Page 1

Altrix™ Precision Temperature Management System

8001

Operations Manual

2016/12 G.1 8001-009-001 REV G

www.stryker.com

Page 2

sample text

Page 3

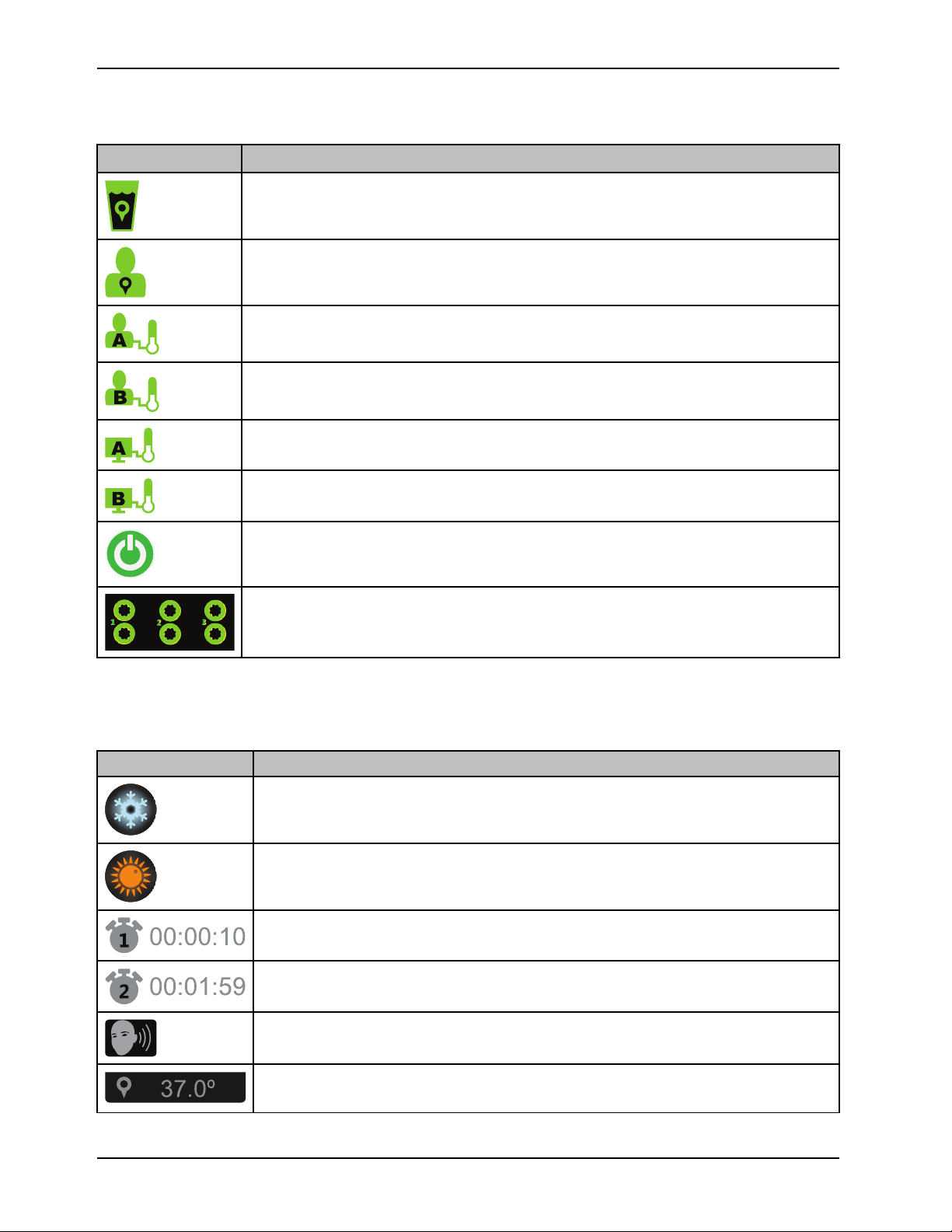

Symbols

~

ONLY

Refer to instruction manual/booklet

General mandatory action sign

Consult instructions for use

General warning

Caution

Warning; electricity

Catalogue number / model

IPX1

Serial number

For US Patents see www.stryker.com/patents

Manufacturer

Mass of equipment

Direct current

Alternating current

Product provides terminal for connection of a potential equalization conductor. The potential

equalization conductor provides direct connection between the product and potential

equalization busbar of the electrical installation.

Protective earth ground

Protection from dripping water from above the device

Defibrillation proof type BF applied part

CAUTION

Federal law (USA) restricts this device to sale by or on the order of a physician.

www.stryker.com 8001-009-0 01 REV G

Page 4

87VL Medical

Electrical Equipment

Symbols

CAUTION

Always use sterile distilled water or water that has been passed through a filter less than or

equal to 0.22 microns with this product.

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic

Equipment, this symbol indicates that the product must not be disposed of as unsorted

municipal waste, but should be collected separately. Contact your local distributor for disposal

information.

Medical Equipment Classified by Underwriters Laboratories Inc. with Respect to Electric Shock,

Fire, Mechanical and Other Specified Hazards Only in Accordance with IEC 60601-1:20 05 (3rd

edition), ANSI/AAMI ES60601-1 (2005, 3rd edition), CAN/CSA C22.2 No. 60601-1:20 08, IEC

80601-2-35:2009, CAN/CSA C22.2 NO 80601-2-35:12, ISO 80601-2-56:2009, CAN/CSA C22.2

NO 80601-2-56:12, IEC 60601-1-8:2007, CAN/CSA C22.2 NO 60601-1-8-08, IEC 60601-110:2008, CAN/CSA C22.2 NO 60601-1-1 0-09, IEC 60601-1-6, CAN/CSA-C22.2 No. 60601-16:11

Liquid level indicator

Fragile, handle with care

Keep dry

Do not stack

This way up

8001-009-0 01 REV G www.stryker.com

Page 5

Table of Contents

Warning/Caution/Note Definition...................................................................................................................4

Summary of safety precautions ....................................................................................................................5

Introduction..............................................................................................................................................7

Product description..............................................................................................................................7

Indications for use ...............................................................................................................................7

Intended users.................................................................................................................................... 8

Expected service life ............................................................................................................................ 8

Contraindications................................................................................................................................. 8

Specifications..................................................................................................................................... 8

Product illustration ............................................................................................................................. 10

Product system ................................................................................................................................. 11

Product functions .............................................................................................................................. 12

Buttons ..................................................................................................................................... 12

Visual indicators.......................................................................................................................... 13

Graphical user interface icons........................................................................................................ 14

Product alarms ................................................................................................................................. 15

Alarm priority and description ......................................................................................................... 15

Contact information............................................................................................................................ 18

Serial number location........................................................................................................................ 18

Date of manufacture .......................................................................................................................... 18

Setup.................................................................................................................................................... 19

Inspecting........................................................................................................................................ 19

Selecting a language.......................................................................................................................... 19

Testing visual and audible alarms ......................................................................................................... 19

Operation .............................................................................................................................................. 21

Placing the product............................................................................................................................ 21

Applying or releasing the wheel locks..................................................................................................... 21

Selecting and connecting a temperature probe ........................................................................................ 22

Connecting the reusable patient temperature output cable ......................................................................... 22

Connecting the insulated hoses............................................................................................................ 23

Disconnecting the insulated hoses ........................................................................................................ 24

Connecting and disconnecting thermal transfer devices............................................................................. 24

Powering on the product ..................................................................................................................... 25

Removing and replacing the reservoir .................................................................................................... 26

Filling the reservoir with sterile distilled water........................................................................................... 26

Selecting and setting the primary probe.................................................................................................. 27

Filling a thermal transfer device............................................................................................................ 28

Selecting a therapy mode.................................................................................................................... 28

Starting Automatic therapy mode .......................................................................................................... 29

Setting or editing the cooling rates......................................................................................................... 29

Setting or editing the warming rates.......................................................................................................30

Starting Manual mode ........................................................................................................................ 30

Starting Monitor mode ........................................................................................................................ 31

www.stryker.com 8001-009-0 01 REV G 1

Page 6

Table of Contents

Switching modes............................................................................................................................... 31

Pausing and resuming therapy .............................................................................................................31

Displaying the data storage.................................................................................................................. 31

Opening and securing items in the storage compartment ........................................................................... 32

Stopping therapy or powering off the product........................................................................................... 33

Draining the thermal transfer devices..................................................................................................... 33

Draining water from the reservoir .......................................................................................................... 33

Draining water from the controller and hoses........................................................................................... 34

Storing the power cord and hoses......................................................................................................... 35

Storing the controller .......................................................................................................................... 35

Transporting the product..................................................................................................................... 36

Cleaning................................................................................................................................................ 37

Cleaning the external surfaces............................................................................................................. 37

Disinfecting ............................................................................................................................................ 38

Disinfecting external surfaces .............................................................................................................. 38

Disinfect the internal water circuit and hoses every 14 days........................................................................ 39

Draining the internal water circuit and hoses for disinfection ....................................................................... 39

Disinfecting the internal water circuit and hoses ....................................................................................... 41

Rinsing the internal water circuit and hoses............................................................................................. 43

Accessories ........................................................................................................................................... 45

Thermal transfer devices .................................................................................................................... 45

Thermal transfer device kits................................................................................................................. 45

Patient temperature probes ................................................................................................................. 46

Cables ............................................................................................................................................ 46

Hoses ............................................................................................................................................. 46

Troubleshooting ...................................................................................................................................... 47

Preventive maintenance............................................................................................................................ 49

Cleaning tools......................................................................................................................................... 50

Alarm conditions...................................................................................................................................... 51

Check patient probe alarm .................................................................................................................. 51

Patient probe malfunction alarm ........................................................................................................... 52

Patient probe disconnect alarm ............................................................................................................ 52

Patient temperature deviation medium alarm ........................................................................................... 52

Patient temperature output deviation alarm ............................................................................................. 52

Normothermia deviation alarm.............................................................................................................. 52

Water temperature deviation alarm group ............................................................................................... 52

Check water flow alarm ...................................................................................................................... 53

Power backup level alarm ................................................................................................................... 53

Therapy paused time out alarm ............................................................................................................ 53

Remove from use mode...................................................................................................................... 54

EMC Information ..................................................................................................................................... 55

Warranty ............................................................................................................................................... 59

Warranty exclusion and damage limitations............................................................................................. 59

2 8001-009-001 REV G www.stryker.com

Page 7

Table of Contents

To obtain parts and service.................................................................................................................. 59

Return authorization........................................................................................................................... 59

Damaged product.............................................................................................................................. 59

International warranty clause ............................................................................................................... 59

www.stryker.com 8001-009-0 01 REV G 3

Page 8

Warning/Caution/Note Definition

The words WARNING, CAUTION , and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note: Provides special information to make maintenance easier or important instructions clearer.

4 8001-009-001 REV G www.stryker.com

Page 9

Summary of safety precautions

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WARNING

• Always turn or re-position the patient over the duration of therapy, if possible, to reduce the risk of pressure ulcers.

Follow your hospital protocol.

• Always check the integrity of the patients skin and temperature according to hospital protocol when using the Altrix

system.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Shock Hazard - Improper handling of the power cord may damage the power cord and cause potential shock

hazards. If damage has occurred to the power cord, immediately remove the temperature management system from

service to avoid the risk of serious injury or death. Contact the appropriate maintenance personnel.

• Take special precautions regarding electromagnetic compatibility (EMC) when using medical electrical equipment

like Altrix. Install and place Altrix into service according to the EMC information located in the EMC section of this

manual. Portable and mobile RF communications equipment can affect the function of Altrix.

• Shock Hazard. If the internal electrical components are exposed, because the side panel or cover are compromised,

remove the product from use.

• Always make sure that the product reaches room temperature before you setup or operate the product.

• Before first use, disinfect the internal water circuit.

• Do not use Altrix located near or stacked with other medical equipment. If it is necessary to locate Altrix near other

medical equipment, make sure it operates as intended.

• Always apply the wheel locks to prevent unintended movement.

• Always use Stryker accessories. Only IEC 60601-1 equipment shall be hooked to the patient temperature ports.

Failure to comply with these instructions may invalidate any or all warranties and may negatively affect the products

EMC performance. This also protects the product from cardiac defibrillation.

• Avoid the use of materials of good thermal conductivity, such as water, gel, or similar substances, with the Altrix

system not powered on. This can decrease the temperature of the body of a patient.

• Do not apply thermal transfer devices to patients with ischemic limbs. This may result in harm to the patient.

• Do not use this product if the patient has a transdermal medication (patch) as this can result in increased drug

delivery.

• Always pre-fill the thermal transfer device with sterile distilled water before you apply it to the patient. This is to

reduce the risk of pressure ulcers.

• Electric shock. This equipment must only be connected to a supply mains with protective earth.

• Always plug this product directly into a properly grounded hospital-grade or medical-grade wall outlet to achieve

grounding reliability.

• Do not use high frequency surgical instruments or endocardial catheters while the Altrix system is in use. This is to

avoid the risk of electrical shock, burns, or electromagnetic interference.

• Explosion risk. This product is not suitable for use in the presence of flammable anesthetic mixture with air or with

oxygen or nitrous oxide other than nasal or mask type.

• Do not place cables, hoses, or power cord in walkways to avoid the risk of trip hazards.

• Avoid reduction in water flow. Do not connect two or more thermal transfer devices in a series on a single port.

www.stryker.com 8001-009-0 01 REV G 5

Page 10

Summary of safety precautions

CAUTION (CONTINUED)

• Do not use three or more adult Mul-T-Blanket’s at the same time to avoid the risk of water overflow when you power

off the controller.

• When you operate the product near ambient temperature limitations of 15.0° C (59.0° F) or 32.0° C (89.6° F), you

may experience a reduction in product performance.

• Do not place your fingers in between the reservoir and the sides of the controller, to avoid the risk of pinching your

fingers.

• Always use sterile distilled water or water that has been passed through a filter less than or equal to 0.22 microns

with this product.

• Always fill the reservoir with room temperature sterile distilled water to reduce the risk of burn.

• Do not overfill the reservoir to avoid the risk of water spillage and fall.

• Always make sure that there are no water leaks before starting a defibrillation.

• When using the temperature controlled Automatic therapy mode for warming (min, med, or custom), switching to

other modes, changing the target patient temperature, or changing the therapy selection may impact the overall

benefit of therapy.

• Always monitor the patient for shivering, temperature, signs of intolerance, and skin condition when using this

product.

• Always store the power cord, cables, and hoses before you transport the product to reduce the risk of trip hazard.

• Do not store the product with water in the device.

• Always store the product within the specified environmental condition values.

• Always use extra care when you transport the product long distances and on inclines greater than five degrees. Ask

for help, if necessary, to avoid the risk of tipping.

• Always use the handle to move the product. Do not attempt to move the product by pulling on cables, hoses, or by

any other means.

• Avoid ramps that are steeper than ten degrees to avoid tipping the product.

• Do not hang items on the controller handle to avoid the risk of tipping the product.

• Do not power wash this product.

• Do not use quaternaries that contain glycol ethers as they may damage the reusable accessories.

• Do not disinfect the internal water system with a thermal transfer device attached as this may cause a leak.

• Do not use bleach or any other cleaning or disinfectant agents for internal circuits. This could result in damage to the

product. Only use approved disinfectant tablets.

• Always drain the product before disinfecting the internal water circuit. Failure to drain the product may reduce the

effectiveness of the disinfection process.

• Always remove the product from use before servicing any components. Contact qualified service personnel for

service.

Notes

• Disinfection of the Altrix internal water system was validated using M. mucogenicum.

6 8001-009-001 REV G www.stryker.com

Page 11

Introduction

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or

maintenance of this product.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

Notes

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current

product information available at the time of printing. There may be minor discrepancies between your product and

this manual. If you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

Product description

The Stryker model 8001Altrix™ Precision Temperature Management System can supply water to an individual or multiple

thermal transfer devices simultaneously with each of these circuits monitored separately. Three operating modes are

available to ease patient care: Automatic, Manual, and Monitor. The controller uses the patient temperature probe to

provide closed loop feedback for automatic patient temperature management and monitoring. The controller alarms

visual and audible indications for when safety parameters are exceeded or it detects system function or performance

irregularities. The Altrix system is able to provide a patient temperature output reference signal to be connected to a nonspecific third party device or system.

The controller regulates water temperatures between 4.0° C (39.2° F) and 40.0° C (104.0° F) and circulates the heated or

cooled water via hose sets through the thermal transfer devices. A graphical display provides the user an interface for

selecting desired water or patient temperature settings, operating modes, help menus, and other key parameters. Visual

indicators are displayed to inform the user of system status or when the user must confirm a setting selection. The

system’s water temperature and flow outputs can be monitored with 400 series compatible devices to optimize system

operation.

The Altrix system includes the following components:

• controller

• reusable hose sets

• thermal transfer devices (blankets, vests, and leg wraps)

• patient temperature probes

• reusable adapter cables

• reusable patient temperature output cable

Note: The blankets, vests, leg wraps, and patient temperature probes are type BF applied parts.

Indications for use

The Altrix system is intended for circulating temperature controlled warm or cold water via patient contact thermal

transfer devices for the application of regulating human body temperature in situations where a physician or clinician with

prescription privileges determines that temperature therapy is necessary or desirable.

Indications for use for the Altrix system include:

• Maintain pre-set body temperature as determined by the physician

• Maintain normal body temperature during surgical procedures

www.stryker.com 8001-009-0 01 REV G 7

Page 12

Introduction

Indications for use (Continued)

• For use in all clinical settings including coronary care units, operating, recovery and emergency departments, burn

units, and medical/surgical units

• Adult and pediatric patients

• Monitoring and controlling patient temperature

• Temperature reduction in patients where clinically indicated, e.g. in hyperthermic patients

Intended users

• Physicians

• Advanced Practice Registered Nurses

• Nurses

Expected service life

The Altrix controller has a five year expected service life under normal use, conditions, and with appropriate periodic

maintenance. See the maintenance manual for preventive maintenance and service information.

Contraindications

For core body temperature regulation:

• Raynaud’s Phenomenon (primary or secondary)

• Application to lower extremities distal to aortic cross-clamping

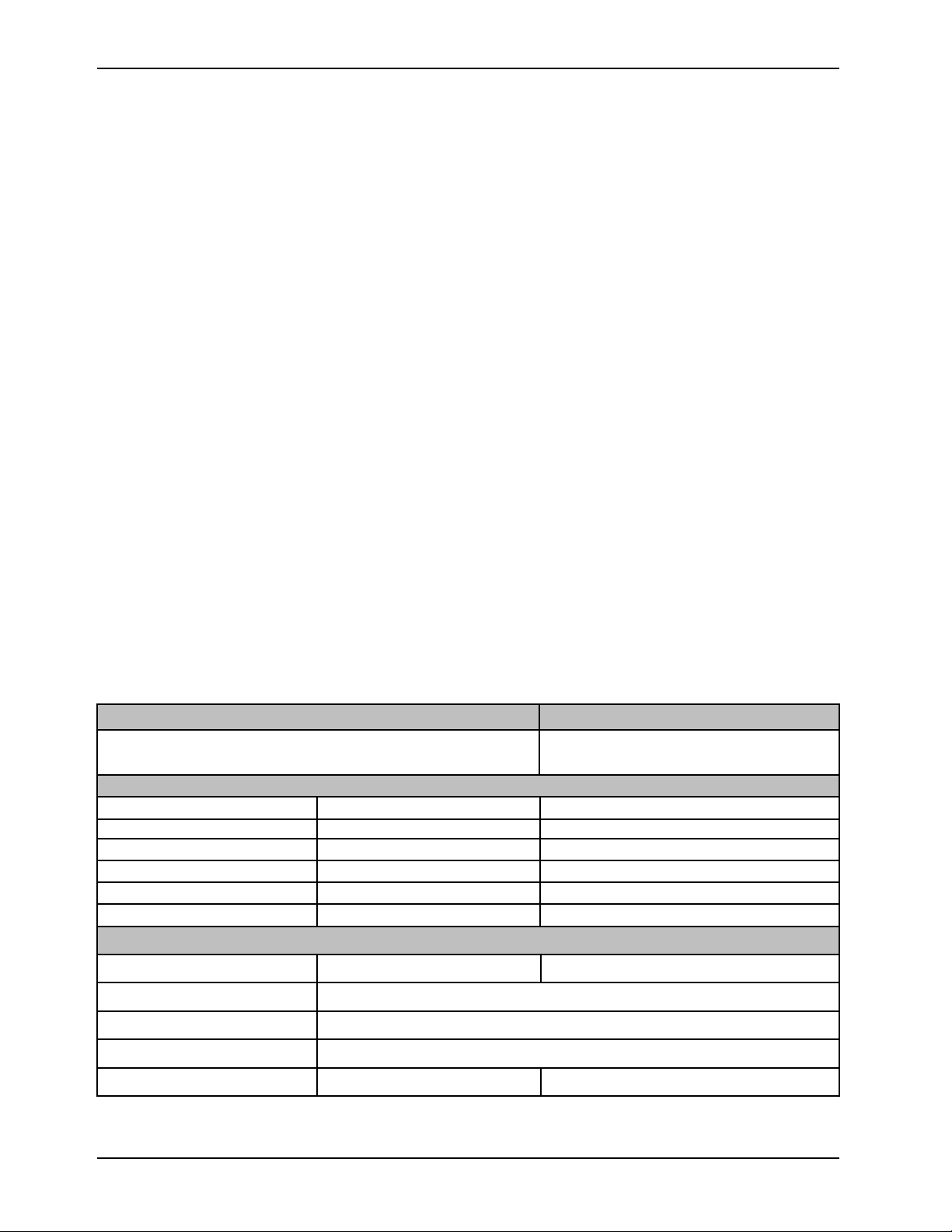

Specifications

Model 8001-000-001

Electrical Requirements - AC Voltage Input Current and Voltage

Ratings

Physical dimensions

Height 42.5 in. 107.9 cm

Width 15.0 in. 38.1 cm

Depth 23.0 in. 58.4 cm

Empty weight 150.0 lb 68.0 kg

Filled weight 160.5 lb 72.8 kg

Reservoir capacity 1.3 gal 5.0 L

Water temperature

Control setting range

39.2° - 104.0° F

120VAC, 60Hz 12A

4.0° - 40.0° C

Control accuracy ±0.3° C (4.0° - 40.0° C)

Display measurement accuracy

Display / resolution setting

Default setting 104.0° F 40.0° C

8 8001-009-001 REV G www.stryker.com

±0.2° C (4.0° - 40.0° C)

0.1° C

Page 13

Specifications (Continued)

89.9°F

(32.2°C)

59°F

(15°C)

140 °F

(60 °C)

-40°F

(-40°C)

140 °F

(60 °C)

-20°F

(-29°C)

75 %

30 %

95 %

10 %

95 %

25 %

1060 hPa

700 hPa

1060 hPa

500 hPa

Patient temperature

Introduction

Control setting range

89.6° - 100.4° F

32.0° - 38.0° C

Control accuracy ±0.1° C (32° - 38° C)

Measurement accuracy

±0.3° C (25.0° - 45.0° C)

±0.4° C (0.0° C - 24.9° C, 45.1° C - 50.0° C)

Display / resolution setting

Display range 32.0° - 122.0° F

Default setting

0.1° C

98.6° F

0.0° - 50.0° C

37.0° C

Controller

Heater capacity, maximum 500 watts

Circulating fluid Sterile distilled water or water that has been passed through a filter less than or

equal to 0.22 microns with this product

Battery 9V Lithium

Alarm tone range

Water flow rate in each hose port

Refrigerant type

Power cord length

Clinical thermometer

75 - 85 dBA per standard IEC 60601-1-8

Typical 1.2 lpm

R134a

14 to 15 feet

Direct mode

4.2 - 4.5 meters

Equipment Class Class I

Rated for continuous operation

Note: The controller takes approximately 9 minutes to heat from 23.0±2° C (73.4° F) to 37.0° C (98.6° F) when not

connected to a patient. Time will vary when connected to a patient.

Stryker reserves the right to change specifications without notice.

For more information about thermal transfer devices, cables, or probes, see the manufacturer’s instructions for use.

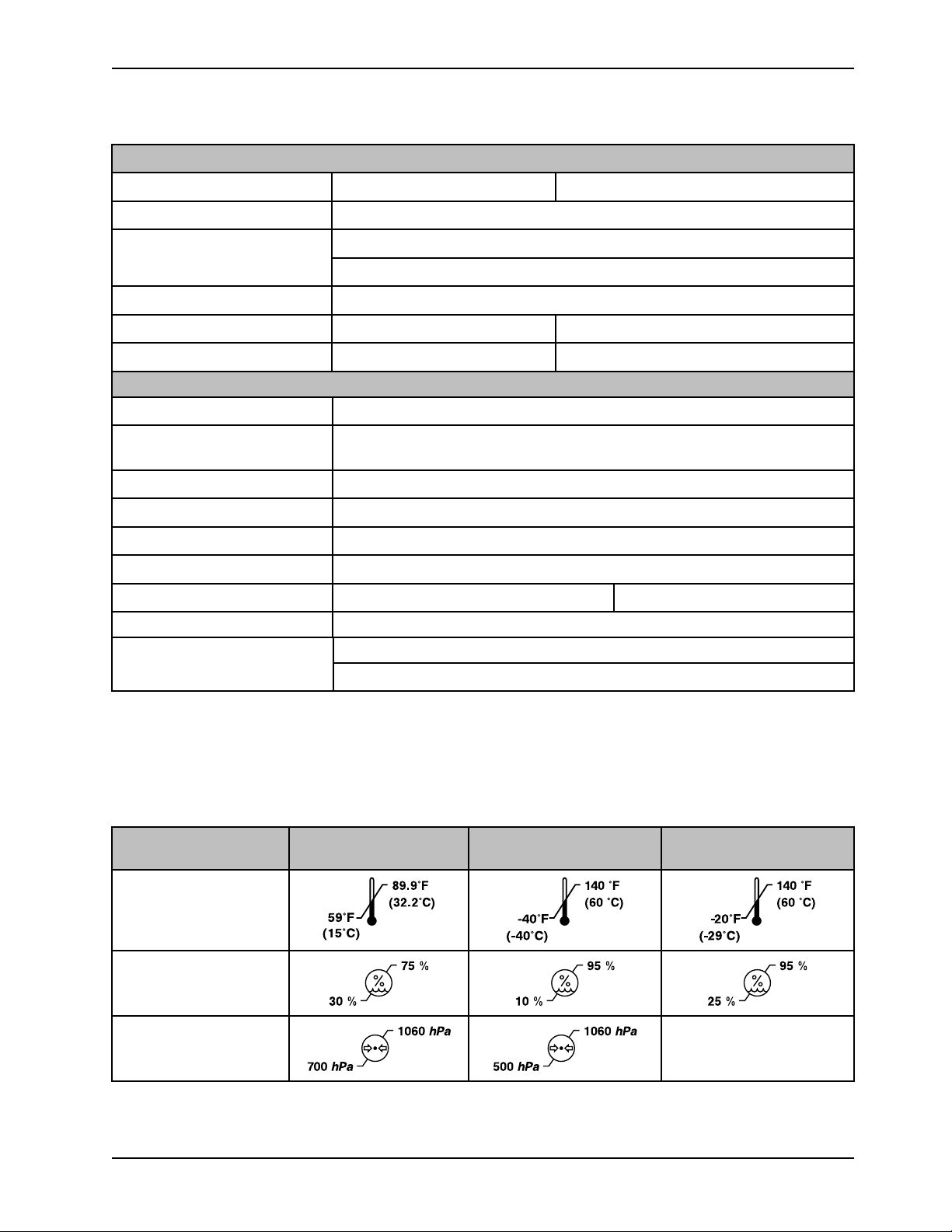

Environmental

conditions

Operation Storage Transporta tion

Ambient temperature

Relative humidity (noncondensing)

Atmospheric pressure

www.stryker.com 8001-009-0 01 REV G 9

Not applicable

Page 14

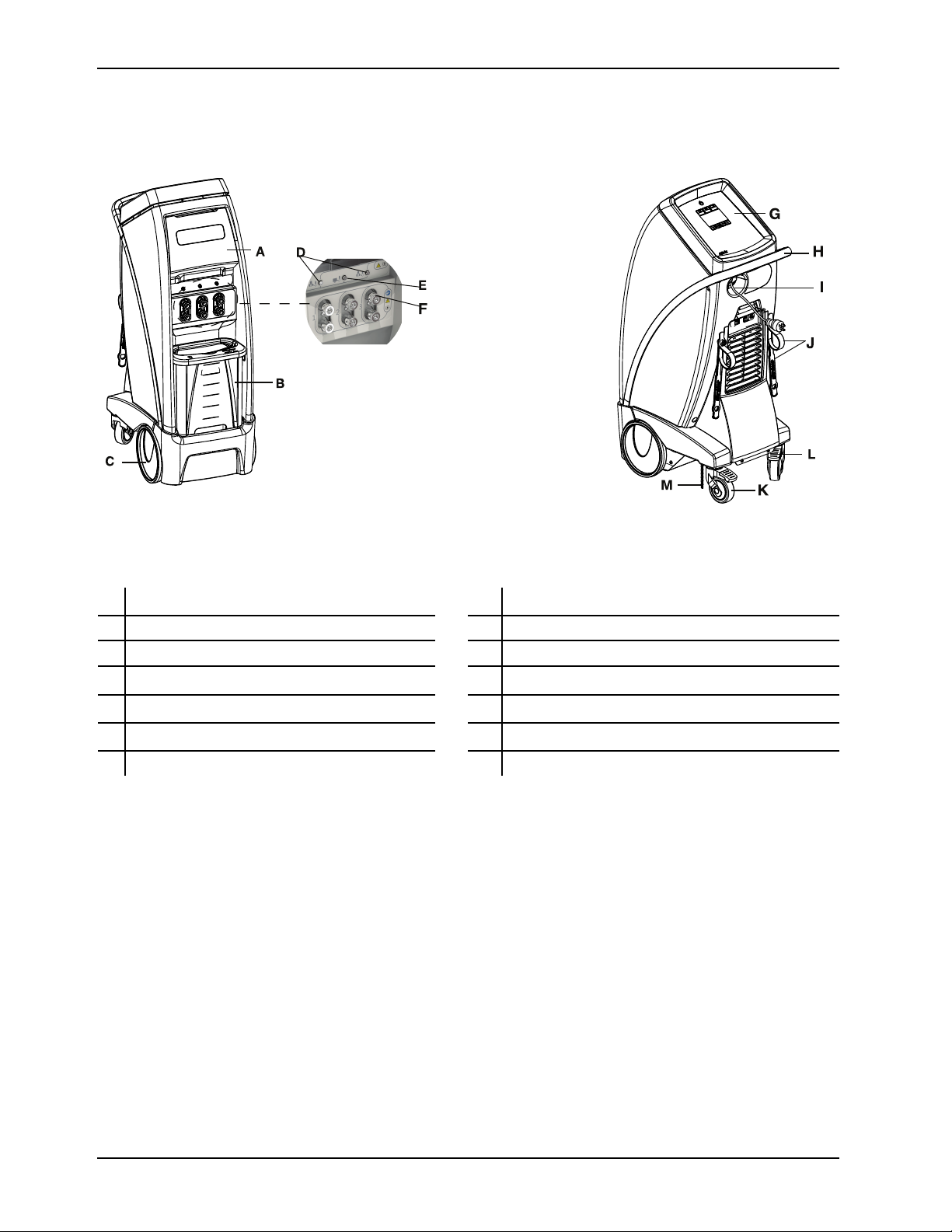

Product illustration

B

C

D

E

F

G

H

I

K

J

L

M

Introduction

Figure 1: Controller, patient front

Figure 2: Controller, patient back

A Storage compartment G Graphical user interface display

B Removable water reservoir H Handle

Front wheels I Power cord

C

D Patient probe ports J Hose and power cord management straps

E Patient temperature output port K

F Hose connection ports L Wheel locks

Swivel casters

M

Ground chain

10 8001-009-0 01 REV G www.stryker.com

Page 15

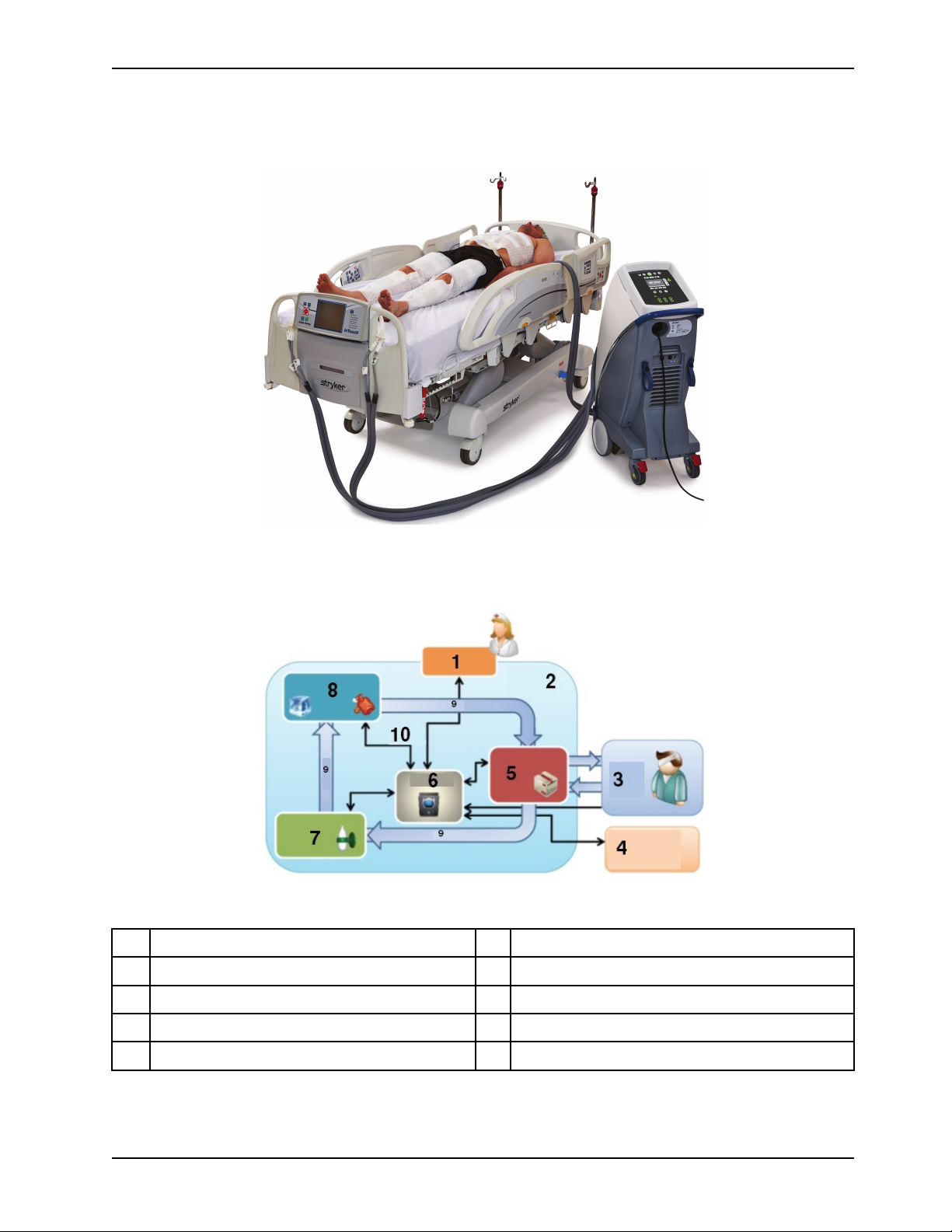

Product system

Introduction

Figure 3: Altrix system - controller with thermal transfer devices

Figure 4: Closed loop system

1

Human machine interface (HMI) system

2 Physical boundary

3 Patient system 8

6

Controls

7

Flow system

Energy transfer system

4

Patient temperature port 9

5

Fluid delivery system 10

www.stryker.com 8001-009-0 01 REV G 11

Water flow

Signals

Page 16

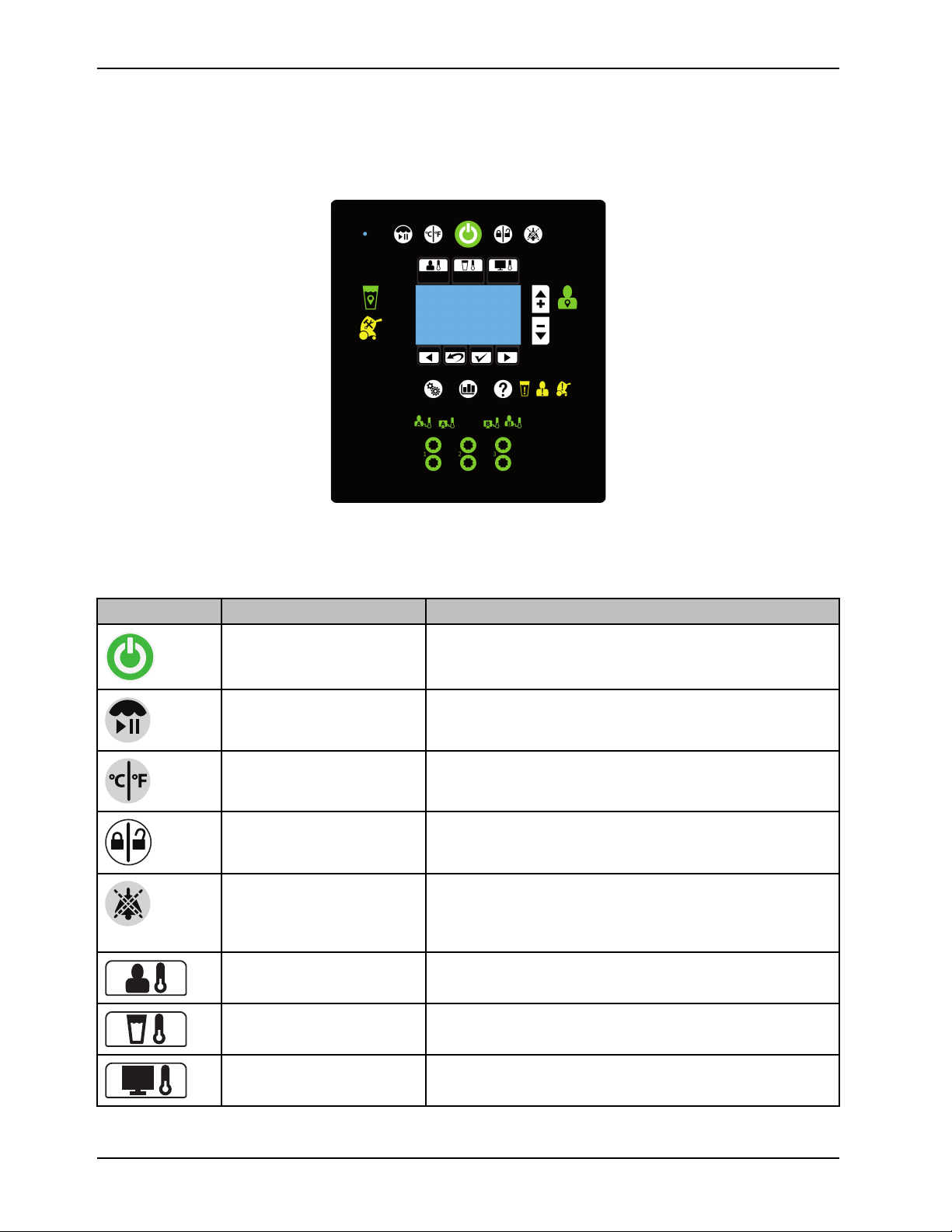

Introduction

Product functions

The graphical user interface shown is for reference only. The image shows where you will see the icons and buttons

illuminate when they are active. At no time will you see all of these icons at the same time.

Buttons

The buttons are located on the outside of the graphical user interface. They are visible when available.

Icon Name Function

Stand-by Press and hold the button for two seconds to stop therapy or

power off

Therapy paused

View temperature

Lock / unlock screen

Audio paused Pause or resume the audible indicator when an alarm is active.

Automatic therapy mode

Press and hold the button for two seconds to pause or resume

therapy

Select temperature degree in Celsius or Fahrenheit

Press and hold the button for two seconds to lock or unlock the

graphical user interface

Silences each alarm for five or ten minutes depending on the

alarm condition. This button breathes¹ to indicate that it is in a

paused state.

Cools or warms the patient to a selected patient target

temperature

Manual therapy mode

Monitor only mode Displays the current patient temperature (no therapy)

12 8001-009-0 01 REV G www.stryker.com

Cools or warms the water to a selected water target temperature

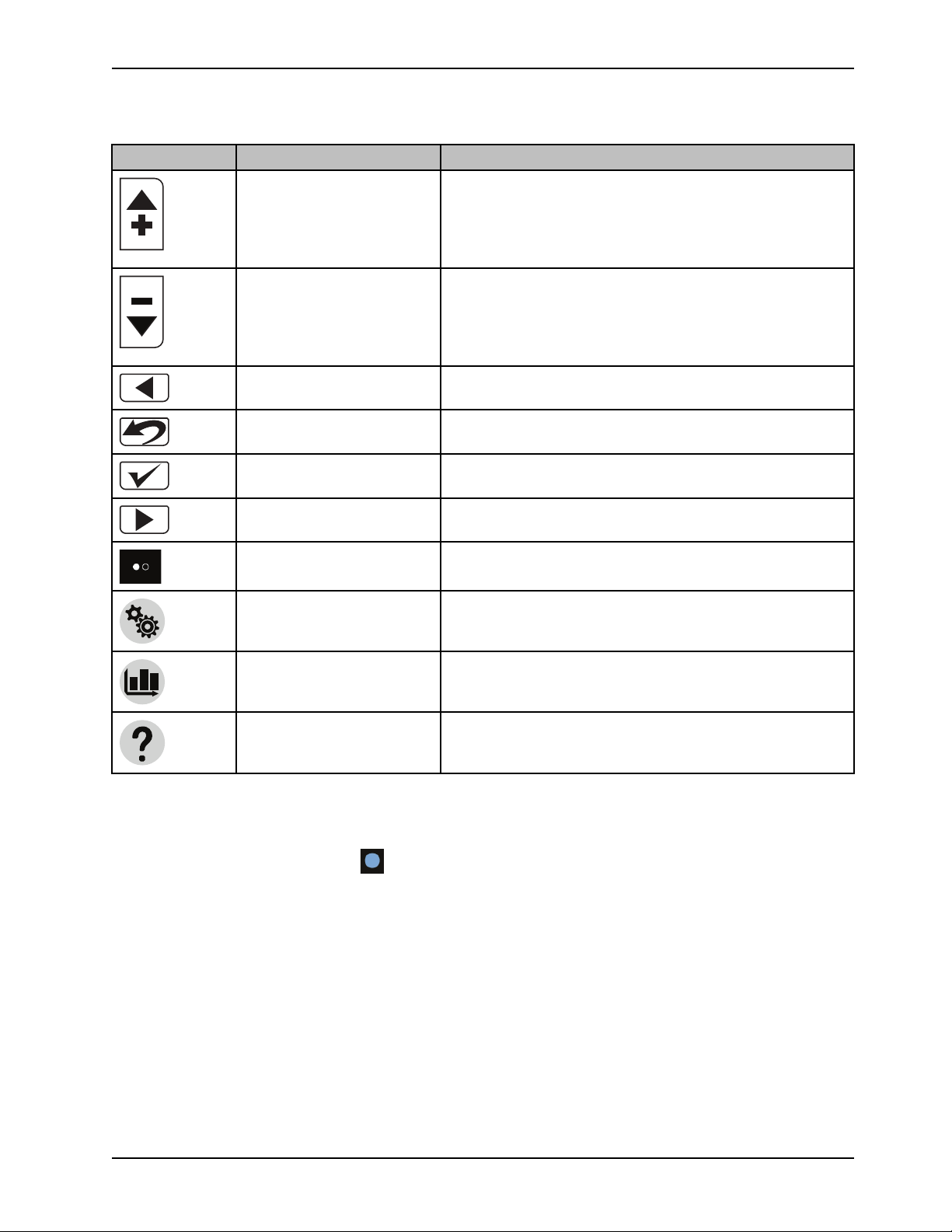

Page 17

Introduction

Product functions (Continued)

Icon Name Function

Increase

Increases the water or patient temperature by 0.1° for cooling or

warming temperature

Note: Press and hold the increase button to move the

temperature up faster.

Decrease

Back Returns to the previous screen or cancel an operation

Edit settings, Exit, or Cancel

Confirm selection

Next or More Changes to the next screen, option, or setting

Page indicators (may also

appear vertical)

Settings Displays the summary of the current, visual / audible, language,

Graph Graphical display of the selected items such as patient

Help

Decreases the water or patient temperature by 0.1° for cooling or

warming temperature

Note: Press and hold the decrease button to move the

temperature down faster.

Edit current settings, exit, or cancel

Accepts the selected settings

Indicates that there is more than one page associated with the

screen topic for the page that is currently displayed

or primary probe settings

temperature, target temperature, water temperature, and power

level

Displays contextual help screens for therapies, navigation,

buttons, and alarm screens. This button breathes to allow the

user to view the alarm screen.

Note: If not specified above, make sure that you tap and release the buttons or icons for you selection to register with the

system.

Note: The Light sensor (non selectable)

Note: ¹Breathe: The brightness of the button or icon will go to a low light and then increase to a bright light. This cycle

repeats.

, dims or brightens the LCD based on the amount of light in the room.

Visual indicators

When the visual indicators are solid green, this indicates that the function is stabilized. The visual indicators breathe to

indicate that the controller is at the intermediate target.

www.stryker.com 8001-009-0 01 REV G 13

Page 18

Product functions (Continued)

3

2

1

1

2

|

|

Icon, green Name

Water temperature on target, solid green when active, does not breathe

Patient temperature on target

Patient probe A port, stabilized

Patient probe B port, stabilized

External device, patient probe A

External device, patient probe B

Introduction

Stand-by

Water flow detected, ports 1, 2, or 3 are active, solid green when active, does not breathe

Graphical user interface icons

Icon Name

Cooling therapy

Warming therapy

Current therapy duration

Total duration

14 8001-009-0 01 REV G www.stryker.com

Visual and audible tests

Target patient or water temperature

Page 19

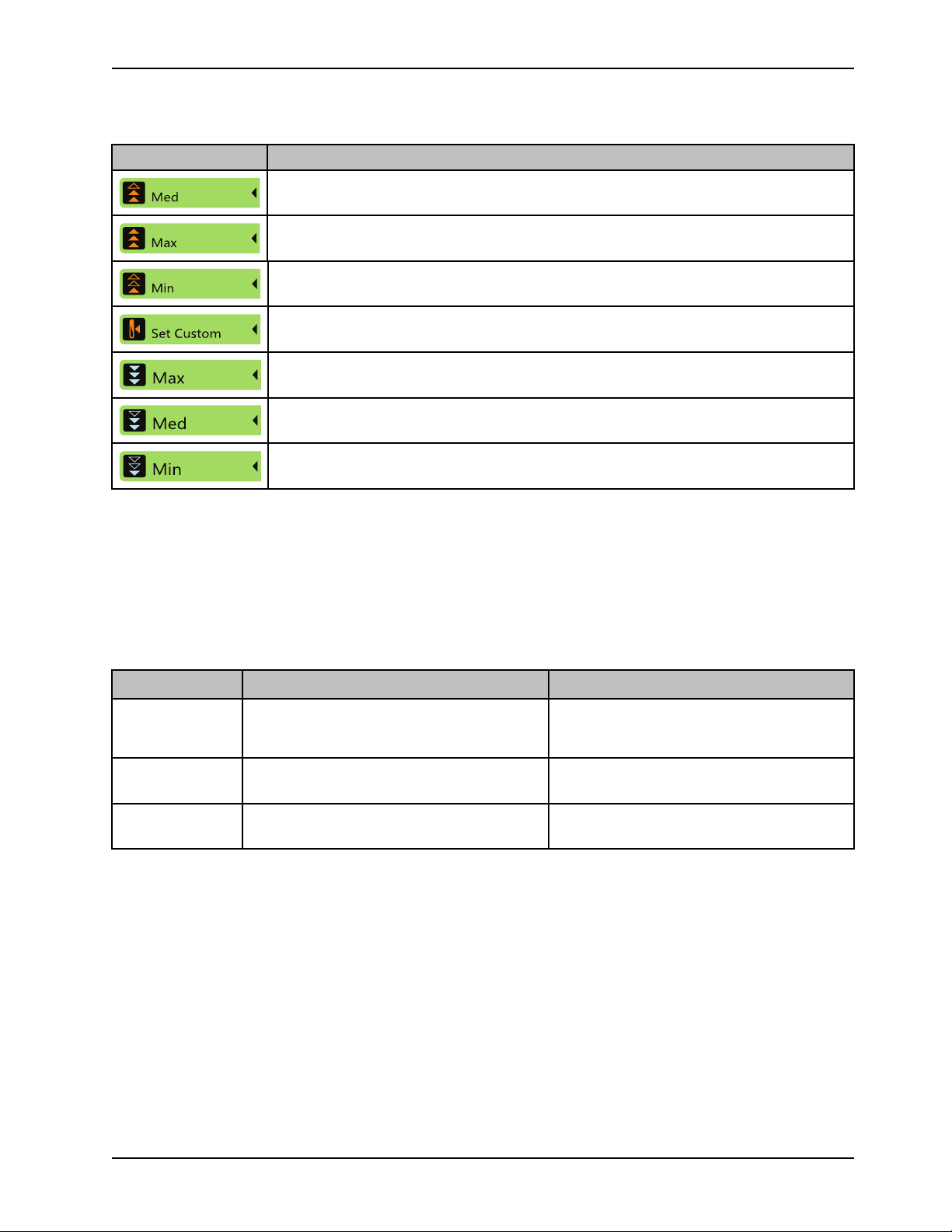

Product functions (Continued)

Med

Max

Min

Set Custom

Max

Med

Min

Icon Name

Medium: patient temperature increases at a rate of 4.0° C in 12 hours (0.33° C/ hour).

Maximum: water temperature approaches water target as fast as possible

Minimum: patient temperature increases at a rate of 4.0° C in 24 hours (0.17° C/hour).

Set Custom: patient temperature increases at a customized temperature and time period the

operator selects. The temperature increases 0.05° C/hour to 0.5° C/hour

Maximum: water temperature approaches water target as fast as possible

Medium: water is cooled to target, with a max of 15.0° C difference between the patient and

the water temperature

Minimum: water is cooled to target, with a max of 10.0° C difference between the patient and

the water temperature

Introduction

Product alarms

Audible alarms work in conjunction with the display.

Alarm priority and description

Priority alarm Audible reminder Icon flashes

Medium

Low

Audio pause Button breathes as a reminder

Note: You can pause the audio alarm. The alarm will resume within five to ten minutes or sooner, if not resolved. The

alarm will resume depending on when the alarms became active and the number of active alarms.

Repetitive burst of three beeps every 25

seconds

Single burst of two beeps The icon does not flash when there is a low

When a medium priority alarms, the icon will

flash to indicate there is an alarm. It will

continue to flash until the alarm is resolved.

priority alarm.

Pausing the alarm will not stop the icon from

flashing.

www.stryker.com 8001-009-0 01 REV G 15

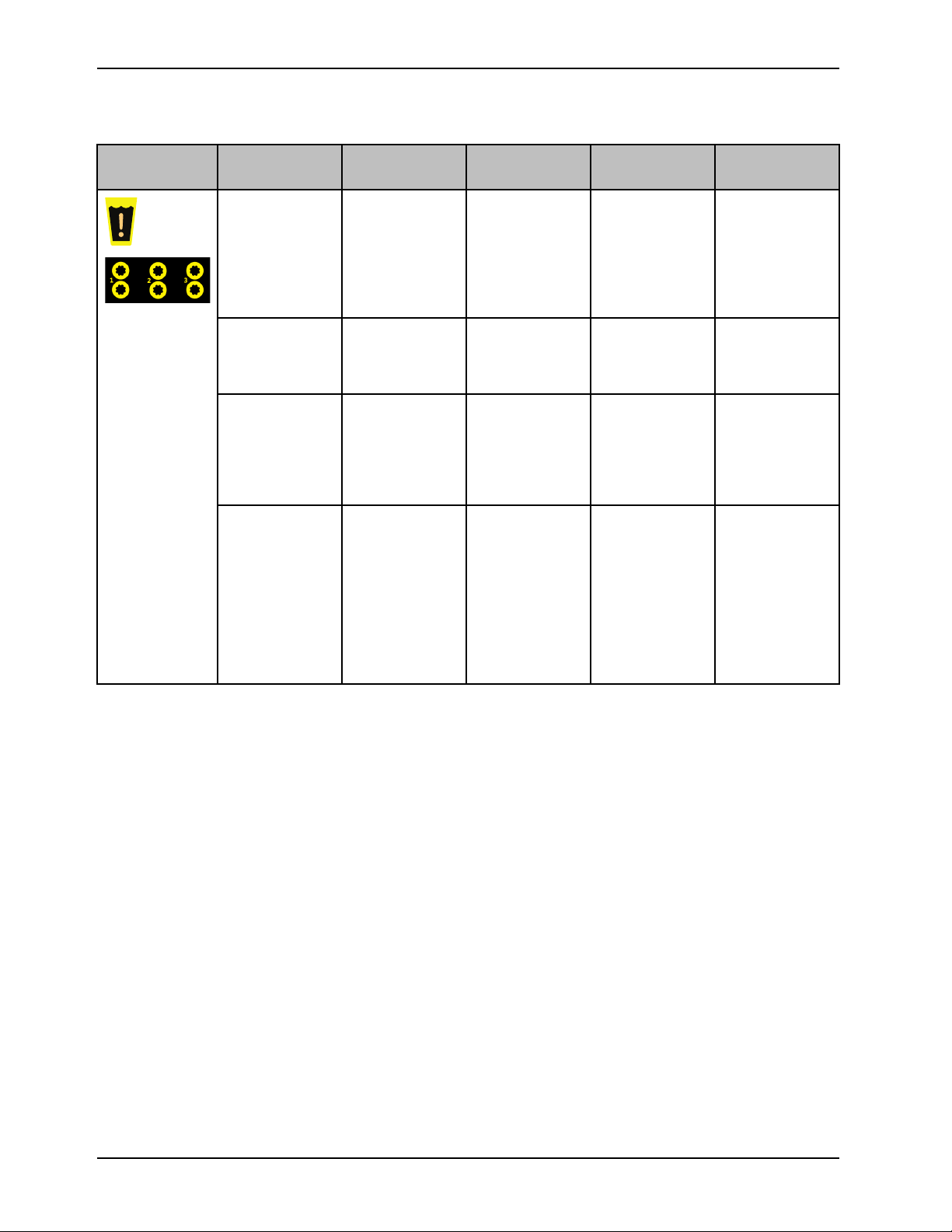

Page 20

Product alarms (Continued)

Introduction

Icon, yellow Name Alarm priority

and delay

Water

temperature

deviation

No water Medium, 20

No water flow

Check water flow

on any port

Medium Water

second delay

Medium, 20

second delay

Medium, 60

second delay

Message Therapy

interrupted

No Temporary

temperature is

±0.8° C (1.4° F)

outside of target

temperature

No water Yes

No flow detected

Reduced flow

detected

Yes

No

Check

condition upon

startup, addition

of thermal

transfer device,

or addition of

water

Check for leaks

Add a minimum

of 2 liters of

water

Check for leaks

and obstructions

at connections,

hoses, and

thermal transfer

devices

Tap Confirm, if

the water port

was removed

intentionally

Check for leaks

and obstructions

at connections,

hoses, and

thermal transfer

devices

16 8001-009-0 01 REV G www.stryker.com

Page 21

Product alarms (Continued)

Introduction

Icon, yellow Name Alarm priority

and delay

Check patient

probe (A or B)

Probe or adapter

malfunction (A or

B)

Adapter cable

disconnected (A

or B)

Patient

temperature

deviation

Medium Abnormal change

Medium, 30

second delay

Medium, 30

second delay

Medium Patient

Message Therapy

interrupted

Yes

in patient

temperature

No temperature

signal detected.

Adapter cable not

detected

temperature is ±

0.5° C (0.9° F)

outside of target

temperature

(Only will appear

after the initial

target is reached.)

Yes

Yes Reinsert the

No Check patient

Check

Check probe

condition,

location, and

connections

Check probe or

adapter cable

condition,

location, and

connections

adapter cable. If

damaged,

replace the

adapter cable

condition,

placement of

thermal transfer

devices, and all

connections

Normothermia

deviation

Therapy pause Medium Therapy is

Battery low Low Battery is low No Maintenance is

Patient

temperature

output (A or B)

Low Patient

temperature is

outside of 36.0° C

(96.8° F) to 38.0°

C (100.4° F)

currently paused

Low Patient

temperature

output is

inaccurate on the

external device,

or outside

supported range

No

Yes To resume, press

No

Check patient

condition,

placement of

thermal transfer

devices, and all

connections

and hold the play

/ pause for 2

seconds

recommended. If

battery is not

replaced, the

product may not

function on the

next startup.

Check output

adapter cable

connection. Tap

Confirm to

reactivate the

output port.

www.stryker.com 8001-009-0 01 REV G 17

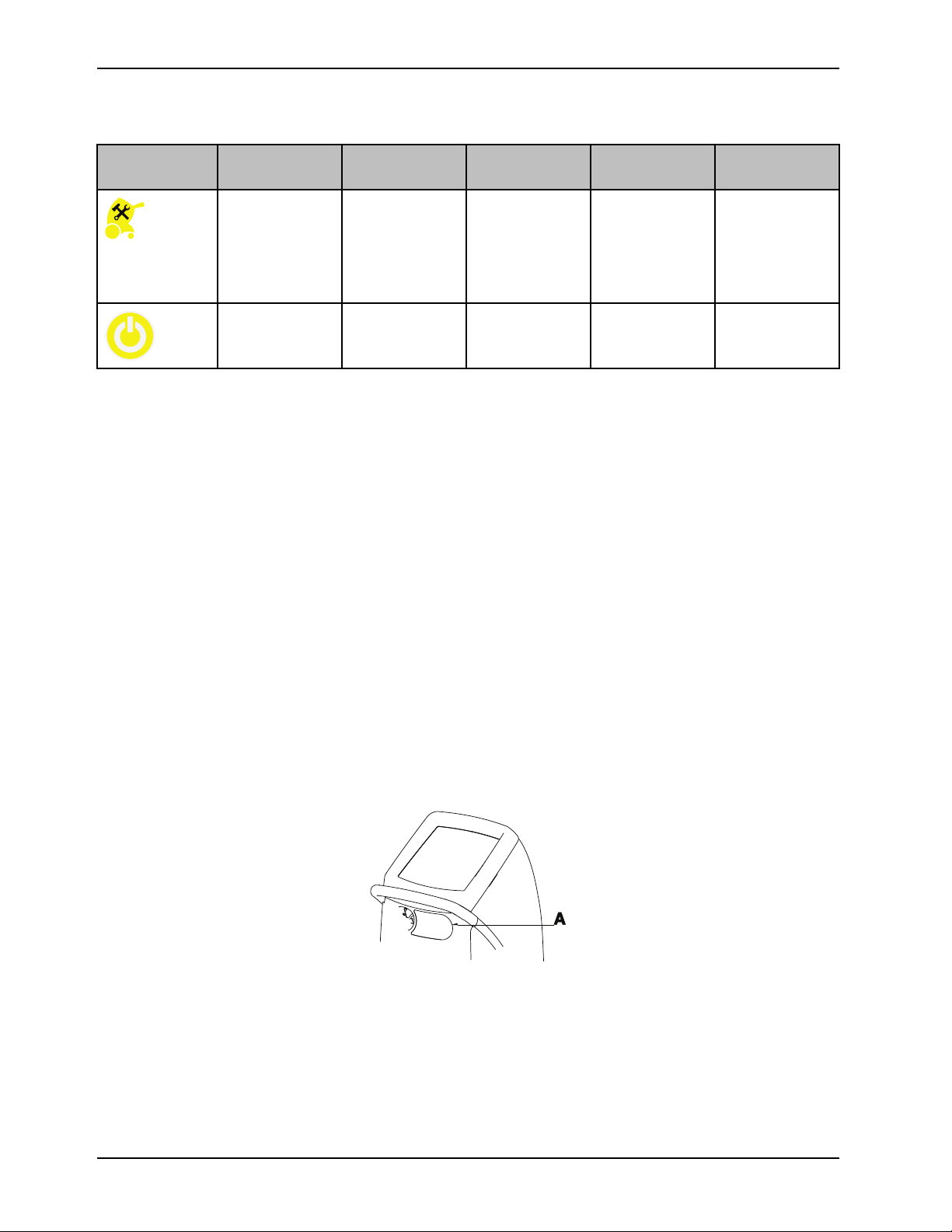

Page 22

Product alarms (Continued)

A

Introduction

Icon, yellow Name Alarm priority

and delay

Remove from use

(RFU)

Power loss Medium Not applicable Yes

Notes

• If any of the alarm conditions persist, call maintenance.

• If page indicators appear on the alarm screen, there are multiple active alarms. The highest alarm is displayed. Tap

Next or Back to view the active alarms.

Medium The system has

Message Therapy

interrupted

Yes Remove the

powered off due

to a malfunction

Check

product from use

immediately.

Notify the

appropriate

personnel.

Check power

cord connection

Contact information

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

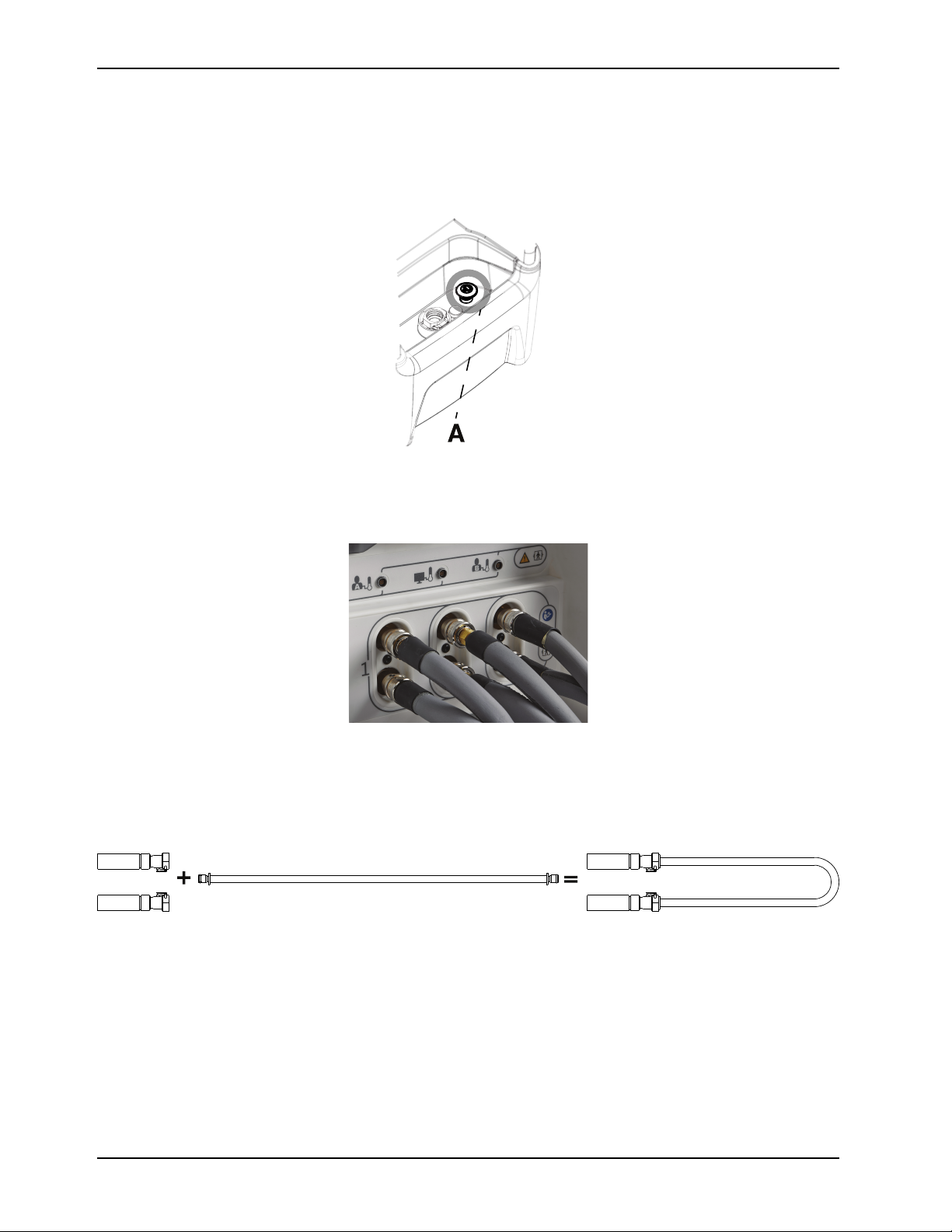

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

Serial number location

Date of manufacture

The year of manufacture is the first four digits of the serial number.

18 8001-009-0 01 REV G www.stryker.com

Page 23

Setup

Unpack the cartons and check all items. Make sure that the product is free from visual damage before putting into

service.

CAUTION

• Shock Hazard - Improper handling of the power cord may damage the power cord and cause potential shock

hazards. If damage has occurred to the power cord, immediately remove the temperature management system from

service to avoid the risk of serious injury or death. Contact the appropriate maintenance personnel.

• Take special precautions regarding electromagnetic compatibility (EMC) when using medical electrical equipment

like Altrix. Install and place Altrix into service according to the EMC information located in the EMC section of this

manual. Portable and mobile RF communications equipment can affect the function of Altrix.

• Shock Hazard. If the internal electrical components are exposed, because the side panel or cover are compromised,

remove the product from use.

• Always make sure that the product reaches room temperature before you setup or operate the product.

• Before first use, disinfect the internal water circuit.

Inspecting

Before you place the product into service, make sure that the controller works.

1. Visually inspect the product for any signs of shipping damage.

2. Plug the product into a properly grounded, hospital grade wall receptacle. Make sure that the power indicator

illuminates on the operator control panel.

3. Before first use, .Disinfect the internal water circuit and hoses every 14 days on page 39

Selecting a language

The Altrix controller has several language choices. English is the default language.

To select a language when in standby mode:

1. Tap the Settings button, to show the Select Language screen.

a. Tap Next, if you are in therapy mode.

2. Tap More to view other languages.

3. Select a language. Tap on the Increase or Decrease buttons or tap the language, to highlight a language of your

choice.

4. Tap Confirm.

Note: If you do not touch the screen for three minutes, the LCD will return to the previous menu.

Testing visual and audible alarms

Before placing the product into service, make sure that the visual and audible alarms are functioning.

1. Tap the Settings button.

2. Tap the Back button.

3. Tap the Visual/Audible icon.

www.stryker.com 8001-009-0 01 REV G 19

Page 24

Setup

Testing visual and audible alarms (Continued)

4. Tap Confirm.

Notes

• The system runs through visual tests of the Green Indicators, Yellow Indicators, White Indicators, and Fluid

Controller Light tests, and audible alarms.

• The test will continue until you stop it.

5. To stop the Visual / Audible test, tap the Back button.

6. To exit settings, tap the Exit button.

20 8001-009-0 01 REV G www.stryker.com

Page 25

Operation

A

Placing the product

When placing the product, do not block access to the hospital-grade plug or medical-grade wall outlet.

CAUTION

Do not use Altrix located near or stacked with other medical equipment. If it is necessary to locate Altrix near other

medical equipment, make sure it operates as intended.

Place the Altrix controller outside of the patient environment by 1.5 m (4.9 ft) (Figure 5 on page 21).

Figure 5: Product placement

Applying or releasing the wheel locks

The wheel locks are to help keep the product in place. The wheel lock prevents the rear caster wheels from rotating but

does not prevent the product from sliding on the floor surface.

CAUTION

Always apply the wheel locks to prevent unintended movement.

To apply the wheel locks, push down (A) (Figure 6 on page 21) with your foot.

To release the wheel locks, pull up (A) (Figure 6 on page 21) with your foot.

Figure 6: Wheel locks

www.stryker.com 8001-009-0 01 REV G 21

Page 26

Operation

A

B

C

Selecting and connecting a temperature probe

CAUTION

• Do not use high frequency surgical instruments or endocardial catheters while the Altrix system is in use. This is to

avoid the risk of electrical shock, burns, or electromagnetic interference.

• Always use Stryker accessories. Only IEC 60601-1 equipment shall be hooked to the patient temperature ports.

Failure to comply with these instructions may invalidate any or all warranties and may negatively affect the products

EMC performance. This also protects the product from cardiac defibrillation.

Use only Stryker temperature probes. See Patient temperature probes on page 46.

To connect the temperature probe:

1. Inspect the temperature probe and reusable adapter cable for wear, breakage, or fraying. Replace, if necessary.

2. Align the red dot on the Reusable Adapter Cable (B) to the controller (A) with the red dot on the patient probe port A

or port B.

Figure 7: Port selected

3. Connect the plug (C) to the patient temperature probe.

4. Apply the temperature probe to the patient. Follow your hospital protocol and the manufacturer’s directions for the

selected temperature probe use.

5. Tap Confirm, if applicable.

Note: Temperature readings may vary between temperature measurement sites.

Connecting the reusable patient temperature output cable

This feature allows the operator to view the temperature on the Altrix system and on an external device. Always connect

the reusable patient temperature output cable to a 400 series compatible external device for temperature accuracy.

CAUTION

Always use Stryker accessories. Only IEC 60601-1 equipment shall be hooked to the patient temperature ports. Failure to

comply with these instructions may invalidate any or all warranties and may negatively affect the products EMC

performance. This also protects the product from cardiac defibrillation.

22 8001-009-0 01 REV G www.stryker.com

Page 27

Operation

Connecting the reusable patient temperature output cable (Continued)

To connect the reusable patient temperature output cable:

1. Insert the reusable patient temperature output cable into the patient temperature port (Figure 8 on page 23).

Figure 8: Patient temperature output port

2. Connect the other end of the reusable patient temperature output cable to the external device.

Note: When Altrix is powered, the calibration of the patient temperature output is completed.

Note: If you need to calibrate the patient temperature output cable, power cycle the product by removing the plug

from the wall.

Note: For the reusable patient temperature output cable to work properly, make sure that you insert a patient

temperature probe into port A or port B.

3. Tap Confirm.

Connecting the insulated hoses

To connect the insulated hoses:

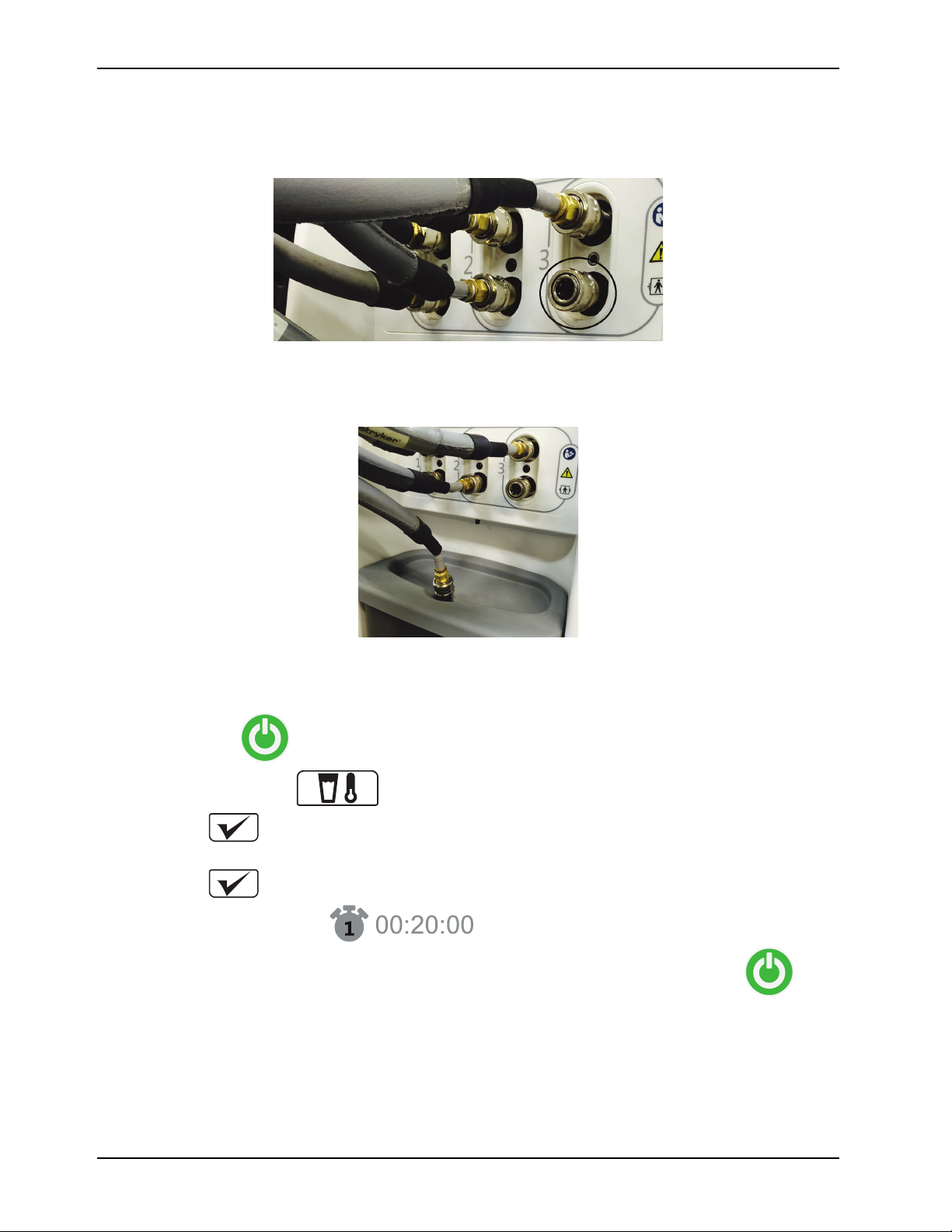

1. To connect, push back on the retaining collar of the port on the controller (Figure 9 on page 23).

Figure 9: Pull back on the retaining collar

2. Push the hose into an upper or lower port (Figure 10 on page 23) and release the collar until the retaining collar

clicks into place (Figure 11 on page 23).

Note: Connect a set of ports for proper water flow.

Figure 10: Connect the hoses

Figure 11: Hoses connected

www.stryker.com 8001-009-0 01 REV G 23

Page 28

Operation

Disconnecting the insulated hoses

To disconnect the insulated hoses:

1. To disconnect, push back on the retaining collar of the port on the controller.

2. Pull the hose to disconnect.

Connecting and disconnecting thermal transfer devices

Read the operations manual for the individual thermal transfer devices for warnings, cautions, and safe operating

instructions before use.

CAUTION

• Avoid the use of materials of good thermal conductivity, such as water, gel, or similar substances, with the Altrix

system not powered on. This can decrease the temperature of the body of a patient.

• Do not apply thermal transfer devices to patients with ischemic limbs. This may result in harm to the patient.

• Do not use this product if the patient has a transdermal medication (patch) as this can result in increased drug

delivery.

• Always use Stryker accessories. Failure to comply with these instructions may invalidate any or all warranties and

may negatively affect the products EMC performance. This also protects the product from cardiac defibrillation.

• Do not use three or more adult Mul-T-Blanket products at the same time to avoid the risk of water overflow when the

controller is powered off.

• Always pre-fill the thermal transfer device with sterile distilled water before you apply it to the patient. This is to

reduce the risk of pressure ulcers.

• Avoid reduction in water flow. Do not connect two or more thermal transfer devices in series on a single port.

• Always clamp the hoses when disconnecting the thermal transfer devices.

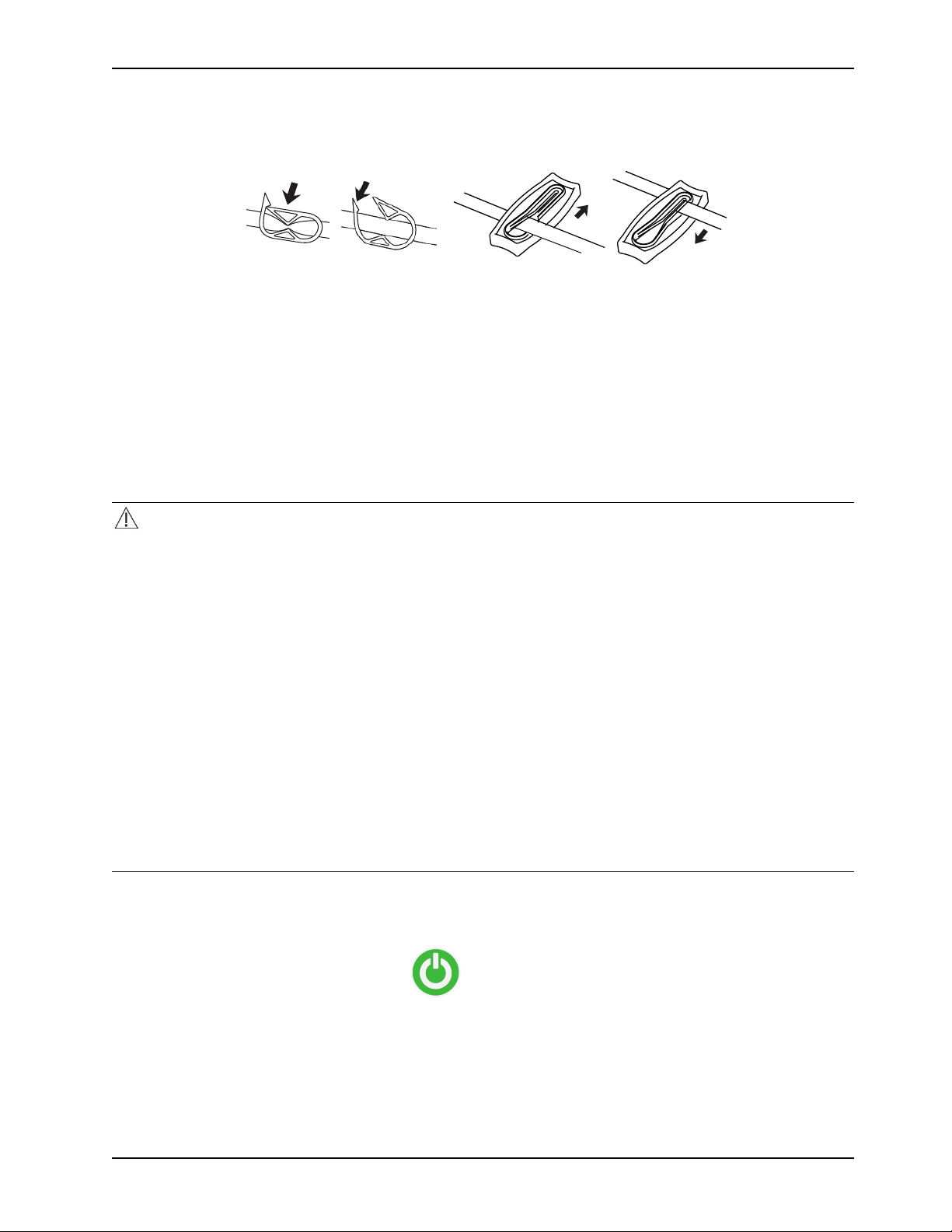

To connect or disconnect the Clik-Tite® connectors (Figure 12 on page 24) to the insulated hoses.

Figure 12: Clik-Tite

To connect or disconnect the Colder style (Figure 13 on page 24) to the insulated hoses.

Figure 13: Colder style connectors

To close or open hose clamps (Figure 14 on page 25).

24 8001-009-0 01 REV G www.stryker.com

Page 29

Operation

Connecting and disconnecting thermal transfer devices (Continued)

Figure 14: Hose clamps

Note: The term “thermal transfer devices” is used throughout this manual and is interchangeable with blankets and

wraps, unless indicated otherwise.

Always clamp the hoses before disconnecting. See Draining the thermal transfer devices on page 33.

Powering on the product

The operator should stand in front of the controller within arm’s reach. This allows the operator to see and respond to the

display notifications.

CAUTION

• Shock Hazard. Improper handling of the power cord may damage the power cord and cause potential shock hazards.

If damage has occurred to the power cord, immediately remove the Altrix system from service to avoid the risk of

serious injury or death. Contact the appropriate maintenance personnel.

• Electric shock. This equipment must only be connected to a supply mains with protective earth.

• Always plug this product directly into a properly grounded hospital-grade or medical-grade wall outlet to achieve

grounding reliability.

• Do not use high frequency surgical instruments or endocardial catheters while the Altrix system is in use. This is to

avoid the risk of electrical shock, burns, or electromagnetic interference.

• Explosion risk. This product is not suitable for use in the presence of flammable anesthetic mixture with air or with

oxygen or nitrous oxide other than nasal or mask type.

• Do not place cables, hoses, or power cord in walkways to avoid the risk of trip hazards.

• Avoid reduction in water flow. Do not connect two or more thermal transfer devices in a series on a single port.

• Do not use three or more adult Mul-T-Blanket’s at the same time to avoid the risk of water overflow when you power

off the controller.

• When you operate the product near ambient temperature limitations of 15.0° C (59.0° F) or 32.0° C (89.6° F), you

may experience a reduction in product performance.

To start the product:

1. Plug the power cord into a wall outlet.

2. Tap the Stand-by button to start the product.

3. If you are going into Automatic mode or Monitor mode, see Selecting and setting the primary probe on page 27. If

manual mode, got to the next step.

4. See Removing and replacing the reservoir on page 26.

5. See Filling the reservoir with sterile distilled water on page 26.

6. Connect up to three thermal transfer devices (with the exception of adult Mul-T-Blankets) to dedicated adapter

hoses and ports.

www.stryker.com 8001-009-0 01 REV G 25

Page 30

Operation

A

B

C

Powering on the product (Continued)

7. Open the clamps on the connector hose and the thermal transfer devices to provide proper water flow.

8. See Filling a thermal transfer device on page 28.

9. See Selecting a therapy mode on page 28.

10. Make sure that the desired port configuration is maintained and that water is flowing through the thermal transfer

devices.

WARNING

Always turn or re-position the patient over the duration of therapy, if possible, to reduce the risk of pressure ulcers.

Follow your hospital protocol.

Removing and replacing the reservoir

The removable reservoir enables you to fill or drain the reservoir away from the controller without interrupting therapy.

You will need to have the reservoir installed before starting a therapy.

CAUTION

Do not place your fingers in between the reservoir and the sides of the controller, to avoid the risk of pinching your fingers.

To remove the reservoir, pull forward at an angle, and lift out the reservoir (Figure 15 on page 26).

Figure 15: Removable reservoir

1. To replace the reservoir, align the base of the reservoir over the drain (C).

2. Align the notch on the back of the reservoir (A) with the hook on the controller (B) (Figure 15 on page 26)

3. Push the reservoir back into place. Make sure that the reservoir is secure to avoid water leakage.

Filling the reservoir with sterile distilled water

The removable reservoir is translucent for you to see the water levels.

26 8001-009-0 01 REV G www.stryker.com

Page 31

Operation

A

Filling the reservoir with sterile distilled water (Continued)

CAUTION

• Always use sterile distilled water or water that has been passed through a filter less than or equal to 0.22 microns

with this product.

• Always fill the reservoir with room temperature sterile distilled water to reduce the risk of burn.

• Do not overfill the reservoir to avoid the risk of water spillage and fall.

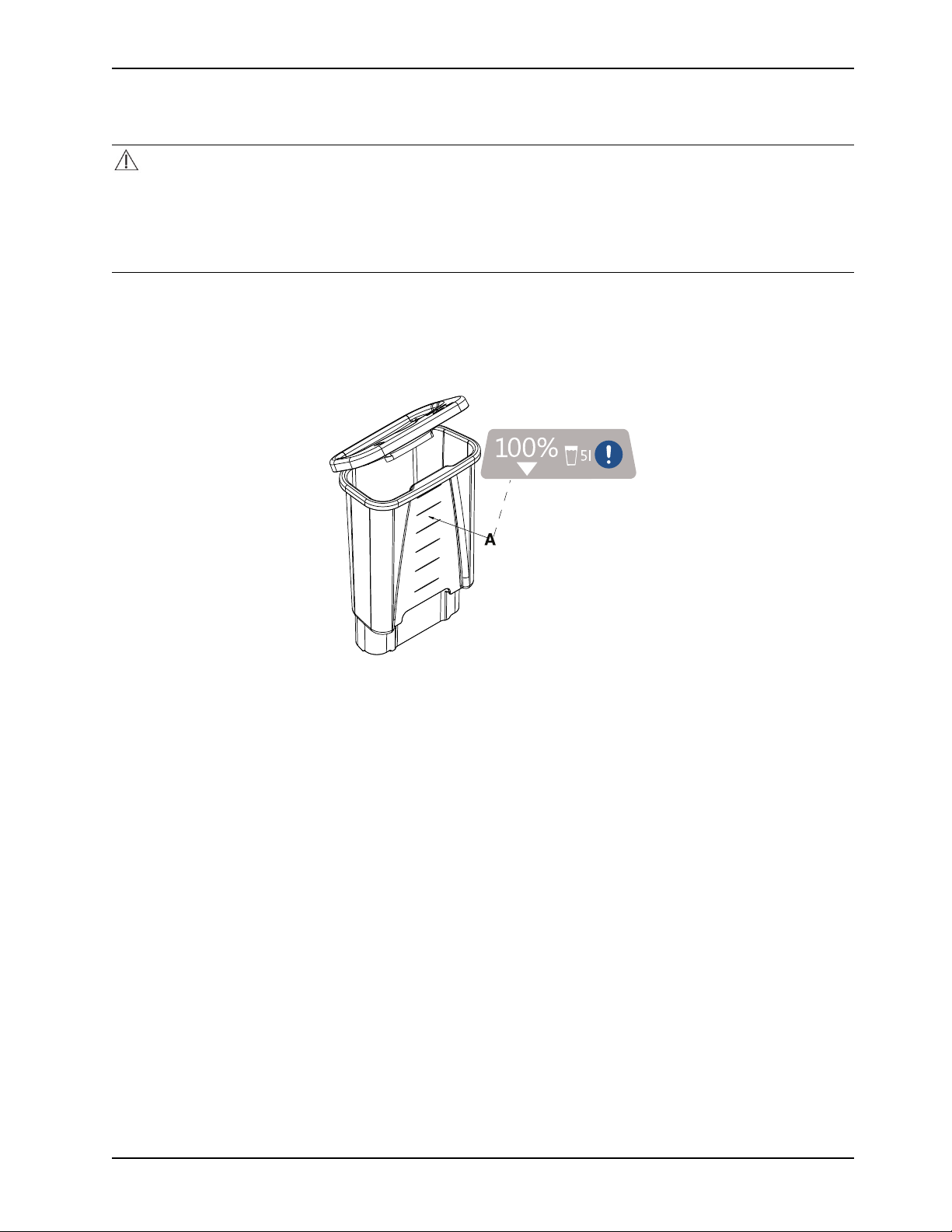

To fill the removable reservoir with sterile distilled water:

1. See Removing and replacing the reservoir on page 26.

2. Fill the reservoir with five liters of sterile distilled water. Do not fill past the top fill line to avoid water overflow (Figure

16 on page 27).

Figure 16: Reservoir fill lines

Selecting and setting the primary probe

A patient probe displays when present, stable, and confirmed. The choice of Probe A or Probe B is highlighted when you

insert the cable into port A and port B. If you only insert one cable, the active port displays.

1. Tap the Settings button.

a. In the standby mode, tap the Back button to display the edit settings screen.

b. In an active therapy mode, tap the Next button.

2. Tap Select Probe to display the Select Primary Probe (Probe A or Probe B) screen. If both probes are present, the

default is probe A.

3. Tap A or B, if applicable.

4. Tap Confirm.

Notes

• The message “Probe stabilization in progress... Please wait” is displayed.

• When you initially select a probe (A or B), detected is checked. When stabilized, the Ready check is displayed.

• If the probe is not stabilized within three minutes, the message “Probe stabilization error” will appear. Tap the

Help button for more detail.

• You can select help at any time to display help with the current screen or icon descriptions.

www.stryker.com 8001-009-0 01 REV G 27

Page 32

Operation

Filling a thermal transfer device

CAUTION

Always pre-fill the thermal transfer device with sterile distilled water before you apply it to the patient. This is to reduce

the risk of pressure ulcers.

Note: These instructions are to pre-fill the thermal transfer devices only, not therapy. See Switching modes on page 31.

To fill a thermal transfer device:

1. Connect a thermal transfer device following: Connecting and disconnecting thermal transfer devices on page 24.

2. Lay the thermal transfer device on a flat surface. Make sure the thermal transfer device is flat for water flow.

3. Open all of the clamps on the connector hose and thermal transfer device.

4. Make sure that the controller is powered.

5. Tap the Stand-by button.

6. Tap the Manual mode button.

7. Tap Confirm.

8. Select a water temperature that aligns with your target patient temperature.

Note: Allow the water to flow from the controller into the thermal transfer device until full.

9. Tap Confirm.

Selecting a therapy mode

You can select from one of three therapy modes and tap Confirm:

• Automatic therapy

• Manual therapy

• Monitor non-therapy

For mode descriptions, tap the Help button.

WARNING

Always check the integrity of the patients skin and temperature according to hospital protocol when using the Altrix

system.

CAUTION

• Explosion risk. This product is not suitable for use in the presence of flammable anesthetic mixture with air or with

oxygen or nitrous oxide other than nasal or mask type.

• Always make sure that there are no water leaks before starting a defibrillation.

• When using the temperature controlled Automatic therapy mode for warming (min, med, or custom), switching to

other modes, changing the target patient temperature, or changing the therapy selection may impact the overall

benefit of therapy.

• Always use Stryker accessories. Failure to comply with these instructions may invalidate any or all warranties and

may negatively affect the products EMC performance. This also protects the product from cardiac defibrillation.

• Always monitor the patient for shivering, temperature, signs of intolerance, and skin condition when using this

product.

• Always pre-fill the thermal transfer devices with water before applying to the patient.

28 8001-009-0 01 REV G www.stryker.com

Page 33

Operation

Max

Med

Min

Starting Automatic therapy mode

In Automatic mode, the therapy cools or warms the patient to a selected patient target temperature. The product in

automatic mode continually measures the patient temperature and automatically adjusts the water temperature until the

selected patient target temperature is achieved. After the selected patient target temperature is achieved, the product

maintains this temperature for the duration of the therapy.

To start Automatic therapy mode:

1. Prepare the thermal transfer devices for therapy.

2. See Filling a thermal transfer device on page 28.

3. Apply the thermal transfer device to the patient.

4. Connect the reusable adapter cable to port A or port B on the product. Make sure that the probe is fully seated.

5. Apply the sensing end of a patient probe to the patient based on your hospital protocol and secure the product to

reduce the risk of accidental dislodgment.

6. Connect the patient temperature probe to the reusable adapter cable. See Selecting and connecting a temperature

probe on page 22.

7. Tap to Confirm the current patient temperature.

8. Tap the Automatic therapy mode button.

9. Select the target patient temperature.

10. See Setting or editing the cooling rates on page 29 or Setting or editing the warming rates on page 30

Notes

• The controller determines Warming or Cooling therapy based on the selected water target temperature and the

current water temperature.

• Do not place additional heat sources between the patient and thermal transfer device.

• After the patient target temperature is achieved, patient temperature is controlled within +/-0.3° C.

• If the patient temperature is not within 0.5° C of the current target temperature, the yellow patient icon will flash

and the patient temperature deviation alarm will sound. This occurs after the initial patient target temperature is

achieved.

Setting or editing the cooling rates

Setting cooling rates is for Automatic Mode only.

1. To set the cooling temperature, highlight your choice of cooling rates.

Select a cooling rate

2. Tap Confirm.

3. Tap the Edit button to make changes.

Description

Maximum: approaches patient target temperature as fast as possible

Medium: water is cooled to target, with a max of 15.0° C difference between the

patient and the water temperature

Minimum: water is cooled to target, with a max of 10.0° C difference between the

patient and the water temperature

www.stryker.com 8001-009-0 01 REV G 29

Page 34

Operation

Max

Med

Min

Set Custom

rr

Setting or editing the warming rates

Setting warming rates is for Automatic Mode only.

1. To set the warming temperature, highlight your choice of warming rates.

Select a warming rate Description

Maximum: approaches patient target temperature as fast as possible

Medium: patient temperature increases at a rate of 4.0° C in 12 hours (0.33° C/ hour).

Minimum: patient temperature increases at a rate of 4.0° C in 24 hours (0.17° C/hour).

Set Custom: patient temperature increases at a customized temperature and time

period the operator selects. The temperature increases 0.05° C/hour to 0.5° C/hour.

2. If you select Set Custom, tap the Increase and Decrease buttons to set the rate (Figure 17 on page 30).

Figure 17: Set custom warming rate

3. Tap Confirm.

4. Tap the Edit button to make changes.

Starting Manual mode

In Manual mode, the therapy will cool or warm the water to a selected water target temperature. The operator must

observe the patient’s temperature and manually adjust the water temperature to obtain the desired patient temperature.

1. If desired, select and place the sensing end of the patient probe based on hospital protocol. Connect the reusable

adapter cable to port A or port B on the product. See Selecting and connecting a temperature probe on page 22.

2. Prepare the thermal transfer devices to be used for therapy.

3. See Filling a thermal transfer device on page 28.

4. Apply the thermal transfer device to the patient.

5. Tap Manual mode. The default water target temperature is 40.0° C (104.0° F) upon initial entry.

6. Tap Confirm.

7. To select the desired water temperature, tap the Increase or Decrease buttons or hold the button to go faster.

a. To edit water temperature, tap the Edit button.

8. Tap Confirm.

30 8001-009-0 01 REV G www.stryker.com

Page 35

Operation

Starting Manual mode (Continued)

Notes

• The controller determines Warming or Cooling therapy based on the selected water target temperature and the

current water temperature.

• In Manual mode, only the water temperature is controlled.

• A temperature probe is not required when operating in Manual mode.

• After the water target temperature is achieved, water temperature is controlled within +/-0.3° C.

Starting Monitor mode

In Monitor mode, no therapy will be delivered, only a display of the current patient temperature.

To start Monitor mode:

1. Connect the reusable adapter cable to port A or port B on the controller. Make sure that the probe is fully seated.

2. Apply the sensing end of patient probe to patient based on hospital protocol. Secure the patient probe to reduce the

risk of accidental dislodgment.

3. Tap the Monitor button.

4. Connect the patient temperature probe to the end of the reusable adapter cable. See Selecting and connecting a

temperature probe on page 22.

Note: If the product senses a patient probe temperature below 36.0° C (96.8° F) or above 38.0° C (104° F), the

normothermia alarm displays and an audible alarm sounds.

5. Tap Confirm. The screen will display the current patient temperature.

Switching modes

Tap Edit and select a different therapy mode.

Pausing and resuming therapy

To pause therapy, press and hold the Pause Therapy button for two seconds.

To resume therapy, press and hold the Pause Therapy button for two seconds.

Displaying the data storage

The system gathers data at five second intervals and is limited to 90 minutes of storage. The graphical display defaults to

show data for all four variables in the Manual and Automatic modes.

www.stryker.com 8001-009-0 01 REV G 31

Page 36

Operation

0

8.0°C

35.4°C

A

B

C

D

Displaying the data storage (Continued)

To display the patient data graph:

1. Tap the Graph icon.

Figure 18: Graphical display

• Primary patient temperature reading from attached probe (A) (Figure 18 on page 32)

• Intermediate target temperature (B)

• Water temperature (C)

• Power level (D)

2. To view data values, hide values, or data lines, tap an icon until the data you desire appears for the selected icon.

3. Tap next to see the current values for each variable.

4. To exit, tap the Graph icon or the Exit button.

Notes

• In monitor mode, only the patient temperature data is displayed (A).

• The graph icon is only available when a therapy is active.

• The patient data remains until the product sleeps or you powered off the product.

• During a power loss the data is lost and not retrievable.

Opening and securing items in the storage compartment

The storage compartment holds a maximum of 3 lb (1.36 kg).

To open the storage compartment door, lift up on the door (Figure 19 on page 33).

The storage compartment secures the following items:

• Two patient probes

• Two reusable adapter cables

• One reusable patient temperature output cable

• Product operations manual

32 8001-009-0 01 REV G www.stryker.com

Page 37

Operation

Opening and securing items in the storage compartment (Continued)

Figure 19: Storage compartment

Notes

• Make sure that the items are securely inside the compartment and not blocking the magnets.

• When closing the storage compartment door, do not place your fingers between the storage compartment door and

the sides of the controller.

Stopping therapy or powering off the product

To stop therapy or power off the controller:

1. Press and hold the Stand-by button for two seconds.

2. Unplug the product from the wall outlet.

Note: If storing the product, see Storing the controller on page 35.

Draining the thermal transfer devices

Read the manufacturer’s operations manual for the individual thermal transfer devices (blankets and wraps) for warnings,

cautions, and safe operating instructions before use. Make sure that you drain the hoses before you put them in storage.

1. Unplug the product.

2. Remove the thermal transfer device from the patient.

3. Open the clamps on the hoses and thermal transfer devices, if applicable. See Figure 14 on page 25.

4. Raise the thermal transfer devices attached to the hose above the ports on the controller. Gravity helps to drain the

water into the controller.

5. Allow most of the water to drain back into the controller. (Approximately 10 minutes).

6. See Connecting and disconnecting thermal transfer devices on page 24.

7. See Disconnecting the insulated hoses on page 24.

8. See Storing the power cord and hoses on page 35.

9. Discard the disposable thermal transfer devices based on your local waste management protocol.

a. Discard the disposable thermal transfer devices based on your local waste management protocol, if applicable.

Draining water from the reservoir

To drain the water from the reservoir:

1. See Removing and replacing the reservoir on page 26.

2. Dispose of the water per hospital protocol.

www.stryker.com 8001-009-0 01 REV G 33

Page 38

Operation

A

Draining water from the reservoir (Continued)

3. Replace the reservoir.

Note: Make sure that the reservoir is dry before you store the product.

Draining water from the controller and hoses

Make sure that the controller and all components are dry before you store the product. Make sure to drain the hoses

before you store them.

1. Place the controller over a floor drain.

2. Remove the reservoir and pull up on the controller drain plug (A) to open the drain (Figure 20 on page 34).

Figure 20: Drain plug

3. Connect a hose to each port.

a. If you have Colder style connector hoses, attach the service tool adapter hose (8001-999-017).

b. If you have Clik-Tite hoses, make sure that the connectors and clamps are open (Figure 21 on page 34).

Figure 21: Clik-Tite open

4. Raise all the hoses completely above the connection ports on the controller.

5. Allow the product to drain for a minimum of two minutes.

6. Push down on the drain plug to close the drain.

7. Replace the reservoir.

34 8001-009-0 01 REV G www.stryker.com

Page 39

Operation

Storing the power cord and hoses

After you complete therapy or when you transport the product, store the power cord and hoses.

CAUTION

• Do not hang items on the controller handle to avoid the risk of tipping the product.

• Always store the power cord, cables, and hoses before you transport the product to reduce the risk of trip hazard.

To store the power cord and hoses:

1. Connect the ends of the connector hoses together, if applicable.

2. Coil and fasten the hose with the management straps (Figure 22 on page 35).

3. Unplug the power cord from the wall outlet and store with the management straps (Figure 22 on page 35).

Figure 22: Management straps

Storing the controller

Storage is equal to or greater than 7 days without use.

CAUTION

• Do not store the product with water in the device.

• Always store the product within the specified environmental condition values.

To store the controller:

1. See Disinfect the internal water circuit and hoses every 14 days on page 39.

2. See Draining the thermal transfer devices on page 33.

3. See Cleaning the external surfaces on page 37.

4. See Disinfecting external surfaces on page 38.

Notes

• Always bring the controller to room temperature after high or low temperature storage.

• Always store the controller with the reservoir in place.

www.stryker.com 8001-009-0 01 REV G 35

Page 40

Operation

Transporting the product

Make sure to follow these procedures for transporting the product to avoid the risk of possible injury or equipment

damage.

CAUTION

• Always use extra care when you transport the product long distances and on inclines greater than five degrees. Ask

for help, if necessary, to avoid the risk of tipping.

• Always use the handle to move the product. Do not attempt to move the product by pulling on cables, hoses, or by

any other means.

• Avoid ramps that are steeper than ten degrees to avoid tipping the product.

• Do not hang items on the controller handle to avoid the risk of tipping the product.

• Always store the power cord, cables, and hoses before you transport the product to reduce the risk of trip hazard.

1. Make sure that the pathway is clear.

2. Unplug the product from the hospital-grade or medical-grade wall outlet. See Storing the power cord and hoses on

page 35.

3. Make sure to place the product with the ports facing the front (Figure 23 on page 36).

Figure 23: Transport position

4. Use the handle to push the product.

5. Limit movement to a slow careful walk.

6. Use two or more operators to move the system on inclines or long distances.

Notes

• Wheel chair ramps are usually less than five degrees.

• The system weighs 150 lb (68.0 kg) when dry. Weight also depends on other items in the storage compartment.

36 8001-009-0 01 REV G www.stryker.com

Page 41

Cleaning

Cleaning the external surfaces

Clean the external surfaces of the controller and system components before each use. System components may be

subject to contamination during use from contact with soiled hands of the user, airborne pathogens, and unexpected or

accidental events. Make sure you remove all visible soils.

CAUTION

Do not power wash this product.

Tools Required:

• Mild soap

• Soft, lint free cloth (2 or more)

Validated mild soap:

• Enzol® Enzymatic Instrument Cleaner by Johnson & Johnson

To clean the external surfaces of the controller and system components:

See Product illustration on page 10 for clarification of product component names and locations.

1. Unplug the power cord from the wall outlet.

2. Apply wheel locks.

3. Undo power cord and hose straps.

4. Unravel and lay out hoses, cables, and power cord.

5. Disconnect the hoses. Push back on the retaining collar of the port on the controller. Pull the hose to disconnect.

6. Disconnect the patient temperature probe cable from the port.

7. Remove the reservoir. Pull forward at an angle, and lift out the reservoir.

8. If necessary, empty the water from the reservoir. Dispose of the water per your hospital protocol.

9. Prepare a mild soap and water solution as described by the manufacture.

10. Wipe the inside and outside of the reservoir and reservoir lid, with a soft, lint free cloth moistened with soap and

water solution.

11. Wipe the hoses and patient temperature probe cables, with a soft, lint free cloth moistened with soap and water

solution.

12. Wipe the controller surfaces while the reservoir is removed with a soft, lint free cloth moistened with soap and water

solution. Also wipe the following system components:

• Hose connectors

• Power cord

• Hose and power cord management straps

• Storage compartment door

• Inside storage compartment

• Graphical user interface display

• Handle

13. Wipe the controller, reservoir and reservoir lid surfaces, and system components with a clean, dry cloth to remove

any excess liquid.

14. Replace the reservoir.

15. Allow the external surfaces of the controller and components to dry thoroughly.

www.stryker.com 8001-009-0 01 REV G 37

Page 42

Disinfecting

Disinfecting external surfaces

Disinfect the external surfaces of the controller and system components before each use. System components may be

subject to contamination during use from contact with soiled hands of the user, airborne pathogens, and unexpected or

accidental events. Follow your hospital protocols for disinfecting the product. Make sure to follow the manufacturer’s

instructions for the disinfectants.

CAUTION

Do not use quaternaries that contain glycol ethers as they may damage the reusable accessories.

Note: If the product is visibly soiled, clean the surface before disinfecting.

Tools Required: