Page 1

N

N

Artec / Portec

Anaesthesia Apparatus

S T E P H A N

0

2

0 , 2

O

2

0

A N E S T H E S I E G M E 2

2

1 2

1 1

1 0

9

8

7

6

5

4

3

2

2

0

2

0 1

2

1 2

1 0

8

6

4

2

1

O N

2

0

2

O F F

Service Instructions

Page 2

Preface

Service Instruction

Please carefully read each step of the procedure that is to be carried out

before beginning the servicing of the unit. Always use the correct tools

and the indicated measuring instruments. Any non-compliance with the

instructions and/or recommendation found in this technical

documentation can lead to a malfunctioning of the equipment or damage

to it.

Use only original replacement parts as supplied by F. S

TEPHAN GMBH,

and that are listed in the Replacement Parts List.

This technical documentation is not to be used in place of the operating

instructions. Each operation and handling of the equipment requires exact

knowledge and observance of the operating instructions. This equipment

is only to be used for the stipulated application.

F. Stephan GmbH

F. Stephan GmbH

- Medizintechnik -

- Medizintechnik Kirchstrasse 19

Kirchstrasse 19

56412 Gackenbach, Germany

56412 Gackenbach, Germany

Subject to technical changes. Subject to technical changes.

Stand: April 1999 Status: April 1999

Version: V1.2

Version: V1.2

2 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 3

®

Table of Contents

Table of Contents.......................................................................................3

1 General Information...........................................................................7

1.1 Equipment designation and manufacturer...............................7

1.2 Technical safety inspections....................................................7

1.3 Maintenance.............................................................................7

1.4 Warranty..................................................................................8

2 Connections on part of the supply system .........................................9

2.1 Check of the plug-in gas couplings O2, N2O, AIR for:............9

2.2 Check of the gas connection tubes O2, N2O, AIR, for:............9

2.3 Check of the screw joints of the connecting threads O2, N2O,

Table of Contents

AIR for:....................................................................................9

2.4 Check of the female connecting threads O2, N2O, AIR for:..10

3 Description of Design and Performance..........................................11

3.1 Gas-mixing-unit 2 and 3 (GME 2/GME 3)............................11

3.1.1 O2-Flush ....................................................................12

3.1.2 AIR / N2O-Change-Over...........................................12

3.1.3 Nitrous Oxide Blocking.............................................13

4 Vaporizer, Vaporizer holding device...............................................15

4.1 Vaporizer...............................................................................15

4.2 Vaporizer holding device.......................................................15

5 Cylinder Supply Unit.......................................................................17

6 Circle System...................................................................................19

6.1 Design and Description of Performance................................19

6.1.1 CL (closed)................................................................20

6.1.2 Pressure Range from 5mbar to 50mbar.....................20

6.1.3 Spontaneous Respiration...........................................20

6.1.4 VOL (volume-controlled ventilation) .......................20

6.1.5 Circle System ............................................................21

7 Performance Test.............................................................................23

7.1 Execution of the Test.............................................................23

7.2 O2-Flush.................................................................................24

7.3 Air / N2O-Change Over (Basic setting).................................24

7.3.1 Execution of the Test.................................................24

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 3

Page 4

Table of Contents

7.4 Check of types of gas and test of the safety devices.............. 25

7.4.1 Execution of the Test.................................................25

7.4.2 Proportioning Valves.................................................25

7.5 Tightness of the Circle System.............................................. 26

7.5.1 Basic setting ..............................................................26

7.5.2 Execution of the Test.................................................27

7.6 Test of the pressure-regulating valve.....................................27

7.6.1 Basic setting ..............................................................28

7.6.2 Execution of the Test.................................................28

7.7 Test of inspiration-and expiration valve................................29

7.7.1 Basic setting ..............................................................29

7.7.2 Execution of the Test.................................................29

8 Diagram of pneumatic control system.............................................31

8.1 Pneumatic control system O2 / N2O / AIR.............................31

8.2 Pneumatic control system O2 / N2O.......................................32

9 Troubleshooting Guide ....................................................................33

9.1 Portec.....................................................................................33

9.2 Circle System.........................................................................34

10 Technical Data.................................................................................35

10.1 Dimensions............................................................................35

10.2 Type of gas connections........................................................35

10.3 Measuring range of the flowmeter tubes ...............................36

10.4 Accuracy of the flowmeter tubes...........................................36

10.5 O2-Failure alarm ....................................................................36

10.6 Technical Data Circle System ...............................................36

11 List of spare parts.............................................................................37

11.1 Circle system .........................................................................37

11.1.1 Semi-annual servicing circle system.........................38

11.2 Absorber ................................................................................39

11.2.1 Semi-annual servicing Absorber...............................39

11.3 Expiration valve.....................................................................40

11.3.1 Semi-annual servicing expiration valve....................40

11.4 Inspiration valve....................................................................41

11.4.1 Semi-annual servicing inspiration valve ...................42

11.5 Artec / Portec.........................................................................42

11.6 Vaporizer...............................................................................44

4 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 5

®

Table of Contents

11.7 Flowmeter tube......................................................................45

11.8 Spindle 46

11.9 Instruction Flowmeter tube....................................................48

12 Measuring of electrical power leakage............................................51

13 Servicing..........................................................................................53

14 Test Certificate.................................................................................55

15 Acceptance of the apparatus ............................................................57

16 Index of Figures...............................................................................59

17 Index of Tables ................................................................................61

18 Notes 63

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 5

Page 6

Page 7

®

1 General Information

1 General Information

1.1 Equipment designation and manufacturer

Equipment designation

Manufacturer

Artec /Portec

F. Stephan GmbH

- Medizintechnik Kirchstrasse 19

56412 Gackenbach, Germany

(+)49 (6439) 9125 – 0

(+)49 (6439) 9125 – 111

info@stephan-gmbh.com

www.stephan-gmbh.com

1.2 Technical safety inspections

Technical safety inspections are to be carried out every six months by the

manufacturer or an authorized Technical Service Team of F. S

GMBH.

1.3 Maintenance

For reasons of equipment safety and reliable functioning, it is

recommended that the maintenance of the inhalation anesthesia units,

A

RTEC / PORTEC, also be carried out in conjunction with the semi-

annual technical safety inspections.

Maintenance is to be carried out only by a service team authorized by F.

S

TEPHAN GMBH.

When carrying out maintenance or servicing, use only those replacement

parts that are supplied by F. S

TEPHAN GMBH.

TEPHAN

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 7

Page 8

1 General Information

1.4 Warranty

The manufacturer grants a 24-month warrant effective from the date of

purchaser.

Any modification or repair work carried out on the equipment may only

be done by F. S

Otherwise the warranty becomes invalidated.

In validation of the warranty can also arise through improper handling

and opertion of the equipment.

TEPHAN GMBH or an authorized technical team.

Claims

Warranty claims that can be attributed to improper operation, insufficient

care and maintenance shall not be honored by the manufacturer.

The manufacturer guarantees only for the safety and reliable operation of

the equipment only if the operating and servicing instructions are strictly

adhered to.

8 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 9

®

2 Connections on part of the supply system

2 Connections on part of the supply

system

2.1 Check of the plug-in gas couplings O2, N2O, AIR for:

correct color coding

correct fit in the gas socket

external damage

2.2 Check of the gas connection tubes O2, N2O, AIR, for:

correct connection of the plug-in gas coupling

correct connection to the screw joint of the connecting thread

correct color coding

external damages

2.3 Check of the screw joints of the connecting

threads O

, N2O, AIR for:

2

Tightness

correct color coding of the individual types of gas

damage to the thread

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 9

Page 10

2 Connections on part of the supply system

2.4 Check of the female connecting threads O2, N2O, AIR for:

firm fit

correct coding of the threads of the individual appliances

correct color coding on the foil

damage to the thread

10 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 11

®

3 Description of Design and Performance

3 Description of Design and Performance

3.1 Gas-mixing-unit 2 and 3 (GME 2/GME 3)

0

0

2

2

12

11

10

9

1

8

0,8

7

0,6

6

0,4

5

4

0,2

3

O

O

2

2

N 0

N

2

12

10

8

6

4

2

1

O

2

2

2

12

11

10

9

1

8

0,8

7

0,6

6

0,4

5

4

0,2

3

2

2

AIR

12

10

0,8

0,6

0,4

0,2

AIR

N 0

2

12

10

8

8

6

6

4

4

2

2

1

1

2

0 FLUSH

2

2

0

N 0

2

0 FLUSH

2

AI R

0

2

N 0

2

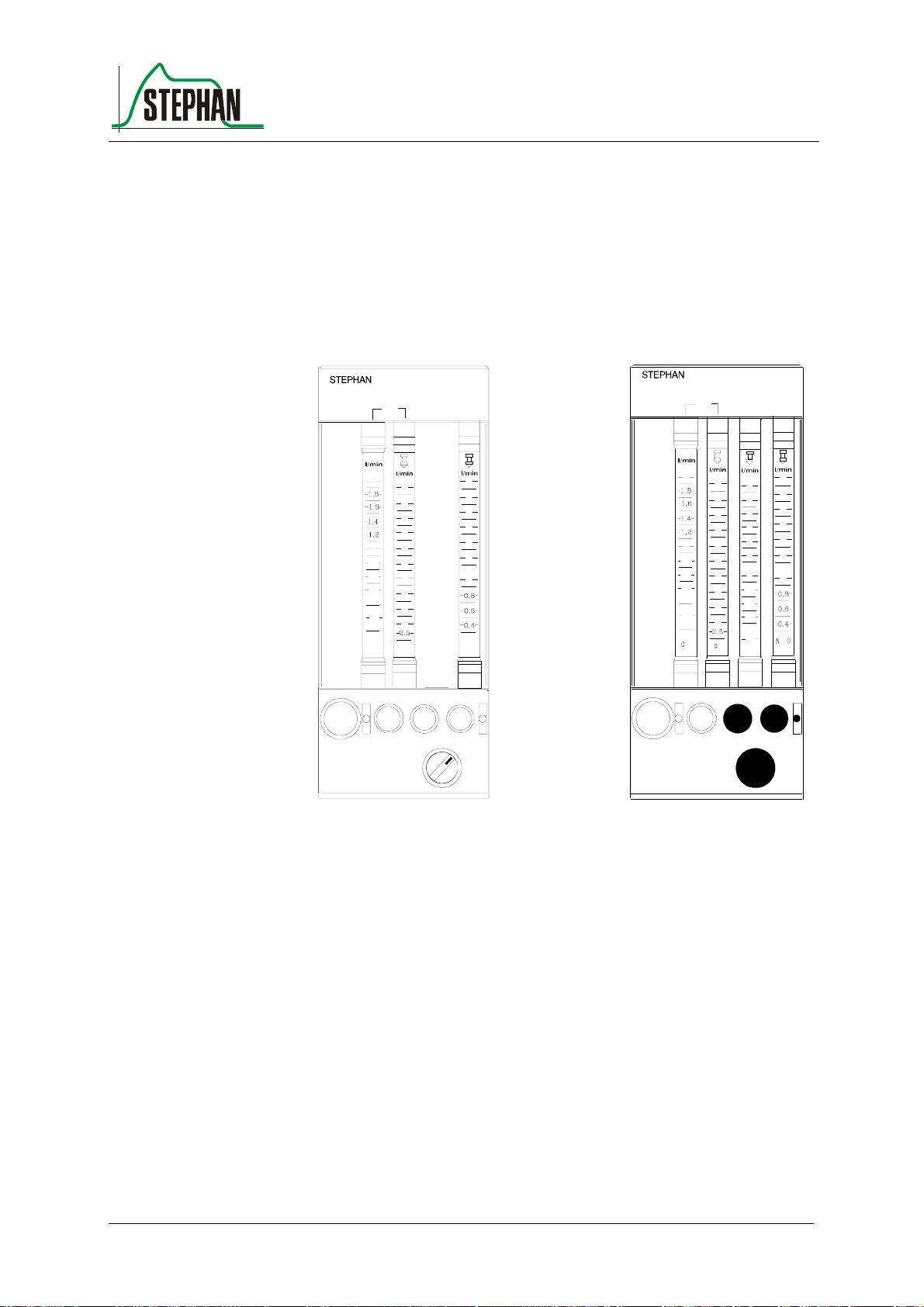

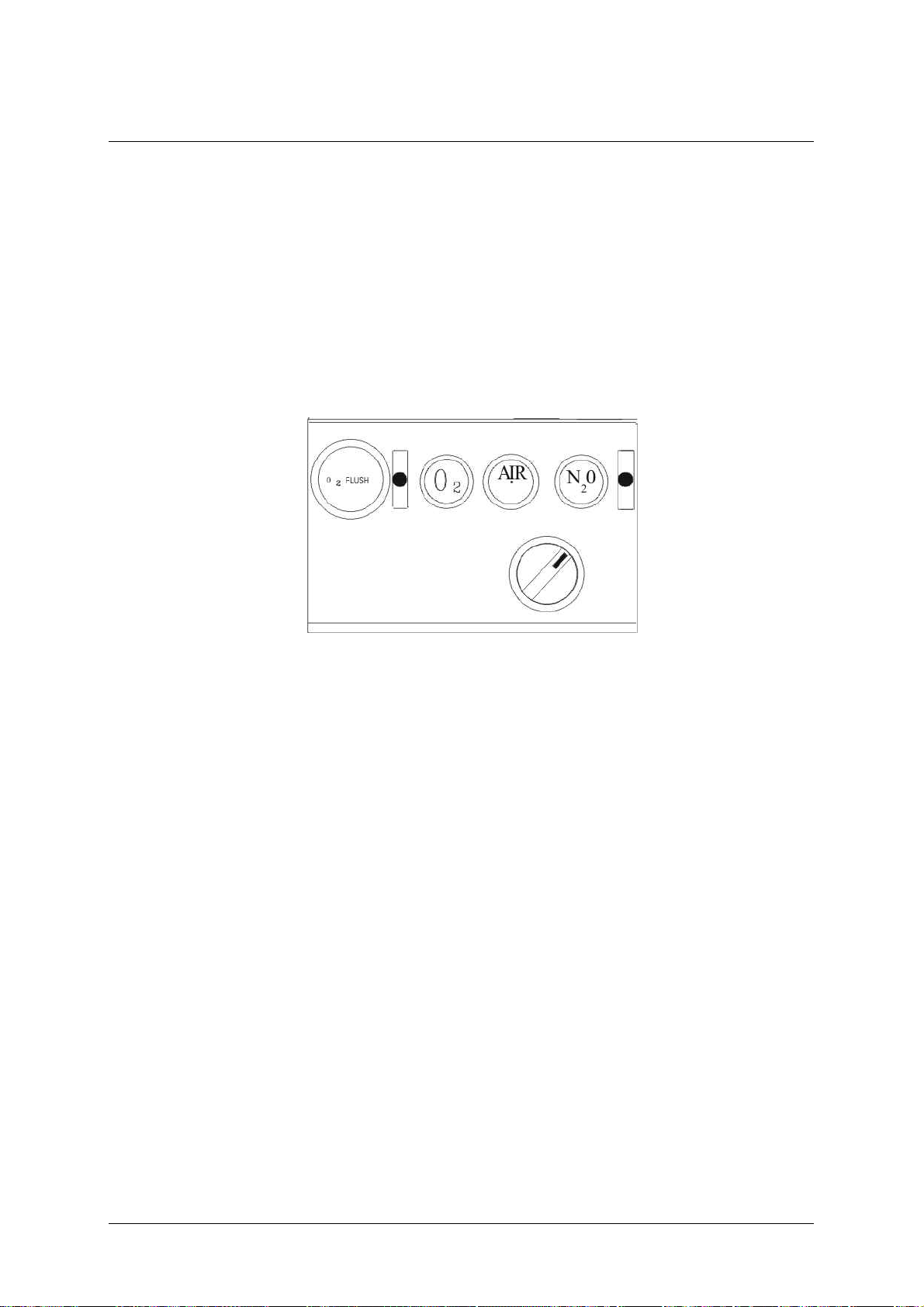

Fig. 1: GME 2 Art.Nr.: 1 150 61 070

GME 3 Art.Nr.: 1 150 61 071

he gas-mixing unit serves as proportioning device for medical gases

T

(e.g. oxygen, nitrous oxide and compressed air).The desired gases can be

mixed in any relation by means of the proportioning valves below the

flowmeter tubes. The types of gas can be clearly recognized on the

control knobs.

To prevent conf

usion, the control knob of the regulating valve for oxygen

differs haptically from the two other valves. Inadvertent shift of the

settings is avoided by a special twisting-prevention device.

he proportioning valves (control knobs) permit a continuous flow, when

T

they are rotated counterclockwise. The measuring area for O

consists of

2

two flowmeter tubes, so that an exact proportioning is guaranteed.

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 11

Page 12

3 Description of Design and Performance

The high precision flowmeter tube (at the left) indicates the measuring

range from 0 to 2 l/min, the "rough" flowmeter tube (at the right)

indicates the flow quantities from 2 to 15 l/min.

Reading line is the upper edge of the float. Graduation of the lower scale

parts of the measuring tubes (AIR/N

Because the dimensions of the lateral parts of the GME 2/3 can be altered

optionally, the use of flowmeter tubes of other manufacturers (e.g. Rota,

KDG and others) is possible.

O) is more closely stepped.

2

Fig. 2: Gas Mixing Unit

3.1.1 O2-Flush

Depressing the O

-flush-button effects a quick oxygen supply

2

(approximately 50 l/min) directly to the outlet for fresh gas ( not via the

vaporizer for anaesthetic agent).

Releasing the O

-flush-button effects return to the initial position.

2

3.1.2 AIR / N2O-Change-Over

The AIR/N

knobs (AIR/N

possible. The appropriate proportioning of the gases is carried out by

means of the regulating valves O

In case of a decrease of pressure in the supply system (oxygen

lower than 2,8 bar ) an audible alarm sounds for at least 7 seconds.

No muting is possible.

O-change-over-switch is situated below the respective control

2

O). It makes preselection of the gases AIR or N2O

2

-Failure Alarm.

2

12 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 13

®

3.1.3 Nitrous Oxide Blocking

If pressure of oxygen further decreases to approximately 2 bar,the portion

of N

O is also reduced proportionally to the portion of oxygen. In case of

2

a total failure of oxygen supply, the flow of N

The readiness for service of the apparatus can only be restored by

providing the prescribed pressure of oxygen of at least 2 bar at the

connection with the supply system.

3 Description of Design and Performance

O is reduced to zero.

2

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 13

Page 14

Page 15

®

4 Vaporizer, Vaporizer holding device

4 Vaporizer, Vaporizer holding device

4.1 Vaporizer

Check setting wheel and stop for performance

Check indication of filling level for damage

Check drain screw for easy running and tightness

Check performance of safety filling socket for performance

Check locking device of vaporizer

Verify concentration values of the vaporizer with the help of a testing

device for anaesthetic gases

maximum admissible tolerance in accordance with DIN 13252: +/-

20% of the set value or 0,2 Vol % absolute, always the higher value of

the two.

4.2 Vaporizer holding device

Check sealing valves for tightness

Exchange O-rings

Check for firm fit

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 15

Page 16

Page 17

®

5 Cylinder Supply Unit

Performance test of the high-pressure gauges for N

Check of the connections for supply cylinders

Check of correct coding of threads

Check of the packings of the supply cylinders

Check screw joints and pipe installations for tightness and damages

Check housing for damages

Check attached components for firm fit

5 Cylinder Supply Unit

O and O2

2

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 17

Page 18

Page 19

®

6 Circle System

6.1 Design and Description of Performance

The circle system together with the patient forms a closed cycle, into

which fresh gas is fed via the fresh gas pipe line. Excess gas escapes

through the excess gas valve (10)from the cycle and is removed from the

field of activity of the anaesthetist by means of the suction system for

anaesthetic gas (13).During the inspiration phase, the gas contained in the

system is transported to the patients' lungs by effecting pressure,

produced either by the respirator or by manual operation of a respiratory

bag. The consequent PRESSURE RELIEF in the system during the

expiration phase and the increase of pressure in the lungs due to the

elasticity of the thorax makes the gas flow back out of the lungs. Thereby

it is the task of the inspiration valve (1) and the expiration valve (7) to

permit the flow of gas only in one direction and so to establish the cycle.

Prior to reaching the patient again, CO

(2). Humidity and heat given off by the patient are fed back to him in

such a semi-closed system, which prevents desiccation and excessive

cooling of the airways. The fresh gas feeder is located on the lower end of

the holding tube. The adjustability of elevation and the possible

swivelling stand for a good adaptation to the local conditions of the

operating theatre. The respiratory pressure gauge(3), which can be

slipped onto the holding device of the circle system, has a measuring

range from - 10 to 100 mbar. It can be replaced by a blind plug.

is removed in the two absorbers

2

6 Circle System

As a standard, a mechanic volumeter (9) is installed below the expiration

valve, which measures all expiratory values of respiratory volume. The

measuring of O

in accordance with DGAI, is carried out by means of a polarographic cell

(by Clark) (1) at the head of the inspiration valve. Moreover, the circle

system is provided with connection tapers in accordance with ISO

respectively DIN 13 252, so that corrugated tubes for the ventilation of

adults as well as tube systems for infants can be used. The excess valve

(10) serves to carry off spent respiratory gases. It can be operated in four

different adjustments.

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 19

-concentration, required

2

Page 20

6 Circle System

6.1.1 CL (closed)

The valve is completely closed. This setting is necessary for operation in

respirator mode. In this mode, the spent respiratory gases are evacuated

via the ejector on the patient component during the expiration phase.

6.1.2 Pressure Range from 5mbar to 50mbar

This setting is used to limit the maximum pressure during manual

ventilation. When the set pressure is reached, the valve evacuates.

6.1.3 Spontaneous Respiration

During spontaneous respiration of the patient under light anaesthesia, the

valve closes in the inspiration phase, the patient now breathes the fresh

gas provided by the apparatus. In the expiration phase, the valve opens

and evacuates the system until ambient pressure is reached.

This setting is to be used in case of assisted ventilation with the patient

triggering the respiration and the respirator deepening the respiration.

Aside of that, it is possible to switch to SP briefly in case of manual

ventilation in the pressure range of 5 to 50 mbar to evacuate an overfilled

respiratory bag.

6.1.4 VOL (volume-controlled ventilation)

With the valve setting VOL, the circle system is closed automatically to

guarantee supply of the patient with the desired respiratory working

volume. Spent and excess respiratory gases escape from the valve at the

end of the expiration phase. During the expiration phase, pressure in the

system never rises above 1,5 mbar.

20 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 21

®

6.1.5 Circle System

Check performance of inspiration- and expiration valve and contact

surfaces of the valves for damages

Check tapers and taper seats for damages

Check absorber for damages and tightness

Check performance of respiratory pressure gauge

Check setting values and performance of the Berner-valve

Check fresh-gas-feed for passage of flow and tightness

Check tube system, Y - piece and mask

In the course of semi-annual servicing, all packings and O-rings must

be exchanged.

6 Circle System

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 21

Page 22

Page 23

®

7 Performance Test

Fig. 3: Gas Mixing Unit

Proportioning valves (1) on flowmeter unit closed

7 Performance Test

7.1 Execution of the Test

Cautiously open the proportioning spindle for oxygen while

observing the respiratory pressure gauge (2). Fill pipe line system,

until the respiratory pressure gauge comes to a standstill at constantly

60 mbar.

The float of the oxygen flowmeter now indicates the dimension of the

leakage.

Fig. 4: Proportioning spindle for oxygen

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 23

Page 24

7 Performance Test

7.2 O2-Flush

Attention

Do not use in the application described above. You will destroy the

manometer.

Prior to putting the apparatus into service, it must be verified, that the O

flush-valve closes immediately and automatically after the key has been

released. For this test, the flush-key must be depressed briefly. When

released, it must return immediately to its initial position.

7.3 Air / N2O-Change Over (Basic setting)

O

- proportioning valve closed

2

N

O-proportioning valve set at 3 l/min

2

Proportioning valve for AIR set at 3 l/min

Change-over-switch in "N

Suction system for anaesthetic gas connected

O

-monitor calibrated and in operation

2

7.3.1 Execution of the Test

O" – position

2

-

2

The flowmeter tube for N

O must indicate 3 l/min, while the

2

flowmeter tube for compressed air must give a reading of zero. The

O

-monitor indicates ca. 0% O2 ( after a brief delay ).

2

When changing over from N

O to AIR (Change-over-switch)

2

without altering the settings of the proportioning valves

the float of the N

O-flowmeter tube must return to zero, while in

2

parallel the reading of the flowmeter tube for compressed air must

rise to 3 l/min. As a confirmation, the O

21 % O

.

2

-monitor shows a reading of

2

24 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 25

®

7 Performance Test

7.4 Check of types of gas and test of the safety devices

(Nitrous oxide blocking and O

Apparatus in operating mode

Suction system for anaesthetic gas connected

Spindles of all proportioning valves opened to 3 l/min

Change-over-switch for AIR/N

7.4.1 Execution of the Test

Separate angular plug for O

The flow of oxygen must decrease continuously

-failure-alarm)

2

O in N2O-position

2

from supply system

2

The O

-failure alarm sounds, when line pressure reaches approximately

2

2,8 bar

When pressure further decreases to approximately 2 bar, the nitrous-

oxide-blocking must set in and lower the N

oxygen flow, until, with the system completely emptied, both volume

flows have decreased to zero.

Oxygen supply is restored by inserting the angular O

When the N

O-supply is interrupted, only the N2O-flow drops to zero

2

After restoring of the nitrous-oxide-supply, finally change over to AIR

and separate this gas from the supply pipe line. Here as well the flow of

O must drop to zero.

N

2

7.4.2 Proportioning Valves

When the proportioning valves are closed, the respective floats of the

corresponding flowmeter tubes must move back to the zero position. If

this is not the case, a leakage of the respective spindle exists, which must

be eliminated by the service technician.

O flow in parallel to the

2

-plug.

2

When carrying out this test, do not forget to change over from N

O to

2

AIR!

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 25

Page 26

7 Performance Test

7.5 Tightness of the Circle System

Fig. 5: Y – piece, feed line for control gas, rspiratory pressure gauge

1 y – piece

2 respiratory pressure gauge

3 feed line for control gas

7.5.1 Basic setting

Flow-regulating valves on flowmeter unit closed

Pressure-regulating valve in position CL

Remove mask from Y – piece

Slip feed line for control gas (3) onto the Y - piece, so that the circle

system forms a closed space.

26 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 27

®

7.5.2 Execution of the Test

While observing the respiratory pressure gauge (2), the zero-position

of which has been verified beforehand, cautiously open the flowregulating valve for oxygen, until the pressure gauge comes to a

standstill at constantly 60 mbar.

Read off the quantity of escaping gas at the corresponding flowmeter

tube

If leakage is less than 250 ml/min, the circle system is sufficiently

tight for operation

If the value of 250 ml/min is exceeded, the following items must be

checked:

Tightness of connecting tapers

Tightness of screw joints

Packings and O – rings

7 Performance Test

Corrugated tubes for damages

If after a repeated tightness test the inadmissibly large leakage could

not be eliminated, the service department must be notified.

7.6 Test of the pressure-regulating valve

Fig. 6: Y – piece, feed line for control gas, rspiratory pressure gauge

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 27

Page 28

7 Performance Test

1 y – piece

2 rspiratory pressure gauge

3 feed line for control gas

7.6.1 Basic setting

Circle system in operating mode

Calibrate respiratory pressure gauge

Remove mask from y - piece

Slip feed line for control gas (3) onto the Y - piece (1), so that the

circle system forms a closed space.

7.6.2 Execution of the Test

Fig. 7: Pressure regulating valve

Adjust the flow of oxygen to 5 l/min

Cover the values imprinted on the pressure regulating valve and

control them by means of the respiratory pressure gauge.

Do not go beyond 50 mbar, otherwise there is danger of overload.

Attention

28 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Tolerance: +/- 5 mbar

If tolerance limits are exceeded, exchange of the valve is necessary.

Page 29

®

7 Performance Test

7.7 Test of inspiration-and expiration valve

Fig. 8: Test of inspiration-and expiration valve

7.7.1 Basic setting

Circle system in operating mode

Remove mask from Y – piece

Connect the Y - piece with a test lung

Adjust fresh gas flow to 2 l/min

Limit pressure regulating valve to 35 mbar

7.7.2 Execution of the Test

Fig. 9: Test of inspiration- and expiration valve

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 29

Page 30

7 Performance Test

Simulate a ventilation

During the inspiration phase , the valve disc of the inspiration valve is

lifted by the gas flow and simultaneously, the valve disc of the

expiration valve is depressed.

During the expiration phase, the valve disc is lifted and the

inspiration valve remains closed.

If the valves do not react in this way, the cause must be determined

and eliminated.

Possible causes

Sticky valve disc

Missing valve disc

Damaged sealing edges of the respective valve

30 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 31

®

8 Diagram of pneumatic control system

8 Diagram of pneumatic control system

8.1 Pneumatic control system O2 / N2O / AIR

Fig. 10: Diagram of pneumatic control system O

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 31

, N2O, AIR

2

Page 32

8 Diagram of pneumatic control system

8.2 Pneumatic control system O2 / N2O

Fig. 11: Diagram of pneumatic control system O

32 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

, N2O

2

Page 33

®

9 Troubleshooting Guide

9.1 Portec

Fault Possible cause Elimination of fault

Floats of the flowmeter

tube do not return to

zero

When changing over

by means of the

AIR/N

switch, the gas that has

not been selected flows

(indicated by theO

Monitor)

O-change-over-

2

Flowmeter tube

contaminated

Change-over valve is

not tight

-

2

9 Troubleshooting Guide

Clean flowmeter tube

Exchange of the

change-over valve by

service department

Oxygen concentration

too high

Flush-valve does not

close properly

Failure-of oxygensupply

Valves defective Exchange of valves by

Tab. 1: Troubleshooting Portec

Proportioning valve for

oxygen is not tight

Exchange of the flush-

Supply pressure is too

low

Loosen control knob

and readjust (Service)

valve by the service

department

Increase setting of

pressure reducer of

supply cylinder

service personnel

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 33

Page 34

9 Troubleshooting Guide

9.2 Circle System

Fault Possible cause Elimination of fault

No pressure is building

up in the circle system

Pressure regulating

valve not closed or not

tight

Respiratory resistance

too high (becomes

evident by delayed

buildup of pressure

resp. decrease of

pressure)

The pressure indicated

by the respiratory

pressure gauge is

higher than the

pressure set on the

pressure regulating

valve

Tab. 2: Troubleshooting Circle System

Leakage in the circle

system

Close pressure

Valve disc sticks in the

valve box

Pressure regulating

valve is incorrectly

calibrated

Pressure gauge is

incorrectly calibrated

Tightness test of the

circle system

regulating valve

Clean flap valves

See functional

capability of the

pressure regulating

valve

Calibrate the

respiratory pressure

gauge

34 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 35

®

10 Technical Data

Fig. 12: Technical Data

STEPHAN

0

2

1

0,8

0,6

0,4

0,2

2

02N 0

ANESTHESIE GME 2

2

12

11

10

9

8

7

6

5

4

3

O

2

10 Technical Data

N 0

0

1

2

OFF

12

10

8

6

4

2

1

N

2

10.1 Dimensions

Weight of the system: ca. 9 kg (16kg)

Length: 330 mm

Height: 800 mm

Width 350 mm

10.2 Type of gas connections

O

: M 12 X 1

2

AIR: M 20 X 1,5

N

O: M 14 X 1

2

Fresh gas M 16 X 1,5

Pressure of supply system 5 bar +/- 0,5 bar

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 35

Page 36

10 Technical Data

10.3 Measuring range of the flowmeter tubes

O

(high precision) 0 to 2 l/min

2

(rough) 2 to 15 l/min

AIR 0 to 15 l/min

N

O 0 to 15 l/min

2

10.4 Accuracy of the flowmeter tubes

+/- 10 % of the respective terminal value of the scale.

In case of integrated high precision measuring range

+/- 10 % of the terminal value of this measuring range (under

standard conditions of 20

o

C and 1,013 bar)

10.5 O2-Failure alarm

Trigger pressure: 2,8 bar

Duration of audible alarm: 7 seconds

N

O - Blocking Trigger pressure: 2,0 bar

2

10.6 Technical Data Circle System

Volume of the complete circle

system with 2 absorbers and tubes: ca. 3 l

Weight: ca. 5,5 kg

Length: 330 mm

Height: 800 mm

Pressure gauge

36 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Pressure range: -10 mbar to 100 mbar

Tolerance: +/- 5 % of the set value

Pressure regulating valve: 0 to 50 mbar

Pressure range: 0 to 50 mbar

Tolerance: +/- 5 mbar

Page 37

®

11 List of spare parts

11.1 Circle system

11 List of spare parts

Fig. 13: spare parts circle system

Item Designation Article No.

1 Inspiration valve 1 155 61 004

2 Absorber jar, co mpl. 1 155 61 003

3 Pressure gauge10 mbar to 50 mbar 1 923 60 004

4 Base holding device of circle system 1 155 42 002

5 Connection tube of circle system 1 155 61 034

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 37

Page 38

11 List of spare parts

Item Designation Article No.

6 Corrugated tube 1 m 1 952 60 011

7 Expiration valve 1 155 61 005

8 Y - piece 1 155 60 035

9 Mechanical volumemeter Haloscale 1 155 60 040

10 Pressure regulating valve 0 to 50 mbar 1 155 60 006

11 Flat packing 33 X 21 X 2 1 951 60 004

12 Flat packing 29 X 21 X 1,5 1 951 60 003

13 Adapter for suction system anaesthetic gas 1 155 60 036

14 Tube for suction system 1 m 1 952 60 016

15 Plug for suction system for anaesthetic gas 1 155 60 037

16 Corrugated tube 1,5 m 1 952 60 012

17 Respiratory bag 2 liter, without reinforcement 1 952 60 013

18 ISO - adapter A 1 155 60 038

19 ISO - adapter I 1 155 60 039

20 Flat packing 1 951 40 007

Tab. 3: spare parts circle system

11.1.1 Semi-annual servicing circle system

Item Designation Article No.

11 Flat packing 33 X 21 X 2 1 951 60 004

12 Flat packing 29 X 21 X 1,5 1 951 60 003

20 Flat packing 1 951 40 007

Tab. 4: List of parts for exchange on the occasion of semi-annual

servicing

38 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 39

®

11.2 Absorber

Fig. 14: spare parts absorber

11 List of spare parts

Item Designation Article No.

1 Absorber - top 1 155 62 026

2 O-ring 50,47 x 2,62 1 950 60 024

3 Absorber jar 1 155 60 025

4 Absorber packing 1 951 40 005

5 Fastening bolt 1 155 60 028

6 Sieve for absorber 1 924 60 003

7 Absorber bottom 1 155 62 003

Tab. 5: spare parts Absorber

11.2.1 Semi-annual servicing Absorber

Item Designation Article No.

2 O-ring 50,47 x 2,62 1 950 60 024

4 Absorber packing 1 951 40 005

Tab. 6: List of parts for exchange on the occasion of semi-annual

servicing

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 39

Page 40

11 List of spare parts

11.3 Expiration valve

Fig. 15: spare parts expiration valve

Item Designation Article No.

1 Cap ring 1 155 62 012

2 Valve cap 1 155 60 015

3 Valve cage 1 155 62 014

4 Valve disc 1 155 60 017

5 O-ring 34,5 x 3,5 1 950 60 023

6 Expiration-valve-box 1 155 62 018

7 Expiration-valve-bottom 1 155 61 020

Tab. 7: spare parts expiration valve

11.3.1 Semi-annual servicing expiration valve

Item Designation Article No.

4 Valve disc 1 155 60 017

5 O-ring 34,5 x 3,5 1 950 60 023

Tab. 8: List of parts for exchange on the occasion of semi-annual

servicing

40 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 41

®

11.4 Inspiration valve

11 List of spare parts

Fig. 16: spare parts inspiration valve

Item Designation Article No.

1 Cap ring 1 155 62 012

2 Seat for O2-sensor 1 155 60 032

2a Valve cap 1 155 60 015

3 O-ring 34,5 x 3,5 1 155 60 023

4 Valve cage 1 155 62 014

5 O-ring 34,5 x 3,5 1 155 60 023

6 Inspiration-valve-box 1 155 62 016

7 Inspiration-valve taper, complete 1 155 61 009

8 Spring ring, circle system 1 919 60 001

9 Filter of inspiration valve 1 924 60 001

10 O-ring 9 x 2 1 950 60 005

11 Cap nut M 16 1 155 62 033

Tab. 9: spare parts inspiration valve

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 41

Page 42

11 List of spare parts

11.4.1 Semi-annual servicing inspiration valve

Item Designation Article No.

3 O-ring 34,5 x 3,5 1 155 60 023

5 O-ring 34,5 x 3,5 1 155 60 023

10 O-ring 9 x 2 1 950 60 005

Tab. 10: List of parts for exchange on the occasion of semi-annual

servicing

11.5 Artec / Portec

1

Fig. 17: spare parts Artec / Portec

2

3

4

5

6

42 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 43

®

11

0 FLUSH

2

12

Fig. 18: spare parts GME

0 FLUSH

2

11 List of spare parts

0

2

l/min

9

1

7

6

3

2

0

2

N 0

AIR

2

l/ min

12

10

8

6

4

2

1

1

0,6

O

2

2

AIR

N 0

2

9

10

5

Item Designation Article No.

1 Flathead screw M 14 x 12 black 1 910 60 001

2 Covering of flowmeter tubes 1 150 30 025

3 Control knob O

N

4 Lexan foil O2

AIR

N

2

O

2

O

2

1 150 42 052

1 150 42 053

1 150 40 044

1 150 40 045

1 150 40 046

5 Threaded pin M 5x5 1 910 60 003

6 Proportioning valve 1 150 31 019

7

Cover plug 6,6 / 5

1 922 60 001

8 Pan head screw M 2,5 X 20 1 910 60 005

9 Twisting-prevention device 1 150 42 018

10 Selector switch AIR - N2O 1 150 60 074

11 Lexan foil "O2-Flush" 1 150 40 051

12 O2 - flush - key 1 150 60 073

Tab. 11: spare parts Artec / Portec

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 43

Page 44

11 List of spare parts

11.6 Vaporizer

Fig. 19: spare parts vaporizer

Item Designation Article No.

1 Thrust pin of latching device 1 151 42 007

2 Plug bolt of latching device 1 151 42 001

3 O - ring 13,94 x 2.62 1 950 60 010

4 O - ring 22 x 2 1 950 60 016

5 Packing for ball, diameter 8 mm 1 951 40 002

6 Ball cage 1 141 40 005

7 Compression spring, top 1 151 40 009

8 Ball, diameter 8 mm 1 921 60 001

9 O - ring 12,42 x 1,78 1 950 60 008

10 Conical compression spring, bottom 1 151 40 010

11 Cartridge valve 1 151 32 003

12 O - ring 9 x 2 1 950 60 005

Tab. 12: spare parts vaporizer

44 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 45

®

11.7 Flowmeter tube

11 List of spare parts

1

2

3

4

5

Fig. 20: spare parts flowmeter tube

Item Designation Article No.

1 Conical compression spring 1 920 40 004

2 O-ring 5,28 x 1,78 1 950 60 002

3 Packing disc 1 150 42 021

4 O-ring 12,42 x 1,78 1 950 60 008

5 Filter for flowmeter tube 1 150 40 017

6 Flowmeter tube 0,1 to 2 l/min O2

2 to 12 l/min O

0,2 to 12 l/min AIR

0,2 to 12 l/min N

2

2

O

1 150 40 013

1 150 40 007

1 150 40 009

1 150 40 008

Tab. 13: spare parts flowmeter tube

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 45

Page 46

11 List of spare parts

11.8 Spindle

10

9

8

7

6

5

4

3

2

1

Fig. 21: spare parts spindle

Item Designation Article No.

1 Packing inset for spindle 1 150 40 014

2 O – ring 3 x 1 1 950 60 001

3 O – ring 6 x 1,8 1 950 60 027

4 O – ring 7,65 x 1,78 1 950 60 004

5 Spindle housing 1 150 32 016

6 Sliding bearing bushing 6 / 9 / 4 1 150 60 027

7 Sliding ring, spindle 1 150 40 010

8 Sliding bearing bushing 6 / 9 / 6 1 150 60 026

9 Nut M 12 x 1, spindle 1 150 42 015

10 Proportioning spindle 1 150 40 011

Tab. 14: spare parts spindle

46 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 47

®

Fig. 22: spare parts spindle

11 List of spare parts

Fig. 23: spare parts spindle

The parts listed below must be exchanged on occasion of the prescribed

semi-annual servicing.

Item Designation Article No.

1 Packing inset for spindle 1 150 40 014

2 O – ring 3 x 1 1 950 60 001

Latching device, type Vapo – Typ TEC 4

3 O – ring 6 x 1,8 1 950 60 027

Tab. 15: spare parts spindle

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 47

Page 48

11 List of spare parts

11.9 Instruction Flowmeter tube

1

2

3

Attention

4

5

Fig. 24: spare parts flowmeter tube

After removing the packing sets (1) and (5),the end plugs (2) and (4) can

be pulled out of the flowmeter tube with the help of a pair of pincers and

the float can be taken out.

The floats, together with the corresponding flowmeter tubes, form a

calibrated system, so that an interchanging must be avoided by all means.

Now the flowmeter tube can be rinsed first with soap suds and then with

clear water.The completely dry tube can be re-installed. After the

plexiglass hood has also been cleaned, the cover of the flowmeter tube

can be screwed up again.

48 SA-103-0499V1.2-STJ-GB © F. Stephan GmbH

Page 49

®

11 List of spare parts

Item Designation Article No.

6 Filter for flowmeter tube 1 150 40 017

Tab. 16: spare parts flowmeter tube

Item 6 must be exchanged on occasion of the semi-annual servicing

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 49

Page 50

Page 51

®

12 Measuring of electrical power leakage

12 Measuring of electrical power leakage

To the A

independent monitors. The O

the anaesthesia gas monitor for supervision of the concentration of

anaesthetic gas.

These electrically operated instruments must, in accordance with their

own service instructions, undergo a measuring of electrical power

leakage.

RTEC – apparatus belong in accordance with MedGv the two

-monitor for determinationof the FiO2 and

2

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 51

Page 52

Page 53

®

13 Servicing

In accordance with MedGV (Ordinance on medical appliances), medicotechnical appliances must undergo an inspection in regular intervals of

time.

This inspection must be carried out only by authorized persons (service

technicians) of the supplier of the appliance.

Periodical maintenance generally is semi-annual.

Best guarantee is a service contract, providing for a semi-annual rhythm

of inspections with automatic exchange of the working parts.

13 Servicing

If servicing is carried out by unexperienced, unauthorized persons, the

liability of the manufacturer for safe performance of the apparatus

automatically becomes void.

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 53

Page 54

Page 55

®

14 Test Certificate

Herewith we confirm the orderly execution of the semi-annual servicing

in accordance with the service instructions on hand, based on the

regulations of the MedGV.

F. Stephan GmbH

Gackenbach

Place

14 Test Certificate

Date

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 55

Page 56

Page 57

®

15 Acceptance of the apparatus

15 Acceptance of the apparatus

Herewith we confirm the acceptance of the serviced inhalation apparatus

ARTEC. Performance of the apparatus and the observance of the

prescribed safety regulations have been verified by us.

Clinic

Place

Date

Responsible for operating the apparatus

(Signature)

Fresh gas Gas mixture

Vaporizer holding device

N

O/AIR-change-over switch

2

O

-flush N

2

O blocking

2

Relief valve O

-failure-of-supply alarm

2

2 bar 2 bar

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 57

Page 58

Page 59

®

16 Index of Figures

Fig. 1: GME 2 Art.Nr.: 1 150 61 070 GME 3 Art.Nr.: 1 150 61 071.. 11

Fig. 2: Gas Mixing Unit.......................................................................... 12

Fig. 3: Gas Mixing Unit.......................................................................... 23

Fig. 4: Proportioning spindle for oxygen................................................ 23

Fig. 5: Y – piece, feed line for control gas, rspiratory pressure gauge.... 26

Fig. 6: Y – piece, feed line for control gas, rspiratory pressure gauge.... 27

Fig. 7: Pressure regulating valve............................................................. 28

Fig. 8: Test of inspiration-and expiration valve...................................... 29

Fig. 9: Test of inspiration- and expiration valve..................................... 29

Fig. 10: Diagram of pneumatic control system O2, N2O, AIR................ 31

16 Index of Figures

Fig. 11: Diagram of pneumatic control system O2, N2O......................... 32

Fig. 12: Technical Data........................................................................... 35

Fig. 13: spare parts circle system............................................................ 37

Fig. 14: spare parts absorber ................................................................... 39

Fig. 15: spare parts expiration valve ....................................................... 40

Fig. 16: spare parts inspiration valve ...................................................... 41

Fig. 17: spare parts Artec / Portec........................................................... 42

Fig. 18: spare parts GME........................................................................ 43

Fig. 19: spare parts vaporizer.................................................................. 44

Fig. 20: spare parts flowmeter tube......................................................... 45

Fig. 21: spare parts spindle...................................................................... 46

Fig. 22: spare parts spindle...................................................................... 47

Fig. 23: spare parts spindle...................................................................... 47

Fig. 24: spare parts flowmeter tube......................................................... 48

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 59

Page 60

Page 61

®

17 Index of Tables

Tab. 1: Troubleshooting Portec............................................................... 33

Tab. 2: Troubleshooting Circle System................................................... 34

Tab. 3: spare parts circle system ............................................................. 38

Tab. 4: List of parts for exchange on the occasion of semi-annual

servicing ......................................................................................... 38

Tab. 5: spare parts Absorber ................................................................... 39

Tab. 6: List of parts for exchange on the occasion of semi-annual

servicing ......................................................................................... 39

Tab. 7: spare parts expiration valve ........................................................ 40

Tab. 8: List of parts for exchange on the occasion of semi-annual

servicing ......................................................................................... 40

17 Index of Tables

Tab. 9: spare parts inspiration valve........................................................ 41

Tab. 10: List of parts for exchange on the occasion of semi-annual

servicing ......................................................................................... 42

Tab. 11: spare parts Artec / Portec.......................................................... 43

Tab. 12: spare parts vaporizer................................................................. 44

Tab. 13: spare parts flowmeter tube........................................................ 45

Tab. 14: spare parts spindle..................................................................... 46

Tab. 15: spare parts spindle..................................................................... 47

Tab. 16: spare parts flowmeter tube........................................................ 49

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 61

Page 62

Page 63

®

18 Notes

18 Notes

© F. Stephan GmbH SA-103-0499V1.2-STJ-GB 63

Page 64

F. Stephan GmbH

- Medizintechnik Kirchstrasse 19

56412 Gackenbach

(+)49 (6439) 9125 – 0

(+)49 (6439) 9125 – 111

info@stephan-gmbh.com

www.stephan-gmbh.com

Loading...

Loading...