Page 1

STIH)

Technical Information

TI_19_2010_30_01_01.fm

englisch / English

New cut-off machines STIHL Cutquik®TS 410-A, TS 420-A – Series 4238

Contents

1. Electronic water control

2. Specifications

3. Servicing accessories

4. Spare parts

5. Servicing

1. Electronic water control

The new cut-off machines STIHL Cutquik®

TS 410-A, TS 420-A are equipped with the new,

innovative electronic water control.

Benefits:

. The optimum amount of water is always fed to

the cutting wheel during use

. The water supply is cut off automatically during

idling

. Easy operation via the ergonomically arranged

control panel

. Time savings, e. g., due to less frequent refilling

of the STIHL pressurized water tank

Both the potential applications and uses as well as

the other product features are equivalent to those of

the cut-off machines STIHL Cutquik

®

TS 410, 420.

1.1 Functional description

The electronic water control consists essentially of

the following components:

– Control panel (1)

– Generator (2) – behind the flywheel

– Solenoid valve (3) – with integral control

1

370TI052 KN

2

3

19.2010

Page 2

Page 2 Technical Information 19.2010

TI_19_2010_30_01_01.fm

The generator ensures that power is supplied to the

solenoid when the engine is running.

Using the buttons of the ergonomically arranged

control panel, the user can adjust both the water

flow rate as well as manually activating and

deactivating the water control.

1.1.1 Before starting work

. While the engine is switched off: Familiarize

yourself with the sequence of motions

. All of the control panel buttons can be operated

with the thumb of the right hand – the right hand

always remains on the rear handle during

operation

. The left hand always remains on the handlebar

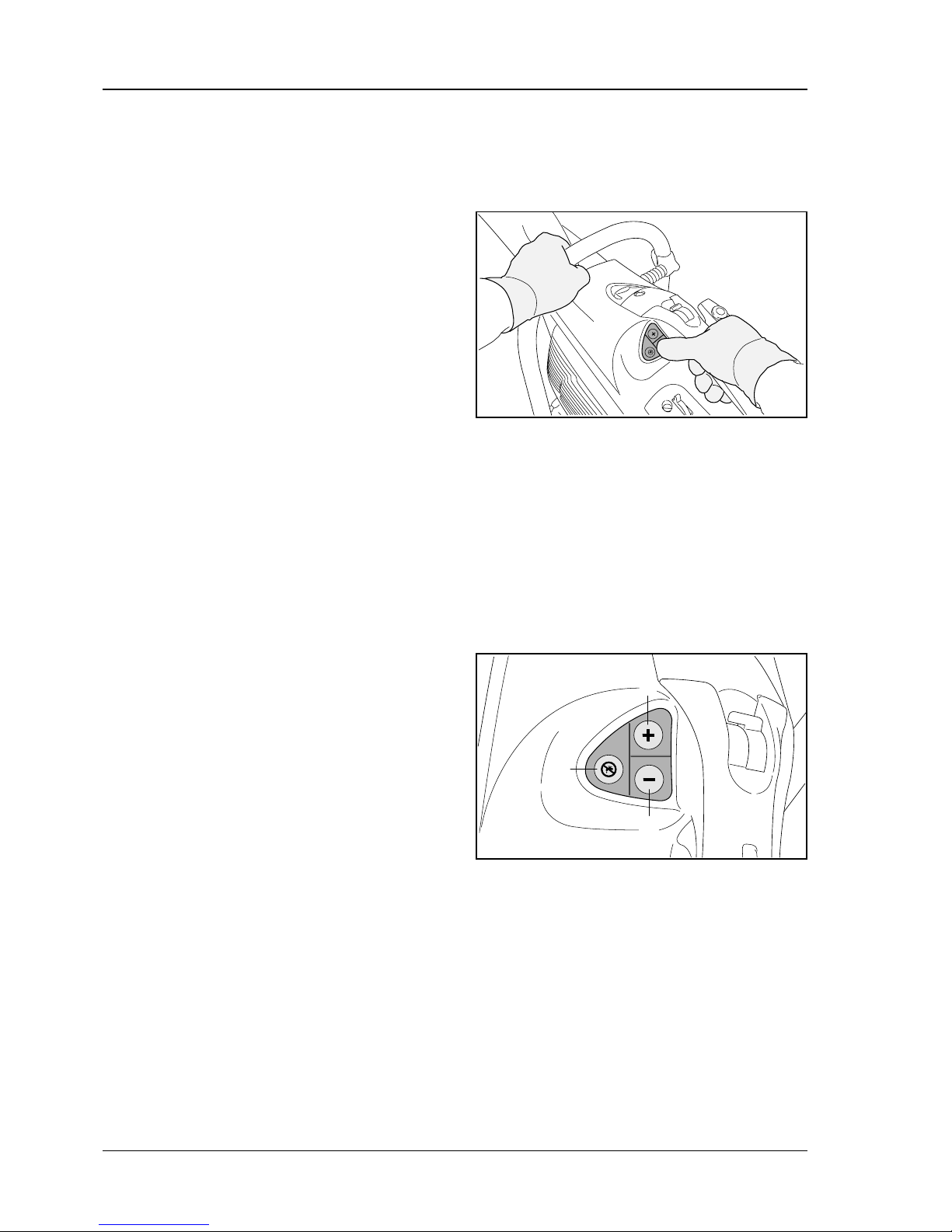

1.1.2 Control Panel

When the engine is running, it is possible to activate

/ deactivate the electronic water control and adjust

the water flow.

1 Button (+):

Activate the electronic water control or increase

water flow to cutting wheel

2 Button (–):

Activate the electronic water control or decrease

water flow to cutting wheel

3 Deactivate electronic water control; no water is

fed to the cutting wheel

370TI053 KN

1

2

3

370TI054 KN

Page 3

Technical Information 19.2010 Page 3

TI_19_2010_30_01_01.fm

1.1.3 Using the Electronic Water Control

. Start the engine in accordance with the

Instruction Manual

. Blip the (+) button or (–) button with the thumb of

the right hand – the right hand always remains

on the rear handle during operation, the left

hand always remains on the handlebar – no

water is fed to the cutting wheel during idling

During use, the set amount of water is fed to the

cutting wheel.

. Adjust water flow if necessary – to do so, blip the

(+) button or (–) button with the thumb of the

right hand until the correct water quantity is

attained – the right hand always remains on the

rear handle during operation, the left hand

always remains on the handlebar

If the engine is idling, no water will be fed to the

cutting wheel – the electronic water control,

however, remains activated, so when work

continues, the last quantity of water set before the

idle phase will be fed to the cutting wheel again

automatically.

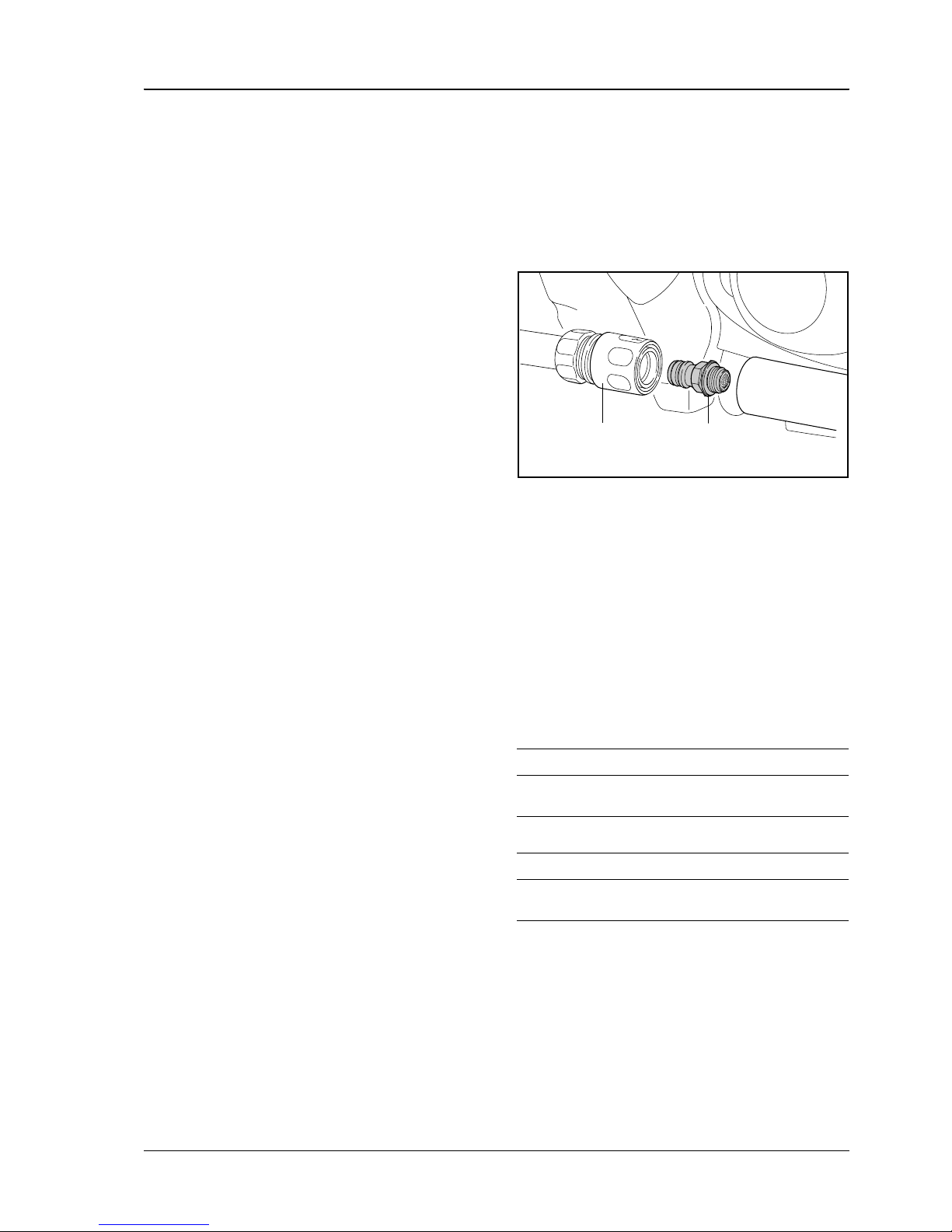

1.1.4 Maintenance and Care

To protect the solenoid valve, a screen is installed in

the water connection.

If too little water or no water is fed to the cutting

wheel during use with the electronic water control

activated:

. Remove the coupling sleeve (1)

. Unscrew "water connection with screen" (2) and

rinse under running water – the screen remains

on the water connection

2. Specifications

2.1 Weight

dry, without cutting wheel

without electronic water control

TS 410: 9.4 kg

TS 420: 9.6 kg

with electronic water control

TS 410-A: 9.9 kg

TS 420-A: 10.1 kg

21

370TI055 KN

Page 4

Page 4 Technical Information 19.2010

TI_19_2010_30_01_01.fm

3. Servicing accessories

3.1 New special tools

3.1.1 Power adapter 4238 400 8500

The power adapter 4238 400 8500 permits fast

troubleshooting (see b 5.1, b 5.2).

3.1.2 Spacer 4238 894 1100

The flywheel must be removed with the previous

puller 1135 890 4500 (to be changed to

5910 890 4504) and the new spacer 4238 894 1100

(see b 5.3), in order to avoid damaging the

generator beneath it.

3.2 Existing special tools

The existing special tools are listed in the Service

Manual for STIHL Cutquik

®

TS 410, 420.

4. Spare parts

The spare parts lists will be available for market

launch and are already contained on the DVD

STIHL Service Communication System (01/2010).

4.1 Clutch

In the new cut-off machines STIHL Cutquik

®

TS 410-A, TS 420-A, the new clutch 4238 160 2002

is used. In the new version, the previous tension

spring 0000 997 0912 with 6 coils is replaced by the

new version 0000 997 5510 with 7 coils.

In the new cut-off machines STIHL Cutquik

®

TS 410-A, TS 420-A, only the new clutch

4238 160 2002 should be used as a replacement

part.

5. Servicing

The safety instructions in the instruction manual

must be observed if the machine has to be started

up during servicing.

5.1 Troubleshooting Plan for the Electronic

Water Control

Possible customer complaint

– No water flow or water flow too low

– Water flow cannot be adjusted via the control

panel buttons

– System leaks

370TI075 KN

370TI057 KN

Page 5

Technical Information 19.2010 Page 5

TI_19_2010_30_01_01.fm

Customer complaint

Customer complaint

remedied?

no

Check water connection / screen and

clean if necessary, see

b 1.1.4

Troubleshooting completed

Leaky solenoid valve, repair or

replace

Leak testing: Engine switched off,

connect machine to water supply

(e. g., pressurized water tank)

Disconnect machine from water

supply. Connect power adapter,

see

b 5.2

System free of leaks?

Solenoid valve / control defective,

repair or replace if necessary

Blip the (OFF) button on the control

panel, see

b 1.1.2

Control panel2) / button / wiring

harness defective, repair or replace

Blip the (+) button on the control panel

several times in succession,

see

b 1.1.2

yes

Can the clicking of the

solenoid valve be heard?

Does frequency1)

increase?

Generator / wiring harness defective,

repair or replace

Control panel2) / button / wiring

harness defective, repair or replace

no

yes

yes

yes

no

no

Blip the (–) button on the control panel

several times in succession,

see

b 1.1.2

Does frequency

decrease?

no

Can the clicking of the

solenoid valve be heard?

yes

Control panel2) / button / wiring

harness defective, repair or replace

yes

no

1) : Frequency increases until the solenoid valve is all the way open; when the solenoid valve is all the way open, no more clicking can

be heard

2) : If the electronics detect a defective control panel, then the solenoid valve is opened all the way during use, thus ensuring the flow

of water

Page 6

Page 6 Technical Information 19.2010

TI_19_2010_30_01_01.fm

5.2 Connecting the Power Adapter

The power adapter 4238 400 8500 permits fast

troubleshooting. Connect the power adapter to the

generator connection on the solenoid valve and the

power source.

With the power adapter connected, all other

components of the electronic water control (control

panel, short circuit wire, solenoid) must be

connected except the generator. If a component is

replaced, then the power adapter must be

disconnected from the generator connection on the

solenoid valve and then reconnected after the

repair.

. Unscrew bolt (1)

. Remove cover (2)

. Disconnect the generator plug (3) from the

solenoid valve

. Connect the plug (4) of the power adapter (5) to

the solenoid valve

. Plug power adapter (6) into a properly installed

power outlet – voltage source and operating

voltage of power adapter must match

Once the power adapter is connected, clicking of the

solenoid valve should be heard (see b 5.1).

5.3 Removing the Flywheel

With the cut-off machines STIHL Cutquik

®

TS 410-A, TS 420-A, the flywheel must be removed

using the previous puller (1) 1135 890 4500 (to be

changed to 5910 890 4504) and the new spacer (2)

4238 894 1100 (see b 3.1.2) in order to avoid

damaging the generator beneath it.

STIHL recommends also using the new spacer (2)

4238 894 1100 in combination with the previous

puller (1) 1135 890 4500 (to be changed to

5910 890 4504) for the cut-off machines

STIHL Cutquik

®

TS 410, 420 without electronic

water control, since this ensures straight positioning

of the puller.

1

370TI058 KN

2

3

370TI059 KN

4

370TI076 KN

5

6

370TI061 KN

1 2

Page 7

Technical Information 19.2010 Page 7

TI_19_2010_30_01_01.fm

5.4 Removing the Shroud

In addition to the previous description "Removing

the Shroud" in the Service Manual STIHL Cutquik

®

TS 410, 420, in machines with electronic water

control, the plug connection between the short

circuit wire and the control panel must be

disconnected.

. Loosen screw (1) – screw (1) remains in cap (2)

. Remove cap (2).

. Remove plug connector (3) from guide

. Unplug connector (3) between short circuit wire

and control panel

. Remove bolts (4)

5.5 Removing the Control Panel

Do not attempt to pry out the control panel with

shroud installed.

. Remove the shroud, see b 5.4

. Remove control panel from the snap mount

5.6 Removing the Air Baffle

In addition to the previous description "Removing

the Air Baffle" in the Service Manual

STIHL Cutquik

®

TS 410, 420, in machines with

electronic water control, the plug connection

between the short circuit wire and the control panel

as well as the short circuit wire plug on the solenoid

valve must be disconnected.

. Remove bolt (1)

. Remove cover (2)

. Disconnect the plug (3) of the short circuit wire

from the solenoid valve

. Remove the shroud, see b 5.4

. Remove the filter cover

. Remove the support foot

. Remove the air baffle with the short circuit wire

370TI062 KN

1

2

3

370TI063 KN

4

4

1

370TI058 KN

2

3

370TI064 KN

Page 8

Page 8 Technical Information 19.2010

TI_19_2010_30_01_01.fm

5.7 Removing the Generator

. Unscrew bolt (1)

. Remove cover (2)

. Disconnect the generator plug (3) from the

solenoid valve

. Remove the fan cover

. Remove the flywheel, see b 5.3

. Unscrew bolt (4) and remove lug (5)

. Remove bolts (6)

. Remove generator (7)

5.8 Cable Routing

To ensure that plug connections remain sealed, fuel,

oil, grease or other lubricants must never be used

when unplugging and plugging in the connectors.

Fuel, oil, grease or other lubricants can cause the

seal to swell.

Do not unplug connections by pulling on the wires,

but instead by pulling on the connector

5.8.1 Generator

. Insert the lug (1) of the black wire (2) as far as it

will go (A) into the retainer (3) – crimped side

facing the bolt head

. Press and/or insert the black wire (2) and yellow

wire (4) into the marked locations (arrow)

. Route the yellow wire (4) under the retainer (3)

in the direction of the generator (5)

. Insert the retainer (3) into recess "crankcase

half, fan side"

. Bolt down the lug (1)

. Bolt down the generator (5)

1

370TI058 KN

2

3

370TI059 KN

4

5

7

370TI065 KN

6

6

1

3

370TI066 KN

4

2

5

4

A

Page 9

Technical Information 19.2010 Page 9

TI_19_2010_30_01_01.fm

5.8.2 Solenoid Valve

Generator wire

Route the cable starting at the generator in the

direction of the solenoid valve (see b 5.8.1).

. Insert bushing (1)

. Insert shrink tube as far as it will go (A)

. Press in and/or insert wires (2) in the marked

locations (arrows)

. Connect the generator plug (3) to the solenoid

valve

Short circuit wire

Route the short circuit wire starting at the air baffle

in the direction of the solenoid valve (see b 5.8.3).

. Insert bushing (4)

. Press in and/or insert short circuit wire (5) in the

marked location (arrow)

. Connect the plug (6) of the short circuit wire to

the solenoid valve

5.8.3 Air Baffle

Short circuit wire

. Insert the blue shrink tube (1) into the air baffle

as far as it will go (A)

. Press in and/or insert short circuit wire (2) in the

marked locations (arrows)

. Slide the bushing (3) over the black shrink tube

A

3

370TI067 KN

4

1

2

5

6

A

370TI068 KN

1

2

3

Page 10

Page 10 Technical Information 19.2010

TI_19_2010_30_01_01.fm

5.8.4 Shroud

Plug connection short circuit wire / control

panel

. Press in and/or insert plug connection/wire in

the marked locations (arrows)

Control panel

Route the cable starting at the control panel in the

direction of the plug connection to the short circuit

wire.

. Press in and/or insert plug wires in the marked

locations (arrows)

5.9 Tightening torques

Additional tightening torques are listed in the

Service Manual for the STIHL Cutquik

®

TS 410, 420.

5.10 Service notes

Service and repair procedures are included in the

Service Manual STIHL Cutquik

®

TS 410, 420.

370TI069 KN

370TI070 KN

Part(s) Thread Tightening

torque

Cap / tank housing P 6x19 6 Nm

Generator /

crankcase

M4x12 3Nm

Solenoid valve / tank

housing

P6x19 6Nm

Cap / shroud M 5x17 4.5 Nm

Ground wire /

crankcase

M4x12 3Nm

Hose connector /

solenoid

G3/8" 3Nm

Page 11

Technical Information 19.2010 Page 11

TI_19_2010_30_01_01.fm

5.11 Repair times

The specified repair times apply for trained and

qualified personnel as well as for properly equipped

repair shops.

The repair times are specified in minutes.

© ANDREAS STIHL AG & Co. KG, 2010 Technical Documentation

D1/MTK-fr

Code Type of Repair

TS410-A

TS420-A

2 Replace wheel guard 20

3 Replace wheel bearing bracket assembly. 25

4 Replace belt pulley on wheel arbor. 15

5 Replace wheel arbor shaft. 15

6 Replace arbor shaft bearing. 25

7 Replace belt pulley on clutch end. 25

8 Replace drive belt. 15

9 Replace front handlebar. 15

10 Replace cast arm from engine to wheel 25

11 Replace crankcase, crankcase gasket or re-seal crankcase. Includes air leak test. 160

12 Replace crankshaft main bearing(s). Includes air leak test. 170

13 Replace crankshaft seal(s). Includes air leak test. 70

14 Perform engine air leak test. 30

15 Replace cylinder and/or piston. Includes air leak test and repair of components causing failure. 90

16 Replace ignition module or flywheel. Includes stop circuit test. 25

17 Replace fuel tank line, vent line, or fuel pick-up body. 40

18 Replace intake or transfer port manifold or intake flange 35

19 Repair or replace carburetor. Includes fuel system testing. 45

20 Repair or replace rewind starter 15

21 Repair or replace clutch, clutch shoes or clutch springs. 20

22 Replace rear handle frame or handle housing 30

23 Replace muffler 25

24 Replace air filter or filter housing 15

25 Repair or replace stop switch. Includes circuit testing. 35

26 Replace fuel tank housing 60

27 Replace control panel. Includes electrical and run test. 25

28 Replace generator. Includes electrical and run test. 30

29 Replace solenoid valve. Includes electrical and run test. 20

30 Replace short circuit wire, air baffle. Includes electrical and run test. 25

40 Miscellaneous repairs and other repairs not listed. 15

45 Handling allowance only-no labor. 10

50 No Labor 0

Loading...

Loading...