Page 1

IMPORTANT

File in your

maintenance

records

Advantage Series

1001 Emergency Care Stretcher

1501 PACU Stretcher

For stretchers with serial numbers of 971 1030538 and above

MAINTENANCE MANUAL

For Parts or Technical Assistance

1–800–327–0770

Page 2

Table of Contents

Introduction

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning / Caution / Note Definition 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance

Cleaning 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Biannual Checklist 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Information

Pneumatic Fowler Adjustment 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal Linkage Adjustment – Dual Side Control Base 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal Linkage Adjustment – Dual End Control Base 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Assembly Replacement 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Cover Installation And Removal 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic System Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Hydraulic Fluid Level 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Of Excess Air (Vacuum) From The Hydraulic System 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

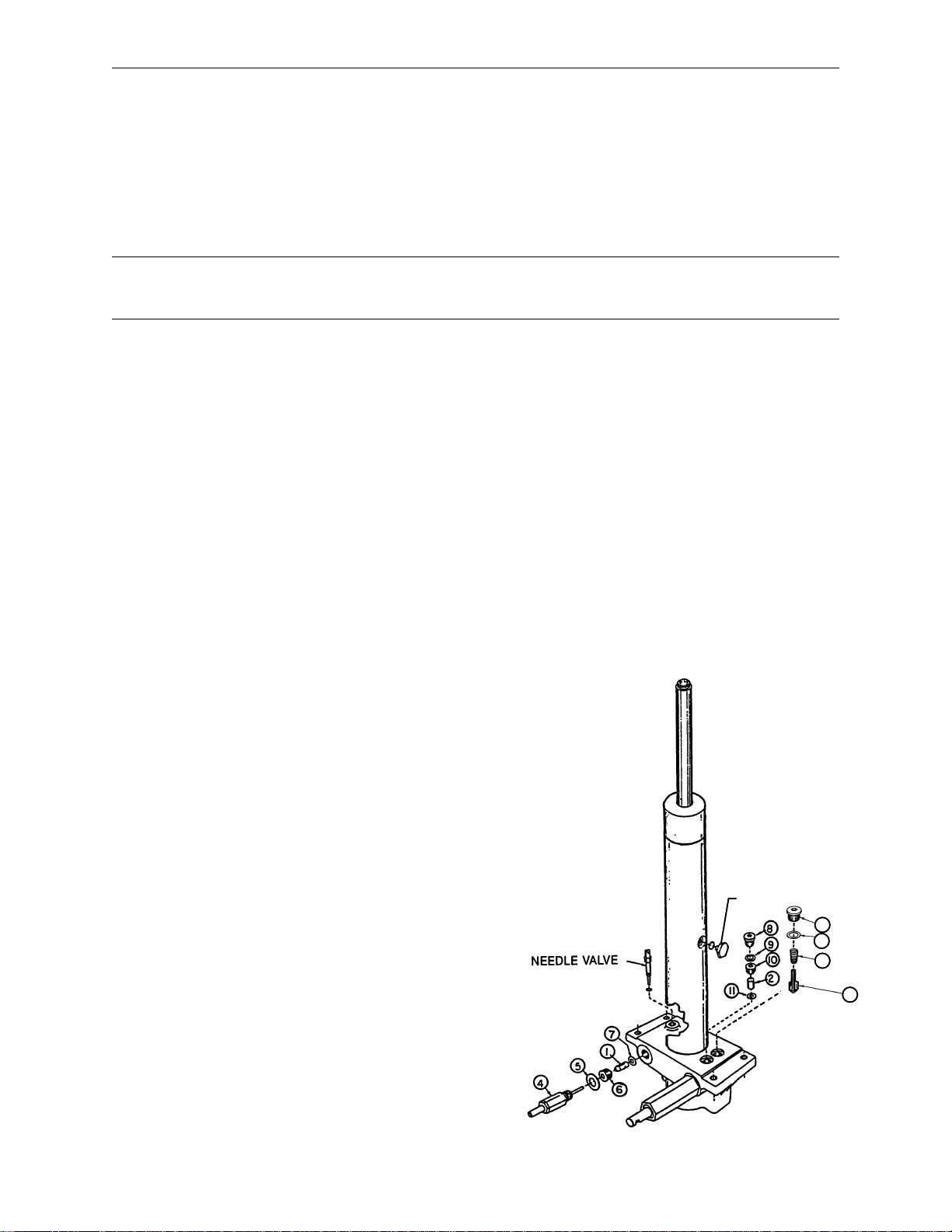

Jack Descent Rate Adjustment 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Check Valve Replacement

Replacement Of Valve #1 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Of Valve #2 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Of Valve (Poppet) #3 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

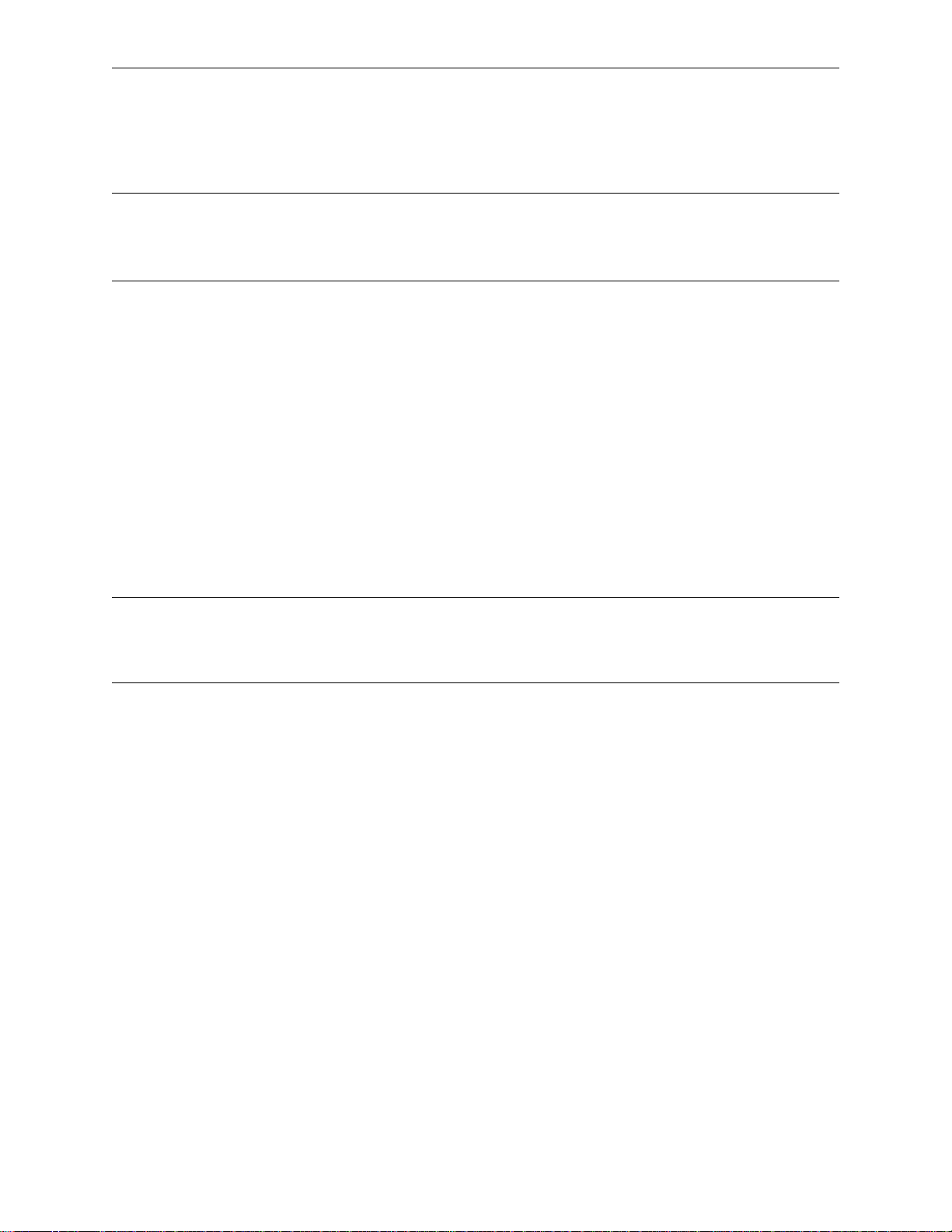

Brake Adjustment 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Lubrication 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly Drawings and Parts Lists

Side Control Base Assembly (with Brakes) 16, 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjuster Assembly 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Cam Assembly 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Control Base Assembly (with Brakes) 20, 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Control Brake Pedal Assembly 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Assembly with Steerlock 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster and Caster Cover Replacement Kits 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fifth Wheel Assembly 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Assembly 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Base Assembly 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

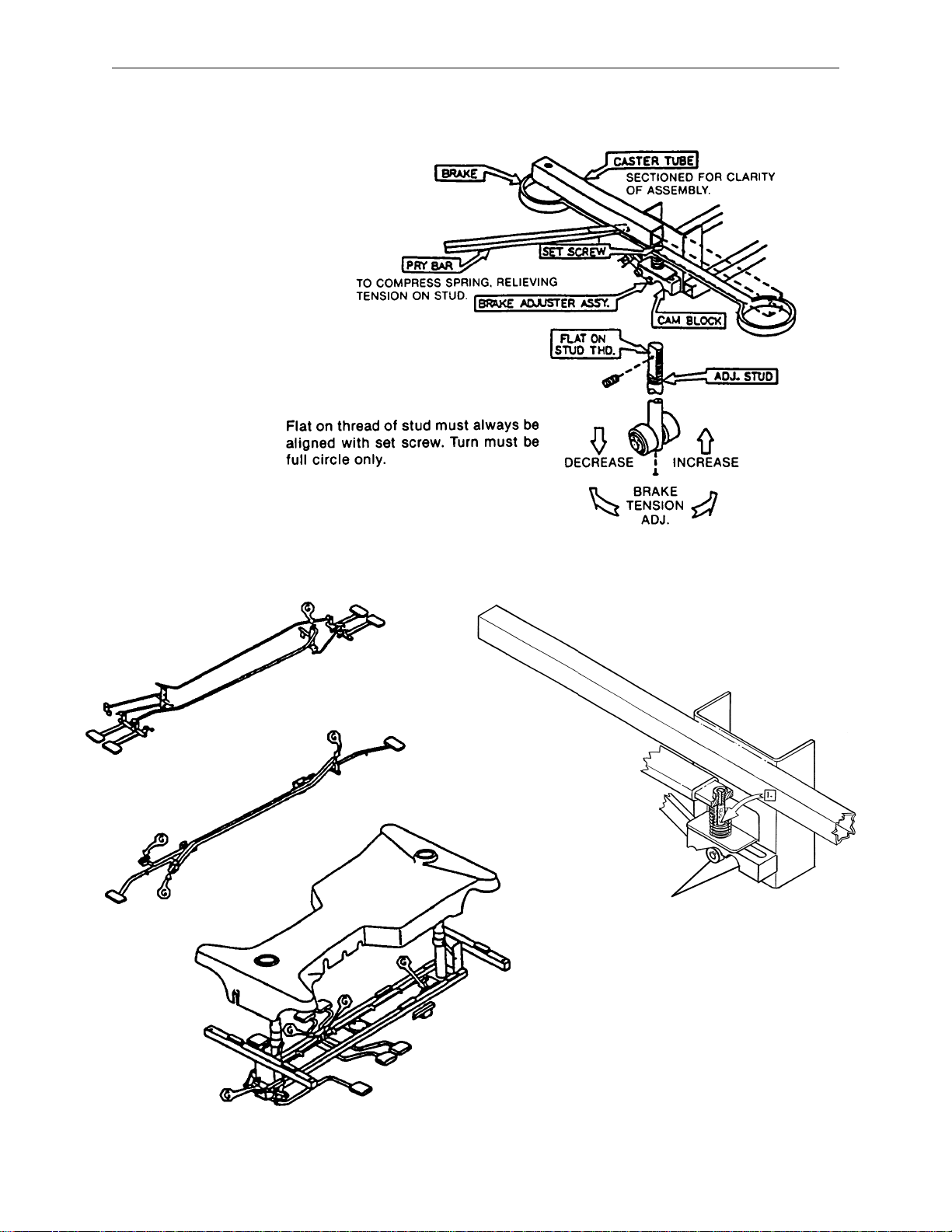

Side Control Base Assembly (with Jacks) 28, 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal Base Assembly, Pump 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal Base Assembly 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

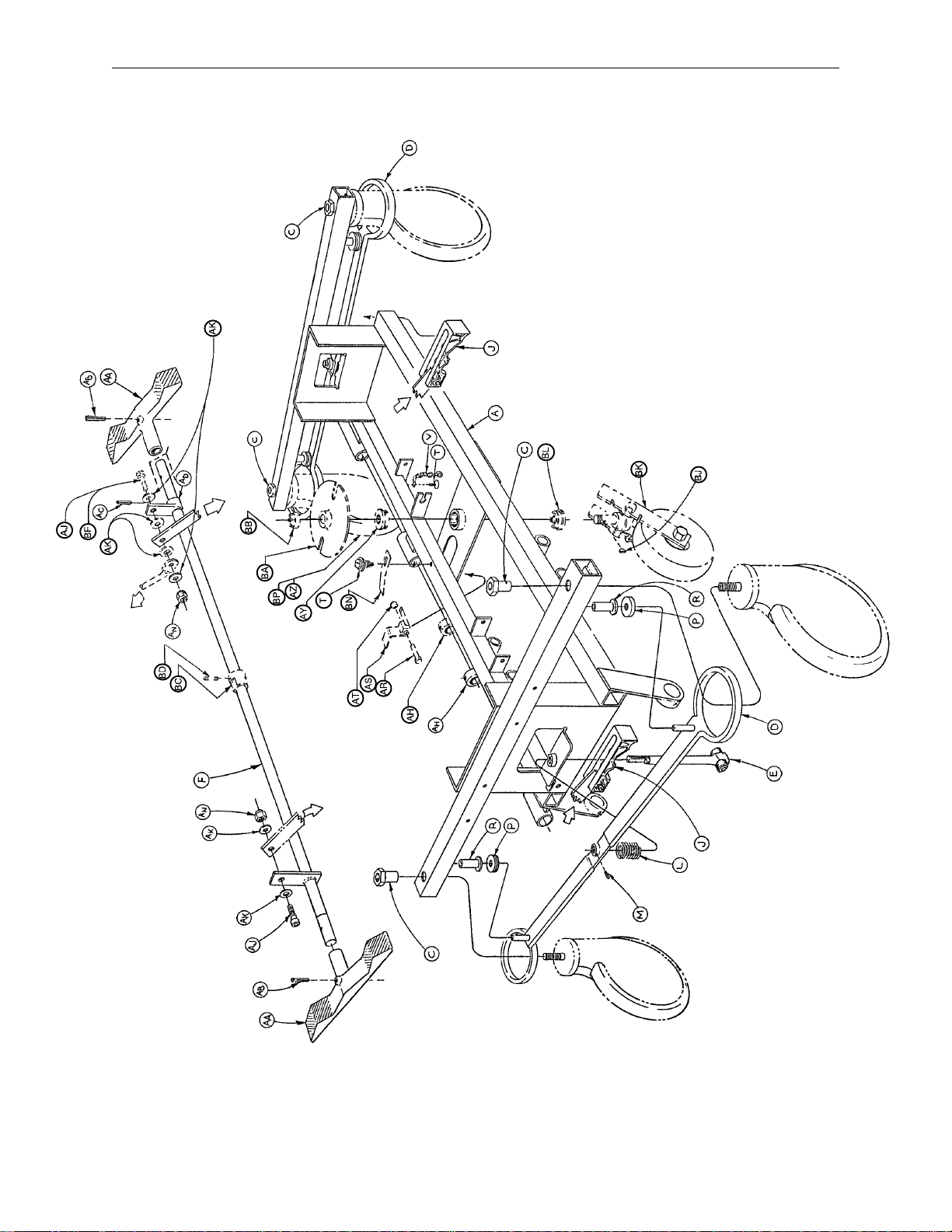

End Control Base Assembly (with Jacks) 32, 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Pedal Assembly 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Control Base Labeling Assembly 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Control Stretcher Graphics 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Control Stretcher Graphics 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Control Base Labeling Assembly 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Fold–to–Head Siderails 39, 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail to Litter Assembly, Fold–to–Head 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly, Fold–to–Foot Siderails 42, 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail to Litter Assembly, Fold–to–Foot 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contents

Assembly Drawings and Parts Lists (Continued)

Siderail Assembly 45, 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head End Siderail Latch Assembly 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stationary Foot End Assembly 48, 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank Knee Gatch Assembly 54–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knee Gatch Crankscrew Assembly 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Fowler Assembly 67–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank Fowler Assembly 75, 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Crankscrew Assembly 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head End Push Bar Assembly 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot End Push Bar Assembly 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–Stage I.V. Pole Assembly 80–86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–Stage I.V. Pole Assembly 88–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tethered I.V. Pole to Frame Assembly 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tethered I.V. Pole Trough Assembly 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tethered I.V. Pole Assembly 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Holder Assembly 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X–Ray Cassette Assembly 100–103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Board/Push Bar Assembly (1001) 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Board/Push Bar Assembly (1501) 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board/Chartholder Assembly 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upright Oxygen Bottle Holder Assembly 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Extension/Defibrillator Tray 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defibrillator Tray 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stirrup and Support Assembly 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Stirrup Support Assembly 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Stirrup Support Assembly 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stirrup Assembly 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–Spine Cassette Holder Assembly 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–Spine Support Pole Assembly 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–Spine Storage Bracket Assembly 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty

Obtaining Parts and Service 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Warranty Coverage 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Authorization 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Introduction

INTRODUCTION

This manual is designed to assist you with the maintenance of the 1001 Emergency Care Stretcher and the

1501 PACU Stretcher. Read it thoroughly before using the equipment or beginning any maintenance on it.

SPECIFICATIONS

1001 1501

Maximum Weight Capacity 500 pounds 500 pounds

Overall Bed Length \ Width 83 1/2” \ 31 1/2” 83 1/2” \ 34”

Minimum \ Maximum Bed Height 22” \ 35” 22” \ 35”

Fowler Angle 0 to 90 degrees 0 to 90 degrees

Knee Gatch Angle 0 to 35 degrees 0 to 35 degrees

Trendelenberg \ Reverse Trendelenberg +12 to –18 degrees +12 to –18 degrees

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

WARNING

Patients should be discouraged from sitting directly on the ends of the stretcher. Excessive weight will cause

the litter surface to tip up, possibly causing patient injury.

Always apply the caster brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure the brakes are securely locked. Always engage the brakes unless the stretcher is being moved. Injury

could result if the stretcher moves while a patient is getting on or off the stretcher.

3

Page 5

Preventive Maintenance

CHECKLIST (PERFORM A MINIMUM OF BIANNUALLY)

All fasteners secure (reference all assembly prints)

Siderails move and latch properly (page 52 & 53)

Engage brake pedal and push on the stretcher to ensure all casters lock securely (page 15)

Steer function working properly

All casters secure and swivel properly

Body restraints working properly

I.V. pole intact and operating properly (page 86–99)

Oxygen bottle holder intact and operating properly (page 106)

Fowler operates and latches properly

Knee Gatch operates properly

Trendelenburg/Reverse Trendelenburg operating properly

No rips or cracks in mattress cover

Ground chain intact

No leaks at hydraulic connections

Hydraulic jacks holding properly (page 10)

Hydraulic drop rate set properly (page 12)

Hydraulic oil level sufficient (page 12)

Lubricate where required, including the brake adjuster assembly and brake cam (page 15)

Accessories and mounting hardware in good condition and working properly

Serial No.______________

______________

______________

______________

______________

Completed By:_________________________________ Date:_____________

4

Page 6

Cleaning

Clean Velcro AFTER EACH USE. Saturate Velcro with disinfectant and allow disinfectant to evaporate. (Appropriate disinfectant for nylon Velcro should be determined by the hospital.)

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or

quaternary type disinfectants can be used with Staph–Chek fabrics. Iodophor type disinfectants are not recommended for use on Staph–Chek fabrics because staining may result. The following products have been

tested by the Herculite Laboratory and have been found not to have a harmful effect on Staph–Chek fabrics

WHEN USED IN ACCORDANCE WITH MANUFACTURERS RECOMMENDED DILUTION.*

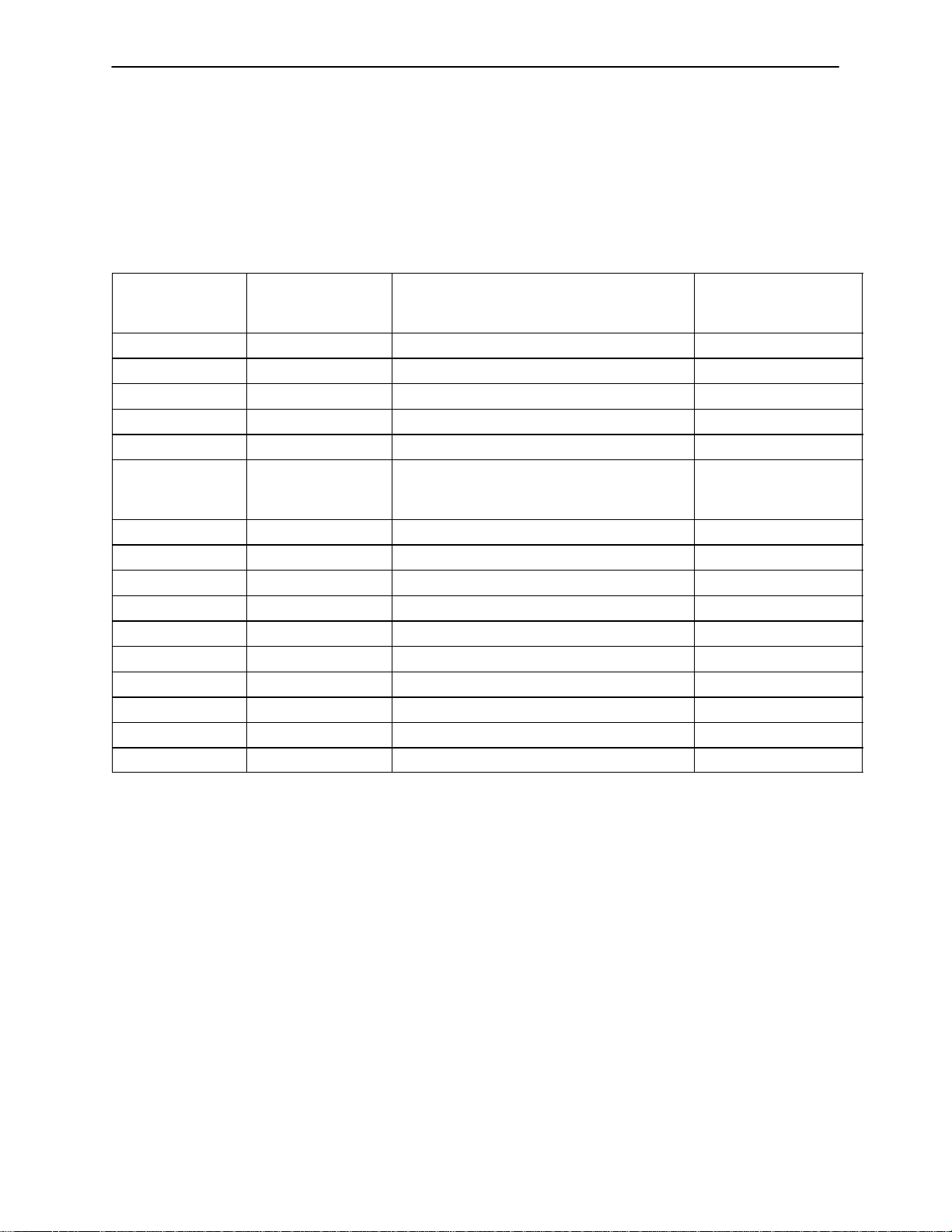

TRADE NAME

A33 Quaternary Airwick (Professional Products Division) 2 ounces/gallon

A33 (dry) Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Beaucoup Phenolic Huntington Laboratories 1 ounce/gallon

Blue Chip Quaternary S.C. Johnson 2 ounces/gallon

Elimstaph Quaternary Walter G. Legge 1 ounce/gallon

Franklin

Phenomysan

F2500

Franklin Sentinel Quaternary Purex Corporation 2 ounces/gallon

Galahad Phenolic Puritan Churchill Chemical Company 1 ounce/gallon

Hi–Tor Quaternary Huntington Laboratories 1/2 ounce/gallon

LPH Phenolic Vestal Laboratories 1/2 ounce/gallon

Matar Phenolic Huntington Laboratories 1/2 ounce/gallon

Omega Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Quanto Quaternary Huntington Laboratories 1 ounce/gallon

Sanikleen Quaternary West Chemical Products 2 ounces/ gallon

Sanimaster II Quaternary Service Master 1 ounce/gallon

Vesphene Phenolic Vestal Laboratories 1 1/4 ounce/ gallon

DISINFECTANT

Phenolic Purex Corporation 1 1/4 ounce/gallon

TYPE

MANUFACTURER

*MANUFACTURER’S

RECOMMENDED

DILUTION

Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach to 100

parts water are not considered mild detergents. These products are corrosive in nature and may cause damage to your stretcher if used improperly . If these types of products are used to clean Stryker patient handling

equipment, measures must be taken to insure the stretchers are rinsed with clean water and thoroughly dried

following cleaning. Failure to properly rinse and dry the stretchers will leave a corrosive residue on the surface

of the stretcher, possibly causing premature corrosion of critical components. Failure to follow the above

directions when using these types of cleaners may void this product’s warranty.

REMOVAL OF IODINE COMPOUNDS

This solution may be used to remove iodine stains from mattress cover and foam footrest pad surfaces.

1. Use a solution of 1–2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area.

Clean as soon as possible after staining occurs. If stains are not immediately removed, allow solution to

soak or stand on the surface.

2. Rinse surfaces which have been exposed to the solution in clear water before returning bed to service.

4.1

Page 7

Notes

4.2

Page 8

Service Information

PNEUMATIC FOWLER ADJUSTMENT (OUTSIDE MOUNTED CYLINDERS)

Required Tools:

5/32” Hex Allen Wrench 1/2” Open End Wrench

Adjustment Procedure:

1. Refer to drawings 1210–31–120 or 1710–31–120 (Pneumatic Fowler Assembly, page 68 or page 72) for

parts reference.

2. For easier access, move Fowler to 75 degrees or higher.

3. Using a 1/2” open end wrench, loosen the nuts (item K) in the actuator arms on the end of the trip bar (F).

4. To adjust the Fowler, use a 5/32” hex Allen wrench to turn the Allen screws (item N) 1 to 2 turns counterclockwise if the Fowler will not move or 1 to 2 turns clockwise if the Fowler will not hold its position.

5. Retighten the nuts. Be sure the Fowler will travel from flat to 90_ and down again and will hold its position

when weight is applied before returning the stretcher to service.

PNEUMATIC FOWLER ADJUSTMENT (CENTER MOUNTED CYLINDERS)

Required Tools:

3/32 Hex Allen Wrench 1/2 Socket w/Ratchet 1/8 Hex Allen Wrench

Channel Lock Pliers 5/32 Hex Allen Wrench Towel or Cloth

7/16 Open End Wrench Thread ”Loctite”

Adjustment Procedure:

1. Refer to drawings 1211–31–10 & 1211–131–20 or 1711–31–10 & 1711–131–20 (Pneumatic Fowler Assembly, page 69 & 70 or page 73 & 74) for parts reference.

2. For easier access, move Fowler to 75 degrees or higher.

3. Using a 3/32” hex Allen wrench, remove set screws (K on p. 70 or 74), located in center of yokes (Y on

p. 70 or 74).

4. Using a 9/16” box end wrench and 5/16” hex Allen wrench, remove the cap screws (A on p. 69 or 73), flat

washers (C on p. 69 or 73) and hex nuts (D on p. 69 or 73) holding the gas cylinders (K on p. 69 or 73)

to the litter frame.

5. To adjust the Fowler, turn the gas cylinder 1 to 2 turns counterclockwise if the Fowler will not move and

1 to 2 turns clockwise if the Fowler will not hold its position.

6. Replace the cap screws (A) and check the Fowler adjustment. Lower the Fowler approximately 10_ to 20_,

release the handle and apply weight to the Fowler to assure it will hold its position. If the Fowler will not

lower or will not hold its position when weight is applied, repeat step 5.

7. When the Fowler is properly adjusted, replace the washers (C) and hex nuts (D) to secure the pivot bolts.

8. Using thread locktite, reinstall set screws (K).

5

Page 9

Service Information

PEDAL LINKAGE ADJUSTMENT – DUAL SIDE CONTROL BASE

Required Tools:

3/32 Hex Allen Wrench

7/16 Open End Wrench

1/2 Open End Wrench

(2) Wooden blocks (10 – 12 inches in length)

Adjustment Procedure:

1. Pump the litter up to full height.

2. Lift the base hood, separating the hood from the base frame. Using the wooden blocks, support the base

hood.

3. To adjust the foot end descent pedal, use a 5/32 hex Allen wrench to loosen the set screw (C) in the stop

collar (D) on the release rod. Hold the pedal parallel to the floor and slide the collar up to the bracket on

the release rod. Tighten the set screw on the stop collar. Be sure the head end and foot end descent

pedals are level with each other. Repeat for the head end pedal, if necessary.

4. Once the pedals are level, be sure the paddle on the end of the release rod for the foot end jack is slightly

touching the actuating stem on the jack base. If it is not, use a 3/32 hex Allen wrench to loosen the set

screw on the paddle hub. Adjust the paddle to JUST touch the stem of the jack. Tighten the set screw

in the paddle hub. Repeat for the head end jack, if necessary.

5. Depress the pedal for the foot end jack. The jack should start to descend about the same time the paddle

on the end of the rod contacts the sleeve on the jack actuating stem. The bracket on the foot pedal body

should hit the stop screw (B). Any further movement could cause damage to the stem components inside

the jack housing. To adjust the stop screw, use a 1/2 open end wrench to loosen the hex jam nut (A).

Turn the screw and re–tighten the hex jam nut. Repeat for the head end jack.

6. Pump the litter up to full height.

7. Step on both descent pedals at the same time. Both ends of the litter should lower with the foot end lowering slightly faster than the head end. If it does not, refer to the procedure for adjusting the jack descent

rate.

8. Remove the wooden blocks supporting the base hood. Use the pedal cut–outs on the side of the hood

as a guide for proper re–positioning.

6

Page 10

Service Information

PEDAL LINKAGE ADJUSTMENT – DUAL END CONTROL BASE

Required Tools:

7/16 Open End Wrench

1/2 Open End Wrench

(2) Wooden Blocks (10 – 12 inches in length)

Adjustment Procedure:

1. Pump the litter up to full height.

2. Lift the base hood, separating the hood from the base frame. Using the wooden blocks, support the base

hood.

3. The descent pedals should be level with each other and there should be approximately 4 inches between

the floor and the bottom of the pedal. To raise the pedal height, use a 1/2 open end wrench to loosen the

hex jam nut (E). Using your hand, turn the screw (D) into the bracket. To lower the pedal height, loosen

the screw. Tighten the hex jam nut (E) after the correct height is achieved.

4. Once the pedals are level, the release rod can be adjusted. Using a 7/16 wrench, turn nut (B) clockwise

to shorten the release length and counterclockwise to increase the length.

5. Depress the pedal and be sure the jack descent is triggered when the pedal is approximately one inch from

the floor. The descent should stop when the pedal is released and the jack height should hold. Repeat

the above procedures for the descent pedal at the other end of the bed.

6. After adjusting each descent pedal individually, depress both pedals at the same time. Both jacks should

start descending when the pedals are approximately one inch from the floor. The foot end should lower

slightly faster than the head end. If it does not, see procedure for adjusting the jack descent rate.

7. Remove the wooden blocks supporting the base hood and secure the hood to the base frame.

7

Page 11

Service Information

CASTER ASSEMBLY REPLACEMENT*

Required Tools:

1/8 Roll Pin Punch Drill with 1/8 inch Drill Bit

Flat Punch (any size larger than 1/8) Hammer

Needle Nose Pliers Floor Jack

3/4 Inch Wrench (2) Wooden Blocks (10 – 12 inches in length)

1 Inch Wrench Torque Wrench (w/ Ft. Lbs. Adjust.)

Replacement Procedure:

1. Pump the litter up to full height.

2. Lift the base hood, separating the hood from the base frame. Using the wooden blocks, support the base

hood.

3. Using a 1/8 roll pin punch and hammer, remove roll pin located in center of lug nut holding wheel assembly

to base frame.

4. Carefully remove plastic wheel covers.

5. Using a floor jack, lift base frame approximately 4 inches off the ground.

6. While holding cap screw with a 3/4 inch wrench, turn lug nut with a 1 inch wrench to loosen wheel assembly

from base frame. Remove wheel.

7. Install the new wheel assembly with new lug nut and tighten down to 60 – 65 foot–pounds torque.

WARNING

Never reuse the old lug nut, cap screw or roll pin once removed from base frame.

8. Lower the floor jack and set aside to be used, if needed, with another wheel.

9. Drill a 1/8 hole in center of lug nut, going completely through the lug nut.

CAUTION

Be careful not to ”oblong” the hole in the lug nut when drilling.

10. Using needle nose pliers, hold on to roll pin and tap into place. Finish driving roll pin with a flat head punch

and a hammer until flush with the lug nut.

11. Install plastic wheel covers onto wheel.

12. Remove the wooden blocks supporting the base hood and secure the hood to the base frame.

*Replacement Part Number 715–100–127 (Caster and Cover Assembly)

1/8 Inch

Dia.

Through

Roll Pin

Lug Nut

(60–65 Ft.–Lb.)

Support Tube

1 Inch

8

Page 12

CASTER MAINTENANCE

Required Tools:

5/8” Wrench

11/16” Wrench

Maintenance Procedure:

Service Information

D

C

A

1. Remove the plastic caster cover (see page 9).

2. Using the 5/8” wrench and the 11/16” wrench, remove the centerlock nut (item A) from the through bolt

(item B) for the caster wheel.

3. Support the corner of the stretcher where the wheel is being removed and remove the through bolt (item

B) and the molded wheel (item C) .

4. Clean the through bolt, molded wheel, and the inside of the caster horn (item D) removing any dirt and

debris. Ensure the bearings in the molded wheel spin freely and easily.

5. Replace the molded wheel and the through bolt.

B

6. Replace the centerlock nut on the through bolt and use the 5/8” and 11/16” wrenches to tighten it securely.

8.1

Page 13

Notes

8.2

Page 14

Service Information

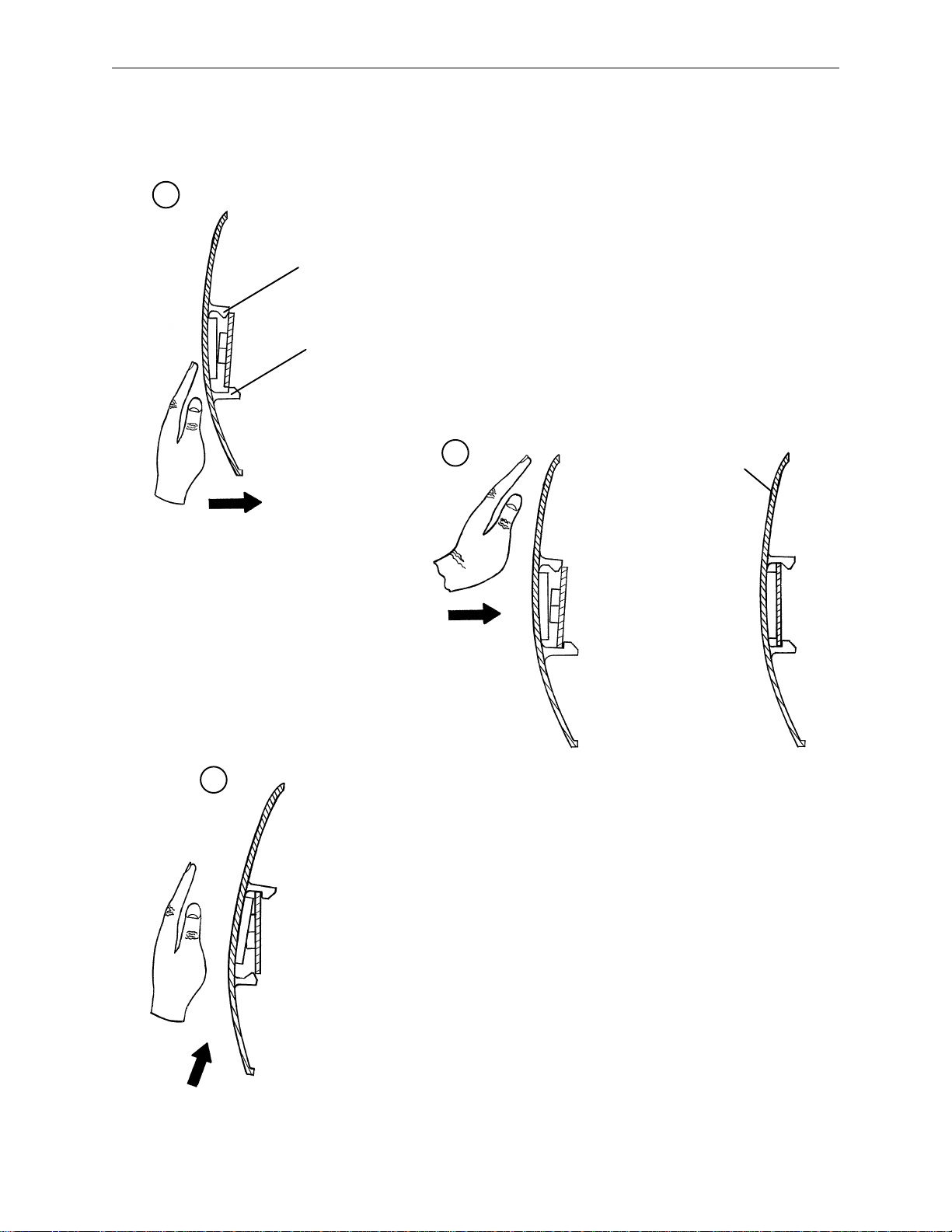

CASTER COVER INSTALLATION AND REMOVAL

1.

Looking through the larger of the two side cut–outs,

Double Prongs

Single Prong

align cover with axle nut or bolt head, as shown.

Push down on the opposite side of the cover until

single prong engages with caster horn.

Top View (Cut–Away)

Push with palm on cover until

double prongs engage.

3.

To remove wheel cover, insert large screwdriver into cut–out in

side of wheel cover and into the space between the double prongs.

Pry up cover to disengage double prongs and push sharply upward

to disengage single prong.

2.

Properly Attached

Cover

Top View (Cut–Away)

Top View (Cut–Away)

9

Page 15

Service Information

HYDRAULIC SYSTEM TROUBLESHOOTING

NOTE

Be sure the pedal linkage has been adjusted properly before beginning service on the jacks (see page 6 or

page 7).

PROBLEM/SYMPTOM SOLUTION

Jack will not raise to full height. Add hydraulic fluid (see p.12). Check for leaks.

Jack will not hold in raised position. Close the needle valve completely. If the jack

holds, replace valve #1 (see p. 14). If the jack

does not hold, replace valve #2 (see p. 15).

Jack will not pump up and the jack actuator rod

does not move.

Jack will not pump up but the jack actuator rod

does move when the pump pedal is activated.

Jack will not pump up and the jack actuator rod

may or may not move.

Close the needle valve. If the jack will now pump

up, replace valve #1. If the jack still will not pump

up after closing the needle valve, replace valve #3

(see p. 15).

Replace valve #2 (see p. 15).

Remove excess air (vacuum) in system (see p.

12).

Contact Stryker technical service at 1–800–327–0770 for further assistance.

10

Page 16

Service Information

BRAKE RING REPLACEMENT

Brake Ring Part Number 715–1–61

Required Tools:

Phillips Screwdriver String or Bungee Cord Floor Jack, Small Crate (or equiv.)

Large Standard Screwdriver 3/32” Allen Wrench 11/16” Socket & Ratchet

5/8” Wrench Needle–Nose Pliers (2) 7/16” Wrenches

Procedure:

1. Remove the four Phillips screws holding the base hood to the frame. Lift and support the base hood using

string or bungee cord. Put the brake/steer pedal in the neutral position. Lift the end of the base needing

service until the casters are approximately 12” off the floor and support it with a jack or the equivalent.

2. Using a 3/32” Allen wrench, loosen the set screw holding the brake adjuster to the brake ring and turn the

adjuster clockwise to remove it.

3. Remove the wheel covers on both casters (see page 9).

4. Remove one of the caster assemblies (see page 8). On the other caster, use an 11/16” socket and ratchet

and a 5/8” wrench to remove the nut and bolt holding the wheel on the caster horn and remove only the

wheel.

5. Using needle–nose pliers, carefully squeeze and remove the spring between the brake cam and the brake

ring.

WARNING

The spring is tightly compressed. Use caution when removing it or personal injury could result.

6. If you are working on an end control base, remove the spring from the pump pedal.

7. Lower the brake ring and remove it from the base. Remove the brake pads and bushings and install them

on the new brake ring.

8. Reverse the above steps to install the new brake ring and reinstall the caster and wheel. Apply and release

the brakes to ensure they operate properly. If adjustment is required, see page 15. Reinstall the base

hood.

BRAKE CAM REPLACEMENT

Brake Cam Part Number 715–1–213

Required Tools:

Phillips Screwdriver String or Bungee Cord 3/32” Allen Wrench

1/8” Allen Wrench

Procedure:

1. Remove the four Phillips screws holding the base hood to the frame. Lift and support the base hood using

string or bungee cord.

2. Using a 3/32” Allen wrench, loosen the set screw holding the brake adjuster to the brake ring and turn the

adjuster clockwise to remove it.

3. Using a 1/8 ” Allen wrench, remove the shoulder bolt and nut holding the brake link on the cam and remove

the cam.

4. Reverse steps 3 and 4 to install the new cam. Apply and release the brakes to ensure they operate properly.

If adjustment is required, see page 15. Reinstall the base hood.

11

Page 17

Service Information

JACK DESCENT RATE ADJUSTMENT

Required Tools:

Screwdriver Bungee Cords (or equivalent)

Adjustment Procedure:

1. Pump the litter up to full height.

2. Lift the base hood, separating the hood from the base frame. Using the wooden blocks, support the base

hood.

3. The descent rate needle valve is located on the base of the jack. Turning the needle valve clockwise, with

a screwdriver, will decrease the rate of descent. Turning it counterclockwise will increase the rate of descent.

4. Adjust the needle valve so that the foot end of the stretcher descends slightly faster than the head end.

NOTE

The larger percentage of a patient’s weight is located in the torso area. Adjust descent rate accordingly.

5. Remove the wooden blocks supporting the base hood and secure the hood to the base frame.

NOTE

The jack descent rate was preset at the factory to drop the foot end faster than the head. It is recommended

that the foot drop faster to avoid patient disorientation.

CHECKING HYDRAULIC FLUID LEVEL

Required Tools:

3/8 Open End Wrench 3/4 Open End Wrench

Procedure:

WARNING

To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning

service on the jacks.

1. Using a 3/8 open end wrench, remove square head set screws from both head and foot end jack support

tubes. Remove litter top and set aside.

2. Lift base hood off base frame and set aside.

3. Be sure there are no hydraulic leaks. If there are, jack replacement will be necessary.

4. Lower the jack to the full down position.

5. Using a 3/4 open end wrench, slowly turn the fill plug located on the side of the reservoir counterclockwise

to allow excess system pressure to vent. Remove the fill plug.

6. The hydraulic fluid should be visible at the bottom of the fill hole. If it is not, add Mobil Aero HFA hydraulic

fluid (Stryker part number 2020–70–475) until the fluid is visible at the bottom of the fill hole. Replace the

fill plug.

CAUTION

Use of other types of oil may damage hydraulic units.

7. Replace the hood and the litter.

12

Page 18

Service Information

HYDRAULIC CHECK VALVE REPLACEMENT

Required Tools:

3/8 Open End Wrench Stiff Wire (with bent, pointed end) Small Needle Nose Pliers

3/4 Open End Wrench Torque Wrench (with Ft. Lbs. adjust.)

7/32 Hex Allen Wrench 1/2 Inch Diameter Rod

Replacement of Valve #1

WARNING

To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning

service on the stretcher.

1. Using a 3/8 open end wrench, remove square head set screws from both head and foot end jack support

tubes. Remove litter top and set aside.

2. Lift base hood off base frame and set aside.

3. Lower the jack to full down position. The actuator must be manually lowered while depressing the appropriate release pedal.

4. Remove the pin body assembly (4) with a 3/4 open end wrench and discard the housing gasket (5).

NOTE

Although the hydraulic fluid is not under pressure, some fluid loss will occur . The fluid loss should be minimal

but covering the floor is advisable.

5. Using a 7/32 hex Allen wrench, remove the valve plug (6).

6. Using a stiff wire with a bent, pointed end, remove and discard the valve (1) and the seal (7).

7. Install the new seal (7) flat to the bottom of its hole with a 1/2 inch diameter rod and install the new valve

(1) with the beveled end out (as shown in the illustration).

8. Install the valve plug (6) with the countersunk end first and the beveled end out. Tighten to 10 foot pounds

torque.

9. Install the pin body assembly (4) with the new housing gasket (5) and tighten to 10 foot pounds torque.

10. Pump up the jack to the maximum height. Apply weight to be sure the jack holds its position and there

are no hydraulic leaks before replacing the base hood and the litter.

ITEM PART NO. PART NAME

1 926–20–153 Check Valve

2 926–20–153 Check Valve

3 715–1–341 Poppet

4 715–100–312 Pin Housing Assembly*

715–270–100 Valve Assembly**

5 715–1–330 Housing Gasket

6 715–1–309 Valve Plug

7 926–20–154 Seal

8 715–1–101 Base Plug

9 926–20–156 Seal

10 715–1–309 Valve Plug

11 926–20–154 Seal

12 715–1–301 Base Plug

13 926–20–156 Seal

14 390–2–134 Conical Comp. Spring

* Used on jack part number 715–100–310.

** Used on jack part number 715–270–10.

(see label on side of jack reservoir for jack part number)

13

FILLER PLUG

12

13

14

3

Page 19

Service Information

HYDRAULIC CHECK VALVE REPLACEMENT (CONT’D)

Replacement of Valve #2

WARNING

To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning

service on the jacks. Lower the jack rod completely to relieve the pressure on the pump piston side of the

jack. This will prevent large hydraulic fluid loss and possible damage when the base plugs are removed.

1. Remove the base plug (8) and discard the seal (9).

2. Remove the valve plug (10).

3. Using a stiff wire with a bent, pointed end, remove the valve (2) and the seal (11) and discard the seal.

4. Install the new seal (11) flat to the bottom of its hole with a 1/2” diameter rod.

5. Install the new valve (2) with the beveled end out (as shown in the illustration).

6. Install the valve plug (10) and tighten to 10 foot–pounds torque.

7. Install the new seal (9) with the base plug (8) and tighten to 10 foot–pounds torque.

8. Pump up the jack to the maximum height.

9. Be sure there are no hydraulic leaks before replacing the base hood and the litter.

Replacement of Valve (Poppet) #3

WARNING

To avoid personal injury or damage to the stretcher, remove the litter and the base hood before beginning

service on the jacks. Lower the jack rod completely to relieve the pressure on the pump piston side of the

jack. This will prevent large hydraulic fluid loss and possible damage when the base plugs are removed.

1. Remove the base plug (12) and discard the seal (13).

2. Remove the compression spring (14).

3. Using a small needle nose pliers, remove the poppet (3).

4. Install the new poppet (3).

5. Install the compression spring (14).

6. Install the new seal (13) and the base plug (12) and tighten to 10 foot–pounds torque.

7. Pump up the jack to the maximum height to check its operation.

8. Check for hydraulic leaks before replacing the base hood and the litter.

REMOVAL OF EXCESS AIR (VACUUM) FROM THE HYDRAULIC SYSTEM

Procedure:

1. Verify all hydraulic linkages are secure and operating properly (see pedal linkage adjustment procedure

page 6 or 7).

2. Using pump pedal, actuate system several times. This will force the air through the system and the jack

should now pump up.

14

Page 20

Required Tools:

3/32” Hex Allen Wrench

Pry Bar

Thread ”Locktite”

Service Information

BRAKE ADJUSTMENT

BASE LUBRICATION

Do not grease area shown.

1. Lubricate brake adjuster rod

around area shown with MPG–2

grease or equivalent.

15

Page 21

Side Control Base Assembly (with Brakes)

Assembly part number 715–1–250

16

Page 22

715–1–250 Side Control Base Assembly (with Brakes)

Item Part No. Part Name Qty.

A 715–1–245 Base Weldment Assembly 1

B38–211 Spring 1

C 715–1–158 Caster Nut 4

D 715–1–61 Caster Brake Assembly 2

E (Page 18) Brake Adjuster Assembly 2

F 715–1–231 Brake/Steering Rod Assembly 1

H 1000–10–62 Steering Lock Linkage Bar 1

J (Page 19) Brake Cam Assembly 2

L 715–1–94 Compression Spring 2

M21–50 Set Screw 2

P 715–1–11 Brake Cushion 4

R 946–1–116 Brake Bar Bushing 4

T23–25 Self–Tapping Screw 2

V 715–1–156 Grounding Chain 1

AA 715–201–201 Brake/Steer Pedal 2

AB 26–261 Groove Pin 2

AC 26–13 Roll Pin 1

AD 715–1–165 Actuator Plate Assembly 1

AH 42–20 Collar w/ Set Screw 2

AJ 8–17 Soc. Hd. Cap Screw 2*

AK 14–2 Nylon Washer 4

AN 16–2 Fiberlock Nut 2

AR 3–20 Hex Hd. Cap Screw 1

AS 715–1–217 Fifth Wheel Latch 1

AT 16–16 Nylock Nut 1

AY 715–1–157 Fifth Wheel Bearing 1

AZ (Page 23) Steering Caster Assembly 1**

BA 715–1–337 Fifth Wheel Plate Assembly 1

BB 16–49 Flexlock Nut 1

BC 715–1–161 Fifth Wheel Cam 1

BD 26–8 Roll Pin 1

BF 8–21 Soc. Hd. Cap Screw 1**

BJ 715–1–149 Woodruff Key 1

BK (Page 25) Fifth Wheel Assembly 1

BL 81–219 Bearing 1

BN 715–1–136 Fifth Wheel Spring 1

BP (Page 24) Caster Wheel Assembly 3 ***

*Item AJ to be used only when fifth wheel is ordered.

**Items AZ and BF to be used only when steerlock caster is ordered.

***Item BP quantity of four when fifth wheel is ordered.

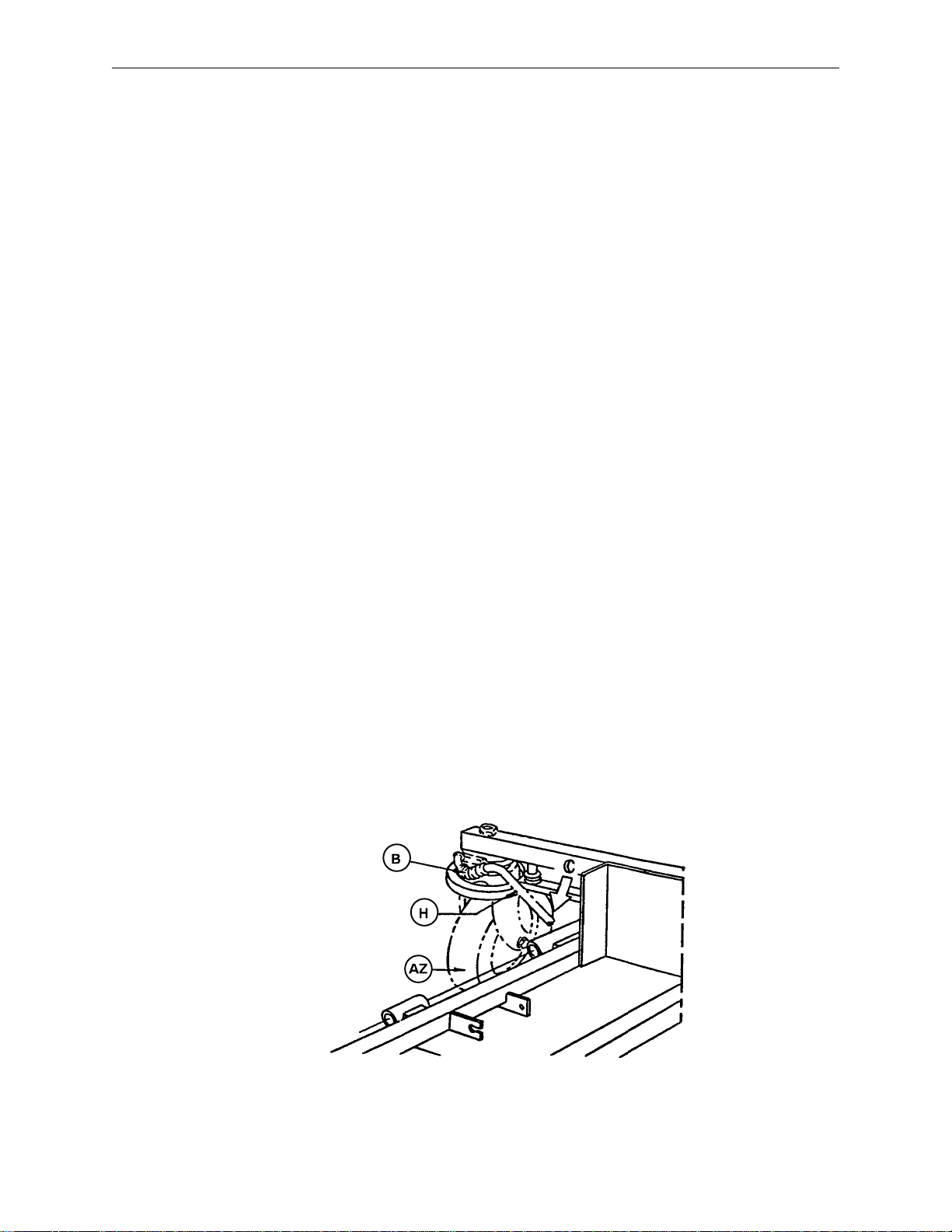

STEERLOCK

ASSEMBLY

DETAIL

17

Page 23

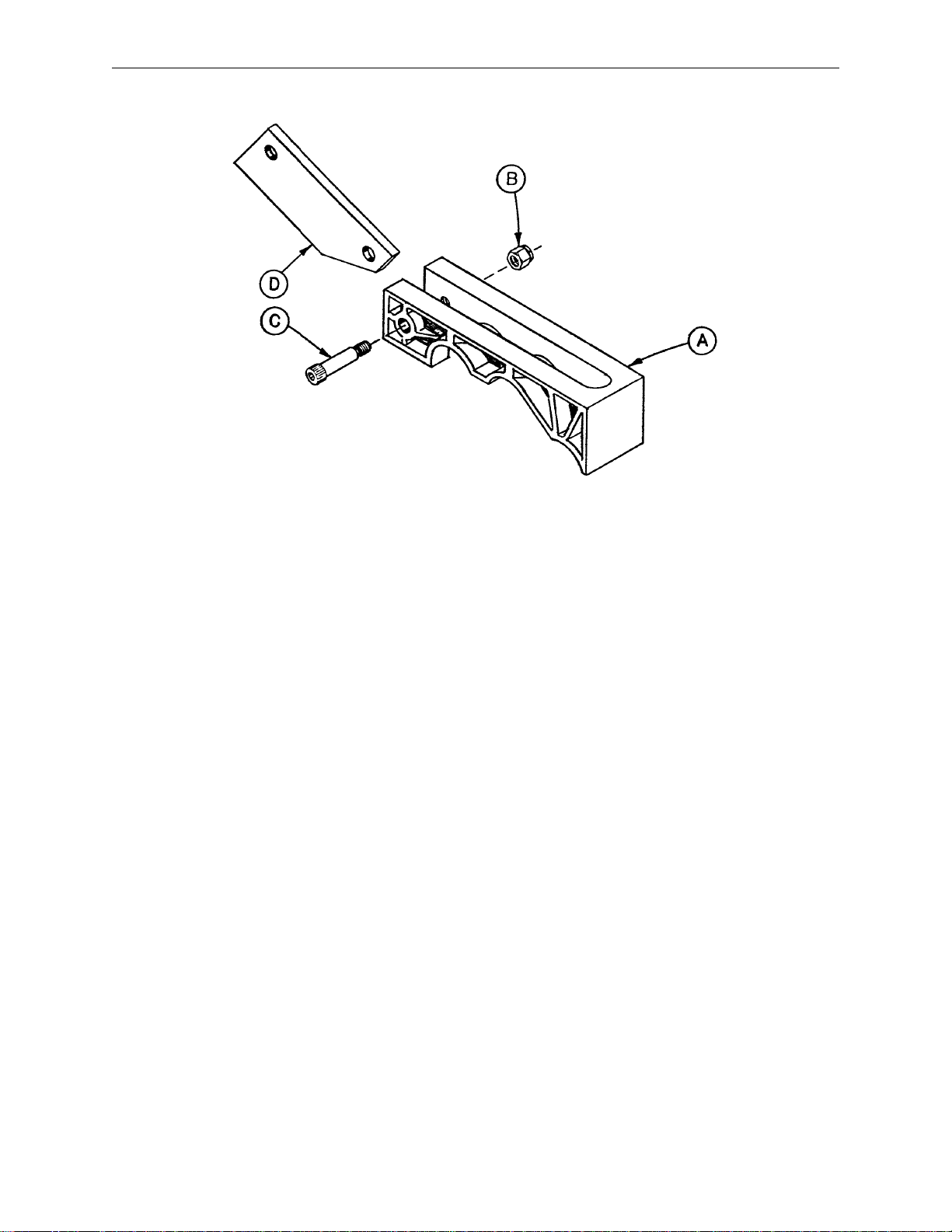

715–1–150 Brake Adjuster Assembly

Item Part No. Part Name Qty.

A 715–1–62 Threaded Stud Assembly 1

B14–4 Nylon Washer 4

C 715–1–180 Bearing 2

D28–8 Retaining Ring 2

18

Page 24

715–1–213 Brake Cam Assembly

Item Part No. Part Name Qty.

A 715–1–221 Brake Cam 1

B16–59 Fiberlock Nut 1

C8–21 Soc. Hd. Cap Screw 1

D 715–1–173 Brake Connecting Link 1

19

Page 25

20

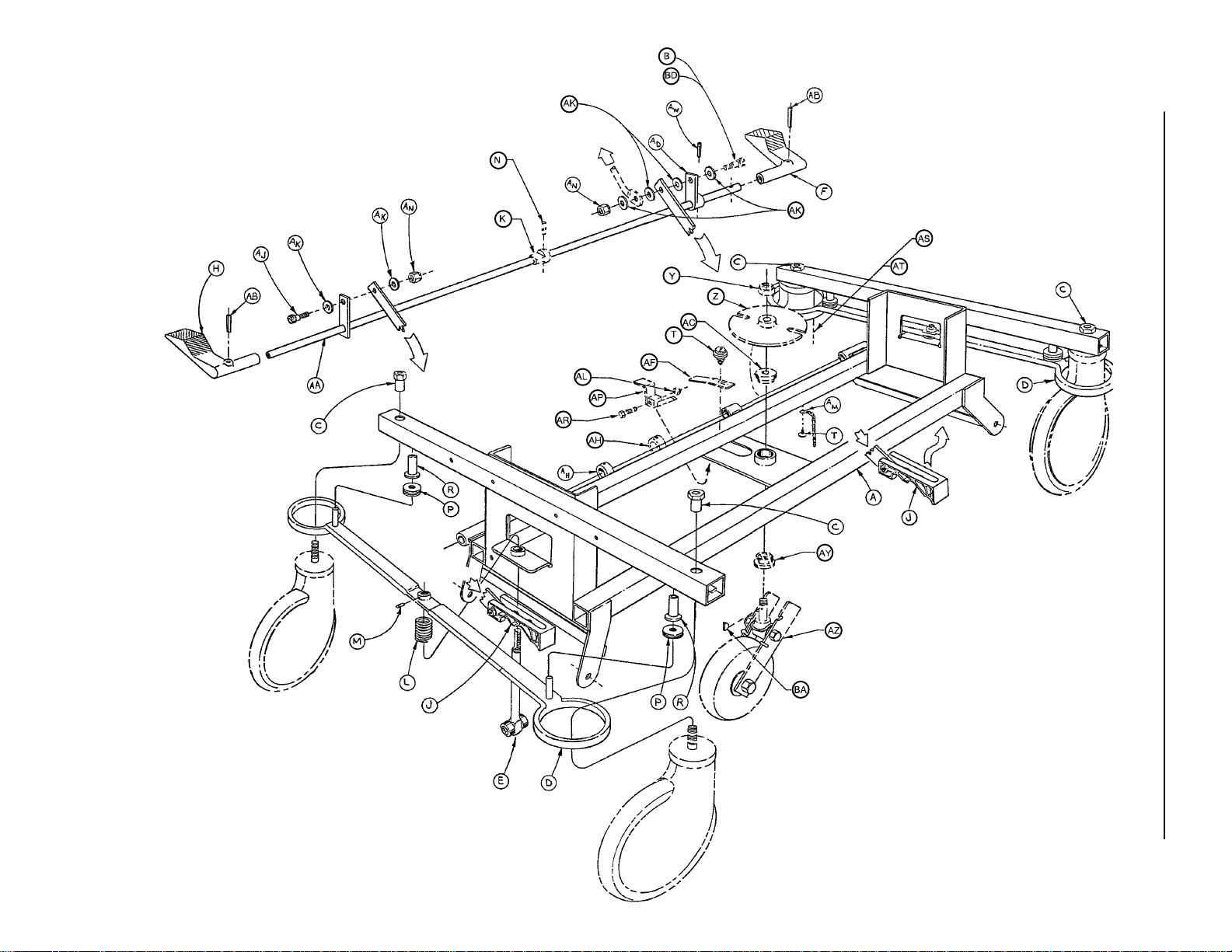

Assembly part number 716–1–251

End Control Base Assembly (with Wheels and Brakes)

Note:

Parts and assemblies drawn with broken

lines are part of optional accessories.

Page 26

End Control Base Assembly (with Wheels and Brakes)

Item Part No. Part Name Qty.

A 716–1–246 Base Weldment Ass’y1

B8–17 Soc. Hd. Shoulder Bolt 1

C 715–1–158 Caster Nut 4

D 715–1–61 Caster Brake Assembly 2

E (Page 18) Brake Adjuster Assembly 2

F 1210–1–345 Brake/Steer Pedal, Ft. End 1

H 1210–1–346 Brake/Steer Pedal, Hd. End 1

J (Page 19) Brake Cam Assembly 2

K26–8 Roll Pin 1

L 715–1–94 Compression Spring 2

M21–50 Set Screw 2

N 715–1–161 Fifth Wheel Cam 1

P 715–1–11 Brake Cushion 4

R 946–1–116 Brake Bar Bushing 4

T23–25 Self–Tapping Screw 2

Y16–49 Flexlock Nut 1

Z 715–1–337 Fifth Wheel Plate Ass’y1

AA 715–1–231 Brake/Steer Rod Weldment 1

AB 26–261 Clevis Pin 2

AC 715–1–157 Fifth Wheel Bearing 1

AD 715–1–165 Actuator Plate Assembly 1

AF 715–1–136 Fifth Wheel Spring 1

AH 42–20 Collar w/ Set Screw 2

AJ 8–17 Soc. Hd. Shoulder Bolt 1

AK 14–2 Nylon Washer 6

AL 16–16 Nylock Nut 1

AM 715–1–156 Grounding Chain 1

AN 16–2 Fiberlock Nut 2

AP 715–1–217 Fifth Wheel Latch 1

AR 3–20 Hex Hd. Cap Screw 1

AS (Page 23) Steering Caster Ass’y1

AT (Page 24) Caster Wheel Ass’y3

AY 81–219 Bearing 1

AW 26–13 Roll Pin 1

AZ (Page 25) Fifth Wheel Ass’y1

BA 715–1–149 Woodruff Key 1

BB 1000–10–62 Steering Lock Linkage Bar 1

BC 38–211 Spring 1

BD 8–21 Soc. Hd. Shoulder Bolt 1

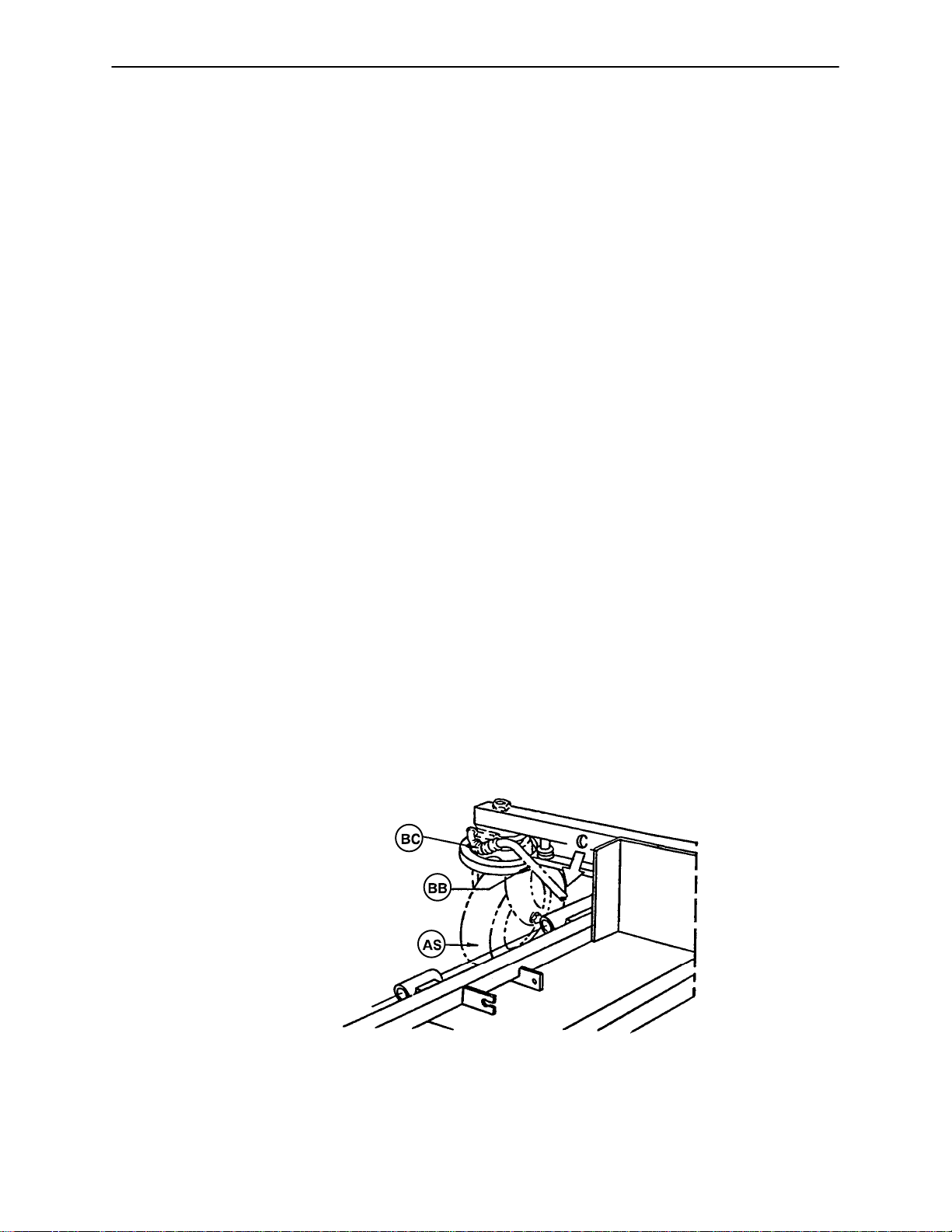

STEERLOCK

ASSEMBLY

DETAIL

21

Page 27

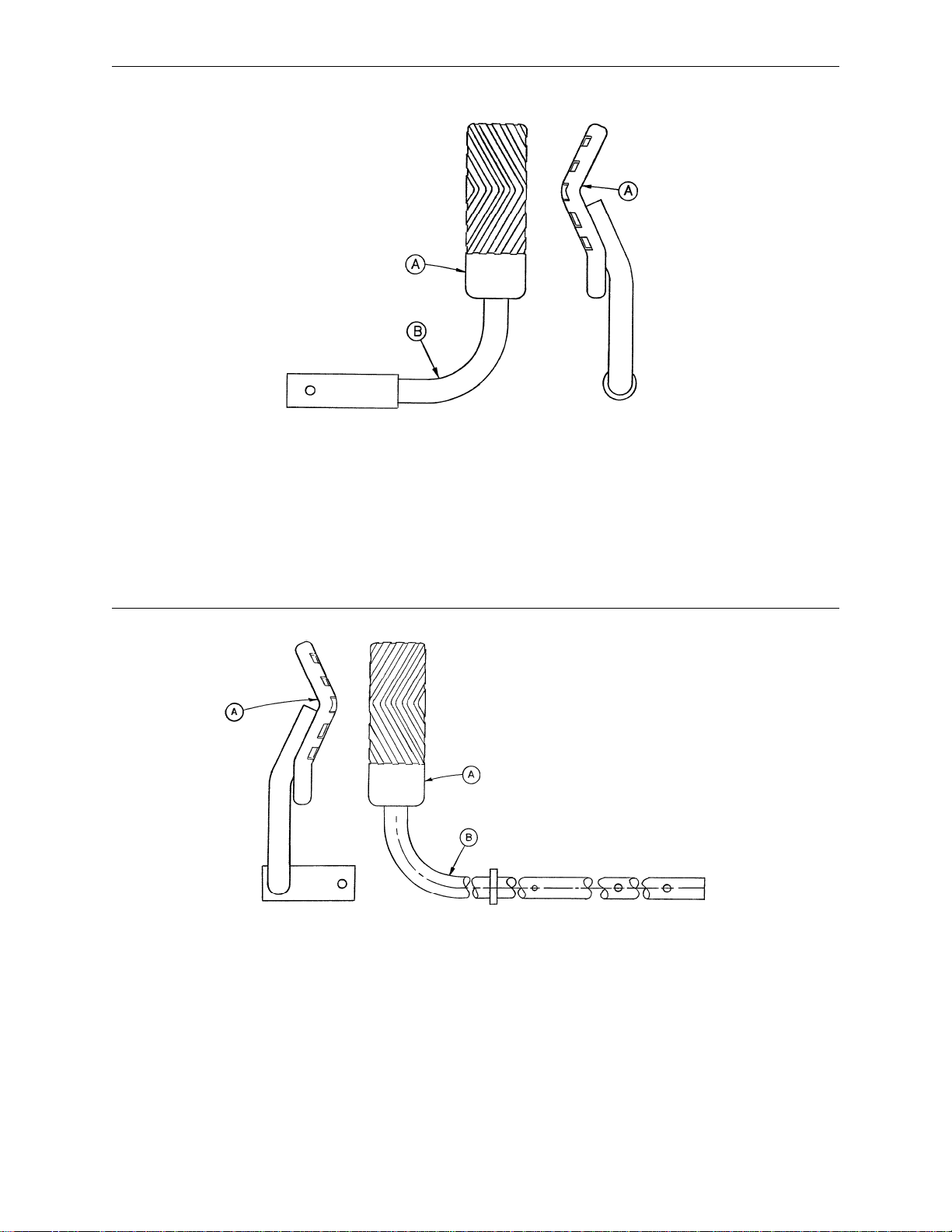

716–1–263 End Control Brake Pedal Assembly, Foot

Item Part No. Part Name Qty.

A 716–1–275 Brake Pedal 1

B 716–1–262 Brake Rod Ass’y, Ft. End 1

716–1–269 End Control Brake Pedal Assembly, Head

Item Part No. Part Name Qty.

A 716–1–275 Brake Pedal 1

B 716–1–267 Brake Rod Ass’y, Welded 1

NOTE

Apply plastic adhesive to the mating surfaces of item A prior to assembly.

22

Page 28

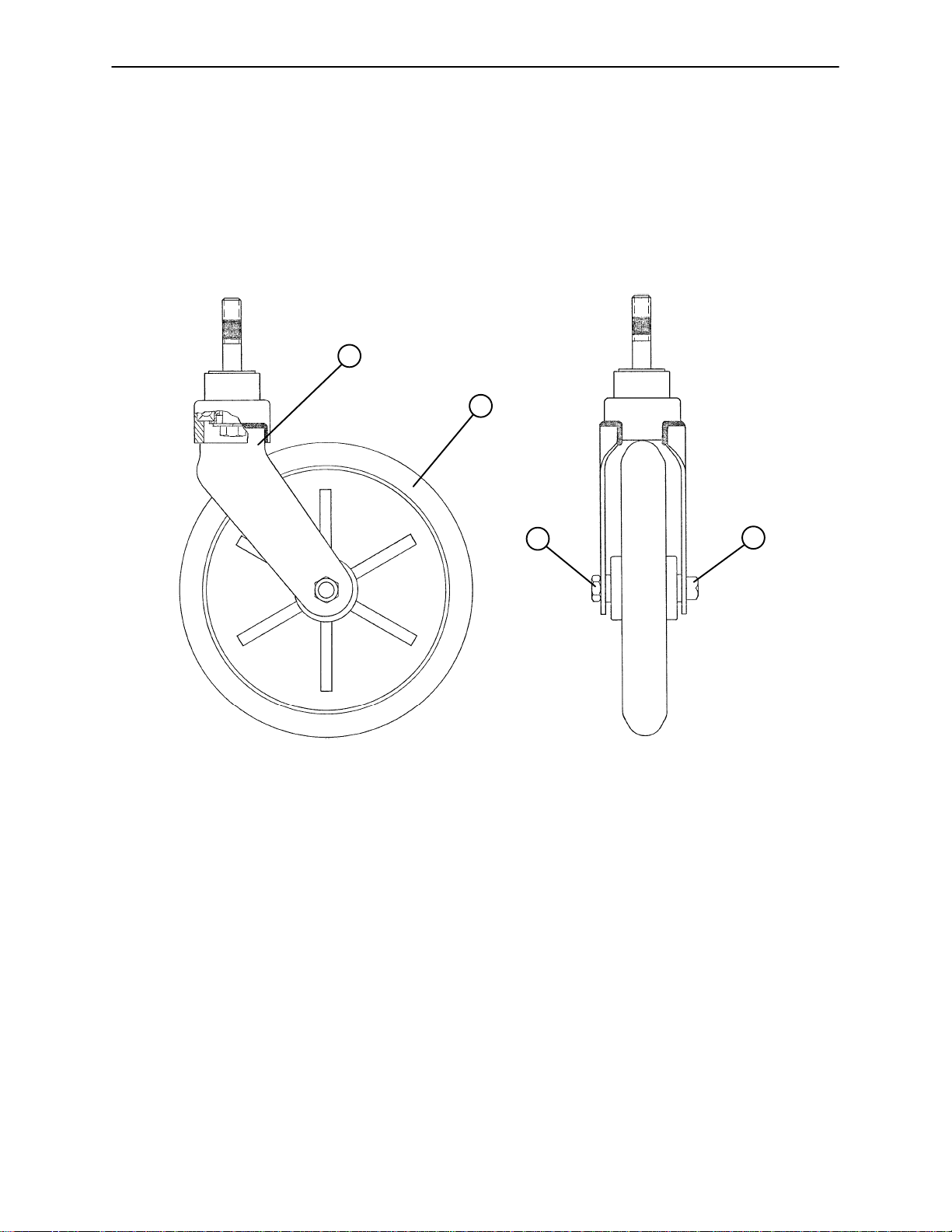

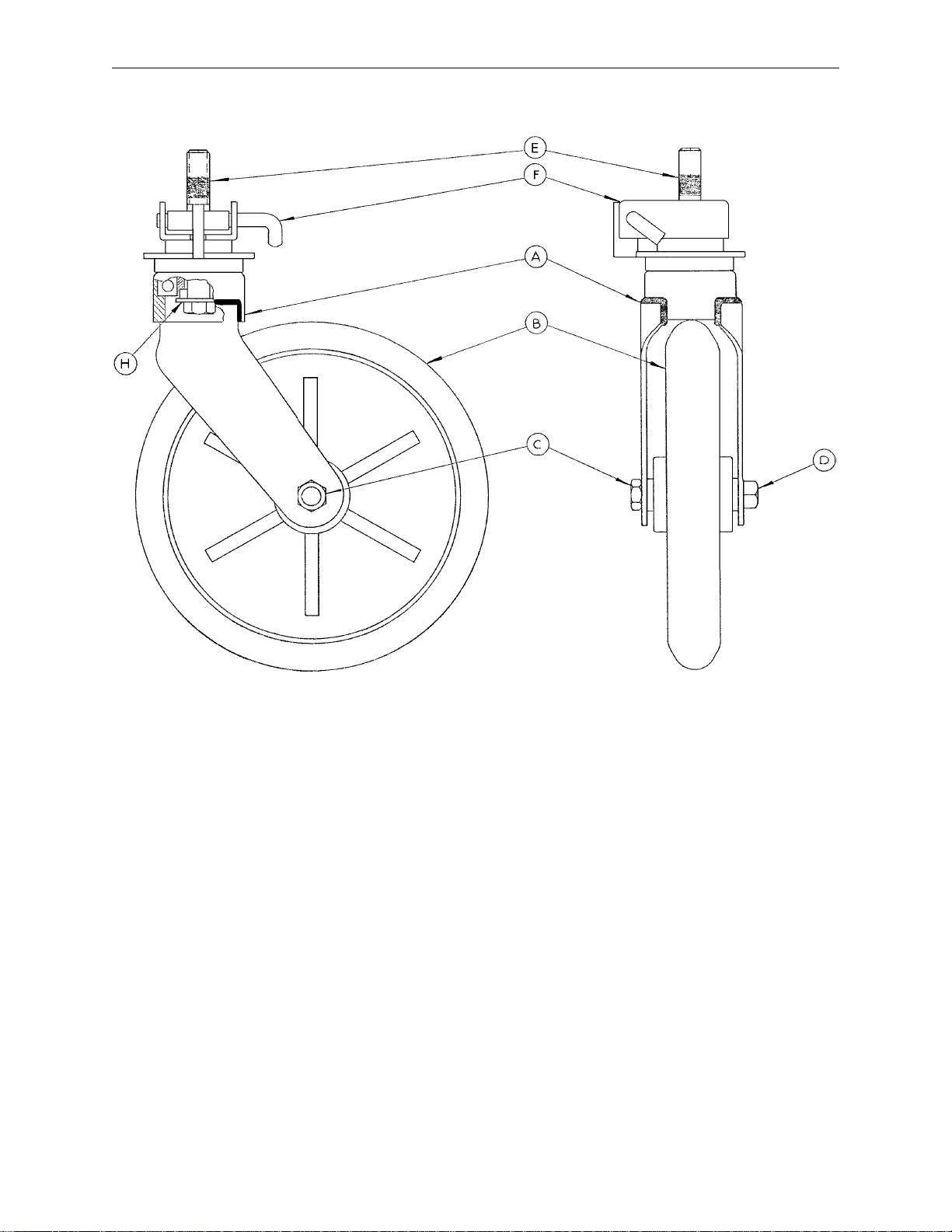

715–2–21 Caster Assembly with Steerlock

Item Part No. Part Name Qty.

A 700–10–50 Steer Lock Caster Weldment 1

B 715–2–25 Caster Wheel 1

C16–60 Hex Nut 1

D3–99 Hex Bolt 1

E 715–3–96 Hex Bolt 1

F 1000–59–10 Latch Assembly 1

H11–310 Flat Washer 1

23

Page 29

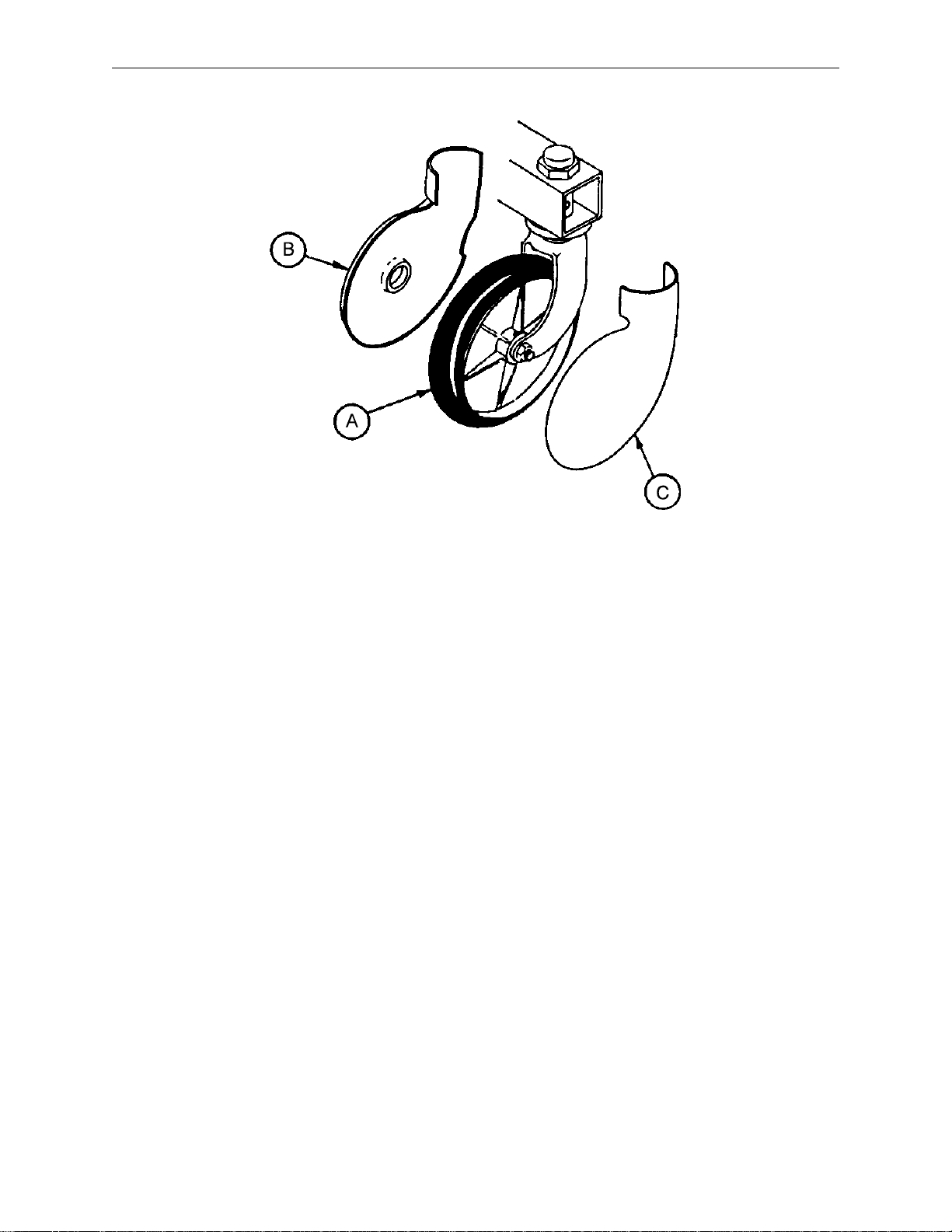

Caster and Caster Cover Replacement Kits

Item Part No. Part Name Qty.

A 715–2–20 Caster Assembly 1

B 715–1–266 Caster Cover, Left 1

C 715–1–265 Caster Cover, Right 1

P/N 715–259–400 – Kit to replace 4 standard caster assemblies with necessary hardware – no caster covers.

P/N 715–269–400 – Kit to replace 3 standard caster assemblies and 1 steerlock caster with necessary hard-

ware – no caster covers.

P/N 715–259–100 – Kit to replace 1 standard caster assembly with necessary hardware – no caster covers.

P/N 1010–56–200 – Kit to replace both caster covers on all four wheels.

24

Page 30

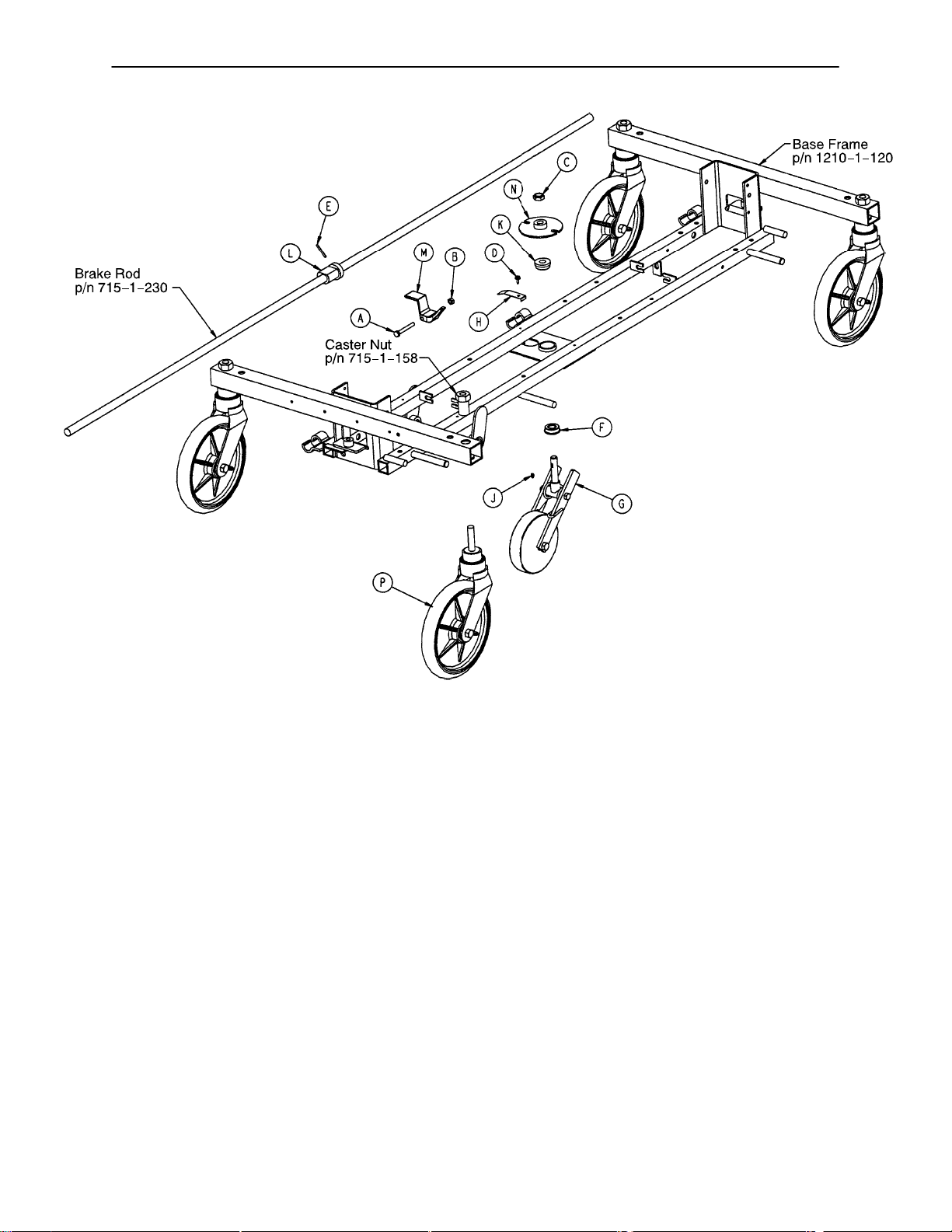

Optional Fifth Wheel Base Assembly

Item Part No. Part Name Qty.

A3–20 Hex Hd. Cap Screw 1

B16–16 Fiberlock Nut 1

C16–49 Nylock Hex Nut 1

D23–25 Hex Washer Hd. Screw 1

E26–8 Roll Pin 1

F81–219 Bearing 1

G (page 25) Fifth Wheel Assembly 1

H 715–1–136 Fifth Wheel Spring 1

J 715–1–149 Key 1

K 715–1–157 Fifth Wheel Bearing 1

L 715–1–161 Fifth Wheel Cam 1

M 715–1–217 Fifth Wheel Latch 1

N 715–1–337 Fifth Wheel Plate 1

P (page 24) Caster Assembly 4

24.1

Page 31

Notes

24.2

Page 32

715–1–25 Fifth Wheel Assembly

Item Part No. Part Name Qty.

A 715–1–339 Fifth Wheel Pivot Assembly 1

B 715–1–17 Fifth Wheel Bushing 1

C16–11 Flexlock Nut 1

D 715–1–15 Spring 1

E 715–1–13 Fifth Wheel Bracket 2

F16–12 Flexlock Nut 1

G 390–1–54 Wheel 1

H3–31 Hex Head Cap Screw 1

J3–82 Hex Head Cap Screw 1

25

Page 33

715–270–400 Jack Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A45–904 O–Ring 1 M 388–1–38 Plug 1

B 715–1–340 Cap Assembly 1 N 715–1–322 Reservoir 1

C 390–1–243 Gasket 1 P 390–1–244 Gasket 1

D 715–1–323 Actuator Cylinder 1 R 390–1–238 Gasket, Actuator 1

E 715–1–325 Actuator 1 S (Page 27) Jack Base Assembly 1

F45–14 O–Ring 1 T 390–2–139 Retaining Collar 2

G 926–20–161 Parker Packing 1 W 715–1–333 Rel. Valve Stop Sleeve 1

H 715–1–331 Piston End 1 Y 715–270–11 Label 1

J 926–20–162 Wear Ring 1 Z 715–1–320 Jack Screen 1

K4–14 Soc. Hd. Cap Screw 1 AA 921–1–252 Serial No. Label 1

L45–110 O–Ring 1 AB 45–978 O–Ring 1

26

Page 34

715–1–300 Jack Base Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A14–50 Bearing Retainer 1 P 715–1–327 Cylinder Wear Ring 1

B38–311 Compression Spring 1 R 715–1–328 Piston Wear Ring 1

C45–6O–Ring 3 S 715–1–329 Pump Seal 1

D45–110 O–Ring 1 T 715–1–341 Poppet 1

E45–966 O–Ring 1 W 715–270–1 Pin 1

F45–967 O–Ring 1 X 715–270–2 Pin Housing 1

H48–147 Base Plug 2 Y 926–20–153 Check Valve 1

J 390–2–134 Conical Comp. Spring 1 Z 926–20–154 Seal 1

K 715–1–307 Needle Valve 1 AA 1210–70–12 Jack Base 1

L 715–1–309 Valve Plug 1 AB 1210–70–13 Base Plug 1

M 715–1–318 Pump Piston 1 AF 715–270–100 Valve Assembly 1

N 715–1–316 Pump Cylinder 1 AF 715–100–325 Pump Piston Ass’y1

27

Page 35

Side Control Base Assembly (with Jacks)

Assembly part number 715–1–260

28

Page 36

Side Control Base Assembly (with Jacks)

Item Part No. Part Name Qty.

A29–7 Dual Lock 2

B (Page 26) Jack Assembly 2

C11–262 Flat Washer 8

D3–62 Hex Hd. Cap Screw 8

E11–3 Flat Washer 12

F16–36 Nylock Hex Nut 16

H 715–1–192 Jack Support 2

J3–85 Hex Hd. Cap Screw 8

L 715–1–193 Jack Support Clamp 2

M13–38 Ext. Tooth Lock Washer 4

P29–9 Dual Lock 2

R 763–1–16 Spring Holder 1

S38–246 Jack Spring 1

T 715–1–133 Collar 1

W 715–1–27 Pump Connect. Rod Ass’y1

Y4–146 Hex Socket Hd. Cap Screw 2

Z16–48 Nylock Hex Nut 2

AA 715–1–333 Release Rod Stop Sleeve 2

AB 715–1–346 Release Paddle 2

AC 21–50 Hex Socket Set Screw 2

AD 715–1–40 Release Rod Ass’y, Ft. End 1

AE 42–13 Shaft Collar w/ Set Screw 2

AF 52–245 Nyliner 2

AH 14–4 Nylon Washer 4

AJ 38–234 Compression Spring 2

AK (page 38) Hood 1

AL 27–4 Cotter Pin 3

AM 715–1–187 Rel. Pedal Sleeve Ass’y2

AR 4–85 Soc. Hd. Cap Screw 4

AS 16–3 Fiberlock Nut 4

AT 715–1–214 Connector Link, Mach’d1

AW (Page 30) Pedal Base Assembly 1

AY 715–1–92 Pump Pedal Shaft 1

AZ 715–1–134 Bellows 2

BA 715–1–46 Rel. Rod Ass’y, Hd. End 1

BC 14–9 Nylon Washer 8

BD 715–1–140 Raufilam Braid Tubing 1

BF (Page 31) Pedal Base Ass’y, Hd. Left 2

BH (Page 31) Pedal Base Ass’y, Hd. Right 2

BJ 3–3 Hex Hd. Cap Screw 2

BK 15–11 Fiberlock Nut 2

BL 11–53 Washer 8

BM 21–22 Set Screw 2

BN 27–3 Cotter Pin 2

BP 921–1–252 Serial Number Label 1

BR 11–262 Washer 4

29

Page 37

Pedal Base Assembly, Pump

Assembly part number 715–1–108

Item Part No. Part Name Qty.

A 715–1–83 Pedal Ass’y Weldm’t, Pump 1

B 715–1–126 Side Control Pedal Pad 2

C81–44 Bearing, Bronze 2

NOTE

Apply plastic adhesive to the mating surfaces of item B prior to assembly.

30

Page 38

715–1–110 Pedal Base Assembly, Head End, Right

Item Part No. Part Name Qty.

A 715–1–97 Release Pedal Weldment 1

B 721–40–25 Pedal 1

715–1–109 Pedal Base Assembly, Head End, Left

Item Part No. Part Name Qty.

A 715–1–98 Release Ped. Wldmt., Hd. Lt. 1

B 721–40–25 Pedal 1

NOTE

Apply plastic adhesive to the mating surfaces of item B prior to assembly.

31

Page 39

32

Assembly part number

716–1–270

End Control Base Assembly (with Jacks)

FOOT END

HEAD END

Page 40

End Control Base Assembly (with Jacks)

Item Part No. Part Name Qty.

A3–4 Hex Head Cap Screw 4

B3–62 Hex Hd. Cap Screw 8

C3–85 Hex Hd. Cap Screw 8

D11–3 Washer 4

E11–13 Flat Washer 4

F11–262 Flat Washer 8

H13–38 Ext. Tooth Lock Washer 4

J14–2 Washer 4

K14–3 Washer 2

L14–7 Nylon Flat Washer 6

M14–9 Washer 2

N15–11 Hex Jam Nut 4

P16–16 Nylock Nut 4

R16–36 Nylock Hex Nut 16

S26–195 Clevis Pin 2

T27–4 Cotter Pin 10

W27–3 Cotter Pin 10

Y28–97 Snap Ring 2

Z29–7 Dual Lock 3

AA 29–9 Dual Lock 3

AB 38–235 Spring 4

AC 38–251 Spring 2

AD 38–326 Extension Spring 2

AE 52–245 Nyliner 4

AF 715–1–133 Spring Collar 1

AH 715–1–140 PVC Tubing 2

AJ 715–1–192 Jack Support 2

AK 715–1–193 Jack Clamp 2

AL 715–1–333 Release Rod Stop Sleeve 2

AM (Page 26) Jack Assembly 2

AN 716–1–15 Release Pivot Bar 2

AP 716–1–52 Pivot Assembly, Foot 1

AR 716–1–61 Pedal Shaft 2

AS 716–1–71 Release Rod Ass’y2

AT 716–1–75 Release Rod 2

AW 716–1–102 Pump Link Wldmt. Ass’y, Ft. 1

AY 716–1–109 Pump Link Bar Wldmt., Hd. 1

BA 716–1–119 Pivot Assembly, Head End 1

BB 716–1–281 Pump Idler Link 2

BC 716–1–286 Cam, Release Pedal 4

BD (Page 34) Pump Pedal Ass’y, Foot 1

BE (Page 34) Pump Pedal Ass’y, Head 1

BF 716–1–293 Rel Pedal, Hd. Lt. & Ft. Rt. 2

BH 716–1–294 Rel. Pedal, Hd. Rt. & Ft. Lt. 2

BJ 763–1–15 Spring 1

BK 763–1–16 Spring Guide 1

BL 1210–1–27 Pump Conn. Rod Ass’y1

BM 1210–1–111 End Release Pedal Bracket 2

BN 1210–1–112 Release Rod Wldmt., Head, Left 1

33

Page 41

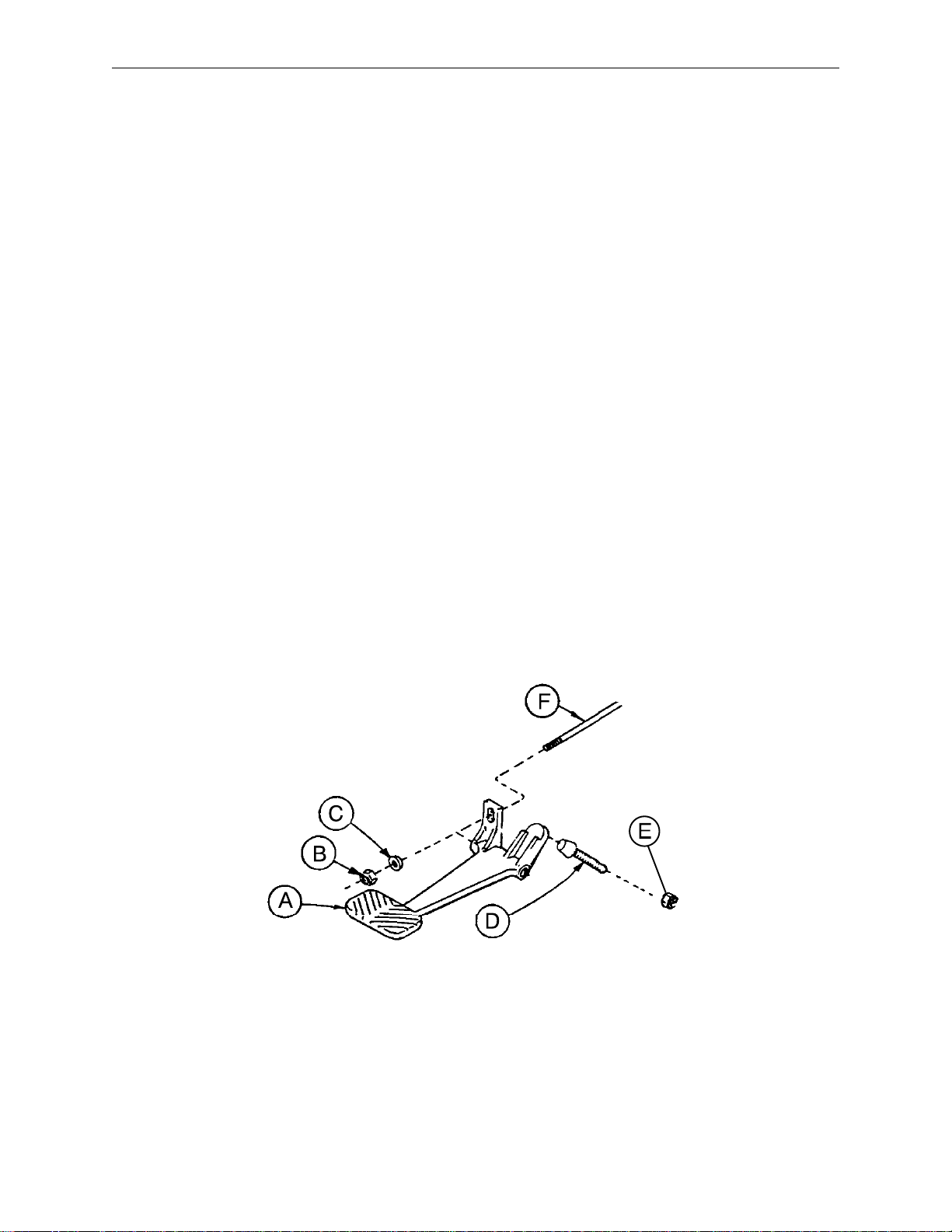

End Control Pump Pedal Assembly, Head

Assembly part number 716–1–292

Item Part No. Part Name Qty.

A 716–1–285 Pump Pivot, Head End 1

B26–12 Roll Pin 1

C 716–1–290 Pump Ped. Wldmt., Head 1

D 721–40–25 Pedal 1

End Control Pump Pedal Assembly, Foot

Assembly part number 716–1–288

Item Part No. Part Name Qty.

A 716–1–283 Pump Pivot, Foot End 1

B26–12 Roll Pin 1

C 716–1–289 Pump Ped. Wldmt., Foot 1

D 721–40–25 Pedal 1

NOTE

Apply plastic adhesive to the mating surfaces of item D prior to assembly.

34

Page 42

End Control Stretcher Base Labeling Assembly

1001 1501

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 1001–100–1 Hood 1 A 1001–100–1 Hood 1

B 715–1–134 Bellows 2 B 715–1–134 Bellows 2

C29–7 Dual Lock (not shown) 1 C 29–7 Dual Lock (not shown) 1

D29–9 Dual Lock (not shown) 1 D 29–9 Dual Lock (not shown) 1

E 946–1–60 Stryker Logo Label 2 E 946–1–60 Stryker Logo Label 2

F 1001–44–20 Specification Label 1 F 1501–44–20 Specification Label 1

35

Page 43

End Control Graphics

Reference below for

dept. label part numbers.

Color Item A Control Label,

Head

RED 1010–800–11 1010–800–12 1010–800–13 1010–700–15

PURPLE 1010–800–21 1010–800–22 1010–800–23 1010–700–25

GREEN 1010–800–31 1010–800–32 1010–800–33 1010–700–35

GRAY 1010–800–41 1010–800–42 1010–800–43 1010–700–45

TEAL 1010–800–51 1010–800–52 1010–800–53 1010–700–55

PINK 1010–800–61 1010–800–62 1010–800–63 1010–700–65

BLUE 1010–800–71 1010–800–72 1010–800–73 1010–700–75

Item B Control Label,

Foot

Item C Stripe Label Litter Bumper Strip

Department Label Part Number Department Label Part Number

Emergency 1010–900–1 Endoscopy 1010–900–7

P.A.C.U. 1010–900–2 Radiology 1010–900–8

Transport 1010–900–3 Nuclear Medicine 1010–900–9

Surgery 1010–900–4 Ambulatory Surgery 1010–900–10

Extended Stay 1010–900–5 G.I. Lab 1010–900–11

Maternity 1010–900–6 Cath. Lab 1010–900–12

36

Page 44

Side Control Graphics

B

A

A

Color Item A Control Label, Right Item B Control Label, Left Litter Bumper Strip

RED 1001–700–111 1001–700–112 1010–700–15

PURPLE 1001–700–121 1001–700–122 1010–700–25

GREEN 1001–700–131 1001–700–132 1010–700–35

GRAY 1001–700–141 1001–700–142 1010–700–45

TEAL 1001–700–151 1001–700–152 1010–700–55

PINK 1001–700–161 1001–700–162 1010–700–65

BLUE 1001–700–171 1001–700–172 1010–700–75

Reference previous page for

dept. label part numbers.

37

Page 45

Side Control Stretcher Base Labeling Assembly

1001 1501

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 1001–100–1 Hood 1 A 1001–100–1 Hood 1

B 715–1–134 Bellows 2 B 715–1–134 Bellows 2

C29–7 Dual Lock (not shown) 1 C 29–7 Dual Lock (not shown) 3

D29–9 Dual Lock (not shown) 1 D 29–9 Dual Lock (not shown) 3

E 741–1–145 Brake/Steer Label, Hd. 1 E 741–1–145 Brake/Steer Label, Hd. 1

F 741–1–146 Brake/Steer Label, Ft. 1 F 741–1–146 Brake/Steer Label, Ft. 1

H 946–1–60 Stryker Logo Label 2 H 946–1–60 Stryker Logo Label 2

J 1001–44–20 Specification Label 1 J 1501–44–20 Specification Label 1

38

Page 46

Litter Assembly, Fold to Head Siderails

Assembly part number

1001–30–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

B3–76 Hex Hd. Cap Screw 4 W 938–1–401 Collar 2

C3–78 Hex Hd. Cap Screw 4 Y 1001–1–36 Hole Plug 4

D4–181 But. Hd. Cap Screw 4 Z 1001–1–37 Jack Supt. Tube, Hd. 2

E14–21 Washer 8 AA 1001–1–41 Hole Plug 2

F11–360 Plastic Spacer 2 AB 1001–26–34 Bumper Channel 2

H16–28 Fiberlock Nut 8 AC 1001–30–29 End Plug 4

J16–35 Nylock Nut 4 AD 1001–201–30 Support Stamping 2

K25–38 Pop Rivet 20 AE 1001–40–12 Foot Board Receptacle 2

L28–23 Retaining Ring 2 AF 1001–201–29 Plastic Insert 2

M37–10 Hole Plug 4 AH 1010–32–85 Support Tube Ass’y1

N46–1 Set Screw 2 AK 1210–800–8 Patent Label 1

P 721–31–65 Hole Plug 2 AL 1001–201–31 Support Tube Ass’y1

T 926–400–142 Bumper Wheel 4

39

Page 47

Litter Assembly, Fold to Head Siderails

Assembly part number

1501–30–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

B3–76 Hex Hd. Cap Screw 4 T 926–400–142 Bumper Wheel 4

C3–78 Hex Hd. Cap Screw 4 W 938–1–401 Collar 2

D4–181 But. Hd. Cap Screw 4 Y 1001–1–36 Hole Plug 4

E14–21 Washer 8 Z 1001–1–37 Jack Supt. Tube, Hd. 2

F11–360 Plastic Spacer 2 AA 1001–1–41 Hole Plug 2

H16–28 Fiberlock Nut 8 AB 1001–26–34 Bumper Channel 2

J16–35 Nylock Nut 4 AC 1001–30–29 End Plug 4

K25–38 Pop Rivet 20 AD 1001–201–30 Support Stamping 2

L28–23 Retaining Ring 2 AE 1001–40–12 Foot Board Receptacle 2

M37–10 Hole Plug 4 AF 1001–201–29 Plastic Insert 2

N46–1 Set Screw 2 AK 1210–800–8 Patent Label 1

P 721–31–65 Hole Plug 2 AL 1501–201–31 Support Tube Ass’y1

AM 1510–32–20 Support Tube Ass’y1

40

Page 48

Assembly

part number

1211–20–10

Siderail to Litter Assembly, Fold to Head

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–78 Hex Hd. Cap Screw 4 R 16–36 Nylock Nut 12

B4–161 But. Hd. Cap Screw 4 S 37–200 Vinyl Sleeve 2

C4–169 But. Hd. Cap Screw 4 T 38–271 Extension Spring 2

D4–199 But. Hd. Cap Screw 12 W (page 45) Siderail Ass’y, Right 1

E7–20 Truss Hd. Mach. Screw 2 Y (page 46) Siderail Ass’y, Left 1

F8–7 Shoulder Bolt 2 Z 1001–26–46 Lock Mtg. Plate, Rt. 1

H11–179 Nylon Washer 4 AA 1001–26–47 Lock Mtg. Plate, Lt. 1

J14–2 Nylon Washer 2 AB 1001–26–51 Timing Link 2

K14–19 Nylon Washer 2 AC 1001–26–53 Latch Hook Ass’y, Lt. 1

M16–2 Fiberlock Nut 2 AD 1001–26–54 Latch Hook Ass’y, Rt. 1

N16–3 Fiberlock Nut 4 AE 1001–26–55 Latch Guard 2

P16–28 Fiberlock Nut 10

41

Page 49

Litter Assembly, Fold to Foot Siderails

Corner Wheel Assembly Detail

Assembly part number

1001–130–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–40 Hex Hd. Cap Screw 2 AA 919–30–28 Rack Guide 2

B3–47 Hex Hd. Cap Screw 4 AB 926–400–142 Bumper Wheel 4

C3–76 Hex Hd. Cap Screw 4 AC 938–1–401 Collar 2

D4–201 Soc. Hd. Cap Screw 4 AD 1001–1–36 End Plug 4

E15–27 Jam Nut 4 AE 1001–1–41 Tube Plug 2

F16–11 Nylock Nut 2 AF 1001–30–28 Thread Sleeve 4

J16–12 Nylock Nut 4 AH 1001–30–29 End Plug 4

L16–28 Nylock Nut 8 AJ 1001–32–29 Carrier Tube 2

M22–10 Drive Screw 2 AK 1001–40–12 Foot Board Receptacle 2

N23–104 Self–Tapping Screw 2 AL 1010–32–64 Carrier Tube 2

P25–38 Pop Rivet 24 AM 1010–201–50 Support Roller 4

R28–23 Retaining Ring 2 AP 1210–800–8 Patent Label 1

S37–30 Hole Plug 2 AR 1211–30–7 Jack Support Wldmt. 1

T42–7 Collar 2 AS 1211–30–18 Jack Support Bracket 2

W46–1 Square Hd. Screw 2 AT 1001–30–44 Bumper Channel 2

Y 721–31–65 Hole Plug 2 AW 1211–31–31 Pneumatic Fowler Rest 2

Z 721–31–107 Roller Sleeve 4 AY 1510–32–20 Support Tube Ass’y1

42

Page 50

Litter Assembly, Fold to Foot Siderails

Corner Wheel Assembly Detail

Assembly part number

1501–130–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–40 Hex Hd. Cap Screw 2 AA 919–30–28 Rack Guide 2

B3–47 Hex Hd. Cap Screw 4 AB 926–400–142 Bumper Wheel 4

C3–76 Hex Hd. Cap Screw 4 AC 938–1–401 Collar 2

D4–201 Soc. Hd. Cap Screw 4 AD 1001–1–36 End Plug 4

E15–27 Jam Nut 4 AE 1001–1–41 Tube Plug 2

F16–11 Nylock Nut 2 AF 1001–30–28 Thread Sleeve 4

J16–12 Nylock Nut 4 AH 1001–30–29 End Plug 4

L16–28 Nylock Nut 8 AJ 1001–32–29 Carrier Tube 2

M22–10 Drive Screw 2 AK 1001–40–12 Foot Board Receptacle 2

N23–104 Self–Tapping Screw 2 AL 1010–32–64 Carrier Tube 2

P25–38 Pop Rivet 24 AM 1010–201–50 Support Roller 4

R28–23 Retaining Ring 2 AP 1210–800–8 Patent Label 1

S37–30 Hole Plug 2 AS 1211–30–18 Jack Support Bracket 2

T42–7 Collar 2 AT 1001–30–44 Bumper Channel 2

W46–1 Square Hd. Screw 2 AW 1211–31–31 Pneumatic Fowler Rest 2

Y 721–31–65 Hole Plug 2 AY 1501–27–23 Support Tube Ass’y1

Z 721–31–107 Roller Sleeve 4 AZ 1711–30–17 Jack Support Wldmt. 1

43

Page 51

Siderail to Litter Assembly, Fold to Foot

Assembly part number 1211–21–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–78 Hex Hd. Cap Screw 4 S 25–79 Pop Rivet 4

B4–161 But. Hd. Cap Screw 4 T 37–200 Vinyl Sleeve 2

C4–169 But. Hd. Cap Screw 4 W 38–271 Extension Spring 2

D4–199 But. Hd. Cap Screw 12 Y (page 45) Siderail Ass’y, Right 1

E7–20 Truss Hd. Mach. Screw 2 Z (page 46) Siderail Ass’y, Left 1

F8–7 Shoulder Bolt 2 AA 1001–26–46 Lock Mtg. Plate, Rt. 1

H11–179 Nylon Washer 8 AB 1001–26–47 Lock Mtg. Plate, Lt. 1

J14–2 Nylon Washer 2 AC 1001–26–51 Timing Link 2

K14–19 Nylon Washer 2 AD 1001–26–53 Latch Hook Ass’y, Lt. 1

M16–2 Fiberlock Nut 2 AE 1001–26–54 Latch Hook Ass’y, Rt. 1

N16–3 Fiberlock Nut 4 AF 1001–26–55 Latch Guard 2

P16–28 Fiberlock Nut 10 AJ 1001–34–48 Latch Cover 2

R16–36 Nylock Nut 12

44

Page 52

Glideaway Siderail Assembly, Right

Assembly part number

1001–26–10

Item Part No. Part Name Qty.

A 1001–26–40 Top Rail, Right 1

B 1001–226–41 Upright, Plated, Right 3

C (page 46.1) Ring Spacer Assembly 2

D 1010–26–82 Sleeve Bearing 6

E 721–26–69 Upright Sleeve 3

F 123–20–52 Spindle Plug 6

H25–114 Semi–Tubular Rivet 6

J 1001–226–31 Lock Upright Ass’y, Rt. 1

L 1001–226–37 Upright Assembly, Rt. 2

M 1001–26–63 Top Rail Cap 1

N 1001–26–66 End Plug 2

45

Page 53

Glideaway Siderail Assembly, Left

Assembly part number

1001–26–11

Item Part No. Part Name Qty.

A 1001–26–30 Top Rail, Left 1

B 1001–226–42 Upright, Plated, Left 3

C (page 46.1) Ring Spacer Assembly 2

D 1010–26–82 Sleeve Bearing 6

E 721–26–69 Upright Sleeve 3

F 123–20–52 Spindle Plug 6

H25–114 Semi–Tubular Rivet 6

J 1001–226–33 Lock Upright Ass’y, Left 1

L 1001–226–38 Upright Assembly, Left 2

M 1001–26–63 Top Rail Cap 1

N 1001–26–66 End Cap 2

46

Page 54

Siderail Ring Spacer Assembly

Assembly part number 1001–26–39

Item Part No. Part Name Qty.

A4–169 Socket Button Hd. Cap Screw 2

B16–3 Hex Nut 2

C 1001–26–32 Ring Spacer 1

46.1

Page 55

Notes

46.2

Page 56

Head End Siderail Latch Option Assembly

Assembly part number

1001–27–10

M

HEAD END

Item Part No. Part Name Qty.

B 1001–27–17 Handle Bracket, Left 1

C 1001–27–18 Handle Bracket, Right 1

D 1001–27–15 Handle Weldment 2

E 1001–27–24 Link, Left 1

F25–79 Pop Rivet 18

H 1001–27–19 Link Channel 6

J 1001–27–23 Link, Right 1

K11–16 Flat Washer 2

L27–8 Cotter Pin 2

M16–3 Nylock Nut 4

N2–89 Rd. Hd. Machine Screw 2

M

47

Page 57

Stationary Foot End Assembly (Fiberresin)

Assembly part number

1010–332–20

Item Part No. Part Name Qty.

A 1010–332–21 Ftsec. Skin, Fiberresin 1

B 7900–1–102 Velcro Pile 24 1/2”

C25–50 Pop Rivet 24

48

Page 58

Stationary Foot End Assembly (Steel)

Assembly part number

1010–232–20

Item Part No. Part Name Qty.

A 1010–232–21 Ftsec. Skin, Fiberresin 1

B 7900–1–102 Velcro Pile 24 1/2”

C25–122 Pop Rivet 24

49

Page 59

Stationary Foot End Assembly (Steel)

Assembly part number

1001–132–20

Item Part No. Part Name Qty.

A25–122 Pop Rivet 22

B 1001–132–21 Footsection Skin (Steel) 1

C 7900–1–102 Velcro Pile 24 1/2”

50

Page 60

Stationary Foot End Assembly (Fiberresin)

Assembly part number

1510–332–20

Item Part No. Part Name Qty.

A 1510–332–21 Ftsec. Skin, Fiberresin 1

B 7900–1–102 Velcro Pile 24 1/2”

C25–50 Pop Rivet 24

51

Page 61

Stationary Foot End Assembly (Steel)

Assembly part number

1501–132–20

Item Part No. Part Name Qty.

A25–122 Pop Rivet 22

B 1501–132–21 Footsection Skin (Steel) 1

C 7900–1–102 Velcro Pile 24 1/2”

52

Page 62

Stationary Foot End Assembly (Steel)

Assembly part number

1510–232–20

Item Part No. Part Name Qty.

A 1510–232–21 Ftsec. Skin, Fiberresin 1

B 7900–1–102 Velcro Pile 24 1/2”

C25–122 Pop Rivet 24

53

Page 63

Crank Knee Gatch Assembly (Steel)

Assembly part number

1001–134–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 51.2) Knee Gatch Assembly 1

B 1001–134–27 Midsection Skin 1

C 1010–234–28 Thigh Skin 1

D 1010–234–126 Calf Skin 1

E25–122 Pop Rivet 31

54

Page 64

Crank Knee Gatch Assembly (Steel)

Assembly part number

1010–434–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 58) Knee Gatch Assembly 1

B 1010–234–27 Midsection Skin 1

C 1010–234–28 Thigh Skin 1

D 1010–234–126 Calf Skin 1

E25–122 Pop Rivet 37

55

Page 65

Crank Knee Gatch Assembly (Fiberresin)

Assembly part number

1211–34–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 59) Knee Gatch Assembly 1

B 1010–334–27 Midsection Skin 1

C 1010–334–28 Thigh Skin 1

D 1010–334–126 Calf Skin 1

E25–50 Pop Rivet 31

56

Page 66

Crank Knee Gatch Assembly (Fiberresin)

Assembly part number

1010–534–10

Frame Assembly (Ref.)

Item Part No. Part Name Qty.

A (page 58) Knee Gatch Assembly 1

B 1010–334–27 Midsection Skin 1

C 1010–334–28 Thigh Skin 1

D 1010–334–126 Calf Skin 1

E25–50 Pop Rivet 31

57

Page 67

Knee Gatch Assembly

Assembly part number

1010–434–20

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–47 Hex Hd. Cap Screw 8 P 721–31–65 Litter Hole Plug 2

B3–76 Hex Hd. Cap Screw 4 R 946–1–65 Label, Gatch Symbol 1

C4–105 Soc. Hd. Cap Screw 1 S (page 66) Gatch Crankscrew Ass’y1

D7–20 Truss Hd. Cap Screw 4 T 1001–34–24 Thigh Support 2

E14–2 Flat Washer 12 W 1001–34–25 End Plug 4

F14–21 Nylon Washer 4 Y 1001–34–48 Latch Cover 2

H16–12 Flexlock Nut 1 Z 1001–34–112 Calf Frame 1

J16–28 Nylock Hex Nut 16 AA 1001–34–120 Garch Riser 1

K25–79 Pop Rivet 8 AB 1001–34–131 Slider Support 2

L27–4 Cotter Pin 4 AC 1010–234–15 Mounting Bracket 2

M52–291 Round Spacer 4 AD 1211–34–11 Thigh Frame 1

N58–56 Edge Cover 1.3’ AE 1211–34–23 Midsection Supt. 1

58

Page 68

Knee Gatch Assembly

Assembly part number

1211–34–20

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–47 Hex Hd. Cap Screw 8 P 1001–34–29 Slider Supt. Wldmt., Lt. 1

B4–105 Soc. Hd. Cap Screw 1 R 1001–34–30 Slider Supt. Wldmt., Rt. 1

C7–20 Truss Hd. Cap Screw 4 S 1001–34–48 Latch Cover 2

D14–2 Flat Washer 12 T 1001–34–49 Slider Support Sleeve 2

E14–21 Nylon Washer 4 W 1010–234–15 Mounting Bracket 2

F16–12 Flexlock Nut 1 Y 1211–34–24 Thigh Support, Left 1

H16–28 Nylock Hex Nut 16 Z 1211–34–25 Thigh Support, Right 1

J25–79 Pop Rivet 8 AA 1501–34–12 Calf Frame Weldment 1

K27–7 Cotter Pin 4 AB 1501–34–20 Gatch Riser 1

L 946–1–65 Label, Gatch Symbol 1 AC 1510–34–90 Slider Pad 2

M (page 66) Gatch Crankscrew Ass’y 1 AD 1211–34–11 Thigh Frame 1

N 1001–34–25 End Plug 4 AE 1211–34–23 Midsection Supt. 1

59

Page 69

Crank Knee Gatch Assembly (Steel)

Assembly part number

1501–134–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 65) Knee Gatch Assembly 1

B 1501–134–27 Midsection Skin 1

C 1510–234–28 Thigh Skin 1

D 1510–234–126 Calf Skin 1

E25–122 Pop Rivet 31

60

Page 70

Crank Knee Gatch Assembly (Steel)

Assembly part number

1510–434–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 64) Knee Gatch Assembly 1

B 1510–234–27 Midsection Skin 1

C 1510–234–28 Thigh Skin 1

D 1510–234–126 Calf Skin 1

E25–122 Pop Rivet 31

61

Page 71

Crank Knee Gatch Assembly (Fiberresin)

Assembly part number

1711–34–10

Frame

Assembly

(Ref.)

Item Part No. Part Name Qty.

A (page 65) Knee Gatch Assembly 1

B 1510–334–27 Midsection Skin (Fiberresin) 1

C 1510–334–28 Thigh Skin (Fiberresin) 1

D 1510–334–126 Calf Skin (Fiberresin) 1

E25–50 Pop Rivet 31

62

Page 72

Crank Knee Gatch Assembly (Fiberresin)

Assembly part number

1510–534–10

Frame Assembly (Ref.)

Item Part No. Part Name Qty.

A (page 64) Knee Gatch Assembly 1

B 1510–334–27 Midsection Skin 1

C 1510–334–28 Thigh Skin 1

D 1510–334–126 Calf Skin 1

E25–50 Pop Rivet 31

63

Page 73

Knee Gatch Assembly

Assembly part number

1510–434–20

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–47 Hex Hd. Cap Screw 8 P 721–31–65 Litter Hole Plug 2

B3–76 Hex Hd. Cap Screw 4 R 946–1–65 Label, Gatch Symbol 1

C4–105 Soc. Hd. Cap Screw 1 S (page 66) Gatch Crankscrew Ass’y1

D7–20 Truss Hd. Cap Screw 4 T 1001–34–24 Thigh Support 2

E14–2 Flat Washer 12 W 1001–34–25 End Plug 4

F14–21 Nylon Washer 4 Y 1001–34–48 Latch Cover 2

H16–12 Flexlock Nut 1 Z 1001–34–131 Slider Support 2

J16–28 Nylock Hex Nut 16 AA 1010–234–15 Mounting Bracket 2

K25–79 Pop Rivet 8 AB 1501–34–112 Calf Frame 1

L27–4 Cotter Pin 4 AC 1501–34–120 Gatch Riser 1

M52–291 Round Spacer 4 AD 1711–34–11 Thigh Frame 1

N58–56 Edge Cover 1.3’ AE 1711–34–23 Midsection Supt. 1

64

Page 74

Knee Gatch Assembly

Assembly part number

1711–34–20

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A3–47 Hex Hd. Cap Screw 8 P 1001–34–29 Slider Supt. Wldmt., Lt. 1

B4–105 Soc. Hd. Cap Screw 1 R 1001–34–30 Slider Supt. Wldmt., Rt. 1

C7–20 Truss Hd. Cap Screw 4 S 1001–34–48 Latch Cover 2

D14–2 Flat Washer 12 T 1001–34–49 Slider Support Sleeve 2

E14–21 Nylon Washer 4 W 1010–234–15 Mounting Bracket 2

F16–12 Flexlock Nut 1 Y 1211–34–24 Thigh Support, Left 1

H16–28 Nylock Hex Nut 16 Z 1211–34–25 Thigh Support, Right 1

J25–79 Pop Rivet 8 AA 1501–34–12 Calf Frame Weldment 1

K27–7 Cotter Pin 4 AB 1501–34–20 Gatch Riser 1

L 946–1–65 Label, Gatch Symbol 1 AC 1510–34–90 Slider Pad 2

M (page 66) Gatch Crankscrew Ass’y 1 AD 1711–34–11 Thigh Frame 1

N 1001–34–25 End Plug 4 AE 1711–34–23 Midsection Supt. 1

65

Page 75

1001–34–19 Knee Gatch Crankscrew Assembly

Item Part No. Part Name Qty.

A 946–33–18 Crank Disc 1

B 1550–1–16 Crank Assembly 1

C26–45 Roll Pin 1

D26–14 Roll Pin 2

E81–176 Thrust Washer 1

F81–175 Thrust Bearing 1

H81–174 Thrust Washer 2

J 938–1–175 Bearing Assembly 1

K 938–1–177 Knob 1

L 378–24–29 Shoulder Bolt 1

M16–5 Conelock Nut 1

N 1001–34–47 Gatch Screw 1

P 1510–34–84 Screw Cover Assembly 1

R 1510–34–55 Gatch Drive Tube Assembly 1

S26–10 Roll Pin 2

T 7900–1–102 Velcro Pile Tape 1

Y 1550–1–14 Magnet 1

Z4–7 Soc. Hd. Cap Screw 1

66

Page 76

Pneumatic Fowler to Frame Assembly

Assembly part number 1210–31–10

Item Part No. Part Name Qty.

A4–182 But. Hd. Cap Screw 2

B4–183 But. Hd. Cap Screw 2

C11–179 Nylon Washer 2

D14–21 Nylon Washer 8

E16–11 Nylock Hex Nut 2

F16–35 Nylock Hex Nut 2

H23–100 Self–Tapping Screw 2

J25–50 Pop Rivet 7

K 1211–31–31 Pneumatic Fowler Rest 2

L 1010–31–78 Gas Cylinder 2

M (page 68) Pneumatic Fowler Ass’y1

N15–59 Hex Jam Nut 2

67

Page 77

Pneumatic Fowler Assembly (Fiberresin)

Assembly part number

1210–31–120

Item Part No. Part Name Qty.

A4–161 Hex Soc. But. Hd. Cap Screw 2

B7–20 Truss Hd. Mach. Screw 4

C25–124 Pop Rivet 2

D15–37 Jam Nut 2

E15–50 Hex Nut 2

F16–28 Nylock Nut 6

H21–125 Set Screw 2

J21–126 Set Screw 2

K 1001–1–36 Hole Plug 2

L 1001–31–13 Fowler Tube 1

M 1010–231–12 Fowler Skin (Fiberresin) 1

N (page 72.1) Outer Housing Ass’y, Right 1

P (page 72.1) Outer Housing Ass’y, Left 1

R 1210–31–118 Trip Bar Assembly 1

68

Page 78

Pneumatic Fowler to Frame Assembly

Assembly part number 1211–31–10

Item Part No. Part Name Qty.

A3–199 Hex Hd. Cap Screw 2

B4–183 But. Hd. Cap Screw 2

C11–179 Washer 4

D16–11 Nylock Hex Nut 2

E16–86 Nylock Hex Nut 2

F25–50 Pop Rivet 7

H25–124 Pop Rivet 2

J52–284 Nylon Spacer 4

K 1010–31–78 Gas Cylinder 2

L (page 70) Pneumatic Fowler Ass’y1

69

Page 79

Pneumatic Fowler Assembly (Fiberresin)

Assembly part number

1211−31−20

Item Part No. Part Name Qty.

A 3−200 Hex Hd. Cap Screw 2

B 4−135 But. Hd. Mach. Screw 2

C 7−20 Truss Hd. Mach. Screw 4

D 11−132 Nylon Washer 4

E 15−37 Jam Nut 2

F 15−50 Hex Nut 2

H 16−28 Nylock Nut 6

K 21−119 Set Screw 2

L 21−126 Set Screw 2

M 28−76 Retaining Ring 4

N 946−35−25 Liner 4

P 1001−1−36 Hole Plug 2

R 1001−31−13 Fowler Tube 1

S 1010−231−12 Fowler Skin (Fiberresin) 1

T 1211−31−14 Pneumatic Pivot Bar Wldmt. 1

W 1211−31−18 Trip Bar Weldment 1

Y 1510−31−28 Yoke 2

70

Page 80

Pneumatic Fowler to Frame Assembly

Assembly part number 1710–31–10

Item Part No. Part Name Qty.

A4–182 But. Hd. Cap Screw 2

B4–183 But. Hd. Cap Screw 2

C11–179 Nylon Washer 2

D14–21 Nylon Washer 8

E16–11 Nylock Hex Nut 2

F16–35 Nylock Hex Nut 2

H23–100 Self–Tapping Screw 2

J25–50 Pop Rivet 7

K 1211–31–31 Pneumatic Fowler Rest 2

L 1010–31–78 Gas Cylinder 2

M (page 72) Pneumatic Fowler Ass’y1

N15–59 Hex Jam Nut 2

71

Page 81

Pneumatic Fowler Assembly (Fiberresin)

Assembly part number

1710–31–120

Item Part No. Part Name Qty.

A4–161 Hex Soc. But. Hd. Cap Screw 2

B7–20 Truss Hd. Mach. Screw 4

C25–124 Pop Rivet 2

D15–37 Jam Nut 2

E15–50 Hex Nut 2

F16–28 Nylock Nut 6

H21–125 Set Screw 2

J21–126 Set Screw 2

K 1001–1–36 Hole Plug 2

L (page 72.1) Outer Housing Ass’y, Right 1

M (page 72.1) Outer Housing Ass’y, Left 1

N 1501–31–13 Fowler Tube 1

P 1510–231–12 Fowler Skin (Fiberresin) 1

R 1710–31–118 Trip Bar Assembly 1

72

Page 82

Outer Housing Assembly, Right and Left

Assembly part number 1210–31–106 (Right)

Item Part No. Part Name Qty.

A25–144 Semi–Tubular Rivet 1

B 1210–31–103 Pivot Tab 1

C 1210–31–104 Outer Housing, Right 1

Assembly part number 1210–31–107 (Left)

Item Part No. Part Name Qty.

A25–144 Semi–Tubular Rivet 1

B 1210–31–103 Pivot Tab 1

C 1210–31–105 Outer Housing, Left 1

72.1

Page 83

Notes

72.2

Page 84

Pneumatic Fowler to Frame Assembly

Assembly part number 1711–31–10

Item Part No. Part Name Qty.

A3–199 Hex Hd. Cap Screw 2

B4–183 But. Hd. Cap Screw 2

C11–179 Washer 4

D16–11 Nylock Hex Nut 2

E16–86 Nylock Hex Nut 2

F25–50 Pop Rivet 7

H25–124 Pop Rivet 2

J52–284 Nylon Spacer 4

K 1010–31–78 Gas Cylinder 2

L (page 74) Pneumatic Fowler Ass’y1

73

Page 85

Pneumatic Fowler Assembly (Fiberresin)

Assembly part number

1711–31–20

Item Part No. Part Name Qty.

A3–200 Hex Hd. Cap Screw 2

B4–135 But. Hd. Cap Screw 2

C7–20 Truss Hd. Mach. Screw 4

D11–132 Nylon Washer 4

E15–37 Jam Nut 2

F15–50 Hex Nut 2

H16–28 Nylock Nut 6

K21–119 Set Screw 2

L21–126 Set Screw 2

M28–76 Retaining Ring 4

N 946–35–25 Liner 4

P 1001–1–36 Hole Plug 2

R 1501–31–13 Fowler Tube 1

S 1510–231–12 Fowler Skin (Fiberresin) 1

T 1711–31–14 Pneu. Pivot Bar Wldmt. 1

W 1711–31–18 Trip Bar Weldment 1

Y 1510–31–28 Yoke 2

74

Page 86

Crank Fowler Assembly (Fiberresin)

Assembly part number

1210–33–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A4–97 Hex But. Hd. Cap Screw 6 M 25–50 Pop Rivet 7

B4–183 But. Hd. Cap Screw 2 N 946–1–64 Fowler Operation Label 1

C7–20 Truss Hd. Mach. Screw 8 P 1001–1–36 Hole Plug 2

D8–15 Shoulder Bolt 2 R 1001–31–13 Fowler Tube 1

E11–179 Washer 2 S 1001–31–31 Pneumatic Fowler Rest 2

F14–3 Thrust Washer 8 T 1001–33–24 Fowler Lever Assembly 1

H14–21 Washer 2 W (page 77) Crankscrew Assembly 1

J16–11 Nylock Hex Nut 2 Y 1010–231–12 Fowler Skin (Fiberresin) 1

K16–28 Fiberlock Hex Nut 16 Z 1010–234–15 Mounting Bracket Ass’y2

L23–100 Ph. Hd. Self–Tap. Screw 4 AA 1550–33–31 Fowler Support Ass’y2

75

Page 87

Crank Fowler Assembly (Fiberresin)

Assembly part number

1710–33–10

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A4–97 Hex But. Hd. Cap Screw 6 M 25–50 Pop Rivet 7

B4–183 But. Hd. Cap Screw 2 N 946–1–64 Fowler Operation Label 1

C7–20 Truss Hd. Mach. Screw 8 P 1001–1–36 Hole Plug 2

D8–15 Shoulder Bolt 2 S 1001–31–31 Pneumatic Fowler Rest 2

E11–179 Washer 2 W (page 77) Crankscrew Assembly 1

F14–3 Thrust Washer 8 Z 1010–234–15 Mounting Bracket Ass’y2

H14–21 Washer 2 AA 1501–31–13 Fowler Tube 1

J16–11 Nylock Hex Nut 2 AB 1501–33–24 Fowler Lever Ass’y1