Page 1

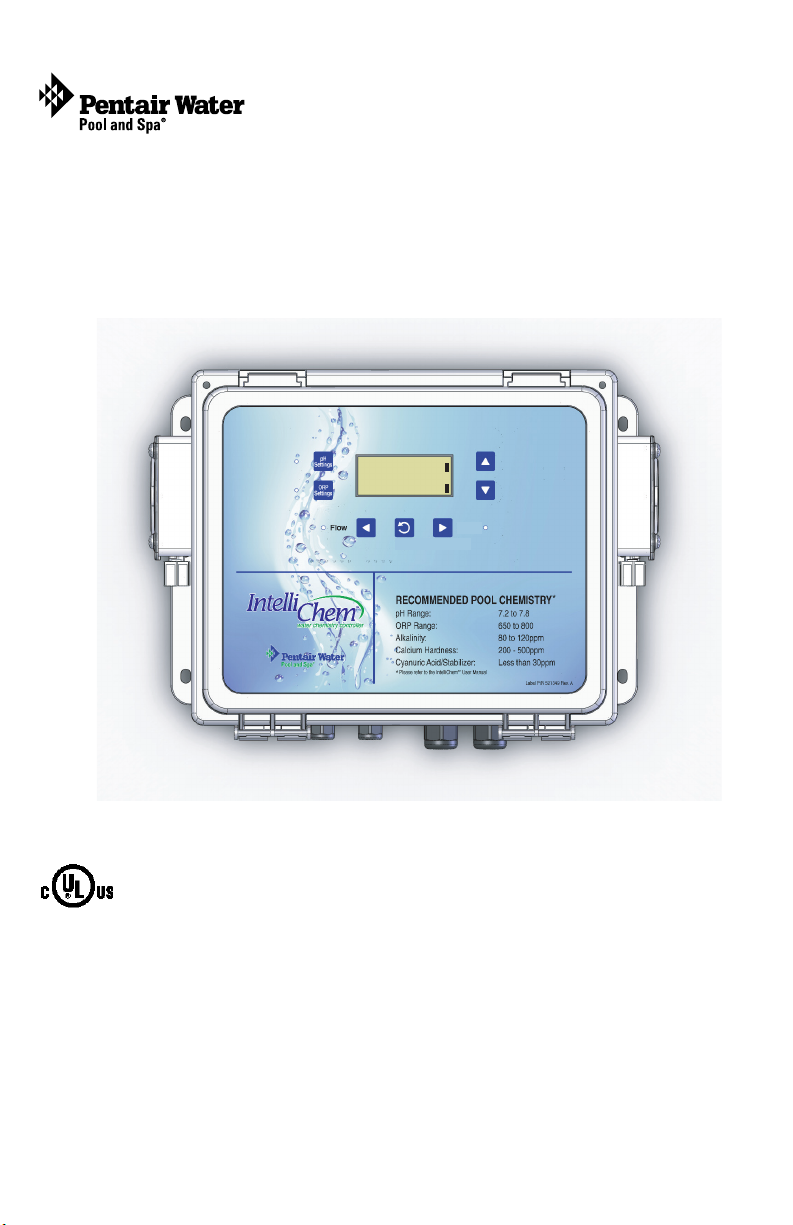

IntelliChem

Water Chemistry Controller

for Swimming Pools

pH OK 7.46

Mixing 00:07:03

ORP OK 450

Mixing 00:07:54

™

Select

Alarm

Menu

Installation and User’s Guide

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IntelliChem™ Installation and User’s Guide

Page 2

Technical Support

Phone: (800) 831-7133 - Fax: (800) 284-4151

visit www.pentairpool.com and www.staritepool.com:

CONTENTS

IMPORTANT WARNING AND SAFETY INSTRUCTIONS ....................................... i

IntelliChem Overview ............................................................................................... 1

Operator Controls Indicators and Alarm LEDs ......................................................... 2

pH Settings and ORP Settings Buttons .................................................................... 3

Auto Setup ................................................................................................................ 6

IntelliChem Menus ................................................................................................... 9

pH Menu ................................................................................................................... 11

ORP Menu ................................................................................................................ 14

Configuration Menu .................................................................................................. 17

Saturation Index ....................................................................................................... 24

Installation ................................................................................................................ 28

Setting up IntelliTouch Automation Control System ................................................. 43

Setting up EasyTouch Automation Control System ................................................. 45

Setting up SunTouch Automation Control System ................................................... 46

Troubleshooting........................................................................................................ 46

Maintenance ............................................................................................................. 51

Replaceable Parts List ............................................................................................. 54

© 2011 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

IntelliChem™, IntelliFlo

®

, IntelliTouch®, EasyTouch®, SunTouch®, IntelliChlor® MobileTouch

and Pentair Water Pool and Spa® are trademarks and/or registered trademarks of Pentair

Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or other

countries. Teflon® is a registered trademark of E.I. Du Pont De Nemoursand Company

Corporation. Unless noted, names and brands of others that may be used in this document

are notused to indicate an affiliation or endorsement between the proprietors of these

names and brands and Pentair WaterPool and Spa, Inc. Those names and brands may be

the trademarks or registered trademarks of those parties or others.

P/N 521363 Rev B - 08/17/11

IntelliChem™ Installation and User’s Guide

®

Page 3

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

SERIOUS BODILY INJURY OR DEATH CAN RESULT IF THIS

PRODUCT IS NOT INSTALLED AND USED CORRECTLY.

INSTALLERS, POOL OPERATORS AND POOL OWNERS MUST

READ THESE WARNINGS AND ALL INSTRUCTIONS BEFORE

USING THIS PRODUCT.

Most states and local codes regulate the construction, installation, and

operation of public pools and spas, and the construction of residential

pools and spas. It is important to comply with these codes, many of which directly

regulate the installation and use of this product. Consult your local building and health

codes for more information.

IMPORTANT NOTICE - Attention Installer: This Installation and User’s

Guide (“Guide”) contains important information about the installation,

operation and safe use of this product. This Guide should be given to the

owner and/or operator of this product.

Before installing this product, read and follow all warning notices

and instructions in this Guide. Failure to follow warnings and

instructions can result in severe injury, death, or property damage.

Call (800) 831-7133 for additional free copies of these instructions. Please refer to

www.pentairpool.com for more information related to this products.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION:

BEFORE WORKING ON INTELLICHEM: Always disconnect power to

the IntelliChem controller at the circuit breaker before servicing.

Failure to do so could result in death or serious injury to service

person, pool users or others due to electric shock.

BE SURE TO DISCONNECT ALL SUPPLY CONNECTIONS BEFORE

SERVICING INTELLICHEM. AC Power may be supplied to the relay

terminals Ex_Relay1 and Ex_Relay2 from other sources. See

page 31 for details.

This product must be installed by a licensed or certified electrician or a qualified pool

professional in accordance with the National Electrical Code (NEC), NFPA 70 or the

Canadian Electrical Code (CEC), CSA C22.2. All applicable local installation codes

and ordinances must also be adhered to. Improper installation will create an electrical

hazard which could result in death or serious injury to pool users, installers or others

due to electrical shock, and may also cause damage to property.

BEFORE USING YOUR POOL, SPA OR HOT TUB, CHECK THE

pH AND SANITIZER LEVELS OF THE WATER.

Do not permit children to operate this equipment.

i

When mixing acid with water, ALWAYS ADD ACID TO WATER.

NEVER ADD WATER TO ACID.When adding any chemical to the pool/

spa, be sure to follow the manufacturer’s instructions thoroughly.

DO NOT MIX SODIUM HYPOCHLORITE AND MURATIC ACID

Risk of electrical shock. Connect IntelliChem to a ground-fault

interrupter-circuit (GFCI). Contact a qualified electrician if you cannot

verify that the receptacle is protected by a GFCI.

IntelliChem™ Installation and User’s Guide

Page 4

ii

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

WARNING CHEMICAL BURN HAZARD: Make sure all pumps are

switched off at the main circuit breakers at the house before drilling into

any pipes. Securely fasten all electrical, water and chemical lines.

Locate chemical feed pumps and chemical storage tanks in a safe and

secure area.

Strictly follow the acid manufacturers safety and handling protocols

including hand, body and eye protection when transferring or handling

acid. Safety precautions should be used when handling Muriatic acid to

control pH water levels. Muriatic acid can cause serious body injury and

damage pool equipment. Extra care must be taken when installing,

maintaining and operating acid pump feed systems. Acid is dangerous

to handle and should be properly contained, transported, poured,

stored, and dispensed.

• Check the pH and sanitizer levels of the water before use.

• Periodically use an independent pH and Chlorine test kit to verify that pH

and chlorine is at a safe level. If the pH and Oxidation Reduction Potential

(ORP) or Flow Cell sensors are broken, depleted or dirty with oils, lotions,

or other contaminants, they can report inaccurate results to the system

causing incorrect water chemistry, which could harm people or

equipment.

• Check the IntelliChem main status display each day to ensure there are

no Alarm messages. See “Troubleshooting” on page 46 for more

information.

When using IntelliChem with a pool pump timer: The Association of Pool and Spa

Professionals (APSP) recommends that all water in a residential pool pass through the

filtration system at least once every 12 hours (referred to as pool water turnover).

However, many factors have an effect on actual pump and filter system run times. Pool

size, source of water, direct sun light, indoor/outdoor, screened and unscreened, filtration

system, cold or hot weather, swimmer load, rain, organic debris, algae, etc., are all factors

which contribute to either more or less pool pump and filter system run times. Because of

these differences, it is extremely difficult to set an initial run time (starting point) for the

pool pump and chlorinating system. Try initially setting the pool pump timer to 12 hours. It

will take a few days to get just the right amount pool pump operating time. When the

Chlorinator is wired with a pool pump timer (see page 6) results will vary greatly from one

pool installation to the next, so this should be discussed with either the pool builder or

your pool professional.

Using CO2 for pH Control

Plaster pools and pools using salt-chlorine generators typically cause a slow pH rise

which must be managed. With IntelliChem, muriatic acid or carbon dioxide (CO2) is

dispensed into the filter system’s return water as needed until the Flow Cell pH sensor

detects the proper pH level. Using CO2 for pH control eliminates the need to handle and

stored acid and can be a safer method. As CO2 gas is injected into the pool water, it

dissolves and creates carbonic acid. This weak acid is very efficient at lowering pH with

the added benefit of self-limiting if the CO2 is over-fed.

IntelliChem™ Installation and User’s Guide

Page 5

Overview

IntelliChem is a pH and ORP sensing device that dispenses correct amount of chlorine

or bromine, muriatic acid or CO2 gas. IntelliChem provides continual analysis of your

swimming pool water sanitation and pH levels, providing real-time status information to

dispense the proper amount of muriatic acid (pH reducer) and chlorine or bromine for the

correct sanitization and pH balance. IntelliChem operates with or without a salt chlorine

generator to provide a self-replenishing supply of chlorine generated from salt.

IntelliChem can also connect to carbon dioxide (CO2) liquid gas tanks to lower pH in

your swimming pool water. When CO2 dissolves into water it produces weak neutral

bicarbonate salts which reduces pH. CO2 is environmentally friendly and produces no

secondary pollution into the treated water by salts such as chlorides or sulfates. CO2

does not corrode metal equipment and does not require any special piping. IntelliChem

supports Pentair Water Pool and Spa® (“Pentair”), EasyTouch®, IntelliTouch® and

SunTouch® automation control systems for pH and ORP control. IntelliChem also

supports IntelliChlor® salt chlorine generator (SCG) to help manage your pool water

sanitizer levels.

Operating IntelliChem

Before operating IntelliChem, it’s important to test and adjust your pool water chemistry

to the recommended pool industry levels found in this manual (see page 19). If you are

using an IntelliChlor salt chlorine generator, adjust the salt levels to the recommended

levels in the IntelliChlor Installation and User’s Guide (P/N 520589). During normal

IntelliChem operation, no user input is required, IntelliChem will automatically sense

ORP and pH levels. The current ORP and pH levels are regularly displayed on the

control panel LCD display. Use the pH Settings or ORP Settings buttons to view or adjust

supply levels. The IntelliChem “Auto Setup” feature provides screen prompts for first-time

setup or standard configurations such as setup reminder times, calculating feed times,

proportional limits and alarms. For details, see page 6.

First Balance Your Pool Water

IMPORTANT: To help keep your pool water balanced follow these steps:

1. Use a Test Kit (with fresh testing reagents) to measure the pH, alkalinity,

and calcium hardness of the pool water. For greater accuracy, Pentair

recommends the AcuCheck3 Test Kit to measure pH, chlorine ppm, and

alkalinity levels (P/N 745000110). “Balanced” water has proper levels of

pH, Total Alkalinity and Calcium Hardness. This “balanced” water is

neither corrosive or scaling. The pH (0-14) value is the scale of relative

acidity or alkalinity. Recommended pH range is from 7.2 to 7.6. The

IntelliChem default pH value is 7.5 (see page 12).

2. Be sure the pool chlorine level is balanced. Ideal free chlorine level

should be between 1.0 - 3.0 parts per million (ppm).

3. Use the online Langelier Saturation Index (LSI) calculator to diagnose

the water balance in your pool or the IntelliChem built-in LSI calculator

(see page 24-27). Refer to:

http://www.pentairpool.com/pool-owner/resources/calculators/langelier/

Note: A Saturation Index value of 0 indicates the water is chemically in balance. If the

Index is a minus (-) value, corrosive tendencies are indicated. If the Index is a plus (+)

value, scale-forming tendencies are indicated. A Saturation Index value between +0.3

to -0.3 is considered satisfactory in a swimming pool. See Saturation Index menu on

page 24.

1

IntelliChem™ Installation and User’s Guide

Page 6

2

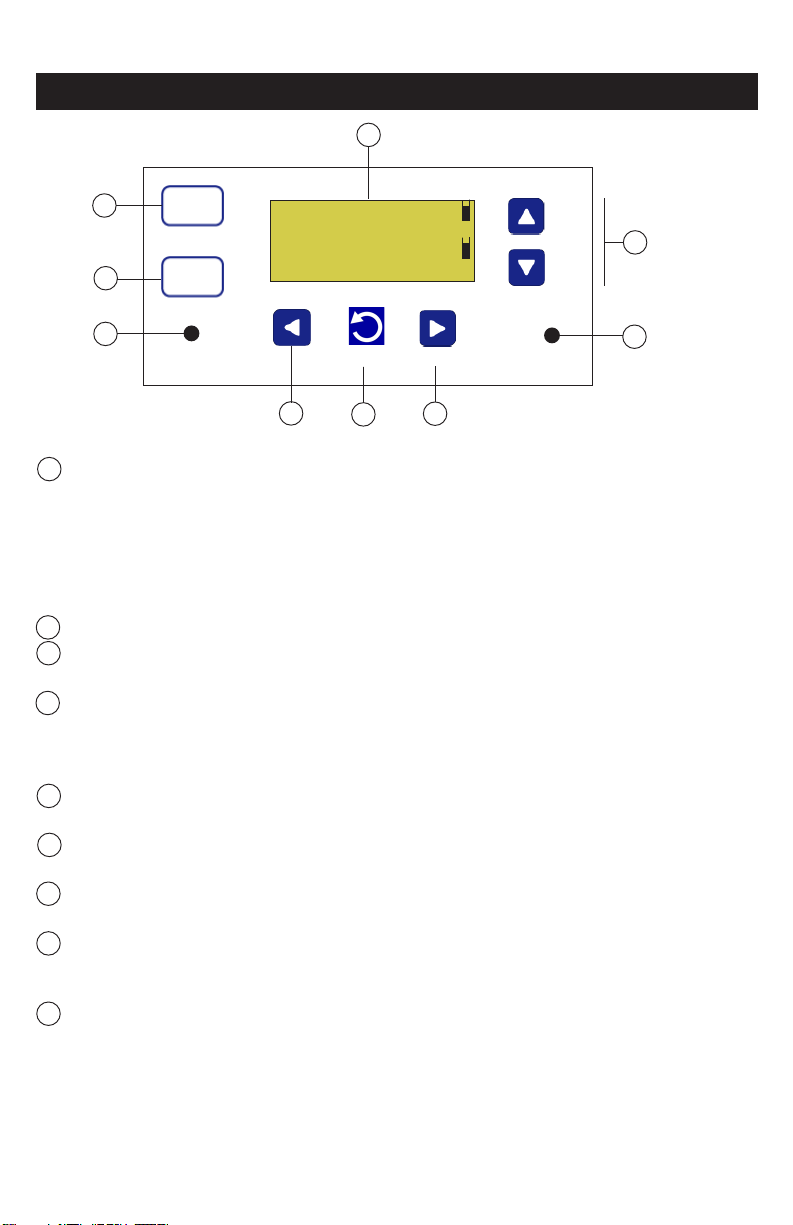

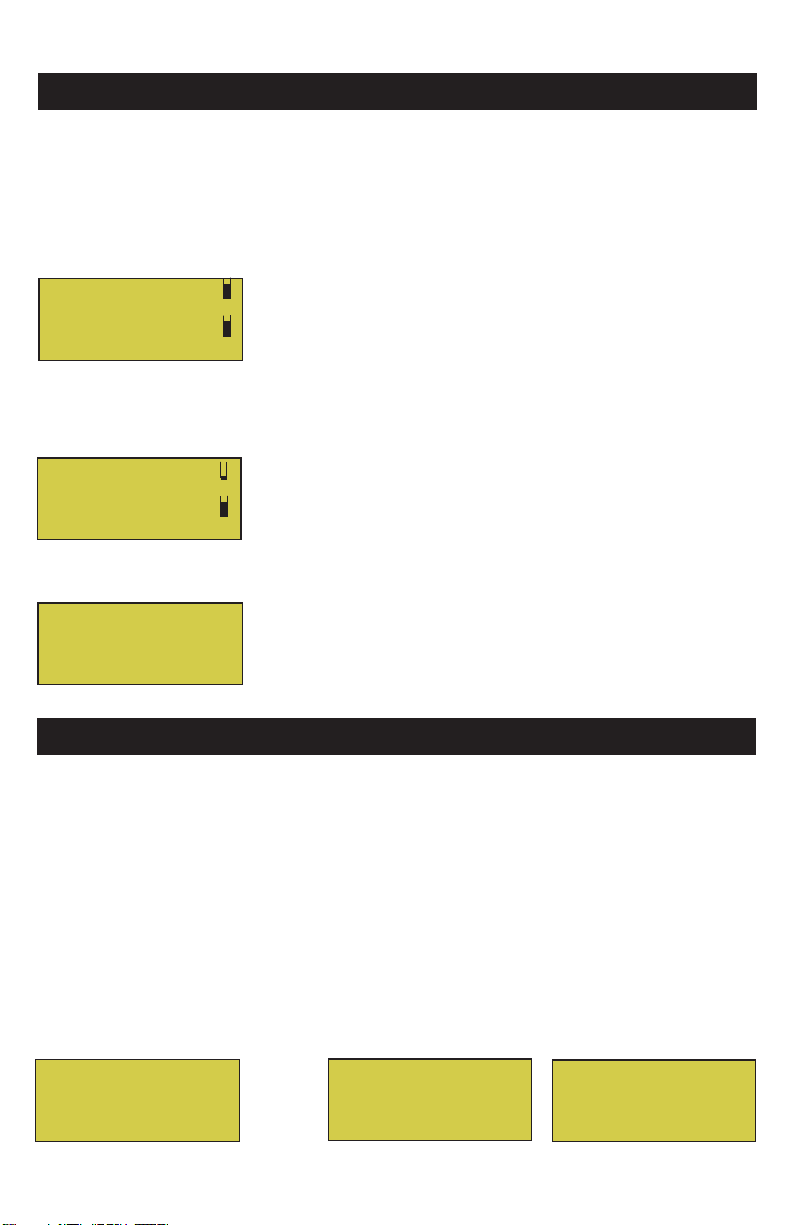

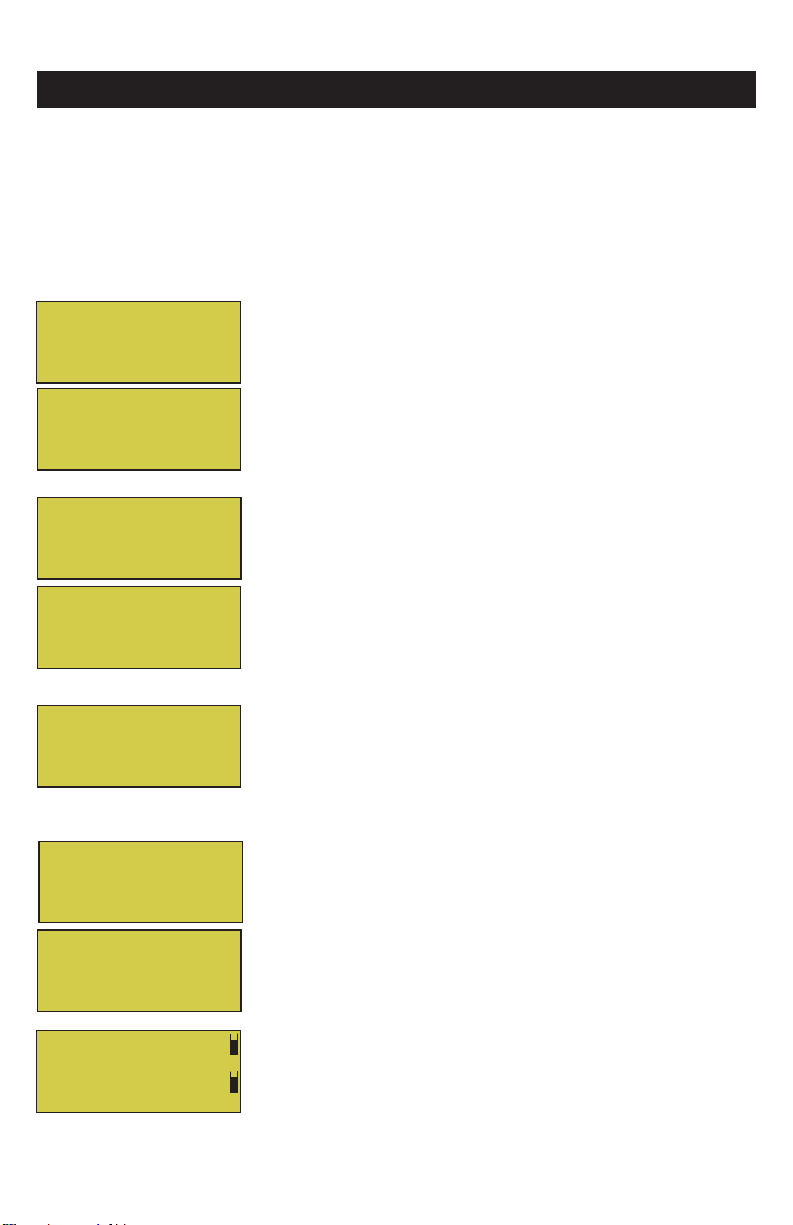

Operator Controls, Indictor and Alarm LEDs

CONTROL PANEL DESCRIPTION

2

pH

SETTINGS

pH OK 7.46

Mixing 00:07:03

ORP OK 450

3

4

ORP

SETTINGS

FLOW

Mixing 00:07:54

5

1

MENU

6

Select

7

ALARM

9

8

Control Buttons and LEDs:

1

Liquid Crystal Display (LCD) with backlighting: Displays system status information

and IntelliChem main menu. Display backlight and menu on and off time (30

seconds to 24 hours) can be set via the “LCD Timeout” menu feature. See

“Configuration” menu page 17).

Display viewing modes: Select between two display modes: Basic: pH and ORP

status with alarms messages. Advanced: pH, ORP, status, alarm messages and

process timers.

pH Settings button: Access the pH settings (see page 3).

2

3

ORP Settings button: Access the Oxidation Reduction Potential (ORP) settings

(see page 3).

Flow LED: Green LED on indicates flow is detected. LED will blink during flow delay.

4

LED off indicates no flow in the system. If flow is not present, no chemical feeding or

IntelliChem activity is allowed. LED brightness can be adjusted via the Configuration

“Display Mode” menu (see page 17).

Left arrow button: Scroll through sub-menu items or move cursor left when editing a

5

setting.

Menu button: Access the IntelliChem main menu (see page 11). While in menu

6

mode, used to exit a menu level. All items are saved as soon as they are changed.

Right arrow button: When in menu mode, selects menu main and sub-menu item,

7

scroll through sub-menu items or move cursor right when editing a setting.

Alarm LED: LED is on if an alarm condition occurs. Display shows alarm message

8

and status (see page 48). LED brightness can be adjusted via the Configuration

“Display Mode” menu (see page 17).

Up/Down arrow button: When in a menu mode, use / to scroll through main

9

menu and sub-menu items, increase, decrease or change a setting or value. Also,

used for moving to next sub-menu page 1/2 - 2/2.

IntelliChem™ Installation and User’s Guide

Page 7

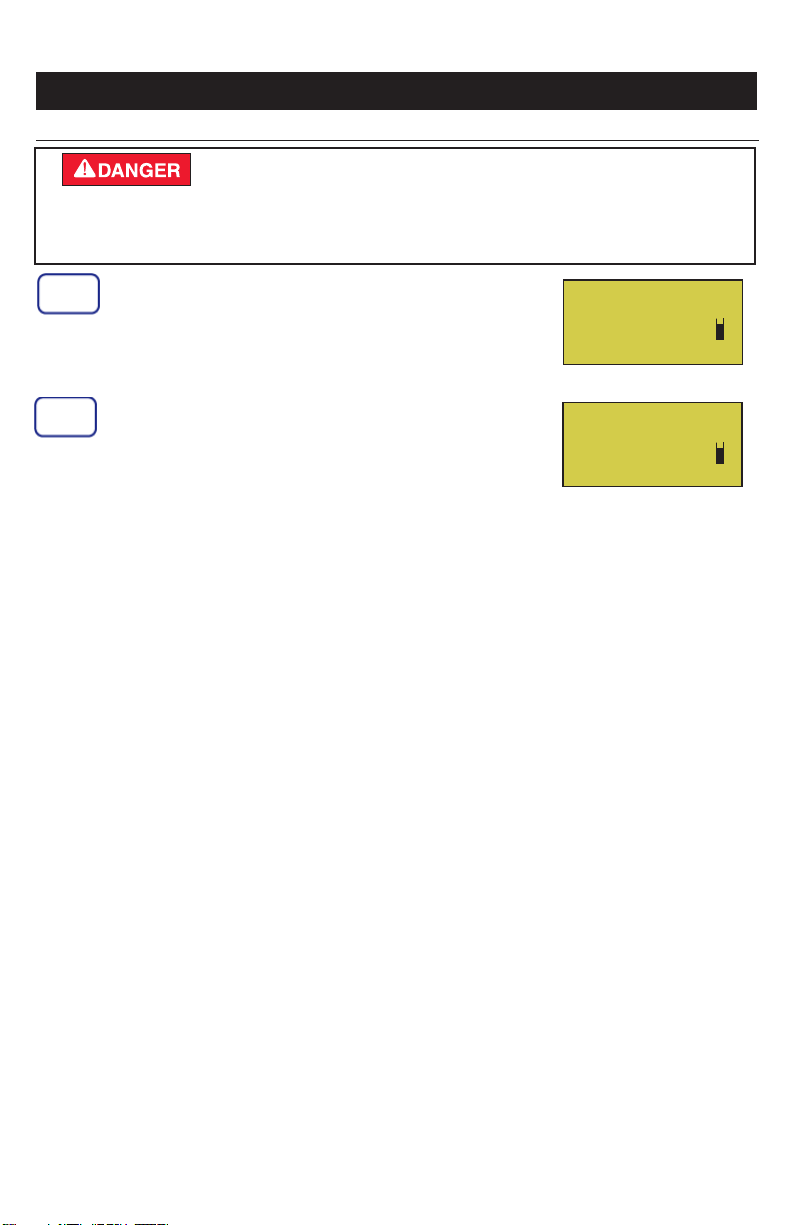

pH Settings and ORP Settings Buttons

pH Dosage (dispense acid)

DO NOT manually feed pH (acid) and ORP sanitizer (chlorine)

at the same time without sufficient water flow through the piping

system. Combining these two chemicals without sufficient water flow for mixing

will result in the formation of hazardous gas. This menu item will be displayed as

Override [Wait] during no-flow and flow-delay time period.

pH Settings button: Press the pH Settings

pH

SETTINGS

button to access the pH dosage settings.

pH Settings

Override [Dose]

Level Gauge: 5

Limit cleared

3

ORP

SETTINGS

ORP Settings button: Press the ORP Settings button

to access the Oxidation Reduction Potential (ORP)

settings. The ORP is the sanitization quality of the

water of a given solution.

ORP Settings

Override [Dose]

Level Gauge: 5

Limit: [Clear ]

Note: To exit pH Settings and ORP Settings, press the MENU button.

Password Protect: The pH Settings and ORP Settings screens are not accessible

when the Password Lock is set to “ALL”. Set the Password Lock to “OFF” or “MENU” to

access these screens (see page 5).

Override (pH): Press the / Right or Left arrow button to toggle between “Dose” or

“Stop”. Select “Dose” to dispense muriatic acid or CO2 and select “Stop” to stop

dispensing acid or CO2 (pH Settings LED is on). To exit, press the MENU button or

press the Down button to select the “Level Gauge” feature. The Override feature is

not available when CO2 is setup to “Feed to Setpoint.”

Override (ORP): Press the / Right or Left arrow button to toggle between “Dose”

or “Stop”. Select “Dose” to dispense chlorine (or bromine) and select “Stop” to stop

dispensing chlorine (ORP Settings LED is on). To exit, press the MENU button or press

the Down button to select the “Level Gauge” feature. The Override feature is not

available when IntelliChlor is setup to “Feed to Setpoint.”

Level Gauge indicator: Press the / Up/Down button to select this feature. The

level gauge (volume based) and hour glass (time based) icon is a visual

representation of the amount of acid (pH Settings) or chlorine (ORP Settings) available

in the container. Press / six times to fill the gauge (container full). The indicator

displays six horizontal bars when full. The level gauge is not available if the doser is

unable to determine the pump dispense rate, the supply volume, or if there is no

supply “reminder” set up (see page 13-15). The gauge is displayed as an “hour glass”

if the supply is based on time rather then volume (see page 6)

Limit [Clear]: Press the / to select this feature. Press the / to clear the current

dosage limit timer. After pressing the button, “CLEARED” is displayed, indicating that

the current dosage limit is cleared.

IntelliChem™ Installation and User’s Guide

Page 8

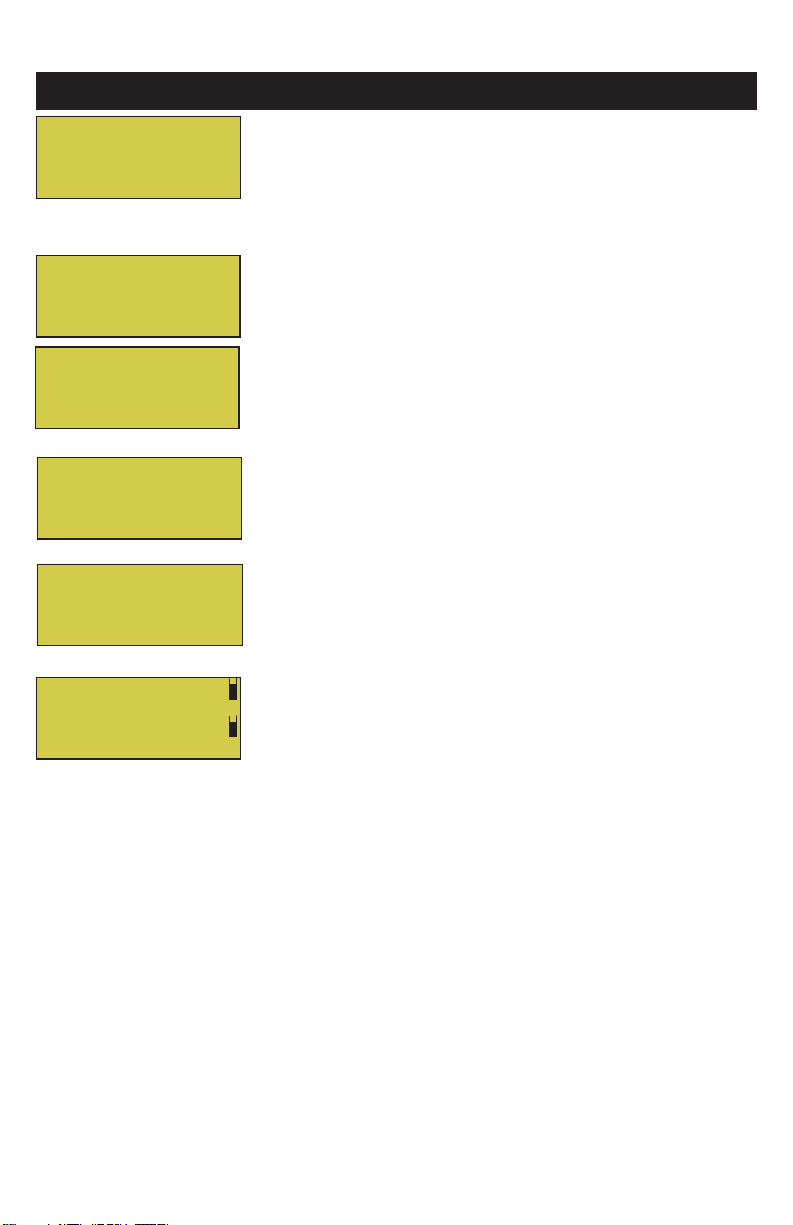

4

IntelliChem System Power Up Screens

IntelliChem

v1.010 01/12/11

Pentair Water

Pool and Spa

AUTO CALIBRATION

Power-up Sequence: During power-up IntelliChem displays

the initialization screens before the main status screen is

displayed. During this initial power up sequence, IntelliChem

performs an internal self test and continues with a system

calibration. The first screen includes the current software

version and date.

AUTO CALIBRATION is displayed each time IntelliChem is

powered up.

AUTO CALIBRATION

pH 6.35 7.65 OK

ORP 738 398 OK

***PASSED***

IntelliChem Auto

__Setup Wizard__

Press MENU to go

to each new step

Awaiting

POWER&FLOW DELAY

H:00 M:14 S:18

please wait...

pH OK 7.5

ORP OK 450

In the next auto-calibration sequence the pH and ORP meters

are tested with on-board circuitry and calibrated to the built-in

reference devices. An out-of-tolerance condition is

immediately reported as an error so the user can have the

unit serviced.

The very first time IntelliChem is powered up and after a

factory reset, the Auto Setup Wizard start screen is displayed.

Otherwise access the wizard from the main menu

(see page 6).

The normal start up screen will simply be this one, awaiting

P

ower On & Flow Delay. The countdown timer shows the

remaining time before the unit starts reading the probes and

controlling the doser.

Main Status Screen: After IntelliChem has completed the

Flow Delay the main status screen displays the

measurements of the connected pH and ORP sensors.

IntelliChem™ Installation and User’s Guide

Page 9

Set Password Protect

The password protect feature prevents access to certain menus and prohibits all menu

changes and manual feeds. For more information, see Set Password on page 18.

To set the password protect:

5

Set Password

PW [1234]

Lock [Off ]

Locked - Please enter

password

> 1234

1. Press MENU / Configuration

and / Set Password.

2. Set Password (PW): Press the / Up/Down

arrow button to select the first password digit (0-9).

3

. Press the / Right/Left arrow button to move the

cursor to the next digit.

4. Press the / Up/Down arrow button to select the

second password digit. Repeat steps 3 and 4 for the

third and fourth password digit.

5. Press the Right arrow button to move the cursor

to the Lock Menu setting.

6. Press the / Up/Down arrow button to select

OFF: Do not enable control panel button lockout.

ALL: Lockout MENU, pH Settings and ORP Settings

buttons). Tank Levels cannot be changed.

MENU: Lockout MENU button (not pH Settings and

ORP Settings buttons). Setpoints or Sat Index values

TA, CYA, CH cannot be changed.

7. To exit, press the MENU button (press three times to

return to the main screen.

Tip: Setting the password 0000 allows you to enter a

protected screen by pressing MENU. Also, once the

password is entered, access is granted for the duration

specified by the Menu timeout setting in the

Configuration/Display Mode menu (see page 17).

Password Protect and IntelliTouch, EasyTouch and SunTouch

Automation Control Systems

Note: If the password lock is enabled from IntelliChem it will also be locked out on

the IntelliTouch, EasyTouch or SunTouch automation control system.

When IntelliChem is controlled by the IntelliTouch, EasyTouch or SunTouch automation

control system, if the password is set and locked on the IntelliChem, it cannot be

changed from the automation control panel. To change a “LOCKED” password from the

automation system, enter the password on the IntelliChem, it will remain active for the

Menu Timeout MM:SS period. During that time, the automation system will be able to set

the appropriate settings, just as you would from the IntelliChem front panel. Receiving

updated settings from automation will continue to extend the Menu Timeout, just as if

you're accessing the menu on the IntelliChem itself.

IntelliChem™ Installation and User’s Guide

Page 10

6

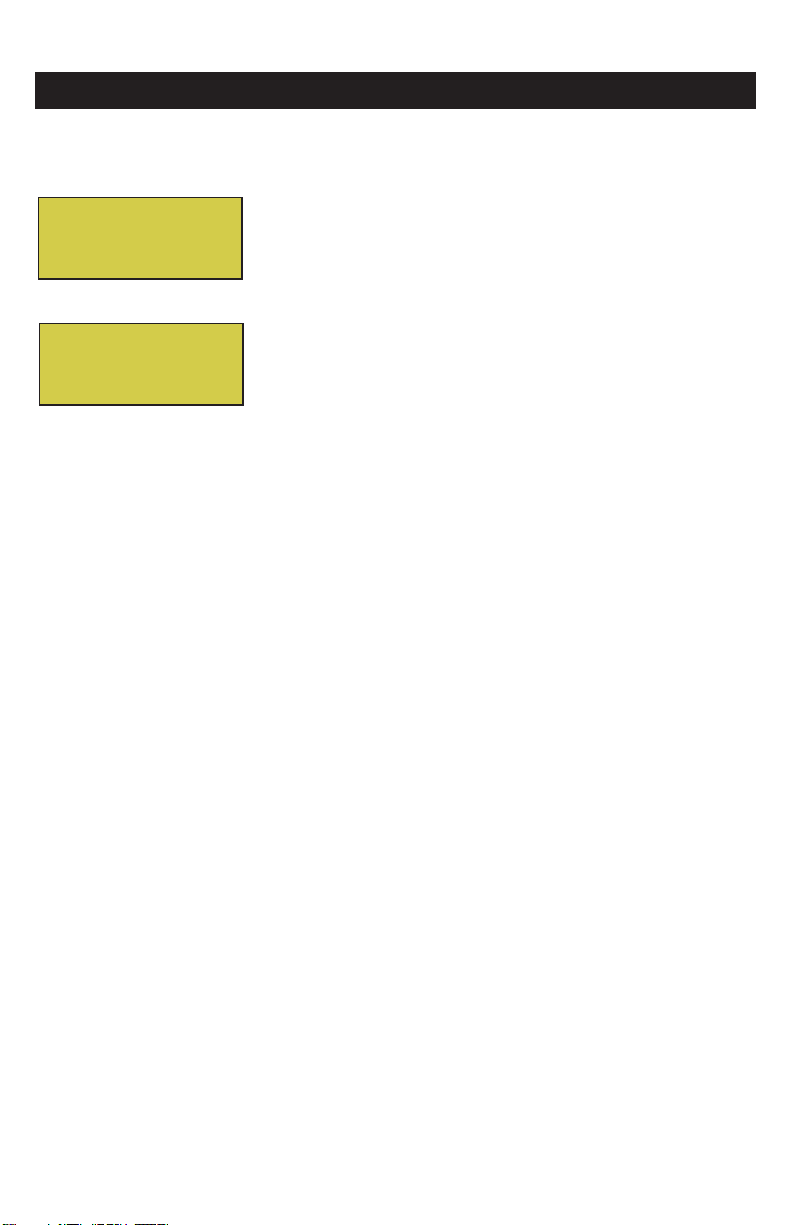

Display Modes

IntelliChem main status screen can be setup to display basic or advanced system

information. To setup the Display Mode, see “Configuration” menu on page 17. The

Basic display mode shows the current pH and ORP measurements including a message

describing any existing pH (line two) and ORP (line four) alarms. The Advanced display

mode shows all the current measurements and alarm messages as well as dose and mix

timers showing the progress of those processes.

Basic display mode

pH >OK 7.4

-.72 Scaling

ORP OK 730

Monitoring

Advanced display mode

pH HIGH 7.91

pH Dose Limit

ORP OK 683

Mixing 00:07:54

Basic and Advanced Display with Error Messages

NO FLOW DETECTED

Check pump, flow

Cell, filter,

and valves.

The Basic mode displays the current pH and ORP

measurements (pH in10th and ORP in 5mV) with any alarms

and tank levels if enabled.

Note: Alarms are displayed on all Basic and Advanced modes.

>OK or <OK is displayed as soon as the value exceeds

alarm trip point. That is replaced with “HIGH/LOW” after the

specific alarm delay time period.

Displays three different Alarms. The example screen shows:

Dose limit, high reading and chemical tank low alarm. These

can co-exist. The advanced mode displays the current pH and

ORP high precision measurements (extra digit. e.g. pH=100th

- ORP=1mV resolution), alarms, tank levels, process

messages and timers.

If IntelliChem detects the pool water circulation pump is not

active, a NO FLOW message is displayed. ORP and pH

values are not measured when there is no flow, and therefore

not displayed.

The displays shows tH CO2 - OR

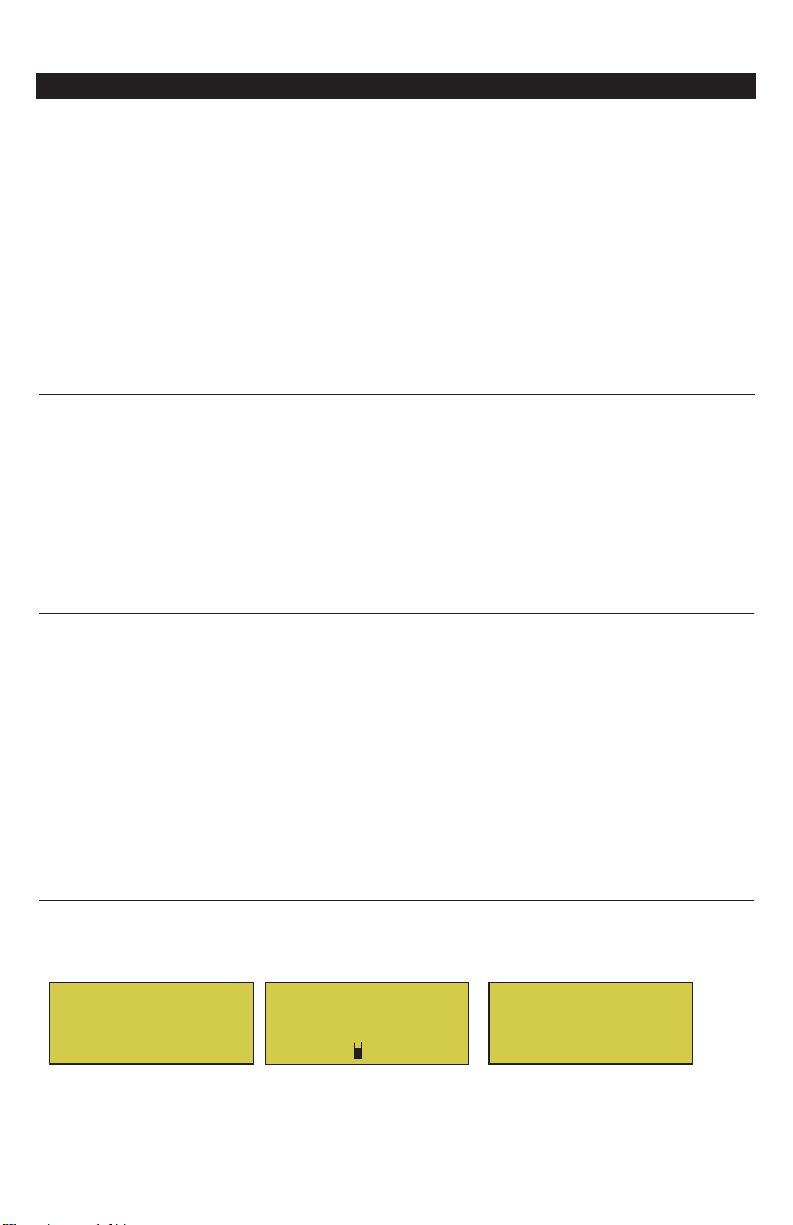

Auto Setup

Use the Auto Setup feature for first-time setup or standard configurations. Follow the onscreen prompts and enter information about your system configuration (pH/ORP internal

or external pumps, pool size, filter time, chemical container size etc. IntelliChem uses

this information to automatically setup reminder times, calculate feed times, proportional

limits and alarms. The following describes the Auto Setup screen. Press the MENU

button to access the Auto Setup menu. To change a menu setting or value press the

Up/Down arrow button. Press the MENU button to save each selection.

Press MENU

Previous Values: Use to recalculate new dose times etc., if no custom settings exist. Not

recommended for custom settings; use the menu directly to make these changes.

Reset All: Make major configuration changes that may have conflicts with previous

settings.

/

Auto Setup

IntelliChem Auto

__Setup Wizard__

Press MENU to go

to each new step

IntelliChem™ Installation and User’s Guide

To exit

Auto

Setup,

press

Dosing will

resume when you

_exit this menu_

Press any button

Would you

like to use

previous values?

[Yes | Reset All]

/

Page 11

Auto Setup (Continued)

What is your

Hardware Setup?

pH ORP

[L_Pump R_pump]

Press the

/

Up/Down arrow button to

scroll through the six configurations.

What is your

Hardware Setup?

pH ORP

[L_Pump ICHLOR]

What is your

Hardware Setup?

pH ORP

[RELAY2 ICHLOR]

What is your

Hardware Setup?

pH ORP

[RELAY2 RELAY1]

What is your

Hardware Setup?

pH ORP

[CO2/R2 L_PUMP]

What size is the

body of water?

Volume: 10.0K

Units: gal-US

What size is the

body of water?

Volume: 10.0K

Units: gal-US

Enter doser pump

rated output for

pH: 1 GPD (1-400)

Select Use Time ("0")

if the doser pump's

GPD (gallons-perday) feed rate is

unknown.

Enter doser pump

rated output for

pH: 1 GPD (1-400)

ORP: 1 GPD

How long should

CO2 dose be

H:00 M:05 S:00

How long does

your filter run?

Daily:H:08 M:00

Press the MENU

select next screen

How long does

your filter run?

Daily: H:24 M:00

What size is the

body of water?

Volume: 10.0K

Units: gal-US

What size is the

body of water?

Volume: 10.0K

Units: gal-US

What size is the

body of water?

Volume: 10.0K

Units: gal-US

What is the pH

Container Size?

1.00 gal-US

Gauge: 6

Enter ORP info on

next screen.

What is the pH

Container Size?

1.0 gal-US

Gauge: 6

How long does

your filter run?

Daily: H:08 M:00

What is the pH

Container Size?

1.0 gal-US

Gauge: 6

How long does

your filter run?

Daily: H:08 M:00

What is the pH

Container Size?

1.0 gal-US

Gauge: 6

Enter ORP info on

next screen.

How long does

your filter run?

Daily: H:08 M:00

pH Chem

Reminder in:

H:00 M:00

7

Continue on next page

What is the pH

Container Size?

1.0 gal-US

Gauge: 6

IntelliChem™ Installation and User’s Guide

Page 12

8

Auto Setup (Continued)

What is your

Hardware Setup?

pH ORP

[CO2/R2 ICHLOR]

Is your pool

water balanced?

[No]

YES

How long should

each CO2 dose

be?

H:00 M:05 S:00

NO

Balance water

chemistry before

beginning auto-

matic control

What size is the

body of water?

Volume: 10.0K

Units: gal-US

Finished Setup.

Verify your new

settings in the

pH & ORP menus!

IntelliChem System Default Values

pH

pH Set Point: 7.5

pH Alarm High: 7.8

pH Alarm Low: 6.8

pH Alarm Delays: 5 min. for both

Sensitivity: Low (Off for CO2)

ORP

ORP Set Point: 700

ORP Alarm High: 750

ORP Alarm Low: 650

ORP Alarm Delays: 5 min. for both

Sensitivity: Low (Off for IntelliChlor)

pH Lockout: 7.8

Miscellaneous Default Values

Display Mode: Basic

Control Panel LED Brightness: 10%

Menu Timer: M:02 S:30

Menu Backlight Timer: M:00 M:20

Power-On Delay: 14 minutes

Flow Switch Delay: 1 minute

Dose Priority: Simultaneous dosing

Password 1234 - Lock = Off

How long does

your filter run?

Daily: H:08 M:00

pH Chem

Reminder in:

H:00 M:00

IntelliChem™ Installation and User’s Guide

Page 13

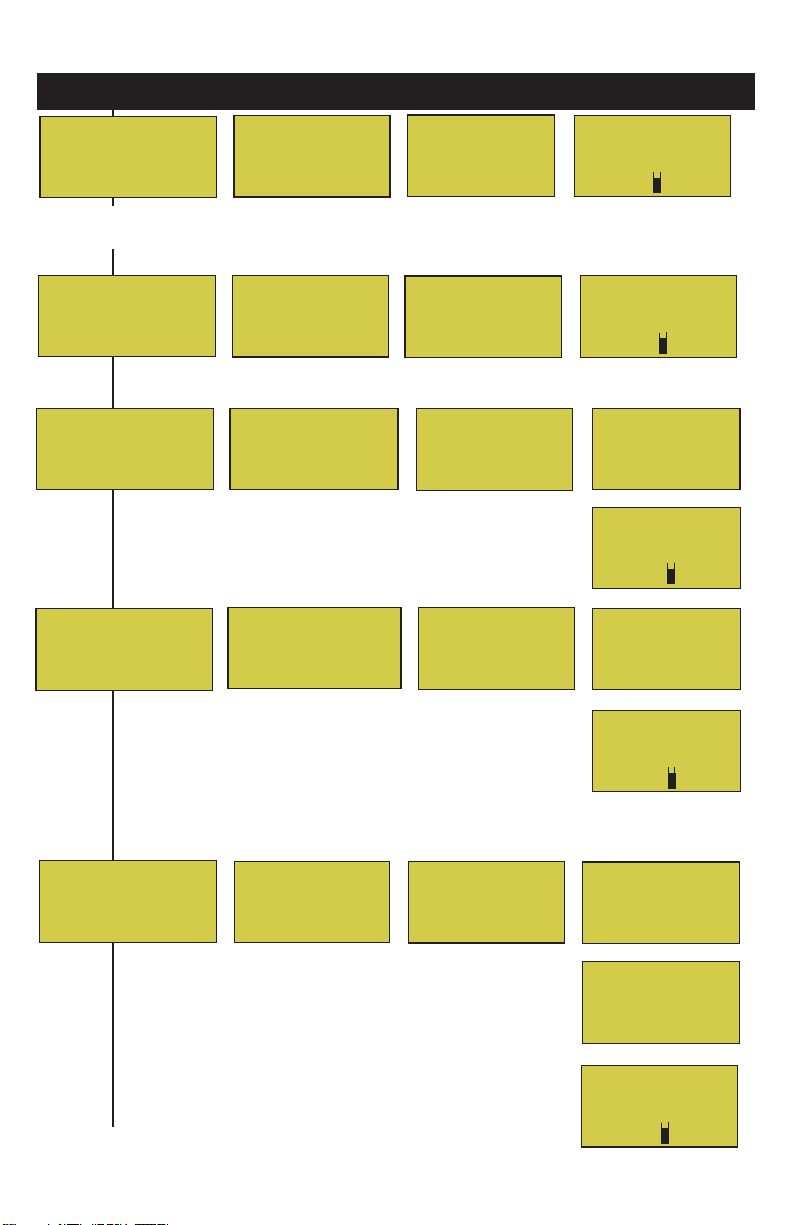

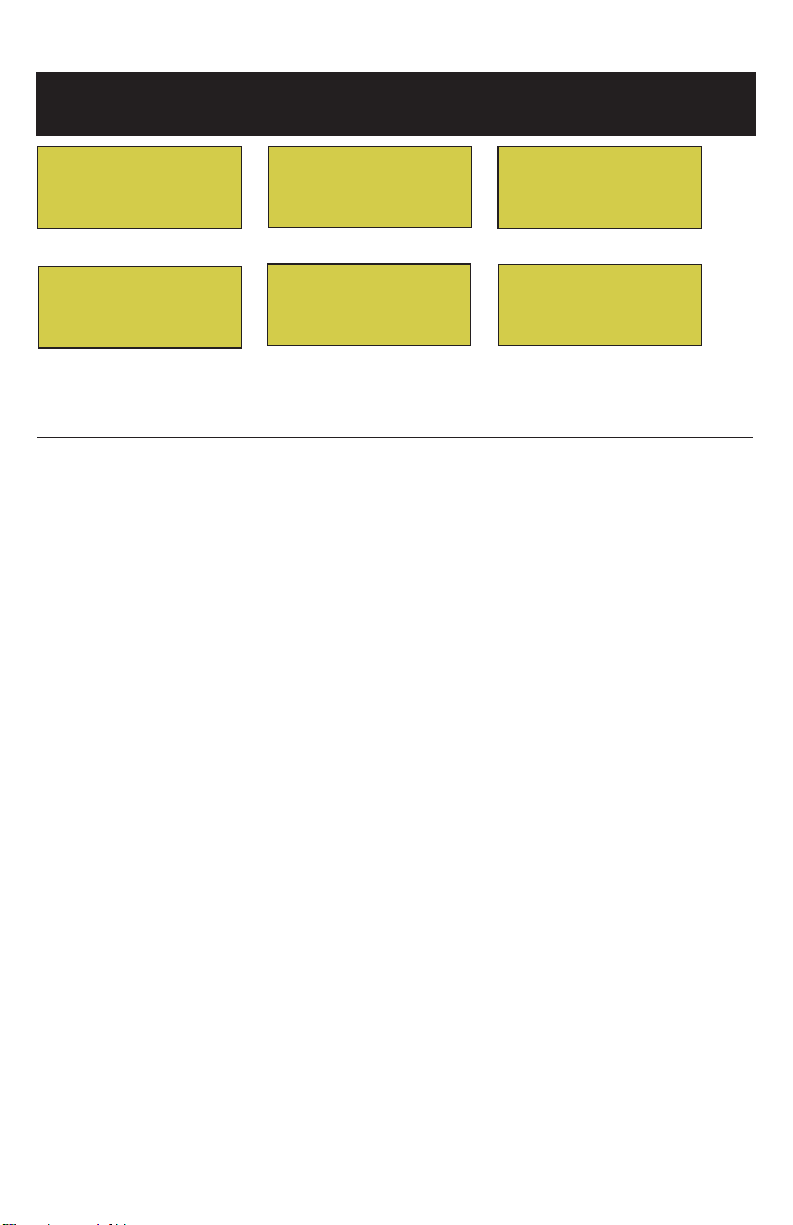

MENUS

MAIN SCREEN

9

PH MENU

(page 11)

ORP MENU

(page 14)

SAT INDEX

AUTO SETUP

pH Dosage (Page 1/2) Dosage (For liquid; Volume/Time):

(For CO2; Time or to set point): Mixing Time: H:24 M:59

pH Dose by Volume (Page 2/2) Dose: [0-9999], Limit: [0-64350],

Units: [oz/ml], Clear [Manual]

pH Dose by Time (Page 2/2) Dose: [00:00:00], Limit: [00:00:00], Clear: [Power-On]

pH Dose to Setpoint (Page 2/2) Limit: [00:00:00], Clear: [24hr Flow]

pH Setpt: 7.5 (use Left/Right button to adjust pH set point)

pH Tweak - reading = 7.xx tweak: 0.0 (+/- 0.3)

pH Supply (Page 1/2) Units: gal-US/gal-UK/Liters/Time, Chemical: [Acid, pH-, Base, pH+] -

Page 2/2 - Capacity: 0.000-200.00 gal-US/galUK/Liters - Gauge: Egg timer or tank gauge -

Page 2/2 Time: Reminder in: H:100 M:00

Sensitivity: - [Low/High/Off] - Full Dose at 0.5pH (Low - Liquid, CO2),

(High 0.2pH from set point).

pH Alarms: Page1/2 High 7.8 - Delay 00:05:00 - Page 2/2 Low: 6.8 Delay 00:05:00

ORP Dosage (Page 1/2) Dosage (For liquid; Volume/Time):

(For SCG; Time or to set point): Mixing Time: H:24 M:59

ORP Dose by Volume (Page 2/2) Dose: [0-9999], Limit: [0-64350], Units: [oz/ml], Clear [Manual]

ORP Dose by Time (Page 2/2) Dose: [00:00:00], Limit: [00:00:00], Clear: [Power-On]

ORP Dose to Setpoint (Page 2/2) Limit: [00:00:00], Clear: [24hr Flow]

ORP Setpt: 700 (use Left/Right button to adjust ORP set point)

ORP Tweak - reading = xxx tweak: 0.0 (+/- 50mV)

ORP Supply (Page 1/2) Units: gal-US/gal-UK/Liters/Time, Chemical: [Chlorine/Bromine] -

Page 2/2 - Capacity: 0.000-200.00 gal-US/galUK/Liters - Gauge: Egg timer or tank gauge -

Gauge: Egg Timer or tank gauge - Page 2/2 Time: Reminder in: H:100 M:00

Sensitivity: - [Low/High/Off] - Full Dose at 50 mV ORP (Low - Liquid),

(High 20 mV from set point, Off (IntelliChlor OFF)

ORP Alarms: Page1/2 High 750 - Delay 01:00:00 - Page 2/2 Low: 650 Delay 02:00:00

See page 24 for details - pH: 7.5 - Temp: 00°F -

See page 6 for details

- CH: xxx - TDS: xxx - TA:xx = CYA: xx Recalc/Tab:

CONFIGURATION

(page 17)

Pool Details:Volume: 0.2K-230K (200-230,000 Liters max) Units:

Gal US (gal-US/gal-UK/Liters), Daily Hrs/Mins

Display Mode: Display Mode: Basic/Advanced, Brightness Front LEDs: (0-100%),

Menu/BkLt Hrs/Mins. (24 hrs -30sec.)

Delays: Power-on: 1-60 mins. (15min default) - FlowSwitch: 1-60 mins. (1 min default) Doser/Probe: Seconds 0,15,30,60secs.

Set Password: PW [1234] - Lock [OFF/MENU/ALL]

Preferences: pH Lockout: 7.8, Preferences 2/2: Saturation Index, Alarm: +/- 0.3,

Delay: 00:30:00. Probe Check: [No/Yes]

Dose Priority: [Simultaneous pH Priority]

Diagnostics: Software Rev, Meter Test {Auto Calibration),

Probe Test (Open Probe Test) Timers,

Chlorinator, Status Codes, Factory Reset, Self Test Sequence

Hardware: pH Control: 1/2 Doser Type [Internal Pump, External/Relay,

CO2 Ext/Relay, None] - pH Control 2/2 Flow: xx GPD

See page 22 for details

IntelliChem™ Installation and User’s Guide

Page 14

10

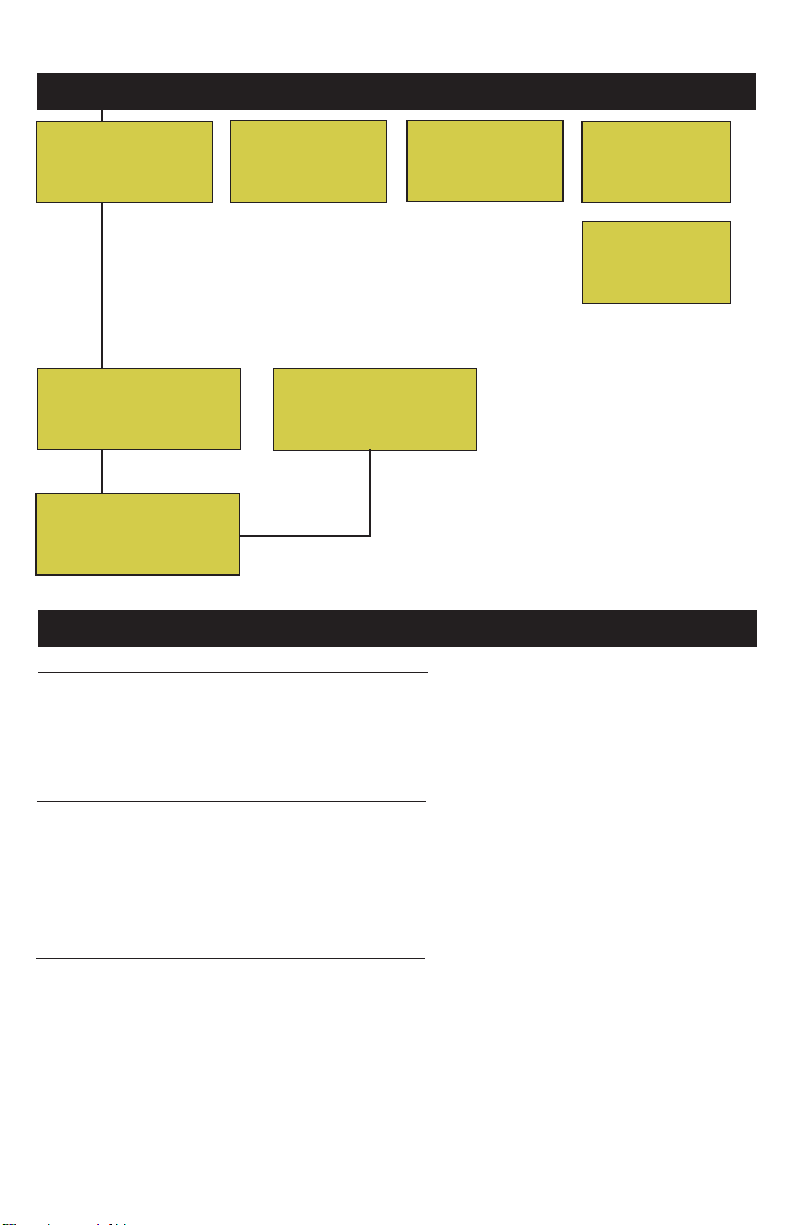

Navigating IntelliChem Menus

The following examples show how to navigate the main menus and sub-menus. Press

the MENU button to access the main menu. Press the

menu item and select items in a sub-menu. Press

. To change a menu setting or value press the

page

the MENU button to exit and return to the previous menu items. Note: Settings are

automatically save when changed.

Example: To change the pH dosage settings (pH Dosage screens 1/2 and 2/2):

Press MENU

pH Menu

/

pH Menu

ORP Menu

Saturatn Index

Auto Setup

ORP Menu

Saturatn Index

Auto Setup

Configuration

pH Dosage

pH Setpt: 7.5

pH Tweak

pH Supplies

pH Dosage 1/2

Dose: by Volume

Mixing Time:

H:00 M:59

pH Dosage

1. Press the / Up/Down arrow button to scroll

through the main menu items. For this example

choose pH menu.

2. Press the Right arrow button to select the

pH menu.

3. Press arrow button to select pH Dosage (page 1

of 2). Press / to toggle between pH Dosage

page 1/2 and page 2/2.

4. From pH Dosage page 1/2, press the to select

Dose (feed method). To change the feed method

press / to change the selection: “by Volume” or

“by Time”.

5. Press the to select the next item. The cursor

moves down to the “Mixing Time” hours setting

(H:00).

6. Press the / to adjust the Mixing Time hours

between feeding acid. Press to select the

pH Dosage 2/2

Dose Limit Units

3 21 [oz]

Clear [Power-On]

minutes. Press

/ to adjust the minutes. After adjustment, the

display shows the new setting. Note: Press either

/ button to scroll forward or backwards within

this sub-menu.

7. Select 1/2 page indicator. Press the / buttons to

pH Dosage 1/2

Dose: by Volume

Mixing Time:

H:09 M:59

pH Menu

ORP Menu

Auto Setup

Configuration

pH OK 7.46

Mixing 00:07:03

ORP OK 450

select the next pH Dosage screen (2/2).

8. Use / buttons and / buttons to select and

change the “Dose” (amount of liquid dispensed

before waiting for a mix time), Limit (amount of

liquid dispensed in one day, Units (apply to dose

and limit) and clear dose limits setting.

9. Press the MENU to return to the previous pH

Dosage page 1/2 menu items.

10. Press the MENU again to exit pH Dosage menu.

Note: All settings are immediately save when

changed.

Mixing 00:07:54

Right arrow button to select a

/

to select previous/next item on a

/

Up/Down arrow button. Press

IntelliChem™ Installation and User’s Guide

Page 15

Menu Description

pH Menu

pH Menu

ORP Menu

Saturatn Index

Configuration

pH Dosage

pH Setpt: 7.2

pH Tweak

pH Supplies

by Volume by Time by Setpoint

pH Dosage 2/2

Dose Limit Units

1200 64100 [mL]

Clear [Manual]

To access the pH Menu: Press MENU

screen 1/2 displays the current dose method (by Volume, Time or to Setpoint).

pH Dosage 2/2

Dose 00:33:45

Limit 04:14:00

Clear [Power-On]

pH Menu

pH Dosage (for Internal and External Pumps)

pH Dosage (page 1/2)

Mixing Time: Select the amount of time in hours and minutes that IntelliChem will wait in

between pH feeding. It should be set to allow sufficient mixing time for the chemicals to

become distributed throughout the pool. The pH Mixing Time is set by Auto Setup.

Dose (by Volume/Time): Choose the feed method: “by Volume” and “by Time” are

available choices for liquid dosers, as determined by the hardware setup. If CO2 is

selected, then the available choices are “by Time” and “To Setpoint”.

pH Dosage (page 2/2)

Dose (Volume): Displays the current dose size (0-9999) in ounces [oz] or milliliters [ml].

Set the amount of ounces (or milliliters) that IntelliChem will feed pH (acid) each time

IntelliChem calls for pH chemicals. The Dose (Volume) is set by Auto Setup wizard based

on pool volume and filter run time.

Dose (Time/Setpoint): Displays the current pH dose (feed) time. Sets the amount of time

in hours, minutes and seconds that IntelliChem will feed pH (acid) each time IntelliChem

calls for pH chemicals. The pH dose time is set by Auto Setup. The Dose (Time) is set by

Auto Setup wizard based on pool volume and filter run time. Dose (to Setpoint) does not

have a dose amount, only a time limit.

Limit (Time/Volume): Displays the current feed limit. Sets the maximum amount of

time/volume in hours, minutes and seconds or volumetric units that will be allowed to

feed pH chemicals. As a safety feature, the IntelliChem will only allow a certain amount

of pH chemicals to feed into the system in a 24 hour period. Set the maximum amount of

time in hours (0-24) that will be allowed to feed. IntelliChem tracks each dose time, and

adds them together. When the maximum dose time is reached or exceeded, the ORP

feed system is prevented from feeding until the next 24 hour period begins, or when the

feed timers are cleared manually. The default pH Limit is based on a safe limit of 2 ppm of

the size of the pool, up to a 5 oz maximum. The Limit (Time/Volume) is set by Auto Setup

wizard based on pool volume and filter run time.

pH Dosage 1/2

Dose: by Time

Mixing Time:

H:00 M26

pH Dosage 2/2

Dose to Setpoint

Limit 00:08:00

Clear [24hr ]

pH Dosage - The ph Dosage

11

Continue on next page.

IntelliChem™ Installation and User’s Guide

Page 16

12

pH Menu (Continued)

pH Dosage (page 2/2)

Continue

Clear: Select Power-On to clear the pH dose limit time when IntelliChem is powered on.

Select Manual to manually clear the pH dose limit timers and select 24 Hrs to clear

timers automatically each 24 hour period of continuous operation.

To protect the pool water, IntelliChem will automatically shutdown pH and ORP feed

control and display an alarm message if IntelliChem (or any other dispensing device)

runs non-stop for more than the selected Limit time or volume. This prevents IntelliChem

from non-stop feeding pH reducer, because of a sensor error or external problem with

the pool. This allows you to evaluate the pool chemistry before continuing with pH

feeding.

pH Set Point

Displays the current pH set point value. Adjust the pH set point to meet pool and spa

chemistry standards. The adjustable range is from 7.2 to 7.6 in increments of 0.1. The

default pH set point value is 7.5.

To adjust the acid feed pH set point:

Press

/

to decrease or increase the current pH set point value.

Press MENU pH Menu

pHSetpt

Note: When using CO2, parameters are the same as above.

pH Tweak

The exact reading of each individual pH sensor can vary because of water makeup and

variances in probe condition age, etc. The pH Tweak menu feature allows you to adjust

the pH sensor reading to match the manual reading taken. The adjustable range is +/-

0.3. After adjusting the pH value, the main screen should now display the same value as

the manual reading.

To adjust the pH sensor level:

Press MENU

/

pH Men

The current value is displayed (reading = x.xx). Press

(+/- 0.3). To remove the tweak, set the level back to 0 (zero).

u

pH Tweak

/

to adjust the pH sensor level

pH Supplies

pH Supply (page 1/2)

Units: Select gal-US, gal-UK, Liters or Time (hours/minutes)*.

Chemical: Use Acid, (pH -) or Base (pH+).

pH Supply 1/2

Unit: USGal

Chemical:

[Acid, pH-]

IntelliChem™ Installation and User’s Guide

pH Supply 2/2

Capacity:

4.00 gal-US

Gauge: 3

pH Supply 2/2

Reminder in:

H:1000 M:00

Gauge: 6

Page 17

13

pH Menu (Continued)

pH Supply (page 2/2)

Capacity: Select from 0 to 200 maximum gal-US, gal-UK, or Liters.

*Time (Reminder in:

feature becomes a Reminder feature, as in an egg-timer. This can be used to trigger an

alarm, based on cumulative feed times as to when to check the CO2 cylinder. Set the

reminder time in hours (0-8760) and minutes (00-59) on ORP Supply page 2/2. Note:

Entering the hours and minutes time (H:00 M:00) will display the hour glass icon on the

main screen.

Level Gauge (liquid only): Displays level gauge when using liquid chemical doser. Tank

icon symbol is used for liquid chemical configurations that include valid supply and

doser feed rate information.

H:xxx M:xx) If the supply Units were set to Time, the Capacity

pH Sensitivity

IntelliChem can adjust the feed times for pH depending on how close the current reading

is to the set point. This helps to prevent overshooting and makes it easier for IntelliChem

to reach the exact set point.

Low= (default) Full dose at 0.5 pH above setpoint

High= Full dose at 0.2 pH above setpoint

Off= Full dose at 0.005 pH above setpoint

For example: When set to LOW (full dose at 0.5 above setpoint), if pH setpoint is 7.2 and

pH reading is 7.7 or above, a full dose amount is dispensed. As the pH comes closer to

setpoint, say 7.45 (0.25 above setpoint - or- half the 0.5 pH value), the dispensed amount

will be 1/2 of the specified dosage. And, at 0.05 (1/10th of 0.5 value) above setpoint

(7.25), the dosage will be 10% of that specified in the dosage menu. In that case, if the

dosage was specified to be 10 ounces, IntelliChem will dispense only 1 ounce at a time.

This can be confusing to someone who is watching the IntelliChem because it will

appear to not be dosing the full amount; therefore, in the Advanced display mode, the

process timer will be shown as "%Dosing 0.1 oz", the "%" indicating that the dosage is

reduced due to this Sensitivity feature.

To set the pH Sensitivity level: Press MENU - pH Menu / pH Sensitivity

pH Alarms

IntelliChem automatically displays a screen message indicating the pH level has

reached or exceeded the HIGH (7.8) or LOW (6.8) pH alarm level settings.

IntelliChem will automatically set a high and low alarm for the pH level. The Delay time is

the amount of time between the detected alarm condition and when IntelliChem displays

the alarm message on the main screen. The Delay setting is adjusted in increments of 15

seconds.

To set the pH alarm “High” level and “Delay” time (page 1/2):

Press MENU pH Menu

(page 1/2 is High Level Alarm, page 2/2 is Low Level Alarm)

Press

to select the alarm, High level and Delay Time (00:50:00).

To set the pH alarm “Low” level and “Delay” time (page 2/2):

Press MENU

Press

/

/

pH Menu

to change pH alarms Low level and Delay Time (00:05:00).

pH Alarms

pH Alarms

/

pH Alarms

/

/

Low / Delay (2/2)

IntelliChem™ Installation and User’s Guide

Page 18

14

ORP Menu

ORP Dosage (dispense chlorine or bromine)

pH Menu

ORP Menu

Saturatn Index

Configuration

ORP Dosage

ORP Setpt: 700

ORP Tweak

ORP Supply

ORP Dosage 1/2

Dose: by Time

Mixing Time:

H:00 M26

by Volume by Time by Setpoint

ORPDosage 2/2

Dose Limit Units

1200 64100 [mL]

Clear [Manual]

To access the ORP Menu: Press MENU

ORP Dosage screen 1/2 displays the current dose method (by Time or to Setpoint).

ORPDosage 2/2

Dose 00:33:45

Limit 04:14:00

Clear [Power-On]

ORP Menu

ORPDosage 2/2

Dose to Setpoint

Limit 00:08:00

Clear [24hr ]

ORP Dosage - The

ORP Dosage (for Internal and External Pumps)

ORP Dosage (page 1/2)

Mixing Time: Select the amount of time in hours and minutes that IntelliChem will wait in

between ORP dosing. It should be set to allow sufficient mixing time for the chemicals to

become distributed throughout the pool. The ORP Mixing Time is set by Auto Setup.

Dose (by Volume/Time): Choose the feed method: “by Volume” and “by Time” are

available choices for liquid dosers, as determined by the hardware setup. If IntelliChlor

(SCG) is selected, then the available choices are “by Time” and “To Setpoint”.

ORP Dosage (page 2/2)

Dose (Volume): Displays the current dose size (0-9999) in ounces [oz] or milliliters [ml].

Set the amount of ounces (or milliliters) that IntelliChem will dose ORP (chlorine/

bromine) each time IntelliChem calls for ORP chemicals. The Dose (Volume) is set by

Auto Setup wizard based on pool volume and filter run time.

Dose (Time/Setpoint): Displays the current ORP dose (feed) time. Sets the amount of

time in hours, minutes and seconds that IntelliChem will feed ORP (chlorine/bromine)

each time IntelliChem calls for ORP chemicals. The ORP dose time is set by Auto Setup.

The Dose (Time) is set by Auto Setup wizard based on pool volume and filter run time.

Dose (to Setpoint) does not have a dose amount, only a time limit.

Limit (Time/Volume): Displays the current feed limit. Sets the maximum amount of

time/volume in hours, minutes and seconds or volumetric units that will be allowed to

feed ORP chemicals. As a safety feature, the IntelliChem will only allow a certain amount

of ORP chemicals to feed into the system in a 24 hour period. Set the maximum amount

of time in hours (0-24) that will be allowed to feed. IntelliChem tracks each dose time,

and adds them together. When the maximum dose time is reached or exceeded, the

ORP feed system is prevented from feeding until the next 24 hour period begins, or when

the feed timers are cleared manually. The default ORP Limit is based on a safe limit of 2

ppm of the size of the pool, up to a 5 oz maximum. The Limit (Time/Volume) is set by Auto

Setup wizard based on pool volume and filter run time.

Clear: Select Power-On to clear the ORP dose limit time when IntelliChem is powered

on. Select Manual to manually clear the ORP dose limit timers and select 24 Hrs to clear

timers automatically each 24 hour period of continuous operation.

IntelliChem™ Installation and User’s Guide

Page 19

15

ORP Menu (Continued)

ORP Set Point

Displays the current ORP set point value. Adjust the ORP set point to meet pool and spa

chemistry standards. The adjustable range is from 650 to 800 in increments of 10. The

default ORP set point value is 700.

To adjust the ORP set point:

Press

/

to decrease or increase the current ORP set point value.

Press MENU ORP Menu

ORP Setpt

Note: When using IntelliChlor SCG, parameters are the same as above.

ORP Tweak

The exact reading of each individual ORP sensor can vary because of water makeup

and variances in probe condition age, etc. The ORP Tweak menu feature allows you to

adjust the ORP sensor reading to match the manual reading taken. The adjustable range

is +/-50mV. After adjusting the ORP value, the main screen should now display the same

value as the manual reading.

To adjust the ORP sensor level:

Press MENU

/

pH Menu

The current value is displayed (reading = x.xx). Press

ORP Tweak

/

to adjust the ORP sensor

level (+/- 50 mV). To remove the tweak, set the level back to 0 (zero).

ORP Supplies

ORP Supply (page 1/2)

Units: Select gal-US, gal-UK, Liters or Time (hours/minutes)*.

Chemical: Use Chlorine or Bromine.

ORP Supply 1/2

Unit: USGal

Chemical:

[Chlorine]

ORP Supply 2/2

Capacity:

4.00 gal-US

Gauge: 3

ORP Supply 2/2

Reminder in:

H:1000 M:00

Gauge: 6

ORP Supply (page 2/2)

Capacity: Select from 0 to 200 maximum gal-US, gal-UK, or Liters.

*Time (Reminder in: H:xxx M:xx) If the supply Units were set to Time, the Capacity

feature becomes a Reminder feature, as in an egg-timer. This can be used to trigger an

alarm, based on cumulative feed times as to when to clean the SCG plates. Set the

reminder time in hours (0-8760) and minutes (00-59) on ORP Supply page 2/2. Note:

Entering the hours and minutes time (H:00 M:00) will display the hour glass icon on the

main screen.

Level Gauge (liquid only): Displays level gauge hour when using liquid chemical doser.

Tank icon symbol is used for liquid chemical configurations that include valid supply and

doser feed rate information.

IntelliChem™ Installation and User’s Guide

Page 20

16

ORP Menu (Continued)

ORP Sensitivity

IntelliChem can adjust the feed times for ORP depending on how close the current

reading is to the set point. This helps to prevent overshooting and makes it easier for

IntelliChem to reach the exact set point.

Low= (default) Full dose at 50mV below setpoint

High= Full dose at 20mV below setpoint

Off= Full dose at 1mV below setpoint

For example: When set to LOW (full dose at 50mV below setpoint), if ORP setpoint is 700

and ORP reading is 650 or below, a full dose amount is dispensed. As the ORP comes

closer to setpoint, say 675mV (25mV below setpoint - or- half the 50mV value), the

dispensed amount will be 1/2 of the specified dosage. And, at 695 (1/10th of 50mV

value) below setpoint (700), the dosage will be 10% of that specified in the dosage

menu. In that case, if the dosage was specified to be 10 ounces, IntelliChem will

dispense only 1 ounce at a time. This can be confusing to someone who is watching the

IntelliChem because it will appear to not be dosing the full amount; therefore, in the

Advanced display mode, the process timer will be shown as "%Dosing 0.1 oz", the "%"

indicating that the dosage is reduced due to this Sensitivity feature.

To set the ORP Sensitivity level: Press MENU - ORP Menu / ORP Sensitivity

ORP Alarms

IntelliChem automatically displays a screen message indicating the ORP level has

reached or exceeded the HIGH (750 mV) or LOW (650 mV) pH alarm level settings.

IntelliChem will automatically set a high and low alarm for the ORP level. The Delay time

is the amount of time between the detected alarm condition and when IntelliChem

displays the alarm message on the main screen. The Delay setting is adjusted in

increments of 15 seconds.

To set the ORP alarm “High” level and “Delay” time (page 1/2):

Press MENU ORP Menu

(page 1/2 is High Level Alarm, page 2/2 is Low Level Alarm)

Press

to select the alar

To set the ORP alarm “Low” level and “Delay” time (page 2/2):

Press MENU

Press

/

/

ORP Menu

to change ORP alar

ORP Alarms

m, High level and Delay Time (00:50:00).

ORP Alarms

ms Low level and Delay Time (00:05:00).

/

ORP Alarms

/

Low / Delay (2/2)

/

IntelliChem™ Installation and User’s Guide

Page 21

Configuration Menu

Pool Details

From this menu, you can set your pool size, units to display and the daily run time which

should match your daily pool pump filtration time.

Volume: Pool volume (size). Select range is 200 - 230,000 gal (gal-US, gal-UK and

Liters).

Units: Select units to display in English (gal-US), (gal-UK) and Metric Liters.

Daily: This daily run time is used for calculating dose and mix times. It is set and used in

the Auto Setup script and should be the amount of time the pool pump/filter runs each

day.

To access the Pool Details menu:

Press MENU

Configuration

Pool Details

Display Modes

Mode: Selects which display mode is displayed: Basic or Advanced, Basic mode

displays the current pH and ORP levels with any alarms and fuel gauge if enabled.

Advanced mode displays high resolution pH and ORP levels and process messages,

timers (see page 6).

LEDs: Adjusts the brightness level (0-100%) of the front panel LEDs.

Menu: Adjusts the amount of time (minutes/seconds) the menu will be on each time the

control panel is activated and also the time the entered password is valid.

BkLt: Adjusts the amount of time (hours/minutes) the controller screen backlight will be

on each time the control panel is activated.

To access the display mode menu: Press MENU

Press

/

to adjust display settings.

Configuration

Display

17

Delays (minutes)

Power-On: Sets the delay time from power up to the first display screen reading. The

adjustable time is from 1 to 60 minutes. The default power on time is 14 minutes

Flow Switch: Sets the delay time from when the Flow Switch is active to the first display

screen reading. The adjustable time is from 1 to 60 minutes. The default flow switch

delay time is one minute.

Doser/Probe: Sets the delay time from when the Doser turns on to when it takes the

next probe measurement. Adjustable time is 0 to 60 seconds. Default is 15 seconds.

Use longer times to prevent interaction of doser from affecting the measurement.

To access the delays menu: Press MENU

Press

/

to set the delay settings.

Configuration

IntelliChem™ Installation and User’s Guide

Delays

Page 22

18

Configuration Menu (Continued)

Set Password

IntelliChem menus, the pH button and ORP button on the control panel can be password

protected. Once a password has been set, IntelliChem will not allow access to the menu

system and no changes to be made without entering the password. For more information

see page 5.

PW: Enter a four digit password [0000]. Each digit can be assigned 0-9.

Lock: Select OFF, MENU (password protect the main menu) or ALL (password protect all

control panel buttons. Once the password is entered, access is granted for the duration

specified by the Menu timeout setting in the Configuration/Display Mode menu. If the

menus are locked, changes via the automation interface will also be locked out.

To access the password menu:

Press MENU

Press

password, first try the default password 1234, then call Customer Support for

assistance.

Configuration

/

to select the digit and

Set Password

/

move to next digit. Note: If you forget the

Preferences (1/2)

To access the delays menu: Press MENU

Press / to adjust the following settings.

/

Configuration Preferences

Preferences 1/2

pH Lockout: 7.8

Probe Check: No

pH Lockout: is the pH reading at which IntelliChem will no longer dose sanitizer

(Chlorine/Bromine). Above pH of 7.8 it is generally understood that the ORP reading is

suppressed and therefore will not be used to administer additional sanitizer. Just

bringing the pH level down will raise the available chlorine and the effective ORP. At this

trip point, an alarm message will be shown on the screen and ORP doses will cease.

Range is 7.7 to 8.2, default is 7.8.

Probe Check: Enables the Open Probe Test which can determine if the pH and ORP

sensor probes are disconnected or non-functional. Although it will not help determine if

probes need cleaning, it will catch many types of conditions including bad wiring,

disconnected cable, and open/broken probe sensor. If enabled, this feature tests the

probes before starting each dose. This validates that the readings used to determine that

the dose is required were accurate. If disabled, the probes should periodically be tested

with the Configuration/Diagnostics/Probe Test menu item. Check all connections and

replace the probes and cables if necessary.

IntelliChem™ Installation and User’s Guide

Page 23

19

Configuration Menu (Continued)

Preferences (2/2)

Preferences 2/2

Saturation Index

Alarm: +/- 0.3

Delay: 00:30:0

Saturation Index

Alarm: +/- 0.3: If the Saturation Index (SI) level is in the “Corrosive” or “Scaling” range,

this feature allows you to enter a Saturation Index (SI) alarm threshold value between +/-

0.1 to +/- 0.9 (+/- 3 default). Select “Disabled” to disable the Alarm feature.

Delay: The Alarm Delay feature sets the delay time before the SI Alarm (see above)

message is displayed. Enter the delay time from 00:15:00 to 24:00:00 (30 minutes

default). Note: Once the SI has passed the threshold for the delay period, an alarm

message is displayed showing the Saturation Index Alarm (along with other pH alarms)

that includes the value and description.

pH >OK 7.44

-.72 Corrosive

ORP OK 730

Monitoring

These alarm messages are also displayed on the IntelliTouch, EasyTouch and SunTouch

control panel.

pH >OK 7.44

+.32 Scaling

ORP OK 730

Monitoring

Dose Priority

To access the delays menu: Press MENU

Press / to select option.

Dose Priority: pH Priority or Simultaneous.

Depending on how the IntelliChem chemical dosers are plumbed and how much water

is circulating in the system where the chemicals are injected into the water stream, it may

be preferred to only feed Chlorine when Acid is not feeding. This would be the pH Priority

setting.

" Simultaneous allows both chemicals to feed at the same time - and can

be used when both feed systems are not liquid chemicals or the injectors

are separated by a safe distance in the water stream. DANGER:

Combining liquid acid and chlorine can result in the formation of

hazardous and explosive gas.

" pH Priority will always feed acid first, and only during the acid mix time or

general monitoring period will the IntelliChem feed the liquid chlorine

sanitizer. If while feeding chlorine, the pH rises above setpoint, the ORP

dose will be stopped and allow acid to feed.

/

Configuration Dose Priority

IntelliChem™ Installation and User’s Guide

Page 24

20

Configuration Menu (Continued)

Diagnostics

Software Rev: Displays the software revision.

Meter Test: Performs an internal self-test of the pH/ORP meter and sensing circuitry.

Ensures both circuits are performing properly First tests the High circuit in the

uncalibrated state, waits for a button press, then tests the Low circuit and waits for a

button press. Once these two tests complete, it proceeds with the self-calibration. A Pass

or Fail message is displayed. If this test fails, disconnect power and check for water or

dirt on the circuit board. Use a can of dry compressed air to clean the board if necessary.

If the test continues to fail, contact technical support.

Probe Test: This test takes approximately 30 seconds. Perform this test with the sensor

cables and probes installed. Probes must be clean and in water. Possible results are :

Both Probes Good

pH: Good ORP:Bad

pH: Bad ORP:Good

pH: Bad ORP:Bad

Timers: This displays the counters used for tracking the cumulating dose volume and/or

time used in determining the Dose Limit. It shows:

"PCs" PH cumulative dose limit timer in Days HH:MM:SS

"Ocs" ORP cumulative dose limit timer in Days HH:MM:SS

"ml" Milliliters of cumulative dose for Ph and Orp (0-9999) stops at 9999 ml

"Run" the RUN TIME in Days, HH:MM:SS since powered up.

If you need to know how much you've dosed during a day, or how long its been running

that day, “Timers” will have this information. The cumulative times/ml get reset when you

clear the dose limits, The Run Time clears on power-up.

IntelliChem™ Installation and User’s Guide

Page 25

Configuration Menu (Continued)

Diagnostics (Continued)

Chlorinator: This screen displays the current IntelliChlor (SCG) status, salt (ppm) levels

and error conditions. The hexadecimal status value is decoded and displayed in the

brackets on the bottom line; multiple error conditions are shown by sequencing through

the messages.

This display can be used to determine if the SCG is connected and responding to the

IntelliChem. If the IntelliChlor is connected, this display may show "Please wait 2-7

minutes for ppm". This indicates the IntelliChlor is responding to initial contact but until

water flow and sufficient salt level is reached, the IntelliChlor will not respond with further

information like salt ppm and status. Sometimes it is helpful to cycle power on the

IntelliChlor and wait 10 minutes for the green lights before it will respond with ppm and

status information; it may not respond if the Salt or Cell lights are flashing red.

If the Configuration / Hardware / ORP Control / Doser Type is set to IntelliChlor, the

IntelliChem will control the IntelliChlor as it would a doser, actively turning it on (100%)

for chlorine demand, and off (0%) when the ORP reaches the desired set point.

For the Chlorinator to work when connected to an Automation controller like the

IntelliTouch, EasyTouch, or SunTouch, those units must be configured with the

IntelliChlor enabled. The displays is as follows:

--------------------------------------

Chlorinator Info:

Salt: 4500 ppm

Status Code=00H

[OK-NO ERRORS ] V

--------------------------------------

To get updated

ppm, cycle SCG

power and wait.

Press any button

--------------------------------------

Possible messages are:

No Flow

Low Salt

Very Low Salt

High Current

Clean Cell

Low Voltage

Cold Water

21

IntelliChem™ Installation and User’s Guide

Page 26

22

Configuration Menu (Continued)

Status Codes: This displays a complex series of values that indicate the real-time status

and alarm conditions.

Top line, Codes: HA= is the automation Home Address that IntelliChem has locked onto.

In the upper-right corner,

R0,1,2,4 which represents the UOC comm status.

R0 = standalone (no KA from Automation since power up)

R1 = Found KA packets within 30 seconds of power up

R2 = Found KA packets later, after 30 seconds, so was operating in standalone for a

while

R4= Was in Automation mode (sending IntelliChlor commands through IntelliTouch) but

has dropped the connection.

The two-digit number (0-99) directly below the R# is the number of seconds it's gone

without a valid KA packet. It should generally be 00-04 seconds. More than that means

that IntelliChem is missing the automation KA packets.

Note: Status and Alarm hexadecimal displayed codes represent the current IntelliChem

status. For further information, contact Technical Support (800) 831-7133.

Factory Reset: Clear all calibrated values and run Auto Setup to initialize IntelliChem.

For Factory Default Settings.

Self Test Sequence: Upon entering a self test sequence, all dosing will pause until the

test is completed. Follow the on-screen prompts. “PASSED” indicates the test was

successful. See Troubleshooting section for error conditions, on page 46.

Hardware

Most common hardware configurations can be selected by using the Auto Setup Wizard.

This menu allow more complex and custom settings.Use the Hardware menu to

configure IntelliChem for the pH and ORP hardware controls and dose being used. Upon

entering the hardware setup menu, all dosing will pause until the hardware setup is

completed.

To access the hardware menu: Press MENU

After pressing the Hardware

button the following message is

displayed.

Dosing will

resume when you

_exit this menu_

Press any button

Configuration

Hardware

pH Control (page 1/2 - 2/2)

Doser Type 1/2: Select the pH Control Dose Type:

- IntelliChem pH feed method being used (INTERNAL PUMP, EXTERNAL

RELA

Y, CO2 EXT/RELAY (Carbon dioxide tanks), NONE.

Doser Type 2/2:

- INTERNAL PUMP: Right, MTR_R, Left, MTR_L

- EXTERNAL RELAY: Ex_Relay 1, Ex_Relay 2

- CO2 EXTERNAL RELAY: Ex_Relay 1, Ex_Relay 2

Flow (Rate) 2/2:

- INTERNAL PUMP (MTR_R/MTR_L): FLOW: xxx GPD (gallons per day) -

(53, 65, 75).

- EXTERNAL RELAY 1 or 2: RATE: xxx GPD (gallons per day). Note: Set to

0 to use time-based feed instead of volumetric (only on the Ext Relays

(not internal motors).

- CO2 EXTERNAL RELAY 1 or 2: Use Time (0) or SCFH (1-400).

IntelliChem™ Installation and User’s Guide

Page 27

Configuration Menu (Continued)

ORP Control (page 1/2 - 2/2)

Doser Type 1/2: Select the ORP control hardware:

- IntelliChem ORP feed method being used (INTERNAL PUMP, EXTERNAL

RELAY, INTELLICHLOR Salt Chlorine Generator (SCG), NONE.

Doser Type 2/2:

- INTERNAL PUMP: Right-Side (MTR_R), Left-Side (MTR_L)

- EXTERNAL RELAY: Ex_Relay 1, Ex_Relay 2

- INTELLICHLOR: All Models (IC20, IC40, IC60)

Flow (Rate) 2/2:

- INTERNAL PUMP (MTR_R/MTR_L): FLOW: xxx GPD (gallons per day)

- EXTERNAL RELAY 1 or 2: RATE: xxx GPD (gallons per day). Note: Set to

0 to use time-based feed instead of volumetric (only on the Ext Relays

(not internal motors).

Hardware settings must be chosen carefully. If both dosers are assigned to the same

nal pump or external relay, the program will display an error message upon

inter

exiting the Hardware menu.

Alarm Output Select the following IntelliChem alarm output information:

- External alarm output: Ex_Relay1 or Ex_Relay2.

or an external alarm indicator, an unused relay may be selected to turn

F

on when the red Alarm LED on the front panel is turned on.

23

The alarm relay must be chosen carefully. If Ex_Relay1 or Ex_Relay2 is

used for a doser, it must not be used for an alarm output. Upon exiting the

Hardware menu, the program will check to be sure the same relay is not

used more than once. If a relay is assigned to more than one function, an

error message will be displayed.

error message:

-------------------------Alarm Relay

conflicts with

Ext Doser Relay

Changed to Ex_R1

-------------------------- or

Changed to Ex_R2

or

Changed to N/A

IntelliChem™ Installation and User’s Guide

Page 28

24

Auto Setup

Auto Setup

See page 6 for details.

Sat Index

Saturation Index

The Saturation Index (SI), also called the Langelier Index, is a chemical equation

or formula used to diagnose the water balance in the pool. The Saturation Index

formula is SI = pH + TF + CF + AF - 12.1 (or 12.2 for salt pools). To calculate the

Saturation Index, you must first test the pool water for pH, temperature, calcium

hardness, and total alkalinity. Refer to a chart for assigned values for your temperature, hardness, and alkalinity readings then add these to your pH value. Subtract

12.1 (or 12.2 for salt pools), which is the constant value assigned to Total Dissolved

Solids and a resultant number will be produced. A result between +/-0.3 indicates

balanced water. Test results not within these values require chemical adjustments

to achieve balance. This formula is more or less reliable but not guaranteed. In

some cases, individual readings for pH, calcium, and Total-Alkalinity might be

beyond normal recommendations, however, combined within the formula can

produce “balanced water.” The SI is useful to pinpoint potential water balance

problems.

To access the Sat Index menu:

Press MENU / Saturatn Index

Press / and /to adjust the Saturation Index values.

pH Menu

ORP Menu

Saturatn Index

Configuration

pH: 6.0 Temp: 77F

CH: 250 TDS1000

TA: 90 CYA:18

SI = -0.9 CORRSV

Sat Index Menu

Note: The pH, Temp, and TDS are entered automatically as the numbers are available

from the measurement and automation system. Each time this display is entered, if

available, the current temperature is obtained from the Automation controller

(IntelliTouch, EasyTouch, etc), TDS is obtained from the IntelliChlor SCG. But these

values can be changed on this screen for calculation purposes.

pH: Enter the current pH value.

Temperature: Enter the current temperature setting.

CH: Enter the current calcium hardness level.

TDS: Enter the current Total Dissolved Solids level.

TA: Enter the current total alkalinity value.

CYA: Enter the current cyanuric acid value.

SI: Displays the last calculated SI value (Corrosive/Scaling/Ideal).

Note: If there is no

flow or Flow Delay is enabled, no SI value displayed.

pH: 6.0 Temp: 77F

CH: 250 TDS1000

TA: 90 CYA:18

SI = N/A No Flow

IntelliChem™ Installation and User’s Guide

pH: 6.0 Temp: 77F

CH: 250 TDS1000

TA: 90 CYA:18

SI = N/A FlowDelay

Page 29

25

Sat Index (Continued)

Recommended Pool Chemistry

pH range: 7.2 to 7.6

ORP range: 650 to 750

Alkanlinity: 80 to 120 ppm

Calcium Hardness: 200 - 500 ppm

Cyanuric Acid/Stablizer: 30-50 ppm

pH: Chlorine produced by the IntelliChlor SCG is close to Neutral pH. However, other

factors usually cause the pH of the pool water to rise. Therefore, the pH in a pool

chlorinated by IntelliChlor tends to stabilize at approximately 7.8. This is within APSP

standards. If the pool pH rises above 7.8, have a pool professional test to see if other

factors such as high Calcium Hardness or Total Alkalinity are the cause and then

balance accordingly.

Temperature: The pool water temperature can affect the saturation index value.

IntelliChem gets the temperature from the EasyTouch, IntelliTouch and SunTouch

automation control system. The automation control system must have the POOL or SPA

pump running to report the proper temperature to IntelliChem, otherwise IntelliChem will

use its own menu's temperature value. To change the IntelliChem default temperature,

select Temp and use the Up/Down arrow to adjust the temperature.

pH Level Test: Test the pH level of your pool water with a reliable test method. If

necessary, adjust according to your pool professional’s recommendations. APSP’s

recommended ideal range for pH is 7.2 to 7.6. Note: Never use dry acid (sodium

bisulfate) to adjust pH in arid geographic areas with excessive evaporation and minimal

dilution of pool water with fresh water. A buildup of by-products can damage the

IntelliChlor SCG

Calcium Hardness

Recommended range for calcium hardness is 200-500 ppm. Calcium Hardness

levels should be tested weekly. Calcium hardness is the calcium carbonate scale

deposited on pool surfaces. The test for Calcium Hardness is a measure of how

“hard” or “soft” the water is testing. “Hard” water can have high levels of calcium

and magnesium. If these levels are too high the water becomes saturated and will

leave calcium carbonate scale deposits (a “white-ish,” crystallized rough spot) on

any surface inside the pool. If the levels are too low, the water becomes “soft” and

will corrode surfaces inside the pool. Use TSP or Hydroquest 100 to lower Calcium

Hardness levels that are too high or add water to the pool which has a lower

calcium hardness content. Levels which are too low require the addition of calcium

chloride.

Total Dissolved Solids (TDS): Adding salt to pool water will raise the TDS level. While

this does not adversely affect the pool water chemistry or clarity, the pool water

professional testing for TDS must be made aware salt has been added to the IntelliChlor

system. The individual performing the TDS test may then subtract the salinity level to

arrive at a TDS level that would be compatible to a TDS reading for a non-salt water pool.

Note: If a salt chlorine generator is being used for your pool, the salt level is the TDS

level of the pool.

IntelliChem™ Installation and User’s Guide

Page 30

26

Sat Index (Continued)

Total Alkalinity

APSP’s recommended ideal range for total alkalinity is 80 to 120 ppm for “gunite”

and concrete pools and 125-170 ppm f

levels weekly and adjust according to your pool professional’s recommendations.

Total Alkalinity can be described as a buffer that keeps pH in order. pH depends on

the ability of the total alkalinity in the water to withstand the changes in pH. If the

total alkalinity is too high, adding acid (similar to pH) lowers the level. Adding a

base (e.g sodium bicarbonate) when total alkalinity is low, raises the level. The

level of total alkalinity in the water is a measurement of all carbonates, bicarbonates, hydroxides, and other alkaline substances found in the pool water.

Cyanuric Acid: Cyanuric acid is needed in outdoor pools to help to stabilize and

maintain proper levels of chlorine. 90% of unstabilized chlorine is destroyed by the UV

radiation from the sun. Cyanuric acid stabilizes chlorine in water from UV degradation.

When using the IntelliChlor SCG, the cyanuric acid level should be maintained between

30-50 ppm.

or painted, vinyl, and fiberglass pools. Test

Optimum Pool Water Chemistry Conditions for Salt Water Pools

(using the IntelliChlor SCG)

In accordance with the Association of Pool and Spa Professionals (APSP) standards,

it is recommended that the pool water chemistry conditions (see page 21) be

maintained on an on going basis to help protect pool users, pool related equipment

and surfaces in and around the pool.

pool equipment in proper operating condition and preventing corrosion, liming or other

problems. The IntelliChlor Electronic Chlorine Generator is warranted to operate properly

only if these conditions are met. For more information, refer to your local agency having

jurisdiction, NSPI (National Spa and Pool Institute), the CDC (Centers for Disease

Control), or the WHO (World Health Organization). Recommended pool water chemistry

is given below:

Free Chlorine: 2.0 - 4.0 ppm. Above 4.0 ppm may cause corrosion of metal components

Combined Chlorine (Chloramines): None (super chlorinate to remove all chloramines)

pH: 7.2 - 7.8 (USE MURIATIC ACID to lower pH and Soda Ash to raise pH.)

Cyanuric Acid: 30 - 50 ppm

Total Alkalinity: 80 - 120 ppm

Calcium Hardness: 200 - 400 ppm

TDS (includes salt): 3000 minium to 5700 to 6000 maximum ppm

Salt: 3000 - 4500 ppm (ideal 3400 ppm)

Metals (Copper, Iron, Manganese): None

Nitrates: None - Phosphates: Less than 125 ppb

These values are important to maintaining the

Using the Langelier Saturation Index (LSI) to Diagnose Water

Balance

Use the Langelier Saturation Index (LSI) calculator to diagnose the water balance in

your pool. Water with a LSI of 1.0 is one unit above a balanced condition. Reducing the

factors by 1 unit will bring the water into equilibrium. To use the LSI calculator, refer to:

http://www.pentairpool.com/pool-owner/resources/calculators/langelier/

IntelliChem™ Installation and User’s Guide

Page 31

Sat Index (Continued)

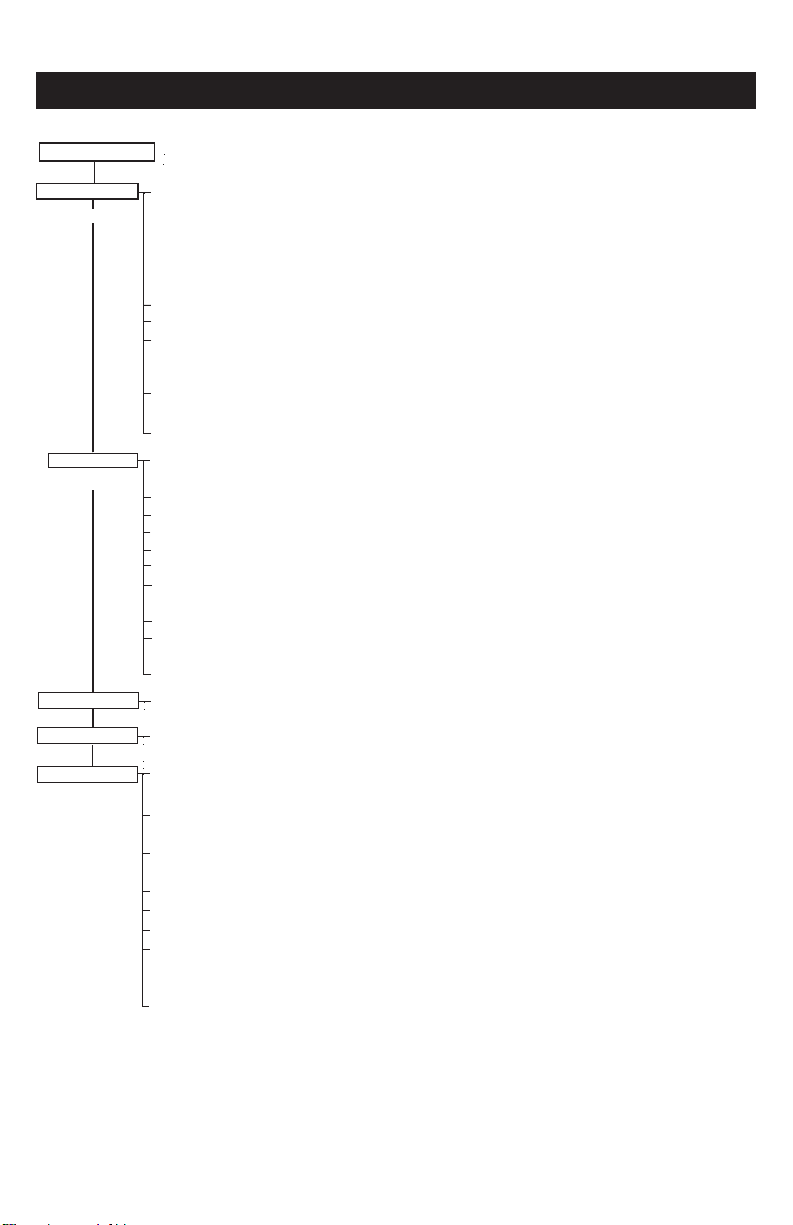

Calculating the Saturation Index

The saturation index is a formula that relates pH, calcium and alkalinity in the pool water.

A well balanced pool water will have a formula result range between -0.3 and 0.3

Outside this range, the pool water is out of balance, potentially damaging pool

equipment or scaling the salt chlorine generator. The equation to calculate Si is:

SI = pH + CHF + AF + TF - TDSF

27

Saturation

Index

pH as