Page 1

OWNER’S MANUAL

Sink Pump System

© 2006 S483 (Rev. 9/26/06)

DP233110V-01

Installation/Operation/Parts

293 Wright Street • Delavan, WI 53115

Page 2

General Safety Information 2

DESCRIPTION

The Sta-Rite Sink Pump System, Model Number

DP233110V-01, is ideal for home wastewater removal

from beautician or utility sinks and wet bars, and for drain

water transfer from air conditioners or dehumidifiers.

1/3 HP submersible pump unit is equipped with a 3-prong

grounding-type power cord. Motor is oil-filled (dielectric

oil) and sealed for cooler running. Upper sleeve/lower

ballbearing on motor shaft never need lubrication.

Automatic reset thermal protection.

SPECIFICATIONS

Power supply required...................................115V, 60 Hz.

Liquid temp. range..........................................32° to 130°F

Individual branch circuit required (minimum)......15 Amps

Discharge...........................................................1-1⁄2" NPT

UNPACKING AND INSPECTION

Handle with care. Check items received against packing

list to be sure that all equipment has been received.

Inspect for shipping damage. If found, file claim with carrier immediately.

GENERAL SAFETY INFORMATION

Electrically powered sump pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. However, unusual circumstances

(interruption of power to the pump, dirt/debris in the

sump, flooding that exceeds the pump’s capacity, electrical or mechanical failure in the pump, etc.) may prevent

the pump from functioning normally. To prevent possible

water damage due to flooding, consult your dealer about

installing a high water alarm. See the “Troubleshooting

Chart” in this manual for information about common

sump pump problems and remedies. For more information, see your dealer or call customer service.

1. Know the pump application, limitations, and potential

hazards.

2. Disconnect power before servicing.

3. Release all pressure within system before servicing any

component.

4. Drain all water from system before servicing.

5. Secure discharge line before starting pump. An unsecured discharge line will whip, possibly causing personal injury and/or property damage.

6. Check hoses for weak or worn condition before each

use, making certain that all connections are secure.

7. Periodically inspect system components. Keep free of

debris and foreign objects. Perform routine maintenance as required.

8. Provide means of pressure relief for pumps whose discharge line can be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times when working with

pumps.

b. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

c. Keep visitors at a safe distance from work area.

d. Make workshop child-proof – with padlocks, mas-

ter switches, and by removing starter keys.

10. When wiring an electrically driven pump, follow all

electrical and safety codes that apply.

11. This equipment is only for use on 115 volt (single

phase) and is equipped with an approved

3-conductor cord and 3-prong, grounding-type plug.

To reduce risk of electric shock, pull plug

before servicing. This pump has not been investigated for

use in swimming pool areas. Pump is supplied with a

grounding conductor and grounding-type attachment plug.

Be sure it is connected only to a properly grounded

grounding-type receptacle. Where a 2-prong wall receptacle is encountered, it must be replaced with a properly

grounded 3-prong receptacle installed in accordance with

codes and ordinances that apply.

12. All wiring should be performed by a qualified

electrician.

13. Make certain power source conforms to requirements

of your equipment.

PERFORMANCE

SPECIFICATIONS

Motor

Full Load Switch Setting Top Bottom

HP Amps On Off Height Width Width Weight

1/3 9.8 7" 2" 13-3/4" 15-1/8" 12" 32 lbs.

GPM of Water @ Total Feet of Head

Model HP 5’ 10’ 15’ 20’ Shutoff

DP233110V-01 1/3 48.0 40.0 29.0 15.0 24’

Page 3

General Safety / Assembly 3

14. Protect electrical cord from sharp objects, hot surfaces,

oil, and chemicals. Avoid kinking cord. Replace or

repair damaged or worn cords immediately.

15. Do not touch an operating motor. Modern motors are

designed to operate at high temperatures.

Risk of electric shock. If your basement has

water or moisture on the floor, do not walk on wet area

until all power has been turned off. If shut-off box is in

basement, call electric company or hydro authority to

shut-off service to house, or call your local fire department

for instructions. Remove and replace system. Failure to follow this warning can result in fatal electrical shock.

Risk of electric shock. Do not handle pump

or pump motor with wet hands or when standing on wet

or damp surface, or in water. Always disconnect the pump

and switch from the electrical power source before doing

any maintenance.

16. Pump water only with this pump.

ASSEMBLY

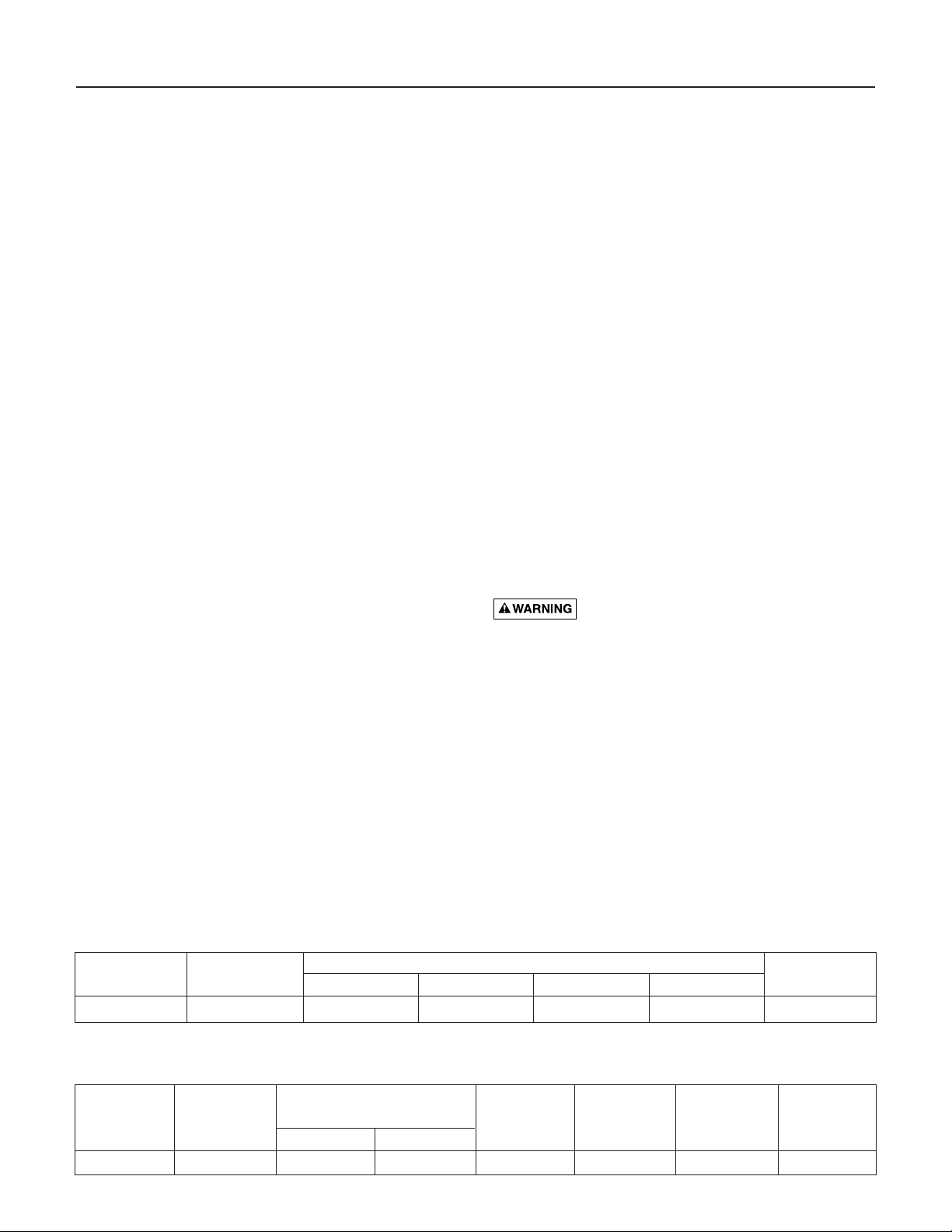

Steps 1 and 2 (See Figure 1)

Step 3 (See Figure 2)

Step 4 (See Figure 3)

Install the discharge pipe hand-tight plus one-half turn.

Step 5 (See Figure 4)

Place the pump in the basin as shown. Align the discharge

with one of the threaded ports in the cover.

Step 6 (See Figure 5)

Turn the cover upside down and ‘lay in’ the basin gasket

as shown.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

1

4

1

1 " NPT

2

Discharge

1

1 " NPT

2

Vent

2

Inlet

Pump

Basin

Locating

Cleats

3

Page 4

Assembly / Installation 4

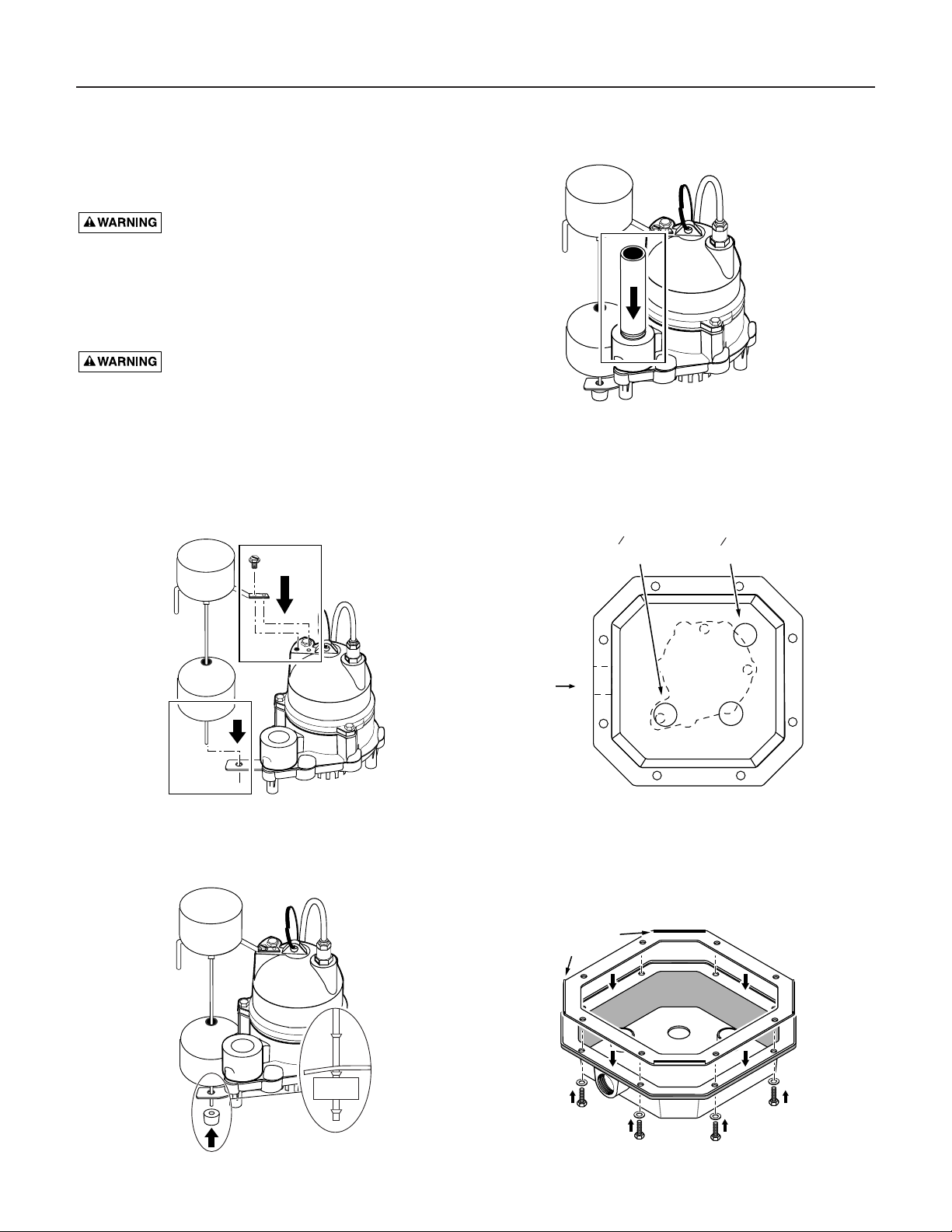

IMPORTANT: To prevent leaks, be sure that the cleats on

the corners of the basin gasket are up with the cover

upside down (that is, not pressed into the sealing face of

the cover).

Step 7 (See Figure 5)

Push the screws with their washers installed up through

the holes in the rim of the cover and in the basin gasket

(the cover will retain the screws).

Step 8 (See Figure 6)

• Align the cover with the discharge pipe and cords.

• Pull the cords through the non-threaded hole in the

basin cover.

• Place the cover over the discharge pipe.

• Install the cords in the cord grommet

• Install the cord/grommet assembly in the non-threaded

hole in the basin cover; don’t pull the cords tight.

Step 9 (See Figure 6)

Fasten the basin cover to the basin with the capscrews

previously inserted in the cover (Step 7).

IMPORTANT: To prevent leaks, be sure the locating cleats

on the corners of the basin gasket are outside the edges of

the basin rim, not pressing against the rim.

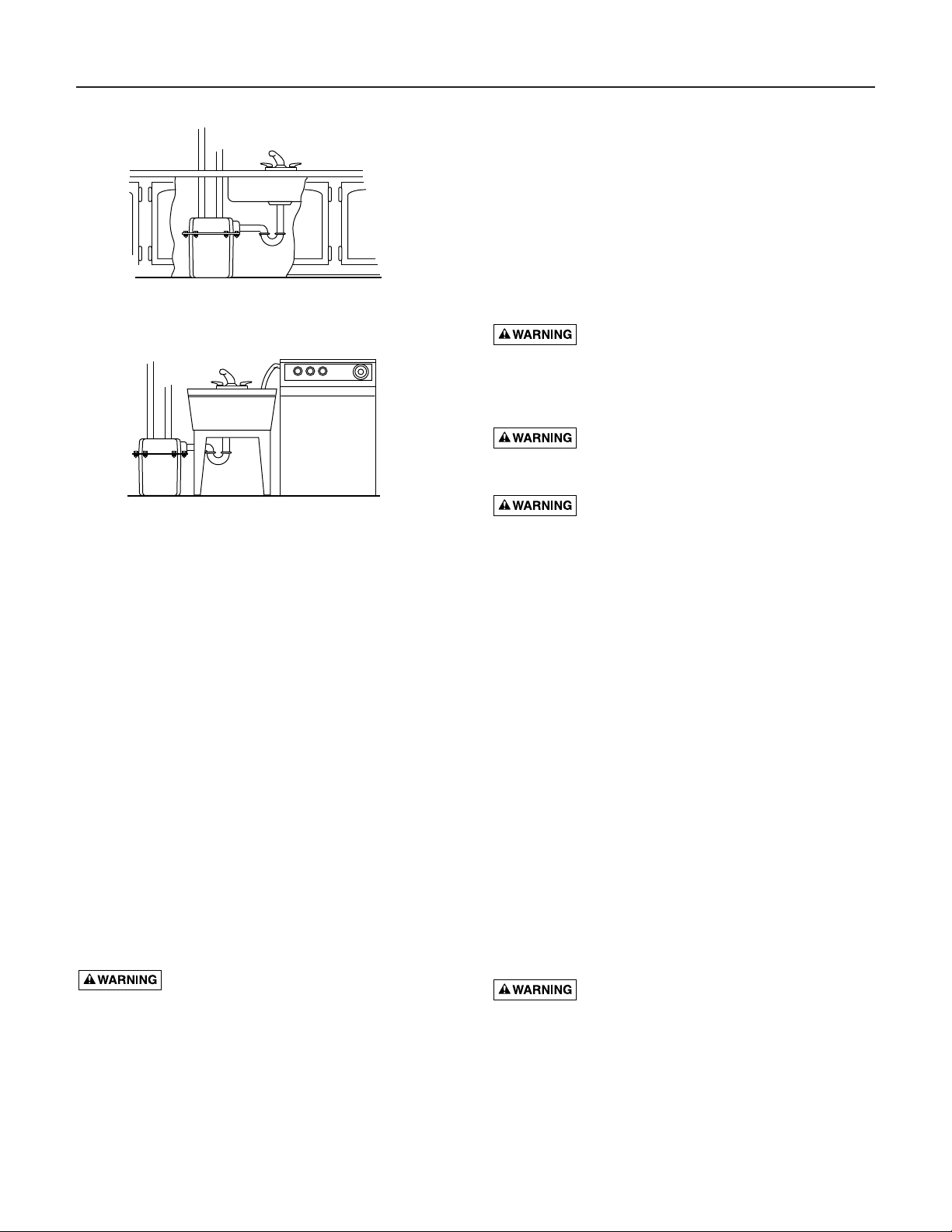

INSTALLATION (See Figure 7)

The basin (system) should be located at the lowest place

possible relative to the area to be drained.

NOTE: Make sure that the inlet of the pre-plumbed system

is lower than the water to be pumped.

1. Install inlet pipe in opening as shown. Use RTV sealants

or Plasto-Joint Stik* to seal threads. See Figures 8, 9, and

10, page 4 and 5, for typical installation arrangements.

*Lake Chemical Co., Chicago, Illinois

Figure 7 – Sink Pump System Dimensions

Figure 6

Figure 8 – Typical installation to remove air conditioner

condensate or dehumidifier water

1

1 " NPT

2

Discharge

1

1 " NPT

2

Vent

Thread pipes into fittings;

don't go past end of threads.

1 " NPT

Vent

1/3 HP

Pump

1

2

1

/

15

8"

1

1 " NPT

2

Discharge

1

1 " NPT

2

Inlet

13

12"

3

/

4"

Cord Grommet

Inlet

Discharge

Pump

Vertical Float Switch

12"

Discharge

Vent

Pump

Page 5

Installation / Maintenance 5

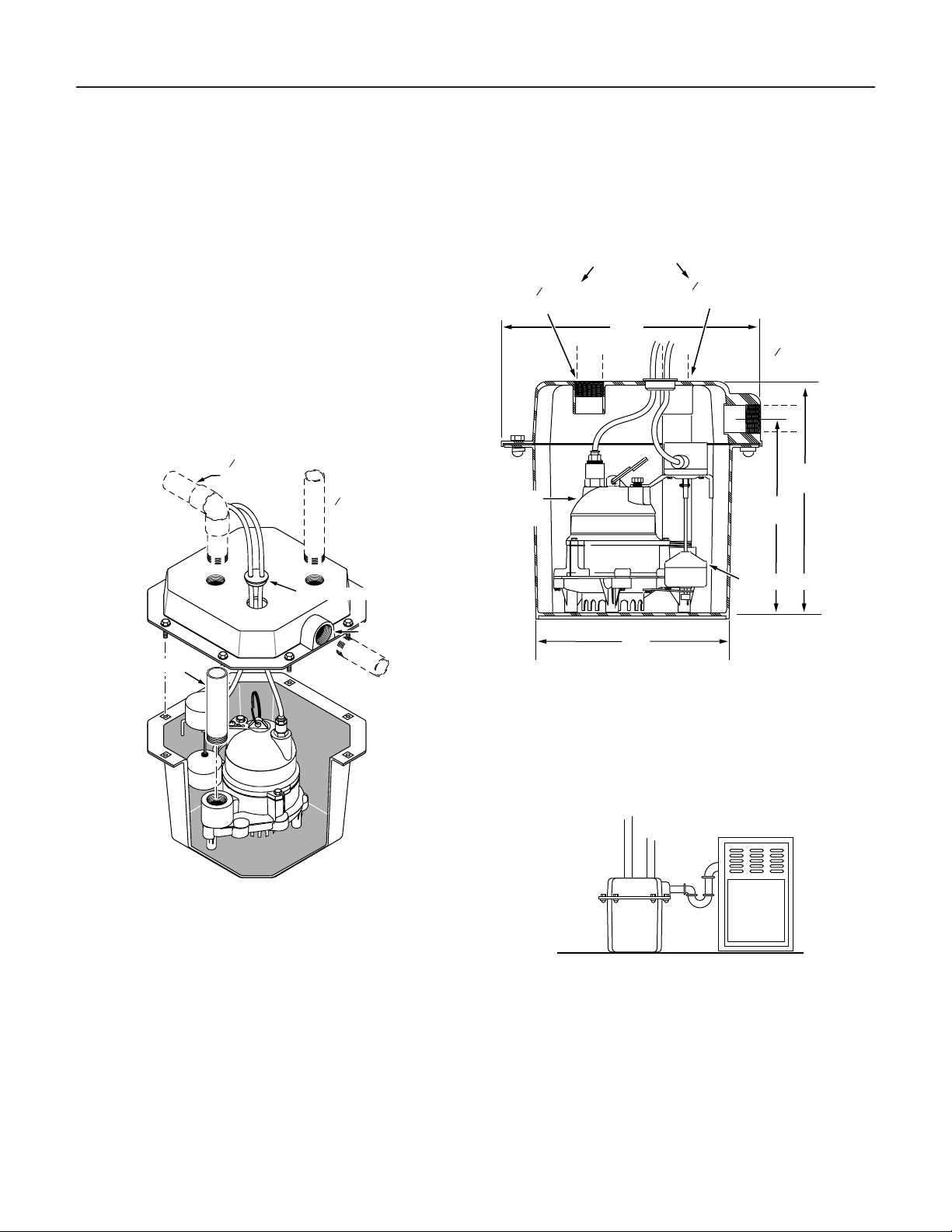

2. Install discharge plumbing. When using rigid pipe, use

plastic pipe. Wrap thread with Teflon tape or use

Plasto-Joint Stik*. Screw pipe into discharge fitting

hand tight +1 – 1-1⁄2 turns.

NOTE: Do not use ordinary pipe joint compound on plastic pipe. Pipe joint compound can attack plastics.

3. To reduce motor noise and vibrations, a short length of

rubber hose (1-7⁄8" I.D., e.g. radiator hose) can be connected into discharge line near pump using suitable

clamps.

4. Install an in-line check valve to prevent flow backwards through pump when pump shuts off.

5. Thread vent pipe into 1-1⁄2" NPT black vent fitting in

basin cover. Pipe should not extend into basin.

Connect vent pipe to sewer vent system.

6. Power Supply: Pump is designed for 115 V., 60 Hz.,

operation and requires a minimum 15 amp individual

branch circuit. Both pump and switch are supplied

with 3-wire cord sets with grounding-type plugs.

Switch plug is inserted directly into outlet and pump

plug inserts into opposite end of switch plug.

Hazardous Voltage. Pump should always be

electrically grounded to a suitable electrical ground such

as a grounded water pipe or a properly grounded metallic

raceway or ground wire system. Do not cut off round

ground pin.

7. If pump discharge line is exposed to outside sub-freezing atmosphere, portions of line exposed must be

installed so any water remaining in pipe will drain to

the outfall by gravity. Failure to do this can cause

water trapped in discharge to freeze which could result

in damage to pump.

8. After piping and check valve have been installed, unit

is ready for operation.

9. Check operation by filling sump with water and

observing pump operation through one complete

cycle.

Risk of flooding. Failure to make this opera-

tional check may lead to improper operation, premature

failure, and flooding.

MAINTENANCE

Risk of electric shock. Make certain that the

pump is unplugged before attempting to service or remove

any component.

Risk of electric shock. Do not handle a

pump or pump motor with wet hands or when standing

on wet or damp surface, or in water.

1. Keep pump inlet screen clear.

2. Shaft seal depends on water for lubrication. Do not

operate pump unless it is submerged in water as seal

may be damaged if allowed to run dry.

3. Motor is equipped with automatic reset thermal protector. If temperature in motor should rise unduly, switch

will cut off all power before damage can be done to

motor. When motor has cooled sufficiently, switch will

reset automatically and restart motor. If protector trips

repeatedly, pump should be removed and checked for

cause of difficulty. Low voltage, long extension cords,

clogged impeller, very low head or lift, etc., could

cause cycling. Refer to Trouble shooting Guide on

Page 6 for additional information.

4. Periodically inspect pump, system components, and

sump for debris and foreign objects. Keep sump free of

all refuse. Perform routine maintenance as required.

Pump Cleaning

NOTE: Attempting to disassemble motor will void warranty.

1. Use the pump ring to lift pump out of basin and place

pump on a clean level surface.

Risk of electrical shock. Shock can burn or

kill. Do not lift pump by power cord.

2. To clean impeller, remove eight screws holding baseplate to motor assembly. Clean impeller as necessary.

3. Re-install baseplate and screws.

4. Use pump ring to replace pump in basin.

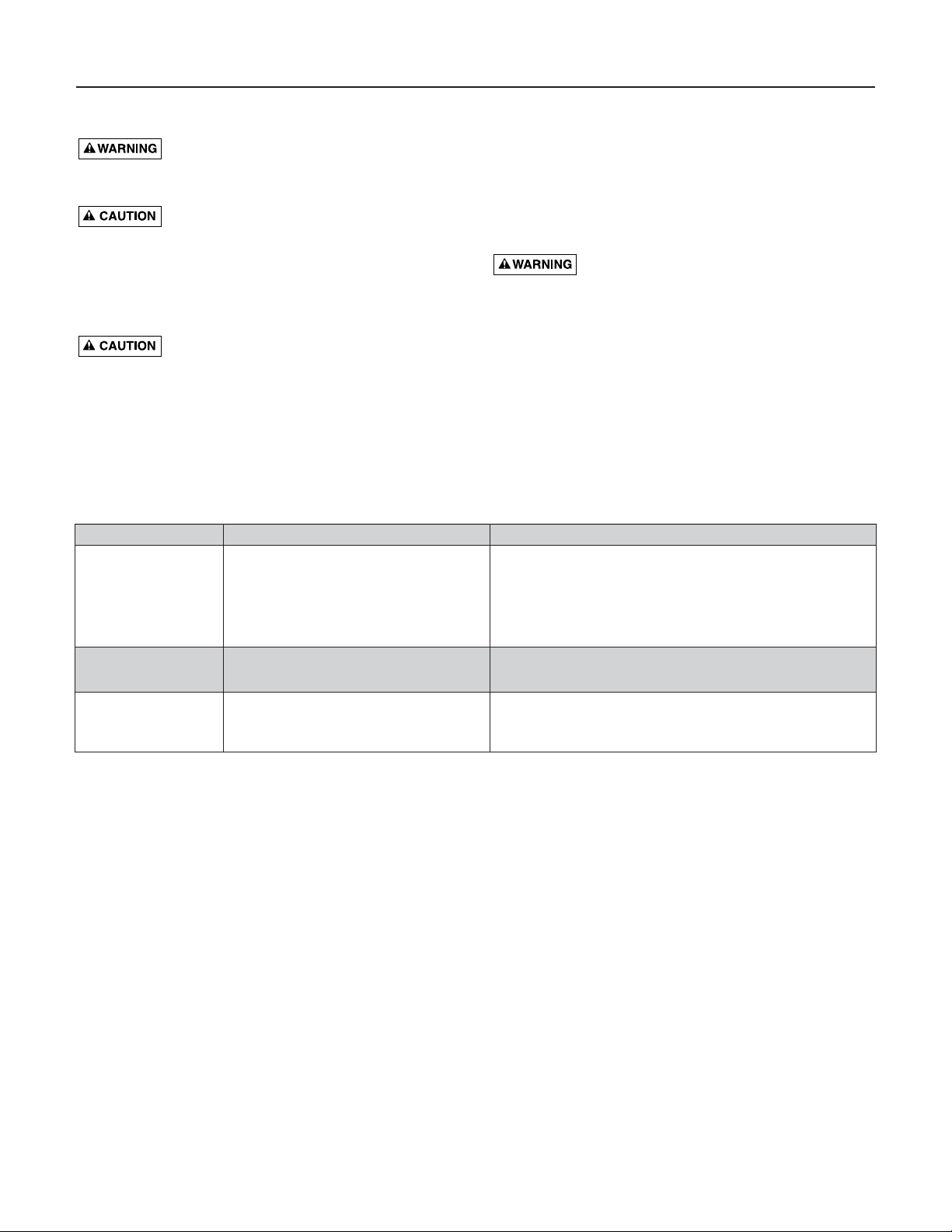

Figure 9 – Typical wet bar installation

Figure 10 – Typical installation for laundry sinks and

washing machines

Discharge

Vent

Pump

Discharge

Vent

Pump

Page 6

Maintenance 6

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump won’t 1. Blown fuse. 1. If blown, replace with fuse of proper size.

start or run.

2. Low line voltage. 2. If voltage under recommended minimum,

check size of wiring from main switch on

property. If OK, contact power company or

hydro authority.

Pump won’t 1. Restricted discharge 1. Remove obstacle in piping.

shut off. (obstacle in piping).

Pump operates 1. Restricted discharge 1. Remove obstacle in piping.

but delivers (obstacle in piping).

little or no water.

Switch Replacement

Risk of electric shock. When servicing

pump, always disconnect power to electrical outlet and

remove pump electric cord from outlet.

Float must be able to complete its entire

cycle without interference from sidewall of basin, plumbing, or any other object.

1. Mount bracket on switch housing using existing screws.

2. Slide rod into slot in bottom of switch housing. Fasten

rod into switch housing with pin.

Make sure pin holds float rod in switch

housing; otherwise pump will not shut off.

NOTE: Pull gently on rod to make sure that it cannot

come out of switch housing.

3. Mount switch assembly on pump using existing

screws. Make sure that nothing interferes with switch

operation.

4. Mount float on rod.

5. Install rod stop on bottom of rod.

6. Run pump through one complete cycle to verify correct switch operation.

Risk of flooding. Drainer Pre-Plumbed

System comes with the automatic float switch mounted on

the motor housing ready for operation. Do not change

switch settings. Switch is set to start at approximately 6.5"

and to stop at approximately 2".

TROUBLESHOOTING

Page 7

Repair Parts 7

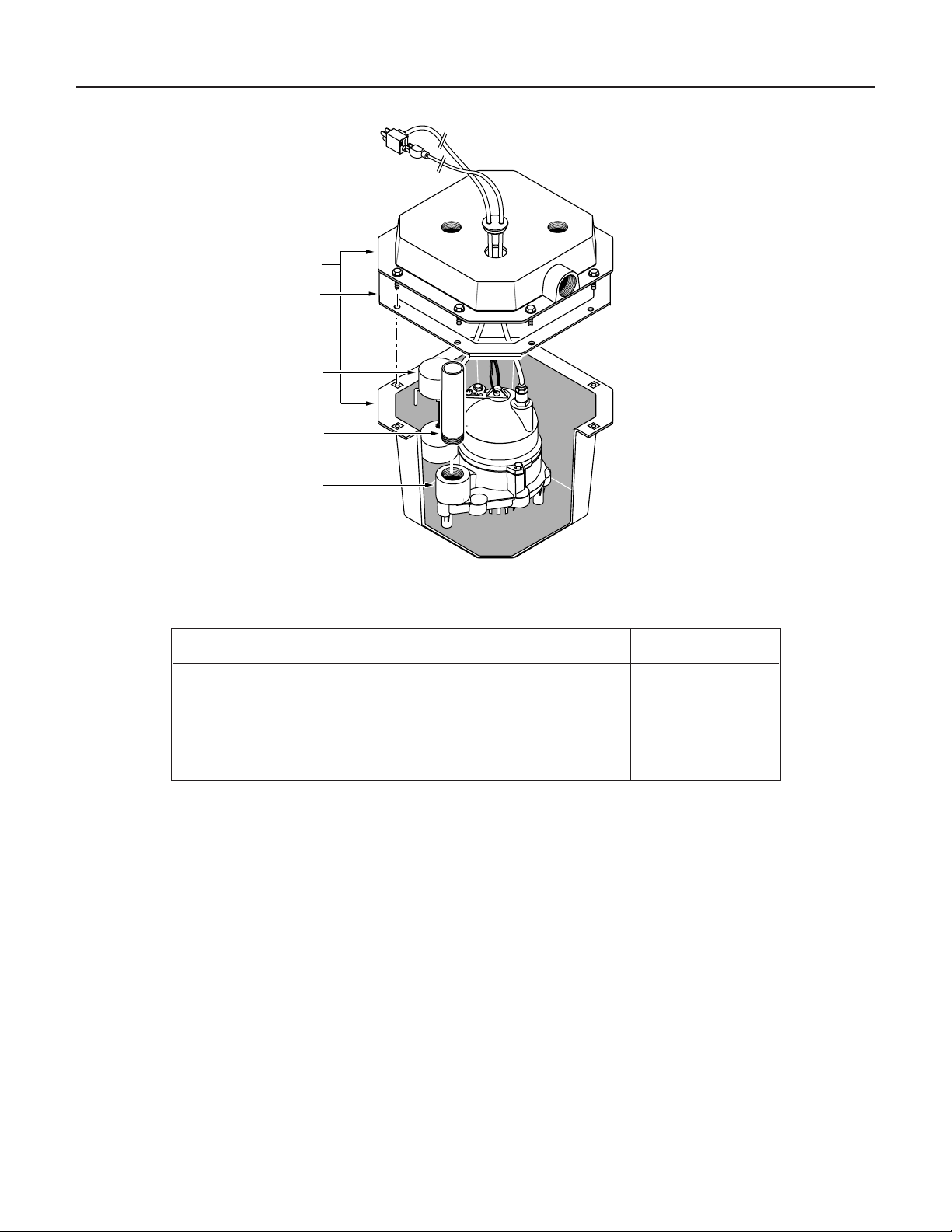

3

2

1

5

4

Key Part

No. Description Qty. DP233110V-01

1 5 gallon Poly basin assembly (includes Key No. 2 and hardware kit) 1 PW73-64

2 Basin Gasket 1 U20-23

3 Automatic Vertical Float Switch 1 PKG 208

4 1-1/2" Discharge Pipe 1 U37-688P

5 1/3 HP Submersible sump pump 1 D33110V

• Hardware kit (includes bolts, washers, and cord grommet) 1 PW198-6

Repair Parts List

• Not illustrated.

Page 8

Warranty 8

LIMITED WARRANTY

Pentair Water (“Pentair”) warrants to the original consumer of the products listed below, that they will be free from defects in material

and workmanship for the Warranty Period from the date of original installation or manufacture as noted.

Product Warranty Period

Jet pumps, small centrifugal pumps,

whichever occurs first:

submersible pumps and related accessories 1 year from date of original installation, or

2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Fibrewound Tanks 5 years from date of original installation

Steel Pressure Tanks 5 years from date of original installation

Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or maintenance. In the

event a three phase submersible motor is operated with single phase power through a phase converter, or if three-leg ambient compensated, extra-quick trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Pentair’s only duty is to repair or replace defective products (at Pentair’s choice). Buyer agrees to pay all labor and

shipping charges associated with this warranty and to request warranty service through the installing dealer as soon as a problem is discovered. If warranty service is requested more than 30 days after the Warranty Period has ended, it will not be honored.

PENTAIR SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of limitations on the duration of

an implied warranty, therefore, the limitations or exclusions herein may not apply.This warranty sets forth specific legal rights and obligations,

however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications.

Pentair Water, 293 Wright St., Delavan, WI 53115

Page 9

INSTRUCTIONS D’UTILISATION

Système de pompage d’évier

© 2006 S483 (Rév. 26/9/06)

Installation/Fonctionnement/Pièces

DP233110V-01

293 Wright Street • Delavan, WI 53115

Page 10

Sécurité générale 2

DESCRIPTION

Le système de pompage d’évier Sta-Rite, modèle nº DP233110V-01,

est idéal pour pomper les eaux résiduaires des éviers des habitations,

des salons de beauté, à usage général ou des minibars, de même

que pour le transvasement des eaux des condensats des climatiseurs

et des déshumidificateurs. La pompe submersible de 1/3 ch est

équipée d’un cordon électrique muni d’une fiche à 3 broches dont

une de mise à la terre. Le moteur est rempli d’huile (huile diélectrique) et il est étanche afin qu’il chauffe moins pendant son fonctionnement. Le roulement à billes inférieur et le palier supérieur de

l’arbre du moteur ne nécessite aucun graissage. Réarmement

automatique de la protection contre les surcharges thermiques.

SPÉCIFICATIONS

Courant d’alimentation ..............................................115 V, 60 Hz

Gamme de la température

du liquide.........................................De 0 ° à 54°C (32 ° à 130 °F)

Circuit de dérivation individuel

requis (minimum) .........................................................15 ampères

Refoulement...............................................................1-1⁄2 po NPT

DÉBALLAGE ET INSPECTION

Manipuler avec prudence. Comparer toutes les pièces reçues par rapport au bordereau d’expédition pour s’assurer que tout l’équipement

a été reçu. Si l’équipement a été endommagé pendant le transport, en

aviser immédiatement le transporteur.

SÉCURITÉ GÉNÉRALE

Normalement, les électropompes de puisard offrent de nombreuses années de service sans ennui si elles sont bien installées,

bien entretenues et bien utilisées. Toutefois, des circonstances

inhabituelles (interruption du courant alimentant la pompe,

saletés et débris pouvant se trouver dans le puisard, conditions

d’inondation qui dépassent le débit de la pompe, pannes électriques ou mécaniques de la pompe, etc.) peuvent empêcher la

pompe de fonctionner normalement. Pour empêcher tout dommage possible que pourrait causer l’eau suite à une inondation,

consulter le marchand pour l’installation d’un système d’alarme

de niveau haut d’eau. Se reporter au «Tableau de recherche des

pannes» à la fin de cette notice pour plus de renseignements concernant les problèmes courants des pompes de puisard et leurs

remèdes. Pour plus de renseignements, s’adresser au marchand

ou appeler le service à la clientèle.

1. Il faut toujours savoir comment utiliser les pompes, et connaître leurs limitations et les dangers potentiels.

2. Avant d’intervenir sur le système, débrancher le courant.

3. Dissiper toute la pression du système avant d’intervenir sur un

composant.

4. Avant d’intervenir sur le système, vider toute l’eau.

5. Immobiliser la conduite de refoulement avant de démarrer la

pompe. Une conduite de refoulement non immobilisée agira

comme un fouet, ce qui risque de causer des blessures corporelles et/ou des dommages matériels.

6. Avant chaque utilisation, s’assurer que les tuyaux souples ne sont

pas usés ni affaiblis, et que tous les raccords sont bien serrés.

7. Périodiquement, inspecter tous les composants du système.

Débarrasser le système des débris et des corps étrangers.

Procéder, selon le besoin, à un entretien périodique.

8. Prévoir un moyen de dissiper la pression des pompes dont la

conduite de refoulement risque d’être fermée ou obstruée.

9. Sécurité personnelle :

a. Toujours porter des lunettes de sécurité lorsque l’on inter-

vient sur une pompe.

b. Garder la zone de travail propre, non encombrée et bien

éclairée - enlever tous les outils et tout l’équipement non

utilisés.

c. Garder les visiteurs à une distance sécuritaire de la zone

de travail.

d. Rendre les ateliers sécuritaires pour les enfants en posant

des cadenas, des interrupteurs principaux et en enlevant

les clés de démarrage.

10. Pour câbler une électropompe, suivre les codes de sécurité et

de l’électricité qui s’appliquent.

11. Cet équipement ne peut être branché que sur le courant

monophasé de 115 volts. Il est équipé d’un cordon électrique

approuvé à 3 conducteurs muni d’une fiche à 3 broches dont

une de mise à la terre.

Pour réduire les risques de secousses électriques, débrancher, avant d’intervenir sur cet équipement, son

cordon électrique de la prise de courant. Cette pompe n’a pas

été mise à l’essai pour être utilisée autour des piscines. La pompe

est livrée avec un cordon électrique à trois conducteurs comportant une fiche à trois broches dont une de mise à la terre.

S’assurer de ne brancher cette fiche que dans une prise de

courant à trois trous adéquatement mise à la terre. Si l’on ne possède qu’une prise de courant à 2 trous, elle devra être remplacée

par une prise de courant à 3 trous adéquatement mise à la terre et

installée conformément aux codes et aux décrets qui s’appliquent.

12. L’installation du câblage ne doit être effectuée que par un

électricien qualifié.

13. S’assurer que le courant électrique se conforme aux carac-

téristiques de l’équipement.

SPÉCIFICATIONS

Charge totale Réglage de

sur le motor l’interrupteur Largeur Largeur

ch (en ampères) Marche Arrêt Hauteur supérieure inférieure Pds

1/3 9,8 17,8 cm 5,1 cm 34,9 cm 38,4 cm 30,5 cm 14,5 kg

RENDEMENT

L/min d’eau à la hauteur totale de refoulement en metres

Modèle ch 1,5 m 3 m 4,5 m 6,1 m Arrêt

DP233110V-01 1/3 181,7 151,4 109,8 56,8 7,3 m

Page 11

Sécurité générale / Montage 3

14. Protéger le cordon électrique des objets tranchants, des surfaces chaudes, de l’huile et des produits chimiques. Éviter de

tordre le cordon électrique. Remplacer ou réparer immédiatement tout cordon électrique endommagé ou usé.

15. Ne pas toucher au moteur pendant qu’il fonctionne. Les

moteurs modernes sont conçus pour fonctionner par des températures élevées.

Risque de secousses électriques. Si le plancher

du sous-sol est recouvert d’eau ou est humide, ne pas marcher sur

la surface humide tant que le courant n’aura pas été coupé. Si la

boîte de sectionnement du courant se trouve dans le sous-sol,

appeler la compagnie électrique pour qu’elle coupe le service de

la maison ou appeler le service des incendies local pour obtenir

des instructions. Déposer et remplacer le système. Ne pas

respecter les recommandations de cet avertissement risque de

causer une électrocution mortelle.

Risque de secousses électriques. Ne pas manip-

uler la pompe ni le moteur de la pompe lorsqu’on a les mains

humides ou lorsqu’on se tient sur une surface mouillée ou humide,

ou dans l’eau. Toujours débrancher la pompe et couper le courant

électrique alimentant la pompe avant de procéder à un entretien.

16. Ne pomper que de l’eau avec cette pompe.

MONTAGE

1° ET 2° Opérations (Voir la Figure 1)

3° Opération (Voir la Figure 2)

4° Opération (Voir la Figure 3)

Brancher le tuyau de refoulement en le serrant à la main, plus un

demi-tour.

5° Opération (Voir la Figure 4)

Mettre la pompe dans le collecteur, comme il est illustré. Aligner

le refoulement avec un des orifices filetés du couvercle.

6° Opération (Voir la Figure 5)

Tourner le couvercle à l’envers, puis poser la panier de collecteur

comme il est illustré.

Figure 1

Figure 2

Figure 3

Figure 4

Refoulement

de 1

1

⁄2 po NPT

Évent de

1

1

⁄2 po NPT

Pompe

Bassin

Admission

Figure 5

Taquets de

positionnement

1

4

2

3

Page 12

Montage / Installation 4

IMPORTANT : Pour empÍcher les fuites, s’assurer que les taquets

des angles de la panier de collecteur sont orientés vers le haut

lorsque le couvercle est à l’envers (c’est-à-dire lorsque la lisière

d’étanchéité n’est pas poussée dans la surface d’étanchéité du

couvercle).

7° Opération (Voir la Figure 5)

Faire passer les vis et leur rondelle dans les trous du rebord du

couvercle, puis dans la panier de collecteur (le couvercle retiendra les vis).

8° Opération (Voir la Figure 6)

• Aligner le couvercle avec le tuyau de refoulement et les cordons.

• Faire passer les cordons dans le trou non fileté du couvercle

du collecteur.

• Mettre le couvercle par-dessus le tuyau de refoulement.

• Faire passer les cordons dans le passe-cordons.

• Poser l’ensemble cordons et passe-cordons dans le trou non

fileté du couvercle du collecteur; ne pas tendre les cordons

en tirant dessus.

9° Opération (Voir la Figure 6)

Fixer le couvercle sur le collecteur à l’aide des vis précédemment

introduites dans le couvercle

(7° opération).

IMPORTANT : Pour empêcher les fuites, s’assurer que les taquets

de positionnement des angles de le panier de collecteur sont à

l’extérieur du rebord du collecteur et qu’ils n’appuient pas contre

le rebord.

INSTALLATION (Voir la Figure 7)

Le bassin (du système) doit être positionné de façon qu’il soit le

plus bas possible par rapport à la zone à vider.

REMARQUE : S’assurer que l’arrivée dans le système est plus

basse que l’eau à pomper.

1. Brancher le tuyau d’arrivée dans l’ouverture, comme il est

illustré. Appliquer du composé résistant aux variations de

température (RTV) ou du Plasto-Joint Stik* sur les filets pour

les rendre étanches. Se reporter aux Figures 8, 9 et 10 des

pages 4 et 5 pour les installations types du système.

*Lake Chemical Co., Chicago, Illinois

Figure 6

Refoulement

de 1

1

⁄2 po NPT

Évent de

1

1

⁄2 po NPT

Passe-cordons

Refoulement

Pompe

Admission

Figure 7 – Dimensions du système de pompage d’évier

Tuyaux filetés dans les raccords;

ne pas visser au-delà des filets.

Évent de

1

1

⁄2 po NPT

Refoulement

de 1

1

⁄2 po NPT

Admission

de 1

1

⁄2 po NPT

34,9 cm

38,4 cm

30,5 cm

30,5 cm

Interrupteur à

flotteur vertical

Pompe

de 1/3 ch

Figure 8 – Installation type pour évacuer les condensats

des climatiseurs ou l’eau des déshumidificateurs

Pompe

Mise à

l’air libre

Refoulement

Page 13

Installation / Entretien 5

2. Brancher les tuyaux de refoulement. Si l’on utilise des tuyaux

rigides, utiliser des tuyaux en plastique. Envelopper les filets

de ruban d’étanchéité en téflon ou les enduire de Plasto-Joint

Stik*. À la main, visser le tuyau dans le raccord de refoulement et le serrer de +1 à 1-1⁄2 tour supplémentaire.

REMARQUE : Ne pas utiliser de composé ordinaire pour raccords

filetés sur les tuyaux en plastique. Le composé ordinaire pour raccords filetés attaque les plastiques.

3. Pour réduire les bruits et les vibrations du moteur, une petite

longueur de tuyau souple en caoutchouc (durite de radiateur

d’un diamètre intérieur de 1-7/8 pouce, par exemple) peut

être posée sur la conduite de refoulement, près de la pompe;

faire tenir cette durite avec des colliers.

4. Poser un clapet antiretour en ligne pour empêcher au refoulement de revenir dans le bassin par la pompe lorsqu’elle s’arrête.

5. Visser le tuyau de mise à l’air libre dans le raccord noir de

1-1⁄2 po NPT de mise à l’air libre du couvercle du bassin. Le

tuyau doit dépasser du bassin. Brancher le tuyau de mise à

l’air libre sur un système de mise à l’air libre d’égout.

6. Courant d’alimentation : La pompe est conçue pour fonctionner sur le courant alternatif de 115 volts, 60 Hz, et elle doit

être branchée sur un circuit de dérivation individuel de 15

ampères minimum. La pompe et l’interrupteur sont livrés avec

des cordons électriques à 3 conducteurs et des fiches à trois

broches dont une de mise à la terre. La fiche du cordon électrique de l’interrupteur se branche directement dans la prise

de courant et la fiche du cordon électrique de la pompe se

branche à l’arrière de la fiche de l’interrupteur.

Tension dangereuse. La pompe doit toujours

être branchée sur une terre électrique adéquate, comme un tuyau

d’eau mis à la terre ou un chemin de câbles métallique adéquatement mis à la terre ou un système de câblage électrique mis à la

terre. Ne pas couper la broche ronde de la fiche.

7. Si la conduite de refoulement de la pompe est exposée à des

températures extérieures inférieures au point de congélation,

la portion de la conduite exposée doit être installée de façon

que l’eau restant dans la conduite se vide d’elle-même par

gravité. Si l’on ne respecte pas cette recommandation, l’eau

restera emprisonnée dans la conduite de refoulement et elle

gèlera, ce qui risque d’endommager la pompe.

8. Après avoir branché les tuyauteries et le clapet antiretour,

l’appareil est prête à être utilisé.

9. S’assurer du fonctionnement en faisant le plein d’eau de la

pompe et en observant le fonctionnement de la pompe pendant un cycle complet.

Risque d’inondation. Ne pas procéder à cette

vérification de fonctionnement peut causer un mauvais fonctionnement, une panne prématurée et une inondation.

ENTRETIEN

Risque de secousses électriques. S’assurer que

la pompe est débranchée avant d’intervenir sur un des composants ou de démonter un des composants.

Risque de secousses électriques. Ne pas

manipuler la pompe ni le moteur de la pompe lorsqu’on a les

mains humides ou lorsqu’on se tient sur une surface mouillée ou

humide, ou dans l’eau.

1. Garder la crépine d’aspiration de la pompe propre.

2. Le joint de l’arbre dépend de l’eau pour sa lubrification. Ne

pas faire fonctionner la pompe si elle n’est pas immergée

dans l’eau, sinon le joint sera endommagé si la pompe tourne

à sec.

3. Le moteur est équipé d’un dispositif de protection thermique

contre les surcharges à réenclenchement automatique. Si la

température du moteur s’élève indûment, couper le courant

avant que le moteur soit endommagé. Après que le moteur

aura suffisamment refroidi, le disjoncteur se réenclenchera

automatiquement et redémarrera le moteur. Si le disjoncteur

se déclenche de façon répétitive, la pompe devra être démontée et vérifiée pour en rechercher les causes. Une basse tension, des cordons prolongateurs trop longs, un impulseur

bouché, une hauteur de refoulement ou d’aspiration extrêmement basse, etc., risquent de causer le fonctionnement

cyclique. Se reporter au Tableau de recherche des pannes de

la page 6 pour de plus amples renseignements.

4. Inspecter périodiquement la pompe, les composants du système et le puisard à la recherche de débris et de corps

étrangers. Le puisard doit toujours être débarrassé de tous les

débris. Procéder à un entretien périodique au besoin.

Nettoyage de la Pompe

REMARQUE : La garantie sera annulée si on essaie de démonter

le moteur.

1. Utiliser l’anneau de la pompe pour la sortir du bassin et la

poser sur une surface plane et propre.

Risque de secousses électriques. Des secousses

électriques risquent de causer des brûlures, voire la mort. Ne pas

lever la pompe par son cordon électrique.

2. Pour nettoyer l’impulseur, déposer les huit vis de fixation de

la plaque du socle sur le moteur. Nettoyer l’impulseur selon

le besoin.

3. Reposer la plaque du socle et les vis.

4. Utiliser l’anneau de la pompe pour la remettre dans le bassin.

Figure 9 – Installation type pour un minibar

Pompe

Mise à

l’air libre

Refoulement

Figure 10 – Installation type pour les bacs à laver et les

laveuses

Pompe

Mise à

l’air libre

Refoulement

Page 14

Entretien 6

SYMPTÔMES CAUSES POSSIBLES REMÈDES

La pompe ne 1. Fusible sauté. 1. Si le fusible saute, le remplacer par un fusible de

démarre pas ou calibre adéquat.

ne fonctionne pas.

2. Tension de ligne basse. 2. Si la tension est inférieure au minimum recommandé,

vérifier le diamètre du câblage du sectionneur principal

de la propriété. Si le câblage est en bon état, contacter

la compagnie d’électricité.

La pompe ne 1. Refoulement bouché 1. Enlever l’obstruction dans la tuyauterie.

s’arrête pas. (obstruction dans la tuyauterie).

La pompe fonctionne 1. Refoulement bouché 1. Enlever l’obstruction dans la tuyauterie.

mais ne débite (obstruction dans la tuyauterie).

presque pas d’eau

ou ne débite pas

du tout.

Remplacement l’interrupteur

Risque de secousses électriques. Lorsque l’on

intervient sur la pompe, toujours couper le courant alimentant la

prise de courant, puis débrancher le cordon électrique de la

pompe de la prise de courant.

Le flotteur doit pouvoir fonctionner sur toute sa

course sans être gêné par les parois du bassin, les tuyaux ou tout

autre objet.

1. Monter le support sur le boîtier de l’interrupteur à l’aide des

vis existantes.

2. Glisser la tige dans la fente qui se trouve à la partie inférieure

du boîtier de l’interrupteur. Fixer la tige dans le boîtier de l’interrupteur à l’aide de l’axe.

S’assurer que l’axe retient bien la tige du flotteur

dans le boîtier de l’interrupteur, sinon la pompe ne s’arrêtera

pas.

REMARQUE : Tirer prudemment sur la tige pour s’assurer qu’elle

ne peut pas sortir du boîtier de l’interrupteur.

3. Monter l’interrupteur sur la pompe à l’aide des vis existantes.

S’assurer que rien ne gêne le fonctionnement de l’interrupteur.

4. Monter le flotteur sur la tige.

5. Poser la butée à la partie inférieure de la tige.

6. Faire fonctionner la pompe sur un cycle complet pour s’assurer du bon fonctionnement de l’interrupteur.

Risque d’inondation. Le système complet d’é-

vacuation des eaux usées est livré complet avec un interrupteur

à flotteur automatique monté sur le carter du moteur prêt à

fonctionner. Ne pas modifier les réglages de l’interrupteur.

L’interrupteur est réglé pour démarrer à environ 16,5 cm (6,5

pouces) et pour s’arrêter à environ 5 cm (2 pouces).

RECHERCHE DES PANNES

Page 15

Pièces détachées 7

3

2

1

5

4

Réf. Désignation Qté DP233110V-01

1 Bassin en polyester de 5 gallons (comprend la réf. 2 et la trousse de fixation) 1 PW73-64

2 Panier de collecteur 1 U20-23

3 Interrupteur à flotteur vertical à fonctionnement automatique 1 PKG 208

4 Tuyau de refoulement de 1-1/2 pouce 1 U37-688P

5 Pompe submersible de puisard de 1/3 de ch 1 D33110V

• Trousse de fixation (comprend les boulons, les rondelles et le passe-cordons) 1 PW198-6

Liste des pièces détachées

• Pièces non illustrées.

Page 16

Garantie 8

GARANTIE LIMITÉE

Pentair Water (<<Pentair>>) garantit à l’acheteur initial des produits énumérés ci-dessous que ces derniers seront exempts de défaut de matériau et de

fabrication pendant la durée de la garantie, laquelle entre en vigueur à compter de la date d’installation d’origine ou de fabrication, selon le cas.

Produits Durée de la garantie

Pompes à éjecteur, petites pompes centrifuges,

Selon le premier terme atteint :

pompes submersibles et accessoires connexes 1 an à compter de la date d’installation d’origine ou

2 ans à compter de la date de fabrication

Filtres Hydro-Flow 1 an à compter de la date d’achat

Réservoirs renforcés de fibre de verre 5 ans à compter de la date d’installation d’origine

Réservoirs sous pression en acier 5 ans à compter de la date d’installation d’origine

Réservoirs enduits de résine époxyde 3 ans à compter de la date d’installation d’origine

Produits pour les puisards/les égouts et les effluents 1 an à compter de la date d’installation d’origine ou

2 ans à compter de la date de fabrication

Nos garanties ne s’appliqueront pas aux produits qui auront fait l’objet de négligence, d’une utilisation abusive ou incorrecte, d’une mauvaise

installation ou d’un mauvais entretien. Si le moteur triphasé d’une pompe submersible (immergée) fonctionne sur le courant monophasé parce

que l’utilisateur utilise un convertisseur de phase ou si des relais thermiques de surcharge à trois pieds à déclenchement extrêmement rapide et

thermocompensés, de calibre ou de puissance recommandé ne sont pas utilisés, nos garanties ne s’appliqueront pas.

Le seul recours de l’acheteur et la seule obligation d’Pentair consistent à réparer ou à remplacer (au choix d’Pentair) les produits défectueux.

L’acheteur accepte de payer tous les frais de main-d’œuvre et d’expédition relatifs à cette garantie et d’exiger qu’un service au titre de la garantie

soit effectué par le marchand installateur, et ceci dès que le problème aura été découvert. Si un service au titre de la garantie est requis plus de

30 jours après l’expiration de la garantie, il sera refusé.

PENTAIR NE PEUT ÊTRE TENU RESPONSABLE D’AUCUN DOMMAGE INDIRECT, ACCIDENTEL OU FORTUIT, QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTES LES GARANTIES EXPRESSES POUVANT EXISTER. LES

GARANTIES IMPLICITES, Y COMPRIS, MAIS SANS S’Y LIMITER, LA DURÉE DES GARANTIES IMPLICITES AYANT TRAIT À LA

COMMERCIALITÉ OU À LA CONVENANCE À UN USAGE PARTICULIER, NE POURRONT PAS DÉPASSER LA DURÉE DES GARANTIES

STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter les dommages fortuits ou indirects, ni de limiter la durée d’une garantie implicite; il se

peut donc que les limitations ou exclusions stipulées dans les présentes ne s’appliquent pas. Des droits juridiques spécifiques sont stipulés dans

la présente garantie, bien que d’autres droits puissent exister, lesquels peuvent varier d’une province à l’autre.

Cette garantie annule et remplace toutes les garanties précédemment publiées.

Pentair Water, 293 Wright St., Delavan, WI 53115

Page 17

MANUAL DE INSTRUCCIONES

Sistema de bomba

para sumidero

© 2006 S483 (Rev. 9/26/06)

DP233110V-01

Instalación/Operación/Piezas

293 Wright Street • Delavan, WI 53115

Page 18

Información general sobre la seguridad 2

DESCRIPCIÓN

El Sistema de Bomba para Sumidero de Sta-Rite, Modelo número

DP233110V-01, es ideal para la remoción de aguas residuales

domésticas en fregaderos de esteticistas, de uso general o de minibares y para la transferencia de agua de drenaje de acondicionadores

de aire y deshumidificadores. La unidad de bomba sumergible de 1/3

CV viene equipada con un cordón de corriente de tipo puesta a tierra

con 3 puntas. El motor está relleno de aceite (aceite dieléctrico) y cerrado herméticamente para un funcionamiento más frío. El manguito

superior/cojinete de bolas inferior en el eje del motor nunca necesita

lubricación. Con protección térmica de reposición automática.

ESPECIFICACIONES

Suministro de energía requerido................................115V, 60 Hz.

Gama de temperatura del líquido...........0° a 54° C (32° a 130° F)

Requiere un ramal individual (mínimo) ......................15 amperios

Descarga........................................................................1-1⁄2" NPT

UNPACKING AND INSPECTION

Manéjelo con cuidado. Inspeccione las piezas recibidas con la lista

de embalaje para asegurarse de que haya recibido todo el equipo.

Verifique que no hayan averías de envío. Si encuentra alguna,

envíe un reclamo a la empresa de transportes inmediatamente.

DESEMPAQUE Y INSPECCIÓN

Manéjelo con cuidado. Inspeccione las piezas recibidas con la lista

de embalaje para asegurarse de que haya recibido todo el equipo.

Verifique que no hayan averías de envío. Si encuentra alguna,

envíe un reclamo a la empresa de transportes inmediatamente.

INFORMACIÓN GENERAL

SOBRE LA SEGURIDAD

Las bombas de sumidero de acción eléctrica, generalmente brindan

muchos años de servicio sin problemas cuando se instalan,

mantienen y usan en forma correcta. Sin embargo, circunstancias

inusuales (interrupción de la corriente hacia la bomba,

suciedad/escombros en el sumidero, desborde que supera la

capacidad de la bomba, fallas eléctricas o mecánicas en la bomba,

etc.) pueden evitar que la bomba funcione normalmente. Para evitar posibles daños causados por agua como resultado de inundaciones, consulte a su representante sobre la instalación de una alarma de alto nivel de agua. Consulte la “Tabla de Localización de fallas” en este manual para obtener información sobre los problemas

comunes de las bombas de sumidero y la resolución de los problemas asociados. Para mayor información, consulte a su representante o llame al departamento de servicio al cliente.

1. Es importante conocer la aplicación de la bomba, sus limitaciones y posibles peligros.

2. Desconecte el suministro de energía antes de realizar trabajos

de reparación.

3. Libere toda la presión dentro del sistema antes de reparar

alguno de sus componentes.

4. Drene todo el agua del sistema antes de realizar trabajos de

reparación.

5. Asegure la línea de descarga antes de poner en marcha la

bomba. Una línea de descarga no asegurada debidamente

podrá dar un golpe y causando posiblemente lesiones personales y/o daños a la propiedad.

6. Verifique que las mangueras no estén en un estado débil o

gastadas antes de cada uso, asegurándose de que todas las

conexiones estén bien firmes.

7. Periódicamente inspeccione los componentes del sistema.

Manténgalos libres de escombros y objetos foráneos. Realice

el mantenimiento de rutina según se requiera.

8. Proporcione medios de liberación de presión para las bombas

cuya línea de descarga pueda cerrase o ser obstruida.

9. Seguridad personal:

a. Use gafas de seguridad en todo momento cuando trabaje

con bombas.

b. Mantenga la zona de trabajo limpia, ordenada y con ilu-

minación adecuada - coloque toda herramienta o equipo

que no utilice de vuelta en su lugar.

c. Mantenga a los visitantes a una distancia segura de la

zona de trabajo.

d. Haga de su taller una zona a prueba de niños, con can-

dados, interruptores maestros y retirando las llaves de

encendido.

10. Cuando realice el cableado de una bomba de acción eléctrica, observe todos los códigos eléctricos y de seguridad que

correspondan.

11. Este equipo se debe usar solamente con 115 voltios

(monofásico) y viene equipado con un cordón de 3 conductores y un enchufe 3 puntas tipo puesta a tierra.

Para reducir el riesgo de choques eléctricos, des-

enchufe la bomba antes de realizar trabajos de reparaciones. Esta

bomba no ha sido investigada para ser usada en zonas de piscinas de natación. La bomba viene con un conductor de puesta a

tierra y un enchufe tipo puesta a tierra. Asegúrese de que esté

conectado solamente a un receptáculo de tipo puesta a tierra y

debidamente conectado a tierra. Cuando se encuentre un tomacorriente de pared con dos puntas, éste se deberá cambiar por un

receptáculo de 3 puntas debidamente puesto a tierra e instalado

confirme a los códigos y reglamentos que correspondan.

12. Todo el cableado debe ser realizado por un electricista competente.

13. Asegúrese de que la fuente de corriente cumpla con los requisitos de su equipo.

ESPECIFICACIONES

Carga total Graduación

del motor del interruptor Ancho Ancho

CV amperios Encendido Apagado Altura superior inferior Peso

1/3 9,8 17,8 cm 5,1 cm 34,9 cm 38,4 cm 30,5 cm 14,5 kg

RENDIMIENTO

L/min. de agua a altura total en metros

Modelo CV 1,5 m 3 m 4,5 m 6,1 m Cierre

DP233110V-01 1/3 181,7 151,4 109,8 56,8 7,3 m

Page 19

Información general sobre la seguridad / Ensamblaje 3

14. Proteja el cordón eléctrico contra objetos filosos, superficies

calientes, aceite y sustancias químicas. Evite torcer el cordón.

Cambie o repare todo cordón que esté gastado o dañado

inmediatamente.

15. No toque un motor en funcionamiento. Los motores modernos han sido diseñados para operar a altas temperaturas.

Riesgo de choques eléctricos. Si su sótano tiene

agua o humedad en el piso, no camine sobre zonas húmedas hasta

que haya desconectado la corriente. Si lo caja de desconexión está

en el sótano, llame a la empresa de electricidad o al servicio eléctrico para que cierren el suministro de energía a su casa, o llame a

su departamento de bomberos local para obtener instrucciones al

respecto. Saque y reemplace el sistema. Si no se observa esta

advertencia, existe el riesgo de choques eléctricos fatales.

Riesgo de choques eléctricos. No maneje la

bomba ni el motor de la bomba con manos húmedas o mientras

esté parado sobre una superficie húmeda o mojada, o en el agua.

Siempre desconecte la bomba y el interruptor de la fuente de

suministro de corriente eléctrica antes de realizar algún trabajo de

mantenimiento.

16. Solamente bombee agua con esta bomba.

ENSAMBLAJE

Pasos 1 y 2 (Ver la Figure 1)

Paso 3 (Ver la Figure 2)

Paso 4 (Ver la Figure 3)

Instale la tubería de descarga apretándola con la mano más

media vuelta.

Paso 5 (Ver la Figure 4)

Coloque la bomba en la pileta según se ilustra. La descarga debe

quedar alineada con una de las aberturas fileteadas en la cubierta.

Paso 6 (Ver la Figure 5)

Invierta la cubierta y coloque la empaquetadura de la pileta

según se ilustra.

Figura 1

Figura 2

Figure 3

Figura 4

Descarga

de 1

1

⁄2" NPT

Admisión

Bomba

Pileta

Venteo de

1

1

⁄2" NPT

Figura 5

Abrazaderas

de ubicación

1

4

2

3

Page 20

Ensamblaje / Instalación 4

IMPORTANTE: Parta prevenir fugas, verifique que las abrazaderas

en las esquinas de la empaquetadura de la pileta estén hacia arriba con la cubierta boca abajo (es decir que no estén oprimidas

contra la superficie de sello de la cubierta).

Paso 7 (Ver la Figura 5)

Empuje los tornillos con sus arandelas instaladas hacia arriba por

los orificios del reborde de la cubierta y dentro de la empaquetadura de la pileta (la cubierta retendrá los tornillos).

Paso 8 (Ver la Figura 6)

• La cubierta debe quedar alineada con la tubería de descarga

y los cordones.

• Pase los cordones por el orificio no fileteado en la cubierta de

la pileta.

• Coloque la cubierta sobre la tubería de descarga.

• Instale los cordones en el aro de refuerzo del cordón.

• Instale la unidad de cordón/aro de refuerzo en el orificio no

fileteado en la cubierta de la pileta, no apriete los cordones.

Paso 9 (Ver la Figura 6)

Sujete la cubierta de la pileta a la pileta con los tornillos pri-

sioneros que se introdujeron previamente en la cubierta (Paso 7).

IMPORTANTE: Parta prevenir fugas, verifique que las abrazaderas

en las esquinas de la empaquetadura de la pileta estén fuera de los

bordes del reborde de la pileta, no oprimidas contra el reborde.

INSTALACIÓN (Ver Figure 7)

La pileta (el sistema) debe estar ubicado en el lugar más bajo

posible con respecto a la zona que se debe drenar.

NOTA: Verifique que la entrada del sistema con plomería esté

por debajo del nivel del agua que se esté bombeando.

1. Instale el tubo de entrada en la abertura según se ilustra. Use

sellos de silicona resistentes a las variaciones de temperatura

o Plasto Joint Stick * para sellar las roscas. Por información

sobre instalaciones típicas, consulte las Figures 8, 9, y 10,

páginas 4 y 5.

*Lake Chemical Co., Chicago, Illinois

Figura 6

Descarga

de 1

1

⁄2" NPT

Venteo de

1

1

⁄2" NPT

Aro de refuerzo

del cordón

Admisión

Descarga

Bomba

Figura 7 – Dimensiones del Sistema de Bomba para

Sumidero

Venteo de

1

1

⁄2" NPT

Enrosque las tuberías en los accesorios, no

pase más allá del extremo de las roscas.

Descarga de

1

1

⁄2" NPT

Admisión

de 1

1

⁄2" NPT

Interruptor de

flotador vertical

Bomba

de 1/3 HP

Figura 8 – Instalación típica para eliminar la

condensación de acondicionadores de aire o el agua

del deshumidificador

Bomba

Ventilación

Descarga

1

/

15

8"

3

/

4"

13

12"

c

12"

Page 21

Instalación / Mantenimiento 5

2. Instale la plomería de descarga. Cuando use un tubo rígido,

use un tubo de plástico. Envuelva la rosca con cinta de teflón

o use Plasto-Joint Stick*. Atornille el tubo en el accesorio de

descarga apretándolo con la mano +1 – 1-1⁄2 vueltas.

NOTA: No use un compuesto común para juntas de tuberías en

tubos de plástico. El compuesto para juntas de tuberías puede

atacar el plástico.

3. Para reducir el ruido y las vibraciones del motor, se pude

conectar un trozo corto de manguera de caucho (1-7/8" de

diámetro interno, por ej. manguera de radiador) en la línea de

descarga cerca de la bomba usando abrazaderas adecuadas.

4. Instale una válvula de retención en línea para evitar reflujo a

través de la bomba cuando la bomba se cierre.

5. Enrosque el tubo de ventilación en el accesorio de ventilación negro de 1-1⁄2" NPT en la cubierta de la pileta. El tubo

no se debe extender hacia adentro de la pileta. conecte el

tubo de ventilación al sistema de ventilación del sumidero.

6. Suministro de energía: La bomba ha sido diseñada para una

operación a 115 V, 60 Hz y requiere un ramal individual de

un mínimo de 15 amperios. Tanto la bomba como el interruptor viene con juegos de cordones de 3 hilos, con enchufes

tipo puesta a tierra. El enchufe de conmutación se coloca

directamente en el tomacorriente y el enchufe de la bomba se

coloca en el extremo opuesto del enchufe de conmutación.

Tensión peligrosa. La conexión eléctrica de la

bomba siempre debe estar puesta a tierra en forma adecuada

como, por ejemplo, una conexión a una tubería de agua puesta a

tierra, una canalización metálica puesta a tierra, o un sistema de

cableado puesto a tierra. No corte la clavija redonda de conexión

a tierra.

7. Si la línea de descarga de la bomba está expuesta a la intemperie con temperaturas por debajo del punto de congelamiento, las porciones de la línea que queden expuestas deberán

ser instaladas de modo de que el agua que permanezca en

las tuberías se desagüe a la salida por gravedad. Si no se

observa este procedimiento, el agua puede quedar atrapada

en la descarga y congelarse, lo que resultaría en daños a la

bomba.

8. Después de que se haya instalado la tubería y la válvula de

retención, la unidad estará lista para funcionar.

9. Inspeccione su funcionamiento llenando el sumidero con

agua y observando el funcionamiento de la bomba a través

de un ciclo completo.

Riesgo de inundación. Si no se realiza este

chequeo operacional, existe el riesgo de un funcionamiento

inadecuado, fallas prematuras e inundación.

MANTENIMIENTO

Riesgo de choque eléctrico. Asegúrese de que la

bomba esté desenchufada antes de tratar de realizar trabajos de

reparaciones o de retirar algún componente.

Riesgo de choque eléctrico. No manipule una

bomba ni el motor de una bomba con manos húmedas o cuando

esté parado sobre superficie mojada o húmeda, o en el agua.

1. Mantenga despejada la red de entrada de la bomba.

2. El sello del eje depende del agua para su lubricación. No

haga marchar la bomba a menos de que esté sumergida en

agua ya que de otro modo el sello se puede dañar si se deja

que la bomba marche en seco.

3. El motor viene equipado con un protector térmico de reposición automática. Si la temperatura en el motor sube indebidamente, el interruptor desactivará toda la corriente antes de

que el motor se pueda perjudicar. Cuando el motor se haya

enfriado lo suficiente, el interruptor se reposicionará

automáticamente y volverá a arrancar al motor. Si el protector

se dispara repetidamente, será necesario sacar la bomba y

verificar cuál es la razón de esa dificultad. Una tensión baja,

cables largos de prolongación, un impulsor tapado, una elevación o altura demasiado baja, etc. puede causar estos ciclos. Consulte la guía de localización de fallas en la página 6

para obtener información adicional.

4. Periódicamente, inspeccione la bomba, los componentes del

sistema y el sumidero para verificar que no hayan escombros

ni objetos foráneos. Mantenga el sumidero libre de todo desecho. Realice el mantenimiento de rutina que se requiera.

Limpieza del al Bomba

NOTA: Si se trata de desarmar el motor, la garantía quedará

anulada.

1. Use el anillo de la bomba para levantar y sacar la bomba de

la pileta, y colóquela sobre una superficie nivelada y limpia.

Riesgo de choque eléctrico. Los choques pueden

quemar o matar. No levante la bomba por medio del cordón

eléctrico.

2. Para limpiar el impulsor, saque los ocho tornillos que

sostienen la plancha de base a la unidad del motor. Limpie el

impulsor según se requiera.

3. Vuelva a instalar la plancha de base y los tornillos.

4. Use el anillo de la bomba para volver a colocarla en la pileta.

Figura 9 – Instalación típica en frigobares

Bomba

Figura 10 – Instalación típica en lavaderos y lavarropas

Bomba

Ventilación

Ventilación

Descarga

Descarga

Page 22

Mantenimiento 6

SÍNTOMA POSIBLE(S) CAUSA(S) ACCIÓN CORRECTIVA

La bomba no 1. Fusible quemado. 1. Si está quemado, cámbielo por un fusible del

arranca ni marcha. tamaño correspondiente.

2. Baja tensión de línea. 2. Si la tensión es más baja del mínimo recomendado,

verifique el tamaño de los cables desde el interruptor

principal de la propiedad. Si es correcto, comuníquese

con la empresa de suministro de energía o el servicio

de corriente eléctrica.

La bomba no 1. Descarga obstruida 1. Saque el obstáculo en la tubería.

se apaga. (obstáculo en la tubería).

La bomba opera 1. Descarga obstruida 1. Saque el obstáculo en la tubería.

pero entrega poca (obstáculo en la tubería).

o nada de agua.

Cambio del Interruptor

Riesgo de choque eléctrico. Cuando realice tra-

bajos de reparación en la bomba, siempre desconecte la corriente

del tomacorriente y saque el cordón eléctrico de la bomba del

tomacorriente.

El flotador debe poder completar todo su

ciclo sin interferencia de la pared lateral de la pileta, de los componentes de plomería ni de ningún otro objeto.

1. Coloque el soporte en la caja del interruptor usando los

tornillos existentes.

2. Deslice la vara en la ranura del fondo de la caja del interrup-

tor. Sujete la vara en la caja del interruptor con un pasador.

Asegúrese de que el pasador sostenga la

vara del flotador en la caja del interruptor; de lo contrario, la

bomba no se apagará.

NOTA: Tire suavemente de la vara para asegurarse de que no se

salga de la caja del interruptor.

3. Coloque la unidad del interruptor en la bomba usando los

tornillos existentes. Asegúrese de que nada interfiera con la

operación del interruptor.

4. Coloque el flotador en la vara.

5. Instale el tope de la vara en el fondo de la misma.

6. Haga marchar la bomba un ciclo completo para verificar que

el interruptor esté funcionando correctamente.

Riesgo de inundación. El Sistema de Desagüe

con Plomería viene con un interruptor de flotador automático

montado sobre la caja del motor y listo para su operación. No

cambie las graduaciones del interruptor. El interruptor está graduado para arrancar aproximadamente a 16,5 cm (6,5") y detenerse

a aproximadamente 5 cm (2").

RESOLUCIÓN DE PROBLEMAS

PRECAUCIÓN

PRECAUCIÓN

Page 23

Partes de reparación 7

3

2

1

5

4

Ref.

No. Descripción Cantidad DP233110V-01

1 Unidad de pileta de polietileno de 5 galones

(incluye Ref. No. 2 y juego de accesorios de ferretería) 1 PW73-64

2 Empaquetadura de la pileta 1 U20-23

3 Interruptor automático de flotador vertical 1 PKG 208

4 Tubo de descarga de 1-1/2" 1 U37-688P

5 Bomba sumergible de sumidero de 1/3 CV 1 D33110V

• Juego de accesorios de ferretería (incluye pernos, arandelas

y aro de refuerzo para el cordón) 1 PW198-6

Partes de Reparación

• No se ilustra.

Page 24

Garantía 8

GARANTÍA LIMITADA

Pentair Water (“Pentair”) garantiza al consumidor inicial de los productos indicados a continuación, que éstos estarán libres de defectos en material y mano de obra, por el Período de Garantía indicado desde la fecha de la instalación inicial o de la fabricación.

Producto Período de Garantía

Bombas de chorro, bombas centrífugas pequeñas,

lo que ocurra primero:

bombas sumergibles y accesorios asociados. 1 año desde la fecha de la instalación

inicial, o 2 años desde la fecha de fabricación

Filtros Hydro-Flow 1 año desde la fecha de compra

Tanques Fibrewound 5 años desde la fecha de la instalación inicial

Tanques de presión de acero 5 años desde la fecha de la instalación inicial

Tanques con revestimiento epoxídico 3 años desde la fecha de la instalación inicial

Productos de sumidero/de aguas residuales/de efluente 1 año desde la fecha de la instalación inicial, o

2 años desde la fecha de fabricación

Nuestra garantía no corresponde en el caso en que un producto haya estado sometido a negligencia, mala aplicación, instalación o mantenimiento inadecuados. La garantía quedará invalidada si un motor sumergible trifásico se hace funcionar con energía monofásica a través de convertidor de fase, o si no se usan relés de tres partes con compensación ambiental o de sobrecarga con disparo extra-rápido del tamaño

recomendado.

El único recurso del comprador y la única responsabilidad de Pentair es la de reparar o reemplazar los productos defectuosos (a criterio de

Pentair). El comprador acepta pagar todos los cargos de mano de obra y de envío asociados con esta garantía y solicitar servicio bajo garantía

por medio del agente instalador tan pronto como se descubra un problema. No se aceptará ningún servicio bajo garantía que se solicite más de

30 días después de la terminación del Período de Garantía.

PENTAIR NO SE HARÁ RESPONSABLE DE NINGÚN PERJUICIO RESULTANTE, SECUNDARIO O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y EN LUGAR DE TODA OTRA GARANTÍA EXPLÍCITA. LAS GARANTÍAS

IMPLÍCITAS, INCLUYENDO, PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIALIDAD E IDONEIDAD PARA UN FIN EN

PARTICULAR NO SE EXTENDERÁN MÁS ALLÁ DEL PERÍODO DE GARANTÍA INDICADO EN LA PRESENTE.

Ciertos estados no permiten la exclusión ni la limitación de perjuicios secundarios o resultantes, o la limitación de la duración de una garantía

implícita, por lo tanto, las limitaciones o exclusiones indicadas en la presente pueden no corresponder. Esta garantía establece derechos y

obligaciones específicos legales, sin embargo, pueden existir otros derechos que varían entre estados.

Sustituye toda publicación anterior.

Pentair Water, 293 Wright St., Delavan, WI 53115

Loading...

Loading...