Page 1

STIH)

Technical Information

Cut-off machine STIHL Cutquik® TS 410, 420 – Series 4238

Contents

1. Guard with defined adjustment range

2. Belt guard, screw

3. Set of instruction labels

4. Summary

1. Guard with defined adjustment

range

1.1 Adjustment range

2

2

1

35.2009

®

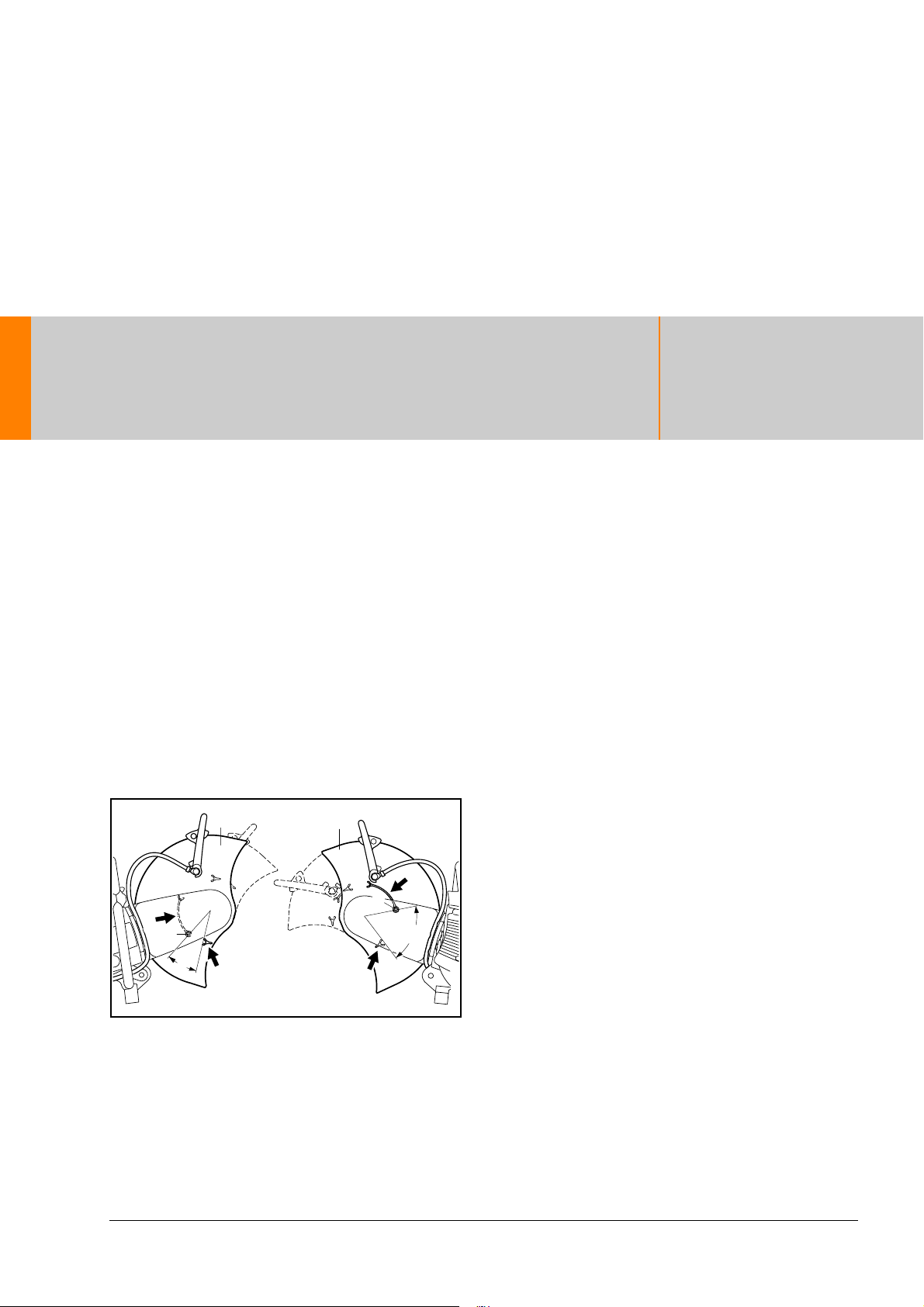

In STIHL Cutquik

the adjustment range (A and B respectively) of the

guard will be determined by the stop pin (1) installed

into the cast arm and by the lugs (arrows) molded

onto the guard (2).

TS 410, 420 cut-off machines,

1

A

Left: Adjustment range (A),

Guard mounted on the inboard side

Right: Adjustment range (B),

Guard mounted on the outboard side

TI_35_2009_30_01_01.fm

B

370TI016 KN

englisch / English

Page 2

Page 2 Technical Information 35.2009

1.2 Cast arm

2

2

The previous versions of the cast arm

4238 701 0201 (TS 410) and cast arm

4238 701 0200 (TS 420) are being replaced by the

new versions of the cast arm 4238 701 0203

(TS 410) and cast arm 4238 701 0202 (TS 420).

The new versions differ by a threaded hole (1) for

installing in the stop pin (see b 1.4) and additional

holes (2) for fastening the limit stop (see b 1.5).

Spare parts

The previous versions of cast arm 4238 701 0201

(TS 410) and cast arm 4238 701 0200 (TS 420)

without a threaded hole and without additional holes

are no longer available. The new versions of cast

arm 4238 701 0203 (TS 410) and cast arm

4238 701 0202 (TS 420) can also be used for older

machines.

1

3701TI017 KN

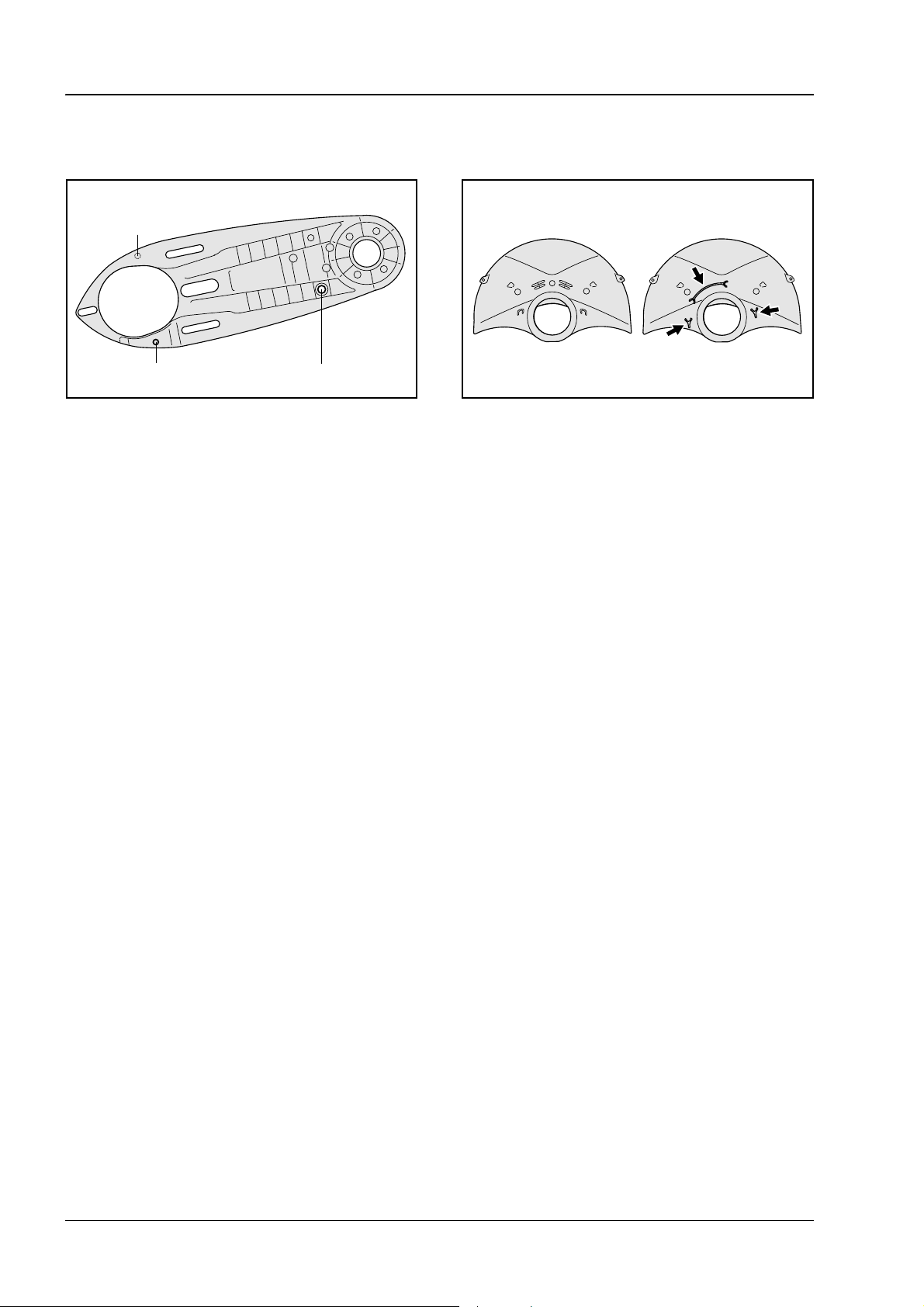

1.3 Guard

3701TI018 KN

Left: Previous versions of the guard

Right: New versions of the guard

The previous versions of the guard dia. 300 mm

(12") (4238 700 8102) and the guard dia. 350 mm

(14") (4224 700 8102) are being replaced by the

new versions of the guard dia. 300 mm (12")

(4238 700 8105) and the guard dia. 350 mm (14")

(4224 700 8108).

The new versions differ from the previous versions

by casted lugs (arrows), together with the stop pins

(see b 1.4) installed into the cast arm (see b 1.2)

to determine the adjustment range (see b 1.1) of

the guard.

Spare parts

The previous versions of the guard dia. 300 mm

(12") (4238 700 8102) and the guard dia. 350 mm

(14") (4224 700 8102) remain available for older

machines.

Service notes

The previous versions of the guard dia. 300 mm

(12") (4238 700 8102) and the guard dia. 350 mm

(14") (4224 700 8102) may only be installed in

machines with the previous guards.

The new versions of the guard dia. 300 mm (12")

(4238 700 8105) and the guard dia. 350 mm (14")

(4224 700 8108) may only be installed in machines

with the new guards.

TI_35_2009_30_01_01.fm

Page 3

Technical Information 35.2009 Page 3

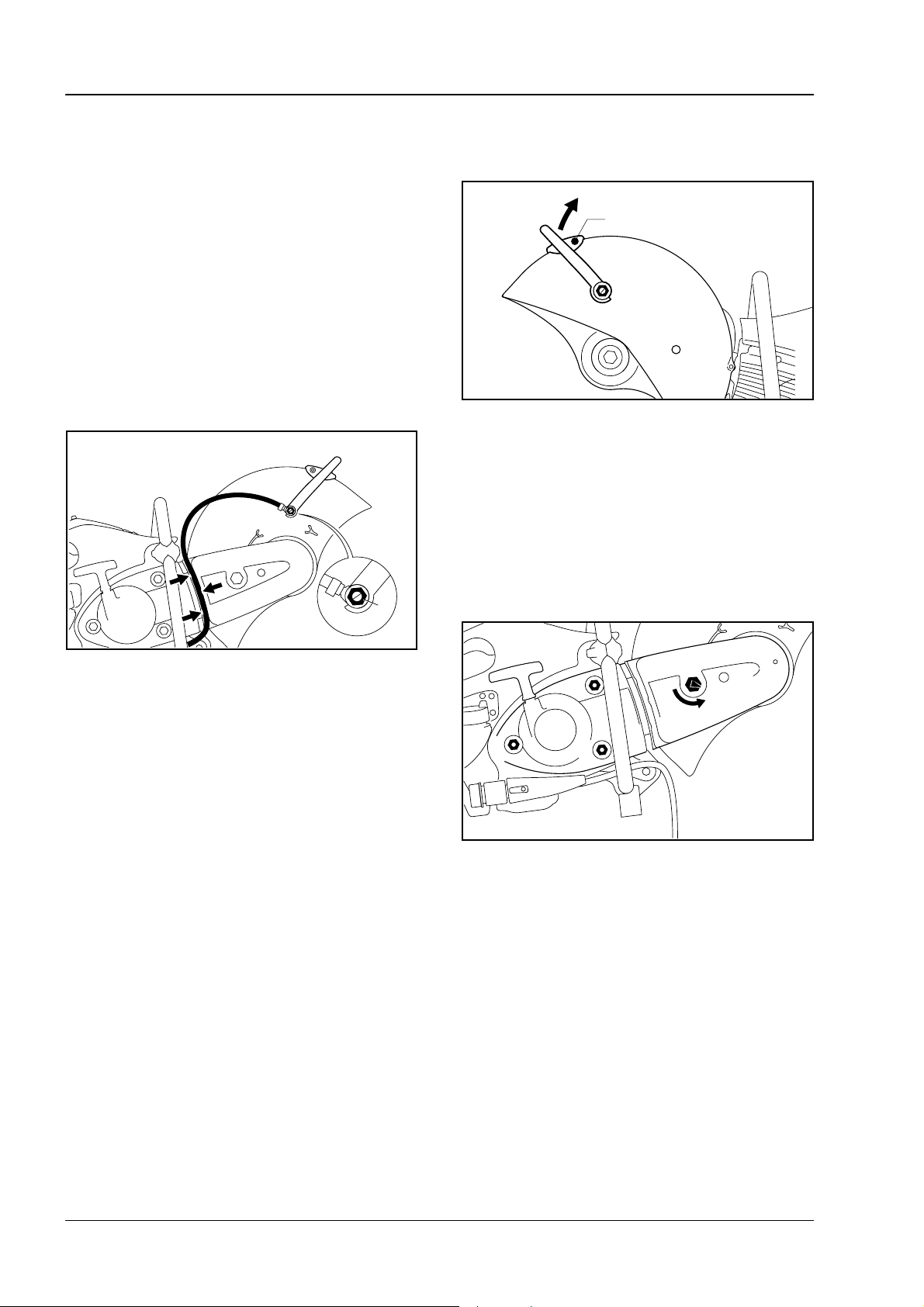

1.4 Stop pin

2

1

With the introduction of the new guards

(see b 1.3), the stop pin (1) 4224 691 0100 and

the limit stop (see b 1.5) are introduced. The stop

pin (1) installed into the cast arm (2), together with

the lugs molded onto the guard (see b 1.3)

determine the adjustment range (see b 1.1).

Tightening torques

Stop pin / cast arm 5 Nm

370TI019 KN

1.6 Rubber buffer

2

3

Left: Previous versions of the cast arm,

rubber buffer and screw

Right: New versions of the cast arm with

guard and the stop pin

The stop pin (1, see b 1.4) and lugs cast onto the

guard (see b 1.3) determine the adjustment range

(see b 1.1), the rubber buffer (2) 4224 790 9300

and the screw IS-M5x6-10.9 (3) (9022 341 0910)

have been eliminated.

1

3701TI071 KN

1.5 Limit stop

1

2

With the introduction of the new guards

(see b 1.3), the limit stop (1) 4238 691 0200 and

the stop pin (see b 1.4) are introduced. The limit

stop (1) is fastened to the cast arm with the pan

head self-tapping screw IS-P4x16 (2)

(9074 478 3025).

Tightening torques

Spare parts

The previous versions of the rubber buffer

4224 790 9300 and the screw IS-M5x6-10.9

(9022 341 0910) remain available for machines with

the previous guards.

370TI020 KN

Limit stop / cast arm 1.8 Nm

TI_35_2009_30_01_01.fm

Page 4

Page 4 Technical Information 35.2009

1.7 Reconfiguring the "cast arm with guard"

– from guard on the inboard side to

guard on the outboard side

The "cast arm with guard" is mounted on the inboard

side by the manufacturer.

The "cast arm with guard" can also be mounted on

the outboard side depending on requirements.

Assembly on the inboard side is recommended for

better balance.

. Remove the abrasive wheel

Remove water attachment

3

1

2

1

Remove the adjusting lever

2

3

1

370TI022 KN

. Loosen the banjo bolt (1) with the combination

wrench and remove it together with the seal – in

the process, remove the square nut from the

guide on the inside of the guard

. Remove bolt (2)

. Turn the adjusting lever (3) upwards and

remove

Slacken the V-belt

. Loosen the banjo bolt (1) with the combination

wrench – in the process, remove the square nut

from the guide on the inside of the guard

. Remove the water hose (2) with connector from

the adjusting lever (3)

. Remove the water hose (2) from the

guide (arrows) in the V-belt guard

370TI021 KN

2

1

1

. Loosen the nuts (1) – do not remove them

. Turn the tensioning nut (2) counterclockwise

with the combination wrench – approx. 1/4 turn,

max. to stop = 0

1

0

370TI023 KN

TI_35_2009_30_01_01.fm

Page 5

Technical Information 35.2009 Page 5

Remove the V-belt guard

2

1

. Loosen screw (1) – in machines with the new

belt guard (see b 2), the screw is secured on

the belt guard to prevent loss

. Raise the V-belt guard (2) slightly and pull off

towards front

4

370TI024 KN

Remove the "cast arm with guard"

3

1

2

1

. Remove the nuts (1)

. Remove the "starter cover with rewind

starter" (2)

. Remove the "cast arm with guard" (3) from the

studs

1

370TI026 KN

3

. Remove the V-belt (3) from the front pulley (4)

Preparing the "cast arm with guard" for

outboard mounting

370TI025 KN

1

370TI027 KN

. Remove stop pin (1)

TI_35_2009_30_01_01.fm

Page 6

Page 6 Technical Information 35.2009

Mount "cast arm with guard" – guard on the

outboard side

A

1

4 5

. Turn the guard so that it is in the position shown

(see picture)

. Install and tighten the stop pin (1)

. Move the adjusting lever (2) to position (A)

. Install the bolt (3) and tighten

. Loosen the bolt (4) of the limit stop (5)

. Remove the limit stop (5)

3 2

6

370TI028 KN

1

2

1

2

4

. Position the oblong holes (1) in the "cast arm

and guard" onto to the studs (2), install the

ribbed V-belt over the front pulley

. Check that the belt adjustment moves easily

. The belt tensioner (3) must nest against the

lug (4)

1

2

3

2

370TI030 KN

4

5

. Turn the "cast arm with guard" so that the guard

is on the outboard side

. Insert limit stop (5) – align the hole in the limit

stop with the hole in the cast arm

. Install the screw (4) and tighten

. Insert the square nut into the guide of the guard

and hold in place

. Install the shorter banjo bolt (6) and washer at

the adjusting lever and tighten with the

combination wrench

370TI029 KN

2

5

6

. Fit the "starter cover with rewind starter" (5) over

the studs (2)

. Tighten the nuts (6) by hand

2

6

6

370TI031 KN

TI_35_2009_30_01_01.fm

Page 7

Technical Information 35.2009 Page 7

Check the adjustment range of the guard

7

8

370TI032 KN

. Push the V-belt guard (7) into place

. Install and tighten screw (8) – in machines with

the new belt guard (see b 2), the screw is

secured on the belt guard to prevent loss

Connect water connection

3

1

2

1

. Insert the longer banjo bolt (1) through the

connector (2) of the water attachment – observe

the position of the connector

. Insert the square nut into the guide of the guard

and hold in place

A

370TI034 KN

. Rotate the guard forwards and backwards as far

as possible – adjustment range (A) must be

limited by the stop pin

370TI033 KN

. Install the support with the longer banjo bolt onto

the adjusting lever (3) – install the banjo bolt and

tighten with the combination wrench

. Insert the water hose into the guide in the V-belt

guard (arrow) from the shut-off cock towards the

guard – avoid tight radiuses

. Tension the ribbed V-belt

TI_35_2009_30_01_01.fm

Page 8

Page 8 Technical Information 35.2009

1.8 Reconfiguring the "cast arm with guard"

– from guard on the outboard side to

guard on the inboard side

. Remove the abrasive wheel

. Remove water attachment

. Remove the adjusting lever

. Slacken the V-belt

3

. Remove the V-belt guard

. Remove the V-belt

. Remove the "cast arm with guard"

Preparing the "cast arm with guard" for inboard

mounting

1 2

. Loosen the bolt (1) of the limit stop (2)

. Remove the limit stop (2)

370TI037 KN

. Turn the guard so that it is in the position shown

(see picture)

. Install and tighten the stop pin (3)

. Install the adjusting lever

. Mount "cast arm with guard" – guard on the

inboard side

. Install the V-belt

. Install the V-belt guard

. Connect water connection

. Tension the ribbed V-belt

Check the adjustment range of the guard

370TI035 KN

3

2

1

. Turn the "cast arm with guard" so that the guard

is on the inboard side

. Insert limit stop (2) – align the hole in the limit

stop with the hole in the cast arm

. Install the screw (1) and tighten

. Remove stop pin (3)

370TI036 KN

A

370TI038 KN

Rotate the guard forwards and backwards as far as

possible – adjustment range (A) must be limited by

the stop pin

TI_35_2009_30_01_01.fm

Page 9

Technical Information 35.2009 Page 9

2. Belt guard, screw

1, 2 3, 4

7567

Left: Previous versions of the belt guard

and the screw

Right: New versions of the belt guard and

the screw

The previous versions of the belt guard (1)

4238 700 8101 (TS 410) and the belt guard (2)

4238 700 8100 (TS 420) are being replaced by the

new versions of the belt guard (3) 4238 700 8107

(TS 410) and the belt guard (4) 4238 700 8109

(TS 420).

Spare parts

The previous versions of the belt guard

4238 700 8101 (TS 410) and the belt guard

4238 700 8100 (TS 420) are no longer available.

The new versions of belt guard 4238 700 8107

(TS 410) and belt guard 4238 700 8109 (TS 420)

can also be used for older machines. The previous

versions of spline screw IS-M5x30x22-10.9

(9022 341 1070) and hollow rivet

DIN7339-7.5x1x6.8 (9443 825 7130) remain

available for older machines.

3701TI072 KN

The new versions of the belt guard (3, 4) are

fastened to the cast arm with the new screw

IS-M5x21 (5) (9022 319 1027). In the versions of

the belt guard (3, 4), the new screw IS-M5x21 (5)

(9022 319 1027) is secured against loss. The

previous versions of the spline screw

IS-M5x30x22-10.9 (6) (9022 341 1070) and the

hollow rivet DIN7339-7.5x1x6.8 (7)

(9443 825 7130) are no longer needed.

Tightening torques

Belt guard / cast arm 6 Nm

TI_35_2009_30_01_01.fm

Page 10

Page 10 Technical Information 35.2009

3. Set of instruction labels

3.1 Set of instruction labels 0000 960 0100 (only for TS 410)

21

Left: Previous versions of the instruction

labels

Right: New versions of the instruction labels

TS 410 only, the previous versions of instruction

label (1) 0000 967 3521 and instruction label (2)

0000 967 3511 are being replaced by the new "set

of instruction labels" (3) 0000 960 0100.

Spare parts/service notes

The previous versions of instruction label (1)

0000 967 3521 and instruction label (2)

0000 967 3511 are no longer available. The new

"set of instruction labels" (3) 0000 960 0100 can

also be used with older STIHL Cutquik

off machines.

Always attach both instruction labels in the new "set

of instruction labels" (3) 0000 960 0100.

3

®

TS 410 cut-

3701TI073 KN

3.2 Set of instruction labels 0000 960 0101 (only for TS 420)

21

3

Left: Previous versions of the instruction

labels

Right: New versions of the instruction labels

TS 420 only, the previous versions of instruction

label (1) 0000 967 3521 and instruction label (2)

0000 967 3520 are being replaced by the new "set

of instruction labels" (3) 0000 960 0101.

Spare parts/service notes

The previous versions of instruction label (1)

0000 967 3521 and instruction label (2)

0000 967 3520 are no longer available. The new

"set of instruction labels" (3) 0000 960 0101 can

also be used with older STIHL Cutquik

®

TS 420 cut-

off machines.

Always attach both instruction labels in the new "set

of instruction labels" (3) 0000 960 0101.

3701TI073 KN

TI_35_2009_30_01_01.fm

Page 11

Technical Information 35.2009 Page 11

4. Summary

Item Part Name Previous New Rem.

1 Cast arm (TS 410) 4238 701 0201 4238 701 0203 1) 2)

2 Cast arm (TS 420) 4238 701 0200 4238 701 0202 1) 2)

3 Guard dia. 300 mm (12") (TS 410) 4238 700 8102 4238 700 8105 3) 4)

4 Guard dia. 350 mm (14") (TS 420) 4224 700 8102 4224 700 8108 3) 4)

5 Stop pin - - - 4224 691 0100

6 Limit stop - - - 4238 691 0200

7 Pan head self-tapping screw IS-P4x16 - - - 9074 478 3025

8 Rubber buffer 4224 790 9300 - - - 3)

9 Spline screw IS-M5x6-10.9 9022 341 0910 - - - 3)

10 Belt guard (TS 410);

including Item 14

11 Belt guard (TS 410);

including Item 16

12 Belt guard (TS 420);

including Item 14

13 Belt guard (TS 420);

including Item 16

14 Hollow rivet DIN7339-7.5x1x6.8 9443 825 7130 - - - 3)

15 Spline screw IS-M5x30x22-10.9 9022 341 1070 - - - 3)

16 Screw IS-M5x21 - - - 9022 319 1027

17 Instruction label (TS 410) 0000 967 3511 - - - 1) 4) 5)

18 Set of instruction labels (TS 410) - - - 0000 960 0100 2) 4)

19 Instruction label (TS 420) 0000 967 3520 - - - 1) 4) 6)

20 Set of instruction labels (TS 420) - - - 0000 960 0101 2) 4)

21 Instruction label (TS 410, TS 420) 0000 967 3521 - - - 1) 4) 7)

4238 700 8101 - - - 1)

- - - 4238 700 8107 2)

4238 700 8100 - - - 1)

- - - 4238 700 8109 2)

Modification to be introduced : continuously

Remarks

1) Previous version of part no longer available from factory

2) New version of part can also be used for older machines

3) Previous version of part remains available for older machines

4) See "Service notes"

5) Previous version of part is replaced by Item 18

6) Previous version of part is replaced by Item 20

7) Previous version of part is replaced by Item 18 in the TS 410 and by Item 20 in the TS 420

© ANDREAS STIHL AG & Co. KG, 2009 Technical Documentation

D1/MTK-fr

TI_35_2009_30_01_01.fm

Loading...

Loading...