the hex nuts to 75 -lbs. Ensure the lock washers are fully compressed.

9. Remove the hex nuts from the all-thread rods applied in step 5 and install a lock washer and hex

nut.

21

Page 22

S

10. Use a Torpedo Level to verify that the down tube ange is level across three horizontal planes.

11. Connect the ground wire (found on the down tube ange) to the ground lug located in the ceiling.

12. Refer to Section 7 to complete installation.

6.3 Flat Panel

1. Place the suspension onto a heavy machinery li device.

2. Use zip ties to tie the horizontal arm and

Spring Arm together to prevent swinging

during installation.

3. Raise the Flat Panel Arm for installation;

position the arm so the stop is in the specied location (the Project Manager should

have this information).

Note e normal stop position is above the bed, allowing 330° of rotation of the upper

arm, with the 30° “dead” spot.

6.4 Booms

Due to door entry height, the ange and drop tube may be removed for entry into the room. e

ange and drop tube must be reinstalled before installation of the equipment boom.

If the MMP200/OSC600 Service Head is not assembled:

1. Place pallet securely on material li (e.g.,

Genie Li).

2. Determine the orientation of the service head before attaching to the down

tube, feel for the notch. e notch will be

mounted to the front of the service Head.

22

Page 23

Shelf End

S

3. Remove the four Allen screws from the

Service Head using a 5mm Allen wrench.

4. Locate the cable kit end and pass through

the service head opening.

MMP200 only

Note e Shelf Wedge kit has a

thick and a thin component.

Orientation of the thin side

towards the front of the service head is important.

0682-001-345 Wedge Kit

If the OSC400 Service Head is not assembled:

5. Verify which Wedge is the thinner wedge

of the 2 halves of the Wedge Kit

6. Place the thinner Wedge towards the front

of the Service Head

7. Place the thicker Wedge towards the rear

of the Service Head.

8. Connect Service Head to articulating arm.

9. Tighten the four Allen screws to 14.75 lb-

(20 Nm) using a 5mm Allen wrench.

10. s

23

Page 24

S

1. Remove the six (6) Allen screws from the

Service Head using a 5mm Allen wrench.

2. Remove the cylinder cover located on the

Down Tube. e two (2) halves can be detached by depressing on the two (2) clips

with a at edge tool.

3. Rotate the Down Tube and determine the

stop location. is point will be installed

to the front of the service head.

4. Locate the cable kit end and pass through the service head opening. In some cases, half of the

pass-thru plate will need to be removed to feed the cable kit completely through.

Caution Be sure to leave enough slack for the EP Module control cable within the

arm set. Failure to do so may result in damage to the cable upon removal

of the EP module.

5. Attach the service head by inserting and tightening the six (6) Allen screws to 7.4 lb- (10 Nm)

using a 5mm Allen wrench.

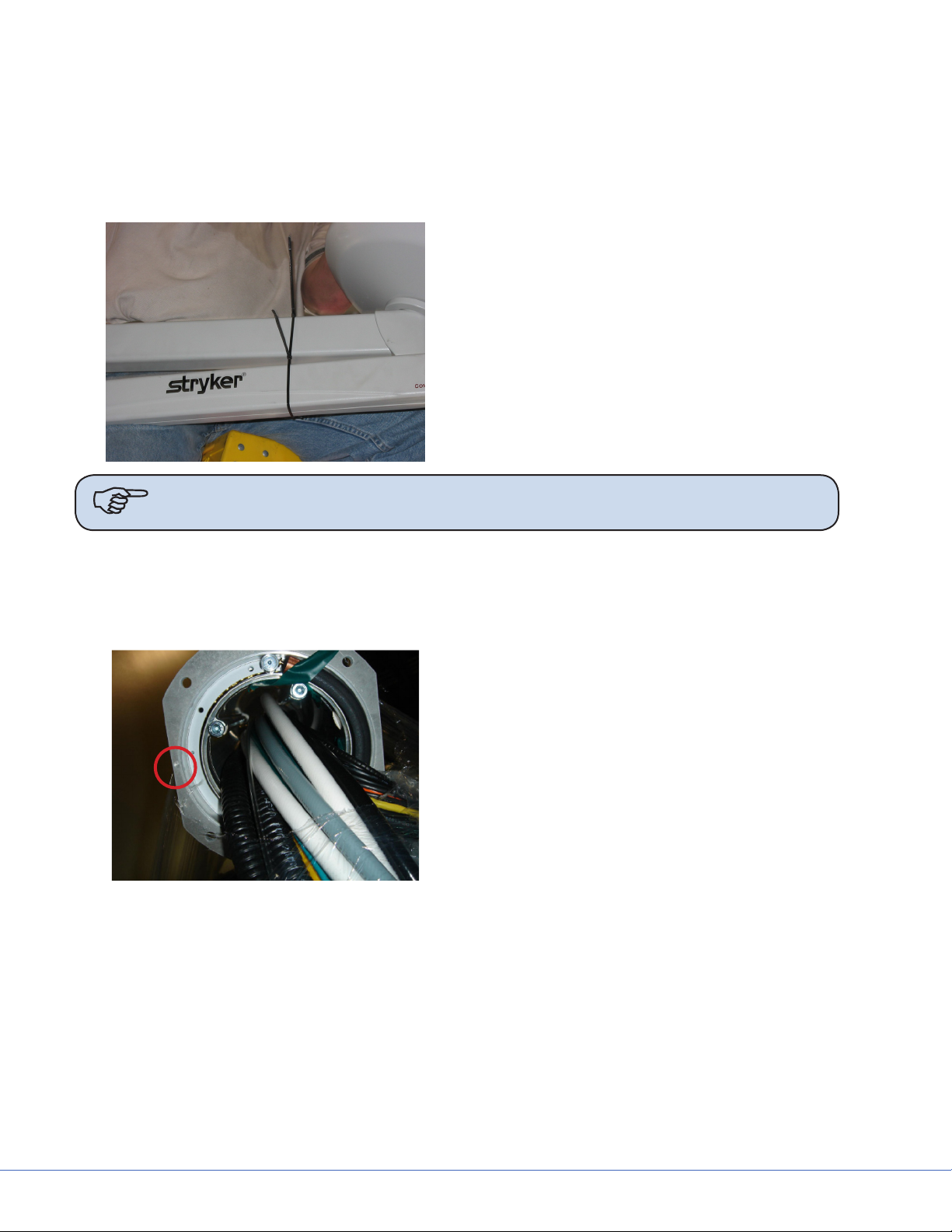

6.5 Routing Cables

is section is only applicable to suspensions with lengthy cable kits.

1. Uncoil the cable kit.

2. Pull the cables from the suspension through the top of the mounting interface plate.

3. Continue to route the cable through the ceiling conduits. Consult your Project Engineer and/or

room drawings to determine cable routing through the conduits.

24

Page 25

S

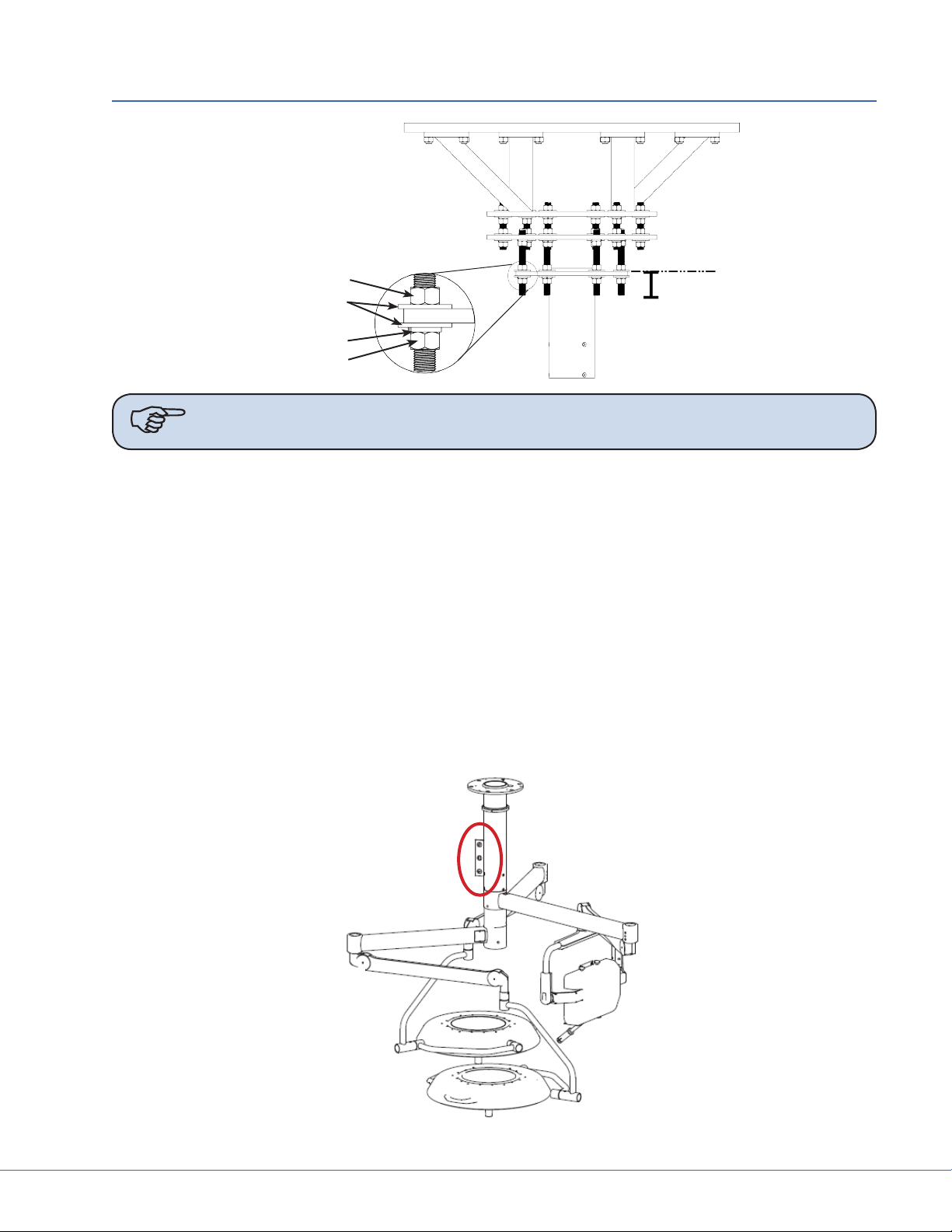

7. Installing the Suspension and Boom Arms

Hex Nut

Flat Washer

Lock Washer

Hex Nut

Note When necessary, Plastic Isolation Discs surround the mounting plate, but are only

required in Europe.

1. Raise the Suspension assembly toward the mount site.

2. Take care when raising the suspension to prevent pinching cables between the all-thread rods

and down tube.

3. Guide the all-thread rods through the holes located on the down tube ange.

e down tube ange must press lightly against the hardware assembly.

4. Pull all cables and electrical connections through the Mounting (Interface) Plate. If ORIS connectivity is going to occur at a later date, tie-wrap cable kit to down tube ange.

5. Place a at washer on alternating all-thread rods followed by a hex nut; tighten the hex nut.

6. Use a Torpedo Level to verify the down tube ange is level across three horizontal planes. If the

ange is not level, adjust the hex nuts until the Torpedo Level indicates the down tube ange

is level across three horizontal planes. Conrm that the down tube is also level by placing the

Torpedo Level on the down tube at three, evenly-spaced locations.

25

Page 26

S

7. Install a at washer, lock washer, and hex nut on the remaining all-thread rods.

Note Plastic Isolation Discs are only required in Europe.

8. Tighten the hex nuts to 75 -lbs. Ensure the lock washers are fully compressed.

9. Remove the hex nuts from the all-thread rods applied in step 10 and install a lock washer and

hex nut.

10. Use a Torpedo Level to verify that the down tube ange is level across three horizontal planes.

11. Connect the ground wire (found on the down tube ange) to the ground lug located in the ceiling.

12. Lower the li device and check the suspension for stability.

13. Pull excess cable through conduit.

7.1 Alternate Light Installation Instructions (Continued)

1. Using a li device, raise the suspension into the down tube.

2. Pull all cables and electrical connections through the Mounting (Interface) Plate. If ORIS connectivity is going to occur at a later date, tie-wrap cable kit to down tube ange.

3. Pull excess cable through conduit.

4. Mount down tube onto suspension. Use the six at head socket cap screws (taped to down tube)

to attach the down tube to the central axis spindle. Tighten all screws with a torque wrench set

to 100 lb-in (8.33 lb-, 11.3 Nm). Once all screws have been tightened, retighten each screw to

ensure correct torque is set.

Note For EHA - Tighten all screws with a torque wrench set to 354 lb-in (29.5 lb-, 40

N-m).

If you are installing a at panel along with a dual light suspension, verify that the at panel cable

kit is routed through the opening in the down tube.

5. Take care when raising the suspension to prevent pinching cables between the down tube and

suspension.

26

Page 27

S

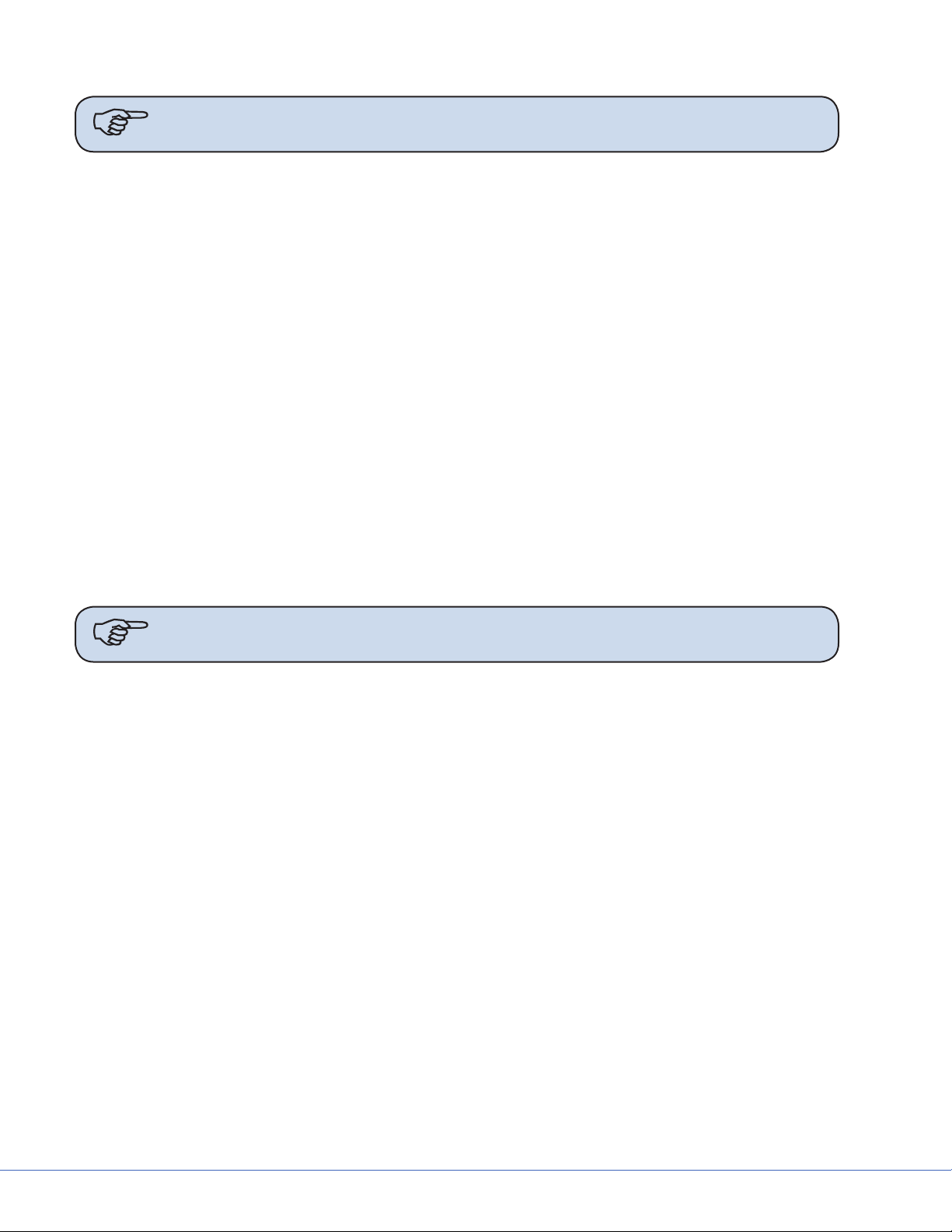

8. Installing Light Heads

8.1 LED and Halogen

Always install the light heads before installing the light handle assembly and In-Light Camera. e

camera light head must be installed on the uppermost Light Spring Arm.

In the case of LED only, the physical dierence between a 5-pole Spring Arm and a 9-pole Spring Arm

is that the 5-pole slip ring is keyed and the 9-pole slip ring is not. e keys resemble rectangles when

viewed from the end of the slip ring.

Note Two people should li the light head to attach it to the Spring Arm.

Light 1 w/

StrykeCam

Note StrykeCam 2 is always associated with Light 1 and is always installed above Light

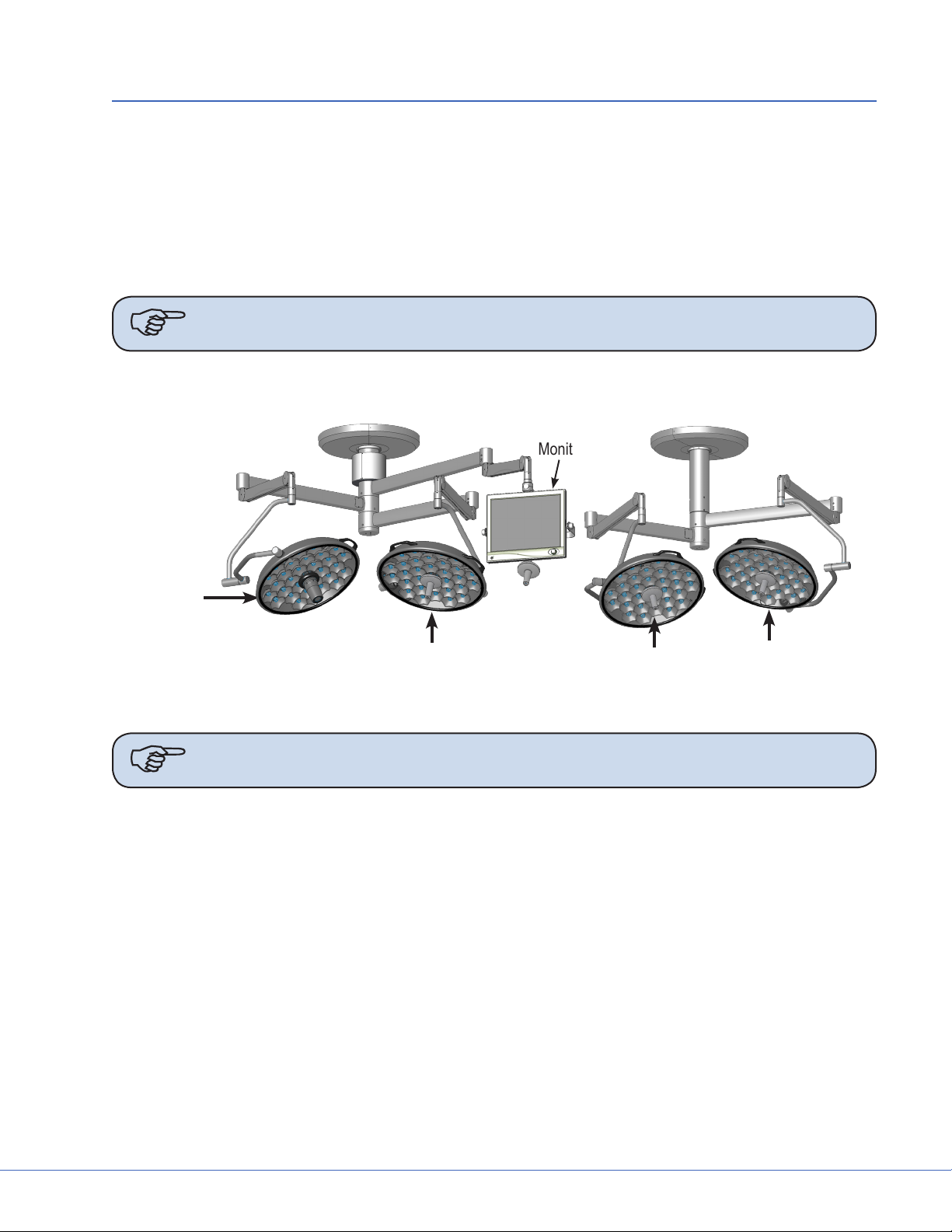

8.1.1 Standard Light

Head 2.

Triple Arm Visum

LED Light Suspension

Light 2

Visum LED Light Suspension

Monitor

Dual Arm Visum LED Light Suspension

Light 4

Light 3

8.1.1.1 5-Pole Light Head

1. Locate the 5-pole Spring Arm and remove the M3 screw.

2. Slide the Safety Segment Cover up to reveal the Safety Segment and re-insert the M3 screw to

hold the cover up.

3. Remove the Safety Segment.

4. Install the 5-pole Light Head.

a. Align the top of the Cardanic Suspension with the bottom of the Spring Arm.

b. Align the rectangle-like keys along the outer wall of the 5-pole slip ring, (located in the light

head) with the notches of the Spring Arm Slip Ring.

c. Raise the light head into the Spring Arm.

5. Reinstall the Safety Segment.

27

Page 28

S

a. Remove the M3 screw and slide the Safety Segment Cover down.

b. Re-insert and tighten the M3 screw to keep the cover in place.

Warning Failure to tighten this screw can cause the Safety Segment Cover to slide

and the light head to fall from the Spring Arm.

8.1.1.2 9-Pole Light Head (LED Only)

1. Locate the 9-pole Spring Arm and remove the M3 screw.

2. Slide the Safety Segment Cover up to reveal the Safety Segment.

3. Remove the Safety Segment.

4. Align the top of the Cardanic Suspension with the bottom of the Spring Arm.

5. Install the 9-pole Light-Head.

Note e 9-pole slip ring is not keyed.

6. Raise the light head into the Spring Arm.

7. Reinstall the Safety Segment.

a. Slide the Safety Segment Cover down.

b. Tighten the M3 screw to keep the cover in place.

Warning Failure to tighten this screw can cause the Safety Segment Cover to slide

and the light head to fall from the Spring Arm.

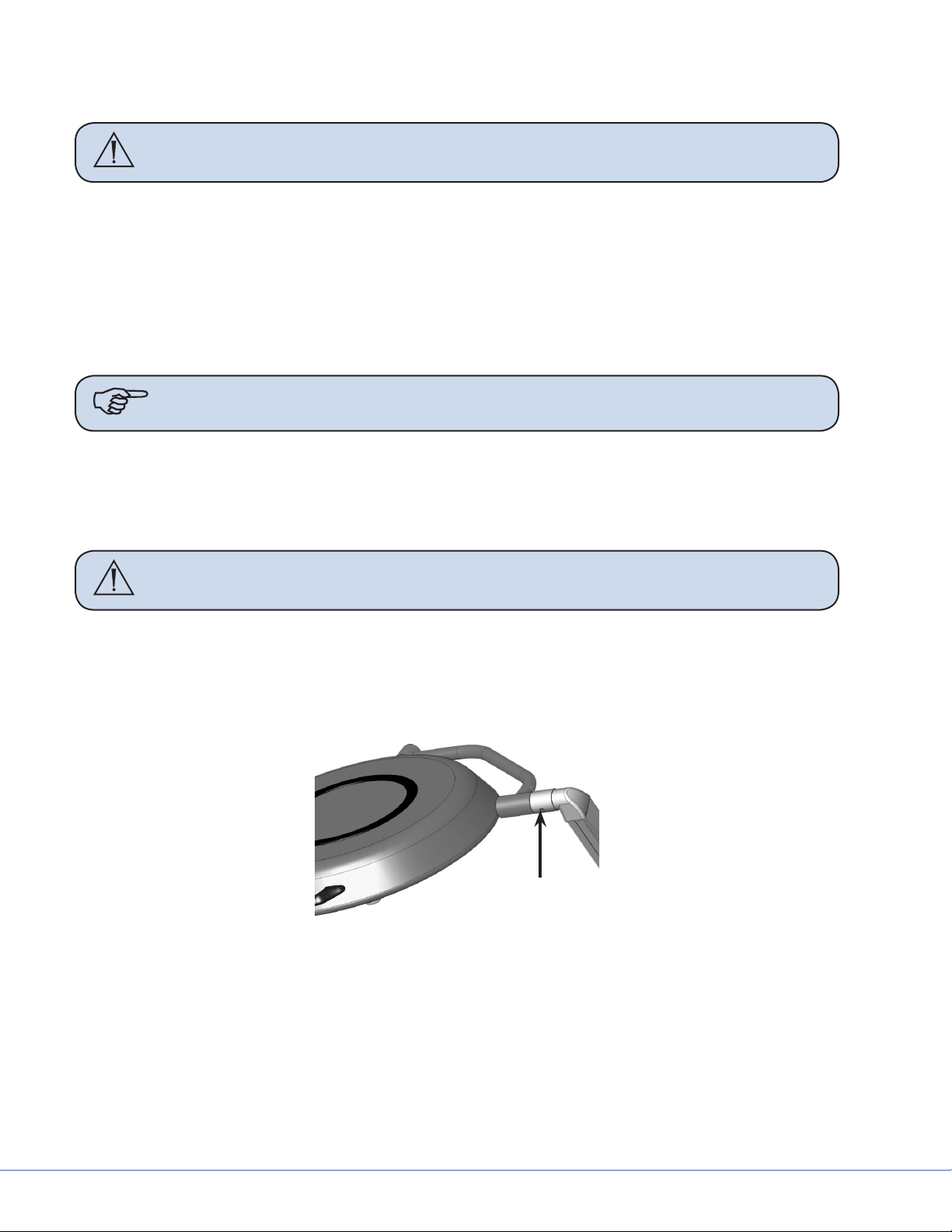

8.1.2 Low Ceiling Light

8.1.2.1 Low Ceiling 5-Pole Light Head

1. Locate the 5-pole Spring Arm and remove the brake screw.

Brake Screw

2. Rotate the cu 90° to reveal the rst retaining screw. Remove the retaining screw from the

Spring Arm.

3. Rotate the cu 180° to reveal the second retaining screw. Remove the retaining screw from the

Spring Arm.

4. Install the 5-pole Light Head.

• Align the rectangle-like keys along the outer wall of the 5-pole slip ring (located in the light

head) with the notches of the Spring Arm slip ring.

28

Page 29

S

• Insert the light head into the Spring Arm. Make sure to support the Spring Arm when assembling.

5. Reinsert the retaining screws removed in steps 2 and 3.

WARNING e cu must be in place before installing the retaining screws.

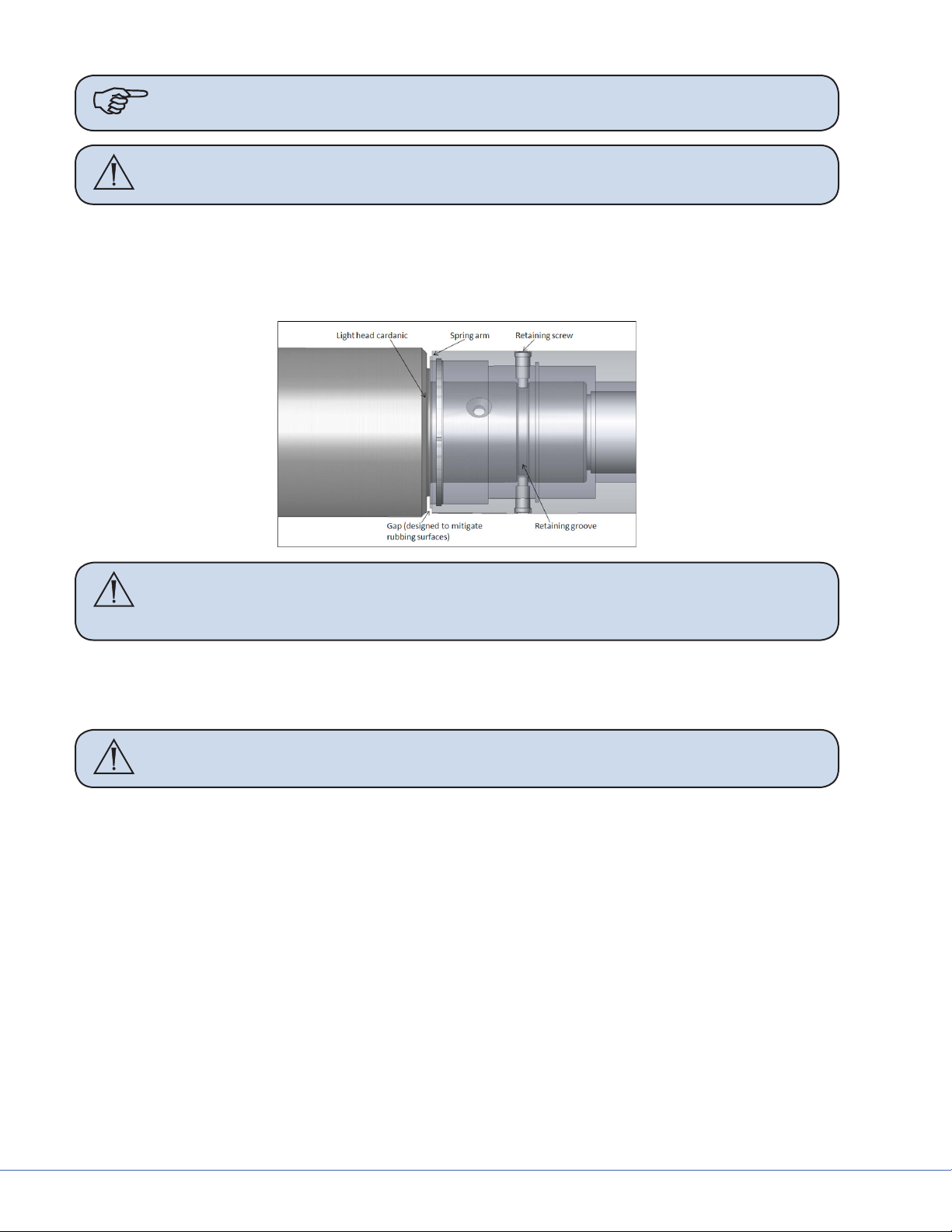

• Align the retaining ring groove feature on the Cardanic of the light head with the retaining

screw holes in the spring arm. A gap will be present between the face of the Cardanic and

face of the spring arm when properly aligned. If needed, back the light head out slightly.

Caution Tightening the retaining screws into the wall of the Cardanic without

aligning them into the retaining ring groove may damage the surface of the

Cardanic.

• Place the rst retaining screw through the opening of the cu and reinstall it. Tighten the

screw completely to ensure that the cu will still rotate freely.

• Rotate the cu 180° to reinstall the second retaining screw. Tighten completely.

Caution Over tightening the Low Ceiling light head to Spring Arm brake screw can

cause permanent damage to the light

• Rotate the cu 90° to insert the brake screw back into place. Tighten the screw until the light

head constantly holds the position in which it is placed.

• When adjusting the brake screw aer installing the light for the rst time or any time aer

performing preventative maintenance, adjust the brake screw and rotate the joint through

a minimum of ve rotations. If aer ve rotations the joint becomes dicult to rotate, the

brake screw is over tightened and needs to be readjusted.

8.1.2.2 Low Ceiling 9-Pole Light Head

1. Locate the 9-pole Spring Arm and remove the brake screw.

2. Rotate the cu 90° to reveal the rst retaining screw. Remove the retaining screw from the

Spring Arm.

3. Rotate the cu 180° to reveal the second retaining screw. Remove the retaining screw from the

Spring Arm.

4. Install the 9-pole light head. Make sure to support the Spring Arm when assembling.

29

Page 30

S

Note e 9-pole slip ring is not keyed.

WARNING e cu must be in place before installing the retaining screws.

5. Reinsert the retaining screws removed in steps 2 and 3.

• Align the retaining ring groove feature on the Cardanic of the light head with the retaining

screw holes in the spring arm. A gap will be present between the face of the Cardanic and

face of the spring arm when properly aligned. If needed, back the light head out slightly.

Caution Tightening the retaining screws into the wall of the Cardanic without

aligning them into the retaining ring groove may damage the surface of the

Cardanic.

• Place the rst retaining screw through the opening of the cu and reinstall it. Tighten the

screw completely to ensure that the cu will still rotate freely.

• Rotate the cu 180° to reinstall the second retaining screw. Tighten completely.

Caution Over tightening the Low Ceiling light head to Spring Arm brake screw can

cause permanent damage to the light

• Rotate the cu 90° to insert the brake screw back into place. Tighten the screw until the light

head constantly holds the position in which it is placed.

• When adjusting the brake screw aer installing the light for the rst time or any time aer

performing preventative maintenance, adjust the brake screw and rotate the joint through

a minimum of ve rotations. If aer ve rotations the joint becomes dicult to rotate, the

brake screw is over tightened and needs to be readjusted.

30

Page 31

9. Powering the System

9.1 Halogen Lights

9.1.1 Electrical and Data Connections

e electrical system consists of the following parts:

• Wall control box

• Power supply box

• Electronics in light head

1. Mount the wall control box into back box and connect the two cables. Top cable is for Light

One (black connector), bottom connection is for Light Two (white connector) and the camera

controls.

2. Place the power supply box

into designated the location

in the documentation station.

e front of the power supply

box has the video connections,

RS-232 connections, and the

low voltage connections to the

lights. e rear has an IEC connector for 115/230VAC power

cord. Additionally a 24VDC

safety power connection is provided for countries with this

requirement.

S

Power Supply Box (Front and Rear View)

Note Proper positioning of the light Power supply box in the Documentation Station

with cable connections in the front.

3. Connect the two cables from the wall control box to the proper connectors.

4. Connect the surgical lighting low voltage and listen for an audible click to conrm proper installation.

5. Connect the data cables to the power supply box.

6. Connect hospital-provided 24 VDC backup power to provided connector (if applicable).

Note Have the hospital designated contractor connect the high voltage cord to the

junction box they installed for Light/ Flat Panel models only. Stryker will not

make high voltage connections. Do not close the circuit breaker yet.

7. Connect low voltage leads from the power supply box to connections at the top of the surgical

lighting suspension.

31

Page 32

S

8. Verify all electrical connections are made, then have contractor turn breaker back on. Power up

the lights using the wall box.

9. Run lights through control, checking the following order:

a. On/o (10 times each light head).

b. Intensity up and down through the full range (10 times per light head).

c. Verify reserve bulb indicator is operational by removing the primary bulb from each light

head. e reserve bulb indicator on the wall control panel should light up. Replace primary

bulb aer turning o the lights.

Caution DO NOT touch the bulb directly with your hands.

9.2 LED Lights

9.2.1 Power Supply Box Wall Mount (Optional)

e power supply box wall mount should be used to securely install and mount a Visum LED power

supply box to a wall.

Mount a standard Hubbell Wiegmann (P/N SC101004) junction box to a wall and then install the

power supply box.

Power

Supply Box

Control

Panel

Note Consult the hospital to determine ideal placement for a power supply box before

mounting the junction box.

Exploded View of

Power Supply Box

Customer Supplied

Back Box*

Wall

Mount

Plate

Vertical Side View of

Power Supply Box

and Back Box

Power Supply Box

Customer

Supplied

Back Box*

*The Back Box is recessed ush within the wall.

Exploded/Side view of Power Supply Box

32

Wall

Page 33

S

9.3 Power Supply Box Connections

Place the power supply box in the designated location in the documentation station.

e front of the power supply box has RS-232 and low voltage connections. e power inlet connector

is located on the rear side of the power supply box for the 115/230VAC power cord.

Light Control

Light Power

Wall

Connection

Port

SORN

Port

SIDNE

Port

Expansion

Power Supply Box, Front View

12.5

(317.5)

Port

Light Control

Light Power

Circuit Breaker

Power Inlet

7.0

(177.8)

Depth 15.5 (393.7)

INCHES (mm)

Power Supply Box, Rear View

Note Avoid blocking the fan exhausts or placing objects within 2 inches of the fan

exhausts.

To control the Visum LED Surgical Light and StrykeCam 2 In-Light Camera from the wall-mounted

control panel, the Light Power Connector and Wall Control Connector must be connected to a power

supply box. Review the sets of instructions and diagrams below for connections.

33

Page 34

S

9.3.1 Power

Light Power

Panel Mount

Light Power

Connector Tabs

Light Power

Connector

Release

Power Supply Box Light Connections

1. Align the Power Connector Tabs

with the slots on the Light Power

Panel Mount.

2. Insert the Power Connector into the

mount and turn it clockwise until

you hear a click.

is ensures that the connection is

secure.

Light Power

Connector

9.3.2 Control

Control Panel

Prongs

Control

Connector

Power Supply Box Control Connections

Control Panel

Mount

Control

Connector

Release

1. Align the prongs on the Control

Panel Mount with the slots on the

Control Connector.

e prongs must t into the slots on

the Control Connector.

2. Insert the Control Connector into

the Control Panel Mount and press

until you hear a click.

is ensures that the connection is

secure.

34

Page 35

9.3.3 Wall Control Unit Port

S

Wall

Control Unit

Port

SORN

Port

SIDNE

Port

Expansion

Port

See the diagram and instructions below to set up

and connect the following ports:

• Wall Control Unit Port

• SORN Port

• SIDNE Port

• Expansion Port

Connection Ports

To enable a connection between the wall-mounted control panel, Visum LED Surgical Lights, and

StrykeCam 2 In-Light Camera, connect the Wall Control Unit Port on the power supply box to the

wall-mounted control panel. Use a Stryker-supplied cable to connect the Wall Control Unit Port to the

Wall Mounted Control Panel.

9.3.4 SORN

SORN is a system that enables device management and networking capability among Stryker equipment. Use an Ethernet or CAT 5e cable to connect the SORN port on the power supply box to a local

hospital network port.

9.3.5 SIDNE

SIDNE is a voice activation platform that enables an operation room and its equipment to be controlled with voice commands. Use a USB A (male) to B (male) cable to connect SIDNE to the power

supply box.

9.3.6 Expansion Port (Optional)

SIDNE can control up to four Visum LED Surgical Lights. To do this, a second power control box is

necessary. Use the Expansion port on the rst power supply box to connect a second power supply box

to control the additional two lights.

To enable SIDNE to control four surgical lights:

1. Connect the

rst power supply box.

2. Insert a second

3. Connect the cable (leading from the Expansion port) to the SIDNE port on the second power

supply box (see diagram below).

USB A to B

USB A to B

cable from an available SIDNE device port to the SIDNE port on the

cable into the Expansion Port on power supply box 1.

35

Page 36

S

Power supply box 1

Connect Power Supply

Box 1 to Power Supply

Box 2 with a USB A to B

cable.

Power supply

box 2

Dual Power Supply Box for Multiple Light Control

Caution Do not connect the SIDNE device port directly to power supply box 2.

4. Connect the power supply box to 110V/230VAC using a medical grade power cord

(included with shipment).

5. Connect the BNC female connectors to the BNC male connectors at the top of the suspension to

establish the S-Video connection.

9.4 Visum LED New Installation Setup

9.4.1 Required Tools

• Laptop with a RS-232 COMM Serial Port

• USB to RS-232 Serial Adapter (0682-400-030; if no Serial Port is present on laptop)

• USB to RS-232 Serial Install Driver

• Visum LED Field Service and Installation Cable (0682-001-691)

• Windows Hyperterminal or other terminal program

9.4.2 Installing USB to RS-232 Adapter (for laptops without Serial Ports)

1. Insert Driver CD.

36

Page 37

S

2. A Driver and User’s Guide window may appear. Close the window. Do not install from this

window.

3. Connect the USB to Serial Adapter. e Found New Hardware Window should open.

4. Select - No, not this time.

5. Click Next.

6. Select - Install from a list of specic location (Advanced). Click Next.

7. Select - Search for the best driver in these locations. Make sure to include the CD-ROM drive by

checking the box that says “Search removable media (oppy, CD-ROM...).” Click Next.

8. Wait while Windows searches for Drivers.

9. Select Appropriate Driver (if using Windows XP/2000 the highlighted driver shown in below).

Make sure to select “usb 2.0 to RS-232 converter.” DO NOT select cable. Click Next.

10. Click Finish.

11. e Found New Hardware Window will appear again. Repeat Steps 4 through 9 once again

selecting the ‘usb 2.0 to RS-232 converter’ and NOT the cable.

12. e USB to RS-232 Serial Adapter is now installed.

9.4.3 Connecting a Laptop to the SIDNE Port on Visum LED System

Note Make sure system is completely connected and fully functional. Failure to do so

may result in improper setup.

1. Insert the USB-B end of the Visum LED Field Service and Installation Cable into the SIDNE

port on the Visum LED power supply box.

2. Insert the DB-9 end of the cable into the Serial port of your laptop (or Serial to USB adapter).

3. Power ON the Visum LED power supply box.

9.4.3.1 Launch Hyperterminal

1. Boot up the laptop and login.

2. Select Windows Start, Programs,

Accessories, Communications, Hyperterminal.

e Connection Description dialog

should display.

3. Enter <VISUM LED> in the Name

eld.

4. Click OK.

e Connect To dialog box displays.

Connection Description Dialog

37

Page 38

S

5. Select a COM Port in the Connect

Using eld and click OK.

A COM Properties Window displays.

Connect To Dialog

6. Select the following options for the

listed elds:

• Bits per second: 19200

• Data bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None

7. Click OK.

e Visum LED - HyperTerminal

Screen should display.

COM Properties Dialog

38

Page 39

Visum LED - HyperTerminal Screen

9.4.4 Visum LED Main Menu

S

is screen indicates that a connection has been established between

your laptop and the Visum LED

system.

To view the Main Menu, press “~” on the

laptop keyboard. e Visum LED Main

Menu should display.

e following information can be accessed

from the main menu:

• New Installation

• Service Menu

• View power supply boxCU info

• Test Menu

Visum LED Main Menu

Note Notice that [NOT INSTALLED] displays aer the menu name in the gure above

to indicate the LED Light System has not been installed.

9.4.5 New Installation

To set up a new installation press “0” on your keyboard. e system will prompt you to provide the following information:

• Region Number

• Account Number

• Location of the Installation (room number or operating room number)

• Light Indication: L1 and L2 or L3 and L4.

• Finished Installation, Are you sure ‘y’ or ‘n’ (program is case sensitive)

Note Obtain the Region Number and Account Number from your Project Manager if

this information is unknown to you.

e system completes the installation aer your response to the last inquiry. Enter <x> to exit the

installation.

e installation is successful if the LED lights on the Wall Control Unit are not ashing.

39

Page 40

S

10. Monitor Assembly

10.1 Light Flat Panel or Single Panel installation

16

17

15

14

11

13

12

4

10

3

2

1

5

9

6

8

7

Yoke Anatomy

Part Description Part Description

1 Shroud 10 Central Monitor Support Bracket

2 Shroud Knobs 10. Monitor Vertical Adjust Bracket

3 Monitor Width Adjust Clamp Bottom 12 Handle Assembly

4 Monitor Width Adjust Clamp Top 13 Le Pivot Arm Cable Cover

5 Right Side Support Tube 14 Le Pivot Arm

6 Outer Right Adjust Clamp 15 Inner Le Adjust Clamp

7 Inner Right Adjust Clamp 16 Outer Le Adjust Clamp

8 Right Pivot Arm 17 Le Side Support Tube

9 Right Pivot Arm Cover

40

Page 41

10.2 Adjusting the Yoke

10.2.1 Adjusting the Width

To adjust the width of the yoke:

1. Remove the power supply from the Central Monitor Support Bracket.

2. Remove the cable cover that is concealing the cables on the le Pivot Arm.

Width Adjust Clamp

Left Pivot Arm

Cable Cover

S

Central Monitor

Support

Right Pivot Arm

Cable Cover

Remove the cable cover

Note It is not necessary to remove the cable cover from both Pivot Arms, only the le

side where the cables are concealed.

3. Remove the Central Support Bracket by removing the eight M6 socket head screws and all

washers using a 5mm Allen wrench.

Caution Before beginning to remove the screws holding the Width Adjust Clamp

together, loosely place two cable ties around each side of the clamp to prevent the yoke from falling once the screws have been removed.

41

Page 42

S

Support Straps

Support strap locations

(each yoke will only contain two support straps

even though four are shown in this gure)

4. Remove the eight M5 screws located under

the Width Adjust Clamp using a 4mm Allen wrench, and pull down the clamp.

5. Loosen the support strap inside the Width

Adjust Clamp that is securing the support

tube in place from either the le or the

right side. Do not remove the strap completely.

Note For ease of installation, adjust one side at a time.

6. Yoke width is adjusted by inserting the tube alignment pins into the numbered holes in the

bottom piece of the Width Adjust Clamp. Use Table 10.1 to determine the correct holes for the

monitor, and seat the alignment pins in their respective bracket holes.

Note Measurements presented in the table are estimates only. Adjustments may need

to be made before completing installation to ensure correct balance and t.

7. Secure the horizontal tube to the lower Width Adjust Clamp by tightening the support straps

with self tapping screws until the strap is torqued. Avoid tearing the strap.

WARNING Failure to tighten the support straps could result in the yoke falling.

Note Use the inside strap locations when possible.

8. Repeat steps 5-7 for the opposite side.

9. Reassemble the Width Adjust Clamp and secure using the M5 socket head screws. Tighten all

screws to 35 lb. in. (3.95 Nm) torque.

WARNING Ensure that all screws are present. Missing screws could result in the yoke

falling.

Note Use a torque wrench to tighten screws. If a torque wrench is not available, do not

attempt to tighten screws yourself, but contact your Stryker representative.

42

Page 43

S

3 and 4

Support

Central Monitor

Handle

Adjust Hole

Hole

Depth

Monitor Adjustment

holes

1 and 2

holes

1 and 2

holes

3 and 4

holes

1 and 2

holes

Vertical

Monitor

Adjustment Hole

Table 10.1 - Bracket Adjustments

Height Pin

Placement

5 3 Bottom screws in 8 4 Bottom 2

1 3 Bottom screws in 10 1 Bottom 2

7 7 Bottom screws in 5 1 Top 2 holes 4 and 5

1 1 Top screws in 5 11 Bottom 2

Monitor Width Pin

Stryker Vision

Elect HDTV 26”

43

Elect 21”

Stryker Vision

Radiance 19” 1 3 Bottom screws in 5 3 Bottom 2

Sony LMD 24” 5 3 Bottom screws in 10 3 Bottom 2

Allowable

Configuration

Most Expanded

Configuration

Most Collapsed

Allowable

Page 44

S

13 13

1 15 5811 8 11

Width Adjust Clamp

10. Using Table 10.1 as a guide, reattach the Central Monitor Support to the Pivot Arms using all

eight socket head screws and related washers, ensuring that each Pivot Arm has a least one serrated washer attached for grounding purposes. Be sure to center the Central Support Bracket

within the general assembly. Tighten all screws to 65 lb. in. (7.34 Nm) torque.

WARNING It is necessary to use serrated washers and scratch them through the paint

layer to the actual metal surface to prevent the possibility of electric shock.

1

2

3

4

5

4

3

2

1

1

2

3

4

5

Pivot Arm

Central Monitor Support Bracket

Warning Ensure that all screws are present. Missing screws could result in the yoke

falling.

Note Use Table 10.1 as a guide on how to properly adjust the yoke to account for the

center of gravity. If the center of gravity is improperly balanced, the yoke will not

perform correctly.

44

Page 45

10.2.2 Adjusting the Height

Left Cable Cover

Le cable cover

S

1. Remove the cable cover from the le Pivot

Arm where the cables are concealed.

Note It is not necessary to remove

the cable cover from both

horizontal arm supports,

only the le side where the

cables are concealed.

2. Remove the M5 screws from either the le

or right Height Adjust Clamp. Use care

when removing the screws, as pieces of the

clamp may fall o.

Note For ease of installation,

adjust the height one arm at

a time.

3. Remove the outer piece of the Height Adjust Clamp and remove the tube alignment pin from

the inner piece.

4. Use Table 10.1 to determine the appropriate hole to seat the alignment pin into in the inner

piece of the Height Adjust Clamp.

Note Measurements presented in the table are estimates only. Adjustments may need

to be made before completing installation to ensure correct balance and t.

5. Set the alignment pins in their respective

bracket holes in the inner Height Adjust

Clamp.

6. Reattach the outer Height Adjust Clamp

and secure with M5 socket head screws.

Tighten all screws to 35 lb. in. (3.95 Nm)

torque.

WARNING Ensure that all screws

are present. Missing

screws could result in

the yoke falling.

Height Adjust Clamp

8. Attach the cable cover to the Le Pivot Arm, using three M4 X 12 button head socket cap

screws. Hand tighten all screws fully.

Note Ensure that cables do not get pinched.

45

7. Repeat steps 1-5 for the opposite Height

Adjust Clamp.

Page 46

S

10.3 Attaching the Monitor

1. Attach the power supply to the Central Support Bracket using cable ties. Tighten the cable ties

to prevent movement of the power supply.

2. Ensure that all monitor cables lay at below the power supply and are routed to the right or le.

Caution Take care not to kink the ber optic cable beyond a 5mm bend radius to

prevent damaging it.

WARNING DO NOT OVERLOAD THE ADJUSTABLE YOKE.

Cable Tie Locations

Cable Tie Locations

Cable tie locations

3. Lay the monitor screen side down on a at surface.

Caution If there are knobs that extrude from the surface of the monitor, take care to

ensure that they hang o the edge of the table to prevent them from being

broken or damaged while installing the Monitor Vertical Adjust Bracket.

Caution Take care not to scratch the monitor screen when placing it face down.

4. Align the holes on the Monitor Vertical Adjust Bracket with the VESA mounting holes on the

back of the monitor, using Table 10.1 as a guide. Ensure that the cutout for the handle assembly

is at the bottom of the monitor.

5. Secure the Monitor Vertical Adjust Bracket to the back of the monitor using four M4 socket

head screws, and tighten using a 3mm Allen wrench.

WARNING Ensure that all screws are present. Missing screws could result in the moni-

tor falling.

6. Align and place the handle assembly on the back of the Monitor Vertical Adjust Bracket using

the screw mounting holes. Take care to ensure that the handle assembly does not interfere with

the base of the monitor.

7. Secure the handle assembly to the Monitor Vertical Adjust Bracket using two M5 socket head

screws and washers; tighten to 35 lb. in. (3.95 Nm) torque.

46

Page 47

S

8. From the position shown in the next gure, rotate the Pivot Arms of the support bracket to determine which side is the top to ensure that the monitor is installed right side up. e pivot arm

will rotate 90º in one direction only; the side that rotates up is the top.

Top

Bracket rotations

9. Place the monitor onto the Central Monitor Support Bracket so that the Monitor Vertical Adjust

bracket is seated outside the Central Monitor Support Bracket.

Vertical Adjust

Bracket

Vertical Adjust

Bracket

Central Monitor

Support

Monitor Vertical Adjust Bracket seated outside the Central Monitor Support Bracket

10. Align the safety guide slots on the Monitor Vertical Adjust Bracket with the center-most two

holes on the Central Monitor Support Bracket. Secure the brackets together using four M6

socket head screws, and loosely tighten using a 5mm Allen wrench. Do not tighten screws completely to allow the monitor to slide freely in the safety guides.

11. Tip the monitor up into a vertical position.

12. Slide the monitor backward or forward so that the end of the Monitor Vertical Adjust Bracket

sits ush with the back of the Central Support Bracket, or to provide enough space for the power

supply. Be sure that the handle does not touch the power supply.

13. Align the bracket adjustment holes on both brackets, and secure them together using four M6

socket head screws and serrated washers. Tighten all screws to 65 lb. in. (7.34 Nm) torque.

14. Connect the cables to the monitor.

47

Page 48

S

15. Attach the shroud to the back of the Adjustable Yoke using the four knob screws.

WARNING Ensure that all screws are present. Missing screws could result in the yoke

falling.

10.4 Balancing the Monitor

When the monitor is balanced correctly

and the brakes are properly adjusted, the

yoke will always hold the position in which

it is placed throughout its range of motion.

Improper balance and brake adjustments

10

11

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

may result in the monitor driing when it is

released. e vertical and horizontal adjustments of the yoke center of gravity are

accomplished by changing the position of

the Monitor Vertical Adjust Bracket either

on the back of the monitor, in relation to the

Central Monitor support bracket, or both.

To test balancing and brake adjustment,

move and release the yoke in various positions throughout it’s range of motion. If the

monitor dris in any position, use Table 10.2

to determine where the center of gravity

is located; use Table 10.1 as an adjustment

guide. Note that the yoke’s center of gravity

may require adjustment in both the vertical

and horizontal directions (for example topheavy or bottom-heavy). If the monitor still

continues to dri, tighten the brakes.

1

2

3

4

5

6

7

8

9

10

11

Monitor Vertical Adjust Bracket (see Table 10.1)

48

11

1

2

3

4

5

6

7

8

9

10

Page 49

Table 10.2 - Adjusting the Center of Gravity

Monitor Center of Gravity and Drift Direction Condition

The center of gravity is aligned with the pitch

adjustment joint, and the yoke is balanced. The

monitor does not drift when released from any

position with little brake force.

Problem: Monitor is top-heavy

Solution: Move monitor down on Vertical Adjust

Bracket

S

Problem: Monitor is bottom-heavy

Solution: Move monitor up on Vertical Adjust

Bracket

Problem: Monitor is front-heavy

Solution: Move monitor and Vertical Adjust

Bracket backward on Central Monitor Support

Problem: Monitor is back-heavy

Solution: Move monitor and Vertical Adjust

Bracket forward on Central Monitor Support

If the monitor does not continue to fall forward or backward on its own, it is properly adjusted.

49

Page 50

S

10.5 Adjusting the Brakes

Once the center of gravity has been properly adjusted, you may need to tighten or loosen the tension

on the brakes.

To adjust the brake tension, insert a 3mm Allen

wrench into the socket head screw located on

the underside of the respective height adjust arm

and tighten the screw in a clockwise direction

or loosen in a counterclockwise direction. Only

tighten or loosen the screw slightly to determine

if it is sucient to hold the monitor in place.

Adjust brake screws identically for both sides

at the same time (i.e., turn the right side one

quarter turn, then turn the le side one quarter

turn). Continue to adjust the brakes a little bit at

Brakes

Brake location

a time until they easily hold the monitor in place

throughout it’s range of motion.

50

Page 51

11. Boom Shelf Attachment and Adjusting Brakes/Stops

11.1 Boom Shelf and Accessories Attachment

11.1.1 FLEXiS Shelf Installation

Shelf with handle attached

S

To install a shelf:

1. Remove the shelf from the packaging. e shelf should include all the parts shown in the gure

above, unless it comes without a handle.

2. Assemble the shelf clamps.

a. Combine the clamp pieces as shown in the gure below (Item 1). Use the M8 clamp screw

(Item 2) and clamp nut (Item 3) to loosely assemble the clamps.

b. Assemble the M10 mounting screws (Item 4) through the clamps into the shelf.

1

2

3

2

4

Shelf Assembly

Part Part Name

1 Shelf Clamps

2 M6 Clamp Screws

3 Clamp Nuts

4 M10 Mounting Screws

51

Page 52

S

3. Loosen the mounting screws (Item 2).

4. Loosen the clamp screws (Item 1 in the following gure) as much as possible without disassembly.

2

1

1

Screw and Nut Locations

5. Slide each clamp assembly apart and position the shelf on the MFRs of the FLEXiS System. e

clamps should be able to open enough to directly install the shelf to the desired location. e

shelf can also be attached by sliding the clamps onto the MFRs.

6. If the clamps cannot close properly, the shelf may not be level.

7. Fully tighten the clamp screws (Item 1).

8. Fully tighten the mounting screws (Item 2).

1 2

Location of Screws on Access Panel

9. If the shelf has a handle, connect the control cable from the FLEXiS System to the

connector on the back of the shelf.

a. Using a Phillips screw driver, open the

access panel (Item 1) on the front or

back of the FLEXiS System by removing

the eight Phillips screws (Item 2).

52

Page 53

Tether Wire Location

S

b. e access panel is attached to the

FLEXiS System via a tether wire inside

the system to prevent it from falling

when removed. Ensure the panel rests

on the tether when it is removed and not

1

on the medical gas hoses.

c. Locate the control cable connector in-

side the FLEXiS System.

Control Cable for a Shelf with Handle

Data Pass-rough Location

d. Pass the control cable through the data

pass-through on the same side as the

shelf with handle.

e. Connect the control cable to the shelf