Page 1

ARTEC

Anaesthesia Machine

Operating Instructions

Status 05.99

01/7-hö

Page 2

Operating Instructions Artec

Table of contents

1 GENERAL INFORMATION 3

2 TECHNICAL DESCRIPTION 4

2.1 Possible Expansion and Upgrading of the Unit 4

2.2 Scope of Use and Application 6

3 DESCRIPTION 7

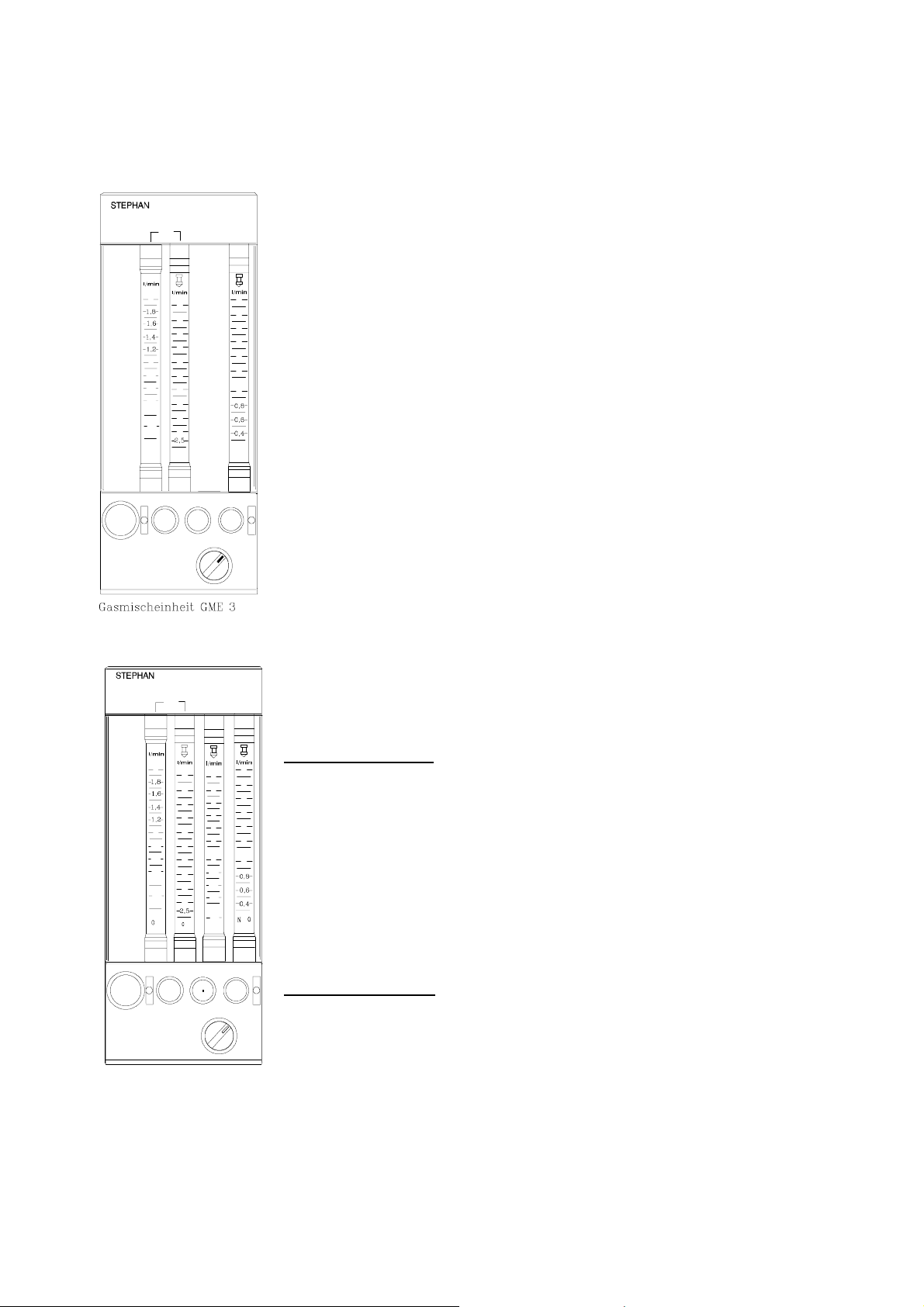

3.1 Gasmixingunit 3 and 4 7

3.2 O

3.3 O

3.4 AIR/N

3.5 O

– Ratiosystem 7

2

-Flush 8

2

O Mode Switch 8

2

- supply deficiency signal 8

2

3.6 Nitrous Oxide Block 8

3.7 Vaporizer 9

3.8 Gas-cylinder Supply Component 10

4 TESTING UNIT FUNCTIONS 11

4.1 Dosage valves of the Gas Mix Unit 11

4.2 O

4.3 AIR / N

-Flush 11

2

O Mode Switch 11

2

5 GAS TYPE TEST AND TESTING SAFETY DEVICES 12

5.1 Testing Gas Type 12

5.2 Testing the Vaporizer / Vaporizer holding rack 13

6 CLEANING AND CARE OF ANESTHESIA UNIT 14

7 NOTES ON POTENTIAL MALFUNCTIONS 15

8 TECHNICAL DATA 16

9 MAINTENANCE AND SERVICING 17

2

Page 3

Operating Instructions Artec

1 General Information

The „ARTEC inhalation anesthesia unit is in compliance with all current directives and

regulations.

During the design and development of the unit, the following regulations and standards

have been taken into consideration.

DIN 13 152 Inhalation Anestesia Units

IEC 601/VDE/0750 Electrical Safety of Medical Products

VBG 62/04.69 Oxygen

VBG62/03.70 Operating Instructions for UVV Oxygen

The Medical Equipment Regulations (MedGV), and the law on technical medical working

materials (MPBetreibV) stipulate that the attention of the operator must be drawn to the

following:

The operation of the Unit must be carried out only by qualified personnel. Exact knowledge

and understanding of the Operating Instructions is a pre-conditioned for operation.

Use of the equipment is solely for that as stipulated in the Operating Instructions.

Inspections and servicing must be duly entered in the Logbook of the Unit. The Equipment

must be inspected at regular intervals by qualified personnel only.

F.Stephan GmbH stipulates a half-yearly inspection and maintenance by one of its

authorized Service Technicians.

Before each use of the unit, a complete function test of the unit must be carried out.

In the case on medico.technical devices with electrical connection, the standards of

particular VDE 0751 and IEC 601 must be closely complied with. According to these

standards, such devices may only be set up and put into operation by the manufacturer or

his expressedly authorized technician or dealership.

Unit equipped with a pressure reducer should undergo a basic overhaul at least every 5

years for reasons of safety.

An emergency ventilation system (e.g. Ambu-Bag) must always be in close proximity of

the unit.

F. Stephan shall assume no responsibility or liability for any damage or defects arising

from non-observance of the above-mentioned information.

3

Page 4

Operating Instructions Artec

2 Technical Description

Driven by customer requests and requirements, the ARTEC model series had been

designed and developed as a compact universal version. At the same time high qualitystandards and maximum economy has been achieved.

The elementary structure ensures a good overview and quick allocation and adjustment of

parameters for the respective unit components. The ARTEC anesthesia unit is an

inhalation anesthesia unit that is equipped with a anesthesia agent specific vaporizer for

use in a semi-closed system

The unit consists of a basic housing of stainless steel in which a drawer is provided.

Located above that is the gas-mix unit (GME, with which the available medical gases O2,

N2O and (optional) compressed air can be dosaged.

The GME consists of an integrated pneumatic unit with relvant safety valves providing for

N20 block and O2 deficiency signal (in compliance with DIN 13252 and the dosage unit for

the above-mentioned medical gases.

On the right-hand side, an anesthesia agent specific vaporizer can be mounted on special

mounting racks ( one or two-fold).

Located on the basic unit and depending on model, there is provided a stainless steel shelf

for additional monitoring or a ventilation module with integrated monitoring (according to

DIN 13252).

On the reverse side of the unit there are standard connections for gas supply linea and

depending on model, holding racks for reserve bottles with integrated high-pressure

reducers.

The unit is also equipped with four plug sockets for electrical power supply for additional

monitors. These sockets are constantly supplied with current regardless of the Ventilators

ON/OFF power supply status.

2.1 Possible Expansion and Upgrading of the Unit

Basic Model

The ARTEC basic model is suitable for wall mounting. For such mounting, the mounting

rails of the basic unit ar attached to the V2A rails.

For wall mounting, exact vertical mounting of the unit must be strictly observed, otherwise

inexact mounting could lead to falsh measuring results of gas flows. An adjustable

distancer device provides a precise alignment of the unit.

Unit Model with Mobile Stand

The unit can be mounted on a mobile stand that enables and ensures variable site

operation.

The basic unit can be mounted on the mobile stand profile (80x30) by tightening the four

mounting bolts. The mobile stand can be equipped with a stand-alone oxygen,

compressed air and vacuum generator module „STAXEL“

4

Page 5

Operating Instructions Artec

Gas Supply:

The unit is designed with a central gas supply coupling connection in compliance with DIN

13253. A set of hoses is supplied with the unit for the three types of gases O

, N2O and

2

compressed air ( if air is provided).

Gas supply can either be via a central gas supply network, or via bottle supply with 10 litre

bottles O2 and N2O. To ensure uninterrupted gas supply, in the event of breakdown of the

central gas supply, 2 litre reserve bottles can be connected.

An alternative to bottled gas supply, the ARTEC anesthesia unit offers the possiblity of a

decentalized oxygen supply via the supply „outlet“. This is the „STAXEL“ that has been

especially developed as an oxygen / compressed air and vacuum generator.

Ventilation Module:

The ventilation module ABVA is

easy to use and can eventually

mounted to the basic unit later on.

For this the V

A shelf is removed

2

from the basic unit. After that the

ventilation module can be mounted

to the basic unit via two mounting

bolts. The compressed air supply of

the ventilator is created via a

connection line to the basic unit.

5

Page 6

Operating Instructions Artec

After attaching the V

A shelf, you now

2

have a respiratory-contolled anesthesia

ventilation system with the current

necessary state-of-the-art monitoring

system.

It is strongly advised to have the

installation carried out by our specially

trained Stephan Service Team.

2.2 Scope of Use and Application

The ARTEC is an inhalation anesthesia unit for the manual anesthesia of infants, children

and adults.

It can be used in conjunction with a ISO circuit system, but can also be operated with open

ventilation systems. The scope of applications of the ARTEC anesthesia unit ranges from

use in the practitioner’s surgery to hospital operation theatres.

6

Page 7

3 Description

N

N

N

N

,

N

,

N

0FLUSH

2

0

2

2

12

11

10

9

1

8

0,8

7

0,6

6

0

4

5

4

0,2

3

O

O

2

2

0

2

0

2

12

10

8

6

4

2

1

O

2

0

2

Operating Instructions Artec

3.1 Gasmixingunit 3 and 4

The gasmixingunit serves as a dosage unit for medical gases (e.g.

O2, N2O, Air). The choosen gases can mixed in a arbitary relation,

but the ratio-system guarantees a O2-concentration higher then 21

% (see below). The different gases are clearly displayed with

rotary buttons.

To avoid mistakes, the O

A unintentional move is prevented by a protection.

The dosing device makes a continuous flow enable, when opening

the valves by rotation against clockwise.

The O2-measuring range contains two measuring devices. This

makes a fine dosage possible.

The left measuring tube has a range from 0 to 2 l/min O2, the right

tube has a range from 2 to 15 l/min O2. As point of observation

serves the upper surface of the floating body.

-rotary button discerns from the others.

2

Art.Nr. 150 61 070

0

2

AIR

2

12

12

11

10

8

10

6

9

4

8

2

7

1

6

0,8

5

0,6

4

4

0

3

0,2

2

AI R

AI R

2

0FLUSH

2

1

0,8

0,6

0,4

0,2

2

0

Gasmischeinheit GME 4

r. 150 61 071

Art .

3.2 O2 – Ratiosystem

The Gasmixingunits GME 3 and GME 4 can be equipped

optionally with a pneumatical system to assure at every flowrange

of N2O a minimum concentration of oxygen of 25 % O2 (+/- 5%).

The so called O2 - Ratiosystem avoids the delivery of pure N2O to

0

2

the breathing system.

Mode of operation

12

10

8

The O2 – Ratiosystem examines the O2 – Flowrate. If there is no

6

4

O2 – Flow the N2O – Line is blocked. Thus it is impossible to apply

2

pure N2O to the breathing system without opening the O2 – Valve

1

at the GME.

Only when the O2 – Valve is opened counterclockwise, a N2O –

flow according the flowrate of O2 can be adjusted. The minimal

2

achievable oxygen concentration is 25 % +/- 5%.

0

2

Control of function

1. Close O2 – and N2O – Valve at the GME.

2. Open N2O – Valve to maximum ⇒ There should be no N2O –

Flow

3. Open O2 – Valve counterclockwise ⇒ N2O – Flow is increasing

4. Adjust 1 l/min O2 ⇒ N2O – Flow should be 3 l/min +/- 0,2 l/min

5. Adjust 3 l/min O2 ⇒ N2O – Flow

should be 9 l/min +/- 0,6 l/min

7

Page 8

Operating Instructions Artec

Caution

The O

– Ratiosystem controls the O2 – concentration in the freshgas.

2

It doesent prevent in any case a hypoxic gasmixture in the circlesystem.

Please do control the inspiratory O

– concentration by using an oxygenmonitor.

2

3.3 O2-Flush

By pressing the O2 Flush push-button, a fast oxygen supply (approx.

50 litres per minute) is activated directly to the fresh-air outlet (not via

the anesthesia vaporizer).

After releasing the O2 Flush push button it must return to it original

position.

3.4 AIR/N2O Mode Switch

The Air / N2O Mode Switch is located below the rotary knobs for (AIR

/N2O). This offers a pre-selection of the gases AIR or N2O. The

respective dosage of the gases is effected via the regulation valve.

3.5 O2- supply deficiency signal

In the event of a pressure drop in the supply system (oxygen below

2.0 to 1.5 bar) an acoustic warning alarm is activated for a duration

of at least 7 seconds. An interruption is not possible).

3.6 Nitrous Oxide Block

In the event of a further fall in presure of oxygen to about 1 bar,the ratio of N2O is reduced

proportionately to the oxygen supply. Should there be a total fallout of oxygen, the N20 flow

is set to zero. Release of N2O is then closed.

The unit stand-by mode can be resumed only by setting the stipulated oxygen pressure of

at least 2 bar at the network inlet.

8

Page 9

Operating Instructions Artec

3.7 Vaporizer

On request, the ARTEC inhalation anesthesia unit can be equipped with various vaporizersystems. In the standard model, the vaporizerss come in use which are equipped with an

„Interlock‘“ locking system to enable alternating operation of two vaporizers.

The anesthetic agent is mounted to the selected

vaporizer rack by means of a click-in

mechanism. The locking lever secures the

vaporizer on the holding rack.

Please read the operating instructions of the

respective model of vaporizer with which the

ARTEC anesthesia unit is equipped.

Vaporizer holding-rack „single“

The unit is equipped with one vaporizer rack holder. Only one vaporizer can be put into

operation.

The vaporizer holding rack is provided with automatic closing valves. The seal between the

vaporizer and the holding rack takes on the function of a gasket ring placed on the valve.

Optionally, a side-rail possiblity for a second vaporizer can be provided besides the active

vaporizer holding rack.

Vaporizer holding rack „two-fold“ Interlock locking system:

The unit is provided with two vaporizer

holding racks. Two vaporizers can be

alternately used. The vaporizers are provided

with locking devices that disables the

vaporizer that is not in operation

Interlock

.

9

Page 10

Operating Instructions Artec

3.8 Gas-cylinder Supply Component

When in the gas-cylinder operation mode, the gas is reduced from 200 or 50 bar to a

working pressure of 5 bar.

The cylinder pressure can be read on the pressure gauge and indicates the status of level

fill of the gas bottles.

The feed of the gases to the actual unit is effected via the quick-fit couplings or the DIN

threaded couplings which are unmistakeably coded according to type of gas being used.

IMPORTANT:

When transporting, it is absolutely necessary to close the cylinder-valves.

10

Page 11

Operating Instructions Artec

4 Testing Unit Functions

4.1 Dosage valves of the Gas Mix Unit

When closing the dosage valves make sure that the respective floating marker of the

respective measuring tubes are re-set to zero. Otherwise, a leakage of the respective

spindle will result that must be remedied by a service technician.

4.2 O2-Flush

Before each operation of the ventilation unit check to see whether the O2 bypass valve

immediately and automatically closes after releasing the push-button.

Basic Setting:

Dosage valve (1) on measuring tube section is closed.

Conducting Test:

Briefly press the bypass button. On release of the push-button it immediately return to its

initial position.

4.3 AIR / N2O Mode Switch

Basic Setting:

O2 dosage valve closed

N2O dosage valve set to 3 litres per minute

AIR dosage valve set to 3 litres per minute

Mode Switch in „N2O“ position

Anesthesia aspiration unit connected

O2 monitor calibrated and in operating mode

Conducting Test:

The measuring tubes for N2O must show 3 litres per minute flow, while the compressed

measuring tube must indicate no flow. The O2 monitor shows approx. 0% O2 (after a brief

waiting time).

When switching from N2O to AIR – without changing dosage valve status – indication of

floating marker of the N2O measuring tube must return to zero, while, at the same time the

display of the compressed-air measuring tube must indicate 3 litres per minute. The O2

monitor shows 21% O2 as comfirmation.

11

Page 12

Operating Instructions Artec

5 Gas Type Test and Testing Safety Devices

5.1 Testing Gas Type:

Check for proper connection of the anesthesia unit to the central gas supply system before

operation of the unit.

Basic Setting:

Unit in operation mode

Anesthesia gas aspiration unit connected

monitor in standby mode and calibrated. Measuring at fresh gas outlet.

O

2

Conducting the test:

Oxygen ( O2):

Open the O2 dosage spindle to approx. 1.5 to 2.0 litres per minute.

The O

Nitrous Oxide (N

Open the N

The O2 monitor must display 0 % O2.

Compressed air (AIR)

Open the AIR dosage spindle to approx. 1.5 to 2.0 litres per minute

The O

In the event of any deviance, the unit must undergo a service inspection!

monitor must display approx. 98 to 99 O2.

2

O):

2

O dosage spindle to approx. 1.5 to 2.0 litres per minute.

2

monitor must display approx. 21% O2

2

12

Page 13

Operating Instructions Artec

5.2 Testing the O2 deficiency signal / nitrous oxide block:

Basic Setting:

Unit in operation mode

Anesthesia aspirator device connected

All dosage valve spindles opened to 3 litres per minute

AIR / N2O Mode Switch in N2O position

Conducting test:

remove angle plug for O2 from circuit

the oxygen flow must continuously decrease

at apprix. 2.0 to 1.5 bar circuit pressure the O2 deficiency signal is activated

When pressure further decreases to approx. 1 bar, the nitrous oxide block is activated and

the N2O flow sinks parallel to the oxygen flow, until for a fully empty system both volumen

flows fall to zero.

By re-connecting the O2 angle plug, the oxygen supply is re-established.

Interruption of the N2O feed line. The N2O flow sinks to zero.

In the event of deviations of the description above, please inform customer service.

5.2 Testing the Vaporizer / Vaporizer holding rack

The anesthesia agent vaporizer is to be check for its proper function before using the unit.

Basic Setting:

Unit set in operation mode

Anesthesia agent vaporizer filled and ready for operation

Conducting the test:

Vaporizer:

Check adjusting and locking device for proper functioning

Check level status display for damage

Check adapter for safety support for damage

Check vaporizer locking lever

Condition of Vaporizer:

Check sealing valve for leakage

Inspect sealing gasket for exterior damage

13

Page 14

Operating Instructions Artec

6 Cleaning and Care of Anesthesia Unit

The anesthesia unit is to undergo a thorough cleaning at appropriate intervals; whereby

servicing measures must also be conducted that will prolong the service life of the

machine.

After removing the vaporizer, the unit can be wiped clean using a common detergent

agent. It is highly recommended to follow this up by using a dry cloth to remove any

moisture and thus limiting any danger of corrosion.

Special attention should be given to the O-rings located at the vaporizer holding rack.

These are to be carefully removed, cleaned and replaced in a dry condition.

Should these rings show damage of any type, they are to be replaced by new O-rings.

14

Page 15

Operating Instructions Artec

7 Notes on Potential Malfunctions

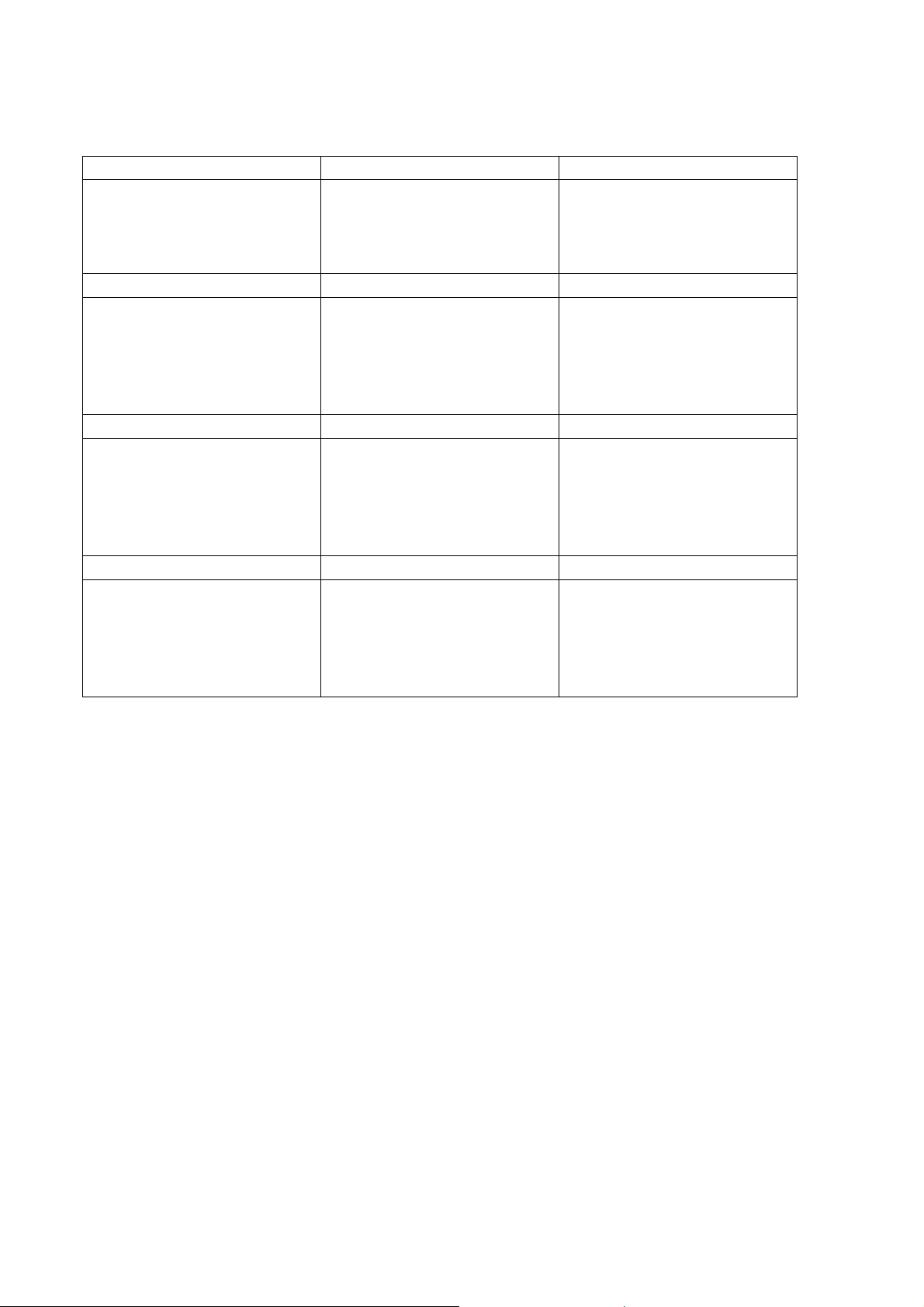

Error Possible Cause(s) Remedy

Floating marker of the

measuring tubes do not

return to zero

When using Mode Switch

AIR/N2O switch, the

selected gas is not

activated (indicated via O2

monitor)

Oxygen concentration too

high

O2 deficiency signal is

constantly activated

Measuring tube is dirty

Dosage valve leakage

Mode switch valve is not

properly sealed.

Leakage in oxygen dosage

valve

Flush Valve does not close

properly

Supply pressure too low

Valve is defect

Clean measuring tube

Loosen rotary knob and reset (Service)

Replace mode switch valve

(customer service)

Loosen rotary knob and reset (customer service)

Replacement of Flush

Valve by customer service

Set pressure reducer of the

bottle supply higher

Have customer serve

replace valve

15

Page 16

Operating Instructions Artec

8 Technical Data

Inhalation Anesthesia Unit MPG-Class 2b, Model Registration Number: 11 / M-01491

Typ: B Protection Class: 1

U: 230 V AC

P: 80 VA (with ventilator)

Dimensions (with Ventilator ABVA)

Width: 500 mm

Height: 1350 mm

Depth: 630 mm

Dimensions (without Ventilator ABVA)

Width: 500 mm

Height: 1240 mm

Depth: 630 mm

Connections (threaded) for Gas Types:

O2: M 12 x 1

AIR: M 20 x 1.5

N2O: M 14 x 1

Fresh Gas: M 16 x 1.5

Circuit pressure 5 bar +/- 0.5 bar

Measuring range for measuring hoses:

O2 (fine) : 0 to 2 litres per minute

(roughly) : 2 to 15 litres per minute

AIR : 0 to 15 litres per minute

N2O : 0 to 15 litres per minute

Precision of Measuring tubes:

+/- 10% of the respective end scale value. For integrated micro measuring range +/- 10%

of the measuring endscale value (under standard conditions 20ºC and 1.013 bar)

O2 deficiency signal:

Trigger pressure: 2.8 bar

Duration of acoustic warning signal 7 seconds

N2O Block:

Trigger pressure: 2.0 bar

16

Page 17

Operating Instructions Artec

9 Maintenance and Servicing

Medico-technical products and required to undergo at regular intervals inspection and

servicing in compliance with MedGV (Medical Equipment Regulations).

Such inspections and servicing are to be carried out by authorized personnel only (Service

Staff) of the Supplier.

Periodic Maintenance is genenally semi-yearly.

Safety Technical Inspections

Recommended Scope:

1. Visual check of necessary identification markings and Exterior detected damage

2. Check for completeness of Unit

3. Check proper functioning and alarm functioning

4. Measure earthing resistance, replacement unit ground contact and the insulation

resistance in comliance with VDE 0751 Part 1/12.84

The Maintenance Agreement ensures the best guarantee, and provides semi-annual

inspections with automatic replacement of parts subject to wear.

Should maintenance and servicing of the unit be carried out by unqualified and

unauthorized persons, the Manufacturer cannot be held reliable for the safe and proper

functioning of the unit.

17

Loading...

Loading...