Page 1

STIHL E 140, 160, 180

STIH)

2003-01

Page 2

1. Introduction 2

2. Specifications 3

2.1 Motor 3

2.2 Gear Drive 3

2.3 Cutting Attachment 3

2.4 Tightening Torques 4

3. Wiring Diagram/

Description 5

4. Removing and

Installing Electrical

Components 6

4.1 Power Cable 6

4.2 Trigger Switch 8

4.3 Capacitor (230 V only) 8

4.4 Overload Circuit Breaker 8

(E 160, E 180 C only)

4.5 Chain Brake Switch 9

5. Motor 10

5.1 Carbon Brushes 10

5.2 Rotor 11

5.3 Rotor Bearing 13

5.4 Fanwheel 13

5.5 Stator 14

6. Chain Drive 15

6.1 Chain Sprocket 16

6.2 Ring Gear and Pinion 16

6.3 Gear Housing 16

7. Chain Tensioner 17

7.1 Front Chain Tensioner 17

7.2 Side Chain Tensioner 17

7.3 Quick Chain Tensioner 18

8. Chain Brake 18

8.1 Removal 18

8.2 Installation 20

9. Chain Lubrication 21

9.1 Oil Tank 21

9.2 Oil Strainer 21

9.3 Oil Pump 21

10. Special Servicing Tools

and Aids 23

10.1 Special Servicing Tools 23

10.2 Servicing Aids 23

©1998,AndreasStihlAG&Co.,Waiblingen

CONTENTS

E140,E160,E180 1

Page 3

This service manual contains

detailed descriptions of all servicing procedures for STIHL model

E140,E160andE180Celectric

chainsaws and can thus be used

as a basis for professional overhauls and repairs on all versions

of these machines.

As the constructional features of

these electric saws are almost

identical, the servicing procedures

generally apply to all three

models. Differences are described

in detail and special reference is

made to the model concerned in

each case.

Caution: When carrying out repairs to electric saws it is essential

to observe all relevant national safety regulations and ordinances.

We recommend that you make

use of the exploded views in the

illustrated parts lists while carrying

out repair work. Most of the illustrations show the installed positions

of the individual components and

assemblies.

Refer to the latest edition of the

parts list for the part numbers of

any spare parts you may require.

Microfilmed parts lists are always

more up to date than printed lists.

Afaultonthepowertoolmayhave

several causes. Consult the

troubleshooting charts for all

assemblies in the "Standard

Repairs, Troubleshooting" handbook and the troubleshooting

charts immediately after the specifications in this manual.

Refer to the "Technical Information" bulletins for engineering changes which have been introduced

since publication of this service

manual. Technical information

bulletins also supplement the parts

list until a revised edition is

issued.

The special servicing tools mentioned in the descriptions are

listed in the last chapter of this manual.

Use the part numbers to identify

the tools in the "STIHL Special

Tools" manual.

The manual lists all special servicing tools currently available

from STIHL.

Symbols are included in the text

and pictures for greater clarity.

The meanings are as follows:

In the descriptions:

•

=Actiontobetakenas

shown in the illustration

(above the text)

-= Actiontobetakenthat

is not shown in the

illustration

(above the text)

In the illustrations:

=Pointer

=Directionofmovement

Servicing instructions and all

technical information bulletins describing engineering changes are

intended exclusively for the use of

STIHL servicing dealers. They

must not be passed to third parties.

Servicing and repairs are made

considerably easier if the electric

saw is mounted to the assembly

stand (1) 5910 890 3100.

This enables the saw to be swivelled to the best position for the ongoing repair and leaves both

hands free.

It is secured with the sprocket cover nut (after removing sprocket

cover). On the E 180 C, remove

the quick chain tensioner and the

secure saw to stand with an M8

nut.

Always use original STIHL

replacement parts.

They can be identified by the

STIHL part number,

the logo

and the STIHL parts symbol

The symbol may appear alone on

small parts.

1. INTRODUCTION

100RA001

1

VA

2 E140,E160,E180

Page 4

2.1 Motor E 140 E 160 E 180 C

Type: Universal motor

Rating (kW): 1.4 1.6 1.8

Rated voltage (V): 120; 230 230 120; 230

Frequency (Hz): 60 50 50 60 50

Rated current (A): 11.7 6.4 7.3 15,0 8.2

Fuse (slow-blowing) (A): 15 16 16 15 16

Overload protection: Thermal overload circuit breaker

Type of enclosure: IP 20

Class of protection: II

Coasting brake: Mechanical

2.2 Gear Drive

Type: Straight-toothed ring gear with pinion, single-stage

Output speed with

bar and chain,

off load (idle): 5900 rpm

1)

6300 rpm 6900 rpm

3)

at rated load: 5000 rpm

2)

5400 rpm 5400 rpm

4)

Lubrication: STIHL multipurpose grease

2.3 Cutting Attachment

Chain sprocket: 7-tooth 3/8" Picco

spur sprocket

Chain lubrication: Fully automatic, speed-controlled reciprocating oil pump

Oil tank capacity: 0.20 l (0.4 US pt)

1)

120 V : 6100 rpm

2)

120 V : 4900 rpm

3)

120 V : 6800 rpm

4)

120 V : 5000 rpm

2. SPECIFICATIONS

3

Page 5

Plastoform screws are used in polymer components. These screws form a permanent thread when

they are installed for the first time. They can be removed and installed as often as necessary without

detrimentally affecting the strength of the screwed assembly, providing the specified tightening torque

is observed.

For this reason always use a torque wrench.

Fastener Thread For component Torque Remarks

size Nm lbf.ft

Self-tapping screw IS-B6.3x32 LH hand guard/motor housing 4.5 3.3

Slotted nut M5 L Drive pinion/rotor shaft 8.0 5.9 1)

Plastoform screw IS-P3x10 Cover plate/sprocket cover 1.0 0.75

Plastoform screw IS-P4.5x25 Commutator cover/motor housing 3.0 2.2

Plastoform screw IS-P4.5x45 Stator/motor housing (1200 W) 3.0 3.0

Plastoform screw IS-P4.5x55 Stator/motor housing (1400, 1600 W) 3.0 3.0

Plastoform screw IS-P4x19 Oil pump/gear housing 2.5 1.8

Plastoform screw IS-P4x19 Handle housing/motor housing 2.0 1.5

Plastoform screw IS-P4x19 Cable clamp/motor housing 1.5 1.1

Plastoform screw IS-P5x20 Spiked bumper/handle housing 4.0 3.0

Plastoform screw IS-P5x20 Gear housing/motor housing 3.0 2.2

Spline screw IS-M6x25 Brake band/gear housing 6.0 4.4

Use the following procedure to fit a ’P’ screw in an existing thread:

–PlacethePscrewintheholeandrotateitcounterclockwiseuntilitdropsdownslightly.

–Tightenthescrewclockwisetothespecifiedtorque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread.

1) Secure slotted nut with Loctite 242.

Note: Screws/nuts secured with adhesive are easier to release if they are heated beforehand with a hot air blower (hairdryer).

Be careful with polymer components!

Power screwdriver speed settings for polymer: Plastoform screws max. 600 rpm,

DG screws max. 500 rpm

2.4 Tightening Torques

4

Page 6

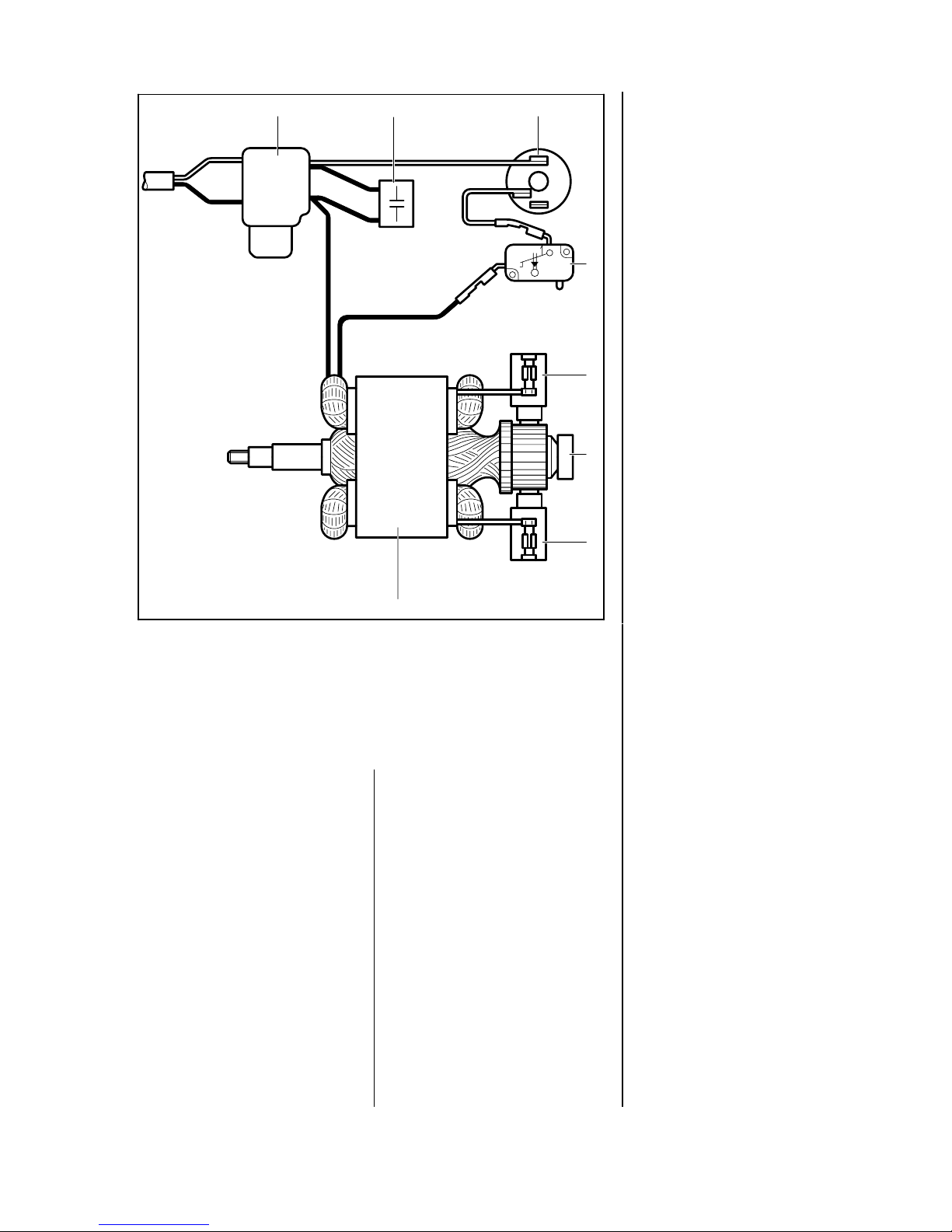

The trigger switch (1) is equipped

with a mechanical starting lockout

(interlock button) which helps prevent unintentional switch-on.

The saws feature a thermal overload circuit breaker (3) to protect

the electric motor from mechanical

overload.

This overload circuit breaker interrupts the power supply to the saw

if the operator continues cutting for

an extended period with an overtensioned chain, uses excessive

feed force, "lugs down" the motor

speed or if the chain is suddenly

stopped by being pinched in the

cut.

Before restarting the saw and continuing work it is necessary to pull

the guide bar out of the cut and

wait for a short period until the

overload circuit breaker has cooled down. The overload circuit

breaker can then be reset by pressing in the button as far as

the stop.

This is not a fault. The remedy in

such a case is to work with less

feed effort. Under no circumstances should the overload circuit

breaker be bypassed, even if the

owner explicitly requests such a

modification.

Chain brake

The brake lever is unlatched when

the "Quickstop" chain brake is

activated, either manually or by

inertia. The power supply is interrupted immediately by the chain

brake switch (4) and the spring-loaded brake band is clamped around

the brake drum at the same instant.

This causes the saw chain to be

brought to a standstill and locked

in position. The chain brake is

disengaged by moving the hand

guard toward the front handle.

Coasting brake

The coasting brake supplements

the chain braking system. It brings

the rotating chain to a standstill

when the operator releases the

trigger switch.

In the idle condition, an additional

spring clamps the brake band around the brake drum.

When the trigger switch is squeezed, the brake band is first disengaged from the brake drum via a

linkage. Only then does the switch

close and start the motor.

3. WIRING DIAGRAM/DESCRIPTION

100RA002

2

3

2

1

2

1

1

2

K

1 2 3

4

5

6

5

7

VA

1Triggerswitch

2Capacitor(230Vonly)

3Overloadcircuitbreaker(E160,E180Conly)

4Chainbrakeswitch

5Brushholderwithcarbonbrush

6Rotor

7Stator

5

Page 7

Important: The electrical safety of

the saws should be checked after

every repair by performingahighvoltage insulation test. Tests of

this kind may only be carried out

by electricians or specially trained

personnel.

Always unplug the machine from

the mains supply.

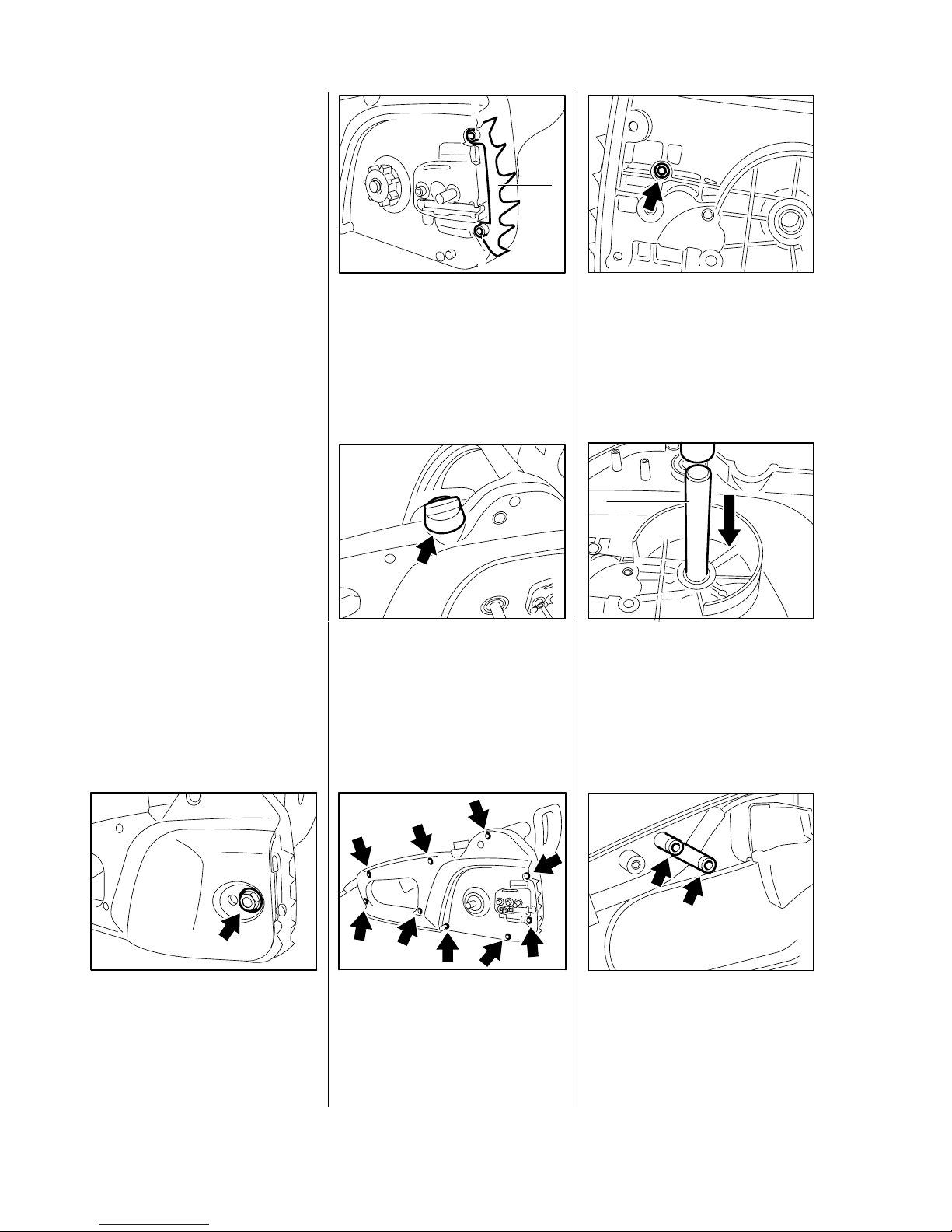

- Remove the quick chain

tensioner, if fitted - see 7.3.

•

Unscrew nut.

- Remove the chain sprocket

cover.

Models with quick chain

tensioner

•

Take out screws (1).

•

Remove the spiked bumper (2).

All models

- Remove the chain sprocket -

see 6.1.

•

Unscrew oil filler cap and remove together with cap retainer.

•

Take out the screws.

- Remove the handle housing.

•

Take out the O-ring.

- Placeasocket (e.g. 19mm)

under the handle housing so that

it supports the bearing bush from

outside.

•

Use drift (1) 1111 893 4700 to

press needle sleeve out of

bearing bush.

•

Take out the screws.

- Remove the strain relief cable

clamp.

100RA005

VA

100RA008

1

VA

100RA004

2

1

1

VA

100RA003

VA

4. Removing and Installing Electrical Components

4.1 Connecting Cord

100RA007

VA

100RA006

VA

100RA009

VA

6

Page 8

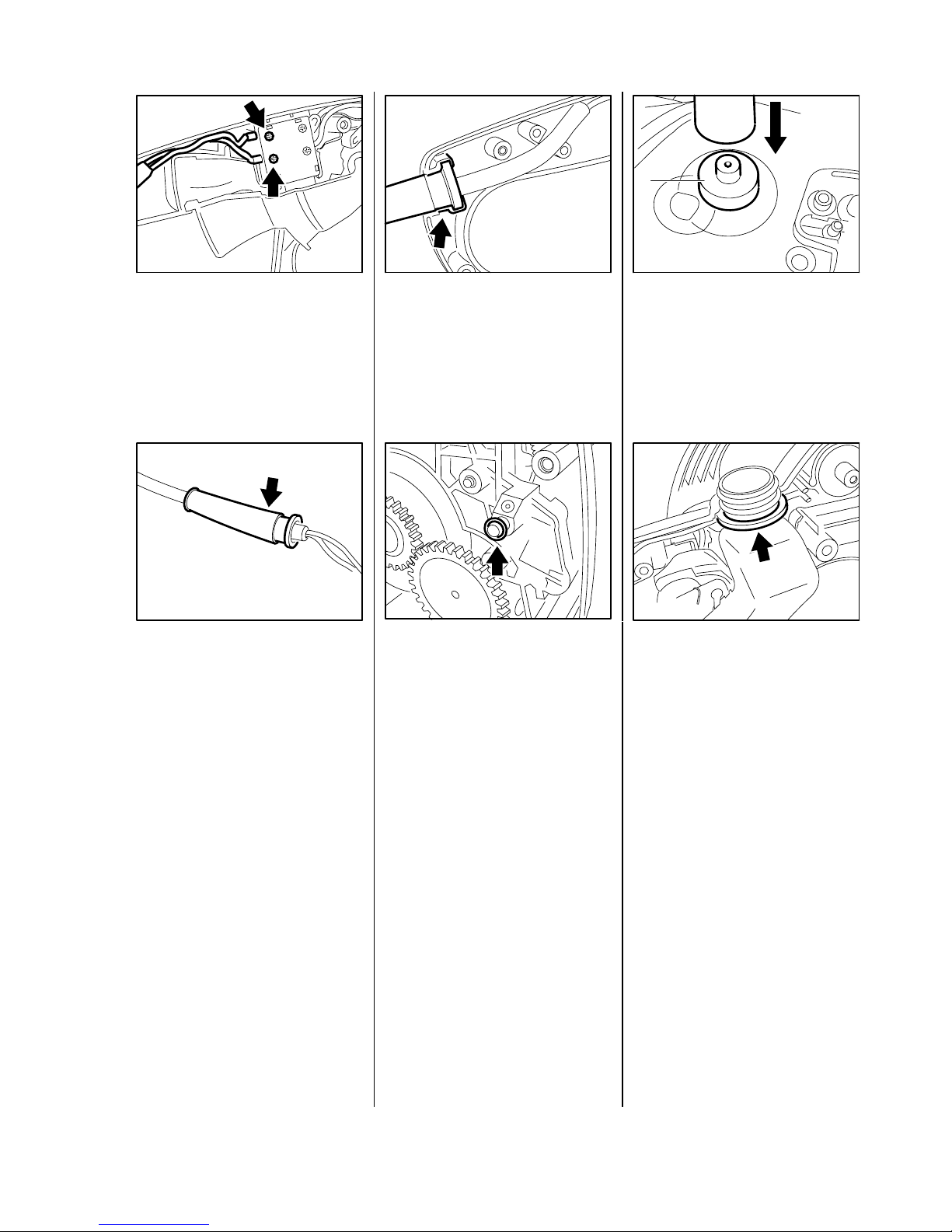

•

Slacken off the screws.

- Pull the wires out of the switch.

•

Pull cable protector off the old

connecting cord.

Installation is a reversal of the

removal sequence.

- Slip the cable protector, thin end

first, over the new connecting

cord.

•

Check that cable protector is

correctly seated.

- Fit the strain relief clamp

and tighten screws to 1.5 Nm

(1.1 lbf.ft).

•

Fit a new O-ring on gear housing

pivot pin.

- Place a socket (e.g. 19mm)

under the handle housing so that

it supports the bearing bush from

inside.

•

Use press arbor (1) 4116 893

7205 to install needle sleeve in

the bearing bush.

•

Check condition of sealing ring

on oil tank and fit a new one if

necessary - see 9.1.

- Tighten the handle housing

mounting screws to 2.0 Nm

(1.5 lbf.ft).

100RA014

1

VA

100RA011

VA

100RA012

VA

100RA015

VA

100RA010

VA

100RA013

VA

7

Page 9

- Remove the handle housing -

see 4.1.

•

Release the screws.

•

Disconnect wires (1) of

connecting cord.

•

Ease the trigger switch slightly

away from the motor housing

and disconnect the wires (2)

from the other side of the switch.

•

Remove the trigger switch (3).

Install in the reverse sequence.

Important: The wires must be reconnected to the same terminals,

see also 3.

- Remove the trigger switch -

see 4.2.

•

Cut the wire end ferrules off the

wires.

•

Pull the capacitor out of the

motor housing.

Install in the reverse sequence.

- Use wire end ferrules to connect

wires from overload circuit breaker and stator to the capacitor’s

wires.

The overload circuit breaker

interrupts the power supply to

protect the motor in the event of

mechanical overload (e.g. cutting

for extended period with excessive

feed force, suddenly stopping the

chain by pinching it in the cut).

Warning: The overload circuit

breaker and chain brake switch

must never be bypassed.

- Remove the oil tank - see 9.1.

•

Release the screw (1).

•

Disconnect the wires from the

switch.

•

Cut wire end ferrule (2) off the

wires.

100RA019

VA

100RA016

VA

100RA017

1

2

3

VA

100RA020

1

2

VA

100RA018

VA

4.2 Trigger Switch 4.3 Capacitor 4.4 Overload Circuit Breaker

(230 V only) (E 160, E 180 C)

8

Page 10

•

Pull off the terminal.

•

Pull overload circuit breaker out

of the motor housing.

Install in the reverse sequence.

•

Use new wire end ferrule to join

the wire from the switch and

capacitor and push into the retainers in the motor housing.

- Remove the handle housing -

see 4.1.

•

Remove the wires from the

brake switch terminals.

•

Lift snap hook (1) a little and

then pull out the chain brake

switch (2).

Install in the reverse sequence.

100RA022

VA

100RA025

VA

1

2

100RA021

VA

100RA023

VA

100RA024

VA

4.5 Chain Brake Switch

9

Page 11

•

Take out the screws.

- Remove the commutator cover.

•

Pull the wire off the connector

tag.

Pull the brush holder forwards and

take it away.

Note: The friction generated by

the carbon brushes causes the

commutator surface to wear gradually and eventually leaves serious scores. These scores cause

increased sparking between the

carbon brushes and commutator.

If the carbon brushes can be reused, do not change their installed

positions.

•

Inspect commutator before fitting

the carbon brushes and replace

the rotor if necessary - see 5.2.

- Check that the carbon brush moves freely in the brush holder.

•

Fit the brush holder so that the

top and bottom lugs slide into the

slots in the housing.

- Push wire onto connector tag.

- Refit commutator cover and

tighten screws to 3.0 Nm

(2.2 lbf.ft).

100RA027

VA

100RA031

VA

100RA028

VA

VA

100RA030

100RA029

VA

5. MOTOR

5.1 Carbon Brushes

10

Page 12

- Remove carbon brushes -

see 5.1.

- Remove oil tank - see 9.1.

Remove the ring gear and spur

gear - see 6.2.

•

Take out the screw (1).

•

Pull off the hand guard (2).

•

Pull wires off connector tags on

chain brake switch.

•

Remove screws from gear

housing.

•

Remove the gear housing and

pull the rotor out of the stator at

the same time.

•

Disconnect the tension springs.

- Useahot air blower to heat the

pinion mounting nut.

•

Hold pinion steady and unscrew

slotted mounting nut in direction

of arrow (left-hand thread).

•

Pry the pinion off the rotor shaft.

•

Pull the rotor out of the ball

bearing.

100RA032

1

2

VA

100RA034

VA

100RA033

VA

100RA024

VA

VA

100RA035

100RA036

VA

100RA037

VA

5.2 Rotor

VA

100RA038

11

Page 13

•

Examine brake drum (1) and fanwheel (2), replace if necessary -

see 5.4.

Note: If brake drum has to be replaced, also check the brake band

- see 8.1

- If brake drum is still serviceable,

clean and roughen its friction

face with emery paper or cloth

(grain size approx. 120µm).

•

Inspect the rotor core assembly

(1) for damage and replace the

rotor if necessary. The fanwheel

and ball bearing have to be removed for this purpose - see 5.4

and 5.3.

•

Inspect the commutator (2).

Note: In case of minor running

marks, dress the commutator

with emery cloth. If running

marks are severe, fit new rotor.

•

Examine ball bearing (3) and

replace if necessary - see 5.3.

Install in the reverse sequence.

- Clean thread of slotted nut and

rotor stub with standard commercial, solvent-based degreasant

containing no chlorinated or

halogenated hydrocarbons -

see 10.2.

- Coat thread of slotted nut with

Loctite, see 10.2, and screw

slotted nut into pinion.

•

Hold pinion steady and tighten

down slotted nut to 8.0 Nm

(5.9 lbf.ft).

•

Attach smaller spring (1) to

brake lever (2).

•

Use assembly tube (2) 1117 890

0900 to hook larger spring (1) to

pivot pin.

- Torque down gear housing

screws to 3.0 Nm (2.2 lbf.ft) and

screw on hand guard to 4.5 Nm

(3.3 lbf.ft).

VA

2

1

100RA040

VA

100RA039

1 2

VA

100RA041

1

2

3

100RA043

VA

1 2

VA

100RA042

12

Page 14

- Remove the rotor - see 5.2.

•

Pull the ball bearing off the rotor

shaft.

•

Remove the nylon washer and

inspect it. Refit it so that its flat

side is against the commutator.

- Heat ball bearing to approx.

50°C (120°F) and push it on as

far as stop.

Check ball bearing in gear housing. If ball bearing is faulty, fit a

new gear housing - see 6.3.

- Install the rotor - see 5.2.

- Remove the rotor - see 5.2.

•

Rest fanwheel flange (see arrow)

on two flat steel bars (5x20x130

mm).

- Position flat steel bars with rotor

inapress.

Note: The rotor must hang freely.

•

Useahot air blower to heat the

hub area of the brake drum.

VA

100RA045

VA

100RA044

VA

100RA047

100RA046

VA

100RA048

VA

5.3 Rotor Bearing 5.4 Fanwheel

13

Page 15

•

Hold the rotor and press it out of

the brake drum and fanwheel.

- Clean stub of rotor shaft with

standard commercial, solvent-

-based degreasant containing

no chlorinated or halogenated

hydrocarbons - see 10.2.

•

Push the fanwheel, flange first,

onto the rotor shaft as far as it

will go.

- Coat the flats on the rotor shaft

with Loctite 648 - see 10.2.

•

Fit the brake drum so that the

closed side faces the fanwheel.

- Stand the rotor upright on a

socket (e.g. 19 mm) with the

brake drum at the bottom.

•

Press the rotor down until the

brake drum locates against the

shaft shoulder.

- Install the rotor - see 5.2.

- Remove the rotor - see 5.2.

•

Pull the air baffle out of the

housing.

•

Release screw (1) on switch (2).

•

Pull wires out of switch. Cut the

end ferrule (3) off the end of the

wires.

•

Take out the screws.

- Press stator out of housing.

5.5 Stator

100RA053

VA

100RA055

VA

100RA052

VA

VA

100RA050 100RA049

VA

100RA051

VA

100RA054

231

VA

14

Page 16

- Check insulation of field coils.

Note: Install a new stator if

insulation is damaged.

- Check condition of stator’s inner

running surface. Replace stator if

necessary.

•

Place stator in position. Use

screwdriver (1) 5910 890 2400 to

press stator home as far as stop.

Warning! Make sure wires for

carbon brushes are not pinched

in this process.

- Fit stator mounting screws and

tighten to 3.0 Nm (3.0 lbf.ft).

Installation is now a reversal of the

removal sequence.

- Remove the chain sprocket

cover - see 4.1.

•

Use screwdriver to remove

E-clip (1).

•

Remove the washer (2).

•

Pull the chain sprocket off the

shaft.

•

Remove the washer.

Install in the reverse sequence.

- Remove the handle housing -

see 4.1.

•

Pull the spur gear out of the oil

pump.

•

Remove washer if it is still

sticking to the spur gear.

•

Take thrust washer off the ring

gear shaft.

6. CHAIN DRIVE 6.2 Ring Gear and Pinion

6.1 Chain Sprocket

100RA056

VA

2 1

VA

100RA061

100RA059

VA

100RA058

VA

100RA065

1

VA

100RA057

VA

100RA060

VA

15

Page 17

•

Pull ring gear out of needle

bearing in gear housing.

•

Take the thrust washer off the

ring gear shaft.

•

Check condition of needle bearing in gear housing and replace

if necessary.

- Check condition of needle bearing in handle housing and

replace if necessary - see 4.1.

- Remove ring gear - see 5.2.

•

Only replace pinion (1) and ring

gear (2) as matching set.

Install in the reverse sequence.

- Coat ring gear and washer with

lubricating grease - see 10.2.

•

Fit washer in oil pump if it was

removed from the spur gear.

- Remove the rotor - see 5.2

- Remove the oil pump - see 9.2.

- Remove chain brake - see 8.1.

•

Lift snap hook (1) a little and

then pull out the chain brake

switch (2).

•

Pull the oil strainer off the stub.

Install in the reverse sequence.

1

100RA071

2

VA

100RA063

VA

100RA062

VA

100RA070

VA

6.3 Gear Housing

100RA064

VA

100RA067

1

2

VA

100RA085

VA

16

Page 18

- Remove the chain sprocket

cover - see 4.1.

•

Pull the cover out of the motor

housing.

•

Unscrew the tensioning nut (1)

from the adjusting screw (2).

•

Take the adjusting screw out of

the cover (3).

Install in the reverse sequence.

- Remove the chain sprocket

cover - see 4.1.

•

Take out the complete chain

tensioner.

•

Remove the thrust pad (1).

•

Rotate the spur gear (2) to

unscrew the adjusting screw (3)

fully from the tensioner slide (4).

•

Pull the spur gear (1) out of the

cover (2).

•

Pull off the tensioner slide (1).

•

Take out the adjusting screw (2).

- Inspect the teeth on the spur

gear and adjusting screw,

replace both parts if necessary.

Install in the reverse sequence.

Note: Coat teeth of adjusting

screw and spur gear with

lubricating grease, see 10.2,

before refitting.

7. CHAIN TENSIONER

7.1 Front Chain Tensioner 7.2 Side Chain Tensioner

100RA074

1 4 3 2

VA

100RA076

21

VA

100RA072

VA

100RA073

VA

100RA075

2 1

VA

143RA052

VA

1

2

3

17

Page 19

•

Pull out hinged handle (1) of

wingnut (2).

•

Unscrew the wingnut and

remove the chain sprocket

cover (3).

•

Ease the wingnut out of the

chain sprocket cover.

- Push the wingnut into the chain

sprocket cover until it snaps into

position.

- Remove the gear housing -

see 5.2.

- Remove brake drum if necessary

- see 5.4.

•

Carefully pull the switch lever off

the pivot.

•

Disconnect brake rod from the

pawl.

•

Pry the pawl out of the switch

lever.

•

Take the torsion spring off the

pawl.

Install in the reverse sequence.

•

Check installed position of

torsion spring.

7.3 Quick Chain Tensioner 8. CHAIN BRAKE

8.1 Removal

100RA077

1

2

3

VA

100RA078

VA

100RA086

VA

100RA087

VA

100RA088

VA

100RA089

VA

100RA090

VA

18

Page 20

- Remove the switch lever -

see 8.1.

- Remove the rotor - see 5.2.

•

Unhook brake rod from brake

lever.

•

Detach the springs.

•

Remove the brake band fasten-

ing screw.

•

Pry the brake band out of the

gear housing.

•

Unhook brake band from brake

lever.

- Inspect brake band and fit new

one if:

- there are definite signs of wear

(large areas of inside diameter

and/or parts of outside diameter)

and

- band thickness is less than 0.6

mm (0.025").

Important: The brake band must

must not be thinner at any point.

- If the brake band is still serviceable, clean and roughen its

entire friction surface (inside of

brake band) with emery paper or

cloth (grain size approx. 120 µm).

•

Pry the carrier and articulated

lever off the bearing pin and lift

them away together.

- Pull the articulated lever out off

the carrier.

•

Remove the flat spring.

- Inspect all parts. Always replace

damaged parts.

- Clean housing recess for chain

brake mechanism.

VA

100RA091

VA

100RA092

100RA093

VA

100RA094

VA

100RA095

VA

100RA097

VA

100RA098

VA

19

Page 21

- Coat all sliding aand pivot points

with STIHL multipurpose grease

or, preferably, with molybdenum

grease (e.g. Molykote) - see 10.2.

- Fit the flat spring.

•

Fit articulated lever (1) in

carrier (2) as shown in the

illustration.

•

Slip the carrier (1) over the bearing pin (2) and the bore (3) of

articulated lever (4) over bearing

pin (5).

•

Check that flat spring (1) is

correctly positioned on face (2)

of bearing boss.

•

Attach brake band to brake

lever.

•

Position brake band in slots in

gear housing and press it home.

•

Fit brake band fastening screw

and tighten to 6.0 Nm (4.5 lbf.ft).

•

Attach the springs.

•

Attach brake rod to brake lever.

- Install the rotor - see 5.2.

- Fit the switch lever - see 8.1.

8.2 Installation

100RA099

1 2

VA

100RA100

2

5

1

4 3

VA

100RA101

2

1

VA

100RA095

VA

100RA102

VA

100RA103

VA

VA

100RA092

VA

100RA091

20

Page 22

- Remove the handle housing -

see 4.1.

•

Remove the oil tank and pull it

off the oil strainer at the same

time.

•

Remove the sealing ring from

the oil tank.

•

Take grommet out of the oil tank.

Install in the reverse sequence.

- Remove the oil tank - see 9.1.

•

Pull the oil strainer off the stub.

- Clean the oil strainer, check it for

damage and fit a new one if

necessary.

Install in the reverse sequence.

- Remove the handle housing -

see 4.1.

•

Pull the spur gear out of the oil

pump.

•

Remove washer if it is still

sticking to the spur gear. If not,

take the washer out of the oil

pump.

•

Take out the screws.

9. CHAIN LUBRICATION

9.1 Oil Tank 9.2 Oil Strainer 9.3 Oil Pump

VA

100RA068

100RA003

VA

100RA105

VA

100RA104

VA

100RA059

VA

100RA060

VA

100RA106

VA

21

Page 23

•

Pull oil pump out of housing.

Note: Make sure the pin does not

fall out of the oil pump.

•

Remove the O-rings.

Install in the reverse sequence.

•

If the pin has fallen out of the oil

pump, refit it with lubricating

grease - see 10.2.

-AlwaysusenewO-rings.

-Tightendownoilpumpmounting

screws to 2.5 Nm (1.8 lbf.ft).

•

Fit the washer in the oil pump.

100RA107

VA

100RA108

VA

100RA109

VA

100RA110

VA

22

Page 24

10. Special Servicing Tools and Aids

10.1 Special Servicing Tools

No. Part Name Part No. Application Rem.

1Assemblytube 11178900900 Attachingsprings

2ScrewdriverT20x100 59108902301 ReleasingISscrews 1)

3SplinescrewsocketT20x120 08125422041 TighteningISscrews

4T-handle screwdriver

QI-T27x150 5910 890 2400 Releasing IS screws, installing 1)

stator

5SplinescrewsocketT27x125 08125422104 TighteningISscrews

6Torquewrench 59108900301 0.5-18Nm 2)

(0.4 - 13.5 lbf.ft)

5910 890 0302 3)

7Torquewrench 59108900311 6-80Nm 2)

(4.4 - 60 lbf.ft)

5910 890 0312 3)

8Assemblystand 59108903100 Holdingsawforservicing

9Crimpingtool 59108908210 Attachingconnectorstoelectrical

wires

10 Assembly drift 1111 893 4700 Removing needle sleeve

from handle housing

11 Press arbor 4116 893 7205 Installing needle sleeve

in handle housing

Remarks:

1) On Plastoform screws, use for releasing only.

2) Always use torque wrench to tighten Plastoform screws.

3) Wrench has optical/acoustic signal.

10.2 Servicing Aids

No. Part Name Part No. Application

1Medium-strengththreadlocking 07861111101 Slottednutforpinion

adhesive (Loctite 242)

2High-strengththreadlocking 07861100126 Securingbrakedrum

adhesive (Loctite 648)

3Standardcommercial, Cleaningrotorshaftstuband

solvent-based degreasant slotted nut

containing no chlorinated or

halogenated hydrocarbons

4Lubricatinggrease 07811201111 Slidingandpivotpoints,pininoilpump

5Molybdenumgrease(eg.Molykote) Pivotpointsofchainbrake

6Multipurposegrease 07811201109 Ringgearandwashers

7Electrician’srepairkit 00000071013

E140,E160,E180 23

Page 25

englisch/English

0455 100 0123. M0,5. C0. Rei. Printed in Germany

Loading...

Loading...