Page 1

STIHL BR 45

Instruction Manual

Owner's Manual

-

-..

..

fP

-

.

.

Page 2

Contents

english / USA

Guide to Using this Manual .............. 2

Safety Precautions ........................... 3

Assembling the Blower ................... 10

Fitting Backpack ............................. 13

Fuel ................................................ 14

Fueling ............................................ 15

Starting / Stopping

the Engine ...................................... 15

Operating Instructions .................... 18

Printing inks contain vegetable oils;

paper can be recycled.

Using the Blower ............................ 19

Cleaning the Air Filter ..................... 20

Motor Management ........................ 20

Adjusting the Carburetor ................ 21

Catalytic Converter* ........................ 22

Checking the Spark Plug ................ 22

Engine Running Behavior ............... 23

Rewind Starter ................................ 24

Storing the Machine ........................ 24

Maintenance Chart ......................... 25

Main Parts and Controls ................. 26

Specifications ................................. 28

Maintenance and Repairs ............... 28

STIHL Incorporated Federal and

California Emission Control

Printed on chlorine-free paper.© 2002 Andreas Stihl AG & Co., Waiblingen

Warranty Statement ........................ 29

Allow only persons who understand this

Manual to operate your blower.

To receive maximum performance and

satisfaction from your STIHL blower, it is

important that you read and understand

the maintenance and safety precautions,

starting on page 3, before using your

blower.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

Manual.

!Warning!

Because a blower is a high-speed tool,

some special safety precautions must

be observed as with any other power

tool to reduce the risk of personal injury.

Careless or improper use may cause

serious or even fatal injury.

STIHL's philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time-to-time. If the

operating characteristics or the

appearance of your blower differs from

those described in this Manual, please

contact your STIHL dealer for

informations and assistance.

* see “Guide to Using this Manual”

STIHl

0458 374 8621. M2,5. G2. PM. Printed in USA

1BR 45

Page 3

english / USA

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

The operating and handling instructions

are supported by illustrations.

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

: Step or procedure without direct

reference to an illustration.

Description of step or procedure that

refers directly to the illustration and

contains item numbers that appear in

the illustration.

Example:

Loosen the screw (1)

Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Warning where there is a risk of

damaging the machine or individual

components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s understanding of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual refers to

several models with different

features. Components that are not

installed in all models and related

applications are marked thus

Such components are available as

special accessories from your

STIHL dealer.

*.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore, we cannot be responsible for

changes, modifications or

improvements not covered in this

manual.

2

BR 45

Page 4

Safety Precautions

english / USA

Warning!

The use of any blower

may be dangerous. It is

important that you read,

fully understand and

observe the following safety

precautions.

!Warning!

Reread the owner`s

manual and the safety

instructions peri-

odically.

!Warning!

Careless or improper use of the machine

may cause serious injury. Have your

STIHL Dealer show you how to operate

your blower. Observe all applicable

local safety regulations, standards and

ordinances.

!Warning!

Minors should never be allowed to use a

blower. Bystanders, especially children,

and animals should not be allowed in the

area where a machine is in use.

Never let the unit run unattended. Do not

lend or rent your machine without the

owner`s manual.

Be sure that anyone using your unit

understands the information contained

in this manual.

Most of these safety precautions and

warnings apply to the use of all STIHL

blowers. Different models may have

different parts and controls.

See the appropriate section of your

owner`s manual for a description of the

controls and function of the parts of your

machine.

Safe use of a blower involves

1. the operator

2. the blower

3. the use of the blower .

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate a

blower when you are fatigued.

Be alert - if you get tired while operating

your machine, take a break. Tiredness

may result in loss of control. Working

with any blower can be strenuous. If you

have any condition that might be

aggra

vated by strenuous work, check

your doctor before operating the

with

machine.

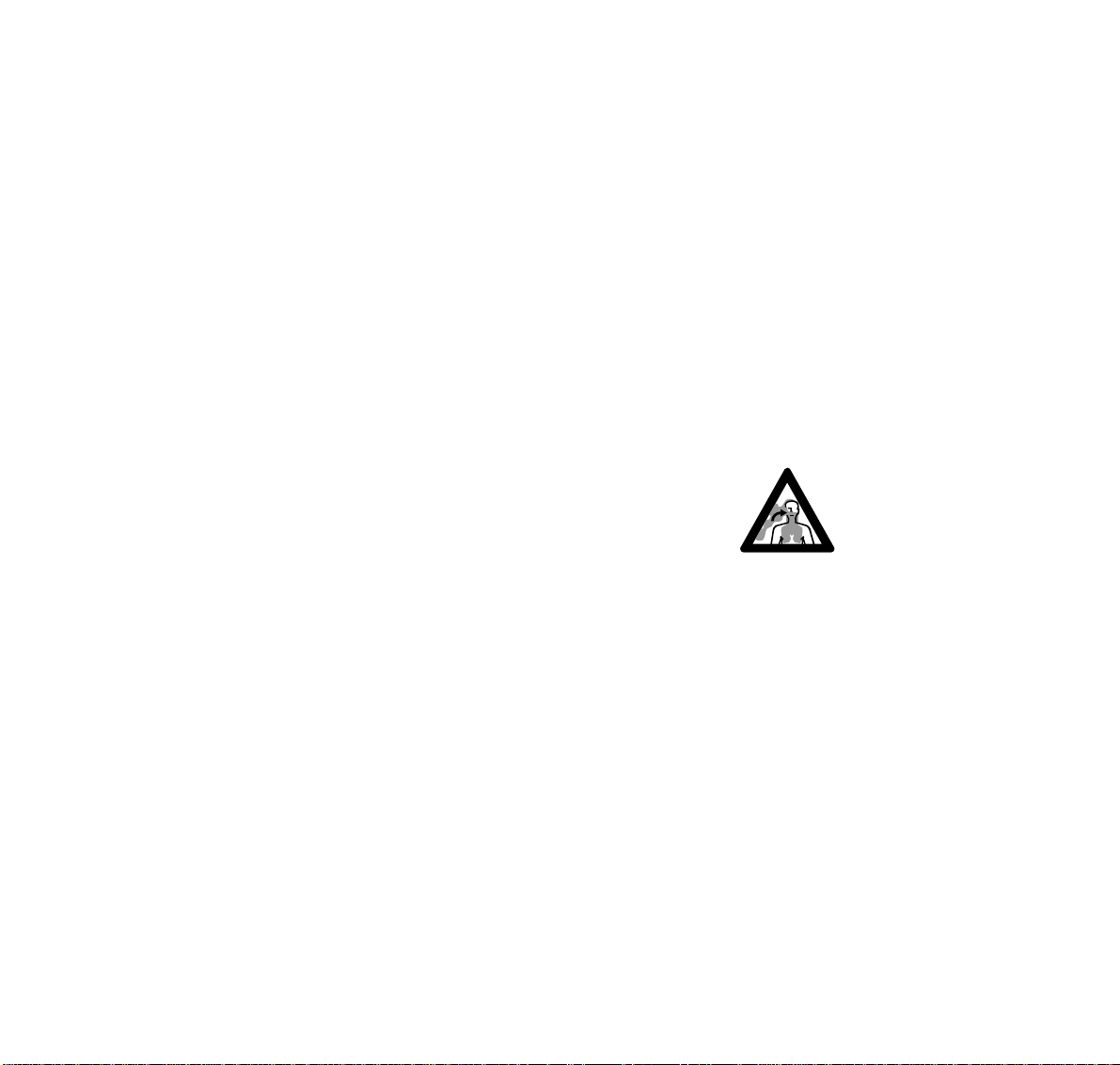

!Warning!

Prolonged use of a blower, (or other

machines) exposing the operator to

vibrations may produce whitefinger

disease (Raynaud`s phenomenon) or

carpal tunnel syndrome. These conditions reduce the hand`s ability to feel

and regulate temperature, produce

numbness and burning sensations and

may cause nerve and circulation

damage and tissue necrosis.

!Warning!

The STIHL blower is equipped with an

antivibration system (AV). The AV

system is designed to reduce the

transmission of engine vibrations to the

operator's hands. An AV system is

recommended for those operators who

use blowers on a regular or sustained

basis.

– Wear gloves and keep your hands

warm.

– Keep the AV system well

maintained. A blower with loose

components or with damaged or

worn AV buffers will tend to have

higher vibration levels.

– Maintain a firm grip at all times and,

take frequent breaks.

3BR 45

Page 5

english / USA

All the above mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore continual and

regular users should monitor closely the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

!Warning!

The ignition system of your unit

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers. To

reduce the risk of serious or fatal injury,

persons with pacemaker should consult

their physician and the pacemaker

manufacturer before operating this tool.

Proper Clothing

Clothing must be sturdy and snug-fitting,

but allow complete freedom of movement.

!Warning!

Avoid loose- fitting jackets,

flared or cuffed pants,

scarfs, unconfined long

hair or anything that could

be drawn into the air

intake.

Wear overalls or long

pants to protect your legs.

Do not wear shorts.

Use of gloves when

working with the blower is

recommended.

Good footing is most

important. Wear sturdy

shoes with nonslip soles.

!Warning!

To reduce the risk of injury associated

with the inhalation of dust, use a face

filter mask when using your blower in

dusty conditions.

!Warning!

Proper eye protection is a must. Even

though the discharge is directed away

from the operator, ricochets and bounce

backs can occur during blower

operations.

Never operate a blower

unless wearing goggles

or properly fitted safety

glasses with adequate

top and side protection

which comply with

ANSI Z 87.1 (or your applicable national

standard).

!Warning!

Blower noise may damage your hearing.

Wear sound barriers (ear plugs or ear

mufflers) to protect your hearing. Continual and regular users should have their

hearing checked regulary.

THE BLOWER

For illustrations and definitions of the

blower parts see the chapter on "Parts

and Controls"!

!Warning!

Never modify a blower in any way. Only

attachments supplied by STIHL or

expressly approved by STIHL for use

with the specific STIHL blower models

are authorized. Although certain

unauthorized attachment are useable for

the STIHL blower, their use may be

extremely dangerous.

4

BR 45

Page 6

english / USA

THE USE OF THE BLOWER

Transport

Always turn off the engine before putting

down blower. When transporting your

unit in a vehicle, properly secure it to

prevent turnover, fuel spillage and

damage to the machine.

Adjust carrying harness to suit your size

before starting work.

!Warning!

Before starting work, always inspect the

rubber buffers which connect the engine

to the pack frame. If the buffers are torn

or damaged, they should be replaced by

your STIHL dealer. Failure of one or

more buffers may cause the engine or

fuel tank to hit or rub against other parts,

and may lead to serious injury from

increased vibrations or from fire as the

result of fuel leakage.

Fueling

This STIHL unit uses an oil-gasoline

mixture for fuel (see the chapter on

"Fuel" of your owner`s manual).

!Warning!

Gasoline is an extremely

flammable fuel. If spilled

or ignited by a spark or

other ignition source, it

can cause fire and serious

burn injury or property

damage.

!Warning!

To reduce the risk of serious injury from

burns, never attempt to refuel the unit

until it has been completely removed

from the operator.

Use extreme caution when handling

gasoline or fuel mix.

Do not smoke or bring any fire or flame

near the fuel.

Fueling instructions

Fuel your machine in well-ventilated

areas, outdoors only. Always shut off the

engine and allow it to cool before

refueling. Relieve fuel tank pressure by

loosening fuel cap slowly. Never remove

fuel filler cap while engine is running.

Select bare ground for fueling and move

at least 10 feet (3 m) from the fueling

spot before starting the engine. Avoid

spilling of fuel or oil. Wipe off any spilled

fuel before starting your blower and

check for leakage.

Always tighten fuel filler cap securely

after fueling.

!Warning!

Check for fuel leakage while refueling

and during operation. If fuel or oil

leakage is found, do not start or run the

engine until leak is fixed and spilled fuel

has been wiped away. Take care not to

get fuel on your clothing. If this happens,

change your clothing immediately.

Always store gasoline in a container

approved for flammable liquids.

Different models may be equipped with

different fuel caps.

Cap with Grip

!Warning!

In order to reduce the risk of fuel spillage

and fire from an improperly tightened

fuel cap, correctly position and tighten

the fuel cap in the fuel tank opening.

To do this with this STIHL

cap, raise the grip on the

top of the cap until it is

upright at a 90° angle.

Insert the cap in the fuel

tank opening with the

triangular marks on the grip of the cap

and on the fuel tank opening lining up.

Using the grip, turn the cap firmly

clockwise as far as it will go (approx. a

quarter turn).

5BR 45

Page 7

english / USA

Fold the grip flush with the

top of the cap. If the grip

does not lie completely

flush with the cap and the

detent on the grip does

not fit in the

corresponding recess in the filler neck,

the cap is not properly seated and

tightened and you must repeat the

above steps.

Screw Cap

!Warning!

Unit vibrations can cause

an improperly tightened

fuel filler cap to loosen or

come off and spill

quantities of fuel. In order

to reduce the risk of fuel

spillage and fire, tighten the fuel filler cap

by hand with as much force as possible.

Before Starting

!Warning!

Never operate your machine if it is

damaged, improperly adjusted or not

completely and securely assembled.

You should always inspect your unit

before starting it. Make sure the unit is

properly assembled, in good operating

condition and the controls and safety

devices are working properly.

!Warning!

To reduce the risk of injury from thrown

parts, check your fanwheel and fan

housing for damage (cracks, nicks,

chipping). If any damage is found, stop

using the unit and contact your STIHL

dealer for repair.

– Throttle trigger must move freely

and spring back to idle position

when released.

– Stop switch must move easily to $

– Tightness of spark plug boot - if boot

is loose, sparks may occur and

ignite the escaping fuel vapor!

Starting

!Warning!

Your blower is a one-person machine.

To reduce the risk of eye or other injury

from thrown objects, insure that bystanders are at least 50 feet (15m) away

during use.

Stop the engine immediately if you are

approached.

For specific starting instructions, see the

appropriate section of your owner`s

manual. Place the machine on firm

ground or other solid surface in an open

area. Maintain good balance and secure

footing.

!Warning!

When you pull the starter grip, don`t

wrap the starter rope around your hand.

Do not allow the grip to snap back, but

guide the starter rope slowly back to

permit the rope to rewind properly.

Failure to follow this procedure may

result in injury to hand or fingers and

may damage the starter mechanism.

Catalytic converter

!Warning!

Some STIHL blower

models are equipped with

a catalytic converter,

which is designed to

reduce the exhaust

emissions of the engine

by a chemical process in the muffler.

Due to this process, the muffler does not

cool down as rapidly as conventional

mufflers when the engine returns to idle

or is shut off. To reduce the risk of fire

and burn injuries, the following specific

safety precautions must be observed.

6

BR 45

Page 8

english / USA

!Warning!

Since a muffler with a catalytic converter

cools down less rapidly than

conventional mufflers, always set your

backpack blower down in the upright

position and never locate it where the

muffler is near dry brush, grass, wood

chips or other combustible materials

while it is still hot. Let the engine cool

down sitting on concrete, metal, bare

ground or solid wood (e.g. the trunk of a

felled tree) away from any combustible

substances.

!Warning!

To reduce the risk of fire or burn injury,

let the unit cool down before refueling

your blower after use.

!Warning!

Never disassemble or modify your

muffler. The muffler could be damaged

and cause an increase in heat radiation

or sparks, thereby increasing the risk of

fire or burn injury. You may also

permanently damage the engine. Have

your muffler serviced and repaired by

your STIHL Servicing Dealer only.

!Warning!

To reduce the risk of fire or burn injury,

keep the area around the muffler clean.

Remove all debris such as pine needles,

branches or leaves.

!Warning!

An improperly mounted or damaged

cylinder housing or a damaged/

deformed muffler shell may interfere

with the cooling effect of the catalytic

converter. To reduce the risk of fire or

burn injury, do not continue work with a

damaged or improperly mounted

cylinder housing or a damaged/

deformed muffler shell.

Your catalytic converter is furnished with

screens designed to reduce the risk of

fire from the emission of hot particles.

Due to the heat from the catalytic

reaction, these screens will normally

stay clean and need no service or

maintenance. If you experience loss of

performance and you suspect a clogged

screen, have your muffler maintained by

a STIHL Servicing Dealer.

Working instructions

Work carefully.

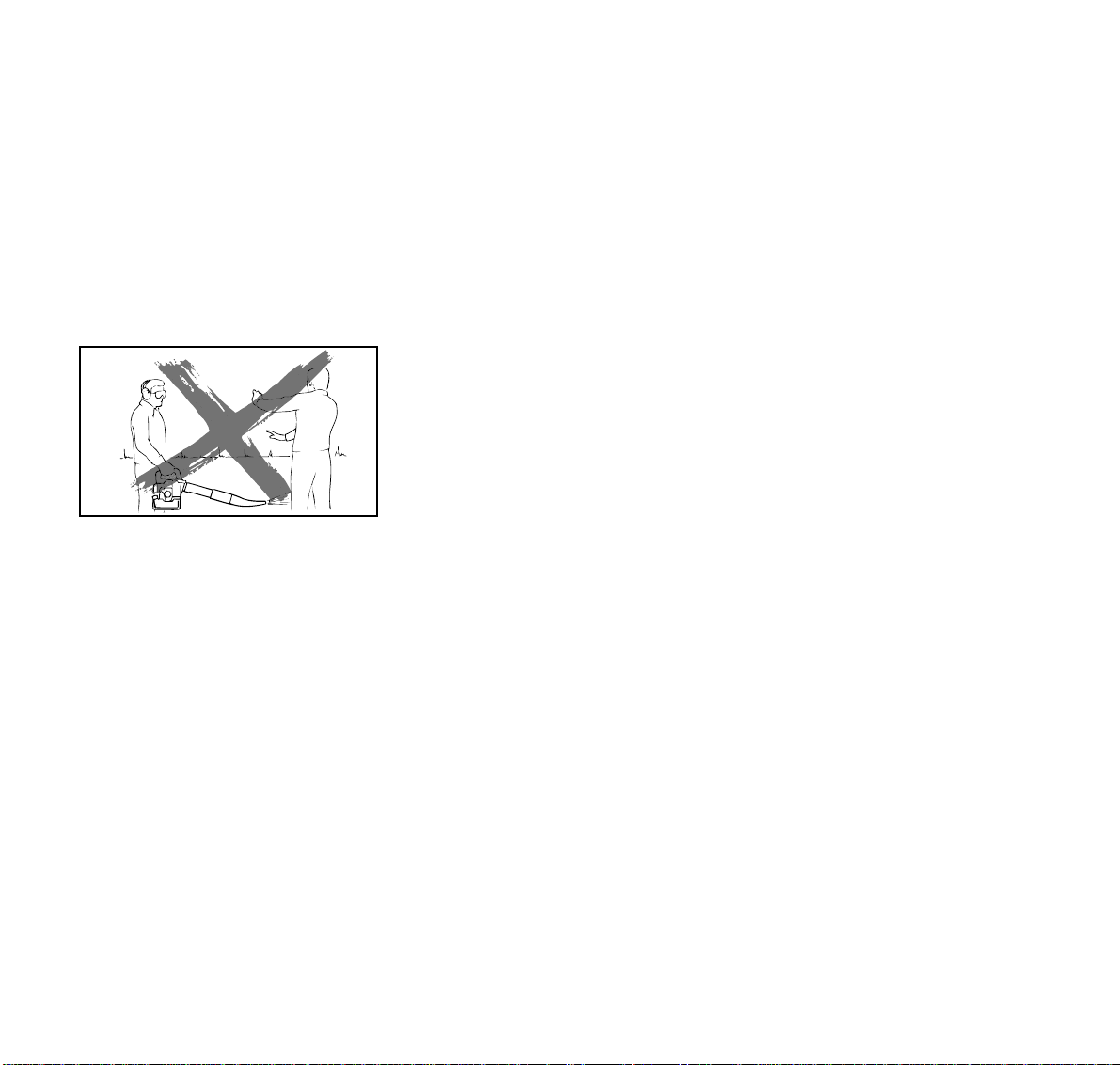

The assistance of another person may

be needed in placing the unit on your

back after starting. In order to reduce the

risk of injury to the assistant from thrown

objects or from contact with fumes, the

engine should be kept at idle speed

during this brief period, and your

assistant should not stand in the area of

the outlet nozzle or exhaust. Otherwise,

the unit should be started and operated

without assistance.

Operate the blower under good visibility

and daylight conditions only.

!Warning!

Your blower produces

poisonous exhaust fumes

as soon as the combus-

tible engine is running.

These gases (e.g. carbon

monoxide) may be colorless and odorless.

To reduce the risk of serious or fatal

injury from breathing toxic fumes, never

start or run the blower indoors or in

poorly ventilated locations. Ensure

proper ventilation when working in

trenches or other confined areas.

Keep the space behind and beside the

engine clear at all times to allow for the

escape of hot and toxic exhaust fumes.

7BR 45

Page 9

english / USA

!Warning!

Use of this product can generate dust,

mists, and fumes containing chemicals

known to cause respiratory disease,

cancer, birth defects, or other reproductive harm. If you are unfamiliar with the

risks associated with the particular dust,

mists or fumes at issue, consult your

employer, governmental agencies such

as OSHA and NIOSH and other sources

on hazardous materials. If the substance

being blown or vacuumed is a commercial substance, review the material

safety data sheet for that substance and

/ or consult the material manufacturer /

supplier. The state of California and

some other authorities, for instance,

have published lists of substances

known to cause cancer, reproductive

toxicity, etc.

Control dust, mist and fumes at the

source where possible. In this regard

use good work practices and follow the

recommendations of OSHA / NIOSH

and occupational and trade associations. When the inhalation of toxic dust,

mists and fumes cannot be eliminated,

the operator and any bystanders should

always wear a respirator approved by

NIOSH / MSHA for the substance at

issue.

!Warning!

Dust with silica in its composition may

contain crystalline silica. Silica is a basic

component of sand, quartz, brick, clay,

granite and numerous other minerals

and rocks, including masonry and concrete products. Repeated and / or substantial inhalation of airborne crystalline

silica can cause serious or fatal respiratory disease, including silicosis. In addition, the state of California and some

other authorities have listed respirable

crystalline silica as a substance known

to cause cancer. When encountering

such materials, always follow the respiratory precautions mentioned above.

!Warning!

Breathing asbestos dust is dangerous

and can cause severe or fatal injury, respiratory illness or cancer. The use and

disposal of asbestos containing

have been strictly regulated by OSHA

and the Environmental Protection

Agency. Do not blow or disturb asbestos

or asbestos containing products, such

as asbestos insulation. If you have any

reason to believe that you might be

disturbing asbestos, immediately

your employer or a local OSHA

representative.

products

contact

374BA001 KN

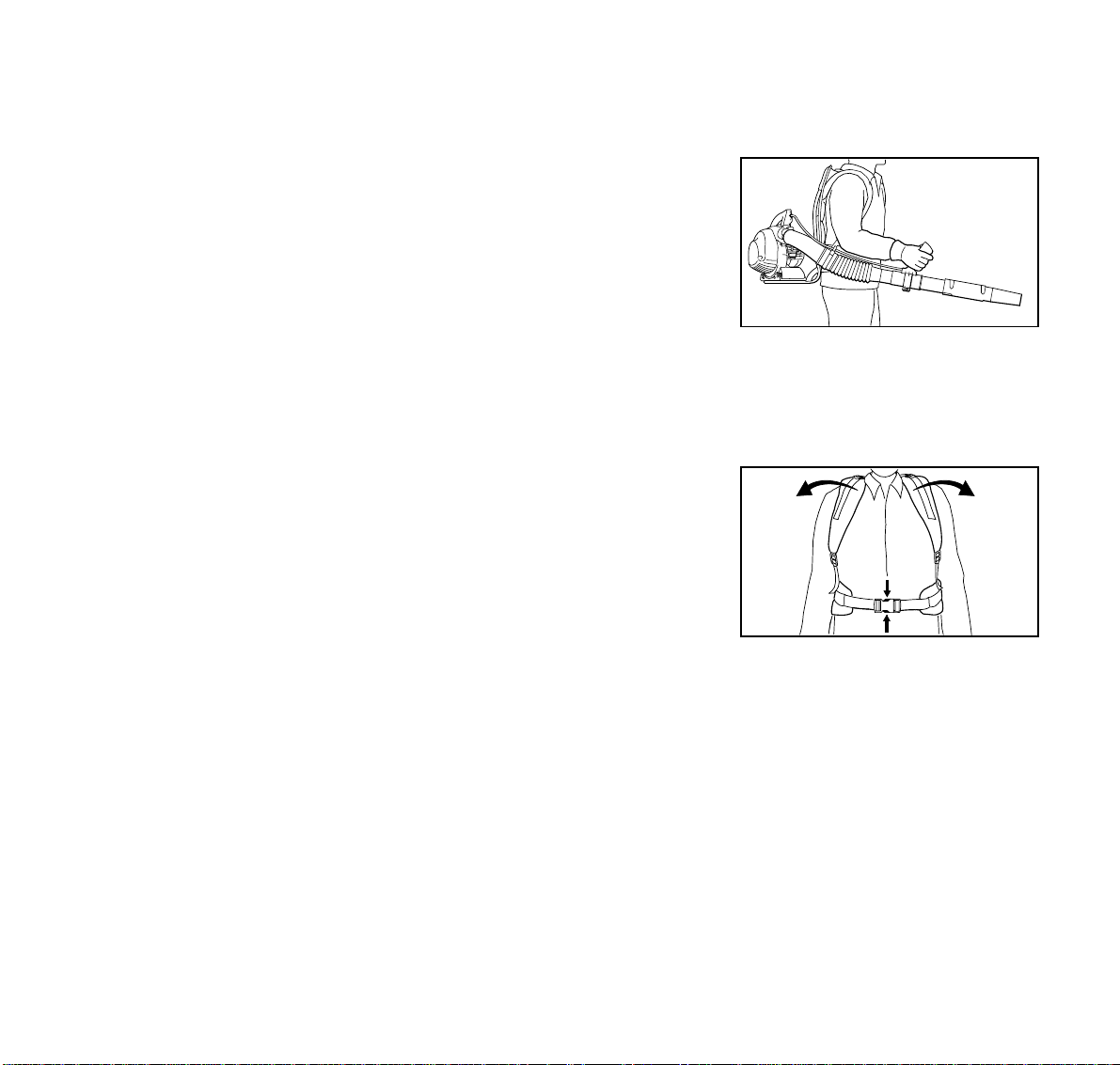

Carry the powerhead on your back.

Hold control handle firmly in your hand

and always keep the handle to the right

side of your body. Make sure you have

good balance and secure footing.

271BA003 KN

In an emergency, throw off the blower

by opening the quick-release fastener

on the waist strap and slipping out of the

shoulder straps.

Before using the blower for the first time,

practice opening the quick-release

fastener several times so that you know

how it works.

8

BR 45

Page 10

english / USA

When working with the blower, always

wrap your fingers tightly around the

handle, keeping the control handle

cradled between your thumb and

forefinger. Keep your hand in this

position to have your machine under

control at all times. Make sure your

control handle is in good condition and

free of moisture, pitch, oil or grease.

!Warning!

To reduce the risk of personal injury, do

not direct air blast towards bystanders,

since the high pressure of the air flow

could injure eyes and could blow small

objects at great speed. Do not direct air

blast towards pets.

!Warning!

Always shut off the engine before

cleaning or servicing the unit or

replacing parts. Always disconnect the

spark plug before performing

maintenance or accessing movable

parts.

The blower fan between the air intake

and output openings rotates whenever

the engine is running. In order to reduce

the risk of injury from contact with the

fan, never operate your unit without a

properly mounted intake screen and

blower tube. Never insert any foreign

object into the air intake or output

openings of the machine.

Pay attention to the direction of the wind,

i.e., do not work against the wind.

To reduce the risk of stumbling and loss

of control, do not walk backward while

operating the machine.

000 LA

A

MAINTENANCE, REPAIR AND

326B

STORING

Maintenance, replacement, or repair

of the emission control devices and

systems may be performed by any

nonroad engine repair establishment

or individual. However if you claim

warranty for a component which has

not been serviced or maintained properly or if nonapproved replacement

parts were used, STIHL may deny

warranty.

Use only identical STIHL replacement

parts for maintenance and repair.

Use of parts manufactured by others

may cause serious or fatal injury.

Follow the maintenance and repair

instructions in the appropriate section of

your owner's manual. Refer to the

maintenance chart at the last pages of

this manual.

!Warning!

Always stop the engine and make sure

that the fan is stopped before doing any

maintenance or repair work or cleaning

the blower. Do not attempt any maintenance or repair work not described in

your owner's manual. Have such work

performed at your STIHL service shop

only.

Check fuel filler cap for leaks at regular

intervals. Use the specified spark plug

and make sure it and the ignition lead

are always in good condition.

!Warning!

A worn or damaged muffler is a fire

hazard and may cause loss of hearing.

Check to see that the muffler is in good

condition. The blower must not be

ted if the muffler is not functioning properly or has been removed.

Remember that the risk of forest fires is

greater in hot weather. Use the spark

arresting muffler supplied with the unit.

Never touch a hot muffler or burn will

result.

opera-

9BR 45

Page 11

english / USA

!Warning!

In order to reduce the risk of fire, do not

modify or remove any part of the muffler

or spark arrestor.

Keep spark plug and wire connection

tight and clean. The spark plug electrode

gap should be checked with a feeler

gauge at least every 50 operating hours

and reset if necessary. Fit a new spark

plug if the electrodes are badly pitted.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of this manual.

Store blower in a dry, high or locked

location place and out of reach of

children.

Before storing for longer than a few

days, always empty the fuel tank.

Assembling the Blower

1

1

4

5

3

2

4

1

374BA002 KN

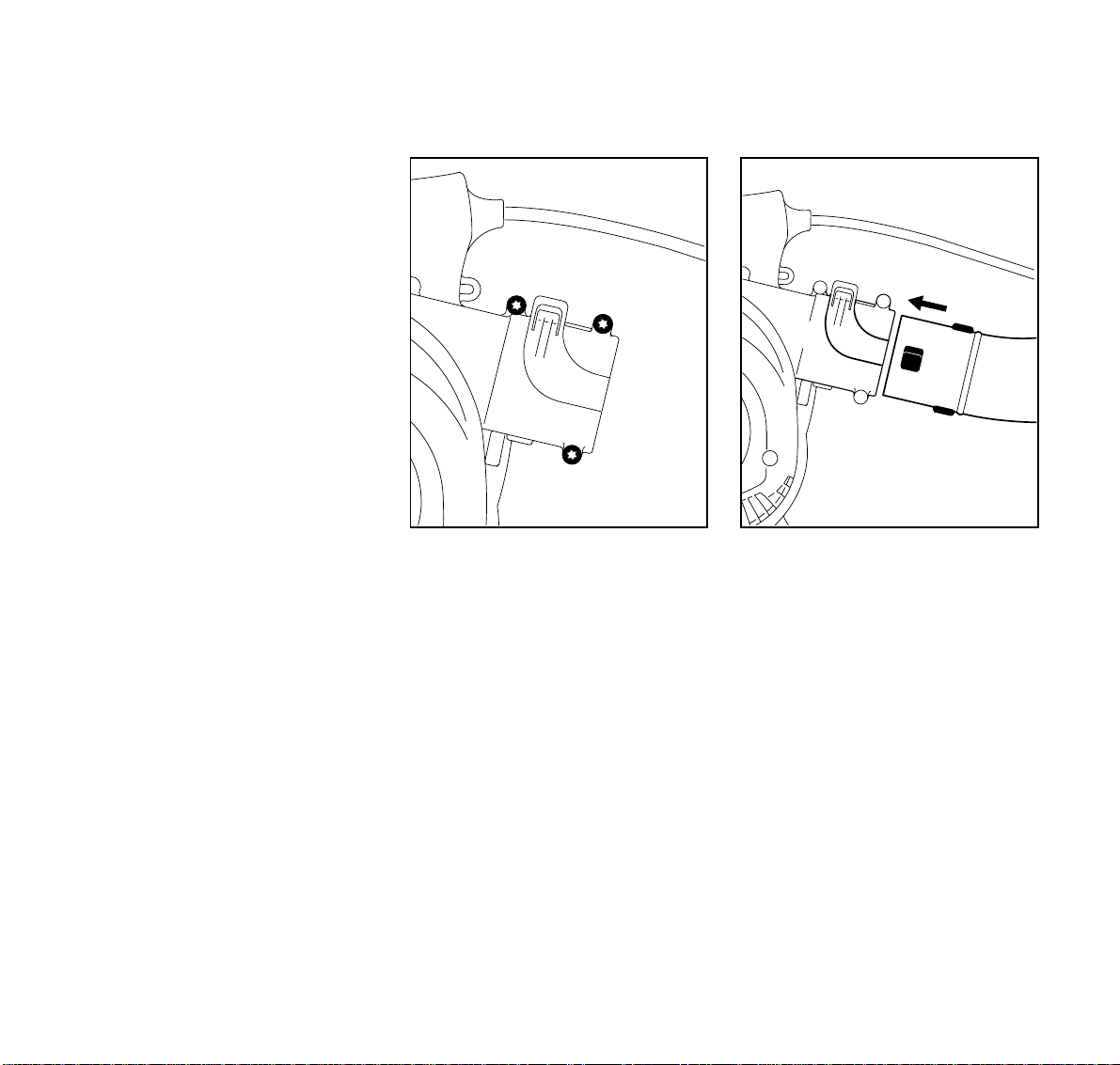

: Loosen the screws (1). : Push the elbow (2) with lug (3) into

the fan housing stub (5) as far as the

stops (4).

374BA003 KN

10

BR 45

Page 12

english / USA

8

1

1

5

4

2

1

: Rotate the elbow (2) in the direction

of the arrow (clockwise) until the

stops (4) line up with the grooves in

the fan housing stub (5) and then

push it home in the direction of the

arrow.

: Tighten the screws (1) firmly.

7

6

374BA004 KN

: Loosen the screw (6).

: Push home the blower tube (7) as

far as stop.

: Tighten the screw (6) firmly.

6

374BA005 KN

Adjusting the Control Handle

: Put the machine on your back.

: Loosen the clamp screw (6).

: Move the control handle (8) along

the tube to the most comfortable

position.

: Tighten the clamp screw (6) firmly.

374BA006 KN

11BR 45

Page 13

english / USA

11

7

: Push nozzle (9) onto the blower

tube (7) as far as pin (10), position a

(long) or position b (short), and

rotate it in the direction of the arrow

to lock in position.

10

a

b

9

374BA007 KN

Removing the Elbow

: Loosen the screws (1).

1

1

5

1

374BA002 KN

: Use a suitable tool to raise the

tab (11) on the fan housing stub (5).

Rotate the elbow in the direction of

the arrow (counterclockwise) and

pull it out.

374BA008 KN

12

BR 45

Page 14

Fitting Backpack

english / USA

A

B

Adjusting the harness straps

: Pull the ends of the straps (A)

downward to tighten the harness.

: Lift the tabs of the sliding adjusters

(B) to slacken the harness straps.

: Close and lock quick-action

fastener (C) by pushing it together.

: Squeeze the hooks to open the

quick-action fastener (D).

3

2

3

2

1

Adjusting backpack

: Close and lock the hip belt (1) and

adjust so that it fits snugly against

your hip.

: Adjust harness straps (2) to correct

length.

: Use straps (3) to fix position of

harness – (adjust to size).

: Back padding must fit firmly and

securely against your back.

C

D

271BA009 KN

Removing backpack

: Open quick-action fastener on hip

belt and take off the backpack.

13BR 45

Page 15

english / USA

Fuel

This engine is certified to operate on

unleaded gasoline and with the mix

ratio 50:1.

Your two-stroke engine requires a

mixture of brand-name gasoline and

quality two-stroke engine oil with the

classification TC.

Use regular branded unleaded gasoline

with a minimum octane rating of 89

RON. If the octane rating of the regular

grade gasoline in your area is lower use

premium unleaded fuel.

Note: Units with a catalytic converter

require unleaded gasoline. The

efficiency of the catalytic converter can

drop more than 50 % if several tankfuls

of leaded gasoline are used.

Fuel with a lower octane rating may

result in preignition (causing "pinging")

which is accompanied by an increase in

engine temperature. This, in turn,

increases the risk of the piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines etc.), but magnesium castings as

well. This could cause running problems

or even damage the engine. For this

reason it is essential that you use only

name branded fuels!

Use only STIHL two-stroke engine oil or

equivalent branded two-stroke aircooled engine oils with the classification

TC for mixing.

We recommend STIHL 50:1 two-stroke

engine oil since it is specially formulated

for use in STlHL engines.

Do not use BIA or TCW (two-stroke

water cooled) mix oils.

Use only STIHL 50:1 heavy-duty

engine oil or equivalent quality two

stroke engine oils for the fuel mix in

models with a catalytic converter.

Take care when handling gasoline.

Avoid direct contact with the skin and

avoid inhaling fuel vapour.

The canister should be kept tightly

closed in order to avoid any moisture

getting into the mixture.

The fuel tank and the canister in which

fuel mix is stored should be cleaned

from time to time.

Fuel mix ages

Only mix sufficient fuel for a few days

work, not to exceed 3 months of storage.

Store in approved safety fuel-canisters

only. When mixing, pour oil into the

canister first, and then add gasoline.

Gasoline

US gal. US fl.oz

12.6

2 1/2 6.4

512.8

Dispose empty mixing-oil canisters only

at authorized disposal locations.

Oil (STIHL 50:1 or

equivalent branded TC oils)

14

BR 45

Page 16

english / USA

Fueling

Before fueling, clean the filler cap and

the area around it to ensure that no dirt

falls into the tank.

Always thoroughly shake the mixture in

the canister before fueling your

machine.

In order to reduce the risk of burns

or other personal injury from

escaping gas vapor and fumes,

remove the fuel filler cap carefully

so as to allow any pressure build-up

in the tank to release slowly.

After fueling, tighten fuel cap

as securely as possible by hand.

373BA030 KN

Change the fuel pick up body

every year.

Before storing your machine for a long

period, drain and clean the fuel tank and

run engine until carburetor is dry.

Starting / Stopping the Engine

1

2

373BA007 KN

Observe safety precautions – see

chapter “Safety Precautions”.

: Slide the stop switch (1) to #

: Move the setting lever (2) to the

center position – this is the

starting throttle position.

The setting lever enables you select and

hold any throttle position between idle

(lower stop) and full throttle (upper stop).

373BA008 KN

373BA009 KN

15BR 45

Page 17

english / USA

4

: Pull the starter grip slowly with your

right hand until you feel it engage

and then give it a brisk strong pull.

Do not pull out the starter rope all

the way – it might otherwise break.

: Do not let the starter grip snap back.

Guide it slowly back into the housing

3

so that the starter rope can rewind

properly.

3

: Set the choke lever (3):

For cold start to g

For warm start to e

: Press the fuel pump bulb (4) at least

five times.

16

374BA009 KN

: Put the machine on the ground.

Check that bystanders are well clear

of the general work area and the

nozzle.

: Make sure you have a firm footing:

Hold the machine firmly with your

left hand on the handle and put one

foot against the base to prevent it

slipping.

374BA010 KN

374BA011 KN

If engine is cold:

(choke lever on gggg)

: Pull the starter rope 5 times.

: Move choke lever (3) to e

: Continue cranking until the engine

runs.

BR 45

Page 18

If conditions are unfavorable and

the engine does not start after 10

pulls of the starter rope with the

choke set to e :

Set choke to gggg, pull the starter rope

5 times, move choke lever to e and

continue cranking.

If engine is warm:

: Continue cranking until the engine

runs (choke lever on e).

2

As soon as engine runs:

: Move the setting lever (2) to the

lower stop so that the engine settles

down to idle speed.

If the engine stops during warm-up or

under acceleration:

: Repeat starting procedure as

described under "If engine is cold".

english / USA

1

373BA014 KN

To stop the engine:

: Move the stop switch (1) to $

If the engine does not start

: Check that all settings are correct

(choke, throttle trigger in starting

throttle position, stop switch on I).

: Repeat starting procedure.

373BA015 KN

Your machine is now ready for

operation.

17BR 45

Page 19

english / USA

Operating Instructions

If the engine still does not start:

: Move stop switch to $

5

: Pull off the spark plug boot (5).

: Unscrew and dry off the spark plug.

: Open the throttle fully.

: Pull the starter rope several times to

clear the combustion chamber.

: Refit the spark plug and connect the

spark plug boot – push it down

firmly.

: Move stop switch to I

: Set choke lever to e

– even if the engine is cold.

: Now start the engine.

4

374BA012 KN

Fuel tank run until dry

: After refueling, press the fuel pump

bulb (4) at least five times – even if

the bulb is filled with fuel.

: Now start the engine.

During break-in period

A factory new machine should not be run

at high revs (full throttle off load) for the

first three tank fillings. This avoids

unnecessary high loads during the

break-in period.

As all moving parts have to bed in during

the break-in period, the frictional

resistances in the engine are greater

during this period. The engine develops

its maximum power after about 5 to 15

tank fillings.

During operation

After a long period of full-throttle

operation, allow engine to run for a while

at idle speed so that the heat in the

374BA013 KN

engine can be dissipated by flow of

cooling air. This protects enginemounted components (ignition,

carburetor) from thermal overload.

After finishing work

Wait for engine to cool down. Drain the

fuel tank. Store the machine in a dry

place. Check tightness of nuts and

screws (not adjusting screws) at regular

intervals and retighten as necessary.

18

BR 45

Page 20

Using the Blower

english / USA

The BR 45 blower is designed for singlehanded operation. It is carried as a

backpack and operated with the right

hand on the control handle.

The powerful ground-level airstream

can be aimed highly accurately and

effectively.

The blower can be used for clearing

leaves, grass, paper, dust and light snow

in yards, gardens, sports stadiums,

parks, driveways and parking lots. It is

also suitable for drying cars and clearing

forest paths.

Working techniques

To minimize blowing time, use rakes and

brooms to loosen debris before blowing.

Recommended working techniques to

minimize airborne debris and pollution:

: In dusty conditions, slightly dampen

surfaces.

: Use the full blower nozzle extension

so the air stream can work close to

the ground.

: Do not direct debris at people,

children, pets, as open windows or

freshly-washed cars. Blow debris

safely away.

: After using blowers, CLEAN UP.

374BA014 KN

Dispose of debris in trash

receptacles. Do not blow debris

onto neighbouring properties.

Recommended working techniques to

minimize noise:

: Operate power equipment only at

reasonable hours - not early in the

morning, late at night or during the

noon-break when people might be

disturbed. Comply with times listed

in local ordinances. Usual

recommendations are 9:00 a.m. to

12:00 a.m. and 03:00 p.m. to 5:00

p.m. on workdays for professionals.

Special considerations should be

given to neighbours on weekends.

: Fewer engines mean less noise;

therefore use only one piece of

power equipment at a time, when

possible.

: Operate power blowers at the

lowest possible throttle speed to do

the job.

: Check your equipment before

operation, especially the muffler, air

intakes and air filters.

Conserve water by using power blowers

instead of hoses for those lawn and

garden applications where a blower can

be properly used, such as cleaning

patios or porches.

19BR 45

Page 21

english / USA

Cleaning the Air Filter

2

1

Dirty air filters reduce engine power

increase fuel consumption and make

starting more difficult.

If there is a noticeable loss of

engine power

: Move choke lever to g

: Squeeze the tabs (1) together,

swing filter cover (2) open and take

it away.

: Clean away loose dirt from around

the filter.

4

295BA019 KN

: Take the filter (3) out of the

housing (4).

: Install a new filter. As a temporary

measure you can knock it out on the

palm of your hand or blow it out with

compressed air – do not wash!

: Replace any damaged parts.

: Fit the filter (3) in the housing (4).

: Fit the filter cover (2) so that it snaps

into positon.

3

Motor Management

Exhaust emissions are controlled by the

design of the fundamental engine

parameters and components (e.g.

carburation, ignition, timing and valve or

port timing) without the addition of any

major hardware.

295BA046 KN

20

BR 45

Page 22

Adjusting the Carburetor

english / USA

General Information

The carburetor comes from the factory

with a standard setting.

This setting provides an optimum

fuel-air mixture under most operating

conditions.

With this carburetor it is only possible to

correct the adjustment of the high speed

screw within fine limits.

Standard Setting

L

H

: Shut off the engine.

: Turn high speed screw (H) counter-

clockwise as far as stop (max.

turn).

: Open the low speed screw (L) one

full turn.

3

/4

Fine Tuning for Operation at High

Altitude or at Sea Level

A slight correction of the setting may be

necessary if engine power is not

satisfactory when operating at high

altitude or at sea level:

: Check air filter and clean if

necessary.

295BA044 KN

: Warm up the engine.

At high altitude

: Turn high speed screw (H) clock-

wise (leaner) no further than stop.

At sea level

: Turn high speed screw (H) counter-

clockwise (richer) no further than

stop.

21BR 45

Page 23

english / USA

Catalytic Converter* Checking the Spark Plug

Adjusting Idle Speed

L

LA

Engine stops while idling

: Open the low speed screw (L) one

full turn.

: Turn idle speed screw (LA)

clockwise until the engine runs

smoothly – then turn it back about

1

/4 turn from that position.

Erratic idling behavior, poor

acceleration

(although low speed screw is one full

turn open)

Idle setting too lean:

: Turn low speed screw (L)

counterclockwise until the engine

runs and accelerates smoothly.

It is usually necessary to change the

setting of the idle speed screw (LA)

after every correction to the low speed

screw (L).

Units with a catalytic converter* may

only be operated with unleaded

gasoline and STIHL two cycle engine

oil or equivalent quality two cycle engine

oils in a mix ratio of 50:1 (see chapter

“Fuel”).

The catalylic converter in the muffler

reduces noxious emissions in the

exhaust gas.

295BA045 KN

Correct adjustment of the carburetor (if

adjustable) and observance of the

specified mix ratio of gasoline and two

cycle engine oil are essential to

minimize harmful exhaust emissions

and ensure a long catalyst service life.

000BA002 KN

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and

unfavorable running conditions (mostly

at part throttle etc.) affect the condition of

the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

22

* see “Guide to Using this Manual”

BR 45

Page 24

english / USA

Engine Running Behavior

If engine is down on power, difficult to

start or runs poorly at idling speed, first

check the spark plug.

: Remove spark plug - see “Starting /

Stopping the Engine“.

: Clean dirty spark plug.

: Check electrode gap (A) and

readjust if necessary – see

"Specifications".

: Use only resistor type spark plugs

of the approved range.

Rectify problems which have caused

fouling of spark plug:

: Too much oil in fuel mix.

: Dirty air filter.

: Unfavorable running conditions,

e.g. operating at part load.

Fit a new spark plug after approx. 100

operating hours

or earlier if the electrodes are badly

eroded.

If engine running behavior is

unsatisfactory even though the air filter

is clean and the carburetor properly

adjusted, the cause may be in the

muffler.

Have the muffler checked for

contamination (coking) by a STIHL

dealer.

1

000BA036 TR

To reduce the risk of fire and burn

injury, use only spark plugs

authorized by STIHL. Always press

spark plug boot (2) snugly onto

spark plug boot (1) of the proper

size. (Note: If boot has detachable

SAE adapter nut, it must be

attached.)

A loose connection between spark

plug boot and ignition wire

connector in the boot may create

arcing that could ignite combustible

fumes and cause a fire.

23BR 45

Page 25

english / USA

Rewind Starter Storing the Machine

To help prolong the wear life of the

starter rope, observe the following

points:

: Pull the starter rope only in the

direction specified.

: Do not pull the rope over the edge of

the guide bush.

: Do not pull out the rope more than

specified since it might break.

: Do not let the starter grip snap back,

guide it slowly into the housing.

See also chapter “Starting /

Stopping the Engine”!

Replace a damaged starter rope in

good time or have it replaced by your

STIHL dealer!

For periods of about 3 months or

longer

: Drain and clean the fuel tank in a

well ventilated area.

: Run engine until carburetor is dry –

this helps prevent carburetor

diaphragms sticking together.

: Thoroughly clean the machine – pay

special attention to the cylinder fins

and air filter.

: Store the machine in a dry, high or

locked location - out of the reach of

children and other unauthorized

persons.

24

BR 45

Page 26

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating

conditions. If your daily working time is longer than normal or working conditions

are difficult (very dusty work area, etc.), shorten the specified intervals

accordingly.

Complete machine

Control handle Check operation

Air filter

Filter in fuel tank

Fuel tank Clean

Carburetor

Spark plug Readjust electrode gap

Cooling inlets Clean

Spark arresting screen in muffler

Accessible screws and nuts

(not adjusting screws)

Anti-vibration elements

Visual inspection (condition, leaks)

Clean

Clean

Replace

Check

Replace

Check idle adjustment

Readjust idle

Check

Clean or replace

Retighten

Visual inspection

Have replaced by STIHL dealer

before

starting work

after finishing

work or daily

after each

refueling stop

weekly

xx

x

xx

xx

x

x

english / USA

monthly

yearly

if problem

if damaged

as required

x

x

x

xx

x

x

x

x

x

x

xx

25BR 45

Page 27

english / USA

Main Parts and Controls

1

3

5

4

6

8

7

9

2

10

11

12

1 Tab

15

16

13

14

17

18

374BA015 KN

2 Muffler (with spark arresting

screen)*

3 Spark plug boot

4 Carburetor adjusting screws

5 Choke lever

6 Starter grip

7 Fuel pump

8 Filter housing

9 Fuel filler cap

10 Fuel tank

11 Setting lever

12 Throttle trigger

13 Stop switch

14 Control handle

15 Shoulder strap

16 Back padding

17 Waist strap

18 Support frame

19 Anti-vibration elements

20 Pleated hose

21 Throttle cable

22 Blower tube

23 Nozzle

26

19 19

# Serial number

21

#

20

2322

374BA016 KN

* see "Guide to Using this Manual"

BR 45

Page 28

Definitions

1. Tab

For attaching blower tube to fan

housing.

2. Muffler

(with spark arresting screen)

Reduces exhaust noises and

diverts exhaust gases away from

operator. Spark arresting screen is

designed to help reduce risk of fire.

3. Spark Plug Boot

Connects the spark plug to the

ignition lead.

4. Carburetor Adjusting Screws

For tuning the carburetor.

5. Choke Lever

Eases engine starting by enriching

mixture.

6. Starter Grip

The grip of the pull starter, which is

the device to start the engine.

7. Fuel Pump

Provides additional fuel feed for a

cold start.

8. Filter Housing

Encloses and protects the air filter.

9. Fuel Filler Cap

For closing the fuel tank.

10. Fuel Tank

For fuel mixture consisting of

gasoline and oil.

11. Setting Lever

Holds throttle in different positions.

12. Throttle Trigger

Controls the speed of the engine.

13. Stop Switch

Stops the engine.

14. Control Handle

Handle for holding and directing

blower tube in the required

direction.

15. Shoulder Strap

For carrying the machine.

16. Back Padding

Improves carrying comfort.

17. Waist Strap

Helps support and distribute load.

english / USA

18. Support Frame

Accommodates powerhead and is

carried on user’s back.

19. Anti-vibration Elements

Designed to help reduce

transmission of engine vibrations to

user’s back.

20. Pleated Hose

For spraying, distributing or

spreading in the required direction.

21. Throttle Cable

Connects the control handle to the

powerhead.

22. Blower Tube

Directs spray or airstream.

23. Nozzle

Aims and widens the spray or

airstream.

27BR 45

Page 29

english / USA

Specifications Maintenance and Repairs

EPA:

The Emission Compliance Period

referred to on the Emissions

Compliance Label indicates the number

of operating hours for which the engine

has been shown to meet Federal

emission requirements.

Category A = 300 hours, B = 125 hours,

C = 50 hours

CARB:

The Emission Compliance Period used

on the CARB Air Index Label indicates

the terms:

Extended = 300 hours

Intermediate = 125 hours

Moderate = 50 hours

Engine

Single cylinder two-stroke engine

Displacement: 1.66 ci (27.2 cc)

Bore: 1.34 in (34 mm)

Stroke: 1.18 in (30 mm)

Idle speed: 2,800 RPM

Engine power: 0.88 HP

(0.65 kW)

Sound level according to

ANSI B 175.2-1999

65 dB(A)

Air flow rate

390 CFM (665 m3/h)

Air velocity

116 MPH ( 52 m/ s)

Ignition System

Type

Electronic magneto ignition

Spark plug (resistor type)

Bosch WSR 6 F, NGK BPMR 7 A or

Champion RCJ 6Y

Electrode gap

0.02 in (0.5 mm)

Spark plug thread

M 14x1.25; 0.37 in (9.5 mm) long

Fuel System

Carburetor

All position diaphragm carburetor with

integral fuel pump

Air filter

Felt mat

Fuel tank capacity

13.5 fl.oz (0.40 L)

Fuel mix

see chapter "Fuel"

The user of this unit should carry out

only the maintenance operations

described in this manual. Other repair

work may be performed only by an

authorized STIHL dealer.

Warranty claims following repairs can be

accepted only if the repair has been

performed by an authorized STIHL

dealer using original STIHL replacement

parts.

Original STlHL parts can be identified by

STIHl

the STIHL part number, the

logo and the STlHL parts symbol ((((.

The symbol may appear alone on small

parts.

STIHl

STIHlSTIHl

28

BR 45

Page 30

STIHL Incorporated Federal and California Emission Control Warranty Statement

english / USA

Your Warranty Rights

and Obligations

The U.S. Environmental Protection

Agency (EPA), the California Air

Resources Board (CARB) and STIHL

Incorporated are pleased to explain the

Emission Control System Warranty on

your model year 2000 and later

equipment type engine. In California,

new small off-road engines must be

designed, built and equipped to meet the

State's stringent anti-smog standards. In

other states, new 1997 and later model

year small off-road equipment engines

must be designed, built and equipped, at

the time of sale, to meet the U.S. EPA

regulations for small non road engines.

The equipment engine must be free from

defects in materials and workmanship

which cause it to fail to conform with

U.S. EPA standards for the first two

years of engine use from the date of sale

to the ultimate purchaser.

STIHL Incorporated must warrant the

emission control system on your small

off-road engine for the period of time

listed below provided there has been no

abuse, neglect or improper maintenance

of your small off-road equipment engine.

Your emission control system includes

parts such as the carburetor and the

ignition system. Also included may be

hoses, and connectors and other

emission related assemblies.

Where a warrantable condition exists,

STIHL Incorporated will repair your

small off-road equipment engine at no

cost to you, including diagnosis (if the

diagnostic work is performed at an

authorized dealer), parts, and labor.

Manufacturer's Warranty

Coverage:

The small off-road equipment engines

are warranted for two years in California.

In other states, 1997 and later model

year small off-road equipment engines

are also warranted for two years. If any

emission-related part on your engine is

defective, the part will be repaired or

replaced by STIHL Incorporated free of

charge.

Owner's Warranty

Responsibilities:

As the small off-road equipment engine

owner, you are responsible for the performance of the required maintenance

listed in your owner's manual. STIHL

Incorporated recommends that you

retain all receipts covering maintenance

on your small off-road equipment

engine, but STIHL Incorporated cannot

deny warranty solely for the lack of

receipts or for your failure to ensure the

performance of all scheduled

maintenance.

Any replacement part or service that is

equivalent in performance and durability

may be used in non-warranty maintenance or repairs, and shall not reduce the

warranty obligations of the engine

manufacturer.

As the small off-road equipment engine

owner, you should be aware, however,

that STIHL Incorporated may deny you

warranty coverage if your small off-road

equipment engine or a part has failed

due to abuse, neglect, improper

maintenance or unapproved

modifications.

You are responsible for presenting your

small off-road equipment engine to a

STIHL service center as soon as a

problem exists. The warranty repairs will

be completed in a reasonable amount of

time, not to exceed 30 days.

If you have any questions regarding your

warranty rights and responsibilities,

please contact a STIHL customer

service representative at

1-800-467-8445 or you can write to

STIHL Inc., 536 Viking Drive,

P.O. Box 2015,

Virginia Beach, VA 23450-2015.

Coverage by STIHL Incorporated

STIHL Incorporated warrants to the

ultimate purchaser and each

subsequent purchaser that your small

off-road equipment engine will be

designed, built and equipped, at the time

of sale, to meet all applicable

regulations. STIHL Incorporated also

warrants to the initial purchaser and

each subsequent purchaser that your

engine is free from defects in materials

and workmanship which cause the

engine to fail to conform with applicable

regulations for a period of two years.

29BR 45

Page 31

english / USA

Warranty Period

The warranty periods will begin on the

date the utility equipment engine is

purchased by the initial purchaser and

you have signed and sent back the

warranty card to STIHL. If any emission

related part on your engine is defective,

the part will be replaced by STIHL

Incorporated at no cost to the owner.

Any warranted part which is not

scheduled for replacement as required

maintenance, or which is scheduled only

for regular inspection to the effect of

"repair or replace as necessary" will be

warranted for the warranty period.

Any warranted part which is scheduled

for replacement as required maintenance will be warranted for the period of

time up to the first scheduled replacement point for that part.

Diagnosis

You, as the owner, shall not be charged

for diagnostic labor which leads to the

determination that a warranted part is

defective. However, if you claim

warranty for a component and the

machine is tested as non-defective,

STIHL Incorporated will charge you for

the cost of the emission test.

Mechanical diagnostic work will be

performed at an authorized STIHL

servicing dealer. Emission test may be

performed either at STIHL Incorporated

or at any independent test laboratory.

Warranty Work

STIHL Incorporated shall remedy warranty defects at any authorized STIHL

servicing dealer or warranty station. Any

such work shall be free of charge to the

owner if it is determined that a warranted

part is defective. Any manufacturerapproved or equivalent replacement part

may be used for any warranty

maintenance or repairs on emissionrelated parts and must be provided

without charge to the owner. STIHL

Incorporated is liable for damages to

other engine components caused by the

failure of a warranted part still under

warranty.

The California Air Resources Board's

Emission Warranty Parts List specifically

defines the emission-related warranted

parts. These warranted parts are:

Carburetor

Choke (Cold start enrichment system)

Intake manifold

Air filter

Spark plug

Magneto or electronic ignition system

(ignition module)

Catalytic converter (if applicable)

Fasteners

Where to make a claim for

Warranty Service

Bring the product to any authorized

STIHL servicing dealer and present the

signed warranty card.

Maintenance Requirements

The maintenance instructions in this

manual are based on the application of

the recommended 2-stroke fuel-oil

mixture (see also instruction "Fuel").

Deviations from this recommendation

regarding quality and mixing ratio of fuel

and oil may require shorter maintenance

intervals.

Limitations

This Emission Control Systems Warranty shall not cover any of the following:

: repair or replacement required

because of misuse, neglect or lack

of required maintenance,

: repairs improperly performed or

replacements not conforming to

STIHL Incorporated specifications

that adversely affect performance

and/or durability, and alterations or

modifications not recommended or

approved in writing by STIHL

Incorporated,

and

: replacement of parts and other

services and adjustments

necessary for required maintenance

at and after the first scheduled

replacement point.

30

BR 45

Page 32

english / USA

31BR 45

Page 33

english / USA

32

BR 45

Page 34

04583748621

english/U.S.A.lCARB/EPA

Loading...

Loading...