Page 1

Provisional version

Specifications for

Compact module

Spec. No D-F0393

Product

Kiosk Printer

NP-211

Revision 0.01 2004.07.30 Provisional version

《Notice》 ・All features and specifications described are subject to change without notice.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

Page 2

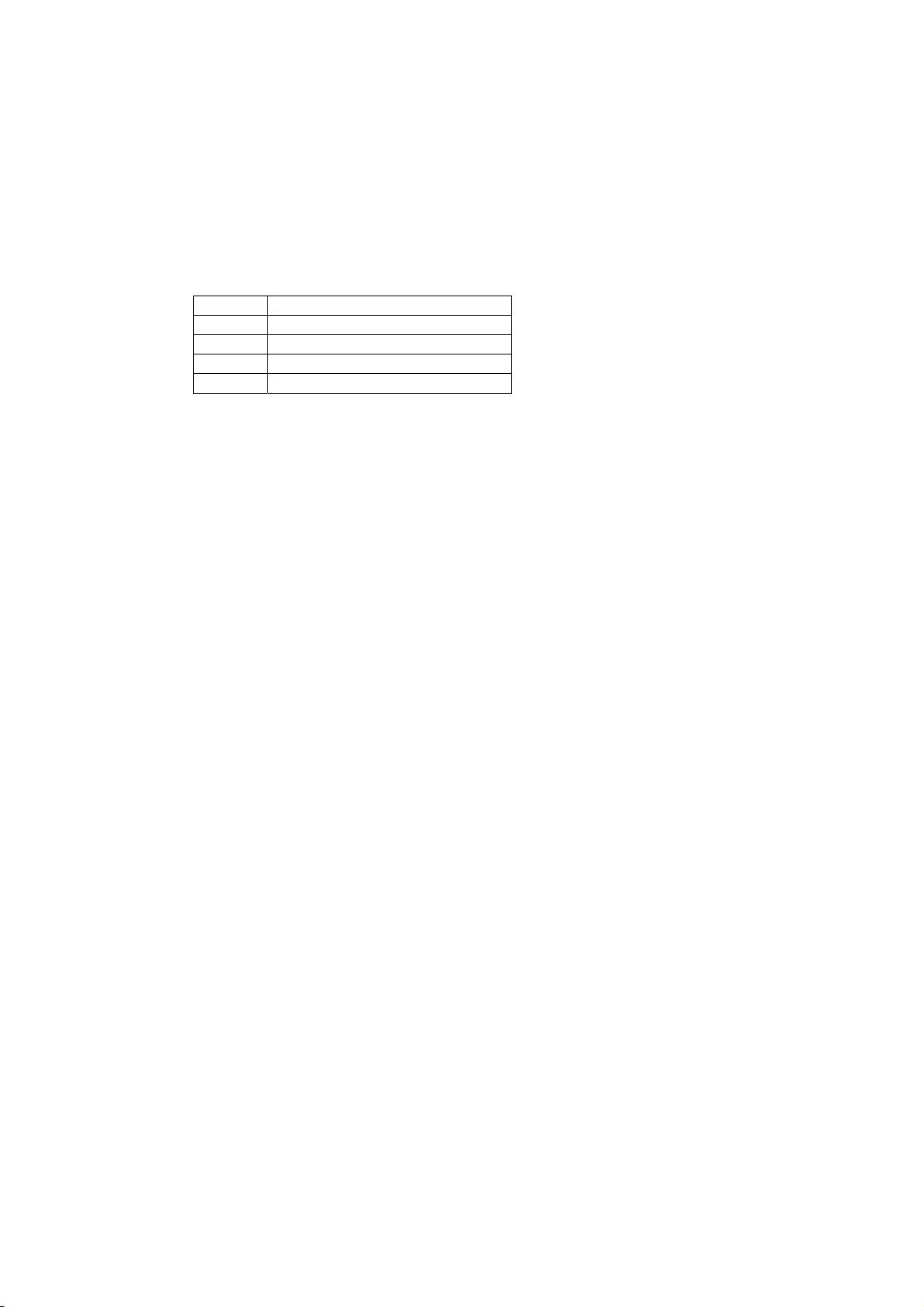

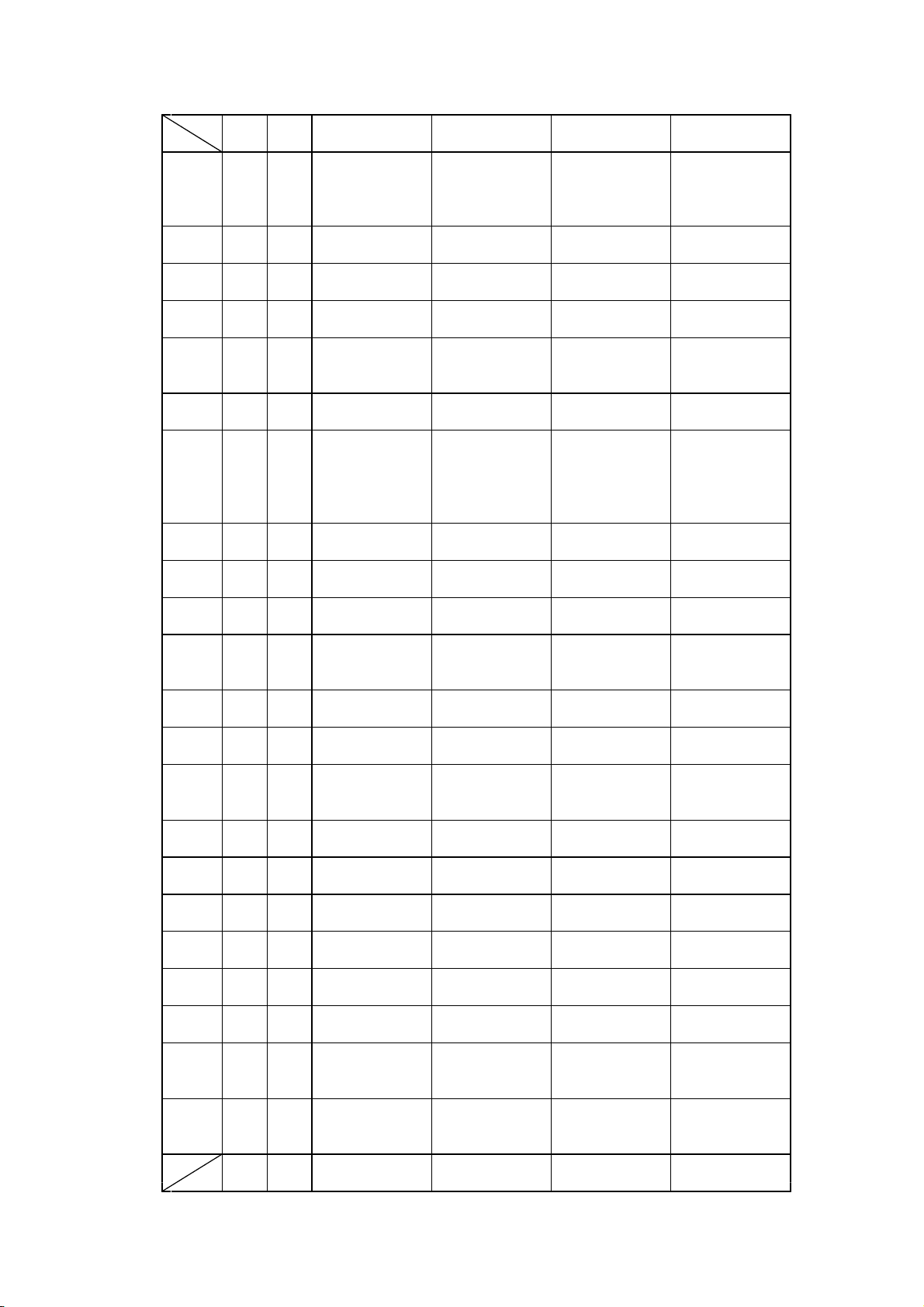

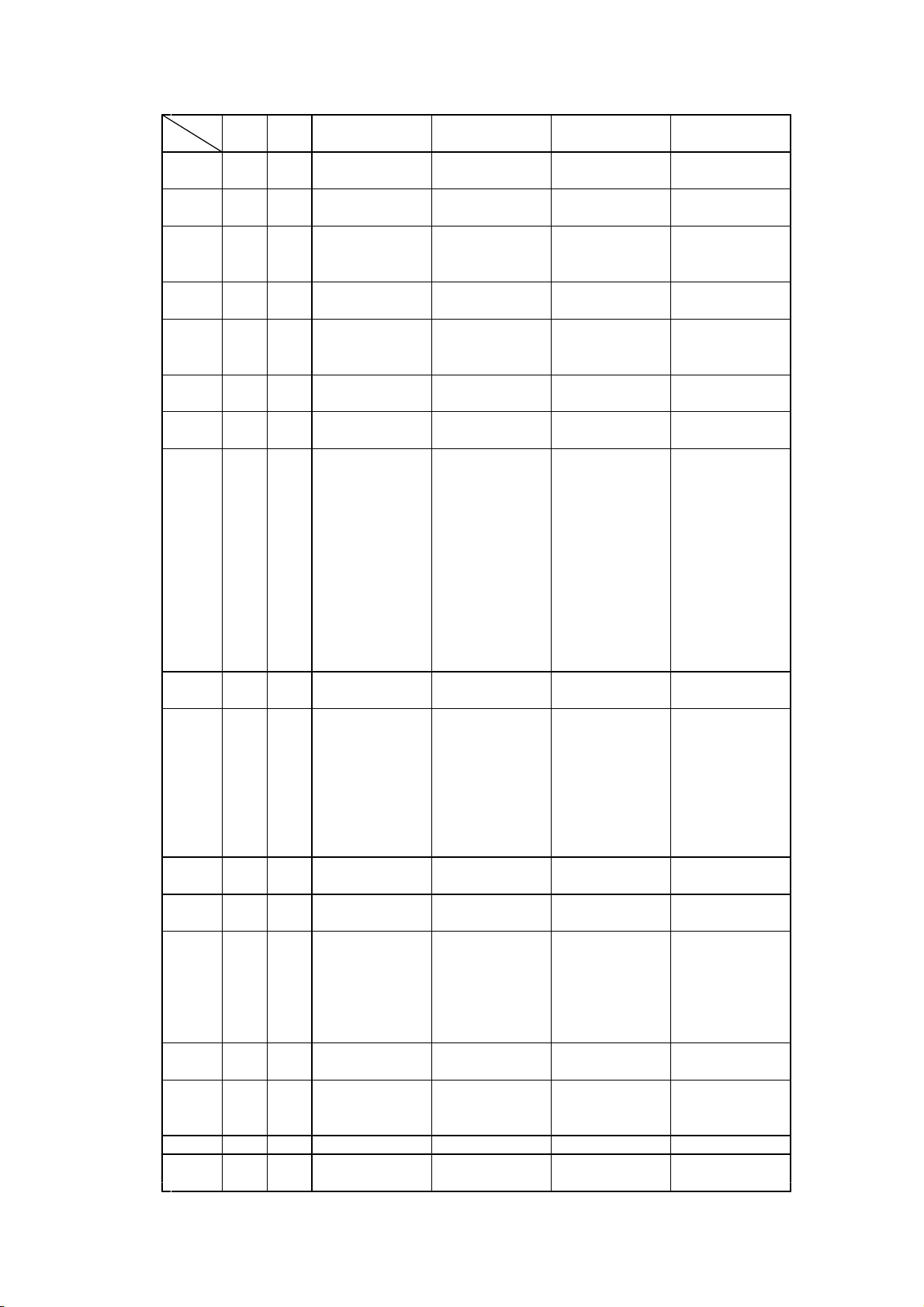

Record of revision

Rev. No.

0.01 - New release Abe

(Provisional)

Page Item Change

Description

Approval PIC

2004.07.30

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

Page 3

Read Carefully Before Using the Printer

Wrong handling of the printer may cause its performance declined and the product damaged. Please

read the notes below before handling.

1. Static discharge prevention must be made for installation and removal of the printer to protect IC

and other electrical parts. Connect it to the earth ground. It is also requested to remove the static

from body of the person before handling, especially, the input terminal.

2. Avoid excessive force to the input terminal for handling.

3. When any type of paper, other than specified in this manual, is used, it may cause deterioration

of the print quality and thermal head reliability.

Examples of troubles

1) Print quality deterioration by using low sensitivity paper.

2) Thermal head wears due to roughness of paper surface.

3) Sticking between heat receipt layer and thermal head, and vibration noise during printing.

4) Print ink disappears on low print durability paper.

5) Electrolyte corrosion on thermal head due to low quality of heat receipt layer.

4. Avoid printing with no paper loaded. It damages platen and thermal head, printer life will be

shorten.

5. Do not scrabble thermal head with sharp edge or something hard, or give impact. The heat

element may be damaged.

6. Set the power of printer off before connecting or removing connecters.

7. When printing in high speed under low temperature of high humidity environment, the paper may

be stained by moisture that appears from paper, or the printer may have condensation. Avoid

dew from dropping down to the thermal head that may cause electrolyte corrosion. Turn the

power off until any dew is removed.

8. The printer is not protected from water or dew formed. Do not water the printer or handle it with a

wet hand, which may cause damage to the printer due to short circuit, or heat or fire.

9. The printer is not protected from dust or dirt. If it is used at dusty place, the thermal head may be

damaged or paper feed is not operated properly.

10. When cooling the printer with a fan, avoid the printer’s paper outlet from locating fan’s air inlet. It

may cause mal-function of printer.

11. Reflection type of infrared ray sensors are used at some locations in the printer. Direct sun light

may cause mal-function of printer. Avoid from such a location for installation.

12. This printer does not support any operations caused by the commands or control commands not

specified in this manual.

Please use both hand to holding the printer.

13.

14. In order to prevent excess current, please put elemental device to external 24V power line

(Please refer to the power supply specification for the details), and also put fuse.

15. Please plug off the printer when you do not use the product for a long time. Please also insert

paper between the platen.

16. When paper jam occurred in the print head, please make sure to slowly remove the paper to

paper exit direction after head up status.

17. The product is designed to use with general electronic devices (Computer, PC, OA, others). This

is not designed and not guaranteed to use with extremely high quality, high reliability product or

product whose failure may danger human life (Atomic power control device, aerospace aircraft

devices, Transportation devices, Traffic signal devices, Ignition control devices, Medical devices,

other safety equipments: we call “Specific application” thereafter). Users take full responsibility

for using with such specific application.

18. The product uses part that includes GaAS (Gallium arsenide). Please do not break the product,

no chemical splitting ,otherwise it may harm human with such part broken pieces.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

Page 4

Table of Contents

1. Overview

1.1 Overview 1

1.2 Features 1

1.3 Configuration 2

2. Specifications

2.1 Basic specifications 3

2.2 Printing area and cut position 5

2.3 Electrical contitions 6

2.4 Reliability 6

2.5 Dimensions 7

3. Interface specifications

3.1 Serial interface (RS-232C compliance) 8

3.2 USB interface (V2.0 FULL SPEED compliance) 8

3.3 Connector signal details 9

4. Functions

4.1 Function setting 10

4.2 Self diagnostic print 12

4.3 Operation panel 12

4.4 Processing errors 13

4.5 Buffer full print 13

4.6 Auto loading 14

4.7 Partition drive 14

5. Control commands

5.1 Control command table 15

5.2 Printer driver 16

5.3 Control command details 17

6. Character code table

6.1 Domestic character code table 37

6.2 Overseas character code table 38

6.3 International character code table 38

6.4 Kanji code 39

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

Page 5

1. Overview

1.1 Overview

The printer is categorized as following.

NP – 211- *

①

① Interface (Factory setting)

R: Serial (RS232C)

U: USB (V2.0 FULL SPEED)

D: Both Serial (RS232C) and USB (V.2.0 FULL SPEED)

1.2

Features

This module printer is designed on the basis of our long experience as a printer manufacturer.

Individual unit such as printer mechanism, controller board and auto-cutter is assembled in compact

with our reliable design concept.

Simple integration to the system requiring only power and data supplies, that contributes to the

short development time and improvement of product reliability.

1) Important areas such as paper entrance and auto-cutter guide are designed professionally on

the basis of our long experience as a printer manufacturer.

2) Small, compact and light weight. Easy to integrate into various kinds of system.

3) Short development time.

4) High quality of printing

5) Either serial or USB interface are available.

6) Various 1-D barcode symbols are available.

7) Various kinds of application are available.

8) Windows drivers (Windows95/98/NT4.0/2000/XP) are available.

9) Easy to write/rewrite F/W by using flash memory. Also, 3 patterns of registration are

available with Fixed bit image.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

1

Page 6

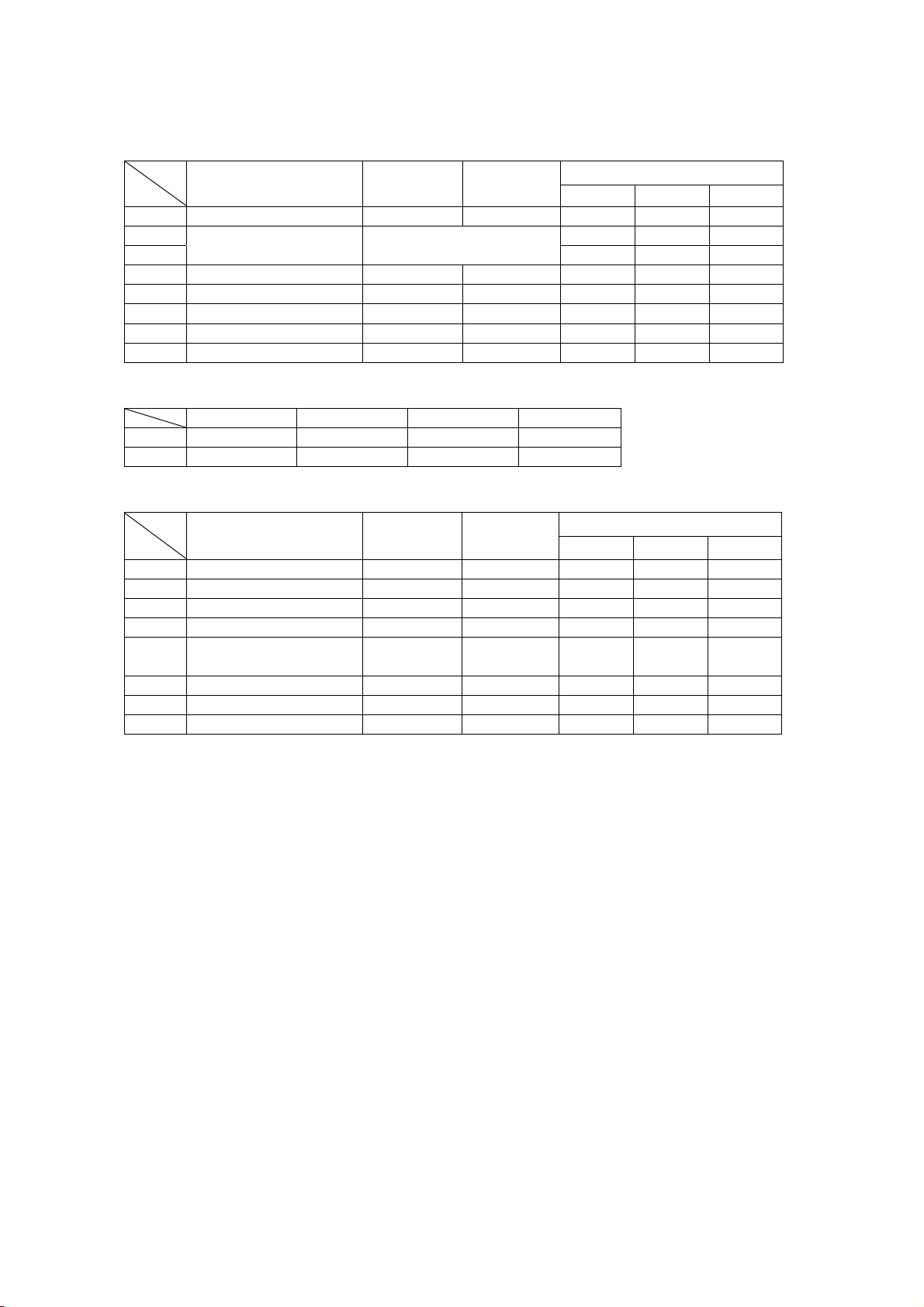

1.3 Configuration (Under review)

The printer consists of the following components.

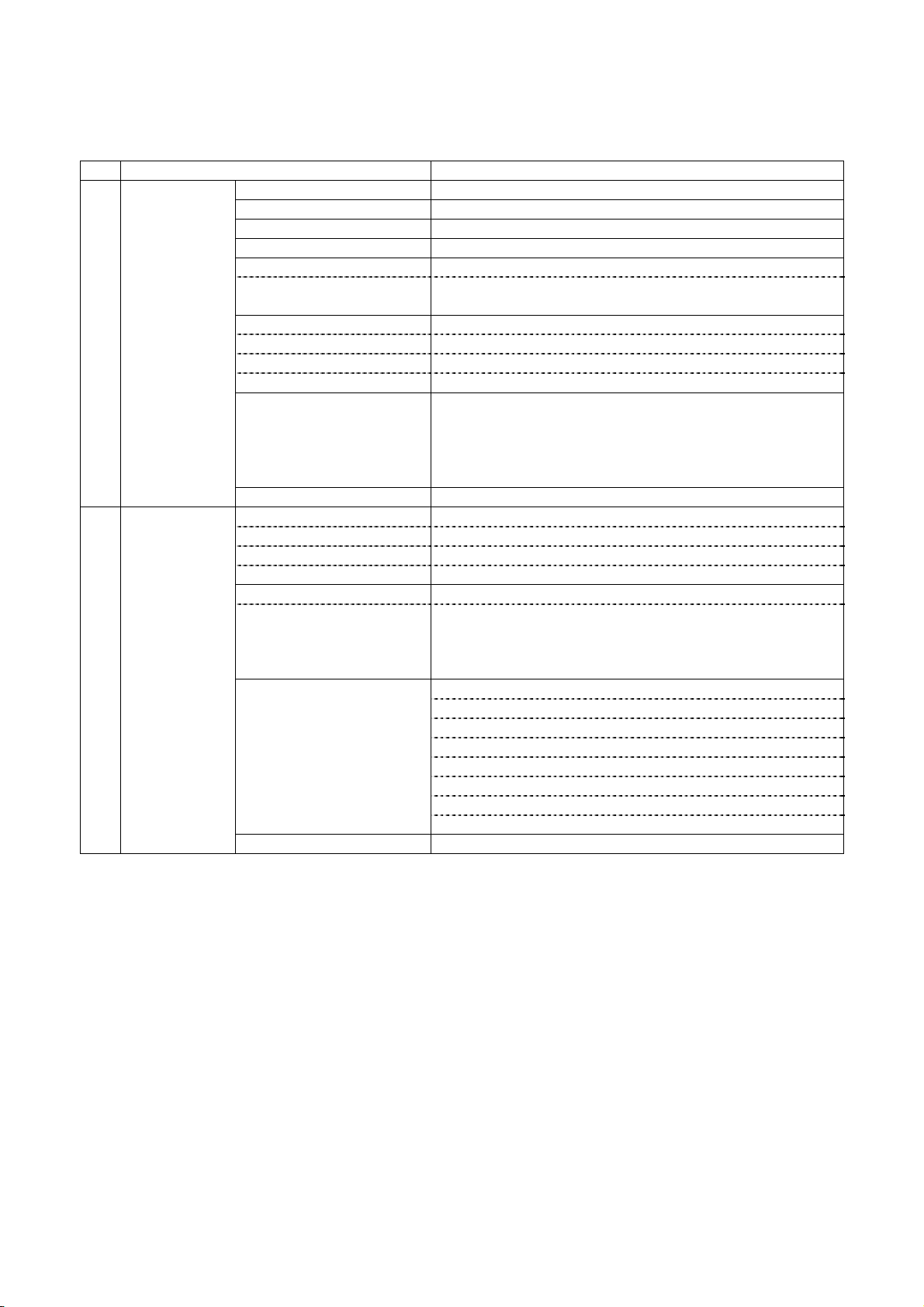

No. Description Specification Part No. Q’ty

1 Printer unit NP-211-* - 1

2 Thermal Paper TF50KS-E2DW58xØ 30(Inner Ø12) 24-X129 1

3

Jack socket ※1

※1 It is attached in R type and D type. Jack socket of the serial connector is for an inch screw.

Please use the attached M2.6 socket if necessary.

Options

17L-003A3 (M2.6 x 0.45) 06-F102 2

No. Description Specification Part No. Q’ty

1 Near empty sensor Factory option - (1)

2 AC adaptor 100V 91ADJ 18-R035 (1)

3 AC adaptor 120V 91ADU 18-R036 (1)

4 AC adaptor 230V 91ADE 18-R037 (1)

5 AC code set JPN 1.5 m 30-353A (1)

6 AC code set UL (3P) 1.5 m 30-354A (1)

7 AC code set EU (Flat 2P) 1.5 m 30-355A (1)

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

2

Page 7

2. Specifications

2.1 Basic specifications

No. Items Specifications

1 Print specs. 1. Print method Line thermal dot

2. Total dots / line 384 dots

3. Dot density 8 dots / mm (203dpi)

4. Print width 48mm

5. Print speed (Max.) Max.50 mm / sec

Condition Head temp. more than 35 ℃/ 64 dots

Except for communication time

6. Print digits

Font A (12×24) 32 digits

Font B (9×17) 42 digits

Kanji (24 x 24) 16digits

7. Space between Adjustable by command setting

characters (Default figures)

Font A 0 mm

Font B 0 mm

Kanji 0 mm

8. Line feed pitch 0.125 mm

2 Character 1. Character size

specs. Font A (12×24) 1.50×3.00 mm

Font B (9×17) 1.13×2.13 mm

Kanji(24 x 24) 3.00x3.00mm

2. Character types

Japanese JIS C 6226 (Full size)

Katakana character set (Half size)

Extended Graphic character set (Half size)

International character (Half size)

3.

Character modification

Double width

Vertical double

Quadruple

Bold

Double strike

Inverted

90°clockwise rotation

Underline

4. Line spacing (Default) 4.25 mm (1/6 inch)

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

3

Page 8

No. Items Specifications

3 Print mode ANK mode

Bit image mode

Barcode mode

4 Barcode 1. 1-D symbology UPC-A

specs UPC-E

EAN-13 (JAN-13)

EAN-8 (JAN-8)

CODE39

ITF

CODABAR

CODE128

5 Interface 1. Serial RS232c compliant

2. USB V2.0 FULL SPEED

6 cutter Tier bar

7 Paper specs. 1. Paper width 58.0 mm

2. Max. diameter Ø70 mm

The following core to be used.

3. Core diameter Inner Ø12mm / Outer Ø18mm

No glue at the end of the roll

4. Papers recommended TF50KS-E2D (Nihon Seishi)

TF77KS-E2 (Nihon Seishi)

TL69KS-HG76 (Nihon Seishi)

8 Receiving Approx. 5K bytes

buffer

9 Environment 1: Operating Temp. 5- 45℃, Humidity 35 – 85%RH, No- condensation.

2: Storage Temp. -10 - 60℃ Humidity 35-90%RH excluding paper

discoloration.

3: Enviroment in use General Office Room.

10 Appearance 1: External dimension 84.0 (W) x 115.0(D) x 77.5(H) mm

2: Weight Approx. 400 g

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

4

Page 9

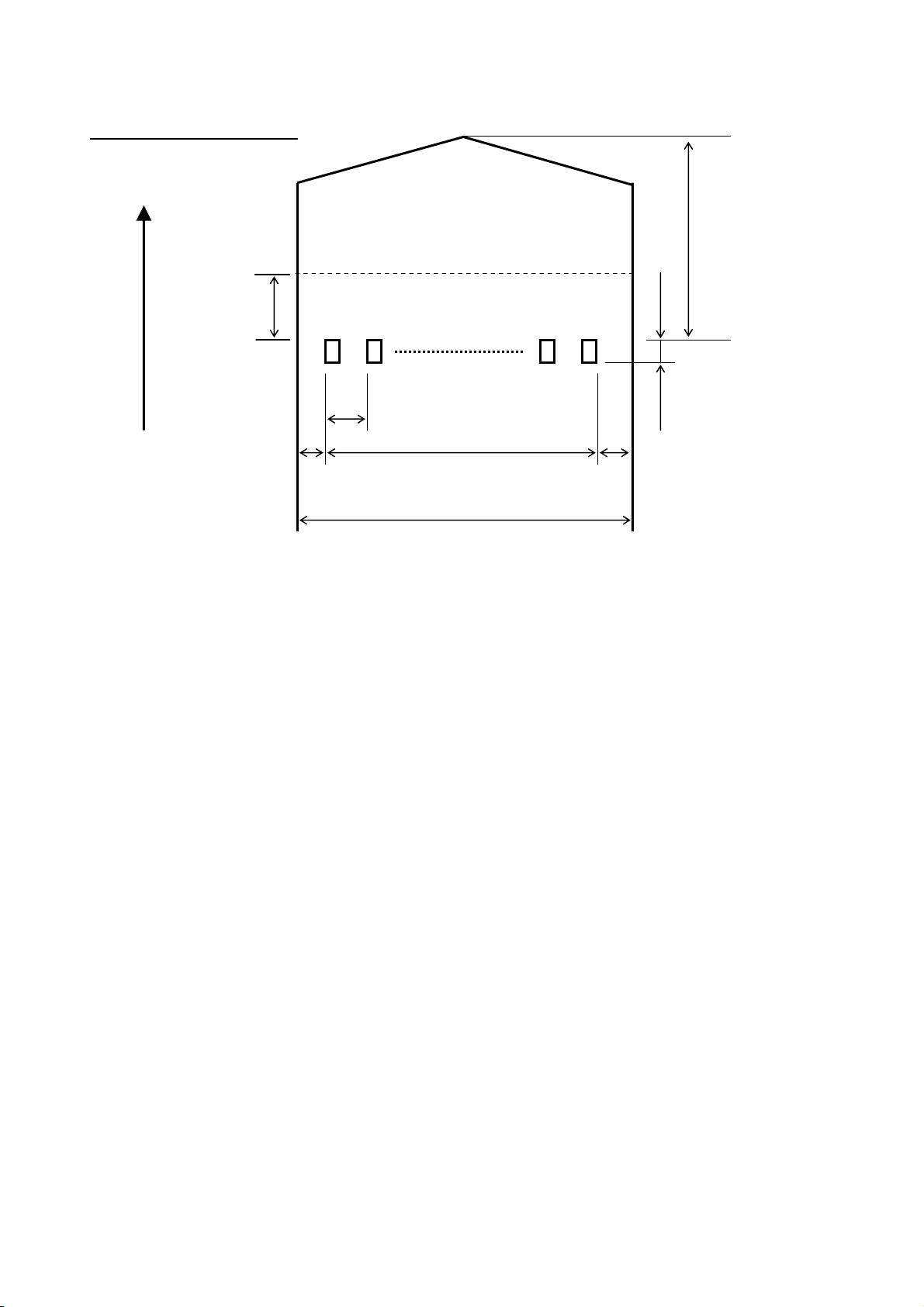

2.2 Printing area and cut position

Cut Position

Tier bar~Head

position

20±1.0mm

Approx.5mm(※) 1dot 2dots 384dots

Feed direction

0.125mm

0.125mm

48±0.2mm

5±1.0mm 5±1.0mm

58 mm

0

-1

(※)There is a line at the approx. 5 mm from print position when cut.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

5

Page 10

2.3 Electrical conditions

1) Operating voltage : DC 8V – 13V

2) Current consumption …. Under review

Current consumption

Printing average of 25% Max. Approx. ** A

Printing average of 100% Max. Approx. ** A

*1: A sufficient volume of power supply is required to maintain print quality due to high peak current that

may run according to printing.

*2: If power supply cable is excessively long, the operation may become unstable. Cable should be

made as short as possible. If not available, connect cables near the printer and place an electrolysis

condenser of 2200µ between power supply and ground. Voltage resistance should be higher than 35V.

*3: For preventing from static electric discharge, make sure to connect FG wire.

2.4 Reliability

1) Head life

Pulse : More than 100 million pulses (with 25% rated energy )

Wear distance : More than 50 km

(with recommended paper, normal temp. humidity)

2) Operation environment : Temperature 5 – 45℃, no condensation

Humidity 35 - 85%RH

3) Storage environment : Temperature -10 – 60℃

Humidity 35 - 90%RH

4) Safety regulation

CE marking (To be certified)

UL60950-1 (To be certified)

5) EMC

EMI : EN55022 (To be certified)

EMS : EN55024 (To be certified)

VCCI : Class A (To be certified)

FCC : Class A (To be certified)

6) USB compliant test (To be certified)

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

6

Page 11

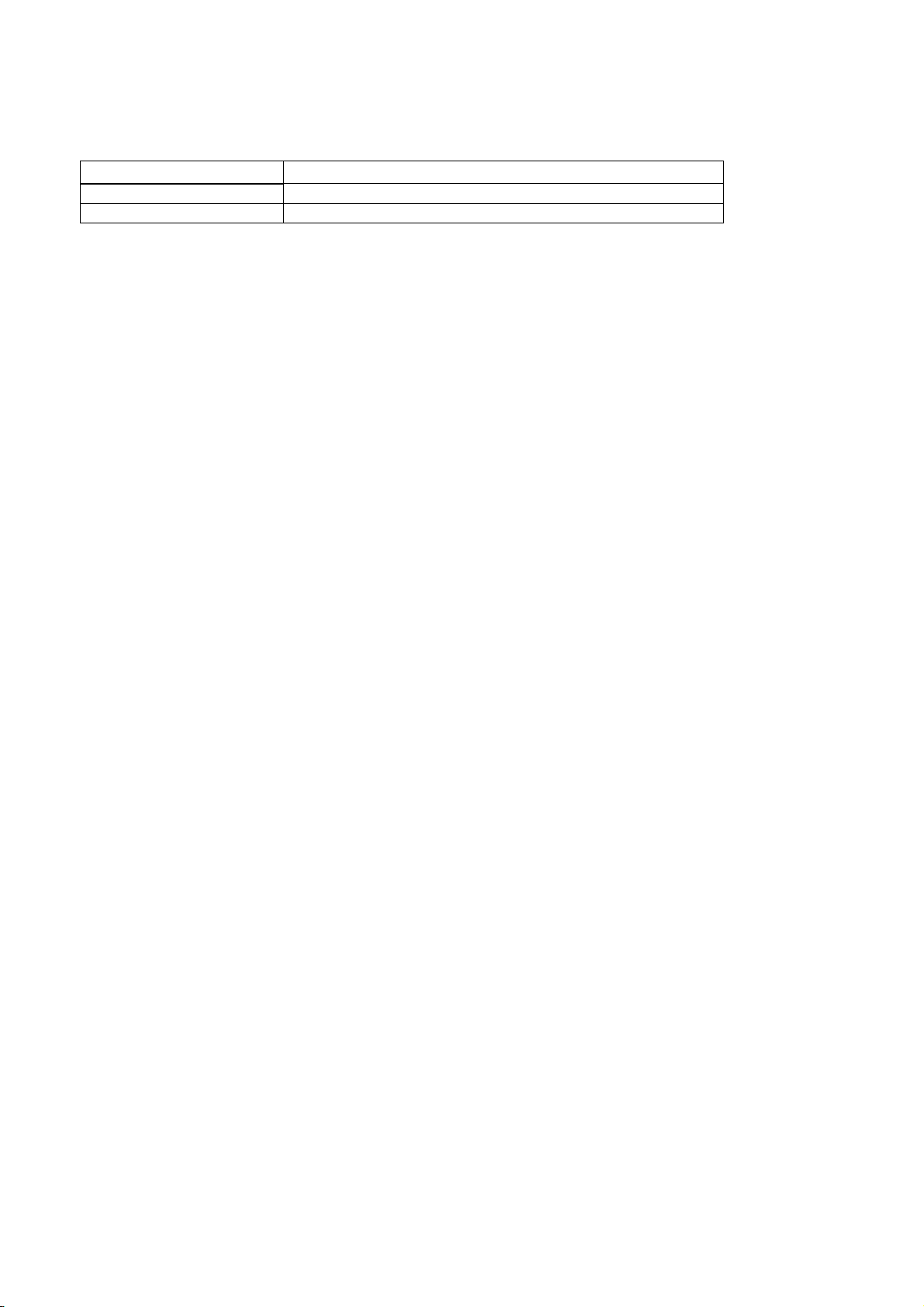

2.5 Dimensions

NEAR ENPTY OPTION

90

77.5

84.0

75.6

42.0

5

1

φ60

MAX DIA 70mm

FEEDENTRYALMPO

115.0

9.3

2.9

PAPER EXIT

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

7

Page 12

3. Interface specifications

3.1 Serial interface (RS-232C compliance)

1) Synchronization : Asynchronous

2) Transmission speed: 9600, 19200, 38400, 115200bps (user selectable)

3) A word consists of

Start bit : 1bit

Data bit : 7 or 8 bit (user selectable)

Parity bit : odd, even or no parity (user selectable)

Stop bit : more than 1 bit

4) Signal polarity

RS-232C

Mark = Logic “1” (-3V ~ -12V)

Space = Logic “0” (+3V ~ +12V)

5) Receive data (RD signal)

Mark = 1

Space = 0

6) Reception control (DTR signal)

Mark = Impossible to receive the data

Space = Possible to receive the data

7) Transmission control (CTS signal)

Mark = Impossible to transmit the data

Space = Possible to transmit the data

8)Transmission control (TD signal)

<< DC1 >> [11] h code, XON :Possible to receive the data

<< DC3 >> [13] h code, XOFF:Impossible to receive the data

3.2 USB interface (V2.0 FULL SPEED compliance)

1) Version : V2.0 FULL SPEED compliance (12Mbps)

2) Port : Upstream port (Mini-B 5P)

3) Power : Self powered

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

8

Page 13

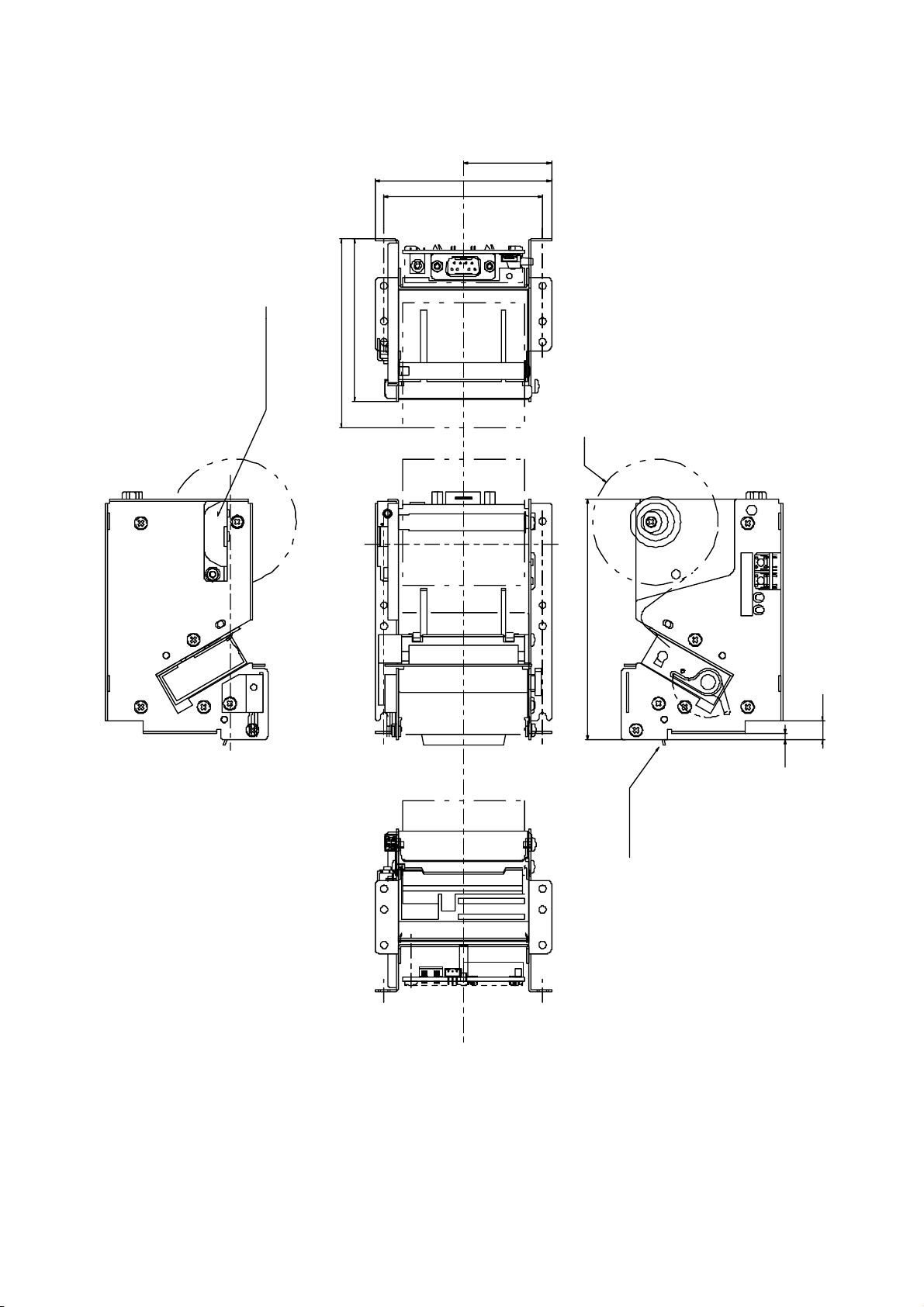

3.3 Connector signal table

1)Power Input connector

Printer side adaptor jack:MOJ-D14(Iizuka electronic)equivalent

Printer side adaptor plug:PJ-2(Sato Parts)equivalent

Pin No. Signal In/Output Function Remark

+ VH Input PowerDC+8V - 13V

- GND

-

PowerGND

※A sufficient volume of power supply is required to maintain print quality due to high peak

current that may run according to printing.

※If power supply cable is excessively long, the operation may become unstable. Cable

should be made as short as possible. If not available, connect cables near the printer and

place an electrolysis condenser of 2200µ between power supply and ground. Voltage

resistance should be higher than 35V.

2)USB data Signal Input Connector (U type, D type)

Printer side connector:Mini-B 5P TCX0101-110100(Hosiden) or equivalent

Mating connector:Mini-B 5Por equivalent

Pin No. Signal In/Output Function Remark

1 VBUS Input Power line Non-twist power supply line

2 D- In/Output Data line Twist pair signal line

3 D+ In/Output Data line Twist pair signal line

4 N.C

5 GND

Shell Shield

-

-

-

GND Non-twist power supply line

FG Frame GND

※Use USB cable which conforms to the standard (FULL SPEED)

3)Serial data signal input connecter (R type, D type)

Printer side connecter: JEC-9S (JST) equivalent

Mating connecter: JEC-9P (JST) equivalent

Pin No. Signal In/Output Function Remark

2 RXD Input Serial receive data

3 TXD Output Serial transmit data

4 DTR Output Data transmit permit signal Connect to No.7

5 GND - GND for signal

7 DTR Output Data transmit permit signal Connect to No.4

8 CTS Input Transmit permit signal

1,6,9 N.C -

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

9

Page 14

4. Functions

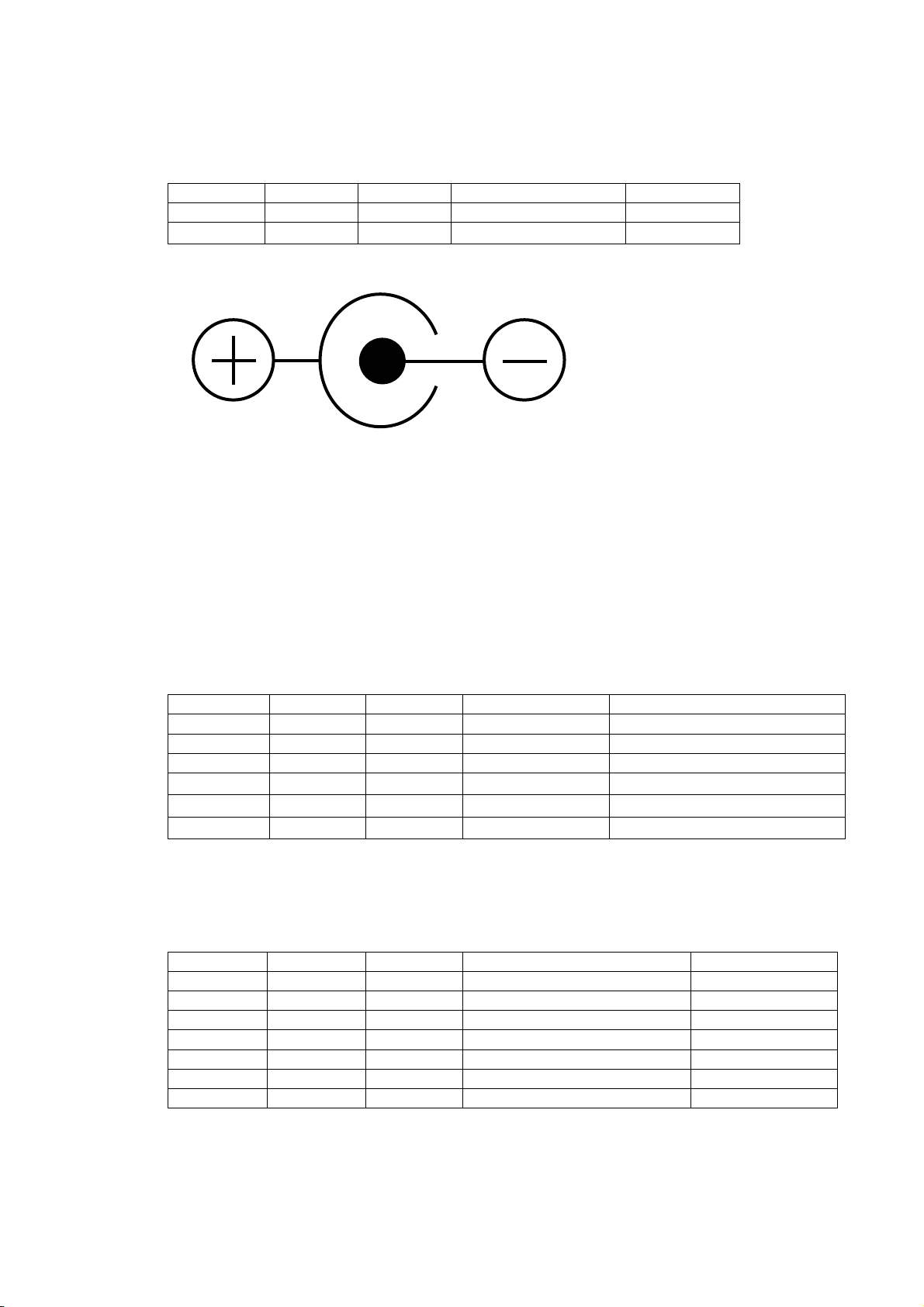

4.1 Function setting

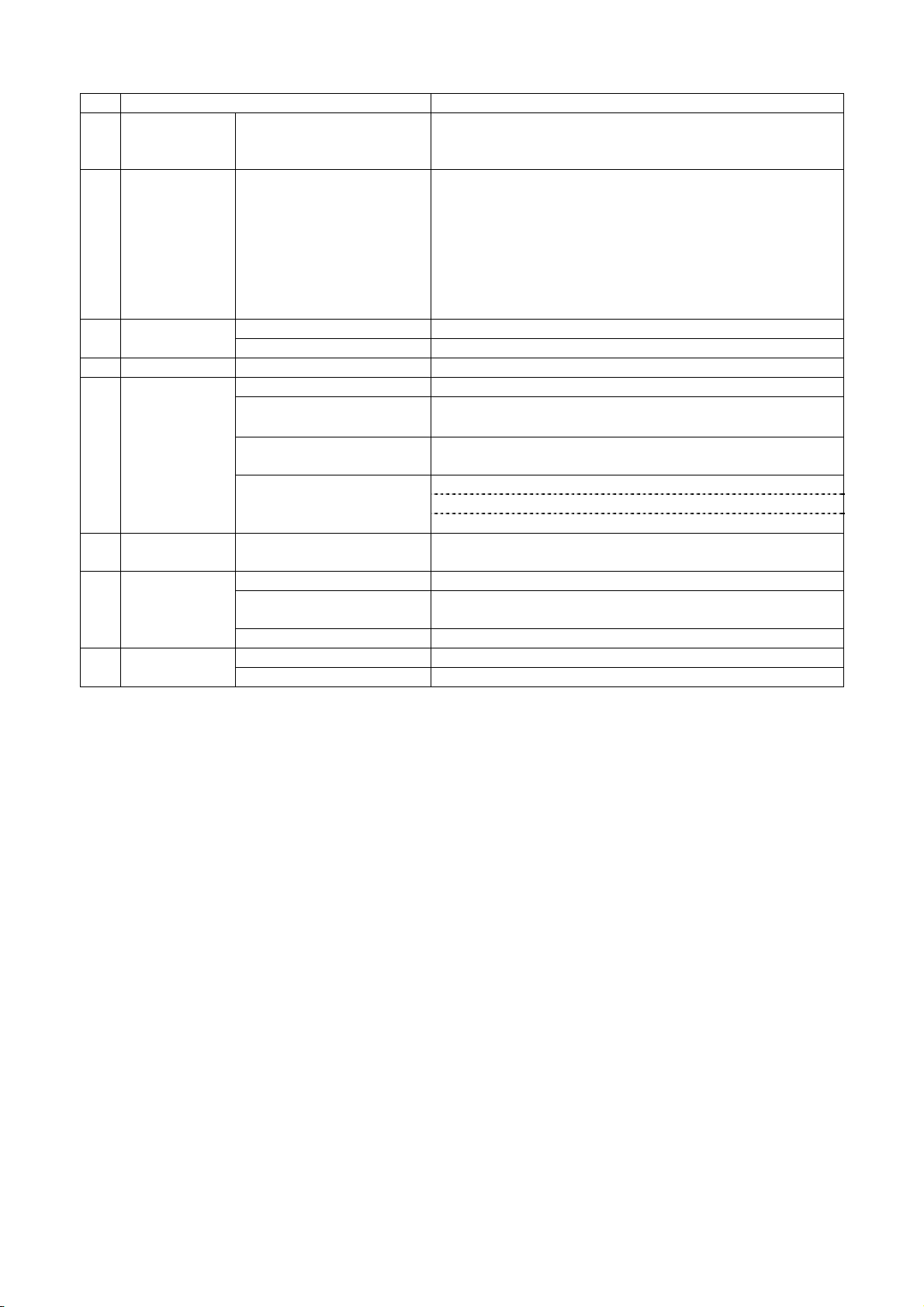

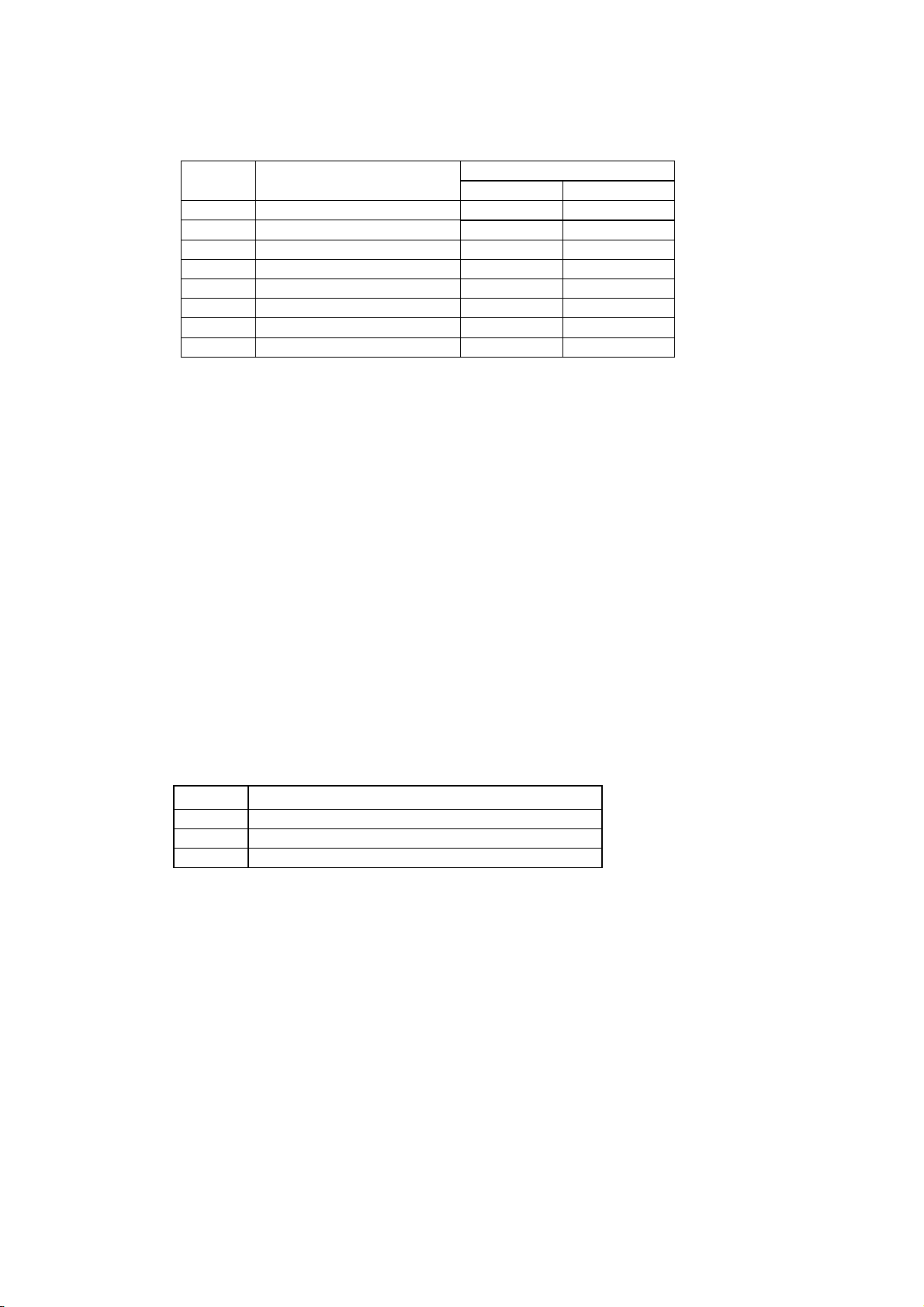

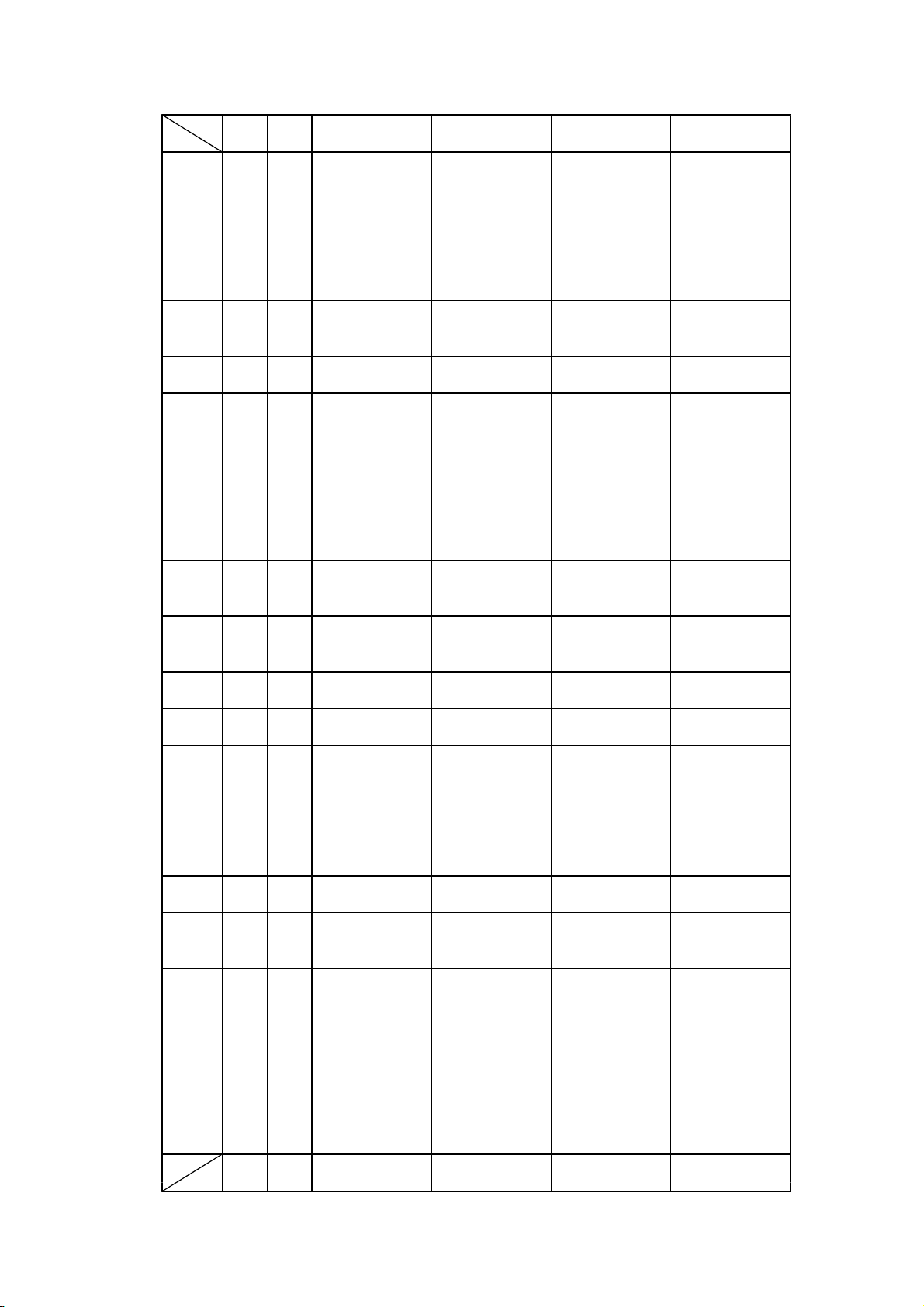

4.1.1 Memory switch S1

Function O N OFF

Factory setting

R-type

U-type D-type

S1-1 Interface Serial USB O N OFF OFF

S1-2 OFF OFF OFF

S1-3

Baud rate

Refer to the following

table

OFF OFF OFF

S1-4 Parity check Yes No OFF OFF OFF

S1-5 Parity bit Odd Even OFF OFF OFF

S1-6 Data bit 7 bit 8 bit OFF OFF OFF

S1-7 Flow control XON/XOFF DTR/DSR OFF OFF OFF

S1-8 Reserved OFF OFF OFF

Baud rate

9600bps 19200bps 38400bps 115200bps

S1-2 OFF OFF O N O N

S1-3 OFF O N OFF O N

4.1.2 Memory switch S2

Function O N OFF

Factory setting

R-type

U-type D-type

S2-1 Character set Overseas Domestic OFF OFF OFF

S2-2 Japanese Kanji Shift JIS JIS OFF OFF OFF

S2-3 Reserved OFF OFF OFF

S2-4 Print density Thick Standard OFF OFF OFF

S2-5 HEX DUMP

HEX

DUMP

Normal OFF OFF OFF

S2-6 Not defined OFF OFF OFF

S2-7 Not defined OFF OFF OFF

S2-8 Not defied OFF OFF OFF

4.1.3 Rewriting Flash ROM

Please do the following procedure to rewrite a program in a Flash ROM. Send the program from

the host, and turn off the powe after confirming the ALM LED turns off completely.

1) Switch operation when rewriting the firmware program

Head up lever: Head up

Feed switch: ON (press)

Entry swich: OFF

Turn the power on, the ALM LED start flashing slowly, then release the feed switch.

2) Switch operation when rewriting boot program

Head up lever: Head up

Feed switch: ON (press)

Entry swich: ON (press)

Turn the power on, the ALM LED start flashing slowly, then release the feed and enrty switch.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

10

Page 15

4.1.4 Setting of Memory switch

For setting or changing Memory switch, first load a roll of paper, then follow the below

procedure for mode setting (1) and switch setting (2).

After completion of the settings, it automatically operate software reset. Please confirm the

setting result by self print.

1)Mode setting

Head up lever: Head down

Feed switch: ON (press)

Entry swich: ON (press)

Then turn the power on, it print "** MEMORY SW SETTING MODE **". This is the

setting mode. You may release the Feed and Entry switch.

2)Memory switch setting

Setting starts from Memory switch S1-1 to S1-8, and from S2-1 to S2-8.

After change to the SETTING MODE, the LED start flashing.

・Press Feed switch when the LED is on, memory switch setting is on, and the result will

be printed.

・Press Feed switch when the LED is off, memory switch setting is off, and the result will

be printed.

Please continue such setting 16 times to complete all the settings.

If you would like to cancel the setting in the middle, please head up and press the feed

switch once, then head down.

If you change the setting when head up state, such change is not effective.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

11

Page 16

4.2 Self diagnostic print

1) By performing self-diagnostic print following items are checked.

a) Proper function of control circuitry

b) Proper function of printer mechanism

c) Print quality

d) Control F/W version

e) Memory switch setting status

f) Correct function of paper out sensor

g) Head wide and head rank (automatically detected)

2) Start and end of self diagnostic print

Set the power on while pressing the FEED switch and release the FEED switch after the printer

mechanism activates to start self-printing.

The self diagnostic print automatically ends when a preset number of characters are finished

printing. While printing, the printer is in Off-line mode.

4.3 Operation panel

Operation switch is attached at the side of the printer.

1)PO (green) [Power lamp]

It is on when power is supplied to printer.

2)ALM(red) [Alarm lamp]

It will be on or flash when printer is in an error status.

I will be flash/on/ off when rewriting to the Flash ROM

3)ENTRY [Setting switch]

It is the switch when change the setting of memory switch.

It is used when rewriting to the Flash ROM.

4)FEED [Feed switch]

It is a feed switch for paper feed.

It is used when the memory switch setting mode, memory switch setting,

rewriting to the Flash memory mode set, and self print.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

12

Page 17

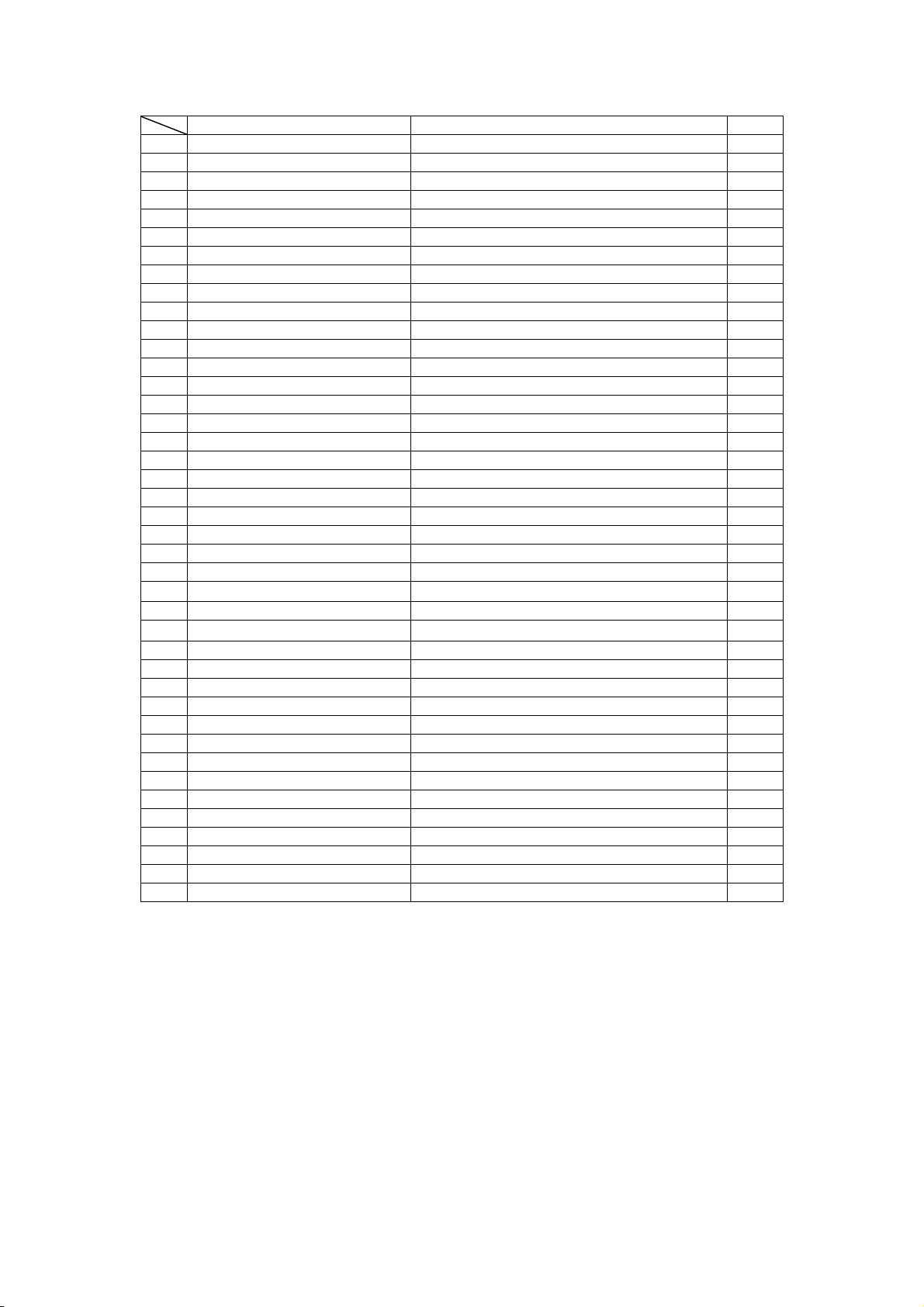

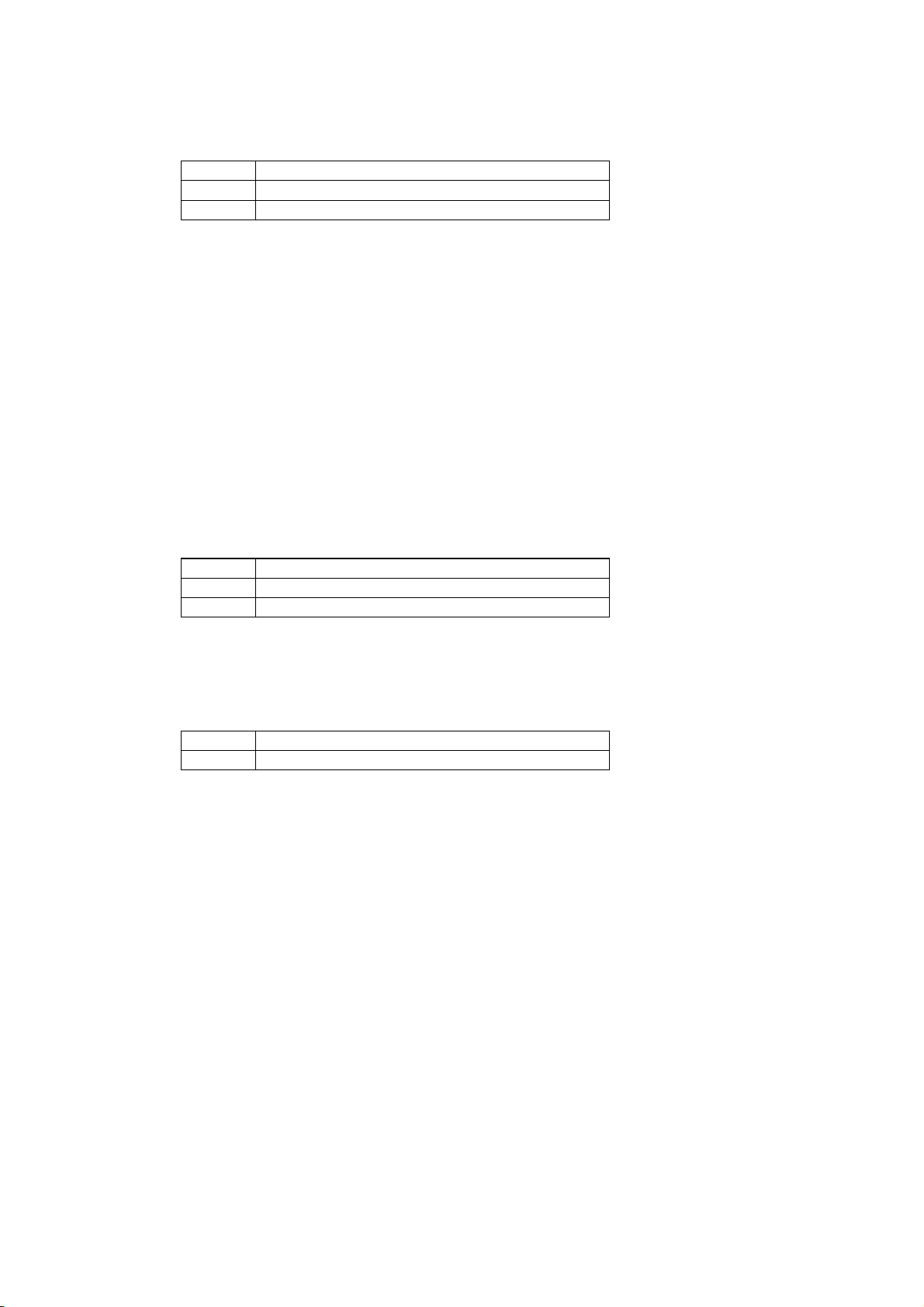

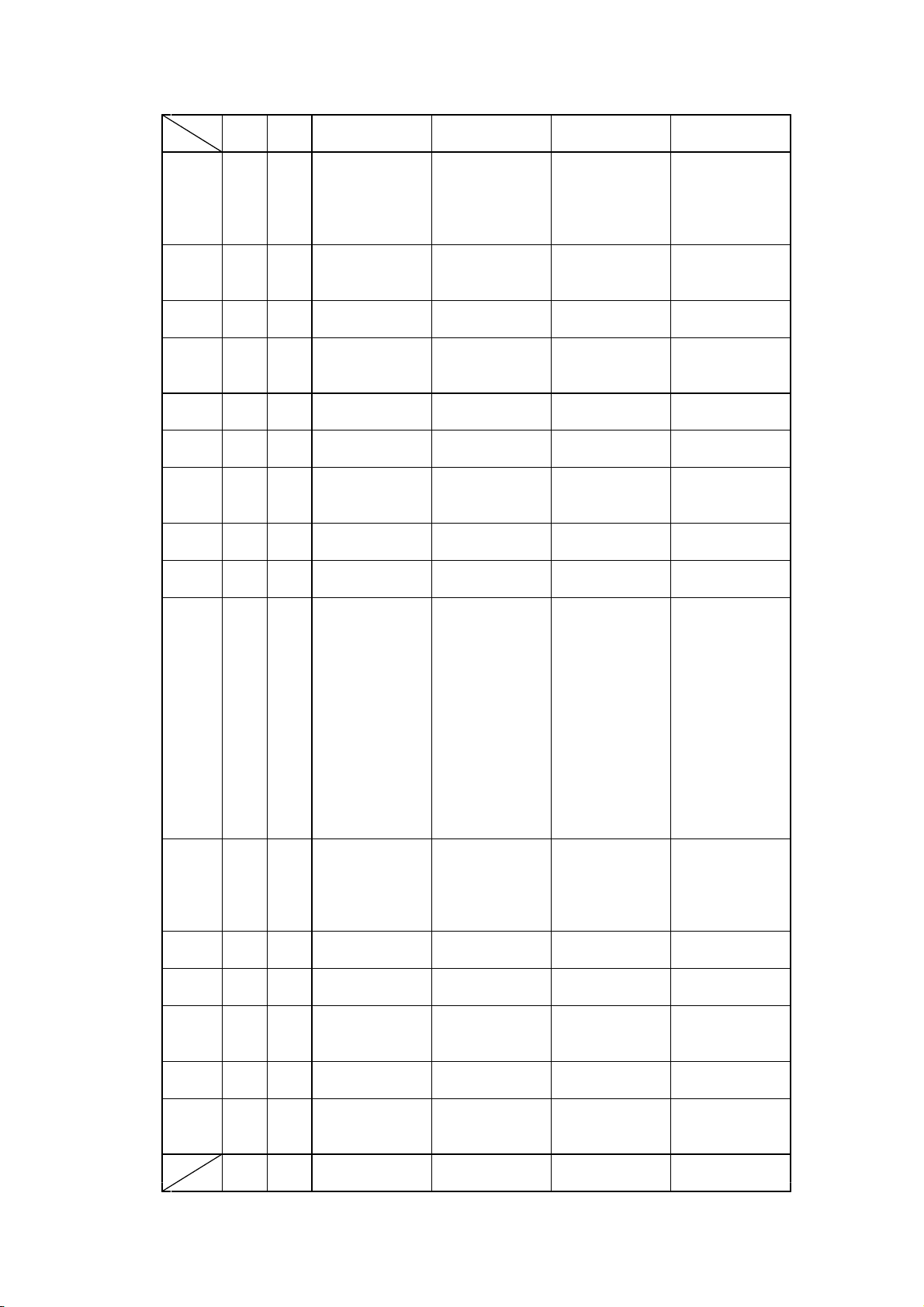

4.4 Processing errors

1) Error detection details

Name Status

232C

status

ALM status Removal

Comm. 232C Comm. error - - Align comm.condition

error Parity

Overrun

Flaming

Data “?” print

Head up Head up 1bit 1 On Head up lever down

Paper end No paper 2bit 1 On Load paper

Head temp

Over 80°C

high

3bit 1 Flash Return normal

with 60°C

Cutter cover Cutter cover open 5bit 1 Flash Cutter cover close

open

When the above errors are detected except transmission error and paper near end error, printer

stops all operations and outputs error signal.

In the case of serial interface:

Error bit in the status information is set to “ON”.

ALM pattern Printer status

1

0

1

0

1

0

0

1

0

0.2sec

0.2sec 1.0sec

0.1sec

2.2sec

0.1secc

2.2sec

Normal

Possible to print

Paper out

Head up

F/W rewrite mode

Head temp. high (over 80 ℃) 1

Head connection error

Cutter cover error

2) Return to normal status from error statuses

Remove causes of error statuses and turn the power on again or input the /INIT signal to

return to normal. When this process is activated, at the time of power switch turned off, the

printer will be initialized, so that settings are required again.

If data remains in the buffer, attention should be paid

4.5 Buffer full print

If there remains data in the buffer after one line of data is received, printer automatically prints

preceding data. The volume of buffer full data varies depending on ASCII characters or bit

images.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

13

Page 18

4.6 Auto loading

If you insert paper to the printer mechanism, paper will be automatically loaded. Please make sure

to insert the paper propaerly so the sensor will detect the paper.

4.7 Partition drive – under review

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

14

Page 19

5. Control commands

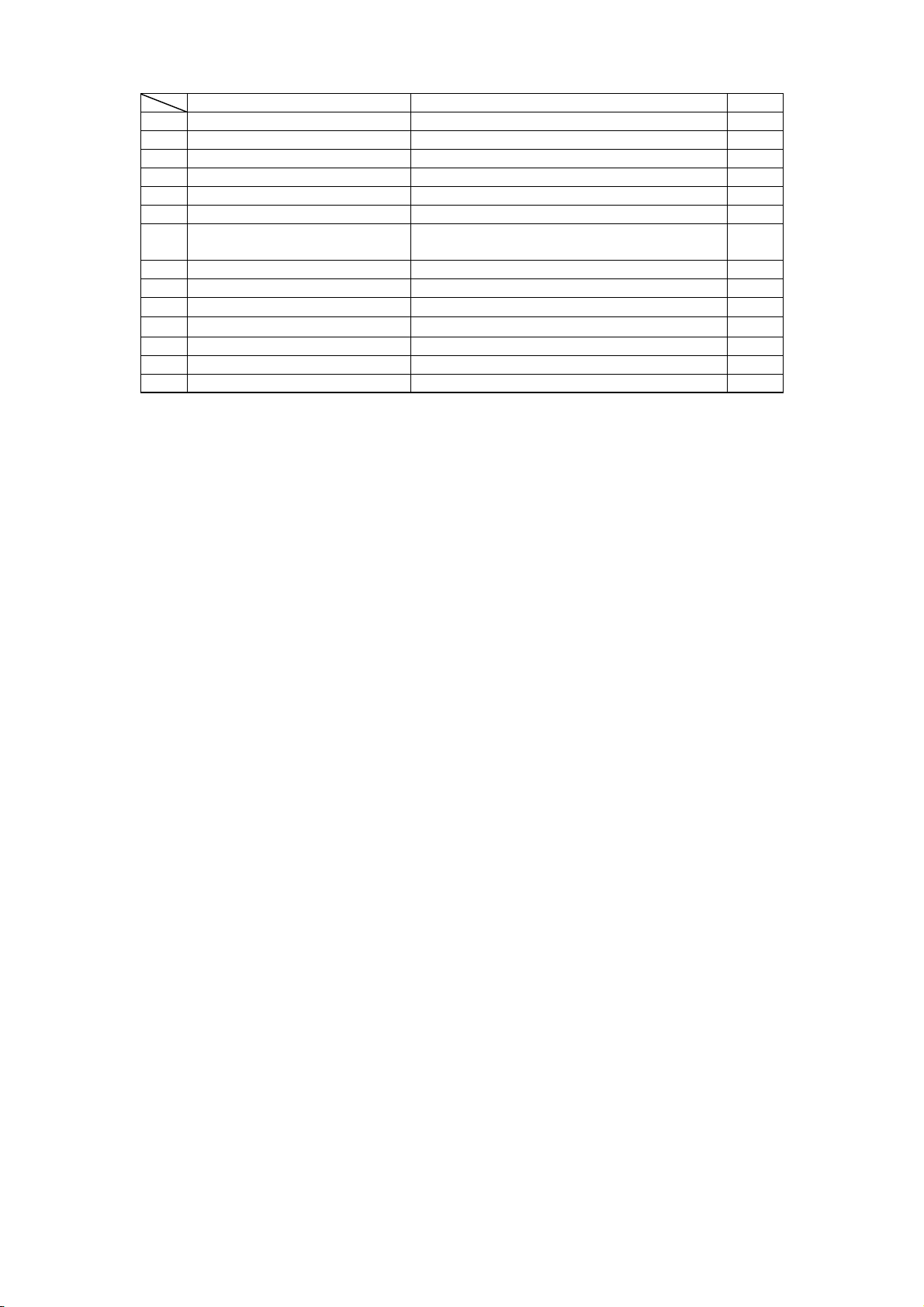

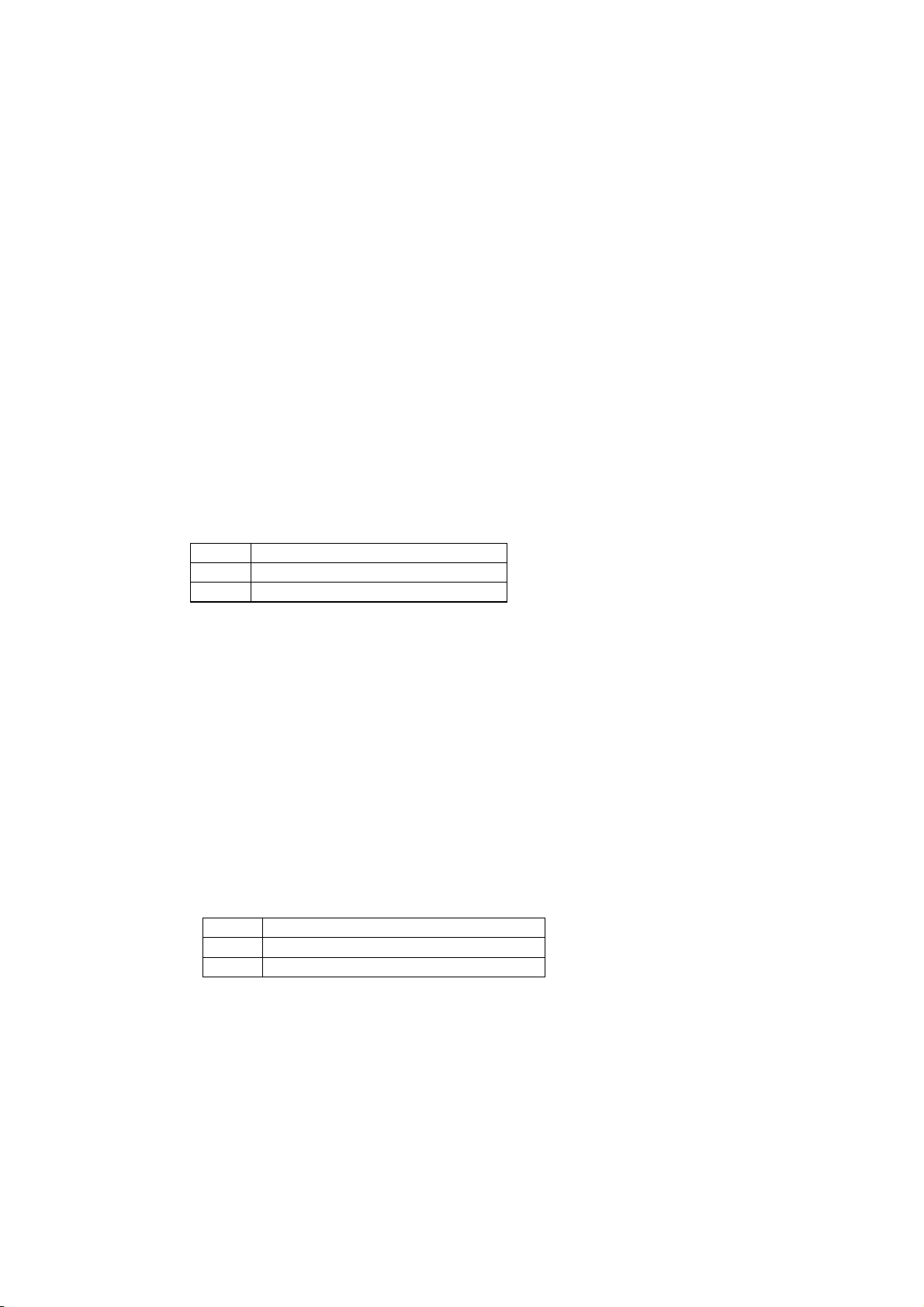

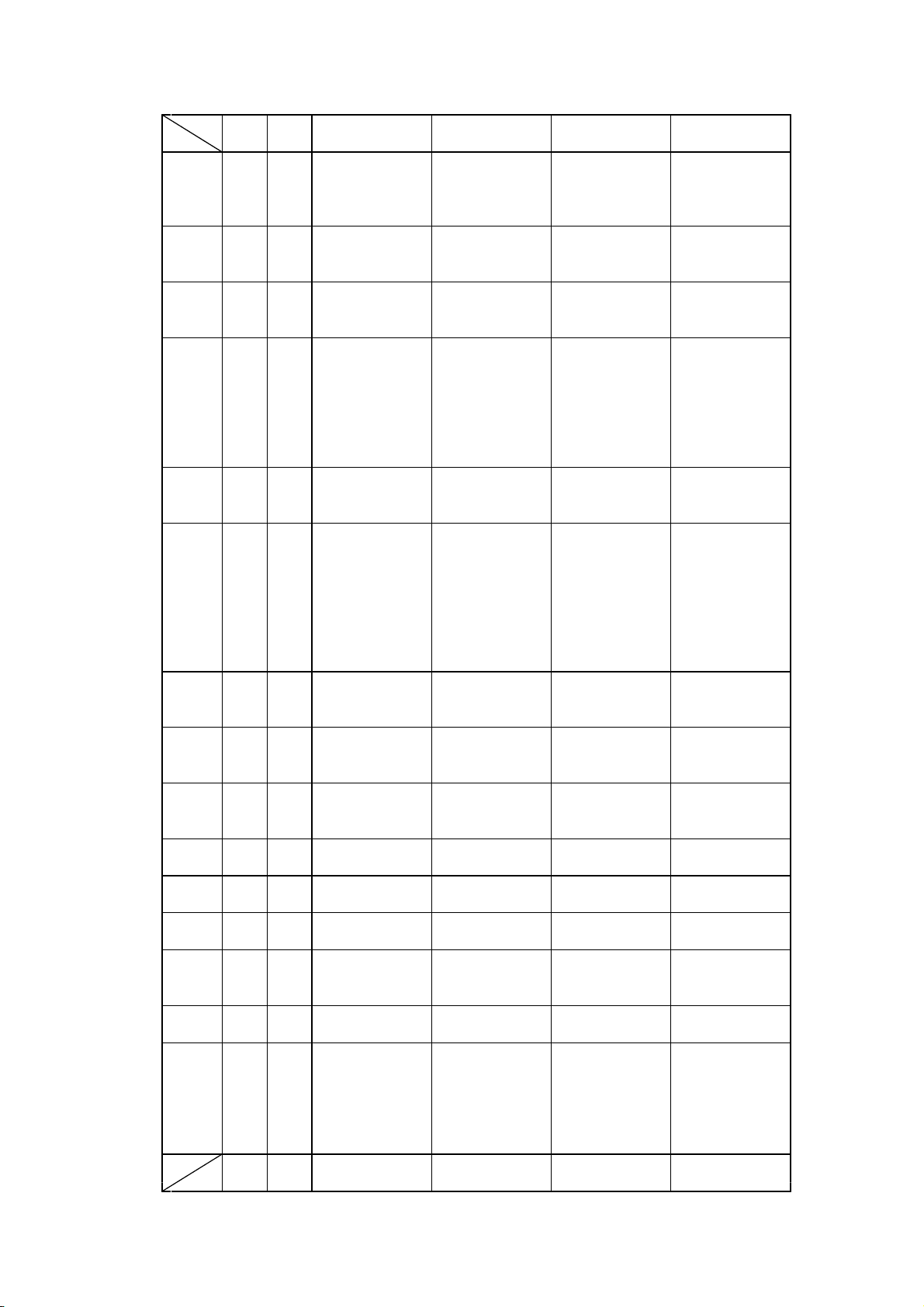

5.1 Control command table

Control codes Functions Pages

1 HT Horizontal tab 17

2 CR Carriage return 17

3 LF Print and line feed 17

4 FF Page feed 17

5 ESC C n Page length set for n lines 17

6 ESC SP n Character right space set 17

7 ESC ! n Print mode overall set 18

8 ESC % n Down load character set/reset 18

9 ESC & s n m a Dn Down load character definition 18

10 ESC * m n1 n2 Dn Bit image mode set 21

11 ESC – n Underline set/rest 23

12 ESC 2 1/6 inches line feed set 23

13 ESC 3 n Smallest line feed pitch set 23

14 ESC @ Initialize printer 23

15 ESC D n1 n2 --- NUL Set horizontal tab position 23

16 ESC E n Bold print set/reset 24

17 ESC G n Double strike print set/reset 24

18 ESC J n Print and smallest pitch line feed 24

19 ESC R n Select international character 24

20 ESC c 5 n Feed switch enable/disable 25

21 ESC d n Print and n line feed 25

22 ESC t n Select character code table 25

23 ESC v Send printer status 25

24 ESC { n Inverted character set/reset 26

25 ESC V n

26 ESC $ n1 n2 Absolute position set 26

27

ESC \ n1 n2

28 GS k n Dn NUL Barcode print 27

29 GS w n Barcode width select 27

30 GS h n Barcode height select 27

31 GS H n HRI character print position select 27

32 GS f n HRI character style select 28

33 GS * n1 n2 Dn Download bit image define 28

34 GS / m Download bit image print 29

35 ESC = n Data input control 29

36 ESC a n Position align 29

37 GS T n Register Fixed bit image 30

38 GS P n Print Fixed bit image 30

39 GS d Dn FirmwareDownload 30

40 DC1 Software reset 30

41 GS ~ n Print density set 30

Character 90° clockwise rotation set/reset

26

Relative position set 26

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

15

Page 20

Control codes Functions Pages

42 FS ! n Japanese Kanji overall print mode setting 31

43 FS & Japanese Kanji mode setting 31

44 FS – n Japanese Kanji underline set / reset 31

45 FS . Japanese Kanji mode reset 31

46 FS C n Japanese Kanji code select 32

47 FS S n1 n2 Japanese Kanji space setting 32

48 FS W n Japanese Kanji Double height and width set

/ reset

49 ESC s n Sending the printer information 32

50 GS : Macro definition, start and end 33

51

GS ^ n1 n2 n3

52 GS B n

53 ESC b n1 n2 n3 Dn Raster bit image 34

54 FS 2 a1 a2 Dn Definition additional character 35

55 ESC B n Back feed 36

Macro execution 33

Black and white reverse print set / reset

32

33

5.2 Printer driver

Please apply the driver stated below for using NP-211 under Windows environment. Refer to the

User’s Manual for a driver.

1) Windows 95/98: NII printer driver Windows 95/98, Version 1.00

2) Windows NT4.0: NII printer driver Windows NT4.0, Version 1.00

3) Windows 2000/XP: NII printer driver Windows 2000/XP, Version 1.00

4) Windows 2000/XP: NII printer driver Windows 2000/XP for USB, Version 1.00

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

16

Page 21

5.3 Control command details

1) Horizontal tab : << HT >>

Code : [09] h

Shift the print position to the next horizontal tab position

* Horizontal tab position is set by [horizontal tab set] command.

* The default of horizontal tab position is every 8th character (9th digit,

17th digit, 25th digit) in font A.

* If the next tab position is not set, this command is ignored.

2) Carriage return : << CR >>

Code : [0D] h

This command is ignored.

3) Line feed : << LF >>

Code : [0A] h

Prints data stored in the input buffer and executes line feed according to data

of feed pitch.

4) Page feed : << FF >>

Code : [0C] h

* Prints data in the print line buffer and executes page feed to the head of next page

according to the page length in the setting.

5) “n” line page length setting : << ESC C n >>

Code : [1B] h + [43] h +n * [01≤n≤FF] h

Sets a page length for “n” lines with current line feed pitch.

* Position is set to the head of page

* Line pitch change after setting will not change page length.

* Default value for “n” is [42] h for 66 lines.

* If printer is initialized, the head of page is also initialized.

6) Setting right space of a character : << ESC SP n >>

Code : [1B] h + [20] h + n * [00≤n≤20] h

Sets the right space of a character by unit of dot (1/203 of an inch). In the case of

double width mode, the space will be doubled. The default value of “n” is [00] h.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

17

Page 22

7) Overall print mode setting : << ESC ! n >>

Code : [1B] h + [21] h + n * [00≤n≤FF] h

Sets print mode. “n” has following meanings

Bit Function

Values

0 1

0 Character font Font A Font B

1 Undefined - 2 Undefined - 3 Bold Reset Set

4 Double height Reset Set

5 Double width Reset Set

6 Undefined - 7 Underline Reset Set

* If double height and double width are set at the same time quadruple character will be formed.

* All of the printed characters will be underlined except for the 90° rotated characters and spaces

created by horizontal tab.

* Underline width is determined by the value set in [Underline set/reset] section.

The default value is “1”.

* Only Bold is effective in Kanji mode.

* Different sizes of character mixed such as double width and normal size can be printed.

* The default value of “n” is [00] h.

8) Download characters set/reset : << ESC % n >>

Code : [1B] h + [25] h + n * [00≤n≤FF]h

Setting or resetting the characters to be downloaded.

* Only LSB (b0) is valid for “n” value. LSB (b0) has the following meanings.

b0 Function

0 Resets download chraracter

1 Sets download chraracter

* Default value is “n” = [00] h

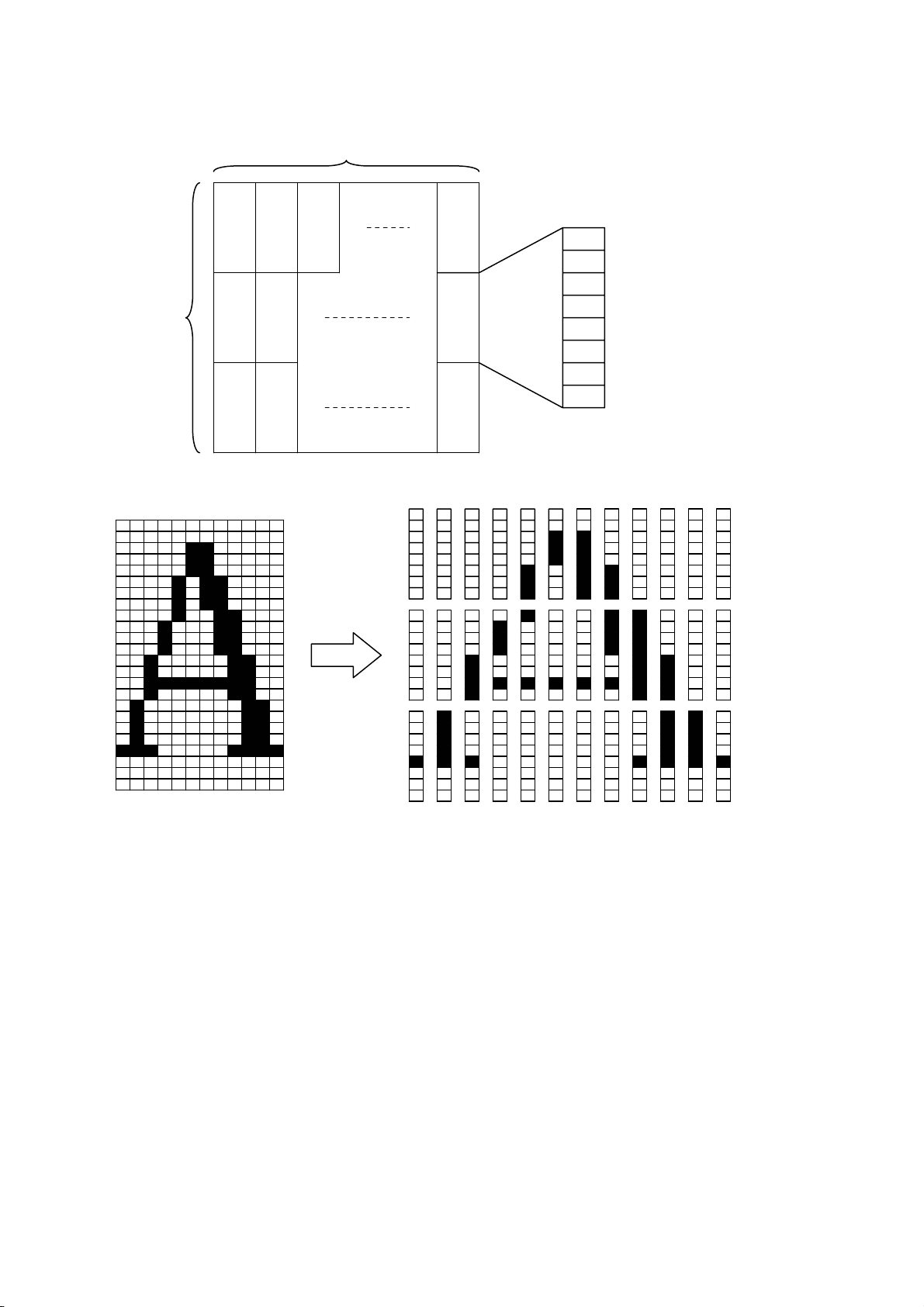

9) Definition of download character :<< ESC & s n m a Dn >>

Code : [1B] h + [26] h + s + n + m + a + Dn

* [s = 03 ] h

* [20≤n≤7E ] h

* [20≤m≤7E ] h

* font A [ 01≤a≤0C ] h

* font B [ 01≤a≤09 ] h

Definition of download character( such as alpha numeric).

* “s” indicates a number of bytes in a vertical direction and “a” is a number of dots in

horizontal direction.

* “n” indicates the start character code, and “m” means the end character code. If only 1

character should be defined, then n = m.

* Definable characters are from <20>h to <7E>h in ASCII code (95 characters).

* “Dn” indicates the data to be defined. It indicates the “a” dots pattern from the left.

Remaining area on the right of a character is filled with spaces.

* Once a download character is defined, it remains valid until the download character is

redefined, printer is initialized, or the power is turned off.

* Only area specified will be reset.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

18

Page 23

< Reference >

In the case of Font A

P1

12dots

P4

P7 P34

MSB

24dots

P2

P3

P5

P6

P35

P36

LSB

P1= [00] h, P4= [00] h, P7= [00] h, P10= [00] h, …

P2= [00] h, P5= [00] h, P8= [0F] h, P11= [72] h, …

P3= [08] h, P6= [F8] h, P9= [08] h, P12= [00] h, …

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

19

Page 24

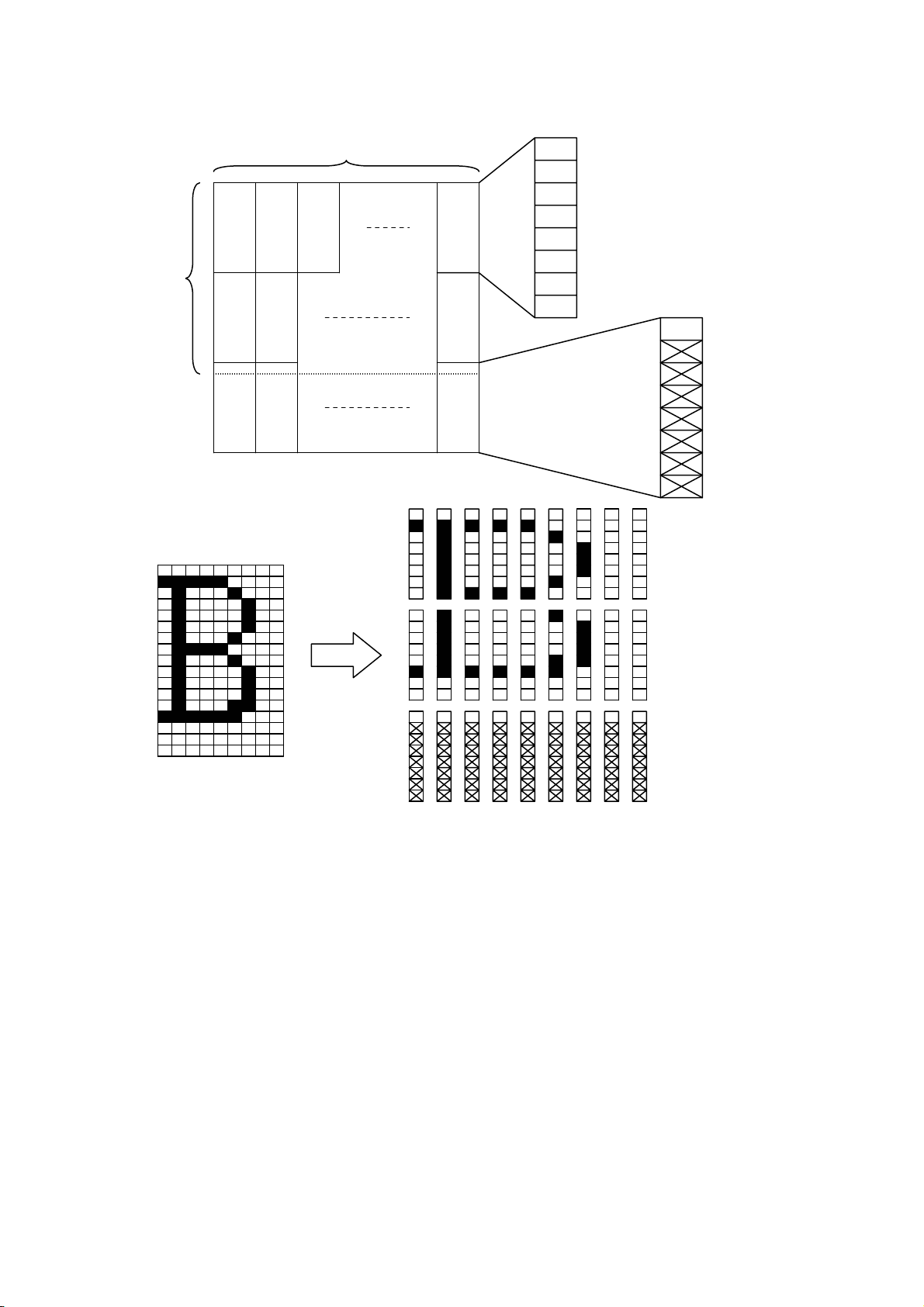

< Reference >

In the case of Font B

9dots

MSB

17dots

P4

P5

P7

P25

P26

LSB

MSB

P1

P2

P27P6 P3

LSB

P1= [40] h, P4= [7F] h, P7= [41] h, P10= [41] h, …

P2= [04] h, P5= [FC] h, P8= [04] h, P11= [04] h, …

P3= [00] h, P6= [00] h, P9= [00] h, P12= [00] h, …

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

20

Page 25

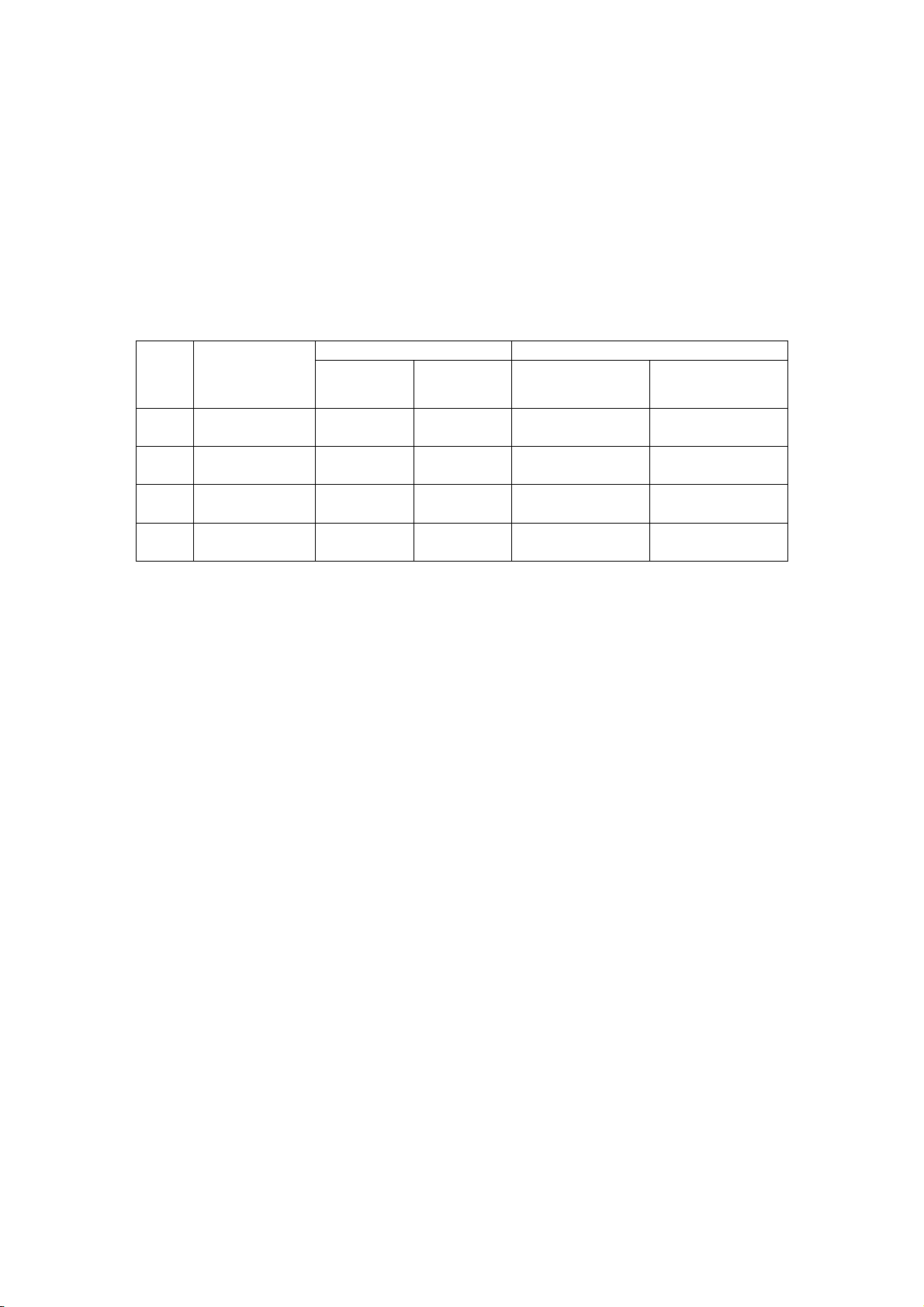

10) Bit image mode set : << ESC * m n1 n2 Dn >>

Code: [1B] h + [2A] h + m + n1 + n2 + Dn * [m = please refer to table below] h

* [00≤n1≤FF] h

* [00≤n2≤01] h

Data is printed in bit image by following the bit image mode specified by “m”.

* Print total dots divided by 256, quotient is n2 and remainder is n1.

* Total dots in bit image mode are n1 + (256 x n2).

* If the bit image input data exceeds specified position, the exceeded data will be disregarded.

* Bit image data (Dn) interprets bit 1 as print and bit 0 as not print.

* Bit image mode is as indicated below.

Vertical direction Horizontal direction

m

(hex)

00

01

20

21,23

Bit image

mode

8 dots single

density

8 dots double

density

24 dots single

density

24 dots

double density

Dot

quantiy

Dot

density

Dot density

8 67DPI 101DPI 192

8 67DPI 203DPI 384

24 203DPI 101DPI 192

24 203DPI 203DPI 384

Maximum dot

number

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

21

Page 26

< Relationship between bit image data and printed dots >

8dots bit image

MSB

D1 D2 D3

D1 D2 D3

LSB

Data

=1dot

Single Double

24 dots bit image

D4 D7 MSB

D1

D1 D2 D3 D7 D8 D9

D4

D5 D6

D2

D5

D8

D3

D6 D9

LSB

Data

=1dot

Single Double

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

22

Page 27

11) Underline set/reset : << ESC - n >>

Code : [1B] h + [2D] h + n * [00≤ n ≤02] h

Sets and resets the underline

* Underline is valid for all characters except for the area skipped by horizontal tab.

* Also Underline is not valid for 90° rotated character.

* Underline is verified with n value as shown bellow.

n(hex) Type of underlines

00 Reset underline

01 Set one dot underline

02 Set two dot underline

* Default value is “n” = [00] h

12) 1/6th of an inch line feed pitch : << ESC 2 >>

Code : [1B] h + [32] h

Sets one line feed to 1/6th of an inch.

13) Sets smallest pitch line feed : << ESC 3 n >>

Code : [1B] h + [33] h + n * [00≤ n ≤FF] h

Sets a line feed pitch to n/203rd of an inch.

* Despite of height set by value, the same space with character height is sent by line feed.

* The default value of n is [22] h

* If n = [00] h is set, printer will not feed by pressing FEED button.

14) Printer initialization : << ESC @ >>

Code : [1B] h + [40] h

Clears the data stored in the print buffer and resets each setting to default values.

* It does not clear the data stored in the internal receive buffer.

* It is stored in the internal receive buffer and activated in sequential.

15) Horizontal tab position set : << ESC D n1 n2 --- NUL >>

Code : [1B] h + [44] h + n1+ n2 + --- + [00] h *[00≤ n ≤FF] h

Sets the horizontal tab position

* “n” indicates the digits number from the left. In this case, n = tab position - 1.

* Tab position is set at the location of character width x n from the beginning of a

line. The character width in this case includes character right space. When double

width function is set, then the width becomes double of ordinary character.

* Maximum number of tab positions is 32. If setting exceeds 32, then

the exceeded values are neglected.

* << ESC D NUL >> clears all tab positions being set. After the tab is cleared,

horizontal tab will be ignored.

* Default value is set at every 8 characters of font A (at 9

th, 17th, 25

th

digit).

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

23

Page 28

16) Bold print set/reset :<< ESC E n >>

Code : [1B] h + [45] h + n * [00≤ n ≤FF] h

Sets and resets the bold print

* “n” is only valid for LSB(b0)

* LSB (b0) is defined as following.

b0 Values

0 Resets bold print

1 Sets the bold print

* Print result may be deformed in case black and white reverse at bold print.

* Bold print and double strike results in the same on this printer.

* The default value of “n” is [00]h.

17) Double strike set/reset :<< ESC G n >>

Code : [1B] h + [47] h + n * [00≤n≤FF] h

Sets and resets the double strike function

* “n” is only valid for LSB (b0)

* Control by “n” is explained as following.

b0 Description

0 Resets double strike

1 Sets double strike

* Double strike and bold print result in the same on this printer.

* The default value of “n” is [00] h.

18) Print and smallest pitch line feed :<< ESC J n >>

Code : [1B] h + [4A] h + n * [00≤n≤FF] h

Prints the data in the print line buffer and feeds the paper by n/203rd of an inch.

* The height of character for a line is always sent by line feed. If the value of height is set

by “n” below the height of character, the same space with character height is sent by

line feed.

* Beginning of a line is a print start position.

19) International character select :<< ESC R n >>

Code : [1B] h + [52] h + n * [00≤n≤0A] h

Selects the international characters.

* The values of “n” have following meanings

n(Hex) Character sets

00 U.S.A.

01 France

02 Germany

03 England

04 Denmark 1

05 Sweden

06 Italy

07 Spain

08 Japan

09 Norway

0A Denmark 2

* Default value of “n” is [08] h.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

24

Page 29

20) FEED switch enable/disable :<< ESC c 5 n >>

Code : [1B] h + [63] h + [35] h + n * [00≤n≤FF] h

Changes the FEED switch valid or invalid.

* “n” is only valid for LSB (b0)

* “n” bit has a following meanings

b0 Description

0 enable FEED switch

1 disable FEED switch

* Default value of “n” is [00] h.

21) Print and “n” line feed :<< ESC d n >>

Code : [1B] h + [64] h + n * [00≤n≤FF] h

Prints the data in the print buffer and feeds paper by “n” lines.

* Beginning of a line is a print start position.

* If there is print data remained, line feed is activated for the same height of character.

22) Character code table select :<< ESC t n >>

Code : [1B] h + [74] h + n * [00≤n≤01] h

* “n” value has following meaning.

n(Hex) character code table

00 Overseas character code table

01 Domestic character code table

* The default value of “n” is set with memory switch (S2-1).

23) Printer status transmission :<< ESC v >>

Code : [1B] h + [76] h

Sends current printer status

* Status to be transmitted consist of 1 byte and the content is explained in the chart below.

* Regarding DTR/DSR control, only one byte is transmitted after confirmation that the

host is able to receive data, that is DSR signal is in SPACE status. For XON/OFF

control, one byte is transmitted without confirmation of DSR signal status.

* For DTR/DSR control, if host is not in a receivable status, it waits until host can receive

data.

bit Functions

0 1

Value

0 Reserved

1 platen open normal head open

2 paper end paper present no paper

3 head temp. abnormal normal Temp. abnormal

4 Undefined

5 Cutter cover open normal Cutter cover open

6 Undefined

7 Undefined

* Make sure that command is issued before transmission of print data.

(commands are stored in the input buffer and executed sequentially)

* Reception is available except in the buffer full status.

* The commands above are valid only for serial interface.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

25

Page 30

24) Inverted character set and reset :<< ESC { n >>

Code : [1B] h + [7B] h + n * [00≤n≤FF] h

Sets or resets the inverted character function

* “n” is only valid for the LSB (b0)

* LSB (b0) has the following meaning

b0 Description

0 resets inverted character

1 sets inverted character

* The command is only valid when it is assigned at the beginning of a line.

* The default value of n is [00] h.

25) 90° clockwise rotated character set and reset :<< ESC V n >>

Code : [1B] h + [56] h + n * [00≤n≤01] h

Sets and resets 90° clockwise rotated character.

* Underline cannot be assigned to the 90° clockwise rotated character.

* “n” has the following meaning.

n(hex) description

00

reset 90° rotated character

01

set 90° rotated character

* Default value for “n” is [00] h.

26) Absolute position set :<< ESC $ n1 n2 >>

Code : [1B] h + [24] h +n1 +n2 * [00≤n1≤FF] h

* [00≤n2≤01] h

Print start position is assigned by dots in 1/203rd of inch from the beginning of line.

* Divide the value of dot by 256, place quotient to n2, and remainder to n1.

* The print start position is n1 + n2 x 256 from top of the line.

* Setting which exceeds end of line is ignored.

* If the command is received in the middle of line, the current position is also valid.

27) Relative position set :<< ESC \ n1 n2 >>

Code : [1B] h + [5C] h + n1 +n2 * [00≤n1≤FF] h

* [00≤n2≤FF] h

Print start position is assigned by dots from current position in unit of 1/203rd of inch.

* Right direction is treated as plus and left as minus.

* For assigning N dots in minus direction (left), it will be: N dots = 65536 - N

* Divide dots by 256, quotient is n2 and remainder is n1.

* Assigning beyond the end of a line is neglected

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

26

Page 31

28) Barcode print : << GS k n Dn NUL >>

Code : [1D] h + [6B] h + n + Dn + [00] h * [00≤n≤07] h

Selects barcode symbology and prints barcode.

* The next print start position is on the line head

* Select following barcode symbology with “n” value.

* Dn indicates the character code to be printed.

n (Hex) Barcode symbology

00 UPC-A

01 UPC-E

02 EAN-13 (JAN-13)

03 EAN-8 (JAN-8)

04 CODE 39

05 ITF

06 CODABAR(NW-7)

07 CODE128

* When there is data in the buffer this command is neglected.

* If character code Dn is not a printable character, following data after Dn will be treated

as normal data.

* If the print character numbers are fixed in the barcode symbology the input character

numbers should match to the print character numbers.

* If horizontal data exceed one line, the exceeded data cannot be printed.

29) Barcode width size select : << GS w n >>

Code : [1D] h + [77] h + n * [02≤n≤04] h

Selects width of barcode

* Default value of “n” is [03] h.

30) Barcode height select :<< GS h n >>

Code : [1D] h + [68] h + n * [01≤n≤FF] h

Description : Selects barcode height

* “n” shows the vertical dot number

* Default value of “n” is 162([A2] h).

31) Select of HRI character print position :<< GS H n >>

Code : [1D] h + [48] h +n * [00≤n≤03] h

Selects the print position of HRI characters in printing barcode.

* “n” has the following meaning.

n (Hex) Print position

00 No printing

01 Above barcode

02 Below barcode

03 Above and below barcode

* HRI characters are the characters selected by “HRI character style select”.

* Default value of “n” is [00] h.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

27

Page 32

32) Select of HRI character style : << GS f n >>

Code : [1D] h + [66] h + n * [00≤n≤01] h

Selects HRI character style in printing barcode

* “n” has the following meanings:

n (hex) Style

00 Font A

01 Font B

* Default value of “n” is [00] h.

33) Download bit image definition :<< GS * n1 n2 Dn >>

Code : [1D] h + [2A] h + n1 + n2 + Dn * [01≤n1≤FF] h

* [01≤n2≤30] h

* [n1 x n2≤51F] h

Defines “download bit image” of number of dots specified by n1 and n2.

* Horizontal dot numbers are obtained by n1 x 8 and vertical dot numbers by n2 x 8.

* Dn is bit image data.

* Once “download bit image” is defined, it is valid until it’s redefined, download

character is defined, external characters are specified, software is reset, power is set

off .

* The relationship between bit image data & defined dots is shown below.

n1x8dots

d1 MSB

dn2+1

dn2x2+1

d2

dn2+2

dn2x2+2

n2x8dots

LSB

dn2

dn1xn2x8

dn2x2

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

28

Page 33

34) Download bit image print :<< GS / m >>

Code : < 1D >h + < 2F >h + m * [00≤m≤03] h

Description : Prints “download bit image” in a mode assigned by “m”.

* Modes to be assigned by m are as follows.

m Modes

Dot density

Vertical Horizontal

00 Normal mode 203 dpi 203 dpi

01 Double width 203 dpi 101 dpi

02 Vertical double 101 dpi 203 dpi

03 Quadruple 101 dpi 101 dpi

* If there are some data left in the print buffer, this command is neglected.

* If “download bit image” is not defined yet, this command is neglected.

* “Download bit image” data exceeding 1 line cannot be printed.

35) Data input control :<< ESC = n >>

Code : [1B] h + [3D] h + n * [00≤n≤FF] h

Description:Selects valid device where data input is possible through host computer.

* Each bit of “n” has the following meaning.

Bit Function

Values

0 1

0 Printer Invalid Valid

1 Not defined

2 Not defined

3 Not defined

4 Not defined

5 Not defined

6 Not defined

7 Not defined

* If printer is not in “no selection” status, printer will discard all received data until it is in

the selection status by this command.

* Even if printer is in no selection status, the status may become BUSY by printer

operation.

* The default value of “n” is [01] h.

36) Position align :<< ESC a n >>

Code : [1B] h + [61] h + n * [00≤n≤02] h

Aligns all data to be printed on the assigned position in a line.

(Fixed bit image is removed.)

* “n” values are assigned to:

n (Hex) Position

00 Left

01 Center

02 Right

* This command is valid only when it is input at the head of a line.

* The default value of “n” is [00] h.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

29

Page 34

37) Register Fixed bit image : << GS T n >>

Code : [1D] h + [54] h + n

Register the predetermined bit image print data.

* It is possible to register from 0 to 2 different kinds of patterns (3 patterns).

* In each pattern, up to the maximum of 10cm length of bit image print data can be

registered. The bit image print data exceeding the maximum length is neglected.

* The registered data is not erased when the power is set on or off or the printer is

initialized.

* “n” has a following meanings.

n (hex) Function

00 Start of pattern 0 registration

01 Start of pattern 1 registration

02 Start of pattern 2 registration

FF End of registration

* When registrations started in the middle of a line, whole line is registered.

* When registration ended in the middle of a line, whole line is not registered.

* Following is a command sequence of pattern 0 registration.

GS T [00] h + (bit image data assigned by ESC *) x n lines + GS T [FF] h

38) Print Fixed bit image : << GS P n >>

Code : [1D] h + [50] h + n * [00≤n≤02] h

Prints the bit image print data registered.

* Selects one of the print pattern among three registered patterns by assigning 0 to 2

value to “n”.

39) Firmware download :<< GS d Dn >>

Code : [1D] h + [64] h + Dn

Download printer firmware in hexadecimal code and rewrite firmware according to the

outcome.

* Dn is firmware’s hex code which complies with INTELLEX Hex format.

40) Software reset : << DC1 >>

Code : [11] h

Restart the firmware as the same procedure as power on.

* This command is stored in the receive input buffer and activated in sequence.

Above means timing is different between command receive and execution

41) Print density set : << GS ~ n >>

Code : [1D] h + [7E] h + n * [41≤n≤87] h

Sets print density in the range between 65% ~ 135% of the standard value, S2-4 Off.

* “n” ranges from 41h(65%) to 87h(135%). However, set it for actual use in the range

[41] h (65%) ≤ n ≤ [82] h (130%).

* At the initial status, 100% or 125% can be selected by the Memory switch, S2-4.

* This command has priority over the setting by Memory switch.

* This setting remain unchaged if execute an initialization.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

30

Page 35

42) Japanese Kanji overall print mode setting : << FS ! n >>

Code : [1C] h + [21] h + n * [00≤n≤FF] h

Set Japanese Kanji overall print mode.

“n” has following meanings

Bit Function

Values

0 1

0 Undefined - 1 Undefined - 2 Double width Reset Set

3 Double height Reset Set

4 Undefined - 5 Undefined - 6 Undefined - 7 Underline Reset Set

* If double height and double width are set at the same time quadruple character will be

formed.

* All of the printed characters will be underlined except for the 90° rotated characters and

spaces created by horizontal tab.

* Underline width is determined by the value set in [Underline set/reset] section.

The default value is “1”.

* Different sizes of character mixed such as double width and normal size can be printed.

* The default value of “n” is [00] h.

43) Japanese Kanji mode setting : << FS & >>

Code : [1C] h + [26] h

Set Japanese Kanji print mode

* It is not effective when selected Shift JIS of Japanese Kanji.

* Default is the reset of Japanese Kanji mode.

44) Japanese Kanji underline set/reset : << FS - n >>

Code : [1C] h + [2D] h + n * [00≤n≤02] h

Set / Rest underline of Japanese Kanji

“n” has following meanings

n(hex) Function

00 Reset underline of Japanese Kanji

01 Set 1 dot underline of Japanese Kanji

02 Set 2 dots underline of Japanese Kanji

* All of the printed characters will be underlined except for the 90° rotated characters and

spaces created by horizontal tab.

* This command is effective only when select Japanese Kanji mode.

* The default value of “n” is [00]h.

45) Japanese Kanji mode reset : << FS . >>

Code : [1C] h + [2E] h

Reset Japanese Kanji print mode

* It is not effective when selected Shift JIS of Japanese Kanji.

* Default is the reset of Japanese Kanji mode.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

31

Page 36

46) Japanese Kanji code select : << FS C n >>

Code : [1C] h + [43] h + n * [00≤n≤01] h

Select Japanese Kanji code

“n” has following meanings

n(hex) Code

00 JIS code

01 Shift JIS code

* Default is the setting of S-2-2 in the Memory switch

47) Japanese Kanji space setting : << FS S n1 n2 >>

Code : [1C] h + [53] h + n1 + n2 * [00≤n1≤20] h

* [00≤n2≤20] h

Set side space of Japanese Kanji by dot unit

* n1 sets the left space. Default value is 0.

* n2 sets the right space. Default value is 0.

* Width of space will be double when selected double width.

48) Japanese Kanji Double height and width set / reset : << FS W n >>

Code : [1C] h + [57] h + n * [00≤n≤FF] h

Last bit (b0) of “n” is effective.

* Default value of “n” is [00] h.

* Last bit “b0” has following meanings

b0 Function

0 Reset double height and width

1 Set double height and width

49) Sending the printer information : << ESC s n >>

Code : [1B] h + [73] h + n * [n=02] h

Sending the printer information

* n has following meanings

n(hex) Function

02 Printer model information

* This command is effective for serial RS232C interface.

Format sending back from the printer:

[FF] h + n (※1) + ASCII string (※2)

※1 n value defined by the command (=[02] h)

※2 Ended with Null (=[00] h)

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

32

Page 37

50) Macro definition, start and end : << GS : >>

Code : [1D] h + [3A] h

Assigns Macro definition start and end. The size of data defined by Macro is up to 1,024

bytes. Exceeding to 1,024 byte cannot be defined.

* Defined Macros cannot be cleared by “Printer initialization”. Therefore “printer

initialization” can be included in the Macro definition.

* During the Macro definition, printing can proceed.

* Once Macro is defined, the contents become effective until software is reset, power is

set off.

51) Macro execution : << GS ^ n1 n2 n3 >>

Code : [1D] h + [5E] h + n1 + n2 + n3 * [00≤n1≤FF] h

* [00≤n2≤FF] h

* [00≤n3≤01] h

Executes Macros being defined

* The definitions of n1, n2 and n3 are:

n1 : times of Macro execution

n2 : wait time of Macro execution

At every execution, there is a wait time of n2 x 100msec.

n3 : Macro execution mode

n3 has a following meanings.

n3(hex) Mode

00 Consecutive execution

01 Execution by FEED switch

* Consecutive execution: Executes “n1” times with a wait time specified at n2.

* FEED switch execute: After a time specified at n2, waits for PE LED blinks and the

FEED switch depressed. After FEED switch is pressed, it executes Macro once.

This action is repeated by n1 times.

* If the printer receives this command during Macro definition, it stops Macro definition.

If it occurs, defined Macros are cleared.

* Nothing occurs if Macro is not defined or n1 = [00] h.

* During Macro execution with n3 = [01] h, line feed by FEED switch is disabled.

52) Black and white reverse print set / reset : << GS B n >>

Code : [1D] h + [42] h + n * [00≤n≤FF] h

Sets and resets black and white reverse print.

* “n” is available only for the least significant bit.

* The least significant bit controls as follows:

b0 Function

0 Resets black-white reverse printing

1 Sets black-white reverse printing

* The characters incorporated and downloaded can be reverse printed.

* The right side space of character set by [Set right space of a character] is also included

for reverse print. However, it does not cover the skipped space made by bit image,

download bit image, NV bit image, barcode, HRI characters, horizontal tab, specify

absolute position, specify relative position.

* It does not include the space between the lines.

* Reverse print has a priority over “underline specified”. If a character is reversed, the

character is not underlined. However, the underline setting remains effective.

* If “highlight” or “double strike” is set on the reverse print, the print may result in damages.

* The default value of “n” is [00] h.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

33

Page 38

53) Raster bit image : << ESC b n1 n2 n3 Dn >>

Code : [1B] h + [62] h + n1+ n2 + n3+ Dn * [01≤n1≤30] h

* [01≤n2≤FF] h

* [01≤n3≤FF] h

Data is printed in a raster bit image.

* Dn is a raster bit image data.

* The printer prints raster bit image of width n1 byte by height n2+(256*n3) dot lines.

* The total byte of the requested raster bit image data (Dn) is n1*(n2+(256*n3)).

* Raster bit image data (Dn) exceeding the printing field will be disregarded.

* Raster bit image data (Dn) interprets bit”1” as print and bit”0” as not print.

* Relation between raster bit image data (Dn) and printed dots are as follows.

n1 byte

D1 D2 Dn1

Dn1+1 Dn1+2 Dn1*2

Dn1*2+1 Dn1*2+2 Dn1*3

n2+(256*n3)dots

Dn1*(n2+(256*n3))

MSB LSB

* Please add the command of << ESC J [00] h >> ([1B] h + [4A] h + [00] h) at the end.

* If you send this command consecutively, please add << ESC J n >> (n≠ [00] h) at the

end of each image, and add the << ESC J [00] h >> at the very end of the image.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

34

Page 39

54) Definition of additional characters : << FS 2 a1 a2 Dn >>

Code : [1C] h + [32] h + a1 + a2 + Dn

JIS Code * [a1=77] h

* [21≤a2≤7E] h

Shift JIS Code * [a1=EC] h

* [40≤a2≤7E, 80≤a2≤9E] h

Definition of additional Kanji characters

* Definition of up to 94 characters available.

* Dn is the data to be defined. Data will be 3 byte(vertical) x 24 dot(horizontal) =72 byte.

* The default status is “space”

* Once defined by command, it will be effective until execution of [Soft reset], power off.

・Only specified area will be redefined.

<Example>

24dots

MSB

P1 P4

P7 P70

P2

24dots

P5 P71

P3 P6 P72 LSB

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

35

Page 40

P1= [02] h, P4= [01] h, P7= [81] h, P10= [40] h, P13= [70] h, P16= [30] h, ...

P2= [00] h, P5= [00] h, P8= [C0] h, P11= [C3] h, P14= [0F] h, P17= [38] h, ...

P3= [40] h, P6= [60] h, P9= [FE] h, P12= [FF] h, P15= [03] h, P18= [00] h, ...

55) Back feed : << ESC B n >>

Code : [1B] h + [42] h + n * [00≤n≤FF] h

Feed the paper backward.

* Paper feed amount is specified by n dot line.

* Paper is not fed backward when [00]h is set.

* If this command is used for many times, paper may be jammed. To avoid this problem,

enter only once and feed paper in the forward direction.

* Double strike print is available by using this command.

* Considering the backlash, there may be a gap of printing.

* When data remains in the print line buffer, it first prints data, then back feeds.

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

36

Page 41

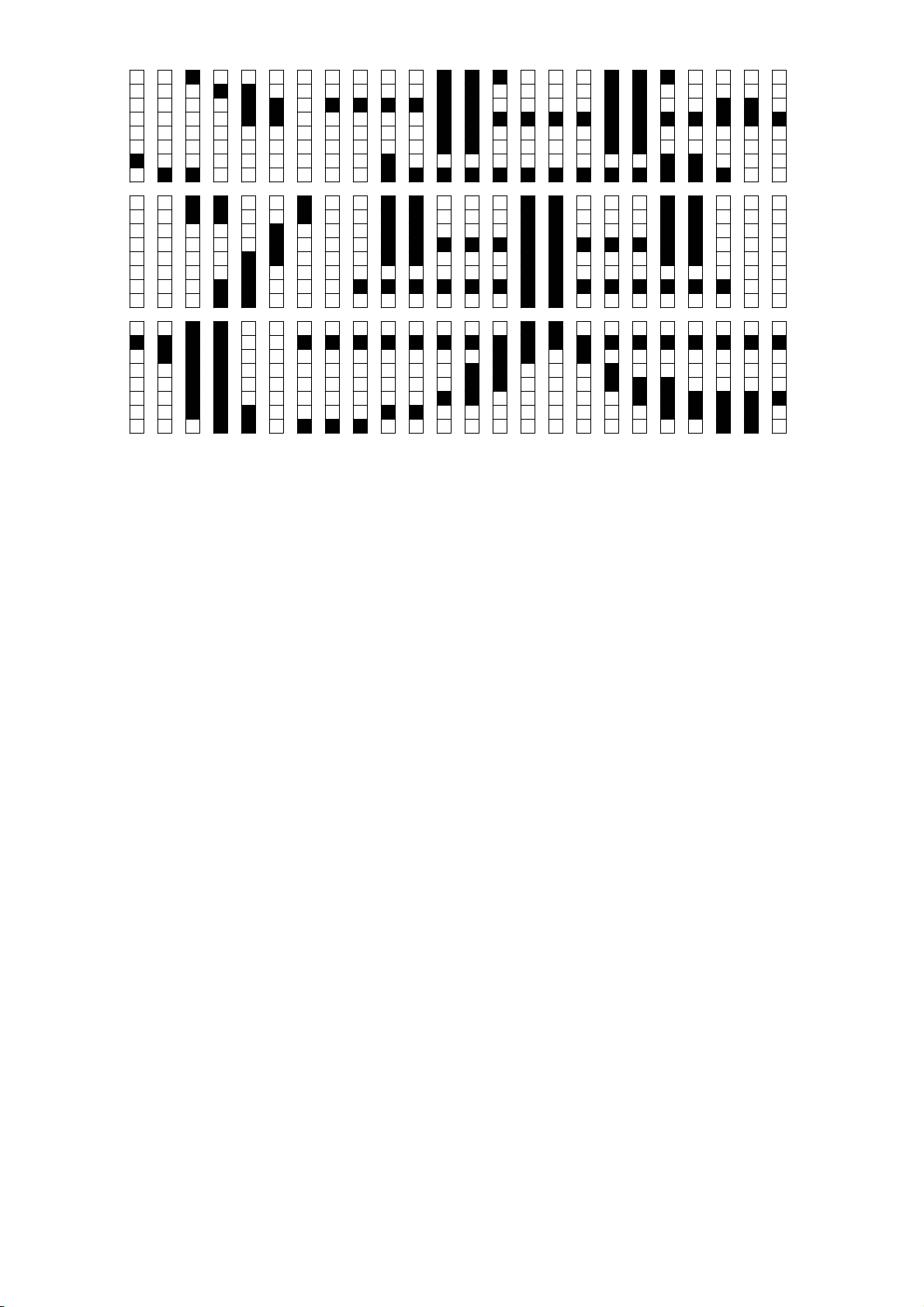

6. Character code table

6.1 Domestic character code table (International character set: Japan)

HEX

0 1 2 3 4 5 6 7 8 9 A B C D E F

HEX BIN

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

* [SP] indicates "space".

* [CR] is neglected.

* Printer operation cannot be guaranteed if the blank control code (codes below [1F] h) is transmitted to

printer.

* This code table indicates simplified symbol and is not print result. There may be a different result

between the code table and print result.

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

NUL

DC1

DC3

HT

LF

ESC

FF FS

CR GS

SP 0 @ P ` p

! 1 A Q a q

” 2 B R b r

# 3 C S c s

$ 4 D T d t

% 5 E U e u

& 6 F V f v

’ 7 G W g w

( 8 H X h x

) 9 I Y i y

* : J Z j z

+ ; K [ k {

, < L ¥ l

- = M ] m }

. > N ^ n ~

/ ? O _ o SP +

SP ー タ ミ

。 ア チ ム

「 イ ツ メ

」 ウ テ モ

、 エ ト ヤ

・ オ ナ ユ

ヲ カ ニ ヨ

ァ キ ヌ ラ

ィ ク ネ リ

ゥ ケ ノ ル

ェ コ ハ レ

ォ サ ヒ ロ

ャ シ フ ワ ● 村

ュ ス ヘ ン ○ 人

ョ セ ホ ゛ /

ッ ソ マ ゜ \ SP

×

円

年

月

日

時

分

秒

〒

市

区

町

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

37

Page 42

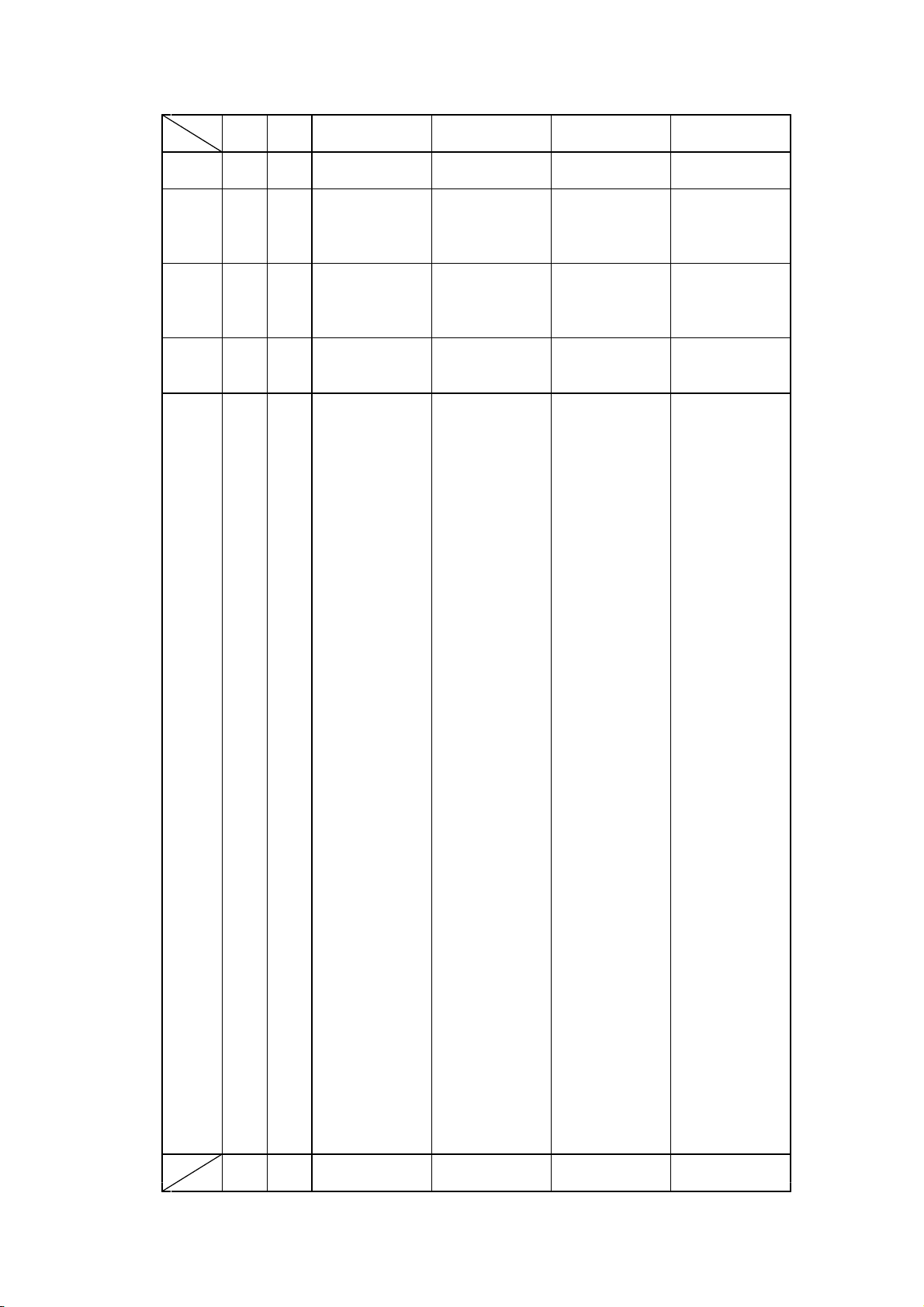

6.2 Overseas character code table (International character set: U.S.A)

HEX

HEX BIN

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

* [SP] indicates "space".

* [CR] is neglected.

* Printer operation cannot be guaranteed if the blank control code (codes below [1F] h) is transmitted to

printer.

* This code table indicates simplified symbol and is not print result. There may be a different result

between the code table and print resul

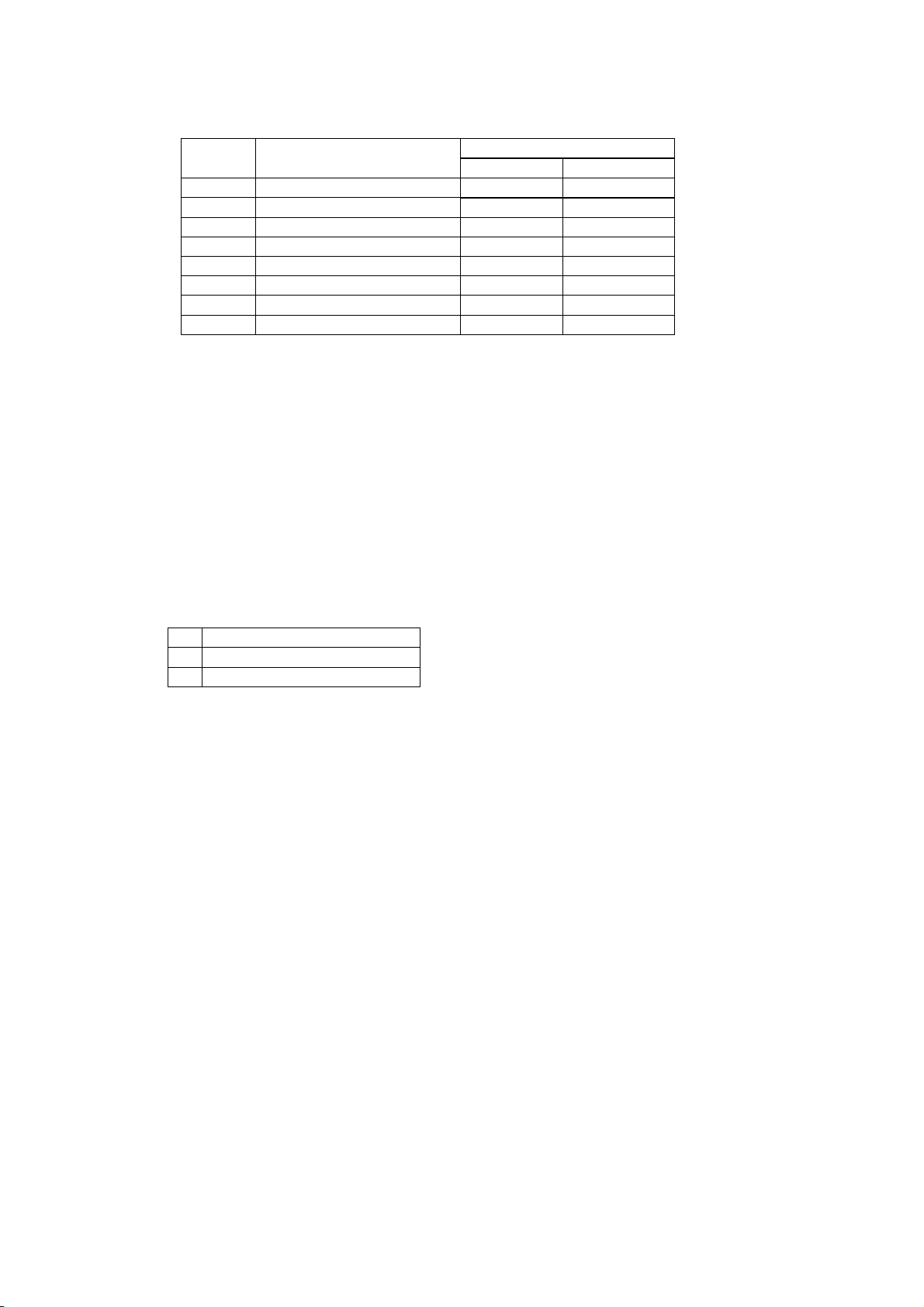

6.3 International character code table

n Character set 23h 24h 40h 5Bh 5Ch 5Dh 5Eh 60h 7Bh 7Ch 7Dh 7Eh

00h U.S.A # $ @ [ \ ] ^

01h France # $

02h Germany # $ §

03h U.K.

04h Denmark1 # $ @

05h Sweden #

06h Italy # $ @

07h Spain

08h Japan # $ @ [ ¥ ] ^

09h Norway #

0Ah Denmark2 # $

* This code table indicates simplified symbol and is not print result. There may be a different result

between the code table and print result

0 1 2 3 456789ABC D E F

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

0000

NUL

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

SP 0 @ P ` p

DC1

DC3

HT

LF

ESC

FF FS

CR GS

! 1 A Q a q

” 2 B R b r

# 3 C S c s

$ 4 D T d t

% 5 E U e u

& 6 F V f v

’ 7 G W g w

( 8 H X h x

) 9 I Y i y

* : J Z j z

+ ; K [ k {

, < L \ l

- = M ] m }

. > N ^ n ~

/ ? O _ o SP

$ @[\]^

\

$ @

¥

§^

^

^

^

^

{

{

{

}

}

}

}

α ≡

β ±

Γ

π

Σ

σ

μ ÷

τ

θ

Ω

δ √

∞

φ

∈

∩ SP

β

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

38

Page 43

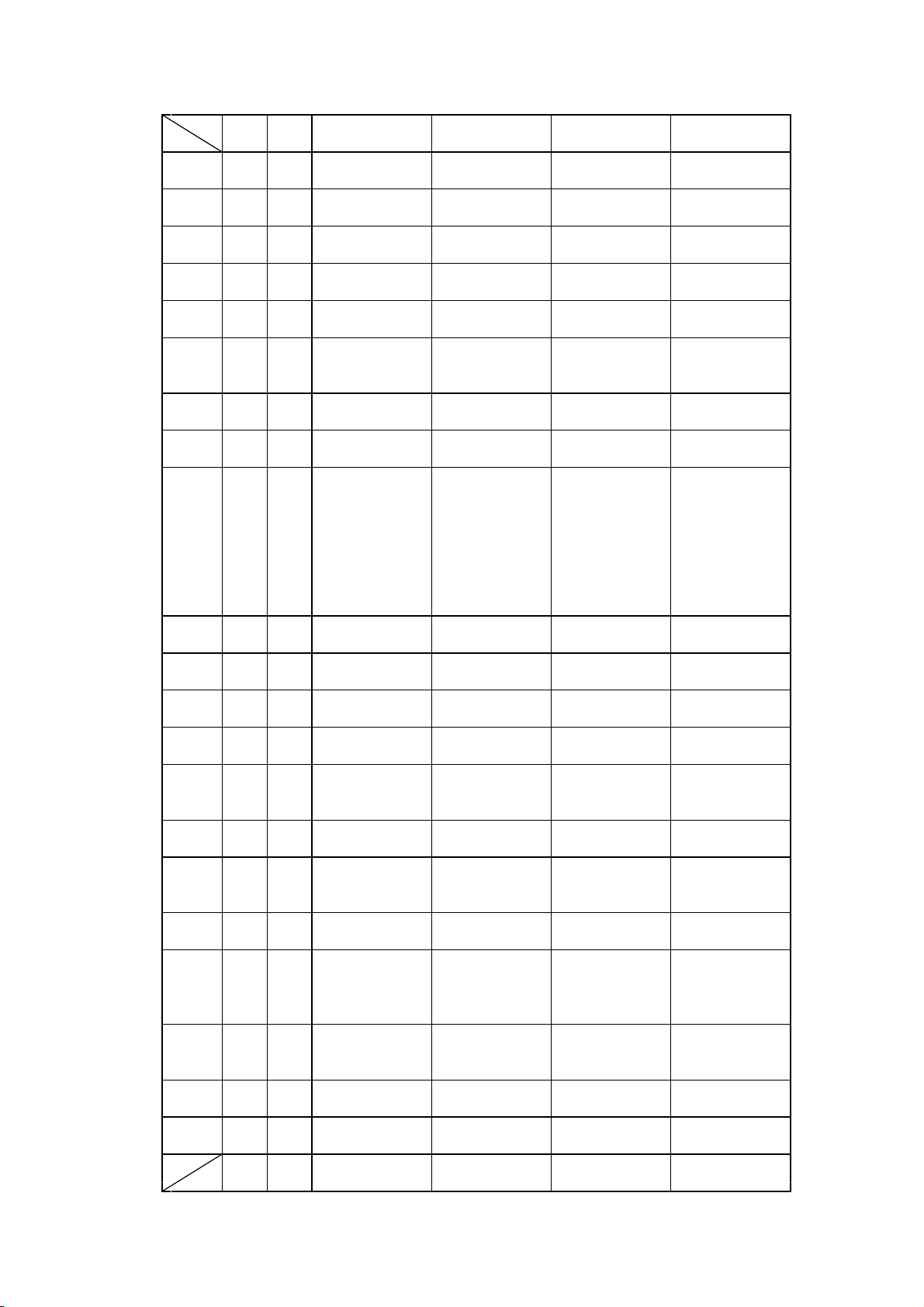

6.4 Kanji code

シフト

JIS0123456789ABCDEF

JIS

記 813F2120 SP、。,.・:;?!゛゜´`¨

号 814F2130^ ̄_ヽヾゝゞ〃仝々〆〇ー―‐/

815F2140\~∥|…‥‘’“”()〔〕[]

816F2150{}〈〉《》「」『』【】+-±×

81802160÷=≠<>≦≧∞∴♂♀°′″℃¥

81902170$¢£%#&*@§☆★○●◎◇

819E2220 ◆□■△▲▽▼※〒→←↑↓〓

81AE 2230 ∈ ∋ ⊆ ⊇ ⊂ ⊃

81BE 2240 ∪ ∩ ∀Ÿ⁄ÿ›¤

81CE 2250 ∃ ∠ ⊥ ⌒ ∂

81DE2260∇≡≒《》√∽∝∵∫∬

81EE 2270 Å ‰ ♯ ♭ ♪ † ‡ ¶ ○

823F 2320 ㈱

824F23300123456789

英 825F2340 ABCDEFGHIJKLMNO

字 826F2350PQRSTUVWXYZ

82802360 abcdefghijklmno

82902370pqrstuvwxyz

ひ 829E2420 ぁあぃいぅうぇえぉおかがきぎく

ら 82AE2430ぐけげこごさざしじすずせぜそぞた

が 82BE2440だちぢっつづてでとどなにぬねのは

な 82CE2450ばぱひびぴふぶぷへべぺほぼぽまみ

82DE2460むめもゃやゅゆょよらりるれろゎわ

82EE2470ゐゑをん

カ 833F2520 ァアィイゥウェエォオカガキギク

タ 834F2530グケゲコゴサザシジスズセゼソゾタ

カ 835F2540ダチヂッツヅテデトドナニヌネノハ

ナ 836F2550バパヒビピフブプヘベペホボポマミ

83802560ムメモャヤュユョヨラリルレロヮワ

83902570ヰヱヲンヴヵヶ

ギ 839E2620 ΑΒΓΔΕΖΗΘΙΚΛΜΝΞΟ

リ 83AE2630ΠΡΣΤΥΦΧΨΩ

シ 83BE2640 αβγδεζηθικλμνξο

ャ 83CE2650πρστυφχψω

記 83DE 2660 ∫ = - :

{

=

}

〈

〉

《

…

》

「

」

『

』

【

)

】

(

〔

〕

[

]

号 83EE 2670 |

ロ 843F2720 АБВГДЕЁЖЗИЙКЛМН

シ 844F2730ОПРСТУФХЦЧШЩЪЫЬЭ

ア 845F 2740 Ю Я

846F2750 абвгдеёжзийклмн

84802760опрстуфхцчшщъыьэ

8490 2770 ю я

記 849E 2820

号 84AE 2830

84BE 2840

84CE 2850

シフト

JIS0123456789ABCDEF

JIS

*"2120" : Not defined , "2121" : "space"

*This code table indicates simplified symbol and is not print result. There may be a different result between the code ta

ble and print result

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

39

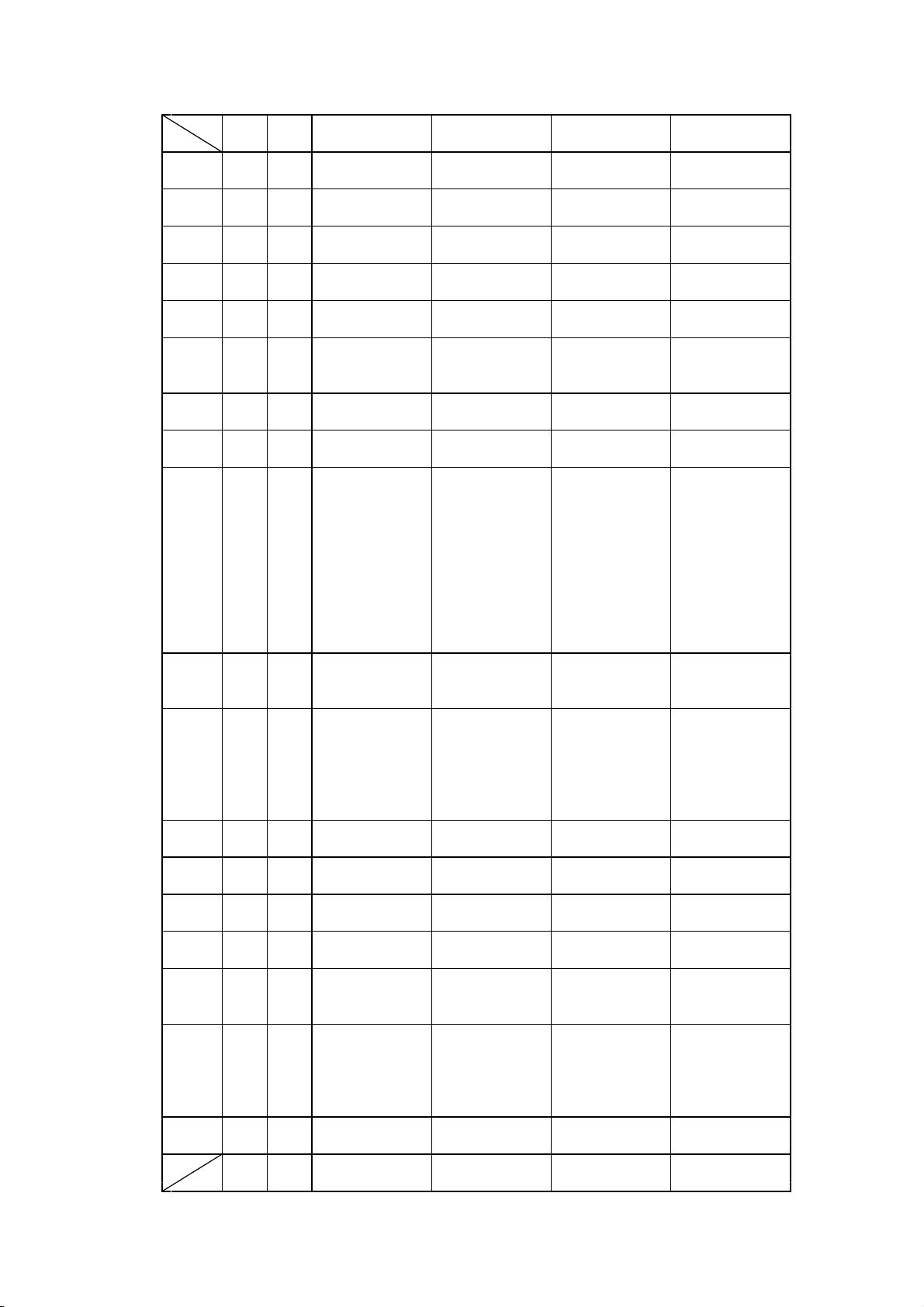

Page 44

シフト

JIS0123456789ABCDEF

JIS

記 84DE 2860

号 84EE 2870

あ 889E3020 亜唖娃阿哀愛挨姶逢葵茜穐悪握渥

88AE3030旭葦芦鰺梓圧斡扱宛姐虻飴絢綾鮎或

88BE3040粟袷安庵按暗案闇鞍杏

い 88BE3040 以伊位依偉囲

88CE3050夷委威尉惟意慰易椅為畏異移維緯胃

88DE3060萎衣謂違遺医井亥域育郁磯一壱溢逸

88EE3070稲茨芋鰯允印咽員因姻引飲淫胤蔭

893F 3120 院 陰 隠 韻 吋

う 893F3120 右宇烏羽迂雨卯鵜窺丑

894F3130碓臼渦嘘唄欝蔚鰻姥厩浦瓜閏噂云運

895F 3140 雲

え 895F3140 荏餌叡営嬰影映曳栄永泳洩瑛盈穎

896F3150頴英衛詠鋭液疫益駅悦謁越閲榎厭円

89803160園堰奄宴延怨掩援沿演炎焔煙燕猿縁

89903170艶苑薗遠鉛鴛塩

お 89903170 於汚甥凹央奥往応

899E3220 押旺横欧殴王翁襖鶯鴎黄岡沖荻億

89AE3230屋憶臆桶牡乙俺卸恩温穏音

か 89AE 3230 下 化 仮 何

89BE3240伽価佳加可嘉夏嫁家寡科暇果架歌河

89CE3250火珂禍禾稼箇花苛茄荷華菓蝦課嘩貨

89DE3260迦過霞蚊俄峨我牙画臥芽蛾賀雅餓駕

89EE3270介会解回塊壊廻快怪悔恢懐戒拐改

8A3F3320 魁晦械海灰界皆絵芥蟹開階貝凱劾

8A4F3330外咳害崖慨概涯碍蓋街該鎧骸浬馨蛙

8A5F3340垣柿蠣鈎劃嚇各廓拡攪格核殻獲確穫

8A6F3350覚角赫較郭閣隔革学岳楽額顎掛笠樫

8A803360橿梶鰍潟割喝恰括活渇滑葛褐轄且鰹

8A903370叶椛樺鞄株兜竈蒲釜鎌噛鴨栢茅萱

8A9E3420 粥刈苅瓦乾侃冠寒刊勘勧巻喚堪姦

8AAE3430完官寛干幹患感慣憾換敢柑桓棺款歓

8ABE3440汗漢澗灌環甘監看竿管簡緩缶翰肝艦

8ACE3450莞観諫貫還鑑間閑関陥韓館舘丸含岸

8ADE3460巌玩癌眼岩翫贋雁頑顔願

き 8ADE 3460 企 伎 危 喜 器

8AEE3470基奇嬉寄岐希幾忌揮机旗既期棋棄

8B3F3520 機帰毅気汽畿祈季稀紀徽規記貴起

8B4F3530軌輝飢騎鬼亀偽儀妓宜戯技擬欺犠疑

8B5F3540祇義蟻誼議掬菊鞠吉吃喫桔橘詰砧杵

8B6F3550黍却客脚虐逆丘久仇休及吸宮弓急救

8B803560朽求汲泣灸球究窮笈級糾給旧牛去居

8B903570巨拒拠挙渠虚許距鋸漁禦魚亨享京

8B9E3620 供侠僑兇競共凶協匡卿叫喬境峡強

8BAE3630彊怯恐恭挟教橋況狂狭矯胸脅興蕎郷

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

40

Page 45

シフト

JIS0123456789ABCDEF

JIS

き 8BBE3640鏡響饗驚仰凝 暁業局曲極玉桐粁僅

8BCE3650勤均巾錦斤欣欽琴禁禽筋緊芹菌衿襟

8BDE3660謹近金吟銀

く 8BDE3660 九倶句区狗玖矩苦躯駆駈

8BEE3670駒具愚虞喰空偶寓遇隅串櫛釧屑屈

8C3F3720 掘窟沓靴轡窪熊隈粂栗繰桑鍬勲君

8C4F3730薫訓群軍郡

け 8C4F3730 卦袈祁係傾刑兄啓圭珪型

8C5F3740契形径恵慶慧憩掲携敬景桂渓畦稽系

8C6F3750経継繋罫茎荊蛍計詣警軽頸鶏芸迎鯨

8C803760劇戟撃激隙桁傑欠決潔穴結血訣月件

8C903770倹倦健兼券剣喧圏堅嫌建憲懸拳捲

8C9E3820 検権牽犬献研硯絹県肩見謙賢軒遣

8CAE3830鍵険顕験鹸元原厳幻弦減源玄現絃舷

8CBE3840言諺限

こ 8CBE3840 乎個古呼固姑孤己庫弧戸故枯

8CCE3850湖狐糊袴股胡菰虎誇跨鈷雇顧鼓五互

8CDE3860伍午呉吾娯後御悟梧檎瑚碁語誤護醐

8CEE3870乞鯉交佼侯候倖光公功効勾厚口向

8D3F3920 后喉坑垢好孔孝宏工巧巷幸広庚康

8D4F3930弘恒慌抗拘控攻昂晃更杭校梗構江洪

8D5F3940浩港溝甲皇硬稿糠紅紘絞綱耕考肯肱

8D6F3950腔膏航荒行衡講貢購郊酵鉱砿鋼閤降

8D803960項香高鴻剛劫号合壕拷濠豪轟麹克刻

8D903970告国穀酷鵠黒獄漉腰甑忽惚骨狛込

8D9E3A20 此頃今困坤墾婚恨懇昏昆根梱混痕

8DAE3A30紺艮魂

さ 8DAE3A30 些佐叉唆嵯左差査沙瑳砂詐鎖

8DBE3A40裟坐座挫債催再最哉塞妻宰彩才採栽

8DCE3A50歳済災采犀砕砦祭斎細菜裁載際剤在

8DDE3A60材罪財冴坂阪堺榊肴咲崎埼碕鷺作削

8DEE3A70咋搾昨朔柵窄策索錯桜鮭笹匙冊刷

8E3F3B20 察拶撮擦札殺薩雑皐鯖捌錆鮫皿晒

8E4F3B30三傘参山惨撒散桟燦珊産算纂蚕讃賛

8E5F3B40酸餐斬暫残

し 8E5F3B40 仕仔伺使刺司史嗣四士始

8E6F3B50姉姿子屍市師志思指支孜斯施旨枝止

8E803B60死氏獅祉私糸紙紫肢脂至視詞詩試誌

8E903B70諮資賜雌飼歯事似侍児字寺慈持時

8E9E3C20 次滋治爾璽痔磁示而耳自蒔辞汐鹿

8EAE3C30式識鴫竺軸宍雫七叱執失嫉室悉湿漆

8EBE3C40疾質実蔀篠偲柴芝屡蘂縞舎写射捨赦

8ECE3C50斜煮社紗者謝車遮蛇邪借勺尺杓灼爵

8EDE3C60酌釈錫若寂弱惹主取守手朱殊狩珠種

8EEE3C70腫趣酒首儒受呪寿授樹綬需囚収周

8F3F3D20 宗就州修愁拾洲秀秋終繍習臭舟蒐

8F4F3D30衆襲讐蹴輯週酋酬集醜什住充十従戎

8F5F3D40柔汁渋獣縦重銃叔夙宿淑祝縮粛塾熟

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

41

Page 46

シフト

JIS0123456789ABCDEF

JIS

し 8F6F3D50出術述俊峻春瞬竣舜駿准循旬楯殉淳

8F803D60準潤盾純巡遵醇順処初所暑曙渚庶緒

8F903D70署書薯藷諸助叙女序徐恕鋤除傷償

8F9E3E20 勝匠升召哨商唱嘗奨妾娼宵将小少

8FAE3E30尚庄床廠彰承抄招掌捷昇昌昭晶松梢

8FBE3E40樟樵沼消渉湘焼焦照症省硝礁祥称章

8FCE3E50笑粧紹肖菖蒋蕉衝裳訟証詔詳象賞醤

8FDE3E60鉦鍾鐘障鞘上丈丞乗冗剰城場壌嬢常

8FEE3E70情擾条杖浄状畳穣蒸譲醸錠嘱埴飾

903F3F20 拭植殖燭織職色触食蝕辱尻伸信侵

904F3F30唇娠寝審心慎振新晋森榛浸深申疹真

905F3F40神秦紳臣芯薪親診身辛進針震人仁刃

906F3F50塵壬尋甚尽腎訊迅陣靱

す 906F3F50 笥諏須酢図厨

90803F60逗吹垂帥推水炊睡粋翠衰遂酔錐錘随

90903F70瑞髄崇嵩数枢趨雛据杉椙菅頗雀裾

909E 4020 澄 摺 寸

せ 909E4020 世瀬畝是凄制勢姓征性成政

90AE4030整星晴棲栖正清牲生盛精聖声製西誠

90BE4040誓請逝醒青静斉税脆隻席惜戚斥昔析

90CE4050石積籍績脊責赤跡蹟碩切拙接摂折設

90DE4060窃節説雪絶舌蝉仙先千占宣専尖川戦

90EE4070扇撰栓栴泉浅洗染潜煎煽旋穿箭線

913F4120 繊羨腺舛船薦詮賤践選遷銭銑閃鮮

914F4130前善漸然全禅繕膳糎

そ 914F4130 噌塑岨措曾曽楚

915F4140狙疏疎礎祖租粗素組蘇訴阻遡鼠僧創

916F4150双叢倉喪壮奏爽宋層匝惣想捜掃挿掻

91804160操早曹巣槍槽漕燥争痩相窓糟総綜聡

91904170草荘葬蒼藻装走送遭鎗霜騒像増憎

919E4220 臓蔵贈造促側則即息捉束測足速俗

91AE4230属賊族続卒袖其揃存孫尊損村遜

た 91AE 4230 他 多

91BE4240太汰詑唾堕妥惰打柁舵楕陀駄騨体堆

91CE4250対耐岱帯待怠態戴替泰滞胎腿苔袋貸

91DE4260退逮隊黛鯛代台大第醍題鷹滝瀧卓啄

91EE4270宅托択拓沢濯琢託鐸濁諾茸凧蛸只

923F4320 叩但達辰奪脱巽竪辿棚谷狸鱈樽誰

924F4330丹単嘆坦担探旦歎淡湛炭短端箪綻耽

925F4340胆蛋誕鍛団壇弾断暖檀段男談

ち 925F 4340 値 知 地

926F4350弛恥智池痴稚置致蜘遅馳築畜竹筑蓄

92804360逐秩窒茶嫡着中仲宙忠抽昼柱注虫衷

92904370註酎鋳駐樗瀦猪苧著貯丁兆凋喋寵

929E4420 帖帳庁弔張彫徴懲挑暢朝潮牒町眺

92AE4430聴脹腸蝶調諜超跳銚長頂鳥勅捗直朕

92BE4440沈珍賃鎮陳

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

42

Page 47

シフト

JIS0123456789ABCDEF

JIS

つ 92BE4440 津墜椎槌追鎚痛通塚栂掴

92CE4450槻佃漬柘辻蔦綴鍔椿潰坪壺嬬紬爪吊

92DE 4460 釣 鶴

て 92DE4460 亭低停偵剃貞呈堤定帝底庭廷弟

92EE4470悌抵挺提梯汀碇禎程締艇訂諦蹄逓

933F4520 邸鄭釘鼎泥摘擢敵滴的笛適鏑溺哲

934F4530徹撤轍迭鉄典填天展店添纏甜貼転顛

935F4540点伝殿澱田電

と 935F4540 兎吐堵塗妬屠徒斗杜渡

936F4550登菟賭途都鍍砥礪努度土奴怒倒党冬

93804560凍刀唐塔塘套宕島嶋悼投搭東桃檮棟

93904570盗淘湯濤灯燈当痘祷等答筒糖統到

939E4620 董蕩藤討謄豆踏逃透鐙陶頭騰闘働

93AE4630動同堂導憧撞洞瞳童胴萄道銅峠鴇匿

93BE4640得徳涜特督禿篤毒独読栃橡凸突椴届

93CE4650鳶苫寅酉瀞噸屯惇敦沌豚遁頓呑曇鈍

な 93DE4660奈那内乍凪薙謎灘捺鍋楢馴縄畷南楠

93EE4670軟難汝

に 93EE4670 二尼弐邇匂賑肉虹廿日乳入

943F 4720 如 尿 韮 任 妊 忍 認

ぬ 943F 4720 濡

ね 943F4720 禰祢寧葱猫熱年

944F4730念捻撚燃粘

の 944F4730 乃廼之埜嚢悩濃納能脳膿

945F4740農覗蚤

は 945F4740 巴把播覇杷波派琶破婆罵芭馬

946F4750俳廃拝排敗杯盃牌背肺輩配倍培媒梅

94804760楳煤狽買売賠陪這蠅秤矧萩伯剥博拍

94904770柏泊白箔粕舶薄迫曝漠爆縛莫駁麦

949E4820 函箱硲箸肇筈櫨幡肌畑畠八鉢溌発

94AE4830醗髪伐罰抜筏閥鳩噺塙蛤隼伴判半反

94BE4840叛帆搬斑板氾汎版犯班畔繁般藩販範

94CE4850釆煩頒飯挽晩番盤磐蕃蛮

ひ 94CE 4850 匪 卑 否 妃 庇

94DE4860彼悲扉批披斐比泌疲皮碑秘緋罷肥被

94EE4870誹費避非飛樋簸備尾微枇毘琵眉美

953F4920 鼻柊稗匹疋髭彦膝菱肘弼必畢筆逼

954F4930檜姫媛紐百謬俵彪標氷漂瓢票表評豹

955F4940廟描病秒苗錨鋲蒜蛭鰭品彬斌浜瀕貧

956F4950賓頻敏瓶

ふ 956F4950 不付埠夫婦富冨布府怖扶敷

95804960斧普浮父符腐膚芙譜負賦赴阜附侮撫

95904970武舞葡蕪部封楓風葺蕗伏副復幅服

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

43

Page 48

シフト

JIS0123456789ABCDEF

JIS

ふ 959E4A20 福腹複覆淵弗払沸仏物鮒分吻噴墳

95AE4A30憤扮焚奮粉糞紛雰文聞

へ 95AE4A30 丙併兵塀幣平

95BE4A40弊柄並蔽閉陛米頁僻壁癖碧別瞥蔑箆

95CE4A50偏変片篇編辺返遍便勉娩弁鞭

ほ 95CE 4A50 保 舗 鋪

95DE4A60圃捕歩甫補輔穂募墓慕戊暮母簿菩倣

95EE4A70俸包呆報奉宝峰峯崩庖抱捧放方朋

963F4B20 法泡烹砲縫胞芳萌蓬蜂褒訪豊邦鋒

964F4B30飽鳳鵬乏亡傍剖坊妨帽忘忙房暴望某

965F4B40棒冒紡肪膨謀貌貿鉾防吠頬北僕卜墨

966F4B50撲朴牧睦穆釦勃没殆堀幌奔本翻凡盆

ま 96804B60摩磨魔麻埋妹昧枚毎哩 幕膜枕鮪柾

96904B70鱒桝亦俣又抹末沫迄儘繭麿万慢満

969E 4C20 漫 蔓

み 969E4C20 味未魅巳箕岬密蜜湊蓑稔脈妙

96AE4C30粍民眠

む 96AE4C30 務夢無牟矛霧鵡椋婿娘

め 96AE 4C30 冥 名 命

96BE4C40明盟迷銘鳴姪牝滅免棉綿緬面麺

も 96BE 4C40 摸 模

96CE4C50茂妄孟毛猛盲網耗蒙儲木黙目杢勿餅

96DE4C60尤戻籾貰問悶紋門匁

や 96DE4C60 也冶夜爺耶野弥

96EE4C70矢厄役約薬訳躍靖柳藪鑓

ゆ 96EE 4C70 愉 愈 油 癒

973F4D20 諭輸唯佑優勇友宥幽悠憂揖有柚湧

974F4D30涌猶猷由祐裕誘遊邑郵雄融夕

よ 974F 4D30 予 余 与

975F4D40誉輿預傭幼妖容庸揚揺擁曜楊様洋溶

976F4D50熔用窯羊耀葉蓉要謡踊 陽養慾抑欲

97804D60沃浴翌翼淀

ら 97804D60 羅螺裸来莱頼雷洛絡落酪

97904D70乱卵嵐欄濫藍蘭覧

り 97904D70 利吏履李梨理璃

979E4E20 痢裏裡里離陸律率立葎掠略劉流溜

97AE4E30琉留硫粒隆竜龍侶慮旅虜了亮僚両凌

97BE4E40寮料梁涼猟療瞭稜糧良諒遼量陵領力

97CE4E50緑倫厘林淋燐琳臨輪隣鱗麟

る 97CE 4E50 瑠 塁 涙 累

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

44

Page 49

シフト

JIS0123456789ABCDEF

JIS

る 97DE 4E60 類

れ 97DE4E60 令伶例冷励嶺怜玲礼苓鈴隷零霊麗

97EE4E70齢暦歴列劣烈裂廉恋憐漣煉簾練聯

983F 4F20 蓮 連 錬

ろ 983F4F20 呂魯櫓炉賂路露労婁廊弄朗

984F4F30楼榔浪漏牢狼籠老聾蝋郎六麓禄肋録

985F 4F40 論

わ 985F4F40 倭和話歪賄脇惑枠鷲亙亘鰐詫藁蕨

986F4F50椀湾碗腕

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

45

Page 50

シフト

JIS0123456789ABCDEF

JIS

一 989E 5020 弌 丐 丕

989E 5020 个 丱

丶 989E 5020 丶 丼

丿 989E 5020 丿 乂 乖 乘

乙 989E 5020 亂

亅 989E 5020 亅 豫 亊

98AE 5030 舒

二 98AE 5030 弍 于 亞 亟

亠 98AE 5030 亠 亢 亰 亳 亶

人 98AE5030 从仍仄仆仂仗

98BE5040仞仭仟价伉佚估佛佝佗佇佶侈侏侘佻

98CE5050佩佰侑佯來侖侭俔俟俎俘俛俑俚俐俤

98DE5060俥倚倨倔倪倥倅伜俶倡倩倬俾俯們倆

98EE5070偃假會偕偐偈做偖偬偸傀傚傅傴傲

993F5120 僉僊傳僂僖僞僥僭僣僮價僵儉儁儂

994F5130儖儕儔儚儡儺儷儼儻

儿 994F5130 儿兀兒兌兔兢竸

入 995F 5140 兩 兪

八 995F 5140 兮 冀

冂 995F 5140 冂 囘 册 冉 冏 冑 冓 冕

冖 995F 5140 冖 冤 冦 冢

996F 5150 冩 冪

冫 996F5150 冫决冱冲冰况冽凅凉凛

几 996F 5150 几 處 凩 凭

9980 5160 凰

凵 9980 5160 凵 凾

刀 99805160 刄刋刔刎刧刪刮刳刹剏剄剋剌

99905170剞剔剪剴剩剳剿剽劍劔劒剱劈劑辨

999E 5220 辧

力 999E5220 劬劭劼劵勁勍勗勞勣勦飭勠勳勵

99AE 5230 勸

勹 99AE 5230 勹 匆 匈 甸 匍 匐 匏

匕 99AE 5230 匕

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

46

Page 51

シフト

JIS0123456789ABCDEF

JIS

匚 99AE5230 匚匣匯匱匳

匸 99AE 5230 匸 區

十 99BE5240卆卅丗卉卍凖

卜 99BE 5240 卞

卩 99BE5240 卩卮夘卻卷

厂 99BE 5240 厂 厖 厠 厦

99CE5250厥厮厰

厶 99CE 5250 厶 參 簒

又 99CE 5250 雙 叟 曼 燮

口 99CE5250 叮叨叭叺吁吽

99DE5260呀听吭吼吮吶吩吝呎咏呵咎呟呱呷呰

99EE5270咒呻咀呶咄咐咆哇咢咸咥咬哄哈咨

9A3F5320 咫哂咤咾咼哘哥哦唏唔哽哮哭哺哢

9A4F5330唹啀啣啌售啜啅啖啗唸唳啝喙喀咯喊

9A5F5340喟啻啾喘喞單啼喃喩喇喨嗚嗅嗟嗄嗜

9A6F5350嗤嗔嘔嗷嘖嗾嗽嘛嗹噎噐營嘴嘶嘲嘸

9A805360噫噤嘯噬噪嚆嚀嚊嚠嚔嚏嚥嚮嚶嚴囂

9A905370嚼囁囃囀囈囎囑囓

囗 9A905370 囗囮囹圀囿圄圉

9A9E 5420 圈 國 圍 圓 團 圖 嗇 圜

土 9A9E5420 圦圷圸坎圻址坏

9AAE5430坩埀垈坡坿垉垓垠垳垤垪垰埃埆埔埒

9ABE5440埓堊埖埣堋堙堝塲堡塢塋塰毀塒堽塹

9ACE5450墅墹墟墫墺壞墻墸墮壅壓壑壗壙壘壥

9ADE5460壜壤壟

士 9ADE 5460 壯 壷 壹 壻 壼 壽

夂 9ADE 5460 夂

夊 9ADE 5460 夊 夐

夕 9ADE 5460 夛 梦 夥

大 9ADE 5460 夬

9AEE5470夭夲夸夾竒奕奐奎奚奘奢奠奧奬奩

女 9B3F5520 奸妁妝佞侫妣妲姆姨姜妍姙姚娥娟

9B4F5530娑娜娉娚婀婬婉娵娶婢婪媚媼媾嫋嫂

9B5F5540媽嫣嫗嫦嫩嫖嫺嫻嬌嬋嬖嬲嫐嬪嬶嬾

9B6F5550孃孅孀

子 9B6F5550 孑孕孚孛孥孩孰孳孵學斈孺

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

47

Page 52

シフト

JIS0123456789ABCDEF

JIS

宀 9B6F 5550 宀

9B805560它宦宸寃寇寉寔寐寤實寢寞寥寫寰寶

9B90 5570 寳

寸 9B90 5570 尅 將 專 對

小 9B90 5570 尓 尠

尤 9B90 5570 尢 尨

尸 9B905570 尸尹屁屆屎屓

9B9E 5620 屐 屏 孱 屬

屮 9B9E 5620 屮

山 9B9E5620 乢屶屹岌岑岔妛岫岻岶

9BAE5630岼岷峅岾峇峙峩峽峺峭嶌峪崋崕崗嵜

9BBE5640崟崛崑崔崢崚崙崘嵌嵒嵎嵋嵬嵳嵶嶇

9BCE5650嶄嶂嶢嶝嶬嶮嶽嶐嶷嶼巉巍巓巒巖

巛 9BCE 5650 巛

工 9BDE 5660 巫

己 9BDE 5660 已 巵

巾 9BDE5660 帋帚帙帑帛帶帷幄幃幀幎幗幔

9BEE5670幟幢幤幇

干 9BEE 5670 幵 并

幺 9BEE 5670 幺 麼

广 9BEE5670 广庠廁廂廈廐廏

9C3F5720 廖廣廝廚廛廢廡廨廩廬廱廳廰

廴 9C3F 5720 廴 廸

廾 9C4F5730廾弃弉彝彜

弋 9C4F 5730 弋 弑

弓 9C4F5730 弖弩弭弸彁彈彌彎弯

彑 9C5F5740彑彖彗彙

彡 9C5F 5740 彡 彭

彳 9C5F5740 彳彷徃徂彿徊很徑徇從

9C6F5750徙徘徠徨徭徼

心 9C6F5750 忖忻忤忸忱忝悳忿怡恠

9C805760怙怐怩怎怱怛怕怫怦怏怺恚恁恪恷恟

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

48

Page 53

シフト

JIS0123456789ABCDEF

JIS

心 9C905770恊恆恍恣恃恤恂恬恫恙悁悍惧悃悚

9C9E5820 悄悛悖悗悒悧悋惡悸惠惓悴忰悽惆

9CAE5830悵惘慍愕愆惶惷愀惴惺愃愡惻惱愍愎

9CBE5840慇愾愨愧慊愿愼愬愴愽慂慄慳慷慘慙

9CCE5850慚慫慴慯慥慱慟慝慓慵憙憖憇憬憔憚

9CDE5860憊憑憫憮懌懊應懷懈懃懆憺懋罹懍懦

9CEE5870懣懶懺懴懿懽懼懾戀

戈 9CEE5870 戈戉戍戌戔戛

9D3F 5920 戞 戡 截 戮 戰 戲 戳

戸 9D3F 5920 扁

手 9D3F5920 扎扞扣扛扠扨扼

9D4F5930抂抉找抒抓抖拔抃抔拗拑抻拏拿拆擔

9D5F5940拈拜拌拊拂拇抛拉挌拮拱挧挂挈拯拵

9D6F5950捐挾捍搜捏掖掎掀掫捶掣掏掉掟掵捫

9D805960捩掾揩揀揆揣揉插揶揄搖搴搆搓搦搶

9D905970攝搗搨搏摧摯摶摎撹撕撓撥撩撈撼

9D9E5A20 據擒擅擇撻擘擂擱擧舉擠擡抬擣擯

9DAE5A30攬擶擴擲擺攀擽攘攜攅攤攣攫

攴 9DAE 5A30 攴 攵 攷

9DBE5A40收攸畋效敖敕敍敘敞敝敲數斂斃變

斗 9DBE 5A40 斛

9DCE 5A50 斟

斤 9DCE 5A50 斫 斷

方 9DCE 5A50 旃 旆 旁 旄 旌 旒 旛 旙

无 9DCE 5A50 无 旡

日 9DCE 5A50 旱 杲 昊

9DDE5A60昃旻杳昵昶昴昜晏晄晉晁晞晝晤晧晨

9DEE5A70晟晢晰暃暈暎暉暄暘暝曁暹曉暾暼

9E3F 5B20 曄 暸 曖 曚 曠 昿 曦 曩

曰 9E3F 5B20 曰 曵 曷

月 9E3F 5B20 朏 朖 朞 朦

9E4F 5B30 朧 霸

木 9E4F5B30 朮朿朶杁朸朷杆杞杠杙杣杤枉杰

9E5F5B40枩杼杪枌枋枦枡枅枷柯枴柬枳柩枸柤

9E6F5B50柞柝柢柮枹柎柆柧桧栞框栩桀桍栲桎

9E805B60梳栫桙档桷桿梟梏梭梔條梛梃梼梹桴

9E905B70梵梠梺椏梍桾椁棊椈棘椢椦棡椌棍

9E9E5C20 棔棧棕椶椒椄棗棣椥棹棠棯椨椪椚

9EAE5C30椣椡棆楹楷楜楸楫楔楾楮椹楴椽楙椰

9EBE5C40楡楞楝榁楪榲榮槐榿槁槓榾槎寨槊槝

9ECE5C50榻槃榧樮榑榠榜榕榴槞槨樂樛槿權槹

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

49

Page 54

シフト

JIS0123456789ABCDEF

JIS

木 9EDE5C60槲槧樅榱樞槭樔槫樊樒櫁樣樓橄樌橲

9EEE5C70樶橸橇橢橙橦橈樸樢檐檍檠檄檢檣

9F3F5D20 檗蘗檻櫃櫂檸檳檬櫞櫑櫟檪櫚櫪櫻

9F4F5D30欅蘖櫺欒欖鬱欟

欠 9F4F5D30 欸欷盜欹飮歇歃歉歐

9F5F5D40歙歔歛歟歡

止 9F5F 5D40 歸

歹 9F5F5D40 歹歿殀殄殃殍殘殕殞殤

9F6F5D50殪殫殯殲殱

殳 9F6F 5D50 殳 殷 殼 毆

母 9F6F 5D50 毋 毓

毛 9F6F 5D50 毟 毬 毫 毳 毯

9F80 5D60 麾 氈

氏 9F80 5D60 氓

气 9F80 5D60 气 氛 氤 氣

水 9F805D60 汞汕汢汪沂沍沚沁沛

9F905D70汾汨汳沒沐泄泱泓沽泗泅泝沮沱沾

9F9E5E20 沺泛泯泙泪洟衍洶洫洽洸洙洵洳洒

9FAE5E30洌浣涓浤浚浹浙涎涕涛涅淹渕渊涵淇

9FBE5E40淦涸淆淬淞淌淨淒淅淺淙淤淕淪淮渭

9FCE5E50湮渮渙湲湟渾渣湫渫湶湍渟湃渺湎渤

9FDE5E60滿渝游溂溪溘滉溷滓溽溯滄溲滔滕溏

9FEE5E70溥滂溟潁漑潅滬滸滾漿滲漱滯漲滌

E03F5F20 漾漓滷澆潺潸澁澀潯潛濳潭澂潼潘

E04F5F30澎澑濂潦澳澣澡澤澹濆澪濟濕濬濔濘

E05F5F40濱濮濛瀉瀋濺瀑瀁瀏濾瀛瀚潴瀝瀘瀟

E06F5F50瀰瀾瀲灑灣

火 E06F5F50 炙炒炯烱炬炸炳炮烟烋烝

E0805F60烙焉烽焜焙煥煕熈煦煢煌煖煬熏燻熄

E0905F70熕熨熬燗熹熾燒燉燔燎燠燬燧燵燼

E09E 6020 燹 燿 爍 爐 爛 爨

爪 E09E 6020 爭 爬 爰 爲

爻 E09E 6020 爻 爼

爿 E09E 6020 爿 牀 牆

E0AE 6030 牋 牘

牛 E0AE6030 牴牾犂犁犇犒犖犢犧

犬 E0AE 6030 犹 犲 狃 狆 狄

E0BE6040狎狒狢狠狡狹狷倏猗猊猜猖猝猴猯猩

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

50

Page 55

シフト

JIS0123456789ABCDEF

JIS

犬 E0CE6050猥猾獎獏默獗獪獨獰獸獵獻獺

王 E0CE 6050 珈 玳 珎

E0DE6060玻珀珥珮珞璢琅瑯琥珸琲琺瑕琿瑟瑙

E0EE6070瑁瑜瑩瑰瑣瑪 瑾璋璞璧瓊瓏瓔珱

瓜 E13F 6120 瓠 瓣

瓦 E13F6120 瓧瓩瓮瓲瓰瓱瓸瓷甄甃甅甌甎

E14F6130甍甕甓

甘 E14F 6130 甞

生 E14F 6130 甦

用 E14F 6130 甬

田 E14F6130 甼畄畍畊畉畛畆畚畩畤

E15F6140畧畫畭畸當疆疇畴疊疉疂

E15F 6140 疔 疚 疝 疥 疣

E16F6150痂疳痃疵疽疸疼疱痍痊痒痙痣痞痾痿

E1806160痼瘁痰痺痲痳瘋瘍瘉瘟瘧瘠瘡瘢瘤瘴

E1906170瘰瘻癇癈癆癜癘癡癢癨癩癪癧癬癰

E19E 6220 癲

癶 E19E 6220 癶 癸 發

白 E19E6220 皀皃皈皋皎皖皓皙皚

皮 E19E 6220 皰 皴

E1AE6230皸皹皺

皿 E1AE6230 盂盍盖盒盞盡盥盧盪蘯

目 E1AE 6230 盻 眈 眇

E1BE6240眄眩眤眞眥眦眛眷眸睇睚睨睫睛睥睿

E1CE6250睾睹瞎瞋瞑瞠瞞瞰瞶瞹瞿瞼瞽瞻矇矍

E1DE 6260 矗 矚

矛 E1DE 6260 矜

矢 E1DE 6260 矣 矮

石 E1DE6260 矼砌砒礦砠砺硅碎硴碆硼

E1EE6270碚碌碣碵碪碯磑磆磋磔碾碼磅磊磬

E23F 6320 磧 磚 磽 磴 礇 礒 礑 礙 礬 礫

示 E23F 6320 祀 祠 祗 祟 祚

E24F6330祕祓祺祿禊禝禧齋禪禮禳

禺 E24F 6330 禹 禺

シフト

JIS0123456789ABCDEF

JIS

D-F0393 NP-211 Product specifications Ver.0.01 Provisional

51

Page 56

シフト

JIS0123456789ABCDEF

JIS

禾 E24F 6330 秉 秕 秧

E25F6340秬秡秣稈稍稘稙稠稟禀稱稻稾稷穃穗

E26F6350穉穡穢穩龝穰

穴 E26F6350 穹穽窈窗窕窘窖窩竃窰

E2806360窶竅竄窿邃竇竊

立 E2806360 竍竏竕竓站竚竝竡竢

E2906370竦竭竰

竹 E2906370 笂笏笊笆笳笘笙笞笵笨笶筐

E29E6420 筺笄筍笋筌筅筵筥筴筧筰筱筬筮箝

E2AE6430箘箟箍箜箚箋箒箏筝箙篋篁篌篏箴篆

E2BE6440篝篩簑簔篦篥篭簀簇簓篳篷簗簍篶簣

E2CE6450簧簪簟簷簫簽籌籃籔籏籀籐籘籟籤籖

E2DE 6460 籥 籬