Page 1

Stephan Uht SyStem

Processing for the dairy industry

Page 2

Stephan continUoUS cooking and

Uht SyStemS for the dairy indUStry

Designed for all kinds of

processed cheese from low

to high viscosity

THE STEPHAN SYSTEMS FOR CONTINUOUS

PROCESSING HAVE BEEN DESIGNED BASED ON

THE DEMANDS OF THE DAIRY INDUSTRY.

TREATMENT OF ALL KINDS OF PROCESSED

CHEESE WITH PRECISE AND FULLY

CONTROLLED PARAMETERS.

EXTREMELY SHORT AND EFFICIENT

PROCESSING STEPS ASSURE FINAL PRODUCTS

WITH BEST QUALITY.

FULLY FLEXIBLE DESIGN ALLOWS A DESIGN OF

PLANTS SPECIFIC FOR CUSTOMERS’ NEEDS.

Advantages for your production

CONSTANT PRODUCT QUALITY

VISCOSITY CONTROL SYSTEM

EFFECTIVE HEATING

BY DIRECT STEAM INJECTION

INTEGRATED EMULSIFYING SYSTEM

EASY TO ADAPT TO NEW MARKET NEEDS

LONG RUNNING TIMES

EASY TO OPERATE

MAINTENANCE FRIENDLY

CIP-CLEANABLE

applicationS and proceSSing StepS

Applications:

PROCESSED CHEESE:

- SPREAD

- BLOCK

- SLICES (IWS/SOS)

ANALOGUE CHEESE

BABY FOOD

Processes:

MIXING

EMULSIFICATION

PASTEURISATION (DIRECT STEAM)

UHT (DIRECT STEAM)

DEAERATION

VACUUM COOLING

VACUUM CREAMING

Page 3

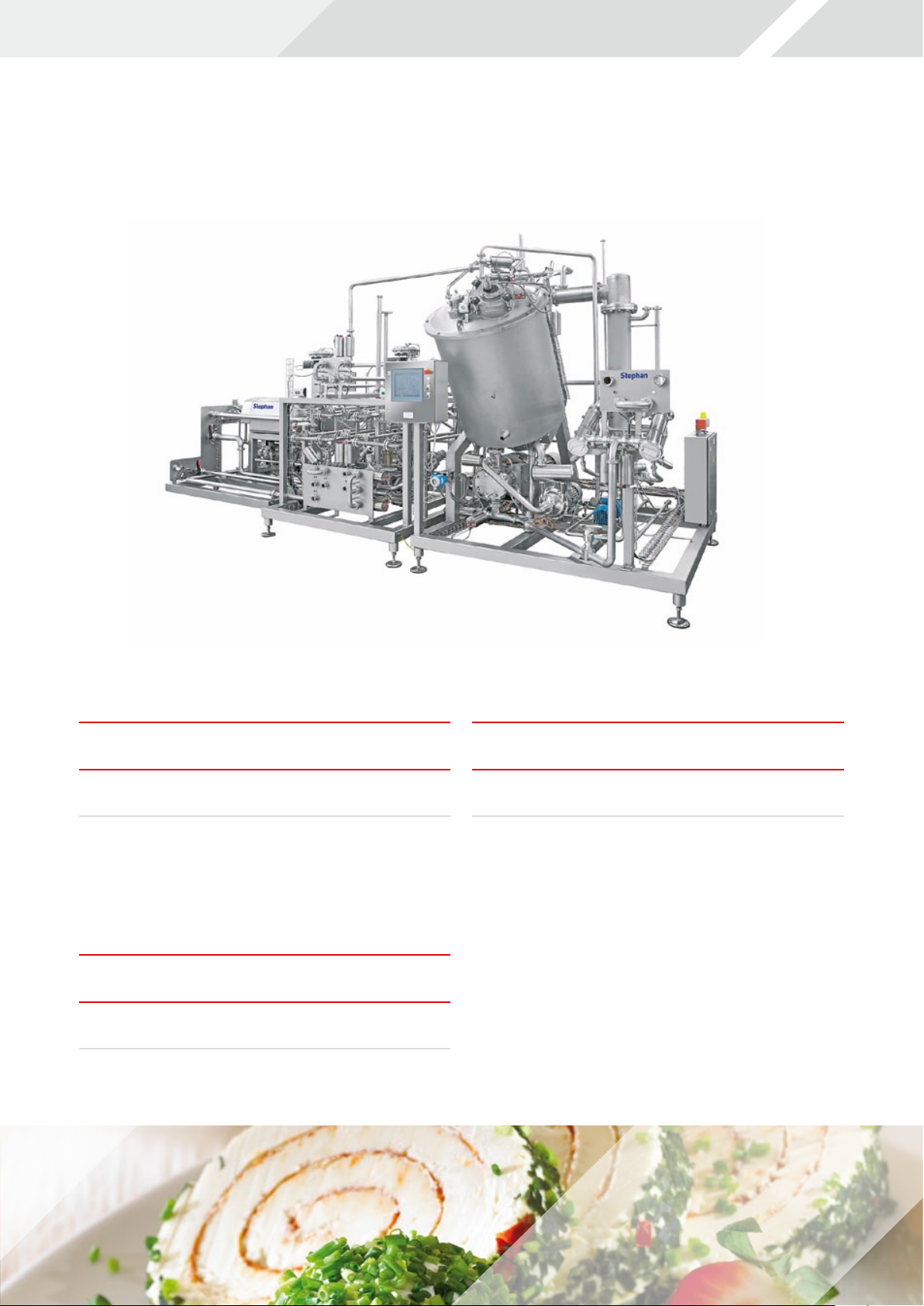

proceSS deScription for proceSSed

cheeSe prodUction

Standardisation

The final product is a blend of raw cheese, various

powdered ingredients, butter, fat / oil and water. The

main ingredients, natural cheese and butter, require

pre-processes such as quality checks, unpacking,

weighing, metal detection and grinding.

The STEPHAN Cheese Blender (1) is used for the

preparation of a standardised homogeneous cheese

blend.

After a laboratory check the blend is discharged into

the STEPHAN Station Vat (2), which is a buffer tank,

prior to processing.

Processing

The processing and heating to the required

temperature (70 – 95°C) can take place in either a

continuous or batch system.

In the STEPHAN Continuous Cooker (3) the product is

heated by direct steam injection combined with a

dynamic and highly efficient mixing system. The final

emulsifying step is achieved by means of a rotor/stator

system which ensures the best product quality.

In the STEPHAN Batch Cooking system (3) all

necessary functions of processing such as cutting,

blending, heating by direct steam injection,

emulsifying and deaeration are achieved within one

single module.

The STEPHAN UHT systems (4) are state of the art

and capable of producing all modern products.

Extension of shelf life is achieved by heating up to

145 °C. For prolonged standing times the UHT can be

designed in a double UHT head execution. To reduce

setting, product contact parts are PTFE coated.

Prior to filling, the product has to be cooled down and

deaerated (5) by controlled vacuum, followed by an

inclined creaming tank for structure rebuilding and

viscosity development under ambient pressure.

The Creaming Tank (6) is equipped with a high

efficiency creaming element and viscosity monitoring.

The product cooling, deaeration and creaming under

vacuum can also be achieved in a single combined

system – the STEPHAN Flash cooling and Creaming

Tank (7).

Additional modules for CIP, steam filtration, product

filtration and pigging systems are also available.

Page 4

machine range and componentS

1 STEPHAN CHEESE BLENDER (CB) 2 STEPHAN STATION VAT (SV)

Capacity (l)

CB 500 CB 1000 CB 2000 CB 3000

500 1000 2000 3000

Capacity (l)

SV 750 SV 1500 SV 2500 SV 4000

750 1500 2500 4000

Page 5

3 STEPHAN CONTINUOUS COOKER (CC) 3 STEPHAN UNIVERSAL MACHINE (UM)

Capacity

(l/h)

CC 1000 CC 2000 CC 4000 CC 6000

300 –

1500

400 –

2000

800 –

4000

1200 -

6000

Batch size (l)

Capacity (l/h)

UM 70 UM 130 UM 200

55 90 170

330 540 1020

Page 6

machine range and componentS

3 STEPHAN COMBITHERM (CT) 4 STEPHAN UHT (UHT)

Batch size (l)

Capacity,

up to (l/h)

CT

800

800 1200 1600

3200 4800 6400

CT

1200

CT

1600

Capacity

(l/h)

UHT

500

100 –

500

UHT

1000

200 –

1000

UHT

2000

400 –

2000

UHT

4000

800 –

4000

6000

1200 -

6000

The machines shown are for illustrative purposes only. Actual machine construction may vary by specification.

UHT

Page 7

5 STEPHAN FLASH COOLING TANK (FK) 6 STEPHAN CREAMING TANK (CR)

Max. cooling

capacity (l/h)

FK

500

500 1500 2000 4000 6000

FK

1000

7 STEPHAN FLASH COOLING

AND CREAMING TANK (FC)

Max. creaming

content (l)

CR

180

180 400 650 1400 2000

CR

400

Creaming time approx. 20 min

FK

2000

CR

650

FK

4000

CR

1400

FK

6000

CR

2000

Max. creaming

content (l)

CR

180

180 400 650 1400 2000

CR

400

Creaming time approx. 20 min

CR

650

CR

1400

CR

2000

Page 8

Stephan Machinery

World Wide at yoUr diSpoSal

HEADQUARTER

STEPHAN MACHINERY GMBH

Stephanplatz 2

31789 Hameln / GERMANY

phone +49 5151 583-0

fax +49 5151 583-189

info@stephan-machinery.com

www.stephan-machinery.com

SUBSIDIARIES/REPRESENTATIVES

BELGIUM

STEPHAN BVBA

Sluis 11

9810 Nazareth / BELGIUM

phone +32 9 3858355

fax +32 9 3858187

info@stephan-belgium.be

FRANCE

STEPHAN MACHINERY FRANCE SARL

ZAC du Mandinet

1-3 rue des Campanules

77185 Lognes / FRANCE

phone +33 1 64805430

fax +33 1 60067414

info.fr@stephan-machinery.com

STEPHAN MACHINERY GMBH

Branch Office Schwarzenbek

Grabauer Straße 6–10

21493 Schwarzenbek / GERMANY

phone +49 4151 8987-0

fax +49 4151 8987-10

info@stephan-machinery.com

www.stephan-machinery.com

USA

STEPHAN MACHINERY INC.

1385 Armour Boulevard

Mundelein, IL 60060 / USA

phone +1 847 2470182

fax +1 847 2470184

info.us@stephan-machinery.com

UNITED KINGDOM

STEPHAN UK LTD

Unit C5

Tenth Avenue

Zone 3 / Deeside Industrial Park

Deeside/Flintshire

CH5 2UA / UK

Deeside

phone +44 845 4560823

fax +44 845 4560824

info@stephan-uk.co.uk

RUSSIA

OOO STEPHAN MACHINERY

ST. PETERSBURG

RUSSIA, 197110, St. Petersburg

Levashovskiy pr. 13, litera G

Business Center “Evro-Auto”, office 332

phone +7 812 7021185

fax +7 812 7021187

info.ru@stephan-machinery.com

POLAND

STEPHAN MACHINERY

POLSKA SP. Z O.O.

ul. Perzycka 11

60-182 Poznan´ / POLAND

phone +48 61 8198888

fax +48 61 8171201

info.pl@stephan-machinery.com

SINGAPORE

STEPHAN MACHINERY

ASIA PACIFIC PTE LTD

23 Tagore Lane

#03-12 Tagore 23 Warehouse

Singapore 787601 / SINGAPORE

phone +65 6455 7670

fax +65 6455 6220

info.sg@stephan-machinery.com

SWITZERLAND

STEPHAN MACHINERY GMBH

SALES REPRESENTATIVE SWITZERLAND

Mr Marcel Heeb

P. O. Box

8332 Russikon / SWITZERLAND

phone +41 44 9550608

fax +41 44 9550688

stephan-machinery@bluewin.ch

07/2013

All content is subject to copyright and is owned and controlled by Stephan Machinery GmbH. The content may not be copied, stored (in any medium), published or otherwise redistributed without the permission of Stephan Machinery GmbH.

Loading...

Loading...