Specifications and Main Features

- Printing Technique: Dot matrix (24-wire)

- Effective Print Area (Width): 254.00mm for fanfold forms while 279.4 mm for cut forms.

- Print Speeds: {various}: UPTO - 210 CPS (High-speed draft: Characters per second) 240 CPS (CPI 15) while 240, 192 and 160 CPS for CPI 12 and 10 respectively (Draft Mode) and 80 CPS (CPI 15) followed by 64 (CPI 12) and 53 (CPI 10) CPS for Letter Quality Speed.

- Fonts Supported: Total – 11 resident fonts plus high-speed draft and draft, and Roman, Roman ProportionalSan- serif, San- serif Proportional, Courier, Courier Proportional, Prestige, Prestige Proportional and Script fonts

- Font Cartridges: Can be added optionally

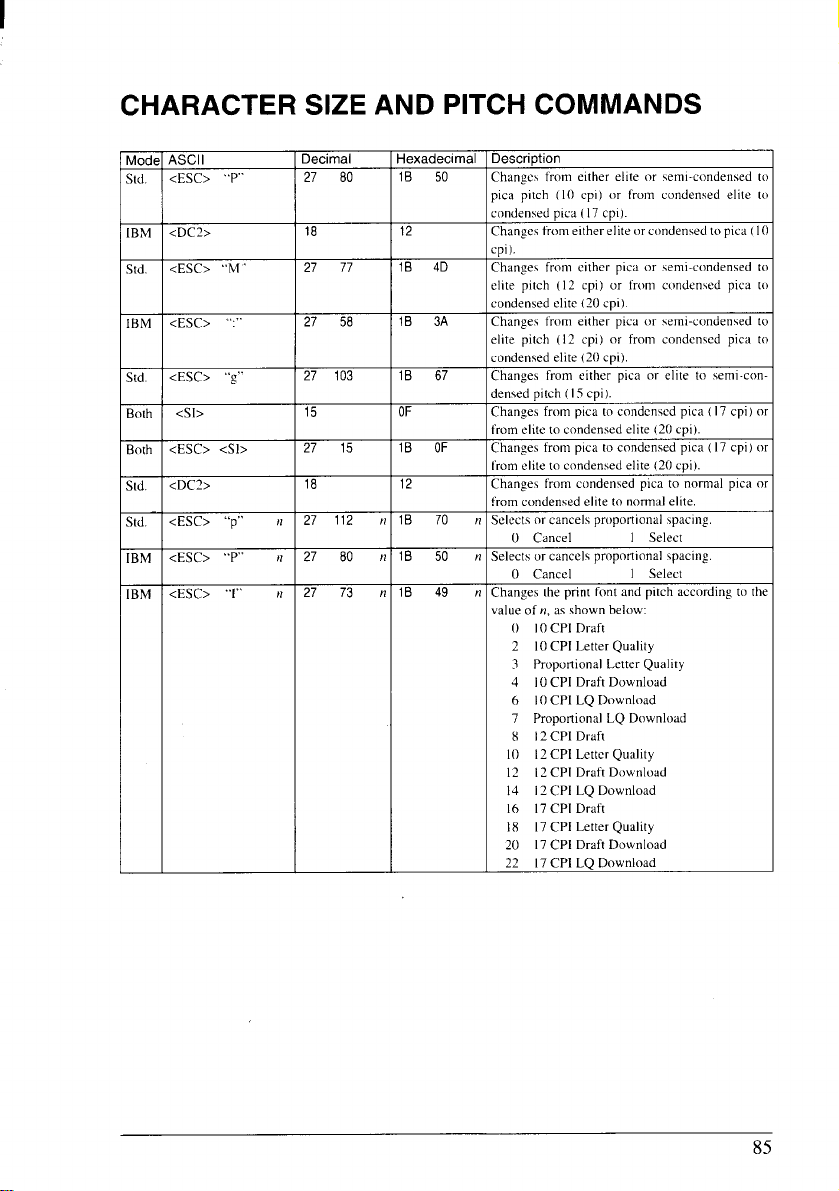

- Character Spacing: 10,12, 15, 17, 20 and 24 CPI on proportional spacing included.

- Paper Types Support Available: Cut forms and stationery, Mult apart forms and Fanfold forms, and preprinted and labeling forms.

- Control Panel: - ON LINE / PAPER FEED / EJECT / PARK / PITCH / FONT - 5 buttons available for use - LCD Display availabe to show status as well as feedback for setting.

Give plain instructions as posted below and finally ensure that features have the following: Characteristics - Operating mode with reduced noise (quiet mode) graphics’ printing resolution: 360 360 and 360 dots per square inch respectively. Paper parking with the function and soft pull, printing mode with the ability to print with less noise compared to standard settings by approximately 50%.

- Paper mode: for tearing out pages of a printed document

- EDS mode: for modifying user configuration settings

Frequently Asked Questions

- Q: Which type of paper is suitable for this printer?

- A: The printer features a wide capability radius therefore it supports normal single sheets, fan fold forms, multi part forms pre printed forms labels and more.

- Q: How to change the ribbon?

- A: Start the process by removing the front cover and remove the old ribbon and put a new one in between the print head and the print head shield and pass the ribbons of the new cartridge.

- Q: The printer is not functioning properly; what steps do I need to take?

- A: Navigate to the troubleshooting chapter of the manual and consult it to figure out necessary check points and routine maintenance operations.

- Q: Are there computers that this printer is compatible with?

- A: Yes it is. The printer accepts standard Epson/IbM printer command set and Ns8530 Compliant which makes is compatible with any appropriate application software

- Q: What constant operations switches this printer to quiet mode?

- A: all the offline modes but this command is easier done with a PAPER FEED button while you are online, with this command the QUIET message on the display comes and the noise brought about is reduced.

- Q: Can this printer also be used for printing designs?

- A: Yes, standard graphics printing is supported by this printer with up to a maximum resolution of 360 x 360 dots per inch.

User Manual

Page 1

USERS MA

NX-2430w,-m

DOT MATRIX PRINTER

ZB

80825520

Page 2

NX-2430

MU

USMA

NOINTEF SA

Page 3

FedeCommuniComm

Interf

test

ha

installa

gener

intc]-

lncrea

equipm

T//(

Cla

Cana

apporeinurndriq

Carm

DC-

(’o.

RadFrequ

Thiequiprnhabe

1 Par1 o FCRuleThelimm desi[ proreasproag

intert’erei a resicfen

cnergamlifnoinstalanusi accorwit instrm cahaint

1 mdico[llrllutlic~i(Howe\thei n gutirthinterw n o i apa

install~i[I thequipmdocwh~ir

h dcrcrminb turnthequipot’to t usiscnct t t cot int

b ono morotthfollnmewu

. Reorio relocthreceWen

.

. Conne[h

connect

. [-ons[hdealo a experiradtechf he

IJn~uthori~modifictiof’t

unleexpresapprob thparrespont’compl

Focompli:iwithFmieNoiIntcrt’Sumthequrea shc

,/.\r(II[>t}I(//@i(ml/(IJriIIHI<{r/ th[!.

anfnut cmnwit Iif aClB didepu

[hseparabetwthequifirece

ina ou!o a cirdit’t’t t w t rei

pmb t uswivoh autt opt eq

‘rhequi

Sta

usa c rar t’

1 rao tclrecw c

ThCanaDeparo Commu

RadInterfRegul

Thidigitapparadonoexcth

senui thRadInterfeRegulao t

L pr:setipptirnum<rin’drpad brumdioc!lddpI liappa

paI minis~deCommunicad

Th(IIJ(I.st<)rct>(1/J/)(IHI(pIitInw)k<; CuI

d l claB prescclI R?gls I brnradic

B limf rannemif diap

Depan Comm

TradeAcknowl

Stato

NX-243NX-24NX-24SF-1PT-IRC-

L[d

IBM-PPS/PC-APropriX24Propr24PSprilnteBu

MachinCmLQ436LQ-85SeiEpsCo

N071

● AlrighTesclmReprnduo a pao thmai m f whaw

STARexprpermisi forhid

● Thcontco thmanw subjt chawitnot

● ,41et’fuh~ibematcrent accLot conotmaa t l of

[{nwevshouW errh detecSTwogretippheino t

● Th:the IIotwithst:lfSTc assn responf a cri t m

SPS Mi

O Copyr19StMicrC L

Page 4

H T U T MA

ref

Chap

fea

Chap

Chap

Chap

Chap

Thmani orgainn chaT l h t m t b

uso yopriy a urt r thch1 t 6

Chap7 thr9 m b tra a

operatetI assa deo kno t o o

compuT chaa a fol

g f pr

Thchaindit pri

functo t pricompa a acexo t m f

stythyopric pro

Thchaexph t g t pruna s u R t

chapbefy d anyel

Thchadesct instf prs a sep

typadjut prig a inspa

Thea a numo cono t frp w p v

functrelt pahanprm a f se

Aftperfot s u o t prir t cha t o t

procet fio h t prwo

1 Intro

2 — SetU t Pr

3 — PaInstaa U

4 — ConPaOpe

o y prt n a

Thchaexph t s t EleD S ( m t

mayoprimayosya son

5 — DefSettim

Page 5

Chap6 — Trouble

an

Thsectsha lio chpot foi y p i n

workpropI alincdeo s roma

operay c peryouI i n hoa cos

manuCayoauthsercei y a uno y a

t caro a mainto seropeo t pr

Chap7 — OptiAcce

Thchapexplt optaccet a avf y

prin

h t insa u th

Chap8 — PriConCom

Thchapexplt diffemuprb y pra

thsoftcommtha ust dri T sei o u i y

arwrito modiprot t advo t prfe

Chap9 — Refe

Thsectprovrefef y pris a spet

pino inteconna t chata

Thcharatachagit difchas av

Page 6

Chap

T O

CO

Chap

Insta

Insta

Insta

Insta

Insta

Chap

Chap

EJECT

INTRO

1

Pricomp

Sumo prifea

Fostexa

2 SETU T PR

Priplac

Unpaa insp

Setu

Remot frco

Connt intca

Confiyosoff t pr

t plk

t ricar

t frco

t pagu

t muco

3 PAINSTAA U

Seleo pa

Adjut prig

Loafanfo

Loat pa

Papar

Paunpa

Teo fun

Loasinsh

4 CONPAOPE

Buta indifun

O LI

PAFE

PI

FO

1

2

4

6

9

9

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

3

3

3

Page 7

Powefunc

Shtemo

Lotemo

Prartemo

Pilomo

Folomo

Foa Pilomo

D adjusmo

Hexaddu

Swicombifunc

Fofe

T o fo

Formicr

Revmicr

Chant auloapos

Cleat buffre

Samadefi

Condiindib mesa to

Sumo dismes

Sumo beto

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

4

4

Chap5 DEFSETTIM

H’t s t E mo

Functo t E set

Chap6 TROUBLE

Chap7 OPTIACCE

AutomShFee

Setu

Loapa

Feea sinsh

PuTraUn

Setu

Loapa

FoCartra R Cart

InterConv

D swifunco t Con

4

4

5

5

6

6

6

6

7

7

7

7

7

7

7

—

Page 8

Cha8 PRICONCO

Para

char

IND

COMM

Foconcom

Chars com

Charsia picom

Vertposcom

Horizposcom

Grapcom

Downcharcom

Otpricom

8

8

8

8

8

9

9

9

9

Cha9 REFE

Specifi

Pino intecon

Serinte

Charse

Stan

Internchas

I chars #

Chars #

I spechas

Proporspata

inte

s #

SUM

9

9

9

9

1

1

1

1

1

1

1

1

1

1

Page 9

Page 10

ch1

chara

gener

Th

The

An

Prop

Prop

wi

Th

Th

Th

inform

IN

Thprih afucompo feamai a exp

foa perscompI supt Epsprc a

caprodThpriacca o t fop

● Sinshe(cfoa sta

● Fanfo(confo

● Multifo

. Preprfo

● Lab

ThMultiprih 1 res(inf w y c p

● High-Dr

● Dr

● Ro

● SansPropo●

‘ Pres

seenai t prj abany c c

botea gra

seleo pay c u i a vaa t t o doy

inc2 Drfo

9 LetQuafo

.

Ro

Co

●

Pre

Sa

●

●

CoPr

S

●

I addiy c pr

varo f b u o F

Cartri

conpah fibuta o L diT L d

anbetoproimmee t undfew y

pret buto t conpa

fibutc opei combt pea suv

o functinclsaa ma

PaParfuneny t k faf p i

readiwhprio sishpa

T g acquawit pricoma capr t t

o t pathfo

1

Page 11

PRI

COM

En$I

Mucov

\

Rel

Cas

..

AdjustIek

Pow

‘ibb/ /

2

\

\

Prihe

A “ ‘ /

/

Contpa

L

_

‘

\

Intcon

- — -

B le

/

R c

Plk

Page 12

Compo

Pap

Rele

Fro

Ent

Pow

Inter

Cartr

Pri

Cla

pre

pa

be

Con

Th

Desc

gu

Alsish( f t h t p

dew pai in

le

Rel

o t p T l m b

baf cutf ( k ) a f f

fanfo( k )

co

Prot prh a o i c

neo y pr

Muco

Reco

Redt prno

Prot trf u a sei

i a outfaf

sl

Conpa

F inssisho p

Indprsta m v c

o prfunsia co

swi

Plakn

conn

sl

Swipoo o o

Advt

ma

Cont cot t pr

Hot opF cao R c

tri

he

H a h resd m (2c

posf outp qu

Ribcart

Adjusle

Trac

le

Bale

Cont prri

Conprdab adf t t

neo fo

pr

t moo faf

Clt tri pl

Opa clt p b w h t

paagt pl

lei a u t l p a t p

t sht o fu

3

Page 13

SUMO PRFE

Cou

Pro

Prop

mo

(Cha

Feat

Domat(24impprin

Extensoft

supp

Fun

HighDrDra Let

prin

I i compw t E a I st

a wow a sot sut

prin

AEmo

AuEmuCh( m i p

t set premuauts

fryopro

Multisup

ThpriincHSD a R

maRoPropSaS

Propo

PresPre

Co

a S f

I addy c prw vao f

b usoptF Car

Carrsi

Astacart pro faf u

t 2 m ( inw a c f u t

27m ( inw

Multi-prin

I HighDr

● 2 C

pra s u t

p sei 1 p

(c

I Drmopra spu t

● 2 C i 1 pi

● 1 C i 1 pi

● 1 C i 1 pi

I Lettemopra s u t

● 8 C i 1 pi

● 6 C i 1 pi

● 5 C i 1 pi

4

Page 14

Feat

LC

st

Red

app

sq

Pap

Pri

fo

Quad

Fan

fo

ED

I Fun

Charspa

Pri 1 1 1 17a 2 C a w a

propsp

Conpa

Bucof fopip m

mea pap fuL m

indcust

Font/Lo

Ignf a p ses f y

coma

o t sef a p

wit copa

Qumo

prn b

5

Howprs i a r

Grapprin

par

Stagrprw reo u

t 3 x 3 d p

i

PafapaY c p o c s

pawiunt f f

styHighcapw t

e

phst

● Doub● DoucDo

● Emp● It● O

c

cOve

● Sh● Su

● Unde

● Qu

● Su

Teo func

foc b t o w a

blfo

Multifo

Pru t thr

I

Ribcart

Cont prri

I

mo

ElecD Sw( m a y t

eacht deseo y p

t may sya son

5

Page 15

FOSTEX

ma

1234

Thfolloexasht

Dr

Ro

Sae i f

Cou

Pres

Scr

FC1Z:

FC-:

FC-:

FC-:

FC10:

FC1 Z :

FC12:

Ora

O t or

LetGo

B1 i p

Ci ne

OC

OC

CO3

UPC

TWi g t

H–Go

Or

O St

Fir

S Scr

S Ro

S TW-

f sty prc p

123A a

123t a

123A a

123A a

123

12

123

123A a

123417o

123A a

lt?3A a

A a

A A

A a

A1a

1111111111l

123121 /

123A a

123A a

123A a

1 A a

123A c

123A a

123A a

123A a

6

Page 16

ResiL foa

wi

Oth

Rochara

Couchar

S

Pripitar

Pipi( CPElp

Semi-coPi( CP

Condelpi( CP

Norpropo

i+

Sach

Prch

( C

Conp p

Conpro

( C

Do

Do1 e

Tr

D 1e i ze

wi

Q i ze .

Vari1i n a chasp:

feat:

Empha

Undini4+%

S U P ERS CRI PT and s u Bs CR 1 p T

Downchar: * * * *

Dograp:

Doe–s1 t i C

W r 1 i ni n ,

9

Page 17

8

Page 18

ch

se

pla

yo

th

pla

pri

SEU T P

Thchadesct folprot s y n p

I y haoptiaccesret Cha

●

Priplac

✎

Unpat cab

●

Mount

●

Instat ribcar

●

Confyosoff t pr

kn

u t p

PRIPLA

Befy stsetu

plao wht loi B “ suiplw m

.

A filesurwhi favibr

●

Awfrexcehe(sa disuhee

●

Awfrexcehum

●

Awfrexcedu

●

A steposu

connt t priF exad n coi t t s c

a a larnoise-apps a a reo a a

condit

●

Masut livoli t vospo t p

identif

prim s t y h a s

i n sut p s s b

●

Inst priwhthi sufr f t f p s

a a pabef i o pro

●

I y a connyoprw a painm s t

t cai wit2 (6o t

A RScou t

optiSPCinteconc b m o l d

9

Page 19

UNPA

con

sup

al

A INS

Nocheeaiti t b agaFi2 t m s t y h

every(thshob s ite

I ano thita mis

P

y

2

FiguZ-lChet masuyoha

guid5 Mutcovean6 Usemanu

1

— . - -,-,... , —., -

S I!e1)twmz rim J rmcarr

LL.—- -.-,-“ n . . .

Page 20

1

Thoptiacceswhy m h orw y p a

● Firibcart(F

● Focartr( ser

● R cart(RCDC

● Serial-conv(SP

“ Autoshfe(SIO

● Putraun(PT-

Fodeto t optacceret Ch7

Page 21

SETU

loca

pr

yo

Plathprini t des

frthpria shi

Fig2-T pamai int

a rea pam

prevdamt t priwhi tra

Yowiwat kea t pacmatalw t

i ca

Figu2-2Remothpackmatefrt prin

hat mot prit a n loc

c

Instt plk

Thplakni pacina accb w o ac

Alithkno t plashwhi loo t ris o

thprinRott kno t shbeput k f i

posit’

k

Pl

Figu2-3Installthplakn

Page 22

Remt

fr

co

NOT

th

prin

c

Opt frcob lifu t b

u t t g o e

sidthremt cob puu ( Fi2

—

Figu2-UpethlrOcova remI D pulu

Y c ket frcoinso t pra s i

Fig2-Bui

c y m t c n t i y

finwit teased

Figu2-Thfrocovcasto t

Teassed

1

Page 23

Instt rica

thete

car

th

Noinstt ribwit folpro

1 Tat sloutofthtu

cartrcloca shb t ar

enk

t r

Figu2-6Takouthslao thribb turt tenkno t ri

2 Guit ribbetthepa t sip h s

makcertht spio t carhof i t s

o

cartits

s

I

Figu2-7Installthribcartr

1

Page 24

3 Masutht rii posbet p h a t

prheshia shi Fi2

4 Tat slo o t riagb tut t k

Figu2-Masuththribi positcorr

Instt frc

Afty hainstt ricarret f c

1 Inst taint slo t prc

2 Swdot reo t frcot c i

Figu2-Instalthfrocov

Page 25

I

gu

co

cov

ma

Instt pa

Folthprocbet inst pagu

1 Inst t slo eisio t pag i t t t o

th

recov

2 Plathpapguhorizo

Figu2-1ln_stalthpapguihorizon

Instt m

a shi Fi2

Folthprocbet inst m co

1

Insthtao t lesio t mucoi t h o t f

cov

2

Insthotht int slo t frco

3 Swi

dobackt clt m co

\

\

“

~b

\

h. ‘. A.

Figu2-f Instathtao thmucovthswdot cli

Leathfra mu

cldunoopT c

Muco

“~

\

~ /’”

,.

\

\

/

~ ,./

/

keeoudua dia redt priopesoO t

covont chat ribo

1

a adj

Page 26

Connt inc

Conn

com

compu

Inte

ca

intercabO a PSo PC/

t prit yocomusa stCep

t m t y u

th25-D-tconna t compa t Am3

piconna t prienT confo t prc

i gii Cha9 shy n a c f cot a

I y net cont a sepou t opSe

ConveSPC

Folt procbet cot inc

1 Tuo t poswb t pra t co

2 Cont intecat t pra s i F 2

Masuthy prt p i t inco

,

\

\

~ <

* \

I

Figu2-7Connecthintercab

#

con

g

\

Intca

‘

3 Moboclint extpro t s o t p u

y hea cli

/

\,

‘

</

&

‘“’“ ~

&

Figu2-1Mothcliunty hea cli

*

4

4 Cont ote o t intc t y coU y

compinstrt att int

1

Page 27

I

pro

men

co

advi

Conf

Moapplicsoftprol y spt t o p y

arusis tht sofc taf advo t prfe

Mao thsoftpac

thpresa lio prin

Thprini set emut Epprcoa t f

I yowat emut I pricomy c s i w t

ElectD Swi(Emo

Choo o t foll( oro preact y

seleEmulmo

#

I 2 I Star NX-2420

3

4 EpLQ

5 StNX-

I yosoftpacdon

whfeatyoprii capo t m coqua

“Cyopripera backa “ i d a haf

feedY shoans“Yt b thque

y sof t p

Stan(Epm

1

StNX-

EpLQ

a inso s p

I m

I P ur

I ProX ]

Pro2

prb n b a i

Masutht ElecD Sw(Ei s f t

emulaa thy haalselt appchs

(Ret Cha5 f detinfoo t E m

I yoari doabt confio y appsos

exp

refer

1

Yosofsupw prb y m qu

p

Page 28

ch

INS

al

con

in

pres

fo

ho

fo

P

Thchadescinstrf prs a sep t

adjust prigaa inspa

A U

SELO P

Yoprinacca o t foltyo pa

● Sinshe(cfoa sta

U t frifeo t opAuS F

● Fanfo

Fanfohahoalt s a peb

t sheTha

jupl“compa

Prino o net perfo

redpriquamist faf o c a p

ja

● Multifo

Y c u multfot h u t t p

origI i recot y l muf u t

botfeslwit optP TrU

U

a a diffi thio 0.o l b t s

edg

caspfocof o

senmul

w b s e g

f f m

t

● Lab

Whprilabalset t moo a c

o bacshwispr

D n t t prlaa c

bacshalals a li

I i recomthy l laf t b f s w

t optiPuTraUn

f u w a t

bel o a s

1

Page 29

NOT

back

lab

3-

1 Nefelab

Lac eap o t b

a g sti t pri

T remlabfrt pap afy fiprf

teo t laba a pobet p s

2 U labonunnoopecon

T laba espesent tema hu

3 D n le

loi t prbej T c

arot plaa m j w y repr

‘ig

sht recompra f e t o p

Fmrt’cfor

18m

Perforat

o

Botto 0

For

o

75

(8t’BotFe~

1

c

Sish

I?

4

IX

5

i

Figu3-1Recommepriarfoacceppap

2

Page 30

ADJT PRG

prin

NOT

dra

Thdistbett prh a t plc b a t

accommdiffpathicT adjl i l a

thlesio t

thprinnart gapuli tot f o t p w

thga

Thearfiposita y c f t l cli e

positT secposfrt r (mw “ i t o m

comm

usf sisho pa

Trdiffposiuny g t b prre

Pust adjl tot r o

Prinwia inappg m

s t l

o t prhe

Figu3-Locato thadjuslev

Thfolltaprot recl pof e

paptya a refe

We

‘a‘J

Sin

(Epa

52g

Thi(

(T

0

Re

L p

2 o 3

( - l

2-

40g

0

2 o 3

( - l

3-

40g

0.1

3 o 4

( - l

2

Page 31

I

LOAFAF

Thprinaccfanfou t 1 wi

Thprinc fefanfoeif t r o f t b

o thprina shi Fi3

Figu3-3Pappafofanffor

Thsectwitay thrt prof lop a

unparfanfofrt r o t pr

I yowat fepafrt boy m u t opP

TracUn(Ret Cha7

2

Page 32

Loat pa

1 Pla sto fanpabea b t pr

2 Tut prinpoO

3 Put relletot fro t pr( ~ ) T h t

effo relet paf t plroa e t

trafe

4 Opt mucoo t frcoa s i F 3

1

Rel

Muc

I

Figu3-Openthmucova corlepos

5 Opt recoust t gro eis a i F 3

R co

I

Figu3-Openthrecov

6 Pat pabett prc a t r c

2

Page 33

7 Opbotracova mot pab alh w t

pio thtraun

Trc

l

Figu3-6Mouthfanfpapovt trauni

Adjt spao t traunb slt a t b u

8

th

clalea t bao e u t rea l t i

positWht cllei u t u i rea w i i

dowt uni loc

Noclt tracovagmas t t p h a

9

aligwit pio t traunI t a n alpr

yowihaprobwipafeeporei t

anjamo t pa

Figu3-7Adjuthtracpositt accomt wio fanfo

10Clot recoa t mucot s t p g i t

horizposia shi Fi3 T w set p

frt unpr

2

pap

Page 34

11Tuo t poust swloa t f o t p T

an

NOT

priwibeindit t pai n y f l A “

meswialflo t L dit cot

Muco

Figu3-Clothrecov

t mucovths t paguhor

12N put baletot fro t prT p w b

f a adjupat prh t a por f p

,

Figu3-Puthbalevtowt fro t prit l pa

D n rett balebacT b l au

rett i oriposaft p g t u t

baleloca

13I y wat s t pat a difpos t p o

b prest 1

O LIJ but s t p b u t

microfunc(Fdetret Ch4

2

Page 35

Papa

yo

beg

wi

un

Tea

fe

upr

Aftloadfanpawiinttru y d n h t

unli why wat pro a c shT prw “ i f

yoi

folt procbe

T

1

paparst

i prinposia t relletot f o t p

( k ).

Pret 1

2

O LII buo t cop t s t p o

linT O LIindiliw t o

Teo t prifoa t l perflen m t

3

abohaa pashoabt frcoI nep t

[

PAPFEI butt fepafo

juabt frcoa t th

t poO fap l

a peri l

,

l

Figu3-1

ofthprinfanfpap

4 Pret I EJECT/I buo t copa

Thpriwiautom

t faf bau t

papi complfro t pl

5 A “Pmeswin apo t L dia a b w

sou

6 Mot relletot r o t pr( ~ )

7 Mout pagui t

pos

Noyoc losinsheT faparep a t b

o thprin

NOTY canpat fanpai y h l i u t

optiPuTraUn

2

Page 36

Paunp

NOT

fun

th

with

NOT

Why wat reusfapat pri a f

1 Rema c fofrt pr

2 Mot pagui t horpo

3 Mot relletot fro t pr( & )

4 Mot baleforT prw autf t

parfanpabai pof pr

Teo

A t e o prinu

1 Opt mucoo t frco

2 Put balefor

3 Teo t prifow t t ase o t f c

4 Put balefor

T pribeinteri y m t r l w

t pai loa

t o fut c o t p f

advablfo

T pawib f t t t o poa t b l w

automacl

T paautomret t prpo

D n retbat leafret t o s

2

Page 37

LOASISH

Thsectwitay thrt prof los s

o pap

Thpappaf c foi shi Fi3

I

I

Figu3-1Pappafocufor

I yoarust optAutShFer t C 7

1 Rait pagui poso t r c o t pr

I

Figu3-1Raithpapguifosinshe

2 Adjt paguit mat s o t p y w b u

Remeth

prinwists dif t lee

o thcarr

2

Page 38

3 Tuo thepoweswloa t f o t p T

al

po

NOT

ba

priwibeindit thi n p i pof p

T “Pmeswi

flo t L dit c t

4 Masutht rellei a r po( ~ )

I fanpapalrmoi t prp t I

EJ]

butt pat pai t offstt m t r l

towt reo t pri

5 Pla sinshbett guplt s o w y

wat prtowt b o t prGep t p d

i t guiuny fei st

Figu3-1Plaa sinshebett gu!

6 N put baletot fro t prT p w b

f int pria adjp t p h t a

r f

prin

D n plt balei t bapoT b l

automarett i orpoa t p g

thrunt

Figu3-1Puthbalevforwt lopa

leloc

2

Page 39

7 I yowat s t pat a difposs t pro

b prest I

O LI

butt s t p pob u

I

thmicrofunc(Fdetret Ch4

3

Page 40

ch4

Th

hold

ind

patt

alig

IND

Th

Th

COP O

conpabutc b prindt p t

operaindib thnaOtfuc b a b

prest conpabuti com

thbutdow y t t prp o o b

Thchaexpa t bua

.

Paprin

.

Fepa(fa slfoa re

●

Pafanfo

●

S t top-opos

✎

Selt prpi

✎

Sela fo

●

Prte

✎

Presoftfrchat pap a f se

✎

Adjut pr

✎

Pra hexaddu

●

Clt prinbu

●

Samadefi

BUA

prii equwif buo t cop F l t

f bi-dpr

rigtha CEDEI

ON LINE ~.

folli a brgut t bua ino t c

fu

FU

EJEC] , / P F \

a

pan

I

D ‘ON‘lTC‘J’’;;:::;’EED

4-Contpan

Figure

n n n U,

ms. . . . . SWITCH SET ,.,., ,“

_ PO

—

3

Page 41

I

rec

co

pow

indic

th

prin

O LI

ThI

O LI

butset prona ofT s

I

chaneatiy prt but

Whthprii on-i c

a prd f t

anwib indib t O LIindbel W t p i

off-li stprina set coma siint i

canaccda

Thprinpowu i t on-stw p i loI p i

noloadt pri

Pow

u offw t 6 mea t

liwiblWhy l pat prg o

lin

Yowiwat prt /

● Befa afa otpaope

O LI

bu

]

Thotlpabutopeo i t ofs P t

O LIN

pre

● T paudur

I yoprt I

butt g offAfpert p op

1

O LI

I

buagt g b on

1

O LI

buduprt p s

]

prina gooff-ally t cht pro c a

contpasettPriresw y p t I

O L

butagt g baon-

PAF

I yoprea relthbuwhofft p w f f

onlinI y hot budot prw peco

lifee

I yoalprt 1

papwifeautomat t t o t n p T i ex

lat

I yopret I

PAPFE/ buwhont w alf

th“QUmessat disW i Qum w t “

messt priwiprslislb a a ren l

3

O LI1btwhy a lint

Page 42

EJECT/PARK

NOTE: This button has no effect if the bottom feed mode is selected.

This button results in different functions depending on the position of the

release lever.

If the release lever isfacing toward the rear of the printer for the cut forms

( ~ ), pressing this button ejects the paper.

If the release lever is facing toward the front of the printer for the fanfold

forms ( ~ ), pressing this button parks the forms.

PITCH

Thisbuttonallowsyouto select the printingpitch.Remember that the printer

must be off-line for you to do this. Successive presses of this button will

display (and select) the following options in order (Note that the supercoridensedpitch isnot availablewith Standard/Epsonmode, andcondensed

proportional pitch is not available with IBM mode):

I Pitch

Pica (10 CPI)

Elite (12 CPI)

Semi-condensed (15 CPI) ;5

Condensed pica (17 CPI) ‘“

Condensed elite (20 CPI) ;;

Super-condensed (24 CPI)

Proportional

Condensed proportional Pc

I LCD Message

II-1

Iu

/r’

:“+

I-/l:

1-J

33

Page 43

FONT

This button selects the font to be printed. Draft font is selected at power-up

unlessthedefault settingsare changed. To changethe font, set theprinteroffline, then press the EE2ED button repeatedly until the proper font is highlighted on the LCD display. The selections cycle in the following order:

Font LCD Message

Roman

Sanserif

Courier

Prestige

Script

High-Speed Draft

jROMAN

ISANSERIF[

\COURIER

;PRESTIGE[

lSCt3ipT

~HS-DRAFT[

Draft iDt3AFT

Optional font

!OPTION

NOTE: Iftheoptional FontCartridge isnot installed,the’’OPTION”message

will not illuminate.

I

I

I

1

J

I

34

Page 44

POWER-UP FUNCTIONS

‘J’’’’’’:E’EED70NLD

35

Inadditionto their normal functions,all of the controlpanel buttonsperform

“special”functionsifyou hold themdown while switching the power button

on.

~,

~

‘0”’““”

n n n n,,=

m,. ,,.. SWITCH SET FWNT

MICRO,,,, - ‘OwER

—-

A

E,(T

I I I I I

Font Pitch Print area Long Short

lock lock test test test

Figure 4-2.Power-up functions of control panel.

Short test mode

If the printer is turned on while the I

ON LINE

printer willenter the shortself-testmode, with the“PI” message onthe LCD

display. The printer will print the version number of the printer’s ROM,

followed by seven lines of thecharacter set.

Each line will be offset by one character from the one before it. The final

result will be something like Figure 4-3.

***VerI,0 ***

I,,#$%&,tJt+,-.

! “#$%& ( ) *+, -./0 t 23456789: ; <=>?@ABCDEFGHI

“#$%& () *+, -. /0 123456789:

#$%& ( ) *+, -./0 123456789:

$%& () *+,–./0123456789:

%&’() *+,-./Ot23456789:

&’ () *+,-./Ol23456789: ;<=> ?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\l ”–’abcdefghi jklmnopqrstu

/0 123451j78g: ;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\ 1‘–’ abcdefghi jkImno

: <=> ?@ABCDEFGHIJKLMNOPQRSTUWVXYZ[ \] “–’ abcdefghi j k lmnorw

: <=> ?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[ \ 1 ‘–’ abcdefgh i j k lmnomr’

: <=> ?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[ \ 1“–’ abcdef ghi j k1Mnopqrs

:<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\l’–’abcdefshi ik1mnopqrst

JKLMNOPQRSTUWVXYZ[\ 1‘– abcdefgtri j klrnnop

button is pressed, the

1

Figure 4-3. ShortseK-test

Since the self-test prints across the full width of the carriage, itisrecommended that the printer is loaded with the widest paper possible to avoid

damage tothe print head and/or platen.

Page 45

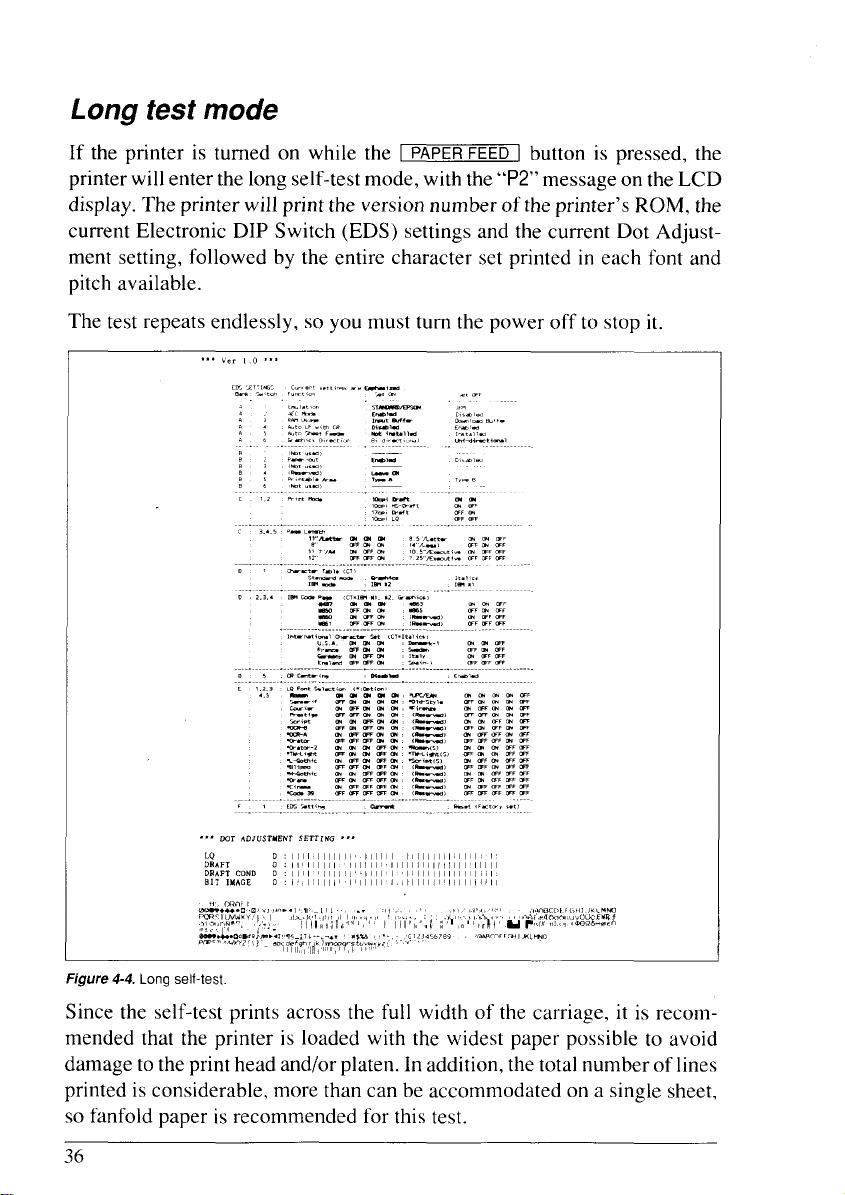

Long test mode

If the printer is turned on while the I

PAPER FEED ] button is pressed, the

printerwillenter thelong self-testmode, with the “P2”message onthe LCD

display. The printer will print the version number of the printer’s ROM, the

current Electronic DIP Switch (EDS) settings and the current Dot Adjustment setting, followed by the entire character set printed in each font and

pitch available.

The test repeats endlessly, so you must turn the power off to stop it,

... ,,, ,.0 . . .

.,, cOr ADJIJSrMENT SETTING . . .

Figure 4-4. Longself-test

Since the self-test prints across the full width of the carriage, it is recom-

mended that the printer is loaded with the widest paper possible to avoid

damage totheprint head and/or platen. In addition, thetotal number of lines

printed is considerable, more than can be accommodated on a single sheet,

so fanfold paper is recommended for this test.

36

Page 46

Print area test mode

By holding the [ EJECT/PARK]buttondown during power-up, theprinterwill

enter the print area test mode. You can find how many lines on your paper

areavailableforprintingwith l/6-inch linefeeding.Theprinterwillshowthe

“P3” message on the LCD display and print the first line message on the

paper, then print the lastlinemessage after feedingto thebottom of the page.

If you have loaded the fanfold paper, only the first line message is printed.

Pitch lock mode

By holding the EEE12iZbutton down during power-up, the print pitch can

onlybe selectedfrom thecontrol panel. Thisprevents software interference.

Youwillhearanacknowledgingbeep, andtheprinter willshowthe’’P-LOCK”

message on the LCD display as power comes on.

After thebeep tone, you can setthe printer off-line, select a printpitch, then

return to on-line and startprinting. The pitch you selected will show on the

LCD display and will not be reset or otherwise changed by any commands

your software may issue.

Font lock mode

By holding the - button during power-up, fonts can only be selected

from the controlpanel. This prevents software interference. There will bean

acknowledgingbeep and“F-LOCK”messageontheLCD display.After which

you can set the printer off-line, select a font, then return to the on-line state

and begin printing.The selected font willnot be changed by any commands

your software may issue.

Font and Pitch lock mode

Ifyou want to protectboth the font andpitch settingsfrom software changes,

press both the _ and - buttons during power-up. There will be

two acknowledging beep tones with “P-LOCK” and “F-LOCK” messages on

the LCD display.

Pressing these buttons during power-up does not prevent you from making

any number of changes later from the control panel.

37

Page 47

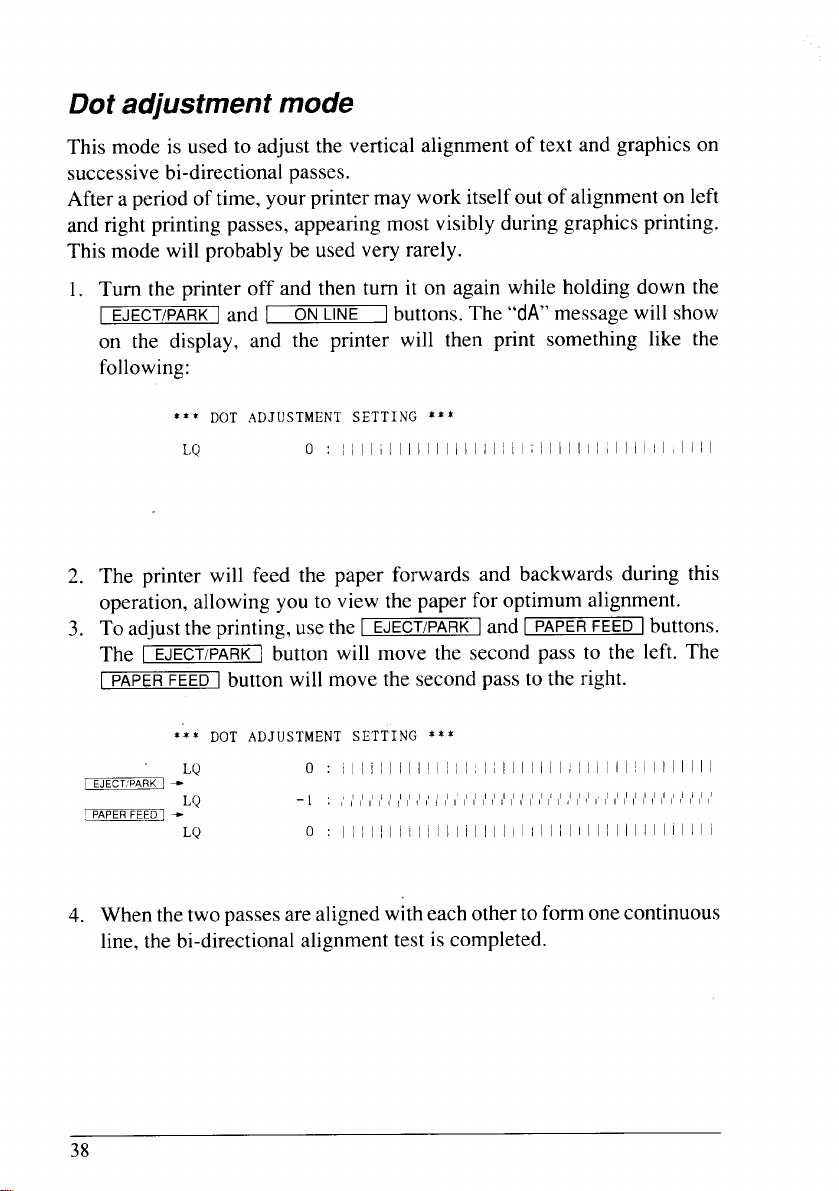

Dot adjustment mode

This mode is used to adjust the vertical alignment of text and graphics on

successive bi-directional passes.

After a period of time, your printer may work itselfout of alignmenton left

and right printing passes, appearing most visibly during graphics printing.

This mode will probably be used very rarely.

1.

Turn the printer off and then turn it on again while holding down the

EJECT/PARK I and 1 ON LINE

on the display, and the printer will then print something like the

following:

*** DOT ADJUSTMENT SETTING ** *

LQ

2.

The printer will feed the paper forwards and backwards during this

o : ! / I

operation, allowing you to view the paper for optimum alignment.

To adjustthe printing, use the [

3.

The

I-EJECT/PARKI button will move the second pass to the left. The

I

PAPER FEED 1 button will move the second pass to the right.

buttons. The “dA” message will show

]

: I I

I i I I I I I I I I I I i I ! I I ~I I I I I I I

EJECT/PARK]and I PAPERFEED [buttons.

i I I I I I I I

4. When the two passes are alignedwith each other toform one continuous

line, the bi-directional alignment test is completed.

38

Page 48

5

To change the mode for which the bi-directional adjustment is per-

. .

formed, press the [

ON LINE

button. This will cycle between “LQ”,

I

“DRAFT”, “DRAFT COND” and “BIT IMAGE”.

Repeat the process for all print modes.

.

ON=!ME.~ -

I

*** Del’

LQ

LQ -1 : ,’,’,s,’,’,’,’,’,’,’t’,’,’,’,’,’,’,’,’1’,’1’1’,’,’,’1’,’,’‘ 1’,’1’ 1’ 1’ 1’ 1’ {’ 1’ 1’

LQ

ADJIJSTMENT ‘jETTING X X *

o:

I 1I I I I I ! I I I I , I I ~I I I i I I I I ! I I I i ! I ~I I I I I

o:

I I I 1I I I I I I I I /I I I I / I I I I I I I I I I I I I JI I I I I !

6. To exit from this mode, press the - button.

$** END x*:

39

Page 49

Hexadecimal dump

Thisfeatureisusefulfor programmers who are debugging printingprograms

and want to see the actual codes the printer is receiving. (Some computers

change the codes the programmer intended.)

Inthismode, alldata received will be printed ina hexadecimal dump format,

rather than the control codes being acted on as command codes.

This mode is accessed with the following procedure:

1. While holding both the I

PAPER FEED 1and [ EJECT/pARK1buttons down,

turn power ON. A beep tone will be heard and the “Hd” message on the

display.

2. Begin printing. In place of the usual printout you will get a formatted

dump showingexactly what data theprinter receives. Each line presents

sixteen characters, their hexadecimal codes to the left and printable

characters printed on the right.

3. At the end of the hexadecimal dump, set the printer off-line with the

ON LINE

button. This is necessary to print the last line.

\

40

Page 50

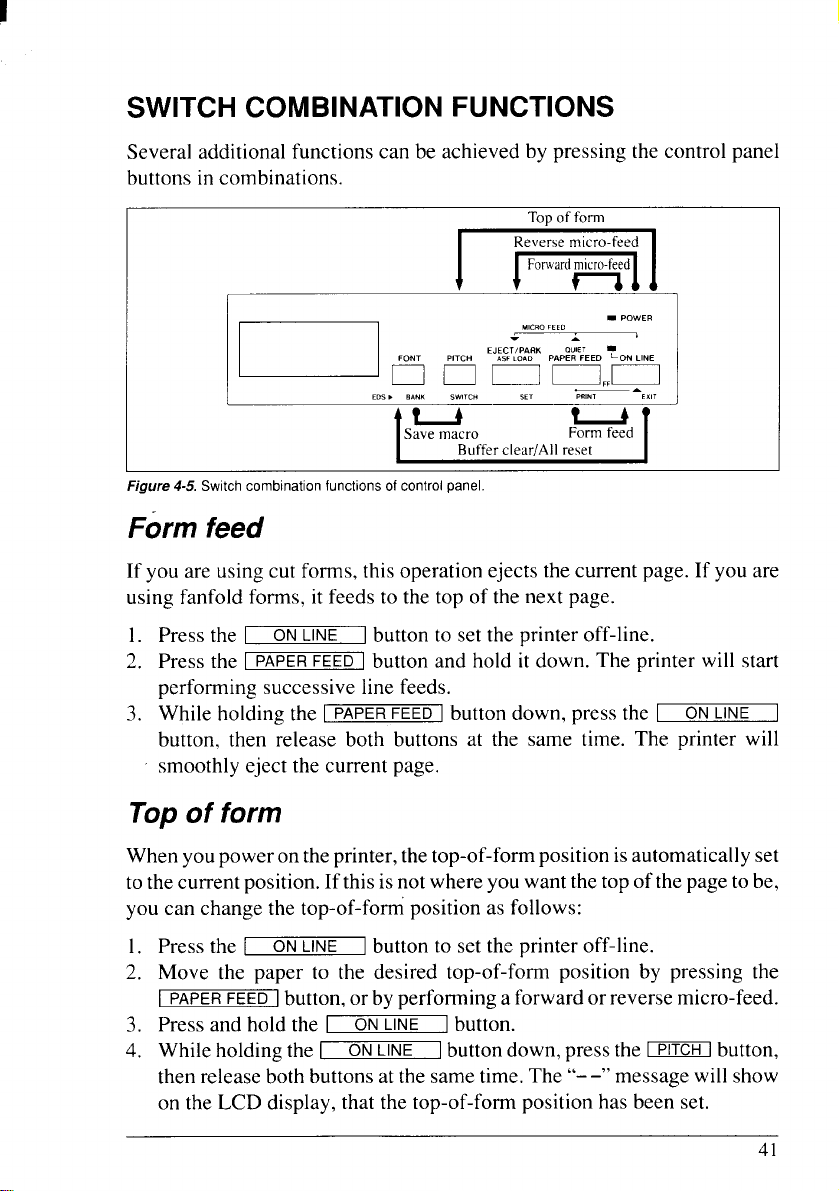

SWITCH COMBINATION FUNCTIONS

Several additional functions can be achieved by pressing the control panel

buttons in combinations.

Top of form

Buffer clear/All reset

Figure 4-5.Switch combination functions of control panel

Form feed

Form feed

If you are using cut forms, this operation ejects the current page. If you are

using fanfold forms, it feeds to the top of the next page.

1.

Press the I

2.

Press the I

ON LINE

PAPER FEED ]button and hold it down. The printer will start

I button to setthe printer off-line.

performing successive line feeds.

While holding the [

3.

PAPER FEED 1 button down, press the I

ON LINE

button, then release both buttons at the same time. The printer will

smoothly eject the current page.

Top of form

When youpower on the printer, the top-of-form positionisautomatically set

to the current position.If this isnot where you want thetop of thepage tobe,

you can change the top-of-foti position as follows:

1. Press the I

2. Move the paper to the desired top-of-form position by pressing the

I

PAPER FEED ] button,or by performing aforward or reverse micro-feed.

3. Press and hold the I

4. While holdingthe [

then releaseboth buttonsat the same time. The “-–” message will show

on the LCD display, that the top-of-fonmposition has been set.

ON LINE

button to set the printer off-line.

]

ON LINE

ON LINE

button.

]

buttondown, pressthe EEEHl button,

]

1

41

Page 51

I

Forward micro-feed

Forfine alignment, you can feed thepaper forward in very small increments

as follows:

1. Press the I

2. press the I

ON LINE

ON LINE

3. While holding the I

button. The paper will start advancing in a series of small steps.

When you want to stop, release both buttons.

Reverse micro-feed

You can also feed the paper in small increments in reverse, to return to a

higher position on the same page.

ON

1.

Press the I

2.

Press the I

While holding the I

3.

button.The paper will start moving backwards ina series of small steps.

When you want to stop, release both buttons.

NOTE: Open thebaillever when theprinter beeps intermittentlyand the

“Er” message shows on the LCD display near the edge of the

paper.

LINE ] button to set the printer off-line.

ON LINE ] button again and hold it down.

button to set the printer off-line.

]

I

button again and hold itdown.

ON LINE ] button down, press the I PAPERFEEtI]

ON LINE

button down, press the [ EJECT/PARK I

\

Changing the auto loading position

Normally, the printer automatically loads the paper one

edge.

If you want to change this value, follow this procedure:

1. Load the paper by moving bail lever toward the front of the printer.

2. Change the print position using the micro feed function.

The value on the LCD display shows the micro-feed value from the

default position.

3. After youget the desired position,pressthe I

ON LINE

the value.

This position will remain unless you power off the printer. If you want to

retainthispositioneven afteryou turn off thepower, store it using the Macro

Definition function, which is described later.

Note that youcan only change thisvalue immediately after loadingpaper. If

you feed paper, you cannot change the auto loading value.

42

line from the top

buttonto save

I

Page 52

Clearing the buffer/All reset

The printer stores received data in a large memory buffer. This creates a

problemwhenyou want to abandonaprintingjob andrestart: theprintermay

beholding moredatainitsbufferthanithasactuallyprinted,andthisunprinted

data mustbe cleared out before restarting. Turning power off is one way to

clear the buffer, but there is another way:

1, Halttheprinting program onthecomputer. Imprintingstopsimmediately,

thebuffer isclear and the rest of thisprocedure isunnecessary, If printing

does not stop,continue as follows:

2. Press the I

now stop, but there may be data remaining in the buffer.

3. Press and hold the 1

4. Whilepressingthe I

button. Continue holding these two buttons down, you willhear a beep

toneandthe “bC>’message appears onthe LCD display. If you hold these

buttons down longer,you will hear three beep tones and the printer has

been initialized to the power-on default settings.

5. Release these buttons, make any necessary control panel settings, then

set the printer back on-line.

Itisessential to stopthe printingprogram on thecomputer before yougooffline. Otherwise, when you go back on-line the computer will start sending

data again and the printer will continue printing, with missing data from

when,the buffer was cleared.

ON LINE

button to set the printer off-line. Printing will

1

ON LINE

ON LINE

button.

I

Ibuttondown,pressandholdthe -

Save Macro Definition

Youcansavethecurrent settingsto theprinterforlater use with thefollowing

procedure:

ON

1. Press the I

2. Press the - button and hold it down.

3. While holding the - button down, press the CElEi31button and

holdthemdownuntilthe“MACRO” messageappearson theLCD display.

4. Release both buttons at the same time after this message appears on the

LCD display to savethe current setting.

If yourelease thesebuttons after the“MACRO” message hasgone out on

the display, the macro has been cleared.

LINE

button to set the printer off-line.

I

43

Page 53

I

NOTE: You can store the following settings with this procedure.

● Current Font

● Current Pitch

● Current auto-loading amount for cut forms

s Current auto-loading amount for fanfold forms

● Current auto-loading amount in ASF mode

Datato be storedarecontrolled inStandard mode and IBM mode separately.

For example, the data stored in the Standard mode are not effective in the

IBM mode, and vice versa.

44

Page 54

CONDITIONS INDICATED BY MESSAGES AND TONES

This sectionhelps you identify the messages and themeanings of the tones.

Summary of display messages

Following table shows the summary of the messages on the LCD display.

LCD Message

ISANSERIF {

~PREsTiGE{

;seRlpT

~Hs-DRAFT{

;DRAFT

]OPTION

PITCH

EDS

I

1

I

Iamii3

Meanings and action

ROMAN LQ font is selected.

SANSERIF LQ font is selected.

COURIER LQ font is selected.

PRESTIGE LQ font is selected.

SCRIPT LQ font is selected.

High-Speed Draft font is selected.

You cannot select print pitch except 10CPI.

Draft font is selected.

You cannot select proportional pitch with the Standard/

Epson mode.

Optional LQ font is selected.

Indicates the message below shows the current pitch.

EDS mode is currently selected and the message on the

right indicates the current Bank and Switch number.

Press the 1

ON LINE

button to exit the EDS mode.

]

Font lock mode is selected.

The printer ignores the font selection commands and

prints with the fontdisplayed on the panel.

Turn off the power switch to cancel the font lock mode.

Pitch lock mode is selected.

The printer ignores the pitch selection commands and

prints with the pitch displayed on the panel.

Turn offthe power switch tocancel the pitch lock mode.

Page 55

LCD Message

ON OFF

Meaninm and action

DisplaysintheEDS mode.Indicates thecurrent statusof

the displayed EDS bank and switch number.

Press the I

EJECT/PARK ]button to change the status.

Quiet mode is selected.

Press the 1

PAPER FEED Ibuttonwhile in theon linemode

to return to the Normal mode.

Front panel settingare saved in theprinter’s memory as

a “MACRO”.

Short print test mode is selected.

Long print test mode is selected.

Turn off the power switch to cancel the long print test

mode.

Print area test mode is selected.

Hexadecimal dump mode is selected.

Turn off the power switch to cancel the hexadecimal

dump mode.

Top of form is setmanually with the control panel.

Buffer is cleared manually with the control panel.

Paper is not loaded to the printer.

Dot Adjustment mode is selected.

Bail lever is closed before the paper goes through the

location of the bail lever. Open the bail lever.

Release lever is moved while the paper is in printing

position.

The memory of EDS settings is accessed.

Print head error. Turn off theprinter and turn iton again.

Carriage home position error. Turn off the printer and

turn it on again.

Paper handling error. Turn off the printer and turn it on

again.

S.W.I. error. Turn off the printer and turn it on again.

RAM check error. Turn off the printer and turn it on

again.

Watch dogerror. Turn off the printer and turniton again.

46

Page 56

Summary of beep tones

Following table shows the summary of beep tones.

Beep tones

Two seconds

tone

Long tone, once

Four short tone

sequence, two

times

Short tone, once

Short tone, twice

Short tone, triple

One-quarter tone

Meanings

Printer detects an error condition.

Turn off the power switch and turn it on again.

Printer detects an error condition.

Turn off the power switch and turn it on again.

Printer is out of paper.

● Buffer is cleared.

● Top of form is set.

● Quiet mode is selected.

● Tear off function is selected.

● EDS mode is selected.

● Macro definition is selected.

● Quiet mode is cancelled.

● Macro definition is cancelled.

● Printer is reset.

● Hexadecimal mode is selected.

● Pitch lock mode is selected.

. Font lock mode is selected.

One-quartertone,

twice

Intermittent tone

One-quarter

tone, twice

Pitch and Font lock mode is selected at a time.

● Release lever is moved while the paper is in printing

position.

● Bail lever is closed before the paper goes through the

location of the bail lever.

47

Page 57

48

Page 58

chapter 5

DEFAULT SETTINGS=EDSMODE

From thecontrol panel you can change the parameters thatdefine how your

printer works.These parameters become yourpower-on settings.This function is called the Electronic DIP Switch (EDS) mode.

HOW TO SET THE EDS MODE

The EDSmode inthisprinter has 16functionsthat you can setas thepoweron default.

Turn the printeron while simultaneously holding the -, -, and

EJECT/PARK ] buttons.

The “EDS” message will show on the LCD display. This indicatesthat you

have entered the EDS mode.

In EDS mode, the buttons on the control panel are used as shown below in

Figure 5-1.

Select Select Change

Bank Switch setting

Figure 5-1. Buttonfunctionsin theEDS mode.

● Use the - button to select the Bank Letter.

● Use the - button to select the Switch Number.

● The LCD display on the control panel shows the current setting, ON or

Print Exit

OFF.

Use the I

● Press the ] PAPER FEED ] button to print the current settings.

● Press the I

EJECT/PARK~button to change the settings.

ON LINE

button to save and exit the EDS mode.

1

49

Page 59

OF THE EDS SETTINGS

The printer storesthe parameters that you can select from the control panel

while in the EDS mode.

Adefaultisthe settingthat the printer willuse if noneis specificallyselected

by aprogram. When you first turn on or later reset your printer thesedefault

settings will take effect. By changing the settings, you can alter various

printer functions to match your specific requirements. The following will

help you choose the proper settings.

BanI-Switch Function

A-1

A-2

A-3 RAM Usage

A-4 Auto LF with CR

A-5 Auto Sheet Feeder

A-6

B-1 - (Not used)

B-2 Paper-out

B-3 (Not used)

B-4 (Reserved)

B-5

B-6 (Not used)

c-1

c-2

c-3

c-4

c-5

D-1

D-2 IBM Code page or

D-3 International

D-4 Character Set

D-5

E-1

E-2

E-3

E-4

Emulation

AEC Mode

Graphics Direction

Printable Area

Print Mode

Page Length

Character Table

(Standard mode)

(IBM mode)

CR Centering

LQ Font Selection

E-5

F-1 EDS Setting

ON

STANDARD/EPSON

Enabled

Input Buffer

Disabled

Not installed

Bi-directional

Enabled ] Disabled

Leave ON

Type A

(See below)

(See below)

Graphics

Set #2

(See below)

Disabled

(See below)

Current

OFF

IBM

Disabled

Download Buffer

Enabled

Iristalled

Uni-directional

I Type B

Italics

[ Set #l

Enabled

Reset

NOTE: The factory default is the “ON” position for all functions except

A-6 which is set to the “OFF” position.

50

Page 60

Switch A-1: Emulation

Select the mode compatible with your computer and software. In the

Standard/Epsonmode,theprinteroperates likethe Epson LQ-860/850.

In the IBM mode, it operates like the IBM Proprinter X24E/24P,

Ps/1 .

The ON position selects Standard/Epson mode. The OFF position

selects IBM mode.

Switch A-2: Auto Emulation Change (AEC) Mode

This switch selects the Auto Emulation Change (AEC) mode.

When the AEC mode is enabled, the printer automatically judges the

Emulation which your application program uses.

Switch A-3: RAM Usage

Inordertodownloadcharacters thisswitchmustbe intheOFF position.

The printer then uses its RAM memory for storing character patterns

and providesonly aone-line printbuffer. If you leave this switch ON,

the printer uses its RAM memory as an input buffer, allowing the

computer to send data faster than the printer prints.

Switch A-4: Auto LF with CR

If youleave this switchat theON position, a separate line-feed code is

required from your computer to obtain a line feed. If you move this

switch tothe OFF position,the printer performs both a carriage return

and line feed each time it receives a carriage-return code.

Mostcomputer systems send a line feed code, or both acarriage return

and linefeed, at the end ofeach line, so this switch should be left ON.

If you get double line spacing when you expect single spacing, or if

lines overprint each other, try changing the setting of this switch.

Switch A-5: Auto Sheet Feeder

In order to use the optional automatic sheet feeder (SF- 1ODS),move

this switch to the OFF position.

Otherwise leave it ON.

Switch A-6: Graphics Direction

When printing in graphics mode, the printer may either print bidirectionally (in alternatedirections) forspeed or inone direction only

(uni-directional for increased accuracy). For practically all purposes,

however, bi-directional printing is sufficiently accurate.

51

Page 61

Switch B-2: Paper-out

When thisswitch isOFF the printer ignoresthe paper-outdetector and

prints down to (and beyond) the bottom edge.

Switch B-4: This switch is used for technical purpose only. Leave this

switch ON.

Switch B-5: Printable area

This printercan use two types ofprinting area format for singlesheets

(cut forms).

ByputtingtheswitchON (’<TypeA“), thetop ofthefirstlineofprinting

willstart 1/6inchfrom the top of thepaper, and the printed area willend

1/6inch from the bottom of the paper.

ByputtingtheswitchOFF (“Type B“),thefirstlineofprinting will start

at one inch from the top of the paper, and the printed area will end to

print 6 mm from the bottom of the printer.

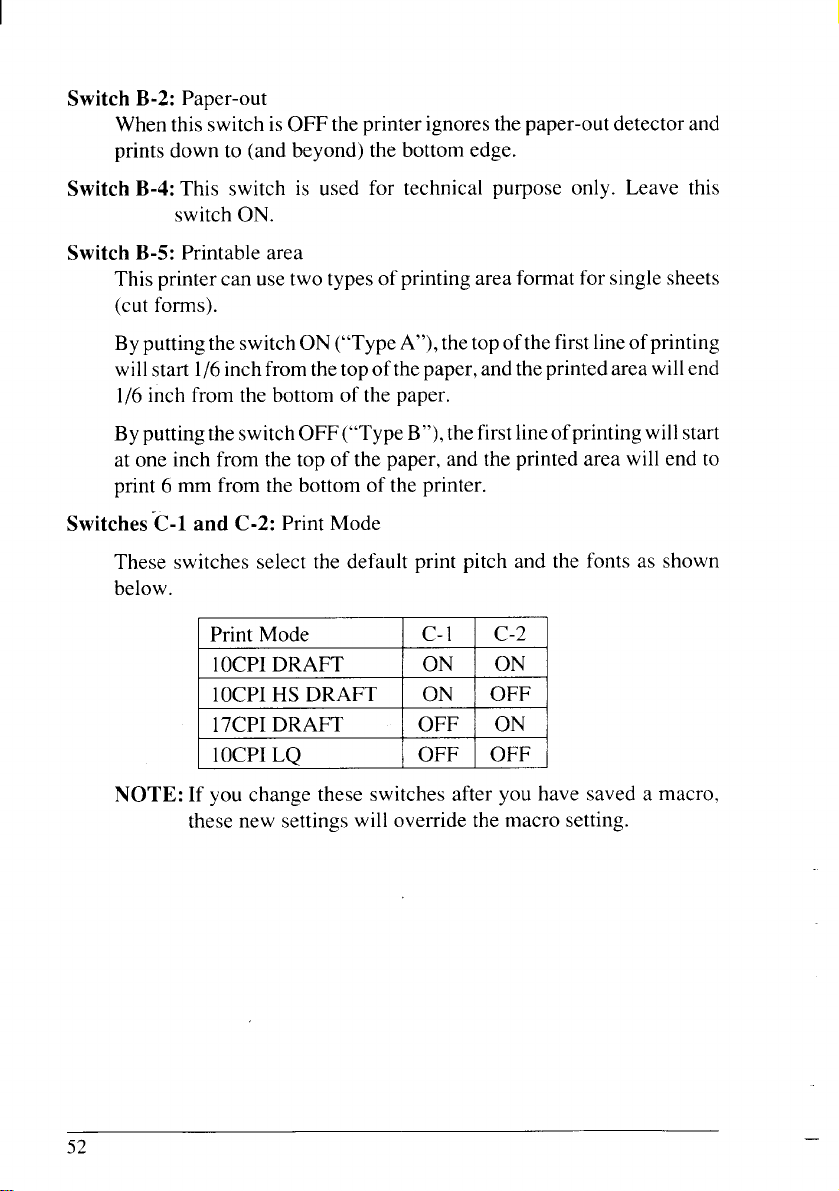

Switches -C-l and C-2: Print Mode

These switches select the default print pitch and the fonts as shown

below.

Print Mode

10CPIDRAFT

10CPIHS DRAFT

17CPIDRAFT

10CPILQ

c-l c-2

ON ON

ON

OFF

OFF ON

OFF OFF

NOTE: If you change these switches after you have saved a macro,

these new settings will override the macro setting.

52

.

Page 62

I

Switches C-3 to C-5: Page Length

Leave these switches ON if you will be using 1l-inch forms. You will

need tochange the switches if you willbe using adifferent pagelength

as shown below:

Page Length

11inches/Letter ON ON ON

8 inches OFF ON ON

11.7inches/A4

12inches OFF OFF

8.5 inches/Letter ON ON

14inches/Legal OFF ON

10.5inches/Executive

I 7.25 inchesiExecutivel OFF I OFF I OFF I

Switch D-1: Character Table

The action of this switch depends on the mode chosen with switch A-

1.

Movethisswitch OFF toselectItalic character tablewith theStandard/

Epson emulation mode. If you leave this switch to the ON position, in

place of italicsyou will get the graphic characters, international characters, and mathematical symbols of IBM character set #2.

In the IBM emulation mode, ON selects character set #2, which has

international characters and fewer control words.

OFF selectscharacter set #1, for computers with a 7-bit interface.

Switches D-2 to D-4: IBM Code Page or International Character Set

c-3

ON

ON

c-4

OFF ON

OFF OFF

c-5

ON

OFF

OFF

Except in the Standard Italic character set, these switches select the

default character code page as shown below:

IBM Code Page

#437U.S.A.

#850Multi-lingual

#860Portuguese

#861Icelandic OFF

D-2

ON

OFF ON

ON OFF ON (Reserved)

D-3 D-4 IBMCodePage D-2

ON

OFF

ON K363CanadianFrenchON ON OFF

ON #865Nordic

ON (Reserved)

OFF

ON

OFF

D-3 D-4

ON OFF

OFF OFF

OFF OFF

Page 63

International character sets differ in their assignment of 12character

codes in the Standard Italic character set. See the character tables in

Chapter 11.With these switches you can select one of eight character

sets as follows:

Country

U.S.A. ON ON ON Denmark I ON ON

France

D-2 D-3 D-4 Country D-2 D-3 D-4

OFF

OFF ON ON Sweden OFF ON OFF

Germany ON OFF ON Italy ON OFF OFF

En.zland OFF OFF ON Spain I OFF OFF OFF

Switch D-5: CR Centering

If you setthis switch OFF, the carriage moves to the center each time

to feed paper nearthe perforation. This way, you can get betterquality

of printing around the preformations.It is recommended to match the

page length settingto yourfanfold paper, otherwise, thisfunction does

not work properly at the perforations.

If you leave this switchON, the carriage does not move when feeding

paper.

Switches

E-1 to E-5: LQ Font Selection

These switchesallows you to choose the default font selectedwhen LQ

mode is selected, as shown below.

FontName

Roman ON ON ON ON ON UPC/EAN* ON ON ON ON OFF

Sanserif

Courier

Prestige OFF OFF ON ON ON (Reserved)

Script ON ON OFF ON ON (Reserved) ON ON OFF ON OFF

OCR-B* OFF ON OFF ON ON (Reserved) OFF ON OFF ON OFF

OCR-A*

Orator*

Orator2*

TW-Li.ght* OFF ON ON OFF ON SLQTW-Light*OFF ON ON OFF OFF

Letter-Gothic* ON OFF ON OFF ON SLQ Script* ON OFF ON OFF OFF

Blippo* OFF OFF ON OFF ON (Reserved) OFF OFF ON OFF OFF

H-Gothic* ON ON OFF OFF ON (Reserved) ON ON OFF OFF OFF

Orane* OFF ON OFF OFF ON (Reserved)

Cinema* ON OFF OFF OFF ON (Reserved) ON OFF OFF OFF OFF

Code39* OFF OFF OFF OFF ON (Reserved)

E-1 E-2 E-3 E-4 E-5 FontName E-1 E-2 E-3 E-4 E-5

OFF ON ON ON ON Old-Style* OFF ON ON ON OFF

ON OFF ON ON ON Firenze* ON OFF ON ON OFF

OFF OFF ON ON OFF

ON OFF OFF ON ON (Reserved) ON OFF OFF ON OFF

OFF OFF OFF ON ON ‘(Reserved) OFF OFF OFF ON OFF

ON ON ON OFF ON SLQRoman* ON ON ON OFF OFF

OFF ON OFF OFF OFF

OFF OFF OFF OFF OFF

54

Page 64

Optional fonts (marked with*) can be selected only when the corresponding font cartridge is installed in the printer.

If the corresponding font cartridge is not installed, the Roman is

selected.

Switch F-1: EDS Setting

Ifyou setthis switch OFF, the currentEDS settings are allcleared, and

restores the Factory Settings,

55

Page 65

56

Page 66

chapter 6

TROUBLESHOOTING

This chapter helpsyou identifyprinter conditionsand problems thatyoucan

often correct yourself.

Remember that your printer is a highly sophisticated electronic device,

which also containshigh voltage inside.For that reason, onlycarry outthose

operations described in this chapter.

CAUTION: Any attempt to carry outoperations other than those described

here may result in electric shock and/or damage to the printer.

When carrying out any repairs or maintenance, always follow

the instructions carefully.

TROUBLESHOOTING

Your printer is a reliable piece of precision machinery, which should not

causeyou anytrouble,provided itisused and treated sensibly.However, the

few elementary tips below should help you avoid having to make unnecessary service calls.

● Power switch is on, but power indicator is off

Probable Cause I Action

Printer is not

getting power.

● Printer sounds as if it isprinting but does not; Printing is weak

Probable Cause I Action

Ribbon is jamming,twisted,or

not between the

printheadandthe

printheadshield.

Adjustment

lever is set

incorrectly.

Make sure that the power cord is correctly connected.

Verify that the power source works.

Make sure thatthe ribbon cartridge iscorrectly installed.

Make sure that the ribbon is between the shield on the

print head and the end of the print head.

Replace the ribbon.

Checkthe settingoftheadjustmentlever. Move the lever

to a darker setting.

57

Page 67

● Printer test works, but printer does not print when attached to computer

Probable Cause

Printer cable has

a problem.

Problem with

] Action

Make surethat theprinter cable is correctly connected at

both ends, printer and computer.

Refer to your application program manual.

the application

program.

Incorrect

emulation is

Select the other emulation with the EDS setting.

See Chapter 5.

selected.

● Printer sounds the audible alarm

Probable Cause I Action

Thismightindicatf

anerroror normal

operation.

● Pitch or font selected is being changed

Probable Cause

Your software is

overriding your

Check the message on the display and the status of the

controlpanel indicatorsand see“Conditionsindicatedby

messages and tones” in Chapter 4.

I Action

Set your printer in Font/Pitch lock. See “Pitch lock

mode” and “Font lock mode” in Chapter 4.

control panel

selection.

58

Page 68

● Printer does not feed paper

Probable Cause

Paperisjamming.

Bailleverisclosed

before paper goes

Action

Remove all forms and pieces of paper.

Openthebaillever.Bailleverautomatically closed when

the paper goes through the bail lever location.

throughthebailleverlocation.

Adjustment lever

is set incorrectly.

Fanfold form is

Checkthesettingof the adjustmentlever.See“Adjusting

the printing gap” in Chapter 3.

Move bail lever forward to unpark the fanfold paper.

parked.

● Line spacing is incorrect or overprinting occurs

Probable Cause

The tractor posi-

tions are incor-

Action

Adjustthetractorpositions.See“Loading fanfoldforms”

in Chapter 3.

rectly adjusted.

Incorrect emulation is selected.

Problem with the

Select the other emulation with the EDS setting. See

Chapter 5.

Refer to your application program manual.

application

program.

Platen knob was

manually turned

while the Power

indicatorwas on.

Forms are jamming between

printing surface

and the print

head.

Set the top of form. See “Top of form” in Chapter 4.

Do notmanually turnthe platen knob when thepower is

on. Use the I

PAPER FEED [button.

Resetadjustmentlever. See “Adjustingthe printing gap”

in Chapter 3.

59

Page 69

● Incorrect number of lines on a page

Probable Cause

Paper is adjusted

Action

Set the top of form. See “Top of form” in Chapter 4.

incorrectly.

Paper has shifted

Readjust forms,

backwards after

several forms

printed correctly.

Incorrect emula-

tion is selected.

Problem with the

Select the other emulation with the EDS setting.

See Chapter 5.

Refer to your application program manual.

application

program.

Distance printer

Move paper closer to the printer.

must pull paper

is too far.

Paper is getting

Move the paper away from any wires or cables.

stuck on cables.

● Line length is wrong; Graphics do not print; Lines are not starting at left

margin

Probable Cause I Action

Incorrect emula-

tion is selected.

Problem with the

Select the other emulation with the EDS setting.

See Chapter 5.

Refer to your application program manual.

application

program.

60

Page 70

● Characters are wrong or missing; formatting control codes do not work

Probable Cause

Action

Problem with the Refer to your application program manual.

application

program.

Some wires are

Printer needs repair.

missing from the

print head.

Wrong default Check thecurrent EDS setting.Modify the EDS setting.

setting with

EDS switches.

● Dots are missing or print quality is poor

Probable Cause

] Action

Adjustment lever Check the position of the adjustment lever.

is set incorrectly. See Chapter 3.

Print head is not Printer needs repair.

working.

● Forms are smudged or printing is too dark

Probable Cause

Adjustmentlever

issetincorrectly.

Ribbonistwisted

or isnot between

the printheadand

the print head

shield.

Print head shield

(or printhead) is

damaged or

missing.

Action

Check the position of the adjustment lever.

Movethe leverto a lighter setting (front).See Chapter 3.

Install the ribbon correctly. See “Installing the ribbon

cartridge” in Chapter 2.

See “Installing the ribbon cartridge” in Chapter 2 to

locate theprint head shield and printhead. Contact your

dealer.

61

Page 71

● Printer is unstable; Wrong characters are printed; Left margin changes;

printing stops

Probable Cause

Static electricity

is resulting from

] Action

I

Increase the humidity.

Movedeviceswithelectric motors away fromtheprinter.

low humidity or

interference from

nearby electrical

devices.

● Left margin moves to the right during printing

Probable Cause I Action

The print head

is not moving

correctly.

Problem with the

Check that the ribbon and paper are correctly installed.

See“Installing ribbon cartridge” in Chapter2 and“Load-

ing paper” in Chapter 3.

Refer to your application program manual.

application

program.

Theadjustment

lever is in the

Reset the adjustment lever. See “Adjusting the printing

gap” in Chapter 3.

wrong position.

● Printer is printing beyond side edge of forms

Probable Cause

Action

Paper is adjusted Adjust both forms tractors and the paper.

incorrectly.

Problem with the Refer to your application program manual.

application

program.

Aprintheadjam

caused by the

ribbonorapaper

Make surethat the ribboncartridge iscorrectly installed.

See “Installing the ribbon cartridge” in Chapter 2.

Clear the paperjam.

jam.

62

Page 72

● Printer case is hot to the touch

Probable Cause

printer’s vents Move object away from the air vents, including the

are blocked.

● Printer is noisy

Probable Cause

The printer

vibrates.

Printer covers

are open.

---J

Action

bottom of the printer.

I Action

Move any objects that touch the printer.

Ensure that the printer is on a level, study surface.

Close covers.

63

Page 73

MAINTENANCE

Essentially,your printer isa robustpiece of equipment, but shouldbe treated

with a modicum of care in order to avoid malfunctions. For example:

● Keep your printer in a “comfortable” environment. Roughly speaking, if

youare comfortable,then theenvironment issuitable for yourprinter (see

Chap[er 2).

● Do not subject the printer to physical shocks or excessive vibration.

● Avoid over-dusty environments. Dust is the enemy of all precision

mechanical devices.

● Toclean theexteriorofthe printer, use acloth barely dampenedwith either

water with alittle detergent or a little alcohol, but do not allow any liquid

to fall inside the printer.

● The interiorof theprintermay be cleaned with a smallvacuum cleaner or

a compi-essed-airaerosol (sold for this purpose). When performing this

operation, be sure not to bend or damage any cable connections or

electronic components.

64

Page 74

chapter 7

OPTIONAL ACCESSORIES

You can select the following accessories as option.

● Automatic sheet feeder (SF-1ODS)

● Pull tractor unit (PT-1OZS)

● Font cartridges (FC series)

● RAM cartridge (RC-32Z, DC-32Z)

● Serial-Parallel Converter (SPC-8K)

This chapter describes how to install and use these optional accessories.

NOTE: When you install or remove the optional accessories, turn off the

power switch.

AUTOMATIC SHEET FEEDER (SF-1ODS)

You can usethe Automatic SheetFeeder (ASF) to print on cut-sheet forms.

Before installing the ASF, check each item in the box against Figure 7-1 to

make sure that you have everything.

Figure 7-7.Check,tomakesureyouhaveallfweitems:1)Sheet Feeder,2) Hopperattachment,3) Stacker

attachment,4) Printer cover,and 5) ASF Users manual.

NOTE: The AutomaticSheetFeeder isprotected bypacking and tapeduring

shipping. Be sureto remove all of the protective material and tape

before use.

65

Page 75

Setting up

The procedure to install the ASF is:

1. Use the printer’s EDS mode to select ASF as “installed”. (For details,

please refer to Chapter 5.)

2. Open the front cover by lifting up the back using the two grips on either

side, then remove the cover by pulling up.

3. Open the rear cover by lifting up the front using the two grips on either

side.

4. Move the printer bail lever toward the front of the printer to open the

paper bail.

Releaselever

Figure 7-2.Remove the front cover, and open the rear cover

5. Tip theAutomatic SheetFeeder forward slightly by aligningthe notches

on the ASF cover with the bail rollers, then put the feeder into place

behind the printer platen roller.

ASF cover

Figure 7-3.Align the notches and the bail rollers, then tip the ASF forward slightly

66

Page 76

6. Lower the rear side of the Automatic Sheet Feeder and attach it to the

holder shaft.

7. Install the printer cover provided with the Automatic Sheet Feeder.

I

Figure 7-4. Installtheprintercover.

8. Insert the hopper attachment on top of the hopper support section as

shown in Figure 7-5.

I

Figure 7-5. Insertthe hopper attachment.

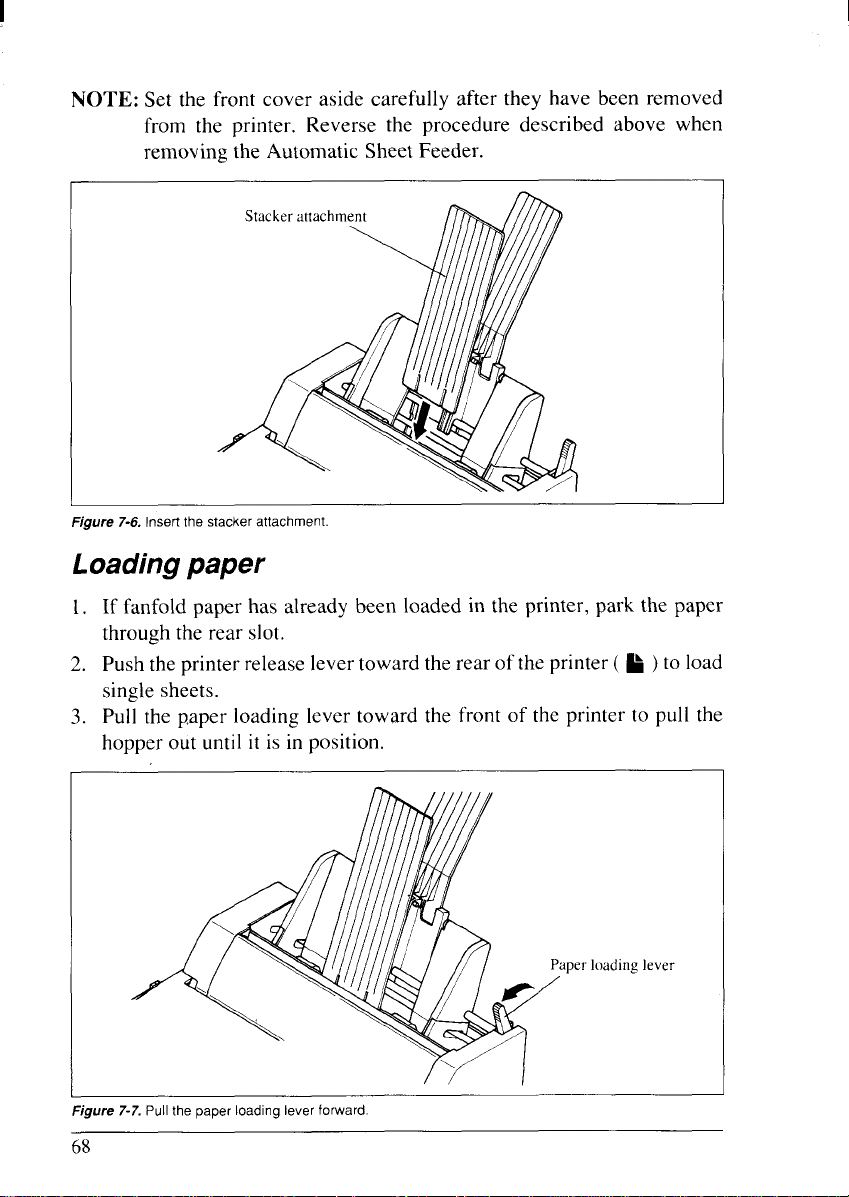

9. Insert the stackerattachment intothe holder onthe front part ofthe sheet

feeder.

NOTE: The flat sideofthe attachment shouldbe locatedtothe rear, as shown

in Figure 7-6.

Now, you can use the ASF by installingthe paper stack into the hopper.

Page 77

NOTE: Set the front cover aside carefully after they have been removed

from the printer. Reverse the procedure described above when

removing the Automatic Sheet Feeder.

Figure 7-6. Insert the stackerattachment

Loading paper

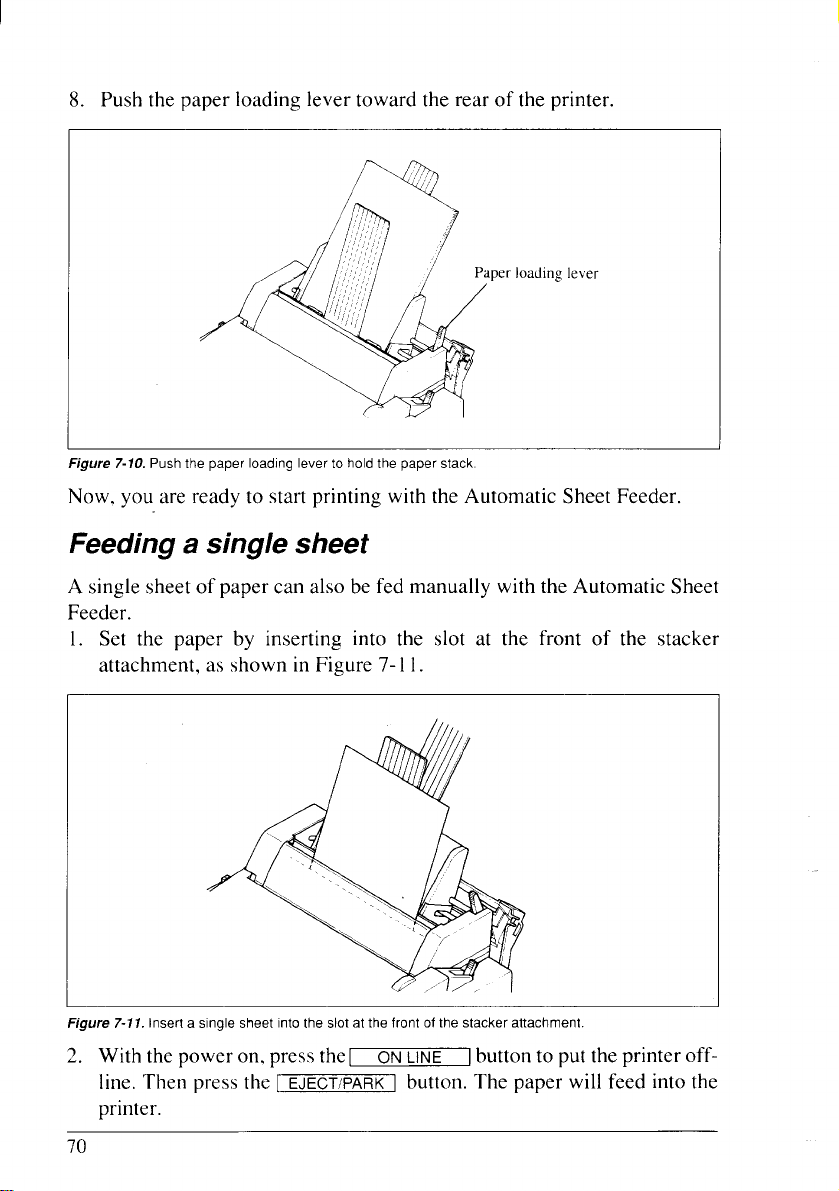

If fanfold paper has already been loaded in the printer, park the paper

1,

through the rear slot.

2.

Push theprinter release lever toward the rear of the printer ( ~ )to load

single sheets.

Pull the paper loading lever toward the front of the printer to pull the

3.

hopper out until it is in position.

I

Figure 7-7.Pull the paper loading lever forward.

68

lever

Page 78

4. Adjust the left paper guide to the desired left position by moving it

horizontally in either direction.

Figure 7-8.Adjustthepaperguidestoaccommodatethe width ofthe paper.

5. Adjust the right paper guide to accommodate the width of the paper.

The guides should be adjusted to restrict the amount of horizontal play

while allowing the paper to slide up and down freely between the two

paperguides. The idealdistance between paper ream andpaper guides is

0.25 mm (0.01”)on both sides at the narrowest part of the paper guides.

6. Fan thepaper stack and square it off properly before inserting it into the

Automatic Sheet Feeder.

Figure 7-9. Fan thepaperbeforeinsertingintotheASF.

7. Insert the paper stack into the Automatic Sheet Feeder.

The stack shouldnot be more than 50 sheets of 20 lb paper.

Ifnecessary, remove some sheets. The ASF may not perform satisfactorily if it is overloaded.

69

Page 79

8. Push the paper loading lever toward the rear of the printer.

Figure 7-10. Pushthe paper Ioadmglever to hold the paper stack.

Now. you are ready to start printing with the Automatic Sheet Feeder.

Feeding a single sheet

A single sheetof paper can also be fed manually with the Automatic Sheet

Feeder.

1. Set the paper by inserting into the slot at the front of the stacker

attachment, as shown in Figure 7-11.

I

Figure 7-71.inserta singlesheetintothe slotat thefrontofthe stackerattachment.

I

2. With the poweron, press thel

line. Then press the [

EJECT/PARK ] button. The paper will feed into the

ON LINE

button to put theprinter off-

printer.

70

Page 80

PULL TRACTOR UNIT (PT-IOZS)

You can use the Pull Tractor Unit to print on fanfold forms or multi-part

forms through the bottom feed slot.

Setting up

The procedure to mount the Pull Tractor Unit is:

1.

Open the front cover by lifting up the back using the two grips on either

side, then remove it.

2.

Open the rear cover by lifting up the front using the two grips on either

side.

3.

Move the printer bail lever toward the front of the printer to open the

paper bail.

4.

Fit the mounting brackets of the Pull Tractor Unit onto the shaft of the

printer mechanism, tilting the Pull Tractor Unit slightly backward.

Figure 7-12. Fitthemountingbracketsofthe Pull Tractor Unitonto the shaft of the printer,

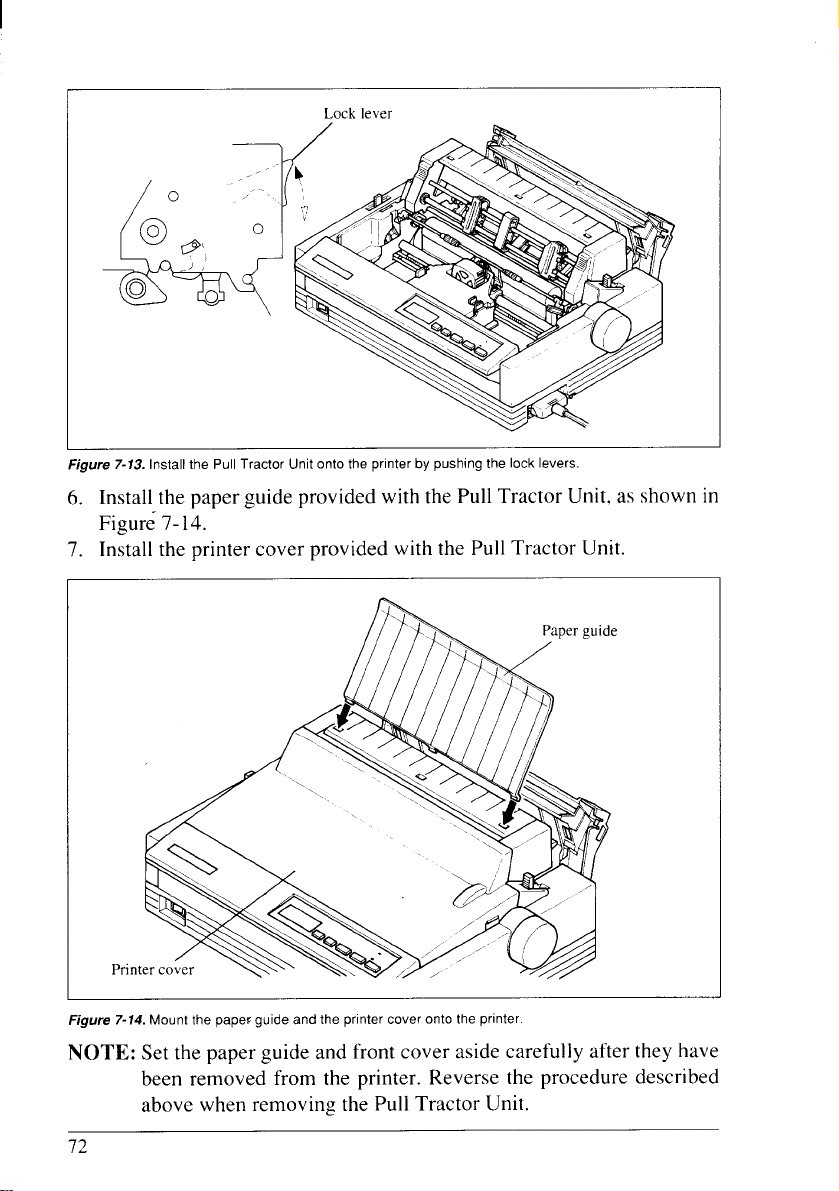

5. Secure the PullTractor Unit firmly by pushing the lock levers on either

side, as shown in Figure 7-13.

71

Page 81

I

Lock lever

Figure 7-13.Install the Pull Tractor Unit onto the printer by pushing the lock levers.

6. Install the paper guide provided with the Pull Tractor Unit, as shown in

Figure 7-14.

7. Install the printer cover provided with the Pull Tractor Unit.

Figure 7-14.Mount the papecguide and the printer cover onto the printer.

NOTE: Set the paper guide and front cover aside carefully after they have

been removed from the printer. Reverse the procedure described

above when removing the Pull Tractor Unit.

72

Page 82

Loading paper

1. Open the printer cover.

2. With the tractor covers open, guide the paper from the bottom of the

printer, by aligning holes with the pins on the tractor unit.

Figure 7-15.Mount the fanfold paper from the bottom of the printer.

3. Adjust the spacingofthetractorunitsby slidingthem along thebar, using

the clamp lever at the back of each unit to release and lock them in

position.When the lever isup, the unit isreleased, and when it is down,

the unit is locked.

4. Now close thetractor covers, again making sure that thepaper holesare

alignedwith thepins on thetractor units. If they are not aligned properly,

you willhave problems withpaper feeding,possibly resulting in tearing

and jamming of the paper.

Page 83

I

p lever

T~actor cover

I

Figure 7-16. Close the tractor covers after adjust the spacing of the tractor units bysliding them along the

bar.

5. After settingupthe paperfromthebottom oftheprinter, installtheprinter

cover.

:1

I

I

Figure 7-17. Mount the printercover.

Now, you are ready to start printing with the Pull Tracter Unit.

74

Page 84

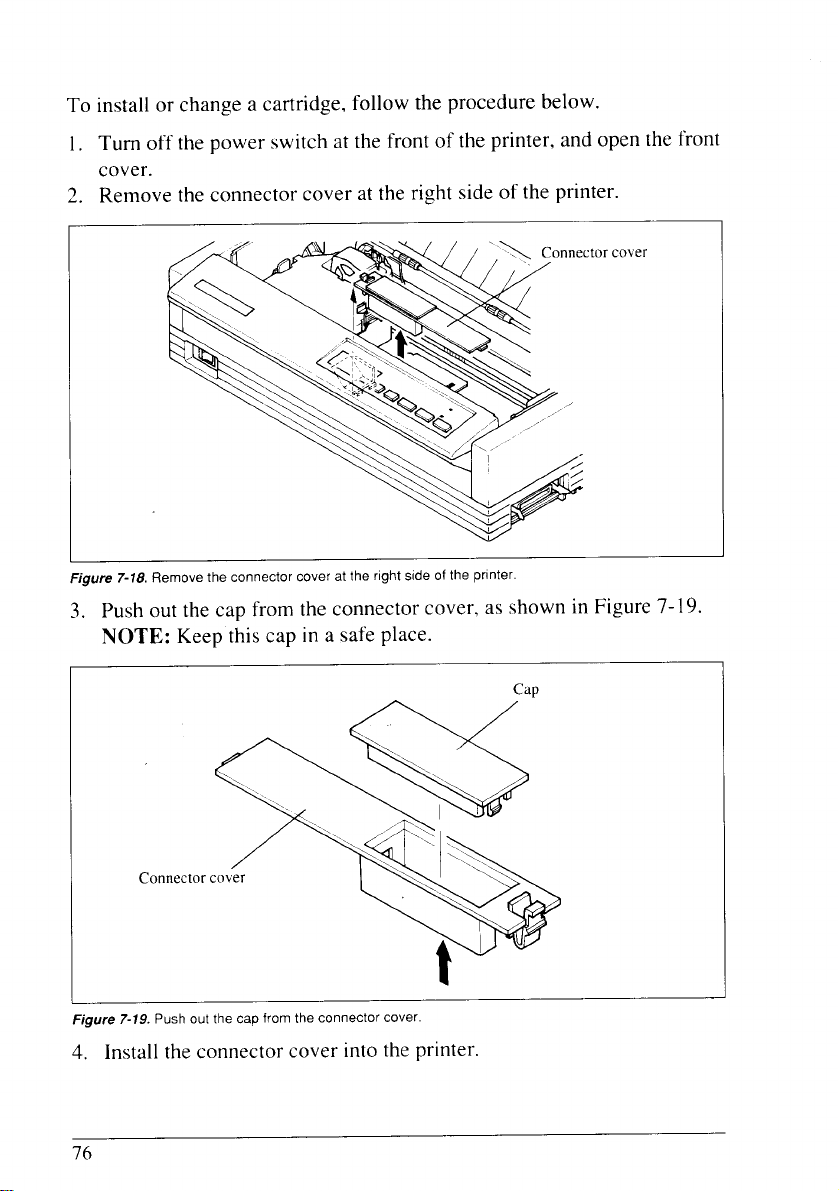

FONT CARTRIDGES AND RAM CARTRIDGES

This printer has five built-in LQ fonts, and a 16K-byte printing buffer.

You can add the following optional fonts or expand the printing buffer by

installing optional cartridges (Font Cartridge or RAM Cartridge).

[Optional Font Cartidges]

I Font Name I Character sample

● FC-IZ

. FC-2Z

FC-3Z TW-Li.ght

.

● FC-4Z

. FC-5Z Old Style

● FC-1OZ SLQ Script

● FC-IIZ SLQ Roman 123456789 ABCDE abc.de

● FC-12Z SLQ TW-Light

Orator

Orator 2

Letter Gothic

I Blippo

123456789

123456789

123456789 ABCDE abcde

I123456789

ABCDE ABCDE

ABCDE abcde

flBCDE abcde I

Cinema 123456789 AllCLIE iibcde

OCR-B

I OCR-A

CODE 39

UPC/EAN

123456789

Il12345L’78q ABCDE abcde

11111111111111111111111111111111111111111111111lllllll

123456789

ABCDE abcde

12345 11111 111[[

123456789 ABCDE abcde

I H-Gothic 1123456789 ABCDE abcde I

I Orane

I123456789 ABCDE Elt)C~E? I

Russian Roman 123456789 ABBrfl =fLLr

GOST

Cyrillic

123456789 ~aeii HfIPCT

123456789 AEBrfl ~e~el

123456789 AIN?!IJEu&TctIe

Firenze