Page 1

®

IntelliFlo

Variable Flow Pump

(Compatible with IntelliTouch® control system and

IntelliComm® communication center)

VF

Installation

Listed

User's Guide

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

and

Page 2

Technical Support

Sanford, North Carolina (8 A.M. to 5 P.M. ET)

Moorpark, California (8 A.M. to 5 P.M. PT)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web sites: www.pentairpool.com and www.staritepool.com

Protected by U.S. Patents Pending

© 2009 Pentair Water Pool and Spa, Inc. All rights reserved

This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Trademarks and disclaimers: IntelliFlo®, IntelliTouch®, EasyTouch®, SunTouch®, IntelliComm® and Pentair Water Pool

and Spa® are trademarks and/or registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated

companies in the United States and/or other counties. Teflon® is a registered trademark of E.I. Du Pont De Nemours and

Company Corporation. Unless noted, names and brands of others that may be used in this document are not used to

indicate an affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and

Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those parties or others.

P/N 350075 Rev D - 7-14-09

Page 3

Contents

Important Safety Precautions ........................................................................................... iii

Section 1: Introduction ...................................................................................................... 1

IntelliFlo Overview................................................................................................................. 1

IntelliFlo Features...................................................................................................... 2

IntelliFlo Motor Assembly .......................................................................................... 2

IntelliFlo Motor Features ............................................................................................ 3

IntelliFlo Drive Assembly and Control Panel ............................................................. 4

Operator Control Panel Features ............................................................................. 4

Section 2: Operator Control Panel................................................................................... 5

IntelliFlo Operator Control Panel ........................................................................................... 5

Controls and LEDs ................................................................................................... 5

Navigating the Menu Structure .............................................................................................. 7

Section 3: Operating IntelliFlo .......................................................................................... 9

Metering the System.............................................................................................................9

Manual Mode ........................................................................................................................ 9

IntelliFlo Control Panel Menu ............................................................................................... 11

Menu Structure .................................................................................................................... 12

Pool Data Mode ....................................................................................................... 13

Priming Mode ........................................................................................................... 14

Priming Menu ........................................................................................................ 14

Filter Mode ............................................................................................................... 16

Filter Menu ............................................................................................................ 16

Programming Cycles Per Day .............................................................................. 17

Filter Cycle Settings.............................................................................................. 18

Clean Filter Pressure Example ............................................................................. 19

Alert Status............................................................................................................ 19

Using Filter mode with Features mode ................................................................. 20

Filter Mode and Flow Control ................................................................................ 21

Flow Control and Filter Mode ................................................................................ 21

Time and Contrast Menu ......................................................................................... 22

Setting System Time ............................................................................................ 22

Setting the LCD Backlight Contrast ...................................................................... 22

Features Mode ......................................................................................................... 23

Features 1 & 2 ...................................................................................................... 23

Features 3 -9 ........................................................................................................ 23

M. O. Flo ............................................................................................................... 23

Feature Settings ................................................................................................... 24

How to set up the Feature 1 or 2 (Flow and Duration) mode ................................ 25

Features 1 – 2 (Flow and Duration) ...................................................................... 26

To run Feature 1 or 2 (Flow and Duration) ............................................................ 26

Features 3 – 9 (Flow, Start/Stop Time) ................................................................. 26

Enabling Features 3 – 9 ........................................................................................ 26

Mo Flo (Modulation Output flow) ........................................................................... 28

i

IntelliFlo VF Installation and User’s Guide

Page 4

ii

Contents (Continued)

External Control with IntelliComm Communication Center....................................... 29

Setting up External Control using IntelliComm.......................................................... 30

Controlling IntelliFlo with IntelliTouch .........................................................................31

Connecting IntelliFlo to IntelliTouch ...........................................................................33

Backwash Mode ....................................................................................................... 33

Backwash menu .................................................................................................... 33

Running Backwash mode...................................................................................... 34

Backwash menu screens ...................................................................................... 34

Vacuum Mode ...........................................................................................................35

Vacuum menu ....................................................................................................... 35

Section 4: Maintenance ..................................................................................................... 37

Pump Strainer Basket Service ............................................................................................. 37

Motor Service .......................................................................................................................38

Winterizing ........................................................................................................................... 39

Manual Priming and Initial Start-up After Service ..................................................................39

Section 5: Installation and Removal................................................................................. 41

Installing the IntelliFlo ............................................................................................................ 41

Location ....................................................................................................................41

Piping ........................................................................................................................ 41

Check Valves ............................................................................................................41

Wiring the IntelliFlo ............................................................................................................... 42

Pump Disassembly .............................................................................................................. 43

Pump Reassembly/Seal Replacement ....................................................................44

Shaft Seal Replacement ........................................................................................... 44

Drive Assembly Removal and Installation ............................................................................. 45

Illustrated Parts List ..............................................................................................................46

Replacement Parts ..............................................................................................................46

IntelliFlo Pump Dimensions .................................................................................................. 47

IntelliFlo Flow and Power vs Flow Pump Curve ................................................................... 47

IntelliFlo Electrical Specifications .......................................................................................... 47

Section 5: Troubleshooting ..............................................................................................49

Alerts and Warnings .............................................................................................................49

Suction Blockage.................................................................................................................. 49

General IntelliFlo Troubleshooting Problems ........................................................................ 50

General Warnings................................................................................................................. 52

Electrical Cost Overview ...................................................................................................... 52

How to make your pool more energy efficient....................................................................... 53

Using your IntelliFlo pump..................................................................................................... 53

Automatic pool sweeps (booster pump style) ...................................................................... 53

Filter during off-peak times ................................................................................................... 53

Setting filtering time .............................................................................................................. 53

Preventive maintenance ....................................................................................................... 54

Energy Efficient IntelliFlo pump ............................................................................................ 54

IntelliFlo VF Installation and User’s Guide

Page 5

IMPORTANT SAFETY PRECAUTIONS

SERIOUS BODILY INJURY OR DEATH CAN RESULT IF THIS PUMP AND SAND FILTER IS NOT

INSTALLED AND USED CORRECTLY.

INSTALLERS, POOL OPERATORS AND POOL OWNERS MUST READ THESE WARNINGS AND

ALL INSTRUCTIONS BEFORE USING THIS PUMP AND SAND FILTER.

This pump ss intended for use in swimming pool applications.

Most states and local codes regulate the construction, installation, and operation of public pools

and spas, and the construction of residential pools and spas. It is important to comply with these

codes, many of which directly regulate the installation and use of this product. Consult your local

building and health codes for more information.

IMPORTANT NOTICE - Attention Installer: This Installation and User’s Guide (“Guide”) contains

important information about the installation, operation and safe use of this pump. This Guide

should be given to the owner and/or operator of this equipment.

Before installing this product, read and follow all warning notices and instructions in this

Guide. Failure to follow warnings and instructions can result in severe injury, death, or

property damage. Call (800) 831-7133 for additional free copies of these instructions.

Please refer to www.pentair.com for more information related to these products.

iii

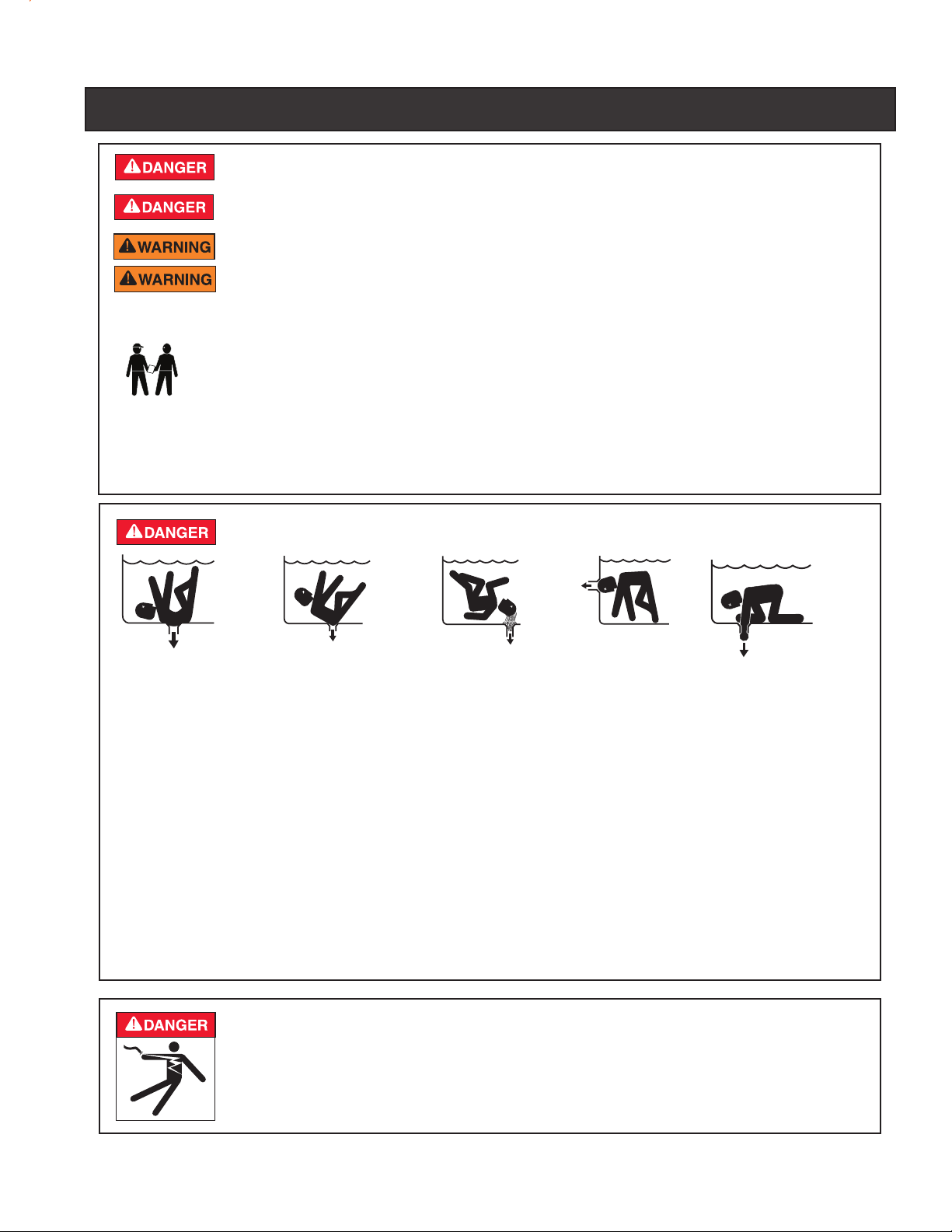

SUCTION ENTRAPMENT HAZARD

F

Pool and spa pumps move large volumes of water, which can pose extreme danger if a person’s hair comes in

close proximity to a drain that is not the proper size for the pump or pumps.

Hair Entanglement – When the hair tangles or knots in the drain cover, trapping the swimmer underwater.

This hazard is present when the flow rating of the cover is too small for the pump or pumps.

Limb Entrapment – When a limb is sucked or inserted into an opening resulting in a mechanical bind or

swelling. This hazard is present when a drain cover is missing, broken, loose, cracked or not properly

secured.

Body Entrapment – When a portion of the body is held against the drain cover trapping the swimmer underwater. This hazard is present when the drain cover is missing, broken or the cover flow rating is not high

enough for the pump or pumps.

Evisceration/Disembowelment – When a person sits on an open pool

(particularly a child wading pool) or spa outlet and suction is applied directly to the intestines, causing severe

intestinal damage. This hazard is present when the drain cover is missing, loose, cracked, or not properly

secured.

Mechanical Entrapment – When jewelry, swimsuit, hair decorations, finger, toe or knuckle is caught in an

opening of an outlet or drain cover. This hazard is present when the drain cover is missing, broken, loose,

cracked, or not properly secured.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION:

PUMPS REQUIRE HIGH VOLTAGE WHICH CAN SHOCK, BURN, OR CAUSE DEATH.

BEFORE WORKING ON PUMP!

Always disconnect power to the pool pump at the circuit breaker from the pump before

servicing the pump. Failure to do so could result in death or serious injury to service person,

pool users or others due to electric shock.

IntelliFlo VF Installation and User’s Guide

Page 6

iv

IMPORTANT SAFETY PRECAUTIONS (continued)

Water temperature in excess of 100° F (37.7° C) may be hazardous to your health. Prolonged

immersion in hot water may induce hyperthermia. Hyperthermia occurs when the internal

temperature of the body reaches a level several degrees above normal body temperature of

98.6° F (37° C.). Effects of hyperthermia include: (1) Unawareness of impending danger. (2)

Failure to perceive heat. (3) Failure to recognize the need to leave the spa. (4) Physical

inability to exit the spa. (5) Fetal damage in pregnant women. (6) Unconsciousness resulting

in danger of drowning. The use of alcohol, drugs, or medication can greatly increase the risk

of fatal hyperthermia in hot tubs and spas.

When setting up pool water turnovers or flow rates the operator must consider local

codes governing turnover as well as disinfectant feed ratios.

DO NOT increase pump size; this may increase the flow rate through the system and

exceed the maximum flow rate stated on the drain cover.

Do not permit children to operate this product.

If this pump is intended for use other than single-family dwellings, a clearly labeled emergency

switch shall be provided as part of the installation. The switch shall be readily accessible to

the occupants and shall be installed at least 5 feet (1.52 m) away, adjacent to, and within

sight of, the unit.

When setting up pool water turnovers or flow rates the operator must consider local codes

governing turnover as well as disinfectant feed ratios.

Before servicing the system, switch the main power OFF and remove the communication

cable from the pump.

Install the pump a minimum of five (5) feet from the inside wall of the pool and spa. Canadian

installations require a minimum of three (3) meters from pool water.

A No. 8 AWG (No. 6 AWG in Canada) or larger conductor must be wired to the motor bonding

lug.

This pump is for use with permanently installed pools and may also be used with hot tubs and

spas if so marked. Do not use with storable pools. A permanently installed pool is constructed

in or on the ground or in a building such that it cannot be readily disassembled for storage. A

storable pool is constructed so that it may be readily disassembled for storage and reassembled

to its original integrity and has a maximum dimension of 18 feet (5.49m) and a maximum wall

height of 42 inches (1.07m).

For hot tubs and spa pumps, do not install within an outer enclosure or beneath the skirt of a

hot tub or spa unless so marked.

The IntelliPro pump is capable of generating systems pressures up to 50 psi. Installers must

ensure that all system components are rated to withstand at least 50 psi. Over pressurizing

the system can result in catastrophic component failure or property damage.

Never exceed the maximum stated pump flow rating.

Only use a pumping system rated for the corresponding flow. FAILURE TO DO SO CAN

RESULT IN HAIR OR BODY ENTRAPMENT WHICH CAN CAUSE SERIOUS PERSONAL INJURY OR DEATH. If in doubt about the rating of your system, consult a

qualified pool service professional.

Pumps are not a substitute for properly installed and secured pool drain covers. An ANSI/

ASME A112.19.8 approved anti-entrapment drain cover must be used for each drain. Pools

and spas should utilize a minimum of two drains per pump. Regularly inspect all covers for

cracks, damage and advanced weathering. If a cover becomes loose, cracked, damaged,

broken or is missing, close the pool or spa immediately, shut off the pump, post a notice

and keep the pool or spa closed until an appropriate VGB 2008 certified cover is properly

installed. Covers deteriorate over time due to exposure to sunlight and pool chemicals.

This cover must be replaced within seven (7) years from installation (or earlier if the cover

becomes damaged in any way).

IntelliFlo VF Installation and User’s Guide

Page 7

IMPORTANT SAFETY PRECAUTIONS (continued)

Entrapment Avoidance Notice:

The suction outlet connected to a swimming pool or spa pump can pull a high vacuum if it

is blocked. Therefore, if only one suction outlet smaller than 18" x 23" is used, anyone

blocking the suction outlet with their body can be trapped and held against the suction

outlet. Disembowelment or drowning can result. Therefore, if small suction outlets are

used with this pump, to prevent this entrapment and possible death, install at least two

suction outlets in the body of water. Separate these suction outlets as described in the

International Residential Code (IRC), the International Business Code (IBC), the Consumer

Products Safety Council (CPSC) Guidelines for Entrapment Hazards: Making Pools and

Spas Safer or ANSI/IAF-7 Standard for Suction Entrapment Avoidance in Swimming Pools,

Wading Pools, Spas, Hot Tubs and Catch Basins. If suction outlets are not used, additional

entrapment avoidance measures as described in the CPSC Guidelines or ANSI/IAF-7 should

be employed.

The covers used on suction outlets should be approved and listed as conforming to the currently

published edition of ANSI/ASME A112.19.8 Standard covering Suction Fittings for Use in

Swimming Pools, Wading Pools, Spas and Hot Tubs. These covers should be inspected

regularly and replaced if cracked, broken or older than the design lifetime indicated on them

by the manufacturer. The maximum possible flow rate of this pump should be less than or

equal to the maximum approved flow rate indicated on the suction outlet cover by the

manufacturer. THE USE OF UNAPPROVED COVERS OR ALLOWING USE OF THE POOL

OR SPA WHEN COVERS ARE CRACKED OR BROKEN CAN RESULT IN HAIR

ENTANGLEMENT WHICH CAN RESULT IN DEATH.

v

The Virginia Graeme Baker Pool and Spa Safety Act imposes certain new requirements on owners and

operators of swimming pools and spas.

Pools or spas constructed on or after December 20, 2008, shall utilize:

(A) No submerged suction outlets, a gravity drainage system with ASME/ANSI cover(s), one or more

unblockable outlets; or

(B) A multiple main drain system without isolation capability with suction outlet covers that meet ASME/

ANSI A112.19.8 Suction Fittings for Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs and

either:

(i) A safety vacuum release system (SVRS) meeting ASME/ANSI A112.19.17 Manufactured Safety Vacuum

Release Systems (SVRS) for Residential and Commercial Swimming Pool, Spa, Hot Tub, and Wading Pool

Suction Systems and/or ASTM F2387 Standard Specification for Manufactured Safety Vacuum Release

Systems (SVRS) for Swimming Pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent system or

(iii) An automatic pump shut-off system.

Pools and spas construction prior to December 20, 2008, with a single submerged suction outlet shall use a

suction outlet cover that meets ASME/ANSI A112.19.8 and either:

(A) A multiple main drain system without isolation capability, or

(B) A safety vacuum release system (SVRS) meeting ASME/ANSI A112.19.17 and/or ASTM F2387, or

(C) A properly designed and tested suction-limiting vent system, or

(D) An automatic pump shut-off system, or

(E) Disabled submerged outlets, or

(F) Suction outlets shall be reconfigured into return inlets.

For information about the Virginia Graeme Baker Pool and Spa Safety Act, contact the Consumer Product

Safety Commission at (301) 504-7908 or visit www.cpsc.gov.

NOTE: Always turn off all power to the pool pump before installing the cover or working on any suction outlet.

IntelliFlo VF Installation and User’s Guide

Page 8

vi

IMPORTANT SAFETY PRECAUTIONS (continued)

General Installation Information

• All work must be performed by a qualified pool professional, and must conform to all

national, state, and local codes.

• Install to provide drainage of compartment for electrical components.

General Installation Information

Pumps improperly sized or installed or used in applications other than for which

the pump was intended can result in severe personal injury or death. These risks

may include but not be limited to electric shock, fire, flooding, suction entrapment

or severe injury or property damage caused by a structural failure of the pump or

other system component.

The pump can produce high levels of suction within the suction side of the

plumbing system. These high levels of suction can pose a risk if a person comes

within the close proximity of the suction openings. A person can be seriously

injured by this high level of vacuum or may become trapped and drown. It is

absolutely critical that the suction plumbing be installed in accordance with the

latest national and local codes for swimming pools.

• These instructions contain information for a variety of pump models and therefore some instructions

may not apply to a specific model. All models are intended for use in swimming pool applications.

The pump will function correctly only if it is properly sized to the specific application and properly

installed.

General Warnings

• Never open the inside of the drive motor enclosure. There is a capacitor bank that holds a

230 VAC charge even when there is no power to the unit.

• The IntelliPro VS-3050 pump is not submersible

• The IntelliPro VS-3050 pump is capable of 174 GPM or 104 feet of head; use caution when

installing and programming to limit pumps performance potential with old or questionable

equipment

• Code requirements for the electrical connection differ from state to state. Install equipment in

accordance with the National Electrical Code and all applicable local codes and ordinances.

• Always Press the Stop button and disconnect the communication cable before performing

maintenance, and always power the unit off by disconnecting the main circuit to the pump

Two Speed Pump Controls Notice (Title 20 Compliance)

Please read the following important Safety Instructions. When using two-speed pumps manufactured on or after

January 1, 2008, the pump's default circulation speed MUST be set to the LOWEST SPEED, with a high speed

override capability being for a temporary period not to exceed one normal cycle, or two hours, whichever is less.

IntelliFlo VF Installation and User’s Guide

Page 9

Section 1

Introduction

IntelliFlo® VF Overview

The IntelliFlo VF variable-flow pump control system offers pool and spa filter automation and advanced

features that include energy conservation and programmable scheduled water features for your pool, spa,

cleaner, waterfall, and other applications.

The IntelliFlo pump can adapt to any application up to 130 gallons per minute, you simply program IntelliFlo to

suit the application. IntelliFlo then dials in the perfect operating conditions for that specific flow rate.

IntelliFlo can reduce energy cost by as much as 90% based on a pool size up to 15,000 gallons, one turn

per day with a 24 hour cycle.

IntelliFlo constantly monitors water flow and electrical current to ensure that the filtration system is operating

at peak efficiency. This can result in maximum energy efficiency savings never before possible – up to 90%

over conventional single speed and two speed pumps. The system protects against loss of prime or

impedance of flow, under and over voltage situations, and thermal overload or freezing.

1

With IntelliFlo there’s no need for pump curves and hydraulic calculations to determine the right pump for

the job. Just set the program for your pool size and desired turnover, and IntelliFlo does the rest.

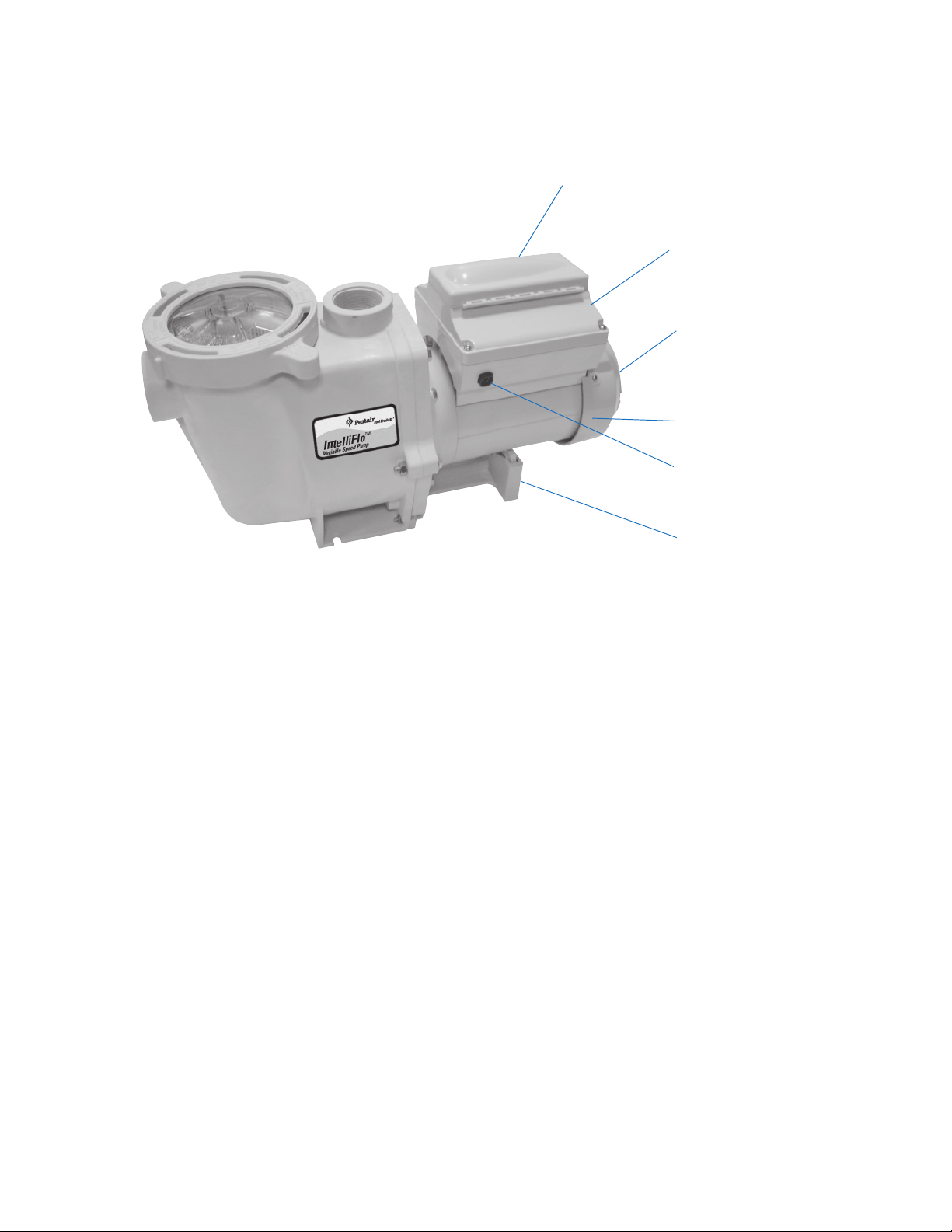

Motor fan cover

Motor assembly

Drive assembly and

electronics enclosure

Communication port for connection

to EasyTouch, IntelliTouch or

SunTouch control system or

IntelliComm communication center

via two-wire RS-485 cable

IntelliFlo VF (variable flow pump)

IntelliFlo VF Installation and User’s Guide

Page 10

2

IntelliFlo Features

• Sizes itself to any pool

• Reduces energy cost by as much as 90%

• Protects against loss of prime or flow blockage

• Prevents thermal overload

• Detects and prevents damage from under and over voltage conditions

• Protects against freezing

• Can communicate with an IntelliTouch or IntelliComm system via a two-wire connection

• Easy to read operator control panel LCD display

• Operator control panel buttons for pump modes

• Built-in strainer pot and volute

• Ultra energy-efficient TEFC Square Flange Motor

• Compatibility with most cleaning systems, filters, and jet action spas

• 16-button LCD control panel

• Drive assembly features permanent magnet synchronous motor

• Heavy-duty, durable construction designed for long life

• Internal 24-hour clock for setting controlled on/off times for filtering and up to ten water features

• UL listed

IntelliFlo Motor Assembly

The IntelliFlo’s three-phase, six-pole, permanent magnet motor operates at 3450 RPM (at 92% efficiency)

and 400 RPM (at 90%). The motor assembly is continually cooled by an external fan. Dual seals on the

motor shaft and at the fan assembly seal the entire motor from any moisture entering the motor assembly.

For added protection, a slinger located in front of the main shaft seal assists in slinging water away from the

shaft opening in the flange.

IntelliFlo VF Installation and User’s Guide

Page 11

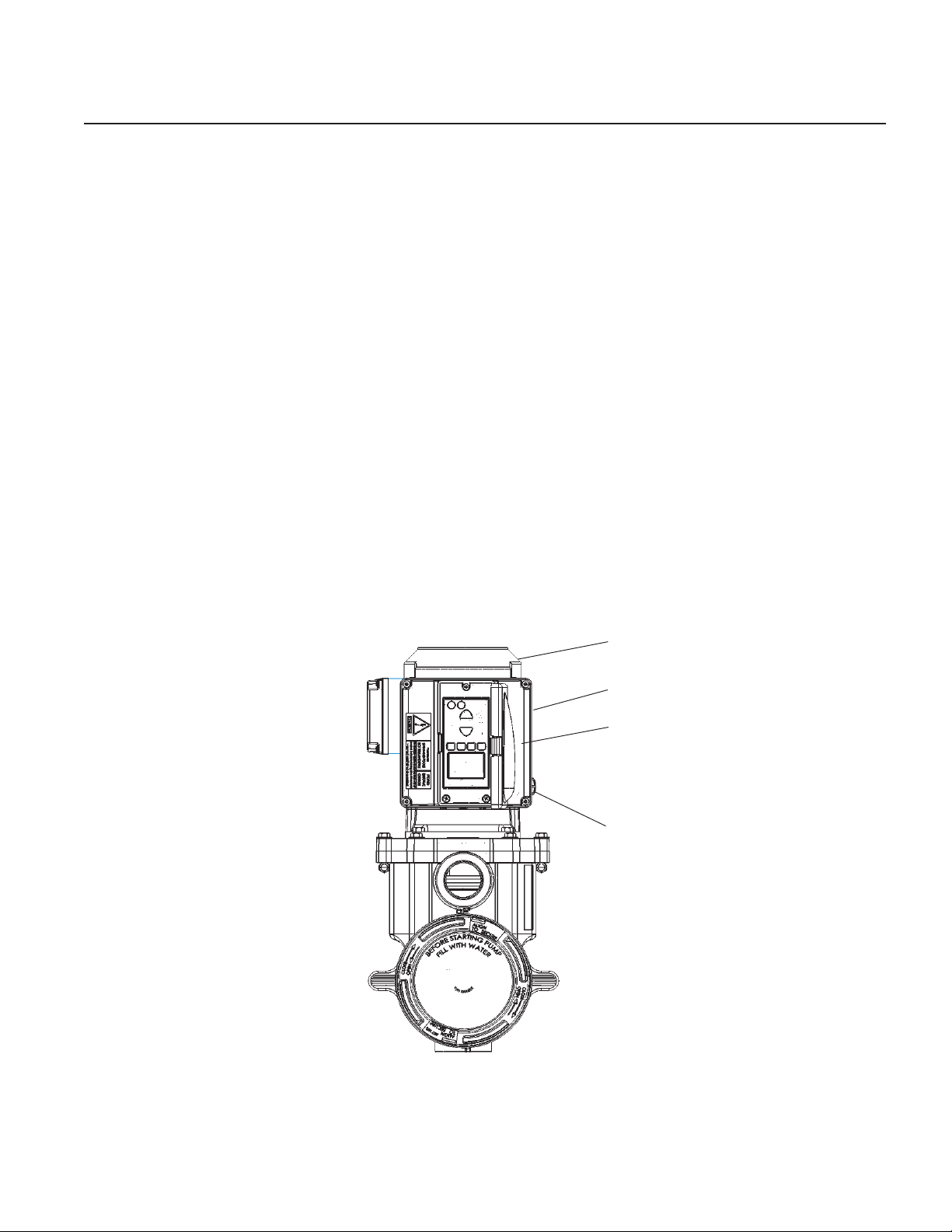

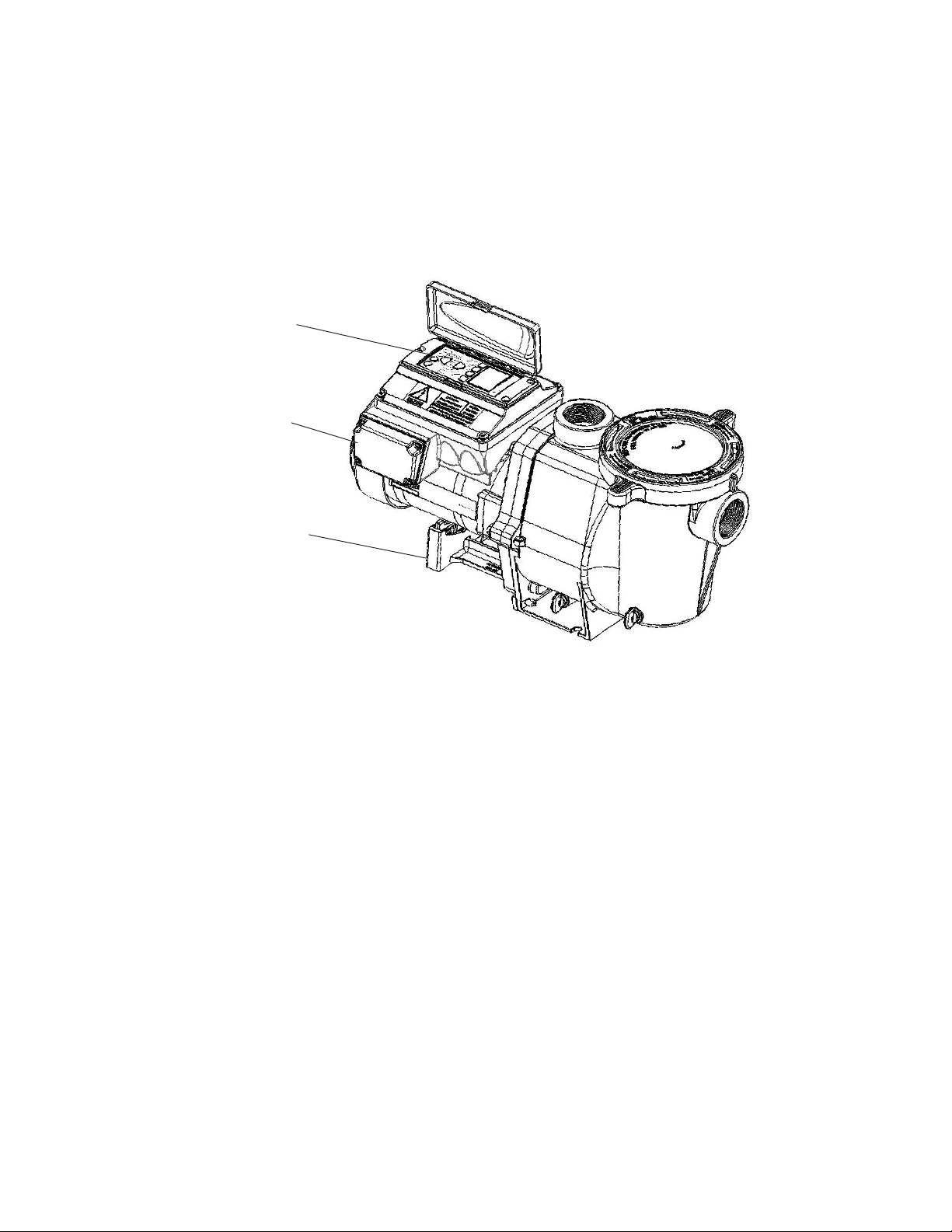

Operator control panel cover

Drive assembly and

electronics enclosure

Motor fan cover

Motor assembly

Communication Port for RS-485

(IntelliTouch and IntelliComm)

3

IntelliFlo VF Motor Assembly

IntelliFlo VF Motor Features

• Permanent Magnet Synchronous Motor (PMSM)

• High efficiency (3450 RPM 92% and 400 RPM 90%)

• Superior speed control

• Operates at lower temperatures due to high efficiency

• Same technology as deployed in hybrid electric vehicles

• Designed to withstand outdoor environment

• Totally Enclosed Fan Cooled

• Three-phase motor

• 56 Square Flange

• Six-Pole

• Low noise

Motor stand

IntelliFlo VF Installation and User’s Guide

Page 12

4

IntelliFlo Drive Assembly and Control Panel

The IntelliFlo drive assembly consists of an operator control panel and the system electronics that drive the

230 VAC single phase (260 VAC~170 VAC) motor. The drive microprocessor controls the motor by

changing the frequency of the current it receives together with changing the voltage to control the rotational

speed.

Operator Control Panel,

buttons and LED

(see page 5)

AC power connection

compartment

(see page 32)

Motor stand

IntelliFlo Drive Assembly

Operator Control Panel Features

• Backwash and Rinse — Informs the user when and how to backwash filter media

• Vacuum — Can be preset using duration and flow parameters to save energy

• Filter — Allows pump to run at peak efficiency, saving users up to 90% in energy cost, based on a

pool size up to 15,000 gallons, one turn per day with a 24 hour cycle

• Feature — Ten feature modes can be programmed to control filtration duration, start and stop time,

and frequency for cleaners, water features, spas, and waterfalls

• Manual — Allows the user to override all programming and run the pump using RPM or flow

(GPM) control parameters. All personnel safety devices and alarms do not operate in speed mode.

IntelliFlo VF Installation and User’s Guide

Page 13

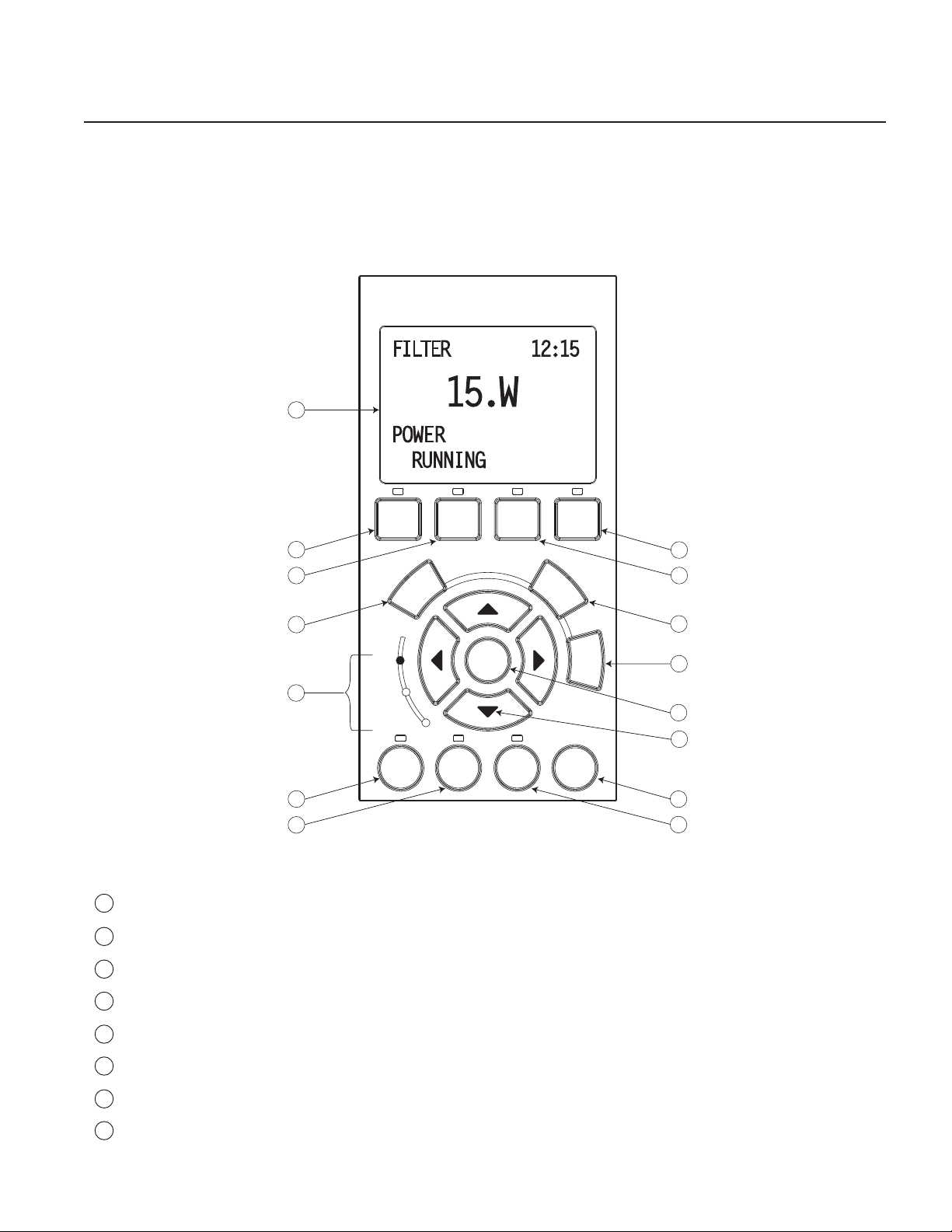

Operator Control Panel

This section describes the operator control panel controls and LEDs.

IntelliFlo VF Operator Control Panel

IntelliFlo

15

5

Section 2

®

Filter

mode

1

2 3

5

On

14

10

11

Warn.

Alarm

Feature

1

Select

Vacuum

mode

Feature

2

Enter

Back

Wash

Start

Stop

Manual

mode

Escape

Menu

Reset

Controls and LEDs

1

Filter button/LED: Starts Filter mode. The LED is on when Filter mode is active.

Vacuum button/LED: Starts Vacuum mode. The LED is on when Vacuum mode is active.

2

4

6

7

8

9

13

12

Backwash button/LED: Starts Backwash mode. The LED is on when Backwash mode is active.

3

4

Manual button/LED: Starts Manual mode. The LED is on when Manual mode is active.

5

Select button: Display available menu items or enters edit mode for changing a value on line two of the display.

6

Escape button: Go to the next level up in the menu structure or stop editing the current setting.

7

Menu button: Access the menu items if the pump is stopped.

8

Enter button: Save current menu item setting. Also, press this button to acknowledge alarms and warning alerts.

IntelliFlo VF Installation and User’s Guide

Page 14

6

Controls and LEDs (Continued)

9

Arrow buttons:

• Up arrow: Move one level up in the menu tree or increase a digit when editing a setting.

• Down arrow: Move one level down in the menu tree or decrease a digit when editing a setting.

• Left arrow: Move cursor left one digit when editing a setting.

• Right arrow: Move cursor right one digit when editing a setting.

Feature 1 button: Starts Feature 1 mode. The LED is lit when mode is active.

10

11

Feature 2 button: Starts Feature 2 mode. The LED is lit when mode is active.

Start/Stop button: Start or Stop the pump. When the LED is lit it indicates that the pump is currently running or

12

in a mode to start automatically.

13

Reset button: Reset alarm or alert.

LEDs

On: This green LED is on when IntelliFlo is powered on.

14

Warning: This LED is on if a warning condition is present.

Alarm: This LED is on if an alarm condition has occurred.

15

Control Panel LCD Display

LCD Display Lines:

• Line 1 - Mode and time. To set A.M. and P.M. time, refer to “Time and Contrast Menu” on page 22.

• Line 2 - Data

• Line 3 - Name of data in line 2

• Line 4 - Run status

IntelliFlo VF Installation and User’s Guide

Page 15

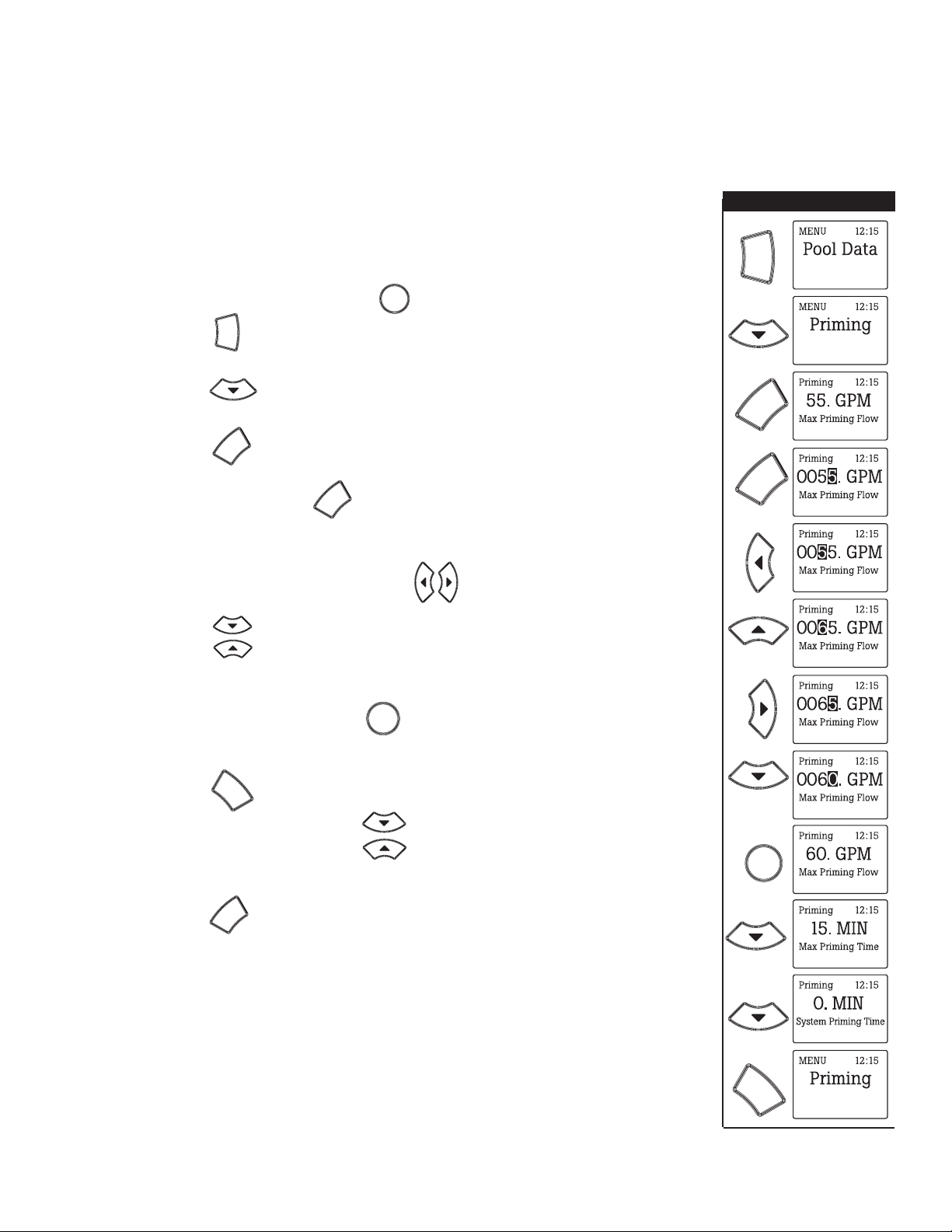

Navigating the Menu Structure

Before navigating the control panel menu structure, first familiarize yourself with the menu buttons. To

change a parameter setting, use the Left and Right arrow buttons to select the digit, then the Up and Down

arrow buttons to edit the digit. The following example shows how to set the GPM and priming time in the

“Priming” menu (see page 14).

Priming Mode Example

7

To set the “Priming” mode settings:

1. Ensure that the green power LED is on and the pump is stopped.

If the pump is running, press the Start/Stop button.

Menu

Start

Stop

2. Press the Menu button. “Pool Data” is displayed.

3. Press the Down arrow to select “Priming”.

4. Press the Select button to access “Max Priming Flow” setting.

5. Set the GPM: Press the Select button to set the gallons per minute

Select

Select

(GPM) value.

6. To change the GPM value, press the Left and Right arrows to select

which digit to modify.

Press the Up and Down arrows to change the selected digit. For setting

values, see “Priming menu options” below.

Menu

Select

Select

7. When you are done, press the Enter button to save the changes. To

Enter

cancel any changes.

Press the Escape button to exit edit mode without saving.

Escape

8. Set the priming time: Use the Up and Down arrows to select “Max

Priming Time” and “System Priming Time.”

Press the Select to edit the setting.

Select

9. Repeat steps 5, 6, and 7 to edit the setting.

5X

Enter

Escape

IntelliFlo VF Installation and User’s Guide

Page 16

8

Blank Page

IntelliFlo VF Installation and User’s Guide

Page 17

Operating IntelliFlo

MANUAL

12:15

15.W

POWER

STOPPED

MANUAL

12:15

10.

RPM

ACTUAL SPEED

STOPPED

MANUAL

12:15

13.

GPM

FLOW

STOPPED

MANUAL

12:15

10.

RPM

Set SPEED

STOPPED

MANUAL

12:15

580.GPM

Set FLOW

STOPPED

This section describes how to use the IntelliFlo pump control panel.

Metering the System

The first step to operating and programming IntelliFlo is to know what is being used in the

pool system. After the devices are selected you can then set valves for the appropriate

features and use the “Manual” mode to measure flow rates for the types or series of

devices that require flow. When an appropriate flow rate or rates are found for a device

or series of devices, you should note that flow rate for programming later.

Note: If the pool system uses a filter, always monitor pressure at the filter when

changing the speed (RPM) or flow (GPM) from IntelliFlo.

Manual Mode

9

Section 3

Operating IntelliFlo in manual mode is typically used for service and testing purposes only.

To operate IntelliFlo in manual mode:

1. Ensure that the green power LED is on.

2. Press the Manual button.

3. Use the Up and Down arrow buttons to view the current power, actual speed and flow:

• Power Menu (Watts): Displays current power to the motor shaft in continuous watts

• Actual Speed (RPM): Displays RPM speed when flow and RPM control is used

• Actual Flow (GPM): Displays actual flow when using flow control

• Set Speed (RPM): Set IntelliFlo to run at a continuous speed

• Set Flow (GPM): Set IntelliFlo in flow control to allow the pump to change speed to manage the

flow rate based on system changes

MANUAL

POWER

STOPPED

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

IntelliFlo

15.W

Back

Wash

Enter

Start

Feature

Stop

2

Manual

®

12:15

Escape

Manual

Reset

Menu

On

Warn.

Alarm

MANUAL

ACTUAL SPEED

STOPPED

Filter Vacuum

Select

Feature

1

IntelliFlo

10.

RPM

Back

Wash

Enter

Start

Feature

Stop

2

®

12:15

Escape

Manual

Reset

Menu

On

Warn.

Alarm

IntelliFlo

MANUAL

13.

FLOW

STOPPED

Filter Vacuum

Select

Feature

Feature

1

2

Enter

GPM

Back

Wash

Start

Stop

®

12:15

Escape

Manual

Menu

Reset

MANUAL

Set SPEED

STOPPED

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

IntelliFlo

10.

RPM

Back

Wash

Enter

Start

Feature

Stop

2

®

12:15

Escape

Manual

Reset

®

IntelliFlo

MANUAL

12:15

580.GPM

Set FLOW

STOPPED

Back

Filter Vacuum

Select

Menu

On

Warn.

Alarm

Feature

1

Feature

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

2

Note: No sensors except the flow control will work while in “Manual” mode. Suction Blockage will

not work in this mode.

IntelliFlo VF Installation and User’s Guide

Page 18

10

MANUAL

Set SPEED

STOPPED

MANUAL

12:15

Set SPEED

STOPPED

12:15

k

W

ash

n

u

MANUAL

12:15

Set SPEED

STOPPED

Manual Mode (Continued)

To change the Set Flow and Set Speed features:

1. Ensure that the green power LED is on.

2. Press the Manual button (LED is on).

3. Set Flow: Use the Up and Down arrow buttons to select Set Flow, then press the Select button to

edit the setting.

4. To change the setting, press the Left and Right arrows to select which digit to modify, then use the

Up and Down arrows to change the selected digit. The preset flow values can be set to 15 to 130

GPM (default 50 GPM).

5. When you are done, press the Enter button to save the changes. To cancel any changes, press the

Escape button to exit edit mode without saving.

6. Set Speed: Use the Up and Down arrows to select Set Speed, then press the Select button to edit

the setting. The preset speed can be set to 400 to 3450 RPM maximum (default 1000 RPM).

IntelliFlo

MANUAL

0010.RPM

Set SPEED

STOPPED

Filter Vacuum

Select

Select

On

Warn.

Alarm

Feature

Feature

2

1

Cursor hi-lights in

black

®

12:15

IntelliFlo

MANUAL

0010.RPM

Set SPEED

STOPPED

Back

alManual

Ma

Wash

Escape

Enter

Menu

Start

Reset

Stop

Filter Vacuum

Select

On

Warn.

Alarm

Feature

Feature

1

Left/Right arrow

buttons to change

Enter

2

digit

Back

Wash

Start

Stop

®

12:15

Manual

Escape

Reset

IntelliFlo

MANUAL

1010.RPM

Set SPEED

STOPPED

Filter Vacuum

Select

Menu

On

Warn.

Alarm

Feature

Feature

1

Press the Enter

button to save.

Press Start/Stop

®

12:15

Manual

Reset

Enter

Start

Stop

Menu

Back

Wash

Escape

Enter

Start

2

Stop

7. To change the setting, press the Left and Right arrows to select which digit to modify, then use the

Up and Down arrows to change the selected digit.

8. When you are done, press the Enter button to save the changes. To cancel any changes, press the

Escape button to exit edit mode without saving.

IntelliFlo VF Installation and User’s Guide

Page 19

Manual Mode (Continued)

9. Press the Start/Stop button (LED is on) to run IntelliFlo in “Manual” mode (LED is on). The pump

will start and control the flow or speed using the last settings made. After the button is pressed, the

display shows “Running.” To stop IntelliFlo, press the Start/Stop button (LED is off). The display

will show “Stopped.”

Note: While IntelliFlo is running in Manual mode, you can view the current power

consumption and what actual speed is being used.

Change Flow and Speed settings while the IntelliFlo is running: The Set Flow and Set Speed

10.

settings can be changed on the fly while the pump is running. To change the flow and speed settings,

perform steps 3 through 8.

• When “Set Flow” is used IntelliFlo will prime then ramp to the current flow rate

• It takes the IntelliFlo about 60 seconds to two minutes to find a flow rate after it is primed. This is best

seen in Actual Speed status display

• While changing the Set Flow setting, IntelliFlo will reprime after a value is changed

11

• While changing the Set Speed setting, IntelliFlo will immediately ramp to the current speed

11. To stop the pump, press the Start/Stop button.

IntelliFlo Control Panel Menu

Use the control panel menu to setup and configure IntelliFlo.

To access the menu features:

• Ensure that the pump is stopped. Press the Menu button. Use the Up or Down arrow button to

scroll through the menu items. Use the Select button to select a menu item. Press the Enter button

to save a setting. Press the Escape button to move up a level from a selected menu item.

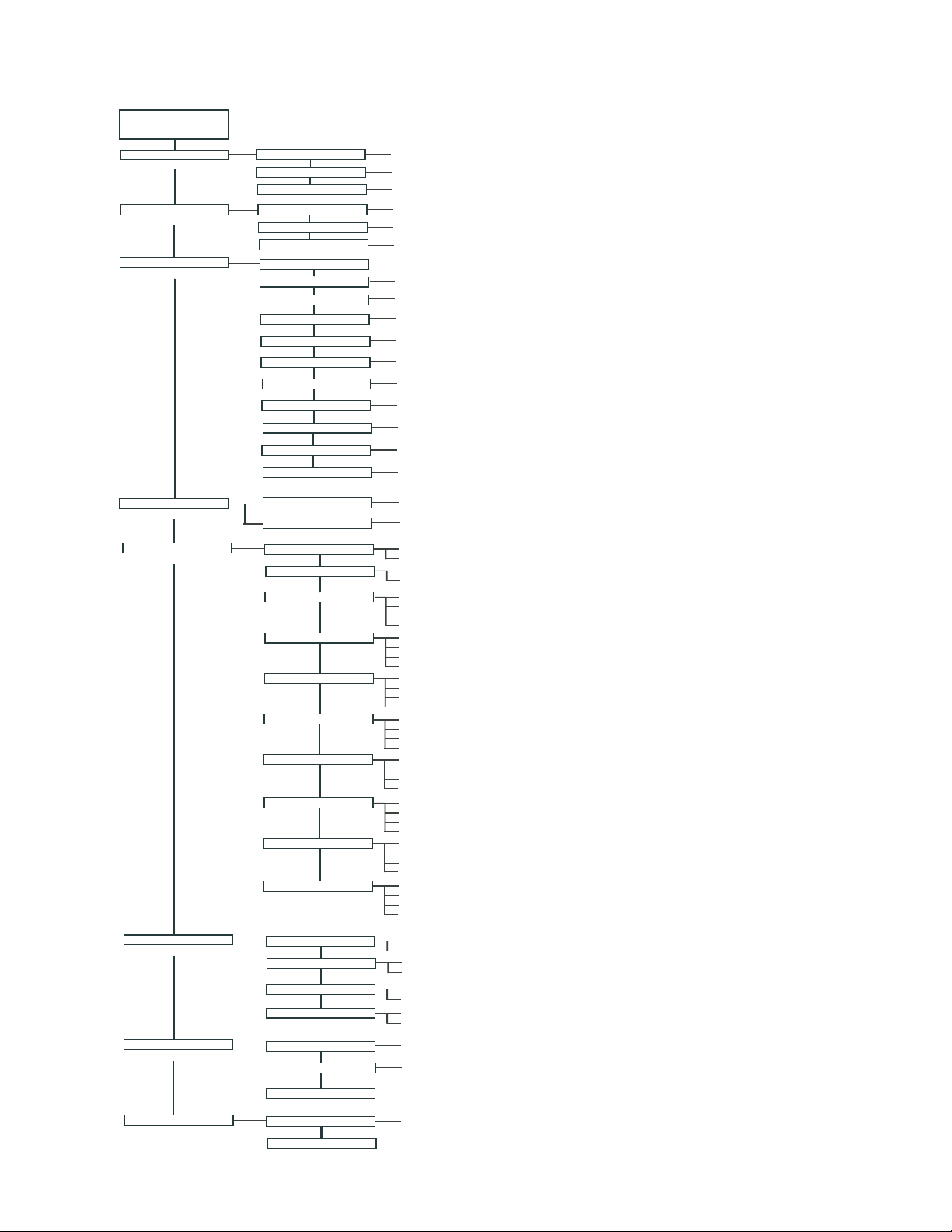

Menu Structure

The IntelliFlo menu structure is shown on the following page.

IntelliFlo Control Panel with IntelliComm or IntelliTouch

• The IntelliFlo control panel remains active when the IntelliFlo is connected to an IntelliComm. For

more information see page 29.

• The IntelliFlo control panel is disabled when the Intelliflo is communicating with an IntelliTouch.

"DISPLAY NOT ACTIVE!" will be displayed. For more information see page 31.

IntelliFlo VF Installation and User’s Guide

Page 20

12

Main Menu

MAIN SCREEN

POOL DATA

(page 13)

PRIMING

(page 14)

FILTER

(page 16)

TIME / CONTR

(page 22)

FEATURES

(page 23)

EXT. CONTROL

(page 29)

BACKWASH

(page 33)

VACUUM

(page 35)

Press MENU button to access menu items

Address

Water Temp

Pool Volume

Max Priming Flow

Max Priming Time

Sys Priming Time

Clean Filter Pressure

Turnovers per Day

Cycles per Day

Start Cycle 1

Stop Cycle 1

Start Cycle 2

Stop Cycle 2

Start Cycle 3

Stop Cycle 3

Start Cycle 4

Stop Cycle 4

Clock

Contrast Level

Features 1

Features 2

Features 3

Features 4

Features 5

Features 6

Features 7

Features 8

Features 9

M.O Flow

Program 1

Program 2

Program 3

Program 4

Backwash Flow

Backwash Duration

Rinse Time

Vacuum Flow

Vacuum Duration

(1 - 16) [Note: 1-8 when connected to IntelliTouch]

(68° - 104° F)

(1 - 1000 Kgal)

(30 - 160 gpm)

(1 - 15 min.)

(0 - 5 min.)

(1 - 50 min.)

(1 - 8 counts)

(1 - 4 counts)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:mm - AM/PM)

(hr:min - AM/PM)

(0 - 9)

Set Flow (15 - 130 gpm)

Set Duration (0:01 - 10:00)

Set Flow (15 - 130 gpm)

Set Duration (0:01 - 10:00)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Start Time (hr:mm AM/PM)

Set Stop Time (hr:mm AM/PM)

Disable/Enable

Set Flow (15 - 130 gpm)

Set Run Time (0:01 - 00:59)

Set Interval Time (0:02 - 4:15)

Disable/Enable

Set Flow (15 130 gpm) / Time Delay Stop (hr:mn) (0:00 - 0:10)

Disable/Enable (15 - 130 gpm)

Set Flow (15 130 gpm) / Time Delay Stop (hr:mn) (0:00 - 0:10)

Disable/Enable

Set Flow (15 130 gpm) / Time Delay Stop (hr:mn) (0:00 - 0:10)

Disable/Enable

Set Flow (15 130 gpm) / Time Delay Stop (hr:mn) (0:00 - 0:10)

(15 - 130 gpm)

(0:01 - 1:00)

(0:01 - 1:00)

(15 - 130 gpm)

(0:01 - 10:00)

IntelliFlo VF Installation and User’s Guide

Page 21

Pool Data Mode

MENU

12:15

Pool Data

Pool Data

12:01

Pump Address

1

Pool Data

12:15

Pool Volume

31.kGAL

Pool Data

12:15

Water Temperature

75.F

Use the Pool Data menu to configure IntelliFlo for the pool and spa system. From this menu you can set an

address for the IntelliFlo pump when connected to an IntelliTouch system, set the volume of pool water, in

1000’s of gallons (kgal) and estimated pool water temperature.

To access the Pool Data menu:

1. Ensure that the green power LED is on and the pump is stopped.

2. Press the Menu button.

IntelliFlo

MENU

Pool Data

13

®

12:15

3. Press the Up and Down arrow buttons to scroll through the menu items. Press the

Select button to access the “Pool Data” menu.

4. To enter the pump volume (pool size): Press the Select button to access “Pool

Volume” setting. To enter the pool volume setting, see step 7.

The “Pool Volume” value is expressed as 1000’s of gallons (Kgal). Enter from 1 to

1000 Kgal for the pool volume. The volume number can be a close estimate, although

the more accurate the better the turns will be done when employing filter mode. Filter

mode uses this value in coordination with the parameters from Filter mode to sustain

turn rates, flows, and times.

5. To set the water temperature: Use the Up and Down arrows to select “Water

Temperature”. To set the water temperature, see step 7.

Enter the current water temperature from 68° F - 104° F (Default 75° F.) The “Water

Temp” is only for the accuracy of the flow sensor. Temperature accuracy is not

critical, just enter an approximate temperature. When the IntelliFlo is connected to an

IntelliTouch system, water and air temperature information is provided by the system

sensors. The flow reading on the IntelliFlo is –0 / +2 GPM. The closer the

temperature to the actual temperature, the more accurate the flow reading on the

IntelliFlo control panel LCD will be while it’s running.

6. To enter the pump address: Press the Select button to access the “Pump Address”

setting. To enter the IntelliFlo pump address, see step 7.

This setting is only used if IntelliFlo is connected to the IntelliTouch system. The

“Pump Address” identifies the pump number (1-16) that is displayed on the

IntelliTouch control panel for programming. For example, if there are multiple IntelliFlo

pumps, pump address 1 can be name as “Spa Pump,” in the IntelliTouch control panel.

The IntelliTouch system can address and control up to eight different pumps using the

RS-485 COM port connection. Note: IntelliFlo pumps cannot be connected in

series with other pumps. Check valves must be used when an IntelliFlo is used in

parallel with other pumps.

7. Press the Select button to change the current setting.

8. To enter a new setting, press the Left and Right arrows to select which digit to modify,

then use the Up and Down arrows to change the selected digit.

Filter Vacuum

Select

Enter

On

Warn.

Alarm

Feature

Feature

2

1

IntelliFlo

Pool Data

Pump Address

Filter Vacuum

Select

Enter

On

Warn.

Alarm

Feature

Feature

2

1

IntelliFlo

Pool Data

31.kGAL

Pool Volume

Filter Vacuum

Select

Enter

On

Warn.

Alarm

Feature

Feature

2

1

IntelliFlo

Pool Data

75.F

Water Temperature

Filter Vacuum

Select

Enter

On

Warn.

Alarm

Feature

Feature

2

1

Back

Manual

Wash

Escape

Menu

Start

Reset

Stop

®

12:01

Back

Manual

Wash

Escape

Menu

Start

Reset

Stop

®

12:15

Back

Manual

Wash

Escape

Menu

Start

Reset

Stop

®

12:15

Back

Manual

Wash

Escape

Menu

Start

Reset

Stop

9. When you are done, press the Enter button to save the changes. To cancel any

changes, press the Escape button to exit edit mode without saving.

IntelliFlo VF Installation and User’s Guide

Page 22

14

MENU

12:37

Priming

Priming

12:44

Max Priming Flow

55.GPM

Priming Mode

To “prime” a pump means filling the pump and suction pipe with water. This process evacuates the air from all

the suction lines and the pump. It may take several minutes to prime depending on the depth of water, pipe size

and length. It is easier to prime a pump if you allow all the air to escape from the pump and pipes. The water

cannot enter unless the air can escape. Pumps do not hold prime, the pool piping system has that task.

Priming is a function used every time the motor is started with a flow as reference. The “Priming Flow” function

ensures the proper operation of the pump. The “System Priming Time” function ensures proper operation of the

whole pool system. When the pump is priming, the control panel LCD displays “Priming” and then for a moment

displays “Primed” when priming is complete.

CAUTION: To avoid permanent damage to the IntelliFlo pump, before starting the system, fill the IntelliFlo

housing strainer with water so that the pump will prime correctly. If there is no water in the stainer the pump will

not prime.

Priming Menu

To enter maximum priming flow (GPM):

1. Ensure that the green power LED is on and the pump is stopped.

2. Press the Menu button. “Pool Data” is displayed.

3. Press the Up or Down arrows to select the “Priming” menu.

4. To set the Max Priming Flow (GPM): Press the Select button to access the “Max

5. To set the Max Priming Time: Press the Select button to access the “Max

IntelliFlo

MENU

Priming

Priming Flow” setting. To enter the maximum flow range (GPM) during the

priming cycle, see step 7.

The “Max Priming Flow” value is entered as gallons per minute (GPM), from 30

to 160 GPM. The default is 55 GPM. The “Max Priming Flow” is a critical

parameter for the pool and equipment. Every time the pump starts this parameter

will negotiate the maximum flow of the pump. If the flow is too high, equipment

damage can occur. If the flow is to low the pump will not prime. This “flow” is

system dependent and may require iteration. The pump will never flow more than

this parameter is set to, however, it is common for the pump to ramp up and down

quickly while priming. Always try to keep this flow as low as possible for cost

savings and safety.

Priming Time” setting. To enter the maximum time for priming before “PRIMING

ERROR”, see step 7 on the following page.

The “Max Priming Time” value is entered in minutes, from 1 to 15 minutes. The

default is 15 minutes. Use this parameter to set the time that you want IntelliTouch

to try and prime before it reports an error. Remember that the IntelliFlo will attain

prime every time it starts and goes through this cycle. The IntelliFlo mechanical

seal can withstand about 15 minutes before severe damage occurs. You can set

this range between 1 minute to 15 minutes. The lower the time the quicker you will

get a priming error if the system is difficult to prime. A well plumbed pool without

having the strainer removed should prime in less than 30 seconds. If the strainer

has been removed for cleaning and a substantial amount of air is in the system it should prime in

about 60 to 90 seconds on the average, however, all systems will be different.

Filter Vacuum

Select

Feature

Enter

Feature

2

1

On

Warn.

Alarm

IntelliFlo

Priming

55.GPM

Max Priming Flow

Filter Vacuum

Select

Feature

Enter

Feature

2

1

On

Warn.

Alarm

Wash

®

12:37

Back

Manual

Escape

Menu

Start

Reset

Stop

®

12:44

Back

Manual

Wash

Escape

Menu

Start

Reset

Stop

IntelliFlo VF Installation and User’s Guide

Page 23

Priming Mode (Continued)

Priming

12:54

Max Priming Time

15.MIN

Priming

1:03

System Priming Time

0.MIN

6. To set the System Priming Time: Press the Select button to access the “System

Priming Time” setting. After the pump is primed it will take sometime before the

system is primed. This time is called “System Priming Time” To enter the maximum

system priming time, see step 7.

The “System Priming Time” value is entered in minutes, from 0 to 5 minutes. The

default is 0 minutes. Remember that the average unit will prime in a short period of

time because the IntelliFlo has the ability to monitor itself to make sure it is

primed. “System Priming Time” is for systems that require high flows that priming

flow can provide but it is deemed that more time is needed to fully relieve all the

air. The builder can program a pre determined amount of time, up to 5 minutes, to

aid in relieving the air from difficult filters or complex vertical plumbing. The

“System Priming Time” should only be used where large air traps become

problems within the system. The display will inform the user when this is engaged

and when it is finished during the priming cycle at each start up cycle.

7. Press the Select button to change the current value.

8. To change the value, press the Left and Right arrows to select which digit to modify,

then use the Up and Down arrows to change the selected digit.

IntelliFlo

Priming

12:54

15.MIN

Max Priming Time

Select

Feature

Back

Wash

Enter

Start

Stop

2

Filter Vacuum

On

Warn.

Alarm

Feature

1

IntelliFlo

Priming

1:03

0.MIN

System Priming Time

15

®

Manual

Escape

Menu

Reset

®

9. When you are done, press the Enter button to save the changes. To cancel any

changes, press the Escape button to exit edit mode without saving.

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

Feature

Back

Manual

Wash

Escape

Enter

2

Menu

Start

Reset

Stop

IntelliFlo VF Installation and User’s Guide

Page 24

16

MENU

1:13

Filter

Filter

1:16

Clean Filter Pressure

14.PSI

Filter

12:00

Turnovers Per Day

1

Filter Mode

IntelliFlo will calculate the required flow rate based on pool size, clean filter pressure, pool turns per day

and cycles per day, and will control the motor speed to keep a constant flow. The filter mode can run

cycles, power save or features. The IntelliFlo internal scheduler will keep track of which function to run.

IntelliFlo is constantly monitoring the filter, when it detects that the system is dirty, it will display an “Alert Service System Soon” message on the control panel display. The user must then clean the filter by

performing a Backwash cycle (see page 33).

Filter Menu

To access the Filter menu settings:

1. Ensure that the green power LED is on and the pump is stopped.

MENU

IntelliFlo

Filter

®

1:13

2. Press the Menu button. Press the Up or Down arrows to select the “Filter” menu.

Press the Select button, “Clean Filter Pressure” is displayed.

3. To set the Clean Filter Pressure: Press the Select button to access the “Clean

Filter Pressure” setting. To edit the pressure setting, see step 6 on the following

page.

This parameter can be set from 1 PSI to 50 PSI. The average setting should be

between 10 PSI and 20 PSI for most pools and filters. The entered PSI value splits

the percentage meter for the filter. The “Service System Soon” alert is activated by

the entered PSI value. When this value is reached the pump stops monitoring flow

rates and starts managing pressure. The value represents the change in pressure

over time from start up (system clean) to present day (system getting dirty). The

changes can come from anywhere in the system, for example clogged skimmers or

pots in pumps. For more information, refer to “Clean Filter Pressure” on page 19.

4. To set the Turnovers Per Day: Press the Select button to access the “Turnovers Per

Day” setting. To edit this setting, see step 6 on the following page.

This setting is the number of times you wish to turn over the water that is setup in the

“Pool Volume” part of the “Pool Data” menu (see page 13).

You can set up to eight turns per day. It is recommended that one turn per day for

energy conservation and requirements be performed for most common residential

pools. Refer to sanitizer recommendation for additional information.

Select

Feature

2

1

IntelliFlo

Back

Wash

Escape

Enter

Start

Stop

®

1:16

Filter Vacuum

On

Warn.

Alarm

Feature

Filter

14.PSI

Clean Filter Pressure

Select

Feature

2

1

IntelliFlo

Select

Feature

2

1

Back

Wash

Escape

Enter

Start

Stop

12:00

Back

Wash

Escape

Enter

Start

Stop

Filter Vacuum

On

Warn.

Alarm

Feature

Filter

Turnovers Per Day

Filter Vacuum

On

Warn.

Alarm

Feature

Manual

Menu

Reset

Manual

Menu

Reset

®

Manual

Menu

Reset

IntelliFlo VF Installation and User’s Guide

Page 25

Filter Mode (Continued)

Filter

12:08

Cycles Per Day

1

Filter

12:02

Stop Cycle 1

Enabled

9:00 pmpm

Filter

12:10

Start Cycle 2

Disabled

9:10 pmpm

Filter

12:01

Start Cycle 1

Enabled

9:00 am

Filter

12:02

Stop Cycle 1

Enabled

7:59 am

Filter

12:10

Start Cycle 2

Disabled

10:15 am

Filter

12:01

Start Cycle 1

Enabled

8:00 am

5. To set the Cycles Per Day: Press the Select button to access the “Cycles Per Day” setting. To edit

this setting, see step 6.

IntelliFlo uses the Cycles Per Day parameter to calculate how much time it has to

complete its filter job. You can program up to four start and stop cycles per day.

The more time the IntelliFlo is given to operate the less power and flow will be

needed for turning over the pool.

Filter

IntelliFlo

17

®

12:08

Note: Consumers in certain areas are charged lower energy rates at non-peak

Cycles Per Day

hours. To take advantage of this, the IntelliFlo can be programmed to run at

Select

Back

Manual

Wash

Escape

any time of the day. The extremely quiet operation of the IntelliFlo makes it

feasible to operate during the early morning or late at night. The easiest and

Filter Vacuum

best way to optimize flow during filter cycles is by adding or subtracting cycle

Feature

Enter

Start

Feature

2

1

Reset

Stop

time. This way, the desired flow effect, for example, skimming action, can be

achieved while maintaining the desired water turnover rate.

On

Warn.

Alarm

6. Press the Select button to change the current value.

7. To change the value, press the Left and Right arrows to select which digit to modify, then use the Up

and Down arrows to change the selected digit.

8. When you are done, press the Enter button to save the changes. To cancel any changes, press the

Escape button to exit edit mode without saving.

Programming Cycles Per Day

Each cycle has two screens, one for the “Start Cycle” and one for “Stop Cycle”. The following examples

shows one for the cycle start/stop time. Only one cycle is entered in the “Cycles Per Day” parameter.

Feature

®

12:10

This screen shows the filter

cycle as “Disabled” for a start/

Back

Wash

Escape

Enter

Start

Stop

2

stop cycle (Cycles Per Day

Manual

programmed to 1). These

screens will still display even

if they are not enabled.

Menu

Reset

IntelliFlo

Filter

9:00 am

Start Cycle 1

Enabled

Filter Vacuum

Select

On

Warn.

Alarm

Feature

Feature

2

1

Feature

®

12:02

Start and Stop

Cycle is displayed

Back

Manual

Wash

Enter

Start

Stop

2

Enabled or disabled is

Escape

displayed depending on

how many cycles are

Menu

selected

Reset

IntelliFlo

Filter

9:10

Start Cycle 2

Disabled

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

®

12:01

IntelliFlo

Filter

9:00

Stop Cycle 1

Enabled

Back

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

Menu

IntelliFlo

Filter

8:00 am

Start Cycle 1

Enabled

Filter Vacuum

Select

On

Warn.

Alarm

Feature

Feature

2

1

Feature

®

This example will

run the pump for 24

12:02

hours. Start and

Stop Cycle is

displayed

Back

Manual

Wash

Enter

Start

Stop

2

Enabled or disabled is

Escape

displayed depending on

how many cycles are

Menu

selected

Reset

IntelliFlo

Filter

10:15 a

Start Cycle 2

Disabled

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

®

12:01

IntelliFlo

Filter

7:59 a

Stop Cycle 1

Enabled

Back

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

Feature

®

12:10

This screen shows the filter

cycle as “Disabled” for a start/

Back

Wash

Escape

Enter

Start

Stop

2

stop cycle (Cycles Per Day

Manual

programmed to 1). These

screens will still display even

if they are not enabled.

Menu

Reset

IntelliFlo VF Installation and User’s Guide

Page 26

18

Filter Mode (Continued)

Filter Cycle Settings

Note: The control panel is disabled when the Intelliflo is communicating with an IntelliTouch.

"DISPLAY NOT ACTIVE!" will be displayed.

EMANEULAVNOITPIRCSED

rePsrevonruT

yaD

repselcyC

yaD

retliFnaelC

erusserP

1

elcyCtratS

1elcyCpotS

2elcyCtratS

2elcyCpotS

3elcyCtratS

)1tluafeD(8-1

)1tluafeD(selcyC4-1

d

41tluafeD(ISP05-1

)ISP

MM.HH95:21-00:1

00:9tluafeD(mp/ma

)ma

MM.HH95:21-00:1

00:9tluafeD(mp/ma

)mp

MM.HH95:21-00:1

01:9tluafeD(mp/ma

)mp

MM.HH95:21-00:1

02:9t

luafeD(mp/ma

)mp

MM.HH95:21-00:1

03:9tluafeD(mp/ma

)mp

tratS emitemasehtsipotsdnatratsfi(1elcycrofemit

potS emitemasehtsipotsdnatratsfi(1elcycro

tratS ,2wolebsi"yadrepsel

.deretne

potS ,2wolebsi"yadrepselcyC"fI.2elcycrofemit

.deretne

tratS ,3wolebsi"yadrepselcyC"fI.3elcycrofemit

.deretne

"emuloVlooP"ni

.yadrepo

.sutatsretlif

liwolFilletnIeht

femit

.devomeblliw

.)7*42nurl

.)7*42nurlliwolFilletnIeht

cyC"fI.2elcycrofemit

putesretawfoemulovehtyadrepsemitforebmunehT

tsumolFilletnIeht)potsdnatrats(selcycforebmunehT

%001oterusserp-0ehtmorferusserplaitnereffidehT

ebtonnacataddnayalpsidehtninwohseblliw"FFO"

ebtonnacataddnayalpsidehtninwohseblliw"FFO"

ebt

onnacataddnayalpsidehtninwohseblliw"FFO"

3elcyCpotS

4elcyCtratS

4elcyCpotS

Based on “Pool Volume”, “Turnovers per day” and the total number of hours for Cycle 1 + 2 + 3 + 4

the flow must be calculated:

Flow

=

×

Note: Only enabled cycles are included in the calculation

IntelliFlo VF Installation and User’s Guide

MM.HH95:21-00:1

04:9tluafeD(mp/ma

)mp

MM.H

H95:21-00:1

05:9tluafeD(mp/ma

)mp

MM.HH95:21-00:1

00:01tluafeD(mp/ma

)mp

CycleCycleCycleCycle

+++

potS ,3wo

.deretne

tratS ,4wolebsi"yadrepselcyC"fI.4elcycrofemit

inwohseblliw"FFO"

.deretne

potS ,4wolebsi"yadrepselcyC"fI.

.deretne

""""

dayprTurnoversPoolVolume

4elcycrofemit

4321

lebsi"yadrepselcyC"fI.3elcycrofemit

ebtonnacataddnayalpsidehtninwohseblliw"FFO"

ebtonnacataddnayalpsidehtn

ebtonnacataddnayalpsidehtninwohseblliw"FFO"

Page 27

Filter Mode (Continued)

Service System Soon

Alert

FILTER

1:37

FLOW

RUNNING Schedule

43.GPM

Service System Soon

Alert

Clean Filter Pressure Example

The following example shows the “Clean Filter Pressure” set to 14 PSI.

19

IntelliFlo

FILTER

®

1:37

43.GPM

FLOW

RUNNING Schedule

Select

Feature

Back

Manual

Wash

Escape

Enter

2

Menu

Start

Reset

Stop

Filter Vacuum

On

Warn.

Alarm

Feature

1

Pump newly installed and

system run for the first

time

Filter

10

psi

IntelliFlo

Alert

Service System Soon

Filter Vacuum

Select

On

Warn.

Alarm

Feature

Feature

1

12 months later filter attains

24 psi of internal pressure

which is a 14 psi increase

®

Back

Manual

Wash

Escape

Enter

2

Menu

Start

Reset

Stop

Alert Status

Once the “Alert” is triggered the yellow warning LED is lit and “Alert” is displayed on

the screen. The pump will reduce speed to maintain 14 PSI of head pressure and stop

managing flow. Note the following:

• The % clean filter pressure has reached 100%.

• If parameter is set to 14 PSI every 10% on the display is 1.4 psi on the filter.

• If the parameter is set to 10 PSI every 10% on the display is 1 psi on the filter.

• The filter must be cleaned or backwashed to reduce the pressure. Even if the

system has a cartridge filter the IntelliFlo must be started in Backwash Mode

with a clean filter to reset the fault and "zero" the IntelliFlo's filter status reading.

24

psi

Filter

IntelliFlo

Service System Soon

Filter Vacuum

Select

On

Warn.

Alarm

Feature

1

Alert

Back

Wash

Enter

Start

Feature

Stop

2

®

Manual

Escape

Menu

Reset

Note: For a complete list of IntelliFlo alert warnings, refer to “Alert and

Warning” on page 49.

IntelliFlo VF Installation and User’s Guide

Page 28

20

Filter Mode (Continued)

Using Filter mode with Features mode

IntelliFlo will start and stop at programmed filter cycles 1-4. The filter cycles can be overridden by

“Feature” (3-9 only) as shown in the example below. This may cause the required filter volume to be

achieved earlier.

The “Feature” function is allowed to take control during “Filter” mode. When the feature function stops,

IntelliFlo will continue in “Filter” mode. If only Feature 3-9 is active during a filter cycle, IntelliFlo will

calculate a new filter cycle.

Example: The IntelliFlo was suppose to run in Filter mode from 1:00 to 11:00 to turnover

10 GPM for 10 hours (10 GPM 10 Hours= 6 kGal).

But because Feature 3 has been running 20 GPM for 4 hours (20 GPM 4 Hours= 4,8 kGal),

the IntelliFlo must stop at 8:00 because; 10 GPM* 3 Hours + 20 GPM 4 Hours= 6,6 kGal.

Flow

20 GPM

10 GPM

Filter

Cycle 1

Feature 3

Time

18411

“Feature” 1 and 2 do not have time-of-day functions and do not affect the filter cycle time. The active time

for “Feature” 1 and 2 will not be calculated into the reduced cycle time as shown in the above example.

IntelliFlo VF Installation and User’s Guide

Page 29

Filter Mode (Continued)

Flow Control and Filter Mode

The Filter Mode feature provides the ability of overcoming head pressure loss to provide the required flow

through the plumbing. The flow that the unit can provide is limited by the installed plumbing. If more flow is

demanded than the IntelliFlo can provide, it will ramp to full speed and create pressure.

The following example shows a ramp as flow increases from 50 to 75 GPM.

Speed

Series of

2

small slow

ramps

50 GPM

1

Ramps in

Speed

Quickly

75 GPM

Power and RPM

stabilize and

3

required flow is

attained

21

Valve is moved

Time

IntelliFlo VF Installation and User’s Guide

Page 30

22

MENU

12:24

Time/Contr

Time/Contr

12:24

Set Time

12:29 amam

Time/Contr

12:36

Contrast Level

5

Time/Contr

12:38

Contrast Level

7

Time and Contrast Menu

Use the “Time and Contr” menu settings to set the IntelliFlo system clock and to adjust the control panel

display contrast. The IntelliFlo system clock controls all scheduled start and stop times, functions, and

programmed cycles. The system clock can store the correct time for up to 96 hours after power is shut off.

After 96 hours the clock must be reset to the correct time.

Setting System Time

To set the IntelliFlo system clock:

1. Ensure that the green power LED is on and the pump is

stopped.

MENU

2. Press the Menu button. “Pool Data” is displayed.

Time/Contr

3. Press the Up or Down arrows and select “Time/Contr.”

4. Press the Select button to access “Time/Contr” setting.

Filter Vacuum

5. Press the Select button to change the current minutes and hour.

6. To change the minute and hour digits, press the Left and Right

arrow buttons to select which digit to modify, then use the Up

On

Warn.

Alarm

Feature

and Down arrow buttons to change the selected digit. Note,

that the hours selection is from 01 to 11 for A.M. and P.M. The

system time is displayed on the main screen, A.M. and P.M. are not displayed.

7. Press the Enter button to save the setting.

Setting the LCD Backlight Contrast

To change the contrast of the control panel display :

1. Ensure that the green power LED is on and the pump is

stopped.

IntelliFlo

Select

Feature

2

1

IntelliFlo

Time/Contr

®

12:24

IntelliFlo

Time/Contr

®

12:24

12:29

Set Time

Select

Feature

2

1

IntelliFlo

Back

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

®

12:38

Back

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

®

12:36

Filter Vacuum

On

Warn.

Alarm

Feature

Time/Contr

2. Press the Menu button. “Pool Data” is displayed.

3. Press the Up or Down arrows and select “Time/Contr.”

4. Press the Select button.

5. Press the Up or Down arrows and select “Contrast Level.”

6. Press the Select button. The contrast levels are 0 to 9. Avoid

using 0 unless screen is unreadable in bright sun

7. Press the Enter button to save the setting.

IntelliFlo VF Installation and User’s Guide

Contrast Level

Filter Vacuum

Select

On

Warn.

Alarm

Feature

Feature

2

1

Contrast Level

Back

Manual

Wash

Escape

Menu

Enter

Start

Reset

Stop

Filter Vacuum

On

Warn.

Alarm

Feature

Back

Manual

Wash

Feature

Escape

Menu

Enter