STIHL Cut-off-Machine Owner's Manual

Working safely with cut-off machines

{

Warning!

Read and follow all safety precautions in

Instruction Manual – improper use can cause

serious or fatal injury.

Contents

English

Safety Precautions and Working

Techniques 2

Sample applications 15

Cutting wheels 18

Composite resin cutting wheels 18

Diamond cutting wheels 18

Maintenance and Care 22

Main Parts 24

Original Instruction ManualPrinted on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

This manual contains the safety

precautions and recommended cutting

techniques outlined in STIHL instruction

manuals for gasoline-powered cut-off

machines. Even if you are an

experienced cut-off machine user, it is in

your own interest to familiarize yourself

with the latest instructions and safety

precautions regarding your cut-off

machine.

Please note that the illustrations in the

chapter "Main Parts of the Machine" in

this manual show the cut-off machine

STIHL Cutquik

®

TS 420.

Other cut-off machine models may have

different parts and controls. You should

therefore always refer to the instruction

manual of your particular cut-off

machine model.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

{

© ANDREAS STIHL AG & Co. KG, 2010

0457-186-3021. M0.B10.xxx.

0000000552_001_GB

Working safely with cut-off machines

1

English

Safety Precautions and

Working Techniques

The use of any cut-off

machine may be hazardous. Because a cut-off

machine is a high-speed,

fast-cutting power tool,

special safety precautions must be observed to

reduce the risk of personal injury and fire.

It is important that you

read, fully understand

and observe the following

safety precautions and

warnings. Read the

instruction manual and

the safety precautions

periodically.

Warning!

Careless or improper use of any cut-off

machine may cause serious or fatal

injury.

Have your STIHL dealer show you how

to operate your cut-off machine.

Observe all applicable national, state

and local safety regulations, standards

and ordinances.

Warning!

Your cut-off machine is for professional

use only. Do not lend or rent your cut-off

machine without the instruction manual.

Be sure that anyone using it understands the information contained in this

manual.

A first-time operator should obtain

practical instruction before using the

machine. Employers should establish a

training program for operators of

gasoline-powered, hand-held portable

cut-off machines to assure safe

operation of these machines. These

safety precautions and warnings apply

to the use of all current STIHL Cutquiks.

Warning!

Use your cut-off machine only for

authorized uses. For instance, it is not

suitable for cutting wood or wooden

objects. Misuse may result in personal

injury or property damage, including

damage to the machine.

Warning!

Minors should never be allowed to use a

cut-off machine. Bystanders, especially

children, and animals should not be

allowed in the area where a cut-off

machine is in use. Never let the cut-off

machine run unattended.

Different models may have different

parts and controls. See the appropriate

section of your instruction manual for a

description of the controls and function

of the parts of your model cut-off

machine.

Safe use of a cut-off machine involves

1. the operator

2. the power tool

3. the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate a

cut-off machine when you are fatigued.

Be alert – if you get tired while operating

your cut-off machine, take a break;

tiredness may result in loss of control.

Working with any cut-off machine can be

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating

a cut-off machine.

Warning!

Prolonged use of cut-off machines (or

other machines) exposing the operator

to vibrations may produce whitefinger

disease (Raynaud's phenomenon) or

carpal tunnel syndrome. These conditions reduce the hand's ability to feel

and regulate temperature, produce

numbness and burning sensations and

cause nerve and circulation damage

and tissue necrosis. All factors which

contribute to whitefinger disease are not

known, but cold weather, smoking and

diseases or physical conditions that

affect blood vessels and blood transport, as well as high vibration levels and

long periods of exposure to vibration are

mentioned as factors in the development of whitefinger disease. In order to

reduce the risk of whitefinger disease

and carpal tunnel syndrome, please

note the following:

2

Working safely with cut-off machines

English

– STIHL cut-off machines are

equipped with an anti-vibration

("AV") system designed to reduce

the transmission of vibrations

created by the machine to the

operator's hands. An AV system is

recommended for those persons

using cut-off machines on a regular

or sustained basis.

– Wear gloves and keep your hands

warm.

– Keep the AV system well

maintained. A cut-off machine with

loose components or with damaged

or worn AV elements will tend to

have higher vibration levels.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

All the above-mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore, continual and

regular users should monitor closely the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

Warning!

The ignition system of your unit produces an electromagnetic field of a very

low intensity. This field may interfere

with some pacemakers. To reduce the

risk of serious or fatal injury, persons

with a pacemaker should consult their

physician and the pacemaker manufacturer before operating this tool.

Proper Clothing

Warning!

To reduce the risk of

injury, the operator

should wear proper protective apparel.

Clothing must be sturdy and snug-fitting,

but allow complete freedom of

movement. Avoid loose-fitting jackets,

scarfs, neckties, jewelry, flared or cuffed

pants, unconfined long hair or anything

that could become caught on any

obstacles or moving parts of the unit.

Wear overalls or long pants to protect

your legs. Do not wear shorts.

Warning!

When cutting metal, a cut-off machine

generates sparks that can ignite clothing. Most fabrics used in clothing are

flammable – even flame-retardant fabrics will ignite at higher temperatures.

To reduce the risk of burn injury STIHL

recommends wearing clothing made of

leather, wool, flame-retardant-treated

cotton or a tightly woven, heavier cotton

such as denim. Some flame-retardant

synthetic fabrics are also suitable, but

others such as polyester, nylon, rayon

and acetate can melt during a fire into a

tar-like matter that burns into the skin.

Check the clothing manufacturer's

instructions. Keep clothing free of oil,

fuel, grease and other flammable

substances.

Always wear gloves

when handling the cut-off

machine. Heavy-duty,

nonslip gloves improve

your grip and help to protect your hands.

Good footing is important

in cut-off machine work.

Wear sturdy boots with

nonslip soles. Steel-toed

safety boots are

recommended.

Warning!

Loose objects may be thrown toward

the operator by the cutting tool.

To reduce the risk of

injury to your eyes never

operate a cut-off machine

unless wearing goggles

or properly fitted safety

glasses with adequate

top and side protection

complying with

ANSI Z 87.1. Proper eye

protection is a must.

Wear an approved safety hard hat to

protect your head. Cut-off machine

noise may damage your hearing. Always

wear sound barriers (ear plugs or ear

mufflers) to help protect your hearing.

Regular users should have their hearing

checked regularly.

Working safely with cut-off machines

3

English

Warning!

When wet cutting at the

recommended flow rate

is not utilized, the operator should always wear

a respirator approved

by NIOSH / MSHA for

the material being cut to reduce the risk

of serious or fatal respiratory illness. For

additional details and warnings on this

subject, see information under "Working

Conditions" in this instruction manual.

THE POWER TOOL

For illustrations and definitions of the

parts of the cut-off machine, see the

chapter "Main Parts."

Warning!

Never modify a cut-off machine in any

way. Only attachments supplied by

STIHL or expressly approved by STIHL

for use with the specific STIHL cut-off

machine models are authorized.

Although certain unauthorized attachments are useable with the STIHL

powerhead, their use may, in fact, be

extremely dangerous.

Abrasive Wheels

Warning!

Before mounting the cutting wheel,

make sure that the maximum operating

wheel speed is above or equal to the

spindle speed of your cut-off machine

as provided in the specifications of this

manual. A wheel that is not so rated

may shatter or break and poses a threat

of serious or fatal injury to the operator

and other nearby persons.

Abrasive wheels for free-hand cutting

are subjected to particularly high

bending and compression stresses.

Warning!

Unauthorized wheels may be more

likely to shatter or break. Use only

STIHL wheels or other authorized

wheels with approved RPM ratings.

Read and follow any addional safety

precautions that accompany the wheel.

Warning!

Inspect the abrasive

wheel frequently and

replace immediately if

the abrasive wheel is

cracked or warped.

Cracked or warped

wheels may shatter or break and cause

serious or fatal personal injury. Out-ofround or unbalanced abrasive wheels

increase vibration and reduce the service life of the cut-off machine.

Unauthorized diamond abrasive wheels

that utilize poor quality steel cores, that

are not properly tensioned, or that have

other design or manufacturing defects

may begin to wobble during use, which

can cause wheel breakage. Such

wobbling can also lead to a severe

binding of the wheel in the kerf, that,

under certain circumstances, can then

result in serious or fatal injury from

reactive forces. See the section entitled

"Reactive Forces including Kickback."

Never use a wheel that wobbles or that

has ever wobbled. Even though such a

wheel may temporarily cease to wobble,

e.g., if run without load, it will always be

prone to wobble again under certain

conditions. Replace it immediately

before further use.

Composite abrasive wheels are heat

sensitive. Always store your cut-off

machine in a place where a composite

wheel is not exposed to direct sunlight or

other sources of heat. Store spare

composite wheels in a dry place where

there is no risk of frost damage. Failure

to follow these directions may cause the

wheel to shatter or crack in use causing

serious or fatal injury.

Warning!

Never use circular saw

blades, carbide tipped

blades, rescue blades,

wood-cutting blades or

toothed blades of any

nature. They can cause

severe personal injury from blade contact, thrown objects and / or reactive

forces, including kickback. See section

on "Reactive Forces." Your STIHL

dealer stocks a range of special abrasive wheels for the many applications of

the cut-off machine.

4

Working safely with cut-off machines

English

Warning!

Use of the wrong abrasive wheel or the

cutting of material for which the wheel

was not designed may cause the wheel

to shatter causing serious or fatal injury.

Only use the abrasive wheel approved

for the type of material to be cut. There

are different types of abrasive wheels,

each specially marked. With respect to

composite wheels, for example:

1. Stone

Also can be used for concrete,

masonry, reinforced concrete and

brick cutting.

2. Steel

Can be used for all ferrous metal

cutting.

3. Asphalt

Also can be used for aggregate

concrete cutting.

4. Ductile iron

Also can be used for certain grades

of cast iron (SG 17-24), bronze and

copper cutting.

For cutting composite materials please

ask your STIHL dealer.

They are not normally suitable for cutting

metal or other materials.

Wet or dry cutting is possible. Water

attachments are included with your

STIHL cut-off machine. See the

appropriate section of your instruction

manual.

Warning!

Do not remount a used diamond abrasive wheel without first inspecting for

under-cutting, flatness, core fatigue,

segment damage or loss, signs of overheating (discoloration) and possible

arbor hole damage. See the chapter

"Diamond Cutting Wheels." Check the

wheel for cracks and make sure that no

pieces have broken off the wheel before

use.

Always fit the wheel so that the arrow on

the wheel points in the direction of the

rotation of the spindle.

THE USE OF THE POWER TOOL

Transporting the STIHL Cutquik

Warning!

To reduce the risk of injury from unintended activation and / or contact with a

moving wheel, always stop the engine

before putting a cut-off machine down or

carrying it. The abrasive wheel continues to rotate (coast down) for a short

while after the throttle trigger is released

(flywheel effect). Bring the wheel to a

stop by lightly contacting the bottom of

the wheel with a hard surface or wait

until the wheel comes to a complete

stop on its own. Carrying a cut-off

machine with the engine running is

extremely dangerous. Accidental acceleration of the engine can cause the

wheel to rotate. Avoid touching the hot

muffler.

By hand: When carrying your cut-off

machine by hand, the engine must be

stopped and the cut-off machine must

be in the proper position. Grip the front

handle and place the muffler at the side

away from the body.

Diamond Abrasive Wheels

Diamond abrasive wheels have a much

better cutting performance than

composite abrasive wheels. The

diamond wheels are steel centered, and

diamond particles are imbedded in their

cutting edges.

They can be used for concrete, asphalt,

natural stone, clay pipe, brick and the

like.

Working safely with cut-off machines

Warning!

Always protect the cutting wheel from

hitting the ground or any other objects.

Damaged wheels may shatter and

cause serious or fatal injury.

By vehicle: Properly secure your cut-off

machine to prevent turnover, fuel

spillage and damage to the cut-off

machine. Never transport with cutting

wheel mounted. A wheel damaged

5

English

during transportation may shatter during

operation and cause serious personal

injury.

Fuel

Your STIHL power tool uses an oilgasoline mixture for fuel (see the

chapter on "Fuel" of your instruction

manual.)

Warning!

Gasoline is an extremely

flammable fuel. If spilled

and ignited by a spark or

other ignition source, it

can cause fire and seri-

ous burn injury or

property damage. Use extreme caution

when handling gasoline or fuel mix. Do

not smoke or bring any fire or flame near

the fuel or the power tool. Note that

combustible fuel vapor may escape

from the fuel system.

Warning!

Dust may collect on the powerhead,

especially around the carburetor, and

may absorb gasoline resulting in danger

of fire. Clean dust from the powerhead

regularly.

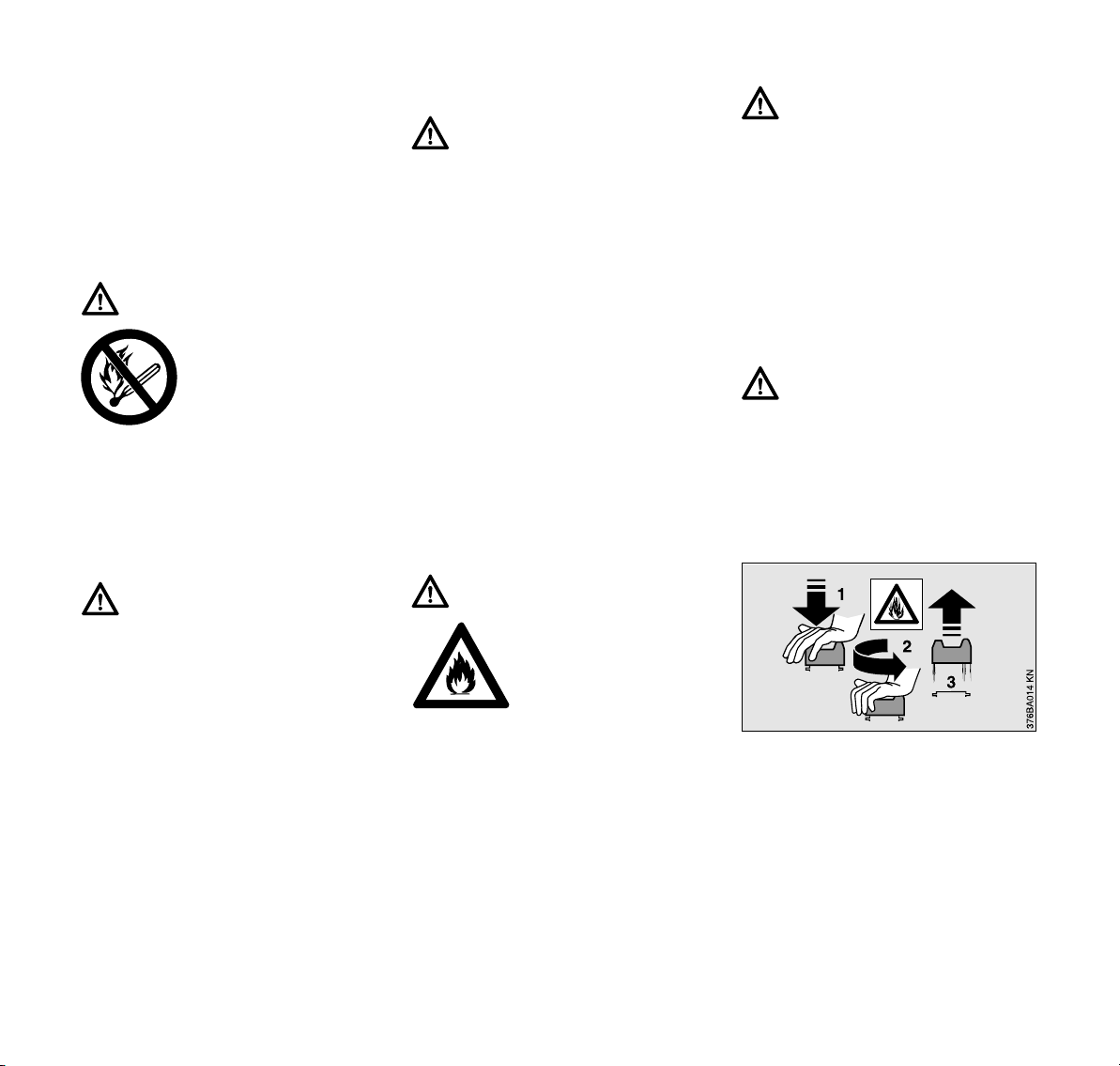

Fueling Instructions

Warning!

Fuel your power tool in well-ventilated

areas, outdoors. Always shut off the

engine and allow it to cool before refueling. Gasoline vapor pressure may

build up inside the fuel tank depending

on the fuel used, the weather conditions

and the tank venting system.

In order to reduce the risk of burns and

other personal injury from escaping gas

vapor and fumes, remove the fuel filler

cap on your power tool carefully so as to

allow any pressure build-up in the tank

to release slowly. Never remove the fuel

filler cap while the engine is running.

Select bare ground for fueling and move

at least 10 feet (3 m) from the fueling

spot before starting the engine. Wipe off

any spilled fuel before starting your

machine.

Warning!

Check for fuel leakage

while refueling and during operation. If fuel

leakage is found, do not

start or run the engine

until the leak is fixed and

any spilled fuel has been wiped away.

Take care not to get fuel on your clothing. If this happens, change your

clothing immediately.

Warning!

If fuel gets spilled on clothes, especially

trousers, it is very important to change

clothes immediately. Do not rely upon

evaporation. Flammable quantities of

fuel may remain on clothes after a spill

for longer than expected. Cutting metal

with a cut-off machine when clothes are

wet or damp from gasoline is extremely

dangerous, as the operator's clothes

might catch fire and cause serious or

fatal injury.

Warning!

An improperly tightened fuel cap can

loosen or come off and spill quantities of

fuel.

Different cut-off machines may be

equipped with different fuel filler caps:

Bayonet Fuel Filler Cap

Never use a tool to open or close the

bayonet fuel filler cap, as this could

damage the cap and cause fuel to leak

out.

The bayonet fuel filler cap must be

closed with care after refuelling.

6

Working safely with cut-off machines

English

Fuel Filler Cap with Screw Thread

Tighten the fuel filler cap

as securely as possible

after refuelling.

This reduces the risk of the cap working

loose due to engine vibrations and fuel

leaking out.

Warning!

Never attempt to force the cap open by

using a tool. It may damage the cap and

allow fuel to leak.

Before use, make sure that the fuel cap

has been properly tightened and any

spilled fuel wiped away. Check for fuel

leakage while refueling and during

operation. If a fuel leak is suspected, do

not start or run the engine until the leak

is fixed and spilled fuel has been wiped

away.

Before Starting

For assembly, follow the procedure

described in the appropriate section of

your instruction manual.

Never operate a cut-off machine that is

damaged, improperly adjusted or not

completely and securely assembled.

Check machine that it is ready for proper

operation.

Keep the handles dry, clean and free of

oil and fuel.

Warning!

Before operation of your cut-off

machine, be sure the controls (e.g.

throttle trigger, throttle trigger lockout,

stop switch) and the safety devices are

working properly, the carburetor idle

and maximum speed are correctly

adjusted, the wheel is properly

mounted, and the wheel guard is in

place and securely fastened to your

unit. All wheels should be carefully

inspected for good condition before

mounting.

Adjust the wheel guard

so that sparks, dust and

cut material are deflected

away from the operator,

and cannot reach flammable surroundings. See

section "Operating

Instructions" of your

instruction manual.

Warning!

Check that the spark plug boot is

securely mounted on the spark plug – a

loose boot may cause arcing that could

ignite combustible fumes and cause a

fire.

Proper tensioning of the ribbed V-belt is

important. In order to avoid an incorrect

setting, the tensioning procedure must

be followed as described in your

manual. Always make sure the

hexagonal collar nuts for the cast arm

are tightened securely.

Check ribbed belt tension after one hour

of operation and correct if necessary.

Starting

002BA058 KN

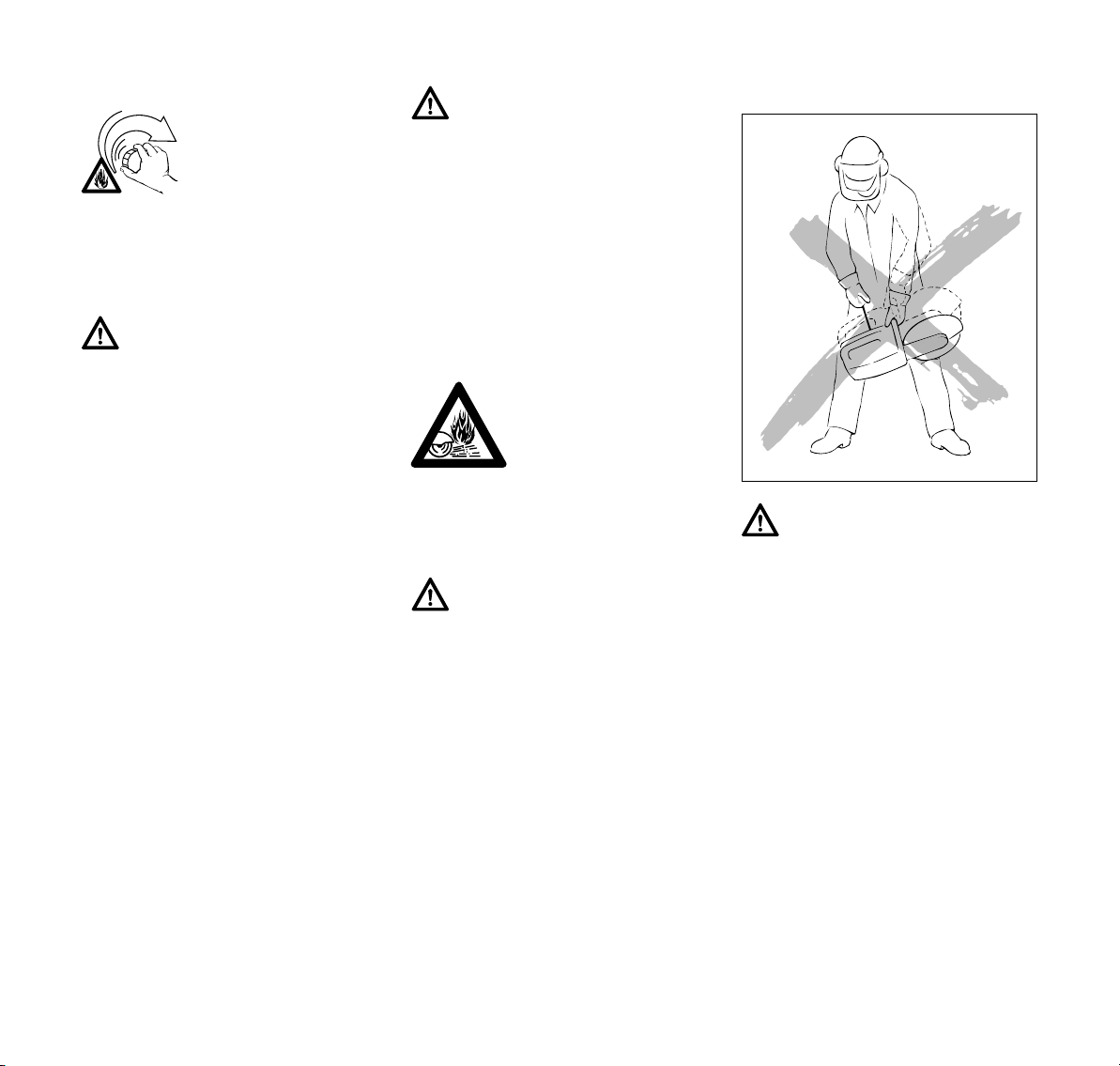

Warning!

Your cut-off machine is a one-person

tool. Do not allow other persons to be

near a running cut-off machine. Start

and operate your cut-off machine without assistance. For specific starting

instructions, see the appropriate section

of your instruction manual.

Do not drop start. This method is very

dangerous because you may lose

control of the cut-off machine. Place the

cut-off machine on firm ground or other

solid surface in an open area. Maintain

good balance and secure footing. Be

absolutely sure that the cutting wheel is

clear of you and all other obstructions

and objects, including the ground. When

the engine starts at starting-throttle,

engine speed will be fast enough for the

clutch to engage the belt pulley and turn

Working safely with cut-off machines

7

Loading...

Loading...