Spec. No D-F0382

Product

Specifications for

Super High Speed

Kiosk Printer

NP-266/366

Revision 1.00 2004.04.20 1st edition

Revision 1.10 2004.06.28 2nd edition

《Notice》 ・All features and specifications described are subject to change without notice.

D-F0382 NP-266_366 Product specifications Ver.1.10

Record of revision-1

Rev. No.

1.00 1 New release Kobayashi Abe

1.10 2 Note Add 19) Kobayashi Abe

1 Model name Add paper width, modified 2004.06.28 2004.06.28

2 Configuration Add jack socket, add notes

3 Print speed Add notes

4 Presenter Added

4 External dimension Add A type

4 Weight Add A type

6 Power specification Modified chart, notes

7 Presenter life Added

7 Safety Regulation certified

8 External drawing Add dimensions

(NP-266)

12 External drawing Added

(NP-366 II AU)

13 Upstream port Modified

14 Datasignalinput Add notes

15 CN9 USB Data signa Added

l input

16 DS1-7: ON 150mm/s, added notes

16 Dip switch R,U type

17 Error details Add presenter error

Add presenter cramp

Add blink-3

20 Presenter drive Add / modify notes

22,45 Presenter compulsory Added

eject

time setting

36 Printer status bit5, bit6

transmission

41 Printer auto status bit5, bit6

transmission

60 Mode status of Add presenter retraction time

settings (line mode) setting

Page Item Change

22,45 Presenter retraction

Description

2004.04.20 2004.04.20

Added

Approval PIC

D-F0382 NP-266_366 Product specifications Ver.1.10

Read Carefully Before Using the Printer

Wrong handling of the printer may cause its performance declined and the product damaged. Please read

the notes below before handling.

1. Static discharge prevention must be made for installation and removal of the printer to protect IC and

other electrical parts. Connect it to the earth ground. It is also requested to remove the static from

body of the person before handling, especially, the input terminal.

2. Avoid excessive force to the input terminal for handling.

3. When any type of paper, other than specified in this manual, is used, it may cause deterioration of the

print quality and thermal head reliability.

Examples of troubles

1) Print quality deterioration by using low sensitivity paper.

2) Thermal head wears due to roughness of paper surface.

3) Sticking between heat receipt layer and thermal head, and vibration noise during printing.

4) Print ink disappears on low print durability paper.

5) Electrolyte corrosion on thermal head due to low quality of heat receipt layer.

4. Avoid printing with no paper loaded. It damages platen and thermal head, printer life will be shorten.

5. Do not scrabble thermal head with sharp edge or something hard, or give impact. The heat element

may be damaged.

6. Set the power of printer off before connecting or removing connecters.

7. When printing in high speed under low temperature of high humidity environment, the paper may be

stained by moisture that appears from paper, or the printer may have condensation. Avoid dew from

dropping down to the thermal head that may cause electrolyte corrosion. Turn the power off until any

dew is removed.

8. The printer is not protected from water or dew formed. Do not water the printer or handle it with a wet

hand, which may cause damage to the printer due to short circuit, or heat or fire.

9. The printer is not protected from dust or dirt. If it is used at dusty place, the thermal head may be

damaged or paper feed is not operated properly.

10. When cooling the printer with a fan, avoid the printer’s paper outlet from locating fan’s air inlet. It may

cause mal-function of printer.

11. Reflection type of infrared ray sensors are used at some locations in the printer. Direct sun light may

cause mal-function of printer. Avoid from such a location for installation.

12. This printer does not support any operations caused by the commands or control commands not

specified in this manual.

13. Please use both hand when you hold the printer.

14. In order to prevent excess current, please put elemental device to external 24V power line (Please

refer to the power supply specification for the details), and also put fuse.

15. Please plug off the printer when you do not use the product for a long time. Please also insert paper

between the platen.

16. When paper jam occurred, please make sure to slowly remove the paper to paper exit direction

after head up status.

17. The product is designed to use with general electronic devices (Computer, PC, OA, others). This is not

designed and not guaranteed to use with extremely high quality, high reliability product or product whose

failure may danger human life (Atomic power control device, aerospace aircraft devices, Transportation

devices, Traffic signal devices, Ignition control devices, Medical devices, other safety equipments: we call

“Specific application” thereafter). Users take full responsibility for using with such specific application.

18. The product uses part that includes GaAS (Gallium arsenide). Please do not break the product, no

chemical splitting ,otherwise it may harm human with such part broken pieces.

19. If less than Ø18 mm roll paper is used, the paper may be prevented to exit. Please do not use roll

paper with coreless.

D-F0382 NP-266_366 Product specifications Ver.1.10

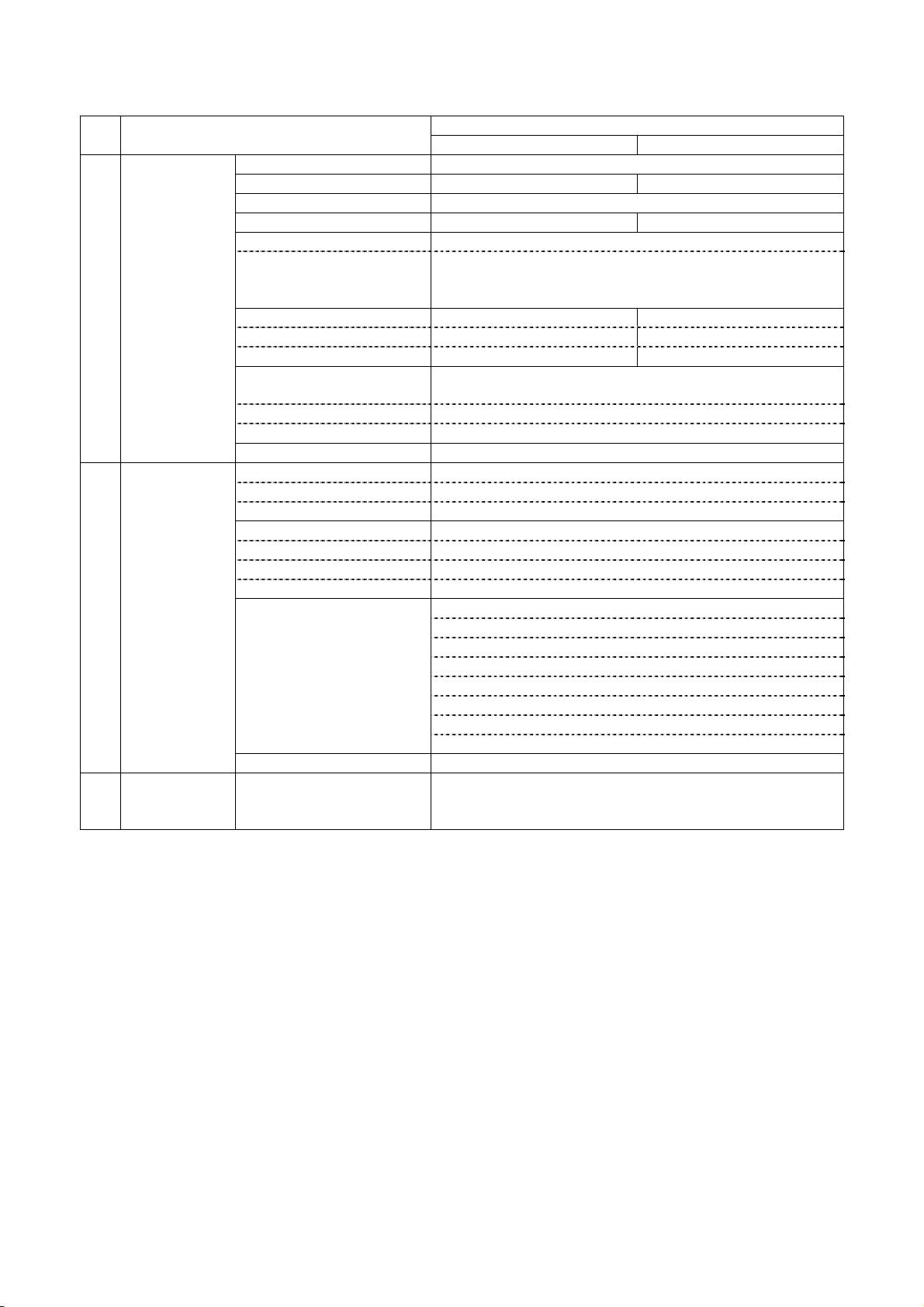

Table of Contents

1. Overview

1.1 Overview 1

1.2 Features 1

1.3 Model name 1

1.4 Configuration 2

2. Specifications

2.1 Basic specifications 3

2.2 Printing area and cut position 5

2.3 Power supply specifications 6

2.4 Reliability 7

2.5 Dimensions 8

3. Interface specifications

3.1 Serial interface (RS-232C) 13

3.2 USB interface (USB) 13

3.3 Connector signal details 14

4. Functions

4.1 Function setting 16

4.2 Processing error 17

4.3 Partition drive 18

4.4 Operation panel 18

4.5 Hex dump print 19

4.6 Self print 20

4.7 Buffer full print 20

4.8 Presenter drive 20

5. Software specifications

5.1 Printer Driver 21

5.2 Line mode command table 21

5.3 Line mode command details 23

5.4 Page mode command table 43

5.5 Page mode command details 44

5.6 Mode status of setting functions (Line mode) 53

5.7 Mode status of setting fundtions (Page mode) 54

6. Character code table

6.1 Domestic character code table 55

6.2 Overseas character code table 56

6.3 International character code table 57

D-F0382 NP-266_366 Product specifications Ver.1.10

1. Overview

1.1 Overview

This printer is 2-inch (NP-266) / 3-inch (NP-366) receipt thermal printer with super high printing

speed. The NP-266/366 is designed compact and user-friendly by adopting easy operation

mechanism. It is a high performance printer unit equipped with auto cutter, featuring super high

speed and high quality printing, supporting a variety of applications.

1.2 Features

1) Easy operation mechanism applied for easy paper replacement

2) Super high printing speed of Max. 220mm/sec (when printing ASCII in full line, head temp. more

than 35 degree C excluding transmission time)

3) Low cost

4) Interface available for USB (V2.0 FULL SPEED) and Serial (RS232C)

5) Downloading the firmware is available by communication.

6) Easy to rewrite firmware by flash memory

7) 3 patterns of registration available with bit image.

8) Emulation: compliant with ESC/POS

9) Universal type AC adapter (AC100V-AC240V) available.(see Note 1 below)

10) Windows drivers (Windows95/98/NT4.0/2000/XP) available.

Note 1: AC adapter is an option

Note 2: Windows Driver supporting USB is Windows 2000/XP version.

1.3 Model name

NP-266 II F U - *

① ② ③ ④ ⑤

1: Paper width (Factory option)

2: 58 mm (2 inch) 3: 80 mm (3 inch)

2: Board specs (Factory option)

I: Direct input to the control board with serial / USB

2 power supply 5V and 24V (18P)

II: Power supply and Interface input through the board

R: D-sub 9 pin connecter

U: USB connector B jack (4P)

Single power supply 24 V

3: Cutter type (Factory option)

F: Full cut

P: Partial cut

A: NPT-305 presenter attached (NP-366 only)

4: Interface (Factory option)

R: Serial (RS232C)

U: USB (V.2.0 Full Speed)

5: OEM number

D-F0382 NP-266/366 Product specifications Ver.1.10

1

1.4 Configuration

The printer consists of the following components

No Product Name Specifiction Part No. Q’ty NP-266 NP-366

1 Printer NP-266***-* - 1

○

2 Printer NP-366***-* - 1

3

Cable ※1

4

Jack socket ※2

5 Thermal roll paper

6 Thermal roll paper

MMK code 4 ASSY 30-438A 1

17L-003A3 (M2.6 x 0.45) 06-F102 2

TF50KS-E2D W58xΦ30

TF50KS-E2D W80xΦ30

24-X129 1

24-X179 1

○ ○

○ ○

○

○

○

※ Note1: It will be attached with Type I only.

※ Note2: It comes with NP-266II*R / NP-366II*R

The equipped jack socket is for inch screw, please use attached socket for M2.6 mm screw.

Option

No Product Name Specifiction Part No. Q’ty

1 PS3-J Adaptor set, Japan 70-243K (1)

2 PS3-U Adaptor set, USA 70-244K (1)

3 PS3-E Adaptor set, Europe 70-245K (1)

D-F0382 NP-266/366 Product specifications Ver.1.10

2

2. Specifications

2.1 Basic specifications

No. Items

NP-266 NP-366

Specifications

1 Print specs. 1. Print method Line thermal dot

2. Total dots / line 432 dots 576 dots

3. Dot density 8 dots / mm(203dpi)

4. Print width 54 mm 72mm

5. Print speed (Max.) Max. 220 mm / sec

Condition Head temp. more than 35 ℃/ ASCII full print

Except for communication time

※Max. 150 mm/sec for A type

6. Print digits

Font A (12×24) 36 digits 48 digits

Font B (9×17) 48 digits 64 digits

7.Space between Adjustable by the command

characters ※Default value

Font A (12 x 24) 0 mm

Font B (9 x 17) 0 mm

8. Line feed pitch 0.125 mm

2 Character 1. Character size

specs. Font A (12×24) 1.50×3.00 mm

Font B (9×17) 1.13×2.13 mm

2. Character types

ASCII 224

Block graphics 80 x 2

International 32

3.

Character modification

Double width

Vertical double

Quadruple

Bold

Double strike

Inverted

90°clockwise rotation

Underline

4. Line spacing (Default) 4.25 mm (1/6 inch)

3 Print mode ANK mode

Bit image mode

Barcode mode

D-F0382 NP-266/366 Product specifications Ver.1.10

3

No. Items

NP-266 NP-366

Specifications

4 Barcode 1. 1-D symbology UPC-A

specs UPC-E

EAN-13 (JAN-13)

EAN-8 (JAN-8)

CODE39

ITF

CODABAR (NW-7)

CODE128

2. 2-D symology QR code

5 Interface 1. Serial RS232C (R type)

2. USB V.2.0 FULL SPEED (U type)

6 Auto-cutter 1. Cut method Guillotine type

2. Applicable paper Thermal 60 - 80 (micro)

3. Cut cycle 30 cuts / minute

4. Cut mode Full cut

Partial cut (a 2mm tab left at the center)

( Factory option setting before ship)

5. Life time 500,000 cuts

7 Presenter 1. Applicable paper - Thermal paper (65μm)

(NP-366*A*) 2. Length to feed - 70-250 mm

3. Feed speed - Max. 690 mm/sec.

4. Eject operation - Cramp

Total eject

Retraction

5. Life - 100,000 papers

8 Paper specs. 1. Paper width 58.0

mm 80.0

+0-1

+0-1

mm

2. Max. diameter Ø80 mm

3. Core diameter Inner Ø12mm

Outer Ø18mm

4. Papers recommended TF50KS-E2D (Nihon Seishi)

PD160R-N (Shin Oji Seishi)

HP220AB1 (Mitsubishi Seishi)

9 Receiving Approx. 10K bytes

buffer

10 Operation ALMLED OUT

SW Line feed SW input

11 Near empty ※1 Approx. Ø24±1mm

12 Environment 1. Operation Temp. 5~45℃, Humidity 35~85%RH No condensation

2. Storage Temp. -10~60℃, Humidity 35~90%RH

Except paper discoloration

3. Normal environment General office use

13 External spec 1. Dimension 103.5(W) x 106.7(D) x 127.2(W) x 106.7(D) x

161.3(H) mm 161.3(H) mm

NP-366*A*

127.2(W) x 154.0(D) x

161.3(H)

2. Weight Approx. 1.1 kg Approx. 1.3 kg

(without paper) (without paper)

NP-366*A *

Approx. 1.6 kg

(without paper)

※1: Paper should not be loosen for proper detection.

D-F0382 NP-266/366 Product specifications Ver.1.10

4

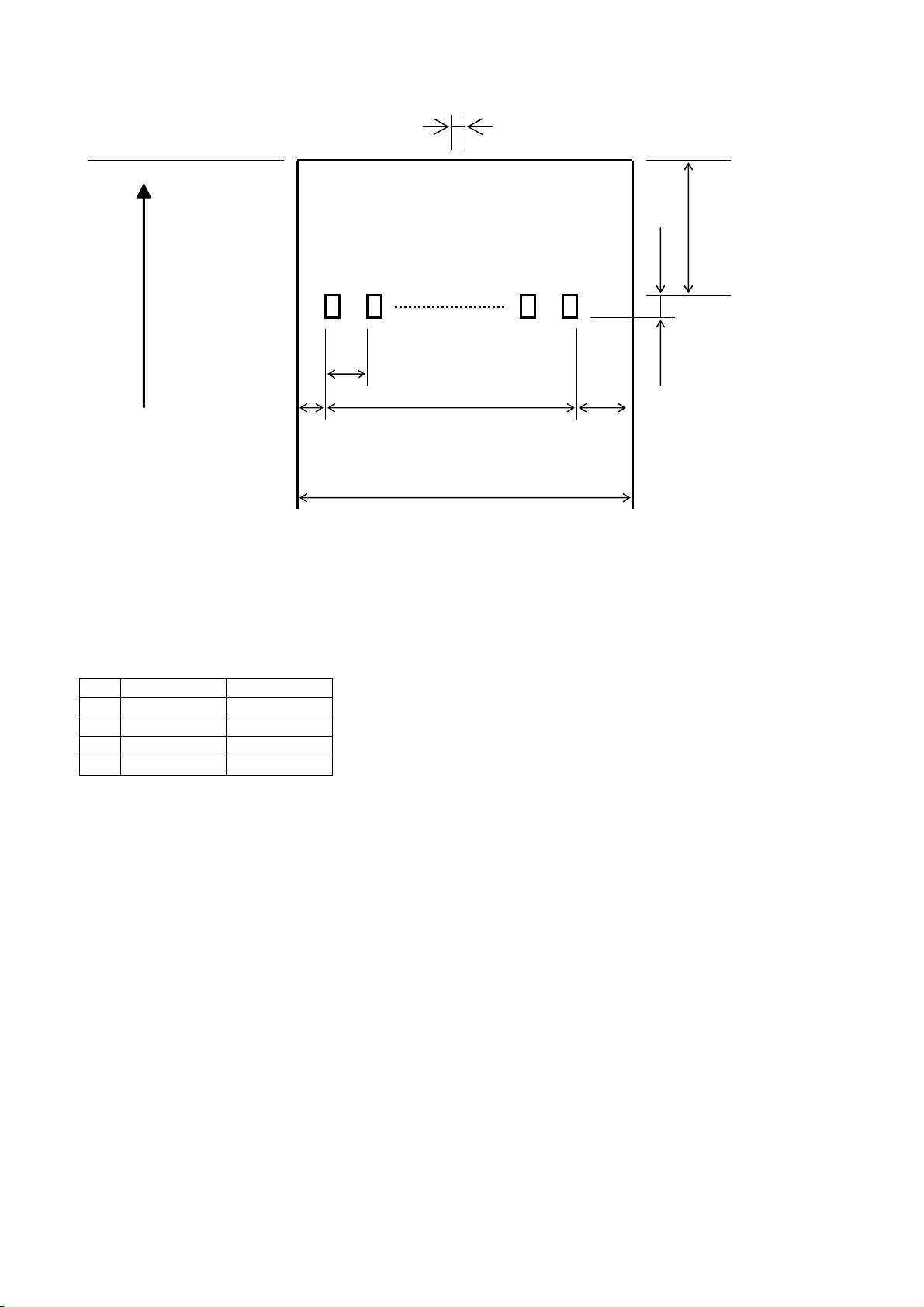

2.2 Printing area and cut position

Partial cut remaining tab: approx. 2 mm (P type only)

Cut Position

Cutter to Head

Approx.13±1.0mm

1dot 2dots D dots (Note1)

Feed direction

0.125mm

0.125mm

B ±0.2mm

(Note1)

A ±1.0mm A ±1.0mm Approx. 6 mm feed will

take place by the

C mm firmware, so the margin

0

-1

will be 19±1mm.

Note2: Please take care not to take the paper very hard after the partial cut, which cause heavy load on

platen and might cause the poor print quality on the head part of next line. To avoid such problem,

please take care by feeding approx. 1 mm at the beginning of print or by take the paper to the direction

to left or right.

Note3: The cut mode (full cut or partial cut) is set by the factory. No change of cut mode is done by the

command setting.

NP-266 NP-366

A 2 4

B 54 72

C 58 80

D 432 576

D-F0382 NP-266/366 Product specifications Ver.1.10

5

2.3 Power supply specifications

1) Power supply input connector

Optional AC adapter will be used for this printer(Power to be supplied from outside)

Connector on printer side :TCS7960-532010 Hosiden or equivalent

Connector on Adapter side :TCP8927-631100 Hosiden or equivalent

2) Electrical condition

Operating Voltage : DC24V±5% (Type II)

: DC24V±5%, DC5V±5% (Type I)

Current Consumption

Standby : Average approx. 0.1 A

Printing :

Power supply Printing average of 25% Printing average of 100 %

NP-266 I 24V Max. approx. 2.10 A Max. approx. 8.33 A

5V Max. approx. 0.16 A Max. approx. 0.17 A

NP-266 II 24V Max. approx. 2.10 A Max. approx. 7.33 A

NP-366 I 24V Max. approx. 2.90 A Max. approx. 11.33 A

5V Max. approx. 0.16 A Max. approx. 0.17 A

NP-366II 24V Max. approx. 2.90 A Max. approx. 10.67 A

NP-366 IA 24V Max. approx. 2.90 A Max. approx. 11.38 A

5V Max. approx. 0.16 A Max. approx. 0.17 A

NP-366IIA 24V Max. approx. 2.90 A Max. approx. 10.72 A

* Paper Feed only : Average approx. 0.30 A

3) Standard Adapter specifications(Option)

Model : POWER SUPPLY PS3 (UP0601S-24P)

Maker : UMEC

Input Power Voltage : AC100V~AC240V

Output Power Voltage : DC24V±5% 2.5A max

Note:

Printing average of 25% is available for the optional AC Adapter PS3 (UP0601S-24P) for NP-266 and

20% for the NP-366. Please use a higher capacity AC adaptor for more than such printing or for the

other power supply prepared by your side.

No Function

1 +24V

2 GND

3 N.C

Shell FG

Connector drawing

1

3

2

D-F0382 NP-266/366 Product specifications Ver.1.10

6

2.4 Reliability

1) Head life

Pulse : More than 100 million pulses (Applied 25℃ of rated energy)

Wear distance : More than 100 km

* Normal temp. Normal humidity with recommended paper

2) Cutter life : 0.5million cut

3) Presenter life : 100, 000 paper feed

4) Operation environment : Temperature 5℃ – 45℃ non-condensation

Humidity 35%-85%RH

5) Storage environment : Temperature -10℃ - 60℃ (paper not included)

Humidity: 35% - 90%RH

6) Safety regulation

CE marking (NP-266 only)

C-UL UL60950 (NP-266 only)

D-F0382 NP-266/366 Product specifications Ver.1.10

7

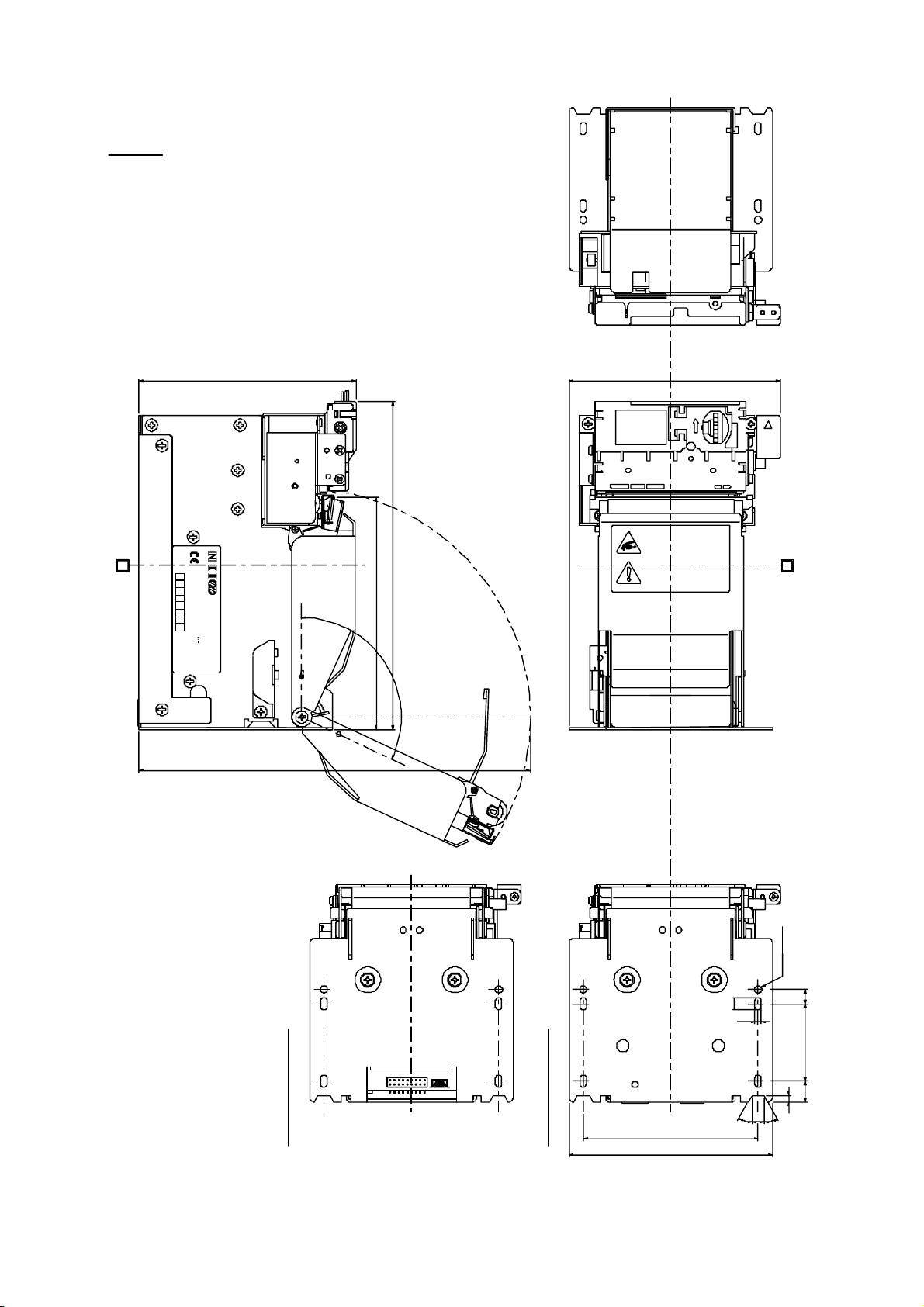

2.5 Dimensions

1) NP-266

Notes

1. More than 195 mm space needed for opening platen.

2. Either full cut or partial cut should be selected

3. Max. roll paper diameter Is 80 mm.

4. This drawing is "NP-266ⅡFU".

Nichipri Industrial Inc.

Revision

B

Hard Ware

12345678

Serial No.

Model

Rating 24V 1.9A

4B0001

NP-266ⅡFU

Made in Japan

106.7

(195)

NP-266Ⅰ**

103.5

押

161.3

paper exit

114.5

115°

NP-266Ⅱ**

・手指をはさまないよう注意して下さい。

Watch your hand when cover is colsed.

・用紙交換時はカバーに注意して下さい。

Pay attention to your when replacing paper.

A

2-φ3.5

6

4ヶ所

3.2

387 10.2

D-F0382 NP-266/366 Product specifications Ver.1.10

15

3

6 30°30°

86

100

±0.2

8

B

7 8

45

ON

1

A

FEED

ALM

POWER

NP-266Ⅱ*R NP-266Ⅰ**

Notes

1. More than 195 mm space needed for opening platen.

2. Either full cut or partial cut should be selected

3. Max. roll paper diameter Is 80 mm.

7 8 23 6

45

36

ON

1

9

165

4. This drawing is "NP-266ⅡFU".

Recommended dimension for mounting plate

387 10.2

2-φ3.5

6

3.2

4ヶ所

7 8 2

45

23 6

ON

1

78 over

3

30°30°

6

±0. 2

86

100

D-F0382 NP-266/366 Product specifications Ver.1.10

Less than 78

9

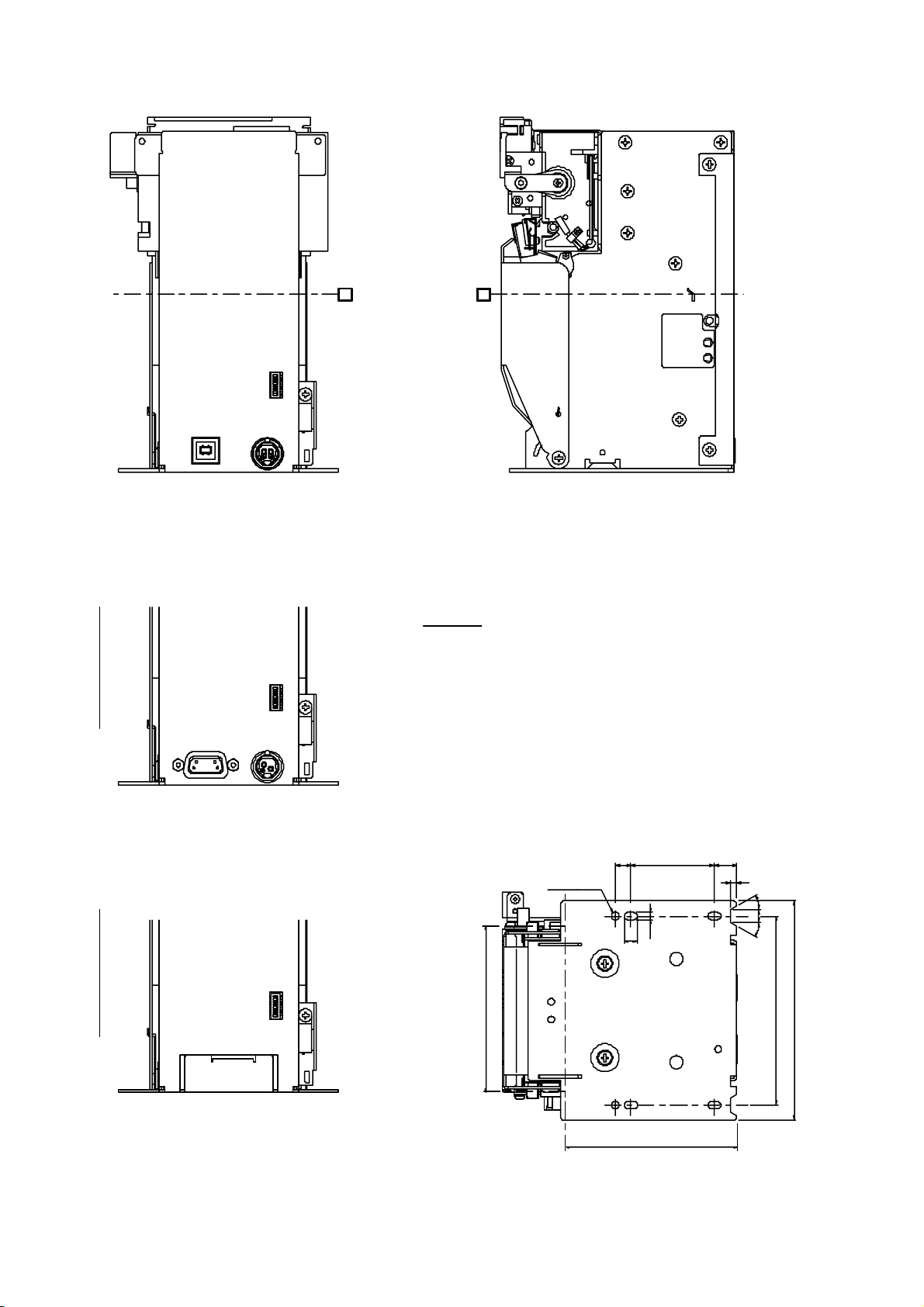

2) NP-366

Notes

1. More than 195 mm space needed for opening platen.

2. Either full cut or partial cut should be selected

3. Max. roll paper diameter Is 80 mm.

4. This drawing is "NP-366ⅡFU".

106.7

Nichipri Industrial Inc.

Revision

B

Hard Ware

12345678

Serial No.

Model

Rating 24V 2.7A

NP-366ⅡFU

4B0001

Made in Japan

161.3

paper exit

114.5

115°

127.2

・手指をはさまないよう注意して下さい。

Watch your hand when cover is cols ed.

・用紙交換時はカバーに注意して下さい。

Pay attention to your when replac ing paper.

押

A

(195)

NP-366Ⅰ**

D-F0382 NP-266/366 Product specifications Ver.1.10

15

10

NP-366Ⅱ**

108.2

122.2

±0.2

2-φ3.5

6

4ヶ所

3.2

387 10.2

3

30°

6

30°

NP-366Ⅱ*R NP-366Ⅰ**

B

ON

1457823 6

A

FEED

ALM

POWER

Notes

1. More than 195 mm space needed for opening platen.

2. Either full cut or partial cut should be selected

3. Max. roll paper diameter Is 80 mm.

4. This drawing is "NP-366ⅡFU".

23 6

ON

14578 23 6

6

195

Recommended dimension for mounting plate

387 10.2

2-φ3.5

6

3.2

4ヶ所

3

30°

6

30°

ON

14578

D-F0382 NP-266/366 Product specifications Ver.1.10

11

100 over

Less than 78

±0.2

108.2

122.2

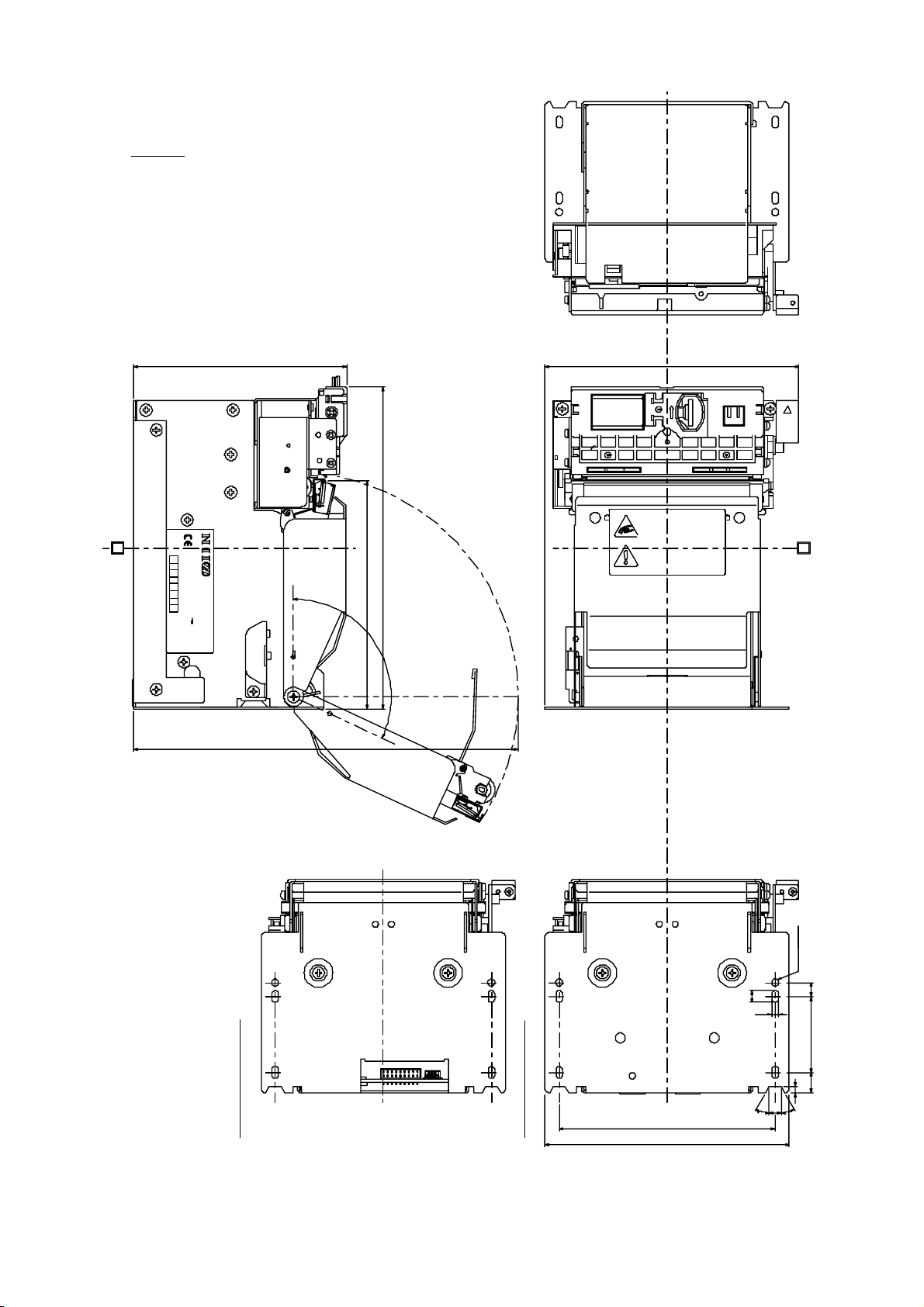

2) NP-366ⅡAU

Revision

Hard Ware

12345678

Made in Japan

154.0

127.2

押

Nichipri Industrial Inc.

Serial No.

Model

Rating 24V 2.7A

4B0001

NP-366ⅡAU

115°

(220)

(108)

161.3

・手指をはさまないよう注意して下さい

paper exit

119.5

Watch your hand when cover is cl osed

・用紙交換時はカバーに注意して下さい

Pay attention to your when repla cing paper

Notes

1. More than 220 mm space needed for opening platen.

2. Max. roll paper diameter Is 80 mm.

3. This drawing is "NP-366ⅡAU".

D-F0382 NP-266/366 Product specifications Ver.1.10

12

108.2

122.2

2-φ3.5

6

4ヶ所

3.2

10.2387

6

±0. 2

30°30°

3. Interface specifications

3.1 Serial interface (RS-232C)

1) Synchronization : Asynchronous

2) Transmission speed:19200, 38400bps (user selectable)

3) A word consists of

Start bit : 1bit

Data bit : 8 bit

Stop bit : more than 1 bit

4) Signal polarity

RS-232C

Mark = Logic “1” (-3V -- -12V)

Space = Logic “0” (+3V -- +12V)

5) Receive data (RD signal)

RS-232C

Mark = 1

Space = 0

6) Reception control (CTS signal)

RS-232C

Mark = Impossible to transmit data

Space = Possible to transmit data

7) Reception control (RTS signal)

Space = Possible to transmit data

Mark = Impossible to transmit data

3.2 USB interface (USB)

1) Version: V2.0 FULL SPEED (12Mbps)

2) Port: Upstream port (B jack or Mini-B)

3) Power Supply: Self Powered

D-F0382 NP-266/366 Product specifications Ver.1.10

13

3.3 Connector signal details

1) Data signal input connector (Serial Type II)

Printer side : 17LE23090-027(D4CK) (DDK) or equivalent

Host side : 17JE13090-02(DDK) or equivalent

Pin No. Signal Input/Output Function Remark

1 N.C -

2 TXD Output Serial transmit data

3 RXD Input Serial receving data

4 N.C -

5 GND - Singnal ground

6 - -

7 CTS Input Transmit permission signal

8 RTS Output Transmit request signal

9 N.C

2) Data signal input connector (Serial Type I)

Data signal and power input

Connecter on printer: DF11-18DP-2DS (52) Hirose

Proper connecter : DF11-18DS-2C Hirose

Pin No. Signal name Input/Output Function Remarks

1 /RESET Input RESET Input (-)

※1

2 RTS Output Printer busy

3 CTS Input Host busy

4 - - N.C.

5 RXD Input Receives data

6 TXD Output Transmitted data

7 GND - Common GND

8 GND - Common GND

9 GND - Common GND

10 GND - Common GND

11 GND - Common GND

12 GND - Common GND

13 +5V Input Circuit power Vcc

14 +5V Input Circuit power Vcc

15 +24V Input Power supply VM for head, cuter, motor

16 +24V Input Power supply VM for head, cuter, motor

17 +24V Input Power supply VM for head, cuter, motor

18 +24V Input Power supply VM for head, cuter, motor

※2

※2

※2

※2

※2

※2

※2

※2

※2

※2

※2

※2

※1. It is reset by “L” pulse input at 50msec (typical). The level is below 0.7V.

/RESET signal input is effective only on Serial Type I.

※2. All pin no.7 -18 to be connected. Please connect thick and short, as large current may flow.

Please take necessary measure to stabilize the power supply by connecting a electrolytic

condenser (approx. 2200μ) or so. Withstand voltage over 35V must be applied.

※3. Pin no.7-18 are the same when USB for type I.

D-F0382 NP-266/366 Product specifications Ver.1.10

14

3) Data Signal Input Connector (USB for type II)

Printer side connector: B jack DUSB-BRA42-T11(DDK) or equivalent

Host side Connector: B plug

Pin No. Signal Input / Output Function Remark

1 VBUS Input Power line Non twist power line

2 D- Input and output Data line Twist pair signal line

3 D+ Input and output Data line Twist pait signal line

4 GND - Power line Non twist power line

Shell Shield -

* Use USB cable which conforms to the standard (FULL SPEED)

* We do not support the operation by using a cable out of the standard.

4) CN9 Data Signal Input Connector (USB for type I)

Printer side connector: Mini-B 5P TCX0101-110100 Hosiden or equivalent

Host side Connector: Mini-B 5P equivalent

Pin No. Signal Input / Output Function Remark

1 VBUS Input Power line Non twist power line

2 D- Input and output Data line Twist pair signal line

3 D+ Input and output Data line Twist pait signal line

4 N.C -

5 GND - GND Non twist power line

Shell Shield - FG frame GND

* Use USB cable which conforms to the standard (FULL SPEED)

* We do not support the operation by using a cable out of the standard.

D-F0382 NP-266/366 Product specifications Ver.1.10

15

Loading...

Loading...